Komatsu PC340LC, 340NLC-7K Service Manual

UEBM001501

PC340LC, 340NLC-7K

MACHINE MODEL SERIAL NUMBER

PC340LC-7K 00 K40001 AND UP 00

PC340NLC-7K 00 K40001 AND UP 00

• This shop manual may contain attachments and optional equipment that are not available in your area.

Please consult your local Komatsu distributor for those items you may require.

Materials and specifications are subject to change without notice.

• PC340LC/NLC-7K mount the SAA6D114E engine.

For details of the engine, see the 114 Series Engine Shop Manual.

© 2002

All Rights Reserved 00-1

Printed in Belgium 12-02

CONTENTS

No. of page

01 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 01-1

10 STRUCTURE, FUNCTION AND MAINTENANCE STANDARD . . . . . . .10-1

20 TESTING AND ADJUSTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20-1

30 DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30-1

90 OTHERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90-1

00

00-2

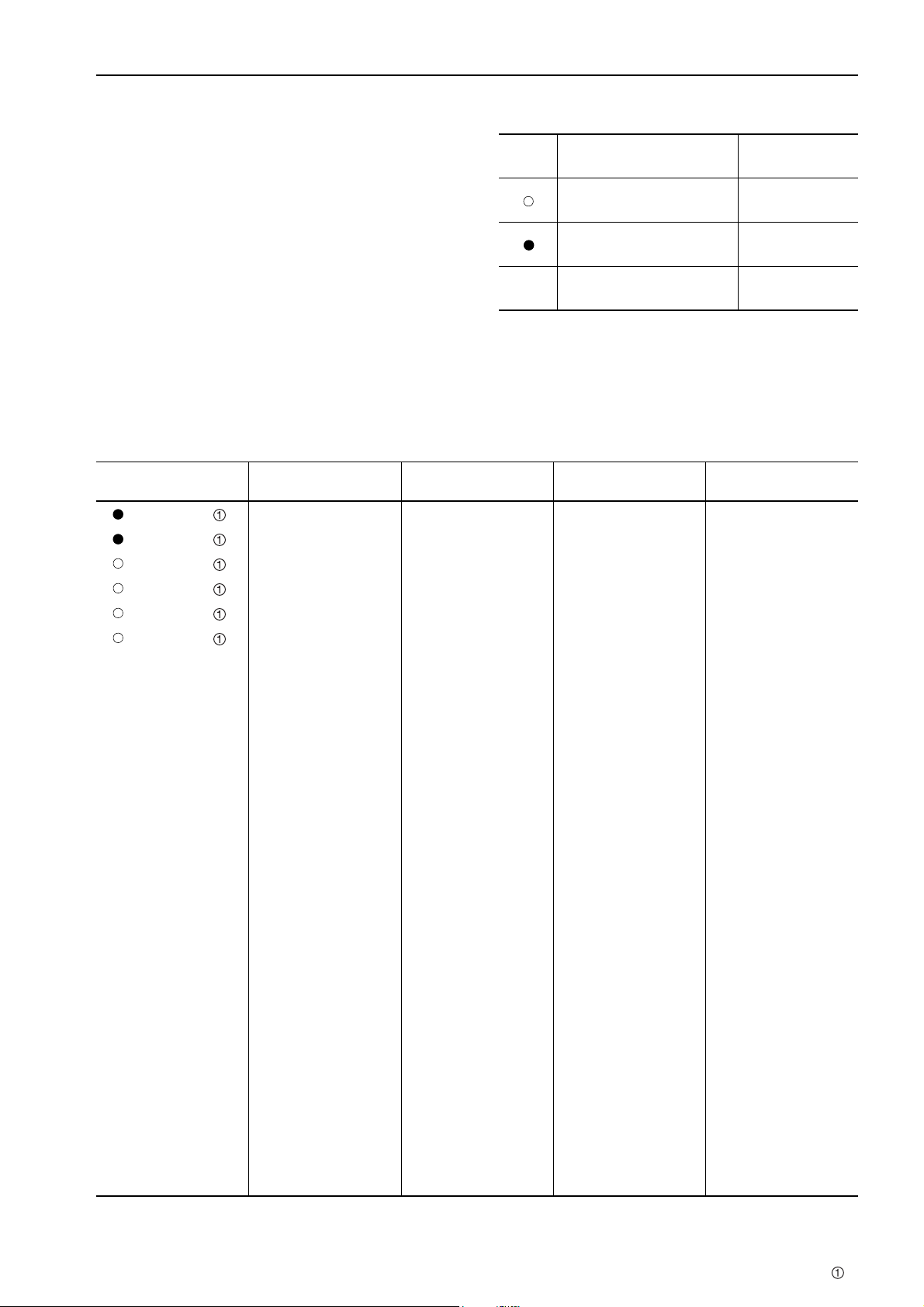

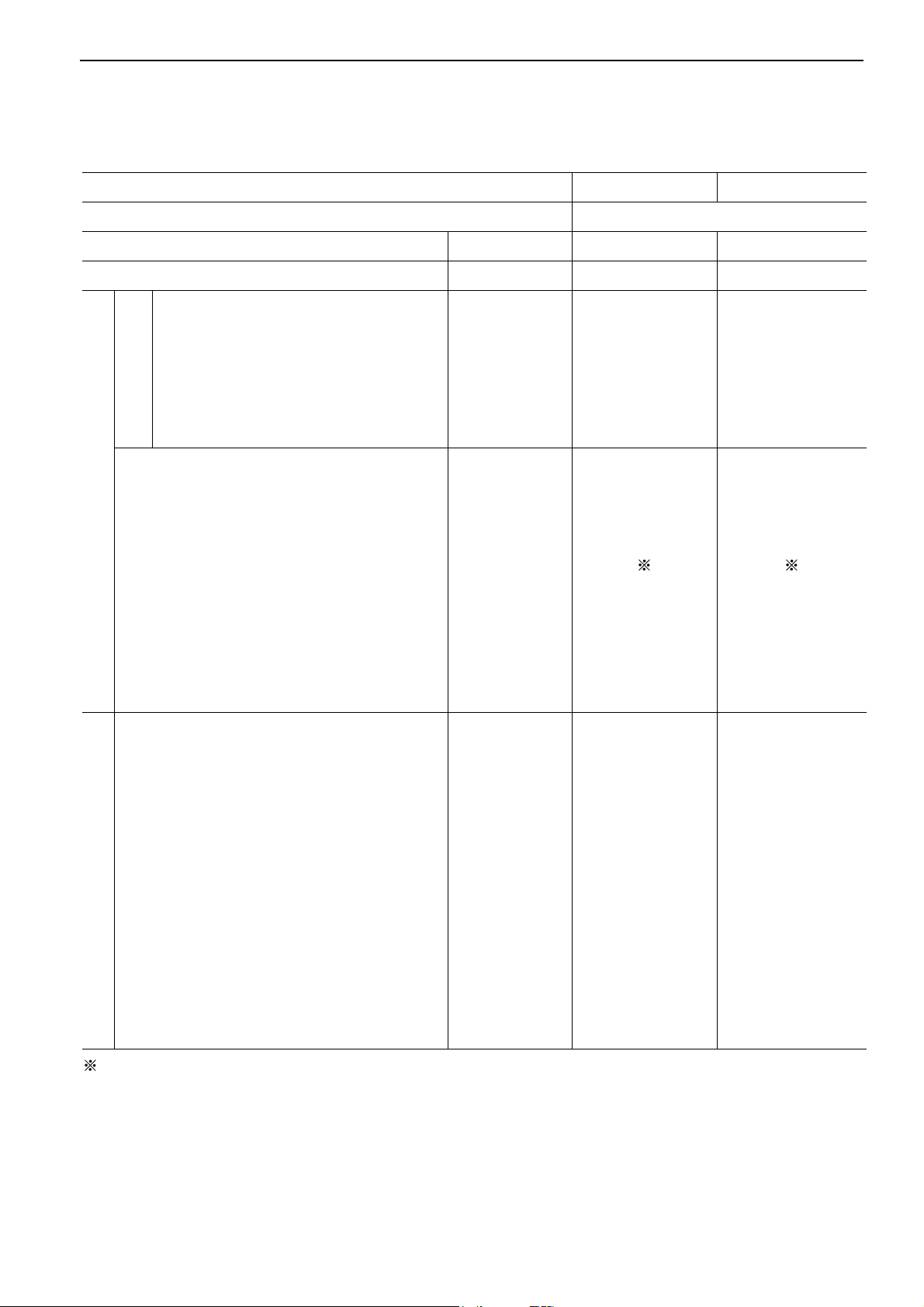

LIST OF REVISED PAGES

The affected pages are indicated by the use of the

following marks. It is requested that necessary

actions be taken to these pages according to the

table below.

LIST OF REVISED PAGES

Mark Page

Time of

revision

Mark Page

00-1 10-13 10-42 10-70 10-100

00-2 10-14 10-43 10-71 10-101

00-2-1 10-15 10-44 10-72 10-102

00-2-2 10-16 10-45 10-74 10-103

00-2-3 10-17 10-46 10-75 10-104

00-2-4 10-18 10-47 10-76 10-105

10-19 10-48 10-77 10-106

10-20 10-50 10-78 10-107

10-21 10-51 10-79 10-108

01-1 10-22 10-52 10-80 10-109

01-2 10-23 10-53 10-81 10-110

01-3 10-24 10-54 10-82 10-111

01-4 10-26 10-55 10-83 10-112

01-5 10-27 10-56 10-84 10-113

01-6 10-28 10-57 10-85 10-114

01-7 10-29 10-58 10-86 10-115

01-8 10-30 10-59 10-87 10-116

10-31 10-60 10-88 10-117

10-1 10-32 10-61 10-89 10-118

10-2 10-33 10-62 10-90 10-120

10-3 10-34 10-62 10-91 10-121

10-4 10-35 10-63 10-92 10-122

10-6 10-36 10-64 10-94 10-123

10-7 10-37 10-65 10-95 10-124

10-8 10-38 10-66 10-96 10-125

10-9 10-39 10-67 10-97 10-126

10-10 10-40 10-68 10-98 10-127

10-12 10-41 10-69 10-99 10-128

Time of

revision

Mark Page

Mark Indication Action required

Page to be newly added Add

Page to be replaced Replace

( ) Page to be deleted Discard

Pages having no marks are those previously revised

or made additions.

