Konica Minolta BIZHUB PRESS C1100, BIZHUB PRESS C1085 Daily Maintenance Manual

2016. 6

Aim of this manual

This manual describes the daily care, both sides adjustment and image quality adjustment

procedures. These daily adjustments are important for stable printings.

This manual will be useful to enable the full capabilities of this machine to realize stable

printings.

Notations and symbols used in this manual

NOTICE

This symbol indicates a risk that may result in damage to this machine or originals.

Follow the instructions to avoid property damage.

Tips

This symbol indicates information that complements the topic or optional devices required to use a certain function.

Reference

This symbol indicates a function or functions that are related to the topic.

This guide describes product names and system configurations as follows.

The meaning of other notations and symbols are as follows.

Notation/Symbol Description

[ ] These brackets indicate the name of a key on the touch panel or of a button on a

computer screen.

Bold Words in bold type indicate the name of a key on the control panel, of a part, of an

option, or of User's Guide.

CAUTION

This symbol indicates that negligence of the instructions may lead to mishandling that may cause injury

or property damage.

Product name Conventions used in this guide

bizhub PRESS C1100/C1085 This machine: Indicates the entire system including options and functions.

The main body: Indicates a main unit that covers printing functions.

The machine: Indicates a mechanical part related to the structure or mechanism.

Microsoft Windows Windows

i

bizhub PRESS C1100/C1085

Intended use of this machine

Intended use

This machine is designed to be used as a digital printing system for the following purposes:

- Print, copy and scan documents.

- Use available finishing functions such as duplexing, stapling, hole-punching, multi-folding and booklet creation

if appropriate options are installed.

- Store documents to reprint on the HDD of this machine.

The intended use also requires that:

- The system is used within the limits of device specifications and specifications of optional components,

- All safety instructions in the related user's guides are observed,

- Legal restrictions on copying or printing (refer to instruction booklet "Safety Information") are observed,

- Inspection and maintenance instructions are adhered to,

- General, national and company safety provisions are observed.

Impermissible operating conditions

The system may not be operated if:

- Errors or damage have been discovered,

- Maintenance intervals have been exceeded,

- Mechanical or electrical functions do not work as they should.

Exclusion of liability

The manufacturer of the system assumes no liability for damages if the system was operated under impermissible

conditions.

Target groups

The Daily Maintenance Guide are intended for the following users of this machine:

- Operator: Person who has been trained by Konica Minolta or authorized partner to operate the system for its

intended use as well as manage consumables, and perform the maintenance and troubleshooting described in

user's guides.

Everyone who uses this system must have read and understood the related user's guides.

ii

Contents

Intended use of this machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Intended use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Impermissible operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Exclusion of liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Target groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

1 DAILY CARE

About daily care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Cleaning timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Cleaning the duplex section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Cleaning section of the duplex section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Cleaning procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Cleaning the centering sensor (Paper feeder unit PF-707/PF-708) . . . . . . . . . . . . . . . . . . . . 1-6

Cleaning the roller of the humidification section

(Relay conveyance unit RU-511). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

2 BOTH SIDES ADJUSTMENT

About both sides adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Adjustment flow

when using a new paper brand, a new paper weight, or a new paper size . . . . . . . . . . . . . . 2-1

Adjustment timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Adjustment order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Regular adjustment flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Adjustment timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Adjustment order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Adjustment flow for each job . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Adjustment timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Adjustment order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Contents of both sides adjustment items. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Placing paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Front side adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Gap adjustment (When not using PF-708 scanner) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Scan measurement adjustment (When using PF-708 Scanner). . . . . . . . . . . . . . . . . . . . 2-16

Registering the paper profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Back side fine adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

3 IMAGE QUALITY ADJUSTMENT

3.1 Image quality adjustment for Image Controller IC-602 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

About Quality Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Regular adjustment flow (High accuracy) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Adjustment timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Adjustment order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Adjustment flow when changing the screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Adjustment timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Adjustment order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Contents of the image quality adjustment items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Change setting of Custom Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Gamma Automatic Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Density Balance Adjustment (for i1Pro/i1Pro2/ES-1000/ES-2000) . . . . . . . . . . . . . . . . . . 3-7

Density Balance Adjustment (for FD-5BT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Added procedures of Density Balance Adjustment

(Registration of color measurement data using a USB memory). . . . . . . . . . . . . . . . . . . 3-24

Maximum Density Auto Adjustment (RU). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

iii

bizhub PRESS C1100/C1085

Check setting of Color Density Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Color Density Manual Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-31

Exact Color (for i1Pro/i1Pro2/ES-1000/ES-2000, or FD-5BT) . . . . . . . . . . . . . . . . . . . . . 3-33

G7 Calibration (for i1Pro/i1Pro2/ES-1000/ES-2000, or FD-5BT) . . . . . . . . . . . . . . . . . . . 3-39

3.2 Image quality adjustment for Image Controller IC-308/IC-310 . . . . . . . . . . . . . . . . . . . . . . . . . 3-45

About Quality Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-45

Regular adjustment flow (High accuracy) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-45

Adjustment timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-45

Adjustment order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-45

Adjustment flow when changing the screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

Adjustment timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

Adjustment order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

Contents of the image quality adjustment items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-47

Change setting of Custom Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-47

Gamma Automatic Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-49

Density Balance Adjustment (for i1Pro/i1Pro2/ES-1000/ES-2000) . . . . . . . . . . . . . . . . . 3-50

Added procedures of Density Balance Adjustment

(Registration of color measurement data using a USB memory) . . . . . . . . . . . . . . . . . . . 3-59

Maximum Density Auto Adjustment (RU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-61

Check setting of Color Density Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-63

Color Density Manual Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-66

Controller Calibration (IC-308/IC-310) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-68

1-1

1 DAILY CARE

About daily care

To reproduce stable output by this machine, be sure to clean the machine before output.

)

Cleaning timing

Check the cleaning section every day before you activate the power of the machine.

Clean the cleaning section when the cleaning section is dirty.

Cleaning section Reference

Duplex section P.1-2

Centering sensor (Paper feeder unit PF-707/PF-708) P.1-6

Roller of the humidification section (Relay conveyance unit RU-511) P.1-7

1-2

bizhub PRESS C1100/C1085

1

Cleaning the duplex section

CAUTION

Be sure to check the cleaning section before you activate the power of the main body.

If you activate the power with closed the door of the main body, the inside of the fusing unit becomes hot. Therefore,

you possibly get burned when you clean near the fusing unit.

)

Cleaning section of the duplex section

- Upper side of the duplex section

- Paper path of the registration unit

- Pre-fusing guide plate

- Fusing unit entrance guide

- Paper path of the duplex unit

- Paper path inside the jam processing guide

NOTICE

- Be careful not to drop any dirt inside the machine when you clean the machine.

)

