Page 1

SERVICE MANUAL

Model

AD-723

FEBRUARY 1999

CSM-AD723

KONICA BUSINESS TECHNOLOGIES, INC.

Page 2

Page 3

AD-723

SERVICE MANUAL

FEBRUARY 1999

Used on Konica Model

7823

Page 4

IMPORTANT NOTICE

Because of the possible hazards to an inexperienced

person servicing this equipment, as well as the risk of

damage to the equipment, Konica Business Technologies strongly recommends that all servicing be performed by Konica-trained service technicians only.

Changes may have been made to this equipment to

improve its performance after this service manual was

printed. Accordingly, Konica Business Technologies,

Inc., makes no representations or warranties, either

expressed or implied, that the information contained in

this service manual is complete or accurate. It is understood that the user of this manual must assume all risks

or personal injury and/or damage to the equipment while

servicing the equipment for which this service manual

is intended.

Corporate Publications Department

© 2001, KONICA BUSINESS TECHNOLOGIES, INC.

All rights reserved.

Printed in U.S.A.

Page 5

CONTENTS

GENERAL, MECHANICAL/ELECTRICAL

1. SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-1

2. PARTS IDENTIFICATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-2

3. CROSS-SECTIONAL VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-3

4. DRIVE SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-4

5. ELECTRICAL COMPONENTS LAYOUT. . . . . . . . . . . . . . . . . . . . M-5

6. DESCRIPTION OF EACH MECHANISM AND CONTROL

6-1. Exit/Turnover Switching Mechanism . . . . . . . . . . . . . . . . . . . M-6

6-2. Fuser Oil Cleaning Mechanism. . . . . . . . . . . . . . . . . . . . . . . . M-7

6-3. Paper Standby Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-7

6-4. Switchback Operation (Turnover). . . . . . . . . . . . . . . . . . . . . . M-8

7. OPERATION AND CONTROL

7-1. No. of Multiple 2-Sided Copies . . . . . . . . . . . . . . . . . . . . . . . . M-9

7-2. Sensor Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-9

7-3. 2-Sided Copying Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . M-10

DIS/REASSEMBLY, ADJUSTMENT

1. DISASSEMBLY

1-1. Removal of the Exterior Covers and Guides . . . . . . . . . . . . . D-1

1-2. Removal of Vertical Transport Clutch CL1. . . . . . . . . . . . . . . D-2

1-3. Removal of the Vertical Transport Roller (Metallic One) . . . D-3

1-4. Removal of the Vertical Transport Roller (Rubber One). . . . D-3

1-5. Removal of the Turnover Entrance Guide . . . . . . . . . . . . . . . D-4

2. ADJUSTMENTS

2-1. Adjustment of Dup. Left-Margin . . . . . . . . . . . . . . . . . . . . . . . D-4

2-2. Adjustment of Exit/Turnover Switching Solenoid SL1. . . . . . D-5

TROUBLESHOOTING

1. MISFEED DETECTION

1-1. Misfeed Detection Conditions . . . . . . . . . . . . . . . . . . . . . . . . . T-1

1-2. Misfeed Troubleshooting Procedures. . . . . . . . . . . . . . . . . . . T-2

APPENDED DIAGRAMS

◆ELECTRICAL WIRING DIAGRAM / ELECTRICAL CIRCUIT DIAGRAM

iii

Page 6

iv

Page 7

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

Installation Environment

Safety considerations usually are directed toward

machine design and the possibility of human error. In

addition, the environment in which a machine is operated must not be overlooked as a potential safety

hazard.

Most electrical equipment is safe when installed in a

normal environment. However, if the environment is

different from what most people consider to be normal, it is conceivable that the combination of the

machine and the room air could present a hazardous

combination. This is because heat (such as from

fusing units) and electrical arcs (which can occur

inside switches) have the ability to ignite flammable

substances, including air.

When installing a machine, check to see if there

is anything nearby which suggests that a poten-

tial hazard might exist. For example, a laboratory

might use organic compounds which, when they

evaporate, make the room air volatile. Potentially dangerous conditions might be seen or smelled. The

presence of substances such as cleaners, paint thinners, gasoline, alcohol, solvents, explosives, or similar items should be cause for concern.

If conditions such as these exist, take appropriate

action, such as one of the following suggestions.

effect may be caused by altering any aspect of the

machine’s design. Such changes have the potential

of degrading product performance and reducing

safety margins.

For these reasons, installation of any modification not

specifically authorized by Konica Business Machines

U.S.A., Inc., is strictly prohibited.

The following list of prohibited actions is not all-inclusive, but demonstrates the intent of this policy.

• Using an extension cord or any unauthorized

power cord adapter.

• Installing any fuse whose rating and physical size

differs from that originally installed.

• Using wire, paper clips, solder, etc., to replace or

eliminate any fuse (including temperature fuses).

• Removing (except for replacement) any air filter.

• Defeating the operation of relays by any means

(such as wedging paper between contacts).

• Causing the machine to operate in a fashion other

than as it was designed.

• Making any change which might have a chance

of defeating built-in safety features.

• Using any unspecified replacement parts.

• Determine that the environment is controlled

(such as through the use of an exhaust hood) so

that an offending substance or its fumes cannot

reach the machine.

• Remove the offending substance.

• Install the machine in a different location.

The specific remedy will vary from site to site, but the

principles remain the same. To avoid the risk of injury

or damage, be alert for changes in the environment

when performing subsequent service on any machine, and take appropriate action.

Unauthorized Modifications

Konica copiers have gained a reputation for being

reliable products. This has been attained by a combination of outstanding design and a knowledgeable

service force.

The design of the copier is extremely important. It is

the design process that determines tolerances and

safety margins for mechanical, electrical, and electronic aspects. It is not reasonable to expect individuals not involved in product engineering to know what

General Safety Guidelines

This copier has been examined in accordance with

the laws pertaining to various product safety regulations prior to leaving the manufacturing facility to

protect the operators and service personnel from

injury. However, as with any operating device, components will break down through the wear-and-tear of

everyday use, as will additional safety discrepancies

be discovered. For this reason, it is important that the

technician periodically performs safety checks on the

copier to maintain optimum reliability and safety.

The following checks, not all-inclusive, should be

made during each service call:

CAUTION: Avoid injury. Ensure that the copier is

disconnected from its power source before continuing.

• Look for sharp edges, burrs, and damage on all

external covers and copier frame.

• Inspect all cover hinges for wear (loose or broken).

• Inspect cables for wear, frays, or pinched areas.

v

Page 8

SAFETY PRECAUTIONS

• Ensure that the power cord insulation is not damaged (no exposed electrical conductors).

• Ensure that the power cord is properly mounted

to the frame by cord clamps.

• Check the continuity from the round lug (GND) of

the power cord to the frame of the copier -- ensure

continuity. An improperly grounded machine can

cause an electrically-charged machine frame.

Safeguards During Service Calls

Confirm that all screws, parts, and wiring which are

removed during maintenance are installed in their

original positions.

• When disconnecting connectors, do not pull the

wiring, particularly on AC line wiring and high

voltage parts.

• Do not route the power cord where it is likely to

be stepped on or crushed.

• Carefully remove all toner and dirt adhering to any

electrical units or electrodes.

• After part replacement or repair work, route the

wiring in such a way that it does not contact any

burrs or sharp edges.

• Do not make any adjustments outside of the

specified range.

Applying Isopropyl Alcohol

Care should be exercised when using isopropyl alcohol, due to its flammability. When using alcohol to

clean parts, observe the following precautions:

• Remove power from the equipment.

• Use alcohol in small quantities to avoid spillage

or puddling. Any spillage should be cleaned up

with rags and disposed of properly.

• Be sure that there is adequate ventilation.

• Allow a surface which has been in contact with

alcohol to dry for a few minutes to ensure that the

alcohol has evaporated completely before applying power or installing covers.

Summary

It is the responsibility of every technician to use professional skills when servicing Konica products. There

are no short cuts to high-quality service. Each copier

must be thoroughly inspected with respect to safety

considerations as part of every routine service call.

The operability of the copier, and more importantly,

the safety of those who operate or service the copier,

are directly dependent upon the conscientious effort

of each and every technician.

Remember...when performing service calls, use good

judgement (have a watchful eye) to identify safety

hazards or potential safety hazards that may be present, and correct these problem areas as they are

identified -- the safety of those who operate the copier

as well as those who service the copier depend on it!

vi

Page 9

GENERAL,

MECHANICAL/

ELECTRICAL

Page 10

Page 11

SPECIFICATIONS

1

Type : Sheet turnover device for making automatic

2-sided copies

Installation : Mounted to the copier

Modes : Exit mode

Duplex mode

Max. Storage

Capacity

Exit Tray Capacity : 250 sheets of 90-g/m2 or 24-lb. paper

Registration : Center

Power Source : DC24V (supplied from copier)

Power Consumption : 30W or less

Dimensions : Width ..... 121 mm or 4-3/4"

Weight : 8.9 kg or 19-1/2 lbs. (including the mount)

Environmental

Requirements

Paper Requirements

- Exit mode Type of Paper : Recommended paper weighing 60 to 90 g/m2 or

Paper Size : A5 lengthwise to A3 lengthwise and A3 Wide or

- Duplex mode Type of Paper : Recommended paper weighing 60 to 90 g/m2 or

Paper Size : A5 lengthwise to A3 lengthwise or 5-1/2" × 8-1/2"

: 2 (A4 crosswise or smaller, two-sheet paper

attraction mode)

Depth ..... 536 mm or 21"

Height ....345 mm or 13-1/2"

: Same as copier

16 to 24 lbs., OHP transparencies, thick paper

weighing 157 g/m2 or 42 lbs. max.

