KOMATSU WA95-M, WA95-3 Maintenance Manual

Operation & Maintenance

Manual

VEAM980500

WA95-3

WHEEL LOADER

SERIAL NUMBERS

WARNING

Unsafe use of this machine may cause serious injury or

death. Operators and maintenance personnel must read

this manual before operating or maintaining this

machine. This manual should be kept near the machine

for reference and periodically reviewed by all personnel

who will come into contact with it.

HA980376

and up

NOTICE

Komatsu has had the operating and maintenance instructions translated into all the languages of the

member states in the European Union. Should you

wish to have a version of the operating instructions

in another language, please don’t hesitate to ask at

your local dealer’s.

Contents

Contents

Information on these Operating Instructions .............................................................. 1-1

Why You Should Read these Operating Instructions .................................................................... 1-3

Notes on Safety Regulations ......................................................................................................... 1-4

Correct Use .................................................................................................................................................................1-4

Safety Notes in the Operating Instructions ................................................................................................................. 1-4

Standards and Guidelines ........................................................................................................................................... 1-6

CE-Conforming Equipment ............................................................................................................ 1-8

CE-Conforming Equipment of the Manufacturer According to Document 42W-93-11130 ....................................... 1-10

Loading and Transporting the Machine........................................................................ 2-1

Loading and Transporting the Machine.......................................................................................... 2-3

Securing the Articulated Steering ............................................................................................................................... 2-3

Lifting the Machine ......................................................................................................................................................2-3

Driving Machine Onto Loading Area of Transport Vehicle ..........................................................................................2-4

Securing the Machine During Transport...................................................................................................................... 2-5

After Transport ............................................................................................................................................................. 2-5

Dimensions, Weights, and Operating Values ................................................................................ 2-6

Technical Data ................................................................................................................................ 2-7

Safety............................................................................................................................... 3-1

General Safety Measures .............................................................................................................. 3-2

Safety Instructions ....................................................................................................................................................... 3-2

Safety Devices ............................................................................................................................................................ 3-2

Emergency Exit ...........................................................................................................................................................3-2

Clothing and Personal Protection ............................................................................................................................... 3-2

Machine Modifications ................................................................................................................................................. 3-3

Before You Leave the Driver's Seat ............................................................................................................................ 3-3

Mounting and Dismounting ......................................................................................................................................... 3-3

Fire Prevention and Fire Fighting ................................................................................................................................ 3-4

Protection Against Asbestos Dust ............................................................................................................................... 3-5

Protection Against Injuries .......................................................................................................................................... 3-5

Working at High Temperatures .................................................................................................................................... 3-5

Roll-Over Protection System (ROPS) ......................................................................................................................... 3-6

Attachment for Protection Against Falling Objects (FOPS) ........................................................................................ 3-6

Attachments ................................................................................................................................................................ 3-6

Battery .........................................................................................................................................................................3-7

Before You Start the Engine .......................................................................................................... 3-8

Workplace Safety ........................................................................................................................................................ 3-8

In the Driver's Cab....................................................................................................................................................... 3-8

In-Door Operation ....................................................................................................................................................... 3-9

Gas, Dust, and Inflammable Vapours .........................................................................................................................3-9

Mirrors, Windows, and Lighting................................................................................................................................... 3-9

Machine Operation ....................................................................................................................... 3-10

Before You Start the Engine .....................................................................................................................................3-10

Reversing .................................................................................................................................................................. 3-10

Driving ....................................................................................................................................................................... 3-10

Driving On Slopes ..................................................................................................................................................... 3-11

Emergency Lowering System ................................................................................................................................... 3-11

Working Close to Overhead Power Transmission Lines...........................................................................................3-12

Loading......................................................................................................................................................................3-12

Good Vision ............................................................................................................................................................... 3-13

Working On Snow .....................................................................................................................................................3-13

Height Limitation .......................................................................................................................................................3-13

Brakes ....................................................................................................................................................................... 3-13

0-1

Contents

Working On Loose Soil .............................................................................................................................................3-13

Working with the Forklift Truck Attachment...............................................................................................................3-14

Parking the Machine ................................................................................................................................................. 3-15

Transport ...................................................................................................................................... 3-16

Loading and Unloading the Machine ........................................................................................................................ 3-16

Transport ................................................................................................................................................................... 3-16

Safety Measures During Maintenance ......................................................................................... 3-17

Personnel ..................................................................................................................................................................3-17

Prior to Start of Maintenance Measures.................................................................................................................... 3-17

During Maintenance ..................................................................................................................................................3-19

Tyres .........................................................................................................................................................................3-23

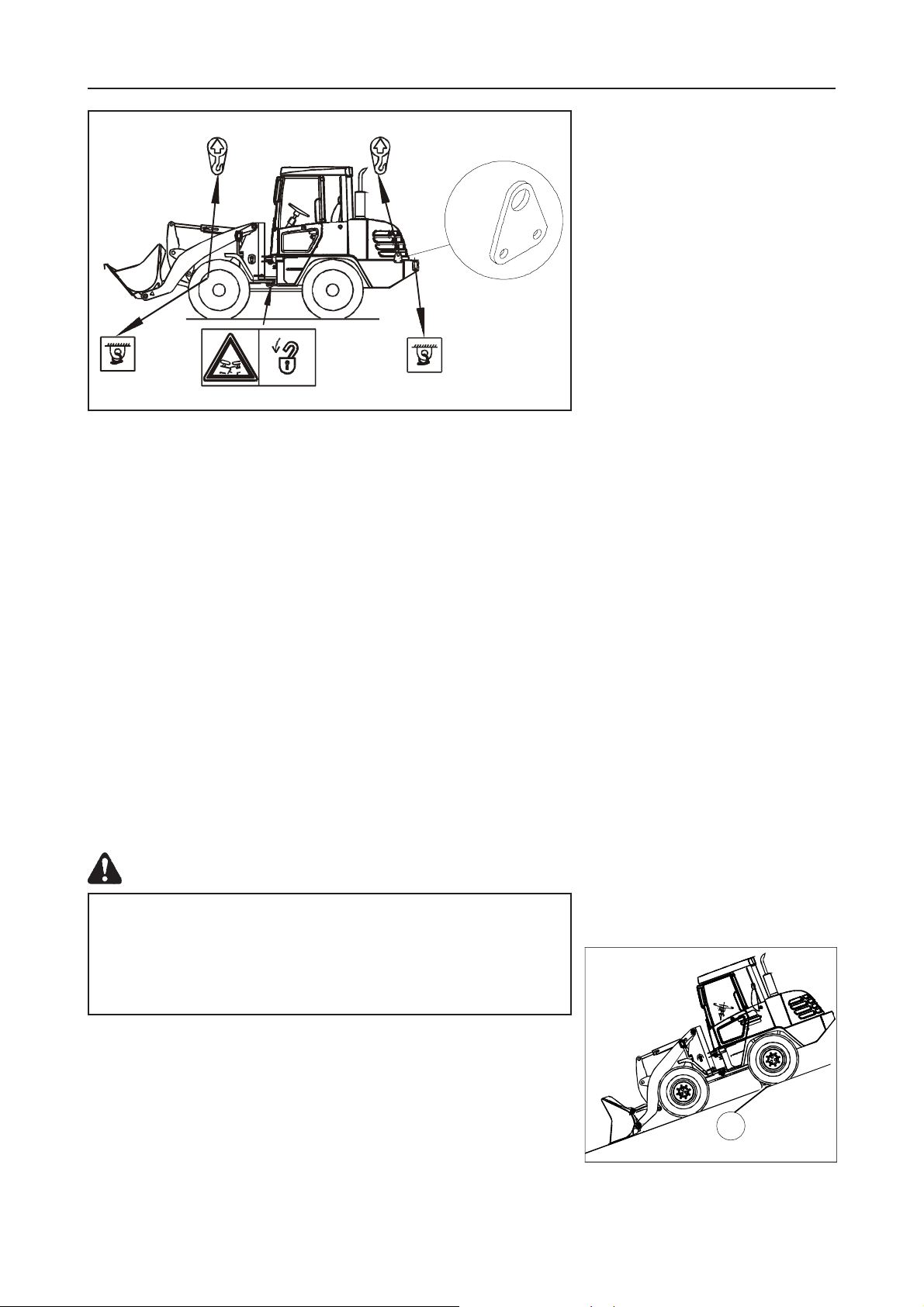

Labeling........................................................................................................................................ 3-24

Positions of Safety Labels ......................................................................................................................................... 3-24

Information Labels.....................................................................................................................................................3-25

Controls and Indicators .................................................................................................4-1

Overall View of the Machine .......................................................................................................... 4-3

Controls and Indicators .................................................................................................................. 4-4

Overall View ................................................................................................................................................................ 4-4

Instrument Panel .........................................................................................................................................................4-5

Warning Lights ............................................................................................................................................................ 4-6

Control Lamps ............................................................................................................................................................. 4-8

Measuring Indicators ................................................................................................................................................. 4-11

Switches ....................................................................................................................................................................4-13

Control Levers, Pedals ..............................................................................................................................................4-19

Articulated Steering Catch ........................................................................................................................................4-23

Traction Device..........................................................................................................................................................4-23

Socket .......................................................................................................................................................................4-23

Door Unlocking System............................................................................................................................................. 4-23

Alarm Horn for Reverse Driving (Option) ..................................................................................................................4-23

Operation ........................................................................................................................ 5-1

Running in the Machine ................................................................................................................. 5-3

Preparing the Machine Start .......................................................................................................... 5-4

Visual Checks (also refer to chapter "Maintenance Prior to Machine Start") .............................................................. 5-4

Adjustments Prior to Machine Start ............................................................................................... 5-6

Adjusting the Driver’s Seat .......................................................................................................................................... 5-6

Adjusting the Steering Column ................................................................................................................................... 5-7

Adjusting the Armrest ..................................................................................................................................................5-7

Adjusting the Rear-View Mirrors .................................................................................................................................5-7

Adjusting the Heating and Ventilation System ............................................................................................................5-8

Operating the Air Conditioning .................................................................................................................................... 5-9

Putting on the Safety Belt .......................................................................................................................................... 5-10

Starting and Switching Off the Engine ......................................................................................... 5-11

Starting the Engine.................................................................................................................................................... 5-11

Switching Off the Engine ........................................................................................................................................... 5-12

Driving .......................................................................................................................................... 5-13

Start-Up .....................................................................................................................................................................5-13

Driving with the high-speed gear...............................................................................................................................5-14

Changing the Driving Direction ................................................................................................................................. 5-15

Reverse Driving ......................................................................................................................................................... 5-15

Turning ......................................................................................................................................................................5-16

Braking ......................................................................................................................................................................5-17

Stopping ....................................................................................................................................................................5-18