Cleaning procedure

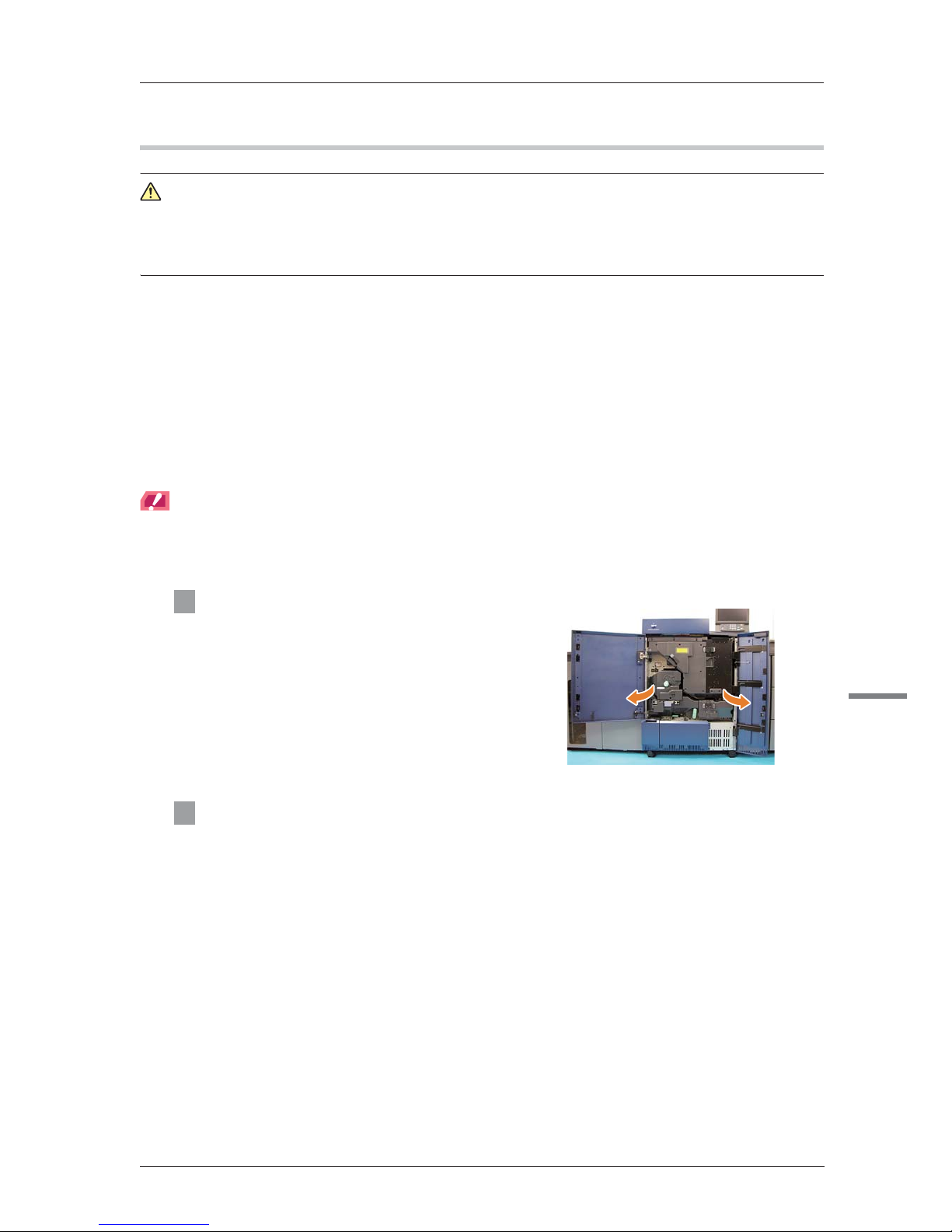

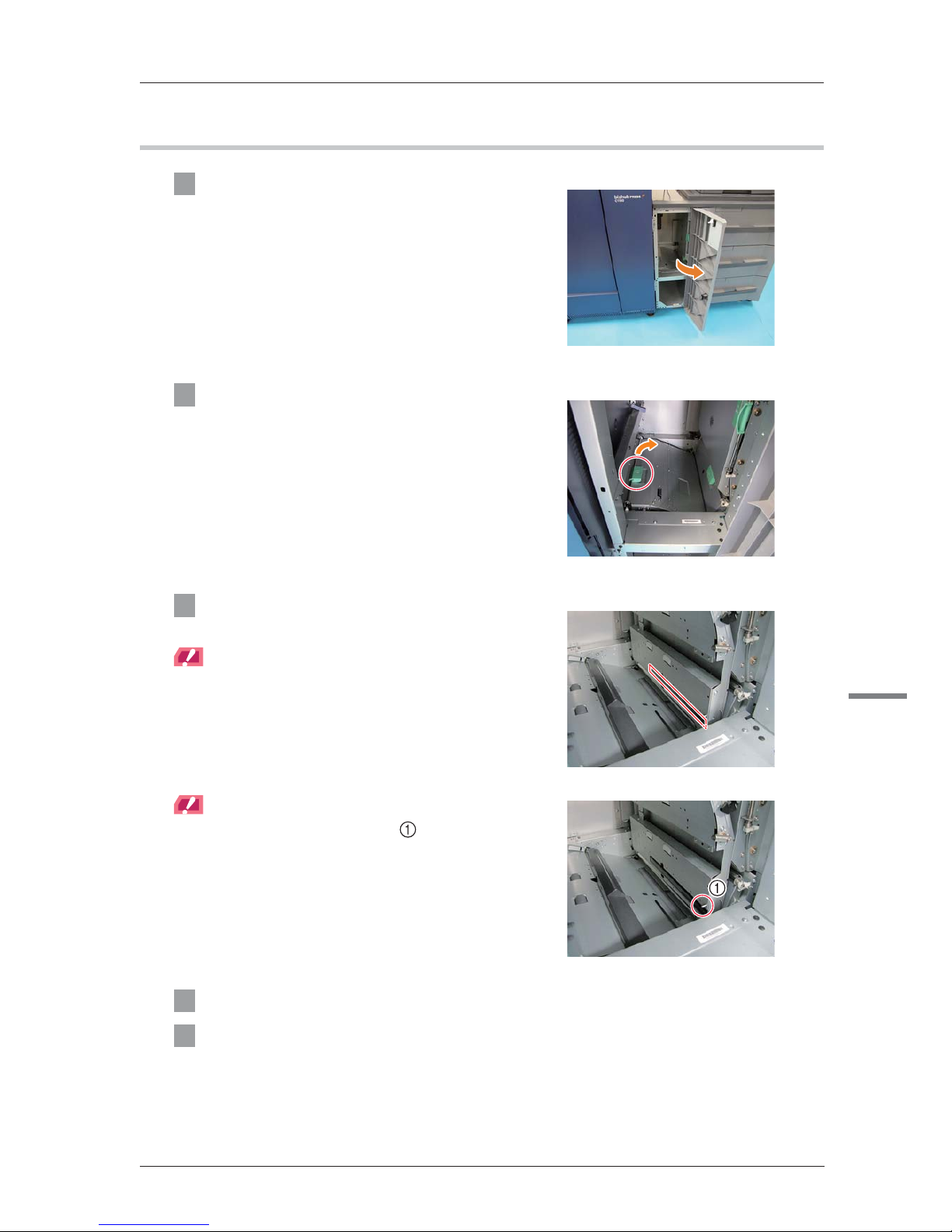

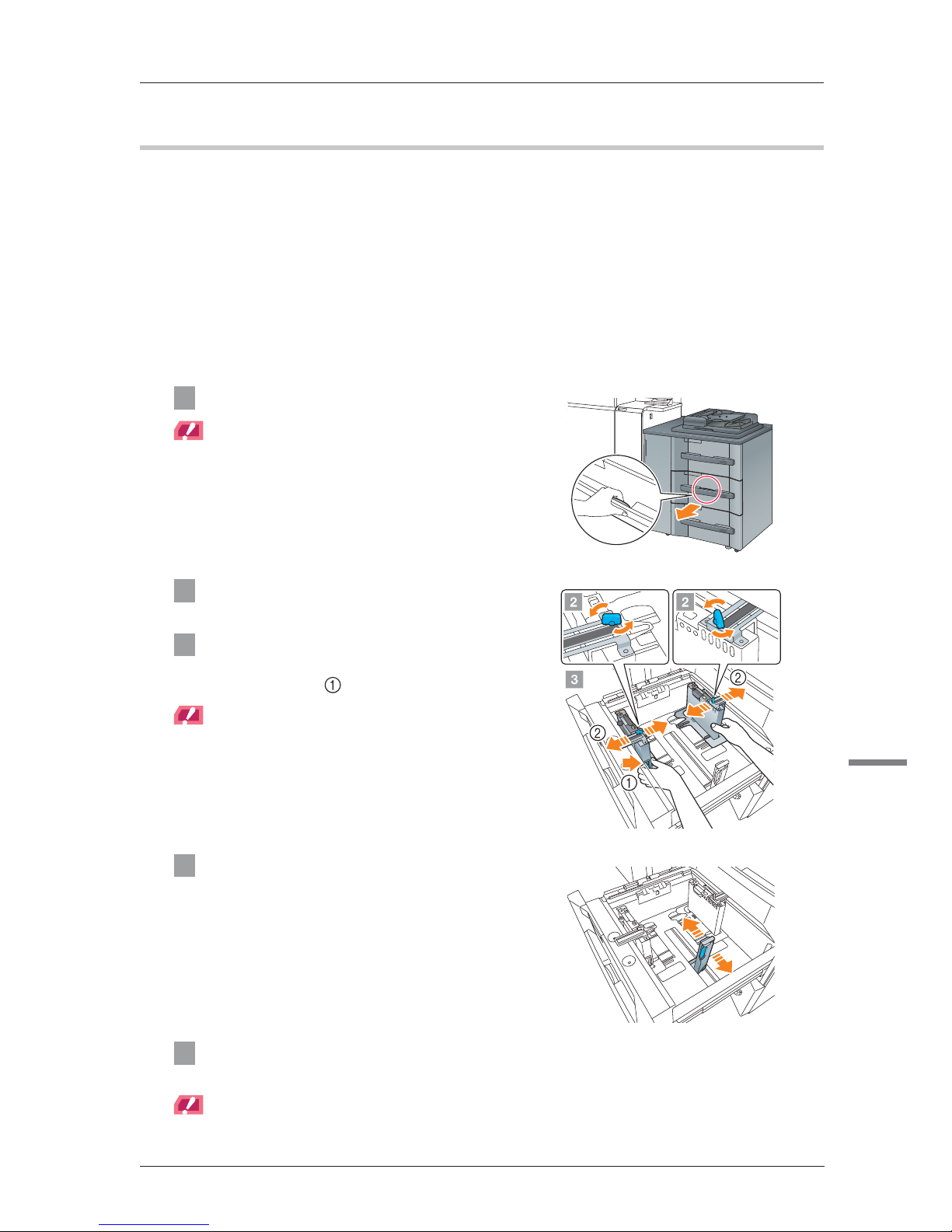

1 Open the right door and the left door of

the main body.

2 Activate the main power switch, then activate the sub power switch.

1-3

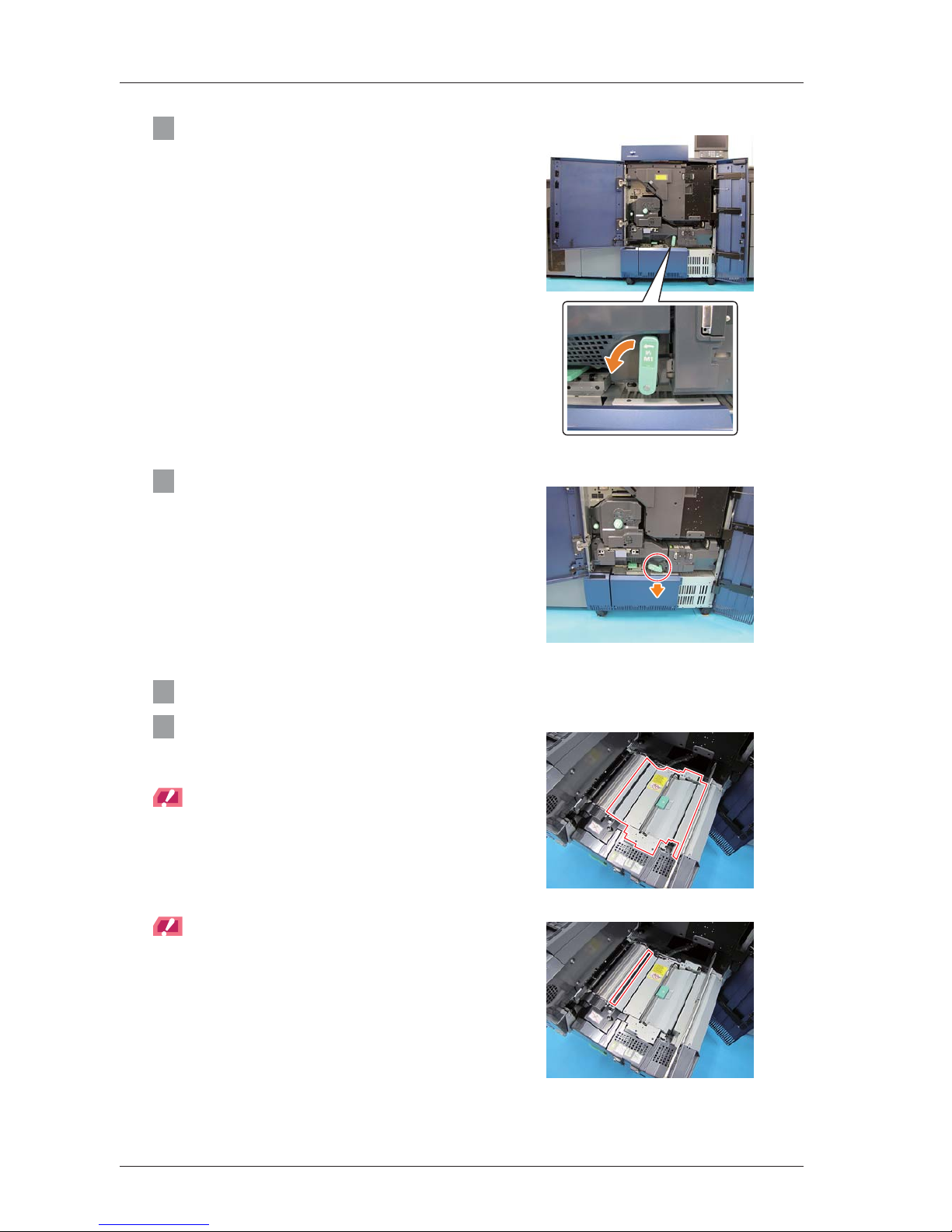

3 Tilt the lever [M1] counterclockwise.

4 Hold the lever [M1], and pull out the

duplex section.

5 Deactivate the sub power switch, then deactivate the main power switch.

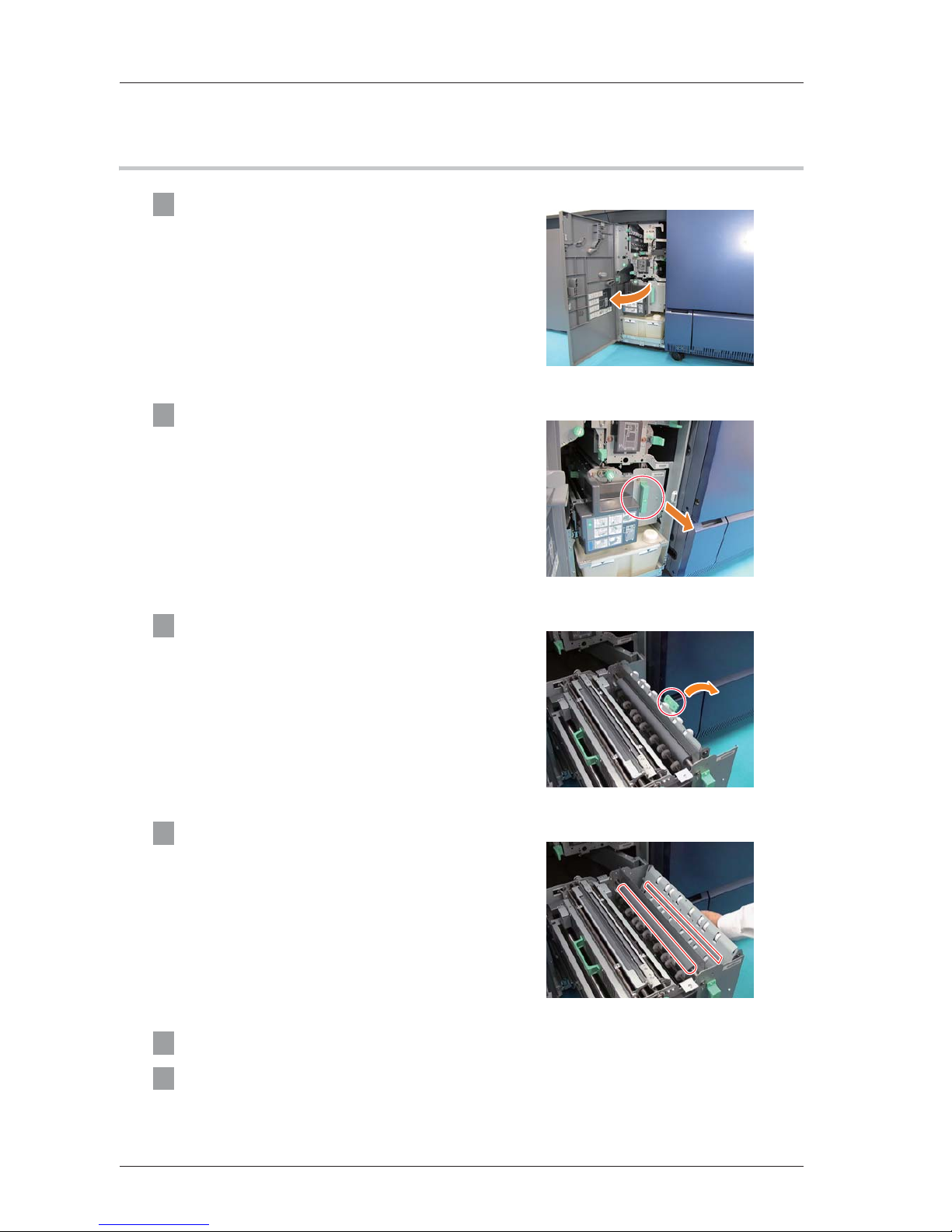

6 Wipe off the dirt at the upper side of the

duplex section with a hydro-wipe (nonwoven fabric without fluff).

NOTICE

- Do not use alcohol when you clean the upper side of

the duplex section.

- Be sure to clean the duplex section in an axial

direction. If you clean the unit in the paper feed

direction, toner drops on the paper path.

NOTICE

- Be sure to clean the duplex section so that the sheet

at the upper side of the duplex section does not

deform.

