Refrigeration Systems

Installation, Use & Care Manual

This manual is updated as new information and models are released.

Visit our website for the latest manual. www.manitowocfsg.com

Specified #1 Among Walk-ins

Part Number 11325 03/08

Safety Notices

! Warning

!

Caution

Important

!

Caution

Important

! Warning

As you work on Manitowoc equipment, be sure to pay

close attention to the safety notices in this manual.

Disregarding the notices may lead to serious injury and/

or damage to the equipment.

Throughout this manual, you will see the following types

of safety notices:

Text in a Warning box alerts you to a potential

personal injury situation. Be sure to read the

Warning statement before proceeding, and work

carefully.

Text in a Caution box alerts you to a situation in

which you could damage the equipment. Be sure to

read the Caution statement before proc eeding, and

work carefully.

Procedural Notices

As you work on Manitowoc equipment, be sure to read

the procedural notices in this manual. These notices

supply helpful information which may assist you as you

work.

Throughout this manual, you will see the following types

of procedural notices:

Read These Before Proceeding:

Proper installation, care and maintenance are

essential for maximum performance and troublefree operation of your Manitow oc equipment. Read

and understand this manual. It contains valuable

care and maintenance information. If you encounter

problems not covered by this manual, do not

proceed, contact Manitowoc Foodservice Group.

We will be happy to provide assistance.

Routine adjustments and maintenance procedures

outlined in this manual are not covered by the

warranty.

PERSONAL INJURY POTENTIAL

Do not operate equipment that has been misused,

abused, neglected, damaged, or altered/modified

from that of original manufactured specifications.

NOTE: SAVE THESE INSTRUCTIONS.

Text in an Important box provides you with

information that may help you perform a procedure

more efficiently. Disregarding this information will

not cause damage or injury, but it may slow you

down as you work.

NOTE: Text set off as a Note provides you with simple,

but useful, extra information about th e pr oce dur e yo u

are performing.

We reserve the right to make product improvements at any time.

Specifications and design are subject to change without notice.

Section 1

General Information

Model Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Serial Number Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Section 2

Installation Instructions

Pre-installation Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Location of Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Refrigerant Piping Hanger Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Installing Model PR Field-charged Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Installing Model PCL Pre-charged Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Evaporator Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Condenser Unit Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Drain Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Panel Penetrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Charging Refrigeration System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Compressor Mounts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Mounting Defrost Time Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Post Installation Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Table of Contents

Condensing Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Multiple Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Walls or Obstructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Field Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Multiple Evaporator Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Oil Traps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Walk-in Coolers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Walk-in Freezers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Polyol Ester (POE) Lubricants (Used with HFC Refrigerants) . . . . . . . . . . 2-6

Refrigerant Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Leak Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Part Number 11325 03/08 i

Section 3

Operation

Section 4

Maintenance

Table of Contents (continued)

Component Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Start-up Proc edure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Sequence of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Defrost Time Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Operational Checks and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Compressor Superheat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Evaporator Superheat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Temperature Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Evaporator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Defrost Time Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Refrigerant Evacuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Cleaning Condensing Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Maintenance Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Section 5

Before Calling for Service

Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Equipment/Service Data Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

System Reference Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Evaporator Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Compressor Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

ii Part Number 11325 03/08

Section 1

Serial Number

KS1005

General Information

Model Numbers

This manual covers the following models:

