Page 1

Operation & Maintenance

Manual

CEAM009402

WB140WB150-

BACKHOE LOADER

WB140-2N A20001

SERIAL NUMBERS

WB150-2N A60001

This material is proprietary to Komatsu Utility Division and is not to be reproduced, used, or disclosed except in accordance

with written authorization from Komatsu Utility Division.

2N

2N

and UP

and UP

It is our policy to improve our products whenever it is possible and practical to do so. We reserve the right to make changes or

add improvements at any time without incurring any obligation to install such changes on products sold previously.

Due to this continuous program of research and development, periodic revisions may be made to this publication. It is

recommended that customers contact their distributor for information on the latest revision.

January 2003 Copyright 2003 Komatsu

DataKom Publishing Division

Page 2

Page 3

PRODUCT PUBLICATIONS INFORMATION

Various product Parts and Service Publications are available to all KOMATSU construction equipment

owners, including operation and maintenance manuals, parts books and service manuals.

Special publications, such as service tool, air conditioning and turbocharger service manuals are also

available as well as selected Operation and Service manuals in foreign languages.

The Publications listed below are available for this particular machine(s).

DESCRIPTION FORM NUMBER

PARTS BOOK - PAPER:

Chassis and Engine (WB140-2N). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . BEPB020801

Chassis and Engine (WB150-2N). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . BEPB021300

OPERATION AND MAINTENANCE MANUAL:

Chassis and Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . CEAM009402

SHOP MANUAL

Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . CEBM009800

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WEBM4D9801

SAFETY MANUAL

Machine specific . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . BL10-3

Parts and Service Publications can only be acquired by authorized KOMATSU distributors using the

Komatsu America International Company Parts Inventory Processing System (PIPS) or the Extranet Literature Ordering System.

If the PIPS system is not available at the distributor location, then the following Requisition for Technical

Service Publications and Service Forms can be used. Form KDC91E is shown on the reverse side of this

page.

WB140-2N Pubinfok.fm 1/24/03

Page 4

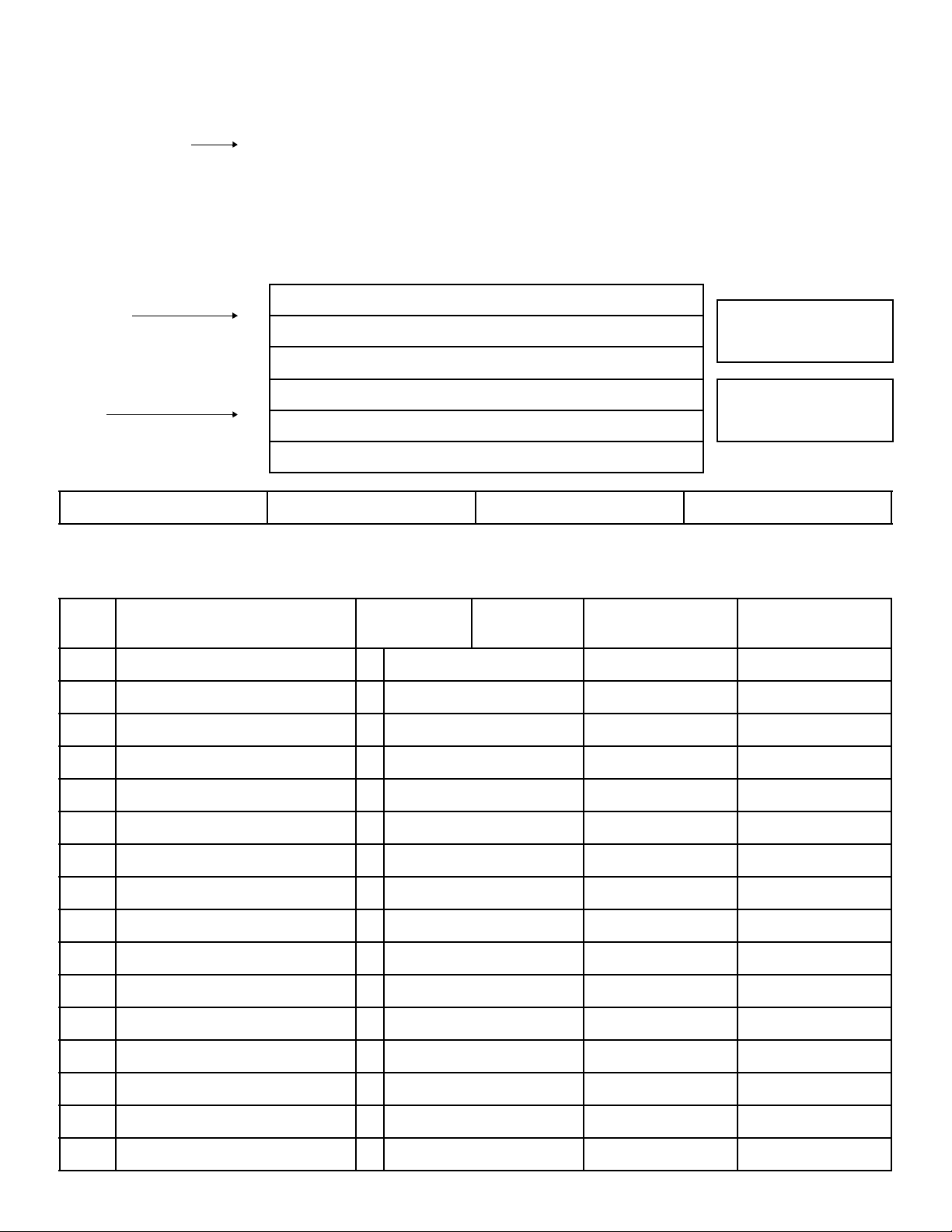

REQUISITION FOR TECHNICAL SERVICE PUBLICATIONS AND SERVICE FORMS

COMPLETE FORM

AND RETURN TO

DataKom Publishing Division

440 North Fairway Drive

Vernon Hills, IL 60061-8112 U.S.A.

Attn: Service Publications

Fax No. (847) 970-4186

Tel No. (847) 970-5887

COMPANY NAME

SHIP TO

TYPE or PRINT

ONLY

PHONE NO. FAX NO. SHIPPING METHOD DISTR/BRANCH CODE

ATTN .

STREET ADDRESS ORDER DATE

CITY, STATE, ZIP CODE

COUNTRY

PURCHASE ORDER NO.

IMPORTANT - TO ASSURE SHIPMENT OF THE CORRECT PUBLICATION(S), THE MODEL NUMBER AND

MACHINE SERIAL NUMBER MUST BE SHOWN.

QTY. PUBLICATION FORM NO. PARTS BOOK PUBLICATION

➥

M-Microfiche

P-Paper

DESCRIPTION

MODEL NUMBER SERIAL NUMBER

KDC91E 040202 CURRENT PRICES WILL BE CHARGED

Page 5

0INTRODUCTION

WB140-2N, WB150-2N

0-1

Page 6

INTRODUCTION

FOREWORD

This manual describes procedures for operation, handling, lubrication, maintenance, checking, and adjustment. It will help the

operator and maintenance personnel achieve peak performance through effective, economical and safe machine operation andmaintenance.

Keep this manual handy and have all personnel read it periodically. If this manual is lost, damaged or becomes dirty and cannot be read, request a replacement manual from your local distributor.

If you sell the machine, be sure to give this manual to the new owner.

Continuing improvements in the design of this machine can lead to changes, which may not be reflected in this manual. Consult your local KOMATSU distributor or for the latest available information on your machine or for questions regarding information in this manual.

This manual may contain attachments and optional equipment that are not available in your area. Consult your local

KOMATSU Distributor or for those items that you may require.

Improper operation and maintenance of this machine can be hazardous and could result in serious injury

or death.

• Operators and maintenance personnel must read this manual thoroughly before operating or maintaining this

machine.

• This manual should be kept near or with the machine for reference and periodically reviewed by all personnel who

operate it.

• Some actions involved in operation and maintenance can cause a serious accident, if they are not performed in the

manner described in this manual.

• The procedures and precautions given in this manual apply only to the intended uses of this machine. If you use

your machine for any unintended uses that are not specifically prohibited, you must be sure that it is safe for you

and others. In no event should you or others engage in prohibited uses or actions as described in this manual.

• KOMATSU delivers machines that comply with all applicable regulations and standards of the country to which it

has been shipped. If this machine has been purchased in another country or purchased from someone in another

country, it may lack certain safety features and specifications that are necessary for use in your country. If there is

any question about whether your product complies with the applicable standards and regulations of your country,

consult your local distributor or KOMATSU before operating the machine.

• The safety description is given in SAFETY INFORMATION and in the SAFETY section 1.

0-2 WB140-2N, WB150-2N

Page 7

INTRODUCTION

SAFETY INFORMATION

Most accidents are caused by failure to follow fundamental safety rules for the operation and maintenance of the machine. To

avoid accidents, read, understand and follow all precautions and warnings in this manual and on the machine before performing maintenance and machine operations.

To identify safety messages in this manual and on machine product graphics, the following signal words are used:

DANGER! - This word is used on safety messages and product graphics where there is a high probability of serious injury or

death if the hazard is not avoided. These safety messages and product graphics usually describe precautions that

must be taken to avoid the hazard. Failure to avoid this hazard may result in serious damage to the machine,

injury or even death.

WARNING! - This word is used on safety messages and product graphics where there is a potentially dangerous situation,

which could result in serious injury or possibly death if the hazard is not avoided. These safety messages and

product graphics usually describe precautions that must be taken to avoid the hazard. Failure to avoid this hazard may result in serious damage to the machine or possible injury.

CAUTION! - This word is used on safety messages and product graphics for hazards, which could result in minor or moderate

injury if the hazard is not avoided. These safety messages and product graphics might also use this word for

hazards where the only result could be damage to the machine.

Remark

This word is used for precautions that must be taken to avoid actions, which could shorten the life or damage

the machine.