1-4

bizhub PRESS C1100/C1085

1

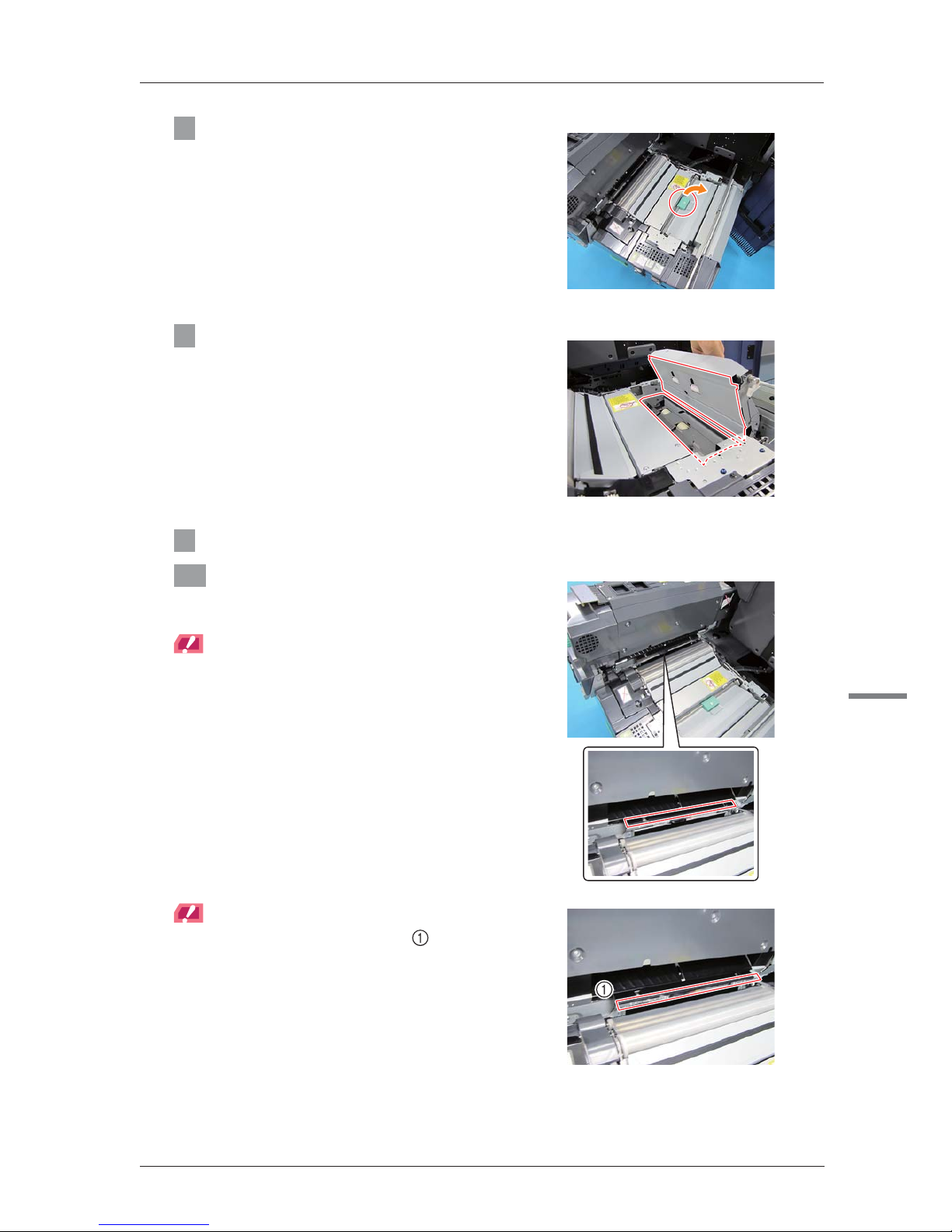

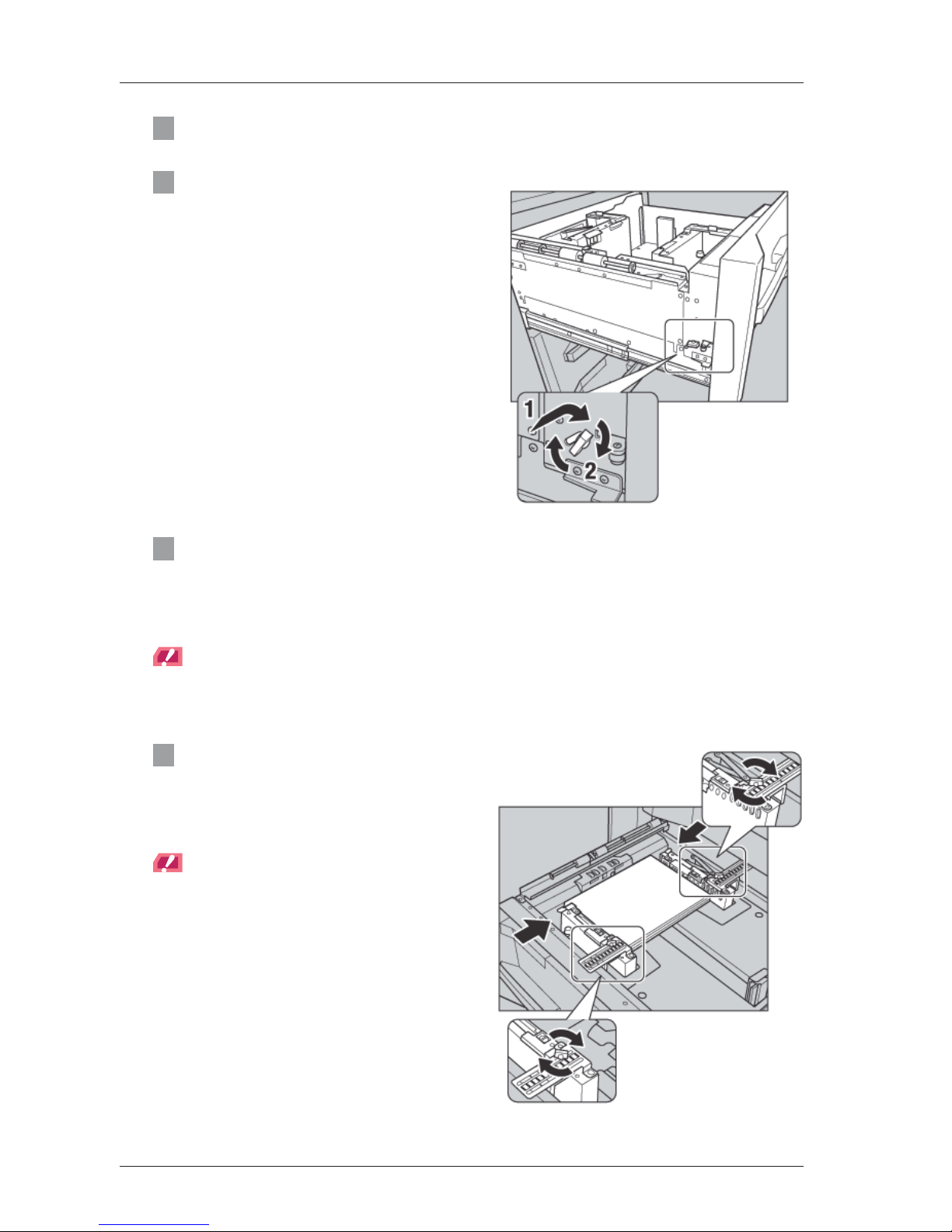

7 Open the cover [M3].

8 Wipe off the dirt at the paper path of the

registration unit with a hydro-wipe (nonwoven fabric without fluff).

9 Close the cover [M3].

10 Wipe off the dirt at the pre-fusing guide

plate with a hydro-wipe (non-woven

fabric without fluff).

NOTICE

- Do not use alcohol when you clean the pre-fusing

guide plate.

NOTICE

- Be careful not to deform the sheet ( ) at the

entrance of the fusing unit when you clean the prefusing guide plate.

1-5

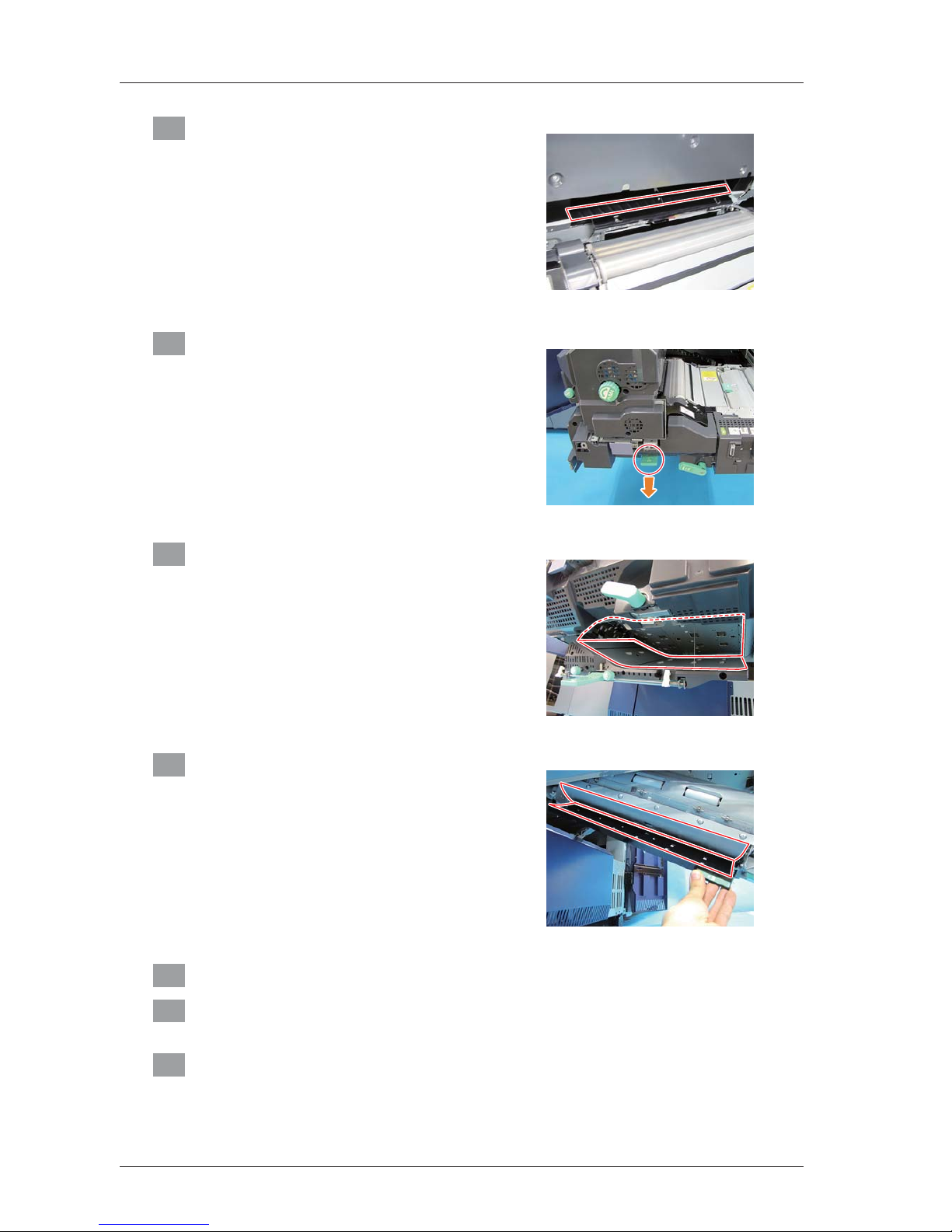

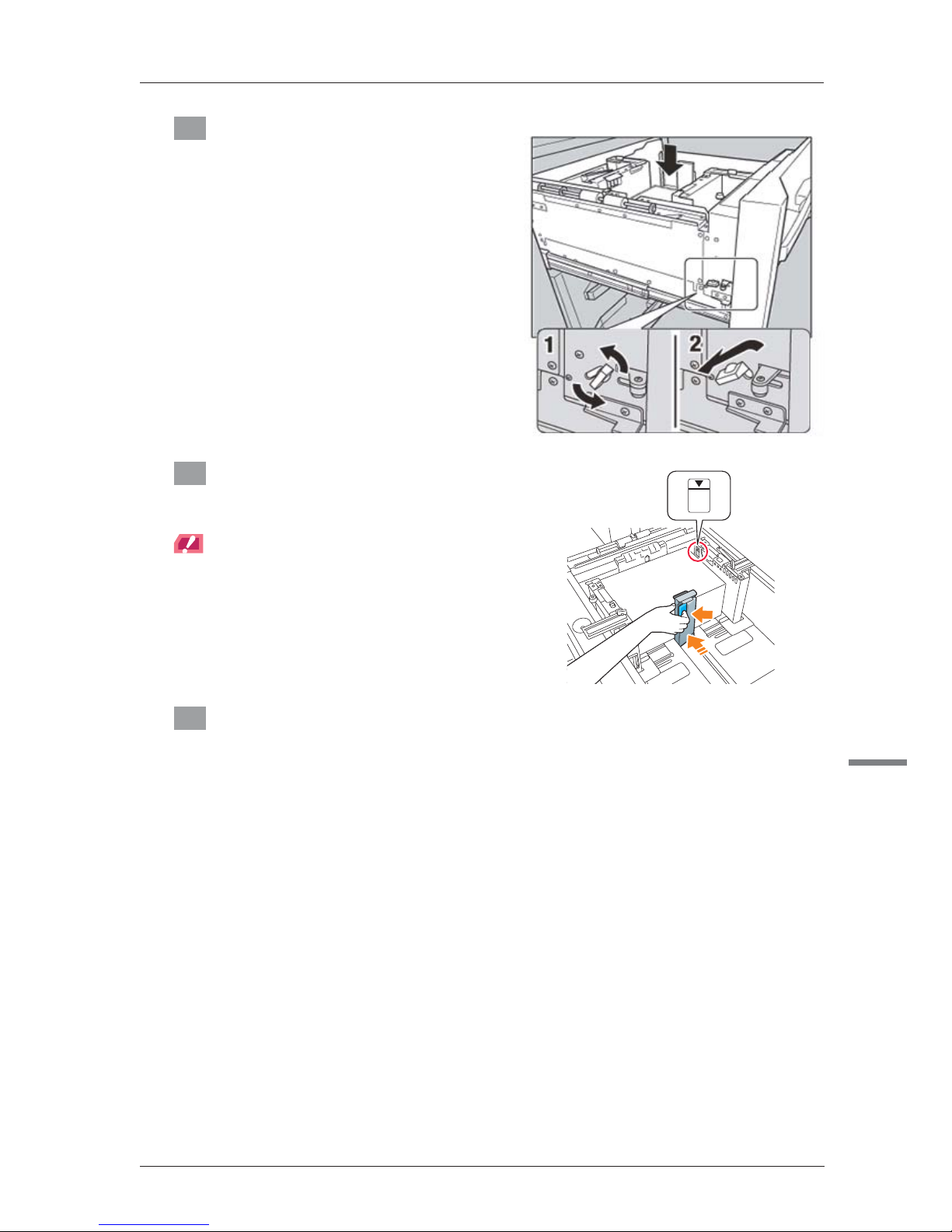

11 Moisten the hydro-wipe (non-woven

fabric without fluff) with isopropyl

alcohol, and clean the dirt of the fusing

unit entrance guide.

