Page 1

WEAM000704

Operation & Maintenance

Manual

WB97S-2

BACKHOE-LOADER

SERIAL NUMBER

WB97S-2 97SF11205 and up

WARNING

Unsafe use of this machine may cause serious injury

or death. Operators and maintenance personnel

must read this manual before operating or maintaining this machine.

This manual should be kept inside the cab for reference and periodically reviewed by all personnel

who will come into contact with the machine.

Page 2

Page 3

FOREWORD

CAUTION

1.1 FOREWORD

• This manual has been carr ied out by Komatsu Utility in o rder to supply thei r customers with al l the necessa ry

information on the mac hine and th e safety regulatio ns rela ted to it, t ogether with the use an d maintena nce instructions tha t enable the o perator to exploit the capaci ty of the machine w ith optimal results a nd to keep the

machine efficient over time.

• The operation manual, together with the spare parts catalogue, is an integral par t of the mac hin e and must ac-

company it, even when it is resold, until its final disposal.

• The manual must be handled with the greatest care and always kept on board the machine, so that it can be

consulted at any moment; it must be placed in the appropriate comp artment be hind the seat, where also the

ownership documents and the logbook are usually kept (see “3.5.10 TECHNICAL DOCUMENTATION”).

• This manual must be given to the persons who have to use the machine and carry out the routine maintenance

operations; they must read the co nten ts c ar ef ull y m or e th an o nce, in s uc h a way as to clear l y un der st an d wha t

are the correct operating conditions and the dangerous conditions that must be avoided.

In case of loss or damage, request a new copy to Komatsu Utility or your Komatsu Utility Dealer.

• The illustrations contained in this manual may represent machine configurations available upon request.

Komatsu Utility machines are constantly improved in order to increase their efficiency and reliability; this manual sums up all the infor mation regarding the m ost recent techniques ap plied at the moment in which the machine is marketed.

For any further and/or updated information, contact your Komatsu Utility Dealer.

• For the various maintenance phases it is advisable to consult the hour meter and in particular the maintenance

plan set on the electron ic unit of th e mach ine frequentl y. The display of the maintenance plan can be obtai ned

by means of an appropriate scre en po si tio ned on the uppe r pa rt of the front dashboard. In any case, the mai ntenance plan can be als o consulted on the r elevant manual provided. Keep to the various maintenance i ntervals indicated on the screen and on the use and maintenance manual.

• Over the years Komatsu Utility Dealers have gathered considerable experience in customer service.

If more information is needed , do n ot hes itate to cont act your Komatsu Utility Dealer : he always knows how to

get the best perform ance from the m achine, he ca n su ggest the u se of the e quipm ent tha t is most suit able for

specific needs and can provide the technical assistance necessary for any change that may be required to conform the machine to the safety standards and traffic rules.

Further more, Komatsu Utility Dealers also ens ure their assistance for the suppl y of Komatsu Utility genuine

spare parts, which alone guarantee safety and interchangeability.

• The table included in th is m anual mus t be filled i n wit h t he ma chine data, which a re th e data that must al ways

be indicated to the Dealer when requiring assistance and ordering spare parts.

• The incorrect use of the machine and inappropriate maintenance operations may cause serious inju-

ries and even death.

• Operators and maintenance personnel must carefully read this manual before using the machine or

performing maintenance operations.

• Any serious accident that may occur during the use of the machine or during main tenance operat ions

is due to failure to comply with the instructions given herein.

• The procedures and precautions described in this manual are valid for application to the machine only

when it is used correctly.

If the machine is used for any purpose or in any way other than those describ ed herein, the operator

shall be responsible for his own safety and for the safety of any other person involved.

1

Page 4

INFORMATION ON SAFETY

IMPORTANT

☞

1.2 INFORMATION ON SAFETY

Many accidents are caused by insuffi cient knowledge of and failure to comply with th e safety regulations prescribed for the maintenance operations that must be performed on the machine.

In order to avoid accidents, before star ting work and before carr ying out any maintenance operation, carefully

read and be sure to understand all the information and warnings contained in this manual and given on the plates

applied onto the machine, so that you can follow the instructions without making mistakes.

To identify the messages regarding safety that are included in this manual and written on the machine plates, the

following words have been used.

DANGER

CAUTION

Komatsu Utility cannot reasonably predict every circumstance that might involve a potential hazard during the operation or maintenance of the mac hi ne; for this reason, the safety mess ag es inclu ded in thi s manual and a ppl ied

onto the machine may not include all possible safety precautions.

If all the procedures and operations prescribed for this machine are kept to, you can be sure that the operator and

the persons in the vicinity can work in total safety, with no risk of damaging the machine. In case of doubt regarding the safety measures necessary for some procedures, contact Komatsu Utility or your local Dealer.

• This word is used in the safety warnings in the manual and on the plates when

the situation is dangerous and it may possibly result in serious injuries or even

death.

These messages describe the safety precautions to be taken in order to avoid

any risk. Non-compliance with these instructions may also res ult in serious

damage to the machine.

• Th is word is used in the safety war n ings in the manua l and on t he p lates t o sig-

nal risks that may cause moderate damage or injuries.

The message can be used even to indicate th e risk of damage t o the machine

only.

• This wor d is used when precautions are indicated, which must be taken to avoid

actions that may shorten the life of the machine.

DANGER

• Before starting any maintenance operation, position the machine on firm and level ground, engage the

safety locks of the equipment and controls, stop the engine and apply the parking brake.

DANGER

• To make the information clearer, some illustrations in this manual represent the machine without safety

guards. Do not use the machine without guar ds and do not start the engine when the engine pr ot ection

casing is open, if this is not expressly prescribed for some specific maintenance operations.

2

Page 5

INFORMATION ON SAFETY

DANGER

DANGER

DANGER

DANGER

• It is strictly forbidden to modify the setting of the hydraulic system safety valves; Komatsu Utility can-

not be held liable for any damage to persons, property or the machine, if this has been tampered with

by modifying the standard setting of the hydraulic system.

• Before carrying out any electrical welding, disconnect the battery, the alternator and the connector of

the gearshift unit installed under the steering wheel (see “2.8.13 PRECAUTIONS CONCERNING THE

BATTERY AND THE ALTERNATOR” - “2.8.15 PRECAUTIONS CONCERNING THE GEARSHIFT”).

• Install only authorized additional equipment (see “6.1 AUTHORIZED OPTIONAL EQUIPMENT”).

• The machine can travel on roads only if provided with homologated equipment; before travelling on

roads, make sure that the equipment with which the machine is provided is homologated and that the

safety locks are correctly connected.

3

Page 6

INTRODUCTION

IMPORTANT

☞

1.3 INTRODUCTION

1.3.1 INTENDED USES

The Komatsu Utility BACKHOE LOADERS d escr ibed i n this manual have been desig ned and constr ucted to be

used mainly for the following functions:

• LOADER

• EXCAVA TOR

Through the installation of optional equipment, the machine can also be used for the following applications:

• HANDLING OF MATERIALS (4IN1 BUCKET - PALLET FORKS)

• SNOWPLOUGH (ANGLEDOZER BLADE - SNOWPLOUGH)

• DEMOLITION (HAND HAMMER - HAMMER ON THE BACKHOE)

• DITCH CLEANING AND DIGGING (SPECIAL BUCKETS)

1.3.2 IMPROPER OR UNAUTHORIZED USES

CAUTION

• This paragraph describes some of the improper or unauthorized uses of the machine; since it is impos-

sible to predict all the possible improper uses, if the machine happens to be used f or particular applications, contact your Komatsu Utility Dealer before carrying out the work.

• The instructions regarding the authorized optional equipment are given in the relevant operation and

maintenance manuals; if the equipment is supplied by Komatsu Utility, these publications are enclosed

to this manual.

• The instructions regarding the assembly of the authorized equipment, the controls requiring special ar-

rangement on the machine and the hydraulic couplings necessary for the operation of the equipment

are grouped in the final section of this manual.

Komatsu Utility backhoe loaders are constr ucted exclusively for the handling, excavation and treatment of iner t

materials; therefore, the following uses are absolutely forbidden:

• USE OF THE MACHINE BY MINORS OR INEXPERIENCED PERSONS.

• USE OF THE MACHINE FOR LIFTING PERSONS OR OBJECTS.

• TRANSPORTATION OF PERSONS even if they are in the operator’s cab.

• TRANSPORTATION OF CONTAINERS with fluids, flammable fluids, loose material, without the approp riate

slinging equipment.

• TRANSPORTATION AND L IFTING (EVEN IF IN EXCEPTIONAL CASES) OF EQUIPMENT OR MATERIALS

THAT PROTRUDE FROM THE BUCKET OR ARE NOT SECURED TO THE BUCKET BY MEANS OF ROPES

OR CHAINS.

• USE OF THE BUCKET FOR DRIVING OR EXTRACTING PILES.

• USE OF THE MACHINE FOR TOWING DAMAGED VEHICLES ON ROADS.

• USE OF THE MACHINE FOR LIFTING DAMAGED VEHICLES.

4

Page 7

INTRODUCTION

IMPORTANT

☞

1.3.3 MAIN CHARACTERISTICS

• Simple and easy operation.

• Servo-assisted steering with priority hydraulic system.

• Three steering modes that can be selected with a push button:

- Two-wheel steering

- All-wheel steering

- Crab steering

• Gearshift with elec tronic gear selection through soleno id valve actuators and t ransmission wi th hydraulic con-

verter; reversal and gear shifting with controls on a single lever.

• Loader control through a single lever ensuring also combined movements that can be modulated proportionally

and continually.

• Backhoe controls with two levers ensuring also combined movements that can be modulated proportionally and

continually.

• Complete series of instruments visible from the two operating positions (loader or backhoe).

• Separate accelerator controls for the two operating positions.

• Foot brake control.

• Easy maintenance with simplified intervals.

• Automatic engagement and disconnection of the differential locking on both axles (front and rear).

1.3.4 RUNNING-IN

Every machine is scrupulously adjusted and tested before delivery.

A new machine, however, must be used car efully for the fir st 100 hours, in order to en sure prop er runni ng-in of

the various components.

If the machine is subj ected to excessive work loa d at the beginni ng of operation, its potential yiel d and its functionality will be shortly and untimely reduced.

Every new machine must be used carefully, paying special attention to the following indications:

• After the star t, let the engine idl e for 5 minutes, in such a way as to warm it up gradually before actual opera-

tion.

• Avoid operating the machine with the limit loads allowed or at high speed.

• Avoid abrupt starts or accelerations, useless sudden decelerations and abrupt reversals.

• After the first 250 hours, carr y out the following operations, in addition to thos e to be performed every 250

hours:

1 - Change the hydraulic transmission oil and filter.

2 - Change the differential unit oil (front and rear axle).

3 - Change the oil in the final reduction gears (front and rear axle).

4 - Check and adjust the engine valve clearance.

5 - Change the hydraulic circuit oil filter.

SYNTHETIC BIODEGRADABLE OIL TYPE HEES

On machines in whic h t he s y nthe tic bi ode gradable oil ty pe HEE S is us ed, the following ope rations ar e t o be per formed besides the standard maintenance operations:

• After the first 50 hours of operation, change the hydraulic circuit drain filter.

• After the first 500 hours of operation, change the hydraulic circuit oil.

• When changing the oil filters (cartridges), check their innner part to make sure that there are no depos-

its.

If considerable deposits are observed, find out what may have caused them before starting the machine.

• The number of operation hours is indicated by the hour meter, while the par tial service hours for the

various maintenance operations to be carried out on the machine are stored and displayed on the electronic screen positioned on the front dashboard.

5

Page 8

PRODUCT IDENTIFICATION

1.4 PRODUCT IDENTIFICATION

The Komatsu Utility backhoe loader a nd its main com ponents are identifi ed by serial numbers s tamped on the

identification plates.