Safety precautions are described in SAFETY section 1.

KOMATSU cannot predict every circumstance that might involve a potential hazard in operation and maintenance. Therefore

the safety message in this manual and on the machine may not include all possible safety precautions. If any procedures or

actions not specifically recommended or allowed in this manual are used, you must be sure that you and others can do such

procedures and actions safely and without damaging the machine or causing injury. If you are unsure about the safety of some

procedures, contact your local KOMATSU Distributor.

WB140-2N, WB150-2N 0-3

Page 8

INTRODUCTION

APPROVED AND NON-APPROVED USES

The Komatsu BACKHOE LOADERS described in this manual have been designed and constructed to be used mainly for the

following functions, any non-approved used may void the warranty, damage the machine or possibly injure the operator.

APPROVED

• LOADING, SCRAPING OR GRADING OPERATIONS.

• EXCAVATING.

Installation of optional equipment can also be used in the following applications, use only KOMATSU approved equipment.

• HANDLING OF MATERIALS (4 IN 1 BUCKET - PALLET FORKS).

• SNOWPLOWING (ANGLE DOZER BLADE - SNOWPLOW).

• DEMOLITION (HAND HAMER - HAMMER ON BACKHOE UNIT).

• DITCH CLEANING AND DIGGING (SPECIAL BUCKETS).

NON-APPROVED

This paragraph describes some of the improper or unauthorized uses of the machine; since it is impossible to predict all the

possible improper uses, if the machine happens to be used for any particular application other than those approved above, it is

important to contact your Authorized Komatsu Dealer before carrying out the work operations.

• USE OF MACHINE FOR LIFTING OR TRANSPORTING PERSONNEL IN ANY MANNOR.

• TRANSPORTATION OF FLAMMABLE LIQUIDS.

• LIFTING, MOVING OR TRANSPORTING OTHER MACHINES WITH THE FRONT END LOADER OR BACKHOE

UNIT.

• TOWING OTHER EQUIPMENT WITH THE TRACTOR UNIT OR WORK EQUIPMENT.

• USING THE BACKHOE UNIT TO MOVE OR REPOSITION THE MACHINE.

• USING THE BACKHOE OR LOADER AS A HAMMER OR FOR STRIKING OR DRIVING OBJECTS.

• TOWING THE MACHINE AT HIGH SPEEDS

• TRAVELING AT HIGH SPEEDS.

0-4 WB140-2N, WB150-2N

Page 9

INTRODUCTION

PRODUCT INFORMATION

Listed are features and machine identification locations. Komatsu backhoe loader and main components are identified by

serial numbers stamped on identification plates or decals attached to the machine or component.

MAIN FEATURES

• Simple and easy operation.

• Power assisted steering with priority hydraulic system.

• Loader control through a single lever ensures combined movements that can be modulated proportionally and continually.

• Wobble stick backhoe controls with two levers ensure combined movements that can be modulated proportionally and-

continually.

• Complete series of instruments visible from the two operating positions (loader or backhoe).

• Separate engine throttle controls for the two operating positions.

• Foot brake control.

• Easy maintenance with simplified intervals.

BREAK-IN PERIOD

Every new machine is properly adjusted and tested before delivery. A new machine must be operated carefully for the first

100 hours in order to ensure proper running-in time for the various components. It the machine is subjected to excessive or

sever work loads at the beginning of it’s operation, it’s functions will be greatly reduced or damaged. Every new machine must

be used carefully, pay special attention to the following indications:

• After start-up, let the engine idle ar a low RPM for 5 minutes, to warm it up the machine gradually before

beginning actual operation.

• Operate the machine with limited loads.

• Avoid abrupt starts, accelerations, sudden decelerations, abrupt reversals or sudden stops.

• After the first 250 hours

at 250 hours

A. Change the hydraulic transmission oil and filter.

B. Change the differential unit oil (front and rear axle).

C. Change the oil in the final reduction gears (front and rear axle).

D. Check and adjust the engine valve clearance.

E. Change the hydraulic system oil filter. SYNTHETIC BIODEGRADABLE OIL TYPES

perform:

, carry out the following maintenance, in addition to normal maintenance performed

SYNTHETIC BIODEGRADABLE OIL TYPES

On machines in which synthetic biodegradable types of oils are used, the following operations are to be performed besides the

standard maintenance operations:

• After the first 50 hours

• After the first 500 hours

of operation, change the hydraulic system filter.

of operation, change the hydraulic system oil and filter.

WB140-2N, WB150-2N 0-5

Page 10

INTRODUCTION

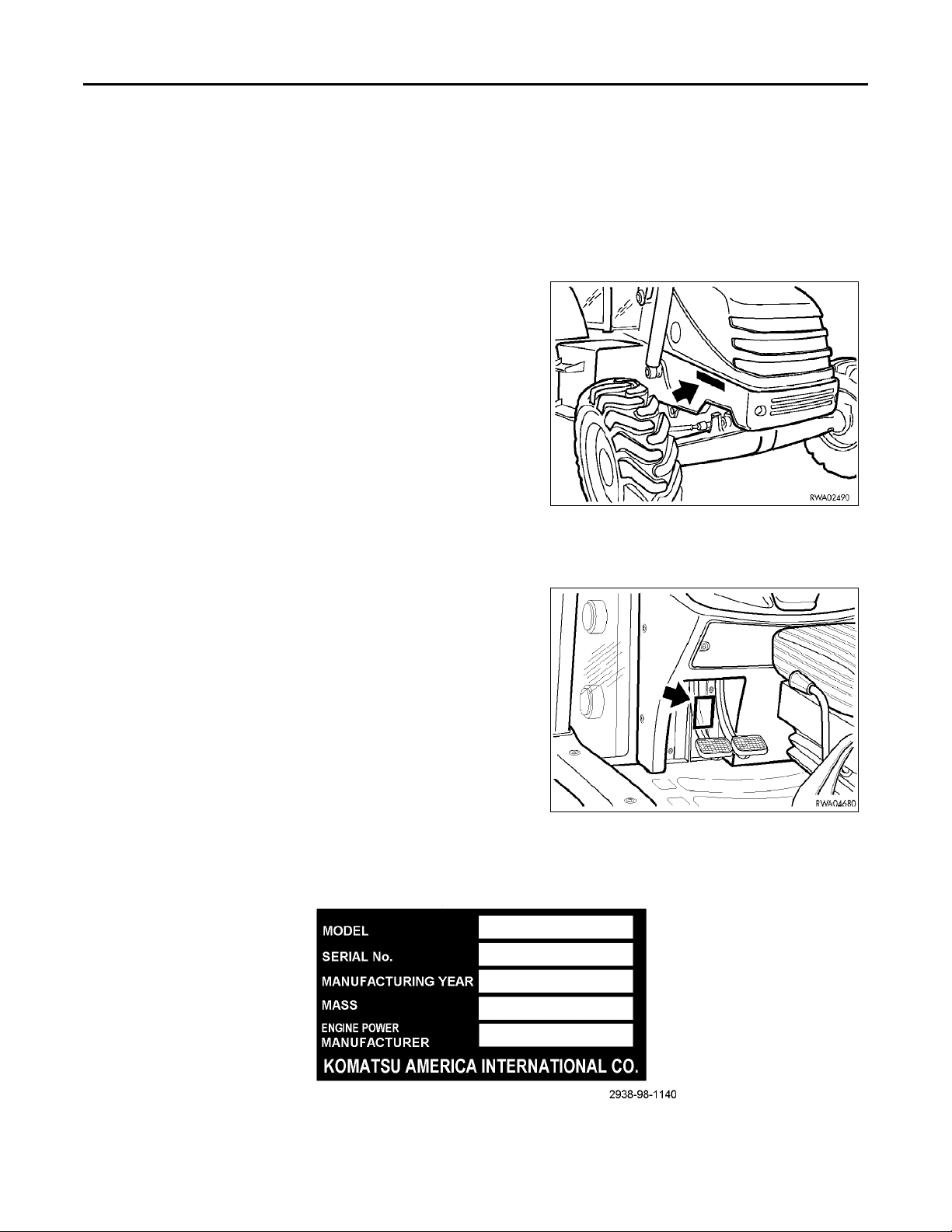

PRODUCT IDENTIFICATION

The serial numbers and model numbers on the components are the only numbers that your dealer will need when requiring

assistance or ordering replacement parts. It is a good idea to record this information in this manual on page 0-9 (Serial Number

and Dealer Information). All views indicated below are viewed from the operators position.

MACHINE SERIAL NUMBER

The machine serial number is stamped on the right side of the front

part of the main tractor frame.

MACHINE IDENTIFICATION PLATE

The Komatsu backhoe loaders described in this manual are provided

with the “CE” mark which certifies that they are in compliance with the

CE standards.

The identification plate is located inside the operators cab on the left

vertical wall of the frame, behind the brake pedals.