12 Hold the lever [M8], and open the paper

path of the duplex unit.

13 Moisten the hydro-wipe (non-woven

fabric without fluff) with isopropyl

alcohol, and clean the dirt of the paper

path of the duplex unit.

14 Hold the lever [M9] and open the jam

processing guide. Then, moisten the

hydro-wipe (non-woven fabric without

fluff) with isopropyl alcohol, and clean the

dirt of the paper path inside the guide.

15 Close the jam processing guide, and close the duplex unit.

16 Push the duplex section into the main body, and move the lever [M1] to the initial

position.

17 Close the left door and the right door of the main body

1-6

bizhub PRESS C1100/C1085

1

Cleaning the centering sensor (Paper feeder unit PF-707/PF-708)

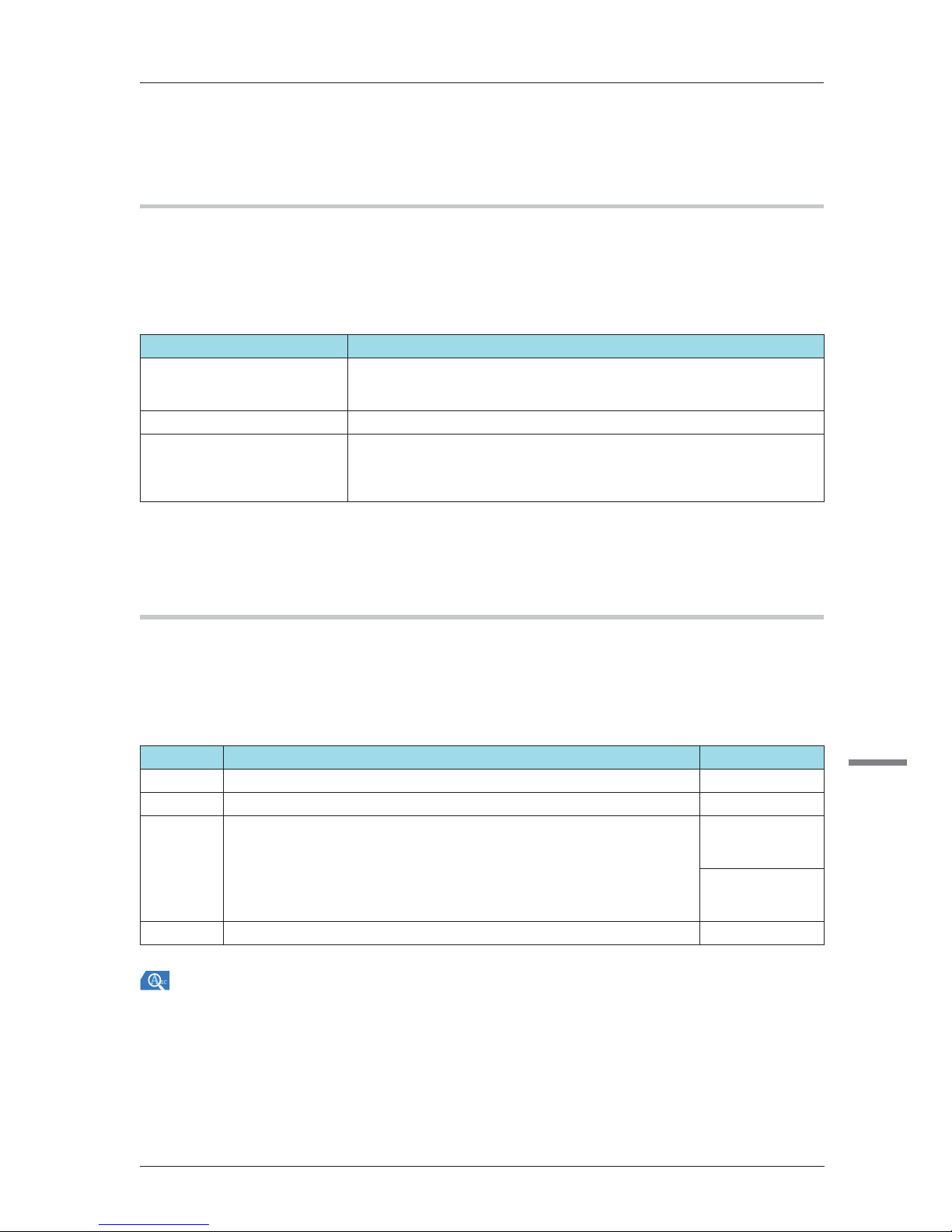

1 Open the front door of the paper feeder

unit.

2 Open the cover [PF4].

3 Clean the centering sensor with a

cleaning pad.

NOTICE

- Do not use alcohol when you clean the sensor. The

surface of the sensor becomes fuzzy.

NOTICE

- Do not touch the positioning pin ( ) with the

cleaning pad since there is grease on the pin.

4 Close the cover [PF4]

5 Close the front door of the paper feeder unit.

1-7

Cleaning the roller of the humidification section

(Relay conveyance unit RU-511)

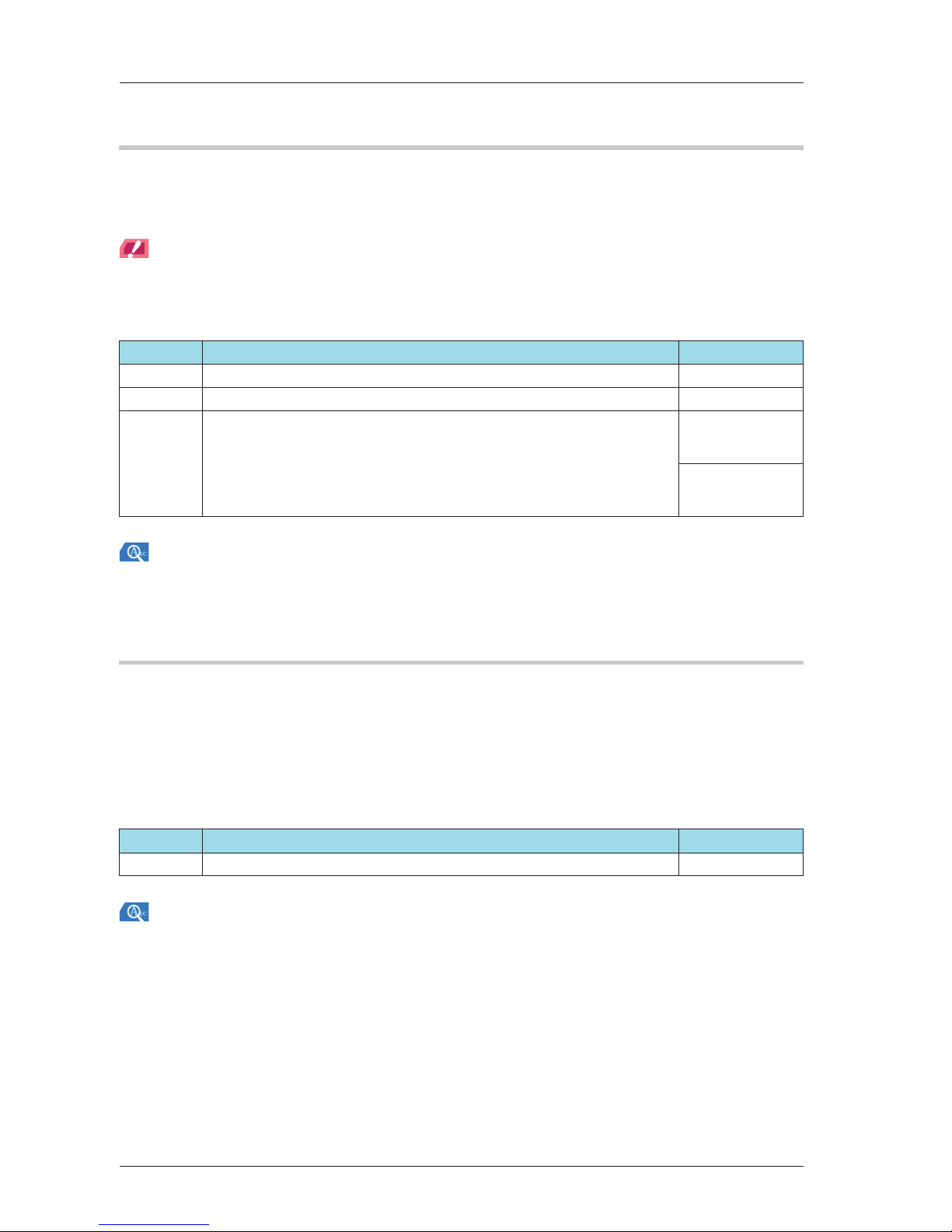

1 Open the front door of the relay

conveyance unit.

2 Hold the handle [HM1], and pull out the

humidification unit.

3 Hold the lever [HM2], and open the paper

path.

4 Moisten the cleaning pad with isopropyl

alcohol, and clean the roller.

5 Hold the handle [HM1], and move the humidification unit to the initial position.

6 Close the front door of the relay conveyance unit.

2-1

bizhub PRESS C1100/C1085

2

2 BOTH SIDES ADJUSTMENT

About both sides adjustment

To maintain stable both sides accuracy against a change in ambient temperature or humidity, a change of this machine

conditions, or a change of the both sides accuracy due to the paper type, perform the both sides adjustment at

periodic intervals.

After you understand the both sides adjustment flow (timing, method, and order), perform the necessary adjustment.

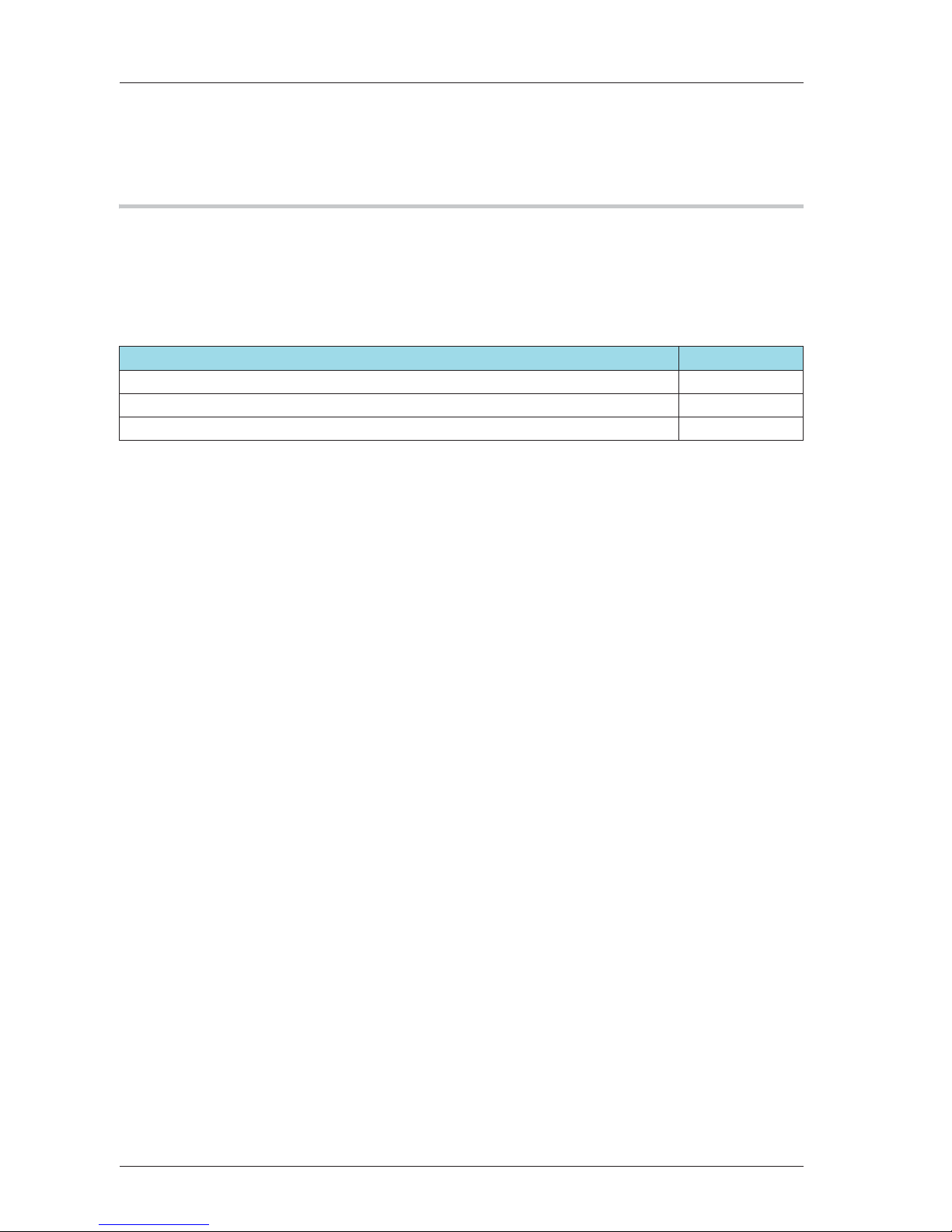

There are three types of both sides adjustment flows as follows.