The serial number and the identification numbers of the components are the only numbers that must be indicated

to the Dealer when requiring assistance and ordering spare parts.

1.4.1 MACHINE SERIAL NUMBER

The machine ser ial number is stampe d on the front par t of the

main frame, on the right side.

RWAB0070

1.4.2 MACHINE IDENTIFICATION PLATE

The Komatsu Utility backhoe loader s described in this manual

are provided with the CE mar k, which certifies th at they are in

compliance with the CE harmonized standards.

The plate with the mark is appl ied inside the operator’s cab, on

the left vertical wall of the frame, in correspondence with the

brake pedals.

RWA04680

MODELLO - MODEL

TYP - MODELE

MATRICOLA N˚ - SERIAL N˚

FABR. NR. - SERIE NR.

ANNO - YEAR

BAUJAHR - ANNEE

MASSA TOTALE MAX - TOTAL MAX WEIGHT

ZUL. GESAMTGEWICHT - POIDS TOTAL MAX

POTENZA MOTORE - ENGINE POWER

LEISTUNG - PUISSANCE MOTEUR

MASSA MAX ASSE ANT. - MAX WEIGHT FRONT AXLE

ZUL. ACHSLAST VORN - POIDS MAX ESSIEU AV

MASSA MAX ASSE POST. - MAX WEIGHT REAR AXLE

ZUL. ACHSLAST HINTEN - POIDS MAX ESSIEU AR

MANUFACTURED BY KOMATSU UTILITY EUROPE S.p.A.

36025 NOVENTA VICENTINA (VI) ITALY

kg

kw

kg

kg

21D-98-12580

RWA34270

MODEL

SERIAL N

YEAR

TOTAL MAX WEIGHT

ENGINE POWER

MAX WEIGHT FRONT AXLE

MAX WEIGHT REAR AXLE

MANUFACTURED BY KOMATSU UTILITY EUROPE S.p.A.

36025 NOVENTA VICENTINA (VI) ITALY

kg

kw

kg

kg

6

Page 9

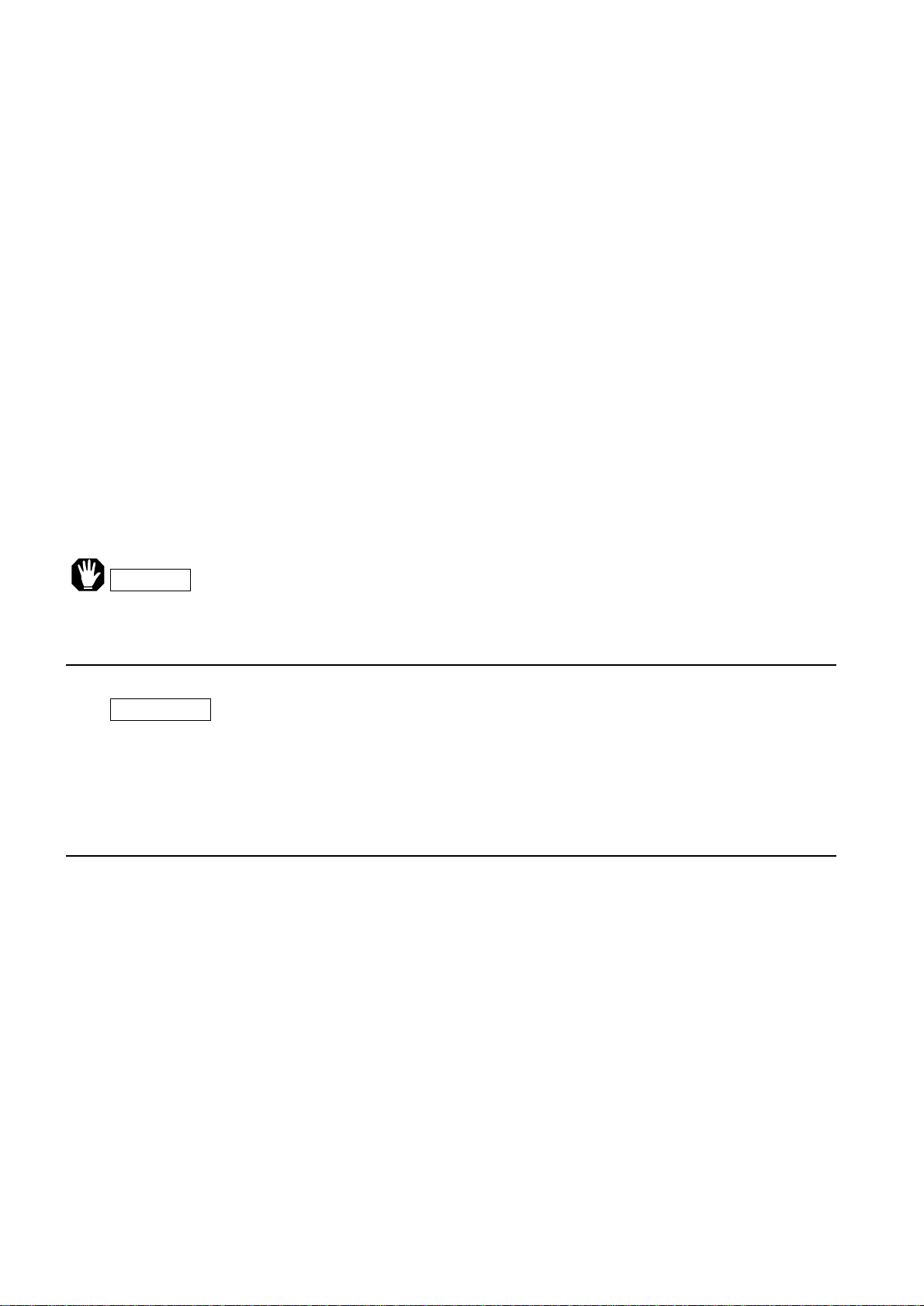

1.4.3 ENGINE SERIAL NUMBER AND EXHAUST GAS EMISSION PLATE

The engine serial number is stam ped on the pl ate posi tioned on

the rear side of the tappet cover.

The plate regardin g the exhaust emission r egulations is applied

to the front side of the tappet cover.

PRODUCT IDENTIFICATION

RWAB0480

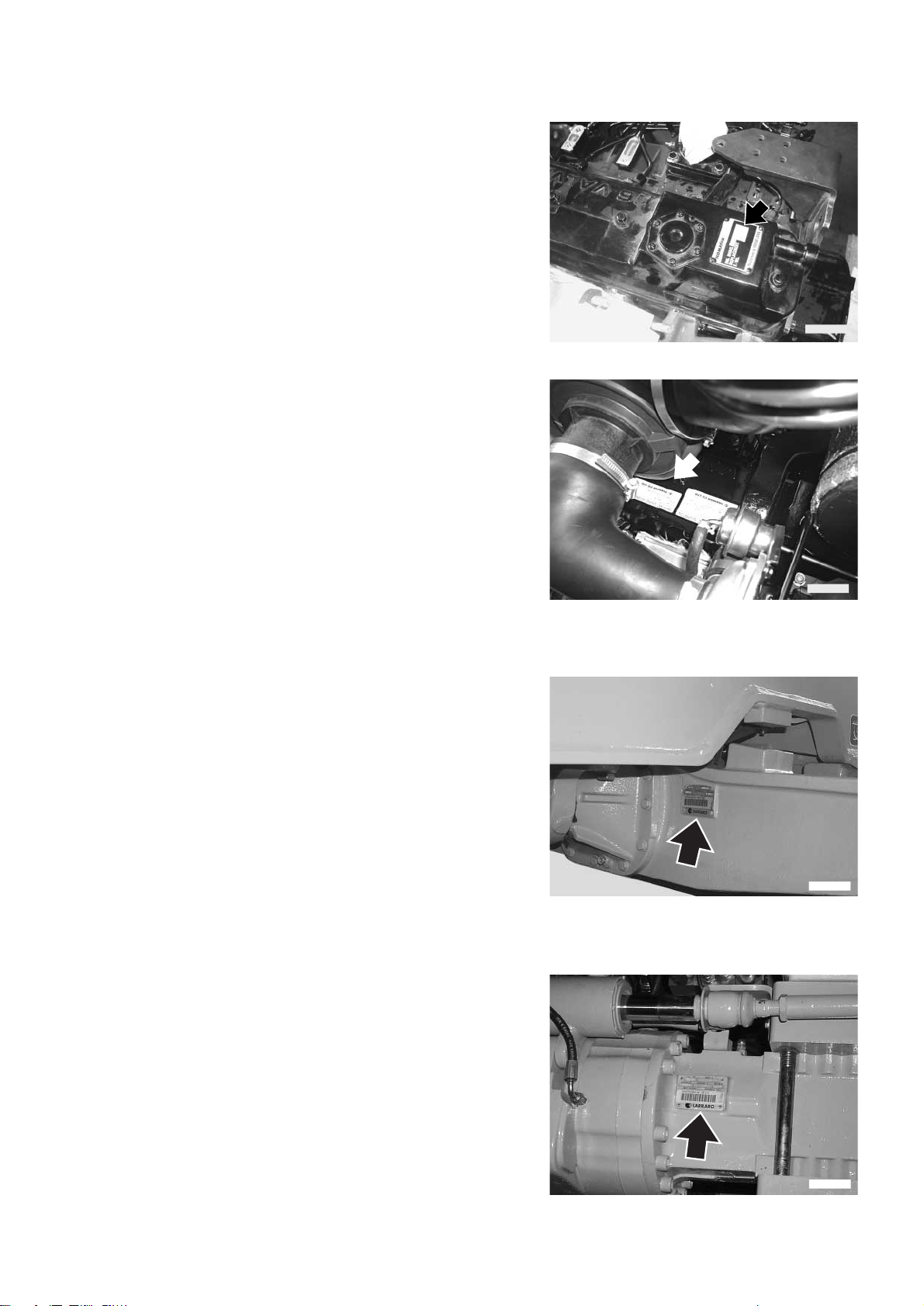

1.4.4 FRONT AXLE SERIAL NUMBER

The serial number of the fro nt axle is st amp ed on the plate positioned on the right side of the axle body.

1.4.5 REAR AXLE SERIAL NUMBER

The serial number o f the rear axle i s sta mped on the pl ate pos itioned on the left side of the axle body.