Pre-charged Lines Field-charged Lines

PCL PR

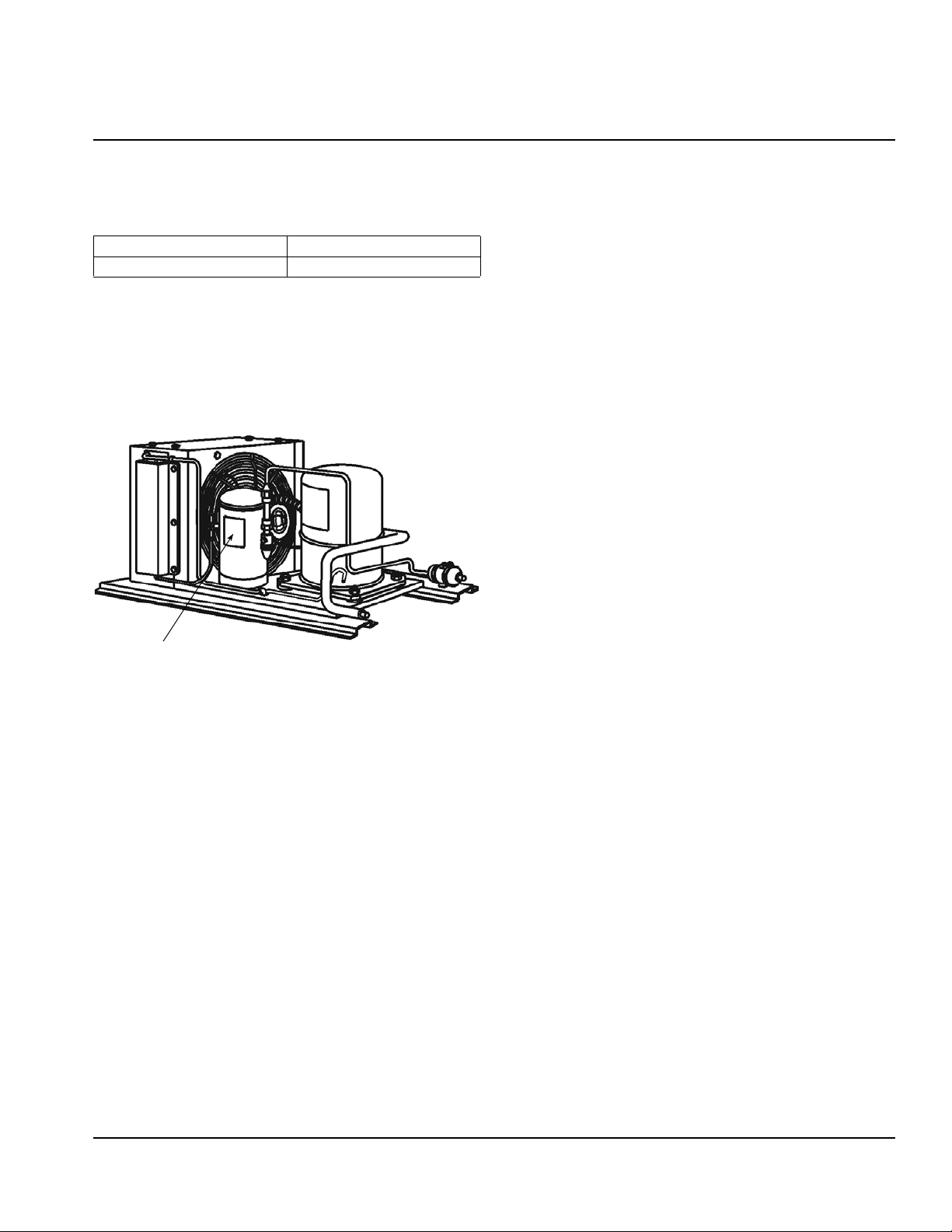

Serial Number Location

This number is required when requesting information

from your local distributor. The serial number is listed on

the SERIAL NUMBER DECAL affixed to the condensing

unit assembly.

Serial Number Location

Part Number 11325 03/08 1-1

General Information Section 1

THIS PAGE INTENTIONALLY LEFT BLANK

1-2

Part Number 11325 03/08

Section 2

!

Caution

!

Caution

Installation Instructions

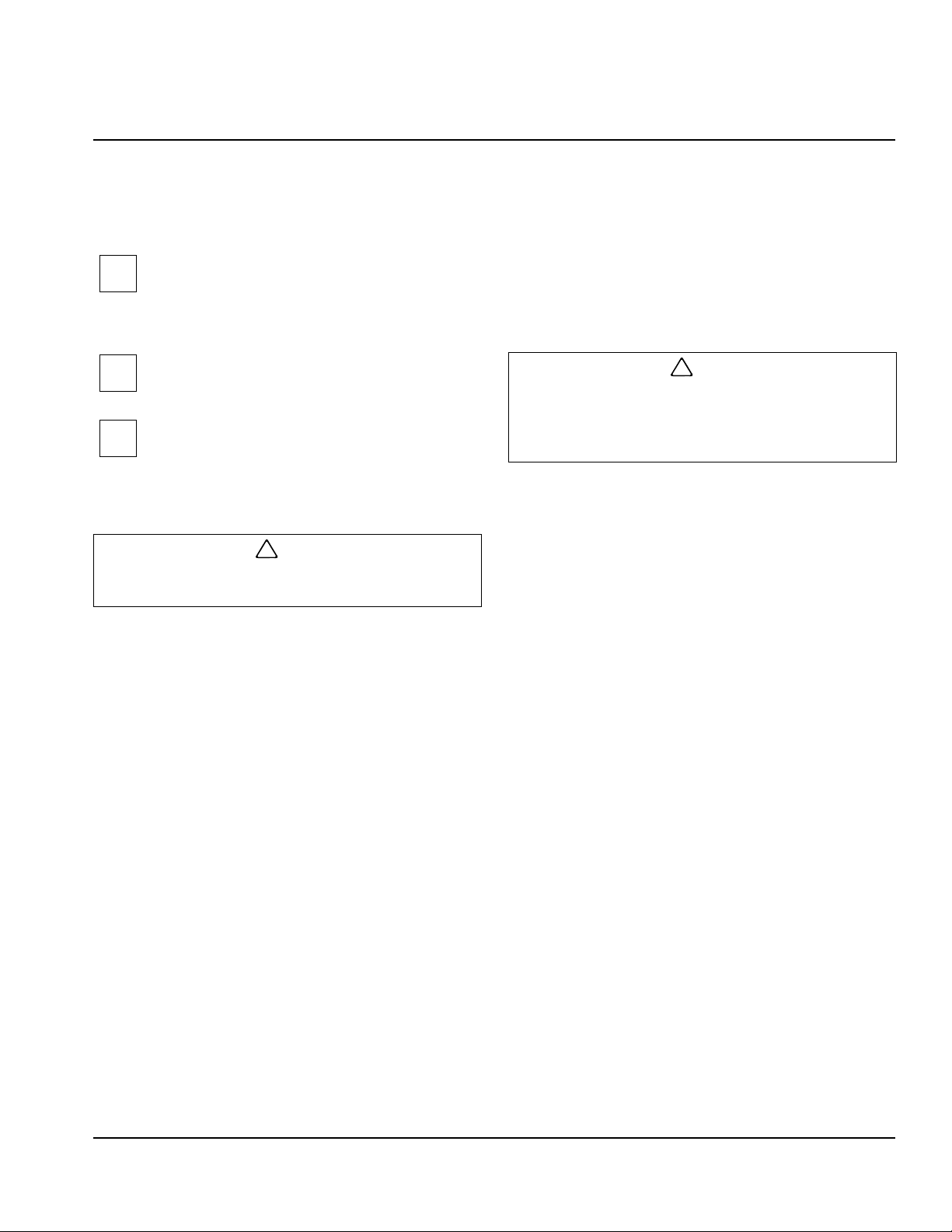

Pre-installation Checklist

Follow these guidelines during the installation process:

Check the selected installation location to

ensure that racks, braces, floor, foundations,

etc., are adequate to support the weight of the

unit.

Verify that system piping is in accordance with

good refrigeration practices.

When brazing refrigerant lines, pass an inert

gas through the line at low pressure to prevent

scaling and oxidation of the tubing. Nitrogen is

recommended.

Do not lift the condensing unit assembly by the

refrigerant tubing. Damage may result.