Adjustment flow

when using a new paper brand, a new paper weight, or a new paper size

)

Adjustment timing

- When you use a new paper brand, a new paper weight, or a new paper size

)

Adjustment order

Reference

For details of each adjustment item, refer to "Contents of both sides adjustment items" (Page 2-3).

Type of adjustment flow Adjustment timing

Adjustment flow when using a

new paper brand, a new paper

weight, or a new paper size

When you use a new paper brand, a new paper weight, or a new paper size

Regular adjustment flow When you change the brand, weight, or size of the paper inside the tray

Adjustment flow for each job • Before you output a job that the both sides accuracy is important

• Before you output a job that the printing area is large

• When you are not satisfied with the both sides accuracy (when you want to

raise the both sides accuracy)

Order Adjustment item Reference

1 Placing paper P.2-3

2 Front side adjustment P.2-6

3 "Gap adjustment" or "Scan measurement adjustment"

P.2-11

(When not using

PF-708 scanner)

P.2-16

(When using PF708 scanner)

4 Registering the paper profile P.2-24

2-2

Regular adjustment flow

)

Adjustment timing

- When you change the brand, weight, or size of the paper inside the tray

NOTICE

When you have not changed the paper inside the tray for more than one day, perform the adjustment before you output

the job (before the adjustment flow for each job).

)

Adjustment order

Reference

For details of each adjustment item, refer to "Contents of both sides adjustment items" (Page 2-3).

Adjustment flow for each job

)

Adjustment timing

- Before you output a job that the both sides accuracy is important

- Before you output a job that the printing area is large

- When you are not satisfied with the both sides accuracy (when you want to raise the both sides accuracy)

)

Adjustment order

Reference

For details of each adjustment item, refer to "Contents of both sides adjustment items" (Page 2-3).

Order Adjustment item Reference

1 Placing paper P.2-3

2 Front side adjustment P.2-6

3 "Gap adjustment" or "Scan measurement adjustment"

P.2-11

(When not using

PF-708 scanner)

P.2-16

(When using PF708 scanner)

Order Adjustment item Reference

1 Back side fine adjustment P.2-26

2-3

bizhub PRESS C1100/C1085

2

Contents of both sides adjustment items

This section describes the contents of the following six adjustment items.

- Placing paper (Page 2-3)

- Front side adjustment (Page 2-6)

- Gap adjustment (When not using PF-708 scanner) (Page 2-11)

- Scan measurement adjustment (When using PF-708 Scanner) (Page 2-16)

- Registering the paper profile (Page 2-24)

- Back side fine adjustment (Page 2-26)

)

Placing paper

1 Pull out the tray to load paper into.

NOTICE

Trays can be pulled out only when this machine is turned

on. Before pulling out the target tray, check that the sub

power switch is turned on.

2 Turn the side guide lock knobs (2 pieces)

counterclockwise to loosen them.

3 Widen the side guide plates on both

sides with pressing the side guide lock

release lever ( ).

NOTICE

To slide the side guide plates, be sure to hold both side

guide plates together. If you move it by holding only either

of the side guide plate, the side guide plate that is held

may become displaced.

4 Widen the rear guide plates on both

sides with pressing the rear guide lock

release lever.

5 Load an appropriate amount of paper into the tray while aligning it to the left-hand side

of the tray.

NOTICE

Load paper with the print side facing up.

2-4

6 Slide the side guide plates on both sides, and press the side guide plates against the

paper.

7 Turn the bottom plate fixing knob

counterclockwise to loosen it, slide it to

the front, and turn it clockwise to fix the

plate.

8 Return the tray to its original position, then withdraw it again after the bottom plate of

the tray goes up completely.

The sound of motor elevating the bottom plate can be heard when the tray is returned in position. After

that automation is completed, again withdraw the tray to find that the bottom plate has been elevated to

the top position.

NOTICE

- Be sure not to withdraw the tray till the motor sound stops. Otherwise, the later operation may be affected

because the bottom plate is not elevated completely to the top.

- Adjust so that the scale marks of the front side and the back side become the same value.

9 Fix the position of the top edges of the

side guide plates.

Move top edges of the side guide plates to align

them to the paper, then turn the two side guide

fixing knobs clockwise to fix the guides.

NOTICE

- Avoid making the space between the side guide

plates too wide or too narrow for the paper to be

seated straight.

- Adjust so that the scale marks of the front side and

the back side become the same value.

2-5

bizhub PRESS C1100/C1085

2

10 Lower the bottom plate of the tray.

Turn the bottom plate fixing knob

counterclockwise to loosen it, slide it to the back,

and turn it clockwise to fix the plate. The bottom

plate automatically goes down.

11 Load the remaining paper into the tray,

then press the rear guide plate against

the paper.

NOTICE

Be careful not to load paper above the , mark that

indicates the height limit on the side guide plate.

Otherwise, a paper jam may occur.

Load paper with the print side facing up.

12 Close the tray.

Push the tray in until it locks into place.

2-6

)

Front side adjustment

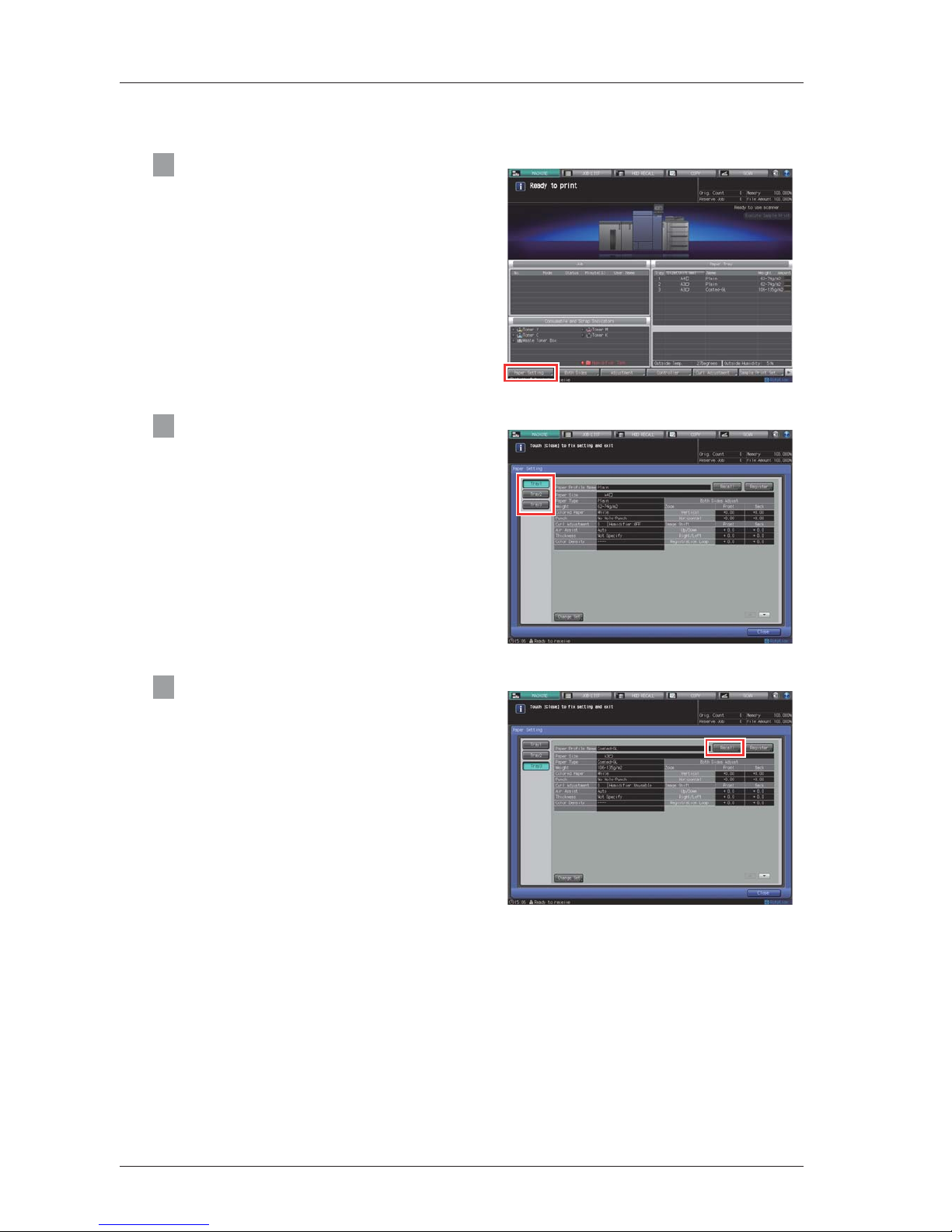

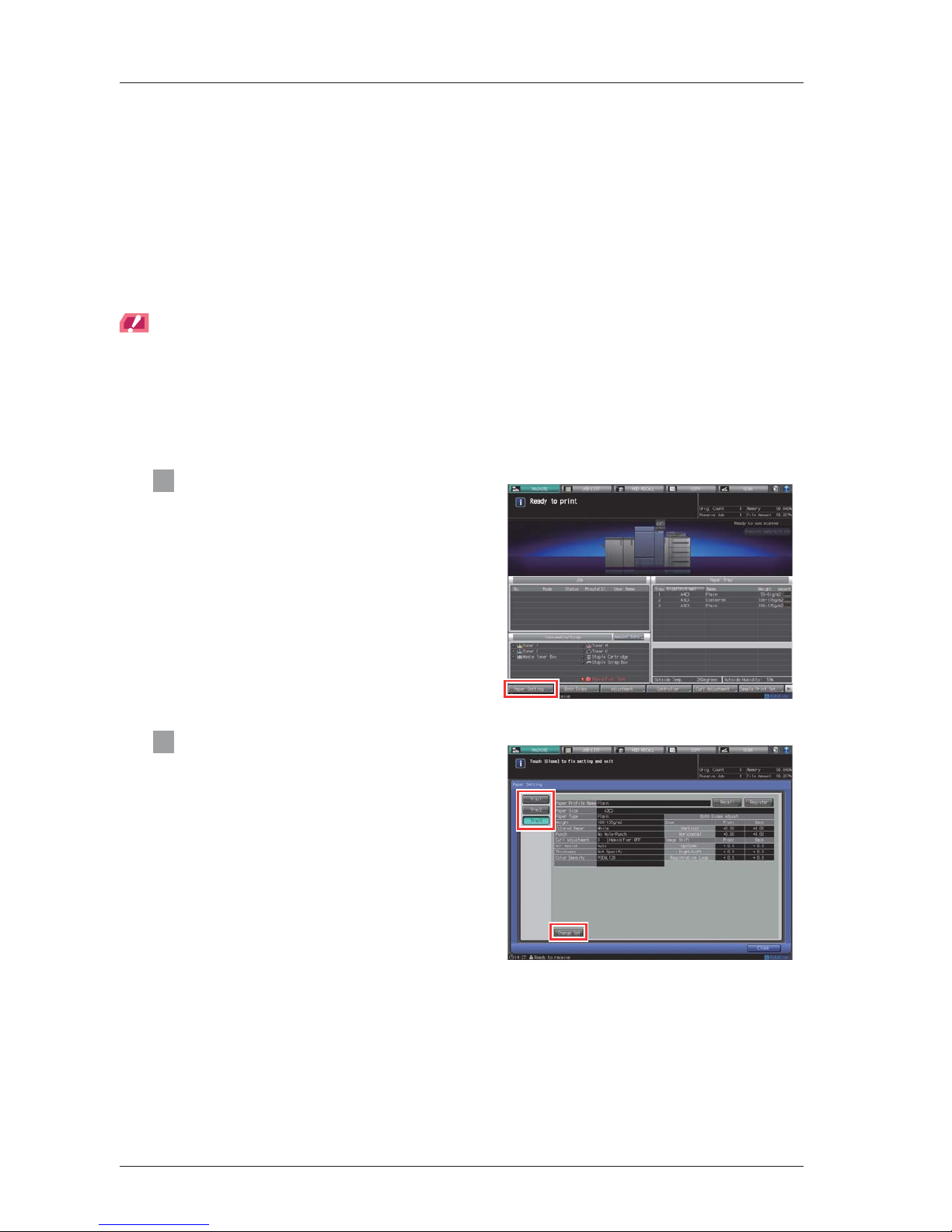

1 Press [Paper Setting] on the [MACHINE]

screen.