Time of

revision

Mark Page

Time of

revision

Mark Page

Time of

revision

PC340-7 00-2-1

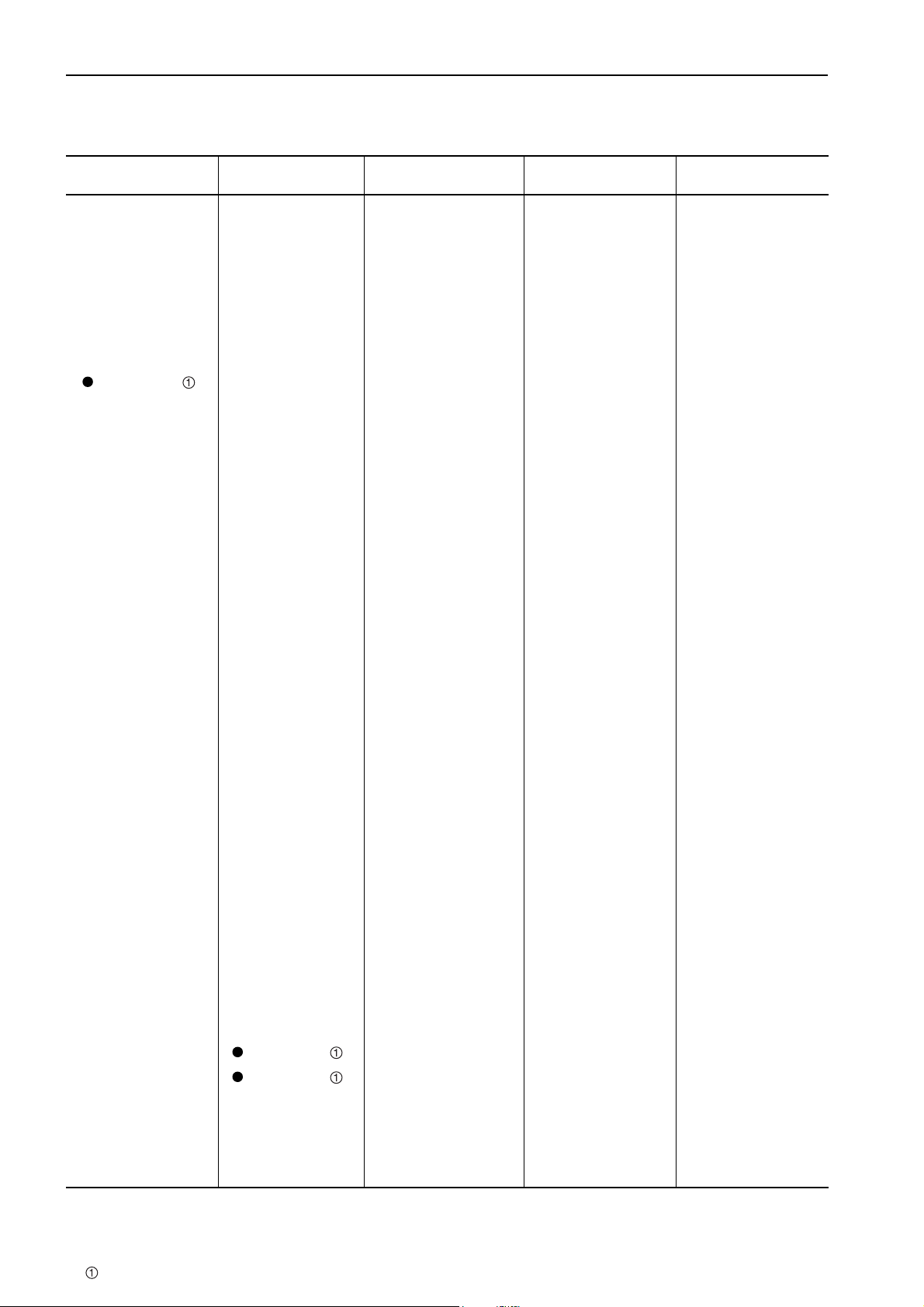

LIST OF REVISED PAGES

Mark Page

Time of

revision

Mark Page

Time of

revision

Mark Page

Time of

revision

Mark Page

Time of

revision

10-129 10-171 20-101 20-141 20-181

10-130 10-172 20-102 20-142 20-182

10-132 10-173 20-103 20-143

10-133 10-174 20-104 20-144

10-134 10-175 20-105 20-145

10-135 10-176 20-106 20-146 20-201

10-136 10-177 20-107 20-147 20-202

10-137 10-178 20-108 20-148 20-203

10-138 10-179 20-109 20-149 20-204

10-139 10-180 20-110 20-150 20-205

10-140 10-181 20-111 20-151 20-206

10-141 10-182 20-112 20-152 20-207

10-142 10-183 20-113 20-153 20-208

10-143 10-184 20-114 20-154 20-209

10-144 10-185 20-115 20-155 20-210

10-146 10-186 20-116 20-156 20-211

10-147 10-187 20-117 20-157 20-212

10-148 10-188 20-118 20-158 20-213

10.149 10-189 20-119 20-159 20-214

10-150 10-190 20-120 20-160 20-215

10-151 10-191 20-121 20-161 20-216

10-152 10-192 20-122 20-162 20-218

10-153 10-193 20-123 20-163 20-219

10-154 10-194 20-124 20-164 20-220

10-155 10-195 20-125 20-165 20-221

10-156 10-196 20-126 20-166 20-222

10-157 10-197 20-127 20-167 20-224

10-158 10-198 20-128 20-168 20-225

10-159 20-129 20-169 20-226

10-160 20-1 20-130 20-170 20-227

10-161 20-2 20-131 20-171 20-228

10-162 20-3 20-132 20-172 20-230

10-163 20-4 20-133 20-173 20-231

10-164 20-5 20-134 20-174 20-232

10-165 20-6 20-135 20-175 20-233

10-166 20-7 20-136 20-176 20-234

10-167 20-8 20-137 20-177 20-235

10-168 20-9 20-138 20-178 20-236

10-169 20-10 20-139 20-179 20-237

10-170 20-140 20-180 20-238

Mark Page

Time of

revision

00-2-2 PC340-7

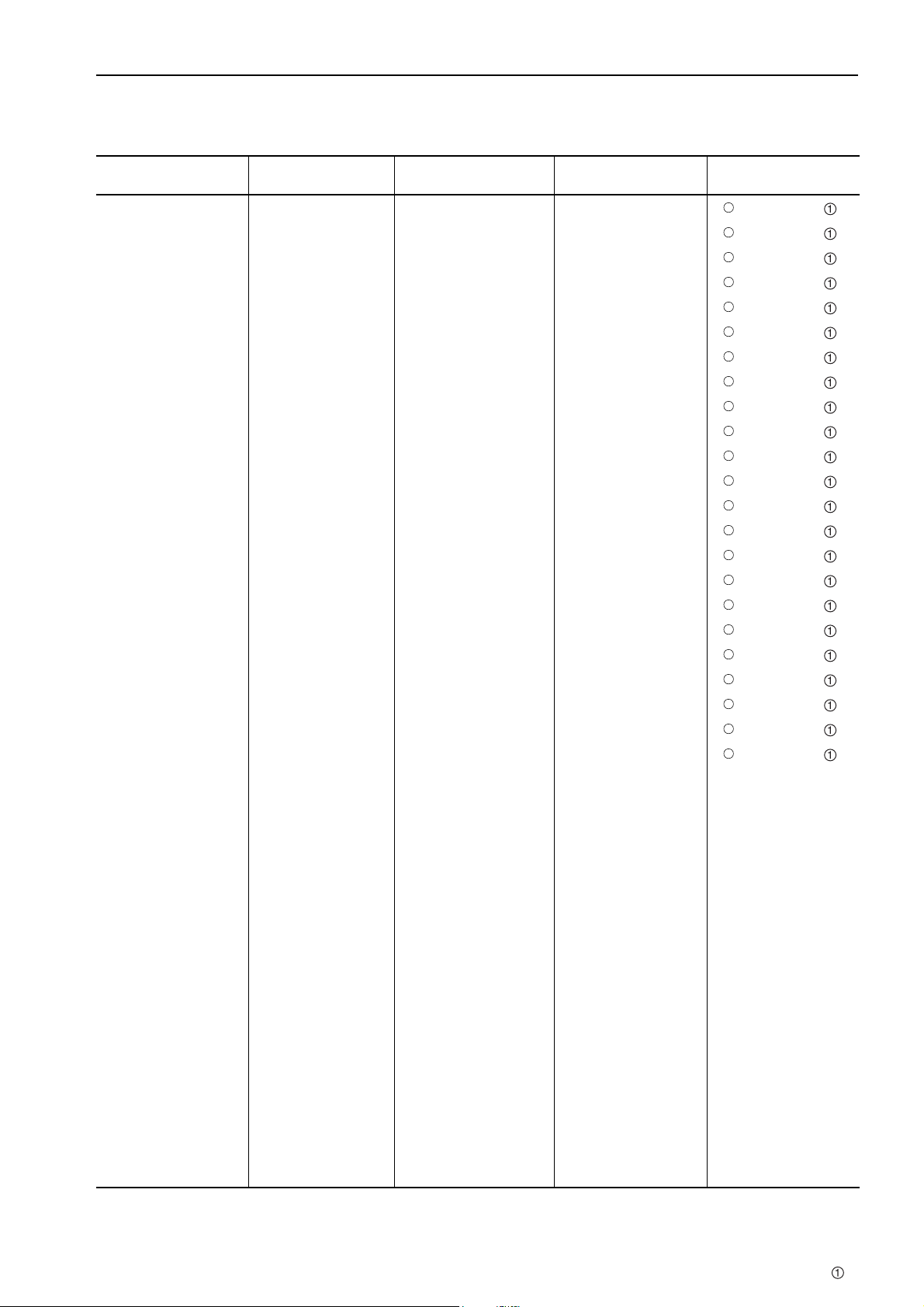

LIST OF REVISED PAGES

Mark Page

Time of

revision

Mark Page

Time of

revision

Mark Page

Time of

revision

Mark Page

Time of

revision

20-239 20-320 20-360 20-514 20-601

20-240 20-321 20-362 20-515 20-602

20-241 20-322 20-363 20-516 20-603

20-242 20-323 20-364 20-517 20-604

20-243 20-324 20-365 20-518 20-605

20-244 20-325 20-366 20-519 20-606

20-245 20-326 20-367 20-520 20-607

20-246 20-327 20-368 20-521 20-608

20-247 20-328 20-369 20-522 20-609

20-248 20-329 20-370 20-523 20-610

20-249 20-330 20-371 20-524 20-611

20-250 20-331 20-372 20-525 20-612

20-251 20-332 20-374 20-526 20-613

20-252 20-333 20-375 20-527 20-614

20-253 20-334 20-376 20-528 20-615

20-254 20-335 20-377 20-530 20-616

20-255 20-336 20-378 20-531 20-617

20-256 20-337 20-379 20-532 20-618

20-257 20-338 20-380 20-533 20-619

20-339 20-381 20-534 20-620

20-340 20-382 20-535 20-621

20-341 20-383 20-536 20-622

20-342 20-384 20-537 20-623

20-301 20-343 20-385 20-538

20-302 20-344 20-386 20-540

20-304 20-345 20-541

20-305 20-346 20-542

20-306 20-347 20-543

20-307 20-348 20-501 20-544 30-1

20-308 20-349 20-502 20-545 30-2

20-309 20-350 20-503 20-546 30-3

20-310 20-351 20-504 20-547 30-4

20-311 20-352 20-505 20-548 30-5

20-312 20-353 20-506 20-549 30-6

20-313 20-354 20-507 30-7

20-314 20-355 20-508 30-8

20-315 20-356 20-510 30-9

20-316 20-357 20-511 30-10

20-317 20-358 20-512 30-11

20-318 20-359 20-513 30-12

Mark Page

Time of

revision

PC340-7 00-2-3

LIST OF REVISED PAGES

Mark Page

Time of

revision

Mark Page

Time of

revision

30-13 30-53 20-93

30-14 30-54 30-94

30-15 30-55 30-95

30-16 30-56 30-96

30-17 30-57

30-18 30-58

30-19 30-59

30-20 30-60 90-1

30-21 30-61 90-3

30-22 30-62 90-5

30-23 30-63 90-7

30-24 30-64 90-9

30-25 30-65

30-26 30-66

30-27 30-67

30-28 30-68

30-29 30-69

30-30 30-70

30-31 30-71

30-32 30-72

30-33 30-73

30-34 30-74

30-35 30-75

30-36 30-76

30-37 30-77

30-38 30-78

30-39 30-79

30-40 30-80

30-41 30-81

30-42 30-82

30-43 30-83

30-44 30-84

30-45 30-85

30-46 30-86

30-47 30-87

30-48 30-88

30-49 30-89

30-50 30-90

30-51 30-91

30-52 30-92

Mark Page

Time of

revision

Mark Page

Time of

revision

Mark Page

Time of

revision

00-2-4 PC340-7

01 GENERAL

Specification Dimension Drawings . . . . . . . . 01-2

Specifications

PC340LC-7, PC340NLC-7. . . . . . . . . . 01-4

Weight Table

PC340LC-7, PC340NLC-7. . . . . . . . . . 01-6

Fuel, Coolant, And Lubricants . . . . . . . . . . . . 01-8

PC340-7

01-1

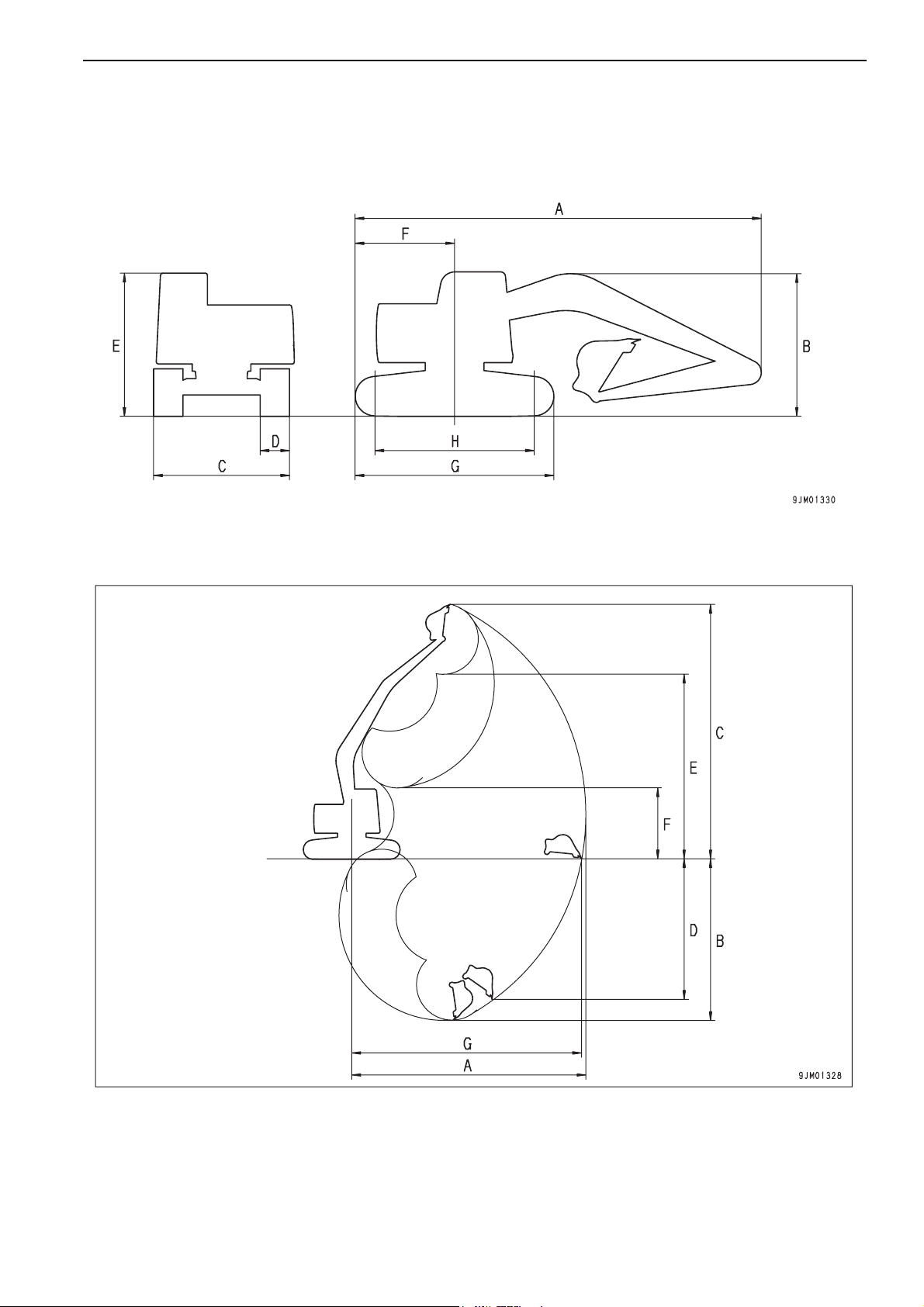

GENERAL SPECIFICATION DIMENSION DRAWINGS

SPECIFICATION DIMENSION DRAWINGS