Location of Equipment

CONDENSING UNIT

For optimum air-cooled equipment performance, these

are the most critical clearance requirements:

• a sufficient supply of ambient air to the condenser

• adequate space for removal of the heated

discharged air from the condensing unit area

If either clearance requirement is ignored, higher

system head pressure will result, causing poor

system operation, shorter equipment life and an

increased risk of equipment failure.

Position the condensing unit:

• in a clean, dry, level area

• away from steam or hot air exhaust sources

• away from corrosive atmospheres

• away from noise-sensitive areas

• with adequate support to minimize undesirable

vibration and noise transmission

Part Number 11325 03/08 2-1

Installation Instructions Section 2

!

Caution

MINIMUM

DISTANCE

MINIMUM

DISTANCE

MINIMUM

DISTANCE

AIR FLOW AIR FLOW

BUILDING WALL

(VIEWED FROM ABOVE)

KS1002

AIR FLOW

MINIMUM

DISTANCE

BUILDING

WALL

MOUNTING SURFACE

KS1003

!

Caution

Important

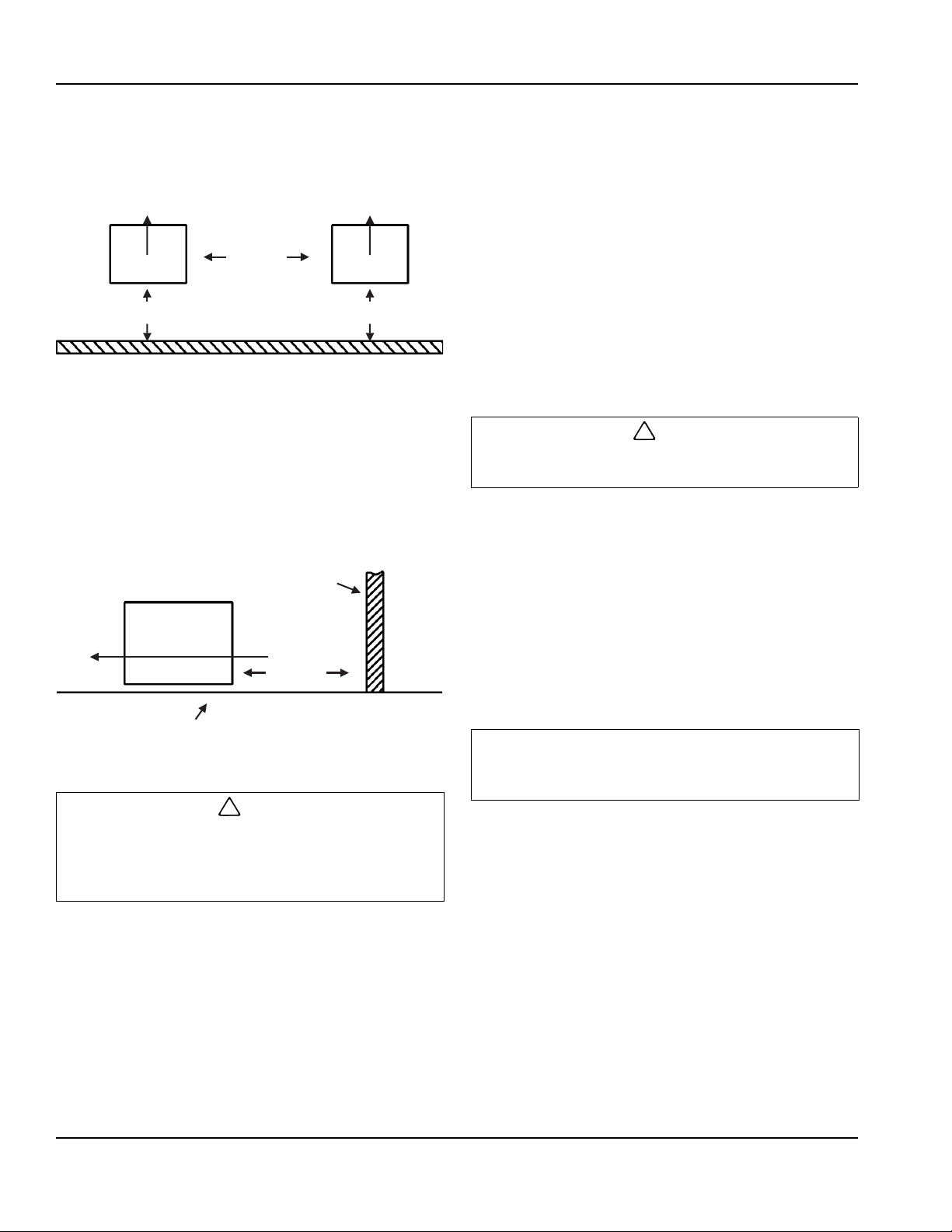

MULTIPLE UNITS

Separate side-by-side units with a minimum distance

equal to the width of the largest unit.

Multiple Units with Horizontal Airflow

WALLS OR OBSTRUCTIONS

To avoid re-circulation of condenser air, an d to allow for

proper airflow and access, all sides of the unit should be

positioned a distance equal to the total width of the

condensing unit away from any wall or obstruction.

Increase this distance where possible to increase airflow

and access to the unit.

Electrical

FIELD WIRING

All electrical connections and routing must conform to

local and national codes. Do not modify the factoryinstalled wiring without written factory approval.

The field wiring must enter through the knockou ts

provided. All field wiring must be properly connected

according to the wiring diagram.

NOTE: The wiring diagram for each unit is located on the

inside of the electrical box within the unit.

Refer to the nameplate rating label on the unit to

determine the correct electrical power supply. Consult

the wiring diagram for proper electrical connections.

Use copper conductors only. The unit must be

grounded.

If a remote defrost timer is used, the timer must be

located outside the refrigerated space.

