Page 1

WEBM000404

Page 2

40-28

PC15R-8

Page 3

CONTENTS

Page

10 STRUCTURE AND FUNCTION........................................................................................ 10-1

20 TESTING AND ADJUSTING ............................................................................................ 20-1

30 DISASSEMBLY AND ASSEMBLY.................................................................................. 30-1

40 MAINTENANCE STANDARD........................................................................................... 40-1

WB91R-2 WB93R-2

00-1

Page 4

PAGE INTENTIONALLY

LEFT BLANK

Page 5

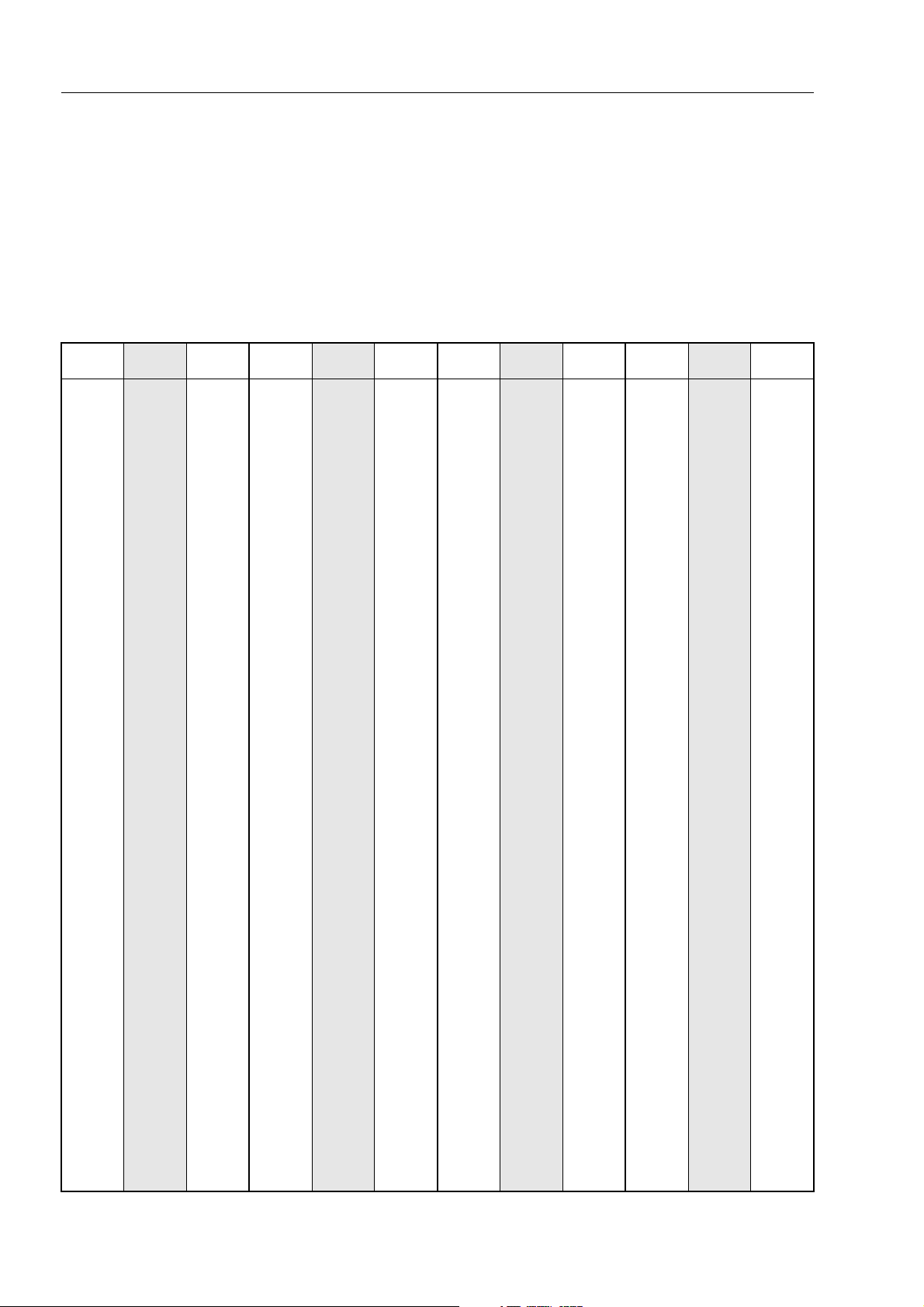

The affected pages are indicated by the use of the

following marks. It is requested that necessary actions be taken to these pages according to table below.

