Page 1

2

ADJUSTMENT

2 ADJUSTMENT

Page 2

2 ADJUSTMENT

Page 3

HOW TO USE THIS SEC-

ADJUSTMENT

ADJUSTMENTS MADE

TION

[1] Scope and Precautions

This section provides detailed information about the

adjustment items and procedures. Before addressing

customer complaints, perform the following checks:

1. Check whether the power supply voltage meets

the specifications.

2. Check whether the power supply is properly

grounded.

3. Check whether this machine shares the power

supply with any other machine that draws large

current intermittently (e.g., elevator and air conditioner that produce electrical noise).

4. Check whether the installation environment is

good.

a. The machine must be installed in a properly ven-

tilated area not exposed to high temperature,

high humidity, and direct sunlight.

b. The machine must be installed on the horizontal

floor.

5. Check whether original has a problem to cause

the defective image.

6. Check whether the selected density value is correct.

7. Check whether the surface of the platen glass

and the slit glass are clean.

8. Check whether correct paper is used for copying.

9. Check whether copying materials and parts

(e.g., developer, drum, and cleaning blade) are

replenished and replaced when they reach the

end of the useful life.

10. Check whether toner remains.

When servicing the machine, observe the following

precautions:

1. Only either side of the AC line is shut off when the

SW1 (main) of this machine is turned off. Always

unplug the power cord before starting the service

work. If it is necessary to service the machine

with the power on, take care not to be caught in

the scanning gear of the exposure unit.

2. Special care should be taken when handling the

fixing unit because it operates at extremely high

temperatures.

3. The developing unit has a strong magnetic field.

Keep watches and measuring equipment away

from it.

4. Take care not to damage the drum with tools and

so on.

5. Do not touch IC pins with bare hands.

WHEN REPLACING

PARTS

Adjustments (including checks) and settings are not

only required when a customer complaint about the

copy image quality is received, but also after replacing

or reassembling parts.

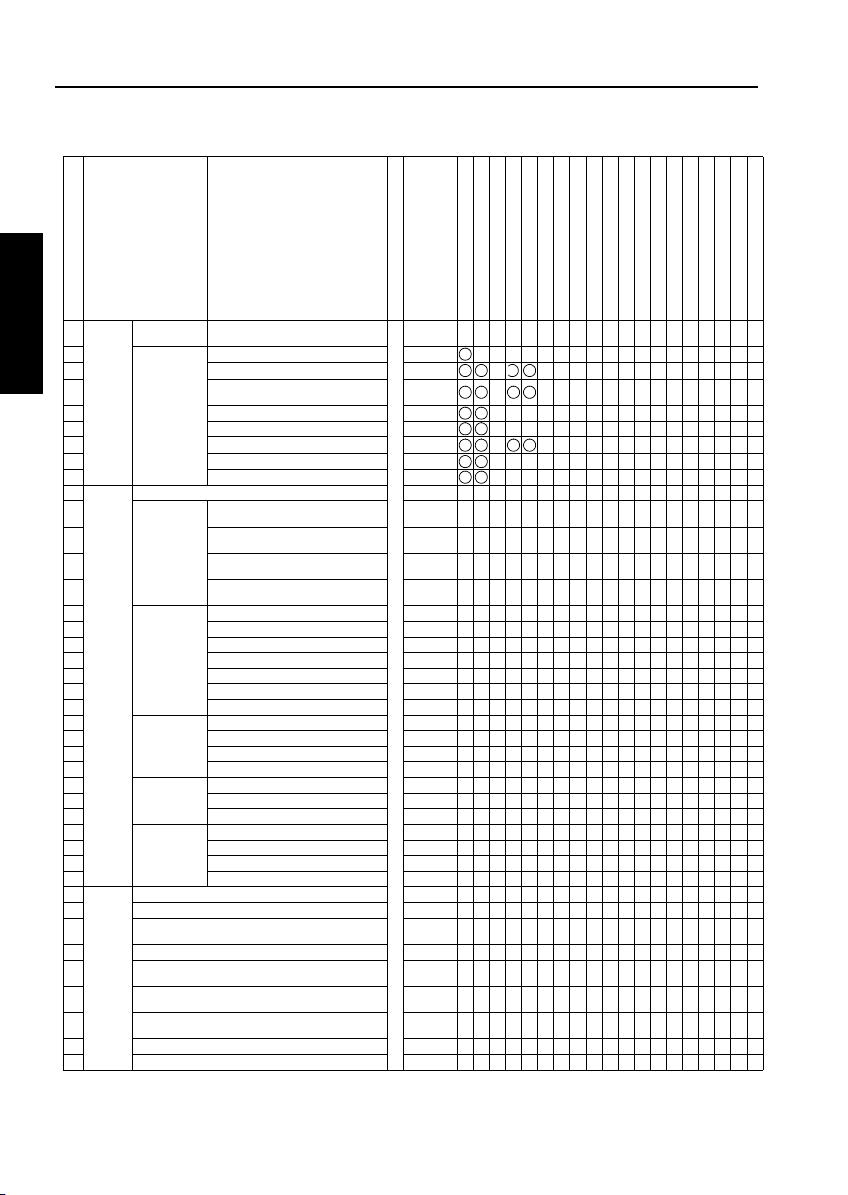

[1] How to Read Tables

Components of the tables used in this section are as

follows:

1. Mode

Adjustment mode to be selected.

[P]: Utility mode

[25]: 25 mode

[36]: 36 mode

[47]: 47 mode

2. Code

Code and copy quantity setting button used in

each mode.

3. Page

Page in the "ADJUSTMENT" section.

4. Circled numbers

2

1

Indicate that adjustments (including

checks) must be made in order of precedence.

(Circle without numeric character):

Indicates that adjustments (including

checks) can be made independently.