The power supply to the unit must meet the following

conditions:

• Single-phase must be within + 10% or – 5% of

nameplate ratings.

Space Requirements Near Walls and Obstructions

Do not position multiple units in a way that would

permit discharge air from one unit to enter the air

inlet of another unit. This could cause system

overheating and equipment failure.

• Three-phase voltages must be ± 10% of nameplate

ratings.

• Phase imbalance cannot exceed 2%.

Connections can become loose during shipment.

Check all wiring connections before operation.

MULTIPLE EVAPORATOR SYSTEMS

To assure complete defrost with multiple evaporator

systems, wire the defrost termination controls in series.

2-2

Part Number 11325 03/08

Section 2 Installation Instructions

!

Caution

Refrigerant Piping Hanger Requirements

Follow these hanger requirements:

• All tubing must be supported in at least two locations

(near each end of the tubing run).

• Long runs will require additional support. As a g uide,

support 3/8" to 7/8" pipe every 5 feet; 1-1/8" to 1-3/8"

every 7 feet; and 1-5/8" to 2-1/8" every 9 to 10 feet.

• Do not leave a corner unsupported when changing

directions in a run of tubing. Place supports a

maximum of 2 feet in each direction from the corner

of the unit.

• Piping attached to a vibrating object (such as a

compressor or compressor base) must be suppor ted

in a manner that will not restrict the movement of the

vibrating object. Rigid mounting will fatigue the

copper tubing.

• Do not use short radius elbows. Short radius elbows

have points of excessive stress concentration and

are subject to breakage at these points.

• Once the equipment is in operation, thoroughly

inspect all piping. Add supports as needed.

Installing Model PR Field-charged Lines

Although the condensing unit was thoroughly cleaned

and dehydrated at the factory, take care to prevent

contamination when installing the piping.

Install all refrigeration system components and piping in

accordance with applicable local and national codes.

Follow industry refrigeration guidelines to maintain

proper operation of the system.

NOTE: The interconnecting pipe size is not necessarily

the same size as the stub-out on the condensing unit or

the evaporator.

INSTALLATION GUIDELINES

Follow these guidelines during the installation process:

• Purge the dry air charge from the unit by opening the

liquid line service valve or by removing the liquid line

outlet fitting (as applicable).

• The maximum air exposure for dehydrated

condensing units or filter-driers is 15 minutes. (See

page 2-6 for more information.)

• Use only refrigeration-grade copper tubing that is

properly sealed against contamination.

• Suction lines must slope 1/4" per 10 feet toward the

compressor.

• Install P-type oil traps at the base of each suction

riser of four feet or more to ensure p roper oil return to

the compressor.

• When brazing refrigerant lines, pass an inert gas

through the line at low pressure to prevent scaling

and oxidation of the tubing. Nitrogen is

recommended. Use only silver solder alloys when

brazing.

• To prevent internal contamination, minimize the use

of flux. Flux only the male portion of the connection.

Remove excess flux after brazing.

OIL TRAPS

Install a suction line trap at the evaporator outlet if the

suction line rises to a point higher than the connection

on the evaporator.

To ensure proper oil return , position a suction tr ap at the

base of all suction risers of four feet or more. The

suction trap must be the same size as the suction line.

Additional traps are necessary for long vertical risers.

Add a trap for each length of pipe (approximately

20 feet) to ensure proper oil return.

Refrigerant lines exposed to high ambient

conditions must be insulated to reduce heat pick-up.

This will prevent the formation of flash gas in the

liquid lines.

Part Number 11325 03/08 2-3

Installation Instructions Section 2

!

Caution

DIAPHRAGMS

CUTTER

KS1006

KS1008

Installing Model PCL Pre-charged Lines

INSTALLATION GUIDELINES

Follow these installation guidelines:

• Route the suction and liquid lines between the

condensing unit and the evaporator. Install lines in

accordance with industry refrigeration guidelines.

• Remove the dust caps from the quick connect fittings

and verify that the O-rings are intact.

Quick Connect Fittings

• Wipe the coupling seals and threaded surfaces with

a clean cloth to prevent contamination.

• Lubricate the threads and O-rings on the quick

connect fitting with Polyol Ester oil.

• Thread the coupling halves together by hand to

ensure proper thread mating.

• Tighten with a wrench until the coupling bodies

“bottom” or until there is definite resistance. Tighten

an additional 1/4 turn to ensure proper

brass-to-brass seating.

• After connection, check the quick connect fittings for

refrigerant leaks. If a leak is found, tighten the fitting

until the leak is stopped.

Evaporator Mounting

1. Use the evaporator for a template to locate and drill

evaporator mounting holes (1/2" diameter).

2. Place the four nylon bolts with washers through the

1/2" diameter holes as shown. Note the location of

the 1-5/8" diameter washers.

3. Place the evaporator below the installation location

and lift it straight upward toward the ceiling of the

walk-in.

4. Continue lifting the evaporator toward the ceiling

until the four nylon bolts extend through the

mounting brackets.

5. Install washers and secure in place with nuts.

NOTE: For additional information, refer to the installation

manual supplied with the evaporator.

NYLON BOLT

1” O.D. WASHER

NUT

NOTE: FASTENERS ARE

SUPPLIED IN THE

MOUNTING KIT

1” O.D. WASHER

1-5/8” O.D. WASHER

CEILING PANEL

EVAPORATOR

MOUNTING

BRACKET

EVAPORATOR

Evaporator Mounting Detail

Condenser Unit Mounting

Refrigerant quick connect fittings will not reseal.

Remove all refrigerant before attempting to

disconnect the fittings. Once disconnected, the

coupling cannot be re-used.

2-4

1. Position the condensing unit asse mb ly on the walkin ceiling.

2. Use a sharp punch to pierce four 1/8" diameter

holes, using the condensing unit mounting holes as

a template.