DIMENSIONS

WORKING RANGES

01-2 PC340-7

GENERAL SPECIFICATION DIMENSION DRAWINGS

12

DIMENSIONS

Item Unit PC340LC-7 PC340NLC-7

A Overall length mm 11,140 11,140

B Overall height mm 3,290 3,280

C Overall width mm 3,190 2,990

D Track shoe width mm 700 600

E Height of cab mm 3,130 3,130

F Tail swing radius mm 3,450 3,450

G Track overall length mm 4,955 4,955

H Length of track on ground mm 4,030 4,030

Min. ground clearance mm 498 498

WORKING RANGES

Item Unit PC340LC-7 PC340NLC-7

A Max. digging reach mm 11,100 11,100

B Max. digging depth mm 7,380 7,380

C Max. digging height mm 10,210 10,210

D Max. vertical wall depth mm 6,480 6,480

E Max. dumping height mm 7,110 7,110

F Min. dumping height mm 2,640 2,640

G Max. reach at ground level mm 10,920 10,920

PC340-7 01-3

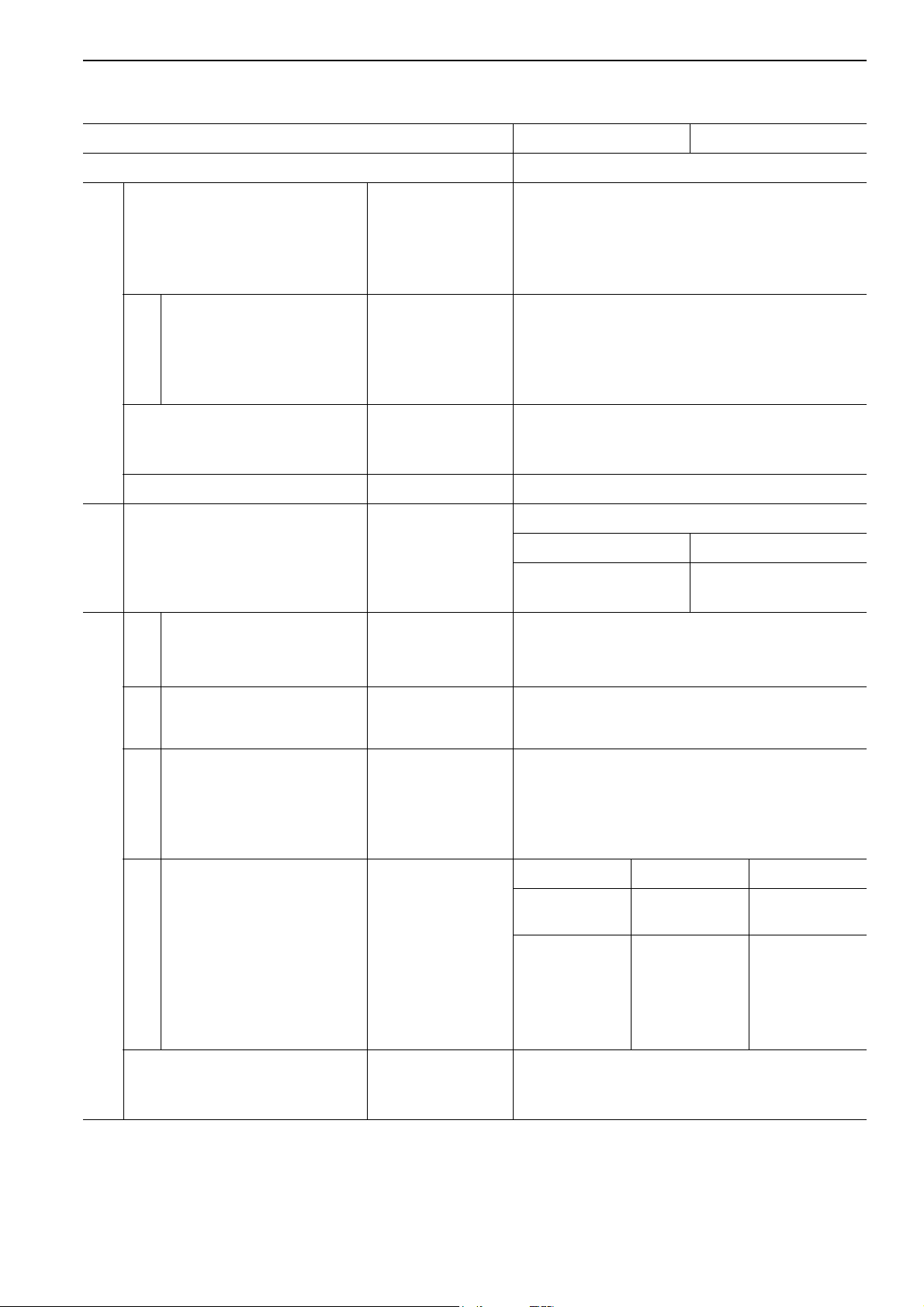

GENERAL SPECIFICATIONS

SPECIFICATIONS

PC340LC-7, PC340NLC-7

Machine model PC340LC-7 PC340NLC-7

Serial Number 40001 and up

Bucket capacity m³ 1.4 1.4

Operating weight kg 33,530 33,230

Max. digging depth

Max. vertical wall depth

Max. digging reach

Max. reach at ground level

Max. digging height

Working ranges

Max. dumping height

Max. digging force

(using power max. function)

Swing speed

Performance

Swing max. slope angle

Travel speed

Gradeability

Ground pressure

[standard shoe width]

Overall length (for transport)

Overall width

Overall width of track

Overall height (for transport)

Overall height to chassis

Ground clearance to bottom of upper structure

Min. ground clearance

Tail swing radius

Dimensions

Min. swing radius of work equipment

Height of work equipment at min. swing radius

Length of track on ground

Track gauge

Height of machine cab

mm

mm

mm

mm

mm

mm

kN {kg}

kN {kg}

rpm

deg.

km/h

deg.

kPa {kg/cm²}

[mm]

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

7,380

6,480

11,100

10,920

10,210

7,110

211.8 {21,600} (226.5

{23,100})

9.5

21

Lo: 3.2 ( Mi: 4.5)

Hi: 5.5

35

53.0 {0.54}

[700]

11,140

3,190

3,290

3,280

3,130

1,186

498

3,450

4,310

8,520

4,030

2,590

3,130

7,380

6,480

11,100

10,920

10,210

7,110

211.8 {21,600} (226.5

{23,100})

9.5

21

Lo: 3.2 ( Mi: 4.5)

Hi: 5.5

35

61.8 {0.63}

[600]

11,140

3,190

2,990

3,280

3,130

1,186

498

3,450

4,310

8,520

4,030

2,590

3,130

: The "Mi" mode is on the multi-monitor specification machine only.

01-4 PC340-7

GENERAL SPECIFICATIONS

12

Machine model PC340LC-7 PC340NLC-7

Serial Number 40001 and up

Model

Type

No. of cylinders - bore x stroke

Piston displacement

Flywheel horsepower

Max. torque

Engine

Under-

carriage

Max. speed at no load

Min. speed at no load

Performance

Min. fuel consumption

Starting motor

Alternator

Battery

Radiator core type CF19-4

Carrier roller 2 on each side

Track roller 7 on each side 8 on each side

Track shoe

Type x No.

Delivery

pump

Set pressure

Hydraulic

Nm/rpm {kgm/rpm}

mm

l {cc}

kW/rpm {HP/rpm}

rpm

rpm

g/kWh {g/HPh}

l/min

MPa (kg/cm²)

4-cycle, water-cooled, in-line, vertical, direct injection, with

Assembly-type triple

grouser, 45 on each side

HPV125+125, variable displacement, Piston type x2

SAA6D114E

turbo charger and aftercooler

6 - 114 x 135

8.27 {8,270}

180.3/1,900 {242/1,900}

1,079/1,400 {110/1,400}

2,160

900

205 {153}

24V, 7.5 kW

24V, 35 A

12V, 126 Ah x 2

Assembly-type triple

grouser, 48 on each side

267.5 x 2

37.8 {380}

valve

Control

motor

Hydraulic

Hydraulic system

Hydraulic cylinder

Hydraulic tank

Hydraulic filter

Hydraulic cooler

Type x No.

Control method

Travel motor

Swing motor

Type

Inside diameter of cylinder

Diameter of piston rod

Stroke

Max. distance between pins

Min. distance between pins

mm

mm

mm

mm

mm

6-spool type + 1-spool type x 1

Hydraulic

HMV160ADT-2, Piston type

(with brake valve, parking brake): x 2

KMF230ABE-5, Piston type

(with safety valve, holding brake): x 1

reverse rotation check valve

Boom Arm Bucket

Double acting

piston

140

100

1,480

3,525

2,045

Double acting

piston

160

110

1,825

4,255

2,430

Closed box type

Tank return side

CFT-1 (Air cooled)

Double acting

piston

140

100

1,285

3,155

1,870

PC340-7 01-5

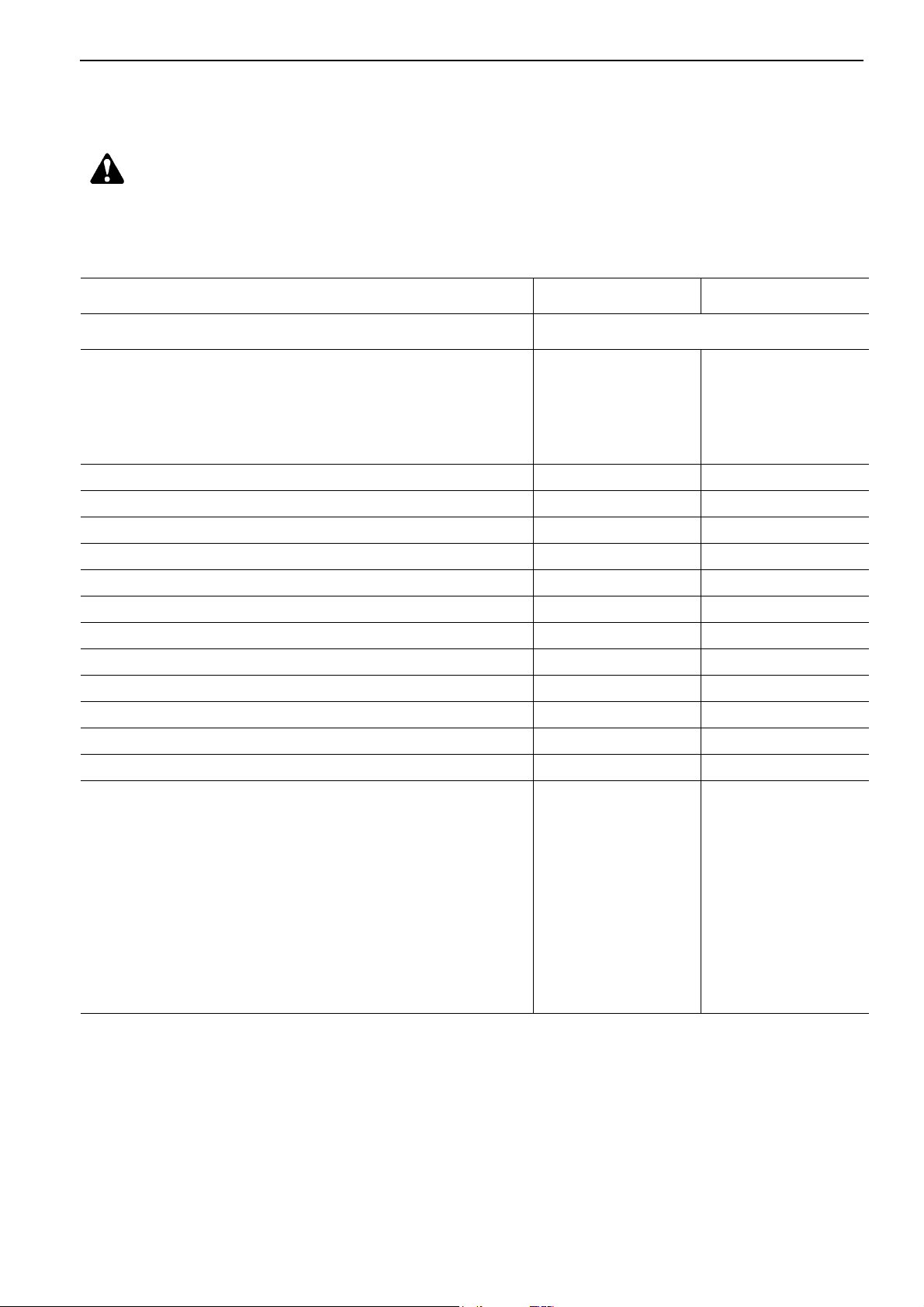

GENERAL WEIGHT TABLE

WEIGHT TABLE

This weight table is for use when handling components or when transporting the machine.