2 ADJUSTMENT

2-1

Page 4

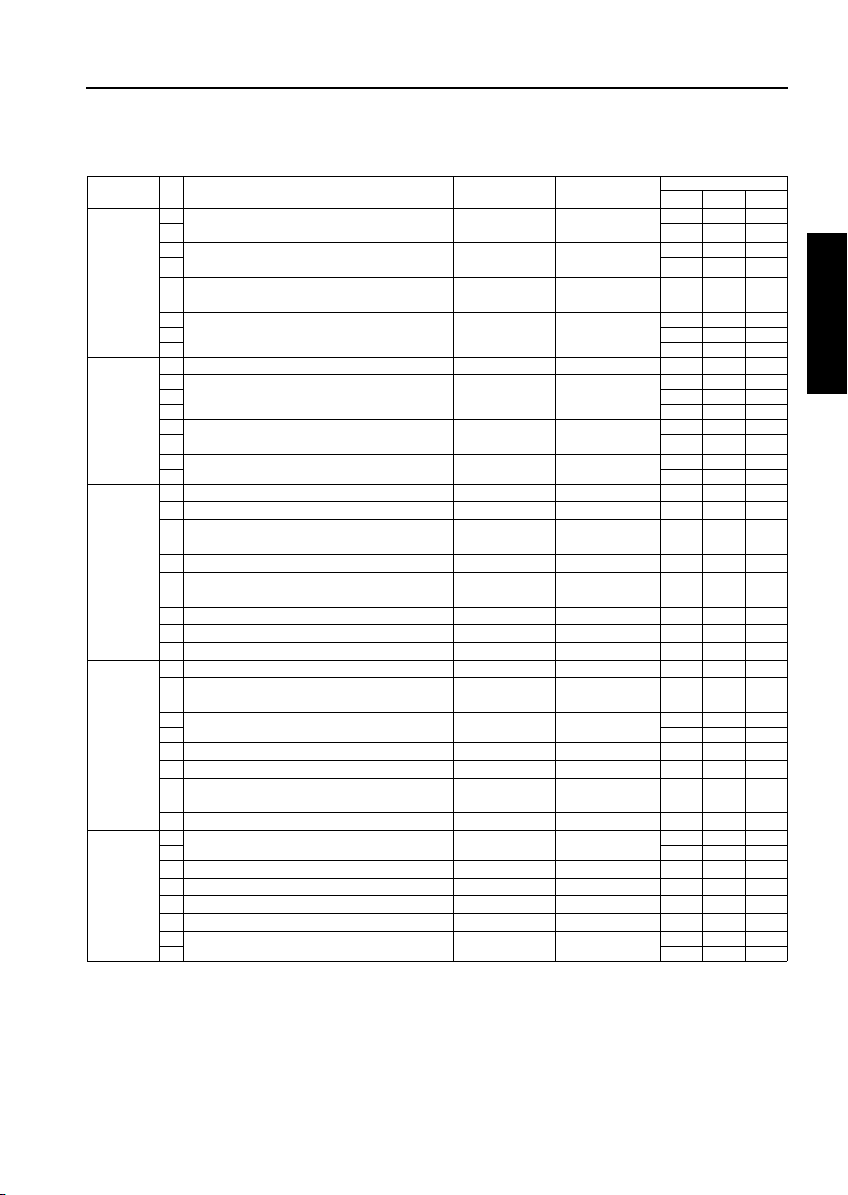

ADJUSTMENT

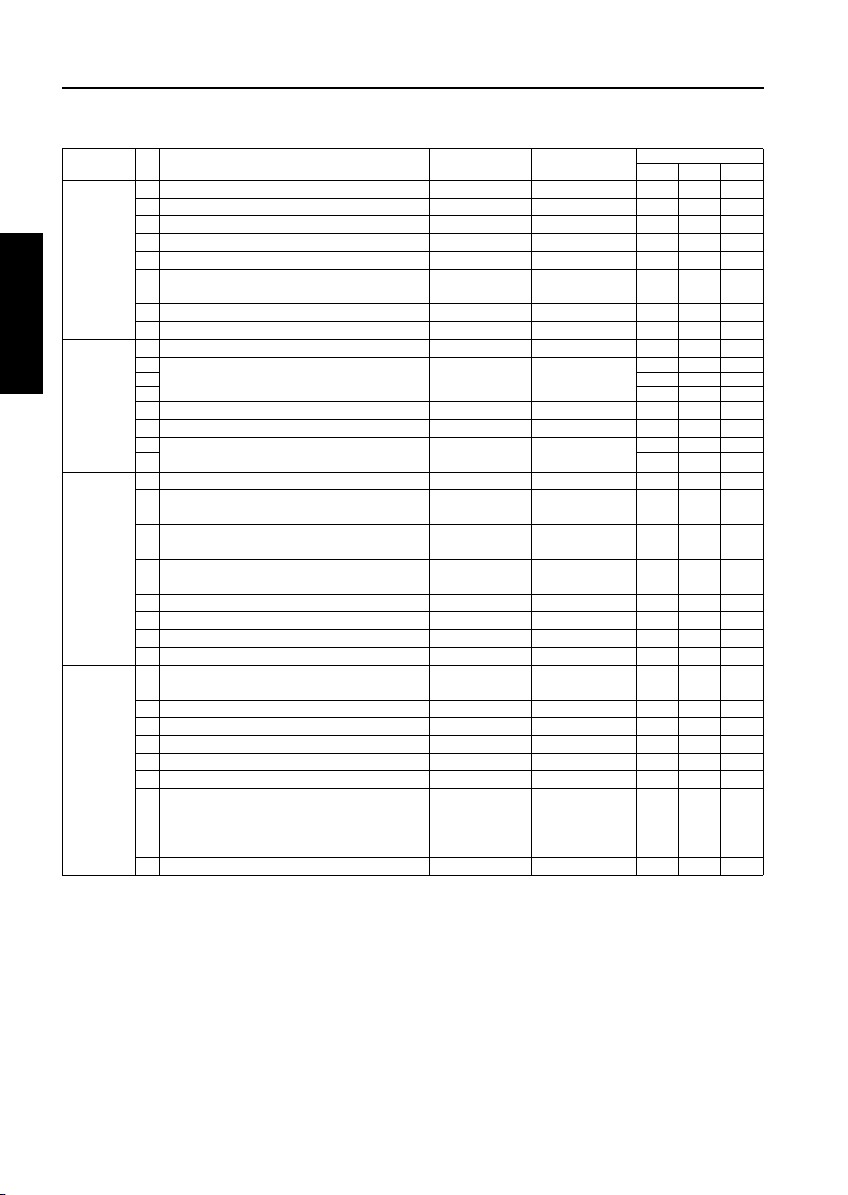

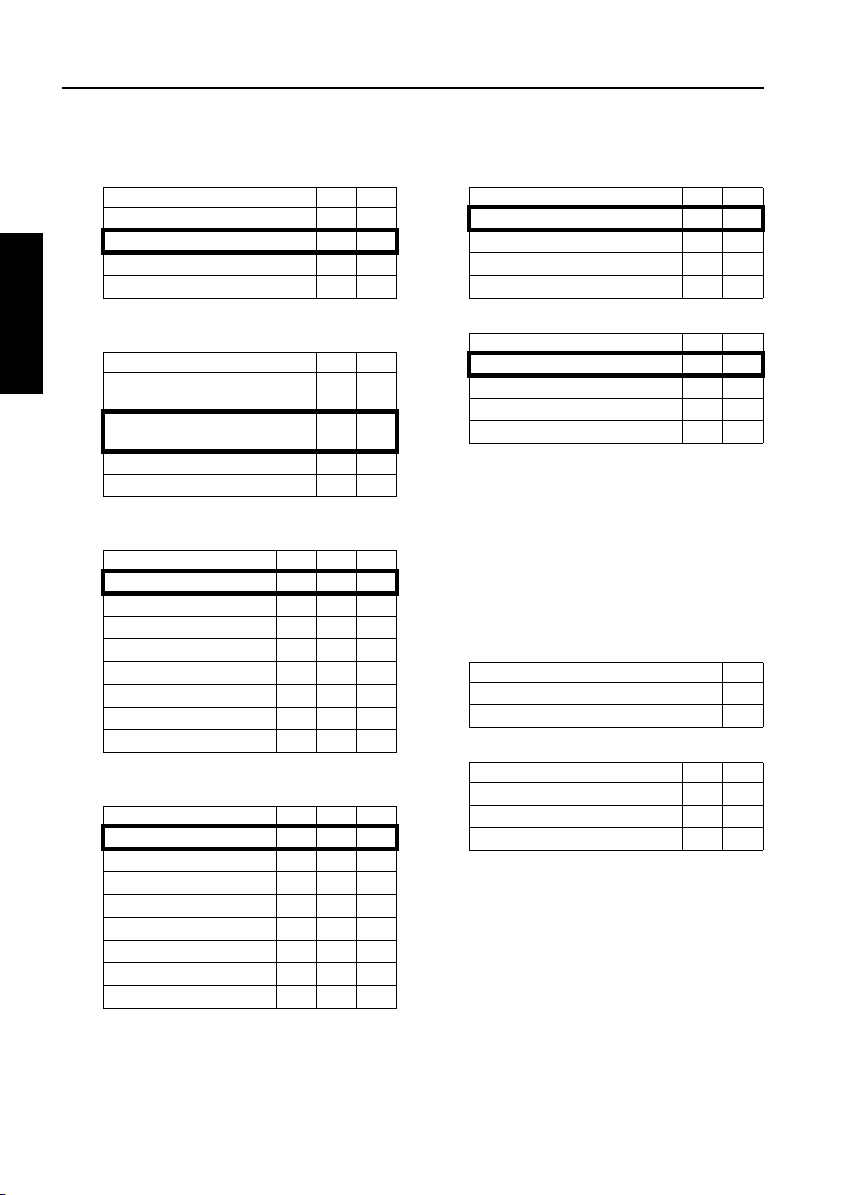

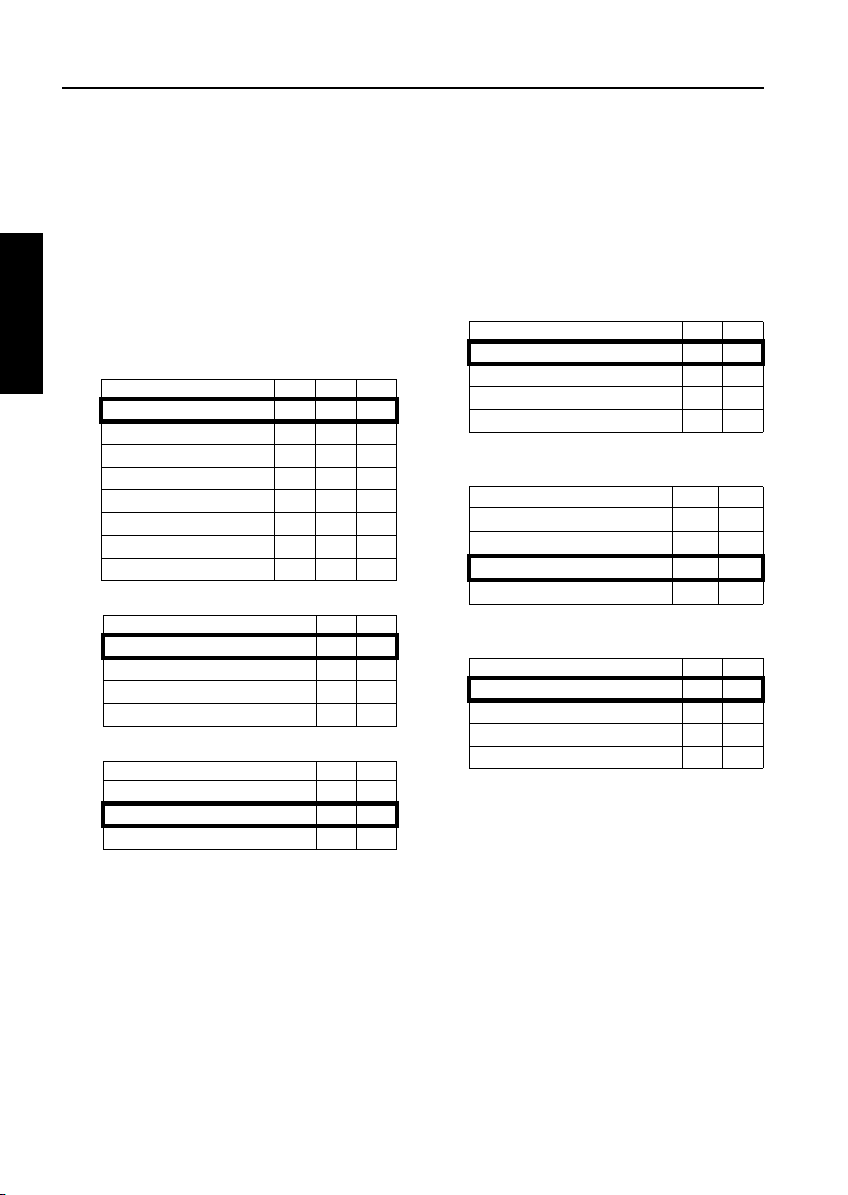

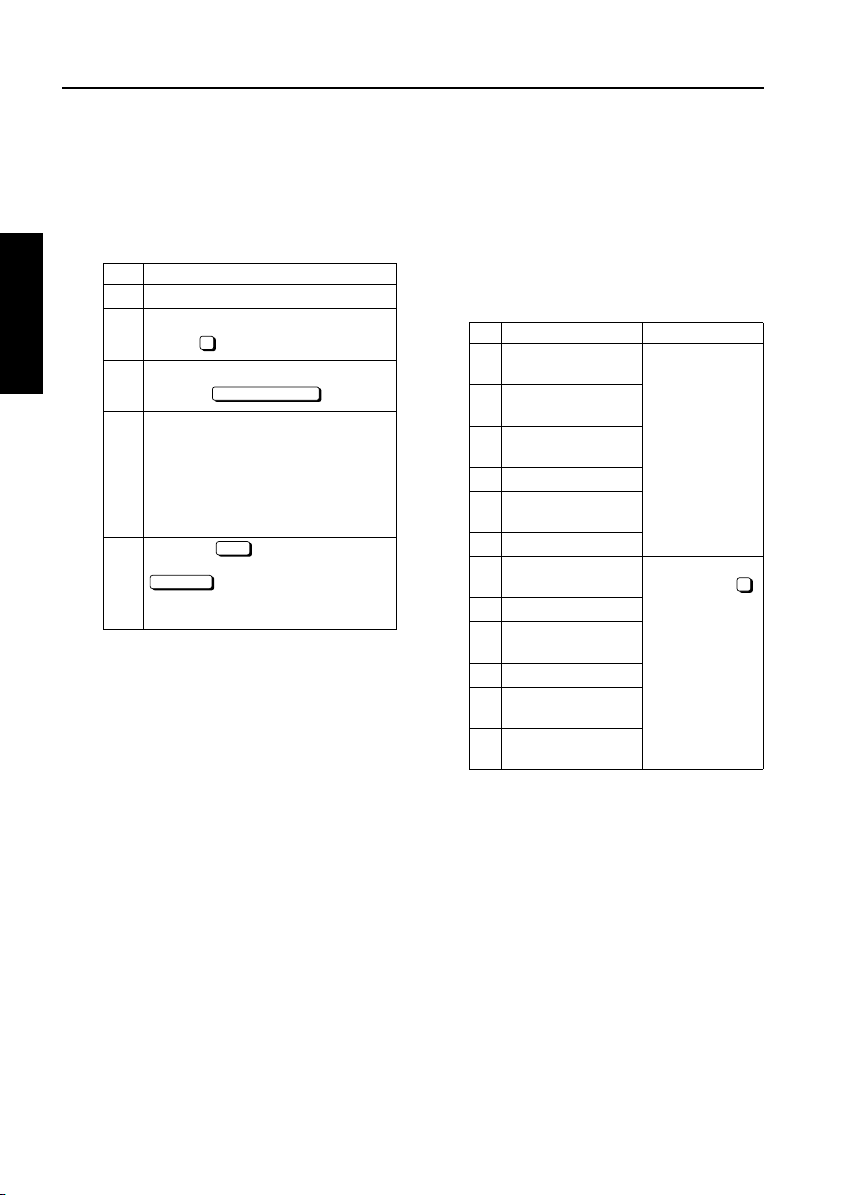

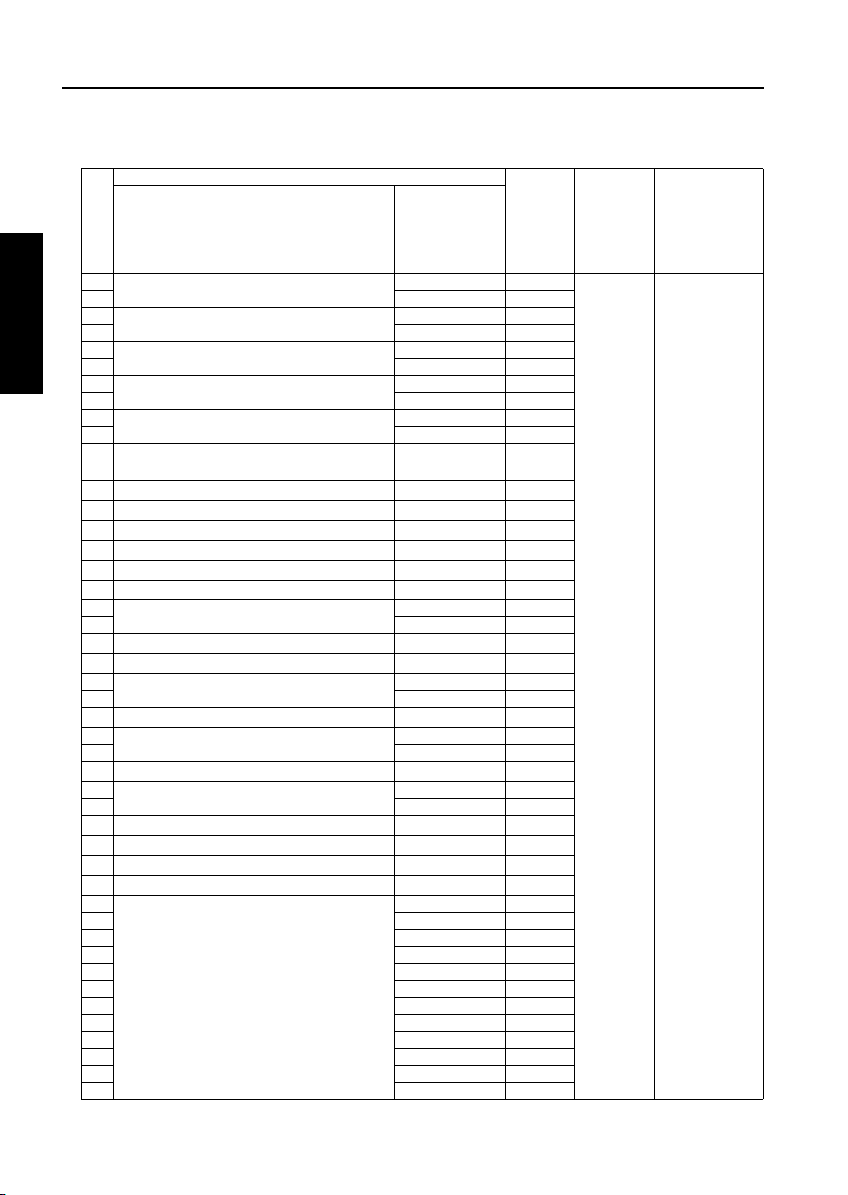

LIST OF ADJUSTMENT ITEMS

Item No.

Process

1

Adjustment

2Drum

2 ADJUSTMENT

3

4

5 Auto dot diameter adjustment 2-53

6 LD1 offset adjustment 2-53

7

8

9

10 Image

Adjust-

11

ment

12

13

14

15 Timing Adjust16 Printer resist loop adjustme nt 2-63

17 Printer pre-resist adjustment 2-63

18 Printer lead edge timing adju stment 2-64

19 Scanner restart timin g adjustment 2-64

20 EDH restart timing adjustment 2-65

21 EDH resist loop adjustment 2-65

22 EDH Adjust23 EDH original size adjustment 2-67

24 EDH sensor sensitivity adjustment 2-67

25 EDH skew offset adjustment 2-68

26 Centering

27 Scanner centering adjustme nt 2-69

28 EDH centering adjustment 2-70

29 Warp adjust30 Scanner (platen) warp (sub-scan) 2- 70

31 Scanner (EDH) warp (ma in scan) 2-70

32 Scanner (EDH) warp (sub-sc an) 2-70

33 Finisher

Adjust-

34 Folding stopper adjustment (FN-7 only) 2-81

ment

35

36 Trimmer stopper adjustment (TMG-2 only) 2-82

37

38

39

40 1st folding position adjustment (ZK-2 only) 2-84

41 2nd folding position adjustment (ZK-2 only) 2-84

Classification by Adjustment

High voltage

adjustment

Peculiarity

Adjustment

Tray Adjustment 2-58

Magnification

Adjustment

ment

ment

Adjustment

ment (Copier)

Stapling and folding stopper adjustment (FN-7 only) 2-81

Cover sheet tray size adjustment

(Cover Inserter C only)

Punch vertical position adjustment

(PK-3 / ZK-2 only)

Punch horizontal position adjustment

(PK-3 / ZK-2 only)

Punch registration loop adjustment

(PK-3 / ZK-2 only)

High Voltage Auto Adjustment

Blade setting mode 2-51

Auto drum potential adjustment

Auto maximum density adjustment

(Dmax adjustment)