3. Perform operational start-up. See page 3-2.

Part Number 11325 03/08

Section 2 Installation Instructions

KS1010Open Drain

!

Caution

Drain Lines

WALK-IN COOLERS

Follow these guidelines:

• Provide a minimum 4" per one-foot pitch for proper

drainage.

• A copper drain is recommended.

• Locate the drain line P-trap outside of the

refrigerated space.

• Wrap any traps exposed to low ambient

temperatures with a drain line heater.

• Provide a heater with 20 watts of heat per foot of

drain line.

WALK-IN FREEZERS

Follow these guidelines:

• Provide a minimum 4" per one-foot pitch for proper

drainage.

• A copper drain is recommended.

• Insulate the drain line and seal where it passes

through the wall.

• Locate the drain line P-trap outside the refrigerated

space.

• Wrap any traps exposed to low ambient

temperatures with a drain line heater.

• Provide a heater with 20 watts of heat per foot of

drain line at 0°F, 30 watts per foot at –20°F.

Panel Penetrations

All walk-ins must have an air-tight seal. Check that

all penetrations (refrigeration, electrical, etc.),

through the walk-in panels are properly sealed.

Sealing discs are supplied on PCL models to seal

electrical and refrigerant line holes. PR models are not

supplied with sealing discs. The sealing discs are

approximately 3-1/2" in diameter and white in color. The

discs are packaged in the evaporator carton with the

evaporator mounting kit.

To apply a disc to the interior of the walk-in:

1. Slit the disc to the center.

2. Remove appropriate center sections to reach the

correct hole size.

3. Remove the backing and place the disc in position

around the conduit and copper tubing.

4. Seal the disc in place with sealant.

To apply a disc to the exterior of the walk-in:

1. Fill the hole with the fiberglass provided.

2. Remove the backing and place the disc in position.

3. Seal the disc in place with sealant.

Typical Drain Installation

Part Number 11325 03/08 2-5

Installation Instructions Section 2

!

Caution

!

Caution

!

Caution

!

Caution

Charging Refrigeration System

POLYOL ESTER (POE) LUBRICANTS

(USED

Polyol Ester (POE) lubricants quickly absorb moisture

from the ambient surroundings. POE lubricants absorb

moisture more rapidly and in greater quantit y tha n

conventional mineral oils. Because moisture levels

greater than 100 PPM will result in system corrosion and

component failure, it is essential that system exposure to

ambient conditions be kept to a minimum.

If a system is left open to the atmosphere for more than

15 minutes, the liquid line drier and compressor oil must

be replaced. Drain at least 95% of the oil from the

compressor suction port. Measure the amount of

removed oil, and replace it with exactly the same

amount of new POE oil.

Lubricants are packaged in specially designed, sealed

containers. Once opened, use the lubricant immediately.

Properly dispose of any unused lubricant.

WITH HFC REFRIGERANTS)

Do not leave a refrigeration system or compressor

using POE oil open to the atmosphere for more tha n

15 minutes. System corrosion and component

failure could result.

REFRIGERANT CHARGING

Follow these instructions:

1. Install a liquid line drier in the refrigerant supply line,

between the service gauge and the liquid service

port of the receiver. The liquid line drier will ensure

that all refrigerant is clean and dry.

2. Add liquid refrigerant directly into the receiver tank

when first charging a system that is in a vacuum.

3. Start the system and charge by weight and sight

glass indication.

4. If refrigerant must be added to the system through

the suction side of the compressor, ch arge in vapor

form only. When charging with R-404A, the

refrigerant must exit the charging cylinder in the

liquid phase. Connect a sight glass between the

charging hose and the compressor suction service

valve to be sure the refrigerant entering the

compressor is in the vapor state.

Charge with liquid through the high side only.

Introducing liquid refrigerant into the motorcompressor can damage the valves, rods, pistons,

etc.

When charging the system to a clear sight glass (as an

indication of proper charge):

Do not leave the system or the compressor open or

unattended.

Mobil EAL™ ARCTIC 22 CC is the preferred Polyol Ester

lubricant because of its particular additives. ICI

Emkarate RL 32S is an acceptable alternative when the

Mobil is not available. These POE lubricants must be

used with HFC refrigerants.

• Verify the co nde nsing temperatu re is ab ove 105°F. If

not, reduce the effective condenser face area to raise

the discharge pressure above the eq uiv ale nt 105 ° F.

Proceed to charge to clear the sight glass.

• Adjust the evaporator superheat at this time. (See

“Evaporator Superheat,” page 3-4.)

• Return to full condenser face area and allow the

system to balance.

Verify that there is not an overcharge of refrigerant.

An overcharge may permit liquid refrigerant to enter

the motor-compressor and damage the valves,

rods, pistons, etc.

2-6

Part Number 11325 03/08

Section 2 Installation Instructions

Important

MOUNTING NUT

(UPPER)

COMPRESSOR

MOUNTING FOOT

MOUNTING

STUD

RUBBER

SPACER

MOUNTING

SPRING

MOUNTING

BASE

MOUNTING NUT

(LOWER)

LOCKING

DEVICE

KS1013

LEAK TESTING

After making all of the connections, perform a leak test

on the entire system. This must include:

• the condensing unit

• the evaporator

• all connecting tubing

• all fittings

• all brazed joints

Leak check the entire system, by pressurizing to the low

side test pressure marked on the unit rating label. Rep air

all leaks found.

Because HFCs have a smaller molecule size, they tend

to leak more readily than CFCs. Consequently, it is

important to employ proper system evacuation and leak

detection procedures.

Compressor Mounts

On most semi-hermetic compressors with external

spring mounts, the grommets are factory-asse mbled and

it is only necessary to loosen the nuts.