5-1/2" × 8-1/2" lengthwise to 11" × 17" lengthwise

and Full Bleed

16 to 24 lbs.

lengthwise to 11" × 17" lengthwise

M-1

Page 12

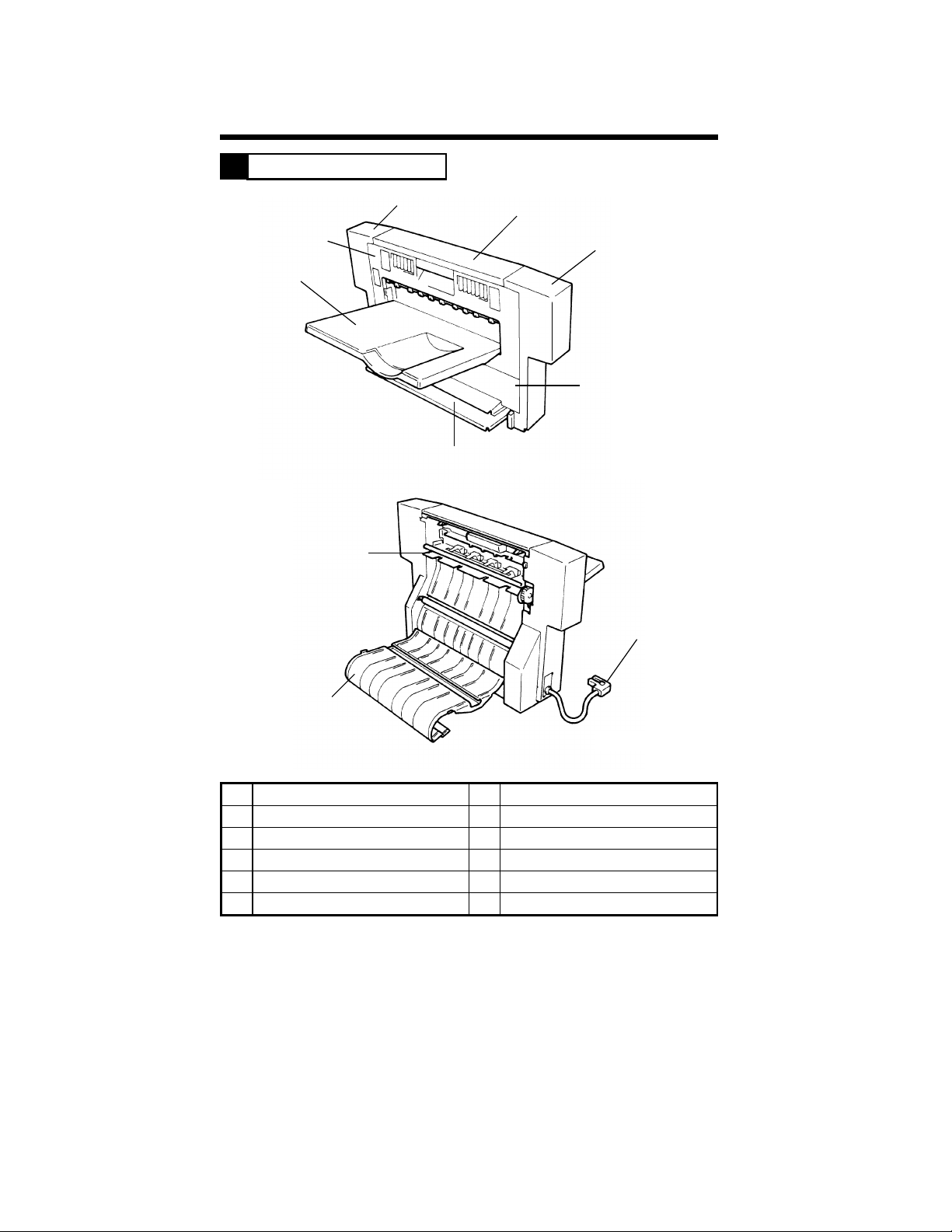

PARTS IDENTIFICATION

2

3

2

1

7

8

4

5

6

4458M001AA

10

9

4458M002AA

No. Name No. Name

1 Exit Tray 6 Exit Section Lower Cover

2 Exit Section Cover 7 Turnover Tray

3 Rear Cover 8 Exit/Turnover Switching Finger

4 Top Cover 9 Vertical Transport Guide

5 Front Cover 10 Hookup Cord

M-2

Page 13

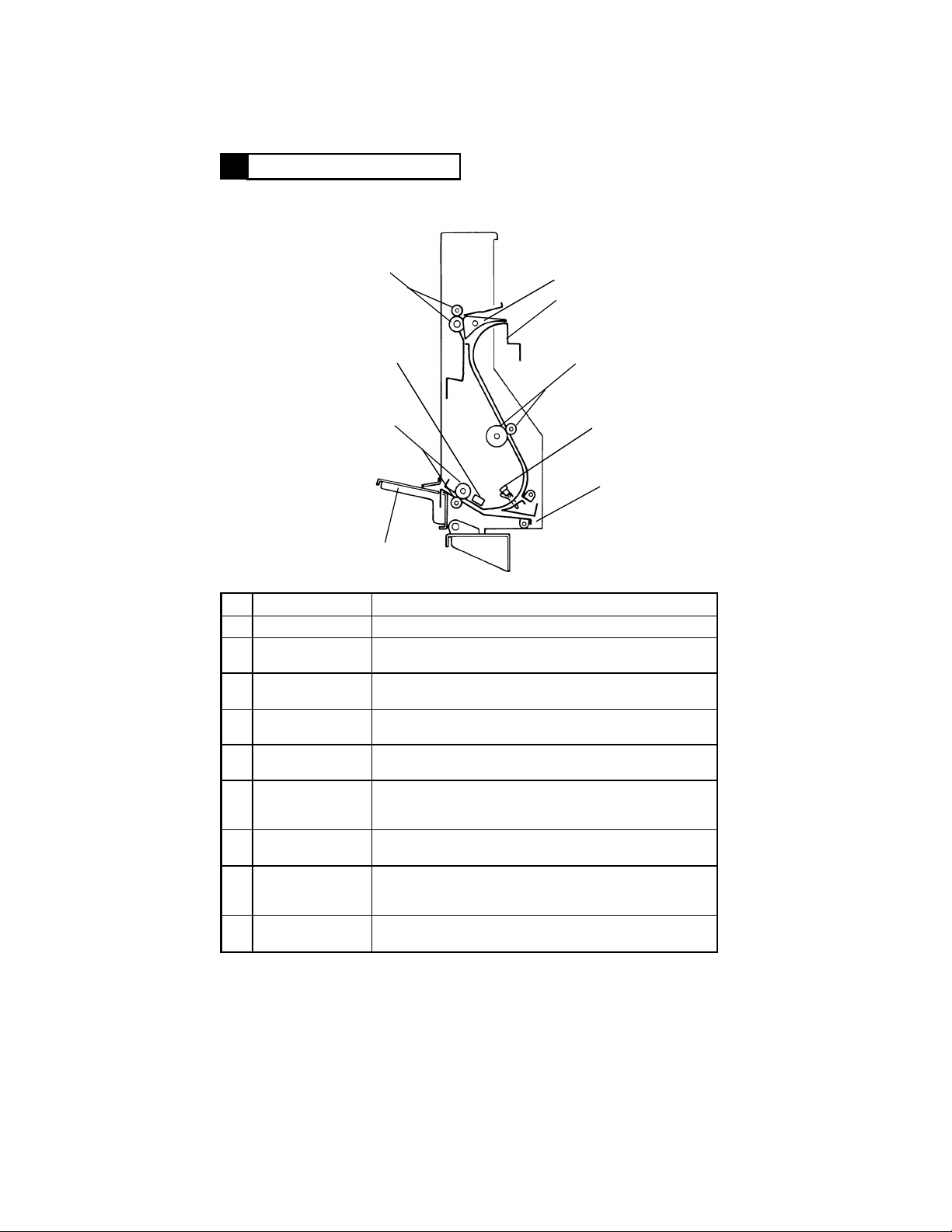

CROSS-SECTIONAL VIEW

3

1

9

8

7

No. Name Function

1 Exit Rollers Feed the copy out onto the Exit Tray.

Exit/Turnover

2

Switching Finger

Vertical Transport

3

Guide

Vertical Transport

4

Rollers

Vertical Transport

5

Sensor PC3

Duplex Paper

6

Take-Up Port

7 Turnover Tray

8 Turnover Rollers

Switchback

9

Sensor PC1

Directs a copy for exit or turnover depending on the

operating mode.

Serves as a guide for the copy for turnover. Used also for

clearing a misfeed.

Transports the copy for turnover. Also removes the fuser

oil from the copy.

Detects a copy to be later turned over. Serves also as a

misfeed sensor.

The port through which the copy which has been turned

over is taken up and fed into the copier for the second

copy cycle.

Prevents the portion of the copy out of the Duplex Unit for

turnover from drooping down.

Reverse the copy fed from the vertical transport section

(switchback motion) so that it can be taken up and fed

again into the copier.

Detects the reference timing for the switchback motion of

the copy fed from the vertical transport section.