2 Press the tray with the target paper

loaded.

3 Press [Recall].

2-7

bizhub PRESS C1100/C1085

2

4 Select the paper profile of the same

paper brand (paper profile name), "Paper

size", "Type of paper" and "Paper

weight" as the paper that you want to

adjust. Then, select [OK].

When there is no paper profile to select, select

[Cancel].

Tips

When the paper profile has a different "Paper size" or "Set

direction" information to the paper that is loaded, the

paper profile is gray out. Therefore, the profile cannot be

selected.

5 Press [Change Set].

6 Press [Both Sides Adj.]

7 Select [Front], then press [Chart

Adjustment].

2-8

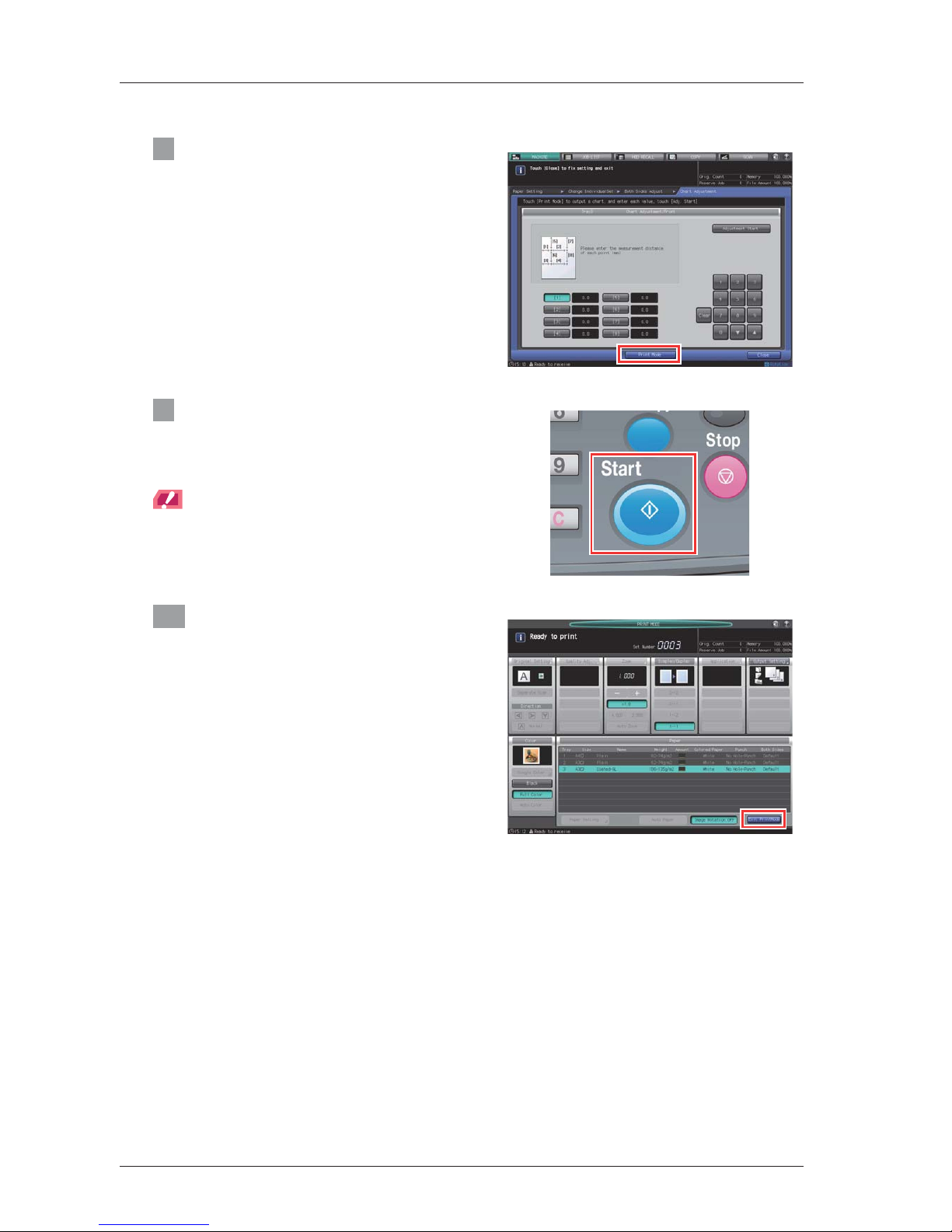

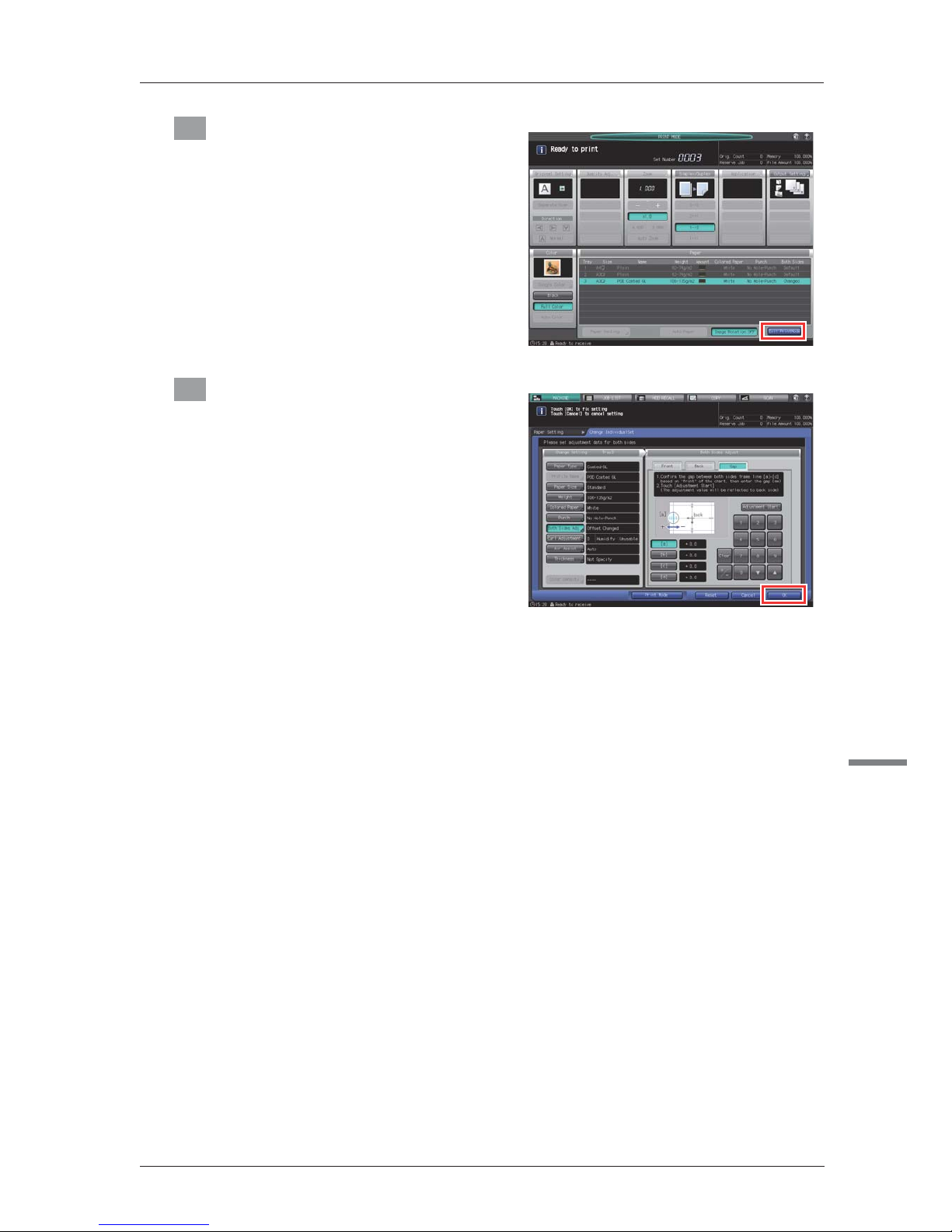

8 Press [Print Mode].

9 When the [PRINT MODE] screen is

displayed, press Start on the control

panel.

A test chart is printed out.

NOTICE

Output about 3 sheets.

10 Press [Exit Print Mode].

2-9

bizhub PRESS C1100/C1085

2

11 Check the length of [2], [4], [6], and [8] of

the charts that are output as the second

and third sheet.

Write down the measured lengths so that you do

not forget them.

When the length of [2], [4], [6], and [8] is within the

following range, press [Close] and then press [OK]

to exit the adjustment.

When the length of [2], [4], [6], and [8] is out of the

following range, measure [1], [3], [5], and [7], and

go to the next step.

[2]: 200mm±0.3mm

[4]: 200mm±0.3mm

[6]: 200mm±0.3mm

[8]: 200mm±0.3mm

12 Press each point number, then enter the

measured length using the keypad on the

screen.

To reset a value, press [Clear].

13 When entry processing is completed,

press [Adjustment Start].

[1]

[5] [7]

[6] [8]

[2]

[3] [4]

[1]

[5]

2-10

14 Output the front side adjustment chart again, and check the length of [2], [4], [6], and

[8] of the charts that are output as the second and third sheet.

Repeat from step 11 to step 14 until the length of [2], [4], [6], and [8] are within the range of the following

values.

[2]: 200mm±0.3mm

[4]: 200mm±0.3mm

[6]: 200mm±0.3mm

[8]: 200mm±0.3mm

15 Press [OK] to exit the adjustment.

2-11

bizhub PRESS C1100/C1085

2

)

Gap adjustment (When not using PF-708 scanner)

NOTICE

The Gap Adjustment is a simple method to adjust only the zoom ratio and image position of the back side. To also

adjust it on the front side, carry out "Front Side Adjustment" (Page 2-6) .

1 Press [Paper Setting] on the [MACHINE]

screen.

2 Press the tray that you conducted "Front

Side Adjustment".

3 Press [Change Set].

2-12

4 Press [Both Sides Adj.].

5 Press [Print Mode].

6 When the [PRINT MODE] screen is

displayed, press Start on the control

panel.

A test chart is printed out.

NOTICE

Output about 3 sheets.