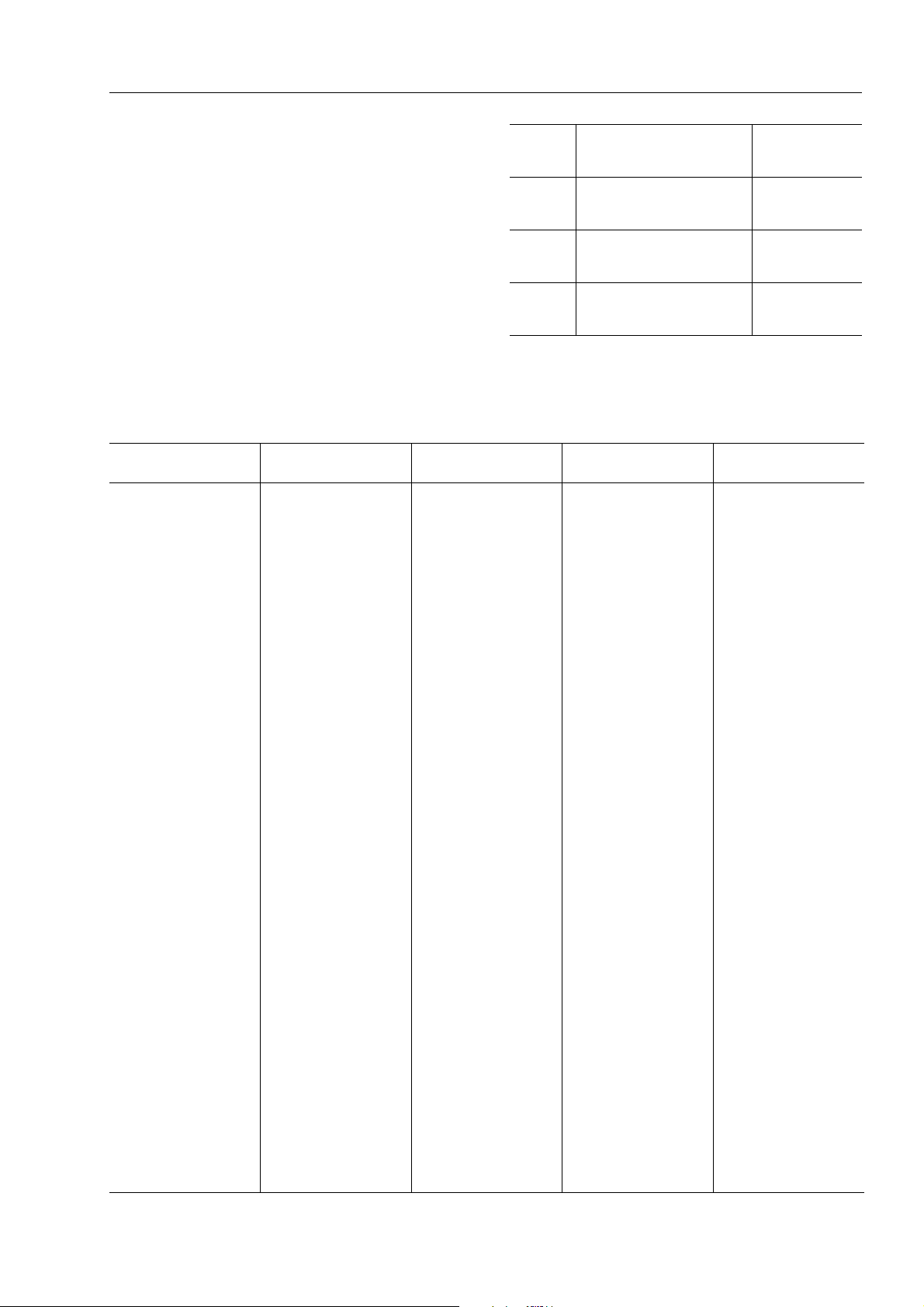

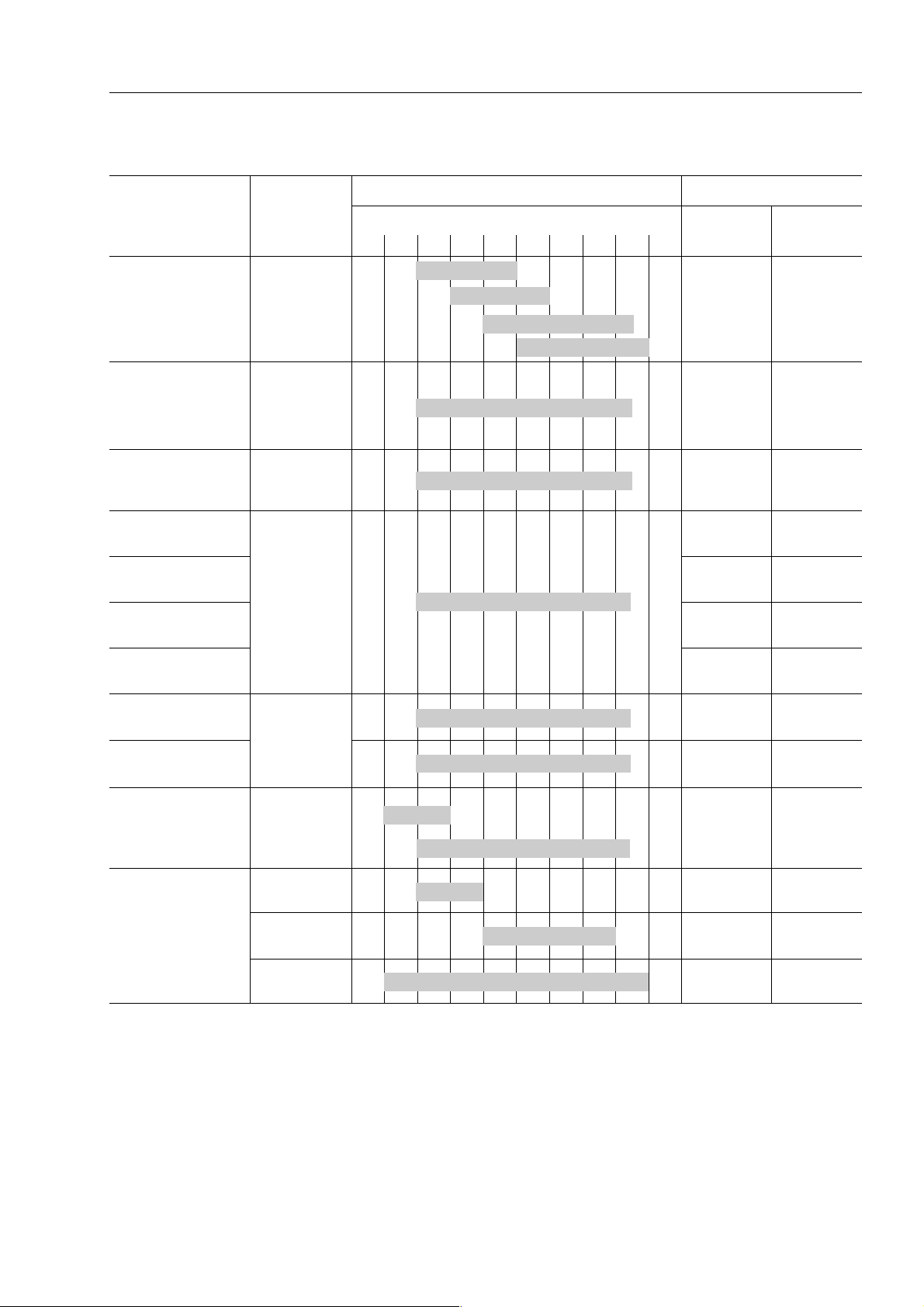

REVISED PAGES

Mark Indication Action required

❍

Page to be newly Add

Mark Page

00-1

00-2

00-2-1

00-2-2

●

00-3

00-4

00-5

00-6

00-7

00-8

00-9

00-10

00-11

00-12

00-13

00-14

00-15

00-16

00-17

00-18

00-19

00-20

00-21

00-22

10-1

10-2

10-3

10-4

10-5

10-6

10-7

10-8

10-9

10-10

10-11

10-12

10-13

10-14

10-15

10-16

Time of

revision

Mark Page

10-17

10-18

10-19

10-20

10-21

10-22

10-23

10-24

10-25

10-26

10-27

10-28

10-29

10-30

10-31

10-32

10-33

10-34

10-35

10-36

10-37

10-38

10-39

10-40

10-41

10-42

10-43

10-44

10-45

10-46

10-47

10-48

10-49

10-50

10-51

10-52

10-53

10-54

10-55

10-56

10-57

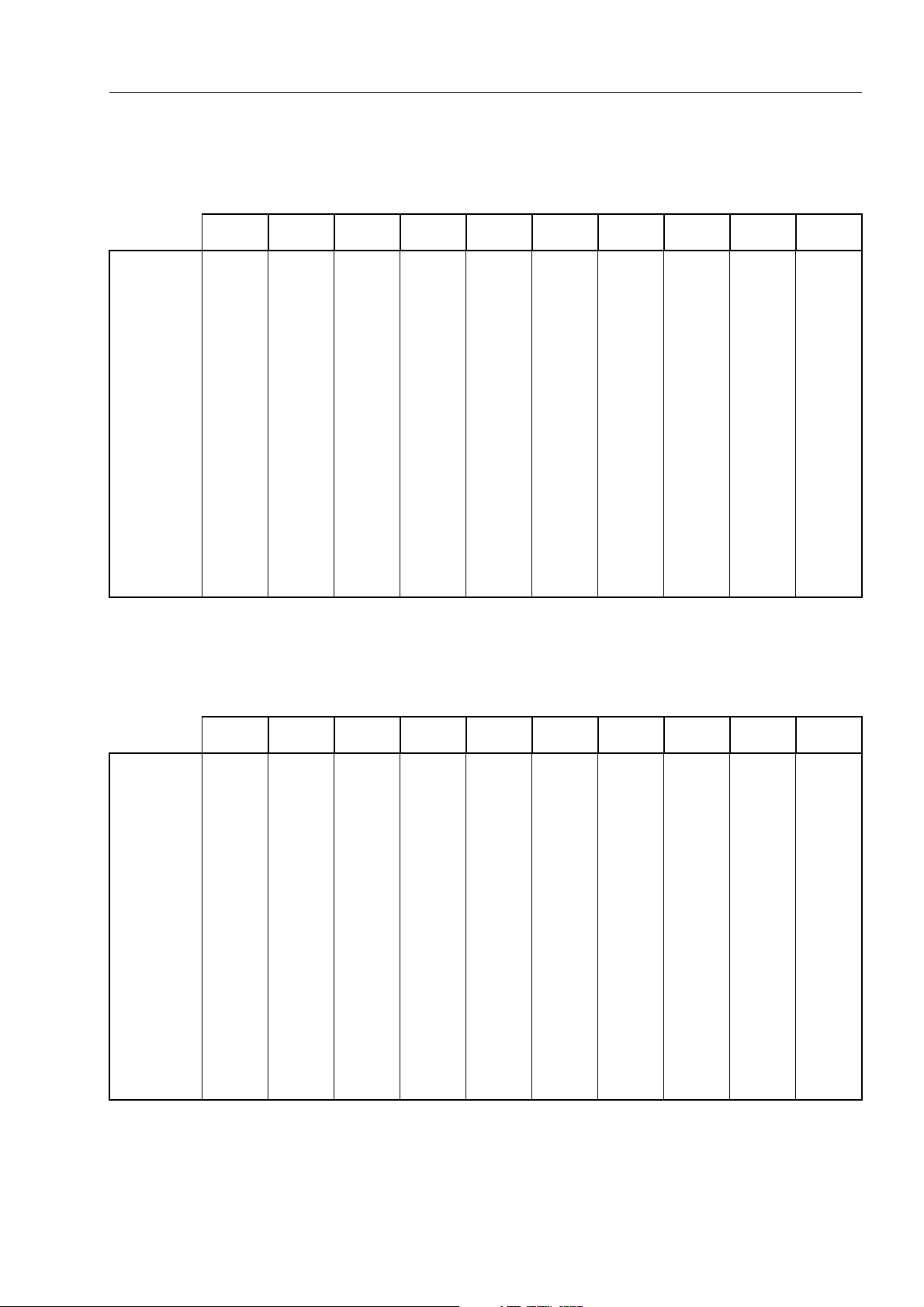

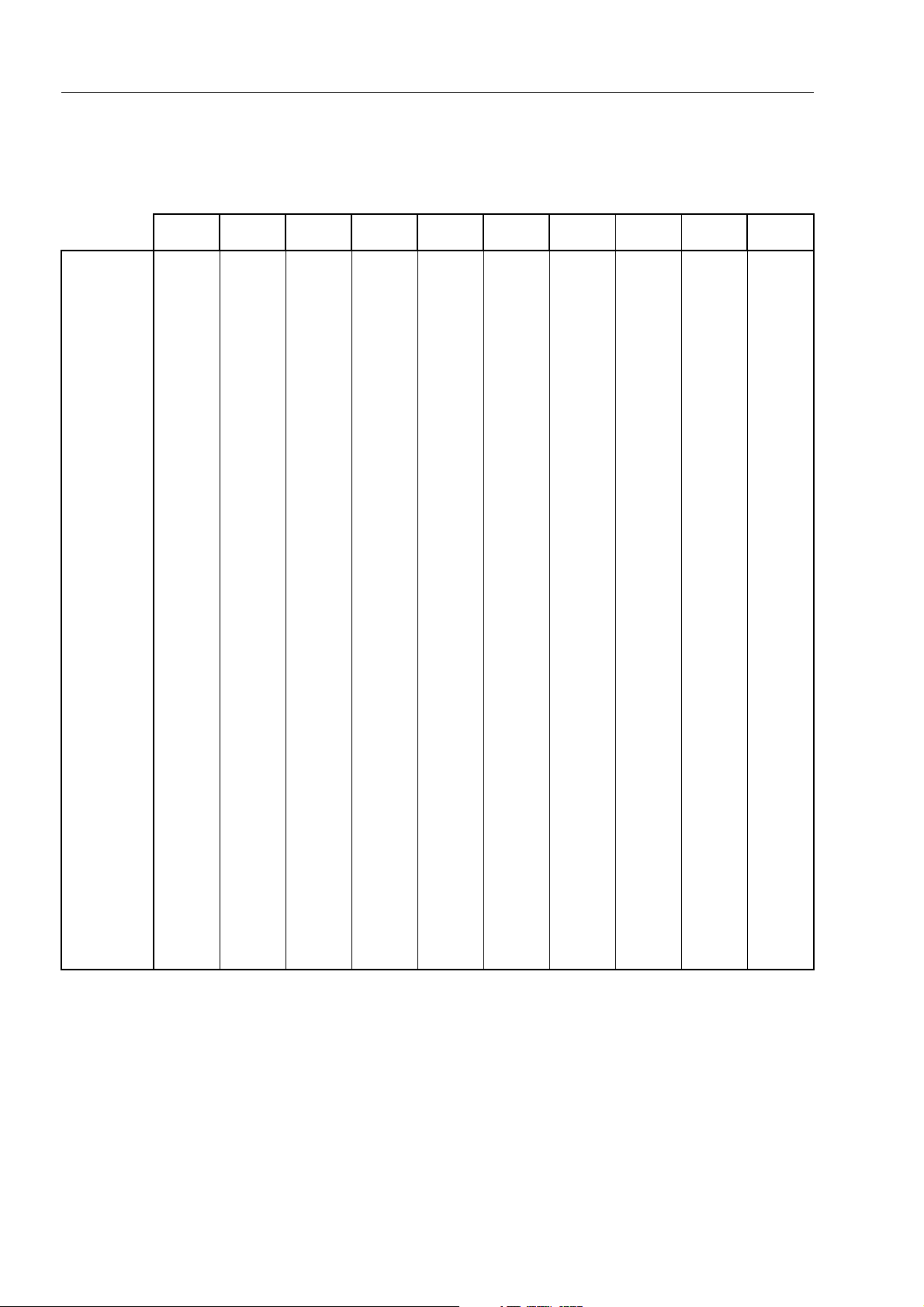

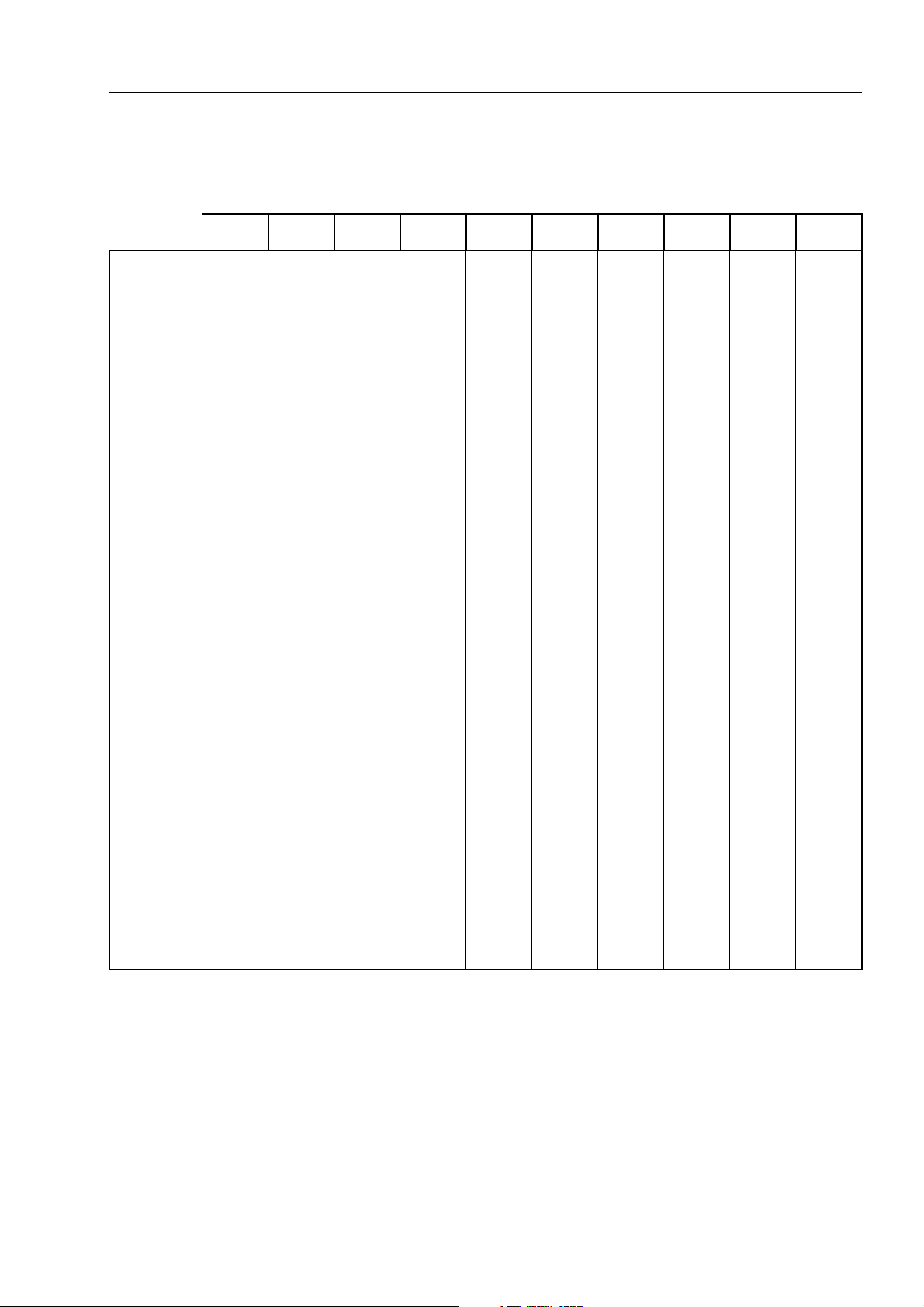

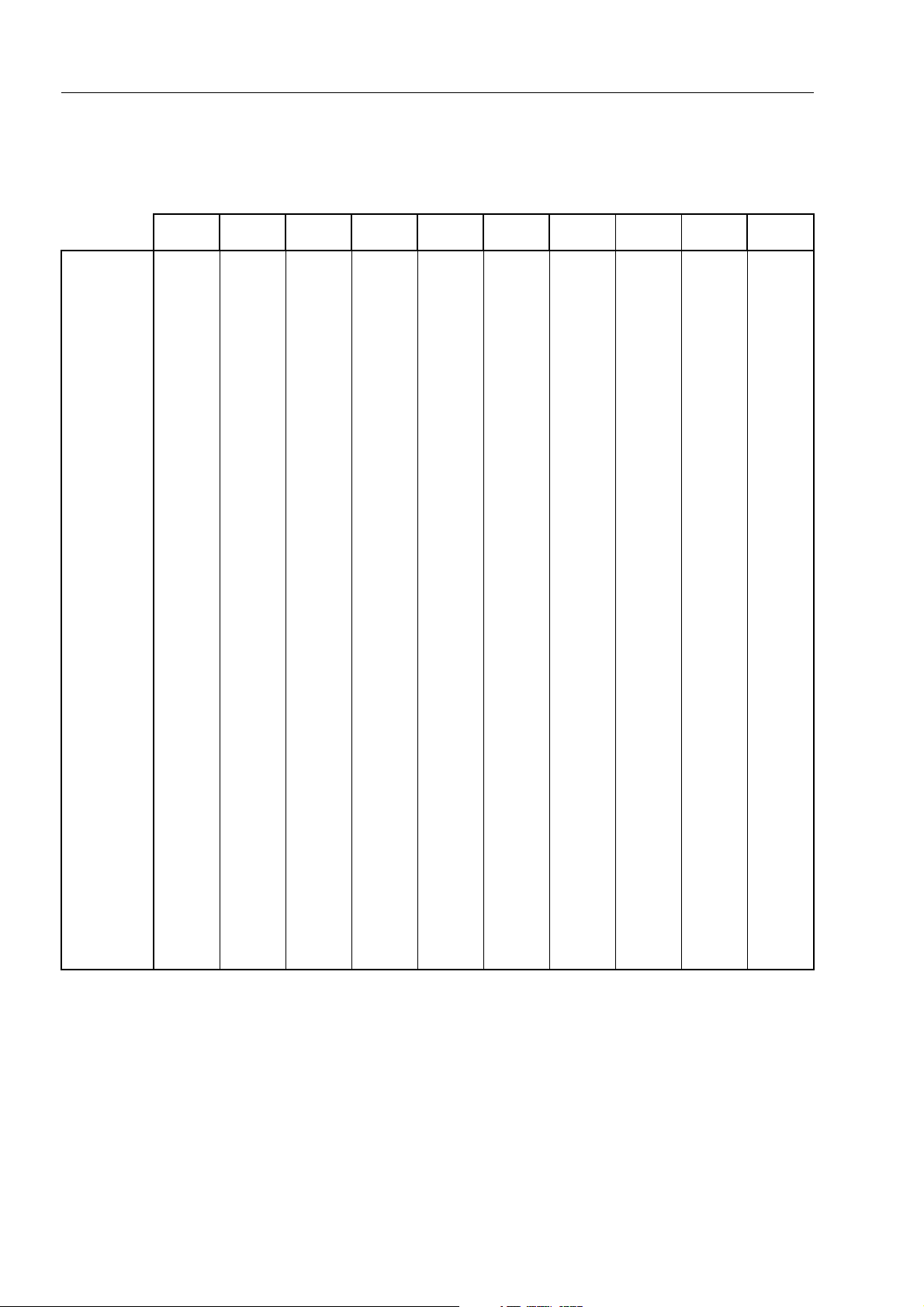

LIST OF REVISED PAGES

Time of

revision

Mark Page

10-58

10-59

10-60

10-61

10-62

10-63

10-64

10-65

10-66

10-67

10-68

10-69

10-70

10-71

10-72

10-73

10-74

10-75

10-76

10-77

10-78

10-79

10-80

10-81

10-82

10-83

10-84

10-85

10-86

10-87

10-88

10-89

10-90

10-91

10-92

10-93

10-94

10-95

10-96

20-1

●

Page to be replaced Replace

( ) Page to b e delete Discar d

Pages having no marks are those previously revised or

made additions.