0-6 WB140-2N, WB150-2N

Page 11

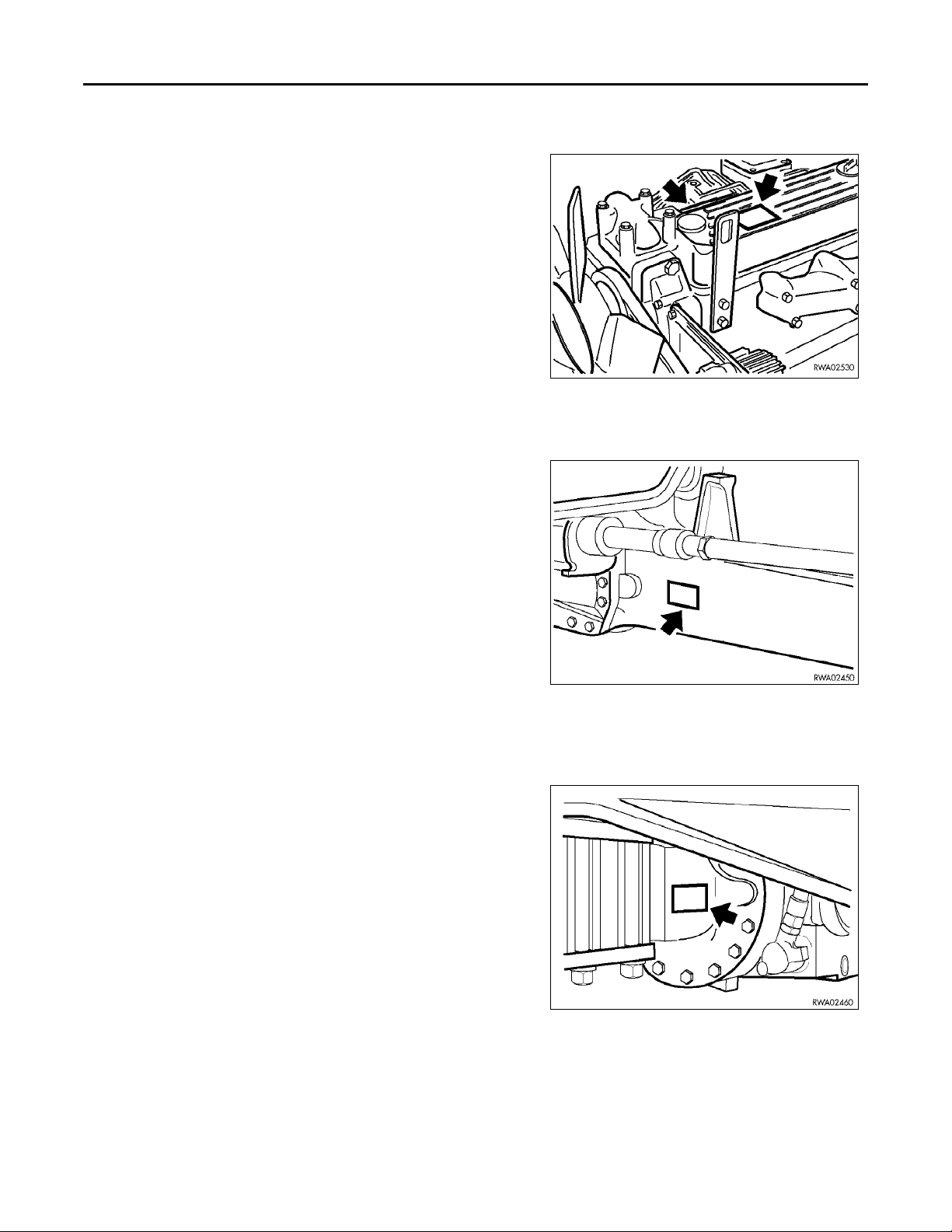

ENGINE SERIAL NUMBER AND EMISSION LABEL

The engine serial number is stamped on a plate located on top of the

engine valve cover.

The emission label is located on the right side of the valve cover.

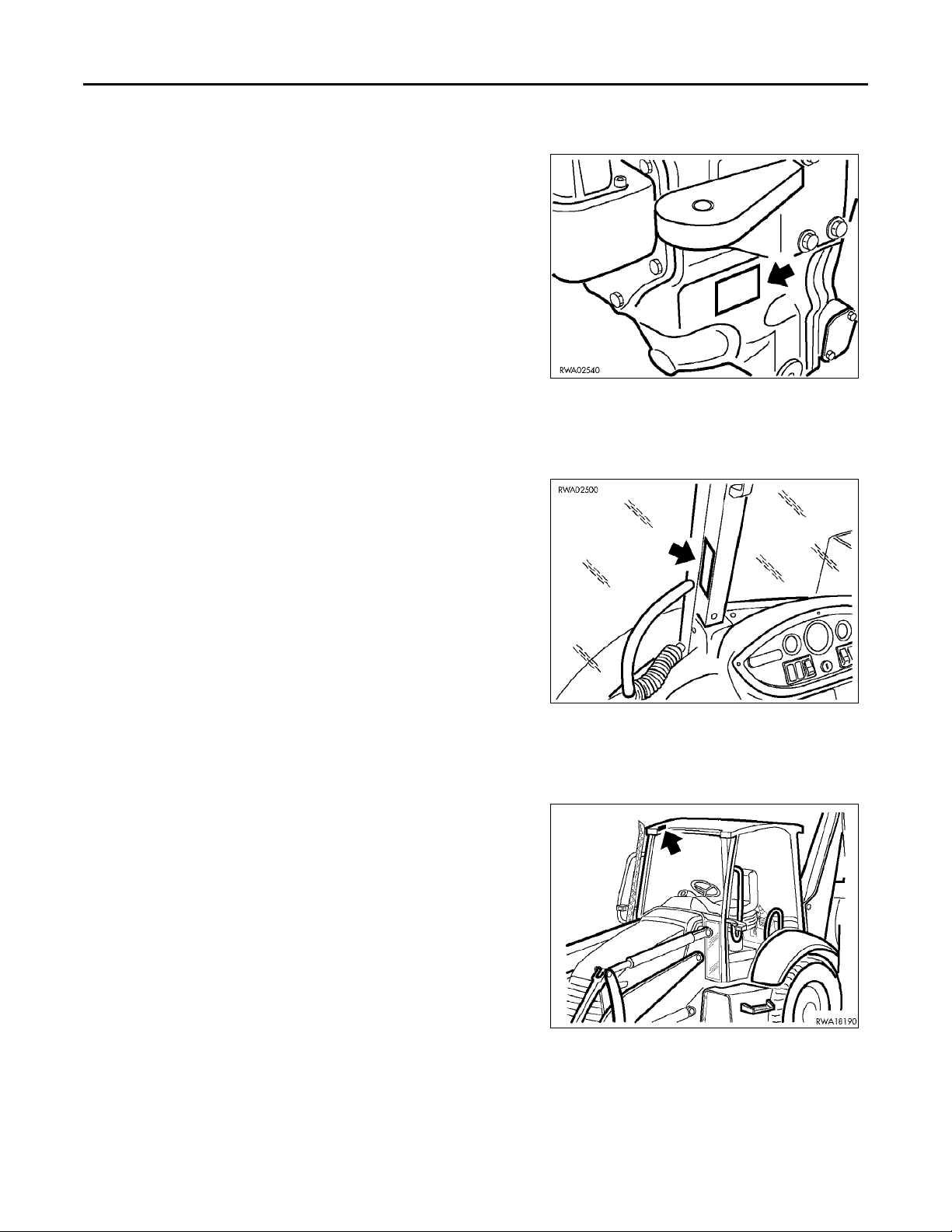

FRONT AXLE SERIAL NUMBER

The serial number for the front axle is stamped on a plate located on the

right side of the axle housing.

INTRODUCTION

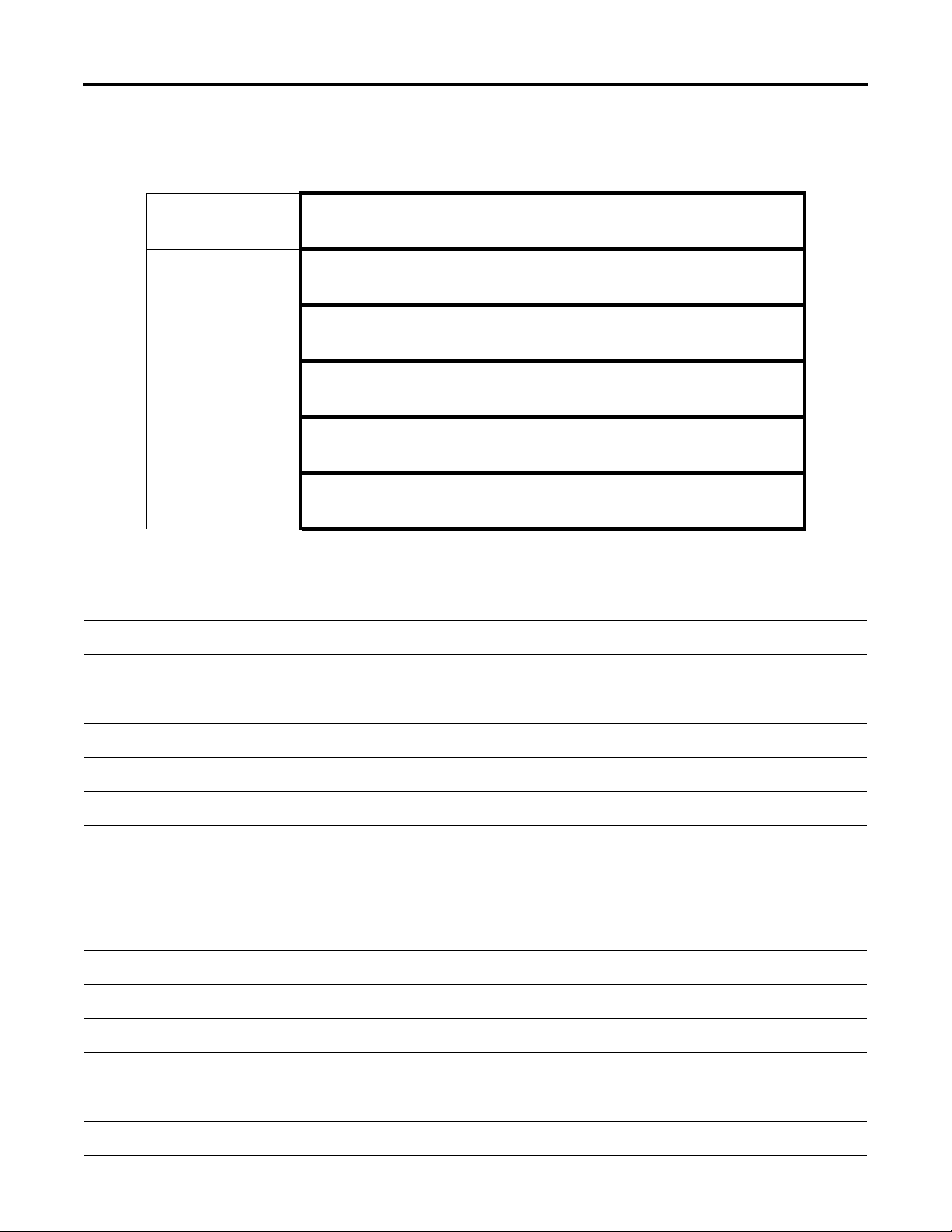

REAR AXLE SERIAL NUMBER

The serial number for the rear axle is stamped on a plate located on the

right side of the axle housing.