If field assembly is required:

1. Remove the hold-down nuts.

2. Place the rubber grommets provided on the studs.

3. Remove the spring steel clips from the mounting

springs

4. Install the nuts. Allow approximately 1/16" between

the nut and the rubber grommet for the compressor

to float freely on the springs.

Hermetic compressor springs are mounted

internally in the compressor. Check the compressor

mounting bolts to make certain the securing nuts

have not loosened during shipment.

Properly Adjusted Compressor Mount

Part Number 11325 03/08 2-7

Installation Instructions Section 2

Mounting Defrost Time Clock

NOTE: Do not locate the timer in the refrigerated area.

Walk-in freezers are supplied with a tim er for controlling

the initiation and frequency of the defrost cycle.

The timer is shipped loose. Mount it in a convenient

location outside of the refrigerated area.

Post Installation Checklist

Check the following before energizing the equipment:

Verify that the suction, discharge and receiver

service valves are open.

Make sure all electrical and refrigerant

connections are tight.

Check/adjust the room thermostat for desired

temperature.

Check condenser fan motor(s) and evapora tor

fan motor(s) for proper operation.

Examine the fan motor mounts carefully for

tightness and proper alignment.

Verify that all refrigerant tubing is properly

insulated, routed and secured.

Defrost Time Clock

Check the defrost controls for initiation and termination

settings.

Set the fail safe at the length of defrost + 25%.

Example:

24 min. defrost + 25% (6 min.) = 30 min. fail safe

NOTE: If the defrost termination thermostat fails to

close, the fail safe setting on the timer will terminate the

defrost.

Verify that all wire routing is appropriate and

properly secured.

2-8

Part Number 11325 03/08

Component Identification

Compressor

Evaporator

Condenser Coil

Condensing

Unit

Ceiling Panel

Condenser Fan

and Motor

Section 3

Operation

Part Number 11325 03/08 3-1

Operation Section 3

!

Caution

!

Caution

Start-up Procedure

Do not start the compressor while it is in a vacuum.

Do not leave the unit unattended until the system

has reached normal operating conditio n s.

Operate the system for at least two hours at normal

conditions. If there is no indication of malfunction,

operate the system overnight on automatic controls.

Perform a thorough re-check of the entire system:

1. Check compressor discharge and suction

pressures. If not within system design limits,

determine the cause and take corrective action.

2. Check liquid line sight glass and expansion valve

operation. If there are indications that more

refrigerant is required, leak-test all connections and

system components and repair any leaks before

adding refrigerant.

3. For semi-hermetics, observe the oil level in the

compressor crankcase sight glass. Add oil as

necessary to bring the level to 3/4 of the sight glass

while idle, or 1/2 of the sight glass when running.

4. Check the thermostatic expansion valve(s) for the

proper superheat setting. Verify that the sensing

bulb is insulated, properly located and in positive

contact with the suction line.

NOTE: High superheat causes low refrigeration

capacity. Low superheat promotes liquid slugging and

compressor bearing washout.

5. Check the line voltage and amperage carefully at the

compressor terminals. Use suitable instruments.

- Voltage must be within + 10% or – 5% of the

voltage rating indicated on the condensing unit

nameplate. If high or low voltage is indicated,

notify the Power Company.

Example:

24 min. defrost + 25% (6 min.) = 30 min. fail safe

7. Check crankcase heater operation (if applicable).

Sequence of Operation

DEFROST TIME CLOCK

The timer starts the defrost cycle automatically at

predetermined times. A setting of two to four defrost

cycles per day is typical. For heavier frost loads,

additional cycles may be required.

When the defrost cycle begins:

1. Switch 2 to 4 opens in the time clock, breaking the

circuit to the room thermostat, liquid line solenoid,

and evaporator fan motors. This allows the

compressor to pump down and shut off.

Simultaneously, switch 1 to 3 closes in the timer,

energizing the defrost heaters.

2. The heaters increase the coil temperature above

32°F, melting the frost off the coil.

3. When the coil warms to 45-55°F, the defrost

termination thermostat closes and energizes the

switching solenoid in the timer. At this time, switch 1

to 3 in the timer opens, terminating the defrost

heaters. Simultaneously, switch 2 to 4 closes in the

time clock, energizing the temperature control

circuit.

4. Suction pressure rises, the low pressure control

closes, and the compressor starts.

5. The fan relay closes when the coil temperature

reaches 23-30°F. This energizes the fan motors.

6. The system operates in the refrigeration cycle until

another defrost cycle is initiated by the timer.

- If amperage draw is excessive, immediately

determine the cause and take corrective actio n.

- On three-phase motor compressors verify there is

a balanced load.

6. Check the defrost control initiation and termination

settings, and set the length of defrost period. Set the

fail safe at the length of the defrost + 25%.

3-2

Part Number 11325 03/08

Section 3 Operation

Important

!

Caution

!

Caution

CHECK THE TEMPERATURE AND

PRESSURE.

THEN, CONSULT A

PRESSURE/TEMPERATURE CHART.

P/T

CHART

Temperature

Pressure

TEMPERATURE, MINUS

PRESSURE CONVERTED

TO TEMPERATURE,

EQUALS SUPERHEAT

KS1011

Operational Checks and Adjustments

COMPRESSOR SUPERHEAT

The system must be balanced to obtain maximum

capacity and ensure trouble-free operation.

Suction superheat is the critical value that must be

checked. Check the suction superheat at the

compressor as follows:

1. Determine the suction pressure at the suction

service valve of the compressor. Use an accurate

gauge.

2. Determine the saturation temperature at the

observed suction pressure using refrigeration

pressure temperature tables.

3. Measure the temperature of the suction line (using

an accurate thermometer) 6-10 inches away from

the compressor.

4. Subtract the saturation temperature reading (Step 2)

from the measured temperature (Step 3). The

difference is the superheat of suction gas.

A high suction superheat will cause excessive

discharge temperatures, which cause a breakdown

of the oil. This causes piston ring w ear, and piston

and cylinder wall damage.