PC340LC-7, PC340NLC-7

Unit: kg

Machine model PC340LC-7 PC340NLC-7

Serial Number 40001 and up

Engine assembly

• Engine

• Damper

• Hydraulic pump

Radiator oil cooler assembly 153 153

Hydraulic tank, filter assembly (excluding hydraulic oil) 176 176

Fuel tank (excluding fuel) 238 238

Revolving frame 2,723 2,723

Operator’s cab 292 292

Operator’s seat 35 35

Counterweight 5,470 5,470

Swing machinery 442 442

Control valve 242 242

Swing motor 88 88

Travel motor 164 x 2 164 x 2

Center swivel joint 29.9 29.9

Track frame assembly

• Track frame

• Swing circle

• Idler

• Idler cushion

• Carrier roller

• Track roller

• Final drive (including travel motor)

1,148

860

14.3

178

7,979

4,441

487

169 x 2

287.5 x 2

31.3 x 4

52.9 x 14

583 x 2

1,148

860

14.3

178

7,979

4096.79

169 x 2

287.5 x 2

31.3 x 4

52.9 x 16

583 x 2

01-6 PC340-7

GENERAL WEIGHT TABLE

12

Unit: kg

Machine model PC340LC-7 PC340NLC-7

Serial Number 40001 and up

Track shoe assembly

• Standard triple grouser shoe (600 mm)

• Standard triple grouser shoe (700 mm)

• Wide triple grouser shoe (800 mm)

• Road liner (rubber pad type) (600 mm)

Boom assembly 2,290 2,290

Arm assembly 1,105 1,105

Bucket assembly 1,015 1,015

Boom cylinder assembly 254 x 2 254 x 2

Arm cylinder assembly 382 382

Bucket cylinder assembly 228 228

Link assembly (large) 316 316

Link assembly (small) — —

Boom pin 76 + 15 x 2 + 56 + 17 + 42 76 + 15 x 2 + 56 + 17 + 42

Arm pin 13 +17 13 +17

3,700

4,300

4,680

—

3,700

4,300

4,680

—

Bucket pin 30 x 2 30 x 2

Link pin 27 x 2 27 x 2

PC340-7 01-7

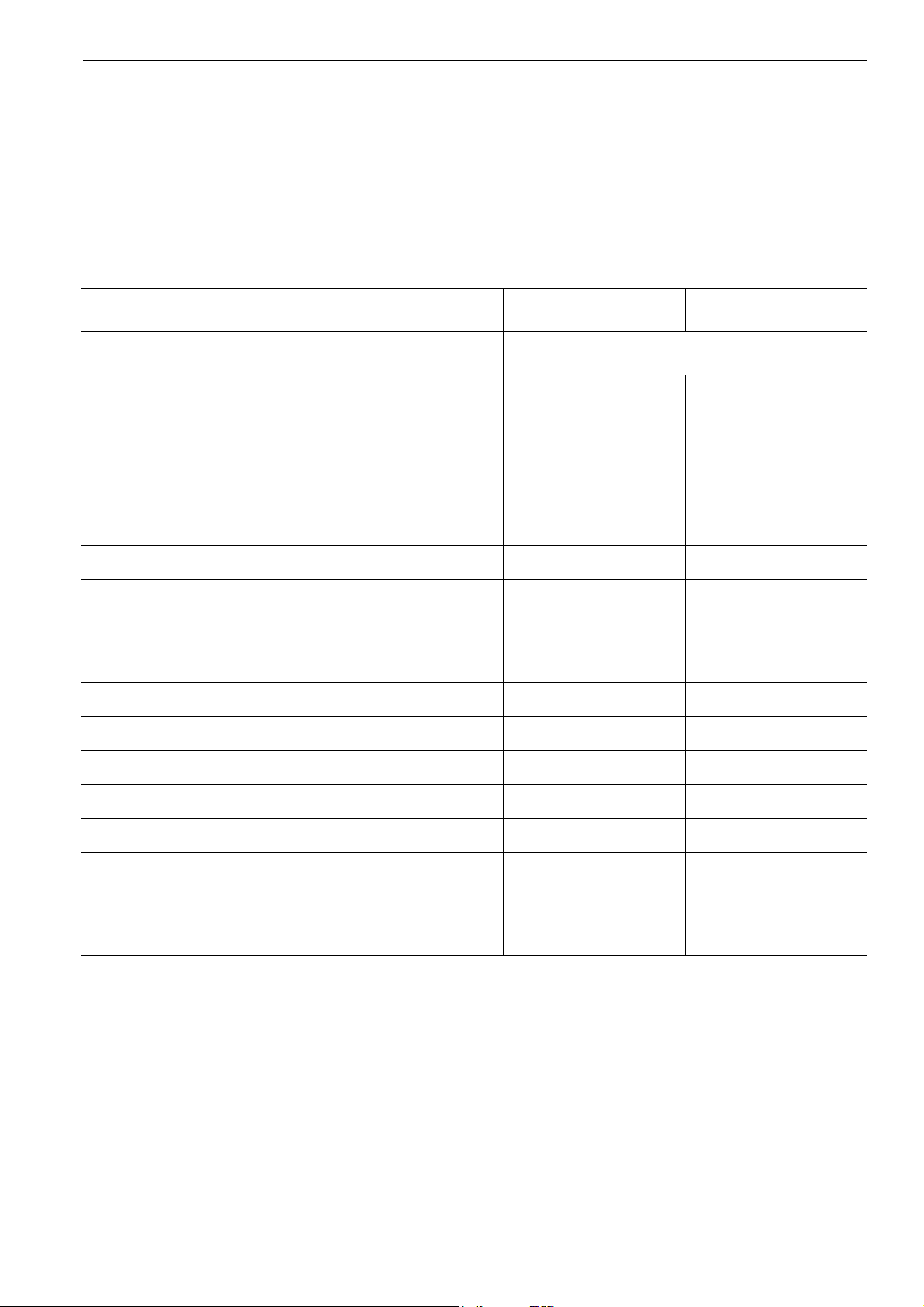

GENERAL FUEL, COOLANT, AND LUBRICANTS

12

FUEL, COOLANT, AND LUBRICANTS

KIND

RESERVOIR

OF

FLUID

Engine oil pan 38 35

Damper case 1.3

Swing machinery case 13.4 13.4

Final drive case (each side)

Idler (1 each) 0.22 ~ 0.24 0.22 ~ 0.24

Track roller (1 each) 0.25 ~ 0.28 0.25 ~ 0.28

Carrier roller (1 each) 0.145 ~ 0.155 0.145 ~ 0.155

Engine

oil

AMBIENT TEMPERATURE CAPACITY (

-22 -4 14 32 50 68 86 104°F

-30 -20 -10 0 10 20 30 40°C

SAE 30

SAE 10W

SAE 10W-30

SAE 15W-40

SAE 30 8.5 8.5

SAE 10W

Specified Refill

l)

—

SAE 10W-30

Hydraulic system 365 188

Hydraulic

oil

Fuel tank

Cooling system Coolant Add antifreeze 32 —

Diesel

fuel

ASTM D975A

No.1

SAE 15W-40

H046-HM (★)

ASTM D975 No. 2

605

★ For the H-046-HM, use the oil recommended by Komatsu.