Time of

revision

Mark Page

20-2

20-3

20-4

20-5

20-6

20-7

20-8

20-9

20-10

20-11

20-12

20-13

20-14

20-15

20-16

20-17

20-18

20-19

20-20

20-21

20-22

20-23

20-24

20-25

20-26

20-27

20-28

20-29

20-30

20-31

20-32

20-33

20-34

20-35

20-36

20-37

20-38

20-39

Time of

revision

Mark Page

20-43

20-44

20-45

20-46

20-47

20-48

20-49

20-50

20-51

20-52

20-53

20-54

20-55

20-56

20-57

20-58

20-59

20-60

20-61

20-62

20-63

20-64

20-65

20-66

20-67

20-68

20-69

20-70

20-71

20-72

20-73

20-74

20-75

20-76

20-77

20-78

20-79

20-80

Time of

revision

20-40

20-41

20-42

30-1

●

30-2

WB91R-2 WB93R-2

00-2-1

Page 6

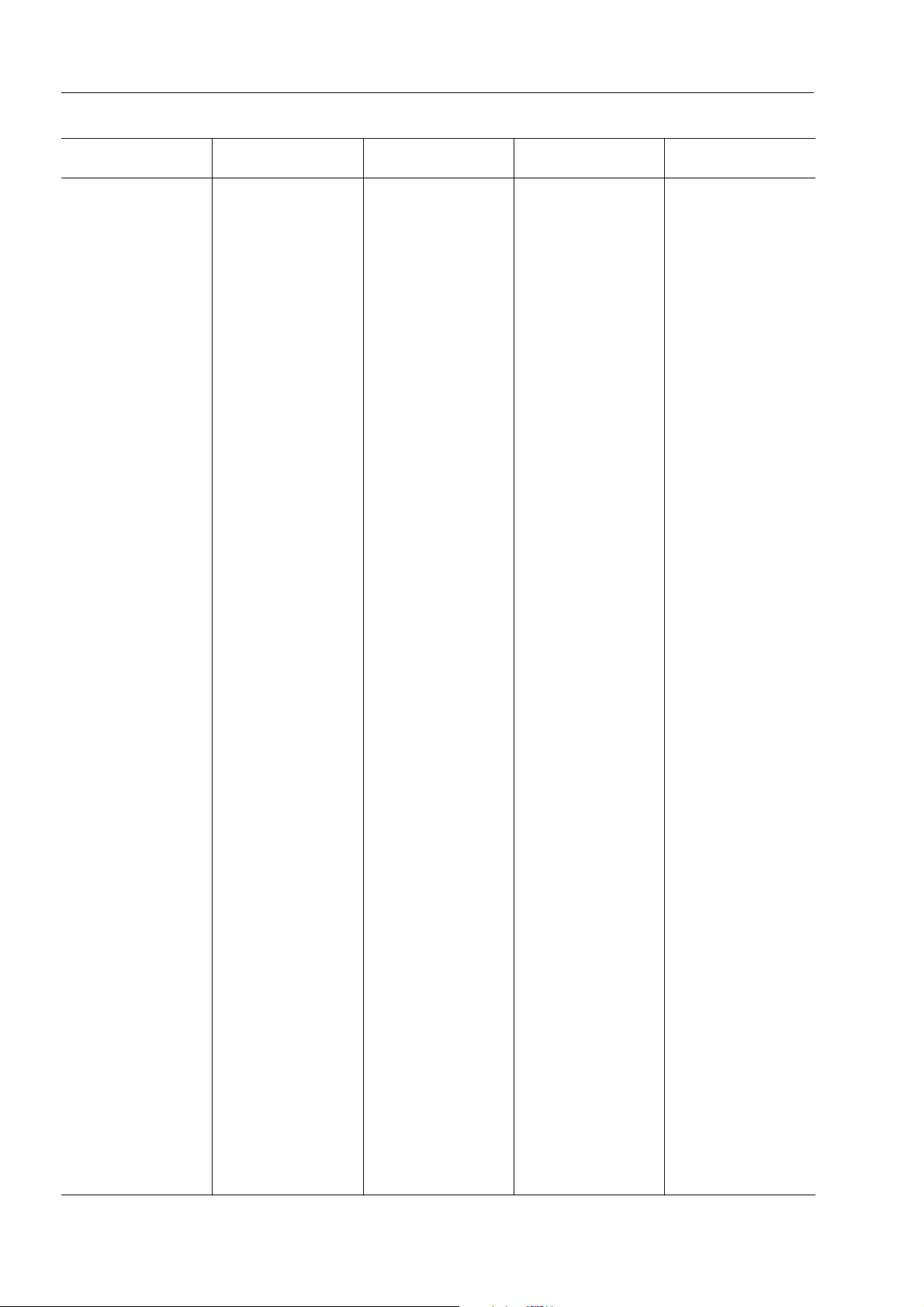

REVISED PAGES

Mark Page

30-3

30-4

30-5

30-6

30-7

30-8

30-9

30-10

30-11

30-12

30-13

30-14

30-15

30-16

30-17

30-18

30-19

30-20

30-21

30-22

30-23

30-24

30-25

30-26

30-27

30-28

30-29

30-30

30-31

30-32

30-33

30-34

30-35

30-36

30-37

30-38

30-39

30-40

30-41

30-42

30-43

30-44

30-45

30-46

30-47

30-48

30-49

30-50

30-51

30-52

30-53

30-54

30-55

30-56

30-57

30-58

30-59

30-60

30-61

Time of

revision

Mark Page

30-62

30-63

30-64

30-65

30-66

30-67

30-68

30-69

30-70

30-71

30-72

30-73

30-74

30-75

30-76

30-77

30-78

30-79

30-80

30-81

30-82

30-83

30-84

30-85

30-86

30-87

30-88

30-89

30-90

30-91

30-92

30-93

30-94

30-95

30-96

30-97

30-98

30-99

30-100

30-101

30-102

30-103

30-104

30-105

30-106

30-107

30-108

30-109

30-110

30-111

30-112

30-113

30-114

30-115

30-116

30-117

30-118

30-119

30-120

Time of

revision

Mark Page

30-121

30-122

30-123

30-124

30-125

30-126

30-127

30-128

30-129

30-130

30-131

30-132

30-133

30-134

30-135

30-136

30-137

30-138

30-139

30-139

❍

30-139

❍

30-139

❍

30-139

❍

❍

30-139

❍

30-139

30-139

❍

❍

30-139

❍

30-139

❍

30-139

❍

30-139

❍

30-139

❍

30-139

❍

30-139

30-140

30-141

30-142

30-143

30-144

30-145

30-146

30-147

30-148

30-149

30-150

30-151

30-152

30-153

30-154

30-155

30-156

30-157

30-158

30-159

30-160

30-161

30-162

30-163

30-164

30-165

Time of

revision

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

Mark Page

30-166

30-167

30-168

30-169

30-170

30-171

30-172

30-173

30-174

30-175

30-176

30-177

30-178

30-179

30-180

30-181

30-182

30-183

30-184

30-185

30-186

30-187

30-188

30-189

30-190

30-191

30-192

30-193

30-194

30-195

30-196

30-197

30-198

30-199

30-200

30-201

30-202

30-203

30-204

30-205

30-206

30-207

30-208

30-209

30-210

30-211

30-212

30-213

30-214

30-215

30-216

30-217

30-218

30-219

30-220

30-221

30-222

30-223

30-224

Time of

revision

Mark Page

30-225

30-226

30-227

30-228

30-229

30-230

30-231

30-232

30-233

30-234

30-235

30-236

30-237

30-238

40-1

40-2

40-3

40-4

40-5

40-6

40-7

40-8

40-9

40-10

40-11

40-12

40-13

40-14

40-15

40-16

40-17

40-18

40-19

40-20

40-21

40-22

40-23

40-24

40-25

40-26

40-27

40-28

40-29

40-30

40-31

40-32

40-33

40-34

40-35

40-36

40-37

40-38

40-39

40-40

40-41

40-42

Time of

revision

00-2-2

WB91R-2 WB93R-2

Page 7

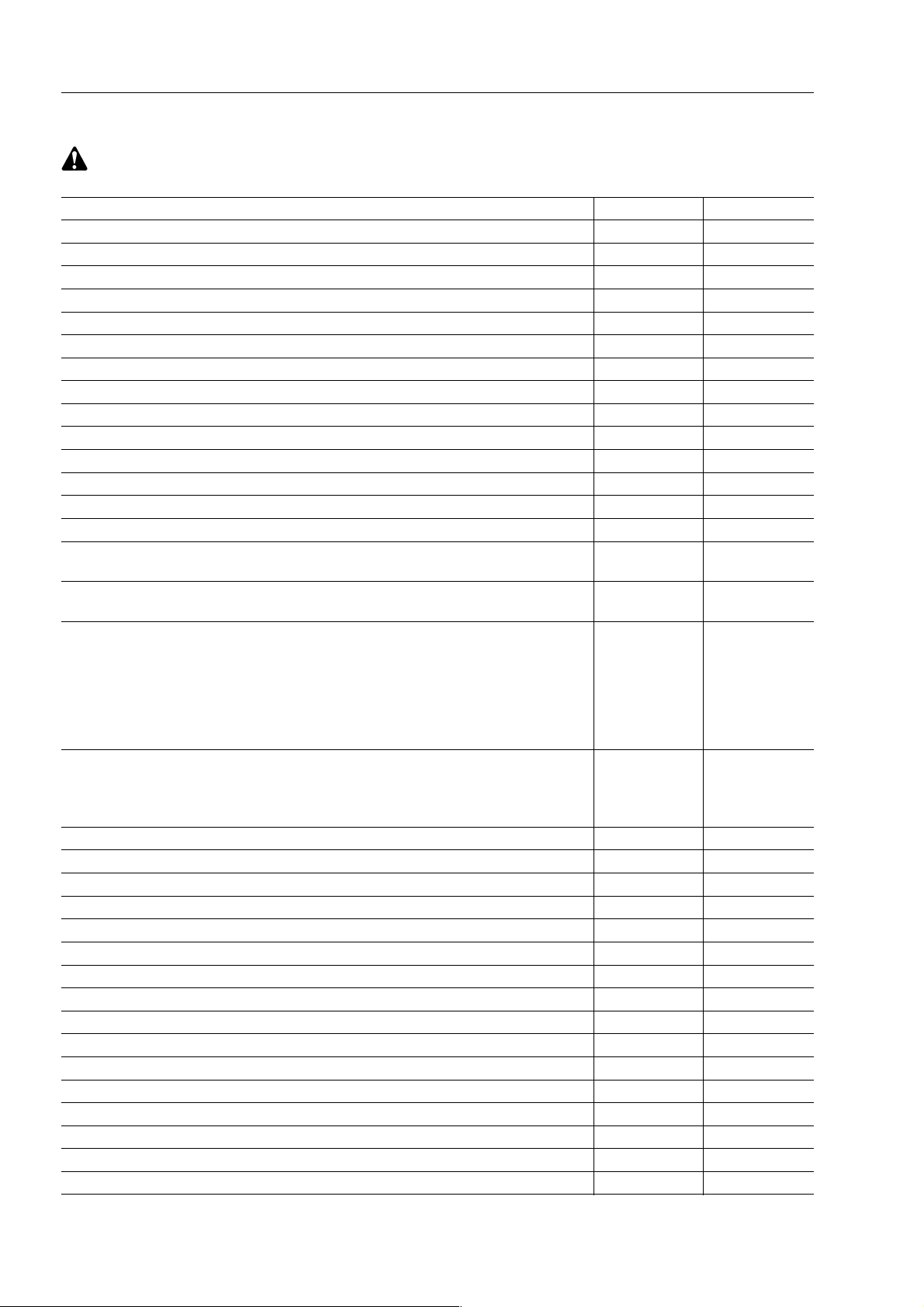

IMPORTANT SAFETY NOTICE

Proper service and repair is extremely important for the safe operation of your machine.

The service andrepair techniquesrecommended byKomatsu Utility anddescribe in thismanual areboth effective and safe methods of operation.Some of these operations require the use of tools speciallydesigned

by Komatsu Utility for the purpose.

To prevent injury to workers, the symbols and are used to mark safety precautions in this manual.

The cautions accompanyingthese symbolsshould alwaysbe carefullyfollowed. Ifany dangerarises ormay

possibly arise, first consider safety, and take necessary steps to face.

SAFETY

GENERAL PRECAUTIONS

Mistakes in operation extremely dangerous.

Read all the Operation and Maintenance Manual carefully BEFORE operating the machine.

1. Before carrying out anygreasing or repairs,read all

theprecautions writtenon thedecals whichare suck

on the machine.

2. Whencarrying outany operation, alwayswear safety shoes and helmet. Do not wear loose work

clothes, or clothes with buttons missing.

• Always wear safety glasses when hitting parts

with a hammer.

• Always wear safety glasses when grinding

parts with a grinder, etc.

3. If welding repairs are needed, always have a

trained, experienced welder carry out the work.

When carryingout welding work, alwayswear welding gloves, apron, glasses, cap and other clothes

suited for welding work.

4. When carrying out any operation with two or more

workers, always agree on the operating procedure

before starting. Always inform your fellow workers

before starting any step of the operation. Before

starting work, hang UNDER REPAIR signs on the

controls in the operator’s compartment.

5. Keepall toolsin goodcondition andlearn thecorrect

way to use them.

6. Decide a place in the repair workshop to keep tools

and removedparts. Always keep thetools andparts

in their correct places. Always keep the work area

clean andmake surethat thereis nodirt or oilon the

floor.

Smoke onlyin the areasprovided forsmoking. Never smoke while working.

PREPARATIONS FOR WORK

7. Before adding or making any repairs, park the machine onhard, level ground,and blockthe wheels to

prevent the machine from moving.

8. Before starting work, lower outrigger, bucket or any

other work equipment to the ground. If this is not

possible, use blocksto prevent thework equipment

from falling down. In addition, be sure to lock all the

control levers and hang warning sign on them.

9. When disassembling or assembling, support the

machine withblocks, jacks or standsbefore starting

work.

10. Remove allmud andoil fromthe stepsor otherplaces used to get on and off the machine. Always use

thehandrails, laddersor stepswhen gettingon oroff

the machine.

Never jump on or off the machine.

If it is impossible to use the handrails, ladders or

steps, use a stand to provide safe footing.

PRECAUTIONS DURING WORK

11. When removing the oil filler cap, drain plug or hydraulic pressure measuring plugs, loosen them

slowly to prevent the oil from spurting out.

Before disconnecting or removing components of

the hydraulic circuit and engine cooling circuit, first

remove the pressure completely from the circuit.

12. The water and oilin thecircuits are not hot whenthe

engine in stopped, so be careful not to get burned.

Wait for the oil water to cool before carrying out any

work on the cooling water circuits.

13. Before startingwork, removethe leadsfrom the battery. Always remove thelead from the negative (– )

terminal first.

SAFETY

WB91R-2 WB93R-2

00-3

Page 8

SAFETY

14. When raising heavy components, use a hoist or

crane. Check that the wire rope, chains and hooks

are free from damage.

Always use lifting equipment which has ample capacity. Install the lifting equipment at the correct

places.

Use a hoist or crane and operate slowly to prevent

the component from hitting any other part.

Do not work with any part still raised by the hoist or

crane.

15. When removing covers which are under internal

pressure or under pressure from a spring, always

leave twobolts inposition on oppositesides. Slowly

release thepressure, then slowly loosenthe boltsto

remove.

16. When removing components, be careful not to

break or damage the wiring.

Damage wiring may cause electrical fires.

17. When removingpiping, stopthe fuelor oil fromspillingout. Ifany fuelor oildrips onto thefloor, wipeit up

immediately.

Fuel or oil on the floor can cause you to slip, or can

even start fires.

18. As ageneral rule,do notuse gasolineto washparts.

In particular, use only the minimum of gasoline

when washing electrical parts.

19. Be sure to assemble all parts again in their original

places. Replace any damage parts with new parts.

When installing hoses and wires, be sure that they

will not be damaged by contact with other parts

when the machine is being operated.

20. When installing high pressure hoses, make sure

that they are not twisted. Damaged tubes are dangerous, so be extremely careful when installing

tubes for high pressure circuits. Also, check that

connecting parts are correctly tightened.

21. When assembling or installing parts, always use

specified tightening torques.

When installing the parts which vibrate violently or

rotate at high speed, be particulary careful to check

that they are correctly installed.

22. When aligning two holes, never insert your fingers

or hand.

23. When measuring hydraulicpressure, checkthat the

measuring toolis correctlyassembled beforetaking

any measurement.

24. Take sure when removing or installing wheels.

00-4

WB91R-2 WB93R-2

Page 9

FOREWORD

FOREWORD

This shop manual has been prepared as an aid to improve the quality ofrepairs by giving the operator an accurate

understanding of the product and by showing him the correct way to perform repairs and make judgements. Make sure

you understand the contents of this manual and use it to full effect at every opportunity.

This shop manual mainly containsthe necessary technical informationfor operations performed in a service workshop.

The manual is dividedinto chapters on each maingroup of components;these chapters are further divided intothe

following sections.

STRUCTURE AND FUNCTION

This sectionexplains thestructure andfunction of eachcomponent. It serves notonly togive an understanding

of the structure, but also serves as reference material for troubleshooting.

TESTING AND ADJUSTING

This sections explains checks to be made before and after performing repairs, as well as adjustments to be

made at completion of the checks and repairs.

Troubleshooting charts correlating «Problems» to «Causes» are also included in this section.

DISASSEMBLY AND ASSEMBLY

This section explains the order to be followed when removing, installing, disassembling or assembling each

component, as well as precautions to be taken for these operations.

MAINTENANCE STANDARD

This section gives the judgement standards when inspecting disassembled parts.

NOTE

The specifications contained in this shop manual are subject to change at any time and without any notice.

Contact your Komatsu Utility distributor for the latest information.

WB91R-2 WB93R-2

00-5

Page 10

HOW TO READ THE SHOP MANUAL

HOW TO READ THE SHOP MANUAL

VOLUMES

Shop manual are issued as a guide to carry out repairs.

These various volumes are designed to avoid duplicating the same information.

DISTRIBUTION AND UPDATING

Any additions, amendments or other changes will be

sent to Komatsu Utility distributors.

Get themost up-to-dateinformation before you startany

work.

FILING METHOD

1. See the page number on the bottom of the page.

File the pages in correct order.

2. Following examplesshow you howto readthe page

number.