2

3

4

5

6

4458M003AA

M-3

Page 14

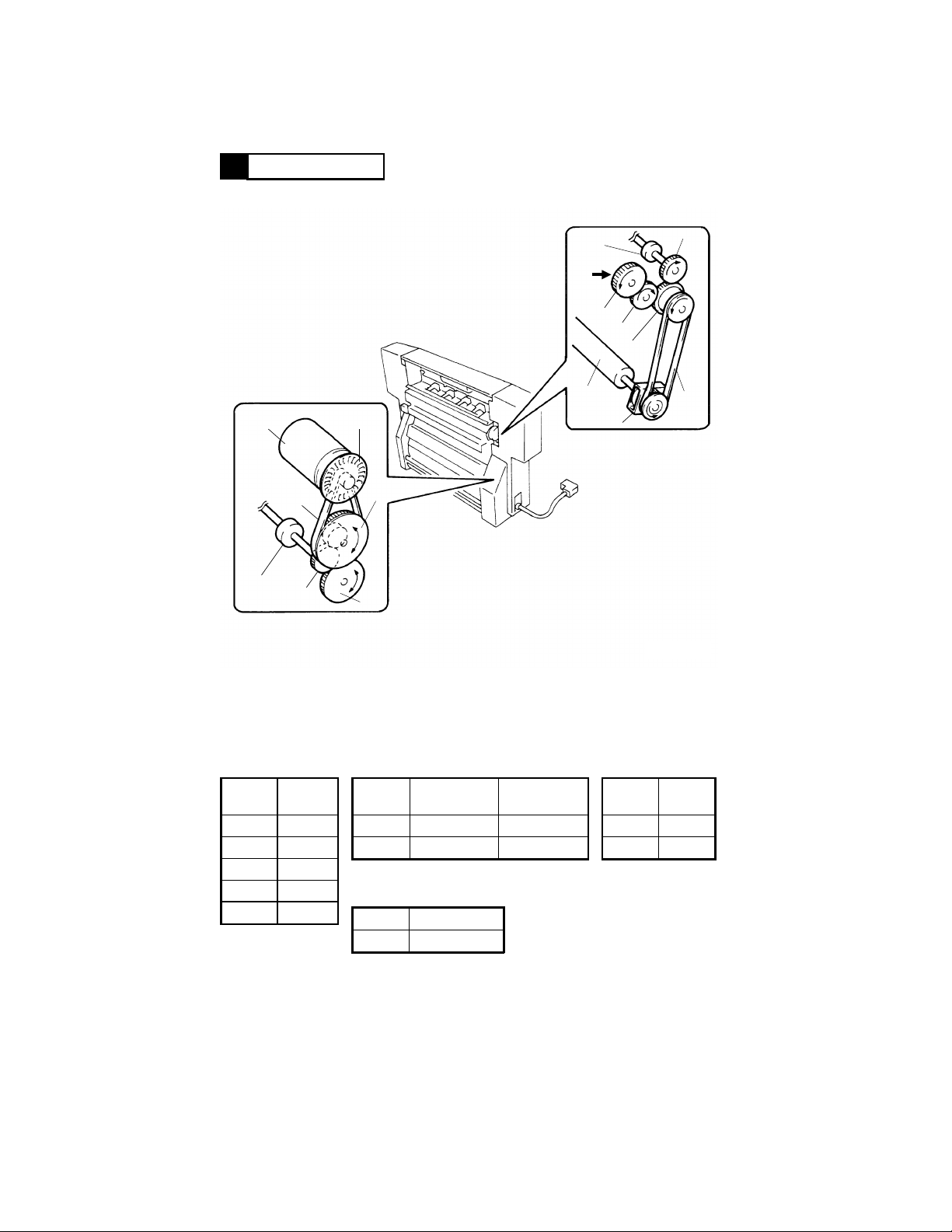

DRIVE SYSTEM

4

M1

Turnover

Roller

B2

G4

P1

PG2

G5

Exit Roller

Drive from

Copier

G1

Vertical

Transport

Roller

G3

G2

PG1

B1

CL1

4458M004AA

Gear

Symbol

G1 30

G2 24

G3 24

G4 19

G5 33

No. of

Teeth

Pulley

Symbol

PG1 31 28

PG2 15 64

No. of

Teeth, Gear

Teeth, Pulley

Pulley

Symbol No. of Teeth

P1 16

M-4

No. of

Belt

Symbol

B1 288

B2 191.01

Length

(mm)

Page 15

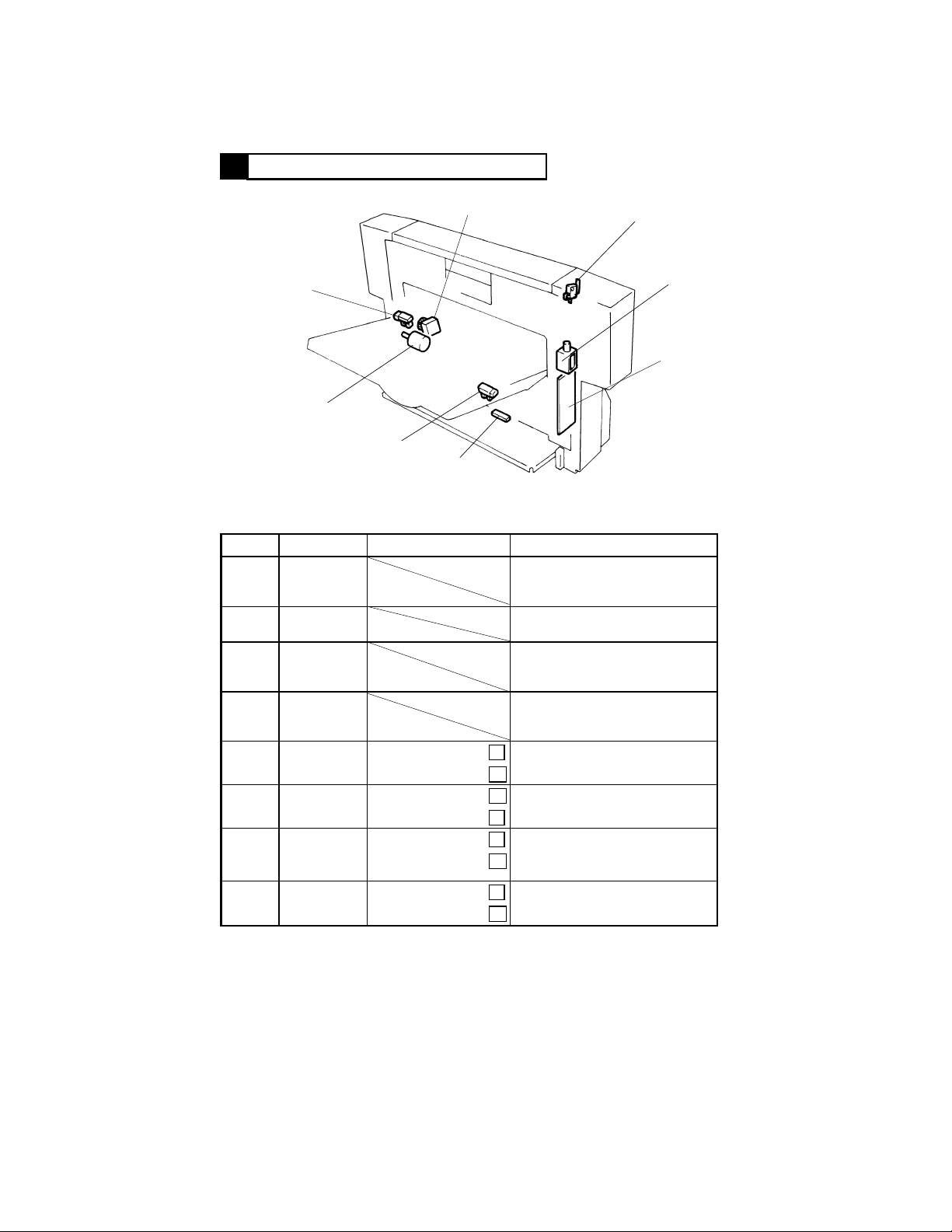

ELECTRICAL COMPONENTS LAYOUT

5

CL1

PC2

M1

PC3

PC1

◆ Function of Each Component

Symbol Name Input Signals (∗) Function

PWB-A Drive Board

M1

SL1

CL1

PC1

(PJ2A-8)

PC2

(PJ3A-2)

PC3

(PJ2A-9)

S1

(PJ2A-6)

Turnover

Motor

Exit/Turnover

Switching

Solenoid

Vertical

Transport

Clutch

Switchback

Sensor

Motor Pulse

Sensor

Vertical

Transport

Sensor

Duplex Unit

Set Switch

Paper present:

Paper not present:

Unblocked:

Blocked:

Paper present:

Paper not present:

Unit in position:

Unit out of position:

Performs communication with the

copier and controls the electrical

components of the Duplex Unit.

Drives the Turnover Rollers to

effect a switchback motion.

Moves the Exit/Turnover

Switching Finger to change the

paper path.

Controls the start and stop of the

Vertical Transport Rollers to keep

the copy in the standby state.

L

Detects the reference timing for a

switchback motion.

H

H

Detects the speed of M1.

L

L

Detects the copy present at the

vertical transport section.

H

L

Detects whether or not the

Duplex Unit is installed in position.

H

S1

SL1

PWB-A

4458M005AA

∗ Signals at the print jack on PWB-A.

