Komatsu WA20-2, WA50-3, WA30-5, WA40-3 Maintenance Manual

SEAM010700

WA20 -2,WA30 -5

WA40 -3,WA50 -3

WHEEL LOADER

WA20 - 11270

SERIAL NUMBERS and up

Unsafe use of this machine may cause serious injury

or death. Operators and maintenance personnel

must read this manual before operating or maintaining this machine. This manual should be kept near the

machine for reference and periodically reviewed

by all personnel who will come into contact with it.

WA30 - 18970

WA40 - 13530

WA50 - 20642

NOTICE

Komatsu has Operation & Maintenance Manuals written in

some other languages. If a foreign language manual is

necessary, contact your local distributor for availability.

1. FOREWORD

This manual provides rules and guidelines which will help you use this machine safely and

effectively. Keep this manual handy and have all personnel read it periodically. If this manual has been

lost or has become dirty and can not be read, request a replacement manual from Komatsu or your

Komatsu distributor.

If you sell the machine, be sure to give this manual to the new owners.

Continuing improvements in the design of this machine can lead to changes in detail which may not

be reflected in this manual. Consult Komatsu or your Komatsu distributor for the latest available

information of your machine or for questions regarding information in this manual.

This manual may contain attachments and optional equipment that are not available in your area.

Consult Komatsu or your Komatsu distributor for those items you may require.

WARNING

‡ Improper operation and maintenance of this machine can be hazardous and could result in serious

injury or death.

‡ Operators and maintenance personnel should read this manual thoroughly before beginning

operation or maintenance.

‡ Some actions involved in operation and maintenance of the machine can cause a serious accident,

if they are not done in a manner described in this manual.

‡ The procedures and precautions given in this manual apply only to intended uses of the machine.

If you use your machine for any unintended uses that are not specifically prohibited, you must

be sure that it is safe for you and others. In no event should you or others engage in prohibited

uses or actions as described in this manual.

‡ Komatsu delivers machines that comply with all applicable regulations and standards of the

country to which it has been shipped. If this machine has been purchased in another country or

purchased from someone in another country, it may lack certain safety devices and specifications

that are necessary for use in your country. If there is any question about whether your product

complies with the applicable standards and regulations of your country, consult Komatsu or your

Komatsu distributor before operating the machine.

‡ The description of safety is given in SAFETY INFORMATION on page 0-2 and in SAFETY from page

1-1.

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of its

constituents are known to the State

of California to cause cancer, birth

defects, and other reproductive

harm.

0-1

2. SAFETY INFORMATION

Most accidents are caused by the failure to follow fundamental safety rules for the operation and

maintenance of machines. To avoid accidents, read, understand and follow all precautions and warnings

in this manual and on the machine before performing operation and maintenance.

To identify safety messages in this manual and on machine labels, the following signal words are

used.

DANGER – This word is used on safety messages and safety labels where there is a high

probability of serious injury or death if the hazard is not avoided. These safety

messages or labels usually describe precautions that must be taken to avoid the

hazard. Failure to avoid this hazard may also result in serious damage to the

machine.

WARNING – This word is used on safety messages and safety labels where there is a

potentially dangerous situation which could result in serious injury or death if

the hazard is not avoided. These safety messages or labels usually describe

precautions that must be taken to avoid the hazard. Failure to avoid this hazard

may also result in serious damage to the machine.

CAUTION – This word is used on safety messages and safety labels for hazards which could

result in minor or moderate injury if the hazard is not avoided. This word might

also be word for hazards where the only result could be damage to the machine.

NOTICE – This word is used for precautions that must be taken to avoid actions which

could shorten the life of the machine.

Safety precautions are described in SAFETY from page 1-1.

Komatsu cannot predict every circumstance that might involve a potential hazard in operation and

maintenance. Therefore the safety messages in this manual and on the machine may not include all

possible safety precautions. If any procedures or actions not specifically recommended or allowed in this

manual are used, you must be sure that you and others can do such procedures and actions safely and

without damaging the machine. If you are unsure about the safety of some procedures, contact your

Komatsu distributor.

0-2

3. INTRODUCTION

3.1 INTENDED USE

This machine is intended mainly for the following operations.

‡ Digging operations

‡ Leveling operations

‡ Pushing operations

‡ Loading operations

For details of the operating procedure, see “12.9 WORK POSSIBLE USING WHEEL LOADER”.

3.2 FEATURES

‡ Easy operation by HST mechanism

‡ High performance

‡ Each kind of safety devices is installed.

3.3 BREAKING IN THE MACHINE

Your Komatsu machine has been thoroughly adjusted and tested before shipment.

However, operating the machine under severe conditions at the beginning can adversely affect the

performance and shorten the machine life.

Be sure to break in the machine for the initial 100 hours (as indicated by the service meter.)

During breaking in:

‡ Idle the engine for 5 minutes after starting it up.

‡ Avoid operation with heavy loads or at high speeds.

‡ Avoid sudden starts, sudden acceleration, sudden steering and sudden stops except in cases of

emergency.

The precautions given in this manual for operating, maintenance, and safety procedures are only

those that apply when this product is used for the specified purpose. If the machine is used for a purpose

that is not listed in this manual, Komatsu cannot bear any responsibility for safety. All consideration of

safety in such operations is the responsibility of the user.

Operations that are prohibited in this manual must never be carried out under any circumstances.

0-3

4. LOCATION OF PLATES, TABLE TO ENTER

SERIAL NO. AND DISTRIBUTOR

4.1 MACHINE SERIAL NO. PLATE POSITION

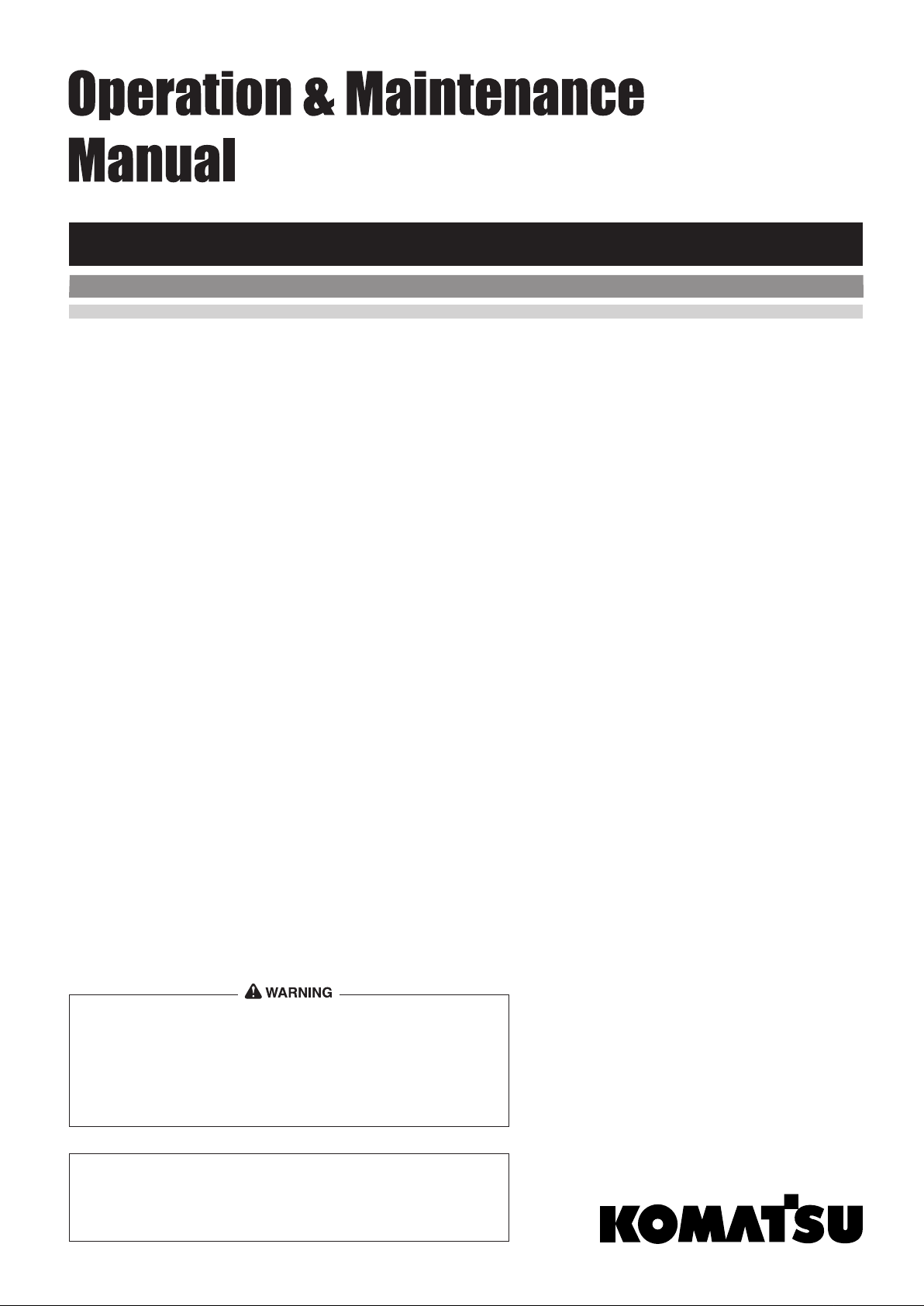

4.1.1 WA20

Position of plate

This plate is on the center of the front frame on the right side of

the machine.

Position of stamp

This is stamped on the center of the front frame on the right side

of the machine.