—

01-8 PC340-7

10 STRUCTURE, FUNCTION AND

MAINTENANCE STANDARD

1252

Engine Related Parts. . . . . . . . . . . . . . . . . . 10-2

Radiator • Oil Cooler • Aftercooler . . . . . . 10-3

Power Train. . . . . . . . . . . . . . . . . . . . . . . . . 10-4

Final Drive . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

Swing Machinery . . . . . . . . . . . . . . . . . . . . 10-8

Swing Circle . . . . . . . . . . . . . . . . . . . . . . . 10-10

Track Frame • Recoil Spring . . . . . . . . . . 10-12

Idler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-14

Carrier roller . . . . . . . . . . . . . . . . . . . . . . . 10-16

Track roller . . . . . . . . . . . . . . . . . . . . . . . . 10-17

Track Shoe . . . . . . . . . . . . . . . . . . . . . . . . 10-18

Hydraulic Equipment Layout Drawing

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-22

Hydraulic tank. . . . . . . . . . . . . . . . . . . . . . 10-24

Hydraulic Pump . . . . . . . . . . . . . . . . . . . . 10-26

Variable Volume Valve . . . . . . . . . . . . . . 10-47

Control Valve . . . . . . . . . . . . . . . . . . . . . . 10-50

CLSS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-66

Self Pressure Reducing Valve. . . . . . . . . . 10-69

Swing Motor . . . . . . . . . . . . . . . . . . . . . . . 10-72

Reverse Prevention Valve. . . . . . . . . . . . . 10-78

Center Swivel Joint. . . . . . . . . . . . . . . . . . 10-80

Travel Motor . . . . . . . . . . . . . . . . . . . . . . . 10-81

Travel Junction Valve. . . . . . . . . . . . . . . . 10-91

Travel PPC Shuttle Valve . . . . . . . . . . . . . 10-94

Valve Control . . . . . . . . . . . . . . . . . . . . . . 10-98

Work Equipment • Swing PPC Valve. . . . 10-99

Travel PPC Valve . . . . . . . . . . . . . . . . . . 10-103

Service PPC Valve . . . . . . . . . . . . . . . . . 10-112

Solenoid Valve . . . . . . . . . . . . . . . . . . . . 10-115

PPC Accumulator . . . . . . . . . . . . . . . . . . 10-117

Return Oil Filter . . . . . . . . . . . . . . . . . . . 10-118

Boom Hydraulic Drift Prevention Valve

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-120

Quick Return Valve . . . . . . . . . . . . . . . . 10-126

Lift Check Valve. . . . . . . . . . . . . . . . . . . 10-128

Attachment Circuit Selector Valve . . . . . 10-129

Hydraulic Cylinder . . . . . . . . . . . . . . . . . 10-132

Work Equipment. . . . . . . . . . . . . . . . . . . 10-134

Air Conditioner . . . . . . . . . . . . . . . . . . . . 10-140

Engine Control . . . . . . . . . . . . . . . . . . . . 10-141

Electronic Control System . . . . . . . . . . . 10-149

Multi Monitor System. . . . . . . . . . . . . . . 10-173

Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-195

PC340-7

10-1

STRUCTURE, FUNCTION, & MAINTENANCE STANDARD ENGINE RELATED PARTS

12

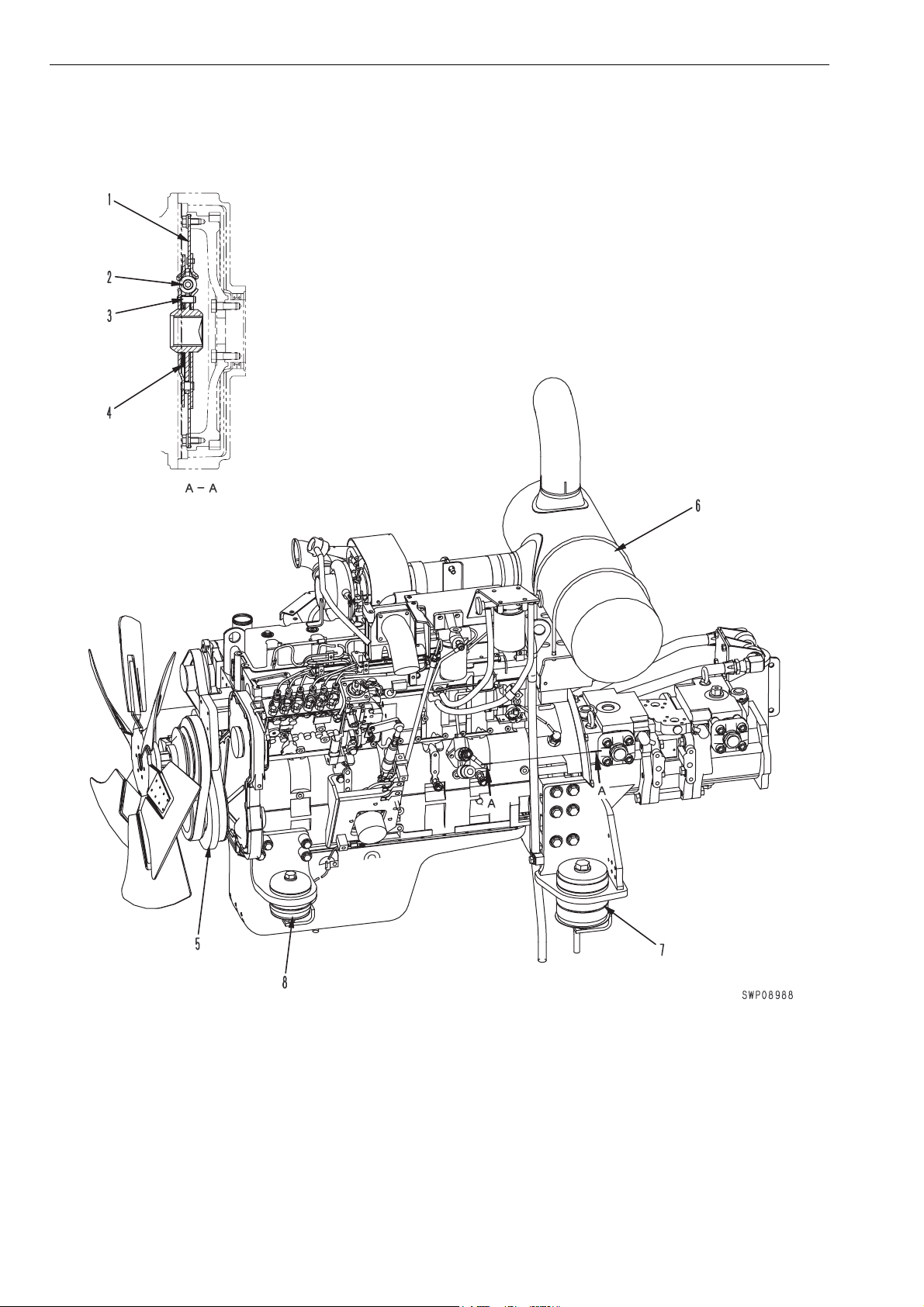

ENGINE RELATED PARTS

1. Drive plate

2. Torsion spring

3. Stopper pin

4. Friction plate

5. Damper assembly

6. Muffler

7. Rear engine mount

8. Front engine mount

OUTLINE

• The damper assembly is a wet type.