7 Press [Exit Print Mode].

2-13

bizhub PRESS C1100/C1085

2

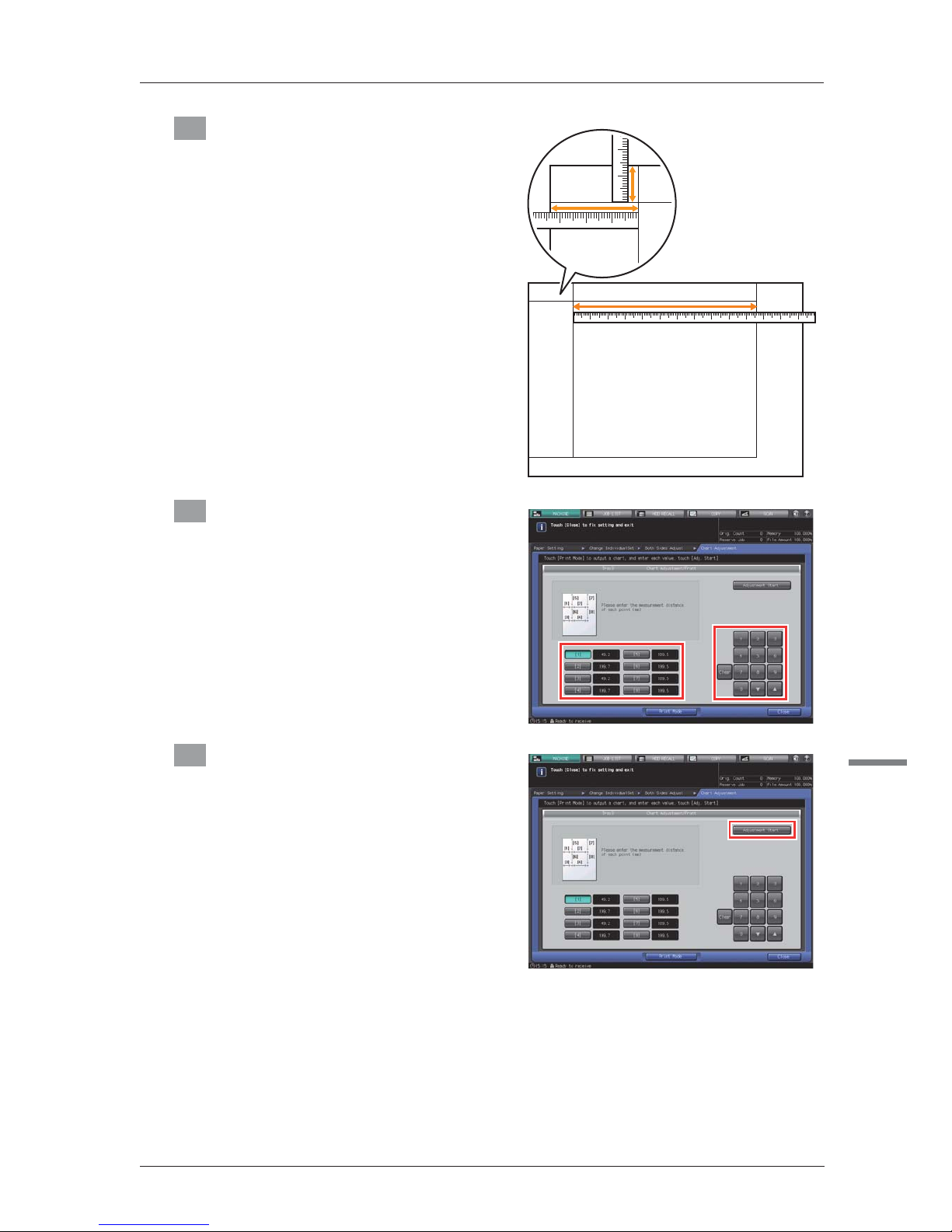

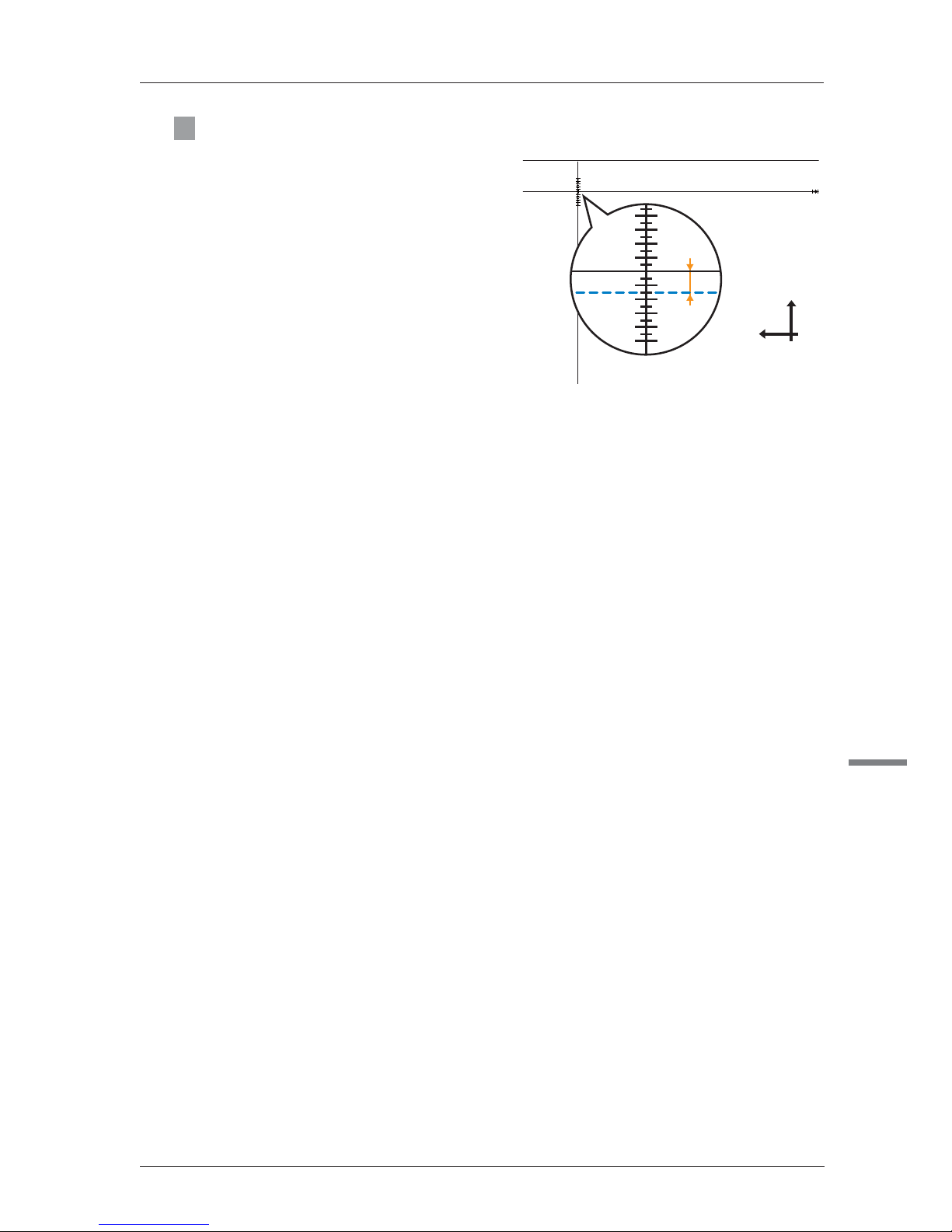

8 Measure the back side image difference

at each point from [a] to [d] that is

positioned at the [back] side of the

second and third output charts.

- The scale resolution is 0.5 mm.

- The black line in the figure shows the back

side, and the blue dashed line shows the

other side (front side).

- The measurement value can be entered in

units of up to 0.1 mm.

- For example, as this figure shows, when the

black line at the back side is shifted by 1.5

mm to the plus direction than the blue dashed

line at the front side, input -1.5 and correct the

difference. Then, the black line at the back

side 1.5 mm is moved to the minus direction.

- Write down the measured values so that you

do not forget them.

EDFN

>D@

[

\

2-14

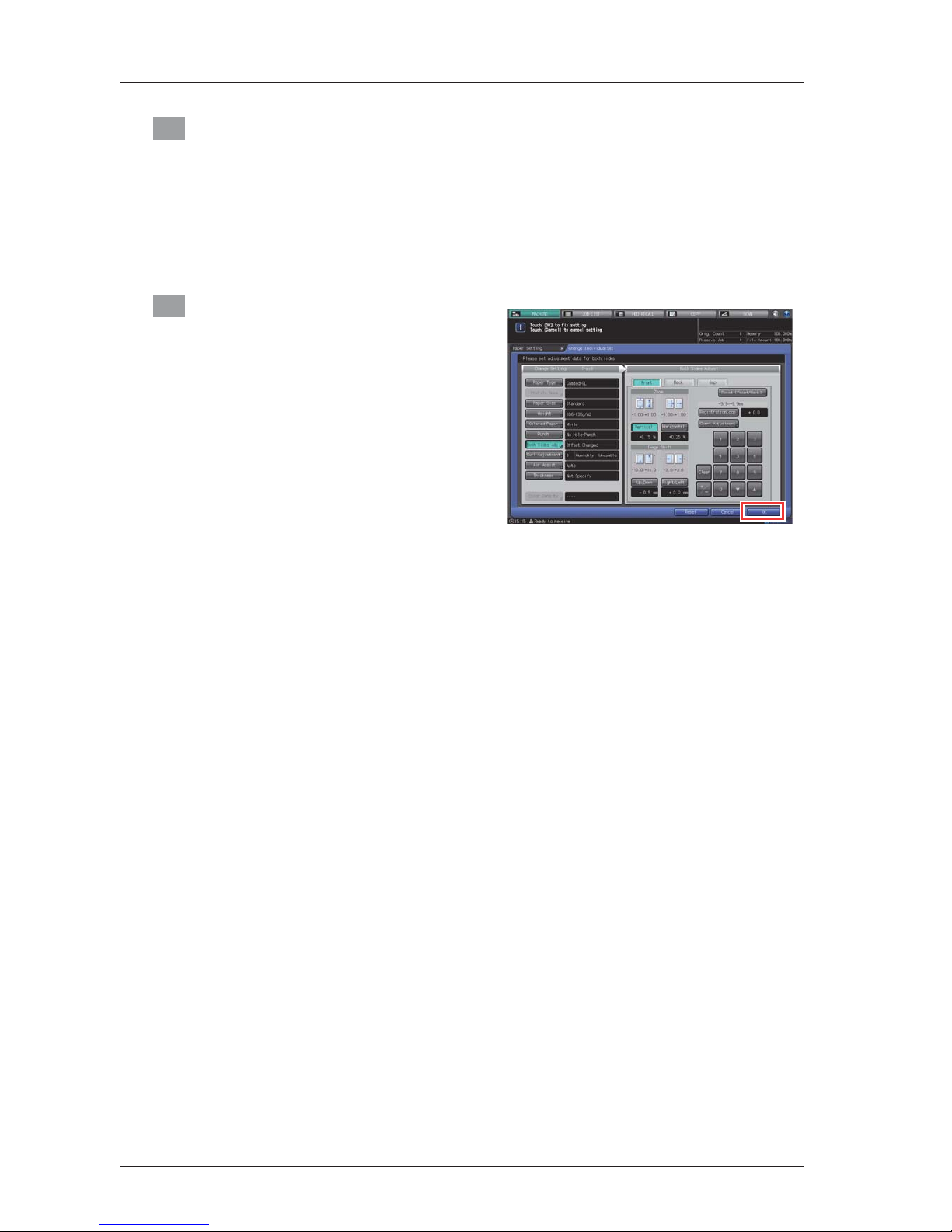

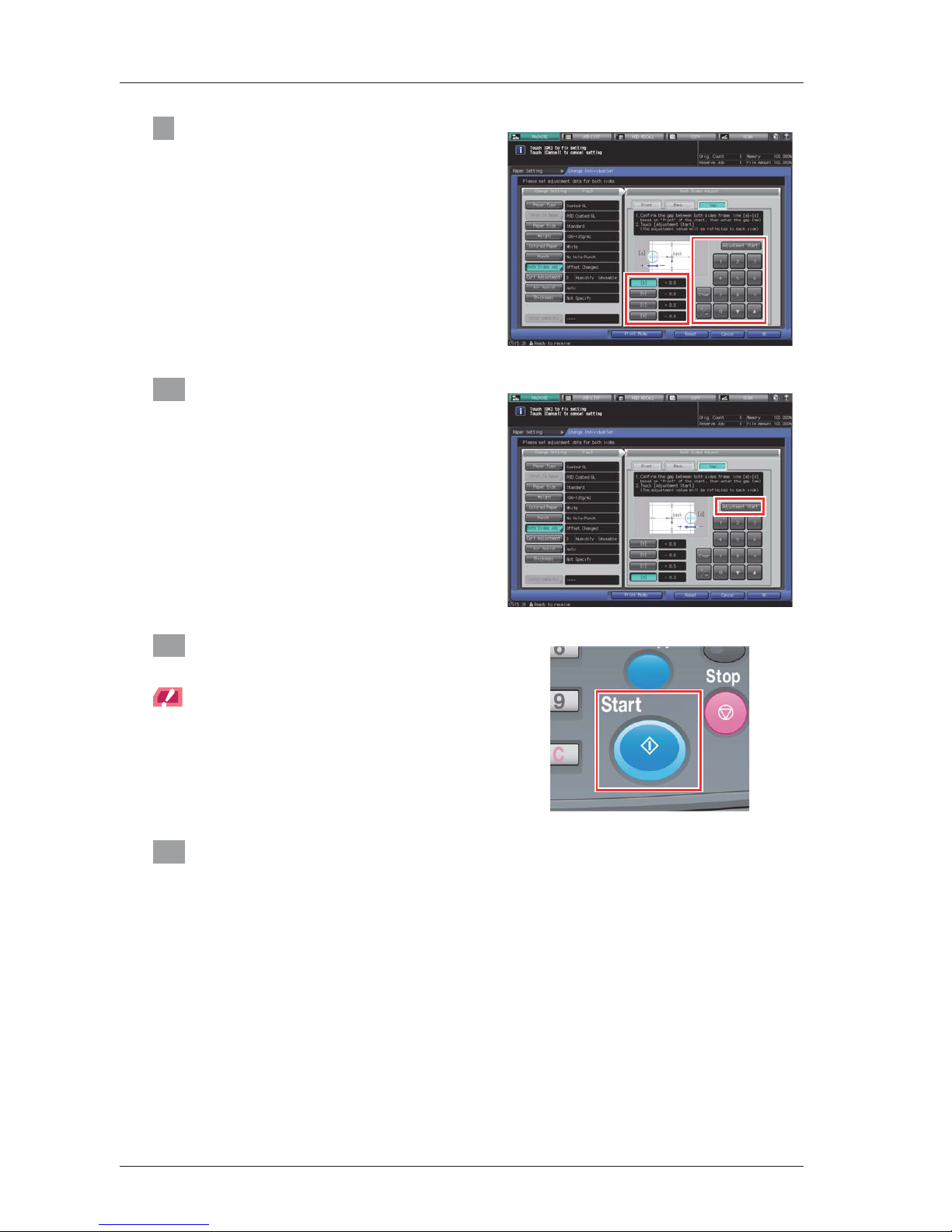

9 Press [a] to [d] of each point, and enter

the adjustment value using the keypad,

[,], or [+] on the screen.

10 When entry processing is completed,

press [Adjustment Start].

The input adjustment value is reflected to the

"Zoom" value and the "Image Shift" value at the

[Back] screen.

When [User Setting] - [Common Setting] - [Back

Side Magnification Adjustment] - is configured to

[OFF], the adjustment value is not reflected to

[Horizontal] at the [Back] screen.

11 Press Start on the control panel.

A test chart is printed out.

NOTICE

Output about 3 charts.

12 Check the gap of the printing position referring to the charts that are output as the

second and third sheet.

Repeat steps 10 to 13 until all gaps between the front and back sides are cleared.

2-15

bizhub PRESS C1100/C1085

2

13 Press [Exit Print Mode].

14 Press [OK] to exit the adjustment.

2-16

)

Scan measurement adjustment (When using PF-708 Scanner)

Adjust the magnification ratio and printing position of the back side with reference to the printing position of the front

side. The magnification ratio and printing position of the back side are automatically adjusted by using the scanner

function of this machine to measure the gap amount in printing position of the back side to the front side. You do not

need to measure the gap amount with a scale. The adjustment is available for paper of all sizes which can be used

with this machine.