Longer-Distance Driving............................................................................................................................................ 5-19

Operating the Machine................................................................................................................. 5-20

Tyre-Appropriate Operation ...................................................................................................................................... 5-22

Adjusting the Bucket Positioner ................................................................................................................................5-23

Loading......................................................................................................................................................................5-24

Transporting .............................................................................................................................................................. 5-26

0-2

Contents

Dumping/Unloading................................................................................................................................................... 5-26

Planing ...................................................................................................................................................................... 5-27

Working With the Forklift Truck Attachment..............................................................................................................5-28

Precautions For Special Operations .........................................................................................................................5-29

After the work is finished ...........................................................................................................................................5-29

Instructions for Winter Operation ..............................................................................................................................5-30

Longer Standstill Periods of the Machine ................................................................................................................. 5-31

Troubleshooting ............................................................................................................. 6-1

Troubleshooting.............................................................................................................................. 6-3

Warning Lights and Indicators ....................................................................................................................................6-3

Electrical System ......................................................................................................................................................... 6-4

Engine ......................................................................................................................................................................... 6-5

Hydraulic System ........................................................................................................................................................ 6-8

Brakes ....................................................................................................................................................................... 6-10

Axles .......................................................................................................................................................................... 6-11

Driver's cab ............................................................................................................................................................... 6-11

Emergency Steering Characteristics ......................................................................................................................... 6-12

Emergency Lowering System ................................................................................................................................... 6-12

Starting the Engine with a Battery Jumper Cable ..................................................................................................... 6-13

Towing the Machine ................................................................................................................................................... 6-15

Inadequate Braking Effect ......................................................................................................................................... 6-17

Maintenance.................................................................................................................... 7-1

Maintenance Basics ....................................................................................................................... 7-3

Cleaning the Machine ................................................................................................................................................. 7-4

Working-Area-Dependent Maintenance .....................................................................................................................7-5

Lubricants and Operating Agents ............................................................................................................................... 7-6

Replacing Safety-Related Parts ................................................................................................................................ 7-11

Spare Parts and Consumable Components ............................................................................................................. 7-12

Electrical System ....................................................................................................................................................... 7-13

Tyres .........................................................................................................................................................................7-15

Tools...........................................................................................................................................................................7-17

Torque for Standard Nuts and Bolts .......................................................................................................................... 7-18

Maintenance Schedule................................................................................................................. 7-21

Maintenance Prior to Start ........................................................................................................... 7-23

Cooling System, Checking the Coolant Level, Topping Up Coolant..........................................................................7-23

Engine, Checking the Oil Level, Topping Up Oil........................................................................................................ 7-24

Engine, Draining Off Oil ............................................................................................................................................7-24

Checking the Fuel Level, Refuelling ......................................................................................................................... 7-25

Checking the Controls ............................................................................................................................................... 7-25

Checking the Electrical Connections ........................................................................................................................ 7-26

Heater / Air conditioning: checking rate of air flow .................................................................................................... 7-26

Other Maintenance Measures Prior to Start.............................................................................................................. 7-26

Maintenance upon Demand ......................................................................................................... 7-27

Checking the Air Conditioning System...................................................................................................................... 7-27

Maintenance Every 10 Operating Hours ...................................................................................... 7-28

Lubrication ................................................................................................................................................................. 7-28

Maintenance After the First 50 Operating Hours ......................................................................... 7-29

Engine, Changing Oil and Replacing the Oil Filter Cartridge....................................................................................7-29

Replacing the Oil Filter Cartridge ..............................................................................................................................7-30

V-Belt, Checking the Condition .................................................................................................................................7-31

V-Belt, Checking and Adjusting the Tension..............................................................................................................7-31

Hydraulic System, Replacing the Filter Insert ...........................................................................................................7-32

Checking and Tightening the Wheel Nuts.................................................................................................................7-32

Front and Rear Axle, Oil Change ..............................................................................................................................7-33

Transfer Box Gearing - Changing Oil ........................................................................................................................7-34

Maintenance Every 50 Operating Hours ...................................................................................... 7-35

Checking the Cooling System, Coolant Level in the Radiator and expanion tank....................................................7-35

Draining Off Water and Dirt Deposits From the Fuel Tank ........................................................................................7-36

Checking the Service Brake and Oil Level, Refilling Oil ........................................................................................... 7-36

0-3

Contents

Checking the Battery and Acid Level ........................................................................................................................7-37

Re-Charging the Battery ...........................................................................................................................................7-38

Lubrication ................................................................................................................................................................. 7-39

Maintenance Every 100 Operating Hours .................................................................................... 7-40

Draining the Water Separator, Removing Water and Dirt Deposits .........................................................................7-40

Maintenance Every 250 Operating Hours .................................................................................... 7-41

Changing the Engine Oil and Oil Filter Cartridge ...................................................................................................... 7-41

Checking the V-Belt Condition ..................................................................................................................................7-41

Checking and Adjusting the V-belt Tension ............................................................................................................... 7-41

Front and Rear Axle, Checking the Oil Level ............................................................................................................ 7-42

Air Filter, Removing and Re-Installing the Filter Insert, Checking and Cleaning the Filter Insert............................. 7-43

Cleaning the Radiator Segments ..............................................................................................................................7-45

Lubrication ................................................................................................................................................................. 7-45

Maintenance Every 500 Operating Hours .................................................................................... 7-46

Changing the Fuel Filter and Filter Element ............................................................................................................. 7-46

Changing the Filter Cartridge of the Hydraulic System ............................................................................................. 7-47

Cleaning the Water Separator .................................................................................................................................. 7-48

Lubrication ................................................................................................................................................................. 7-49

Transfer Box Gearing, Checking the Oil Level and Refilling Oil................................................................................7-49

Air Filter, Replacing the Filter Insert, Replacing the Safety Filter .............................................................................7-50

Heater/Air Conditioning: cleaning/replacing Filter Fleece

or cleaning Condenser ............................................................................................................................................. 7-51

Checking the ALS-Accumulator Gas Pressure (Option) ........................................................................................... 7-52

Maintenance Every 1000 Operating Hours .................................................................................. 7-53

Cooling System, Exchanging Coolant and Cleaning the System ............................................................................7-53

Front Axle, Oil Change ..............................................................................................................................................7-55

Rear Axle, Oil Change...............................................................................................................................................7-55

Transfer Box Gearing, Oil Change ............................................................................................................................7-55

Service Brake ............................................................................................................................................................7-55

Checking and Adjusting System Pressures .............................................................................................................. 7-55

Checking and Adjusting the Valve Play .................................................................................................................... 7-55

Checking and Adjusting the Injection Nozzles, Nozzle Pressure and Fuel-Jet Pattern............................................ 7-55

Checking the Accumulator Gas Pressure of third Control Circuit .............................................................................7-55

Maintenance Every 2000 Operating Hours .................................................................................. 7-56

Hydraulic System, Oil Change ..................................................................................................................................7-56

Ventilating the Hydraulic Oil Tank ..............................................................................................................................7-57

Cooling System, Checking the Antifreeze Content of the Coolant ........................................................................... 7-57

Checking the Cooling System ...................................................................................................................................7-57

Checking the Fuel Pump ........................................................................................................................................... 7-57

Checking the Fuel and Coolant Tubes, Replacing the Tubes (if required) ...............................................................7-57

Checking the Water Pump ........................................................................................................................................ 7-57

Checking and Adjusting the Fuel Injection and Injection time .................................................................................. 7-58

Technical Data................................................................................................................. 8-1

Technical Data ................................................................................................................................ 8-2

Noise Emission Levels ................................................................................................................................................ 8-3

Vibration Level ............................................................................................................................................................ 8-3

Limit Values for Slopes ............................................................................................................................................... 8-3

Special Equipment and Attachments ........................................................................... 9-1

ALS-Electronics.............................................................................................................................. 9-3

Structure and Functioning Principle of the ALS-Electronics .......................................................................................9-3

Precautionary Measures for Switching on the ALS-Electronics .................................................................................. 9-3

Operation of the ALS-Electronics ................................................................................................................................ 9-3

Handling of the Pressure Accumulator ....................................................................................................................... 9-4

Index .............................................................................................................................. 10-1

0-4

Information on these Operating

Instructions

Information on these Operating Instructions

1 - 2

Information on these Operating Instructions

Why You Should Read these Operating Instructions

The machine must be operated, cleaned, and maintained very carefully

to ensure safe and troublefree operation. If you operate the machine

correctly, these operating instructions will help you to avoid injuries and

damage to property. To ensure this, these operating instructions take

into account all applicable legal regulations and directives; the operating

instructions comprise the following information:

• Notes on the Operating Instructions

• Notes on Transport

• Notes on Safety Regulations

• Operating Instructions

• Troubleshooting

• Maintenance Instructions

• Technical Data

• Notes on Lubricants and Operating Agents

The operating instructions are part of the machine and must always be

available at hand in the machine. If the operating instructions have been

lost or if they have become unreadable, because they are dirty, you may

receive a new copy from Komatsu or your local Komatsu dealer. If the

machine is resold, the operating instructions, the EU Declaration of

Conformity (CE), and the licence are to be handed over to the new owner.

The owner of the machine has to ensure that

• all persons driving the machine have the legally required

minimum age and are physically and mentally fit to perform the

tasks they are charged with.

• all persons in charge with operating or maintaining the machine

are appropriately instructed before operation or maintenance

is started. They must have completely read and understood

these operating instructions. In particular, this applies to the

following section "Notes on Safety Regulations" and the chapter

"Safety".

• all persons driving the machine have read the accompanying

leaflet "Notes on Operation of Komatsu Construction Machines in Public Traffic" - applying to operation of construction

machines with a speed of more than 20 km/h on German public

roads.

• the machine is correctly operated.

• the machine is not improperly modified.

Please note:

If the owner modifies safety-related parts of the machine, the certificate

of conformity of the manufacturer will lapse and the person who has

performed the modification has to issue a new certificate. Should you

have any questions concerning this point, please do not hesitate to ask

Komatsu.

1 - 3

Information on these Operating Instructions

Our continuous effort to improve the machine's design may lead to

changes of machine details. However, the introduction of these

improvements does not oblige us to perform them on machines which

have already been delivered and are already in use.

If these improvements result in minor changes, these minor changes will

not be described in the operating instructions. Should you require new

available information about your machine or have any questions

concerning the information given in the operating instructions, please do

not hesitate to contact either Komatsu or your responsible Komatsu dealer.

These operating instructions may refer to attachments and special

equipment not available from your local Komatsu dealer. Should you

require attachments or special equipment, ask your responsible Komatsu

dealer.

Notes on Safety Regulations

The procedures and precautionary measures concerning operation and

maintenance only apply on the provision that the machine is used as

intended.

