Page 1

Page 2

A C K H O E

B

O A D E R S

L

W

ALK

Komatsu backhoe loaders

-A

ROUND

bring together the versatility of

a backhoe loader with the performance of an excavator. Komatsu’s

exclusive HydrauMindTMhydraulic system is the ultimate combination

of power and precision creating one of the most productive backhoe

loaders in the world.

High altitude/high ambient

Increased hydraulic speed

during loader and backhoe operations

for increased productivity

temperature package available as

an option

Komatsu’s new Tier 2 engine

Improved

accelerator and parking brake

lever design

operator-friendly

provides for low emissions and

excellent fuel economy

New loader bucket design

for better penetration into thepile

and easier loading of material

3

1.0 m

offers increased capacity (1.04 m31.36 yd3bucket

available for WB150AWS)

1.3 yd3multi-purpose loader bucket

Steel reinforced front grille

and tiltable plastic hood for durability

and ease of service

Improved brake performance

new 4-wheel braking feature(4th gear only)

2

with

Lateral engine air intake

for improved visibility to bucket

during loader operation

Page 3

B

Newberry Manufacturing Operation

We constantly strive to bring new innovations to the market

High visibility maintenance

eyebrow panels with white backed

gauges for improved visibility

Improved air filtration

system

Flexible fenders

are impact and crack resistant

Two Backhoe Function Modes

- Power

- Economy

for longer service life

for increased power and speed

excavating around in-ground utilities

A C K H O ELO A D E R S

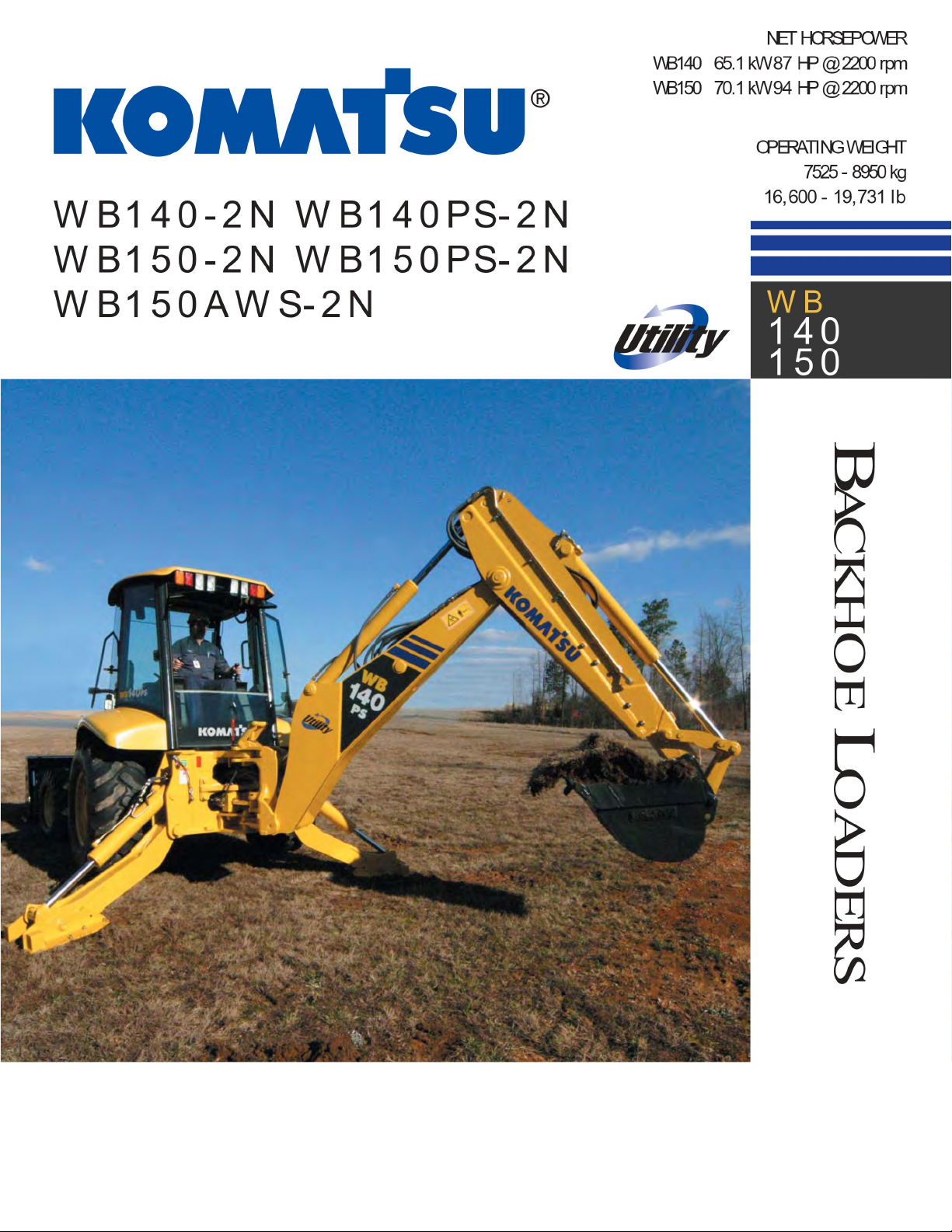

NET HORSEPOWER

WB140 65.1 kW87 HP @2200 rpm

WB150 70.1 kW94 HP @2200 rpm

OPERATING WEIGHT

7525 - 8950 kg

16,600 - 19,731 lb

for fine control when

Newly designed

boom transport lock

for enhanced reliability

Photos may include optional equipment.

Excavator type Backhoe controls

(optional)

New backhoe buckets

with KVX style teeth (optional)

Greaseless telescopic

arm wear pads

reduced maintenance cost

for

Three lever with

foot swing

control pattern

(optional)

3

Page 4

A C K H O E

B

O A D E R S

L

PERATOR

O

OMFORT

C

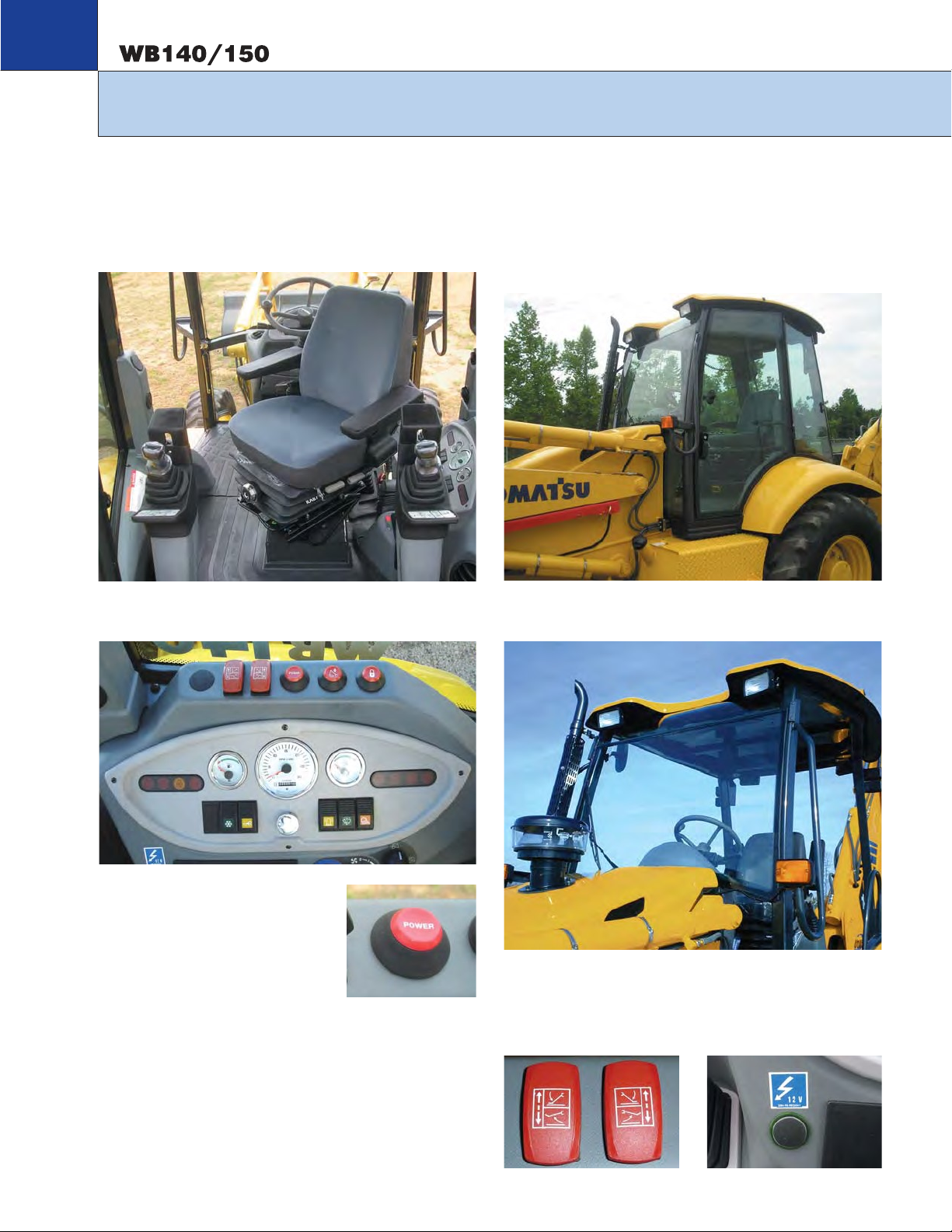

Engineered For Maximum Operator Performance and Comfort

Impro ved 360° Visibility and Mo re Leg Room

Cab interior design with excavator-type controls (optional)

