Kolpak WALK-INS Brochure

WALK-INS

• Walk-in Coolers & Freezers

• Refrigerated Systems

• Refrigerated Warehouses

Specified #1 in Cold Food Storage

Exactly What You Need To Specify “A” Quality Walk-in Cooler/Freezer

Choose Kolpak modular walk-ins.

Full size or nominal size walk-in coolers, freezers, or dual-temp units can easily be assembled in any size from

Kolpak’s modular panels. To enlarge or relocate, disassembly is equally as easy. The modular concept makes

Kolpak walk-ins, quick and simple to install. Precision formed panels with urethane insulation are lightweight and

easy to handle. All sections have tongue and groove joints for a better, more secure fit. On the average, two men

can assemble an 8' x 10' walk-in cooler or freezer in three hours.

General Specifications include:

I Panel Sizes

Nominal size panels standard, full size panels

on special request.

I Urethane insulation throughout

4" thick urethane offers many advantages

over conventional-t ype materials: mor e than

twice the insulating value of fiberglass; strong

an d rig id, won ’ t sag or ma t ; imp ervio us to

moisture; vermin proof and odor proof.

CONVERSION CHART

Nominal

4'-0"

5'-0"

6'-0"

7'-0"

8'-0"

9'-0"

10'-0"

11'-0"

12'-0"

13'-0"

14'-0"

15'-0"

16'-0"

17'-0"

18'-0"

19'-0"

20'-0"

21'-0"

22'-0"

23'-0"

24'-0"

25'-0"

26'-0"

27'-0"

28'-0"

29'-0"

30'-0"

Actual

3'-11"

4'-101/2"

5'-10"

6'-91/2"

7'-9"

8'-81/2"

9'-8"

10'-71/2"

11'-7"

12'-61/2"

13'-6"

14'-51/2"

15'-5"

16'-41/2"

17'-4"

18'-31/2"

19'-3"

20'-21/2"

21'-2"

22'-11/2"

23'-1"

24'-1/2"

25'-0"

25'-111/2"

26'-11"

27'-101/2"

28'-10"

1

Because of its superior insulating properties,

ur e t hane in s u lation s i g nific a n tly red u c es

operating costs. R-values and K-factors (thermal

conductivity) of Kolpak panels are as follows:

4-inch 5-inch 6-inch

R Value 29 36 43

K Factor .138 .138 .138

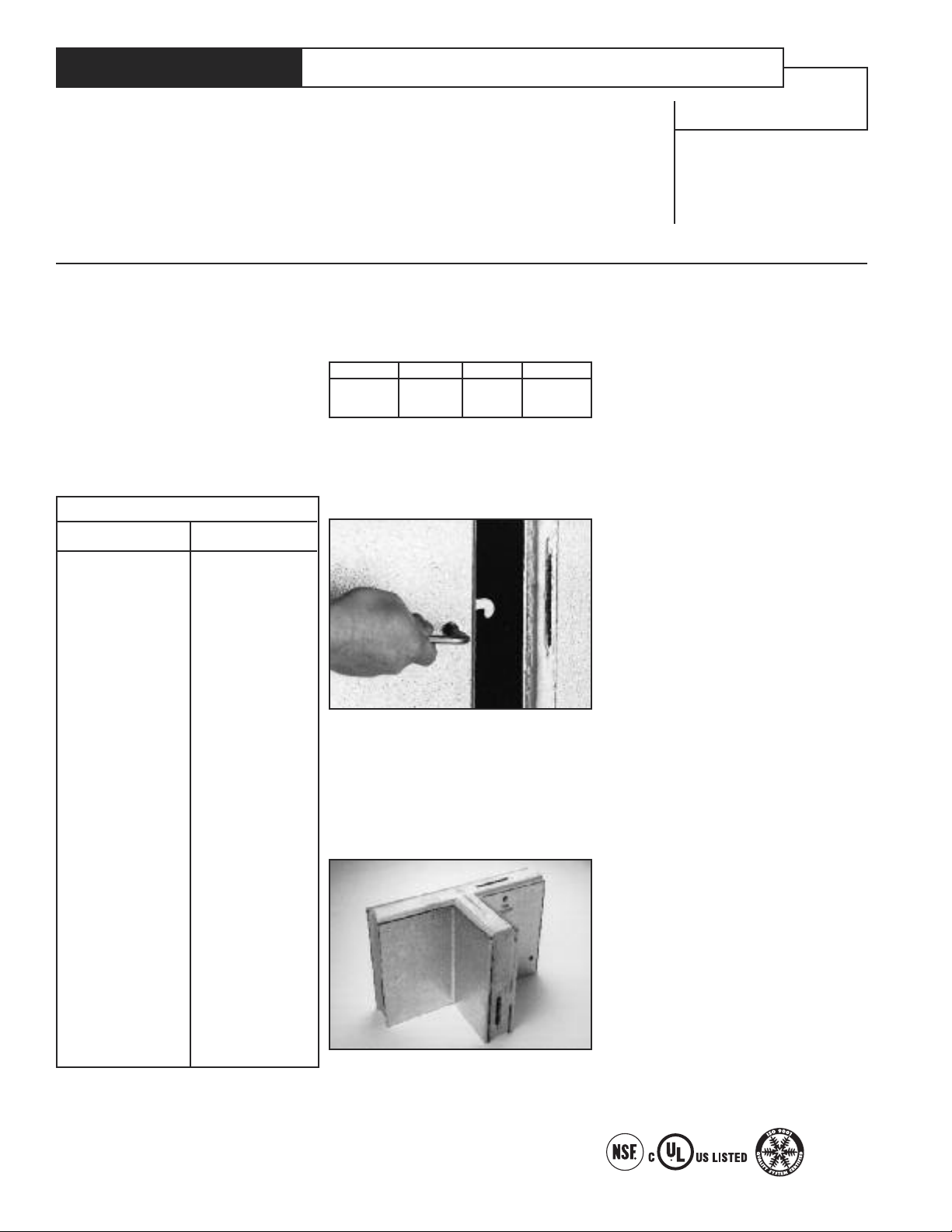

I Posi-loc assembly

Permanently foamed-in-place for fast perfect

alignment of sections. Access holes are covered

by snap-on plug buttons for a neater appearance

and greater sanitation.

I Gasketed tongue and groove

Tongue sides of all panels are provided with

double PVC gaskets foamed-in-place to eliminate

costly, time-consuming caulking between panels,

and to assure a tight secure fit. Gaskets won’t

pull out or “snake” during assembly, no butt

joints are used.

I Fully coved “T” panels

A co m plete br e ak in me t al cont i n uity

eliminates frost conduction between compartments.

No need for extra breaker strips and heater wires

which can increase operation costs.

I Coved corners

Floor edges are 3/8" radius coved for easier

cleaning, and greater sanitation. No dirt-catching

seams or sharp angled corners!

I Door Jambs

Do o r jambs an d door plug p e r imete r

fa b r icated u s ing pate n t ed FRP ( Fiber g l ass

reinforced plastic). Dramatically reduces thermal

conductivity on all doors up to 42" wide.

I Choice of finishes

Standard metal finish for wall skins is 26

gauge stucco embossed galvanized steel for

maximum value.

Other available wall finishes are:

• 26 gauge embossed galvalume

• Galvanized pre-painted white,

beige, or brown

• .032 embossed aluminum

or pre-painted white

• 22 gauge or 20 gauge stainless steel

Kolpak striv es to fulfi l l all y our wa lk-i n

needs; requests for finishes not listed here are

not a problem.

Standard floor metal finish is .100 smooth

aluminum. Other available floor finishes are

.100 aluminum treadplate, 16 gauge stainless

steel, or 16 gauge galvanized steel (for tile and

grout applic ations). Floo rless op tions us ing

metal or vinyl screeds are also available.

Code approvals and

industry standards

Ko lpak m e ets t h em, resul t i ng i n lower

insurance rates and no construction delays. Here

are just a few:

• National Sanitation Foundation

• Underwriter’s Laboratories

• Factory Mutual

• 2009 Federal Energy Standards

Flame spread 25 rating

Classified according to ASTME-84 (UL 723),

flame spread rating of 25 or less and certified

with UL label.

ISO 9001:2000

Quality System

Certified

Size and Capacity Nominal Size (NS) Walk-ins

O.D 7'-6" HEIGHT 8'-6" HEIGHT O.D. 7'-6" HEIGHT 8'-6" HEIGHT

ACTUAL AREA CU. FT. CU. FT. ACTUAL AREA CU. FT. CU. FT.

FLOOR SIZE SQ. FT. CAPACITY CAPACITY FLOOR SIZE SQ. FT. CAPACITY CAPACITY

'11" x 5'10" 23 114 130 9'8" x 21'2" 205 1261 1445

3

5'10" x 5'10" 34 182 209 10'7

5'10" x 7'9" 45 250 287 10'7

5'10" x 9'8" 56 318 364 10'7

5'10" x 11'7" 68 385 442 10'7

5'10" x 13'6" 79 453 520 10'7

5'10" x 15'5" 91 531 609 10'7

1

6'9

/2" x 7'9" 53 296 340 10'71/2" x 22'11/2" 235 1460 1674

1

6'9

/2" x 9'8" 67 377 432 10'71/2" x 24'1/2" 266 1655 1824

1

'9

x 11'7" 79 457 524 11'7

6

/2"