Correct Use

A loader is a machine which has its own drive and which is moving on

either tracks or wheels. By moving in forward direction, a loader can load

material or cut the ground with the work unit (use of bucket) provided for

loading which is attached to its front.

The standard working cycle of a loader comprises filling and lifting the

loading bucket, transporting material, and emptying the loading bucket.

If you use the machine for any other purpose than specified above, we

will not accept any responsibility for safety. All considerations concerning

safety will then be up to the owner or the operating and maintenance

personnel. In any case, neither you nor any other person are/is authorised

to perform work and functions explicitly prohibited in these operating

instructions.

Safety Notes in the Operating Instructions

Most accidents are caused by disregard of basic safety regulations during

operation and maintenance of machines. In order to avoid accidents and

thus damage to persons and property, read all applicable safety notes

and warnings in these operating instructions and on the machine, before

you start operation or maintenance of the machine and always adhere to

these safety notes and warnings.

1 - 4

Information on these Operating Instructions

The chapter "Safety" starting on page 1-1 contains a summary of all

safety notes applying to this machine. We cannot, however, predict all

circumstances resulting in potentially dangerous situations when operating

and maintaining the machine. For this reason, it may be possible that the

safety notes in these operating instructions and on the machine do not

comprise all possible safety measures. If procedures or measures are

required which are not recommended or approved, you must ensure that

performing them is neither dangerous nor involving potential damage to

the machine. Should you have any doubt concerning safety of a procedure,

either directly contact Komatsu or your responsible Komatsu dealer.

The following signal words are used to indicate safet notes in these

operating instructions and on the labels attached to the machine:

DANGER This word is used in the safety notes and on

safety labels in situations or places where severe

injuries cannot be ruled out, if the danger is not

avoided. The safety notes or labels contain

precautionary measures which must be heeded

to avoid this danger.

WARNING This word is used in the safety notes and on

safety labels, if there is a potentially dangerous

situation which may lead to severe injury, if the

danger is not avoided. The safety notes or labels

contain precautionary measures that must be

realised to avoid this danger.

CAUTION This word is used in the safety notes and on

safety labels in dangerous situations which may

lead to minor injury, if the danger is not avoided.

It may also refer to dangers which may lead to

damage of the machine.

NOTE This word is used for precautionary measures

which must be realised to exclude processes

which would shorten the service life of the

machine.

IMPORTANT This word is used for important additional

information.

1 - 5

Information on these Operating Instructions

Standards and Guidelines

This machine is labelled with the CE mark indicating that it meets all

basic requirements concerning safety and protection of health of the EU

Machinery Directive 89/392/EEC, its supplements 91/368 EEC and

93/44 EEC for Europe, and the regulation 95/27/EEC. In addition, the

harmonised European standards EN 292-2 and EN 474/1 of 1994, and

EN 474-3 of 1996 were applied for manufacture of the machine. This

fact is documented in the EU Declaration of Conformity (CE) which is

supplied together with the machine.

This means that in those cases in which the machine is modified in such

a way that safety of the machine is affected, the person responsible for

safety of the machine is the one who has arranged for the machine to be

modified. If you use the machine for any other purpose than that defined

as correct use, you are the person who has to ensure that safety is

maintained. Modifications of the machine or use of the machine for any

other purpose than that specified as correct use may require a new CE

mark and thus new issuing of an EU Declaration of Conformity.

If a machine is used in other countries than Germany, it may be possible

that special national safety devices and specifications are missing which

may be required for the application in the relevant country. For example,

for Komatsu machines, the manufacturer has to design the cab roof in

such a way that a warning beacon can be attached to the roof. However,

when driving the machine on roads, this warning beacon must be covered.

Should you have any questions concerning standards and guidelines in

the respective country the machine is to be used in, please ask your

Komatsu dealer before you start commissioning the machine.

In addition to the operating instructions, you must also adhere to all legal

regulations on public traffic and all applicable regulations on prevention

of accidents. A corresponding leaflet "Notes on Operation of Komatsu

Construction Machines in Public Traffic" - applying to operation of

construction machines with a speed of more than 20 km/h on German

public roads - has been handed over to the dealer together with the

machine papers.

The expert inspection for earthmoving machines has to be performed

according to VBG 40 § 50 (VBG: German Administrative Professional

Association). The requirements for this expert inspection are defined in

the paragraphs 1 to 3 as follows:

1) Prior to first commissioning and after major modifications, earthmoving

machines must be inspected by an expert before they are put into service

again.

2) Earthmoving machines must be inspected by an expert at least once

every year. Moreover and depending on the respective operating and

local conditions, they must additionally be inspected by an expert, when

required.

3) The inspection results must be recorded in writing and stored at least

until the next inspection is due.

1 - 6

Information on these Operating Instructions

Notes on Later Installation of Electrical and Electronical Devices

and Components

Electrical or electronical devices and/or components installed later emit

electromagnetic radiation which may influence the proper function of

electronic components and parts of the machine. This may impair safety

of the machine and endanger persons. For this reason, strictly adhere to

the following safety notes.

If you later install electrical and electronical devices and/or components

in the machine and connect them to the vehicle electrical system, you

are responsible for any malfunctions of the vehicle electronics or other

components resulting from this installation. Above all, check that all

electrical and electronical components which you install later comply with

the valid version of the EMC directive 89/336/EEC and that they are

labelled with the CE mark.

The following requirements must additionally be met for a later installation

of mobile communication systems (e.g. radio, telephone):

• Only install devices which have a licence referring to valid national

regulations (e.g. BZT-licence in Germany).

• The device must be stationary.

• Only use portable or mobile devices in the cab, if they are connected

to a stationary external aerial.

• Install the sender in such a way that it is physically separated from

the vehicle electronics.

• When installing the aerial, make sure that it is installed correctly with

a good chassis earth connection between the aerial and the chassis

of the vehicle.

In addition, adhere to all information about installation and connection of

cables and maximum power input indicated in the manufacturer's

installation instructions of the machine.