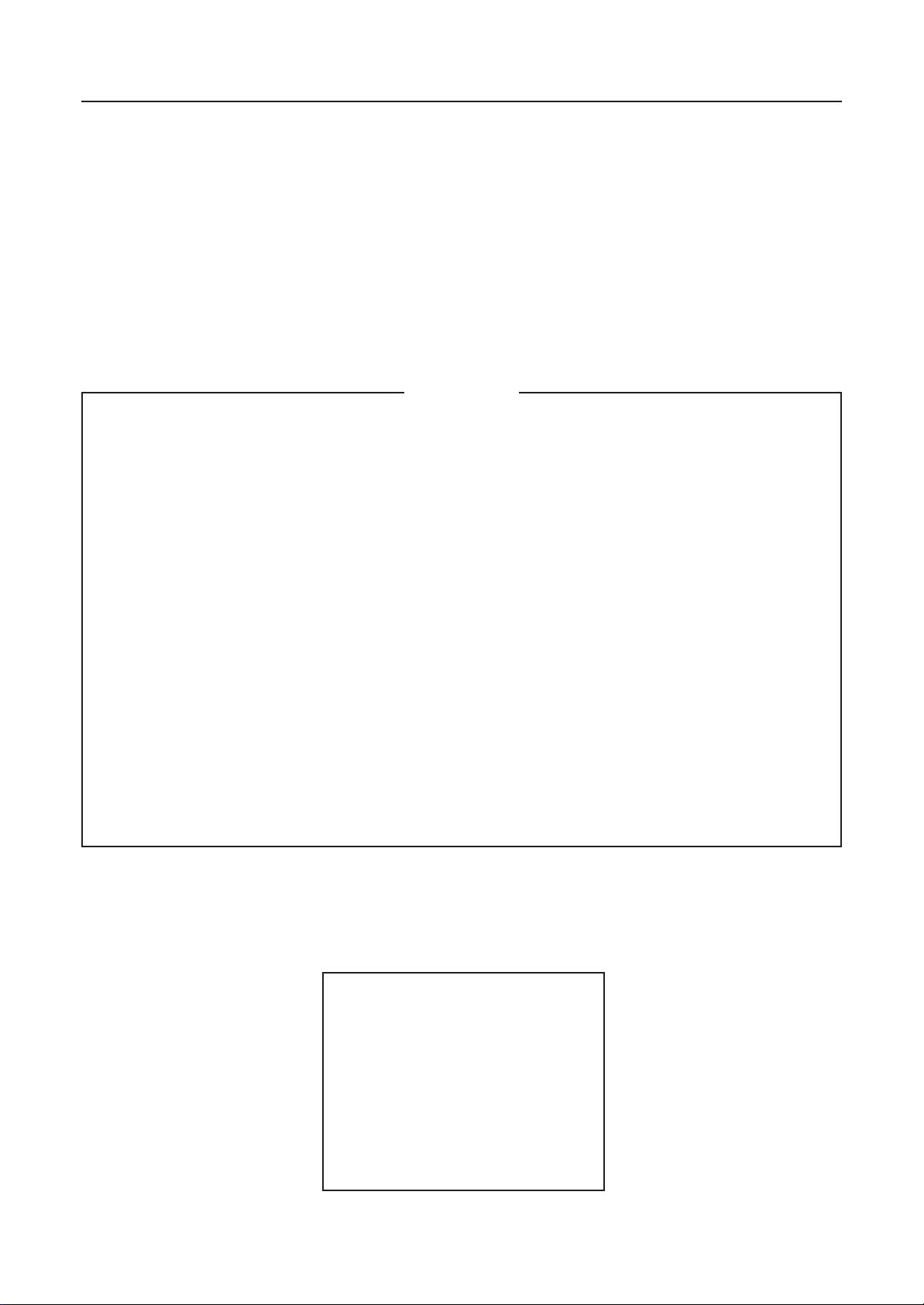

4.1.2 WA30, 40, 50

Position of plate

This plate is on the center of the front frame on the right side of

the machine.

Position of stamp

This is stamped on the center of the front frame on the right side

of the machine.

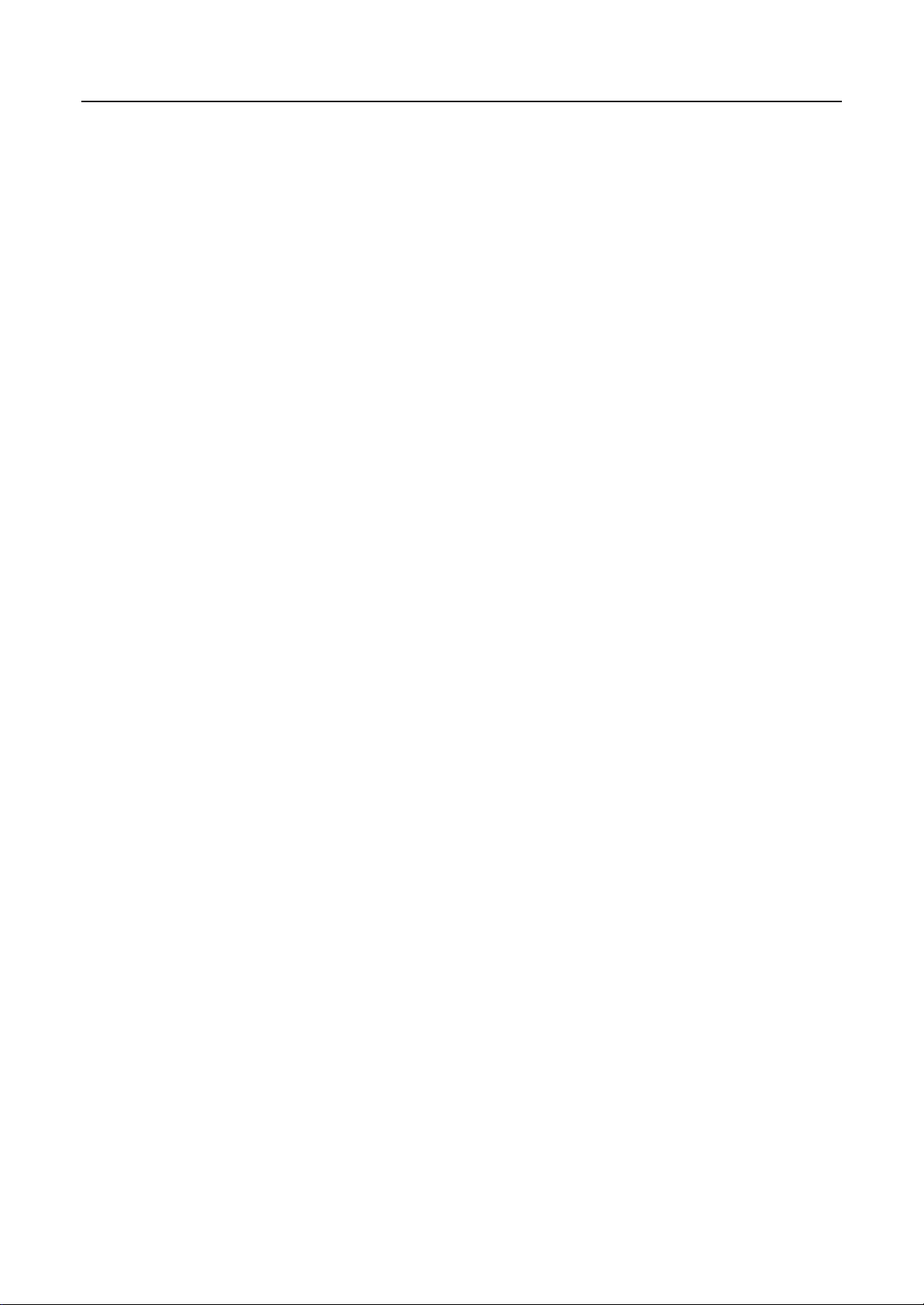

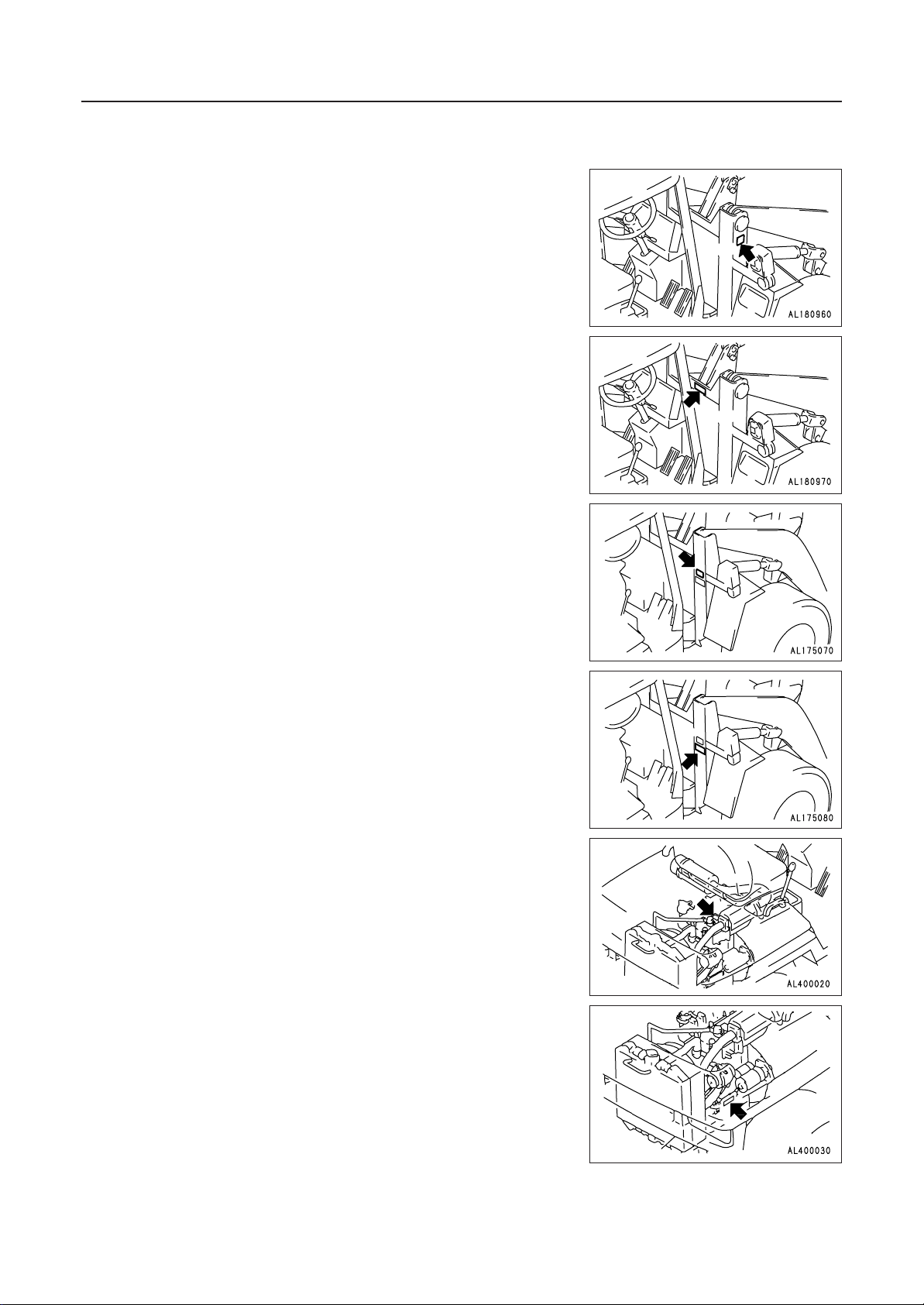

4.2 ENGINE SERIAL NO. PLATE POSITION

Position of plate

This plate is on top of the engine cylinder head cover.

Position of stamp

This is stamped on the right side of the engine cylinder block as

seen from the fan.