System capacity decreases as the suction superheat

increases. For maximum system capacity, keep the

suction superheat as low as practical. Copeland requires

a minimum compressor superheat of 20°F. Kolpak

recommends a compressor superheat between 25°F

and 40°F.

Adjust the expansion valve at the evaporator when

adjustments to the suction superheat are necessary.

Refer to “Evaporator Superheat” on the next page for

more information.

A low suction superheat can cause liquid to return

to the compressor. This will cause dilution of the oil

and eventual failure of the bearings, rings and

valves.

Determining Compressor Superheat

Part Number 11325 03/08 3-3

Operation Section 3

Important

CHECK THE TEMPERATURE AND PRESSURE.

THEN, CONSULT A PRESSURE/TEMPERATURE CHART.

P/T

CHART

TEMPERATURE, MINUS

PRESSURE CONVERTED TO

TEMPERATURE,

EQUALS SUPERHEAT

Temperature

Pressure

KS1012

!

Caution

EVAPORATOR SUPERHEAT

Check the evaporator superheat once the box has

reached the desired temperature. Generally, systems

with a design TD of 10°F should have a superheat value

of 6-10°F for maximum efficiency.

NOTE: A minimum compressor suction superheat of

20°F may override these recommend at ion s on syste m s

with short line runs.

The condensing unit must have the discharge

pressure above the equivalent 105°F condensing

pressure. See “Refrigerant Charging,” on page 2-6.

To determine the evaporator superheat:

1. Determine the suction pressure at the evaporator

outlet. Use an accurate gauge.

2. Determine the saturation temperature at the

observed suction pressure using the refrigeration

pressure temperature tables.

3. Measure the temperature of the suction line at the

expansion valve bulb with an accurate thermometer.

4. Subtract the saturation temperature reading (Step 2)

from the measured temperature (Step 3). The

difference is the superheat of suction gas.

TEMPERATURE CONTROL

A temperature control thermostat, a solenoid valve and a

low-pressure switch control all systems.

Set the temperature control to the desired temperature.

Use a thermometer to verify accuracy at the set point.

When the temperature reaches the set point, the

temperature control contacts will open. This

de-energizes the solenoid valve and stops the flow of

refrigerant.

The compressor continues to lower the pressure in the

evaporator. When the pressure reaches the set point of

the low pressure switch, the contacts will open, and the

compressor and condenser fan motor(s) cycle off.

EVAPORATOR

Frost build-up on the evaporator depends on:

• the temperature of the room

• the type of product being stored

• how often a new product is brought into th e room

• the percentage of time the door to the room is open

It may be necessary to periodically change the number

of defrost cycles per day.

DEFROST TIME CLOCK

Instructions for setting the timer are on the inside cover

of the time clock.

Determining Evaporator Superheat

REFRIGERANT EVACUATION

1. Connect a reliable vacuum pump to both the low and

high side valves with copper tubing or a high

vacuum hose (1/4" minimum inside diameter).

2. Evacuate the system to 250 microns or lower.

NOTE: Kolpak strongly recommends a vacuum decay

test to assure the system is dry and free of leaks.

Do not use the refrigeration compressor to evacuate

the system. This may cause damage to the

equipment.

3-4

Part Number 11325 03/08

Section 4

!

Caution

Maintenance

Cleaning Condensing Unit

Failure to keep the condenser coil clean will result in

reduced airflow through the condenser, resulting in

poor system performance and premature

compressor failure.

This will not be covered under your compressor

warranty.

Maintenance Chart

Area T ask Frequency

Evaporator Check for proper defrosting Monthly

Clean the coil and drain pan Every 6 months

Check for proper drainage

Condenser Inspect/clean the coil if the air supply is near polluting sources (such as cooking appliances) Monthly

Clean the coil surface Every 3 months

General Check/tighten all electrical connections Every 6 months

Check all wiring and insulators

Check contactor for proper operation and contact point deterioration

Check all fan motors

Tighten fan set screws, and motor mount nuts and bolts

For semi-hermetics, check the oil level in the system

Check the operation of the control system

Make certain all safety controls are operating properly

Check operation of the drain line heater and examine fo r cuts and abrasions

Check/tighten all mechanical/flare connections

Part Number 11325 03/08 4-1

Maintenance Section 4

THIS PAGE INTENTIONALLY LEFT BLANK

4-2

Part Number 11325 03/08

Section 5

Before Calling for Service

Checklist

If a problem arises during operation of your refrigeration system, follow the checklist below before calling service.

Routine adjustments and maintenance procedures are not covered by the warranty.

EVAPORATOR CHECKLIST

Problem Possible Cause To Correct

Fan(s) will not operate. Main switch open. Close switch.

Blown fuse(s). Replace fuse(s). Check for short circuits

or overload conditions.

Defective motor. Replace motor.

Defective timer or defrost thermostat. Replace defective component.

Unit in defrost cycle. Wait for completion of cycle.

Walk-in temperature too high. Thermostat set too high. Adjust thermostat.

Superheat too high. Adjust thermal expansion valve.

System low on refrigerant. Locate and repair leak, recover, evacuate

and recharge.

Coil iced up. Manually defrost coil. Check defrost

controls.

Ice accumulating on ceiling around

evaporator and/or on

fan guards, venturi, or blades.

Frost on coil after defrost cycle. Coil temperature not getting above

Ice accumulating in drain

pan.

Defrost duration is too long. Adjust defrost termination thermostat

(if adjustable).

Fan delay not delaying fans after defrost

period.

Defective defrost thermostat or timer. Replace defective component.

Too many defrost cycles per day. Reduce number of defrost cycles per

freezing point during defrost.

Not enough defrost cycles per day. Adjust timer for more defrost cycles per

Defrost cycle too short. Adjust timer for longer cycle, check

Defective timer or defrost thermostat. Replace defective component.