1 - 7

Information on these Operating Instructions

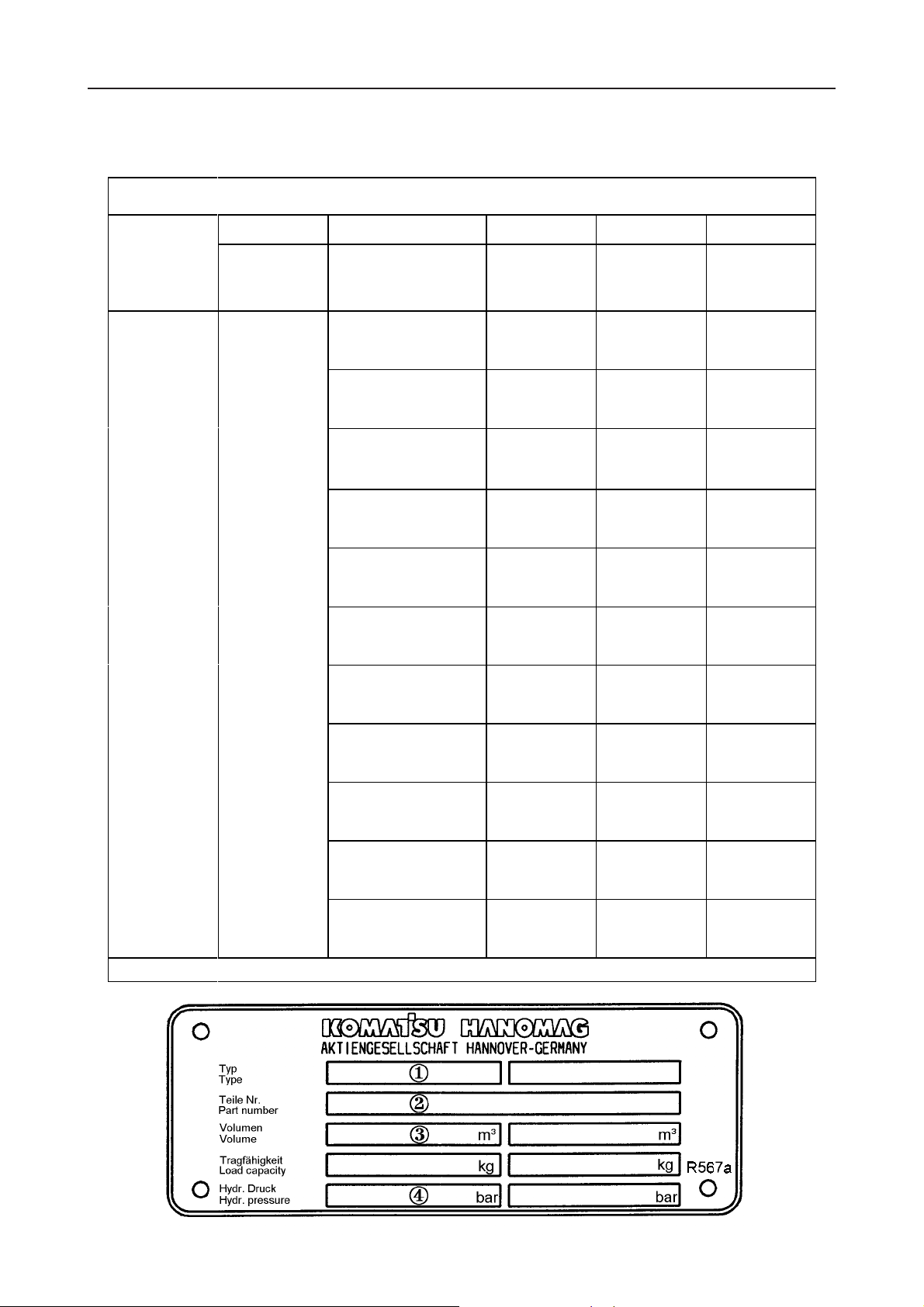

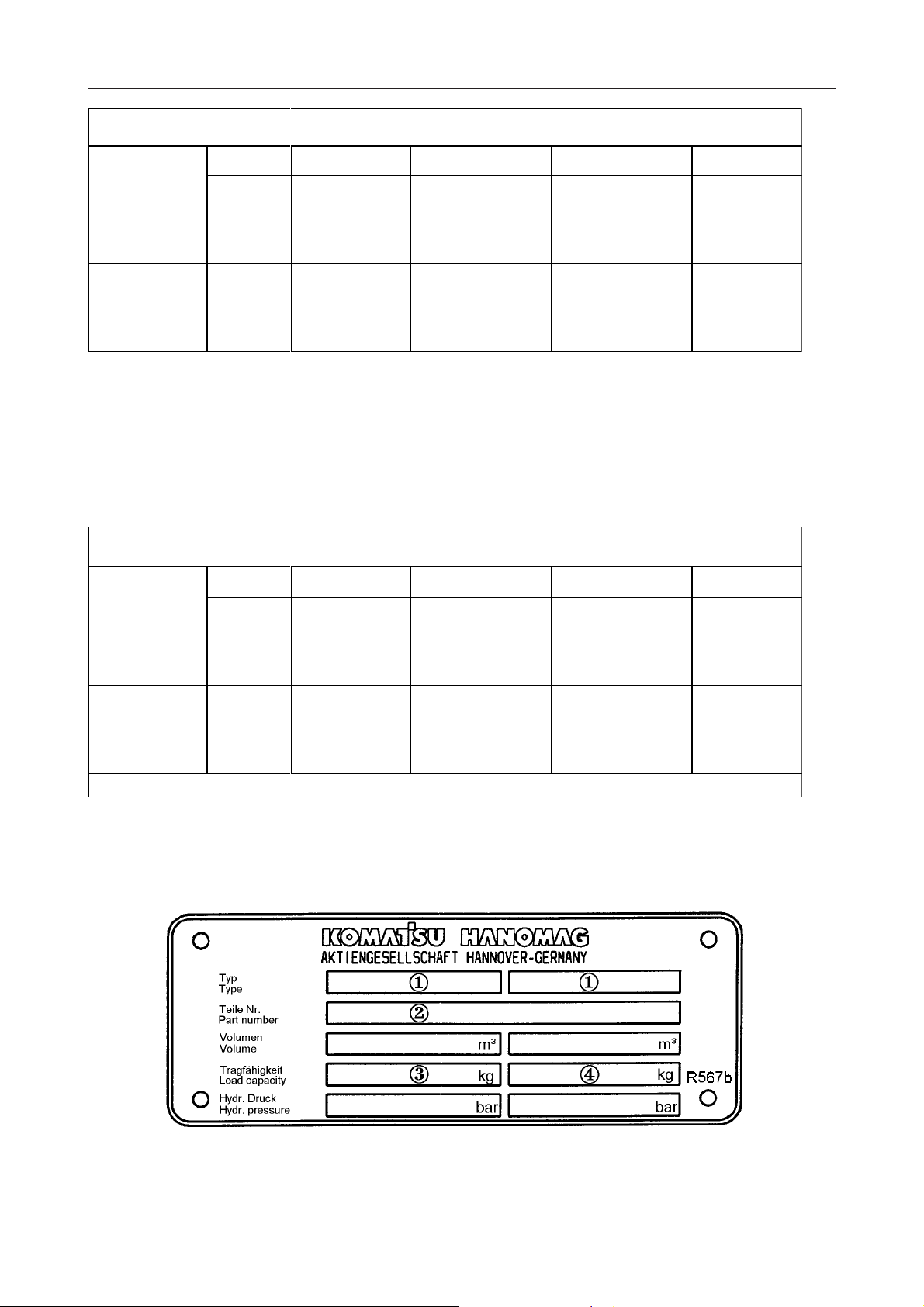

CE-Conforming Equipment

CE-conforming equipment

1 2 3 4 –

WA 95-3

Bucket

Type Part No.

42W-70-12021 1,1 --- 387

42W-70-12030 1,1 --- 411

42W-70-12090 0,9 185 670

42W-70-12100 0,9 185 620

42W-70-12210 1,0 185 700

WA95-3

42W-70-12240 1,0 185 640

42W-70-12051 1,25 --- 410

Volume

m³

Hydr.

pressure

bar

Weight

kg

42W-70-12061 1,6 --- 420

42W-70-12120 1,0 185 540

42W-70-12080 1,5 185 770

42W-70-12110 1,0 185 615

CE_1WA95.TBL

1 - 8

Information on these Operating Instructions

CE-conforming equipment

1 2 3 4 –

WA 95-3

Type Part No.

Fork carrier

*) Standing security 80% of the tipping load on firm and level ground

**) Standing security 60% of the tipping load on uneven ground

STD Machine in standard version

CTW Machine with counterweight

WA95-3 42U-70-12080

Work load of fork

carrier STD

kg / pair

*) 2500

**) 1870

Work load of fork

carrier with CTW

*) 2600

**) 1950

CE-conforming equipment

1 2 3 4 –

WA 95-3

Type Part No.

Carrying capacity

mm / kg

Carrying capacity

kg / pair

mm / kg

Weight

kg

121

Weight

kg

crane boom

WA95-3 42U-70-12530 500 / 1500 1000 / 1300 100

CE_2WA95.TBL

1 - 9

Information on these Operating Instructions

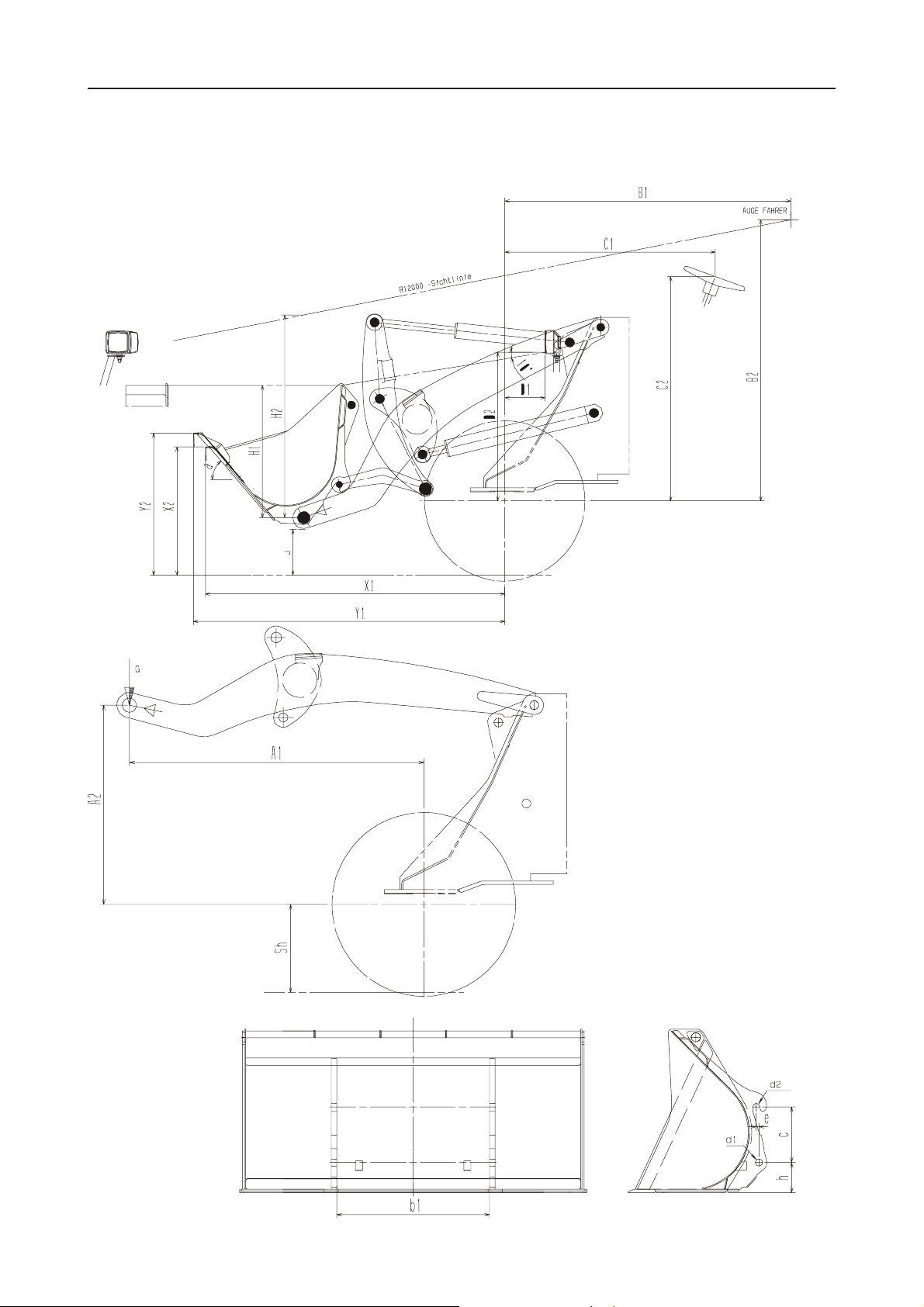

CE-Conforming Equipment of the Manufacturer

According to Document 42W-93-11130

1 -10

U:\DTP\BA75\CEAUS75.WMF

Information on these Operating Instructions

CE-Conforming Equipment of the

Manufacturer According to Document 42W-9311130

The responsibility for observing the regulations which are valid for wheel

loaders with "exchangeable equipment/attachments" (e. g. bucket or

forklift truck attachment), which is supplied by other manufacturers

lies with the supplier of the relevant parts which were subsequently

fitted to the machine.

The guidelines for CE Conformity and road-traffic registration are

deemed to have been fulfilled when the manufacturer of the equipment

confirms fulfilment of the document 42W-93-11130.

The certificate must be sent to the customer and the manufacturer of

the wheel loader. Only then will the CE conformity declaration for the

specific wheel loader be valid.

The dimensions X1, X2, Y1 and Y2 must be provided by the

manufacturer of the equipment for approval for use on public roads. *)

It is required to add the dimension Sh to the dimension D2 (smallest

tyre radius).

The figure G (in kg) represents the maximum load (equipment and

operating load) permitted to act at this point.