RWAB0620

RWAA8910

RWAA8920

7

Page 10

PRODUCT IDENTIFICATION

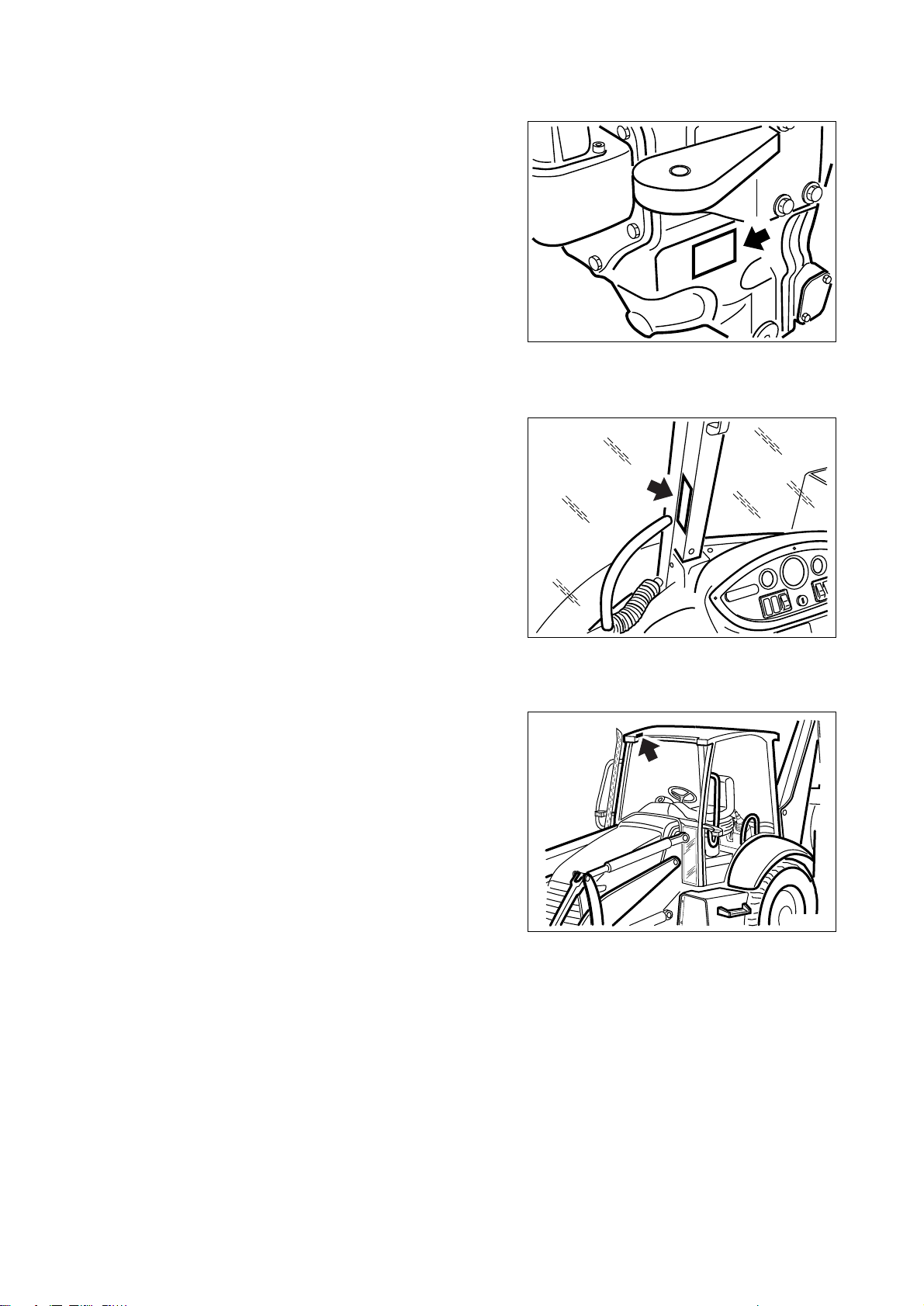

1.4.6 TRANSMISSION SERIAL NUMBER

The transmission serial number is stamped on the plate postioned on the right side of the transmission case.

RWA02540

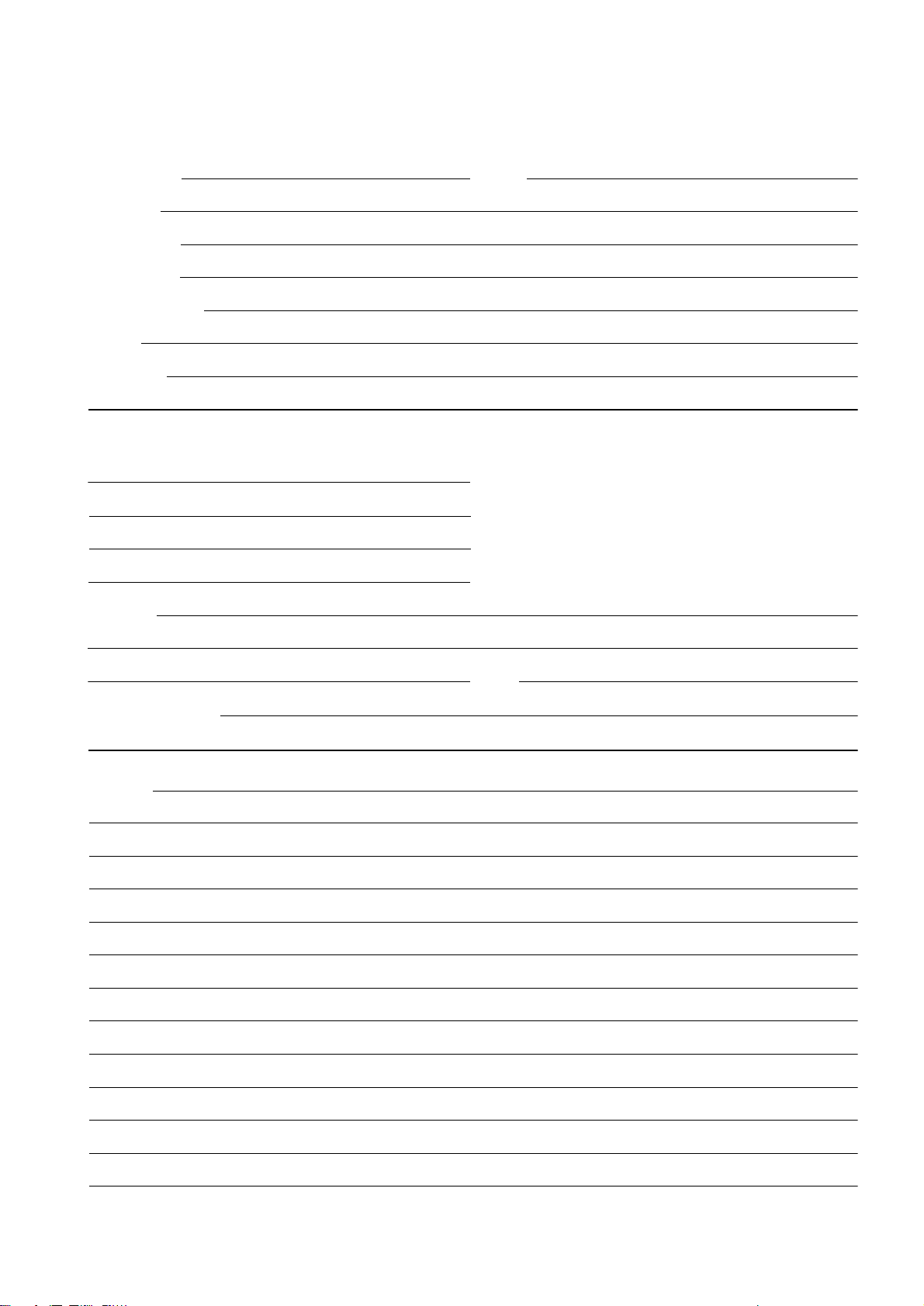

1.4.7 CAB SERIAL NUMBER

The cab serial number is stamped on the plate positioned on the

right center pillar.

1.4.8 CANOPY SERIAL NUMBER (if provided)

The serial number is stam ped on the plate po sitioned inside the

canopy, on the front right part.

RWA02500

RWA18190

8

Page 11

1.4.9 SERIAL NUMBERS AND DEALER’S ADDRESS

Machine n. Model

Engine n.

Front axle n.

Rear axle n.

Transmission n.

Cab n.

Canopy n.

Dealer:

PRODUCT IDENTIFICATION

Address:

Person to contact:

NOTES:

Tel.

9

Page 12

THIS PAGE WAS INTENTIONALLY LEFT EMPTY

10

Page 13

TABLE OF CONTENTS

Page

TABLE OF CONTENTS

1.1 FOREWORD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 INFORMATION ON SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3.1 INTENDED USES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3.2 IMPROPER OR UNAUTHORIZED USES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3.3 MAIN CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3.4 RUNNING-IN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 PRODUCT IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4.1 MACHINE SERIAL NUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4.2 MACHINE IDENTIFICATION PLATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4.3 ENGINE SERIAL NUMBER AND EXHAUST GAS EMISSION PLATE. . . . . . . . . . . . . . . . . 7

1.4.4 FRONT AXLE SERIAL NUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4.5 REAR AXLE SERIAL NUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4.6 TRANSMISSION SERIAL NUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4.7 CAB SERIAL NUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4.8 CANOPY SERIAL NUMBER (if provided) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4.9 SERIAL NUMBERS AND DEALER’S ADDRESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

SAFETY AND ACCIDENT PREVENTION

2.1 SAFETY, NOISE AND VIBRATION PLATES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.1.1 POSITION OF THE SAFETY PLATES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.1.2 PICTOGRAMS AND RELEVANT MEANINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.1.3 POSITION OF THE NOISE PLATES ON MACHINES WITH CAB . . . . . . . . . . . . . . . . . . . . 26

2.1.4 VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED . . . . . . . . . . . . . . . . . . . . . . . 27

2.2 GENERAL PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.2.1 GENERAL SAFETY RULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.2.2 SAFETY DEVICES AND GUARDS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.2.3 CLOTHING AND PERSONAL PROTECTION ITEMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.2.4 UNAUTHORIZED MODIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.2.5 LEAVING THE OPERATOR’S SEAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.2.6 GETTING ON AND OFF THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.2.7 CHECKING THE REAR-VIEW MIRRORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.2.8 PREVENTING FIRES DUE TO FUEL AND OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.2.9 PREVENTING BURNS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.2.10 PREVENTING DAMAGE DUE TO ASBESTOS POWDER. . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.2.11 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT . . . . . . . . . . . . . . . . . . . 32

2.2.12 FIRE EXTINGUISHERS AND FIRST AID KIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.2.13 PRECAUTIONS CONCERNING THE CAB STRUCTURE . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.2.14 PRECAUTIONS CONCERNING THE EQUIPMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.3 PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . 33

2.3.1 SAFETY ON THE WORK SITE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.3.2 FIRE PREVENTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.3.3 PRECAUTIONS TO BE TAKEN FOR THE OPERATOR'S CAB. . . . . . . . . . . . . . . . . . . . . . 33

2.3.4 ROOM VENTILATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.3.5 CLEANING WINDOWS, MIRRORS AND LIGHTS - CHECKING THE WINDSHIELD

WIPER BLADES AND THE BULBS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

11

Page 14

TABLE OF CONTENTS

Page

2.4 PRECAUTIONS TO BE TAKEN WHEN WORKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.4.1 STARTING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.4.2 RULES FOR ROAD TRAVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.4.3 CHECKS FOR TRAVELLING IN REVERSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.4.4 MOVING THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.4.5 WORKING ON SLOPES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2.4.6 PREVENTING ELECTROCUTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2.4.7 VISIBILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2.4.8 WORKING ON ICY OR SNOW-COVERED SURFACES . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2.4.9 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT. . . . . . . . . . . . . . . . . . . . 39

2.4.10 WORKING ON LOOSE GROUND. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2.4.11 PARKING THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2.5 TRANSPORTING THE MACHINE ON OTHER VEHICLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2.5.1 LOADING AND UNLOADING THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2.5.2 THE ROUTE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2.6 BATTERY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2.6.1 SAFETY PRECAUTIONS FOR WORK ON BATTERIES . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2.6.2 STARTING WITH BOOSTER CABLES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2.7 PRECAUTIONS FOR EMERGENCY RECOVERY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2.8 PRECAUTIONS TO BE TAKEN DURING MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