0-4

4. LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

4.3 TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

Machine serial No.:

Engine serial No.:

Distributor name:

Address: Phone:

Service personnel for your machine:

REMARKS

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

0-5

5. CONTENTS

1. Foreword ............................................................................................................................................. 0- 1

2. Safety information .............................................................................................................................. 0-2

3. Introduction .......................................................................................................................................... 0- 3

4. Location of plates, table to enter serial No. and distributor ........................................................ 0- 4

SAFETY

6. General precautions ............................................................................................................................ 1- 2

7. Precautions during operation ............................................................................................................ 1- 7

7.1 Before starting engine ............................................................................................................. 1- 7

7.2 Operating machine ................................................................................................................... 1- 9

7.3 Transportation ........................................................................................................................... 1-14

7.4 Battery ....................................................................................................................................... 1-15

7.5 Towing ....................................................................................................................................... 1-16

8. Precautions for maintenance ............................................................................................................. 1-17

8.1 Before carrying out maintenance ........................................................................................... 1-17

8.2 During maintenance ................................................................................................................ 1-21

8.3 Tires ............................................................................................................................................ 1-25

9. Position for attaching safety labels .................................................................................................. 1-27

OPERATION

10. General view ....................................................................................................................................... 2- 2

10.1 General view of machine ........................................................................................................ 2- 2

10.2 General view of controls and gauges .................................................................................... 2- 3

11. Explanation of components ............................................................................................................... 2- 4

11.1 Meter, lamps ............................................................................................................................. 2- 4

11.2 Switches ..................................................................................................................................... 2- 8

11.3 Control levers, pedals .............................................................................................................. 2-10

11.4 Cap with lock ............................................................................................................................ 2-14

11.5 Safety bar .................................................................................................................................. 2-14

11.6 Tilt hood ..................................................................................................................................... 2-15

11.7 Towing pin ................................................................................................................................ 2-15

11.8 Fuse ............................................................................................................................................ 2-15

11.9 Fusible link ................................................................................................................................ 2-16

11.10 Manual pocket ........................................................................................................................... 2-17

11.11 Connectors ................................................................................................................................ 2-17

0-6

5. CONTENTS 5. CONTENTS

12. Operation .............................................................................................................................................. 2-18

12.1 Check before starting engine .................................................................................................. 2-18

12.2 Starting engine .......................................................................................................................... 2-29

12.3 Operations and checks after starting engine ......................................................................... 2-32

12.4 Moving machine off .................................................................................................................. 2-34

12.5 Changing direction .................................................................................................................... 2-36

12.6 Turning ....................................................................................................................................... 2-36

12.7 Stopping machine ..................................................................................................................... 2-37

12.8 Operation of work equipment ................................................................................................. 2-38

12.9 Work possible using wheel loader .......................................................................................... 2-39

12.10 Precautions for operation ......................................................................................................... 2-43

12.11 Adjusting work equipment posture ........................................................................................ 2-45

12.12 Parking machine ........................................................................................................................ 2-46

12.13 Checks after completion of operation .................................................................................... 2-47

12.14 Stopping engine ........................................................................................................................ 2-48

12.15 Check after stopping engine .................................................................................................... 2-48

12.16 Locking ....................................................................................................................................... 2-48

12.17 Handling the tires ...................................................................................................................... 2-49

13. Transportation ..................................................................................................................................... 2-52

13.1 Loading, unloading work ......................................................................................................... 2-52

13.2 Precautions for loading ............................................................................................................ 2-53

13.3 Lifting machine .......................................................................................................................... 2-53

13.4 Precautions for transportation ................................................................................................. 2-56

13.5 Removing and installation of canopy ..................................................................................... 2-56

14. Cold weather operation ..................................................................................................................... 2-58

14.1 Precautions for low temperature ............................................................................................. 2-58

14.2 Precautions after completion of work .................................................................................... 2-60

14.3 After cold weather ..................................................................................................................... 2-60

15. Long-term storage .............................................................................................................................. 2-61

15.1 Before storage ........................................................................................................................... 2-61

15.2 During storage ........................................................................................................................... 2-61

15.3 After storage .............................................................................................................................. 2-61

16. Troubleshooting .................................................................................................................................. 2-62

16.1 When machine runs out of fuel .............................................................................................. 2-62

16.2 Towing the machine ................................................................................................................ 2-63

16.3 If battery is discharged ............................................................................................................. 2-66

16.4 Other trouble .............................................................................................................................. 2-70

0-7

5. CONTENTS 5. CONTENTS

MAINTENANCE

17. Guides to maintenance ...................................................................................................................... 3- 2

18. Outlines of service ............................................................................................................................. 3- 5

18.1 Outline of oil, fuel, coolant ...................................................................................................... 3- 5

18.2 Outline of electric system ........................................................................................................ 3- 8

19. Wear parts list ..................................................................................................................................... 3- 9

20. Use of fuel, coolant and lubricants according to ambient temperature ..................................... 3-10

21. Standard tightening torques for bolts and nuts ........................................................................... 3-14

21.1 Introduction of necessary tools ............................................................................................... 3-14

21.2 Torque list .................................................................................................................................. 3-16

22. Periodic replacement of safety critical parts .................................................................................. 3-17

23. Maintenance schedule chart .............................................................................................................. 3-24

23.1 Maintenance schedule chart .................................................................................................... 3-24

24. Service Procedure ............................................................................................................................... 3-27

24.1 Initial 250 hours service ........................................................................................................... 3-27

24.2 When required ........................................................................................................................... 3-28

24.3 Check before starting ................................................................................................................ 3-42

24.4 Every 50 hours service ............................................................................................................. 3-48

24.5 Every 250 hours service ........................................................................................................... 3-49

24.6 Every 500 hours service ........................................................................................................... 3-54

24.7 Every 1000 hours service ......................................................................................................... 3-57

24.8 Every 2000 hours service ......................................................................................................... 3-60

SPECIFICATIONS

25. Specifications ....................................................................................................................................... 4- 2

OPTIONS, ATTACHMENTS

26. Optional parts and attachments ....................................................................................................... 5- 2

27. Seat belt ............................................................................................................................................... 5- 3

27.1 Fastening and removing belt .................................................................................................. 5- 3

27.2 Adjust belt length ...................................................................................................................... 5- 4

27.3 Check seat belt and mounts .................................................................................................... 5- 4

28. Equipment with cab ............................................................................................................................ 5- 5

28.1 Switches ..................................................................................................................................... 5- 5

28.2 Rear window .............................................................................................................................. 5- 9

28.3 Check and maintenance ........................................................................................................... 5-10

0-8

SAFETY

WARNING

Read and follow all safety precautions. Failure to do so may result

in serious injury or death.

This safety section also contains precautions for optional equipment and attachments.

1-1

6. GENERAL PRECAUTIONS

SAFETY RULES

‡ ONLY trained and authorized personnel can operate and maintain the machine.

‡ Follow all safety rules, precautions and instructions when operating or performing maintenance

on the machine.

‡ Do not operate the machine if you are not feeling well, or if you are taking medicine which will

make you sleepy, or if you have been drinking. Operating in such a condition will adversely affect

your judgement and may lead to an accident.

‡ When working with another operator or a person on worksite traffic duty, be sure all personnel

understand all hand signals that are to be used.

SAFETY FEATURES

‡ Be sure all guards and covers are in their proper position. Have guards and covers repaired if

damaged.

Proper position ➞ See “12.1.1 WALK-AROUND CHECK”.

WARNING: For reasons of safety, always

follow these safety precautions.

‡ Use safety features such as the safety lock lever and seat belts properly.

‡ NEVER remove any safety features. ALWAYS keep them in good operating condition.

Safety lock lever ➞ See “12.12 PARKING MACHINE”.

‡ Improper use of safety features could result in serious bodily injury or death.

CLOTHING AND PERSONAL PROTECTIVE ITEMS

‡ Avoid loose clothing, jewelry, and loose long hair. They can catch on controls or in moving parts

and cause serious injury or death. Also, do not wear oily clothes because they are flammable.

‡ Wear a hard hat, safety glasses, safety shoes, mask or gloves when operating or maintaining the

machine. Always wear safety goggles, hard hat and heavy gloves if your job involves scattering

metal chips or minute materials - this is so particularly when driving pins with a hammer and when

cleaning the air cleaner element with compressed air.

Check also that there is no one near the machine.

‡ Check the function of all protective equipment before use.

Cleaning of air cleaner element ➞ See “24.2 WHEN REQUIRED” in service procedure.

1-2

A0055010

WARNING: Failure to follow these safety precautions may lead

to a serious accident.

6. GENERAL PRECAUTIONS

UNAUTHORIZED MODIFICATION

‡ Any modification made without authorization from Komatsu can create hazards.

‡ Before making a modification, consult your Komatsu distributor. Komatsu will not be responsible

for any injury or damage caused by any unauthorized modification.

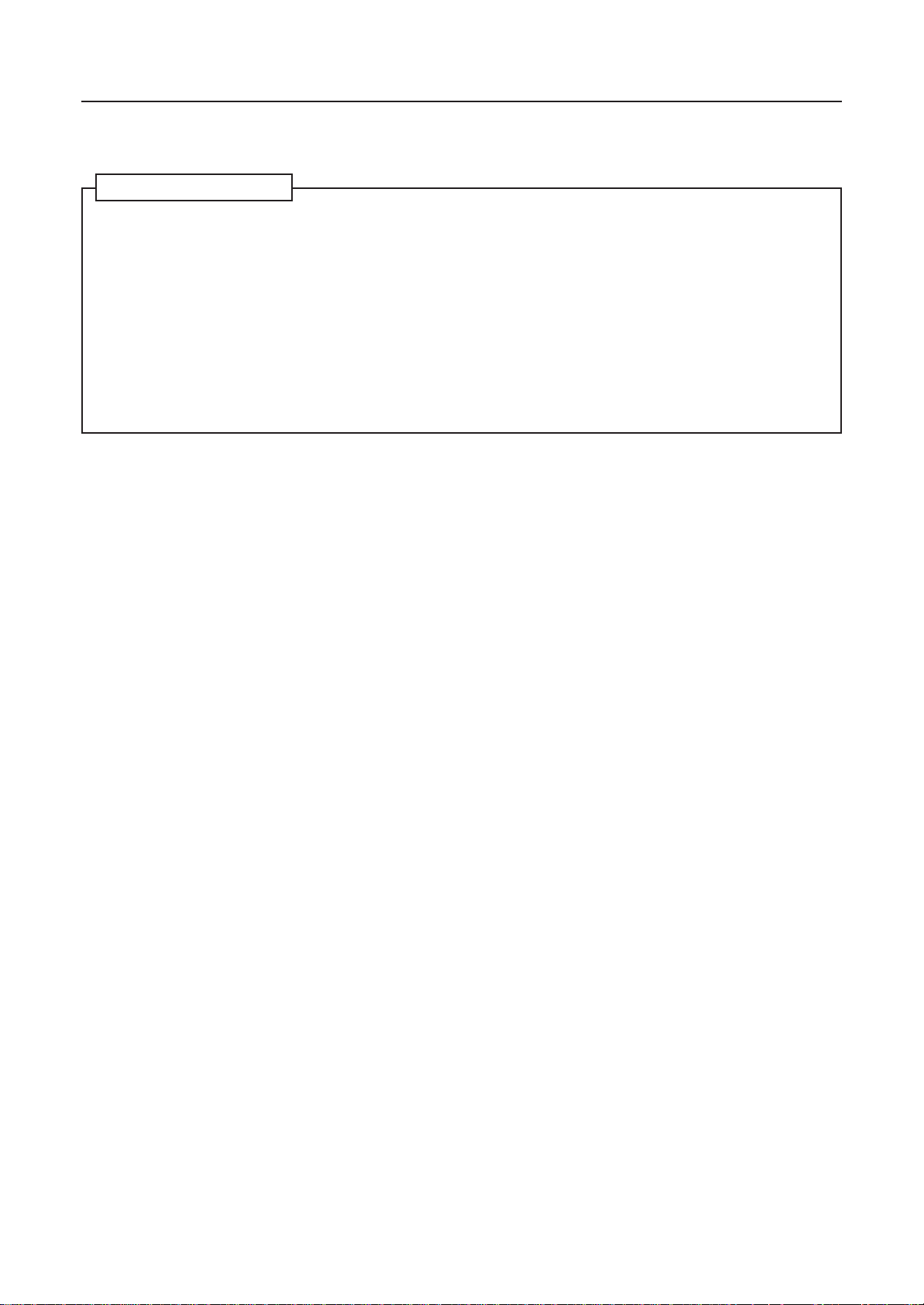

ALWAYS APPLY LOCK WHEN LEAVING OPERATOR’S SEAT

‡ When standing up from the operator’s seat, always place the safety lock lever securely in the LOCK