*) valid in Germany

A1 Distance bucket pivoting point - front axle, horizontal

A2 Distance bucket pivoting point- front axle, vertical

B1 Distance driver's eye - front axle, horizontal

B2 Distance driver's eye - front axle, vertical

D1 Distance front axle- lower edge of headlights, horizontal

D2 Distance front axle- lower edge of headlights, vertical

G Weight of the equipment and carrying load without additional

counterweight

H1 Distance bucket pivoting point - upper edge of bucket, vertical

(carrying position)

H2 Distance bucket pivoting point - to visual line, vertical

(carrying position)

J Distance road level - lower edge of bucket in carrying position

(to be considered during driving on public roads)

Sh Distance road level - front axle

X1 Distance cutter protection - front axle, horizontal

X2 Distance cutter protection - road level, vertical

Y1 Distance teeth protection - front axle, horizontal

Y2 Distance teeth protection - road level, vertical

a tip-in angle

b1 Bucket connection dimension boom width, interior

c Bucket connection dimension between d1 and d2, vertical

d1 Bucket connection dimension bolts for boom

d2 Bucket connection dimension bolt for tip-in rod

e Bucket connection dimension d1- d2 horizontally displaced

h Distance lower edge of bucket - drill hole of boom bolt

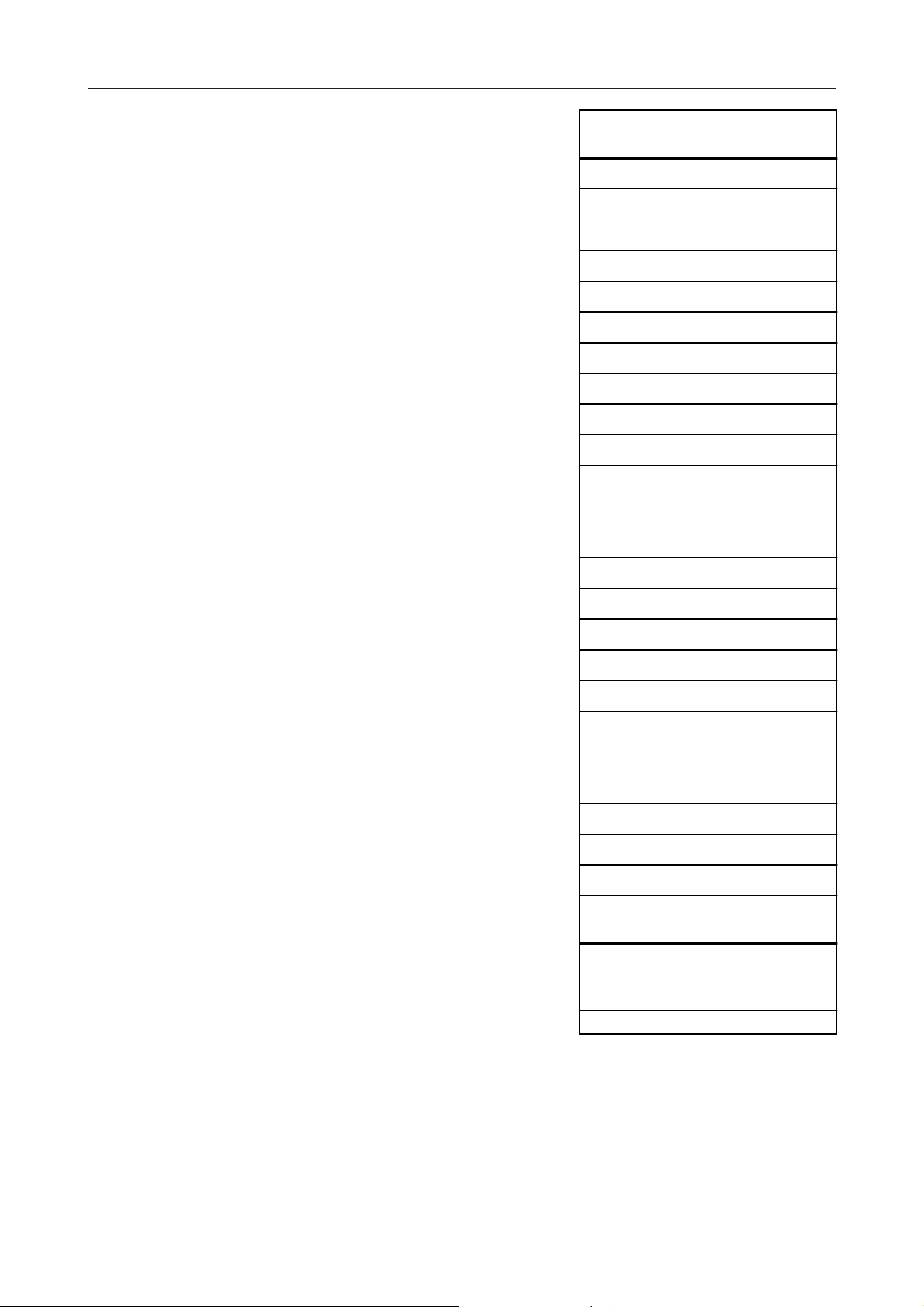

WA 95 42W-93-11130

A1 1,670

A2 1,180

Sh 545

B1 1,980

B2 1,860

C1 1,490

C2 1,490

D1 285

D2 1,075

G 2,480

H1 1,030

H2 1,400

J 270

X1

X2

Y1

Y2

a 52

b1 860

c 312

d1 40

d2 40

e 15

h 200

Tyre Dunlop 455/70 R20

Bucket

42W-70-12030

1.1 m³

CEDok95.TBL

1 -11

Information on these Operating Instructions

1 -12

Loading and Transporting the Machine

Loading and

Transporting the

Machine

2- 1

Loading and Transporting the Machine

2- 2

Loading and Transporting the Machine

Loading and Transporting the Machine

If you have to transport the machine over far distances, either use a low

bed loader or a railway wagon. You may lift the machine onto the transport

vehicle. Optionally, you may drive it onto the low bed loader or railway

wagon via loading ramp (also refer to "Safety Measures During Operation, Transport"). Before you start driving, check that the following

requirements are fulfilled: the roads are broad enough, the bridges are

wide enough, the clearance heights of tunnels and the like are sufficient,

the carrying capacities of roads and bridges are sufficient.

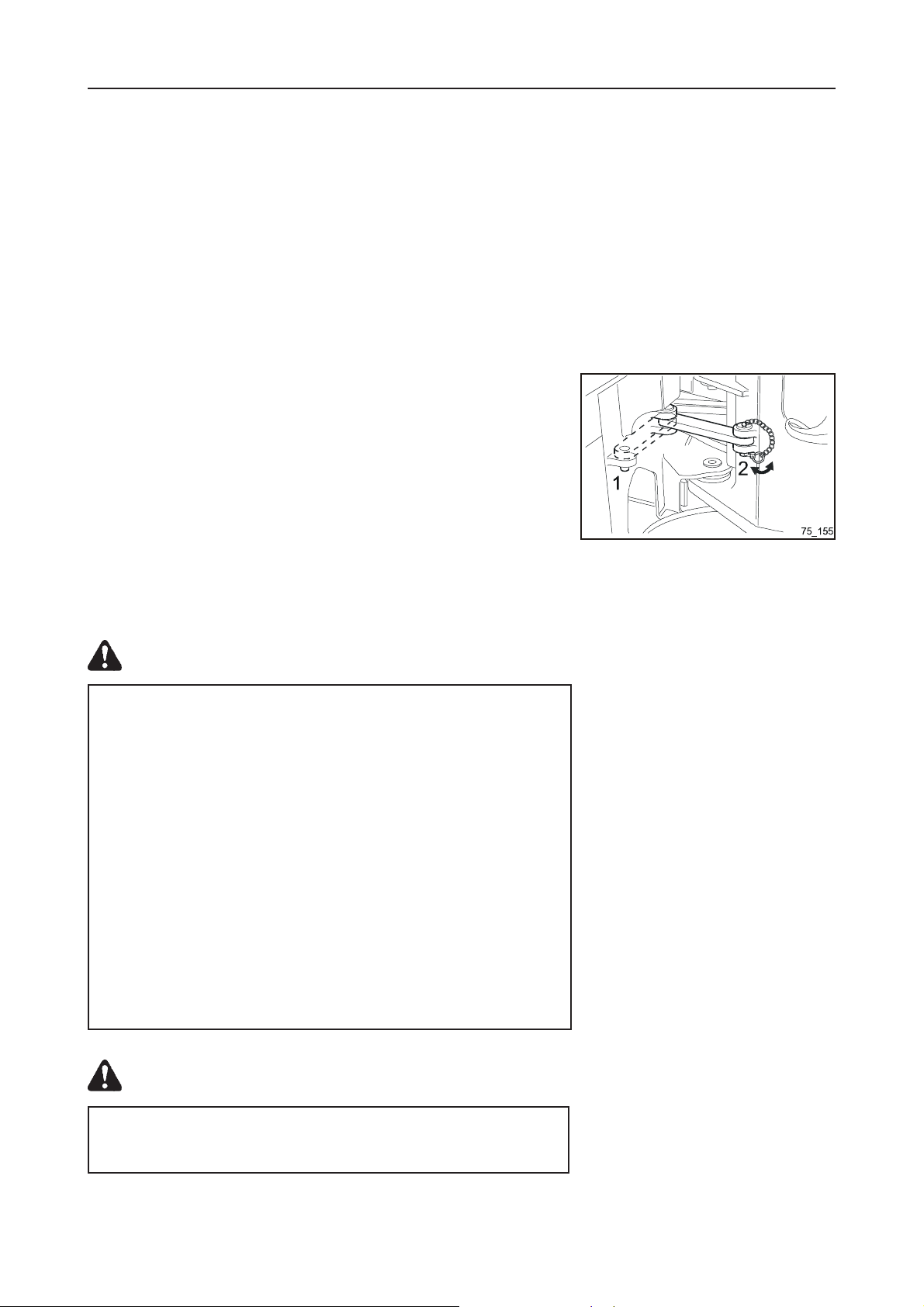

Securing the Articulated Steering

Secure the articulated steering before you lift up the machine or start to

perform repair measures.

1. Set the machine to straight driving.

2. Loosen the spring bolt and remove the bolt.

3. Turn the locking bar from position '1' to position '2'.

'1' Articulated steering unlocked

'2' Articulated steering locked

4. Insert the bolt and secure it with the spring bolt.

Lifting the Machine

DANGER

• Danger of pinching! An unlocked articulated steering may

suddenly move!

Secure the articulated steering before you lift up the

machine.

• Danger of accidents! Carrying ropes with insufficient

carrying capacities may tear so that the machine may fall

down!

Only lift up the machine using carrying ropes with sufficient

carrying capacities.

• Hoisting equipment with insufficient carrying capacities may

suddenly bend and cause severe accidents!

Only use hoisting equipment capable of carrying the

machine's operating weight.

• Objects lying on the machine may fall down and cause

injuries when the machine is lifted up!

Remove all loose objects from the machine before you lift

up the machine.

CAUTION

Incorrectly attached ropes may damage the machine!

Only fasten the eye hooks of the carrying ropes at the marked

attachment points.

There are two attachment points each at the front part and the rear part

of the machine. These attachment points are shown in the following figure.

2- 3

Loading and Transporting the Machine

“

X

„

75_162a

Information signs attached to the machine indicate the attachment points.To

avoid damage to the machine, attach the eye hooks only to the attachment

points.

X = Machine accessories:

- 2 brackets, order no. 42U-98-12A10

- 4 screws M16 x 40

+ strength 10.9, order no. 01016-51640

+ screws in rear frame, inside, screwed in.

+ torque: 280 Nm

When selecting the lifting equipment, take the operating weight of the

machine into account. Insufficient carrying capacities of the lifting equipment may cause severe accidents. Also use carrying ropes with

appropriate carrying capacities for the operating weight of the machine.

Carrying ropes with insufficient carrying capacities may tear when the

machine is lifted up and cause severe accidents. The operating weight

of the machine depends on the attached bucket. You find the operating

weights of the machine in the chapter "Dimensions, Weights, and

Operating Values".