M-5

Page 16

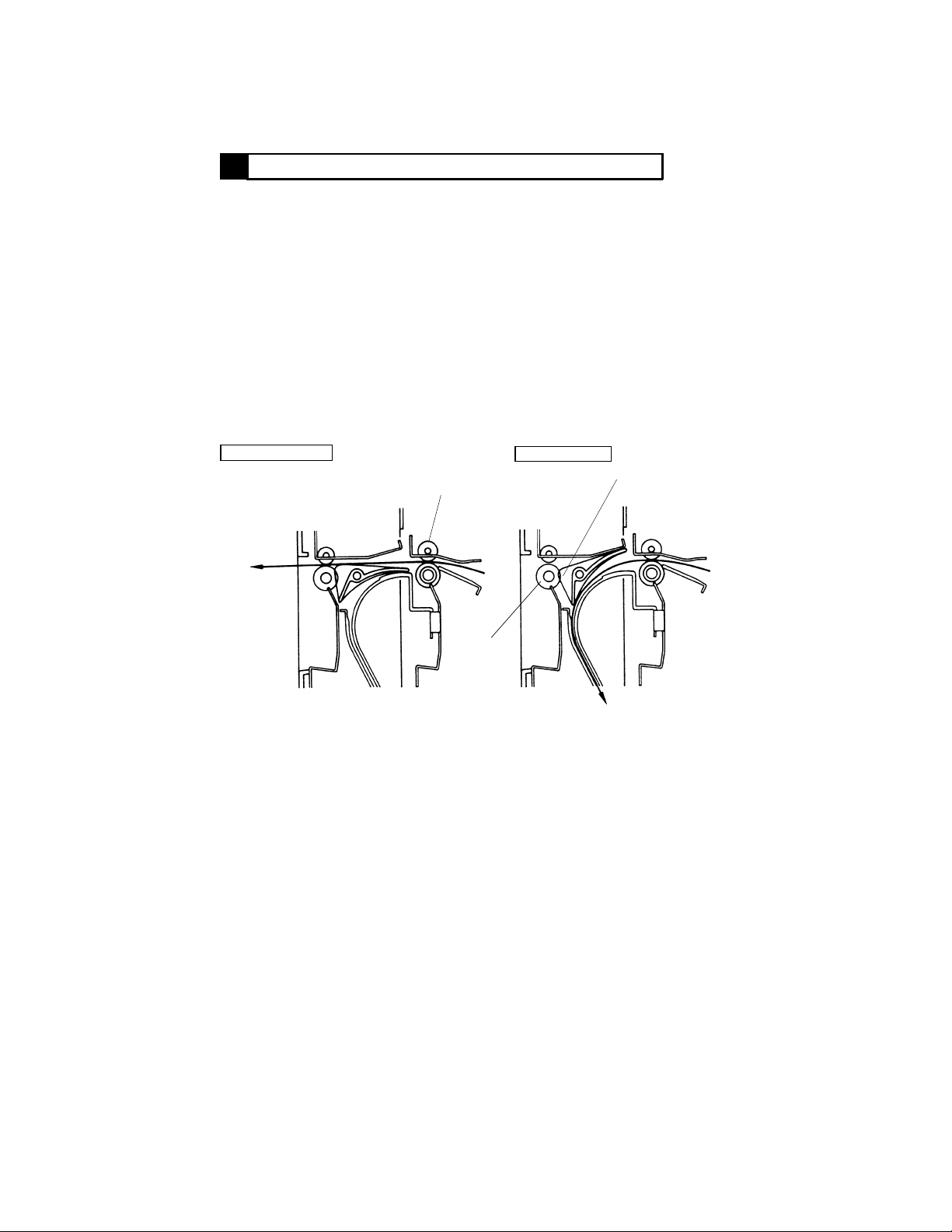

DESCRIPTION OF EACH MECHANISM AND CONTROL

6

6-1. Exit/Turnover Switching Mechanism

• The exit/turnover switching mechanism uses the Exit/Turnover Switching

Finger that is moved to change the paper path either for exit or turnover.

• When in the Exit mode or when the copy is to be fed out in the Duplex

mode, Exit/Turnover Switching Solenoid SL1 remains deenergized and the

copy moves above the Exit/Turnover Switching Finger and is fed out of the

copier by the Exit Rollers.

• When the copy is to be turned over in the Duplex mode, SL1 is energized

and the copy moves beneath and along the Exit/Turnover Switching Finger

and is fed by the Vertical Transport Rollers of the Duplex Unit down

towards the turnover section.

• As noted above, SL1 moves the Exit/Turnover Switching Finger to change

the paper path. It is energized when a LOW signal from the copier is input

to PJ2A-1 on PWB-A.

SL1: Deenergized

Exit

Paper Exit

Roller of Copier

Exit Roller

SL1: Energized

Exit/Turnover

Switching Finger

To Turnover Section

4458M006AA

M-6

Page 17

6-2. Fuser Oil Cleaning Mechanism

• Since fuser oil is on the front side of the paper after the fusing process, it is

transferred onto the surface of the PC Drum via the Transfer Film during

the second copy process of 2-sided copying, which results in image

problems. Silicone rubber rollers are used as the Vertical Transport

Rollers of the Duplex Unit. They function to recover fuser oil from the

surface of the paper.

6-3. Paper Standby Control

• In a Duplex mode making two or more copy sets of an original set (which

involves two-sheet paper attraction), two sheets of paper are present in the

Duplex Unit, one waiting for take-up from the Duplex Unit following the

turnover cycle and the other remaining stationary at the vertical transport

section. (See "7. OPERATION AND CONTROL" that follows.)

• There is no problem with the paper waiting for take-up from the Duplex Unit

as it is driven independently of the copier drive. The paper at the vertical

transport section is, however, being transported and the drive from the

copier must be cut off. To accomplish this, Vertical Transport Clutch CL1

is mounted on the shaft of the Vertical Transport Roller and it couples or

cuts off the copier drive to the roller.

• CL1 is energized to stop the Vertical Transport Roller rotation when a LOW

signal from the copier is input to PJ2A-4 on PWB-A.

M-7

Page 18

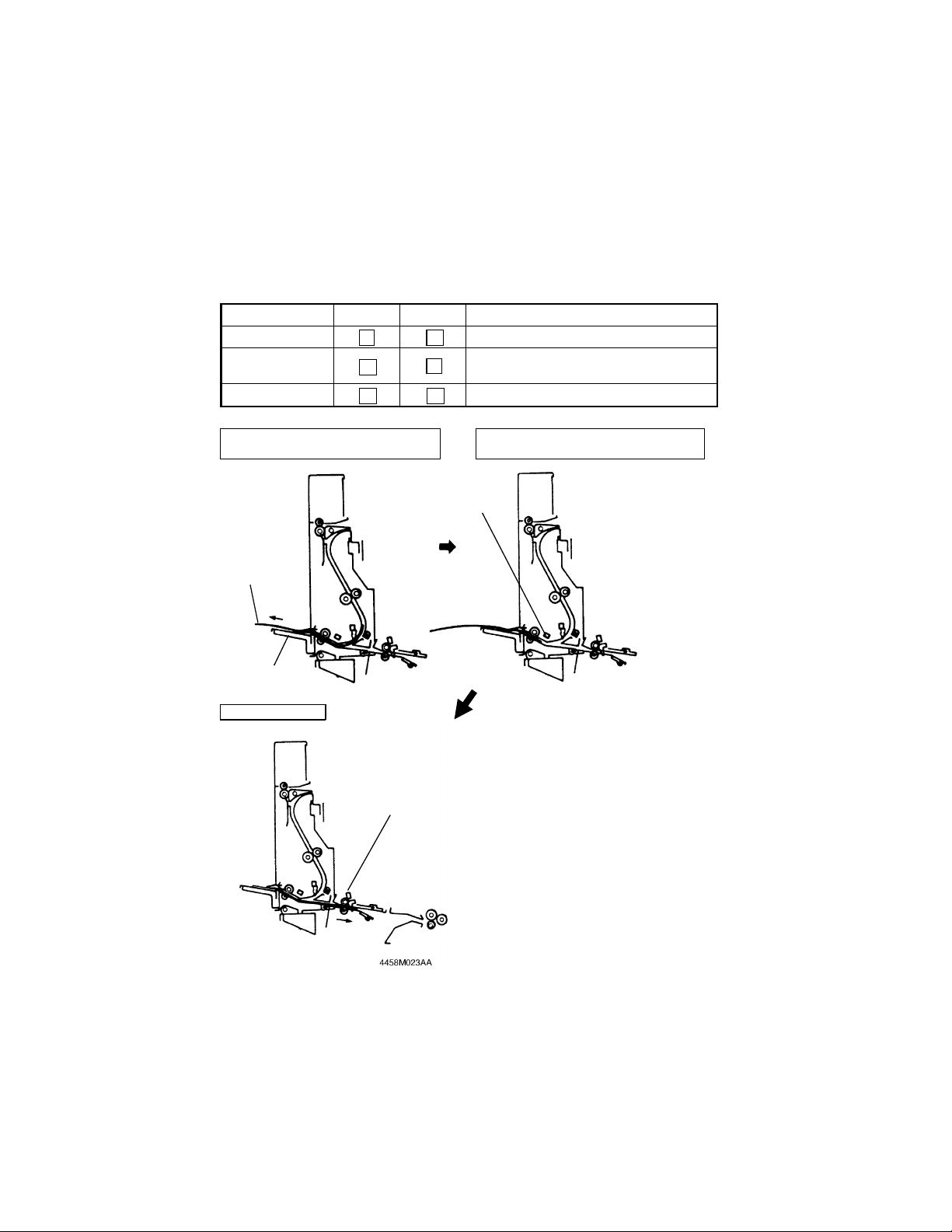

6-4. Switchback Operation (Turnover)

• The Turnover Roller turns forward to transport the copy to the turnover

section and, as soon as the trailing edge of the copy moves past

Switchback Sensor PC1, it stops turning. The Turnover Roller then turns

backward to turn over the copy and feed it back into the copier.