LD2 offset adjustment

Auto Gamma Adjustment

Cartridge set mod e

Printer vertical magnification adjustment

Printer horizontal magnification

adjustment

Scanner (platen) vertical adjustment

Scanner (EDH) vertical magnification adjustment

Printer restart timing ad justment 2-62

EDH density adjustment 2-66

Printer centering adjustment 2-69

Scanner (platen) warp (ma in scan) 2-70

Adjustment Item

Mode

Page

Drum

Developer

High Voltage unit

Write unit

Dust-proof glass

Each tray unit

Bypass paper feed unit

Paper up/down plate hoist wires

Tray pick-up solenoid

Registration roller

Registration unit

Registration Clutch

Mis-centering detection sensor

ADU unit

Read unit

Fixing unit

Memory board

EDH unit

2-50

2-52

2-52

2-54

2-56

2-56

2-59

2-60

2-60

2-61

36

2-82

2-83

2-83

2-84

OO

1

2 2 2 2

3 3 1 1

4 4

5 5

6 6 3 3

7 7

8 1

OO O

OO O

OO

OO

OOO

O OOO O

OO

OOO

OOO

OO

OOO

Finisher

O

O

O

O

O

O

O

O

O

O

O

O

O

OO

OO

O

O

O

O

OO

OO

OO

OO

OO

OO

OO

OO

OO

2-2

Page 5

ADJUSTMENT

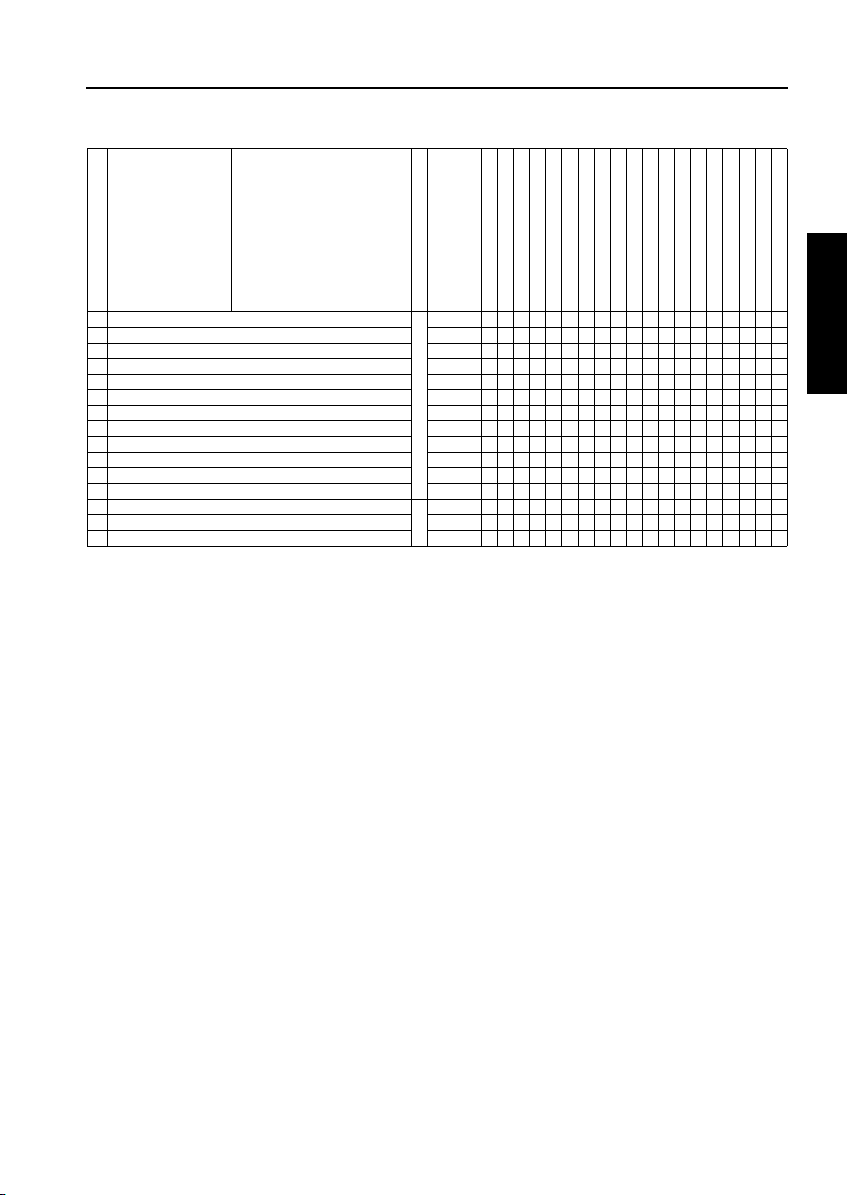

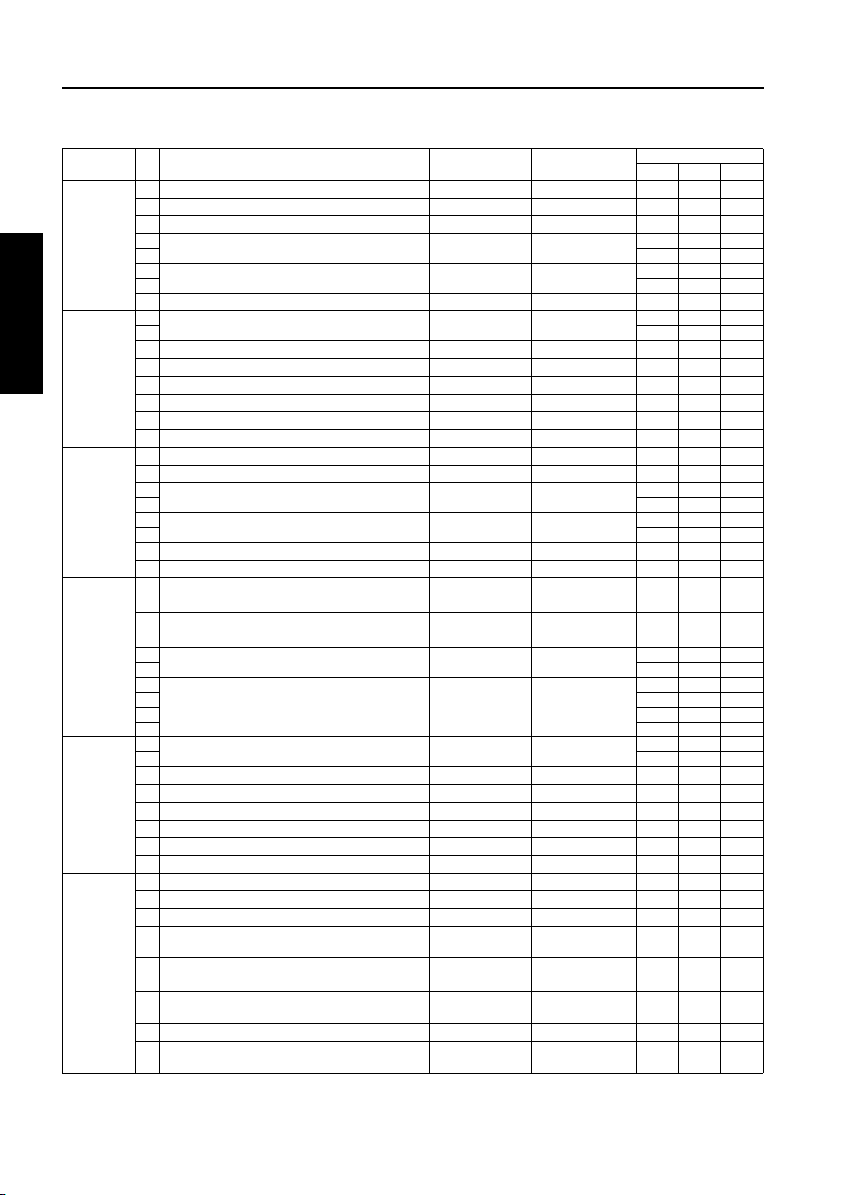

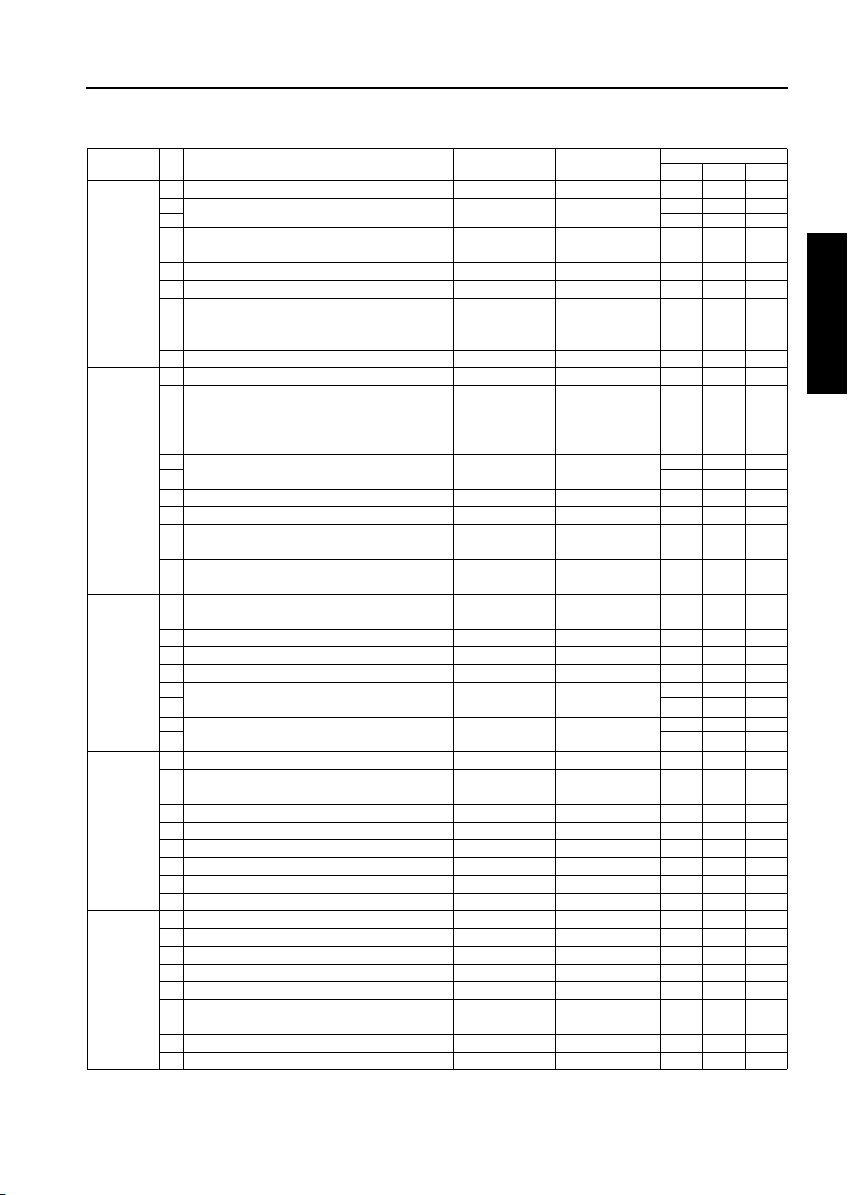

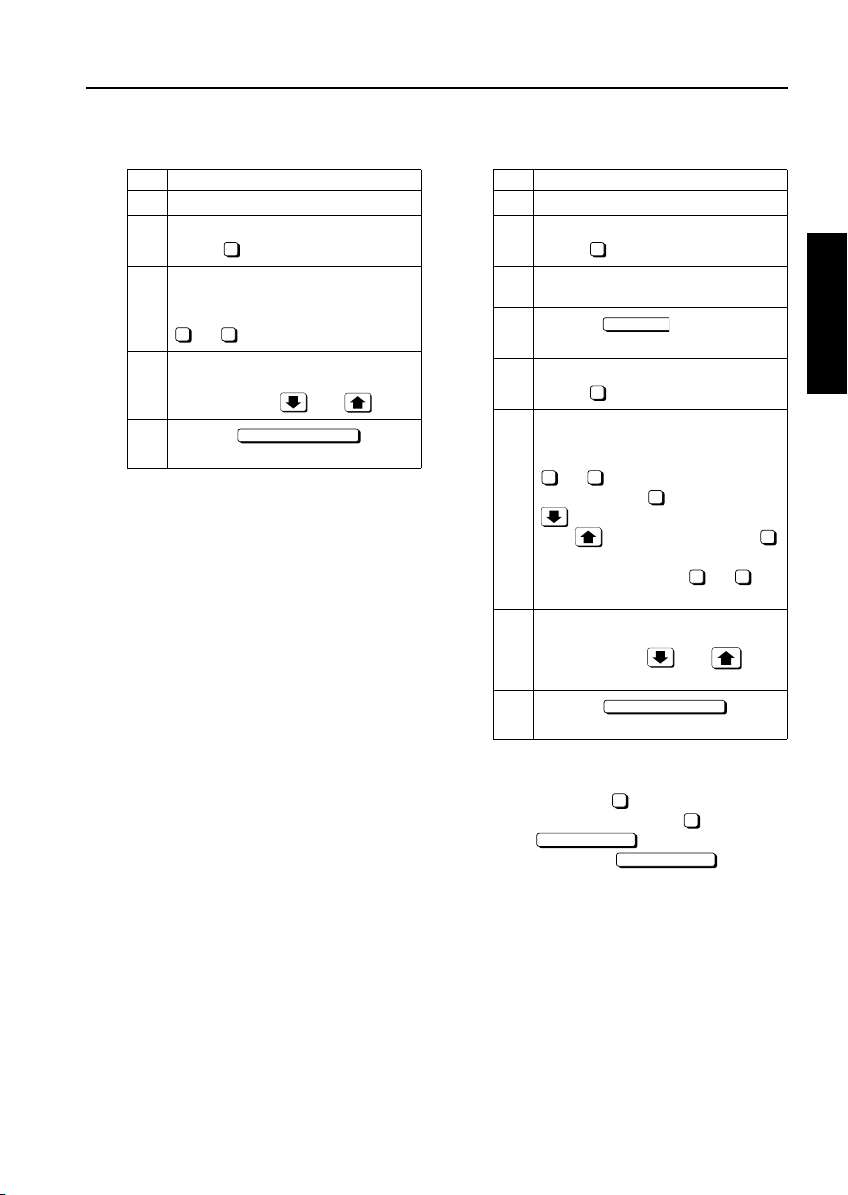

Item No.

42 Centering Adjustment 2-101

43 Paper up/down plate horizontal adjustment 2-105

44 Skew Adjustment 2-107

45 Tray Spring Pressure Adjustment 2-109

46 Paper Feed Height (Upper Limit) Adjustment 2-111

47 Pick-up Release Amount Adjustment 2-113

48 Alignment with drive unit 49 AC and DC drawer positioning 50 ADU gate gap adjustment 51 EDH Mounting Position Adjustment 2-115

52 EDH Hinge Spring Pressure Adjustment 2-118

53 EDH Skew Adjustment 2-116

54 Drum count reset

55 Fixing cleaning web count reset 2-40

56 Developer count reset 2-40

Classification by Adjustment

Adjustment Item

Mode

Page

Drum

Developer

High Voltage unit

Write unit

Dust-proof glass

Each tray unit

Bypass paper feed unit

Paper up/down plate hoist wires

Tray pick-up solenoid

Registration roller

Registration unit

O

O

2-40

25

O

O

Caution: Replacing the image control board

• When a damaged image control board is replaced, the memory board on this board must be used on

the new image control board.

Only when the memory board is damaged, use a new memory board. Since the new memory board

does not have adjustment data, the above adjustments are required. Before making the above adjustments, make the “47-92(output)” setting to make the new memory board effective.

• After making any adjustment, make the “47mode-96(output) setting”. After made the “47mode-96(output)” setting, the adjustment data is saved.

• However, the “47mode -92” and -96" settings are protected to prevent them from careless operation.

In order to make “47mode -92” and -96" settings using the saved adjustment data, the protection must

be disabled. For the unprotection method, contact the service section of the authorized distributor.

Registration Clutch

Mis-centering detection sensor

ADU unit

Read unit

Fixing unit

Memory board

EDH unit

Finisher

2 ADJUSTMENT

O

O

O

O

O

2-3

Page 6

ADJUSTMENT

LCD ADJUSTMENT

[1] Control Panel Adjustment

Enter the key operator mode and select " Touch

panel adjustment" to adjust the LCD touch panel.

*If you cannot select the touch panel adjustment

mode after entering the key operator mode

because the touch panel is displaced absolutely,

press numeric keys to select " Touch panel

adjustment".

2 ADJUSTMENT

[2] LCD Panel Contrast/Key Sound

Adjustment

Enter the key operation mode and select " LCD

Panel contrast/Key sound adjustment" to adjust the

contrast, backlight, and/or buzzer as desired.

10

SETTINGS AND

ADJUSTMENTS MADE

10

WITH THE UTILITY

FUNCTION

The Utility function allows you to perform following

numerical value checks using the Utility key:

1. Total counter

2. Copier counter

3. Printer counter

4. * PM counter

7

5. Density Shift (Auto <Text/Photo>)

6. Density Shift (Increase Contrast)

7. Density Shift (Photo)

8. Density Shift (Text)

* PM counter is only displayed when Check

key is pressed on the counter list view screen.

!

[1] Checking and Printing the Utility

function

1. Turn ON the main switch.

2. Press the Utility key.

3. Counter list is displayed.

4. Press the key.

5. Press the START button to print out the counter

list. The Utility function is cancelled automatically.

6. If the counter list need not be displayed, press

the key.

COUNTER MENU

EXIT

[2] Setting up the Utility function

1. Turn ON the main switch.

2. Press the key.

3. Press the Text/Photo ENHANCE key to set the

density shift, then press the Utility key.

4. Enter a value (0-5) with a numeric key, then press

the key. The smaller the value, the darker

the density.

5. Press the key to return to the Basic

screen.

OK

SPECIAL

ORIGINAL

OK

2-4

Page 7

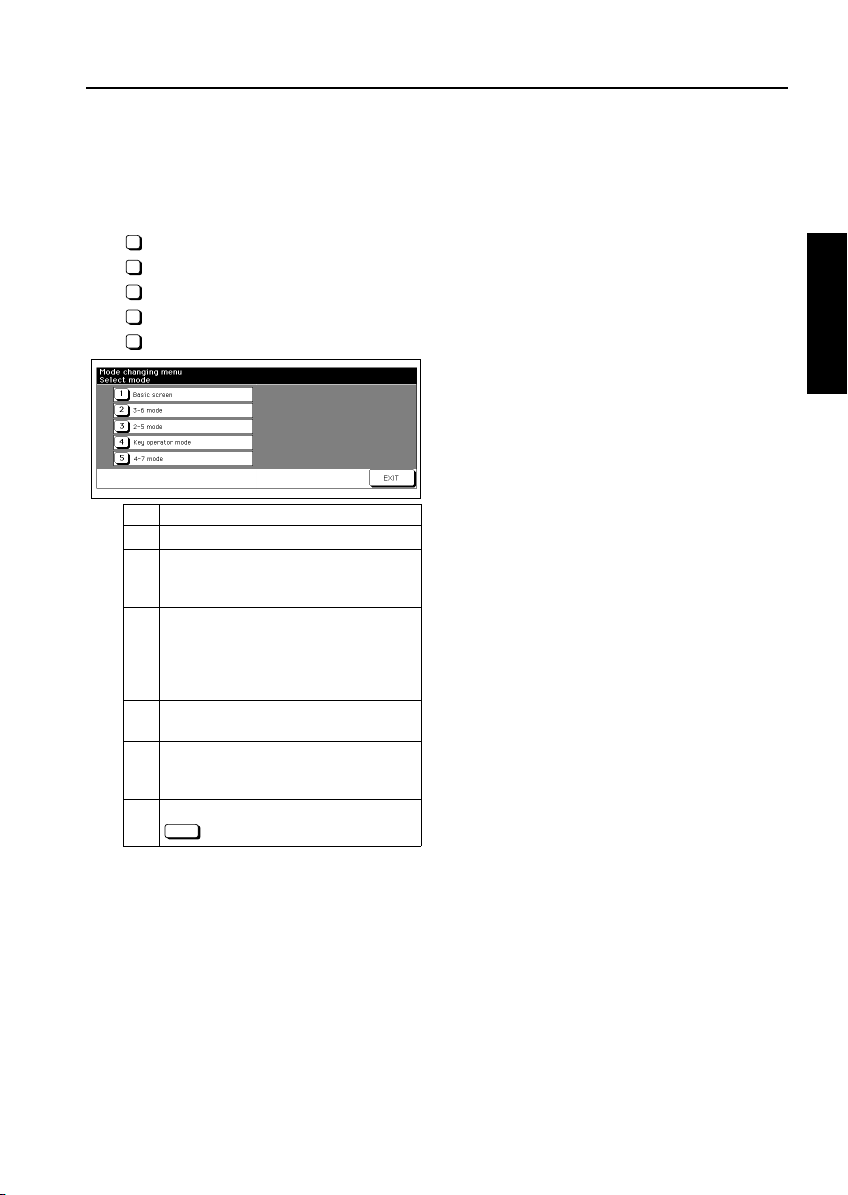

MODE CHANGING MENU

[1] Mode Selection

You can select a mode from the following [Mode changing menu: [Select mode] without turning OFF and ON

the power switch.

1

Basic screen

2

3-6 mode

3

2-5 mode

4

Key operation mode

5

4-7 mode

Step Operation

Turn on the main switch.

1

Press Utility key and wait until [Enter

password for mode selection] message

2

appears.

Enter the password 9272 and press the

Start button.

Note that this password is fixed and can-

3

not be changed.

The [Mode changing menu] appears.

Enter the number to select the desired

4

mode.

To return to the [Mode changing menu],

press Utility key and wait until the menu

5

appears again.

Upon completion of the adjustment, press

6

EXIT

key to return to the Basic screen.