2.8.1 WARNING PLATES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

2.8.2 TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

2.8.3 PERSONNEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

2.8.4 EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

2.8.5 WORKING UNDER THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

2.8.6 KEEPING THE MACHINE CLEAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

2.8.7 USE OF THE ENGINE DURING MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

2.8.8 PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY . . . . . . . . . 46

2.8.9 STOP THE ENGINE BEFORE CARRYING OUT ANY MAINTENANCE OPERATION

OR INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

2.8.10 RULES FOR REFUELLING AND ADDING OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

2.8.11 CHECKING THE COOLANT LEVEL IN THE RADIATOR . . . . . . . . . . . . . . . . . . . . . . . . . . 48

2.8.12 USING LAMPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

2.8.13 PRECAUTIONS CONCERNING THE BATTERY AND THE ALTERNATOR . . . . . . . . . . . . 49

2.8.14 PRECAUTIONS CONCERNING THE STARTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

2.8.15 PRECAUTIONS CONCERNING THE GEARSHIFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

2.8.16 HANDLING HIGH-PRESSURE PIPES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

2.8.17 PRECAUTIONS TO BE TAKEN WHEN HANDLING HIGH-PRESSURE OIL . . . . . . . . . . . 50

2.8.18 PRECAUTIONS FOR MAINTENANCE WORK INVOLVING HIGH TEMPERATURES

AND PRESSURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

2.8.19 COOLING FAN AND FAN BELT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

2.8.20 WASTE MATERIALS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

2.8.21 PRECAUTIONS TO BE TAKEN WHEN INFLATING TYRES . . . . . . . . . . . . . . . . . . . . . . . . 52

2.8.22 PRECAUTIONS FOR THE INSTALLATION OF THE EXHAUST SYSTEM TAILPIPE. . . . . 52

2.8.23 PRECAU TIONS FOR THE USE OF THE SYNTHE TIC BIODEGRADABLE OIL

TYPE HEES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

12

Page 15

TABLE OF CONTENTS

Page

DESCRIPTION AND USE OF THE MACHINE

3.1 SAFETY LOCKS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

3.1.1 FRONT LOADER LOCKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

3.1.2 BACKHOE LOCKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

3.2 GENERAL VIEWS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

3.2.1 FRONT GENERAL VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

3.2.2 BACKHOE GENERAL VIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

3.2.3 CAB INSIDE GENERAL VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

3.2.3.1 CAB INSIDE GENERAL VIEW (Standard version) . . . . . . . . . . . . . . . . . . . . . . 61

3.2.3.2 CAB INSIDE GENERAL VIEW (Version with servcontrols available on request) 62

3.3 INSTRUMENTS AND CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

3.3.1 FRONT INSTRUMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

3.3.2 SIDE INSTRUMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

3.3.2.1 SIDE INSTRUMENTS (Standard version) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

3.3.2.2 SIDE INSTRUMENTS (Version with servo controls available on request) . . . . . 76

3.3.3 PUSH BUTTONS ON THE FRONT LOADER CONTROL LEVER . . . . . . . . . . . . . . . . . . . . 84

3.3.4 ELECTRICAL ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

3.3.5 MACHINE CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

3.3.5.1 MACHINE CONTROLS (Standard version) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

3.3.5.2 MACHINE CONTROLS (Version with servo controls available upon request) . . 87

3.4 FUSES AND RELAYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

3.4.1 EQUIPMENT FUSES AND RELAYS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

3.4.1.1 FUSES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

3.4.1.2 RELAYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

3.4.2 ENGINE LINE FUSES AND RELAYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

3.4.2.1 FUSES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

3.4.2.2 RELAYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

3.4.3 SIDE DASHBOARD RELAYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

3.4.4 SIDE DASHBOARD RELAYS AND FUSES (Only with servo controls) . . . . . . . . . . . . . . . . 131

3.4.4.1 RELAYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

3.4.4.2 FUSES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

3.5 GUARDS, CAB AND DRIVER’S SEAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

3.5.1 ENGINE HOOD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

3.5.2 CANOPY (if provided) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

3.5.3 CAB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

3.5.4 VENTILATION AND HEATING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

3.5.5 AIR CONDITIONER (if installed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

3.5.6 SEAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

3.5.6.1 SEAT (STANDARD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

3.5.6.2 SEAT (OPTIONAL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

3.5.7 SAFETY BELT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

3.5.8 FIRE EXTINGUISHER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

3.5.9 FIRST AID KIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

3.5.10 TECHNICAL DOCUMENTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

3.5.11 ADDITIONAL TOOL BOX (if provided) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

3.6 USE OF THE MACHINE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

3.6.1 CHECKS BEFORE STARTING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

3.6.1.1 VISUAL CHECKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

3.6.1.2 DAILY CHECKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

3.6.1.3 OPERATIONAL CHECKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

13

Page 16

TABLE OF CONTENTS

Page

3.6.2 STARTING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

3.6.2.1 STARTING WITH WARM ENGINE OR IN TEMPERATE CLIMATES . . . . . . . . 145

3.6.2.2 STARTING WITH COLD ENGINE OR IN COLD CLIMATES . . . . . . . . . . . . . . . 146

3.6.3 WARMING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

3.6.4 HEATING THE HYDRAULIC OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

3.6.5 HOW TO MOVE THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

3.6.5.1 ENGAGING THE FOUR-WHEEL DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

3.6.5.2 MOVING ON SLOPES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

3.6.5.3 MAXIMUM IMMERSION DEPTH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

3.7 PARKING THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

3.7.1 PARKING ON LEVEL GROUND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

3.7.2 PARKING ON SLOPES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

3.8 STOPPING THE ENGINE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

3.9 TRANSPORTING THE MACHINE ON OTHER VEHICLES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

3.9.1 LOADING AND UNLOADING THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

3.9.2 TRANSPORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

3.10 PRECAUTIONS TO BE TAKEN IN THE COLD SEASON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

3.10.1 FUEL AND LUBRICANTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

3.10.2 COOLANT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

3.10.3 BATTERY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

3.10.4 OTHER PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

3.10.5 PRECAUTIONS TO BE TAKEN AT THE END OF WORK . . . . . . . . . . . . . . . . . . . . . . . . . . 158

3.11 PRECAUTIONS TO BE TAKEN IN THE WARM SEASON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

3.12 USING THE MACHINE AS A LOADER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

3.12.1 BUCKET POSITION INDICATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

3.12.2 ORGANIZING THE WORK AREA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

3.12.2.1 LOADING HEAPED AND LEVEL MATERIAL . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

3.12.2.2 LOADING OPERATIONS ON SLOPES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

3.12.3 CHANGING THE STANDARD FRONT BUCKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

3.13 USING THE MACHINE AS AN EXCAVATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

3.13.1 POSITIONING THE BUCKET ACCORDING TO THE WORK TO BE CARRIED OUT. . . . . 163

3.13.2 POSITIONING THE MACHINE FOR DIGGING OPERATIONS . . . . . . . . . . . . . . . . . . . . . . 164

3.13.3 SLIDING THE BACKHOE UNIT SIDEWARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

3.13.4 DIGGING METHOD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

3.13.5 CHANGING THE BACKHOE BUCKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

3.14 LONG PERIODS OF INACTIVITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

3.14.1 BEFORE THE PERIOD OF INACTIVITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

3.14.2 DURING THE PERIOD OF INACTIVITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

3.14.3 AFTER THE PERIOD OF INACTIVITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

3.15 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

3.15.1 HOW TO REMOVE THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

3.15.2 IF THE FUEL HAS BEEN COMPLETELY DEPLETED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

3.15.3 IF THE BATTERY IS DEPLETED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

3.15.3.1 STARTING WITH BOOSTER CABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

3.15.4 OTHER TROUBLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

3.15.4.1 ELECTRICAL CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

3.15.4.2 HYDRAULIC SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

3.15.4.3 BRAKING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

3.15.4.4 CONVERTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

3.15.4.5 ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

14

Page 17

TABLE OF CONTENTS

Page

MAINTENANCE

4.1 GUIDE TO MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

4.2 MAINTENANCE NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

4.2.1 NOTES REGARDING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

4.2.1.1 ENGINE OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

4.2.1.2 COOLANT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

4.2.1.3 FUEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

4.2.2 NOTES REGARDING THE HYDRAULIC SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

4.2.3 NOTES REGARDING THE ELECTRICAL SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

4.2.4 NOTES REGARDING LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

4.2.5 PARTS SUBJECT TO WEAR THAT PERIODICALLY NEED CHANGING. . . . . . . . . . . . . . 183

4.3 FUEL, COOLANT AND LUBRICANTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

4.3.1 HOMOLOGATED HEES SYNTHETIC BIODEGRADABLE LUBRICANTS. . . . . . . . . . . . . . 186

4.4 DRIVING TORQUES FOR SCREWS AND NUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

4.4.1 STANDARD DRIVING TORQUES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

4.4.2 SPECIFIC DRIVING TORQUES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

4.5 LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

4.5.1 LUBRICATION DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

4.5.2 LUBRICATION DIAGRAM (4in1 bucket and pallet forks) . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

4.5.3 LUBRICATION DIAGRAM (Front bucket rapid couplings) . . . . . . . . . . . . . . . . . . . . . . . . . . 190

4.5.4 LUBRICATION DIAGRAM (Telescopic arm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

4.5.5 LUBRICATION DIAGRAM (Offset device). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

4.6 PERIODICAL CHANGE OF THE COMPONENTS CONNECTED WITH SAFETY . . . . . . . . . . . . . . 193

4.6.1 CRITICAL PARTS FOR SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

4.7 MAINTENANCE PLAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

4.7.1 WHEN REQUIRED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

4.7.1.a CHECKING, CLEANING OR CHANGING THE AIR CLEANER CARTRIDGE . . 202

4.7.1.b CHECKING AND CLEANING THE CAB AIR FILTER . . . . . . . . . . . . . . . . . . . . . 203

4.7.1.c CHECKING AND CLEANING THE RECIRCULATING AIR FILTER

(only for machines with air conditioner) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

4.7.1.d BLEEDING THE BRAKING CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

4.7.1.e CLEANING THE WATER SEPARATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

4.7.1.f CHECKING AND ADJUSTING THE WHEEL TOE-IN . . . . . . . . . . . . . . . . . . . . . 206

4.7.1.g CHECKING AND ADJUSTING THE PARKING BRAKE . . . . . . . . . . . . . . . . . . . 207

4.7.1.h CHECKING THE BRAKING EFFICIENCY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

4.7.1.j CHECKING AND ADJUSTING THE BRAKE PEDAL STROKE. . . . . . . . . . . . . . 209

4.7.1.k ADJUSTING THE AUTOMATIC RETURN-TO-DIG DEVICE

OF THE FRONT BUCKET (if installed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

4.7.1.l CHECKING AND ADJUSTING THE STABILIZER SLACK . . . . . . . . . . . . . . . . . 210

4.7.2 MAINTENANCE INTERVALS IN CASE OF USE OF THE DEMOLITION HAMMER . . . . . . 211

4.7.2.a CHANGING THE HYDRAULIC OIL FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

4.7.2.b CHANGING THE HYDRAULIC OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

4.7.3 CHECKS BEFORE STARTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

4.7.3.a VARIOUS CHECKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

4.7.3.b CHECKING THE COOLANT LEVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

4.7.3.c CHECKING THE FUEL LEVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

4.7.3.d CHECKING THE ENGINE OIL LEVEL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

4.7.3.e CHECKING THE HYDRAULIC CIRCUIT OIL LEVEL . . . . . . . . . . . . . . . . . . . . . 214

4.7.3.f DRAINING THE WATER SEPARATOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

4.7.4 MAINTENANCE EVERY 10 HOURS OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

4.7.4.a LUBRICATING THE JOINTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

15

Page 18

TABLE OF CONTENTS

4.7.5 MAINTENANCE AFTER THE FIRST 50 HOURS OF OPERATION

(Only for machines in which the synthetic biodegradable oil type HEES is used) . . . . . . . . . 218

4.7.6 MAINTENANCE EVERY 50 HOURS OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

4.7.6.a CHECKING THE RADIATOR FLUID LEVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

4.7.6.b CHECKING THE BRAKING SYSTEM OIL LEVEL. . . . . . . . . . . . . . . . . . . . . . . . 218

4.7.6.c LUBRICATING THE PROPELLER SHAFTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