• The drive for the Turnover Roller comes from Turnover Motor M1 which is

turned forward, backward, or stopped by the signals fed from the copier as

follows.

PJ2A-2 PJ2A-3 Copy Motion

Turning forward Transported towards Turnover Tray

Turning backward

Stopped Stationary

L

H

H

H

Transported towards Duplex paper

L

take-up side

H

Copy Transported Towards Turnover

Tray

Copy

Turnover Tray

Standby Position

Horizontal Transport

Sensor of Copier

Turnover Position (Copy is temporarily

stationary)

Switchback

Sensor PC1

4458M007AB

M-8

Page 19

OPERATION AND CONTROL

7

7-1. No. of Multiple 2-Sided Copies

• Copier does not store in memory the image data it scanned. For these

reasons, the number of multiple 2-sided copies that can be made varies

depending on the paper size, copying mode, and whether the Duplexing

Document Feeder is used or not. Here are the details.

Copy Paper Size A5, A4C (∗1) A4L, B4L, A3L

Original Placement ADF Glass ADF Glass

1-sided → 2-sided 99 sets (*2) 2 set 2 set 2 set

2-sided → 2-sided 2 set

Book → 2-sided

Copying Mo de

*L: Lengthwise; C: Crosswise; ADF: Duplexing Document Feeder

*1: Only when two sheets of paper can be placed on Original Glass. For the

other size paper, the same control is provided as that for the paper size of A4L

or larger.

*2: The originals are fed by the 2-in-1 mode and a book copy cycle is repeated in

which two 2-sided copies are made.

*3: A cycle is repeated in which two 2-sided copies are made.

99 sets (*3)

2 set

7-2. Sensor Locations

• The illustration below locates different sensors that provide reference for

paper movement throughout the Duplex Unit.

PC3

PC1

Duplex Unit Side

• PC1: Switchback Sensor

• PC3: Vertical Transport

Sensor

S10

PC24

Copier Side

• PC18: Paper Leading Edge Detecting Sensor

• PC19: Transport Roller Sensor

• PC21: Separating Failure Detecting Sensor

• PC24: Horizontal Transport Sensor

• S10: Paper Exit Switch

PC18

PC21

PC19

Transfer Drum

4458M009AA

M-9

PC Drum

Page 20

7-3. 2-Sided Copying Operation

1) Making 2-Sided Copies from 2-Sided Original Using ADF (One A4C

original, one copy set)

Paper Position Operation Sequence

The copy is separated from the Transfer Drum after

the image transfer process.

Separating Failure Detecting Sensor PC21 is

activated.

The copy reaches Paper Exit Switch S10.

4458M101AA

Exit/Turnover Switching Solenoid SL1 is energized.

The copy is transported to the vertical transport

section to reach Vertical Transport Sensor PC3.

Turnover Motor M1 turns forward.

4458M010AA

4458M011AA

4458M012AA

4458M013AA

The copy reaches Switchback Sensor PC1.

Turnover Motor M1 turns forward to transport the

copy onto the Turnover Tray.

The trailing edge of the copy moves past PC1.

M1 is temporarily deenergized and then starts turning

backward. (The copy is turned over, and then taken

up and fed into the copier.)

The copy reaches Horizontal Transport Sensor PC24.

As Horizontal Transport Drive Clutch CL23 is

energized, the copy is fed onto the Synchronizing

Rollers.

The image transfer to the second face of the copy is

completed and then the copy undergoes separation

and fusing before being fed out of the copier.

4458M014AA

M-10

Page 21

2) Making 2-Sided Copies from 1-Sided Original Using ADF (Two A4C

originals, two copy sets)

Paper Position Operation Sequence

Two sheets of paper for the first original are

separated from the Transfer Drum after the image

transfer process.

The first copy activates Separating Failure Detecting

Sensor PC21.

4458M015AA

4458M016AA

4458M017AA

4458M018AA

The first copy reaches Paper Exit Switch S10.

Exit/Turnover Switching Solenoid SL1 is energized.

The first copy is transported to the vertical transport

section to reach Vertical Transport Sensor PC3.

Turnover Motor M1 turns forward.

The first copy reaches Switchback Sensor PC1.

Turn over Motor M1 turns forward to transport the

first copy onto the Turnover Tray.

As Vertical Transport Clutch CL1 is energized, the

second copy is stationary at the vertical transport

section.

The trailing edge of the first copy moves past PC1.

M1 is temporarily deenergized and then starts turning

backward. (The first copy is turned over, and then

take up and fed into the copier.)

The first copy reaches Horizontal Transport Sensor

PC24.

As Horizontal Transport Drive Clutch CL23 is

energized, the first copy is fed onto the

Synchronizing Rollers.

The first copy reaches Paper Leading Edge Detecting

Sensor PC18 and stops at the Synchronizing Rollers.

➀

4458M019AA

➁

M-11

Page 22

Paper Position Operation Sequence

➀

➁

As CL1 is deenergized and M17 is energized, the

second copy is transported to the turnover section.

The second copy reaches PC1.

M1 turns forward to transport the second copy to the

4458M020AA

Turnover Tray.

The trailing edge of the second copy moves past PC1.

M1 is temporarily deenergized and then starts turning

backward. (The second copy is turned over, and

then take up and fed into the copier.) At the same

time, the first copy is again attracted to the Transfer

Drum.

4458M021AA

The first and second copies are attracted to the

Transfer Drum. When the image transfer to the

second faces of the copies is completed, the copies

undergo separation and fusing before being fed out

of the copier.

4458M015AA

4458M022AA

M-12

Page 23

DIS/REASSEMBLY,

ADJUSTMENT

Precautions for Disassembly, Reassembly and Adjustment

CAUTION

1. Before attempting to disassemble the unit, always make sure that no power is

being supplied from the copier.

2. While power is being supplied to the unit, do not attempt to remove/install the

print jacks from/to the PWBs or unplug/plug in the connectors.

3. If the unit is run with its covers removed, use care not to allow your clothing to

be caught in revolving parts such as the timing belt.

4. The basic rule is do not run the unit any time during dis/reassembly.

Important

1. A toothed washer is used with the screw that secures the ground wire to

ensure positive conduction. Do not forget to insert this washer at reassembly.

2. To reassemble the unit, reverse the order of disassembly unless otherwise

specified.

3. Do not attempt to loosen or remove the screw to which red paint has been

applied.

4. The screw to which blue paint has been applied may be removed, but needs to

be adjusted whenever it has been removed.

Purpose of Applying Red Paint

Red paint is applied to those screws that cannot be readjusted or reinstalled in

the field.

Page 24

Page 25

DISASSEMBLY

1

1-1. Removal of the Exterior Covers and Guides

1

6

4

4458M008AA

3

No. Cover/Guide Name No. of Screws Steps Required Before Removal

1 Rear Cover 4 None

2 Front Cover 4 None

3 Exit Section Lower Cover 4 Removal of the Front and Rear Covers

4 Exit Section Cover 2 Removal of two ornamental covers

5 Turnover Lower Guide 2 Removal of the Front and Rear Covers

6 Vertical Transport Guide 2 Removal of the Front and Rear Covers

5

4458M008AA

2

D-1

Page 26

1-2. Removal of Vertical Transport Clutch CL1

1. Remove the Front and Rear Covers.

2. Remove the Exit Section Lower Cover.

3. Unplug the connector of CL1.

4458D001AA

4. Loosen the screw shown to release the belt tension.

*

Do not forget to tighten this screw at reinstallation.

4458D005AA

5. Snap off one plastic ring and remove the flange and

belt.

4458D002AA

Frame

Collar

0

4458D003AA

CL1

4458D004AA

6. Loosen one screw with an Allen wrench to remove

CL1 and the collar.

*

When reinstalling CL1, press it against the collar and,

at the same time, tighten the screw.

Hook the lock of the clutch onto the frame.

D-2

Page 27

1-3. Removal of the Vertical Transport Roller (Metallic One)

1. Remove the Front and Rear Covers.

2. Unhook two tension coil springs.

4458D006AA

3. Remove the plastic rings and bushings from the front

and rear ends and then remove the Vertical Transport

Roller.

4458D007AA

1-4. Removal of the Vertical Transport Roller (Rubber One)

1. Remove the Front and Rear Covers.

2. Remove the Exit Section Lower Cover.

3. Remove Vertical Transport Clutch CL1 and collar.

4. Remove the plastic ring and bearing from the rear end.

4458D008AA

4458D009AA

5. Remove the plastic rings and bushings from the front

end.

6. Remove the Vertical Transport Roller.

D-3

Page 28

1-5. Removal of the Turnover Entrance Guide

1. Remove the Front and Rear Covers.

2. Remove the Turnover Lower Guide.

3. Remove four screws at the front and rear and the

Turnover Entrance Guide.

4458D014AA

*

Try to press the Turnover Entrance Guide up as

shown at reinstallation.

0

ADJUSTMENTS

2

Vertical

Transport

Frame

Turnover Entrance

Guide

4458D015AA

2-1. Adjustment of Dup. Left-Margin

Requirements: The distance between the front edge of the paper and the front edge of the test

pattern should be 3 ±1.5mm.