ADJUSTMENT

2 ADJUSTMENT

2-5

Page 8

ADJUSTMENT

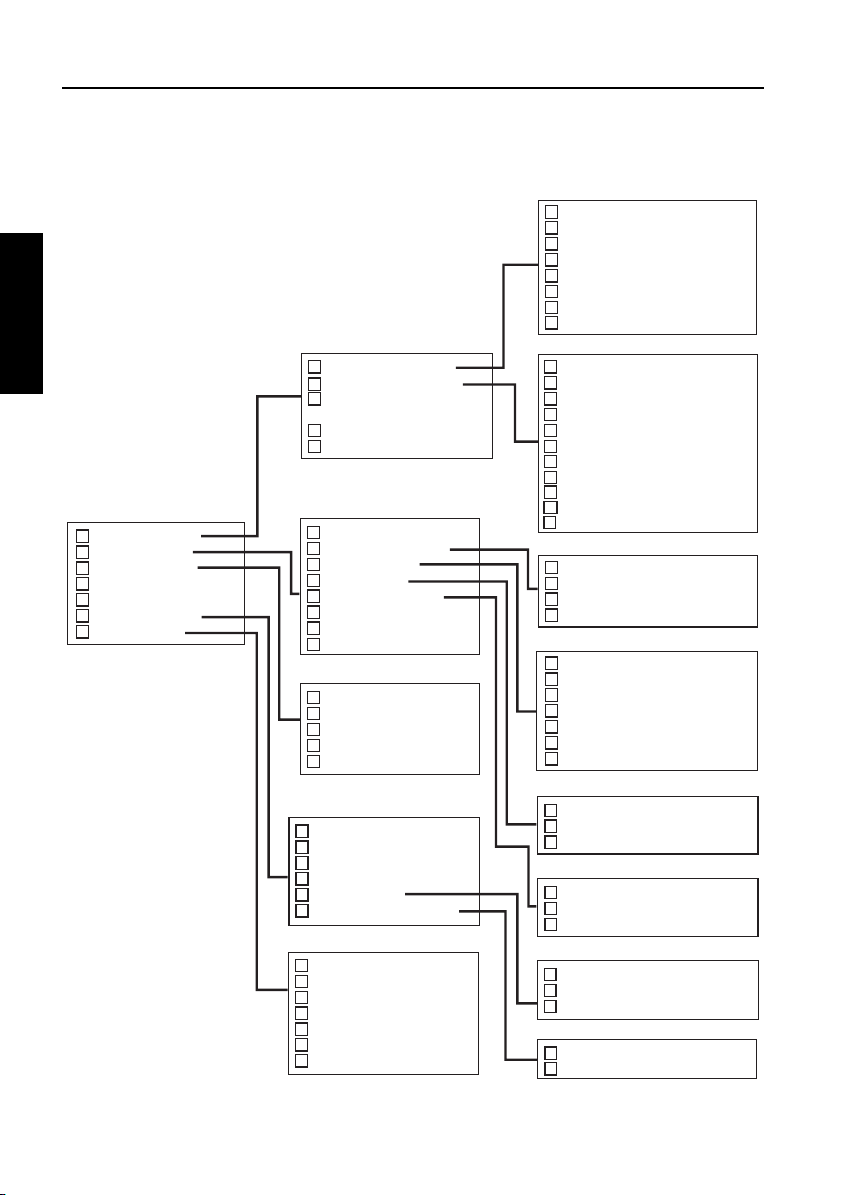

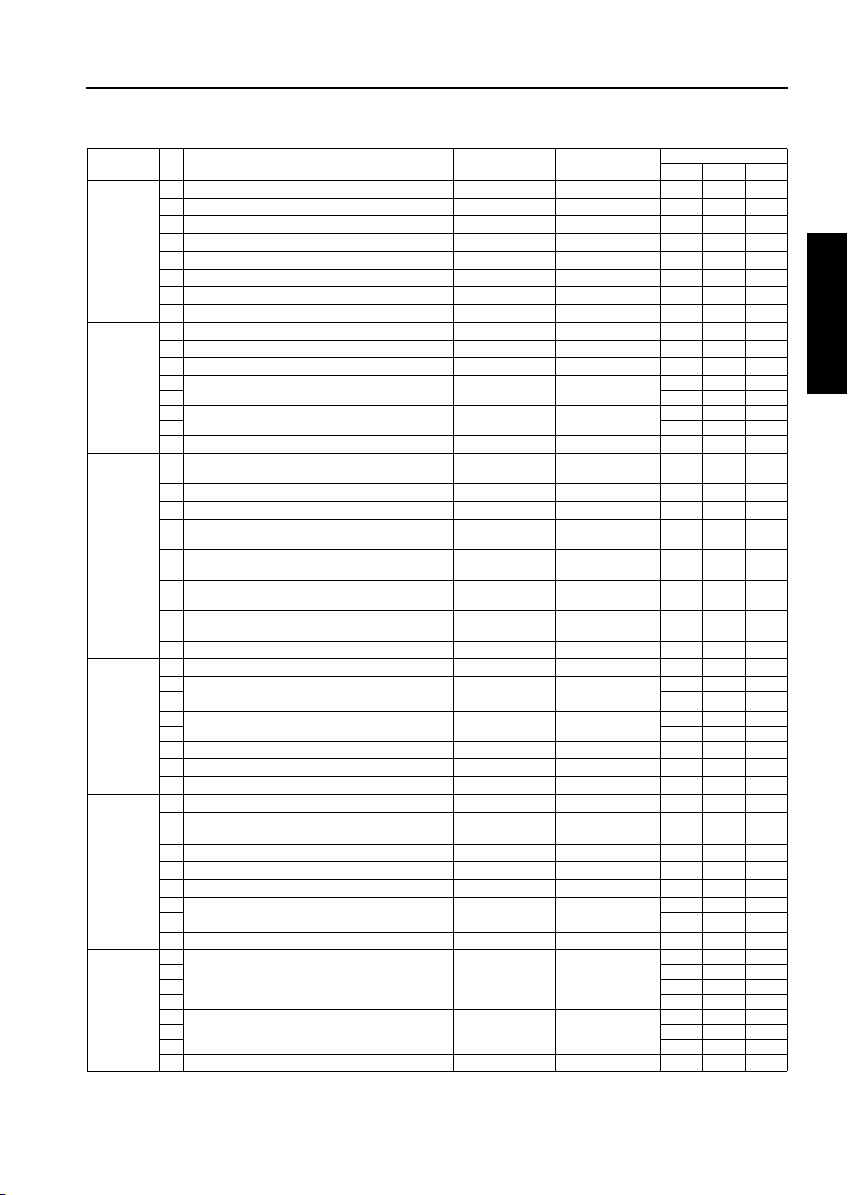

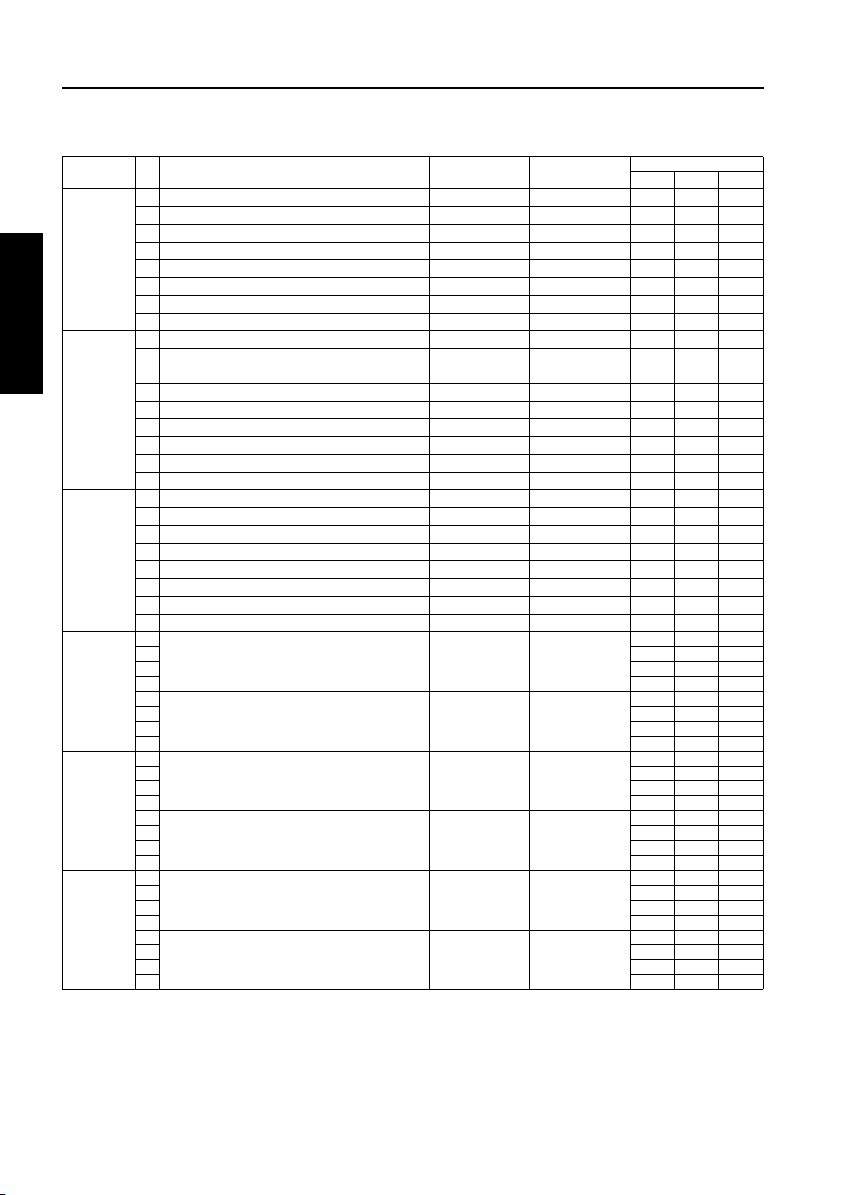

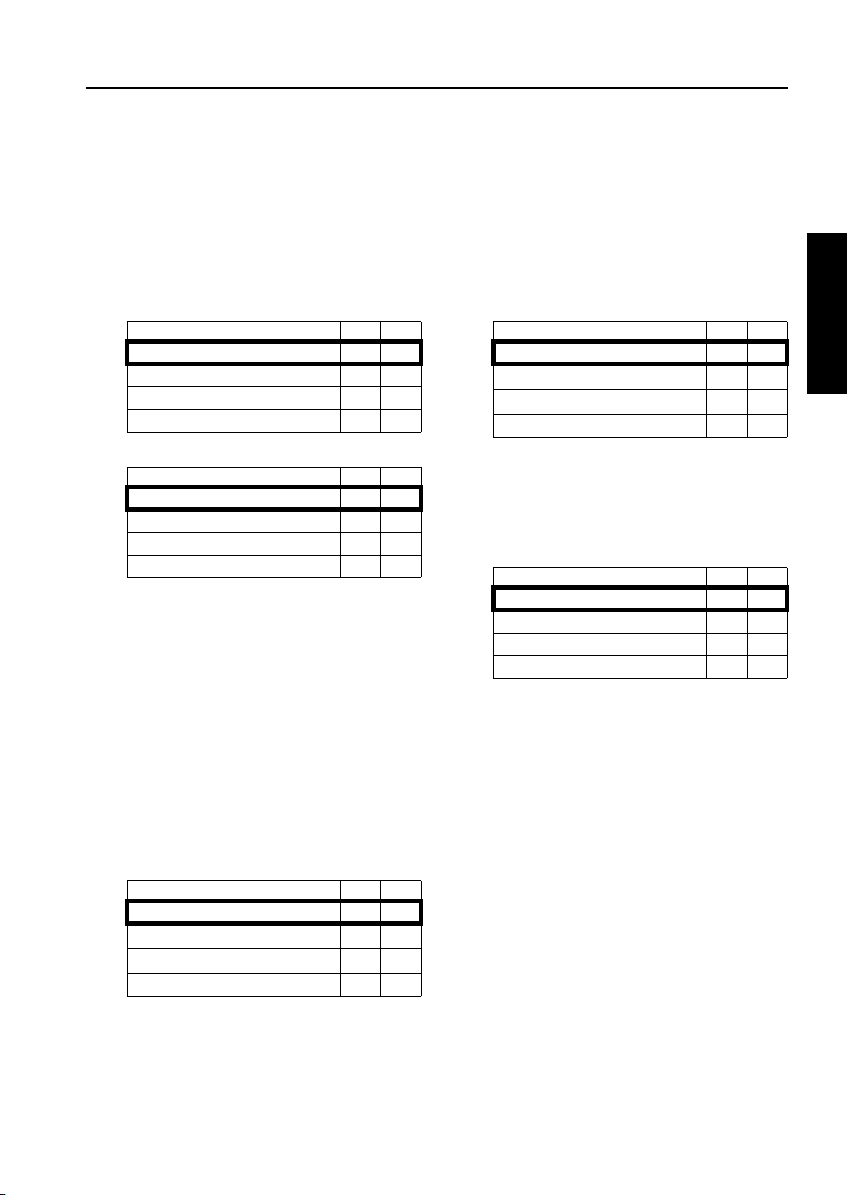

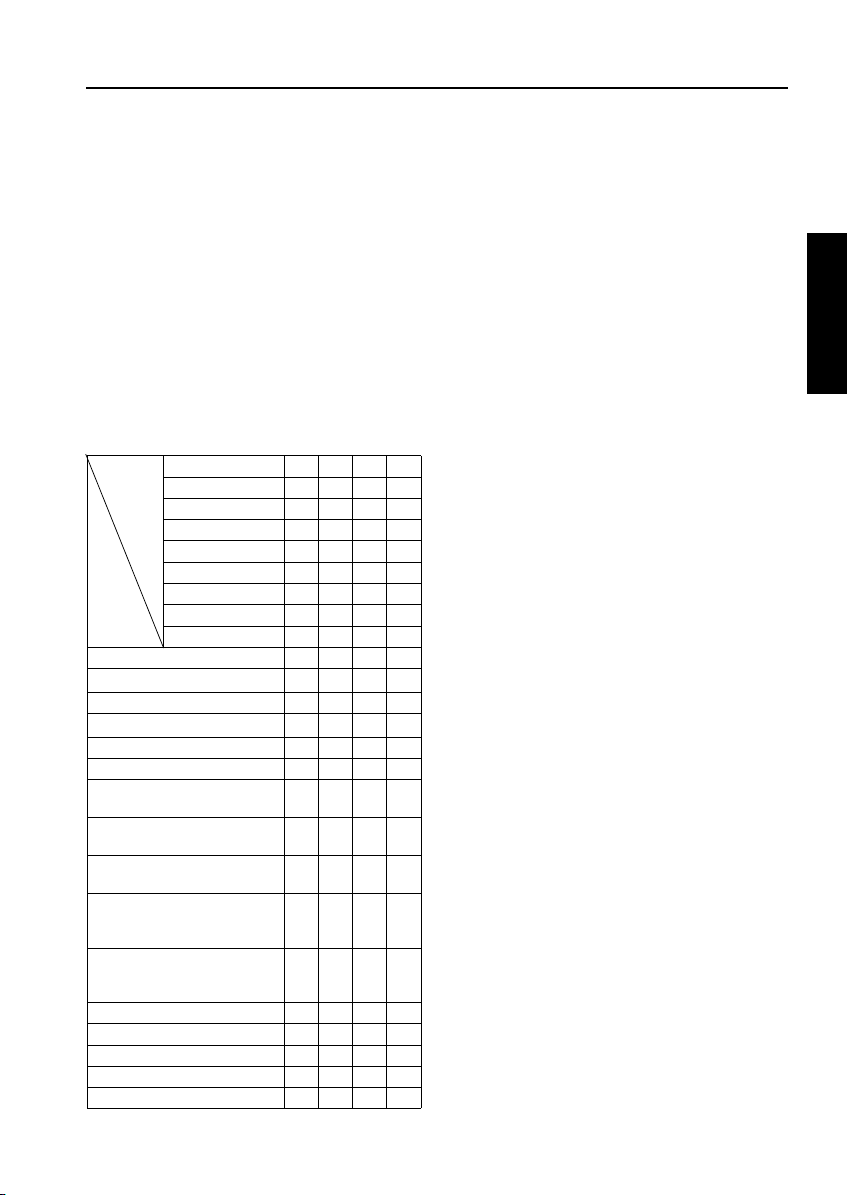

[2] Display transition of 36 modes

x : Factory exclusive use. Service is not used.

