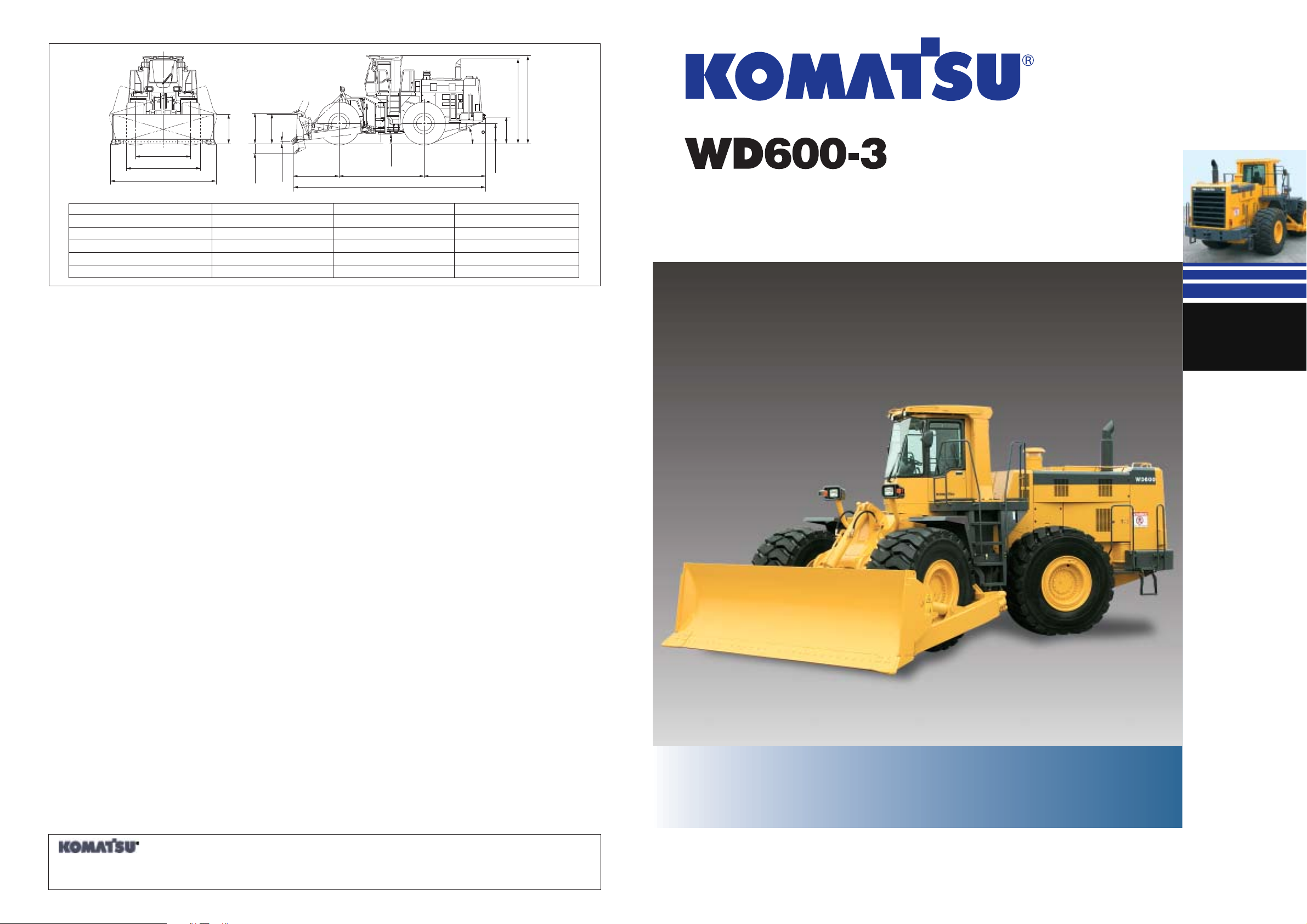

komatsu WD600-3 SPECIFICATIONS

BLADE CAPACITY

8.0– 22.5 m

3

10.5– 29.4 cu.yd

OPERATING WEIGHT

42900– 45700 kg

94,580– 100,750 lb

WHEEL DOZER

Photo may include optional equipment.

SPECIFICATIONS

DIMENSIONS

ENGINE

Model ...................................... Komatsu SAA6D170E-3

Type........................................ Water-cooled, 4-cycle

Aspiration................................ Turbocharged, aftercooled

No.of cylinders ........................ 6

Bore x stroke........................... 170mm x 170mm 6.69" x 6.69"

Piston displacement................ 23.15 ltr. 1,413 cu.in

Performance:

Flywheel horsepower.......... 362 kW 485 HP (SAE J1349)

362 kW 492 PS (DIN 6270)

Rated RPM ......................... 2,000 RPM

Fuel system ............................ Direct injection

Governor................................. Electronic, all-speed control

TRANSMISSION

Torque converter:

Type.................................... 3-element, single-stage,

2-phase

Transmission:

Type.................................... Full-powershift, planetary

gear type

Travel speed:km/h MPH

Measured with 35/65-33-24PR tires

*1st **2nd **3rd **4th

Forward 6.5 4.0 11.8 7.3 20.8 12.9 36.2 22.5

Reverse 7.2 4.5 13.0 8.1 23.0 14.3 40.0 24.9

* Torque converter drive

** Torque converter lockup drive

AXLES & FINAL DRIVES

Drive system ........................... Four-wheel drive

Front ....................................... Fixed, full-floating

Rear ........................................ Center-pin-support, full-

floating 26° total oscillation

Reduction gear ....................... Spiral bevel gear

Differential gear ...................... Straight bevel gear

Final reduction gear ................ Planetary gear, single

reduction, oil bath

BRAKES

Service brakes ........................ 4-wheel, separate front-rear

wheel, hydraulically actuated,

wet disc

Parking brake..........................

Dry-disc type, hydraulic released,

spring applied on front axle

input shaft

Secondary brake..................... Uses parking brake

STEERING SYSTEM

Type........................................ Articulated type, full-

hydraulic power steering

Steering angle......................... 40° each direction

Minimum turning radius at the

center of outside tire ............... 6,980 mm 22'11"

HYDRAULIC SYSTEM

Steering system:

Hydraulic pump ........................Gear pump

Relief valve setting...................210kg/cm

2

3,000PSI

Hydraulic cylinders:

Type .......................................Double-acting, piston type

No. of cylinders.......................2

Bore x stroke......................140 mm x 495 mm

5.5" x 19.5"

Dozer control:

Hydraulic pump ........................Gear pump

Relief valve setting...................210 kg/cm

2

3,000 PSI

Hydraulic cylinders:

Type .......................................Double-acting, piston type

No. of cylinders-bore x stroke:

Lift cylinder.........................1-160 mm x 1,080 mm

6.3" x 42.5"

Tilt and pitch cylinder .........2-180 mm x 236.5 mm

7.1'' x 9.3''

Control valve ............................Spool type

Control positions:

Blade lift control......................Raise, hold, lower and float

Blade tilt and pitch control ......Tilt-left, hold and tilt-right,

pitch forward and back

ROPS & CAB

Structure complies with ISO 3471 and SAE J1040c ROPS

(Roll-Over Protective Structure) standards, as well as ISO

3449 FOPS (Falling Object Protective Structure) standards.

The cab is mounted on viscous mounts and well insulated.

SERVICE REFILL CAPACITIES

Cooling system...................................... 160 ltr. 42.3 U.S.gal

Fuel tank................................................ 670 ltr. 177 U.S.gal

Engine ................................................... 47 ltr. 12.4 U.S.gal

Hydraulic system................................... 215 ltr. 56.8 U.S.gal

Axle (each front and rear)...................... 124 ltr. 32.8 U.S.gal

Torque converter and transmission....... 110 ltr. 29.1 U.S.gal

This specification sheet may contain attachments and optional equipment that are not available in your area. Please consult your local Komatsu

distributor for those items you may require. Materials and specifications are subject to change without notice.

Form No. HESS5981 Printed in Japan 200306 IP.AD (15)

Blade type Straight blade U-blade Coal blade

Blade capacity (SAE Rated) 8.0 m310.5 cu.yd 11.5 m315.0 cu.yd 22.5 m329.4 cu.yd

Blade width 5100 mm 16'9" 5190 mm 17'0" 5800 mm 19'0"

Max. lift above ground 1500 mm 4'11" 1485 mm 4'10" 1530 mm 5'0"

Max. drop below ground 450 mm 1'6" 490 mm 1'7" 475 mm 1'7"

Max. tilt adjustment 1430 mm 4'8" 1415 mm 4'8" 1530 mm 5'0"

3

4

5

L

/

6

5

R

-

P

7'3"

3

4

3

-

2

4100 mm 13'5"

9285 mm 30'6"

1500 mm

4'11"

4'10"

1430 mm

4'8"

2650 mm 8'8"

3570 mm 11'9"

5100 mm 16'9"

1470 mm

450 mm

1'6"

150 mm

5.9"

3

495 mm

1'7"

4

5

L

/

6

5

R

-

P

3

4

3

-

2

2975 mm 9'9"2210 mm

24

1295 mm

990 mm

3'3"

4125 mm 13'6"

4'3"

4250 mm 13'11"

Automatic transmission is used with joystick steering.

Kick-down

switch

Tilt Steering Column

& One-Glance Monitors

The steering column can be easily tiltadjusted to the most comfortable position with one lever. The two-spoke

steering wheel allows maximum visibility of the monitor panel and the forward work environment.

Easy to Use Joystick

Steering (Optional)

A joystick steering system has been

incorporated to allow steering and forward/reverse selection to be controlled

by wrist and finger without the operator

having to move his arm from the arm

rest.

Faster Pile-Penetration

& Dozing

A kick-down switch down-shifts the

transmission from forward 2nd to 1st

gear, for increased rim pull and

improved dozing. When the direction

control lever is set to reverse, it automatically up-shifts from 1st gear to

2nd, to reduce cycle time.