1

6'9

/2" x 13'6" 92 528 616 11'7" x 12'61/2" 168 1029 1179

1

6'9

/2" x 15'5" 105 621 708 11'7" x 14'51/2" 190 1172 1343

1

6'9

/2" x 17'4" 117 714 800 11'7" x 18'31/2" 212 1315 1507

7'9" x 8'8

7'9" x 10'7

7'9" x 12'6

7'9" x 14'5

7'9" x 16'4

7'9" x 18'3

7'9" x 20'2

7'9" x 22'1

8'8

8'8

8'8

8'8

8'8

1

/2" 67 390 448 11'7" x 20'21/2" 234 1458 1671

1

/2" 83 482 553 11'7" x 22'11/2" 256 1600 1835

1

/2" 97 575 660 11'7" x 24'1/2" 278 1742 1999

1

/2" 113 668 765 12'61/2" x 14'51/2" 182 1119 1283

1

/2" 127 761 872 12'61/2" x 16'41/2" 206 1275 1461

1

/2" 142 853 978 12'61/2" x 18'31/2" 230 1430 1639

1

/2" 156 946 1084 12'61/2" x 20'21/2" 254 1586 1818

1

/2" 172 1039 1191 12'61/2" x 22'11/2" 278 1741 1996

1

/2" x 8'81/2" 76 442 508 12'61/2" x 24'1/2" 302 1897 2174

1

/2" x 10'71/2" 93 548 627 12'61/2" x25'111/2" 328 2052 2353

1

/2" x 12'61/2" 110 653 748 13'6" x 16'41/2" 221 1378 1579

1

/2" x 14'51/2" 126 757 868 13'6 x 18'31/2" 247 1546 1772

1

/2" x 16'41/2" 143 863 990 13'6" x 20'21/2" 274 1714 1964

9'8" x 9'8" 93 554 635 13'6" x 22'1

9'8" x 11'7" 112 671 770 13'6" x 24

9'8" x 13'6" 131 789 905 13'6" x 25'11

9'8" x 15'5" 149 907 1040 13'6" x 27'10

9'8" x 17'4" 160 1025 1175 13'6" x 28'10" 390 2470 2832

9'8" x 19'3" 186 1143 1310

FLOOR GROSS GROSS FLOOR GROSS INTERIOR

1

/2" x 10'71/2" 107 678 777

1

/2" x 12'61/2" 130 808 927

1

/2" x 14'51/2" 154 938 1076

1

/2" x 16'41/2" 174 1069 1226

1

/2" x 18'31/2" 195 1199 1375

1

/2" x 20'21/2" 216 1330 1525

1

/2"

1

x 12'6

/2"

1

/2" 297 1882 2157

1

/2" 324 2050 2350

1

/2" 351 2218 2543

1

/2" 376 2386 2735

145 886 1016

Architectural Specifications Nominal Size Walk-ins

1. General

Walk-in coolers or freezers provided under

th i s port i on of t he spe c ifica t ions sh all be

pr e f abrica t e d, of mo d u lar desig n a n d

construction. They shall be designed to allow

convenient and accurate field assembly and

future enlargement by the addition of panels.

2. Panel fabrication

Standard wall, ceiling, and floor panels shall

be nomi nal 2' and 4' in width and shall be

interchangeable with like panels. Standard

heights of walk-ins shall be_____. Co rner

panels shall be 90° angles with actual 12"

exterior horizontal measurements. Nominal 1'

and 3' panels shall be used if required to meet

jobsite conditions.

Av aila ble heigh ts wi th fl oor or 4" vinyl

screeds: 7'6" 8'6", 9'6", 10'6", 11'6", 12'6".

Available heights without floor, with 1

vinyl screeds: 7'4", 8'4", 9'4", 10'4", 11'4",

12'4".

Panels shall consist of foam ed-in-pl ace

urethane insulation (see paragraph 4),

sandwiched between interior and exterior metal

“skin” (see paragraph 5) which has been dieformed and gauged for uniformity in size.

Edges of panels shall be foamed-in-place

to n g ue and groo v e w i th locki n g f a cilit i e s

foamed-in-place at time of fabrica tion (see

paragraph 6).

3. Floor construction (select one)

a. Floor Panels: Panels shall be fabricated

similar to other pan els, desi gned to readily

withstand uniformly distributed loads of 700 lbs.

pe r s quare foot . Floor ( w ill; will n o t) b e

recessed. Floor (will; will not) be covered by the

tile and grout, or concrete wearing floor.

b. Floorless: Provide 1

1

/2" high or 4" high

Temp-Guard vinyl screeds. Screeds must be

coved on both sides and sit flat on the floor.

1

Screeds shall be nailed or lag screwed to floor

/2"

through center. No exposed fasteners shall be

allowed. Wall panels lock to screeds on 2'0"

centers.

COMPONENT SIZE

Corners 12" x 12"

12" x 61/4"

Tee Walls 23" x 12"

Walls 11

1

/2"

23"

341/2"

46"

Door Section 46"

With 34" Door 57

1

/2"

69"

4. Insulation

Each panel shall be filled with rigid “FoamedIn-Place” urethane having a thermal conductivity

(K fact or) of 0. 138 BTU/ hr./ ft

2

pe r deg ree s

Fahrenheit/inch and an overall coefficient of heat

tran sfer (U factor) of not more than 0. 034.

“R” factor shall be 29 or greater. Insulation shall

ha ve a 97% clo sed cel l st ructure. Ov era ll

thickness shall be 4". Fire hazard classification

according to ASTME-84 (UL 723) is a flame

spread rating of 25* of less and certified with UL

label. Factory Mutual approved and listed.

NOTE: 5" and 6" thick panels available.

5. Metal finishes

Panel skins, standard models, standard and

optional metal finishes are as follows: (Specify

one or a combination of the following.)

*This rating is not intended to reflect hazards presented by this

or any other material under actual fire conditions.

2

Loading...

Loading...