2 ADJUSTMENT

3-6 Modus / Adjustment mode

1 Process adjustment

2 Image adjustment

3 Running test mode

4 Test pattern output mode

5 Test pattern density setting

6 Finisher adjustment

7 List output mode

Process adjustment mode menu

1 High voltage adjustment

2 Drum peculiarity adjustment

3 Drum peculiarity adjustment

(hand op) x

4 User paper setting

5 Recall standard data

Image adjustment mode menu

1 Tray adjustment

2 Magnification adjustment

3 Timing adjustment

4 EDH adjustment

5 Centering adjustment

6 Warp adjustment (Copier)

7 Non-image area erase check

8 Recall standard data

Running test mode menu

1 Intermittent copy mode

2 Paperless running mode

3 Paperless mode

4 Paperless endless mode

5 Running mode

Finisher adjustment mode menu

1 Stapling&Folding stopper adjustm.

2 Folding stopper adjustment

3 Cover sheet tray size adjustment

4 Trimmer stopper adjustment

5 Punch adjustment

6 Z-Folding position adjustment

List output mode menu

1 Machine management list 1

2 Adjustment data list

3 Black ratio data list

4 Machine management list 2

5 Parameter list

6 Memory dump list

7 Font pattern

High voltage adjustment mode menu

1 High voltage auto adjustment

2 HV adjustment (Transfer) x

3 HV adjustment (Transfer) x

4 HV adjustment (Separation-AC) x

5 HV adjustment (Separation-DC) x

6 HV adjustment (Charging grid voltage) x

7 HV adjustment (Bias of development) x

8 Transfer guide confirm x

Drum peculiarity adjustment mode menu

1 Blade setting mode

2 Auto drum potential adjustment

3 Auto maximum density adjustment

4 Auto dot diameter adjustment

5 LD 1 offset adjustment

6 LD 2 offset adjustment

7 LD 1 bias adjustment x

8 LD 2 bias adjustment x

9 LD sub-pitch offset adjustment x

10 Auto gamma adjustment(1dot)

11 Cartridge set mode

Magnification adjustment mode menu

1 Printer drum clock adjustment

2 Printer horizontal adjustment

3 Scanner drum clock adjustment

4 EDH drum clock adjustment

Timing adjustment mode menu

1 Printer restart timing adjustment

2 Printer resist loop adjustment

3 Printer pre-resist adjustment

4 Printer lead edge timing adjustment

5 Scanner restart timing adjustment

6 EDH restart timing adjustment

7 EDH resist loop adjustment

EDH adjustment mode menu

1 EDH density adjustment

2 EDH original size adjustment

3 EDH sensor sensitivity adjustment

Centering adjustment mode menu

1 Printer centring adjustment

2 Scanner centring adjustment

3 EDH centring adjustment

Punch adjustment mode menu

1 Punch vertical position adjustment

2 Punch horizontal position adjustment

3 Punch resist loop adjustment

Z-folding position adjustment mode menu

1 1st Z-holding position adjustment

2 2nd Z-holding position adjustment

2-6

Page 9

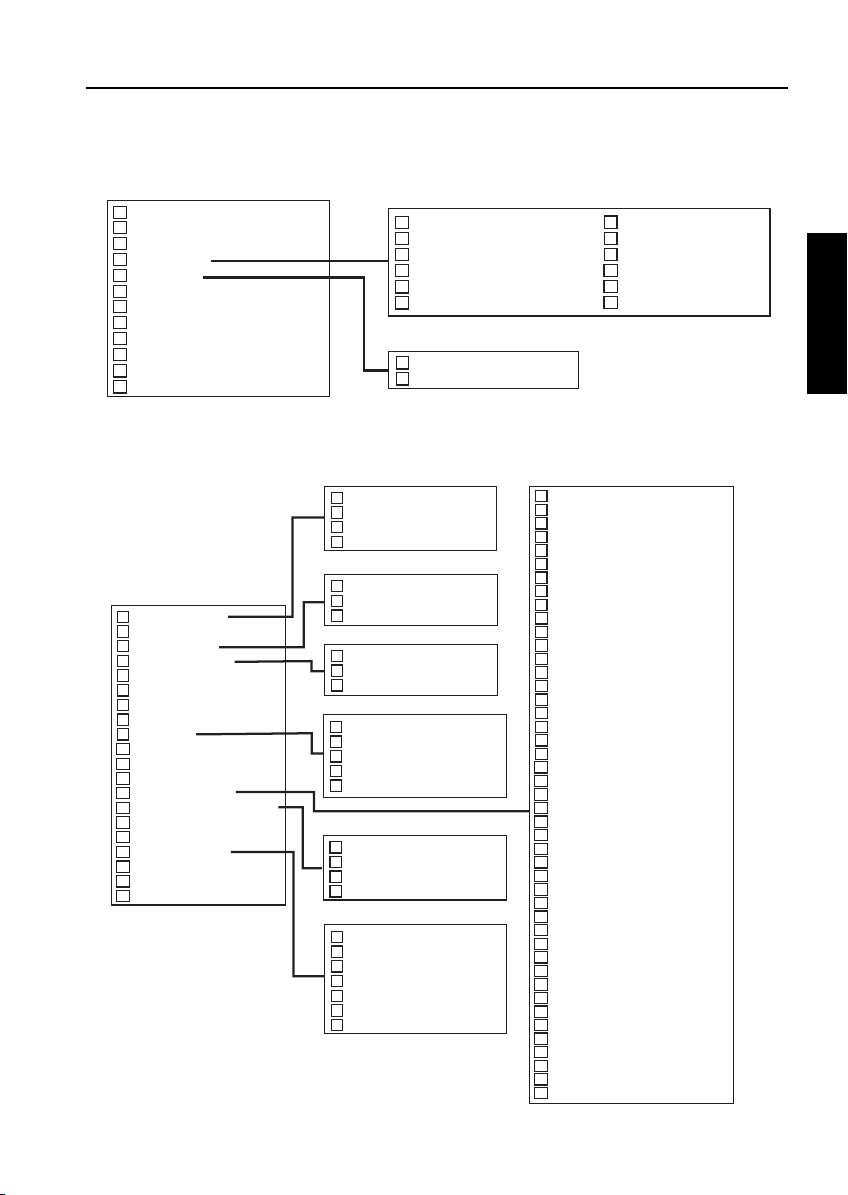

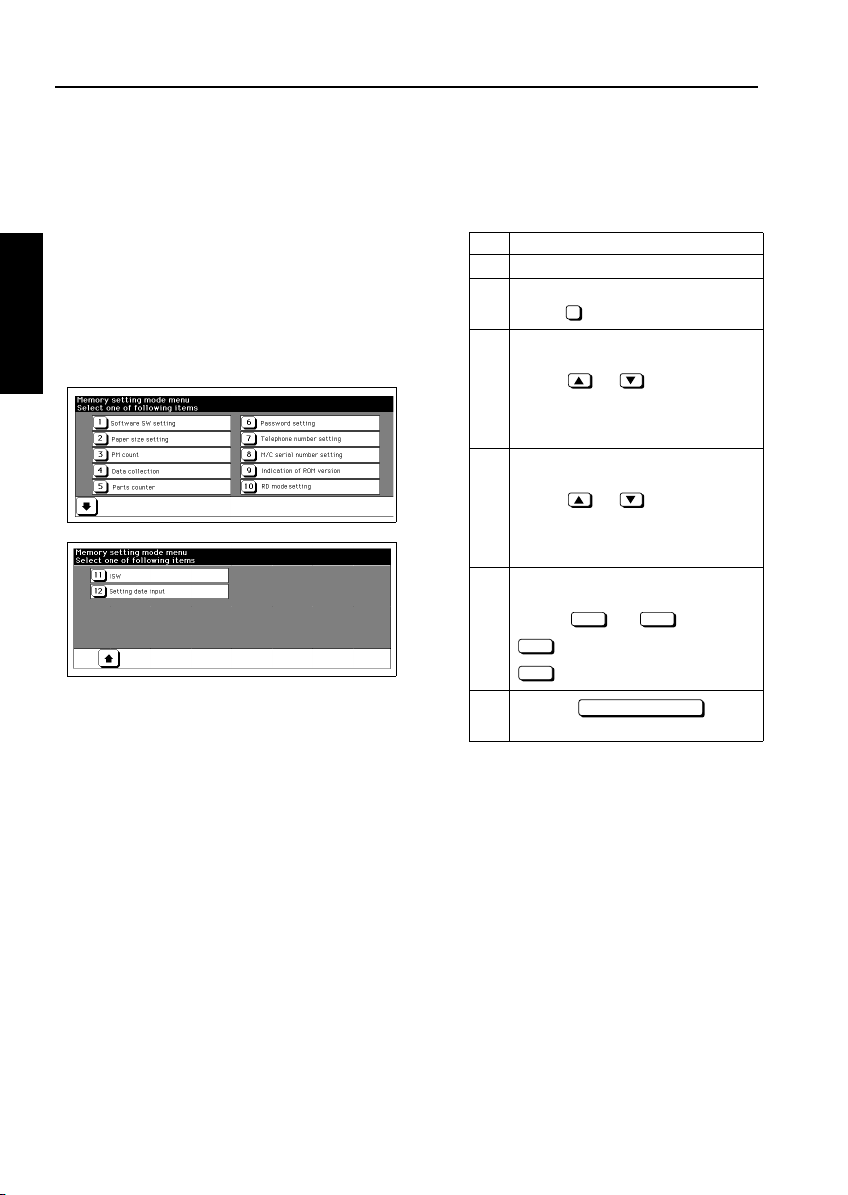

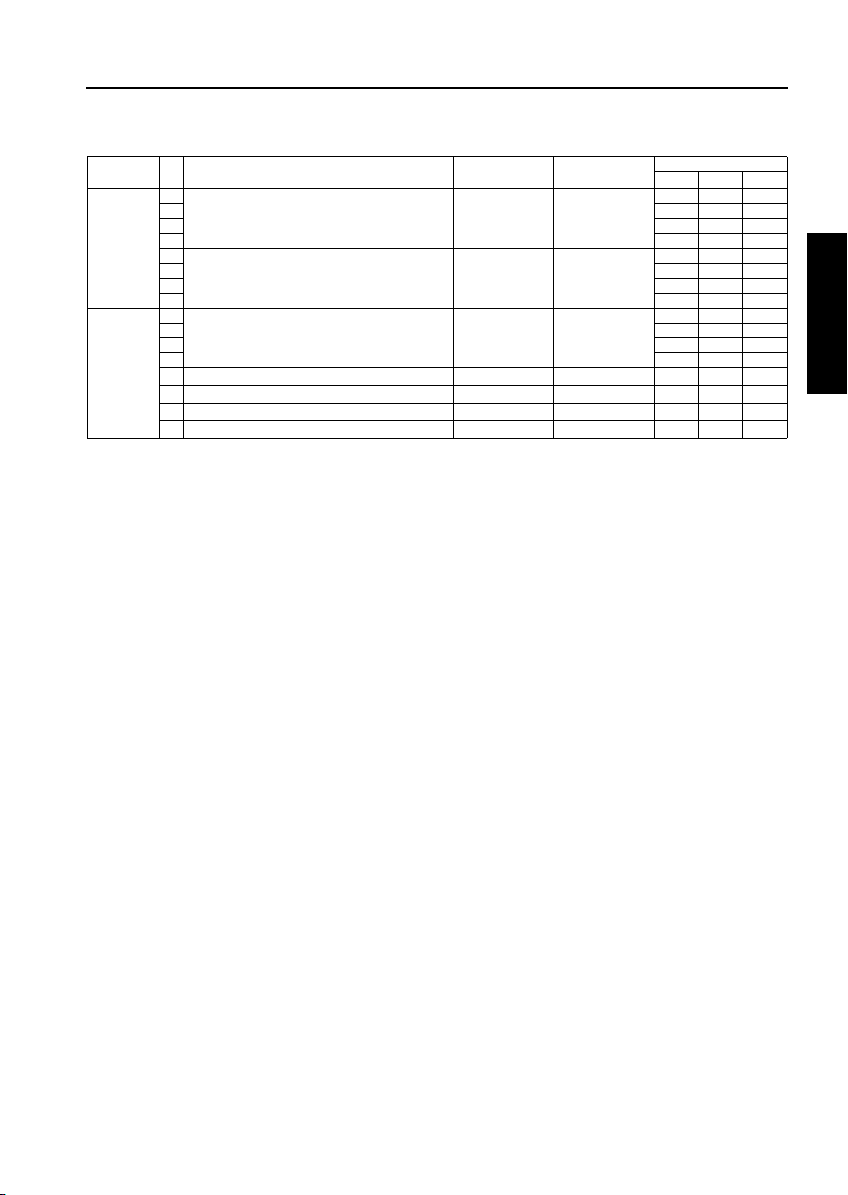

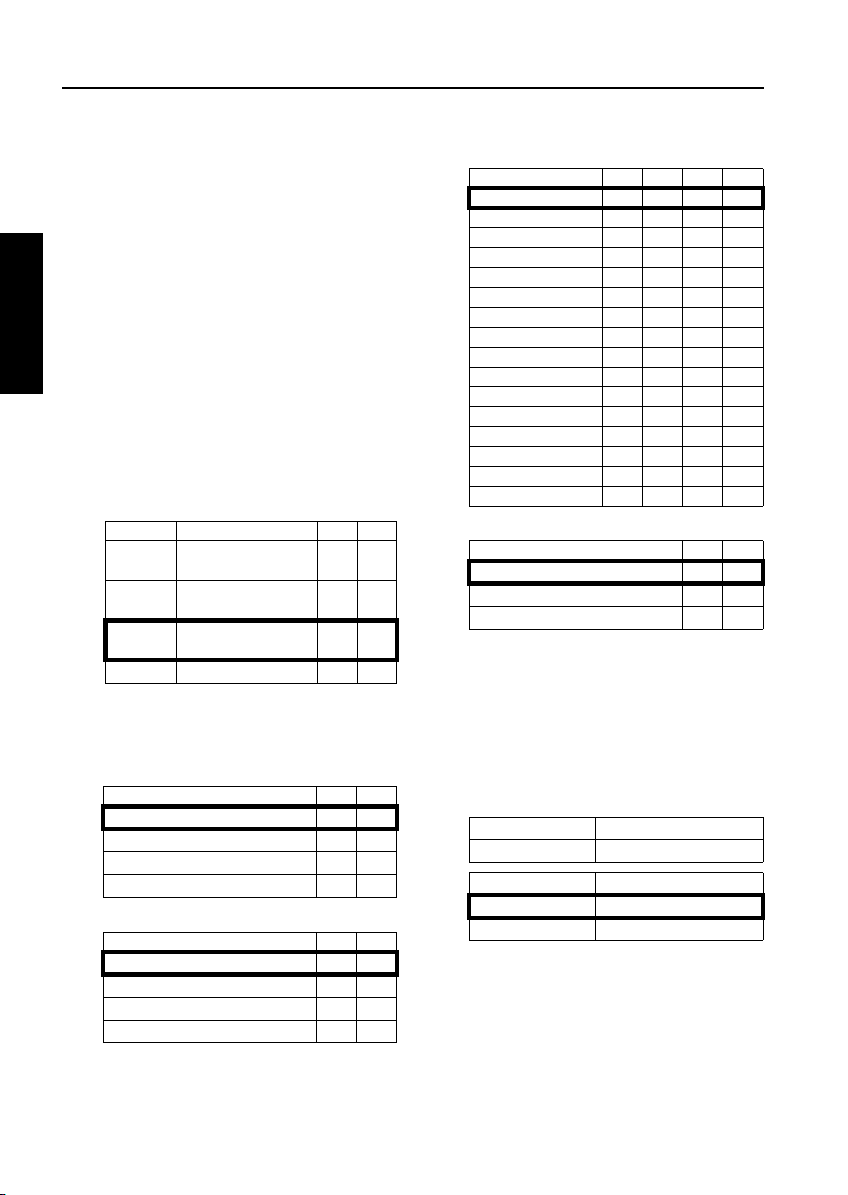

[3] Display transition of 25 modes

ADJUSTMENT

2-5 Modus /Memory setting mode

1 Software SW setting

2 Paper size setting

3 PM count

4 Data collection

5 Parts counter

6 Password setting

7 Telephone number setting

8 M/C serial number setting

9 Indication of ROM version

10 RD mode setting

11 ISW

12 Setting date input

Collecting data menu

1 Total count of each paper size

2 Copy count of each paper size

3 Print count of each paper size

4 EDH count

5 Black ratio of each sction

6 Black ratio ranking list

Copy count of part menu

1 Count of special parts

2 Count of each parts

[4] Display transition of Key Operation modes

System initial setting menu

1 Date & Time setting

2 Language select setting

3 IP adress setting / Tandem

4 E-mail transmission setting

User setting mode menu

Key operator mode menu

1 System initial setting

2 Copier initial setting

3 User setting mode

4 E.K.C function setting

5 Lock / delete program memory

6 Paper type / Special size set

7 Panel contrast / Key sound adj.

8 Key operator data setting

9 Weekly timer

10 Control panel adjustment

11 Tray auto select setting

12 Energy saver setting

13 Memory switch setting

14 Machine management list print

15 * Not use Minolta!

16 Side 2 lens adjustment

17 Finisher adjustment

18 HDD management setting

19 Scanner transmission setting

20 Non-image area erase setting

*1 Name of system

E.K.C : Except USA area

E.C.M : USA area only

1 User density level 1setting

2 User density level 2 setting

3 User lens mode ratio setting

Enter E.K.C Master code: *1

1 E.K.C data edit

2 E.K.C all count reset

3 E.K.C function setting

Weekly timer setting menu

1 Weekly timer ON/OFF setting

2 Timer setting

3 Timer action ON/OFF setting

4 Lunch hour off setting

5 Timer interrupt password set

Management list print mode menu

1 Program memory list

2 User management list

3 E.K.C. management list

4 Font pattern list

Finisher adjustment mode menu

1 Stapling & Folding stopper adjust.

2 Folding stopper adjustment

3 Trimmer stopper adjustment

4 Punch adjustment

5 Z-Folding position adjustment

6 Three-Folding position adjustment

7 2-Positions staole pitch adjustment

7 JAM data of time series

8 JAM count

9 Count of each copy mode

10 SC count

11 JAM count of each section

12 SC count of each section

Memory switch menu

1 Panel reset timer

2 Panel reset key function

3 EDH-Original effect

4 Program memory auto recall -305 Finisher mode by Full-Auto

6 Initial by Key Counter insert

7 Erasure outside area of original

8 EDH frame erasure selection

9 Automatic tray switching

10 Platen APS

11 EDH APS

12 Platen AMS

13 EDH AMS

14 Select tray when APS cancel

15 Platen original size detect

16 EDH original size detect

17 Platen original size detect (SMALL)

18 Rotation

19 Staple mode reset function

20 Job offset operating

21 Continuation print

22 SDF auto start

23 Key click sound

24 1 Shot indication time

25 Power save screen

26 Start Key latch function

27 Stop Key function

28 Auto select of booklet copy

29 E.K.C. Password

30 Arrow key change [Image shift]

31 Exit direction of 1 sheet

32 An interruption suspended way

33 E.K.C. password input timing

34 Key click sound (No paper/ Jam)

35 Reserve copy function

36 Scan stop by pull out tray

37 Change page no. Pos. (booklet)

38 Trimmer (Std./ Non Std size)

39 Timer which prohibits print

40 Bookmark fanction

41 Delete of overlay image

42 Orig. direction/binding mode

43 Image stored conti. (SRV)

44 Image recalled conti. (SRV)

45 Exit direction

2 ADJUSTMENT

2-7

Page 10

ADJUSTMENT

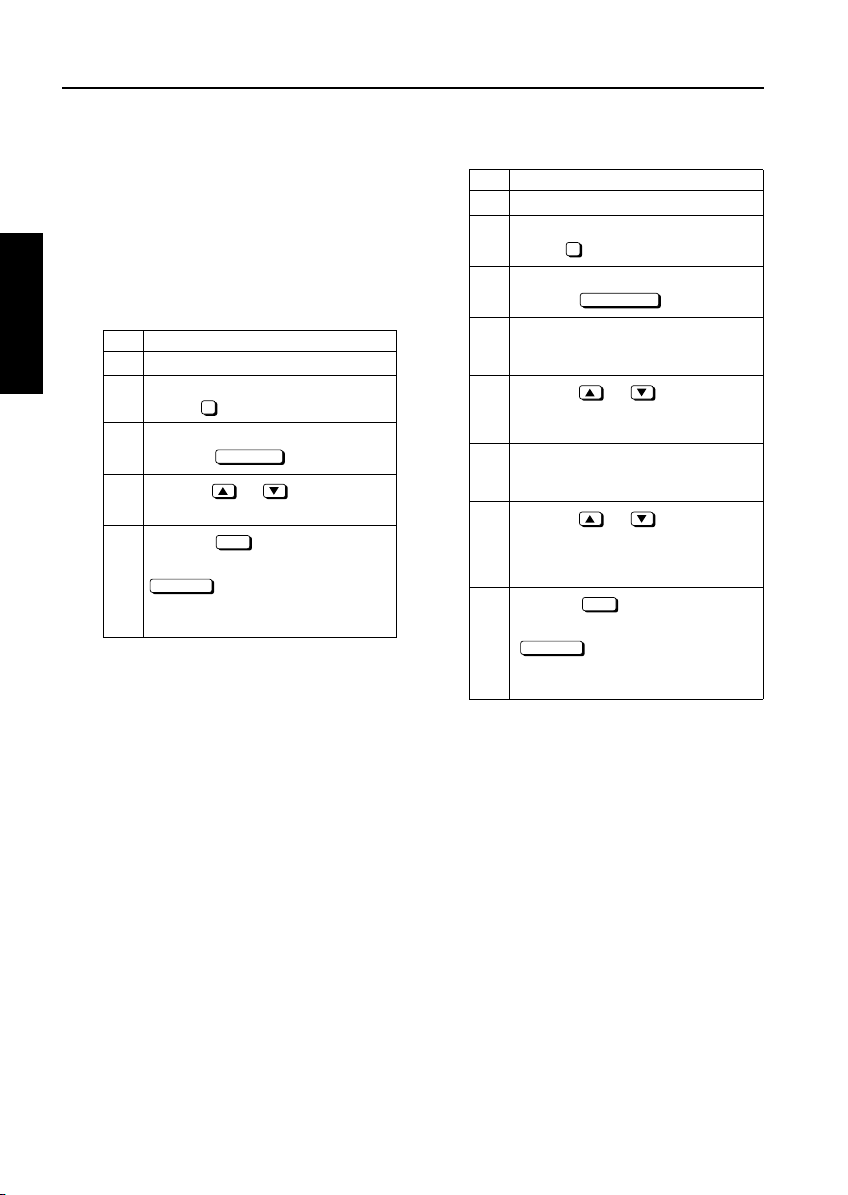

25 MODE

[1] Setting the 25 Mode

This machine has an adjustment mode called the "25

Mode". Select this mode to rewrite data in the non-volatile memory or make various settings.

1. Turn OFF the main switch.

2. While pressing the copy quantity setting buttons

2 and 5, turn ON the main switch.

The 25 Mode Menu screen will appear.

Now the machine is in the 25 mode, disabling

normal copy operations.

2 ADJUSTMENT

[25 Mode Menu. Screen]

3. Press the numeric button of the desired setting

item.

The associated setting screen will appear.

4. Enter data in the setting screen.

5. Turning OFF the main switch cancels the 25

mode.

6. New data will take effect after restart.

[2] Setting Software DIP Switches

1. Procedure

Bring up the Software DIP SW Setting screen

and set software DIP switches.

Step Operation

Enter the 25 mode.

1

[Memory setting mode menu]

2

Select " Software DIP SW setting".

1

Software switch setting mode 05

Select a DIP switch number.

Use the or key at the left.

3

To use numeric keys, invert the DIP

switch number at the left before entering

a DIP switch number.

Select a bit number of the selected DIP

switch.

Use the or key at the right.

4

To use numeric keys, invert the bit number at the upper center before entering a

DIP switch number.

Select ON (=1), or OFF (=0) of the

switch.

Use the or key.

5

Press the key to

6

return to the 25 Mode Menu. Screen.

ON OFF

: Sets 1.

ON

: Sets 0.

OFF

PREVIOUS SCREEN

2-8

Page 11

ADJUSTMENT

< List of Software Switches >

DIPSW

No.

DIPSW 1

DIPSW2

DIPSW3

DIPSW4

DIPSW5

Note1:

Bit Function 0 1

0 Condition for stopping copying after indica-

tion of toner supply

1 000

2 Method for stopping copying after indica-

tion of toner supply

3 000

Inhibition of copying when PM count is

4

reached

5

Number of copies made before inhibition of

6 000

copying when PM count is reached

7 000

Hard disk connection

0

1

Electrode cleaning cycle (when power is

2 000

turned ON)

3 000

4 Electrode cleaning cycle (after power is

turned ON)

5 000

6

Blade automatic switching cycle

7 000

Regular toner supply amount

0

SC latch

1

25, 36, 47 mode password request (pass-

2

word: 9272)

Charging corona unit cleaning function

3

Transfer /separation corona unit cleaning

4

function

Movement of blade to transportation

5

47 mode 15-01 data collection clearing

6

-

7

ADF automatic skew adjustment

0

Inhibition of thick paper / double sided copy

1

paper mode

2

Destination selection

3 001

Key counter removal recovery

4

Inhibition of magnified APS

5

Fixed magnification rate setting change in

6

key operator mode

A3 (11x17) counting method

7

0

Toner concentration threshold

1 000

- - -

2

-

3

- - -

4

-

5

6

2 dot PWM density in photo mode

7 000

* 1 * 1

* 2 * 2

Not Inhibited Inhibited 0 0 0

* 3 * 3

Disconnected Connected 0 0 0

* 4 * 4

* 5 * 5

* 6 * 6

* 7 * 7 0 0 0

Unlatched Latched 0 0 0

Not requested Requested 0 0 0

ON OFF 0 0 0

ON OFF 0 0 0

Disabled Enabled 0 0 0

Disabled Enabled 0 0 0

- -000

Enabled Disabled 0 0 0

Disabled Enabled 0 0 0

* 8 * 8

Disabled Enabled 0 0 0

Enabled Disabled 0 1 0

Enabled Disabled 1 0 0

Increments of 1 Increments of 2

* 9 * 9

- -000

- -000

* 10 * 10

Initial Value

Japan Inch Metric

111

111

000

000

000

000

010

000

000

000

000

000

This bit is used to keep the cleaning blade off the drum to protect the drum and cleaning blade during transportation

of the main body.

To keep the blade off the drum, set this DIP switch to 1, open the front door to turn OFF the interlock, and start

up the 47 mode. The blade switching operation is performed at this time. If blade 1 is used, do not forget blade

charge and 36 mode blade set mode at reinstallation. This DIPSW will be reset to 0 automatically.

2 ADJUSTMENT

2-9

Page 12

ADJUSTMENT

DIPSW

DIPSW 6

2 ADJUSTMENT

DIPSW 7

DIPSW8

DIPSW 9

DIPSW10

DIPSW11

Note 2: This bit determines whether drum potential adjustment is to be made using a drum potential sensor.

Bit Function 0 1

No.

- - -

0

-

1

- - -

2

3 Transfer/separation output for thick paper

4 000

5 Transfer/separation output for thin paper

6 000

Auto drum potential adjustment (Note 2)

7

0 Developing potential control for image area

1 000

-

2

-

3

-

4

-

5

-

6

-

7

-

0

- - -

1

2 Fixing roller initial rotation

3 111

4 Fixing roller initial rotation time setting

5 000

A3(11 × 17) PM counter switch

6

Store on hard disk

7

Operation at key counter removal (copy) Same as stop

0

Operation at key counter removal (Print) Ignored Same as

1

2 Message switching

3 000

4 Copy count limit

5 000

6 000

7 000

0 Page memory allocation at power on Ditto.

1 000

Page memory allocation at job starts

2

-

3

-

4

-

5

-

6

-

7

-

0

-

1

-

2

SC/E code screen switchover

3

Selection of filter for jagged edges on slant-

4

ing lines

Gradation switchover in Photo mode 2bitED-2dot

5

-

6

JAM indication screen type Without Jam

7

- -000

* 11 * 11

* 12 * 12

Enabled Disabled 0 0 0

* 13 * 13

- -000

- -000

- -000

- -000

- -000

- -000

- -000

* 14 * 14

* 15 * 15

1 count 2 count 0 0 0

Enable Disable 0 0 0

Immediate stop

key

(JAM)

DIPSW9-0

* 16 * 16

* 17 * 17

* 18 * 18

* 19 * 19 0 0 0

- -000

- -000

- -000

- -000

- -000

- -000

- -000

- -000

Switched

Not switched

(All are F codes)

Not selected Selected 0 0 0

1bitED-2dot

PWM

PWM

- -000

code

With Jam code 0 0 0

Initial Value

Japan Inch Metric

000

000

000

000

000

000

000

011

0 0 0

000

000

000

000

000

000

This setting is used to check whether an image problem has been caused by a faulty drum potential sensor.