Driving Machine Onto Loading Area of Transport Vehicle

WARNING

If the transport vehicle or the loading ramp starts skidding while

you are driving up the loading ramp, the machine may fall off

the ramp and cause severe accidents!

Secure the transport vehicle against accidental movement.

Secure the wheels of the low bed loader with wheel chocks or

wedges.

The transport vehicle for the machine must have an appropriate work

load. The operating weight of the machine depends on the attached

equipment. The operating weights of the machine can be found in the

respective table in the chapter "Dimensions, Weights, and Operating

Values".

The articulated steering must be unlocked before the machine is driven

onto the transport vehicle to ensure that the machine remains steerable.

Remove any mud, snow, or ice adhering to the wheels to ensure that you

can drive onto the ramps without danger of skidding. Do not load the

machine via landing stage unless you have checked that the landing

stage is broad enough and that its strength is sufficient to carry the load.

2- 4

1

75_269

Loading and Transporting the Machine

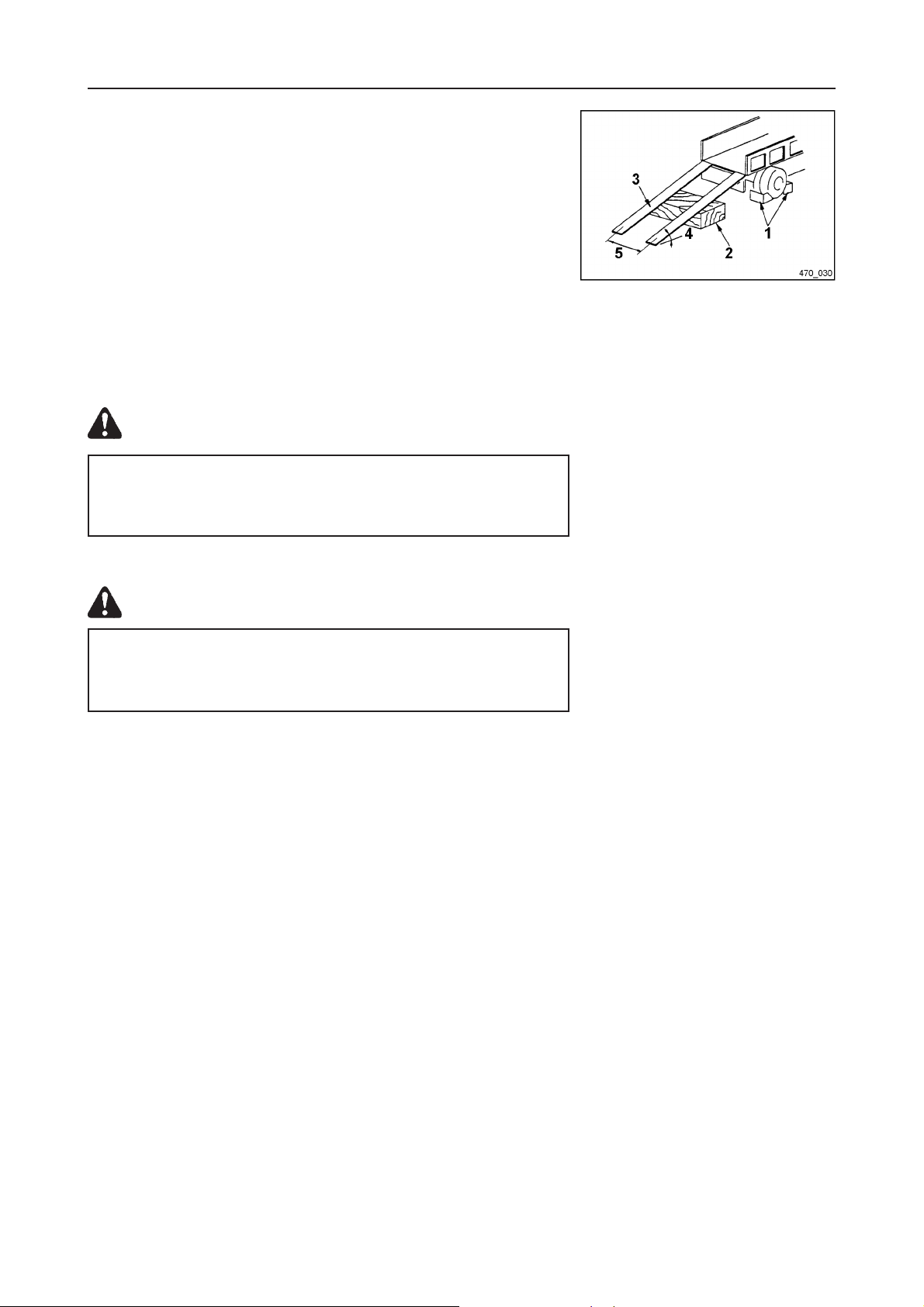

The loading ramps (3) must be aligned to the wheel tracks (5) of the

machine. The loading ramps must be secured in such a way that they

cannot slip while the machine is being loaded. Support the loading ramps

by placing support blocks (2) under both ramps. Make sure that the

transport vehicle may neither tip over, start to skid, or roll away while you

are driving it onto the transport vehicle. Secure the wheels of the low bed

loader with wheel chocks (1) or wedges.

Position the machine straight in front of the loading ramp and slowly

drive up the loading ramp. Do not perform steering movements on the

ramp. If required, drive off the ramp, correct the position of the machine

on the ground and drive up the ramp again.

Securing the Machine During Transport

DANGER

If the machine is insufficiently secured, it may start to skid or

fall off the transport vehicle and cause severe accidents!

Always secure the machine with ropes and wheel chocks or

wedges to avoid falling down and skidding.

CAUTION

Stay ropes that are incorrectly attached may damage the

machine!

Only fasten the eye hooks of the stay ropes at the marked

attachment points.

When the machine is on the loading area of the transport vehicle, secure

the articulated steering as described in the chapter "Securing the

Articulated Steering". Then, block the wheels of the machine with wheel

chocks or wedges and secure the machine with ropes in such a way that

it will neither start to skid nor tip over during transport. To avoid damage

to the machine, only fasten the eye hooks of the stay ropes at the marked

attachment points. The attachment points to be used are the two eye

hooks at the front frame and the tie bolt at the rear frame of the machine.

The positions of the attachment points are shown in the figure on the

previous page.

After Transport

After transport, remove all securing devices, such as wheel chocks or

wedges and ropes. Remove the catch of the articulated steering before

you drive the machine off the transport vehicle. For this purpose, reverse

the steps 1 through 4 described in the chapter "Securing the Articulated

Steering".

2- 5

Loading and Transporting the Machine

g

g

g

gkg

g

g

g

g

y

g

g

g

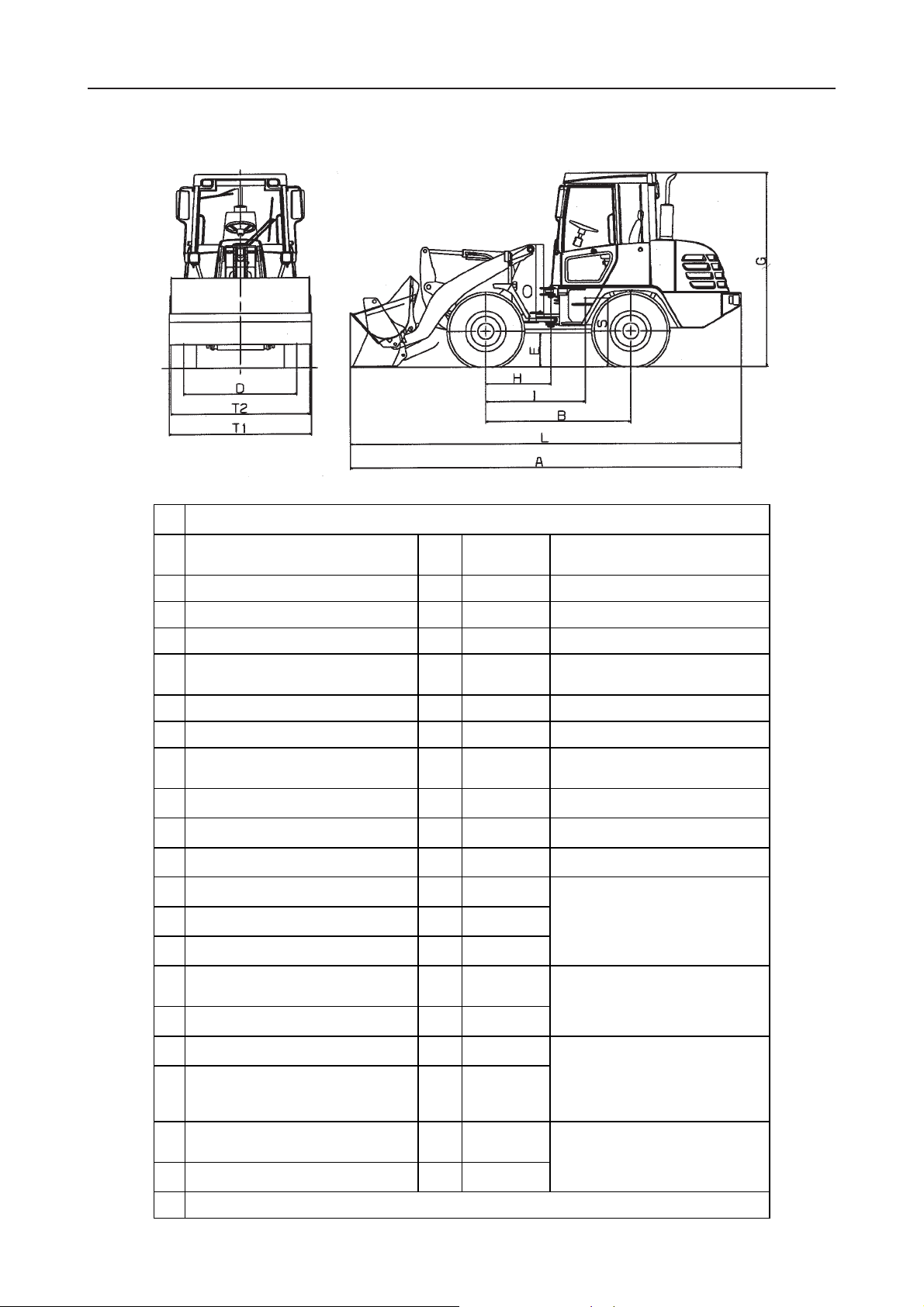

Dimensions, Weights, and Operating Values

Dimensions, Operating Values

Bucket capacity according to

ISO 7546

Loose weight t/m³ 2.0

Stat. tipping load, straight k

Stat. tipping load, bent by 40° k

Working load without CTW

Workin

load with CTW

Tear-out force, hydraulic kN 72.5

Hydr. lifting capacity on ground kN 57.0

Operating weight k

Turning radius over bucket mm 4455

Bucket length in transport position mm 5550

L

Bucket length during planin

A

Width with bucket mm 2150

T1

Width without bucket (above wheels) mm 2060

T2

Height, including ROPS mm 2750

G

Track (front section)

D

Track (rear section)

Width over tyres mm 2150

B

m³ 1.1

k

mm 5580

mm

mm

4860

4200

2500

2600

5830

1590

1590

The 1.1 m³ standard bucket given in

the table is also available with blade

125 m³ li

m³ li

attachment.