4458D018AA

4458D017AA

1. Set the copier into the Service mode and select the

following functions in that order:

"Machine Adjust," "PRT Area," and "Dup. Left-Margin."

2. Select the drawer to be adjusted and press the Start

key.

3. Measure dimension "A" on the test print fed out of the

copier.

*: No adjustments are necessary if the measurement

is 3 ±1.5mm.

4. If the measurement taken in step 3 falls outside the

specified range, adjust using the ▲ or ▼ key.

D-4

Page 29

2-2. Adjustment of Exit/Turnover Switching Solenoid SL1

1. Remove the Front Cover.

2. Remove the harness of Duplex Unit Set Switch S1

from the edge cover.

SL1

3. Unplug the connector from Drive Board PWB-A.

SL1

PWB-A

4458D010AA

4458D011AA

4458D012AA

Upper Guide Plate

Exit/

Turnover

Switching

Finger

4. Remove one screw and the solenoid assy.

5. Unhook the tension coil spring.

6. Remove two screws and the solenoid.

*

When securing the solenoid at reinstallation, slide it

downward as far as it will go.

*

When securing the solenoid assy, ensure that the

Exit/Turnover Switching Finger is in contact with the

sponge of the Upper Guide Plate with the solenoid in

the energized position.

7. After reinstallation, check that the switching finger

operates smoothly.

4458D013AA

D-5

Page 30

D-6

Page 31

TROUBLESHOOTING

General Precautions

CAUTION

1. When servicing the unit with its covers removed, use utmost care to prevent

your hands, clothing, and tools from being caught in revolving parts.

2. Before attempting to replace parts and unplugging connectors, make sure that

no power is being supplied from the copier.

Important

1. Never create a closed circuit across connector pins except those authorized in

the text and on the PWB.

2. When creating a closed circuit and measuring a voltage across connector pins

specified in the text, be sure to use the green wire (GND).

3. Keep all disassembled parts in good order and keep tools under control so that

none will be lost or damaged.

Reading the Text

1. If a component on a PWB or any other functional part including a motor is

defective, the text only instructs you to replace the whole PWB or functional

part and does not give troubleshooting procedure applicable within the

defective part.

2. The text assumes that there are no breaks in the harnesses and cords and all

connectors are plugged into the right positions.

Page 32

Page 33

MISFEED DETECTION

1

1-1. Misfeed Detection Conditions

• A misfeed in the Duplex Unit is detected under any of the following conditions and a misfeed

indication is given on the control panel of the copier. A misfeed can be reset by unlocking and

locking the Duplex Unit.

• A misfeed at the vertical transport section

Type Detection Timing

Paper left Vertical Transport Sensor PC3 is unblocked ( L ) when the Power

Leading edge of paper PC3 is not unblocked ( L ) even after the lapse of approx. 3.3 sec. after

Trailing edge of paper PC3 is not blocked ( H ) even after the lapse of approx. 3.3 sec. after

• A misfeed at the turnover section

Type Detection Timing

Paper left Switchback Sensor PC1 is activated ( L ) when the Power Switch is

Leading edge of paper PC1 is not activated ( H ) even after the lapse of approx. 1.2 sec. after

Trailing edge of paper PC1 is activated ( L ) even after the lapse of approx. 4.8 sec. after PC1

Paper which has been

turned over

Switch is turned ON, a misfeed is reset, or the Front Door is opened and

closed.

Paper Exit Switch S10 of the copier has detected the leading edge of the

paper.

S10 of the copier has detected the trailing edge of the paper.

turned ON, a misfeed is reset, or the Front Door is opened and closed.

PC3 has detected the leading edge of the paper.

has detected the leading edge of the paper.

PC1 detects no paper at a timing when it should have detected paper

after it has been turned over (e.g., when the paper which has been turned

over is pulled out).

• A misfeed at the Duplex paper take-up section

Type Detection Timing

Paper left Horizontal Transport Sensor PC24 of the copier is blocked ( L ) when

Leading edge of paper PC24 of the copier is not blocked ( L ) even after the lapse of approx.

Trailing edge of paper PC24 is not unblocked ( H ) even after the lapse of approx. 1.8 sec.

the Power Switch is turned ON, a misfeed is reset, or the Front Door is

opened and closed.

1.8 sec. after PC1 has detected the leading edge of the paper which was

turned over.

after PC1 has detected the trailing edge of the paper which was turned

over.

T-1

Page 34

1-2. Misfeed Troubleshooting Procedures

• A Misfeed at the Vertical Transport Section

Symptom

A misfeed

occurs

immediately

after the

Power Switch

has been

turned ON.

A misfeed

occurs before

paper

reaches the

vertical

transport

section.

A misfeed

occurs before

paper

reaches PC3.

Step

No.

1 Is Vertical Transport Sensor

PC3 unblocked by a sheet of

paper present at the vertical

transport section of the Duplex

Unit?

2 Does the actuator of PC3

operate properly?

3 Is the voltage across PJ2A-9 on

PWB-A and GND DC5V? Does

that voltage change to DC0V

when PC3 is unblocked?

1 Is Exit/Turnover Switching

Solenoid SL1 energized during

the Duplex mode?

2 Does the voltage across PJ2A-1

on PWB-A and GND change

from DC5V to DC0V when SL1

is energized?

3 Has the Exit/Turnover Switching

Finger been adjusted properly?

1 Do the Vertical Transport Rollers

turn when drive is transmitted

from the copier?

2 Is the voltage across PJ2A-4 on

PWB-A and GND DC5V

normally?

3 Are the Vertical Transport

Rollers dirty or scratched?

Check Item Result Action

YES Remove the paper from the

vertical transport section.

NO Check the installed position of

PC3 and check the actuator for

deformation and foreign matter.

YES Make checks on the copier side.

NO Check the wiring between

PWB-A and PC3 and, if it is

intact, replace PC3 or PWB-A.

YES Go to step 3.

YES Check the wiring between

PWB-A and SL1 and, if it is

intact, replace SL1 or PWB-A.

NO Make checks on the copier side.

YES Clean the Exit/Turnover

Switching Finger and guide plate.

NO Adjust SL1.

YES Go to step 3.

YES Check the wiring between

PWB-A and Vertical Transport

Clutch CL1 and, if it is intact,

replace CL1 or PWB-A.

NO Make checks on the copier side.

YES Clean or replace the defective

Vertical Transport Roller.

NO Clean the Vertical Transport

Guide and check it for

deformation.

T-2

Page 35

• A Misfeed at the Vertical Transport Section

Symptom

A misfeed

occurs after

paper has

reached

Vertical

Transport

Sensor PC3.

Step

No.

1 Does Turnover Motor M1 turn

when paper is fed into the

Duplex Unit?

2 Does the voltage across PJ2A-2

on PWB-A and GND change

from DC5V to DC0V when M1 is

energized?

3 Does the actuator of PC3

operate properly?

4 Is the voltage across PJ2A-9 on

PWB-A and GND DC5V? Does

that voltage change to DC0V

when PC3 is unblocked?

Check Item Result Action

YES Go to step 3.

YES Check the wiring between

PWB-A and M1 and, if it is

intact, replace M1 or PWB-A.

NO Make checks on the copier side.

NO Check the installed position of

PC3 and check the actuator for

deformation and foreign matter.

YES Make checks on the copier side.

NO Check the wiring between

PWB-A and PC3 and, if it is

intact, replace PC3 or PWB-A.

T-3

Page 36

• A Misfeed at the Turnover Section

Symptom

A misfeed

occurs

immediately

after the

Power Switch

has been

turned ON.

Paper is yet

to reach PC1.

Paper is

stationary at

the Turnover

Rollers.

Paper is not

transported to

the Duplex

paper take-up

side.

Step

No.

1 Is Switchback Sensor PC1

activated by a sheet of paper

present at the turnover section

of the Duplex Unit (or dust on

the underside of the sensor)?

2 Is PC1 installed correctly? NO Correct the installed position of

3 Is the voltage across PJ2A-8 on

PWB-A and GND DC5V? Does

that voltage change to DC0V

when a sheet of paper is

inserted to activate PC1?

1 Is the Turnover Entrance Guide

deformed or dirty?

1 Does Turnover Motor M1 turn

when paper is fed into the

Duplex Unit?

2 Does the voltage across PJ2A-2

on PWB-A and GND change

from DC5V to DC0V when M1 is

energized?

1 Does M1 turn backward after

paper has been fed out onto the

Turnover Tray?

2 Does the voltage across PJ2A-3

on PWB-A and GND change

from DC5V to DC0V when M1 is

energized?

Check Item Result Action

YES Remove the paper from the

turnover section. Or clean the

underside of the sensor.

PC1.

YES Make checks on the copier side.

NO Check the wiring between

PWB-A and PC1 and, if it is

intact, replace PC1 or PWB-A.

YES Clean or replace the Turnover

Entrance Guide.

NO Check the Vertical Transport

Guide and Vertical Transport

Rollers for dirt and deformation.

YES Clean the Turnover Rollers and

Turnover Guide.

YES Check the wiring between

PWB-A and M1 and, if it is

intact, replace M1 or PWB-A.

NO Make checks on the copier side.

YES Clean the Turnover Rollers and

Turnover Guide.

YES Check the wiring between

PWB-A and M1 and, if it is

intact, replace M1 or PWB-A.

NO Make checks on the copier side.

T-4

Page 37

• A Misfeed at the Duplex Paper Take-Up Section

Symptom

A misfeed

occurs

immediately

after the

Power Switch

has been

turned ON.