position. If you accidentally touch the travel or swing lever when they are not locked, the work

equipment may suddenly move and cause serious injury or damage.

‡ When leaving the machine, lower the work equipment completely to the ground, set the safety

lock lever to the LOCK position, then stop the engine and use the key to lock all the equipment.

Always take the key with you.

Work equipment posture ➞ See “12.12 PARKING MACHINE”.

Locks ➞ See “12.16 LOCKING”.

MOUNTING AND DISMOUNTING

‡ NEVER jump on or off the machine. NEVER get on or off a moving machine.

‡ When getting on or off the machine, face the machine and use the handhold and steps.

‡ Never hold any control levers when getting on or off the machine.

‡ Maintain three-point contact (both feet and one hand or one foot and both hands), and be sure

that you are supported securely by the handrail and steps.

‡ If there is any oil, grease, or mud on the handholds or steps, wipe it off immediately. Always keep

these parts clean. Repair any damage and tighten any loose bolts.

1-3

6. GENERAL PRECAUTIONS

WARNING: For reasons of safety, always

follow these safety precautions.

FIRE PREVENTION FOR FUEL AND OIL

Fuel, oil, and antifreeze can be ignited by a flame. Fuel is particularly FLAMMABLE and can be

HAZARDOUS.

‡ Keep flame away from flammable fluids.

‡ Stop the engine and do not smoke when refueling.

‡ Tighten all fuel and oil tank caps securely.

‡ Refueling and oiling should be made in well ventilated areas.

‡ Keep oil and fuel in the determined place and do not allow unauthorized persons to enter.

A0055020

A0055030

A0055040

PRECAUTIONS WHEN HANDLING AT HIGH TEMPERATURES

‡ Immediately after operations are stopped, the engine coolant, engine oil, and hydraulic oil are at

high temperatures, and are still under pressure. Attempting to remove the cap, drain the oil or

water, or replace the filters may lead to serious burns. Always wait for the temperature to go down,

and follow the specified procedures when carrying out these operations.

‡ Before removing the radiator cap, stop the engine and let the radiator cool. Turn the cap slowly

to release the internal pressure before removing the cap.

‡ As a result, oil may spurt out when the hydraulic tank cap is removed.

Always turn the cap slowly to release the internal pressure before removing the cap.

A0055050

1-4

WARNING: Failure to follow these safety precautions may lead

to a serious accident.

6. GENERAL PRECAUTIONS

ASBESTOS DUST HAZARD PREVENTION

Asbestos dust can be HAZARDOUS to your health if it is inhaled.

If you handle materials containing asbestos fibers, follow these guidelines as given below:

‡ NEVER use compressed air for cleaning.

‡ Use water for cleaning to keep down the dust.

‡ Operate the machine with the wind to your back, whenever possible.

‡ Use an approved respirator if necessary.

A0055060

CRUSHING OR CUTTING PREVENTION

‡ Do not enter, or put your hand or arm or any other part of your body between movable parts such

as between the work equipment and cylinders, or between the machine and work equipment.

If the work equipment is operated, the clearance will change and this may lead to serious damage

or personal injury.

A0060760

FIRE EXTINGUISHER AND FIRST AID KIT

‡ Be sure fire extinguishers have been provided and know how to use them.

‡ Provide a first aid kit at the storage point.

‡ Know what to do in the event of a fire.

‡ Be sure you know the phone numbers of persons you should contact in case of an emergency.

A0055070

1-5

6. GENERAL PRECAUTIONS

WARNING: For reasons of safety, always

follow these safety precautions.

PRECAUTIONS WHEN USING ROPS

If ROPS is installed, the ROPS must never be removed when operating the machine.

The ROPS is installed to protect the operator if the machine should roll over. It is designed not only

to support the load if the machine should roll over, but also to absorb the impact energy.

The Komatsu ROPS fulfills all of the regulations and standards for all countries, but if it is rebuilt

without authorization or is damaged when the machine rolls over, the strength will drop and it will

not be able to fulfill its function properly. It can only display its performance if it is repaired or

modified in the specified way.

When modifying or repairing the ROPS, always contact your Komatsu distributor.

Even if the ROPS is installed, it cannot show its full effect if the operator does not fasten the seat

belt properly. Always fasten the seat belt when operating.

PRECAUTIONS FOR ATTACHMENTS

‡ When installing and using an optional attachment, read the instruction manual for the attachment

and the information related to attachments in this manual.

‡ Do not use attachments that are not authorized by Komatsu or your Komatsu distributor. Use of

unauthorized attachments could create a safety problem and adversely affect the proper operation

and useful life of the machine.

‡ Any injuries, accidents, product failures resulting from the use of unauthorized attachments will

not be the responsibility of Komatsu.

1-6

7. PRECAUTIONS DURING

OPERATION

7.1 BEFORE STARTING ENGINE

SAFETY AT WORKSITE

‡ Before starting operations, thoroughly check the area for any

unusual conditions that could be dangerous.

‡ Examine the shape of the ground and the quality of the soil

at the jobsite, and determine the optimum method of operation.

‡ When working on public roads, position flagmen and erect

barriers to ensure the safety of passing traffic and pedestrians.

‡ In places where there are buried objects, such as water pipes,

gas pipes, or pipes for high voltage cables, contact the company in charge to confirm the position of the buried object,

and be careful not to damage the object during operations.

‡ When working in water or when crossing sand banks, first

check the condition of the ground and the depth and speed of

flow of the water. Be sure not to exceed the permitted water

depth.

Permissible water depth ➞ See “12.10 PRECAUTIONS FOR

OPERATION”.

WARNING: Failure to follow these safety

precautions may lead to a serious accident.

FIRE PREVENTION

‡ Thoroughly remove wood chips, leaves, paper and other flam-

mable things accumulated in the engine compartment. They

could cause a fire.

‡ Check fuel, lubrication, and hydraulic systems for leaks. Have

any leaks repaired. Wipe up any excess oil, fuel or other

flammable fluids.

Check point ➞ See “12.1.1 WALK-AROUND CHECK”.

‡ Be sure a fire extinguisher is present and working.

‡ Do not operate the machine near any flame.

IN OPERATOR’S CAB

‡ Do not leave tools or spare parts lying around in the operator’s compartment. They may damage

or break the control levers or switches. Always put them in the tool box on the right side of the

machine.

‡ Keep the cab floor, controls, steps and handrails free of oil, grease, snow, and excess dirt.

‡ Check the seat belt, buckle and hardware for damage or wear. Replace any worn or damaged

parts. Always use seat belts when operating your machine.

Seat belts ➞ See “27. SEAT BELT”.

A0055020

1-7

7. PRECAUTIONS DURING OPERATION

WARNING: For reasons of safety, always

follow these safety precautions.

VENTILATION FOR ENCLOSED AREAS

‡ If it is necessary to start the engine within an enclosed area, provide adequate ventilation. Exhaust

fumes from the engine can KILL.

A0055060

PRECAUTIONS FOR MIRRORS, WINDOWS AND LIGHTS

‡ Remove all dirt from the surface of the windows and lights to ensure that you can see well.

‡ Adjust the side mirror so that you can see clearly from the operator’s seat, and always keep the

surface of the mirror clean. If any glass is broken, replace it with a new part.

‡ Check that the head lamps and working lamps light up properly.

CHECK MACHINE

‡ Before starting the engine, adjust the operator’s seat so that you can carry work easily and in

comfort.

If the operator’s seat is not properly adjusted, it will cause mistaken operation and fatigue, with

the danger that this will cause an accident.

‡ Adjust the seat so that you can operate the control levers and pedals properly with your back

against the seat back.

Adjustment of operator’s seat ➞ See “12.1.3 ADJUSTMENT BEFORE OPERATION”.

‡ Before starting the engine, check that the safety lock levers are at the LOCK position.

‡ Before starting the engine, always carry out the walk-around check, checks before starting, and

operations and checks before starting the engine.

Walk-around check ➞ See “12.1.1 WALK-AROUND CHECK”.

Checks before starting ➞ See “12.1.2 CHECK BEFORE STARTING”.

Operations and checks before starting engine ➞ See “12.1.4 OPERATIONS AND CHECKS BE-

FORE STARING ENGINE.”.

Carry out the above checks and check that there is no abnormality. If there is damage which can not

be repaired, attach the warning tag to the work equipment control lever.

1-8

WARNING: Failure to follow these safety precautions may lead

to a serious accident.

7. PRECAUTIONS DURING OPERATION

7.2 OPERATING MACHINE

WHEN STARTING ENGINE

‡ Walk around your machine again just before mounting it, checking for people and objects that

might be in the way.

‡ NEVER start the engine if a warning tag has been attached to the control.

‡ When starting the engine, sound the horn as an alert.

‡ Start and operate the machine only while seated.

‡ Do not allow any person other than the operator in the operator’s compartment or any other place

on the machine.

‡ For machines equipped with a back-up alarm buzzer, check that the alarm buzzer works properly.