Special buckets:

ht weight material bucket 1.6

ht weight material bucket

0.9 m³ multi-purpose bucket

Distance articulated steer. - front axle mm 1035

H

Ground clearance, axle /

transfer

E

Centre of gravity,

F

hei

Centre of gravity, distance to front axle mm 1440

I

ear

round clearance, cardan shaft

ht above axle centre

mm

mm

mm 420

395

505

These values apply to machines with

455/70 R20 t

*) CTW = additional counterweight

res

ABM_95E.TBL

2- 6

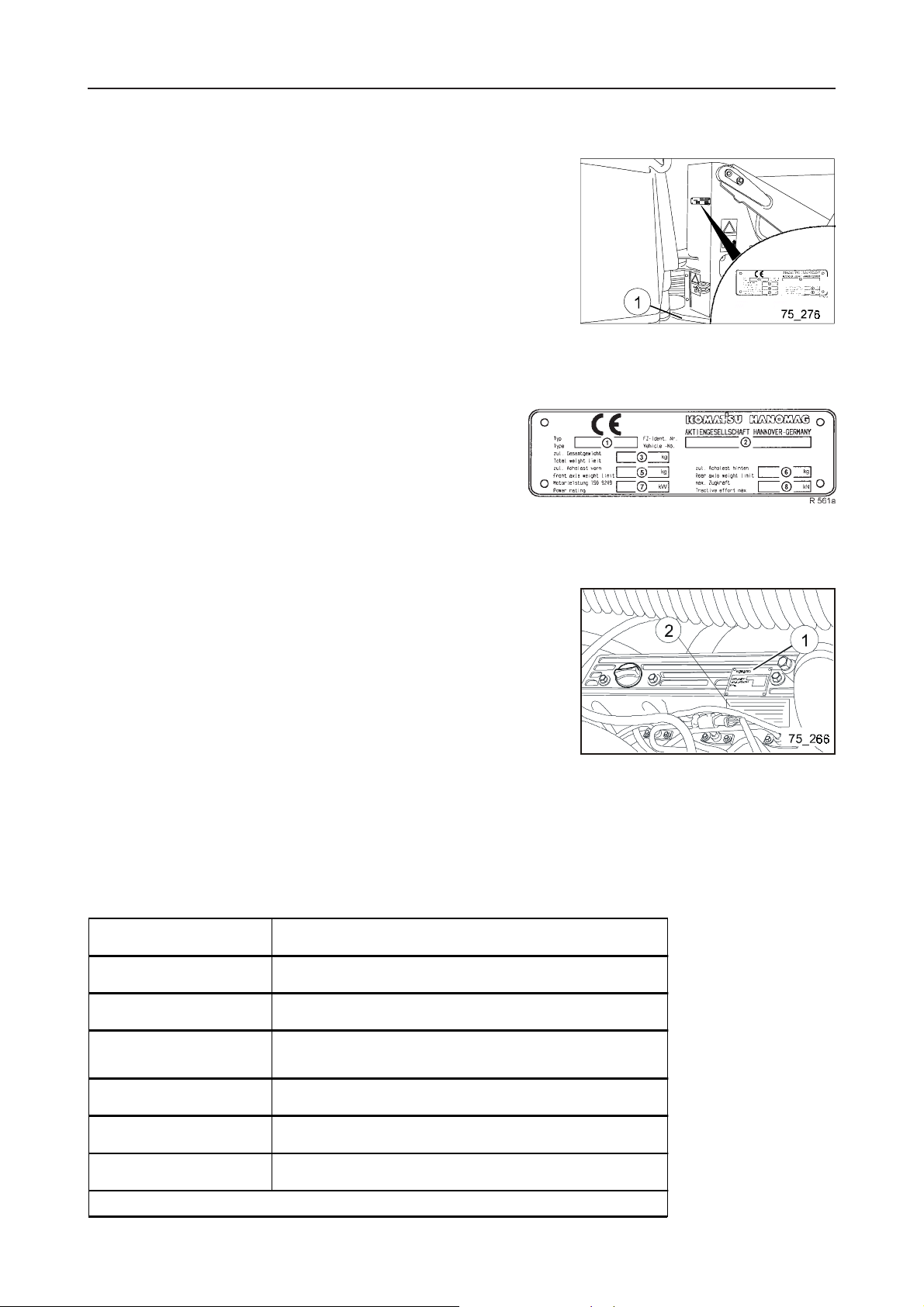

Technical Data

Machine name-plate position

(see enlargement)

Serial no. stamp marking (1)

Machine name-plate with serial no.

Loading and Transporting the Machine

Engine name-plate (1) with serial no.

EPA label (2)

Serial no. and address of manufacturer

Must be filled in before machine is put into service:

Serial No. Machine

Serial No. Engine

Dealer Name

..................................................................................

..................................................................................

..................................................................................

Dealer Address

Telephone

Fax

Maintenance Personnel

..................................................................................

..................................................................................

..................................................................................

..................................................................................

..................................................................................

SE-NO_75.TBL

2- 7

Loading and Transporting the Machine

2- 8

Safety

DANGER

Failure to adhere to these safety instructions can lead to

accidents with serious injuries!

Read and adhere to all safety instructions.

This chapter also contains safety instructions for special equipment

and attachments.

General Safety Measures

General Safety Measures

Safety Instructions

• Do not operate or service the machine unless you have been trained

and are authorised to do so.

• Always adhere to all instructions, measures, and safety instructions

when operating or servicing the machine.

• When working together with other persons, agree beforehand on all

hand signals that you want to use to avoid accidents due to

misunderstandings.

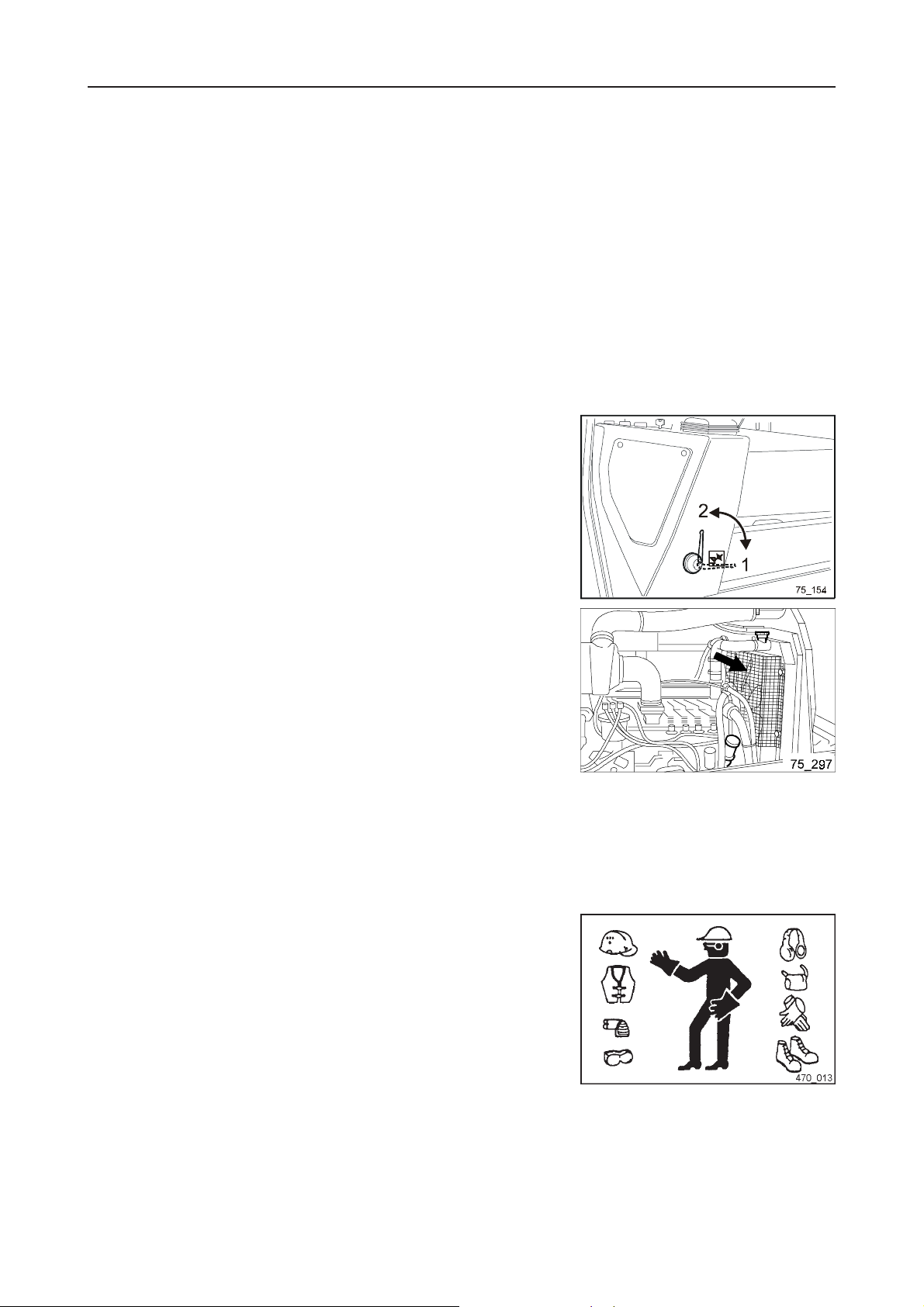

Safety Devices

• Check that all safety devices and covers of the machine are correctly

installed.

• Ensure that damaged safety devices and covers are repaired before

you start the machine.