4.7.6.d LUBRICATING THE FRONT AXLE JOINTS AND CENTRAL COUPLING

AND THE REAR AXLE JOINTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

4.7.6.e CHECKING THE TYRE PRESSURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

4.7.6.f CHECKING THE ELECTRICAL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

4.7.7 MAINTENANCE AFTER THE FIRST 250 HOURS OF OPERATION . . . . . . . . . . . . . . . . . . 222

4.7.8 MAINTENANCE EVERY 250 HOURS OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

4.7.8.a ADJUSTING THE FAN BELT TENSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

4.7.8.b ADJUSTING THE A/C COMPRESSOR BELT TENSION

(Only for machines with air conditioner) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

4.7.8.c CHECKING THE BATTERY ELECTROLYTE LEVEL . . . . . . . . . . . . . . . . . . . . . 225

4.7.8.d CHECKING THE FRONT AXLE OIL LEVELS . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

4.7.8.e CHECKING THE REAR AXLE OIL LEVELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

4.7.8.f CHECKING THE HYDRAULIC TRANSMISSION OIL LEVEL . . . . . . . . . . . . . . . 227

4.7.8.g CHECKING THE WHEEL NUT DRIVING TORQUE . . . . . . . . . . . . . . . . . . . . . . 227

4.7.9 MAINTENANCE AFTER THE FIRST 500 HOURS OF OPERATION

(Only for machines in which the synthetic biodegradable oil type HEES is used) . . . . . . . . . 228

4.7.10 MAINTENANCE EVERY 500 HOURS OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

4.7.10.a CHANGING THE ENGINE OIL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

4.7.10.b CHANGING THE ENGINE OIL FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

4.7.10.c CHANGING THE HYDRAULIC SYSTEM OIL FILTER . . . . . . . . . . . . . . . . . . . . 230

4.7.10.d CHANGING THE FUEL FILTER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

4.7.10.e DRAINING THE FUEL TANK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

4.7.10.f DRAINING THE HYDRAULIC OIL TANK

(Only for machines in which the synthetic biodegradable oil type HEES is used) 235

4.7.10.g CLEANING THE OUTSIDE OF THE RADIATORS . . . . . . . . . . . . . . . . . . . . . . . 236

4.7.10.h CLEANING THE OUTSIDE OF THE A/C CONDENSER

(Only for machines with air conditioner) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

4.7.11 MAINTENANCE EVERY 1000 HOURS OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . 238

4.7.11.a CHANGING THE FRONT AXLE OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

4.7.11.b CHANGING THE REAR AXLE OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

4.7.11.c CHANGING THE HYDRAULIC TRANSMISSION OIL . . . . . . . . . . . . . . . . . . . . . 240

4.7.11.d CHANGING THE HYDRAULIC TRANSMISSION FILTER. . . . . . . . . . . . . . . . . . 241

4.7.11.e CHECKING AND ADJUSTING THE ENGINE VALVE CLEARANCE . . . . . . . . . 241

4.7.12 MAINTENANCE EVERY 2000 HOURS OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . 242

4.7.12.a CHANGING THE HYDRAULIC SYSTEM OIL AND CLEANING THE SUCTION

FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

4.7.12.b CHANGING THE COOLANT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

4.7.12.c CHANGING THE BRAKING SYSTEM OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

4.7.12.d CHECKING THE ALTERNATOR AND THE STARTER . . . . . . . . . . . . . . . . . . . 246

4.7.12.e CHECKING THE QUANTITY OF COOLANT IN THE A/C SYSTEM

(Only for machines with air conditioner) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

4.7.13 MAINTENANCE EVERY 4000 HOURS OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . 248

4.7.13.a CHANGING THE A/C DEHYDRATING FILTER

(Only for machines with air conditioner) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

4.7.13.b CHECKING THE OPERATING CONDITIONS OF THE A/C COMPRESSOR

(Only for machines with air conditioner) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Page

16

Page 19

TABLE OF CONTENTS

Page

TECHNICAL SPECIFICATIONS

5.1 TECHNICAL DATA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

5.1.1 STANDARD OVERALL DIMENSIONS WITH CENTERED BACKHOE . . . . . . . . . . . . . . . . 250

5.1.2 STANDARD OVERALL DIMENSIONS WITH FOLDED BACKHOE . . . . . . . . . . . . . . . . . . 250

5.1.3 TECHNICAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

5.1.4 LIFTING CAPACITIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

5.1.4.1 SYMBOL TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

5.1.4.2 LIFTING CAPACITY (STANDARD BOOM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

5.1.4.3 LIFTING CAPACITY (OFFSET BOOM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

AUTHORIZED OPTIONAL EQUIPMENT

6.1 AUTHORIZED OPTIONAL EQUIPMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

6.1.1 CHARACTERISTICS OF THE OPTIONAL EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

6.2 FRONT EQUIPMENT QUICK COUPLING DEVICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

6.2.1 MANUAL CONTROL QUICK COUPLING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

6.2.2 HYDRAULIC CONTROL QUICK COUPLING FOR STANDARD BUCKET. . . . . . . . . . . . . . 258

6.2.3 HYDRAULIC CONTROL QUICK COUPLING FOR 4IN1 BUCKET AND OPTIONAL

EQUIPMENT WITH UNIDIRECTIONAL OIL FLOW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