A misfeed

occurs before

paper

reaches

Horizontal

Transport

Sensor PC24.

A misfeed

occurs after

paper has

reached

PC24 of the

copier.

Step

No.

1 See TROUBLESHOOTING of

the copier.

1 Is the Turnover Entrance Guide

or Turnover Lower Guide

deformed or dirty?

2 Is the Turnover Roller or the

Duplex Paper Take-Up Guide of

the copier deformed or dirty?

1 See TROUBLESHOOTING of

the copier.

Check Item Result Action

YES Clean or replace the Turnover

Entrance Guide or Turnover

Lower Guide.

YES Clean or replace the Turnover

Roller or the Duplex Paper

Take-Up Guide of the copier.

NO Check Horizontal Transport

Drive Clutch CL23 of the copier.

T-5

Page 38

T-6

Page 39

WIRING DIAGRAMS

Page 40

Page 41

WIRING DIAGRAMS

NOT AVAILABLE IN

PDF FORMAT

Page 42

Page 43

PARTS CATALOG

Model

AD-723

FEBRUARY 1999

KONICA BUSINESS TECHNOLOGIES, INC.

Page 44

Page 45

How to use this catalog

This parts catalog includes illustrations and part numbers for all replacement parts and assemblies used in this model.

Model-specific parts are identified in the illustrations with reference

numbers. Use the reference number to locate the corresponding part

number on the facing page.

Common hardware items, such as screws, nuts, washers, and pins,

are identified in the illustrations with reference letters. Use the reference

letter to locate the corresponding part number on the hardware listing in

the lower right hand corner of the facing page.

If you know a part number, but don’t know where the part is used, use

the numerical index to determine the page number and reference number for that part. Because some common parts are used in several

places, there may be more than one entry. Refer to the illustrations to

see where the part may be used.

If you know a part’s description, but don’t know where to look to find

the part number, use the alphabetical index to determine likely page and

reference numbers. Then look at the illustrations to determine that you

have identified the correct part. Locate the part number using the listing

on the opposite page.

Retail pricing that appears with the numerical index, while valid when

this catalog was printed, is subject to change without notice. The prices

are only suggested prices and are provided only for reference. Dealers

may determine their own selling prices. For up-to-date pricing, refer to

current Konica price lists or contact the Konica Parts Distribution Center.

How to order parts

Use standard Konica parts ordering procedures to obtain these parts.

For ordering options, contact Konica’s Parts Distribution Center.

When ordering parts, be sure to specify part numbers exactly as listed in

this catalog.

NOTE: Electrical parts may include previously used components.

Model AD-723 Konica Business Technologies, Inc. Page iii

1st Edition February, 1999

Page 46

This page left blank intentionally.

Page iv Konica Business Technologies, Inc. Model AD-723

February, 1999 1st Edition

Page 47

How to use this catalog . . . . . . . . . . . . . . . . . . . . . . . . . iii

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Machine parts

Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Driving Section . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Alphabetical index . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Numerical index, Retail price list . . . . . . . . . . . . . . . . . . . . 11

Contents

Model AD-723 Konica Business Technologies, Inc. Page 1

1st Edition February, 1999

Page 48

Housing

Page 2 Konica Business Technologies., Inc. Model AD-723

February, 1999 1st Edition

Page 49

REF. PART NUMBER DESCRIPTION

NO.

1 12ZN97010 Label (Caution Hot)

2 12ZN44010 Rear cover

3 12ZN44020 Cord bushing

4 12ZN44030 Bracket

5 25TU05120 Edge cover

6 12ZN44050 Bracket

7 12ZN44060 Torsion spring

8 12ZN44070 Lock lever

9 12ZN44080 Bracket

10 12ZN97020 Label (Look Release)

11 12ZN44090 Cover

12 25TU12060 Cover

13 12ZN44110 Cover

14 12ZN44120 Bracket

15 12ZN44130 Guide plate

16 12ZN44140 Shoulder screw

17 12ZN44150 Cover

18 12ZN97030 Label (Jam Removal)

19 12ZN44160 Front frame

20 12ZN44170 Shaft

21 12ZN44180 Cushion

22 12ZN44190 Lock plate

23 12ZN44200 Lock release lever

24 12ZN44210 Top cover

25 12ZN97040 Label

26 12ZN44220 Plate spring

27 25TU40140 Roll

28 12ZN44240 Seal

29 12ZN44250 Guide plate

30 12ZN44260 Sponge

31 12ZN44270 Support plate

32 12ZN44280 Shaft

33 25TU40150 Plate spring

34 12ZN44300 Label (Caution Hot)

35 12ZN44310 Turnover tray

36 12ZN44760 Cover

HARDWARE

REF.

LTR.

a 25TU01440

b 25TU01530

c 25TU01590

d 25TU02410

e 25TU02460

f 25TU02850

g 25TU03420

h 25TU03630

i 25TU03710

j 25TU03730

PART

NUMBER

Model AD-723 Konica Business Technologies., Inc. Page 3

1st Edition February, 1999

Page 50

Driving Section

Page 4 Konica Business Technologies., Inc. Model AD-723

February, 1999 1st Edition

Page 51

REF. PART NUMBER DESCRIPTION

NO.

1 12ZN77010 Gear (Z=30)

2 12ZN77020 Gear (Z=24)

3 12ZN44320 Flange

4 12ZN78010 Timing belt

5 12ZN44330 Pulley (Z=31)

6 12ZN44080 Bracket

7 12ZN44350 Pulley (Z=16)

8 12ZN78020 Timing belt

9 25TU85010 Photosensor

10 12ZN44360 Bracket

11 12ZN80010 Motor

12 12ZN77030 Gear (Z=33)

13 12ZN77040 Pulley gear (Z=64,15)

14 12ZN77050 Gear (Z=19)

15 12ZN44370 Tension spring

16 25TU75470 Bushing

17 12ZN44380 Roll

18 12ZN44390 Bracket

19 12ZN44400 Tension spring

20 12ZN75020 Bushing

21 25TU78010 Gear (Z=24)

22 12ZN44410 Bracket

23 12ZN44420 Tension spring

24 12ZN82010 Clutch

25 12ZN44430 Washer

26 25TU75660 Ball bearing

27 12ZN44440 Guide plate

28 25TU40300 Sponge

29 25TU40330 Holder

30 12ZN90010 Harness

31 12ZN44470 Ferrite core

32 12ZN44480 Retaining ring

33 25TU53120 Shaft

34 25TU40320 Actuator

35 25TU40290 Torsion spring

36 25TU85140 Photosensor

37 12ZN44520 Guide plate

38 12ZN44530 Guide plate

39 12ZN90020 Harness

40 25TU20290 PWB support

41 12ZN-9010 PW board (A)

42 25TU60860 PWB support

43 12ZN44560 Bracket

44 12ZN82020 Solenoid

45 12ZN44570 Guide plate

46 12ZN44580 Guide plate

47 12ZN44590 Neutralizing brush

48 25TU10150 Bracket

49 25TU85070 Microswitch

50 12ZN44610 Torsion spring

HARDWARE

REF.

LTR.

a 25TU01170

b 25TU01400

c 25TU01630

d 25TU01520

e 25TU02140

f 25TU04010

g 25TU02410

h 25TU02430

i 25TU02450

j 25TU02460

k 25TU03210

m 25TU03710

n 25TU03720

PART

NUMBER

Model AD-723 Konica Business Technologies., Inc. Page 5

1st Edition February, 1999

Page 52

Driving Section

Page 6 Konica Business Technologies., Inc. Model AD-723

February, 1999 1st Edition

Page 53

REF. PART NUMBER DESCRIPTION

NO.

51 25TU10140 Shoulder screw

52 12ZN75040 Bushing

53 25TU75420 Bushing

54 12ZN75060 Bushing

55 12ZN44140 Shoulder screw

56 12ZN44640 Tension spring

57 12ZN44650 Lever

58 12ZN97060 Label

59 25TU40260 Knob

60 12ZN44670 Cushion

61 12ZN44680 Sponge

62 12ZN44690 Guide plate

63 12ZN44700 Guide lever

64 12ZN44710 Neutralizing brush

65 12ZN44720 Roller

66 12ZN44730 Roller

67 12ZN44740 Roller

68 12ZN44750 Roller

69 12ZN83010 Fuse

HARDWARE

REF.

LTR.

a 25TU01170

b 25TU01400

c 25TU01630

d 25TU01520

e 25TU02140

f 25TU04010

g 25TU02410

h 25TU02430

i 25TU02450

j 25TU02460

k 25TU03210

m 25TU03710

n 25TU03720

PART

NUMBER

Model AD-723 Konica Business Technologies., Inc. Page 7

1st Edition February, 1999

Page 54

This page left blank intentionally.

Page 8 Konica Business Technologies, Inc. Model AD-723

February, 1999 1st Edition

Page 55

Alphabetical index

PART PAGE REF.

DESCRIPTION NO. NO.