New Gray Color Cab/ROPS

Less glare and reflection inside the cab, improved visibility,

and safer operation

Excavator-Type Control Dash Panel

Fun ction Mode Butt on

(ju st like Komatsu exc avators)

• Power mode for increased power

and speed

• Economy mode for fine control

when excavating around in-ground

utilities

• Increased sensitivity during

backhoe operations while

maintaining maximum performance

• Increased fuel efficiency

ROPS Canopy Windshield with Wiper and Washer

(op ti onal)

Stabilizer Switches

Controlled by the operator

in either the front or rear

working positions

Protects operator during roading operation

12V Cell Phone Power

Outlet

4

Page 5

Easier Control

Excavator-Type Controls

B

A C K H O ELO A D E R S

Serv o-Controlled J oy sticks

for Backhoe Operation

• Excellent metering and fine control

• Telescopic arm is electro-hydraulically

controlled

• Very low effort

• Ergonomic joysticks

• Control pattern change valve in cab,

allows easy conversion from

excavator to backhoe control

patterns

• More legroom

• Better visibility of the entire boom

area

Two Tiltable Control Towers

• Tilt of 15° is easily adjusted to always

provide the best visibility of the

excavation area

• Wrist support (with adjustable height)

for more comfort during operation

• Comfort: every operator can easily

find the correct working position

thanks to the mechanical memory

lock

Shift -on-the-Fly Gear Selector

(PS vers ion only)

Just twist shifter up or down to change

gear selection

• User-friendly design for ease of use

• Improved cycle times

• Less operator fatigue

Infinitely Adjustable Joyst ic ks

Can move the joysticks to any position

within a 15° range

5

Page 6

A C K H O E

B

O A D E R S

L

P

RODUCTIVITY

F

EATURES

High Productivity and Low Fuel Consumption

A powerful Komatsu S4D106-2XFH/2SFA

Turbocharged water-cooled diesel

engine provides output of 65.1 kW 87 HP

for the WB140-2N/WB140PS-2N, and

output of 70.1 kW 94 HP for

the WB150-2N/ WB150PS2N/ WB150AWS-2N. This

engine is EPA Tier 2, EU

and Japan emissions

certified without sacrificing

power or machine

productivity. The large piston

displacement of these

engines, 4.4 ltr 269 in

ensures high torque and

power, and above all exceptional

reliability.

3

,

New fuel filter

Feed pump with electric control

New injection pump

New fuel hoses layout

Improved Air Filtration

Donaldson Filter

Tremendous Hydraulic Power

Under Your Complet e Control

With Proven HydrauMind

Excavator Technology

Komatsu’s exclusive HydrauMind

hydraulic system is the ultimate

combination of power and precision

creating one of the most productive

backhoe loaders in the world. The

system consists of a single variable

flow axial piston pump and an

Cooling SystemAir Filter

Large Capacity Side-by-Side

Radiator

"intelligent" hydraulic circuit that allows

the machine to adapt instantaneously

to the specific operation being carried

out. Superior lift capacities and

breakout forces are achieved with

HydrauMind.

Clo sed-Center Load Sens ing

Sys tem (CLSS)

The Closed-Center Load Sensing

System, together with the variable flow

pump, means that only the amount of

oil necessary for ensuring high

operating pressure is generated and

used. This guarantees greater

efficiency, lower fuel consumption and

quiet operation.

Lo ad Independent Flow Divider

(LIFD)

Another Komatsu innovation is the

Load Independent Flow Divider

hydraulic valve block. The speed of

each movement is completely

independent from that of the others,

and the proportions between the various

movements remain constant even

when the load resistance varies,

resulting in shorter cycle times and

greater productivity. Engine power is

transmitted hydraulically to a transfer

case, then manually out to the

differentials and out to the four driving

wheels.

6

Page 7

B

A C K H O ELO A D E R S

NCREASED

I

ELIABILITY

R

More Dependable

Komatsu backhoe loaders are the only machines that

combine the versatility of a backhoe loader with the

performance of an excavator.