Example:

10

-

3

Item number (10. Structure and

Function)

Consecutive page number for each

item

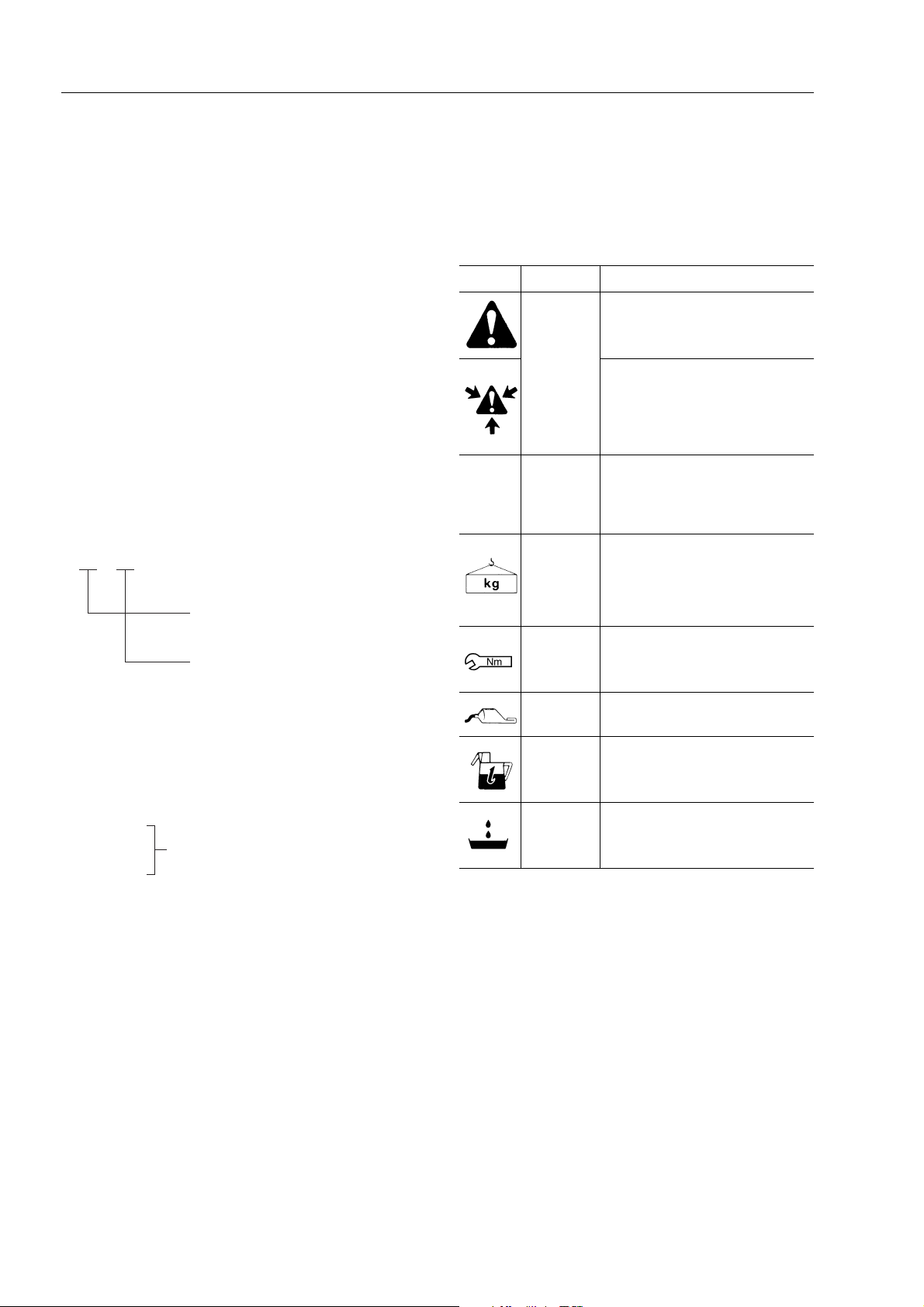

SYMBOLS

In order to make the shop manual greatly chelpful, important points about safety and quality are marked with

the following symbols.

Symbol Item Remarks

Special safety precautions

are necessary when

performing the work.

★

Safety

Caution

Weight

Tightening

torque

Extra special safety precautions

are necessary when performing

the work because it is under internal pressure.

Special technical precautions or

other precautions for preserving

standards are necessary when

performing the work.

Weight of parts or systems.

Caution necessary when selecting hoisting wire, or when working posture is important, etc.

Parts that require special attention for the tightening torque during assembly.

3. Additional pages: additional pagesare indicated by

a hyphen (–) and number after the page number.

Fle as in the example.

Example:

10-4

10-4-1

Added pages

10-4-2

10-5

REVISED EDITION MARK

➀ ➁ ➂ ....)

(

When a manual is revised, an edition mark is recorded

on the bottom outside corner of the pages.

REVISIONS

Revised pages areshown on the LIST OFREVISED PAGES between the title page and SAFETY page.

Coat

Oil, water

Drain

Parts to be coated with adhesives and lubricants etc.

Places where oil, water or fuel

must be added, and their quantity.

Places where oil or water must

be drained, and quantity to be

drained.

00-6

WB91R-2 WB93R-2

Page 11

HOISTING INSTRUCTIONS

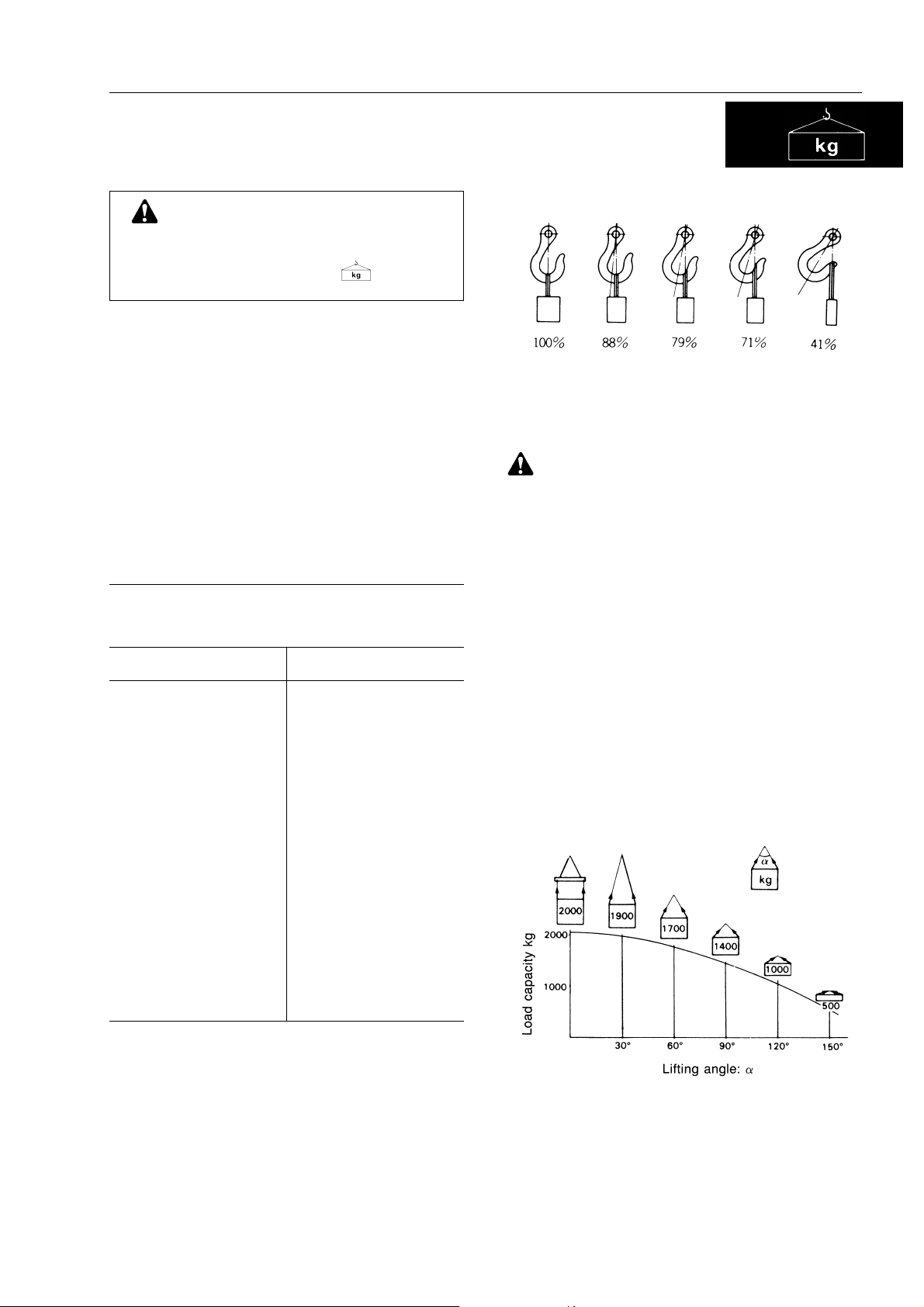

Heavy parts (25 kg or more) must be lifted

with a hoist etc. In the

section, every part weighing 25 kg or more is

bly

clearly indicated with the symbol

1. If a part cannot be smoothly removed from the machine by hoisting, the following checks should be

made:

• Check for removal of all bolts fastening the part

to the relative parts.

• Check for any part causing interference with

the part to be removed.

2. Wire ropes

1) Use adequate ropes depending on the weightof

parts to be hoisted, referring to the table below:

(Standard «S» or «Z» twist ropes

without galvanizing)

Rope diameter (mm) Allowable load (tons)

10.0

11.2

12.5

14.0

16.0

18.0

Disassembly and Assem-

WIRE ROPES

1.0

1.4

1.6

2.2

2.8

3.6

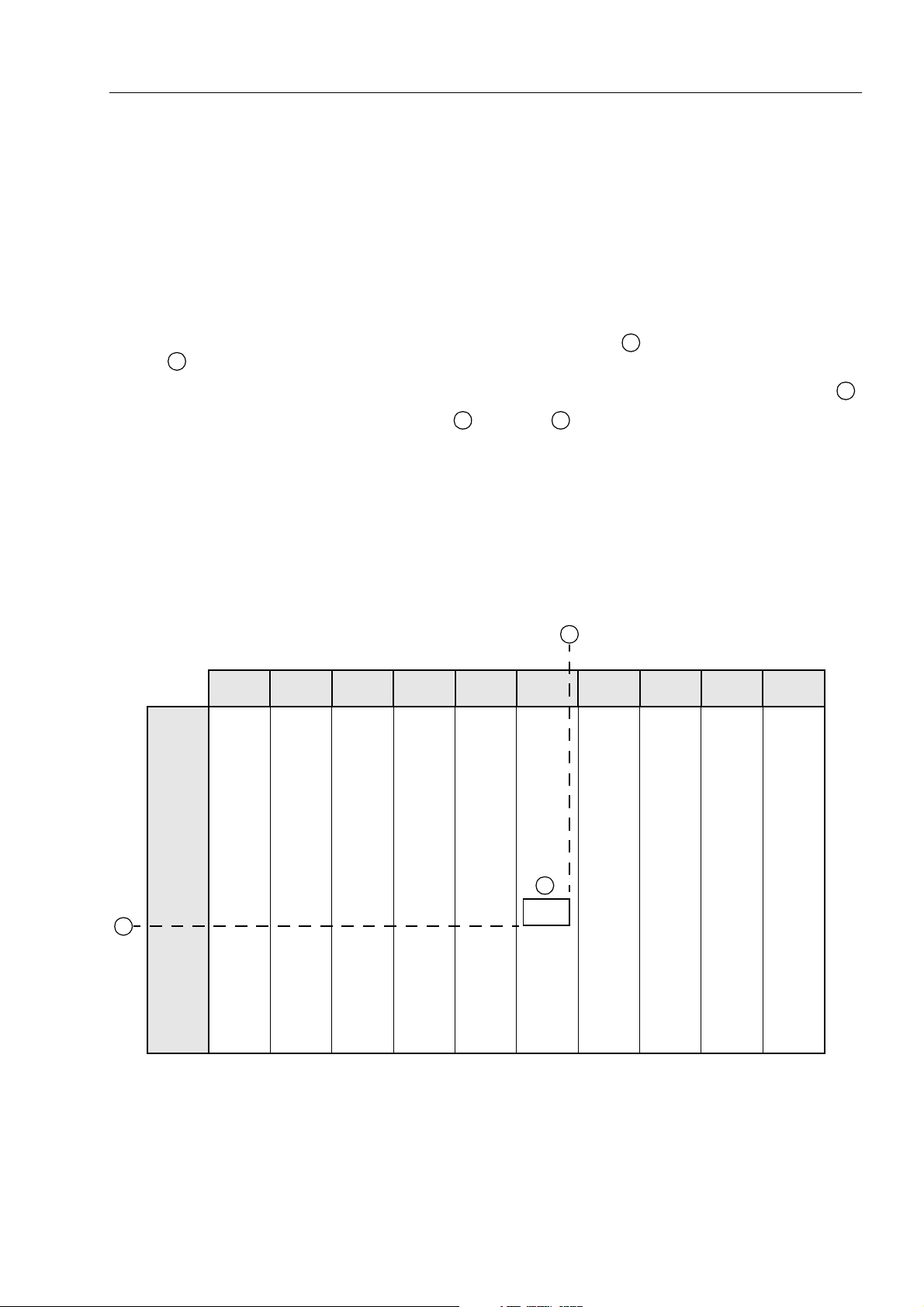

HOISTING INSTRUCTIONS

Hooks have maximum strength at the middle portion.

3) Do not sling a heavy load with one rope alone, but

sling with two or more ropes symmetrically wound

on to the load.

Slingingwith one rope maycause turningof theload

during hoisting, untwistingof the rope, or slipping of

the rope from its original winding position on the

load, which can cause dangerous accidents.

4) Do not sling a heavy load with ropes forming a wide

hanging angle from the hook.

When hoisting a load with two or more ropes, the

force subjected to each rope will increase with the

hanging angles.

The table below shows the variation of allowable

load (kg) when hoisting is made with two ropes,

each of which is allowed to sling up to 1000 kg vertically, at various handing angles.

When tworopes slinga loadvertically, upto 2000kg

of total weight can be suspended.

This weight becomes 1000 kg when two ropes

make a 120° hanging angle.

On the otherhand,two ropesaresubjected toan excessiveforce aslarge as4000 kgif theysling a2000

kg load at a lifting angle of 150°.

20.0

22.4

30.0

40.0

50.0

60.0

The allowable load value is estimated to be onesixth or one-seventh of the breaking strength of the

rope used.

2) Slingwire ropesfrom themiddle portionof thehook.

Slinging near the edge of the hook may cause the

rope to slip off the hook during hoist

rious accident can result.