A

Actuator . . . . . . . . . . 5 34

B

Ball bearing . . . . . . . . 5 26

Bracket . . . . . . . . . . . 3 4

Bracket . . . . . . . . . . . 3 6

Bracket . . . . . . . . . . . 3 9

Bracket . . . . . . . . . . . 3 14

Bracket . . . . . . . . . . . 5 6

Bracket . . . . . . . . . . . 5 10

Bracket . . . . . . . . . . . 5 18

Bracket . . . . . . . . . . . 5 22

Bracket . . . . . . . . . . . 5 43

Bracket . . . . . . . . . . . 5 48

Bushing . . . . . . . . . . 5 16

Bushing . . . . . . . . . . 5 20

Bushing . . . . . . . . . . 7 52

Bushing . . . . . . . . . . 7 53

Bushing . . . . . . . . . . 7 54

C

Clutch . . . . . . . . . . . 5 24

Cord bushing . . . . . . . . 3 3

Cover . . . . . . . . . . . . 3 11

Cover . . . . . . . . . . . . 3 12

Cover . . . . . . . . . . . . 3 13

Cover . . . . . . . . . . . . 3 17

Cover . . . . . . . . . . . . 3 36

Cushion . . . . . . . . . . 3 21

Cushion . . . . . . . . . . 7 60

E

Edge cover . . . . . . . . . 3 5

F

Ferrite core . . . . . . . . . 5 31

Flange . . . . . . . . . . . 5 3

Front frame . . . . . . . . . 3 19

Fuse . . . . . . . . . . . . 7 69

PART PAGE REF.

DESCRIPTION NO. NO.

Gear (Z=30) . . . . . . . . 5 1

Gear (Z=33) . . . . . . . . 5 12

Guide lever . . . . . . . . . 7 63

Guide plate . . . . . . . . . 3 15

Guide plate . . . . . . . . . 3 29

Guide plate . . . . . . . . . 5 27

Guide plate . . . . . . . . . 5 37

Guide plate . . . . . . . . . 5 38

Guide plate . . . . . . . . . 5 45

Guide plate . . . . . . . . . 5 46

Guide plate . . . . . . . . . 7 62

H

Harness . . . . . . . . . . 5 30

Harness . . . . . . . . . . 5 39

Holder . . . . . . . . . . . 5 29

K

Knob . . . . . . . . . . . . 7 59

L

Label . . . . . . . . . . . . 3 25

Label . . . . . . . . . . . . 7 58

Label (Caution Hot) . . . . 3 1

Label (Caution Hot) . . . . 3 34

Label (Jam Removal) . . . 3 18

Label (Look Release) . . . 3 10

Lever . . . . . . . . . . . . 7 57

Lock lever . . . . . . . . . 3 8

Lock plate . . . . . . . . . 3 22

Lock release lever . . . . . 3 23

M

Microswitch . . . . . . . . . 5 49

Motor . . . . . . . . . . . . 5 11

N

Neutralizing brush . . . . . 5 47

Neutralizing brush . . . . . 7 64

PART PAGE REF.

DESCRIPTION NO. NO.

Photosensor . . . . . . . . 5 9

Photosensor . . . . . . . . 5 36

Plate spring . . . . . . . . . 3 26

Plate spring . . . . . . . . . 3 33

Pulley (Z=16) . . . . . . . . 5 7

Pulley (Z=31) . . . . . . . . 5 5

Pulley gear (Z=64,15) . . . 5 13

R

Rear cover . . . . . . . . . 3 2

Retaining ring . . . . . . . . 5 32

Roll . . . . . . . . . . . . . 3 27

Roll . . . . . . . . . . . . . 5 17

Roller . . . . . . . . . . . . 7 65

Roller . . . . . . . . . . . . 7 66

Roller . . . . . . . . . . . . 7 67

Roller . . . . . . . . . . . . 7 68

S

Seal . . . . . . . . . . . . . 3 28

Shaft . . . . . . . . . . . . 3 20

Shaft . . . . . . . . . . . . 3 32

Shaft . . . . . . . . . . . . 5 33

Shoulder screw . . . . . . . 3 16

Shoulder screw . . . . . . . 7 51

Shoulder screw . . . . . . . 7 55

Solenoid . . . . . . . . . . 5 44

Sponge . . . . . . . . . . . 3 30

Sponge . . . . . . . . . . . 5 28

Sponge . . . . . . . . . . . 7 61

Support plate . . . . . . . . 3 31

T

Tension spring . . . . . . . 5 15

Tension spring . . . . . . . 5 19

Tension spring . . . . . . . 5 23

Tension spring . . . . . . . 7 56

Timing belt . . . . . . . . . 5 4

Timing belt . . . . . . . . . 5 8

Top cover . . . . . . . . . . 3 24

Torsion spring . . . . . . . . 3 7

Torsion spring . . . . . . . . 5 35

Torsion spring . . . . . . . . 5 50

Turnover tray . . . . . . . . 3 35

G

Gear (Z=19) . . . . . . . . 5 14

Gear (Z=24) . . . . . . . . 5 2

Gear (Z=24) . . . . . . . . 5 21

P

PW board (A) . . . . . . . . 5 41

PWB support . . . . . . . . 5 40

PWB support . . . . . . . . 5 42

W

Washer . . . . . . . . . . . 5 25

Model AD-723 Konica Business Technologies, Inc. Page 9

1st Edition February, 1999

Page 56

This page left blank intentionally.

Page 10 Konica Business Technologies, Inc. Model AD-723

February, 1999 1st Edition

Page 57

Numerical index

PART PAGE REF.SUGGESTED

NUMBER NO. NO. RETAIL

12ZN-9010 . . . . 5 41

12ZN44010 . . . 3 2

12ZN44020 . . . 3 3

12ZN44030 . . . 3 4

12ZN44050 . . . 3 6

12ZN44060 . . . 3 7

12ZN44070 . . . 3 8

12ZN44080 . . . 3 9

12ZN44080 . . . 5 6

12ZN44090 . . . 3 11

12ZN44110 . . . . 3 13

12ZN44120 . . . 3 14

12ZN44130 . . . 3 15

12ZN44140 . . . 3 16

12ZN44140 . . . 7 55

12ZN44150 . . . 3 17

12ZN44160 . . . 3 19

12ZN44170 . . . 3 20

12ZN44180 . . . 3 21

12ZN44190 . . . 3 22

12ZN44200 . . . 3 23

12ZN44210 . . . 3 24

12ZN44220 . . . 3 26

12ZN44240 . . . 3 28

12ZN44250 . . . 3 29

12ZN44260 . . . 3 30

12ZN44270 . . . 3 31

12ZN44280 . . . 3 32

12ZN44300 . . . 3 34

12ZN44310 . . . 3 35

12ZN44320 . . . 5 3

12ZN44330 . . . 5 5

12ZN44350 . . . 5 7

12ZN44360 . . . 5 10

12ZN44370 . . . 5 15

12ZN44380 . . . 5 17

PART PAGE REF.SUGGESTED

NUMBER NO. NO. RETAIL

12ZN44390 . . . . 5 18

12ZN44400 . . . . 5 19

12ZN44410 . . . . 5 22

12ZN44420 . . . . 5 23

12ZN44430 . . . . 5 25

12ZN44440 . . . . 5 27

12ZN44470 . . . . 5 31

12ZN44480 . . . . 5 32

12ZN44520 . . . . 5 37

12ZN44530 . . . . 5 38

12ZN44560 . . . . 5 43

12ZN44570 . . . . 5 45

12ZN44580 . . . . 5 46

12ZN44590 . . . . 5 47

12ZN44610 . . . . 5 50

12ZN44640 . . . . 7 56

12ZN44650 . . . . 7 57

12ZN44670 . . . . 7 60

12ZN44680 . . . . 7 61

12ZN44690 . . . . 7 62

12ZN44700 . . . . 7 63

12ZN44710 . . . . 7 64

12ZN44720 . . . . 7 65

12ZN44730 . . . . 7 66

12ZN44740 . . . . 7 67

12ZN44750 . . . . 7 68

12ZN44760 . . . . 3 36

12ZN75020 . . . . 5 20

12ZN75040 . . . . 7 52

12ZN75060 . . . . 7 54

12ZN77010 . . . . 5 1

12ZN77020 . . . . 5 2

12ZN77030 . . . . 5 12

12ZN77040 . . . . 5 13

12ZN77050 . . . . 5 14

12ZN78010 . . . . 5 4

PART PAGE REF.SUGGESTED

NUMBER NO. NO. RETAIL

12ZN78020 . . . . 5 8

12ZN80010 . . . . 5 11

12ZN82010 . . . . 5 24

12ZN82020 . . . . 5 44

12ZN83010 . . . . 7 69

12ZN90010 . . . . 5 30

12ZN90020 . . . . 5 39

12ZN97010 . . . . 3 1

12ZN97020 . . . . 3 10

12ZN97030 . . . . 3 18

12ZN97040 . . . . 3 25

12ZN97060 . . . . 7 58

25TU05120 3 5

25TU10140 . . . . 7 51

25TU10150 . . . . 5 48

25TU12060 . . . . 3 12

25TU20290 . . . . 5 40

25TU40140 . . . . 3 27

25TU40150 . . . . 3 33

25TU40260 . . . . 7 59

25TU40290 . . . . 5 35

25TU40300 . . . . 5 28

25TU40320 . . . . 5 34

25TU40330 . . . . 5 29

25TU53120 . . . . 5 33

25TU60860 . . . . 5 42

25TU75420 . . . . 7 53

25TU75470 . . . . 5 16

25TU75660 . . . . 5 26

25TU78010 . . . . 5 21

25TU85010 . . . . 5 9

25TU85070 . . . . 5 49

25TU85140 . . . . 5 36

25TUO5120 . . . 3 5

Model AD-723 Konica Business Technologies, Inc. Page 11

1st Edition February, 1999

Page 58

This page left blank intentionally.

Page 12 Konica Business Technologies, Inc. Model AD-723

February, 1999 1st Edition

Loading...

Loading...