Defective heater. Replace heater.

Unit not pitched properly. Check and adjust.

Drain line plugged. Clean drain line.

Defective drain line heater. Replace heater.

Defective timer or thermostat. Replace defective component.

Replace defective defrost thermostat.

day.

Check heater operation.

day.

defrost thermostat mounting.

Part Number 11325 03/08 5-1

Before Calling for Service Section 5

COMPRESSOR CHECKLIST

Problem Possible Cause To Correct

Compressor will not run. Main switch open. Close switch.

Fuse blown. Check electrical circuits and motor

winding for shorts or grounds.

Investigate for possible overloading.

Replace fuse after fault is corrected.

Thermal overloads tripped. Overloads are automatically reset. Check

unit closely when unit comes back on

line.

Defective contactor or coil. Repair or replace.

System shut down by safety devices. Determine type and cause of shutdown

and correct.

No cooling required. Wait until cooling is required.

Liquid line solenoid will not open. Repair or replace coil.

Low pressure switch will not close. Replace switch.

Motor electrical trouble. Check motor for open windings or short

circuit.

Loose wiring. Check all wire junctions. Tighten all

terminal screws.

Compressor noisy or vibrating. Flooding of refrigerant into crankcase. Check superheat setting of expansion

valve.

Improper pipe support. Relocate or add hangers.

Worn compressor. Replace compressor.

High discharge pressure. Non-condensables in system. Recover, evacuate and charge.

System overcharged with refrigerant. Remove excess charge.

Discharge shutoff valve partially closed. Open valve.

Fan not running. Check electrical circuit or replace

defective fan motor.

Insufficient condenser air supply. Check for cause and correct.

Dirty condenser coil. Clean coil.

Low discharge pressure. Faulty head pressure control. Check head pressure control operation.

Suction shutoff valve partially closed. Open valve.

Insufficient refrigerant in system. Locate and repair leak, recover, evacuate

and recharge.

Low suction pressure. See “Low suction pressure” below.

High suction pressure. Excessive load. Reduce load or add additional

equipment.

Expansion valve overfeeding. Secure and insulate TXV bulb or if

required adjust superheat.

Low suction pressure. Lack of refrigerant. Locate and repair leak, recover, evacuate

and charge.

Evaporator dirty or iced. Clean.

Clogged liquid line or suction line

filter-drier.

Expansion valve malfunctioning. Check and reset for proper superheat.

Condensing temperature too low. Check head pressure control.

Improper TXV. Check for proper sizing.

Replace filter-drier.

5-2

Part Number 11325 03/08

Section 5 Before Calling for Service

COMPRESSOR CHECKLIST (Continued)

Problem Possible Cause To Correct

Compressor loses oil. Lack of refrigerant. Locate and repair leak, recover, evacuate

and recharge.

Excessive compression ring blow-by. Replace compressor.

Refrigerant floodback. Maintain proper superheat at

compressor.

Improper piping or traps. Correct piping.

Compressor thermal protector switch

open.

Operating beyond design. Add facilities so that operating conditions

are within allowable limits.

Discharge valve partially shut. Open valve.

Dirty condenser coil. Clean coil.

Overcharged system. Correct charge.

Part Number 11325 03/08 5-3

Before Calling for Service Section 5

Equipment/Service Data Sheet

A permanent data sheet must be prepared on each inst allation. The owner, the installing contractor and the intended

service agency, will retain a copy.

System Reference Data

The following information should be filled out and signed by Refrigeration Installation Contractor.

Date System Installed: / /

Installer and Address: ____________________________________________________________________

____________________________________________________________________

Phone Number: ( ) -

Service Agency: ____________________________________________________________________

____________________________________________________________________

Phone Number: ( ) -

Condensing Unit: Model Number: _____________________________________________________ __

Serial Number: _______________________________________________________

Compressor Model Number: _______________________ Compressor Model Number: __________________

Compressor Serial Number: _______________________ Compressor Serial Number: ___________________

Electrical: ________________ Volts:___________ Phase:__________________

Voltage at Compressor: L1: ____________ L2: ____________ L3: ____________

Amperage at Compressor: L1: ____________ L2: ____________ L3: ____________

Evaporator(s): Quantity: _______

Evaporator Model Number: _____________________ Evaporator Model Number: ___________________

Evaporator Serial Number: ______________________ Evaporator Serial Number: ____________________

Electrical: ________________ Volts:___________ Phase: ___________________________________

Expansion Valve Manufacturer/Model Number: _____________________________________________________

Ambient at Start-Up: _______________ °F

Design Box Temperature: _______________ °F _______________ °F

Operating Box Temperature: _______________ °F _______________ °F

Thermostat Setting: _______________ °F _______________ °F

Defrost Settings: ______/day _______ minutes failsafe _______/day ________ minutes failsafe

Compressor Discharge Pressure: ______________ PSIG _______________ PSIG

Compressor Suction Pressure: _ _____________ PSIG _______________ PSIG

Suction Line Tempe rature at Compressor: _________ °F _______________ °F

Discharge Line Temperature at Compressor:_______ °F _______________ °F

Superheat at Compressor: ______________ °F _______________ °F

Suction Line Temperature at Evaporator: __________ °F _______________ °F

Superheat at Evaporator: ______________ °F _______________ °F

Evacuation: # Times ____ Final Micron ____ # Times _____ Final Micron ____

Evaporator Drain Line Trapped Outside of Box: Yes ❏ No ❏

5-4

Part Number 11325 03/08

© 2008 Manitowoc

Continuing product improvements

may necessitate change of

specifications without notice.

Part Number 11325 03/08

2915 Tennessee Avenue North

Parsons, TN 38363, USA

Ph: 731-847-5365 Fax: 731-847-5387

Visit us online at: www.manitowocfsg.com

Kolpak

Loading...

Loading...