4.4

5.6

10.0

18.0

28.0

40.0

ing, and a se-

WB91R-2 WB93R-2

00-7

Page 12

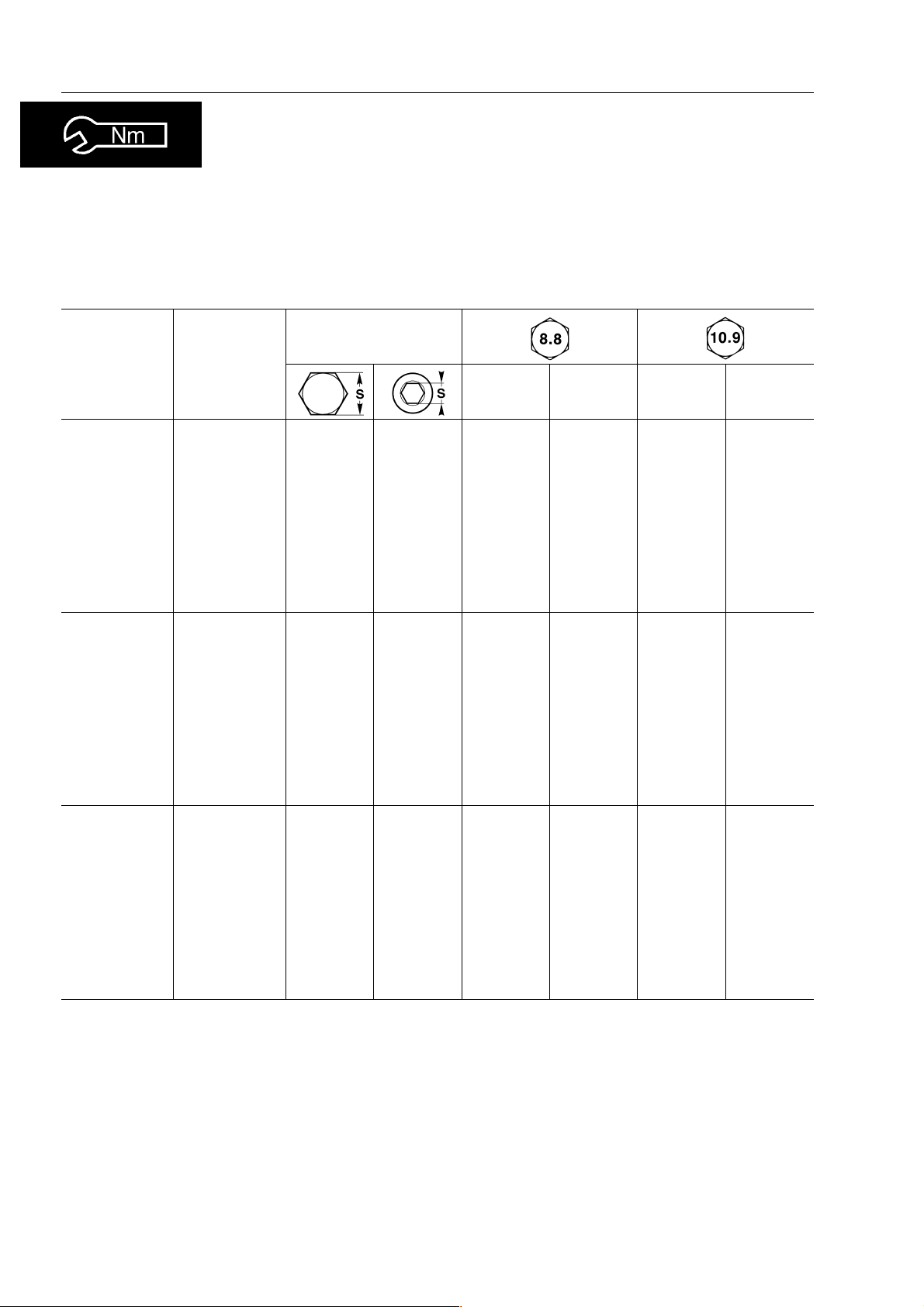

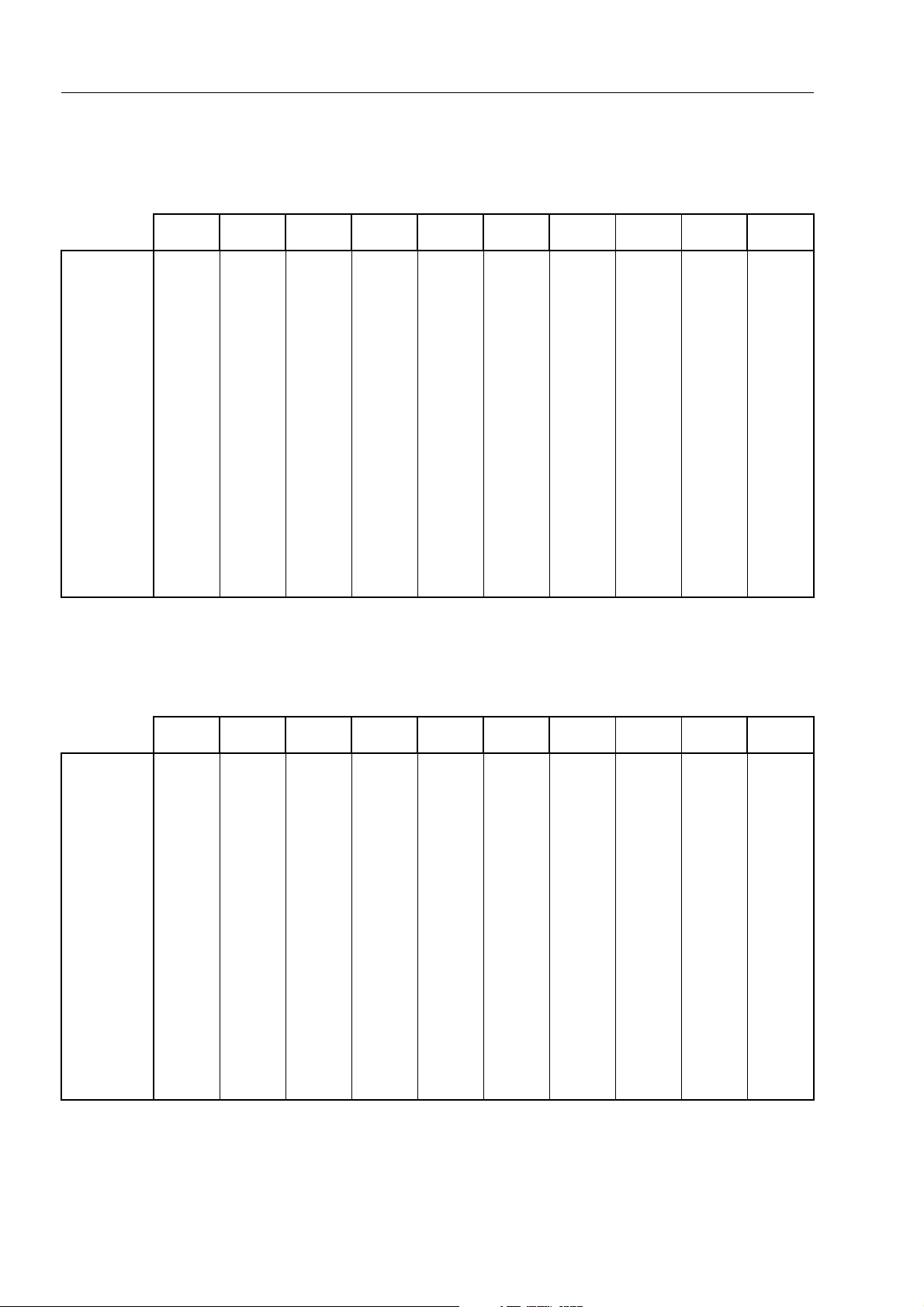

STANDARD TIGHTENING TORQUE

The following charts give the standard tightening torques of bolts and nuts.

Exceptions are given in section of «Disassembly and Assembly».

1. STANDARD TIGHTENING TORQUE OF BOLTS AND NUT

Width across flat

Thread

diameter ofbolts

(mm)

Pitch of

bolts

(mm)

(mm)

kgmNmkgmNm

STANDARD TIGHTENING TORQUE

10

12

14

16

18

20

22

24

27

30

6

8

1

1.25

1.5

1.75

2

2

2.5

2.5

2.5

3

3

3.5

10

13

17

19

22

24

27

30

32

36

41

46

10

12

14

14

17

17

19

19

22

8

6

8

0.96

2.3

4.6

7.8

12.5

19.5

27

38

52

66

96±10

131

±0.1

±0.2

±0.5

±0.8

±1

±2

±3

±4

±6

±7

±14

9.5

23

45

77

122

191

262

372

511

644

945

1287

±1

±2

±4.9

±8

±13

±21

±28

±40

±57

±70

±100

±140

1.3

3.2

6.5

17.5

92

135

184

±0.15

±0.3

±0.6

±1

11

27

±3

±4

37

53

±6

73

±8

±10

±15

±20

±2

13.5

32.2

63

108

172

268

366

524

719

905

1329

1810

±1.5

±3.5

±6.5

±11

±18

±29

±36

±57

±80

±98

±140

±190

33

36

39

This torque table does not apply to bolts or nuts which have to fasten nylon or other parts non-ferrous metal washer.

3.5

4

4

50

55

60

24

27

----

177

230

295

±20

±25

±33

1740

2250

2900

±200

±250

±330

250

320

410

±27

±35

±45

2455

3150

4050

±270

±350

±450

★ Nm (newton meter): 1 Nm = 0.102 kgm

00-8

WB91R-2 WB93R-2

Page 13

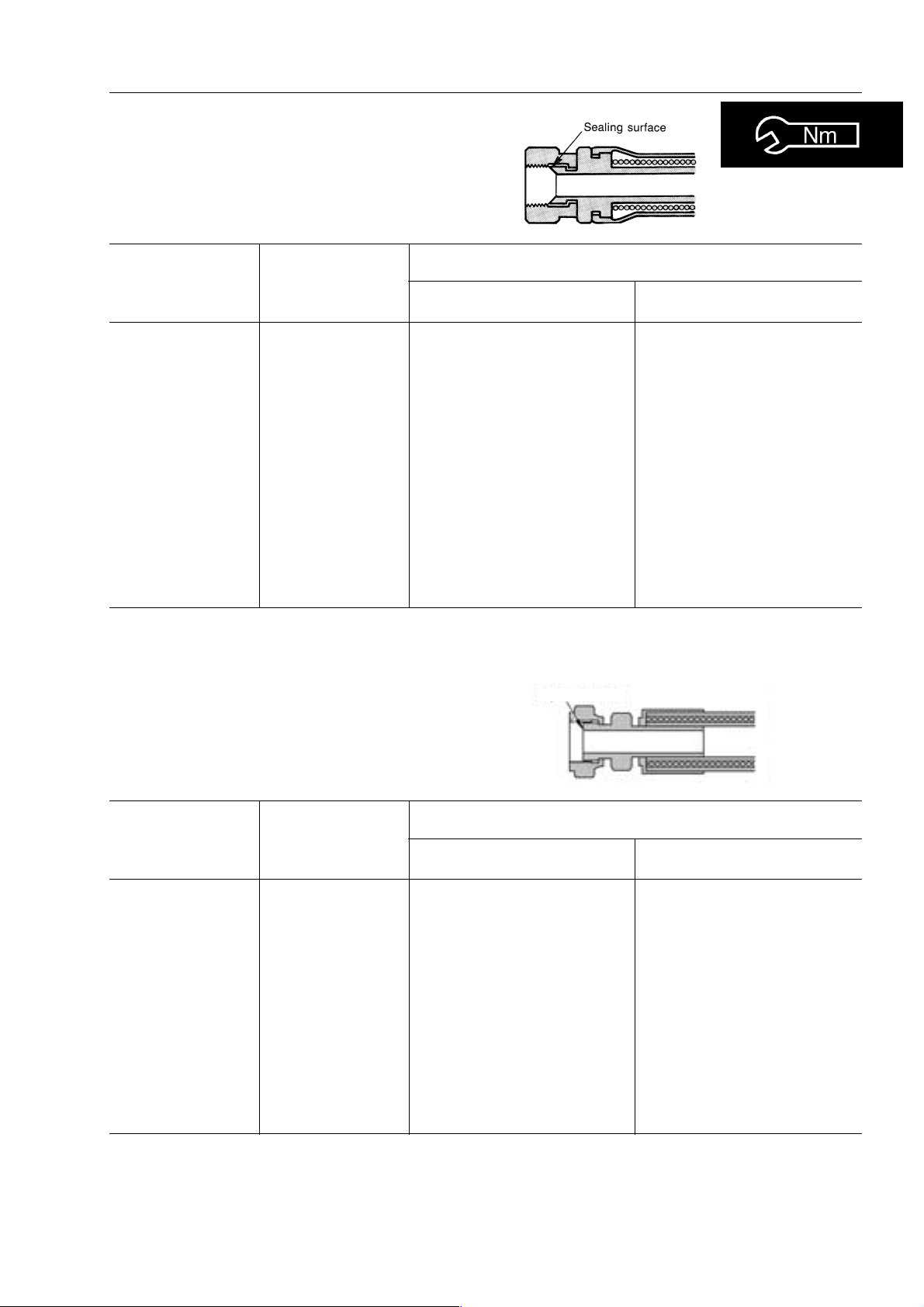

2. TIGHTENING TORQUE FOR NUTS OF FLARED

Use these torques for nut part of flared.

STANDARD TIGHTENING TORQUE

Thread diameter

of nut part

(mm)

1/2” -20

9/16” -18

3/4” -16

7/8” -14

1.1/16 - 12

1.5/16 - 12

1.5/8 - 12

22

33

Width across flats

of nut part

(mm)

17

17

22

27

32

38

50

27

41

TIGHTENING TORQUE

kgm Nm

2.6

4

6.7

9.7

17

20

20

±0.5

±0.5

±2

8

±2

±3

±3

±5

8

±2

±5

Sealing surface

25.5

39.2

65.7

78.5

95.15

166.7

196.2

78.5

196.2

±4.9

±4.9

±19.6

±19.6

±29.4

±29.4

±49

±19.6

±49

Thread diameter

of nut part

(mm)

9/16” -18

11/16” -16

13/16” -16

1” -14

1.3/16 - 12

1.7/16 - 12

1.11/16 - 12

2” -12

WB91R-2 WB93R-2

Width across flats

of nut part

(mm)

17

22

24

30

36

41

50

57

TIGHTENING TORQUE

kgm Nm

2.3–2.5

3.4–3.9

5.2–5.8

8.2–9.2

12.2–13.3

15.3–17.3

18.4–20.4

20.4–24.4

23–25

33–38

51–57

80–90

120–130

150–170

180–200

200–240

00-9

Page 14

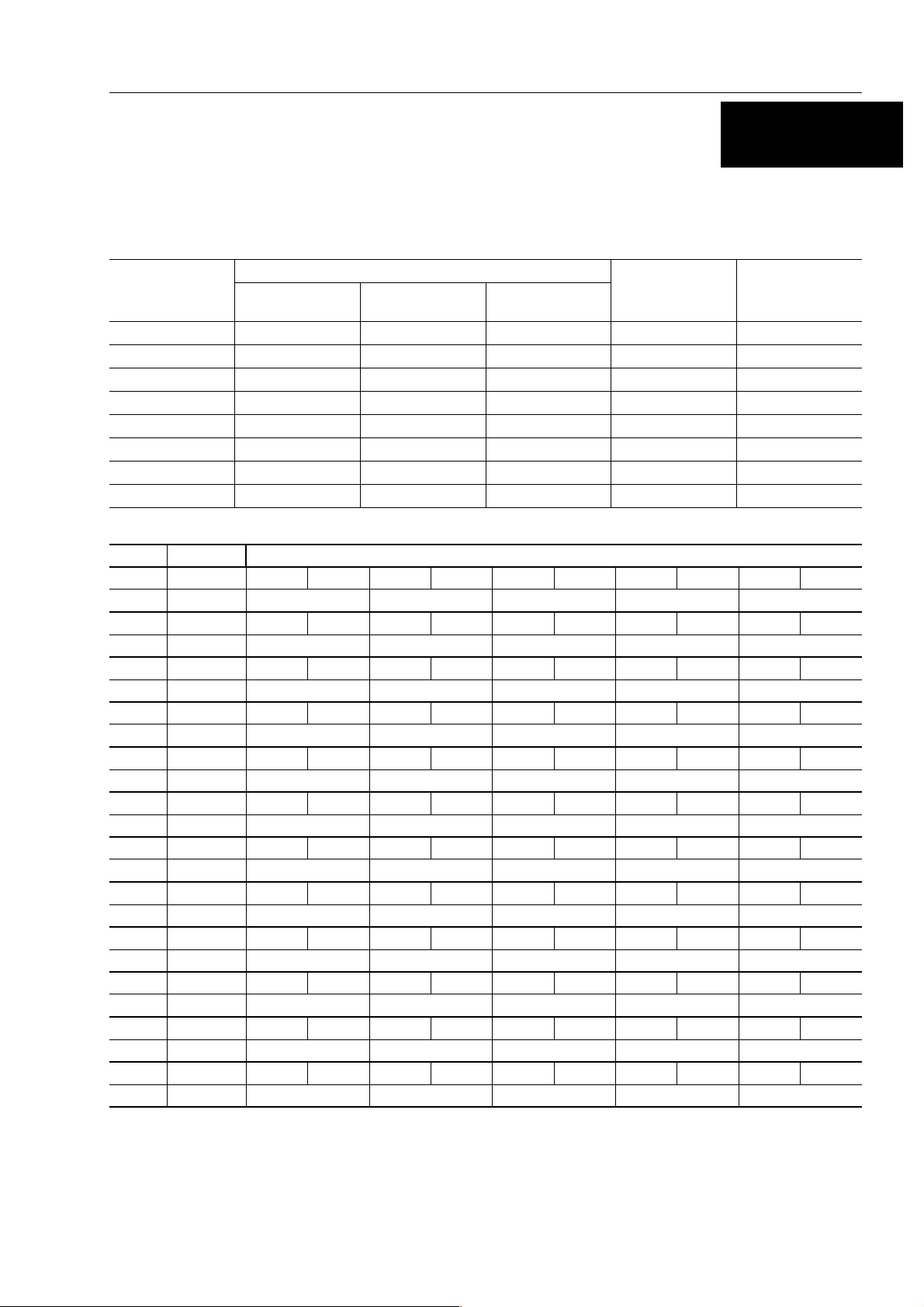

COAT I NG M ATER I A LS

COATIN G MAT ERIAL S

The recommended coating materials prescribed in Komatsu Utility Shop Manuals are listed below:

Nomenclature Code Applications

ASL800010 Used to apply rubber pads, rubber gaskets and cork plugs.