Steel Reinforced Fro nt Grill

Protects radiator/oil cooler from external damage

ND

A

Flex ible Fenders

Impact and crack resistant and maintain their shape

ERVICEABILITY

S

Cab and Canopy Roof / Improved Lighting

New design provides more strength, durability, and better visibility with four lights,

front and rear (optional).

Front View

Reinforced Struct ure

Rear View

Retu rn -to-Dig Sensor

New design for enhanced durability

View from underneath

7

Page 8

A C K H O E

B

S

PECIFICATIONS

EN GI N E REFILL CA PACI TIES

Model WB140-2N/WB140PS-2N . . . . . . . . . . . . . . Komatsu S4D106-2XFH

WB150-2N/WB150PS-2N/WB150AWS-2N . . Komatsu S4D106-2SFA

Type . . . . . . . . . . . . . . . . . . . . . . . .Vertical, 4-cycle water-cooled diesel engine

Aspiration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Turbocharged

Combustion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Direct injection

Compression ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17:1

Number of cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Cylinder, bore x stroke . . . . . . . . . . . . . . . . . . . . . 106 x 125 mm 4.2" x 4.9"

Piston displacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.4 ltr 269 in

Horsepower rating - WB140-2N/WB140PS-2N

Gross horsepower @2200 rpm . . . . . . . . . . . . . . . . . . . . . 69.5 kW93 Hp

Flywheel/net horsepower @ 2200 rpm (SAE J 1349) . . . . . 65.1 kW87 Hp

Max. torque @1400 rpm . . . . . . . . . . . . . . . . . . . . . . . . . 348 Nm 257 ft lb

Horsepower rating - WB150-2N/WB150PS-2N/ WB150AWS-2N

Gross horsepower @2200 rpm . . . . . . . . . . . . . . . . . . . . 74.5 kW100 Hp

Flywheel/net horsepower @ 2200 rpm (SAE J 1349) . . . . . 70.1 kW94 Hp

Max. torque @1600 rpm . . . . . . . . . . . . . . . . . . . . . . . . . 368 Nm 271 ft lb

Air cleaner . . . . . . . . . . . dry, dual element with dust evacuator and indicator

EL ECTRICAL SY ST EM

Electric circuit with protected connections in all exposed areas

Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12 V

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120 Ah (860 cca)

Alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80 A

Electric starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 kW

O A D E R S

L

Engineoil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.9 ltr 2.1US gal

Cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 ltr 3.7 USgal

Diesel tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130 ltr 34.3 USgal

Hydraulic oil tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92 ltr 24.3 USgal

Front axleoil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.5 ltr 2.3 USgal

Rear axleoil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17.5 ltr 4.6 USgal

Gear box oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 ltr 4.5 USgal

3

WB140-2N/WB140PS-2N/WB150-2N/WB150PS-2N

The front wheels arecontrolled by a hydrostatic load sensing steering

priority valvesystem

Turning radius at outer edge of front tire:

Without Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4300 mm 14'1"

With Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3400 mm 11'2"

WB150AWS-2N

The new Komatsu steering system ensures excellent maneuverability and

versatility and allows theoperator to choose from the following three

different steering modes by the push of a button: Two Wheel Steering, Four

Wheel Coordinated Steering, Crab Steering

Turning radius (4 wheel coordinated steering mode, w/o individual braking):

Edge of tire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4175 mm 13'8"

Edge of bucket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4700 mm 15'5"

ST EERI NG

HYDRA ULI C SY ST EM

The Hydraumind hydraulic system affords the operator very precise backhoe

movements. This system is energy efficient and incorporates two different

workingmodes: economy and constant power. Theadvanced hydraulic system

includes the “speed up” function to increase the working speed of the front

loader.

System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . HydrauMind

Type . . . . . . . . . . . . . . . . . . . . . . . Closed center Load Sensing System (CLSS)

with economy/power selector switch

(power mode is the default setting)

Pump type . . . . . . . . . . . . . . . . . . . . . . . . . . Variable displacement axial piston

Pump control system . . . . . . . Load Sensing set to adjust thehydraulic power

Main Valve . . . . . . . . . . . .“Load Independent Flow Divider” LIFD modular type

Max delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165 ltr/min 43.6 gal/min

Work pressure

WB140-2N/WB140PS-2N . . . . . . . . . . . . . . . . . . . . . . . . 207 bar 3,000 psi

WB150-2N/WB150PS-2N/ WB150AWS-2N . . . . . . . . . . 221 bar 3,200 psi

AXL ES

WB140-2N/WB140PS-2N/WB150-2N/WB150PS-2N

Heavy duty axles with planetary reduction gears in thewheel hubs. Front

axle total oscillation angleis 20°. Differential lock in the rear axle controlled

by electro-hydraulic system with a switch on loader lever.