6.3 4in1 BUCKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

6.3.1 DESCRIPTION AND CONTROLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

6.3.2 SAFETY DEVICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

6.3.3 INSTALLING THE 4in1 BUCKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

6.3.4 USING THE 4in1 BUCKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

6.3.5 MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

6.4 PALLET FORKS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

6.4.1 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

6.4.2 SAFETY DEVICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

6.4.3 USING THE FORKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

6.4.3.1 PREPARING THE PALLET FORKS FOR USE . . . . . . . . . . . . . . . . . . . . . . . . . 263

6.4.3.2 OVERTURNING THE FORKS FOR TRAVEL ON ROADS . . . . . . . . . . . . . . . . . 264

6.4.4 REMOVING THE FORKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

6.4.5 INSTALLING THE FORKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

6.4.6 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

6.5 BACKHOE TELESCOPIC ARM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

6.5.1 DESCRIPTION AND CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

6.5.1.1 VERSION WITH STANDARD CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

6.5.1.2 VERSION WITH SERVO CONTROLS (if installed) . . . . . . . . . . . . . . . . . . . . . . . 266

6.5.2 SAFETY DEVICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

6.5.3 USING THE TELESCOPIC ARM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

6.5.4 MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

6.5.4.1 ADJUSTING THE GUIDE SLACK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

17

Page 20

TABLE OF CONTENTS

Page

6.6 ARRANGEMENT FOR THE INSTALLATION OF THE DEMOLITION HAMMER . . . . . . . . . . . . . . 270

6.6.1 DESCRIPTION AND CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

6.6.1.1 VERSION WITH STANDARD CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

6.6.1.2 VERSION WITH SERVO CONTROLS (if installed) . . . . . . . . . . . . . . . . . . . . . . 270

6.6.2 USE OF THE DEMOLITION HAMMER AND RULES TO BE OBSERVED. . . . . . . . . . . . . . 271

6.6.3 INSTALLING AND REMOVING THE DEMOLITION HAMMER . . . . . . . . . . . . . . . . . . . . . . 275

6.6.3.1 INSTALLING THE HAMMER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

6.6.3.2 REMOVING THE HAMMER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

6.6.4 USING THE HAMMER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

6.6.5 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

6.7 APPLICATION OF THE OFFSET DEVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

6.7.1 DESCRIPTION AND CONTROL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

6.7.1.1 VERSION WITH STANDARD CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

6.7.1.2 VERSION WITH SERVO CONTROLS (if installed) . . . . . . . . . . . . . . . . . . . . . . 279

6.7.2 MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

6.8 ARRANGEMENT FOR THE OPERATION OF OPTIONAL EQUIPMENT WITH UNIDIRECTIONAL

OIL FLOW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

6.8.1 DESCRIPTION AND CONTROL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

6.8.1.1 VERSION WITH STANDARD CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

6.8.1.2 VERSION WITH SERVO CONTROLS (if installed) . . . . . . . . . . . . . . . . . . . . . . 280

6.8.2 INSTALLING AND CONNECTING THE EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

6.8.3 MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

6.9 ARRANGEMENT FOR THE INSTALLATION OF THE CLAMSHELL BUCKET . . . . . . . . . . . . . . . 282

6.9.1 DESCRIPTION AND CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

6.9.1.1 VERSION WITH STANDARD CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

6.9.1.2 VERSION WITH SERVO CONTROLS (if installed) . . . . . . . . . . . . . . . . . . . . . . 283

6.9.2 INSTALLING THE CLAMSHELL BUCKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

6.9.3 USING THE CLAMSHELL BUCKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

6.9.4 MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

6.10 ARRANGEMENT FOR THE INSTALLATION OF THE MANUAL HYDRAULIC HAMMER . . . . . . . 286

6.10.1 DESCRIPTION AND CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

6.10.2 CONNECTING AND REMOVING THE HAMMER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

6.10.2.1 CONNECTING THE HAMMER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

6.10.2.2 REMOVING THE CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

6.10.3 USING THE HAMMER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

6.10.4 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

6.11 LOAD STABILIZER SYSTEM (LSS) (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

6.11.1 ACCUMULATOR OF THE LOAD STABILIZER SYSTEM (LSS) . . . . . . . . . . . . . . . . . . . . . 289

6.12 REAR EQUIPMENT RAPID COUPLING DEVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

6.12.1 EQUIPMENT COUPLING AND RELEASE PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . 291

6.12.2 MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

18

Page 21

SAFETY AND

ACCIDENT PREVENTION

Page 22

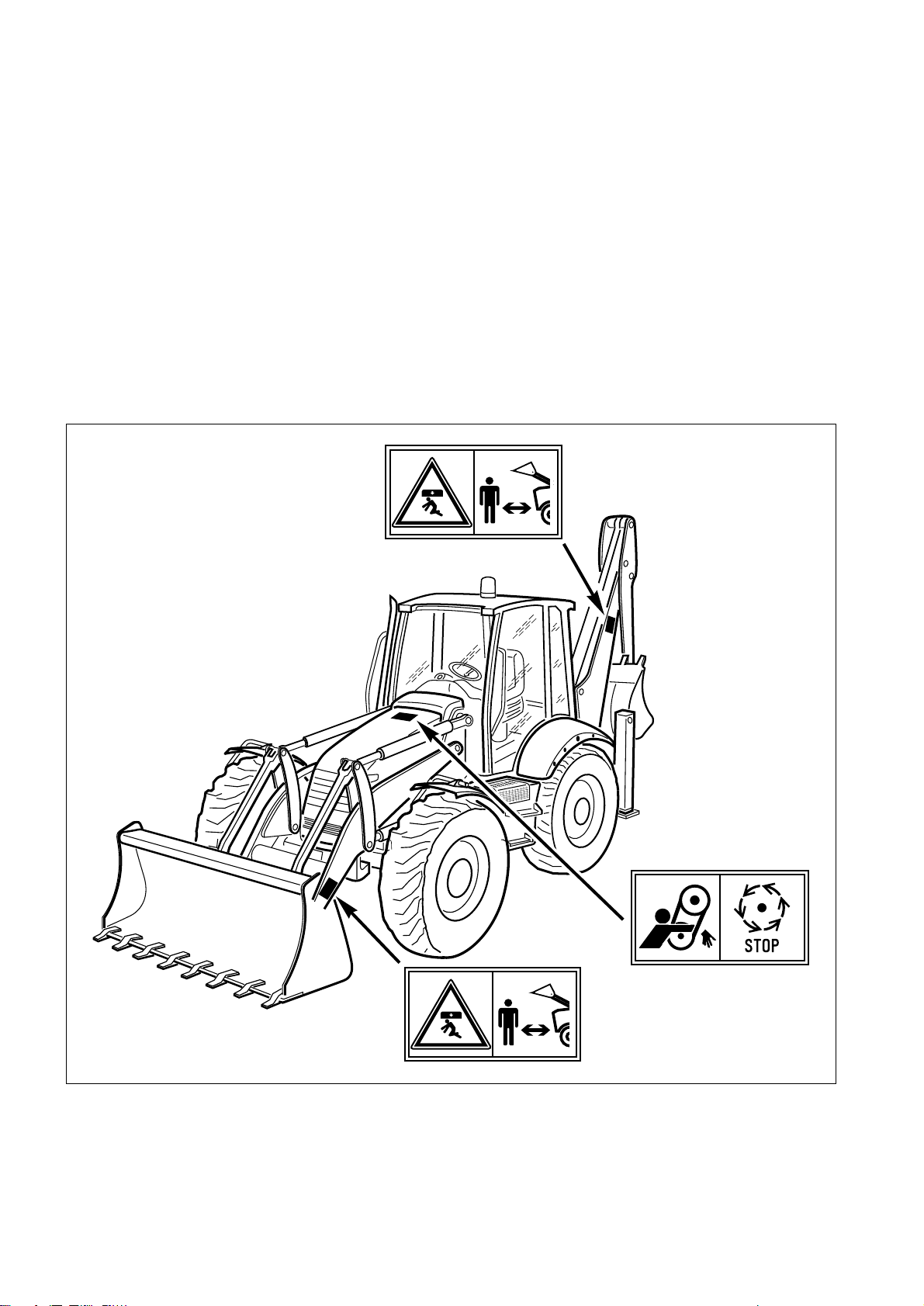

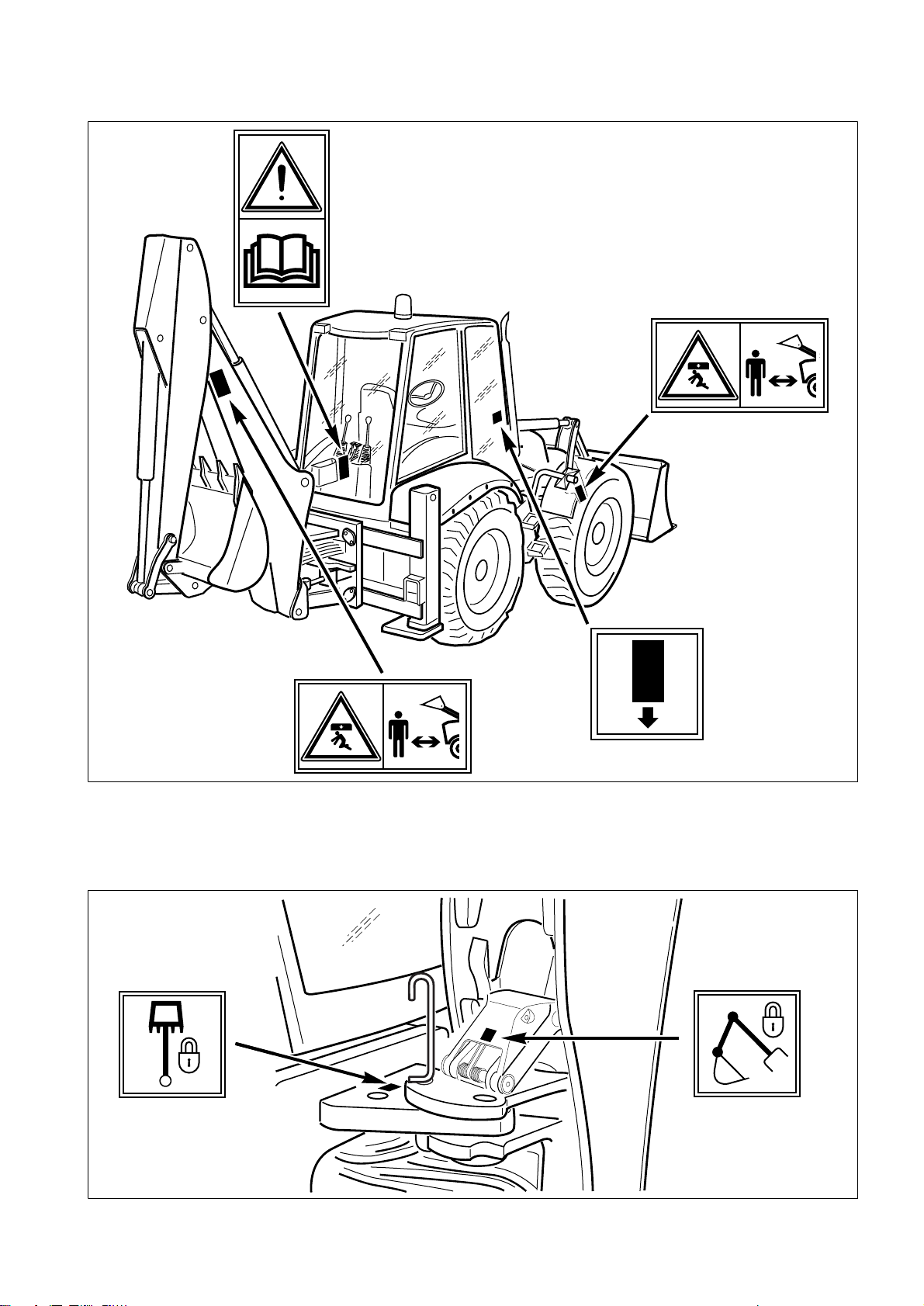

SAFETY, NOISE AND VIBRATION PLATES

2.1 SAFETY, NOISE AND VIBRATION PLATES

2.1.1 POSITION OF THE SAFETY PLATES

• The safety plates must always be legible and in good conditions; for this reason, if they are dirty with dust, oil or

grease, it is necessary to clean them with a solution made of water and detergent.

Do not use fuel, petrol or solvents.

• If the plates are damaged, ask for new ones to Komatsu Utility or to your Komatsu Utility Dealer.

• In case of replacement of a component provided with a safety plate, make sure that this plate is applied also on

the new piece.

• The machine can be p rovided with other pla tes in addition to those indicated below; keep also to the instr uc-

tions given in the additional plates, in any case.

RWA26140

RWA00020

20

RWA00010

RWA00020

Page 23

RWA26150

SAFETY, NOISE AND VIBRATION PLATES

RWA00030

RWA00020

RWA00150

RWA00190

RWA00020

RWA00160

RWA37700

21

Page 24

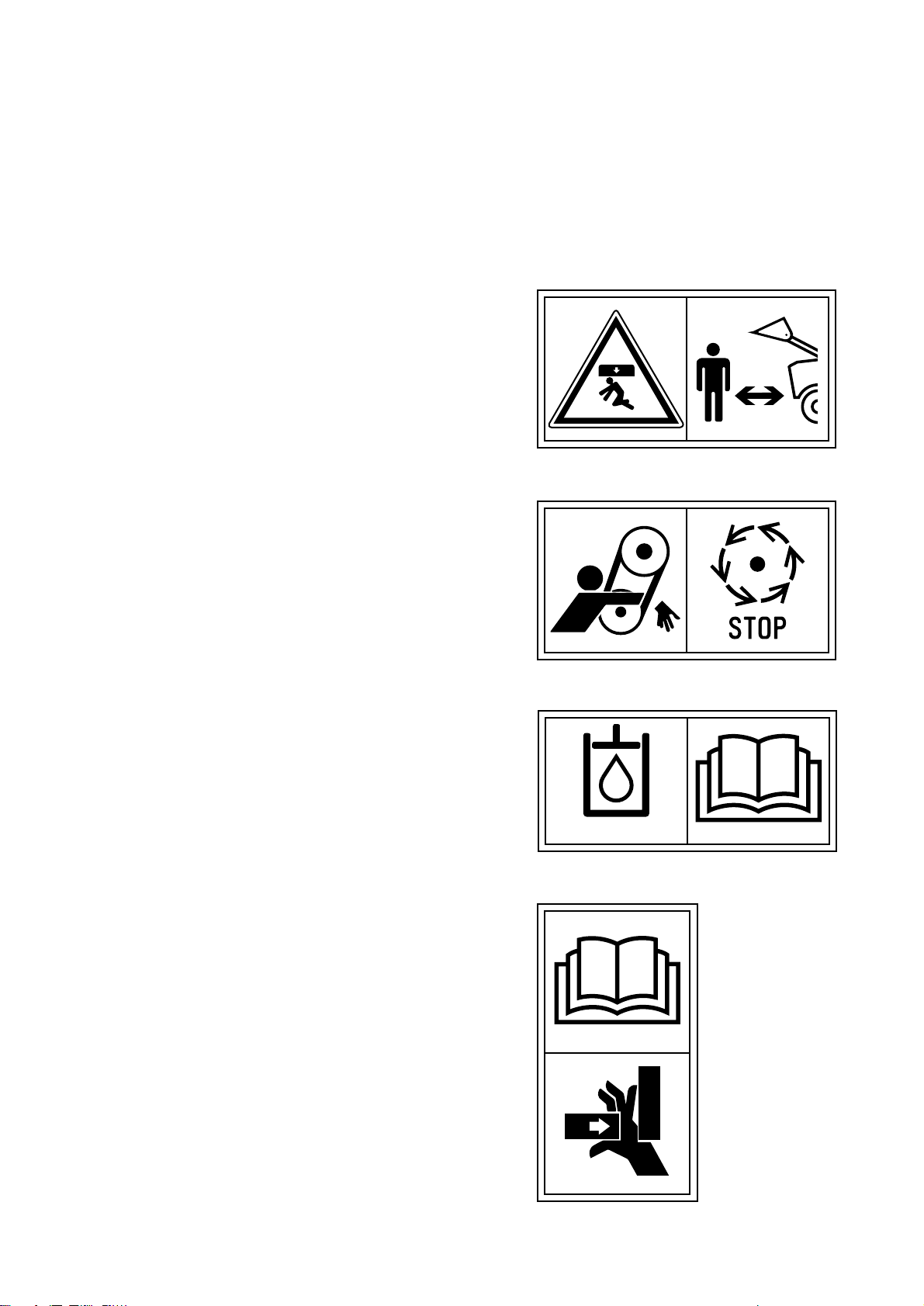

SAFETY, NOISE AND VIBRATION PLATES

2.1.2 PICTOGRAMS AND RELEVANT MEANINGS

The warning and danger plates applied onto the machine are accompanied or represented by pictograms.

The personnel in charge with the operation and maintenance of the machine must know the symbols contained in

the pictograms perfectly; the following description illustrates what they look like and their respective meanings.

DANGER IN THE WORK AREA

• Do not approach or stand in the equ ipment operating radius

when the boom and the bucket are raised.

RWA00020

DO NOT OPEN THE HOOD

• Do not open or remove the hood when the engine is running.

FILLING THE HYDRAULIC SYSTEM WITH

OIL

(Only for machines in which the synthetic biod egr adable oil

type HEES is used)

O VERTURNING THE FORKS

• When the forks are overturned for use or storage, be care-

ful to the grasping points, since hands and feet may be injured and even cut.