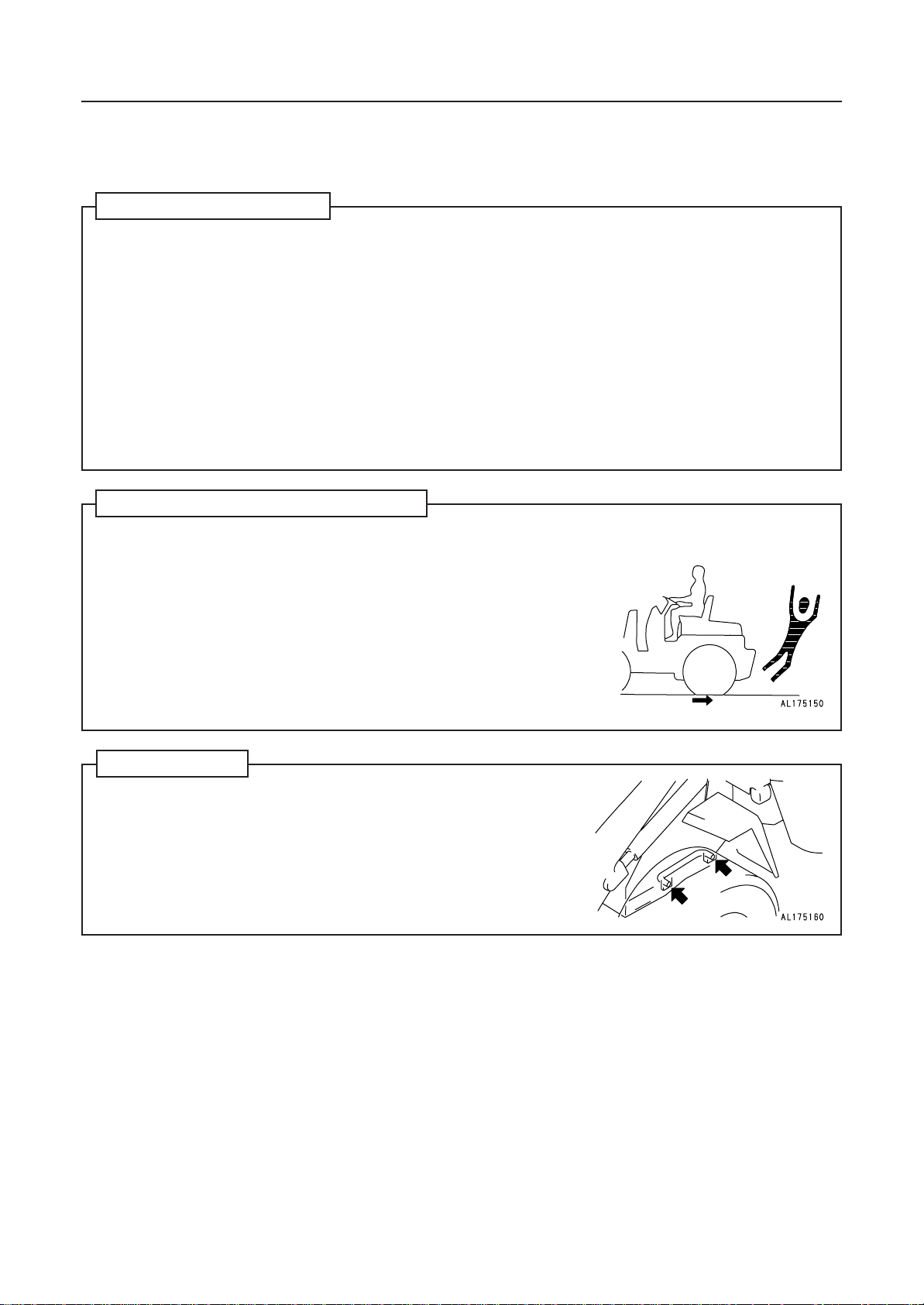

CHECK WHEN TRAVELING IN REVERSE

Before operating the machine or work equipment, do as follows.

‡ Sound the horn to warn people in the area.

‡ Check that there is no one near the machine. Be particularly

careful to check behind the machine.

‡ If necessary, designate a person to check the safety. This is

particularly necessary when traveling in reverse.

‡ When operating in areas that may be hazardous or have poor

visibility, designate a person to direct worksite traffic.

‡ Do not allow any one to enter the line of travel of the machine.

This rule must be strictly observed even on machines equipped

with a back-up alarm or rear view mirror.

CHECK SAFETY

Before traveling or operating, check that the safety bar is securely fixed in the free condition.

1-9

7. PRECAUTIONS DURING OPERATION

WARNING: For reasons of safety, always

follow these safety precautions.

PRECAUTIONS WHEN TRAVELING

‡ It is dangerous to look around you when carrying out operations. Always concentrate on your

work.

‡ Excessive speed, sudden starting, sudden stopping, sudden turns, and coasting when traveling

are dangerous. Always drive carefully.

‡ If you find any abnormality in the machine during operations (noise, vibration, smell, abnormali-

ties in gauges), move the machine immediately to a safe place, then park the machine and

investigate the cause.

‡ Travel on level roads with the bucket 25 – 45 cm (10 – 18 in) above the ground surface.

‡ When traveling on rough ground surfaces, travel at low speed, and avoid sudden turning when

changing direction.

‡ If the engine stops when the machine is traveling, the steering will not work. This is dangerous,

so apply the brakes immediately and stop the machine.

‡ To avoid hitting other machines, always keep a safe distance from other machines during

operations an when traveling.

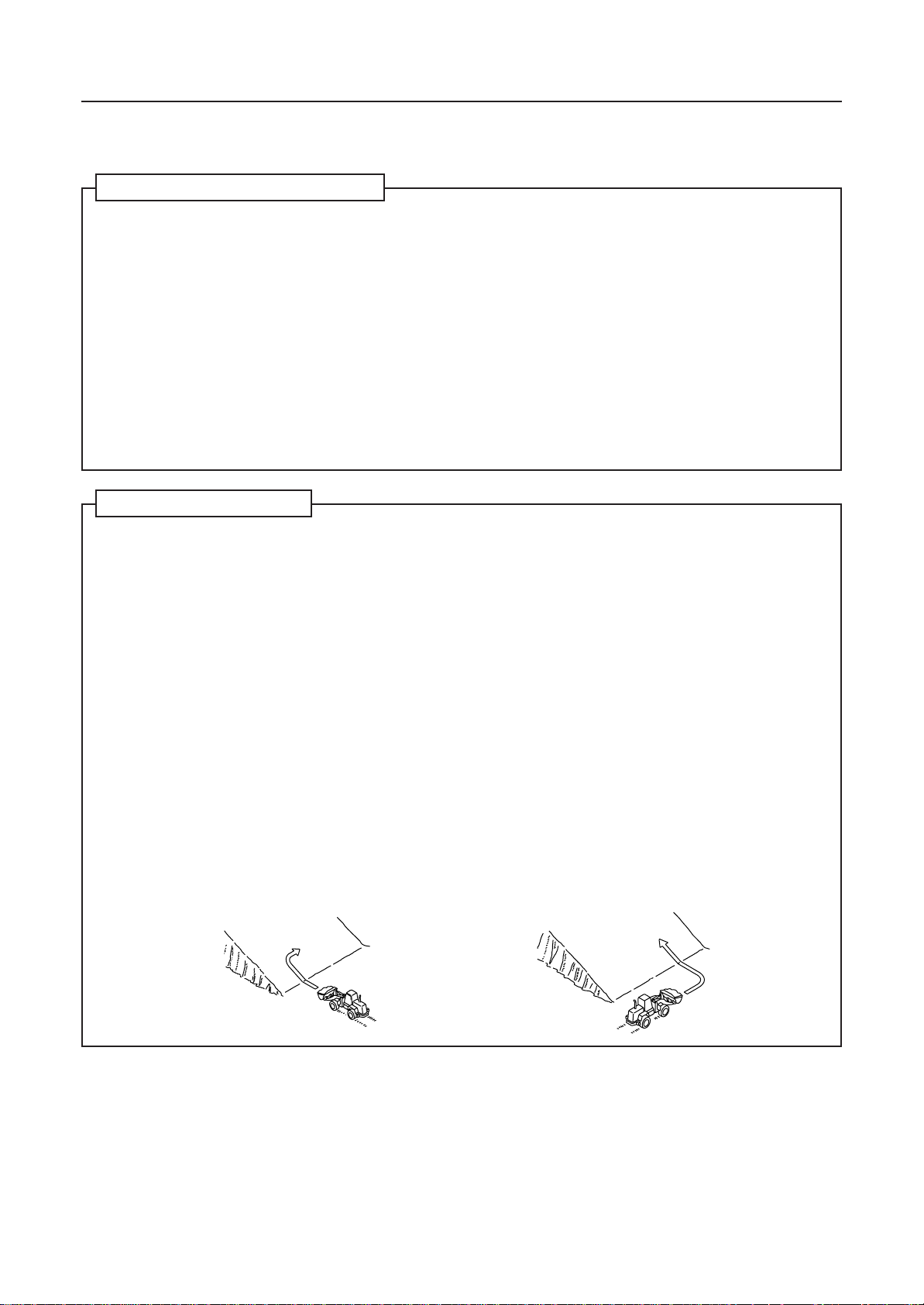

TRAVELING ON SLOPES

‡ Traveling on hills, banks or slopes that are steep could result in the machine tipping over or

slipping.

‡ On hills, banks or slopes, carry the bucket closer to the ground, approximately 20 to 30 cm (8 to

12 in) above the ground. In case of emergency, quickly lower the bucket to the ground to help the

machine stop and prevent it from tipping over.

‡ Do not turn on slopes or travel across slopes. Always go down to a flat place to perform these

operations.

‡ Do not travel up and down on grass, fallen leaves, and wet steel plates. These materials may allow

the machine to slip, if it is traveling sideways. Keep travel speed very low.

‡ When traveling down a slope, use the braking force of the engine and travel slowly.

‡ If the engine stops on a slope, depress the brake immediately, lower the bucket, and apply the

parking brake to stop the machine.

‡ When carrying a load, travel forward when going uphill and in reverse when going downhill.

INCORRECT CORRECT

AE060800

AE060810

1-10

WARNING: Failure to follow these safety precautions may lead

to a serious accident.