WB140-2N, WB150-2N 0-7

Page 12

INTRODUCTION

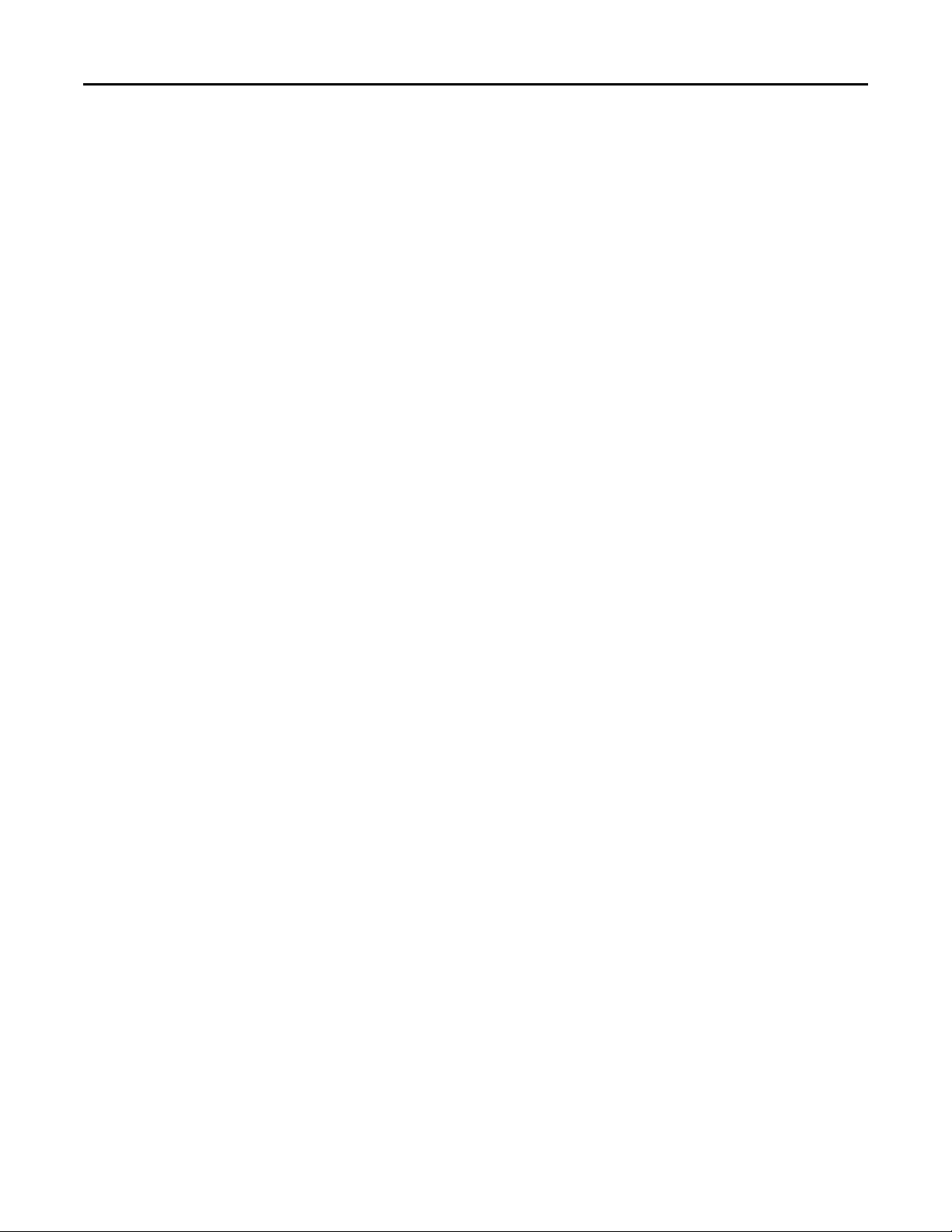

TRANSMISSION SERIAL NUMBER

The serial number for the transmission is stamped on a plate located on

the right side of the transmission case.

CAB SERIAL NUMBER

The serial number for the cab is stamped on a plate located on the right

center pillar.

CANOPY SERIAL NUMBER

The serial number for the canopy is stamped on the plate located on the

inside upper right corner.

0-8 WB140-2N, WB150-2N

Page 13

SERIAL NUMBERS AND DEALER INFORMATION

MODEL: WB140-2N / WB150-2N

Machine #

Engine #

Front axle #

Rear axle #

Transmission #

Cab or Canopy #

INTRODUCTION

Dealer:

Address:

Phone #

Contacts:

NOTES:

WB140-2N, WB150-2N 0-9

Page 14

INTRODUCTION

CONTENTS

INTRODUCTION

FOREWORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-2

SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-3

APPROVED AND NON-APPROVED USES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-4

APPROVED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-4

NON-APPROVED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-4

PRODUCT INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-5

MAIN FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-5

BREAK-IN PERIOD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-5

SYNTHETIC BIODEGRADABLE OIL TYPES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-5

PRODUCT IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-6

MACHINE SERIAL NUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-6

MACHINE IDENTIFICATION PLATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-6

ENGINE SERIAL NUMBER AND EMISSION LABEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-7

FRONT AXLE SERIAL NUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-7

REAR AXLE SERIAL NUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-7

TRANSMISSION SERIAL NUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-8

CAB SERIAL NUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-8

CANOPY SERIAL NUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-8

SERIAL NUMBERS AND DEALER INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-9

MODEL: WB140-2N / WB150-2N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-9

CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-10

SAFETY

GENERAL SAFETY RULES AND PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

GENERAL SAFETY RULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

SAFETY FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

PERSONAL PROTECTIVE EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

UNAUTHORIZED MODIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

LEAVING OPERATOR’S COMPARTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

MOUNTING AND DISMOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

FIRE PREVENTION FOR FUEL AND OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

DUST HAZARD PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

CRUSH OR PINCH POINT DANGERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

FIRE EXTINGUISHER AND FIRST AID KIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

INSIDE OPERATOR’S COMPARTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

PRECAUTIONS WHEN USING ROPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

PRECAUTIONS FOR ATTACHMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

PRECAUTIONS BEFORE STARTING WORK OPERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

PRE-OPERATIONAL CHECKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

PERFORM A WALK AROUND CHECK OF YOUR MACHINE . . . . . . . . . . . . . . . . . . . . . 1-8

UNDER THE HOOD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

IN THE OPERATOR’S CAB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

START-UP CHECKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

STARTING YOUR WORK OPERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

0-10 WB140-2N, WB150-2N

Page 15

INTRODUCTION

WORK SITE HAZARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

WORKING CLEARANCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

RULES FOR ROAD TRAVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

RULES FOR TRAVELING IN REVERSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

TRAVELING ON ICY OR SNOW-COVERED SURFACES . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

WORKING ON LOOSE OR UNSTABLE GROUND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

PRECAUTIONS DURING MAINTENANCE OPERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

WARNING TAGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

EQUIPMENT STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

WORKING UNDER THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

USING DROP LAMPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

KEEPING THE MACHINE CLEAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

RUNNING THE MACHINE DURING MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

RULES FOR REFUELING THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

COOLING SYSTEM PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

BATTERY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

STARTING THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

HIGH PRESSURE HOSES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

HIGH TEMPERATURES AREAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

ROTATING PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

DISPOSAL OF WASTE MATERIALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

INFLATING TIRES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

CRITICAL PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

VIBRATIONS TO WHICH THE OPERATOR IS EXPOSED . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

SAFETY AND WARNING DECALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

LOCATION OF THE SAFETY DECALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

LOCATION OF THE PICTOGRAM DECALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

OPERATION

GENERAL VIEW OF MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

FRONT VIEW OF MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

REAR VIEW OF MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

PICTOGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

WORK AREA DANGERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

MOVING OR ROTATING ENGINE COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

FILLING THE HYDRAULIC SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

ENGINE OIL FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

BRAKE FLUID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

FUEL FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

ENGINE COOLANT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

AIR FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

ENGINE COOLANT PRESSURE WARNING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

HYDRAULIC OIL LEVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

HYDRAULIC OIL FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

TRANSMISSION OIL LEVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

TRANSMISSION FLUID FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

ANCHORAGE POINT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

EMERGENCY EXIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

WB140-2N, WB150-2N 0-11

Page 16

INTRODUCTION

BOOM LOCK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

SWING LOCK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

DESCRIPTION OF MACHINE OPERATION CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

INSIDE THE CAB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

FRONT INSTRUMENT BEZEL AND CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

TRANSMISSION OIL TEMPERATURE ALERT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

ENGINE COOLANT TEMPERATURE ALERT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

FOUR-WHEEL DRIVE (IN/OUT) INDICATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

LOW FUEL ALERT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

DIRECTIONAL SIGNAL INDICATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

HIGH BEAM INDICATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

PARKING BRAKE AND BRAKE FLUID ALERT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

DIFFERENTIAL (LOCK/UNLOCK) INDICATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

MULTIFUNCTIONAL DIRECTIONAL SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

FOUR-WHEEL DRIVE SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

WINDSHIELD WIPER/WASHER SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

FRONT WORK LAMPS SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

EMERGENCY (HAZARD) SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

OPTIONAL EQUIPMENT SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

SIDE INSTRUMENT BEZEL AND CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

FUEL LEVEL GAUGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

TACHOMETER AND HOUR METER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

ENGINE COOLANT TEMPERATURE GAUGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