Print out 1 to 20 sheets of the adjustment chart having both front and back sides printed, and scan them 4 times per

sheet. The average value of gap amounts in printing position of the back side to the front side, which can be obtained

by scanning up to 20 sheets of the adjustment chart, will be calculated in order to adjust the magnification ratio and

printing position of the back side.

NOTICE

The [Scan Meas.] adjustment provides the coordination based on the average value of gap amounts, taking into

account the gap in printing position between the first and last sheets which can be produced when multiple sheets are

output.

Performing the [Scan Meas.] adjustment may require readjustment of the "Zoom and Image Shift Adjustment"

registered in a paper profile.

The [Scan Meas.] adjustment is a simple method to adjust only the magnification ratio and image position of the back

side. To adjust both front and back sides, perform the "Front side Adjustment" (Page 2-6).

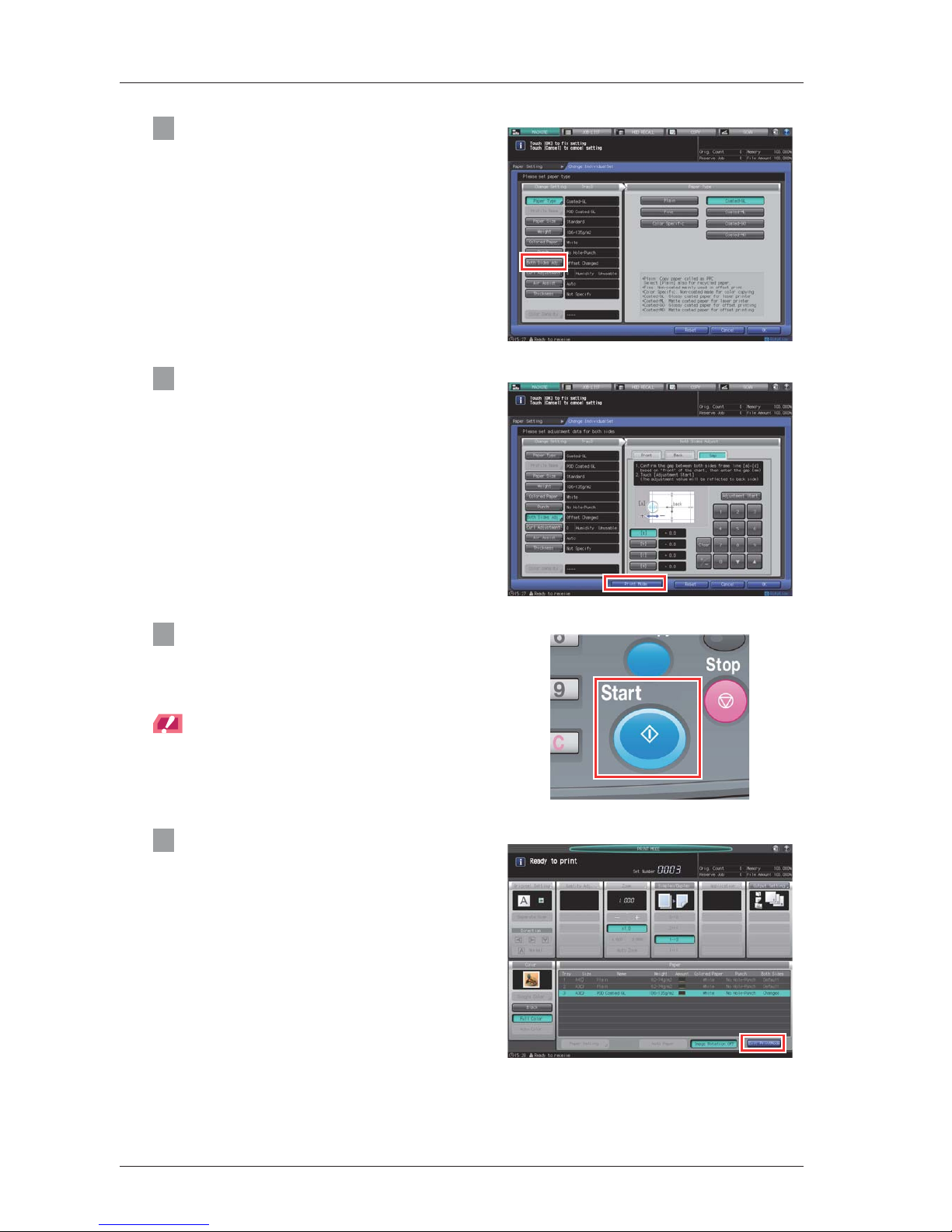

1 Press [Paper Setting] on the [MACHINE]

screen.

2 Select the tray with the target paper

loaded, then press [Change Set].

2-17

bizhub PRESS C1100/C1085

2

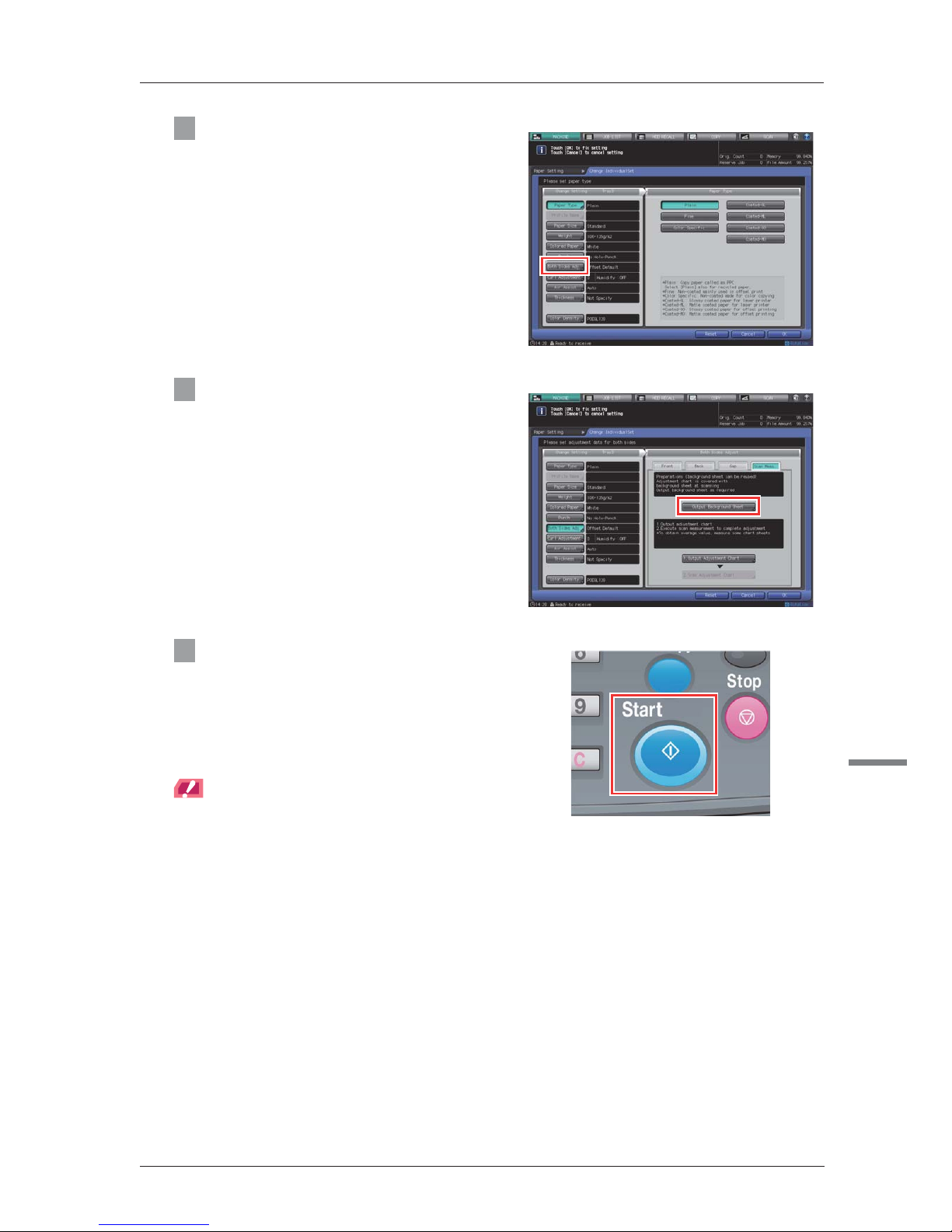

3 Press [Both Sides Adj].

4 Check that [Scan Meas.] is displayed,

then press [Output Background Sheet].

5 When the [PRINT MODE] screen is

displayed, press Start on the control

panel.

A background sheet is printed out. If you already

have the background sheet available for

measurement, you do not need to print out a

background sheet. Proceed to Step 7.

NOTICE

Use paper of A3 or larger, or 11 e 17 or larger to output

the background sheet. When you press [Output

Background Sheet] to display the PRINT MODE Screen

for the background sheet, the tray selected in step 2 is

automatically selected on the screen, but it can be

changed as desired. Select a tray loaded with A3 or larger,

or 11 e 17 or larger paper. You can also change the print

count, but only one sheet is needed. If the background

sheet size is smaller than A3 or 11 e 17, the scan

measurement may not be performed.

2-18

6 Press [Exit Print Mode].

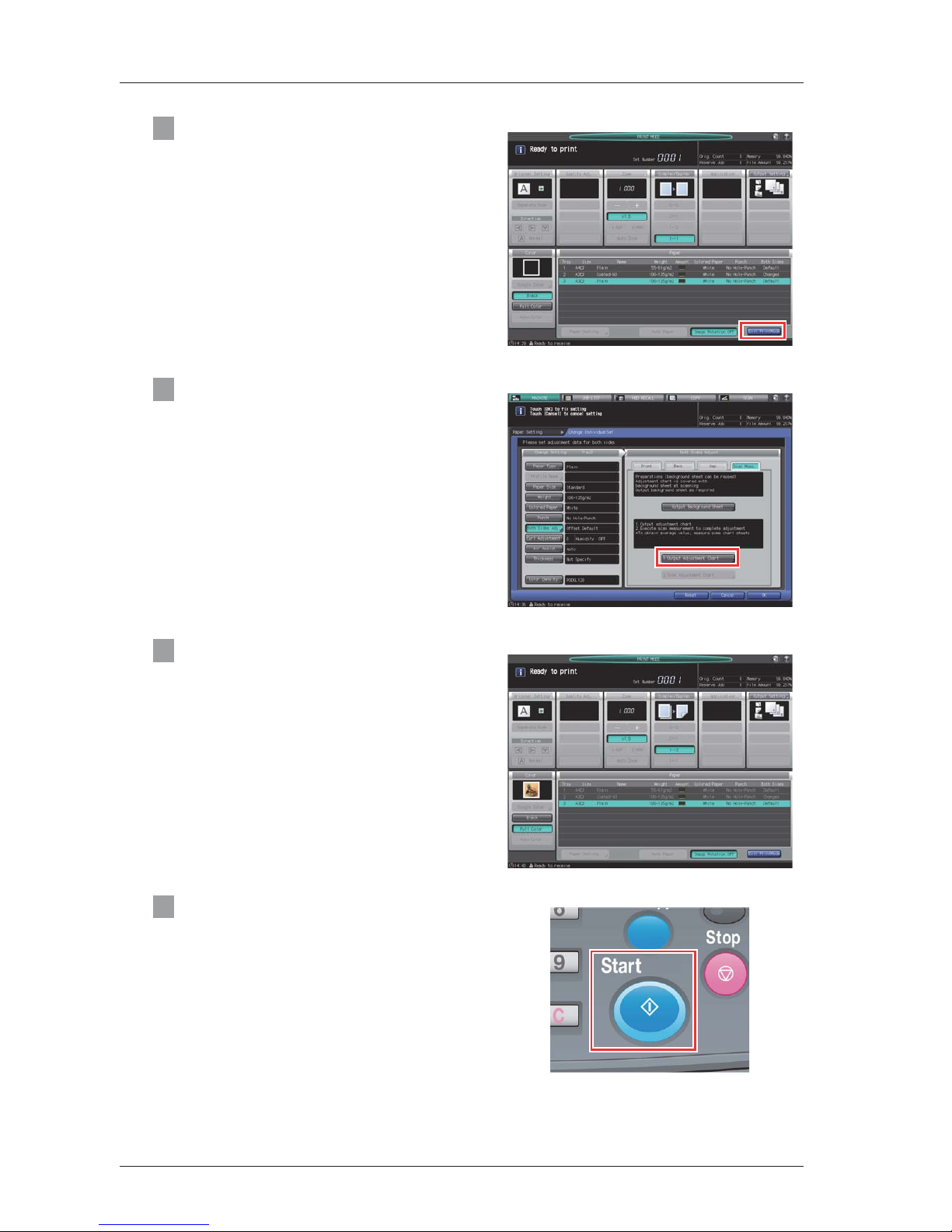

7 Press [1. Output Adjustment Chart].

8 Enter the number of adjustment charts

you want to print out.

however, only up to 20 adjustment charts can be

scan-measured continuously.

9 Press Start on the control panel.

Adjustment charts are printed on both sides of the

paper in the tray you selected in Step 2.

Loading...

Loading...