Adhesives

Gasket sealant

ASL800020

Loctite 222 Used for low resistance locking of screws, check nuts and adjustment nuts.

Loctite 242

Loctite 262 Used forhigh resistantof threadedparts thatcan be removed with normal tools.

Loctite 270

Loctite 542 Used for sealing the union threads for hydraulic tubes.

Loctite 573

Loctite 601

Loctite 675

ASL800060

Loctite 510

Used to apply resin,rubber, metallicand non-metallicparts whena fast,strong

seal is needed.

Toprevent theloosening ofbolts, nutsand plugsand the leakageof oil.Used for

medium resistance locking of screws and nuts of every type, and for locking

keys and bearings.

Used for high resistant locking and for sealing threaded parts, bolts and stud

bolts.

Used forsealing ratherexact planesurfaces whenthe optionof possiblefuture

dismantling is required.

Used forhigh resistantlocking ofmechanical componentsthat canbe removed

only after heating

Used to lock cylindrical couplings and for the permanent locking of threaded

parts, and also to lock shafts to bearings, gears, pulleys, pins, bushings, etc.

Used by itself to seal grease fittings, tapered screw fittings and tapered screw

fittings in hydraulic circuits of less than 50 mm in diameter.

Used by itself on mounting flat surface

(Clearance between surfaces within 0.2 mm)

Antifriction compound

(Lubricant including

Molybdenum disulfide)

Grease

(Lithium grease)

Vaseline

00-10

Loctite 518

ASL800040

ASL800050

-----

Used by itself on mounting flat surface

(Clearance between surfaces within 0.5 mm

Applied to bearings and taper shaft to facilitate press-fitting and to prevent

sticking, burning or rusting.

Applied to bearings, sliding parts and oil seals for lubrication, rust prevention

and facilitation of assembling work.

Used for protecting battery electrode terminals from corrosion

WB91R-2 WB93R-2

Page 15

ELECTRIC WIRE CODE

ELECTRIC

In the wiring diagrams various colour and symbols are employed to indicate the thickness of wires.

This wire code table will help you understand WIRING DIAGRAMS.

Example: R–N 1.5 indicates a cable having a nominal number 1.5 and red coating with black stripe.

CLASSIFICATION BY THICKNESS

Nominal

number

0.5 16 0.20 0.35 1.55 3.5

1 14 0.30 0.99 2.80 11

1.5 21 0.30 1.48 3.35 14

2.5 35 0.30 2.47 3.80 20

4 56 0.30 3.95 4.60 28

6 84 0.30 5.93 5.20 37

10 84 0.40 10.55 7.10 53

50 399 0.40 50.11 14 160

Number

strands

Copper wire

Ø of strands

(mm)

Cross section

(mm)

Cable O.D.

(mm)

Current rating

(A)

CLASSIFICATION BY COLOUR AND CODE

Primary Auxiliary

Code A A–BA/BA–G – A–NA/NA–RA/RA–VA/V

Colour Light Blue Light Blue–White Light Blue–Yellow Light Blue–Black Light Blue–Red Light Blue–Green

Code B B–G – B–NB/NB–RB/R – B/V ––

Colour White White–Yellow White–Black White–Red White–Green –

Code C C–BC/BC–L – C–N –––––

Colour Orange Orange–White Orange–Blue Orange–Black ––

Code G G–NG/NG–R – G–V –––––

Colour Yellow Yellow–Black Yellow–Red Yellow–Green ––

Code H H–G – H–L – H–NH/NH–R –––

Colour Grey Grey–Yellow Grey–Blue Grey–Black Grey–Red –

Code L L–BL/BL–G ––L/N ––––

Colour Blue Blue–White Blue–Yellow Blue–Black ––

Code M M–B – M–NM/NM–V –––––

Colour Brown Brown–White Brown–Black Brown–Green ––

Code N ––––––––––

Colour Black –––––

Code R R–G – R–NR/NR–V –––––

Colour Red Red–Yellow Red–Black Red–Green ––

Code S S–G – S–N –––––––

Colour Pink Pink–Yellow Pink–Black –––

Code V V–B – V–NV/N ––––––

Colour Green Green–White Green–Black –––

Code Z Z–BZ/BZ–NZ/N ––––––

Colour Violet Violet–White Violet–Black –––

COMPOSITION OF THE COLOURS

The coloration of two-colour wires is indicated by the composition of the symbol listed.

Example: G–V = Yellow-Green with longitudinal colouring

G/V = Yellow-Green with transversal colouring

WB91R-2 WB93R-2

00-11

Page 16

WEIGHT TABLE

WEIGHT TABLE

This weight table is a guide for use when transporting or handling components.

Unit: kg

Machine model WB91R-2 WB93R-2

From serial number 91F20145 93F23453

Engine assembly - Muffler - Exhaust pipe 400 410

Radiator - exchanger 37 37

Hydraulic oil tank (empty) 77 77

Fuel tank (empty) 73 73

Front counterweight 300 300

Engine hood 27 27

Cabin (without seat) 595 595

Seat 34 34

Engine-gear box-pump group 730 740

Piston pump 28 28

Transmission 230 230

Front axle 316 316

Rear axle 511 511

Front wheel

Rear wheel

2-spool control valve

3-spool control valve

Work equipment

• Boom

• Bucket

• Fulcrum lever

• Tilt lever

• Raise cylinder

• Tilt cylinder

Work equipment

• with standard arm

• with long arm

• with jig arm

Boom 323 323

Arm 213 213

Long arm 245 245

Boom swing bracket 133 133

Backframe 237 237

Control valve (6-spool) 47 47

Control valve (7-spool) 53 53

Control valve (8-spool) 59 59

Jig arm 392 392

Outriggers 57 57

Boom cylinder 65 78

Arm cylinder 69 69

Bucket cylinder 49 49

Outriggers cylinder 42 42

Swing cylinder 30 30

Bucket 156 156

65

163

24

30

960

370

427

13x4

48x2

40x2

45x2

850

885

1030

65

163

24

30

960

370

427

13x4

48x2

40x2

45x2

850

885

1030

00-12

WB91R-2 WB93R-2

Page 17

TABLE OF OIL AND COOLANT QUANTITIES

TABLE OF OIL AND COOLANT QUANTITIES

RESERVOIR

Crankcase sump

Hydraulic circuit

Hydraulic circuit

with biodegradable

oil

Front axle

• Differential

• Final reduction gear

(each.)

Rear axle:

• Differential

KIND OF

FLUID

OIL

• API CD

OIL

• API CD

OIL

• UTTO FLUID

AMBIENT TEMPERATURE CAPACITY (

--30--20--

SAE 10W

1001020304050°C

SAE 20W-20

SAE 30

SAE 40

SAE 10W-30

ᐉ)

Specified Refill

7.9 7.9

150 92

150 92

6.5 6.5

11

14.5 14.5

• Final reduction gear

(each.)

Hydraulic

transmission

Braking

system

Fuel tank DIESEL OIL 130 –

Engine coolant

system

OLIO

GM DEXRON® II D

(DEXRON® is a

registered

General Motors

Corporation)

✽

ASTM D975 N.2

WATER +

ANTI-FREEZE

WATER 14 –

PERMANENT

LIQUID

1.5 1.5

20 17

0.8 0.8

14 –

14 –

✽ ASTM D975 N.

ASTM: America Society of Testing and Materials

SAE: Society of Automotive Engineers

API: American Petroleum Institute

MIL: Military Specification

CCMC: Common Market Constructors Committe

First filling quantity:

total quantity of oil, including the oil for the components and pipes.

Oil change quantity:

quantity of oil necessary to fill the system or unit during the normal inspection and maintenance operations.

WB91R-2 WB93R-2

00-13

Page 18

TABLE OF OIL AND COOLANT QUANTITIES

NOTE:

(1) When the diesel oilsulphur content isless then 0.5%, change the engine oilaccording to theperiodic maintenance

intervals indicated in the operationand maintenancemanual. Inthe dieseloil sulphurcontent exceeds0.5% change

the engine oil according to the following table:

Sulphur content Engine oil change interval

from 0.5 to 1.0% 1/2

over 1.0% 1/4

(2) When startingthe engineat temperatures below0 °C, useengine oil SAE10W, 20W-20 and 10W-30,even if during

the day the temperature increases by 10 °C.

(3) Use engineoil with CD classification; ifoil with CD classificationis used, reduce the engineoil change interval by a

half.

(4) Use originalproducts, which havecharacteristics specifically formulatedand approvedfor theengine, the hydraulic

circuit of equipment and for reductions.

of regular interval

of regular interval

00-14

WB91R-2 WB93R-2

Page 19

CONVERSION TABLE

METHOD OF USING THE CONVERSION TABLE

Theconversiontableinthissectionisprovidedtoenablesimpleconversionoffigures.

For details of the method of using the conversion table, see the example given below.

EXAMPLE

• Method of using the conversion table to convert from millimeters to inches.

1. Convert 55 mm into inches.

CONVERSION TABLE

0.236

0.630

1.024

A

, then drow a horizontal line from

1 mm = 0.03937 in.

0.276

0.669

1.063

0.315

0.709

1.102

0.354

0.748

1.142

1 - Locate the number 50 in the vertical column at the left side, take this as

A

.

2 - Locate the number 5 in the row across the top, take this as , then draw a perpendicular line down from .

3 - Take the point where the two lines cross as . This point gives the value when converting from mil-

limeters to inches. Therefore,

2. Convert 550 mm into inches

1 - The number 550 does not appearin the table, so divide by 10 (move the decimal point one place to the left) to

convert it to 55 mm.

2 - Carry out the same procedure as above to convert 55 mm to 2.165 in.

3 - The originalvalue (550 mm) wasdivided by10, somultiply 2.165in. by 10(move the decimalpoint one placeto

the right) to return to the original value. This gives 550 mm = 21.65 in.

From millimeters to inches

0 1 2 3 4 5 6 7 8 9

0.039

0.433

0.827

10

20

0

0

0.394

0.787

55 mm =2.165 in.

0.079

0.472

0.866

0.118

0.512

0.906

C C

0.157

0.551

0.945

0.197

0.591

0.984

B

B

30

40

50

1.181

1.575

1.969

A

60

70

80

90

2.362

2.756

3.150

3.543

WB91R-2 WB93R-2

1.220

1.614

2.008

2.402

2.795

3.189

3.583

1.260

1.654

2.047

2.441

2.835

3.228

3.622

1.299

1.693

2.087

2.480

2.874

3.268

3.661

1.339

1.732

2.126

2.520

2.913

3.307

3.701

1.378

1.772

C

2.165

2.559

2.953

3.346

3.740

1.417

1.811

2.205

2.598

2.992

3.386

3.780

1.457

1.850

2.244

2.638

3.032

3.425

3.819

1.496

1.890

2.283

2.677

3.071

3.465

3.858

1.536

1.929

2.323

2.717

3.110

3.504

3.898

00-15

Page 20

From mm to in.

CONVERSION TABLE

1 mm = 0.03937 in.

0123456789

0

10

20

30

40

50

60

70

80

90

From kg to lb.

0

0.394

0.787

1.181

1.575

1.969

2.362

2.756

3.150

3.543

0.039

0.433

0.827

1.220

1.614

2.008

2.402

2.795

3.189

3.583

0.079

0.472

0.866

1.260

1.654

2.047

2.441

2.835

3.228

3.622

0.118

0.512

0.906

1.299

1.693

2.087

2.480

2.874

3.268

3.661

0.157

0.551

0.945

1.339

1.732

2.126

2.520

2.913

3.307

3.701

0.197

0.591

0.984

1.378

1.772

2.165

2.559

2.953

3.346

3.740

0.236

0.630

1.024

1.417

1.811

2.205

2.598

2.992

3.386

3.780

0.276

0.669

1.063

1.457

1.850

2.244

2.638

3.032

3.425

3.819

0.315

0.709

1.102

1.496

1.890

2.283

2.677

3.071

3.465

3.858

1 kg = 2.2046 lb.

0.354

0.748

1.142

1.536

1.929

2.323

2.717

3.110

3.504

3.898

0

10

20

30

40

50

60

70

80

90

0123456789

0

22.05

44.09

66.14

88.18

110.23

132.28

154.32

176.37

198.42

2.20

24.25

46.30

68.34

90.39

112.44

134.48

156.53

178.57

200.62

4.41

26.46

48.50

70.55

92.59

114.64

136.69

158.73

180.78

202.83

6.61

28.66

50.71

72.75

94.80

116.85

138.89

160.94

182.98

205.03

8.82

30.86

51.91

74.96

97.00

119.05

141.10

163.14

185.19

207.24

11.02

33.07

55.12

77.16

99.21

121.24

143.30

165.35

187.39

209.44

13.23

35.27

57.32

79.37

101.41

123.46

145.51

167.55

189.60

211.64

15.43

37.48

59.53

81.57

103.62

125.66

147.71

169.76

191.80

213.85

17.64

39.68

61.73

83.78

105.82

127.87

149.91

171.96

194.01

216.05

19.84

41.89

63.93

85.98

108.03

130.07

152.12

174.17

196.21

218.26

00-16

WB91R-2 WB93R-2

Page 21

From liter to U.S. Gall.

0123456789

CONVERSION TABLE

1 ᐉ = 0.2642 U.S. Gall.

0

10

20

30

40

50

60

70

80

90

0

2.642

5.283

7.925

10.567

13.209

15.850

18.492

21.134

23.775

From liter to U.K. Gall.

0.264

2.906

5.548

8.189

10.831

13.473

16.115

18.756

21.398

24.040

0.528

3.170

5.812

8.454

11.095

13.737

16.379

19.020

21.662

24.304

0.793

3.434

6.076

8.718

11.359

14.001

16.643

19.285

21.926

24.568

1.057

3.698

6.340

8.982

11.624

14.265

16.907

19.549

22.190

24.832

1.321

3.963

6.604

9.246

11.888

14.529

17.171

19.813

22.455

25.096

1.585

4.227

6.869

9.510

12.152

14.795

17.435

20.077

22.719

25.361

1.849

4.491

7.133

9.774

12.416

15.058

17.700

20.341

22.983

25.625

2.113

4.755

7.397

10.039

12.680

15.322

17.964

20.605

23.247

25.889

1 ᐉ = 0.21997 U.K. Gall.

2.378

5.019

7.661

10.303

12.944

15.586

18.228

20.870

23.511

26.153

0

10

20

30

40

50

60

70

80

90

0123456789

0

2.200

4.399

6.599

8.799

10.998

13.198

15.398

17.598

19.797

0.220

2.420

4.619

6.819

9.019

11.281

13.418

15.618

17.818

20.017

0.440

2.640

4.839

7.039

9.239

11.438

13.638

15.838

18.037

20.237

0.660

2.860

5.059

7.259

9.459

11.658

13.858

16.058

12.257

20.457

0.880

3.080

5.279

7.479

9.679

11.878

14.078

16.278

18.477

20.677

1.100

3.300

5.499

7.969

9.899

12.098

14.298

16.498

18.697

20.897

1.320

3.520

5.719

7.919

10.119

12.318

14.518

16.718

18.917

21.117

1.540

3.740

5.939

8.139

10.339

12.528

14.738

16.938

19.137

21.337

1.760

3.950

6.159

8.359

10.559

12.758

14.958

17.158

19.357

21.557

1.980

4.179

6.379

8.579

10.778

12.978

15.178

17.378

19.577

21.777

WB91R-2 WB93R-2

00-17

Page 22

From Nm to lb.ft.