AIR CLEANER RESTRICTION ALERT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

ENGINE OIL PRESSURE ALERT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

GLOW PLUGS PREHEAT INDICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

ALTERNATOR ALERT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

ENGINE COOLANT TEMPERATURE ALERT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

OPTIONAL EQUIPMENT ALERT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

AUDIBLE WARNING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

REAR WORK LAMPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

WINDSHIELD WIPER/WASHER SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

EMERGENCY FLASHING LIGHT SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

REAR HORN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

LOAD STABILIZER SWITCH (OPTIONAL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

AIR CONDITIONING SWITCH (OPTIONAL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

IGNITION SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

BLOWER SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

BACKHOE POWER CONTROL SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

BACKHOE BOOM LOCK SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

OPTIONAL SWITCH LOCATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

FRONT END LOADER CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

LOADER DECLUTCH CONTROL BUTTON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

DIFFERENTIAL LOCK BUTTON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

BUCKET OPEN BUTTON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

BUCKET CLOSE BUTTON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

FRONT END LOADER SPEED CONTROL BUTTON . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

GEAR SHIFT LEVER CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

DECLUTCH BUTTON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

0-12 WB140-2N, WB150-2N

Page 17

INTRODUCTION

CHANGING SPEED RANGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

DIRECTIONAL CONTROL LEVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

BRAKES, PARKING BRAKE, ACCELERATOR AND THROTTLE CONTROL . . . . . . . . . . 2-19

BRAKE PEDALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

PARKING BRAKE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

ACCELERATOR PEDAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

HAND THROTTLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

CAB ENVIRONMENT AND SAFETY EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

HEATING AND VENTILATION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

AIR CONDITIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

HEATING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

SEAT AND SEAT BELT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

SEAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

SEAT BELT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

SAFETY EQUIPMENT AND STORAGE AREAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

FIRE EXTINGUISHER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

FIRST AID KIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

DOCUMENT STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

TOOL CASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

CAB AND GUARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

CAB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

DOORS AND WINDOWS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

ENGINE HOOD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

ELECTRICAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

SWITCHES AND EXTRA ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

OVERHEAD LAMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

BATTERY DISCONNECT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

OPTIONAL ELECTRICAL SWITCH LOCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

FUSES AND RELAYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

FUSE AND RELAY PANEL LOCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

DASHBOARD RELAY LOCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

FUSE AND RELAY PANEL LAY OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

ENGINE FUSE AND RELAY LOCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

OPERATING THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

CHECKING THE FUEL SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

STARTING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

STARTING THE ENGINE IN COLD WEATHER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

WARMING THE MACHINE UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

SHUTTING THE ENGINE DOWN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

OPERATING THE FRONT END LOADER AND BACKHOE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

OPERATING THE FRONT END LOADER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

CONTROL LEVER POSITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

PERFORMING LOADING OPERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

BUCKET POSITION INDICATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

ORGANIZING YOUR WORK AREA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

LOADING HEAPED MATERIAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

LOADING A TRUCK BED OR TRAILER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

WORKING ON SLOPES WITH A LOADED BUCKET . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

CHANGING THE FRONT BUCKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

WB140-2N, WB150-2N 0-13

Page 18

INTRODUCTION

OPERATING THE BACKHOE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

POSITIONING THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

ADJUSTING THE DIGGING BUCKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

DIGGING METHODS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

CHANGING THE BACKHOE BUCKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

ISO BACKHOE CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

KOMATSU BACKHOE CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-43

SAFETY LOCK USAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-44

BACKHOE LOCKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-46

MOVING OR TRAVELING WITH THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47

TRAVELING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47

TRAVELING ON SLOPES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-48

TRAVELING OR WORKING IN SWAMPY OR WET AREAS . . . . . . . . . . . . . . . . . . . . . 2-49

PARKING THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-50

FOR SHORT OR LONG PERIODS OF TIME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-50

PARKING ON AN INCLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-51

TRANSPORTING THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-52

LOADING AND SECURING THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-52

EMERGENCY RECOVERY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-53

HOW TO MOVE THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-53

PRECAUTIONS DURING SEASONAL CHANGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-54

COLD SEASONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-54

FUEL AND LUBRICANTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-54

COOLANT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-54

BATTERY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-54

WARM SEASONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-55

BASIC TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-56

THE BATTERY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-56

SERVICING THE BATTERY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-56

REMOVAL AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-56

STARTING THE ENGINE WITH BOOSTER CABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-57

ELECTRICAL CIRCUITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-59

HYDRAULIC SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-59

BRAKING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-60

TORQUE CONVERTER SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-60

ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-61

MAINTENANCE

GUIDE TO MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

MAINTENANCE NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

NOTES REGARDING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

ENGINE OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

COOLANT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

FUEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

NOTES REGARDING THE HYDRAULIC SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

NOTES REGARDING THE ELECTRICAL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

NOTES REGARDING LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

PARTS SUBJECT TO WEAR THAT PERIODICALLY NEED CHANGING . . . . . . . . . . . . . . 3-6

0-14 WB140-2N, WB150-2N

Page 19

INTRODUCTION

FUEL, COOLANT, AND LUBRICANTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

PROPER SELECTION ACCORDING TO THE AMBIENT TEMPERATURE . . . . . . . . . . . . . 3-7

GREASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

HOMOLOGATED (HEES) SYNTHETIC BIODEGRADABLE LUBRICANTS . . . . . . . . . . . . . . 3-11

LUBRICATION DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

MULTIPURPOSE BUCKET AND PALLET FORKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

FRONT BUCKET QUICK COUPLINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

TELESCOPIC ARM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

PERIODIC REPLACEMENT OF COMPONENTS CONNECTED WITH SAFETY . . . . . . . . . . . 3-16

CRITICAL PARTS FOR SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

FUEL SUPPLY SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

DELIVERY / RETURN HYDRAULIC SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

LOADER AND BACKHOE HYDRAULIC SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

OPERATOR’S SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

STANDARD TIGHTENING TORQUE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

STANDARD TIGHTENING TORQUE FOR BOLTS AND NUTS . . . . . . . . . . . . . . . . . . . . . . 3-21

SPECIFIC TIGHTENING TORQUES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

MAINTENANCE PLAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

CHECKS BEFORE STARTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

VARIOUS CHECKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

CHECKING FUEL LEVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

CHECKING COOLANT LEVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

CHECKING ENGINE OIL LEVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

CHECKING HYDRAULIC SYSTEM OIL LEVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

DRAINING WATER SEPARATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

MAINTENANCE EVERY 10 HOURS OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

LUBRICATING JOINTS (GREASE FITTINGS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

JOINT LUBRICATION POINTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

FRONT LOADER LUBRICATION LOCATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

BACKHOE LUBRICATION LOCATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-31

MAINTENANCE AFTER FIRST 50 HOURS OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

MAINTENANCE EVERY 50 HOURS OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

CHECKING RADIATOR FLUID LEVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

CHECKING BRAKE SYSTEM OIL LEVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

LUBRICATING PROPELLER SHAFTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

LUBRICATING FRONT AXLE JOINTS CENTRAL COUPLING . . . . . . . . . . . . . . . . . . . . . . 3-34

CHECKING TIRE PRESSURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

CHECKING ELECTRICAL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

MAINTENANCE AFTER THE FIRST 250 HOURS OF OPERATION . . . . . . . . . . . . . . . . . . . . . 3-35

MAINTENANCE EVERY 250 HOURS OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

ADJUSTING FAN BELT TENSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

CLEANING OUTSIDE OF RADIATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

CHECKING BATTERY ELECTROLYTE LEVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

CHECKING FRONT AXLE OIL LEVELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

CHECKING REAR AXLE OIL LEVELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

CHECKING HYDRAULIC TRANSMISSION OIL LEVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-39

CHECKING WHEEL LUG NUT TORQUE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-39

MAINTENANCE AFTER FIRST 500 HOURS OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . 3-40

WB140-2N, WB150-2N 0-15

Page 20

INTRODUCTION

MAINTENANCE EVERY 500 HOURS OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

CHANGING ENGINE OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

CHANGING ENGINE OIL FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42

CHANGING HYDRAULIC SYSTEM OIL FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43

CHANGING FUEL FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

FUEL FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

BLEEDING THE CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

DRAINING FUEL TANK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-45

DRAINING HYDRAULIC OIL TANK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

MAINTENANCE EVERY 1000 HOURS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-47

CHANGING FRONT AXLE OIL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-47

DIFFERENTIAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-47

PLANETARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-47

CHANGING THE REAR AXLE OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-48

DIFFERENTIAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-48

PLANETARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-48

CHANGING HYDRAULIC TRANSMISSION OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-49

CHANGING HYDRAULIC TRANSMISSION FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-50

CHECKING AND ADJUSTING ENGINE VALVE CLEARANCE . . . . . . . . . . . . . . . . . . . . . . 3-50

MAINTENANCE EVERY 2000 HOURS OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-51

CHANGING HYDRAULIC SYSTEM OIL AND CLEANING SUCTION FILTER . . . . . . . . . 3-51

CHANGING COOLANT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-53

CHANGING THE BRAKING SYSTEM OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-55

CHECKING ALTERNATOR AND STARTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-55

WHEN REQUIRED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-56

CHECKING, CLEANING, OR CHANGING AIR CLEANER CARTRIDGE . . . . . . . . . . . . . . 3-56

CHECKING AND CLEANING CAB AIR FILTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-57

BLEEDING BRAKE SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-58

FLUSHING COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-59

CLEANING THE WATER SEPARATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-61

CHECKING AND ADJUSTING FRONT WHEEL TOE-IN . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-61

CHECKING AND ADJUSTING PARKING BRAKE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-62