Max front strength (Dynamic) . . . . . . . . . . . . . . . . . . . .6300 daN 14,175 lb

Max front strength (Static) . . . . . . . . . . . . . . . . . . . . . 15750 daN 35,406 lb

Max rear strength (Dynamic) . . . . . . . . . . . . . . . . . . . 12000 daN 27,000 lb

Max rear strength (Static) . . . . . . . . . . . . . . . . . . . . . . 32500 daN 73,060 lb

WB150AWS-2N

Axles arelimited slip, allowing for power traction, even while turning. Front

axle total oscillation angel is 16°.

Max front strength (Dynamic) . . . . . . . . . . . . . . . . . . . 10000 daN 22,480 lb

Max front strength (Static) . . . . . . . . . . . . . . . . . . . . . 25000 daN 56,200 lb

Max rear strength (Dynamic) . . . . . . . . . . . . . . . . . . . 10000 daN 22,480 lb

Max rear strength (Static) . . . . . . . . . . . . . . . . . . . . . . 25000 daN 56,200 lb

8

Page 9

B

TRA NSMIS SI ON

WB140-2N/WB150-2N

Switching between 2WD and 4WD is achieved through an electro-hydraulic

system. The transmissionis operated through a torque converter and a power

shift reversing shuttle; themechanical 4-speed gearbox is synchronized.

Travel

Speeds

Forward 6.3 3.9 11.4 7.1 21.3 13.2 37.8 23.5

Reverse 6.3 3.9 11.4 7.1 21.3 13.2 37.8 23.5

WB140PS-2N/WB150PS-2N/WB150AWS-2N

Electronically-controlled, four-wheel-drive, full powershift transmission. Twist

Grip or EGMTM(Electronic Gear Management) gear Controlsfor changing

driving direction and gears at full power without disengaging thedrive.

Twist Grip Controls in manual modeon WB140PS-2N/WB150PS-2N

EGMTMGear Controls in automatic or manual modeon WB150AWS-2N

Travel

Speeds

Forward 6.5 4.0 12.0 7.5 23.0 14.3 4.0 24.9

Reverse 6.35 4.0 12.0 7.5 23.0 14.3 — —

1st 2nd 3rd 4th

km/h mp h km/h mph km/h mph km/h mph

1st 2nd 3rd 4th

km/h mp h km/h mph km/h mph km/h mph

A C K H O ELO A D E R S

LOA DER

The design of thefront loader allows for better tensilestrengthdistributionand

parallel movements when lifting and lowering the bucket. Due to the linkage

geometry, thegreasing points have been dramatically reduced.

Standard bucket width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2355 mm 7'9"

Capacity (SAE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.95 m31.25yd

STD bucket weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .454 kg 1,000 lb

Lifting capacity at maximum height:

WB140-2N/WB140PS-2N . . . . . . . . . . . . . . . . . . . . . . . 3675 daN 8,270 lb

WB150-2N/WB150PS-2N/WB150AWS-2N . . . . . . . . . . 3965 daN 8,925 l b

Lifting capacity at ground level:

WB140-2N/WB140PS-2N . . . . . . . . . . . . . . . . . . . . . . 4700 daN 10,580 lb

WB150-2N/WB150PS-2N/WB150AWS-2N . . . . . . . . . 5075 daN 11,420 lb

Breakout force:

WB140-2N/WB140PS-2N . . . . . . . . . . . . . . . . . . . . . . 5685 daN 12,790 lb

WB150-2N/WB150PS-2N/WB150AWS-2N . . . . . . . . . 6145 daN 13,825 lb

BAC K HOE

Theboom has a rounded profile and a reinforced structure built with cast

ends, allowing 180° rotation while maintaining high rotation torque.

Bucket breakout force:

WB140-2N/WB140PS-2N . . . . . . . . . . . . . . . . . . . . . . 6005 daN 13,515 lb

WB150-2N/WB150PS-2N/WB150AWS-2N . . . . . . . . . 6525 daN 14,685 lb

Dipper digging force:

WB140-2N/WB140PS-2N . . . . . . . . . . . . . . . . . . . . . . . 3925 daN 8,825 lb

WB150-2N/WB150PS-2N/WB150AWS-2N . . . . . . . . . . 4155 daN 9,350 l b

3

9

Page 10

A C K H O E

A

B

L

DI MEN SI ON S AND WORK I N G R ANGE

M

O A D E R S

R

O

B

C

D

H

F

E

G

I

J

K

L

T

S

N

P

Q

10

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Loading...

Loading...