7. PRECAUTIONS DURING OPERATION

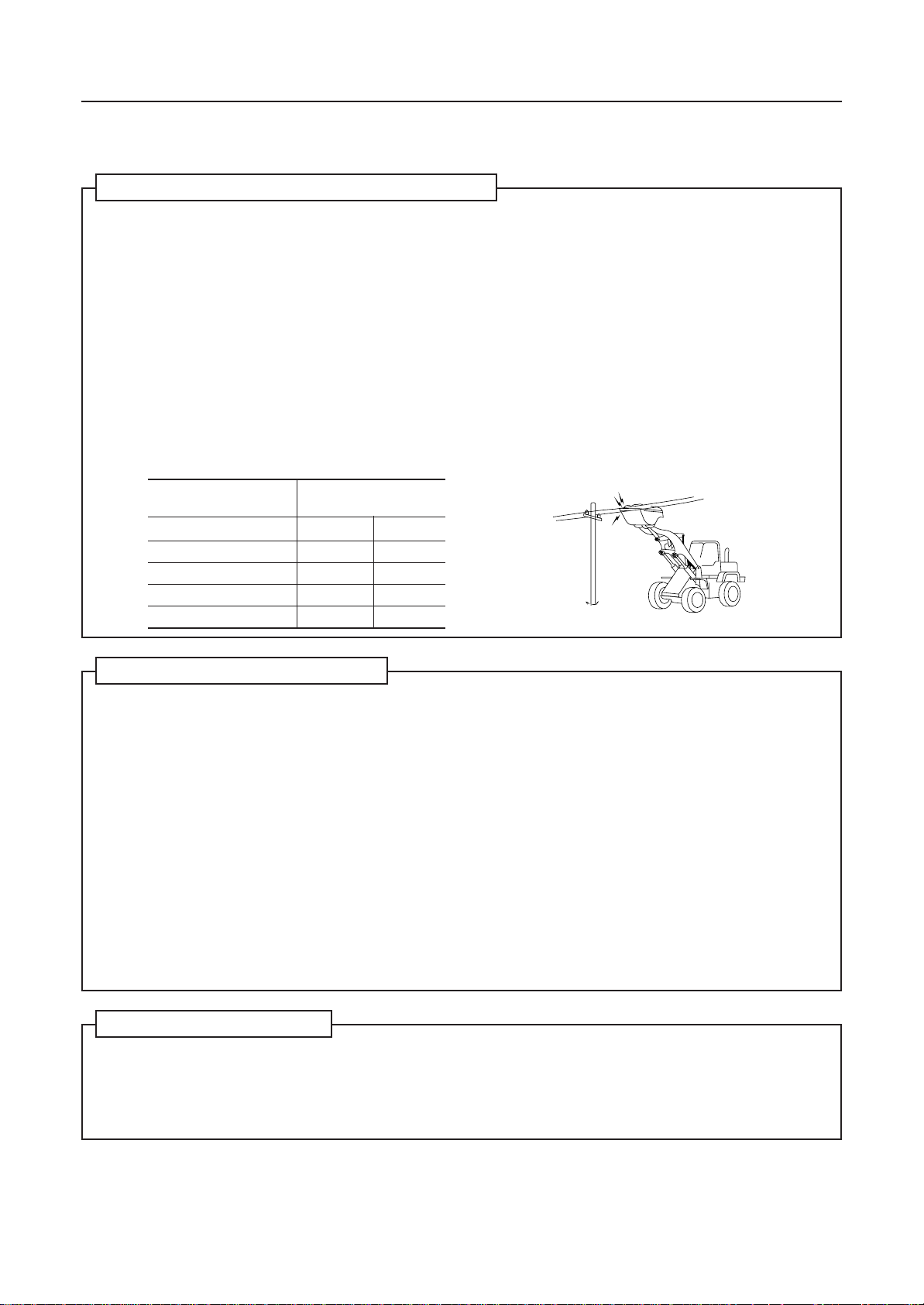

DO NOT GO CLOSE TO HIGH-VOLTAGE CABLES

‡ Going close to high-voltage cables can cause electric shock. Always maintain the safe distance

given below between the machine and the electric cable.

‡ The following actions are effective in preventing accidents.

1) Wear shoes with rubber or leather soles.

2) Use a signalman to give warning if the machine approaches too close to the electric cable.

‡ If the work equipment should touch the electric cable, the operator should not leave the operator’s

compartment.

‡ When carrying out operations near high voltage cables, do not let anyone come close to the

machine.

‡ Check with the electricity company about the voltage of the cables before starting operations.

Voltage

Min. safety

distance

6.6 kV 3 m 10ft

33.0 kV 4 m 14ft

66.0 kV 5 m 17ft

154.0 kV 8 m 27ft

275.0 kV 10 m 33ft

A0060820

PRECAUTIONS WHEN OPERATING

‡ Be careful not to approach too close to the edge of cliffs.

When making embankments or landfills, or when dropping soil over a cliff, dump one pile, then

use the next pile of soil to push the first pile.

‡ Be careful not to let the bucket hit the dump truck or the side of the excavated ditch.

‡ The load suddenly becomes lighter when the soil is pushed over a cliff or when the machine

reaches the top of a slope. When this happens, there is danger that the travel speed will suddenly

increase, so be sure to reduce the speed.

‡ Always carry out loading operations up-wind to protect yourself from dust.

‡ When the bucket is fully loaded, be particularly sure to avoid sudden starting, turning, or stopping.

‡ When loading a dump truck, check that there is no one in the area. Be careful also that the load

does not drop when it is being loaded.

ENSURE GOOD VISIBILITY

‡ When working in dark places, install working lamps and head lamps, and set up lighting in the

work area if necessary.

‡ Stop operations if the visibility is poor, such as in mist, snow, or rain, and wait for the weather

to improve to a condition that allows the operation to be carried out safely.

1-11

7. PRECAUTIONS DURING OPERATION

WARNING: For reasons of safety, always

follow these safety precautions.

OPERATE CAREFULLY ON SNOW

‡ When working on snow or icy roads, there is danger that the machine may slip to the side on even

the slightest slope, so always travel slowly and avoid sudden starting, turning, or stopping.

‡ Be extremely careful when carrying out snow-clearing operations. The road shoulder and other

objects are buried in the snow and cannot be seen.

‡ When traveling on snow-covered roads, always install tire chains.

‡ When traveling on snow-covered slopes, never use the brakes to stop the machine suddenly.

Lower the bucket to the ground to stop the machine.

‡ The load will change greatly according to the type of snow, so reduce the load and be careful not

to let the machine slip.

DO NOT HIT WORK EQUIPMENT

‡ When working in places where there are height limits, such as in tunnels, under bridges, under

electric cables, or in garages, be extremely careful not to hit the work equipment.

METHOD OF USING BRAKES

‡ Do not put your foot on the brake pedal unless necessary.

‡ Do not depress the brake pedal repeatedly unless necessary.

‡ When traveling downhill, use the engine as a brake, and always use the right brake pedal.

WORKING ON LOOSE GROUND

‡ Avoid operating your machine too close to the edge of cliffs, overhangs, and deep ditches. If these

areas collapse, your machine could fall or tip over and result in serious injury or death. Remember

that the soil after heavy rain or blasting is weakened in these areas.

‡ Earth laid on the ground and the soil near ditches are loose. They can collapse under the weight

or vibration of your machine.

‡ When operating in places where there is danger of falling rocks or danger of the machine turning

over, always install ROPS and a seat belt.

1-12

WARNING: Failure to follow these safety precautions may lead

to a serious accident.

7. PRECAUTIONS DURING OPERATION

PARKING THE MACHINE

‡ When parking the machine, stop on a flat firm road surface where there is no danger of falling

rocks, landslides, or floods, and lower the work equipment to the ground. If the machine must be

stopped on a slope, block the wheels to prevent the machine from moving.

CORRECT

‡ When parking on public roads, park the machine so that the machine, flags, and fences do not

obstruct traffic, and provide fences, signs, flags, or lights, and put up any other necessary signs

to ensure that passing traffic can see the machine clearly.

Parking procedure ➞ See “12.12 PARKING MACHINE”.

‡ When leaving the machine, lower the work equipment completely to the ground, set the safety

lock lever to the LOCK position, then stop the engine and use the key to lock all the equipment.

Always take the key with you.

Work equipment posture ➞ See “12.12 PARKING MACHINE”.

Places to lock ➞ See “12.16 LOCKING”.

1-13

7. PRECAUTIONS DURING OPERATION

WARNING: For reasons of safety, always

follow these safety precautions.