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-62

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-62

CHECKING THE BRAKING EFFICIENCY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-63

CHECKING AND ADJUSTING BRAKE PEDAL STROKE . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-64

ADJUSTING AUTOMATIC RETURN OF FRONT BUCKET TO THE DIGGING POSITION 3-64

MAINTENANCE INTERVALS IN CASE OF DEMOLITION HAMMER USE . . . . . . . . . . . . . . . 3-65

CHANGING HYDRAULIC OIL FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-65

CHANGING HYDRAULIC OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-65

LONG TERM STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-66

BEFORE STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-66

DURING STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-67

AFTER STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-67

SPECIFICATIONS

TECHNICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

STANDARD OVERALL DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

0-16 WB140-2N, WB150-2N

Page 21

INTRODUCTION

TECHNICAL CHARACTERISTICS WB140-2N (ASPIRATED ENGINE) . . . . . . . . . . . . . . . . 4-3

TOTAL MASS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

STANDARD BUCKET CAPACITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

ASPIRATED ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

ELECTRICAL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

TRAVEL SPEEDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

TIRES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

TECHNICAL CHARACTERISTICS WB140-2N (TURBOCHARGED ENGINE) . . . . . . . . . . . 4-4

TOTAL MASS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

STANDARD BUCKET CAPACITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

ASPIRATED ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

ELECTRICAL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

TRAVEL SPEEDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

TIRES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

TECHNICAL CHARACTERISTICS WB150-2N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

TOTAL MASS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

STANDARD BUCKET CAPACITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

ASPIRATED ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

ELECTRICAL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

TRAVEL SPEEDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

TIRES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

LIFTING CAPACITIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

SYMBOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

LIFTING CAPACITY WB140-2N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

LIFTING CAPACITY WB150-2N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

OPTIONAL ATTACHMENTS

AUTHORIZED OPTIONAL EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

BASIC PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

OPTIONAL EQUIPMENT MEASUREMENTS FOR (WB140-2N) . . . . . . . . . . . . . . . . . . . . . . . 5-3

FRONT END LOADER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

BACKHOE UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

OPTIONAL EQUIPMENT MEASUREMENTS FOR (WB150-2N) . . . . . . . . . . . . . . . . . . . . . . . 5-4

FRONT END LOADER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

BACKHOE UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

FRONT EQUIPMENT QUICK COUPLING DEVICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

MANUAL CONTROL QUICK COUPLING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

MULTIPURPOSE BUCKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

BUCKET OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

BUCKET USES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

PALLET FORKS KIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

REMOVING AND INSTALLING THE FORKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

BACKHOE TELESCOPIC ARM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

DESCRIPTION AND CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

SAFETY LOCKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

DEMOLITION HAMMER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

WB140-2N, WB150-2N 0-17

Page 22

INTRODUCTION

DESCRIPTION AND CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

RULES FOR HAMMER USAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

ALWAYS AVOID THE FOLLOWING USES: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

INSTALLATION AND REMOVAL OF THE DEMOLITION HAMMER . . . . . . . . . . . . . 5-17

CLAMSHELL BUCKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

DESCRIPTION AND CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

INSTALLATION AND REMOVAL OF THE CLAMSHELL BUCKET . . . . . . . . . . . . . . . 5-19

OPERATING THE CLAMSHELL BUCKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

HYDRAULIC JACK HAMMER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

DESCRIPTION AND CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

CONNECTING AND REMOVING THE JACK HAMMER . . . . . . . . . . . . . . . . . . . . . . . . 5-21

USING THE JACK HAMMER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

0-18 WB140-2N, WB150-2N

Page 23

1SAFETY

WARNING!

Read and follow all safety precautions. Failure to do so may

result in serious injury or death.

This safety section also contains precautions for optional

equipment and attachments.

WB140-2N, WB150-2N

1-1

Page 24

SAFETY

GENERAL SAFETY RULES AND PRECAUTIONS

GENERAL SAFETY RULES

Only trained and authorized personnel shall be allowed to operate and service this machine.

Before operating this machine it is important to study the operator’s manual thoroughly and become familiar with all

controls and safety decals. Keep this manual with your machine at all times for easy reference.

Safety must always be the operator’s most important concern. Never operate a machine that is unsafe or in poor operating condition.

Always perform a pre-operational check on your machine before operating it.

If the machine is equipped with a seat belt and rollover protective structure, OSHA law requires the operator remain within the

confines of the rollover protective structure, with the seat belt fastened snugly around their waist before operating the machine.

OSHA law states if your equipment is designed for operation by one person, it is for one person only, never allow other personnel to ride on your machine.

Never leave your machine running and unattended. Always park the machine in a level area, lower any work equipment to the

ground, set the parking brake, lock the controls and turn the engine off before exiting the operator’s compartment.

Be sure that all personnel are at least 12 m (40 ft.) away from any point on the machine before moving or operating themachine. Never allow anyone to stand near the machine while in operation. Remember, the larger the machine the more restricted

your visibility will be.

If pedestrians are in the area proceed slowly and sound your horn. Keep in mind, pedestrians have the right away, and a loaded

or smaller machine has the right away over an unloaded machine.

Never use your machine for tasks it was not designed for, damage to the machine or injury to the operator may result.

Follow all safety rules, precautions, and instructions when operating or performing maintenance on the machine.

It is the owner and /or operator’s responsibility to replace any safety or warning decals if they are defaced or removed from the

machine.

Think before you act, study the job carefully. Careful operator’s and service personnel are the best insurance against accidents.

The operator of this machine must be alert, physically fit, and free from the influences of alcohol, drugs or medications that

might affect there eyesight, hearing, or reactions.

When working with another person on a work site, or during traffic control, be sure all personnel involved understand all hand

signals that are to be used.When leaving a job site for long periods of time always lower all work equipment to the ground,

neutralize work equipment controls and lock and secure your machine properly to avoid tampering by other personnel.

Never drive up to anyone standing in your path of travel. Always be sure all personnel are standing to the side when you

approach them and acknowledge your approach.

Follow all rules relating to safety as outlined in this manual and by your company, never get involved in horseplay.

1-2 WB140-2N, WB150-2N

Page 25

SAFETY

SAFETY FEATURES

Be sure all guards and covers are in place especially after servicing the machine.

Have guards or covers repaired immediately if they are damaged. See “PRECAUTIONS BEFORE STARTING WORK

OPERATIONS” on page 1-8.

Use safety equipment such as safety locks and seat belt properly.

Never remove any safety features. Always keep them in good operating condition.

Always secure the machine in a safe position: See “PARKING THE MACHINE” on page 2-50.

Seat belt: See “INSIDE OPERATOR’S COMPARTMENT” on page 1-7.

Improper use of safety features could result in serious bodily injury or death.

Be sure the machine has the correct equipment required by local rules and regulations.

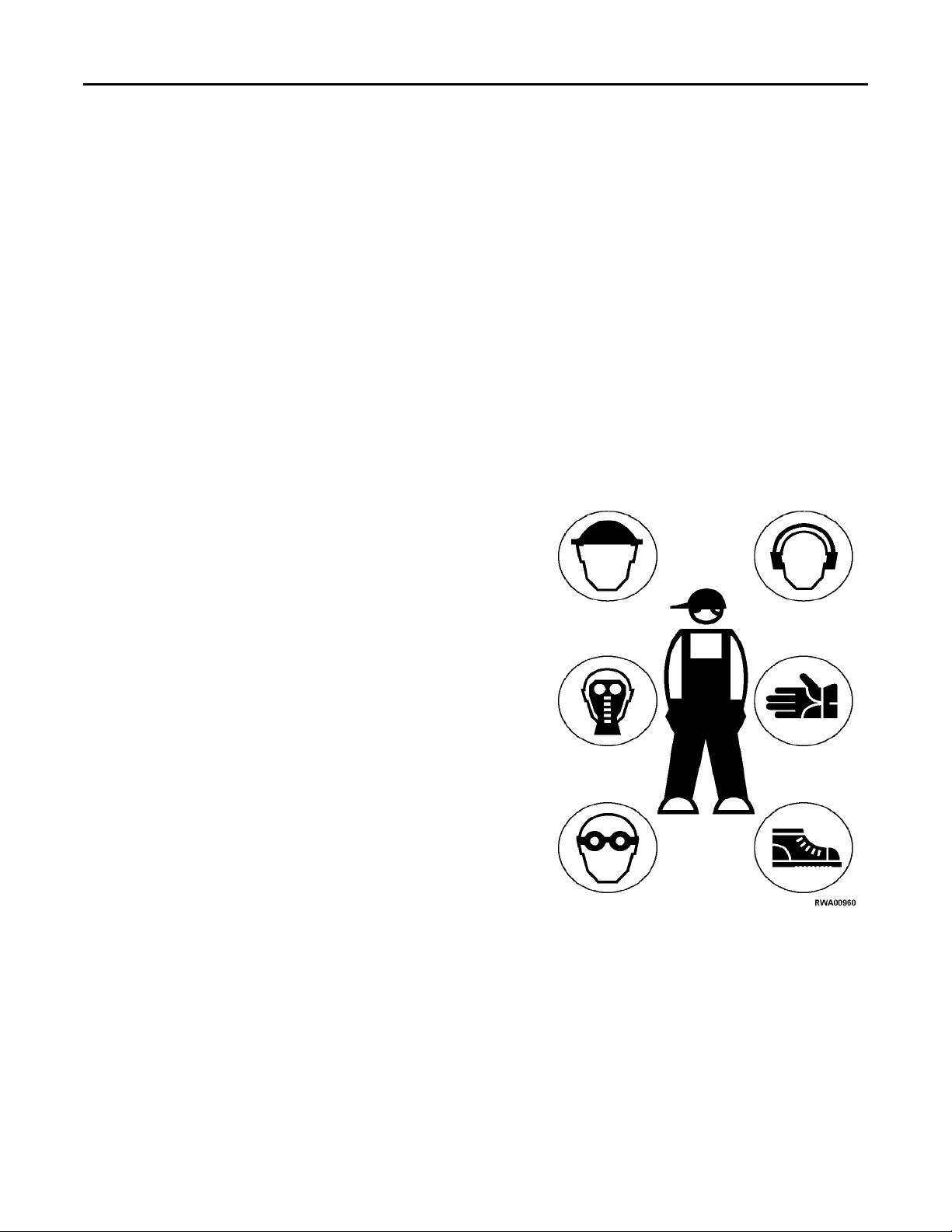

PERSONAL PROTECTIVE EQUIPMENT

If your machine is equipped with safety equipment OSHA law requires

this equipment to be used when operating your machine.