0123456789

CONVERSION TABLE

1 Nm = 0.737 lb.ft.

0

10

20

30

40

50

60

70

80

90

100

110

120

0

7.370

14.740

22.110

29.480

36.850

44.220

51.590

58.960

66.330

73.700

81.070

88.440

0.737

8.107

15.477

22.847

30.217

37.587

44.957

52.327

59.697

67.067

74.437

81.807

89.177

1.474

8.844

16.214

23.584

30.954

38.324

45.694

53.064

60.434

67.804

75.174

82.544

89.914

2.211

9.581

16.951

24.321

31.691

39.061

46.431

53.801

61.171

68.541

75.911

83.281

90.651

2.948

10.318

17.688

25.058

32.428

39.798

47.168

54.538

61.908

69.278

76.648

84.018

91.388

3.685

11.055

18.425

25.795

33.165

40.535

47.905

55.275

82.645

70.015

77.385

84.755

92.125

4.422

11.792

19.162

26.532

33.902

41.272

48.642

56.012

63.382

70.752

78.122

85.492

92.862

5.159

12.529

19.899

27.269

34.639

42.009

49.379

56.749

64.119

71.489

78.859

86.229

93.599

5.896

13.266

20.636

28.006

35.376

42.746

50.116

57.486

64.856

72.226

79.596

86.966

94.336

6.633

14.003

21.373

28.743

36.113

43.483

50.853

58.223

65.593

72.963

80.333

87.703

95.073

130

140

150

160

170

180

190

95.810

103.180

110.550

117.920

125.290

132.660

140.030

96.547

103.917

111.287

118.657

126.027

133.397

140.767

97.284

104.654

112.024

119.394

126.764

134.134

141.504

98.021

105.391

112.761

120.131

127.501

134.871

142.241

98.758

106.128

113.498

120.868

128.238

135.608

142.978

99.495

106.865

114.235

121.605

128.975

136.345

143.715

100.232

107.602

114.972

122.342

129.712

137.082

144.452

100.969

108.339

115.709

123.079

130.449

137.819

145.189

101.706

109.076

116.446

123.816

131.186

138.556

145.926

102.443

109.813

117.183

124.553

131.923

139.293

146.663

00-18

WB91R-2 WB93R-2

Page 23

From Nm to kgm

0123456789

CONVERSION TABLE

1 Nm = 0.102 kgm

0

10

20

30

40

50

60

70

80

90

100

110

120

0

1.020

2.040

3.060

4.080

5.100

6.120

7.140

8.160

9.180

10.200

11.220

12.240

0.102

1.222

2.142

3.162

4.182

5.202

6.222

7.242

8.262

9.282

10.302

11.322

12.342

0.204

1.224

2.244

3.264

4.284

5.304

6.324

7.344

8.364

9.384

10.404

11.424

12.444

0.306

1.326

2.346

3.366

4.386

5.406

6.426

7.446

8.466

9.486

10.506

11.526

12.546

0.408

1.428

2.448

3.468

4.488

5.508

6.528

7.548

8.568

9.588

10.608

11.628

12.648

0.510

1.530

2.550

3.570

4.590

5.610

6.630

7.650

8.670

9.690

10.710

11.730

12.750

0.612

1.632

2.652

3.672

4.692

5.712

6.732

7.752

8.772

9.792

10.812

11.832

12.852

0.714

1.734

2.754

3.774

4.794

5.814

6.834

7.854

8.874

9.894

10.914

11.934

12.954

0.816

1.836

2.856

3.876

4.896

5.916

6.936

7.956

8.976

9.996

11.016

12.036

13.056

0.918

1.938

2.958

3.978

4.998

6.018

7.038

8.058

9.078

10.098

11.118

12.138

13.158

130

140

150

160

170

180

190

13.260

14.280

15.300

16.320

17.340

18.360

19.380

13.362

14.382

15.402

16.422

17.442

18.462

19.482

13.464

14.484

15.504

16.524

17.544

18.564

19.584

13.566

14.586

15.606

16.626

17.646

18.666

19.686

13.668

14.688

15.708

16.728

17.748

18.768

19.788

13.770

14.790

15.810

16.830

17.850

18.870

19.890

13.872

14.892

15.912

16.932

17.952

18.972

19.992

13.974

14.994

16.014

17.034

18.054

19.074

20.094

14.076

15.096

16.116

17.136

18.156

19.176

20.196

14.178

15.198

16.218

17.238

18.258

19.278

20.298

WB91R-2 WB93R-2

00-19

Page 24

From kgm to lb.ft.

0123456789

CONVERSION TABLE

1 kgm = 7.233 lb.ft.

0

10

20

30

40

50

60

70

80

90

100

110

120

0

72.3

144.7

217.0

289.3

361.7

434.0

506.3

578.6

651.0

723.3

795.6

868.0

7.2

79.6

151.9

224.2

296.6

368.9

441.2

513.5

585.9

658.2

730.5

802.9

875.2

14.5

86.8

159.1

231.5

303.8

376.1

448.5

520.8

593.1

665.4

737.8

810.1

882.4

21.7

94.0

166.4

238.7

311.0

383.4

455.7

528.0

600.3

672.2

745.0

817.3

889.7

28.9

101.3

173.6

245.9

318.3

390.6

462.9

535.2

607.6

679.9

752.2

824.6

896.9

36.2

108.5

180.8

253.2

325.5

397.8

470.2

542.5

614.8

687.1

759.5

831.8

904.1

43.4

115.7

188.1

260.4

332.7

405.1

477.4

549.7

622.0

694.4

766.7

839.0

911.4

50.6

123.0

195.3

267.6

340.0

412.3

484.6

556.9

629.3

701.6

773.9

846.3

918.6

57.9

130.2

202.5

274.9

347.2

419.5

491.8

564.2

636.5

708.8

781.2

853.5

925.8

65.1

137.4

209.8

282.1

354.4

426.8

499.1

571.4

643.7

716.1

788.4

860.7

933.1

130

140

150

160

170

180

190

940.3

1012.6

1084.9

1157.3

1129.6

1301.9

1374.3

947.5

1019.9

1092.2

1164.5

1236.8

1309.2

1381.5

954.8

1027.1

1099.4

1171.7

1244.1

1316.4

1388.7

962.0

1034.3

1106.6

1179.0

1251.3

1323.6

1396.0

969.2

1041.5

1113.9

1186.2

1258.5

1330.9

1403.2

876.5

1048.8

1121.1

1193.4

1265.8

1338.1

1410.4

983.7

1056.0

1128.3

1200.7

1273.0

1345.3

1417.7

990.9

1063.2

1135.6

1207.9

1280.1

1352.6

1424.9

998.2

1070.5

1142.8

1215.1

1287.5

1359.8

1432.1

1005.4

1077.7

1150.0

1222.4

1294.7

1367.0

1439.4

00-20

WB91R-2 WB93R-2

Page 25

From bar to psi (lb/in2)

0123456789

CONVERSION TABLE

1 bar = 14.503 psi

0

10

20

30

40

50

60

70

80

90

100

110

120

0

145.0

290.0

435.1

580.1

725.1

870.2

1015.2

1160.2

1305.3

1450.3

1595.3

1740.4

14.5

159.5

304.6

449.6

594.6

739.6

884.7

1029.7

1174.7

1319.8

1464.8

1609.8

1754.9

29.0

174.0

319.1

464.1

609.1

754.1

899.2

1044.2

1189.2

1334.3

1479.3

1624.3

1769.4

43.5

188.5

333.6

478.6

623.6

768.6

913.7

1058.7

1203.7

1348.8

1493.8

1638.8

1783.9

58.0

203.0

348.1

493.1

638.1

783.2

928.2

1073.2

1218.2

1363.3

1508.3

1653.3

1798.4

72.5

217.5

362.6

507.6

652.6

797.7

942.7

1087.7

1232.7

1377.8

1522.8

1667.8

1812.9

87.0

232.0

377.1

522.1

667.1

812.2

957.2

1102.2

1247.2

1392.3

1537.3

1682.3

1827.4

101.5

246.5

391.6

536.6

681.6

826.7

971.7

1116.7

1261.8

1406.8

1551.8

1696.8

1841.9

116.0

261.0

406.1

551.1

696.1

841.2

986.2

1131.2

1276.3

1421.3

1566.3

1711.3

1856.4

130.5

275.6

420.6

565.6

710.6

855.7

1000.7

1145.7

1290.8

1435.8

1580.8

1725.8

1870.8

130

140

150

160

170

180

190

200

210

220

230

240

1885.4

2030.4

2175.4

2320.5

2465.5

2610.5

2755.6

2900.6

3045.6

3190.7

3335.7

3480.7

1899.9

2044.9

2189.9

2335.0

2480.0

2625.0

2770.0

2915.1

3060.1

3205.2

3350.2

3495.2

1914.4

2059.4

2204.4

2349.5

2494.5

2639.5

2784.6

2929.6

3074.6

3219.7

3364.7

3509.7

1928.9

2073.9

2218.9

2364.0

2509.0

2654.0

2799.1

2944.1

3089.1

3234.2

3379.2

3524.2

1943.4

2088.4

2233.5

2378.5

2523.5

2668.5

2813.6

2958.6

3103.6

3248.7

3393.7

3538.7

1957.9

2102.9

2248.0

2393.0

2538.0

2683.0

2828.1

2973.1

3118.1

3263.2

3408.2

3553.2

1972.4

1217.4

2262.5

2407.5

2552.5

2697.7

2842.6

2987.6

3132.6

3277.7

3422.7

3567.7

1986.9

2131.9

2277.0

2422.0

2567.0

2712.1

2857.1

3002.1

3147.1

3192.2

3437.2

3582.2

2001.4

2146.4

2291.5

2436.5

2581.5

2726.6

2871.6

3016.6

3161.6

3306.7

3451.7

3596.7

2015.9

2160.9

2306.0

2451.0

2596.0

2641.1

2886.1

3031.1

3176.1

3321.2

3466.2

3611.2

WB91R-2 WB93R-2

00-21

Page 26

CONVERSION TABLE

TEMPERATURE

Fahrenheit-Centigrade conversion; a simple way to convert a Fahrenheit temperature reading into a Centigrade temperature reading or vice versa is to enter the accompanying table in the center or boldface column of figures.

These figures refer to the temperature in either Fahrenheit or Centigrade degrees.

If itisdesired to convert fromFahrenheit to Centigrade degrees,consider thecenter columnas atable ofFahrenheit temperatures and read the corresponding Centigrade temperature in the column at the left.

If itis desiredto convert from Centigradeto Fahrenheit degrees,consider thecenter columnas atable ofCentigrade values and read the corresponding Fahrenheit temperature on the right.