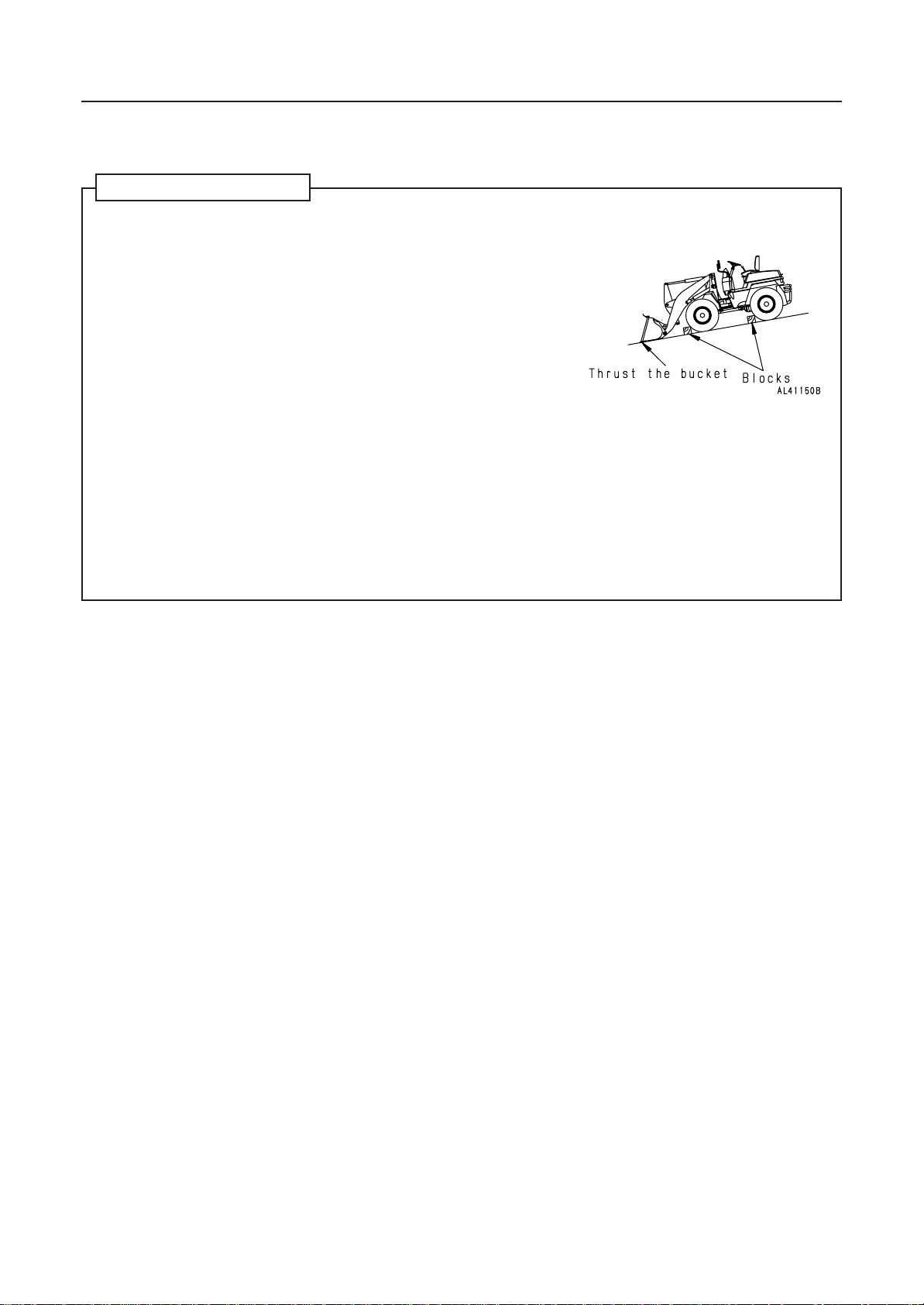

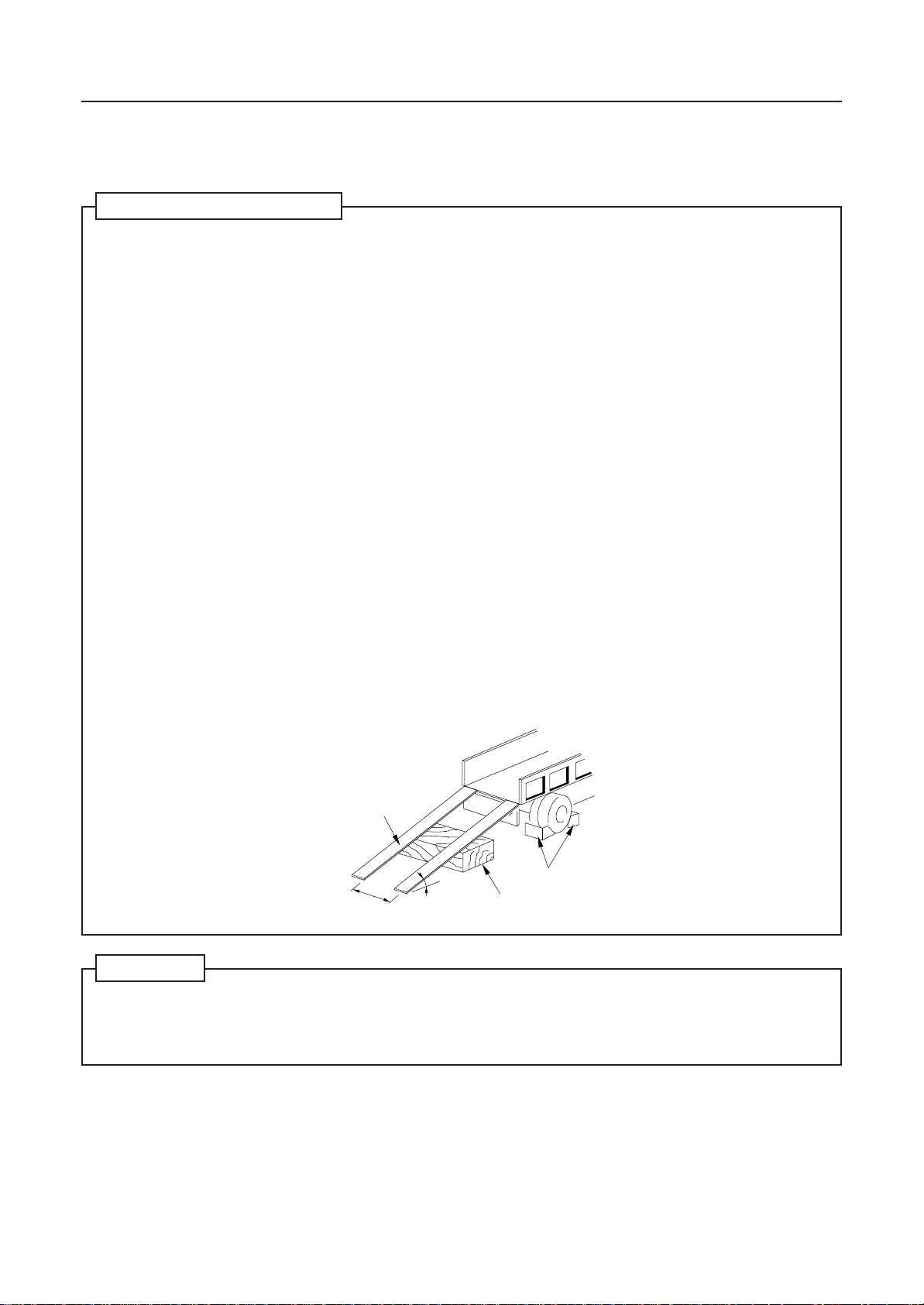

7.3 TRANSPORTATION

LOADING AND UNLOADING

‡ Loading and unloading the machine always involves potential hazards. EXTREME CAUTION

SHOULD BE USED.

When loading or unloading the machine, run the engine at low idling and travel at low speed.

‡ Perform loading and unloading on firm, level ground only. Maintain a safe distance from the edge

of a road.

‡ ALWAYS block the wheels of the hauling vehicle and place blocks under both ramps before

loading and unloading.

‡ ALWAYS use ramps of adequate strength. Be sure the ramps are wide and long enough to provide

a safe loading slope.

‡ Be sure that the ramps are securely positioned and fastened, and that the two sides are at the same

level as one another.

‡ Be sure the ramp surface is clean and free of grease, oil, ice and loose materials. Remove dirt from

the machine tires.

‡ NEVER correct your steering on the ramps. If necessary, drive away from the ramps and climb

again.

‡ After loading, block the machine tires and secure the machine with tie-downs.

Loading and unloading ➞ See “13. TRANSPORTATION”.

Tie-downs ➞ See “13. TRANSPORTATION”.

CORRECT

Ramp

Blocks

Distance between ramps

Max. 15° Block

A0060840

SHIPPING

‡ When shipping the machine on a hauling vehicle, obey all state and local laws governing the

weight, width, and length of a load. Also obey all applicable traffic regulations.

‡ Determine the shipping route while taking into account the width, height and weight of the load.

1-14

WARNING: Failure to follow these safety precautions may lead

to a serious accident.

7. PRECAUTIONS DURING OPERATION

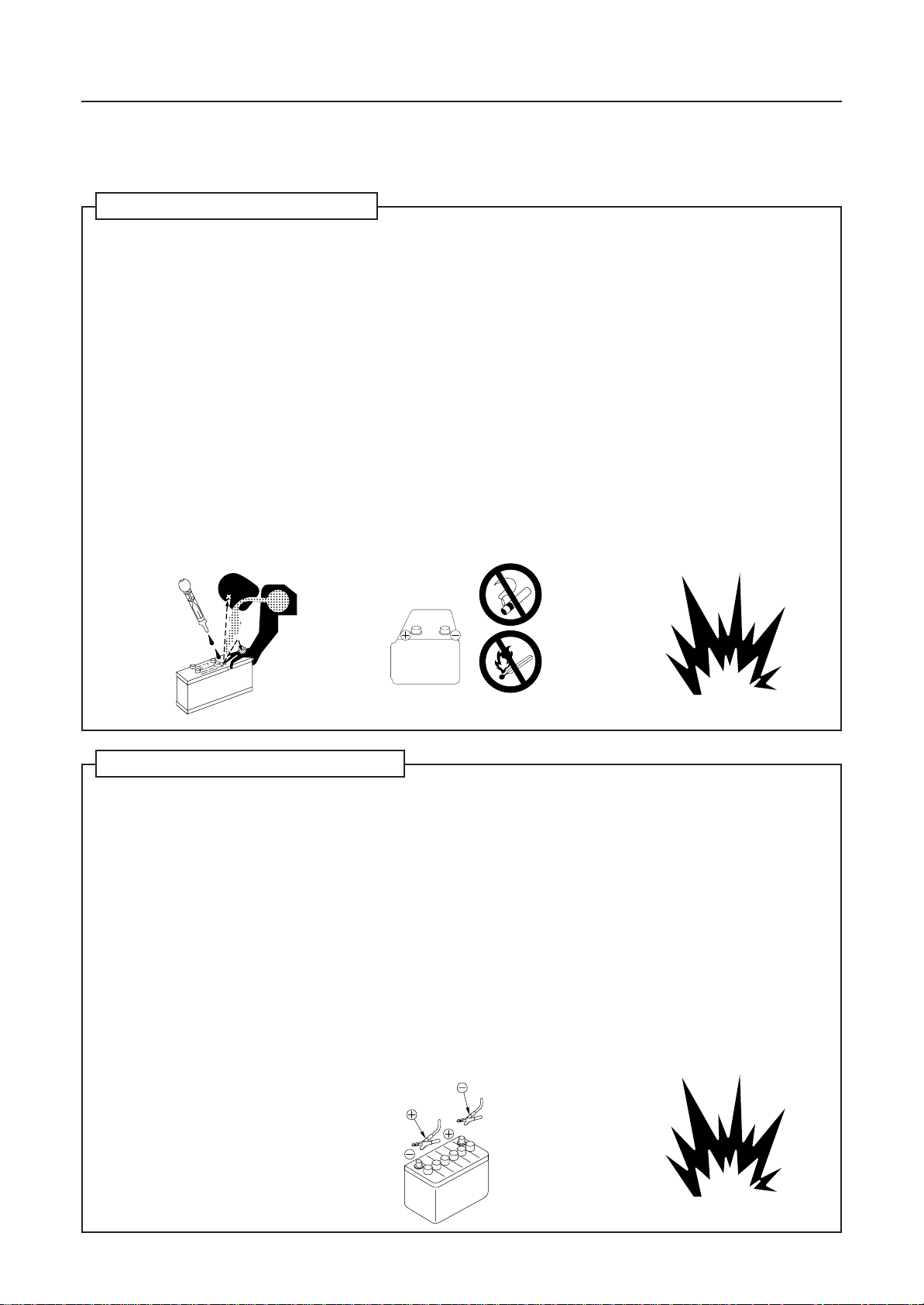

7.4 BATTERY

BATTERY HAZARD PREVENTION

‡ Battery electrolyte contains sulfuric acid and can quickly burn the skin and eat holes in clothing.

If you spill acid on yourself, immediately flush the area with water.

‡ Battery acid could cause blindness if splashed into the eyes. If acid gets into the eyes, flush them

immediately with large quantities of water and see a doctor at once.

‡ If you accidentally drink acid, drink a large quantity of water or milk, beaten egg or vegetable oil.

Call a doctor or poison prevention center immediately.

‡ When handling the battery, always wear safety glasses and rubber gloves. The electrolyte inside

the battery may cause burns or loss of sight.

‡ Batteries generate hydrogen gas. Hydrogen gas is very EXPLOSIVE, and is easily ignited with a

small spark or flame.

‡ Before working with batteries, stop the engine and turn the starting switch to the OFF position.

‡ Avoid short-circuiting the battery terminals through accidental contact with metallic objects, such

as tools, across the terminals.

‡ When removing or installing, check which is the positive (+) terminal and negative (–) terminal.

‡ Tighten the battery cap securely.

‡ Tighten the battery terminals securely. Loosened terminals can generate sparks and lead to an

explosion.