Avoid loose fitting clothing, jewelry and loose long hair. These can

catch on controls or in moving parts and cause serious injury.

Wear a hard hat, safety glasses, safety shoes, mask or gloves when operating or maintaining the machine.

Always wear safety goggles, hard hat and heavy gloves, if your job

involves driving pins with a hammer or cleaning the air cleaner element

with compressed air.

Check to be sure no one is near your work area.

Check to be sure all personal protective equipment are in good condition

before using.

UNAUTHORIZED MODIFICATIONS

Any modification made without authorization from Komatsu can create a hazards. Before making any modifications, consult

your local distributor. Komatsu will not be responsible for any injury or damage caused by any unauthorized modifications.

WB140-2N, WB150-2N 1-3

Page 26

SAFETY

LEAVING OPERATOR’S COMPARTMENT

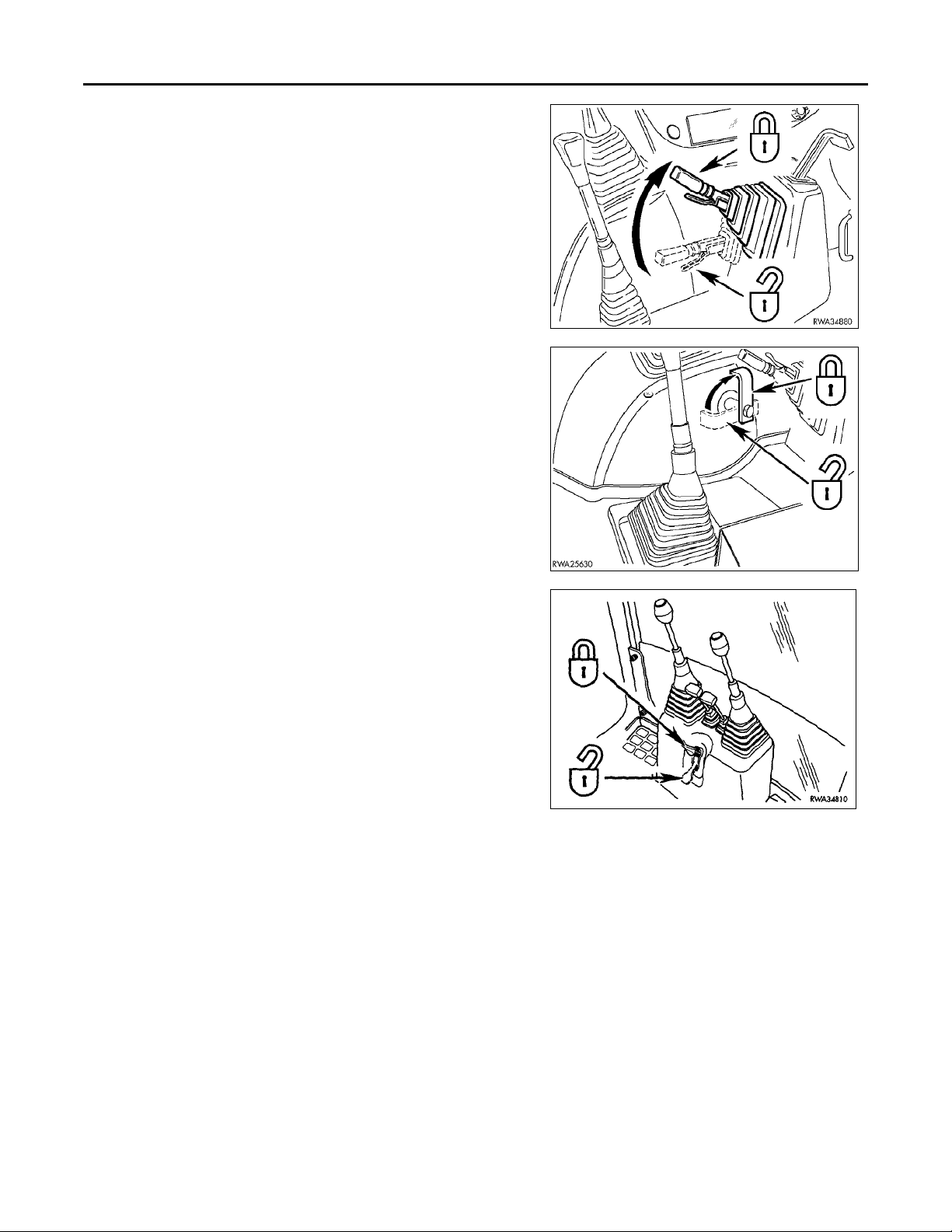

Below are listed procedures that must be followed when exiting the

operator’s cab.

1. Park the machine in a level area, lower all work equipment to the

ground.

2. Engage the parking brake.

3. Place safety lock lever for loader control in the (LOCKED) position.

4. Place safety lock lever for backhoe controls in the (LOCKED)

position.

5. Remove ignition key and keep the key with you.

6. Use the key to lock and secure all the equipment locks. This will prevent other unauthorized personnel from tampering

with your machine. Keep in mind you are responsible for securing your machine.

Remark

Never leave your machine running and unattended, even for a moment.

Work equipment posture: See “PARKING THE MACHINE” on page 2-50.

Lock:See “SAFETY LOCK USAGE” on page 2-44.

1-4 WB140-2N, WB150-2N

Page 27

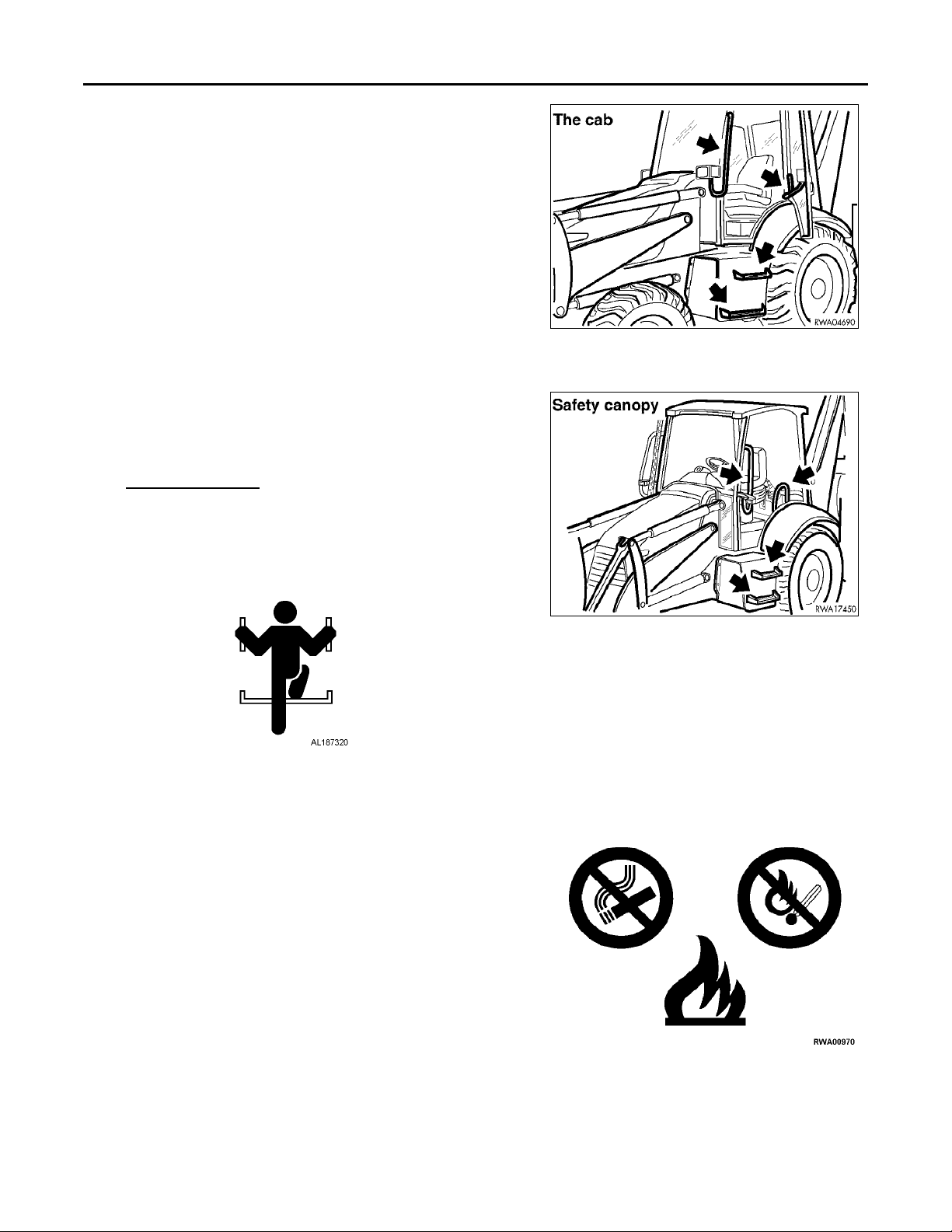

MOUNTING AND DISMOUNTING

Use all hand holds and step plates on your machine.

Never jump off or on to the machine.