BIO-OIL

RWA00010

RWA34380

22

RWA35830

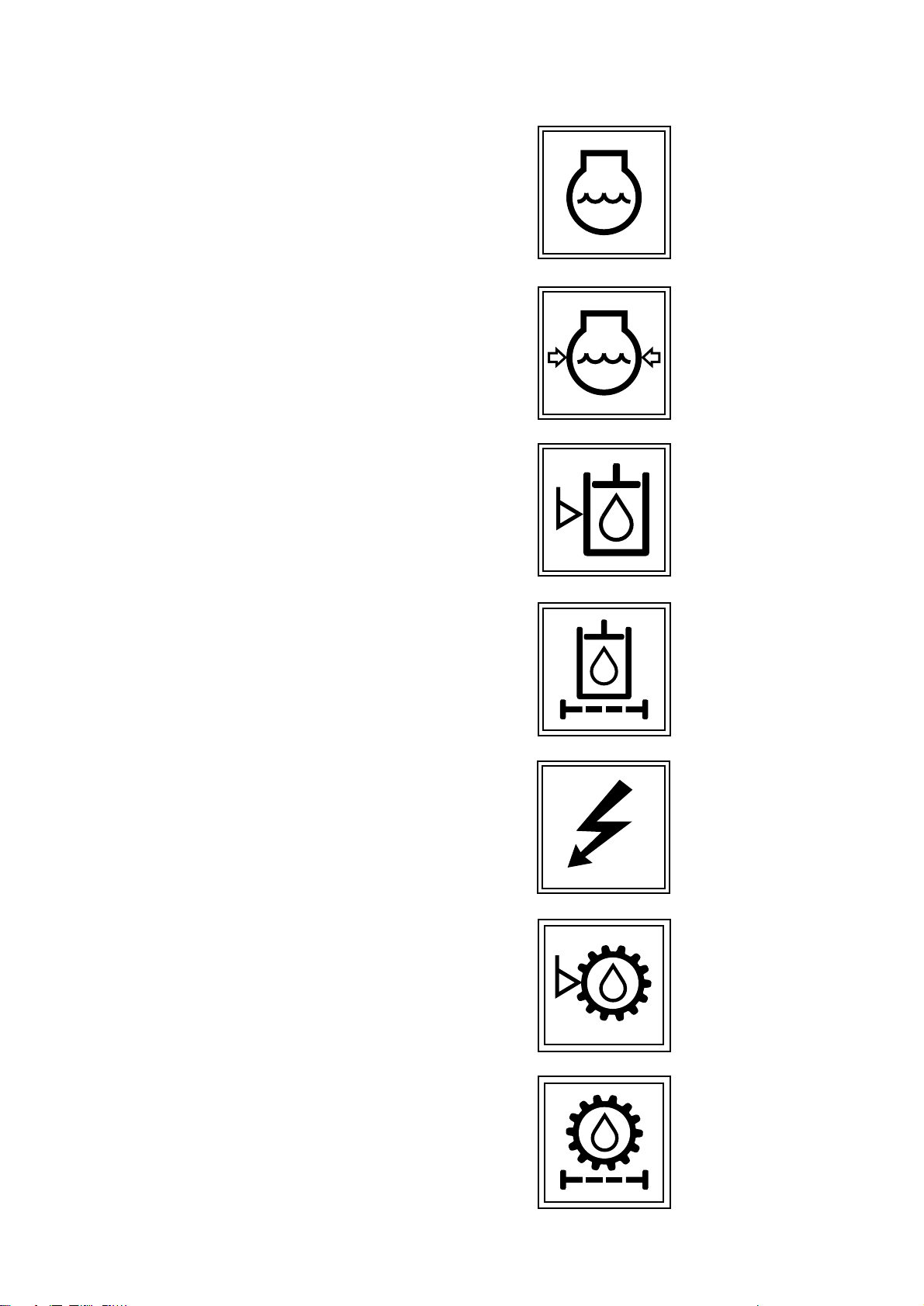

Page 25

CONSULT THE MANUAL

• Carefully read the contents of the manual before using the ma-

chine or performing maintenance operations.

HYDRAULIC OIL TOPPING UP

SAFETY, NOISE AND VIBRATION PLATES

RWA00030

REFUELLING

ENGINE LUBRICATING OIL FILTER

FUEL FILTER

RWA00050

D

RWA00040

RWA00080

D

ENGINE AIR SUCTION FILTER

RWA00060

RWA00090

23

Page 26

SAFETY, NOISE AND VIBRATION PLATES

ENGINE COOLANT

ENGINE COOLANT PRESSURE

HYDRAULIC OIL LEVEL

RWA00130

RWA00110

HYDRAULIC OIL FILTER

ELECTRIC OUTLET

TRANSMISSION OIL LEVEL

RWA00120

RWA00100

RWA00070

12 V

HYDRAULIC TRANSMISSION OIL FILTER

24

RWA00180

RWA00170

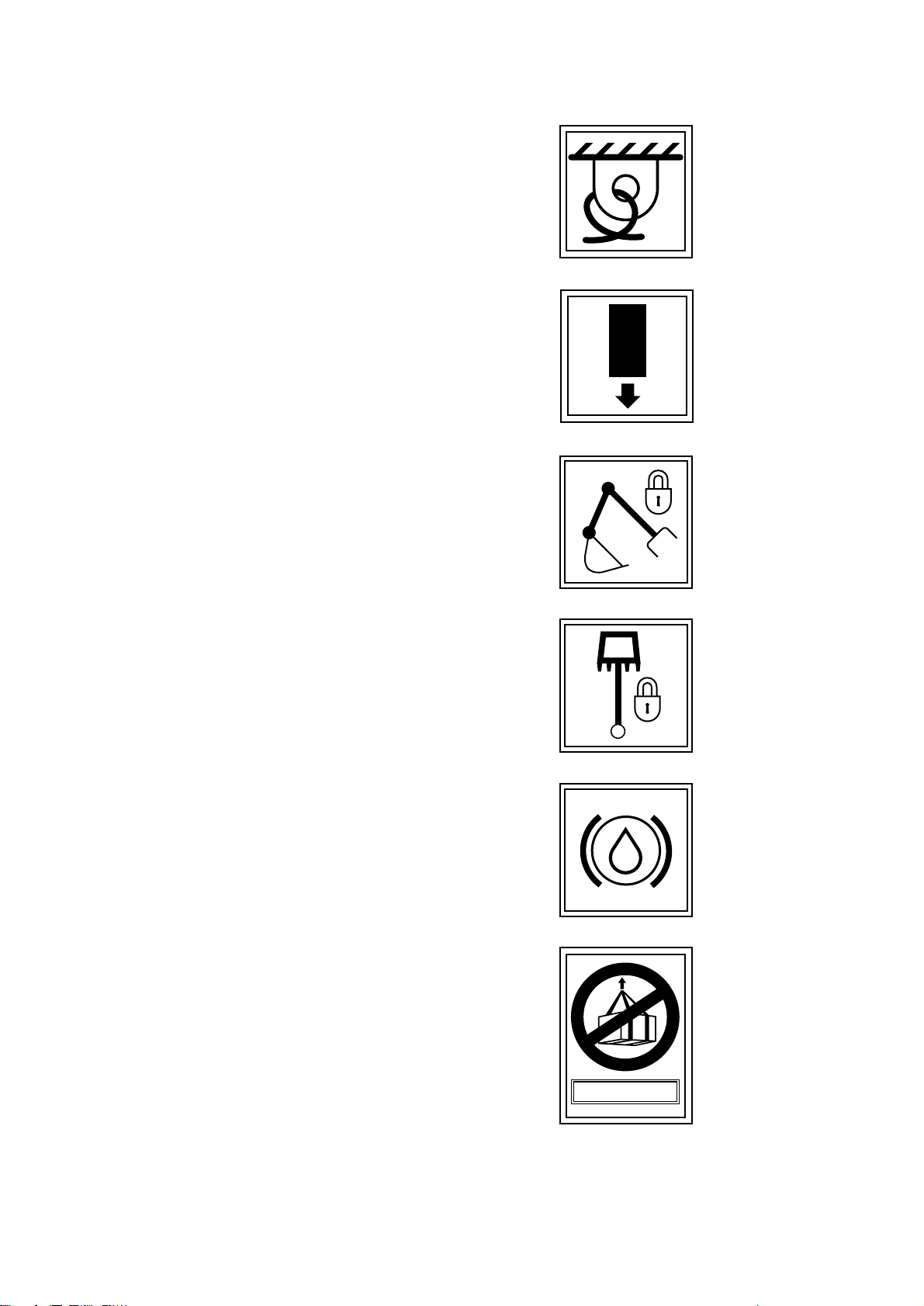

Page 27

ANCHORAGE POINT

EMERGENCY EXIT

BOOM LOCK

SAFETY, NOISE AND VIBRATION PLATES

RWA00200

RWA00190

SWING LOCK

BRAKE OIL

DO NOT LIFT MORE THAN 1000 kg

RWA00160

RWA00150

RWA00140

> 1000 Kg

RWA00210

25

Page 28

SAFETY, NOISE AND VIBRATION PLATES

2.1.3 POSITION OF THE NOISE PLATES ON MACHINES WITH CAB

• The noise plates must always be legible and in good conditions; for this reason, if they are dirty with dust, oil or

grease, it is necessary to clean them with a solution made of water and detergent.

Do not use fuel, petrol or solvents.

• If the plates are damaged, ask for new ones to Komatsu Utility or to your Komatsu Utility Dealer.

• In case of replacement of a component provided with a noise plate, make sure that this plate is applied also on

the new piece.

ISO 6396

NOISE OUTSIDE THE CAB

• This value indicates the noise level outside the machine and

refers to the noise perceived by persons in the vicinity of th e

work area.

NOISE INSIDE THE CAB

• This value indicates the maximum noise level perceived by the

operator’s ears inside the cab when this is completely closed.

2000/14/EC

2000/14/EC

RWA37710

RWA37720

26

ISO 6396

RWA37730

Page 29

SAFETY, NOISE AND VIBRATION PLATES

2.1.4 VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED

• According to the res ults of the test s carried out t o determine the vibrations transmi tted to the operator by the

machine, the upper limbs are subjected to vibrations lower than 2.5 m/sq.sec., while the seated part of the body

is subject to vibrations lower than 0.5 m/sq.sec.

27

Page 30

GENERAL PRECAUTIONS

2.2 GENERAL PRECAUTIONS

2.2.1 GENERAL SAFETY RULES

• Only trained and authorized personnel can use the machine and perform maintenance operations.

• Follow all the safety rules, precautions and instructions when using the machine or performing maintenance op-

erations.

• When working with other op erators or w hen the wor k site is often occup ied by other op erators, make sure that

everyone knows and understands all t he signals described above and, in any cas e, that everyone works in

such a way as to be able to see the machine and to be visible to the operator.

2.2.2 SAFETY DEVICES AND GUARDS

• Make sure that all the g uards and covers are in the correct posit ion. Have guards and covers chang ed or re-

paired if damaged. Neither use the machine without guards, nor rem ove the guards when the engine is running.

• Always use the proper safety devices to lock the machine when parking and fasten the safety belt.

• For the safety devices, see “3.1 SAFETY LOCKS”.

• For the safety belt, see “3.5.7 SAFETY BELT”.

• Do not remove the safety devices and always keep them in good operating conditions.

• Any improper use of the safety devices may result in serious injuries or even death.