2-10

Page 13

ADJUSTMENT

DIPSW

No.

DIPSW 12

DIPSW 13

DIPSW14

DIPSW15

DIPSW16

DIPSW17

Bit Function 0 1

Black stripe creation interval

0

-

1

-

2

Printer automatic centering correction

3

High voltage output in 36/47 mode

4

-

5

-

6

-

7

Size detection 1

0

Size detection 2

1

Size detection 3

2

3 Size detection 4

4 010

5 F4 size detection

6 000

-

7

Size detection 5 (main body)

0

-

1

-

2

Size detection 5 (by-pass feed)

3

Size detection 5 (platen)

4

Size detection 5 (ADF)

5

Size detection selection (PI)

6

-

7

-

0

1 Maximum number of sheets that can be

stapled

2 000

3 FNS alarm stop SW

4 000

RD mode connection recognition

5

Dmax. value in printer mode

6

-

7

-

0

Multi-job Reservation

1

-

2

C(K) counting in printer mode

3

TC start date indication (Utility mode)

4

5 Non-original area erasure mode judge-

ment level

6 000

-

7

0 WT summer time setting

1 111

2 111

3 000

4 Density selection for scanning tab paper

5 000

6 000

-

7

Not performed Every 5 copies

- -000

- -000

Enable Disable 0 0 0

Not output Output 1 1 1

- -000

- -000

- -000

A5 5.5 x 8.5 0 1 0

A4R 8.5 x 11R 0 1 0

8.5 x 14 F4 0 0 1

* 20 * 20

* 21 * 21

- -000

B4 : 11 x 17/

B5 : 8.5 x 11

- -000

- -000

B4 : 11 x 17/

B5 : 8.5 x 11

B4 : 11 x 17/

B5 : 8.5 x 11

B4 : 11 x 17/

B5 : 8.5 x 11

B4 : 11 x 17/

B5 : 8.5 x 11

- -000

8K/16K 0 0 0

8K/16K 0 0 0

8K/16K 0 0 0

8K/16K 0 0 0

8K/16K 0 0 0

- -000

* 22 * 22

* 23 * 23

Disconnect Connect 0 0 0

1.43 1.35 0 0 0

- -000

- -000

Reservation

enabled

disabled

- -000

Not counted Counted 0 0 0

Indicated Not indicated 0 0 0

* 24 * 24

- -000

* 25 * 25

* 26 * 26

- -000

Initial Value

Japan Inch Metric

000

000

000

000

000

000

000

000

000

2 ADJUSTMENT

2-11

Page 14

ADJUSTMENT

2 ADJUSTMENT

DIPSW

No.

DIPSW18

DIPSW 19

DIPSW20

DIPSW21

Bit Function 0 1

Tray 1's faulty part isolation

0

Tray 2's faulty part isolation

1

Tray 3's faulty part isolation

2

Tray 4's (LCT's) faulty part isolation

3

ADF faulty part isolation

4

Folding, stapling and folding, trimmer faulty

5

part isolation

PI faulty part isolation

6

Hard disk faulty part isolation

7

-

0

1 Fixing temperature setting switching

2 000

3 000

PZ faulty part isolation

4

PK faulty part isolation

5

6 Sel ection of a default resolution for IP scan-

ner

7 000

Group stapling

0

Original size scanning with shift function

1

(Note1)

Stamp page number switching Based on origi-

2

Keyboard layout ABC layout QWERTY lay-

3

-

4

-

5

-

6

-

7

Mixed sized print stapling inhibition

0

(Print)

LCT size setting in key operator mode

1

Original count display

2

-

3

Output on Tandem

4

Allocation recovery on Tandem

5

Special paper APS response

6

Normal Unavailable 0 0 0

Normal Unavailable 0 0 0

Normal Unavailable 0 0 0

Normal Unavailable 0 0 0

Normal Unavailable 0 0 0

Normal Unavailable 0 0 0

Normal Unavailable 0 0 0

Normal Unavailable 0 0 0

- -000

* 27 * 27

Normal Unavailable 0 0 0

Normal Unavailable 0 0 0

* 28 * 28

Disabled Enabled 0 0 0

Normal Original priority 0 0 0

Based on trans-

nal

fer paper

out

- -000

- -000

- -000

- -000

Enabled (real-

time output)

Disabled (batch

processing)

Disabled Enabled 0 0 0

Displayed Not displayed 0 0 0

- -000

Realtime Batch 0 0 0

Enabled Disabled 0 0 0

Enabled (All

Disabled

except Thick 2

papers and

Initial Value

Japan Inch Metric

000

000

000

000

000

000

Thick 3 papers)

-

7

- -000

Note1:When "Normal" is selected, the original size is compared with the copy paper size and the smaller

one is assumed to be the image area size. When "Original priority" is selected, the original size is

compared assumed to be the image area size only when the image shift mode is selected.

2-12

Page 15

ADJUSTMENT

DIPSW

No.

DIPSW22

DIPSW23

DIPSW24

DIPSW25

DIPSW28

Bit Function 0 1

IP address setting

0

1 Number of punched holes

2 001

Standard position of image on Nonstand-

3

ard size original

Function of Power save button

4

-

5

Operation on staple empty of FNS Requesting

6

-

7

-

0

Output operation when EKC user ID

unmatching

1

Disabled Enabled 0(1) 0(1) 0(1)

* 29 * 29

User selected APS of ADF 0 0 0

Enabled Disabled 0 0 0

- -000

Selectable sta-

staple supply

ple supply or

without stapling

- -000

- -000

Enabled

(counted by

other user

Disabled (registered non-output list)

Initial Value

Japan Inch Metric

010

000

000

2 ADJUSTMENT

account)

2 Image density selection (toner density

selection of developer)

3 000

-

4

-

5

Job memory registration of the special

6

paper setting on the bypass tray

Face-up ejection of the thick paper 2 to

7

sub-tray (Print)

HDD JOB recall operation

0

-

1

-

2

-

3

4 Maximum number of sheets with z-folding

(main tray)

5 111

6 Maximum number of sheets with z-folding +

stapling (main tray)

7 000

-

0

Maximum number of sheets with Booklet

1

Mode

- - -

2

- - -

3

- - -

4

- - -

5

- - -

6

- - -

7

- - -

0

- - -

1

- - -

2

- - -

3

- - -

4

Timing and centring adjustment in key

5

operator mode

- - -

6

- - -

7

* 30 * 30

- -000

- -000

Disabled Enabled 0 0 0

Disabled Enabled 0 0 0

Password

Password + file

name

- -000

- -000

- -000

* 31 * 31

* 32 * 32

- -000

20 sheet 16 sheet

Disabled Enabled 0 0 0

000

000

000

000

000

000

000

000

000

000

000

000

000

000

000

000

000

000

2-13

Page 16

ADJUSTMENT

2 ADJUSTMENT

DIPSW

No.

DIPSW29

DIPSW30

DIPSW31

DIPSW33

DIPSW34

DIPSW35

Bit Function 0 1

- - -

0

- - -

1

- - -

2

- - -

3

- - -

4

- - -

5

- - -

6

- - -

7

- - -

0

25 mode collection data 5-11 for checking Display restric-

1

- - -

2

- - -

3

- - -

4

- - -

5

- - -

6

Passwords to save/access hard disk JOB Not displayed Displayed

7

- - -

0

- - -

1

- - -

2

- - -

3

- - -

4

- - -

5

- - -

6

-

7

0 Normal paper process control switchover

1 000

2 000

3 000

4 Recycled paper process control switchover

5 000

6 000

7 000

0 Colored paper process control switchover

1 000

2 000

3 000

4 Special paper process control switchover

5 000

6 000

7 000

0 High-quality paper process control

1 000

switchover

2 000

3 000

4 Exclusive paper A paper process control

5 000

switchover

6 000

7 000

tion

* 33 * 33

* 33 * 33

* 33 * 33

* 33 * 33

* 33 * 33

* 33 * 33

No display

restriction

- - 000

Initial Value

Japan Inch Metric

000

000

000

000

000

000

000

000

000

111

000

000

000

000

000

000

000

000

000

000

000

000

000

000

000

000

000

000

000

2-14

Page 17

ADJUSTMENT

DIPSW

No.

DIPSW36

DIPSW37

Bit Function 0 1

0 Exclusive paper B paper process control

1 000

switchover

2 000

3 000

4 Exclusive paper C paper process control

5 000

switchover

6 000

7 000

0 Exclusive paper D paper process control

1 000

switchover

2 000

3 000

- - -

4

- - -

5

- - -

6

-

7

* 33 * 33

* 33 * 33

* 33 * 33

- - 000

Initial Value

Japan Inch Metric

000

000

000

000

000

000

2 ADJUSTMENT

2-15

Page 18

ADJUSTMENT

*1 Condition for stopping copying after indication of

toner supply request

Mode 1-1 1-0

Stops after printing 1,500 copies

Stops after printing 3,000 copies

Stops after printing 4,000 copies

Stops after printing 5,000 copies

*2 Method for stopping copying after indication of

toner supply request

2 ADJUSTMENT

Mode 1-3 1-2

Stops after ejecting the paper

remaining in the machine

Stops after printing specified number of copies

Stops at the end of the current job

Does not stop

*3 Number of copies made before inhibition of copy-

ing when PM count is reached

Mode 1-7 1-6 1-5

1,000 copies

2,000 copies

3,000 copies

4,000 copies

5,000 copies

1,000 copies

1,000 copies

1,000 copies

000

001

010

011

100

101

110

111

*4 Electrode cleaning cycle (fixing temperature is

50°C or lower when power is turned ON)

Mode 2-3 2-2 2-1

When power is turned ON

5,000 copies

10,000 copies

15,000 copies

20,000 copies

25,000 copies

30,000 copies

Not cleaned

000

001

010

011

100

101

110

111

00

01

10

11

00

01

10

11

*5 Electrode cleaning cycle (after power is turned

ON)

Mode 2-5 2-4

10,000 copies

30,000 copies

40,000 copies

50,000 copies

00

01

10

11

*6 Blade automatic switching cycle

Mode 2-7 2-6

250,000 copies

300,000 copies

400,000 copies

500,000 copies

00

01

10

11

*7 Regular toner supply amount

When copying the original which black ratio is low

(less than 1 %), gray background image is

caused because the toner density of developer

increases. In this case, changing this bit to 1,

decreases the amount of toner supplied regularly, thus preventing gray background image.

Note: When copying the original which black

ratio is normal, changing this bit to 1

causes the image to be lighter.

Mode 3-0

Standard

Decrease regular toner supply amount

0

1

*8 Destination selection

Mode 4-3 4-2

Japan

Inch area

Metric area

00

01

10

2-16

Page 19

ADJUSTMENT

*9 Toner concentration threshold

This bit sets the read level of the toner concentration patch formed on the drum to determine

the toner concentration. The setting can be

made by shifting the threshold of black color to

the positive or negative side.

• Standard -3: The image becomes darker.

• Standard +3: The image becomes lighter.

• Standard +5: The image becomes far lighter.

Mode 5-1 5-0

Standard

Standard -3

Standard +3

Standard +5

00

01

10

11

*10 2 dot PWM table in photo mode

Mode 5-7 5-6

Standard

Light

Dark

Not use

00

01

10

11

*11 Transfer/separation corona unit output for thick

paper

This bit is used when “Thick 1”, “Thick 2” or “Tab

paper” is selected for “Paper type/special size

setting” in the key operator mode.

When “No specification” is selected, data for

“Thick 1:170 g/m

2

” or “Thick 2: 200 g/m2” is used

(the data for “Thick 2” is also used for tab paper).

When other than “No specification” is selected,

the selected output data is used for both “Thick 1”

and “Thick 2.”

When this bit cannot be used with "Thick 2"

selected, "Thick 3" can be selected in the key

operator mode.

(Changing DIP SW is not required.)

Mode 6-4 6-3

No specification

2

paper

200 g/m

2

170 g/m

paper

Postcard

00

01

10

11

*12 Transfer/separation corona unit output for thin

paper

This bit is used when "Thin" is selected for "Paper

type/special size setting" in the key operator

mode.

When "No specification" is selected, the output

data by destination (

: 16lb, paper,

area

Japan

: 50 g/m2 paper,

Metric area

: 60 g/m2 paper) is

Inch

used.

Mode 6-6 6-5

No specification

2

paper

50 g/m

2

paper

60 g/m

16 lb paper

00

01

10

11

*13 Developing potential control of image area

Change the charging potential and developing

bias to decrease the developing potential of

image area.

This bit is used to gain a lighter image for such

use as printing books..

Mode 7-1 7-0

Standard

-100 V

-150 V

-200 V (light)

00

01

10

11

2 ADJUSTMENT

2-17

Page 20

ADJUSTMENT

*14 Fixing roller initial rotation

Fixing may be insufficient in the morning if the

temperature of the place where the machine is

installed is low. To prevent this, increase the

warm-up time (fixing roller initial rotation time) to

allow the fixing lower roller to be warmed up to

the normal temperature. This bit specifies the

condition(s) under which initial rotation of the fixing roller is required.

• Low temperature:

Initial rotation of the fixing roller is carried out

2 ADJUSTMENT

only under the low temperature condition.

• Low and normal temperatures:

Initial rotation of the fixing roller is carried out

under low and normal temperature conditions.

• Low, normal, and high temperatures:

Initial rotation of the fixing roller is carried out

under low, normal, and high temperature conditions

Mode 8-3 8-2

Japan,

Low temperature

Inch area

Metric

area

For al l destination

Low and normal

temperature

Low, normal, and high

temperatures

No rotation

*15 Fixing roller initial rotation time setting

This bit sets the maximum time of initial rotation

of the fixing roller. When 0 second is specified,

initial rotation of the fixing roller is not carried out.

Mode 8-5 8-4

60 seconds

30 seconds

15 seconds

0 seconds

*16 Message switching

Mode 9-3 9-2

Please insert key counter.

Please insert copy card.

Please insert coin.

Please insert key counter.

00

01

10

11

00

01

10

11

00

01

10

11

*17 Copy count limit

Mode 9-7 9-6 9-5 9-4

No limit 0000

1 copy 0001

3 copies 0 0 1 0

5 copies 0 0 1 1

9 copies 0 1 0 0

10 copies 0 1 0 1

20 copies 0 1 1 0

30 copies 0 1 1 1

50 copies 1 0 0 0

99 copies 1 0 0 1

No limit 1010

No limit 1011

No limit 1100

No limit 1101

No limit 1110

No limit 1111

*18 Page memory allocation when power on

Mode 10-1 10-0

No allocation

32 MB

64 MB

00

01

10

*19 Page memory allocation at job start

When this mode is selected and the copy mode

use the page memory, the page memory is allocated at the start of a job so that the data that has

been read is output normally at occurrence of a

memory overflow.

The page memory size is determined by the resolution and the number of gradations as shown in

the table given below.

1 bit ED

2 bit ED

Mode

No allocation

Allocated

18 MB (A3 x 2)

36 MB (A3 x 2)

10-2

0

1

If DIP switches 10-0 and 10-1 are set to allocate

the page memory, they take priority over this

mode.

2-18

Page 21

ADJUSTMENT

*20 Size detection 4

Destination Mode 13-4 13-3

Metric series

A5R 0 0

B6R 0 1

Inch series

5.5 x 8.5R 1 0

*21 F4 size detection

Mode 13-6 13-5

8 x 13

8.25 x 13

8.125 x 13.25

8.5 x 13

00

01

10

11

*22 Maximum number of sheets that can be stapled

Except for FN-115

Mode 15-2 15-1

50 sheets

45 sheets

40 sheets

35 sheets

00

01

10

11

FN-115 (When the length in the paper feed direction is 400mm or more, the maximum number of

sheets to be stapled is the same when machines

other than FN-115 are used.)

*23 FNS alarm stop SW

Mode 15-4 15-3

Stop immediately after detection

Stop at end of copy after detection

No alarm stop

No alarm stop

00

01

10

11

*24 Selection of area to be erased in non-original

area automatic erasure

These bits are used to make a setting associated

with the non-original automatic erasure mode

(application function).

Mode 16-6 16-5

Standard

Dark original

Coping with light interference

00

01

10

*25 WT summer time setting

Mode

0 minute

10 minutes

20 minutes

30 minutes

40 minutes

50 minutes

60 minutes

70 minutes

80 minutes

90 minutes

100 minutes

110 minutes

120 minutes

130 minutes

140 minutes

150 minutes

17-3 17-2 17-1 17-0

0000

0001

0010

0011

0100

0101

0110

0111

1000

1001

1010

1011

1100

1101

1110

1111

*26 Density selection for scanning tab paper

The higher the brightness level, the higher the

density.

Mode 17-6 17-5 17-4

80 (brightness level)

40

60

100

120

160

200

255(not clipped)

000

001

010

011

100

101

110

111

2 ADJUSTMENT

2-19

Page 22

ADJUSTMENT

*27 Fixing temperature setting switch over

This bit is used to change the fixing temperature

when fixing is insufficient or paper curl is curled

largely.

This setting is effective only for plain paper. It is

not reflected in thick paper, thin paper and low

power mode.

• Standard: Standard setting.

• Standard+5°C to +15°C:

• Standard-5°C to -20°C:

2 ADJUSTMENT

Standard

Standard+5 °C

Standard+10 °C

Standard+15 °C

Standard-5 °C

Standard-10 °C

Standard-15 °C

Standard-20 °C

*28 Selection of a default resolution for IP scanner

400dpi

600dpi

200dpi

300dpi

*29 Number of punched holes

2 holes (Japan)

3 holes (Inch area)

4 holes (Metric area)

Set when fixing is insufficient.

Set when paper is curled largely.

Mode 19-3 19-2 19-1

000

001

010

011

100

101

110

111

Mode 19-7 19-6

Mode 22-2 22-1

00

01

10

11

00

01

10

*30 Toner density selection of developer

If gray background image is caused by an excessive amount of toner density in the developer, the

toner threshold can be changed with this switch

to reduce and eliminate the background. The

rotation speed of the developing sleeve

increases in proportion to the decrease in the

toner density of developer, keeping the image

density constant.