Before getting on the machine, if there is any oil, grease, or mud on your

shoes, rails, steps or platforms, wipe it off immediately, always keep

these areas clean, and in good condition.

Never get on or off a moving machine. These actions may lead to serious injury. Always bring the machine to a full stop.

Be sure machine is at a full stop, equipment lowered and parking brake

set before entering or exiting machine.

Never hold any control levers or the steering wheel when getting on or

off the machine.

When getting on or off the machine, always face the machine and maintain a Three Point Contac

both hands) with the handrails, steps and platforms to ensure that you

support yourself properly.

t (both feet and one hand or one foot and

SAFETY

FIRE PREVENTION FOR FUEL AND OIL

Fuel and oil are flammable. Fuel is particularly flammable and can be

hazardous. Always observe the following:

• Keep any open flames away from flammable fluids.

• Stop the engine and do not smoke when refueling.

• Tighten all fuel and oil caps securely.

• Refueling or adding oil should be made in well ventilated areas.

• Keep oil and fuel in its proper place.

• Clean up any fluid spills.

WB140-2N, WB150-2N 1-5

Page 28

SAFETY

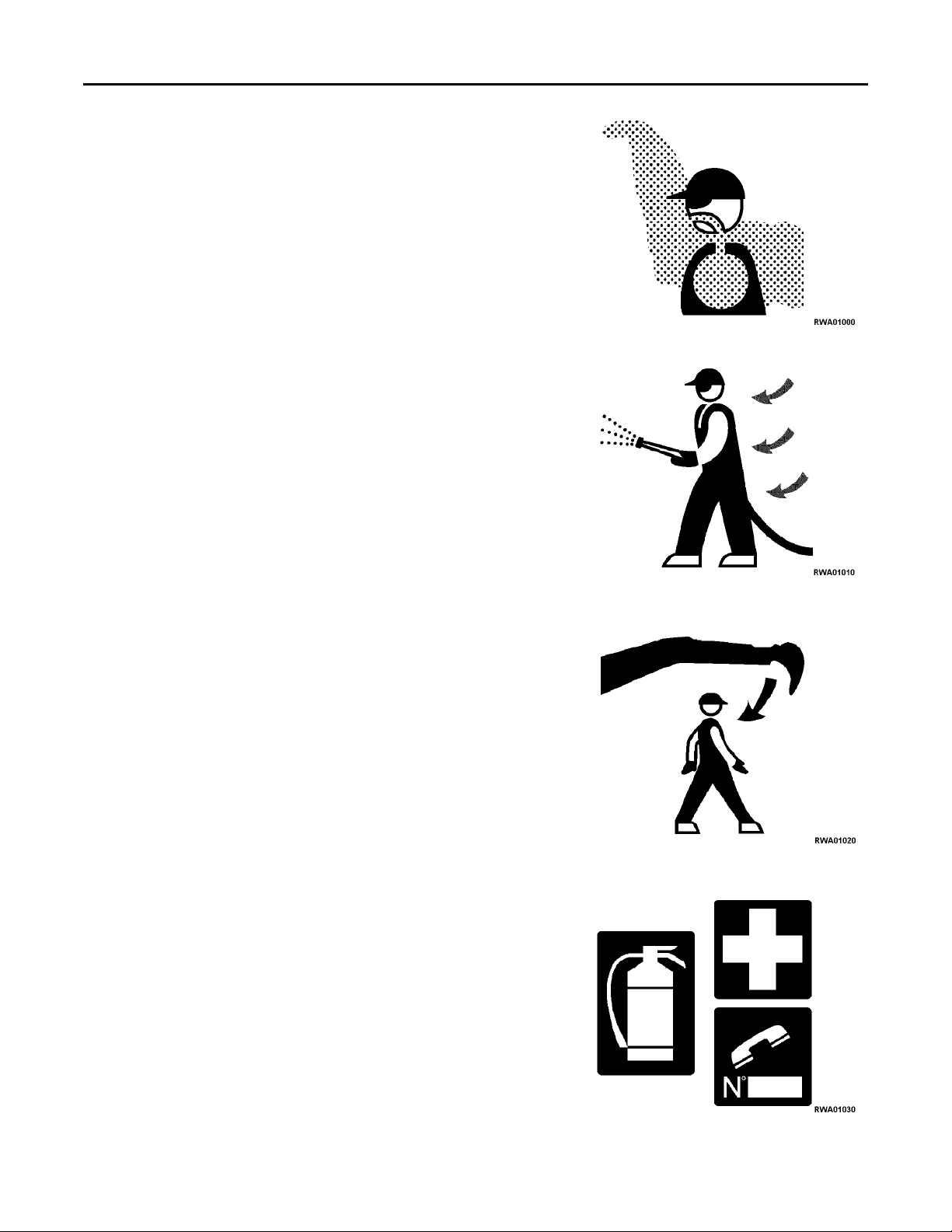

DUST HAZARD PRECAUTIONS

Dust can be hazardous to your health if it is inhaled. Komatsu does not

use asbestos in its products, but if you handle materials containing

asbestos fibers or other dust materials during demolition operations,

always do as follows.

• Never use compressed air for cleaning.

• Use water to keep down the dust when cleaning.

• If there is a danger there may be asbestos dust in the air, operate the

machine with the wind to your back whenever possible.

• Use an approved respirator.

• Do not allow any other person into the area during operation.

• There may be a danger that non genuine parts may contain asbestos,

use only genuine Komatsu parts.

• Always observe rules and regulations related to the job site and

working environment.

CRUSH OR PINCH POINT DANGERS

Never stand under or place any part of your body between the movable

components such as the work equipment and cylinders or between the

machine and work equipment.

Keep in mind, when the work equipment is operated, the clearance will

change, this may lead to serious personal injury or death.

Never drive up to any one standing in front of a solid object or your path

of travel. The brakes could fail or the machine could slide on a slippery

surface causing injury or even death.

FIRE EXTINGUISHER AND FIRST AID KIT

As a precaution if a fire or an injury should occur, always keep a fire

extinguisher and first aid kit on your machine and do as follows:

• Be sure that fire extinguisher is in good condition and read the label

on it to ensure you know how to use it.

• Keep a first aid kit in the storage area. Check the kit periodically

and make any additions if necessary.

• Keep a list of emergency phone numbers in case of an accident.

1-6 WB140-2N, WB150-2N

Page 29

SAFETY

INSIDE OPERATOR’S COMPARTMENT

When entering the operator’s compartment, always remove mud and oil from the

soles of your shoes. If you operate the brake pedal with mud or oil on your shoes,

your foot may slip and may cause an accident.

After using the ashtray, make sure matches or cigarettes are properly extinguished and

be sure to close the lid. If the ashtray is left open, there is danger of fire.

Do not leave lighters or aerosol cans lying around the operator’s compartment. If the

temperature inside the operator’s compartment get’s too high, there is danger that the

lighter may explode.

Do not stick suction pads to the window glass. Suction pads may act as a lens and

could cause fire.

Do not use cellular telephones inside the operator’s compartment when driving or operating the machine.

Never bring any dangerous objects such as flammable or explosive items into the operator’s cab.

To ensure safety, do not use the radio or music headphones when operating the machine.

Keep the operator’s compartment clean, never allow trash or tools to accumulate, these may hinder the operation of the controls or pedals.

When operating the machine, do not put your hands or head out of the window or beyond the protection of the ROPS.

Always use the seat belt equipped with your machine. Even when using the loader or backhoe unit. Be sure the seat belt is fastened snugly around your waist before operating the machine.

PRECAUTIONS WHEN USING ROPS

The ROPS (Roll Over Protective Structure) must never be removed from the machine. The ROPS is installed to protect the

operator if the machine should roll over. It is designed not only to support the load if the machine should roll over, but also to

absorb the impact of the energy.

The ROPS fulfills all the regulations and standards for all countries, but if it is modified without authorization or is damaged,

the strength may be reduced and it may not able to fulfill its function properly.

PRECAUTIONS FOR ATTACHMENTS

When installing and using an optional attachment, read the instruction manual for the attachment and information related to

the attachments.

Do not use attachments that are not authorized by your Komatsu Distributor. Use of unauthorized attachments could create a

safety problem and adversely affect proper operation and useful life of the machine.

Any injuries, accidents, product failures resulting from use of unauthorized attachments will not be the responsibility of

Komatsu.

WB140-2N, WB150-2N 1-7

Page 30

SAFETY

PRECAUTIONS BEFORE STARTING WORK OPERATIONS

Before starting your work operations it is important to perform several procedures to be sure your equipment is in a safe operating condition. It is also important to be aware of the hazards involved when operating your machine.

PRE-OPERATIONAL CHECKS

Before starting your machine and preceding with any work operations it is important to be sure your machine is safe to operate. Below is a list of some basic items to check before any work is to begin. If any problems are found during your Pre-operational Check, have them repaired immediately. Never operate a machine that is unsafe, damaged or in need of repair.

PERFORM A WALK AROUND CHECK OF YOUR MACHINE

A. Look for any obvious missing or damaged items.

B. Check the condition of the loading and backhoe buckets, look for loose or missing attachment pins, damaged surfaces

or missing parts.

C. Check the condition of all visible hydraulic hoses, look for worn or leaking fittings, cut, scuffed or cracked hose sur-

faces. If any hose is found to be worn, cracked or leaking have it repaired or replaced immediately.

D. Check for leaking or damaged hydraulic cylinders. If any cylinder is damaged or leaking have it repaired immedi-

ately.

E. Inspect the mechanical lift, dump and backhoe arms and pivot points. Look for any loose or missing parts, cracked,

bent or damaged areas.

F. Be sure all safety decals are in place and are not damaged. Be sure they are clean and visible for all personnel to see.

G. Check the condition of the front and rear tires. Look for excess wear or cut surfaces, objects imbedded in the tire or

under inflation.

H. Check under the machine for any build-up of debris, trash or leaks. Remove any debris that is found and have the leak

checked by authorized personnel.