1 °C = 33.8°F

°C

–40.4

–37.2

–34.4

–31.7

–28.9

–28.3

–27.8

–27.2

–26.7

–26.1

–25.6

–25.0

–24.4

–23.9

–23.3

–22.8

–22.2

–21.7

–21.1

–20.6

–40

–35

–30

–25

–20

–19

–18

–17

–16

–15

–14

–13

–12

–11

–10

–9

–8

–7

–6

–5

°F °C °F °C °F °C °F

–40.0

–31.0

–22.0

–13.0

–4.0

–2.2

–0.4

1.4

3.2

5.0

6.8

8.6

10.4

12.2

14.0

15.8

17.6

19.4

21.2

23.0

–11.7

–11.1

–10.6

–10.0

–9.4

–8.9

–8.3

–7.8

–7.2

–6.7

–6.1

–5.6

–5.0

–4.4

–3.9

–3.3

–2.8

–2.2

–1.7

–1.1

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

51.8

53.6

55.4

57.2

59.0

60.8

62.6

64.4

66.2

68.0

69.8

71.6

73.4

75.2

77.0

78.8

80.6

72.4

84.2

86.0

7.8

8.3

8.9

9.4

10.0

10.6

11.1

11.7

12.2

12.8

13.3

13.9

14.4

15.0

15.6

16.1

16.7

17.2

17.8

18.3

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

144.8

116.6

118.4

120.2

122.0

123.8

125.6

127.4

129.2

131.0

132.8

134.6

136.4

138.2

140.0

141.8

143.6

145.4

147.2

149.0

27.2

27.8

28.3

28.9

29.4

30.0

30.6

31.1

31.7

32.2

32.8

33.3

33.9

34.4

35.0

35.6

36.1

36.7

37.2

37.8

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

117.8

179.6

181.4

183.2

185.0

186.8

188.6

190.4

192.2

194.0

195.8

197.6

199.4

201.2

203.0

204.8

206.6

208.4

210.2

212.0

–20.0

–19.4

–18.9

–18.3

–17.8

–17.2

–16.7

–16.1

–15.6

–15.0

–14.4

–13.9

–13.3

–12.8

–12.2

00-22

–4

–3

–2

–1

10

24.8

26.6

28.4

30.2

0

32.0

1

33.8

2

35.6

3

37.4

4

39.2

5

41.0

6

42.8

7

44.6

8

46.4

9

48.2

50.0

–0.6

0.0

0.6

1.1

1.7

2.2

2.8

3.3

3.9

4.4

5.0

5.6

6.1

6.7

7.2

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

87.8

89.6

91.4

93.2

95.0

96.8

98.6

100.4

102.2

104.0

105.8

107.6

109.4

111.2

113.0

18.9

19.4

20.0

20.6

21.1

21.7

22.2

22.8

23.3

23.9

24.4

25.0

25.6

26.1

26.7

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

150.8

152.6

154.4

156.2

158.0

159.8

161.6

163.4

165.2

167.0

168.8

170.6

172.4

174.2

176.0

40.6

43.3

46.1

48.9

51.7

54.4

57.2

60.0

62.7

65.6

68.3

71.1

73.9

76.7

79.4

105

110

115

120

125

130

135

140

145

150

155

160

165

170

175

221.0

230.0

239.0

248.0

257.0

266.0

275.0

284.0

2930

302.0

311.0

320.0

329.0

338.0

347.0

WB91R-2 WB93R-2

Page 27

GROUP

10

Page 28

40-28

PC15R-8

Page 29

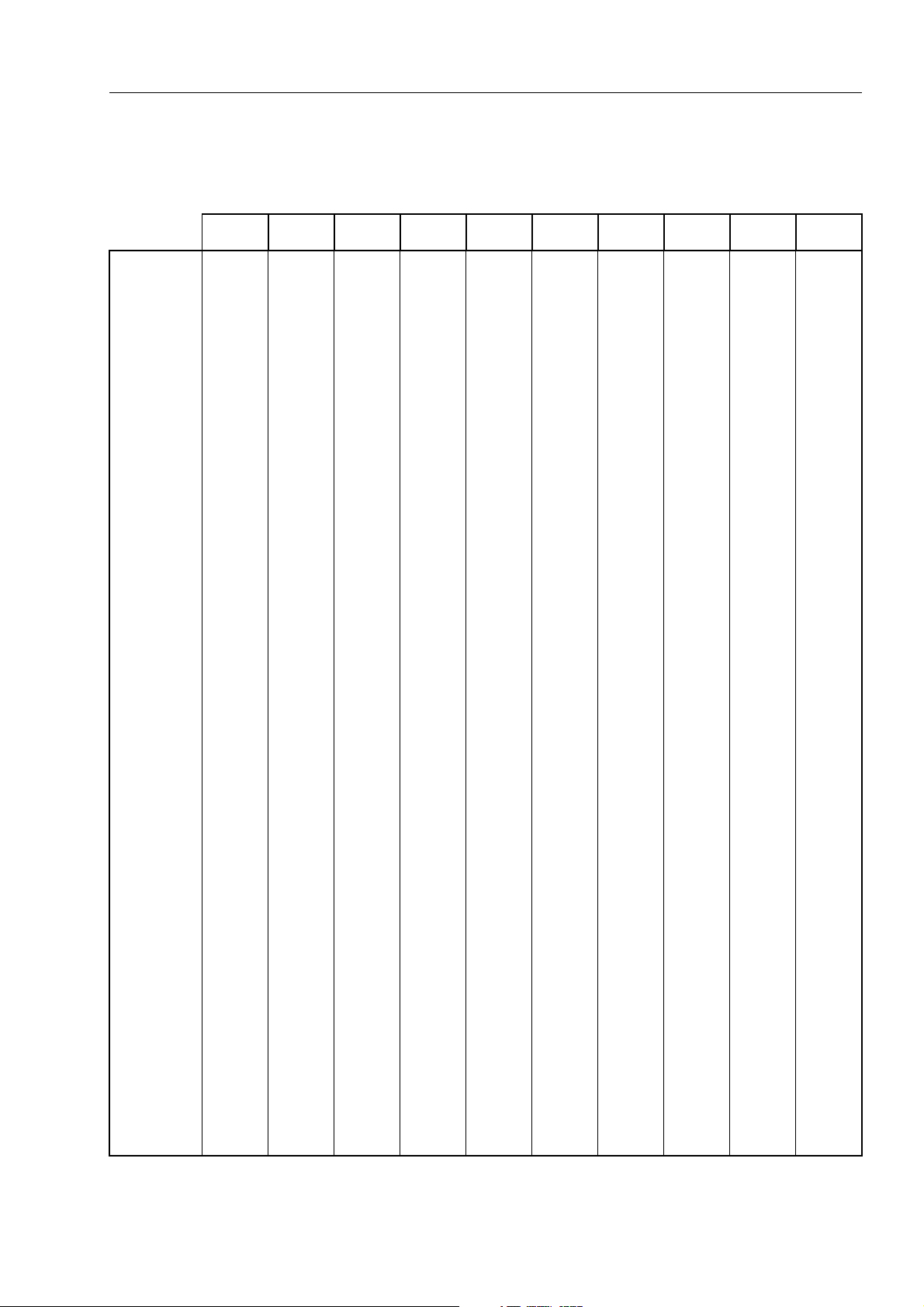

STRUCTURE AND FUNCTION

Power train ................................................................ 2

Transmission (4WD).................................................. 4

Drive shafts................................................................ 9

Control valve block .................................................. 11

Front axle................................................................. 12

Rear axle ................................................................. 15

Hydraulic pump........................................................ 20

Steering unit ............................................................ 41

Hydraulic circuit ....................................................... 43

Shovel control valve ................................................ 44

Backhoe control valve ............................................. 50

CLSS ....................................................................... 57

Solenoid valve ......................................................... 71

Safety valve..............................................................72

Brake pump ..............................................................74

Shovel cylinder .........................................................75

Backhoe cylinder ......................................................76

Air-conditioning unit..................................................80

How the air-conditioning unit functions.....................81

Electrical diagram (1/6) ............................................83

Electrical diagram (2/6) ............................................85

Electrical diagram (3/6) ............................................87

Electrical diagram (4/6) ............................................89

Electrical diagram (5/6) ............................................91

Electrical diagram (6/6) ............................................93

Electrical diagram (Air conditioning).........................95

WB91R-2 WB93R-2

10-1

Page 30

STRUCTURE AND FUNCTION

POWER TRAIN

POWER TRAIN

1

5

2

3

7

4

8

6

RKZ01061

DESCRIPTION

• The driving power for the engine (1) is transmitted

through the flywheel to the converter (2).

The converter (2) uses hydraulic oil to convert the

torque transmitted by the engine (1) into driving

power. The converter (2) transmits motion to the

drive shaft of the transmission (3) and to the drive

shaft of the hydraulic pump (4).

• The transmission (3) has two hydraulically-activated clutches that can be selected by an electricallycontrolled gearselector. It alsohas manual gear selection (four forward gears and four reverse gears).

10-2

• The driving power is transmitted from the transmission flanges (3) to the front (5) and rear (6) axles

through the Cardan drive shafts (7 and 8).

• The driving power transmitted to the front (5) and

rear (6) axles is reducedby thedifferentials andthen

transmitted to the planetary gear through the differential shafts.

WB91R-2 WB93R-2

Page 31

STRUCTURE AND FUNCTION

POWER TRAIN

Gears

1st gear 4.280

2nd gear 2.372 33.939 2.965 50.633

3rd gear 1.236 17.685 1.544 26.367

4th gear 0.662 9.472 0.827 14.123

Transmission Differential Planetary Total Transmission Differential Planetary Total

Front axle Rear axle

61.238 5.350

2.385 6.000

6

Z=37

2.846 6.000

Z=75

91.362

Z=15

4

Z=13

9

8

3

1. Diesel engine

2. Convertor

3. Transmission

4. Hydraulic pump

2

7

1

Z=13

5

5. Front axle

6. Rear axle

7. Front Cardan drive shaft

8. Rear Cardan drive shaft

Z=31 Z=75

9. Rear wheels

10. Front wheels

10

Z=15

RKZ01031

WB91R-2 WB93R-2

10-3

Page 32

STRUCTURE AND FUNCTION

TRANSMISSION (4WD)

Diagram of the power train

TRANSMISSION (4WD)

6

7

Z=27 Z=29

4

5

3

Z=27

Z=29

2

Z=38 Z=28 Z=33

Z=19

Z=24

Z=45

Z=49

Z=36

8

Z=43Z=12

9

1. Engine

2. Convertor

3. Forward clutch

4. Transmission

5. Reverse clutch

10-4

1

RKZ01040

6. Hydraulic pump

7. Rear flange

8. 4WD engagement device

9. Front flange

WB91R-2 WB93R-2

Page 33

STRUCTURE AND FUNCTION

Hydraulic convertor-transmission circuit diagram

TRANSMISSION (4WD)

0.5-3.5 bar with

reverse/forward gear engaged

0.5-5 bar in neutral

4

2

Ø2

Bearing

gear

Ø3

nd

2

Ø4

gear

st

1

gear

Ø4

rd

4

5

Forward

Ø5-Ø7

t°

11-13 bar

Ø 0.75

Hose Hose

Ø3.5

Ø1.3

Ø3.5

Ø4.5

Reverse

11-13 bar

gear

Ø3

th

3

6

Ø2

Bearing

11-13 bar

Air breather

7

Opening 23 bar

3

Valve open

3.45 bar

3

15

Opening

3.5-5.5 bar

0.5-9.0 bar

1

1. Convertor pressurization valve

2. Convertor

3. Engine

4. Oil cooler

5. Forward clutch

6. Reverse clutch

7. Max. pressure valve: calib. 23 bar

8. Spin-on filter (15

mm)

13

12

8

11

13-15.5 bar - 2200 rpm

13-14 bar - 900 rpm

14

9. Pump

10. Suction filter (250

11. 4WD engagement device

12. Check valve

13. Pressure control

14. 4WD engagement solenoid

15. Control valve group

mm)

9

4WD

10

Transmission oil sump

RKZ04921

WB91R-2 WB93R-2

10-5

Page 34

STRUCTURE AND FUNCTION

TRANSMISSION

TRANSMISSION

b 2

c

E

1

FF

d

3

a

A

4

E

D

D

A

5

7

B

6

B

8

a. From the oil cooler

b. To the oil cooler

c. To the solenoid valve group ST1 (Port P)

d. From the solenoid valve group ST1 (Port T)

RKZ00972

1. Gear lever

2. Convertor

3. Filter

4. Oil temperature sensor

5. Suction filter

6. Y5 Reverse gears command solenoid

7. Y4 Forward gears command solenoid

8. Y2 4WD command solenoid

10-6

WB91R-2 WB93R-2

Page 35

STRUCTURE AND FUNCTION

TRANSMISSION

34

1

2

5

6

17

16

15

1. Hydraulic pump drive shaft

2. Propeller shaft

3. Reverse gears command clutch

4. Forward gears command clutch

5. Reverse gears idler shaft

6. Drive shaft

7. Flange

8. 3rd gear driven gear

9. 4th gear driven gear

14

13

Section A - A

Sezione A - A

10. 4WD drive gear

11. 1st gear driven gear

12. 4WD driven gear

13. 4WD engagement device

14. Front output shaft

15. Flange

16. 2nd gear driven gear

17. Rear output shaft

12

11

10

9

8

7

RKZ04910

WB91R-2 WB93R-2

10-7

Page 36

STRUCTURE AND FUNCTION

C

1

2

9

C

TRANSMISSION

10

4

3

5

6

78

9

10

Section D - D

Sezione D - D

1. Gear-shift piston

2. Spring

3. Spring

4. Ball

5. 3rd and 4th gear selecting fork

6. 1st and 2nd gear selector piston

7. 3rd and 4th gear selector piston

8. 1st and 2nd gear selecting fork

9. 4th gear selecting sensor

12

Section B - B

Sezione B - B

13

10. 3rd and 4th gear selecting fork

11. 1st and 2nd gear selecting fork

12. Suction filter (250

13. Spin-on filter (15

14. Valve

15. Spring

16. Ball

17. Spring

11

15

14

Section E - E

Sezione E - E

mm)

mm)

Section C - C

Sezione C - C

17

16

RKZ00991

10-8

WB91R-2 WB93R-2

Page 37

STRUCTURE AND FUNCTION

DRIVE SHAFTS

Drive shaft for forward and reverse movement

1

6

5

DRIVE SHAFTS

2

bc

a

a. Port commanding reverse clutch

b. Port commanding forward clutch

c. Lubrication port

Driven gear shaft

1

4

1. Reverse gear clutch (Z=29)

2. Forward gear clutch (Z=29)

3. Forwardclutchpiston

4. Reverseclutchpiston

5. Thrust ring

6. Driven shaft

2

3

4

3

5

RKZ00950

6

8

1. Driven gear for 2st gear (Z=43)

2. Driven gear for 1st gear (Z=49)

3. 4WD drive gear (Z=45)

4. Driven gear for 4th gear (Z=24)

WB91R-2 WB93R-2

8

5. Driven gear for 3rd gear (Z=33)

6. Rear output shaft

7. Thrust ring

8. Synchronizer

7

RKZ01010

10-9

Page 38

STRUCTURE AND FUNCTION

4WD driven shaft

DRIVE SHAFTS

1

a. 4WD disengagement command port 1. Front output shaft

a

6

5

4

2. 4WD driven gear (Z=36)

3. Thrust ring

4. Cylinder

5. Spring

6. Disc

2

3

RKZ01021

10-10

WB91R-2 WB93R-2

Page 39

STRUCTURE AND FUNCTION

CONTROL VALVE BLOCK

CONTROL VALVE BLOCK

15

2

1

34

14

Section F - F

Sezione F - F

5

67 8

9

10

11

12

13

12

RKZ01000

1. Ball

2. Spring

3. Piston

4. Spring

5. Spring

6. Spring-guide pin

7. Valve

8. Spring

WB91R-2 WB93R-2

9. Valve

10. Rod

11. Spring

12. Spool return spring

13. Spool

14. Forward gear command solenoid

15. Reverse gear command solenoid

10-11

Page 40

STRUCTURE AND FUNCTION

FRONT AXLE

Differential

FRONT AXLE

3

2

1

1

4

5

17

1. Planetary gear

2. Ring bevel gear (Z=31)

3. Bevel gear

4. Lock nut

5. Half-axle

6. Pin

7. Differential housing

8. Spacer

9. Bearing

7

16

7

15

8

14

9

13

10

12

6

11

10. Seal

11. Flange

12. Cover

13. Lock nut

14. Bearing

15. Bevel pinion (Z=13)

16. Pin

17. Oil drain plug

RKZ00581

10-12

WB91R-2 WB93R-2

Page 41

STRUCTURE AND FUNCTION

Final reduction - joint

3

2

4

1

24

FRONT AXLE

7

5

8

9

6

10

11

23

22

21

1. Planetary carrier

2. Planetary (Z =29)

3. Ring gear (Z=75)

4. Ring gear carrier

5. Wheel hub

6. Seal

7. Pin

8. Shim

9. Protection

10. Bushing

11. Seal

12. Axle body

20

19

18

17

16

13

14

15

13. Bearing

14. Joint

15. Pin

16. Protection

17. Seal

18. Bearing

19. Snap ring

20. Steady pin

21. Stud bolt

22. Plug

23. Sun gear (Z=15)

24. Snap ring

12

RKZ00611

WB91R-2 WB93R-2

10-13

Page 42

STRUCTURE AND FUNCTION

Steering cylinder

FRONT AXLE

A

C

A

B

1

B

2

3

ab

Section A - A

Sezione A - A

1. Steering cylinder

2. Oil refilling plug

3. Oil drain plug

4. Nut

5. Adjustment screw

6. Nut

7. Bushing

7

7

5

4

Section B - B

Sezione B - B

6

Detail C

Particolare C

RKZ00591

a Port - From the steering unit (L Port)

b Port - From the steering unit (R Port)

10-14

WB91R-2 WB93R-2

Page 43

STRUCTURE AND FUNCTION

REAR AXLE

Differential

REAR AXLE

15

12

14

7

13

3456

8

9

7

10

1. Bearing

2. Planetary gear

3. Bevel gear

4. Ring bevel gear (Z=37)

5. Differential housing

6. Lock nut

7. Half-axle

8. Pin

WB91R-2 WB93R-2

12

11

RKZ04970

9. Bearing

10. Nut

11. Seal

12. Flange

13. Spacer

14. Bevel pinion (Z=13)

15. Differential housing

10-15

Page 44

STRUCTURE AND FUNCTION

Final reduction

REAR AXLE

16

10

15

14

4

2

3

5

6

7

8

1

9

11

1. Planetary gear carrier

2. Stud bolt

3. Wheel hub

4. Planetary gears (Z=28)

5. Ring bevel gear carrier

6. Bearing

7. Seal

8. Joint

9. Half-axle

10-16

13

12

RKZ04980

10. Planetary gear (Z=15)

11. Bushing

12. Snap ring

13. Ring gear (Z=75)

14. Oil plug

15. Steady pin

16. Pin

WB91R-2 WB93R-2

Page 45

STRUCTURE AND FUNCTION

Brakes

B

REAR AXLE

A

1

A

9

7

8

3

4

10

2

6

5

1

Detail B

Particolare B

Section A - A

Sezione A - A

RKZ04990

1. Bushing

2. Parking brake control rod

3. Bleeder valve

4. Parking brake lever

5. Parking brake control cam

WB91R-2 WB93R-2

6. Brake disk

7. Piston

8. Spring

9. Pressure disk

10. Intermediate disk

10-17

Page 46

STRUCTURE AND FUNCTION

Differential locking

REAR AXLE

1

2

8

a

7

6

a. From the solenoid valve block ST1 (Port 2)

1. Sleeve

2. Pin

3. Control rod

4. Spacer

5. Fork

6. Piston

7. Cover

8. Snap ring

10-18

5

3

4

RKZ05000

WB91R-2 WB93R-2

Page 47

PAGE INTENTIONALLY

LEFT BLANK

Page 48

STRUCTURE AND FUNCTION

HYDRAULIC PUMP

1

HYDRAULIC PUMP

A

3

D

c

BB

D

A

ba

2

d

1. Delivery variation group

2. Y1 solenoid valve working mode

3. Delivery control valve

10-20

RKZ04930

a. Port L1 - To the intake flange (Spool Port)

b. Port B - To the shovel control valve (Port P)

c. Port X2 - From the shovel control valve

(Port LS)

d. Port L - To the hydraulic oil tank

e. Port S - To the hydraulic oil tank

WB91R-2 WB93R-2

Page 49

STRUCTURE AND FUNCTION

HYDRAULIC PUMP

CC

3

4

2

1

5

Section A - A

Sezione A - A

1. Seal

2. Bearing

3. Central spring

4. Bearing

5. Control rod

6. Swash plate

7

8

9

6

11

12

Section B - B

Sezione B - B

10. Positioning piston

11. Piston

12. Guide shoe

10

7. Positioning piston

8. Spring

9. Cylinder block

RKZ00380

WB91R-2 WB93R-2

10-21

Page 50

STRUCTURE AND FUNCTION

HYDRAULIC PUMP

1

2

Section C - C

Sezione C - C

3

8

4

9

7

10

5

6

15

POWER GOVERNOR

1. Spring

2. Piston rod

3. Bushing

4. Initial adjustment spring

5. Pressure cut calibration spring

6. Pressure cut calibration screw

7. Initial adjustment calibration screw

PC VALVE

8. Spool

9. Spring (internal)

10. Spring (external)

10-22

14

Section D - D

Sezione D - D

13

12

LS VALVE

11. External spring

12. Internal spring

13. Throttles

14. Throttles

15. Spool

11

RKZ00642

WB91R-2 WB93R-2

Page 51

STRUCTURE AND FUNCTION

FUNCTION

• The rotation and torque transmitted to the pump

shaft is converted into hydraulic energy and pressurized oil is deliveredaccording tothe loadrequirements.

• The amount of oil delivered can be modified by

changing the angle of the swash plate.

HYDRAULIC PUMP

1

2

B