Toner standard density

Reducing appx. 0.5 %

Reducing appx. 1.0 %

Reducing appx. 1.5 %

*31 Maximum number of sheets with Z-folding (main

tray)

Up to 50 sheets

Up to 40 sheets

Up to 30 sheets

Up to 20 sheets

*32 Maximum number of sheets with Z-folding + sta-

ple

Up to 5 sheets

Up to 8 sheets

Up to 10 sheets

Up to 3 sheets

Mode 23-3 23-2

00

01

10

11

Mode 24-5 24-4

00

01

10

11

Mode 24-7 24-6

00

01

10

11

2-20

Page 23

ADJUSTMENT

*33 Paper type process control switchover

1. Setting method

This bit is used when "-----," "Normal," "Recycled," "Color," "Special," "HIGH Q," "Exclusive

paper A," "Exclusive paper B," "Exclusive paper

C," or "Exclusive paper D" is selected for "Paper

type/special size setting" in the key operator

mode.

When "User paper" is selected with this bit, the

transfer/separation corona unit output for the

"user paper setting" made in the 36 mode is

applied. When "No specification (-----)" is

selected, the output data by destination and

paper size (Japan:64 g/m

area:20 lb plain paper, Metric area:80 g/m

2

plain paper, Inch

2

plain

paper) is used.

Key

Plain paper 33-3 33-2 33-1 33-0

operator

Recycled paper 33-7 33-6 33-5 33-4

selecting

key

Colored paper 34-3 34-2 34-1 34-0

Special paper 34-7 34-6 34-5 34-4

High-quality paper 35-3 35-2 35-1 35-0

Exclusive paper A 35-7 35-6 35-5 35-4

Transfer/

separation

table

Exclusive paper B 36-3 36-2 36-1 36-0

Exclusive paper C 36-7 36-6 36-5 36-4

Exclusive paper D 37-3 37-2 37-1 37-0

No specification (default) 0 0 0 0

Standard paper 64 g/m

2

0001

Standard paper 20 lb 0 0 1 0

Standard paper 80 g/m

2

0011

Thick paper 0 1 0 0

Thin paper 0 1 0 1

High-quality paper for printing

press 64 g/m

High-quality paper for printing

press 81.4 g/m

High-quality paper for printing

press 127 g/m

High-quality paper for printing

books 64 g/m

paper 64 g/m

High-quality paper for printing

books 81.4 g/m

paper 81.4 g/m

2

2

2

2

and Coated

2

2

and Coated

2

0110

0111

1000

1001

1010

Reserve 1 1011

Reserve 2 1100

PPC paper 2 1 1 0 1

Low-strength paper 1 1 1 0

User paper 1 1 1 1

2. Paper type

(1) High-quality paper for printing press

This paper has only little difference in paper quality between the front and the back side, and has

much strength.

(2) Paper for printing books

This paper has lower paper density than highquality paper. Cream color is often used as a suitable color for books.

(3) Coated paper

This paper is high and standard-quality paper, to

one side of which 10 grams/m

2

of clay is applied.

(4) Low-strength paper

In spite of being 20 lb plain paper (inch area), the

paper strength is lower than normal plain paper,

and winds itself around the drum easily.

2 ADJUSTMENT

2-21

Page 24

ADJUSTMENT

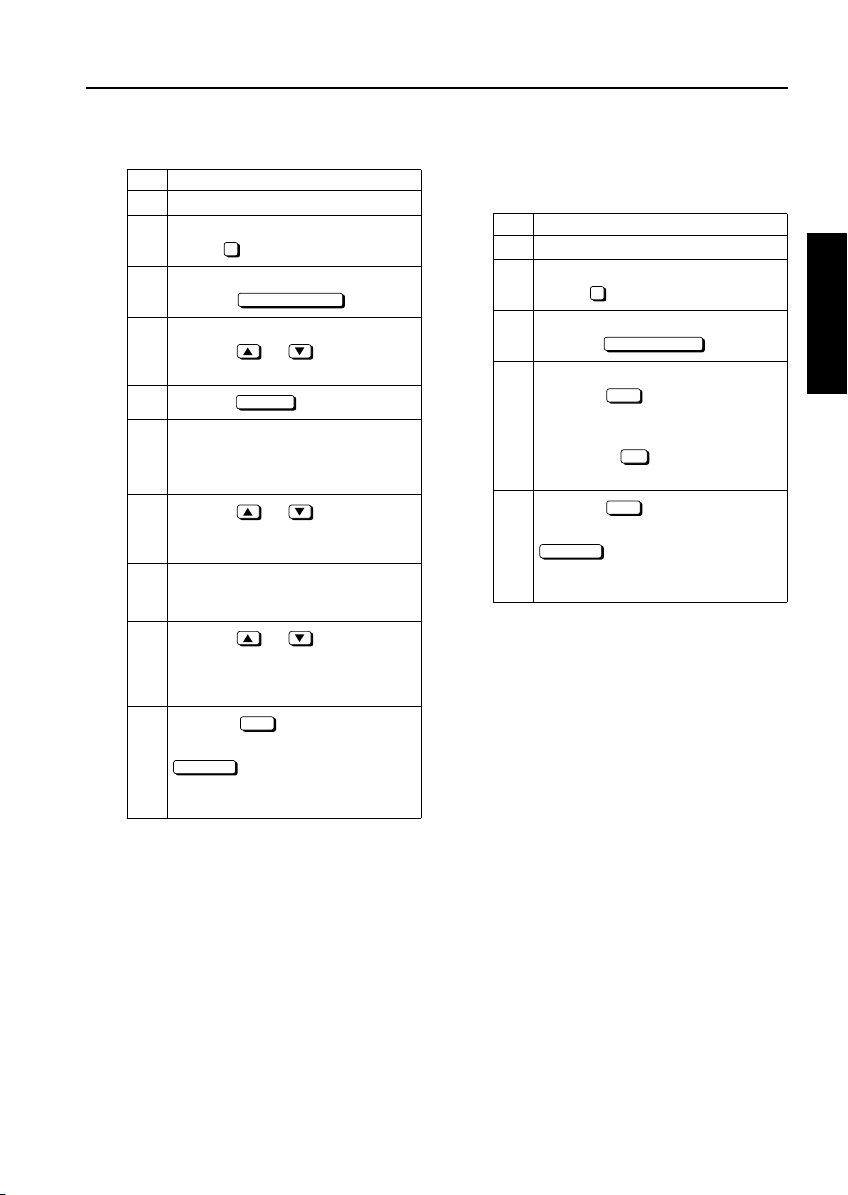

[3] Setting the Paper Size

When the LCT paper type is changed, it must be stored

in the main unit. This setting is effective when an

optional LCT is added.

Select a paper size among standard, non-standard

paper sizes. After selecting a tray size, specify a paper

size.

1. Setting the standard size

Step Operation

2 ADJUSTMENT

1 Enter the 25 mode.

2 [25 Mode Menu. Screen]

2

Select " Paper size setting".

3 [Paper size setting mode Screen]

Press the key.

4

Press the or button to select

STD SIZE

a paper size.

5

Press the key to finish setting.

OK

To cancel the new setting, press the

CANCEL

key,

Pressing either key will display the 25

Mode Menu screen again.

2. Setting the non-standard size

Step Operation

1 Enter the 25 mode.

2 [25 Mode Menu. Screen]

Select " Tray Size Setting."

2

3 [Paper size setting mode Screen]

Press the key.

4 Press the key for specifying the main

(vertical) scanning direction to display it

in reverse video.

5

Press the or key or numeric

keys to enter the size in the main (verti-

cal) scanning direction. Max. 314 mm

6 Press the key for specifying the sub (hor-

izontal) scanning direction to display it in

reverse.

7

Press the or key or numeric

keys to enter the size in the sub (horizon-

tal) scanning direction. Max. 223 mm

(A4LCT), 459 mm (A3LCT)

8

Press the key to finish setting.

To cancel the new setting, press the

CANCEL

Pressing either key will display the 25

Mode Menu. Screen again.

Non STD size

OK

key.

2-22

Page 25

ADJUSTMENT

3. Setting the wide paper

Step Operation

1 Enter the 25 mode.

2 [25 Mode Menu. Screen]

Select " Paper size setting."

2

3 [Paper size setting mode Screen]

Press the key.

4 [Paper size selecting Screen]

Press the or key to select a

wide paper size.

5

Press the key.

6 [Paper size input Screen]

Press the key for specifying the main

(vertical) scanning direction to display it

in reverse.

7

Press the or key or numeric

keys to enter the size in the main (verti-

cal) scanning direction. Max. 314 mm

8 Press the button for specifying the sub

(horizontal) scanning direction to highlight it.

9

Press the or key or numeric

keys to enter the size in the sub (horizontal) scanning direction. Max. 223 mm

(A4LCT), 459 mm (A3LCT)

10

Press the key to finish setting.

To cancel the new setting, press the

CANCEL

Pressing either key will display the 25

Mode Menu. Screen again.

Wide size paper

Input size

OK

key.

[4] PM Count Resetting

Care should be taken not to reset the PM count by mistake.

Step Operation

1 Enter the 25 mode.

2 [25 Mode Menu. Screen]

Select " PM count".

3

3 [PM count/cycle Screen]

Press the key.

4 [Reset Confirmation Screen]

Press the key.

The PM count is reset and the start date

is input automatically.

Pressing the key closes the Reset

Confirmation screen at once.

5

Press the key to finish setting.

To cancel the new setting, press the

CANCEL

Pressing either key will display the 25

Mode Menu. Screen again.

COUNT RESET

YES

NO

OK

key.

2 ADJUSTMENT

Reference 1:

Each time the current tray size is changed on this

screen, the new setting will be written into the

non-volatile memory.

2-23

Page 26

ADJUSTMENT

[5] Setting the PM Cycle

This function allows you to change the PM cycle.

Caution: The PM cycle is factory-set. Use this

2 ADJUSTMENT

function to change the factory-set PM

cycle.

Step Operation

1 Enter the 25 mode.

2 [25 Mode Menu. Screen]

Select " PM count".

3

3 [PM count/cycle Screen]

Press the key.

4 After making sure that three digits of the

cycle value are displayed in reverse

video, enter a desired cycle value using

numeric keys.

Only the three digits of the cycle value

can be entered. The entered digits will

be shifted to the left one after another.

5 Press the key to finish setting.

To cancel the new setting, press the

CANCEL

Pressing either key will display the 25

Mode Menu. Screen again.

PM Cycle Setting

OK

key.

[6] Collecting Data

This function allows you to view various data retained

by the machine.

Reference: The above data can also be viewed

1. Data that can be Viewed

No. Data Type Pre-operation

1

2

3

4

5

6

7

8

9

10

11

12

using the data collection function of

the.

Total count of

each paper size

Copy count of

each paper size

Print count of

each paper size

EDH count

Black ratio of each

section

Black ratio ranking list

JAM data of time

series

JAM count

Count of each copy

mode

SC count

JAM count of each

section

SC count of each section

Enter the 25

mode, select "

Software DIPSW

Setting", and set

bit 1 of address

30-1 to 1. (Note 1)

1

2-24

Note: When bit 1 of DIP switch 30 is set to 0,

only collected data 1 to collected data 6

can be viewed.

Page 27

ADJUSTMENT

2. Viewing Collecting Data No.1 to No.6 3. Viewing Collecting Data No.7 to No.12

Step Operation

1 Enter the 25 mode.

2 [25 Mode Menu. Screen]

Select " Data collection".

4

3 [Collecting data menu Screen]

Select the collecting data you want to

view by pressing one of numeric keys

to .

1 6

4 [Individual data view Screen]

View the selected data by scrolling the

screen using the and keys.

5

Press the key to

PREVIOUS SCREEN

return to the 25 Mode Menu. Screen.

Step Operation

1 Enter the 25 mode.

2 [25 Mode Menu. Screen]

Select " Software DIP SW setting".

1

3 [Software DIP SW Setting Screen]

Set bit 1 of DIP switch 30-1 to 1.

4

Press the key to return to the

PREVIOUS

25 Mode Menu. Screen.

5 [25 Mode Menu. Screen]

Select " Data Collection".

4

6 [Collecting data menu Screen]

Select the collected data you want to

view by pressing one of numeric keys

to .

7 12

To select the key or later press the

11

key.

If the key is pressed with key

displayed, the Collected Data Selection

screen containing keys to

1 12

appears again.

7 [Individual data view Screen]

View the selected data by scrolling the

screen using the and keys.

(Note)

8

Press the key to

PREVIOUS SCREEN

return to the 25 Mode Menu. Screen.

2 ADJUSTMENT

11

2-25

Note: On the Individual Data View screen show-

ing the JAM count of each section (collected data ) or SC count of each

section (collected data ), the

COUNT RESET

Pressing the key resets

11

12

key appears.

COUNT RESET

the selected data count.

Page 28

ADJUSTMENT

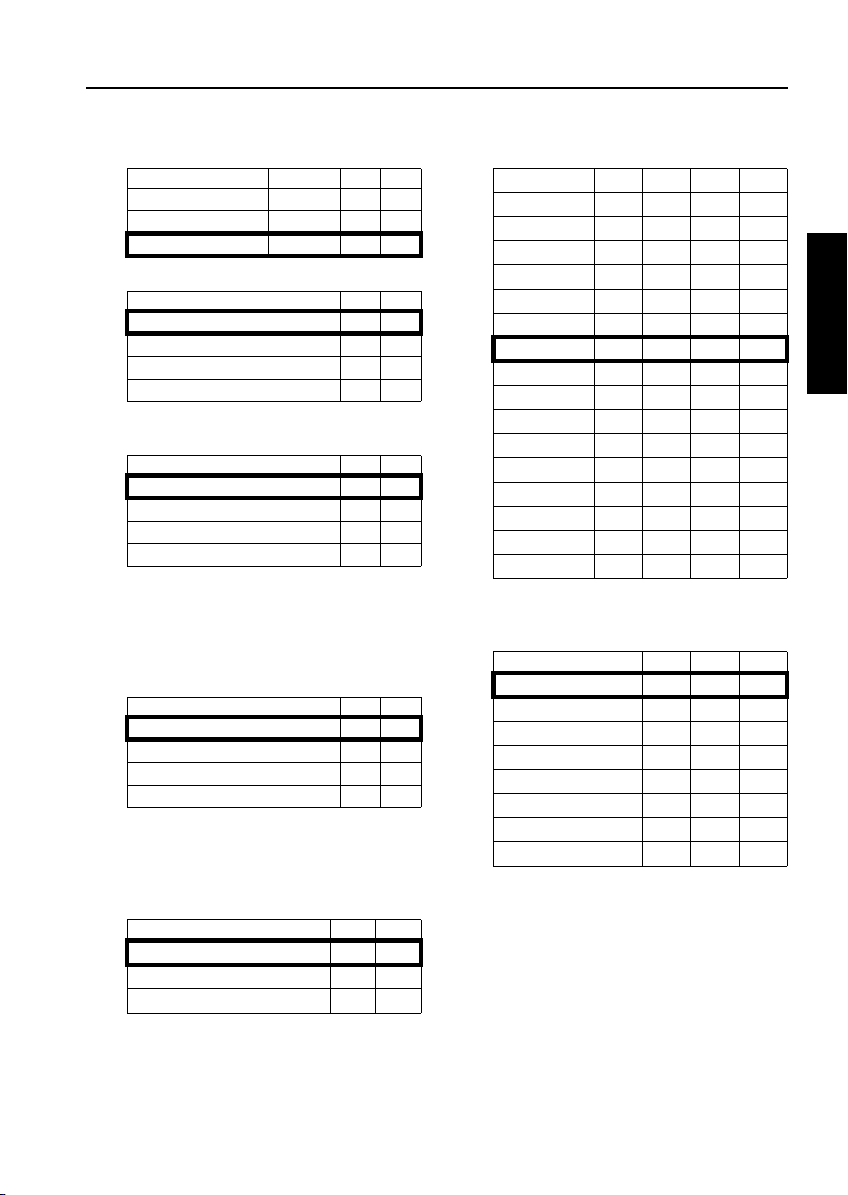

4. Details on Display Data

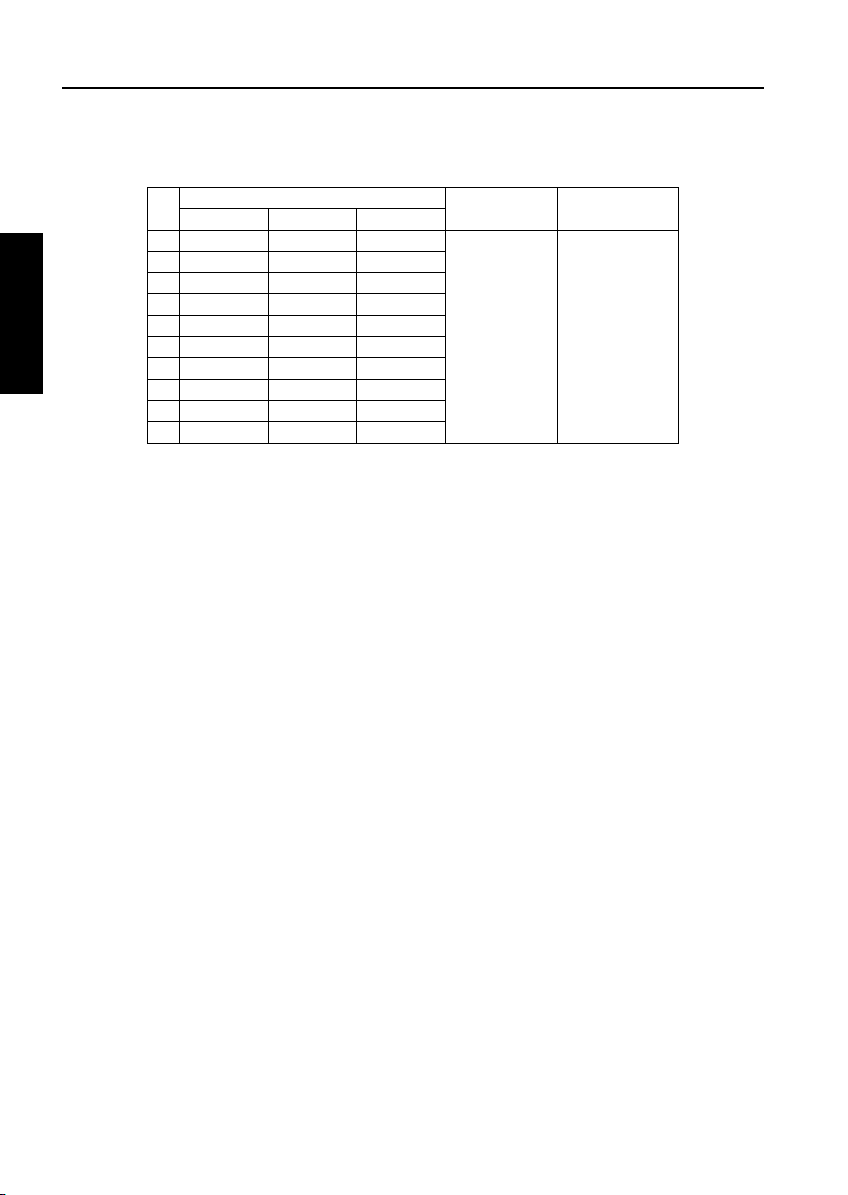

(1) Collecting data No.1 to No.3: Total / copy / print counts of each paper size

NO

Japan Inch area Metric area

1 A2 17 x 22 A2

2 A3 11 x 17 A3

3 B4 8.5 x 14 B4 (8K)

4 A4 8.5 x 11 A4

5 B5 5.5 x 8.5 B5 (16K)

2 ADJUSTMENT

1. Each time a printed copy is ejected, the counter is increments of 1 regardless of the paper size.

2. If the size of the paper used is none of the paper sizes 1-9 listed above, the counter is incremented in a

6A5 - A5

7B6 - F4

8 8.5x14 - -

98.5x11 A4 -

10 Special Special Special

special manner (short edge feed and long edge feed are counted assuming that they are of the same size.)