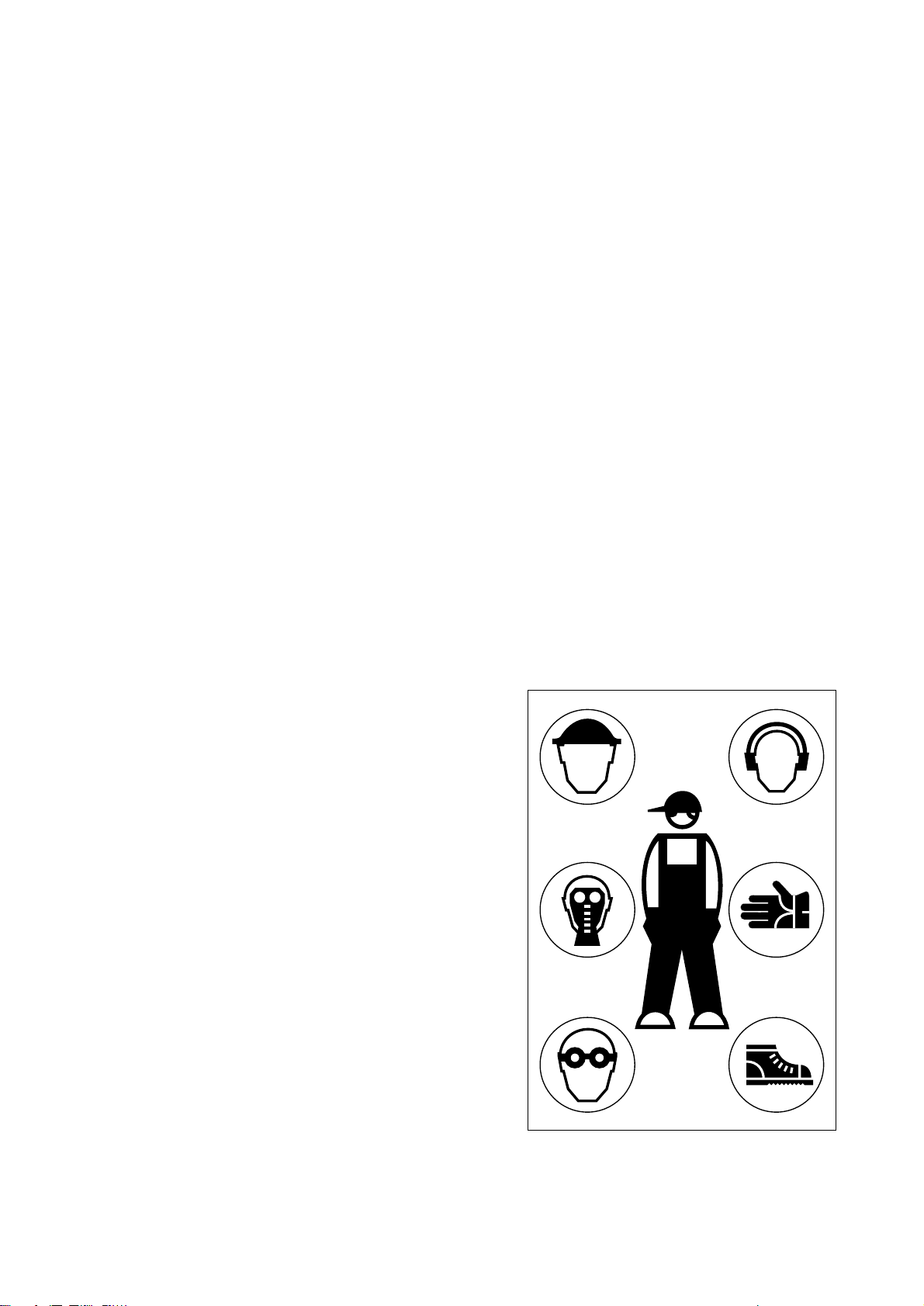

2.2.3 CLOTHING AND PERSONAL PRO-

TECTION ITEMS

• Do not wear large or loos e clothes, ri ngs and watches and d o

not approach the machi ne with lo ose long h air, since they can

get entagled in the moving parts of the machine and cause serious injuries or damage.

Avoid also wearing clothes dir ty with oi l or fuel, since they are

flammable.

• Wear a hard hat, goggles, safety shoes, mask, gloves and

headphones when ope rating the m achine or pe rforming maintenance operations.

• Always wear safety goggles, a hard hat and heavy gloves if

your job involves scattering metal chips or minute materials;

these precautions are particularly useful when driving the

equipment connection pi ns with a hammer and when blowing

compressed air into the air filter and the radiator to clean them.

During these opera tions, make also sure that no one i s sta nding or working near the machine without the necessary protections.

• When working for 8 hours with a noise level exceeding 90

dBA, it is necessar y to use headphones or ear plu gs and be

particularly careful, especially at the end of the work shift.

28

RWA00960

Page 31

GENERAL PRECAUTIONS

IMPORTANT

☞

2.2.4 UNAUTHORIZED MODIFICATIONS

• Any modification made without the authorization of Komatsu Utility can involve hazards.

• Before making a modification, consul t your Komatsu Utility Dealer. Komatsu Utility declines any respo nsibility

for injuries or damage caused by unauthorized modifications.

2.2.5 LEAVING THE OPERATOR’S SEAT

• When leaving the operator’s seat, even if temporarily, make

sure that t h e m ac h ine is in a safe positio n. (See “2.4.11 PARKING THE MACHINE”).

• Before leaving the operator’s seat, carry out the following oper-

ations in the sequence indicated below:

1 - Rest the equipment onto the ground.

2 - Connect the safety devices of the controls.

3 - Apply the parking brake.

4 - Shift the reversing gear lever to the neutral position.

5 - Stop the engine.

RWA31250

• If the machine is equipped with backhoe servo controls,

before leaving the operator seat always engage the control locking safety device by pressing the relevant switch,

see “3.3.5.2 MACHINE CONTROLS (Version with servo

controls)”, pos. 26.

If you have to go so far away that you will not be able to see the

machine, extract the ignition key.

RWA34810

RWA35030

29

Page 32

GENERAL PRECAUTIONS

2.2.6 GETTING ON AND OFF THE MA-

CHINE

• Do not jump on or off the machine, either when it is at rest and

when it is moving.

• When getting on or off the ma chine, always use the handles

and the safety ladders; get on and off t he machine very carefully.

• Never hold or rest on the steering wheel or the gearshift lever.

• Either when getting on and when get ting off the machine, al-

ways maintain three points of contact (holding or resting

points), in order to avoid losing your balance and falling down.

• Tighten the handle and ladder connect ion screws if they are

loose and clean the handl es and steps if they are dirty with oil

or grease.

Carefully clean the cab floor if it is dirty with oil , grease, mud

or rubble.

The cab

RWA25650

Safety canopy

2.2.7 CHECKING THE REAR-VIEW MIR-

RORS

• Make sure that the rear-view mirrors are clean and correcly

positioned; they must allow the opera tor to see the rear of th e

machine with no need to move the chest with respect to the

normal work position.

• If the rear-view mirrors should move or break during work, stop

the machine immediately and fasten or change them.

• Working without checking the back of the machi ne is danger-

ous, since the machine may hit persons who are in cautiously

standing in the wor k area, fixed obstacl es or manoeu vring vehicles.

2.2.8 PREVENTING FIRES DUE TO FUEL

AND OIL

Fuel, oil and some types of antifreeze can be easily ignited if

they get in contact with a flame. Fuel is par ticularly flammable

and therefore extremely hazardous.

• Keep any naked flame away from flammable fluids.

• Stop the engine and do not smoke when refuelling.

• Top up with fu el and oil only after stopping the engine and in

well ventilated areas.

• Top up wi th fuel an d oil in a well deli mited area a nd do not al-

low unauthorized persons to approach.

RWA25760

RWA25860

RWA00970

30

Page 33

• When refuelling, hold the fuel gun firmly and keep it constantly

in contact with the filler until you have finished, in order to

avoid sparks due to static electricity.

• After topping up, tighten the fuel and oil safety caps securely.

• Do not fill the tank completely, in order to leave room for the fu-

el to expand.

• In case some fuel is spilled, wipe it up immediately.

2.2.9 PREVENTING BURNS

• If the engine coolant, the engi ne oil and the hydraulic oil are

hot, use heavy cloths and wear gloves, heavy clothing and

safety goggles before carryi ng out any check or touching the

hot parts.

• Before checking the coolant level, stop the en gine and let the

fluid cool down.

If a check is necessary du e to the overheating of the engine,

slowly loosen the radia tor plug to release any residual pressure before removing it. The hot fluid that spurts out may

cause serious burns.

• Before checking the engine oil and hydraulic circuit oil level,

stop the engine and l et the oil cool down. The hot oil that can

be sprayed out of the tank may cause serious burns.

GENERAL PRECAUTIONS

RWA00980

RWA00990

2.2.10 PREVENTING DAMAGE DUE TO ASBESTOS POWDER

• Asbestos powder can be hazardous to your health if it is in-

haled.

• If you handle materials contai ning asbes tos fib ers, keep to the

instructions given below:

1 - Do not use compressed air, b ut only aspirators to clean the

machine and make sure that the room in which you are

working is properly ventilated.

2 - Use low-pressure water to keep down the dust when clean-

ing.

3 - If there is danger that there may be asbestos powder in the

air, operate the machine with the wind to your back whenever possible.

4 - Even if the cab provides suitable protection, use an ap-

proved and homologated respirator.

5 - The powder gathered during the cleaning operations must

be dampened and put in a sealed and marked container, so

that it can be safely disposed of according to the regulations in force.

RWA01000

RWA01010

31

Page 34

GENERAL PRECAUTIONS

2.2.11 PREVENTING D AMAGE CA USED BY THE WORK EQUIPMENT

• Do not stand within or approach the operating radius of the

work equipment, even when the operator is on board th e machine and the engine is running.

• Do not stand or work unde r the arms or the articul ati ons whe n

the arms are lifted, if you are not sure that the safety locks

have been duly engaged.

• Do not carry out any operation requiring the lifting of the arms,

if you are not sure that the locks are correctly positioned and

coupled to the arms.

2.2.12 FIRE EXTINGUISHERS AND FIRST AID KIT

• Make sure that fire extinguishers have been provided and

check their position.

• Periodically make sure that th e fire extinguishers are loaded

and that you know how to use them.

RWA01020

• Find out where the first aid kit has been located.

• Periodically make sure that the first aid kit conta ins the neces-

sary disinfectants, bandages, medicins, etc.

• It is necessary to know what to do in case of fire.

• Make sure that you have the phone numbers of the persons or

structures you may need to contact in case of an emergency at

hand (either at the wor k site and where maintenance operations are performed).

RWA01030

2.2.13 PRECAUTIONS CONCERNING THE CAB STRUCTURE

• If the cab is inadvertently hit or the machine overturns during work, the cab may be damaged with cons eq uen t

reduction of its stiffness and of the safety that must be guaranteed to the operator (Rops/Fops homologation).

Contact Komatsu Utility or an Authorized Komatsu Utility Dealer to have the cab structure and resistance

checked in case of impact or damage.

2.2.14 PRECAUTIONS CONCERNING THE EQUIPMENT

• When installing and using optional equipment, carefully read the relevant instruction manual and keep to the in-

dications given therein.

• Do not use optional o r special equipment without the authorization of Komatsu Utility or th e Komatsu Utility

Dealer.

The installation and us e of unauthori zed equipment may create safety problems and ad versely affect the efficiency and life of the machine.

• Komatsu Utility cannot be held li able for any injury, accident, product failure resulting fr om the installa tion and

use of unauthorized equipment.

32

Page 35

PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE

2.3 PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE

2.3.1 SAFETY ON THE WORK SITE

• Before starting the engine, thoroughly check the area for any

unusual condition of the ground due to which work may be

dangerous.

• Check the conditions of the ground at the work site an d before

starting the engine defin e the work pl an and the best and s afest operating procedure.

• Make the ground surface as level as possible before carr ying

out any operation.

• In case of work on the road, protect pedestr ians and cars by

designating a person for work site traffic duty and install fences

around the work site.

• If water lines, gas lines, and telephone or high-voltage electr i-

cal lines are locate d under the work si te, contact the relevant

utility company in order to find out their exact positions or to

make them inneffective until the end of the operations. Be

careful not to sever or damage any of these lines.

RWA00220

• Check the depth and flow of water before operating in water or

on river banks.

2.3.2 FIRE PREVENTION