Oil capacity: 1.3 l

10-2 PC340-7

STRUCTURE, FUNCTION, & MAINTENANCE STANDARD

12

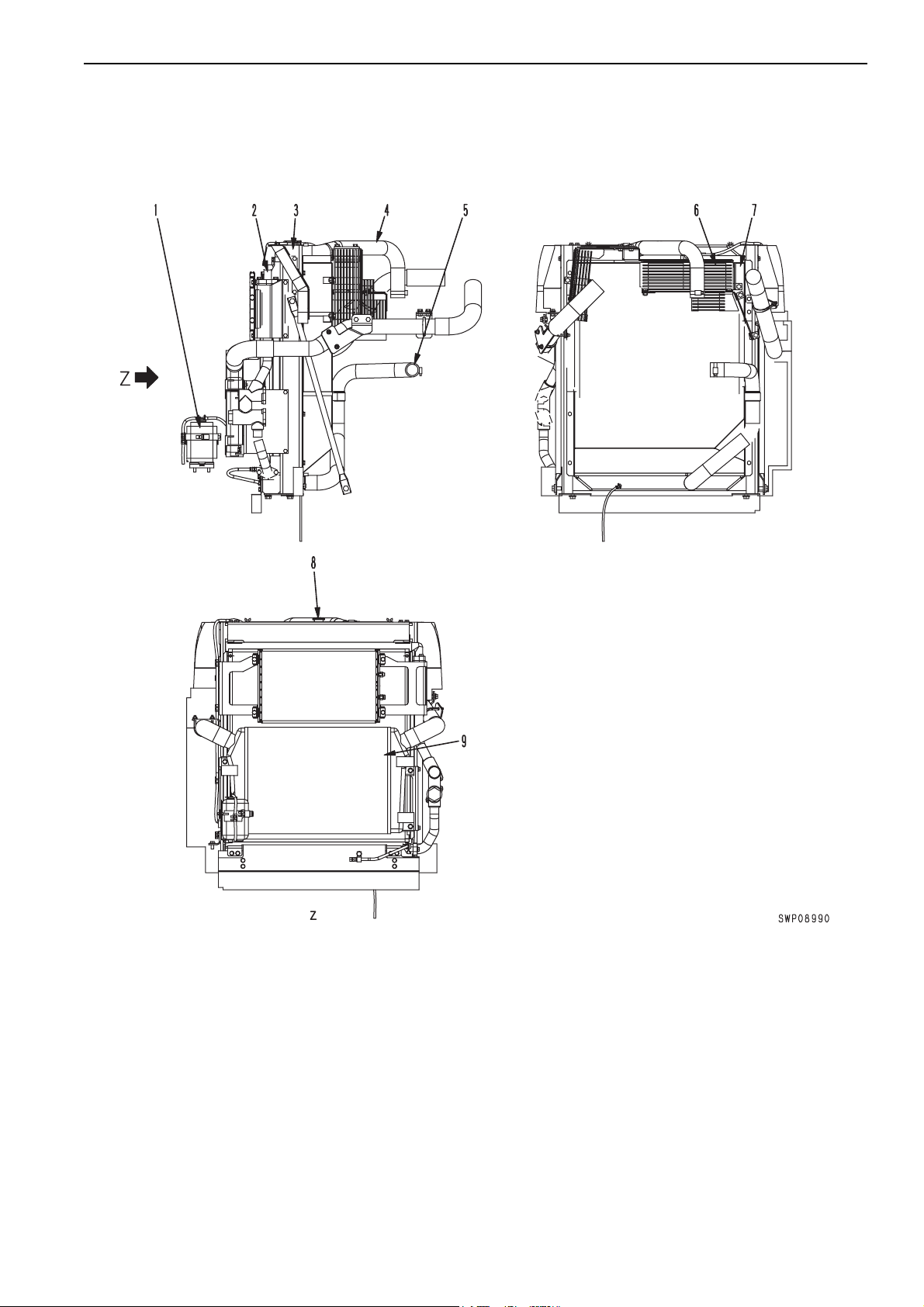

RADIATOR • OIL COOLER • AFTERCOOLER

RADIATOR • OIL COOLER •

AFTERCOOLER

SWP08671

1. Reservoir tank

2. Oil cooler

3. Radiator

4. Radiator inlet hose

5. Radiator outlet hose

6. Net

7. Shroud

8. Radiator cap

9. Aftercooler

PC340-7

SPECIFICATIONS

Radiator : CF19-4

Oil cooler : CF40-1

10-3

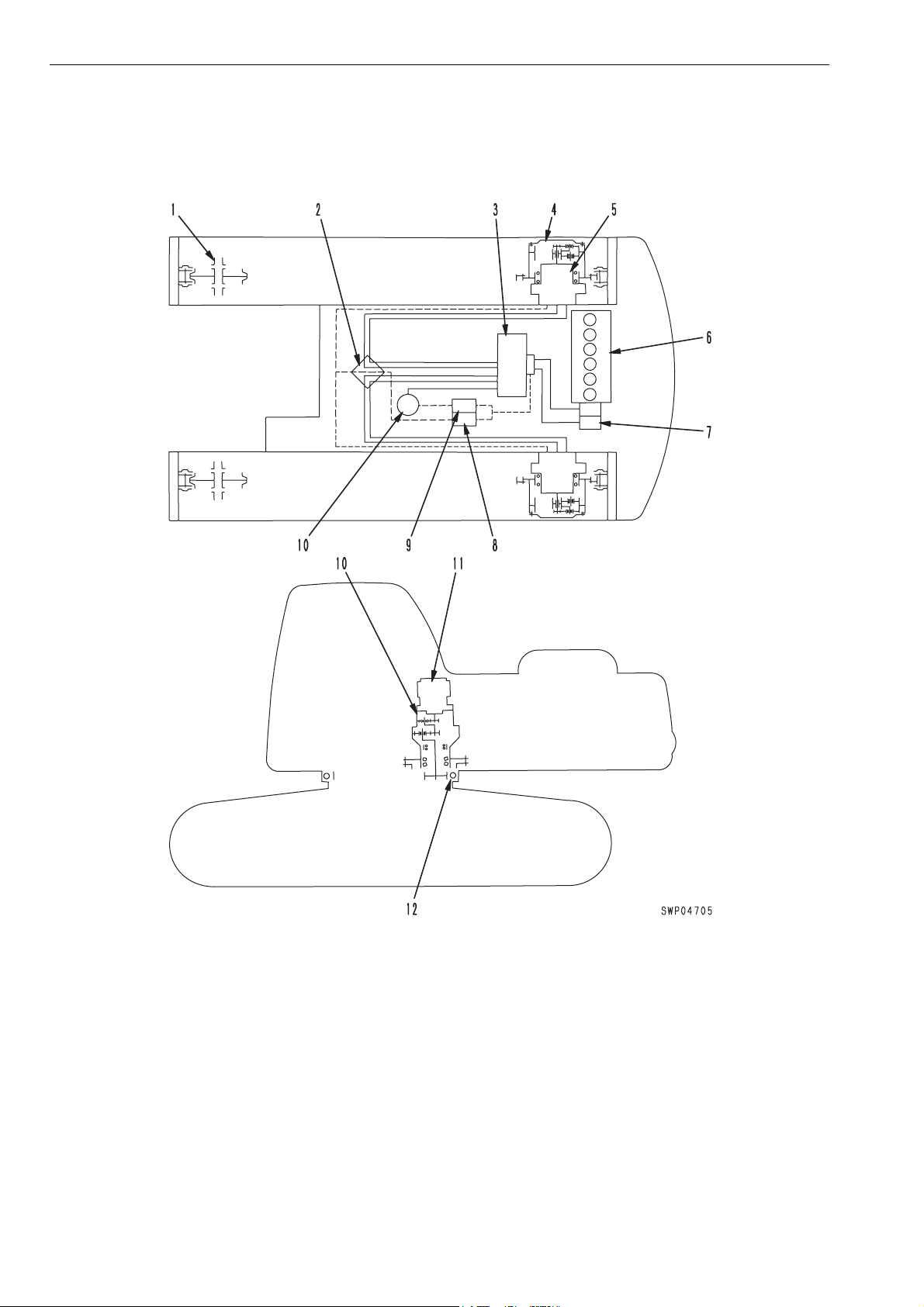

STRUCTURE, FUNCTION, & MAINTENANCE STANDARD POWER TRAIN

12

POWER TRAIN

1. Idler

2. Center swivel joint

3. Control valve

4. Final drive

5. Travel motor (HMV 160ADT-2)

6. Engine (SAA6D114E)

7. Hydraulic pump (HPV125+125)

8. Travel speed solenoid valve

9. Swing brake solenoid valve

10. Swing machinery

11. Swing motor (KMF230ABE-5)

12. Swing circle

10-4 PC340-7

12

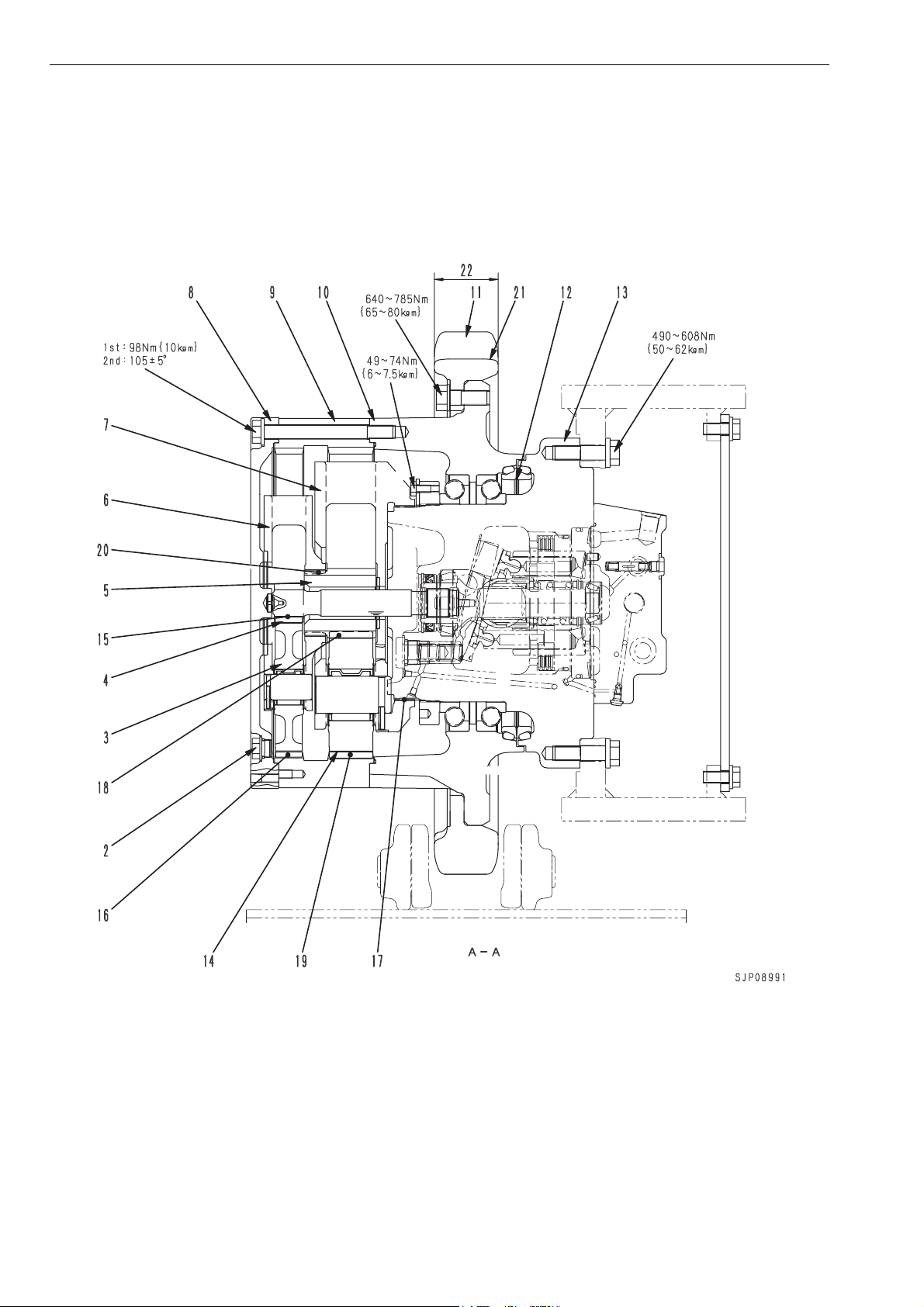

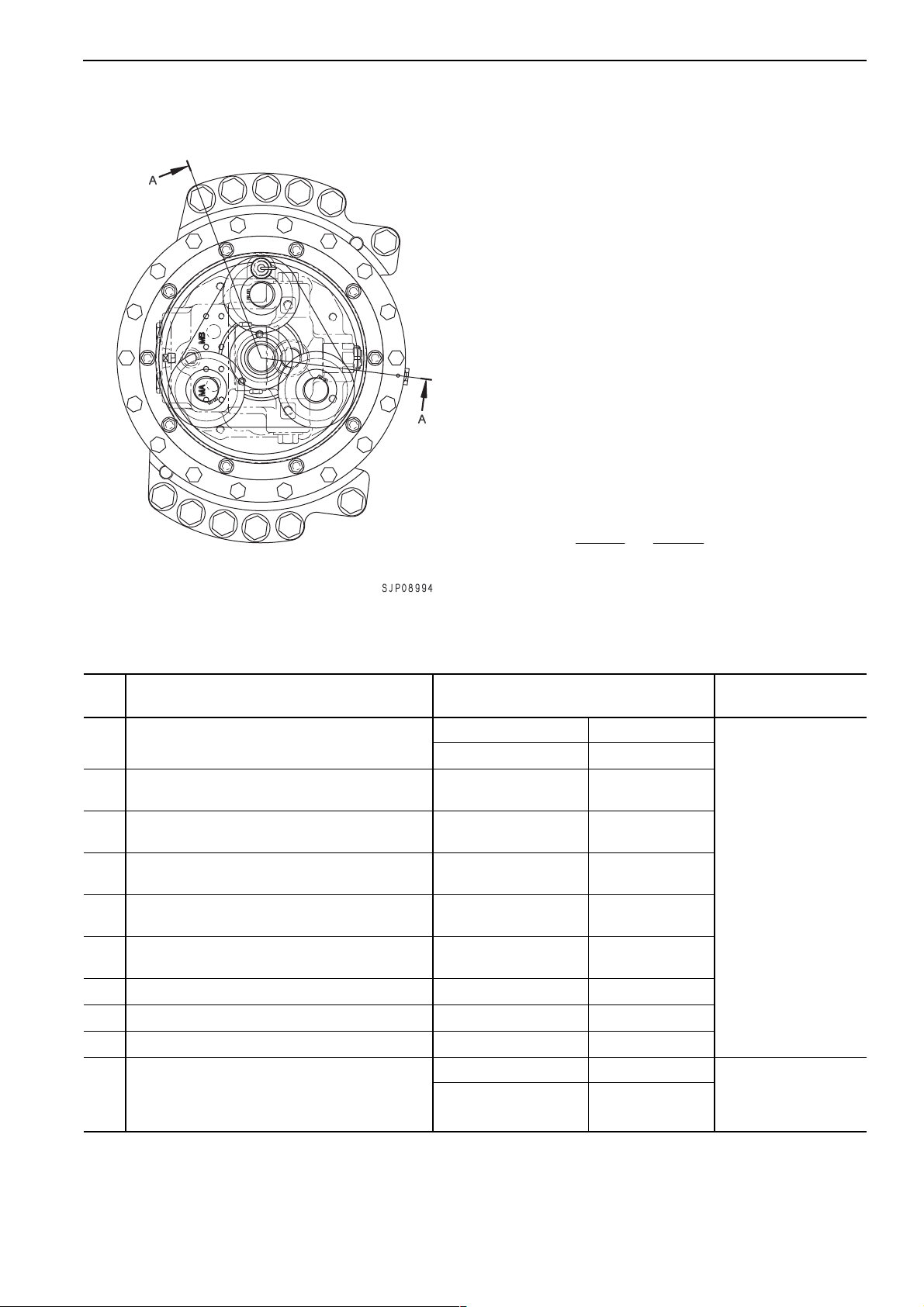

STRUCTURE, FUNCTION, & MAINTENANCE STANDARD FINAL DRIVE

12

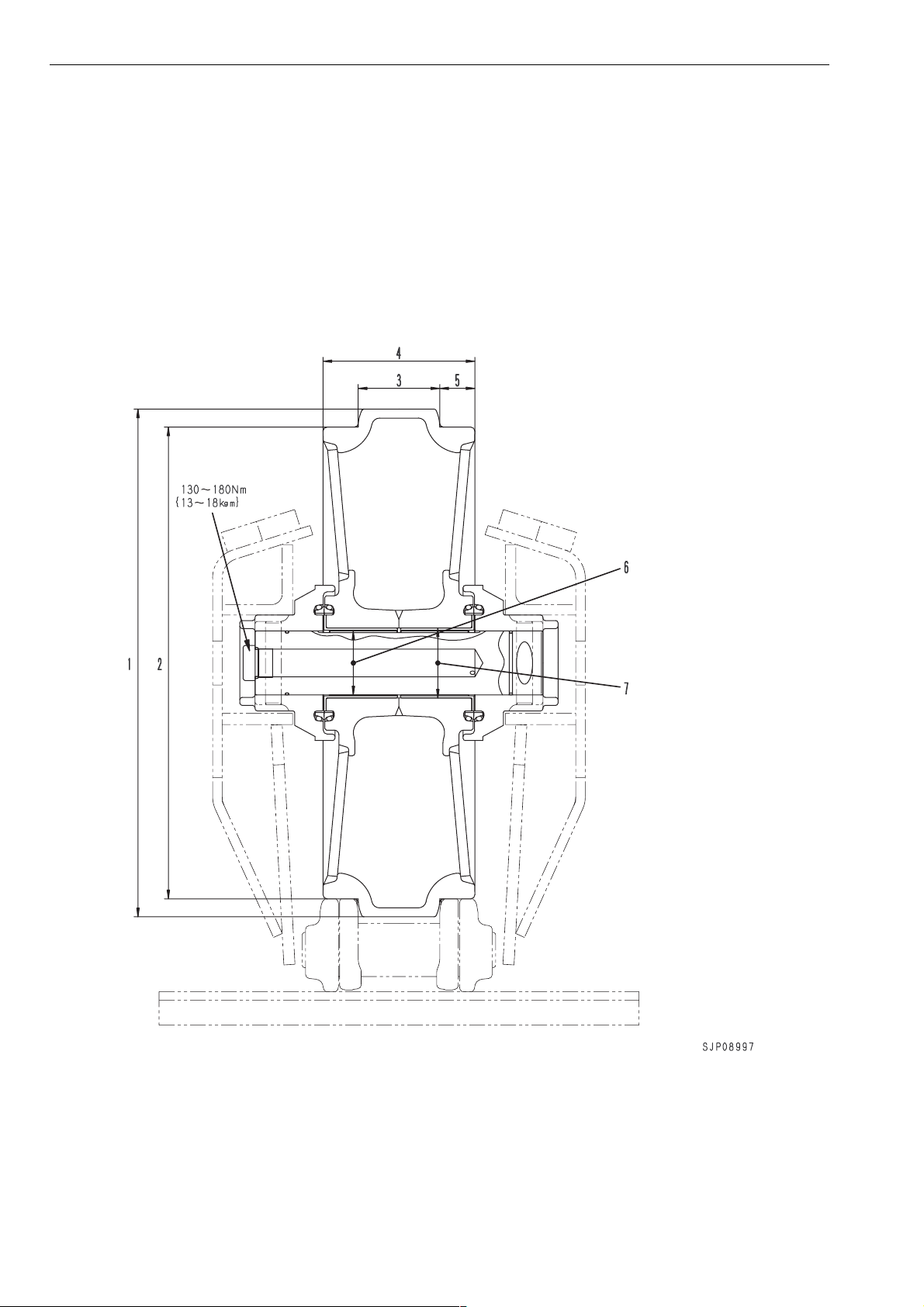

FINAL DRIVE

10-6 PC340-7

STRUCTURE, FUNCTION, & MAINTENANCE STANDARD FINAL DRIVE

12

1. Level plug

2. Drain plug

3. No. 1 planetary gear (No. of teeth: 42)

4. No. 1 sun gear (No. of teeth: 11)

5. No. 2 sun gear (No. of teeth: 19)

6. No. 1 planetary carrier

7. No. 2 planetary carrier

8. Cover

9. Ring gear (No. of teeth: 97)

10. Hub

11. Sprocket

12. Floating seal

13. Travel motor

14. No. 2 planetary gear (No. of teeth: 38)

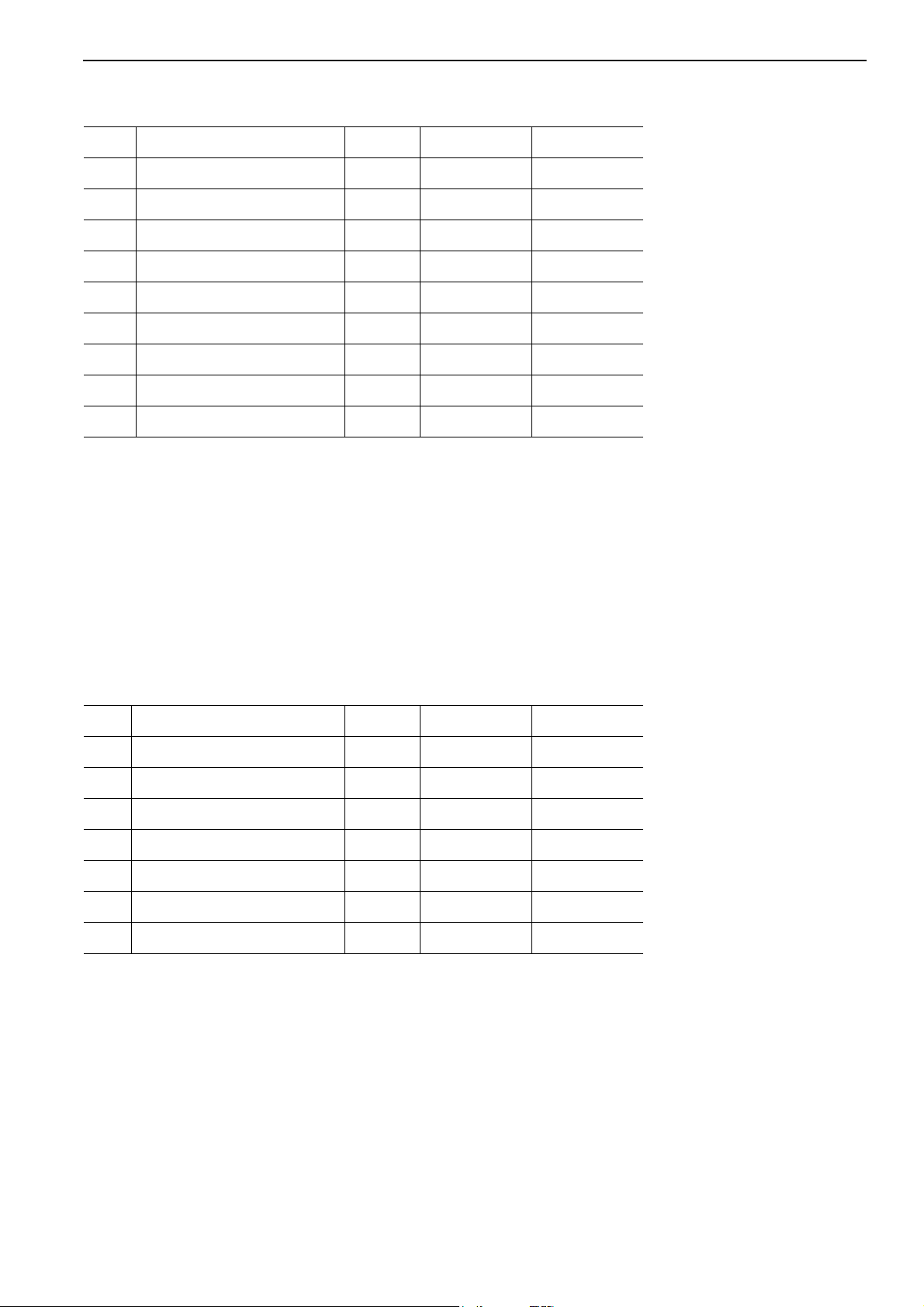

SPECIFICATIONS

Reduction ratio:

9711

+

11

×

−

No. Check item Criteria Remedy

Backlash between No. 1 sun gear and No. 1

15

planetary gear

Backlash between No. 1 planetary gear and

16

ring gear

Backlash between No. 2 planetary carrier and

17

motor

Backlash between No. 2 sun gear and No. 2

18

planetary gear

Backlash between No. 2 planetary gear and

19

ring gear

Standard clearance Clearance limit Replace

0.12 ~ 0.44 0.90

0.18 ~ 0.62 1.20

0.06 ~ 0.25 —

0.15 ~ 0.51 1.00

0.19 ~ 0.66 1.30

9719

+

19

943.58

−=

Unit: mm

Backlash between No. 2 planetary carrier and

20

No. 2 sun gear

21 Amount of wear on sprocket tooth Repair limit: 6

22 Width of sprocket tooth

PC340-7 10-7

0.39 ~ 0.80 1.60

Standard size Repair limit

87 84

Rebuild or

replace

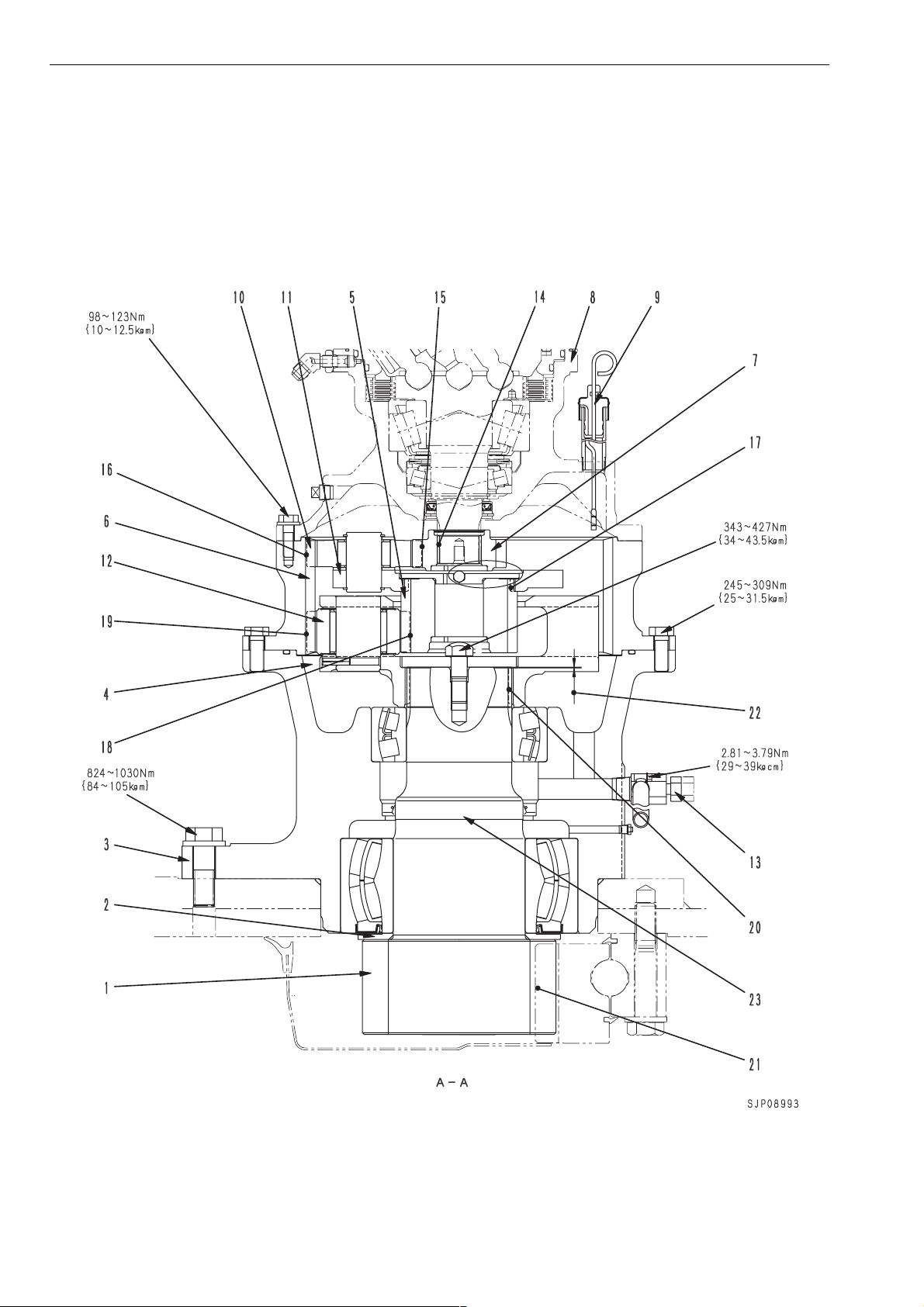

STRUCTURE, FUNCTION, & MAINTENANCE STANDARD SWING MACHINERY

12

SWING MACHINERY

10-8 PC340-7

STRUCTURE, FUNCTION, & MAINTENANCE STANDARD SWING MACHINERY

12

1. Swing pinion (No. of teeth: 13)

2. Spacer

3. Case

4. No. 2 planetary gear

5. No. 2 sun gear

6. Ring gear

7. No. 1 sun gear

8. Swing motor

9. Oil level gauge

10. No. 1 planetary gear

11. No. 1 planetary carrier

12. No. 2 planetary carrier

13. Drain plug

SPECIFICATIONS

Reduction ratio:

—

—

—

—

24

6824

+

553.17

=

Replace

Apply hard chrome

plating, recondition, or

replace

6819

+

19

×

1.00

1.10

1.20

1.00

1.10

2.00

No. Check item Criteria Remedy

Backlash between swing motor shaft and No. 1 sun

14

gear

Backlash between No. 1 sun gear and No. 1 plane-

15

tary gear

Backlash between No. 1 planetary gear and ring

16

gear

Backlash between No. 1 planetary carrier and No. 2

17

sun gear

Backlash between No. 2 sun gear and No. 2 plane-

18

tary gear

Backlash between No. 2 planetary gear and ring

19

gear

20 Backlash between coupling and swing pinion

21 Backlash between swing pinion and swing circle

22 Clearance between plate and coupling

Wear of swing pinion surface contacting with oil

23

seal

Standard clearance Clearance limit

~ 0.28

0.18

0.15

~ 0.51

0.17

~ 0.60

0.40

~ 0.75

0.16

~ 0.55

0.17

~ 0.60

0.08

~ 0.25

~ 1.21

0.00

0.57

~ 1.09

Standard size Repair limit

0

145

-0.100

Unit: mm

PC340-7 10-9

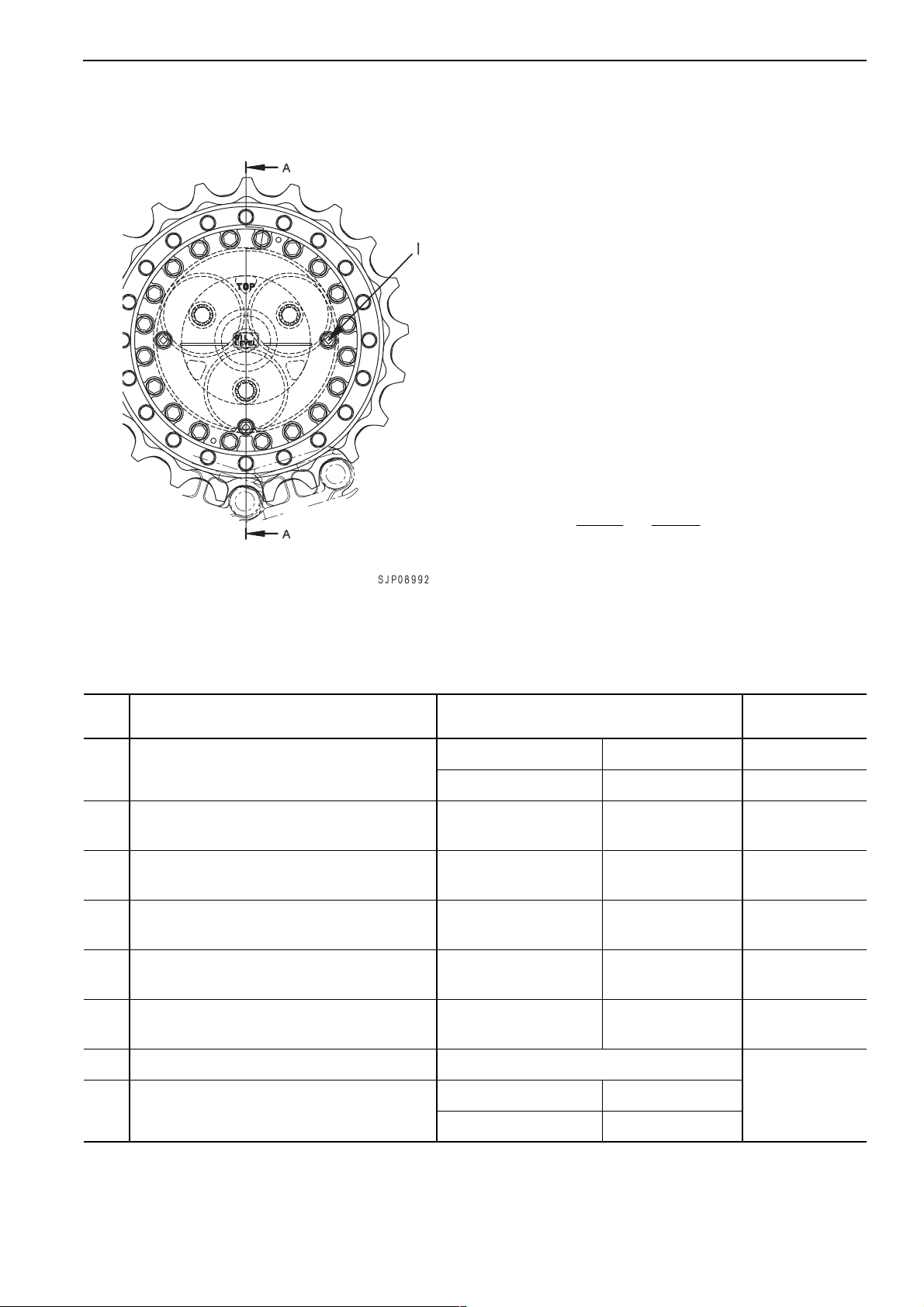

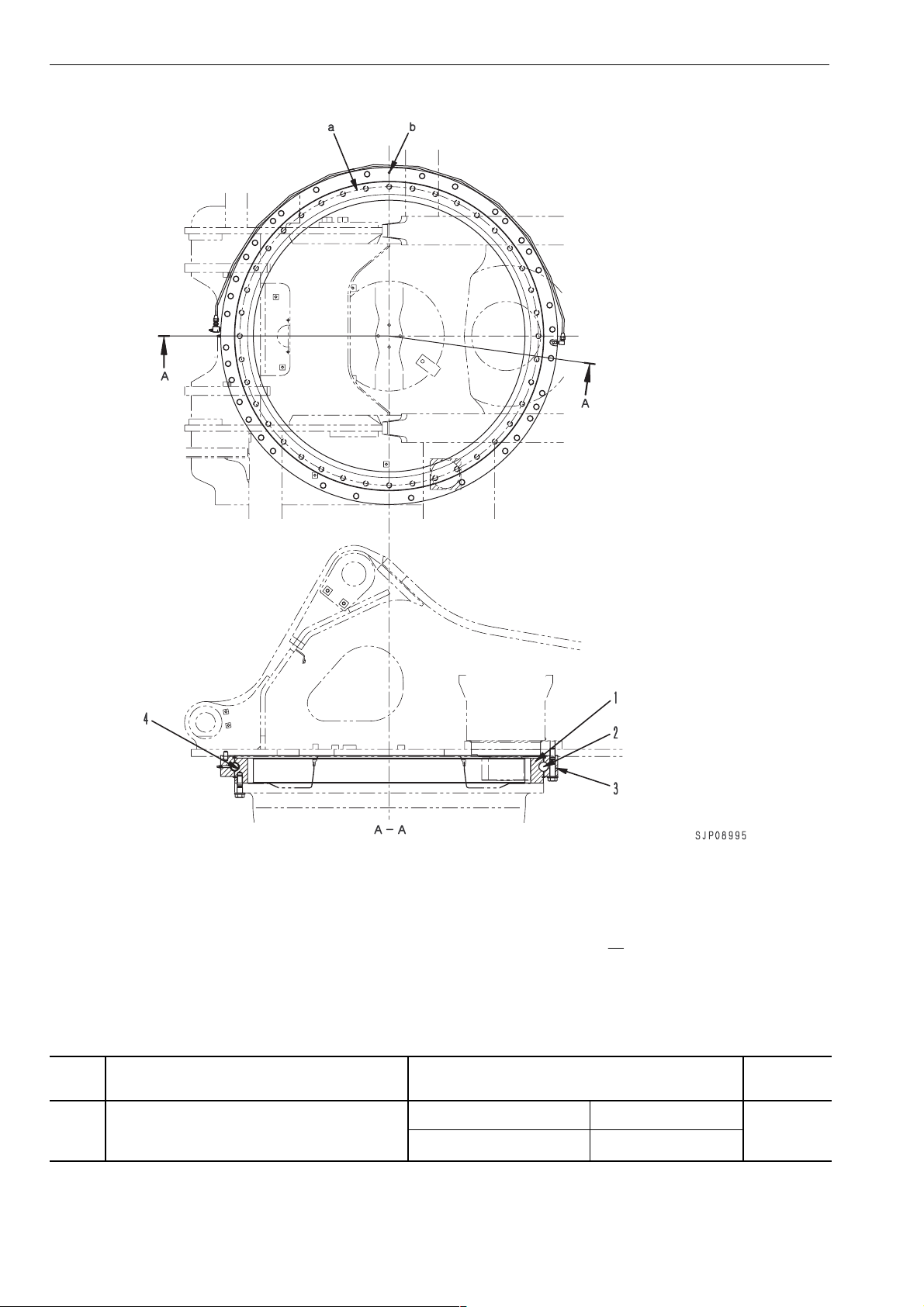

STRUCTURE, FUNCTION, & MAINTENANCE STANDARD SWING CIRCLE

SWING CIRCLE

1. Swing circle inner race (No. of teeth: 90)

SPECIFICATIONS

2. Ball

3. Swing circle outer race

a. Inner race soft zone S position

Reduction ratio:

90

13

923.6

−=−

b. Outer race soft zone S position

Amount of grease: 33 l (G2-LI)

Unit: mm

No. Check item Criteria Remedy

Axial clearance of bearing

4

(when mounted on chassis)

Standard clearance Clearance limit

0.5

~ 1.6

3.2

Replace

10-10 PC340-7

12

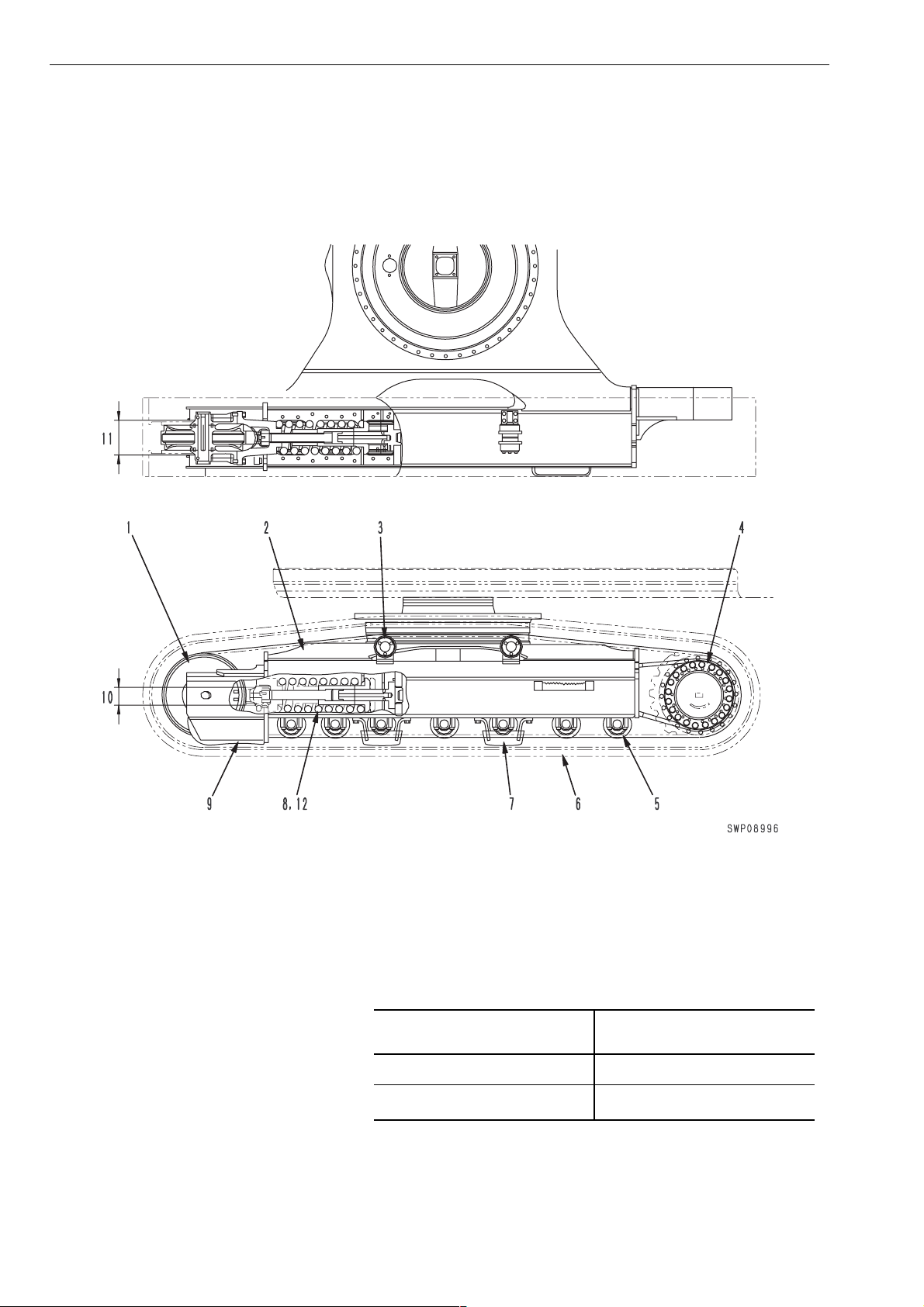

STRUCTURE, FUNCTION, & MAINTENANCE STANDARD TRACK FRAME • RECOIL SPRING

TRACK FRAME • RECOIL SPRING

SWP08996

1Idler

2 Track frame

3 Carrier roller

4 Final drive

5 Track roller

6 Track shoe

7 Center guard

8 Recoil spring

9Front guard

• The dimensions and the number of track rollers depend on the

model, but the basic structure is not different.

• Number of track rollers

Model Q’ty

PC340LC-7 8

PC340NLC-7 8

10-12 PC340-7

STRUCTURE, FUNCTION, & MAINTENANCE STANDARD TRACK FRAME • RECOIL SPRING

12

Standard shoe

Model

Item

PC340LC-7 PC340NLC-7

Shoe width 700 mm 600 mm

Link pitch 216 mm 216 mm

No. on track (one side) 48 (pieces) 48 (pieces)

Unit: mm

No. Check item Criteria Remedy

Standard size Tolerance Repair limit

10 Vertical width of idler guide

11 Horizontal width of idler guide

Track frame 123

+2

-1

Idler support 120 ± 0.5 118

Track frame 266

+3

-1

127

Rebuild or

replace

271

Idler support 261 — 259

Standard size Repair limit

12 Recoil spring

Free length

x O.D.

795 X 241 648

Installation

length

Installation

load

173.3 kN

(17,680 kg)

Free length

—

Installation

load

138.56 kN

(14,140 kg)

Replace

PC340-7 10-13

STRUCTURE, FUNCTION, & MAINTENANCE STANDARD IDLER

12

IDLER

10-14 PC340-7

STRUCTURE, FUNCTION, & MAINTENANCE STANDARD IDLER

12

Unit: mm

No. Check item Criteria Remedy

1 Outside diameter of protruding

2 Outside diameter of tread 590 578

3 Width of protrusion 102 —

4 Total width 190 —

5 Width of tread 44 50

6 Clearance between shaft and bushing

Interference between idler and bush-

7

ing

Standard size Repair limit

635 —

Standard

size

80

Standard

size

87.6

Tolerance

Shaft Hole

-0.225

-0.325

Shaft Hole

+0.087

+0.037

+0.130

-0.024

Tolerance

-0.027

-0.079

Standard clear-

ance

~ 0.455

0.201

Standard inter-

ference

~ 0.166

0.064

Rebuild or

replace

Clearance limit

1.5

Replace

bushing

Interference

limit

—

PC340-7 10-15

STRUCTURE, FUNCTION, & MAINTENANCE STANDARD CARRIER ROLLER

12

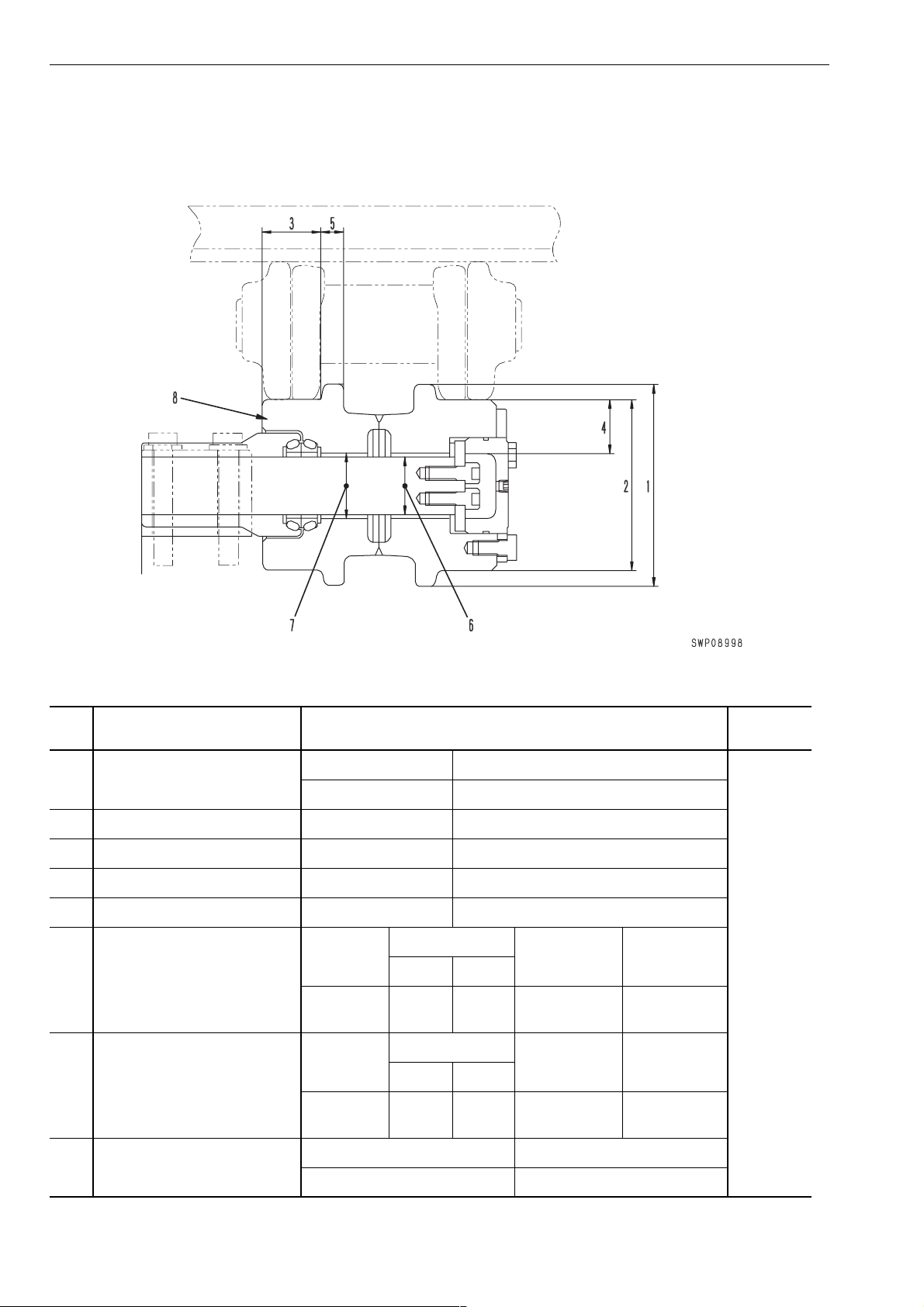

CARRIER ROLLER

SWP08998

Unit: mm

No. Check item Criteria Remedy

1 Outside diameter of flange

2 Outside diameter of tread 148 106

3 Width of tread 50.3 —

4 Thickness of tread 32 29.5

5 Width of flange 19 —

Interference between shaft and

6

bushing

Interference between roller and

7

bushing

Standard size Repair limit

175 —

Standard

size

50

Standard

size

57

Tolerance

Shaft Hole

-0.250

-0.270

Shaft Hole

+0.117

+0.087 0-0.040

+0.099

-0.032

Tolerance

Standard inter-

ference

~ 0.369

0.218

Standard inter-

ference

0.087

~ 0.158

Clearance limit

Replace

—

Interference

limit

—

8 Axial clearance of roller

Standard clearance Clearance limit

0.60 - 0.80 —

10-16 PC340-7

Loading...

Loading...