Destination

Maximum count Remarks

99999999

All counters are

8-digit counters.

2-26

Page 29

(2) Collecting data No.4: EDH mode

NO Items

Number of originals fed in EDH mode

1

Number of originals fed in EDH mode

2

Number of 1-sided SDF original fed

3

Number of 2-sided SDF original fed

4

Number of 1-sided mixed original fed

5

Number of 2-sided mixed original fed

6

Number of 1-sided Z-folded mode original fed

7

Number of 2-sided Z-folded mode original fed

8

9

10

11

12

Undefined

13

14

15

16

1. The counter is incremented each time one original side has been scanned in each mode.

2. Counters 1 and 2 count original sides independently of counters 3-8.

(3) Collecting data No.5: Black ratio of each section *1

This allows checking the average black ratio of 5000 prints for the latest 30 data.

Maximum

count

99999999

Remarks

All counters are 8-digit

counters.

ADJUSTMENT

2 ADJUSTMENT

(4) Collecting data No.6: Black ratio ranking list *1

This allows checking black ratio data, number of prints, transfer paper size, mode, and date for the top 15

job data ranked from highest rates of black ratio.

(5) Collecting data No.7: JAM data of time series

A jam code, total count, date and time of occurrence, tray type, paper size, and magnification can be displayed

for the latest 100 jams.

*1 This black ratio is the theoretical value obtained by converting the black dot area on the image data and the

area of the transfer paper, therefore it is different from the black ratio obtained by the actual printing.

2-27

Page 30

ADJUSTMENT

(6) Collecting data No.8: JAM count / Collecting data No.11: JAM count of each section (can be reset)

Description of JAM

Code displayed

NO

when display of

jam code is

selected by

25DIPSW

1

By-pass paper feed

2 10-2 5

3

Tray 1 paper feed

4 11-2 1

5

2 ADJUSTMENT

Tray 2 paper feed

6 12-2 2

7

Tray 3 paper feed

8 13-2 3

9

Tray 4 ( L C T)

10 14-2 4

Paper feed conveyance

11

(common to all trays)

Paper feed conveyance (tray 1)

12

Paper feed conveyance (tray 2/3)

13

Paper feed conveyance (tray 2)

14

Paper feed conveyance (tray 3)

15

Paper feed conveyance (LCT)

16

Drum

17

18

Second paper feed conveyance

19 31-2 9

Fixing unit /exit (straight ejection)

20

Fixing unit /exit (reverse and eject/ADU)

21

22

Fixing unit /exit (reverse and eject)

23 32-4 10

Fixing unit /exit

24

25

ADU inlet paper conveyance

26 92-2 11

ADU paper reversal and conveyance

27

28

ADU exit paper conveyance

29 94-2 12

Vertical paper conveyance jam access door

30

LCT side door

31

Front door

32

Finisher door

33

34

10-1 5

11-1 1

12-1 2

13-1 3

14-1 4

17-1 8

17-2 6

17-3 6

17-4 6

17-5 6

17-6 7

21-1 9

31-1 8

32-1 10

32-2 10

32-3 10

32-5 10

92-1 12

93-1 12

94-1 12

19-1 6

19-2 13

51-1 13

71-1 13

62-1 14

Jam position display on

operation

panel

Maximum

count

999999

35 62-2 14

36 62-3 14

37 62-4 14

38 62-5 14

39 62-6 14

ADF

40 62-7 14

41 62-8 14

42 62-9 14

43 62-10 14

44 63-1 15

45 63-2 15

Counting

conditionLocation of jam

All counts are

6-digit counters.

2-28

Page 31

ADJUSTMENT

Description of JAM

NO

46

47 63-4 15

48 63-5 15

49 63-6 15

50 63-7 15

ADF

51 63-8 15

52 63-9 15

53 63-10 15

54 63-11 15

55 61-1 56 61-2 57

58 72-17 13

59 72-18 13

60 72-19 13

61 72-20 13

62 72-21 13

63 72-22 17

64 72-23 17

65 72-24 18

FNS

66 72-25 18

67 72-26 18

68 72-27 13

69 72-28 13

70 72-29 13

71 72-30 13

72 72-32 18

73 72-33 18

74 72-34 18

75

PI

76 72-36 17

77 72-37 17

78

FNS

79 72-82 13

80 72-83 13

TU

81

82

83 72-39 20

84 72-40 20

85 72-41 20

86 72-42 20

87 72-43 20

FNS

88 72-44 20

89 72-45 20

90 72-46 20

91 72-47 20

92 72-48 20

93 71-03 -

Code displayed

when display of

jam code is

selected by

25DIPSW

63-3 15

72-16 13

72-35 17

72-81 13

71-2 -

72-38 20

Jam position display on

operation

panel

Maximum

count

999999

Counting

conditionLocation of jam

2 ADJUSTMENT

All counts are

6-digit counters.

2-29

Page 32

ADJUSTMENT

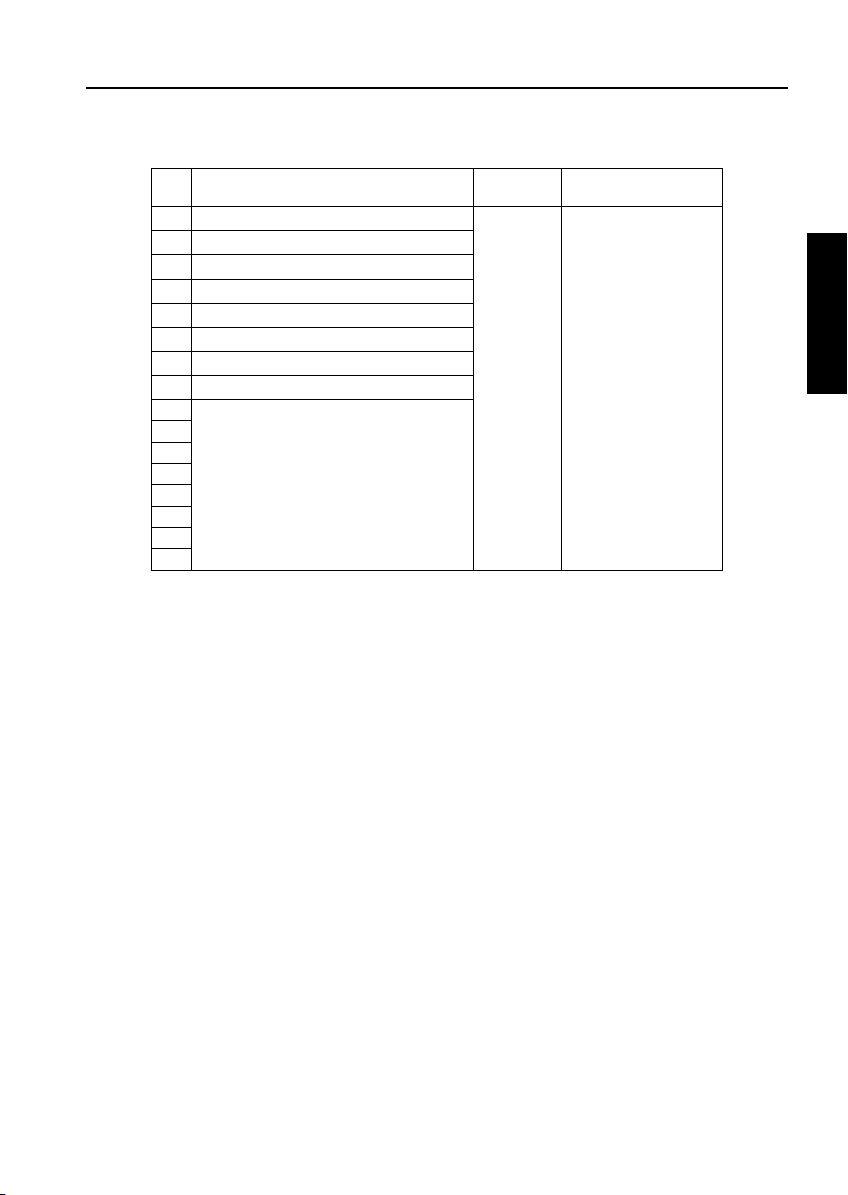

(7) Collecting Data No.9:Count of each copy mode

NO Item

1-1 mode

1

1-2 mode

2

2-1 mode

3

2-2 mode

4

EDH1-1 mode

5

EDH1-2 mode

6

Mixed original mode

7

SDF mode

2 ADJUSTMENT

8

Z-folded original mode

9

LEF/Lengthwise, SEF/Crosswise normal set

10

LEF/Crosswise, SEF/Lengthwise normal set

11

LEF/Lengthwise, SEF/Crosswise reverse set

12

LEF/Crosswise, SEF/Lengthwise reverse set

13

Auto (text/photo)

14

Tex t

15

Photo

16

Increase Contrast

17

Non STD size

18

1 oblique staple (Upper Left)

19

1 staple (upper-right)

20

2 parallel staples (Left binding)

21

2 parallel staples (Upper binding)

22

Left-binding

23

Right-binding

24

Top-binding

25

Tab original

26

Stapling and Folding

27

Folding

28

Main tray: Group

29

Main tray: Sort

30

Main tray: Non sort

31

Subtray: Group (FACE DOWN)

32

Subtray: Group (FACE UP)

33

Subtray: Sort (FACE DOWN)

34

Subtray: Sort (FACE UP)

35

Subtray: Non sort (FACE DOWN)

36

Subtray: Non sort (FACE UP)

37

Cover sheet

38

Trimmer

39

Real size copy

40

Preset magnification E4

41

Preset magnification E3

42

Preset magnification E2

43

Preset magnification E1

44

Preset magnification R4

45

Maximum

count

99999999

Counting condition

All counters are 8-digit counters.

2-30

Page 33

ADJUSTMENT

NO Item

Preset magnification R3

46

Preset magnification R2

47

Preset magnification R1

48

User lens mode 1

49

User lens mode 2

50

User lens mode 3

51

Zoom

52

Vertical/Horizontal zoom

53

Maximum zoom

54

Minimum zoom

55

APS

56

AMS

57

AE

58

User density level 1

59

User density level 2

60

Interrupted copy

61

Automatic image rotation cancellation

62

Sheet/cover interleave

63

Chapter control

64

Combination

65

Booklet copy

66

OHP interleave (copy)

67

OHP interleave (blank)

68

Image insert

69

Dual Page

70

Program job

71

Non-image area erase

72

Reverse image

73

Auto repeat

74

Manual repeat

75

STD size repeat

76

Frame erasure

77

Fold erasure

78

Auto layout

79

Full-image Area

80

Image Shift

81

Reduction shift

82

Overlay

83

Water mark

84

Stamp

85

Date / Time

86

Page

87

Numbering

88

Set quantity 1

89

Set quantity 2-5

90

Set quantity 6-10

91

Maximum

count

99999999

Counting condition

2 ADJUSTMENT

All counters are 8-digit counters.

2-31

Page 34

ADJUSTMENT

NO Item

Set quantity 11 or more

92

Time while power remote 1 is on Total period of time during which image

93

Time while power remote 2 is on Total period of time during which remote

94

2 ADJUSTMENT

Time while power remote3 is on Total period of time during which remote

95

Time while power remote 4 is on Total period of time during which remote

96

Time during low power mode Total period of time during which low

97

Time during warm up time Total period of time during which fixing

98

Time during front door open Total period of time during which front

99

Ope. time in 1side straight exit Total time from start to end of printing.

100

Ope. time in 1 side reverse exit

101

Ope. time in 2 side print

102

Operation time in EDH mode Total operation time of ADF. The count is

103

Morning Correction count The count is incremented by 1 each time

104

Time during APS sensor on Total period of time during which APS

105

N of main tray used jobs

106

N of sub tray used jobs

107

N of stapling folding used jobs

108

N of folding used jobs

109

N of EDH NF occurred

110

N of EDH special error1 occurred Original size detection error occurrence

111

N of EDH special error2 occurred Next original information error occur-

112

N of EDH special error3 occurred Mixed loading prohibited original size

113

Maximum

count

99999999

Counting condition

All counters are 8-digit counters.

control board is energized (remote

power supply 1 is ON). 1 is counted per

minute. This value is written into non-volatile

power supply 2 is ON. 1 is counted per

minute. This value is written into non-volatile memory when image control is

turned OFF.

power supply 2 is ON and 24 V relay is

ON. The count is incremented by 1 per

minute. This value is written into non-volatile memory when image control is

turned OFF.

power supply 3 is ON. The count is incremented by 1 per minute. This value is

written into non-volatile memory when

image control is turned OFF.

power mode is selected. The count is

incremented by 1 per minute.

unit heater is ON when machine is not

ready for fusing. The count is incremented by 1 per second.

door is open. The count is incremented

by 1 per second.

The count is incremented by 1 per second. Data is output per minute. (Halt time

(machine is not operational due to jam,

etc.) is excluded.)

incremented by 1 per second.

correction is made before starting work

in the morning.

sensor is ON. The count is incremented

by 1 per second. Data is output per

minute.

Number of jobs

count

rence count

error occurrence count

2-32

Page 35

ADJUSTMENT

NO Item

N of Scanner scanned

114

N of electrode cleaned

115

N of memory overflow

116

N of fixing alarm occurred

117

N of no toner stop occurred

118

N of AGC retry

119

N of sub scan beam correct error

120

N of mis-centering correct error

121

N of EDH distortion adjust error

122

N of EDH distor tion data error

123

Compression memory overflow

124

Page memory overflow (scan)

125

Page memory overflow (print)

126

FNS alarm (tray/trimming)

127

FNS alarm (staple)

128

Scanner count

129

N of EDH special error 4 occurred Ready-time out error

130

Storing for HDD (Sync. with Copying)

131

Storing for HDD (SRV mode scan-> HDD)

132

Storing for PC (SRV mode scan-> PC)

133

Storing for PC (SRV mode HDD-> PC)

134

Recalling from HDD (SRV mode HDD)

135

Recalling from PC (SRV mode PC)

136

Image edit count by SRV

137

Wide paper count (A3W)

138

Wide paper count (A4W)

139

Wide paper count (A4RW)

140

Wide paper count (A5W)

141

Wide paper count (Others)

142

Punch

143

Z-fold

144

Shift amount abnormality in repeat mode

145

Maximum

count

99999999

The count is incremented by 1 each time

Platen Mode Copy button is pressed.

Counting condition

2 ADJUSTMENT

2-33

Page 36

ADJUSTMENT

(8) Collecting data No.10: SC count / Collecting data No.12: SC count of each section

Trouble

NO

code

113 1

213 2

313 3

41811

51812

61813

71810

2 ADJUSTMENT

81821

91822

10 18 23

11 18 20

12 18 31

13 18 32

14 18 33

15 18 30

16 18 41

17 18 42

18 18 43

19 18 40

20 18 51

21 18 52

22 18 53

23 21 1

24 21 2

25 21 3

26 21 4

27 21 5

28 21 6

29 23 1

30 23 2

31 23 3

32 23 4

33 23 5

34 23 6

35 23 7

36 23 8

37 23 9

38 23 10

39 23 11

40 24 1

41 24 2

42 24 3

43 24 4

44 28 1

45 28 2

Paper feed MT EM

LCT conveyance MT EM

Loop roller motor fuse blowing detection

Tray 1 up error 1

Tray 1 up error 2

Tray 1 up error 3

Tray 1 up MT EM error

Tray 2 up error 1

Tray 2 up error 2

Tray 2 up error 3

Tray 2 up MT EM error

Tray 3 up error 1

Tray 3 up error 2

Tray 3 up error 3

Tray 3 up MT EM error

LCT up/down error 1

LCT up/down error 2

LCT up/down error 3

LCT up/down MT EM

By-pass tray up error 1

By-pass tray up error 2

By-pass tray up error 3

Charging corona unit cleaning MT error 1

Charging corona unit cleaning MT error 2

Charging corona unit cleaning MT error 3

Transfer/separation corona unit cleaning MT error 1

Transfer/separation corona unit cleaning MT error 2

Transfer/separation corona unit cleaning MT error 3

Toner bottle MT EM

Developing MT EM

Blade motor excessive current detection

Drum ready1 1

Drum ready1 2

Drum ready1 3

Blade ready 1

Blade ready 2

Blade ready 3

Drum ready2

Toner screw motor fuse blowing

Drum temperature sensor break detection

Drum temperature sensor grounding error detection

* Not use this count

* Not use this count

Charging EM

Transfer EM

Description

Maximum

count

9999

Remarks

All counters are 4digit counters.

2-34

Page 37

ADJUSTMENT

Trouble

NO

code

46 28 3

47 28 4

48 29 1

49 29 2

50 29 3

51 29 4

52 29 5

53 29 6

54 29 7

55 29 8

56 29 9

57 29 10

58 29 11

59 29 12

60 29 13

61 29 14

62 29 15

63 32 1

64 32 2

65 32 3

66 32 4

67 32 5

68 32 6

69 32 7

70 33 1

71 33 2

72 33 3

73 33 4

74 33 5

75 33 6

76 34 1

77 34 2

78 34 3

79 34 4

80 35 1

81 35 2

82 36 1

83 36 2

84 36 3

85 36 4

86 36 5

87 36 6

88 41 1

89 41 2

90 41 3

91 41 4

Description

Separation EM

High-voltage 24 V fuse blowing

Maximum density correction error 1

Maximum density correction error 2

Maximum density correction error 3

γ correction error 1

γ correction error 2

γ correction error 3

Dot diameter correction error 1

Dot diameter correction error 2

Potential correction error 1

Potential correction error 2