Engine Speed Setting

System

Activating the system allows the

operator to increase (decrease) the

engine speed and maintain the

desired speed setting. This makes

long-distance travelling easy since

the vehicle can be operated with

operator’s foot released from the

accelerator pedal.

Ergonomically-Designed

Controls

All controls are ergonomically

designed to minimize operator fatigue.

The steering wheel and instrument

panel are similar to those of a car.

The blade controls have PPC valves

and short-stroke levers, to reduce

operator effort. The electrically controlled transmission and finger operated control levers allow direction and

gearshift operations to be performed

without the operator removing a hand

from the steering wheel.

Roomy, Quiet Cab

With Power Windows

The cab is large, with a comfortably

spacious interior and power windows.

Also, a wide viewing angle is guaranteed because the cab is pillar-less.

The high-capacity air conditioner

ensures operator comfort, no matter

the exterior conditions.

Low Vibration & Noise

The cab rests on Komatsu viscous

damping mounts (rubber and silicon

oil) to reduce vibration and noise. All

hydraulic equipment is mounted on

high-resistance rubber to further

reduce vibration and noise.

STANDARD EQUIPMENT

485HP/2,000RPM KOMATSU SAA6D170E-3

diesel engine, C200 battery, 50A alternator, wet

type disc brake, electronic display/monitoring system, electrically controlled transmission, torque

converter with lockup clutch, tilt steering wheel,

engine key stop, engine speed setting system,

ROPS bracket, speedometer, adjustable suspension seat, ladders (right & left), front compartment,

front fender, head lamps, rear working lights, turn

indicators (front & rear), horn, fan guard, counterweight, 4 x 35/65-33-24PR L4 rock deep tread type

tubeless tire

OPTIONAL EQUIPMENT

U-blade Floor mat

Coal blade Heater and defroster

Joystick steering Automatic transmission

ROPS canopy Auto-greasing system

Steel cab with front wiper, Seat belt

windshield washer, power window Sun visor

Air conditioner Rear under view mirror

Supplementary steering Air suspension seat

Non-spin differential (rear axle only) 35/65-33-24PR(L4) tire

Fire extinguisher 35/65-33-24PR(L5) tire

Power train guard 35/65-33-30PR(L4) tire

Tool kit 35/65-33-30PR(L5) tire

Ordinary spare parts 35/65-R33(L4) tire

Viscous damping mounts

Rubber

Silicon oil

High Productivity and Reliability Operator Environment

Proven Power

The Komatsu SAA6D170E-3 delivers

power and efficiency to get the job

done quickly and cost-effectively

while meeting EPA and EU Tier 2

emission regulations. The engine is

a water-cooled, four-stroke, six-cylinder in-line, turbocharged, air-to-air

aftercooled, direct injection engine

that produces high performance and

excellent fuel economy.

Torque Converter Lockup

System

Switching the torque converter lockup system on transmits all of the

engine power directly to the transmission for greater efficiency during

long pushes. The result is efficient

use of engine power, less fuel consumption, and faster cycle times.

Reliable Power Train

The engine, torque converter and

transmission, as well as the

hydraulic equipment and electrical

parts, undergo strict quality control

checks for enhanced reliability and

durability.

Durable Blade

Komatsu blades are manufactured

using high-tensile strength steel providing excellent rigidity and

increased dozing capacity.

Flywheel horsepower

362kW 485HP

@2000RPM

Blade capacities

8.0-22.5m

3

(10.5-29.4cu.yd)

Built-in Blade Tilt Piping

Blade piping is built into the straight

frame to protect it from damage.

High-Rigidity Frames

Front and rear frames are designed to

work in the toughest applications and

provide high rigidity for the power train

and dozer equipment. The high-rigidity

frames, together with the reinforced

dozer linkage, reduce dozing stress

and shock.

High-Quality Paint

Exterior surfaces are treated with a

cationic electro-deposition undercoat

and melamine baked final paint for

rust resistance and longer service life.

Non-Spin Differential

(Optional)

The field-proven non-spin differential

prevents tire slippage on slippery terrain such as soft or sandy ground, so

stable travel is ensured and tire wear

is reduced to a minimum for maximum

tire life.

Maintenance-Free

Braking System

Service brakes utilize two hydraulically-actuated independent circuits for

increased safety and are adjustmentfree, fully-sealed, wet disc units, preventing intrusion of dirt and dust. Since

the brake system does not use air, it

provides many benefits such as

absence of condensation, dependable

braking even in cold conditions, no

need for drainage, and rust free piping.

Charging time after engine starting is

drastically shortened and pedal effort is

reduced.

Simple Checks,

Easy Maintenance

The main monitor and the maintenance monitor (EDIMOS II) are neatly

arranged on the instrument panel for a

quick, clear reading of machine functions at all times. The main monitor

also has a diagnostic function.

Maintenance monitor

Fully-sealed wet disc brake

System ON/OFF

switch

Engine speed

UP/DOWN

switch

Loading...

Loading...