A0055090

A0055100

A0055110

STARTING WITH BOOSTER CABLES

‡ ALWAYS wear safety glasses or goggles when starting the machine with booster cables.

‡ When starting from another machine, do not allow the two machines to touch.

‡ Be sure to connect the positive (+) cable first when installing the booster cables. Disconnect the

ground or negative (–) cable first when removing them.

‡ If any tool touches between the positive (+) terminal and the chassis, it will cause sparks. This is

dangerous, so be sure to work carefully.

‡ Connect the batteries in parallel: positive to positive and negative to negative.

‡ When connecting the ground cable to the frame of the machine to be started, be sure to connect

it as far as possible from the battery.

Starting with booster cables ➞ See “16. TROUBLESHOOTING”.

INCORRECT

A0067322

A0055110

1-15

7. PRECAUTIONS DURING OPERATION

WARNING: For reasons of safety, always

follow these safety precautions.

7.5 TOWING

WHEN TOWING, FIX WIRE TO HITCH PIN

‡ Towing in the wrong way may lead to serious personal injury or damage.

‡ When using another machine to tow this machine, use a wire rope with ample strength for the

weight of this machine.

‡ Never tow a machine on a slope.

‡ Do not use any towing rope that has kinks or is twisted.

‡ Do not stand astride the towing cable or wire rope.

‡ When connecting a machine that is to be towed, do not let any

one come between the towing machine and the machine that

is being towed.

‡ Set the coupling of the machine being towed in a straight line

with the towing portion of the machine, and secure it in

position.

Towing method ➞ See “16. TROUBLESHOOTING”.

1-16

A0055120

8. PRECAUTIONS FOR

MAINTENANCE

WARNING: Failure to follow these safety

precautions may lead to a serious accident.

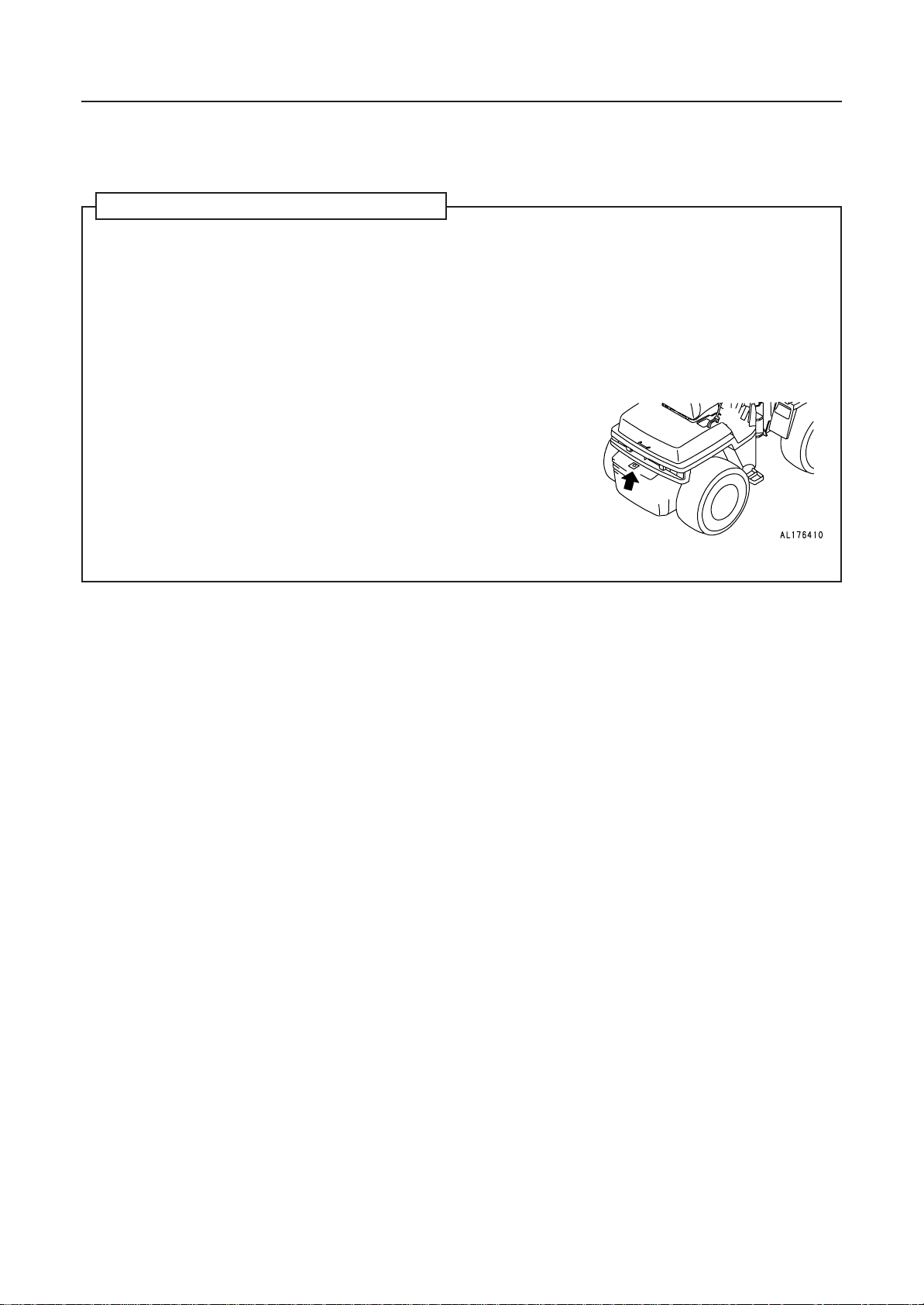

8.1 BEFORE CARRYING OUT MAINTENANCE

WARNING TAG

‡ If others start the engine or operate the controls while you are performing service or lubrication,

you could suffer serious injury or death.

‡ ALWAYS attach the WARNING TAG to the control lever in the operator’s cab to alert others that

you are working on the machine. Attach additional warning tags around the machine, if necessary.

‡ These tags are available from your Komatsu distributor. (Part No. 09963-03000)

DO NOT operate

When this plate is not being used

keep it in the storage compartment.

09963-03000

PROPER TOOLS

‡ Use only tools suited to the task. Using damaged, low quality, faulty, or makeshift tools could

cause personal injury.

Tools ➞ See “21.1 INTRODUCTION OF NECESSARY TOOLS”.

1-17

8. PRECAUTIONS FOR MAINTENANCE

WARNING: For reasons of safety, always

follow these safety precautions.

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

‡ Replace the following fire-related components periodically:

Fuel system: Fuel hose, spilling hose, and fuel tube cap

Hydraulic system: Pump outlet hose

‡ Replace these components periodically with new ones, regardless of whether or not they appear

to be defective. These components deteriorate over time.

‡ Replace or repair any such components if any defect is found, even though they have not reached

the time specified.

Replacement of safety critical components ➞ See “22. PERIODIC REPLACEMENT OF SAFETY

CRITICAL PARTS”.

STOP THE ENGINE BEFORE CARRYING

OUT INSPECTION AND MAINTENANCE

‡ When carrying out inspection and maintenance, always stop

on a flat firm road surface where there is no danger of falling

rocks, landslides, or floods. Then lower the work equipment

to the ground, set the safety lock levers to the LOCK position,

and stop the engine.

‡ If it is necessary to run the engine when carrying out mainte-

nance, such as when cleaning the inside of the radiator, place

the safety lock lever at the LOCK position and carry out the

operation with two workers.

‡ One worker should sit in the operator’s seat so that he can

stop the engine immediately if necessary. He should also be

extremely careful not to touch any lever by mistake. Touch the

levers only when they have to be operated.

‡ The worker carrying out the maintenance should be extremely

careful not to touch or get caught in the moving parts.

LOCK FRONT AND REAR FRAMES

Lock the front and rear frames with the safety bar.

OFF

HEAT

ON

START

AM089160

WORK EQUIPMENT SUPPORT

When carrying out inspection and maintenance with the work equipment raised, fit a stand under

the lift arm securely to prevent the work equipment from coming down. In addition, set the work

equipment control levers to the HOLD position and lock with the safety lock.

1-18

WARNING: Failure to follow these safety precautions may lead

to a serious accident.

8. PRECAUTIONS FOR MAINTENANCE

RULES TO FOLLOW WHEN ADDING FUEL OR OIL

‡ Always stop the engine before adding fuel or oil.

‡ Spilled fuel and oil may cause you to slip, so always wipe it up immediately.

‡ Always tighten the cap of the fuel and oil fillers securely.

‡ Never use fuel for washing any parts.

‡ Always add fuel and oil in a well-ventilated place.

A0055020

A0055030

A0055040

RADIATOR WATER LEVEL

‡ When checking the water level, stop the engine and wait for the engine and regulator to cool down,

then check the water level in the sub-tank.

‡ When adding water, add water through the sub-tank.

‡ Loosen the cap slowly to release the internal pressure before removing the cap.

A0067380

USE OF LIGHTING

‡ When checking fuel, oil, coolant, or battery electrolyte, always use lighting with anti-explosion

specifications.

If such lighting equipment is not used, there is danger of explosion.

DO NOT STAND ON ENGINE HOOD

Never climb on to the engine hood. There is danger that you will slip and fall.

A0055160

1-19

8. PRECAUTIONS FOR MAINTENANCE

WARNING: For reasons of safety, always

follow these safety precautions.

PREVENTION OF FIRE

Carrying out maintenance involves handling objects such as fuel and batteries which may cause a

fire. To prevent fire, do as follows.

‡ Keep fuel and other flammable oil and fluids well away from fire.

‡ Always use a non-flammable oil for washing parts.

‡ Put out any fires that may cause the fuel or oil to ignite.

‡ Always have a fire extinguisher or other fire-fighting equipment available.

‡ Do not smoke when carrying out inspection and maintenance operations.

1-20

WARNING: Failure to follow these safety precautions may lead

to a serious accident.

8. PRECAUTIONS FOR MAINTENANCE

8.2 DURING MAINTENANCE

PERSONNEL

‡ Only authorized personnel can service and repair the machine. Extra precaution should be used

when grinding, welding, and using a sledge-hammer.

ATTACHMENTS

‡ Place attachments that have been removed from the machine in a safe place so that they do not

fall. If they fall on you or others, serious injury could result.

A0055130

WORK UNDER THE MACHINE

‡ Always lower all movable work equipment to the ground or to their lowest position before

performing service or repairs under the machine.

‡ Always block the tires of the machine securely.

‡ Never work under the machine if the machine is poorly supported.

A0055140

KEEP THE MACHINE CLEAN

‡ Spilled oil or grease, or scattered tools or broken pieces are dangerous because they may cause

you to slip or trip.

Always keep your machine clean and tidy.

‡ If water gets into the electrical system, there is danger that the machine may not move or may

move unexpectedly.

Do not use water or steam to clean the sensors, connectors, or the inside of the operator’s

compartment.

A0055150

1-21

Loading...

Loading...