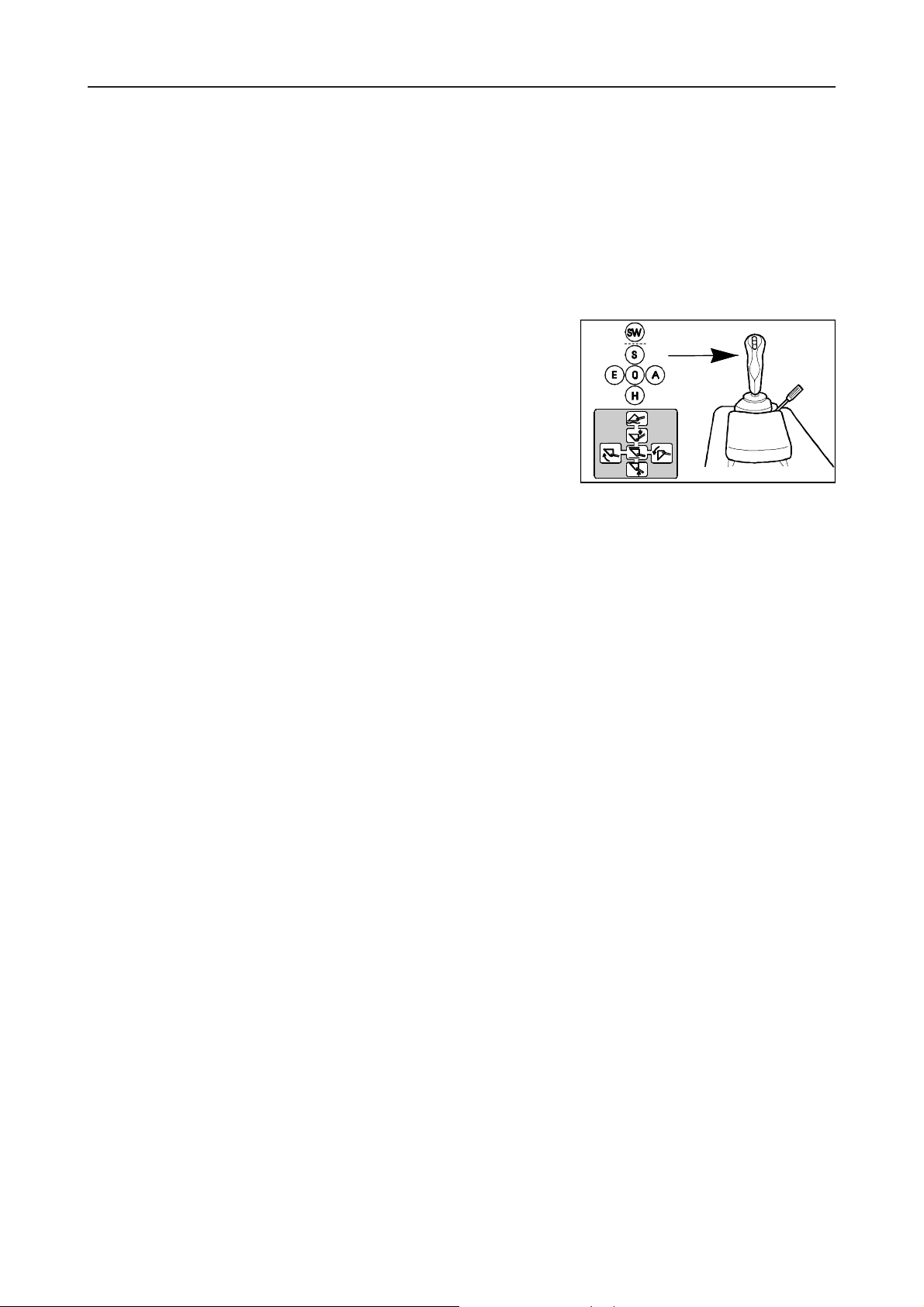

• Use all safety devices as prescribed, e.g. the safety lever for the work

hydraulic system (see opposite figure) and the safety belt.

• Do not remove any of the safety devices e.g. the protective grid above

the fan (see opposite figure). Safety devices must be kept in perfect

condition.

Emergency Exit

In an emergency situation, you can use the door on the right-hand side

of the driver's cab (seen from the driving direction) as an emergency

exit.

Clothing and Personal Protection

• Do not wear loose-fitting clothing, jewellery, or open long hair. There

is danger that you get caught by control elements or moving parts

leading to serious injuries.

• Immediately replace clothing stained with highly inflammable

substances.

• When operating and servicing the machine, wear the appropriate

protective equipment, e.g. safety helmet, safety goggles, safety shoes,

dust protection mask, and safety gloves.

• Always wear safety goggles, safety helmet, and protective clothing, if

it is likely that chippings or splinters will be produced while operating

the machine (e.g. when removing or driving in bolts or cleaning with

compressed air).

• Ensure that no unauthorised person is within the danger zone.

3- 2

Machine Modifications

• Komatsu will not be liable for modifications performed without prior

expressed consent by the manufacturer.

• Komatsu will not be liable for any injuries or damage resulting from

unapproved modifications.

Before You Leave the Driver's Seat

1. Lower the work unit onto the ground.

2. Switch off the engine.

3. Press slowly the multi-function lever to the front into position 'S'. The

remaining hydraulics pressure will be reduced.

4. Remove the ignition key before you leave the driver's seat. Store the

ignition key in a safe place.

5. Close the cabin door.

General Safety Measures

75_016

Mounting and Dismounting

• Do not jump on or off the machine. Do not mount on or dismount from

a moving machine.

• Always use the handle bars and tread steps for mounting or

dismounting the machine. Do not hold onto the control levers while

mounting and dismounting.

• To ensure safe hold, hold the handle bar with one hand and stand on

the tread steps with both feet. Optionally, stand on the tread steps

with one foot and hold the handle bars with both hands.

• To reach the left rear mudguard for checking of the coolant level, set

one foot into the driver's cab and use it as the fourth step. Dismount

backwards.

3- 3

General Safety Measures

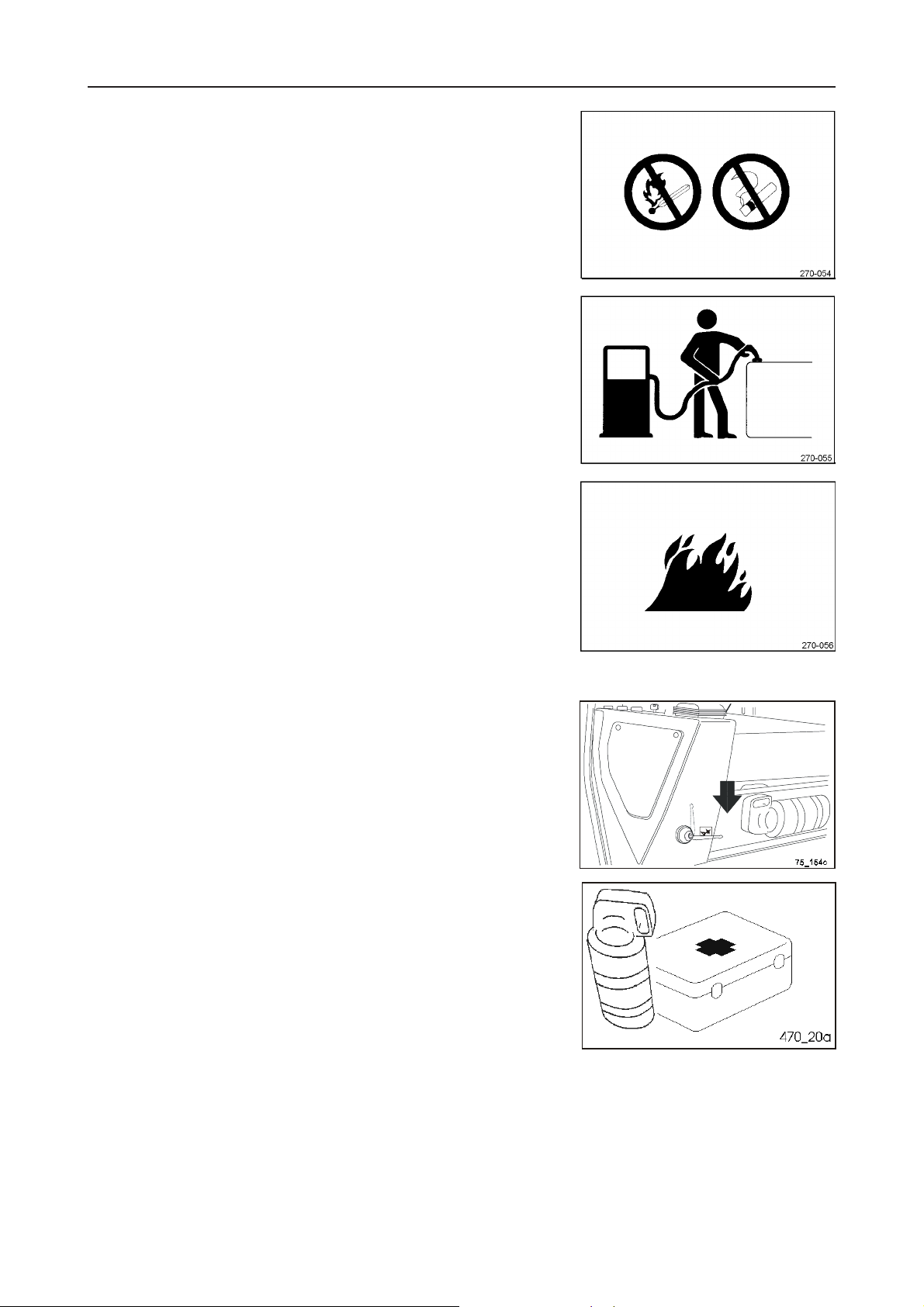

Fire Prevention and Fire Fighting

• Fuel, oil, and antifreezing compound are highly inflammable and could

cause a fire.

• Do not approach inflammable material with naked light.

• Prior to refuelling, switch off the engine and stop smoking.

• Refuelling and refilling of oil are to be performed in sufficiently ventilated

places.

• Store oil and fuel in special places appropriate for this purpose. Ensure

that unauthorised persons do not have access to these places.

• Tightly close all cover caps.

• Check the fuel system, the lubrication system, and the hydraulic system

for leaks. Have leaks repaired. Remove any excess oil, fuel, or other

inflammable substances.

• Carefully and completely remove wooden chippings, leaves, paper,

and other highly inflammable materials that may have collected in the

engine compartment, since they could cause a fire.

• Do not operate the machine in the vicinity of naked light.

Fire Extinguisher and First-Aid Kit

• A fire extinguisher can be stored in the compartment under the driver's

seat. Two appropriate fastening points are already attached to the

back of the compartment.

• A fully operational fire extinguisher must be available at hand.

• If, in the course of certain operations, there is danger of fire, fire

extinguishers must be at hand. Familiarise with the use of the fire

extinguishers.

• Inform yourself on measures to be taken in the event of a fire.

• The first-aid kit can be stored in the compartment under the driver's

seat next to the fire extinguisher.

• Make sure that you know all telephone numbers of the persons that

you need to contact in an emergency.

3- 4

Loading...

Loading...