Kolpak PCL249LOP Manuel de service

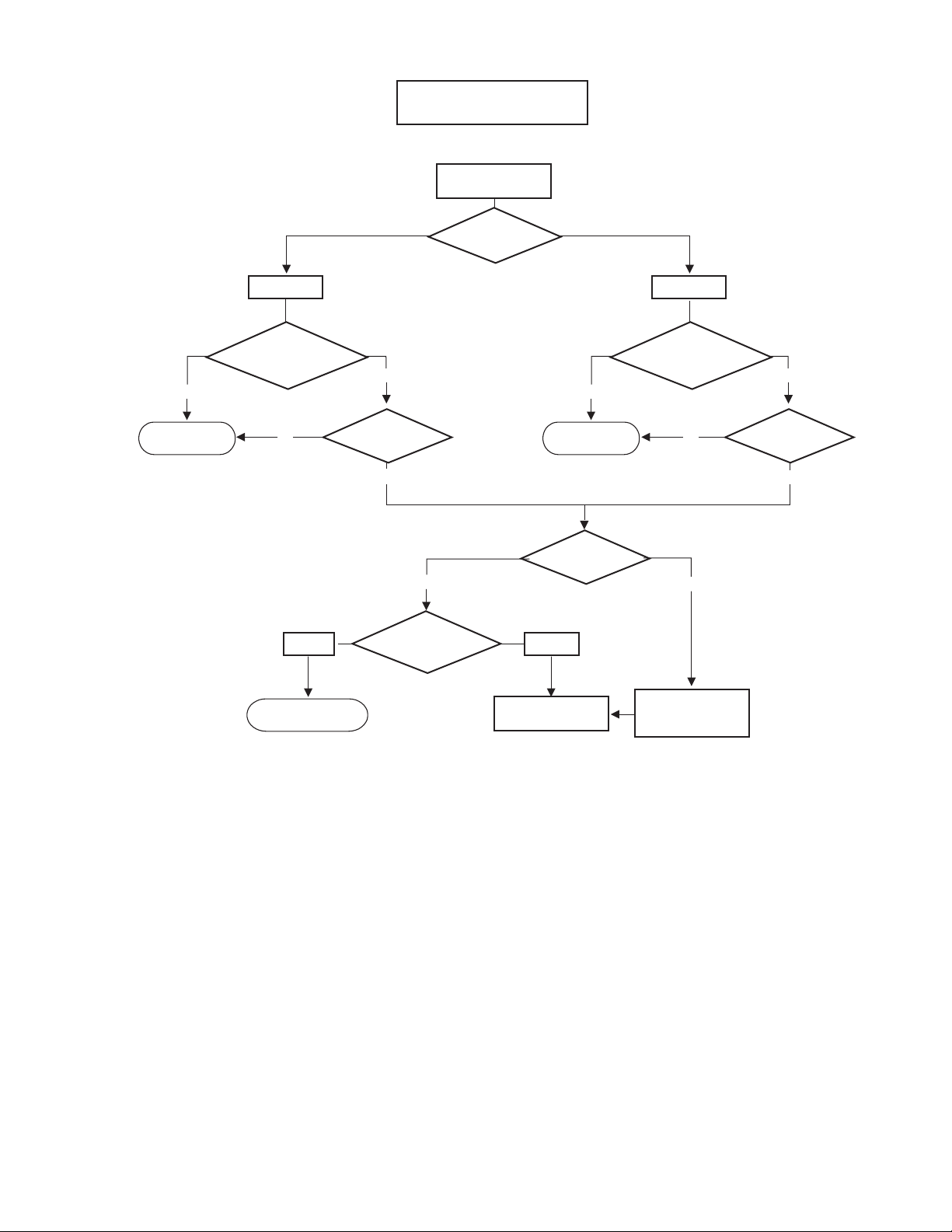

Electrical Problems

Fuse(s) blow or circuit

breaker trips

Does the unit use circuit

breakers or fuses?

No

Replace with correct

fuse(s)

Fuse(s)

Are the fuses dual element

time delay?

No

Fan motor

Check for siezed fan motor

or bad run capacitor

Circuit breakers

Is the circuit breaker

Yes

No

Is it the

correct amp rating for

the application?

Yes Yes

Yes

Is the

fan motor or

compressor drawing

excessive current?

Replace with correct

circuit breaker

Is the amp draw

excessive at start up?

Compressor

See compressor

diagnostics

HACR rated?

No

No

Fuse blowing due to short.

Check fan motor, if OK

then see comp diagnostics

Yes

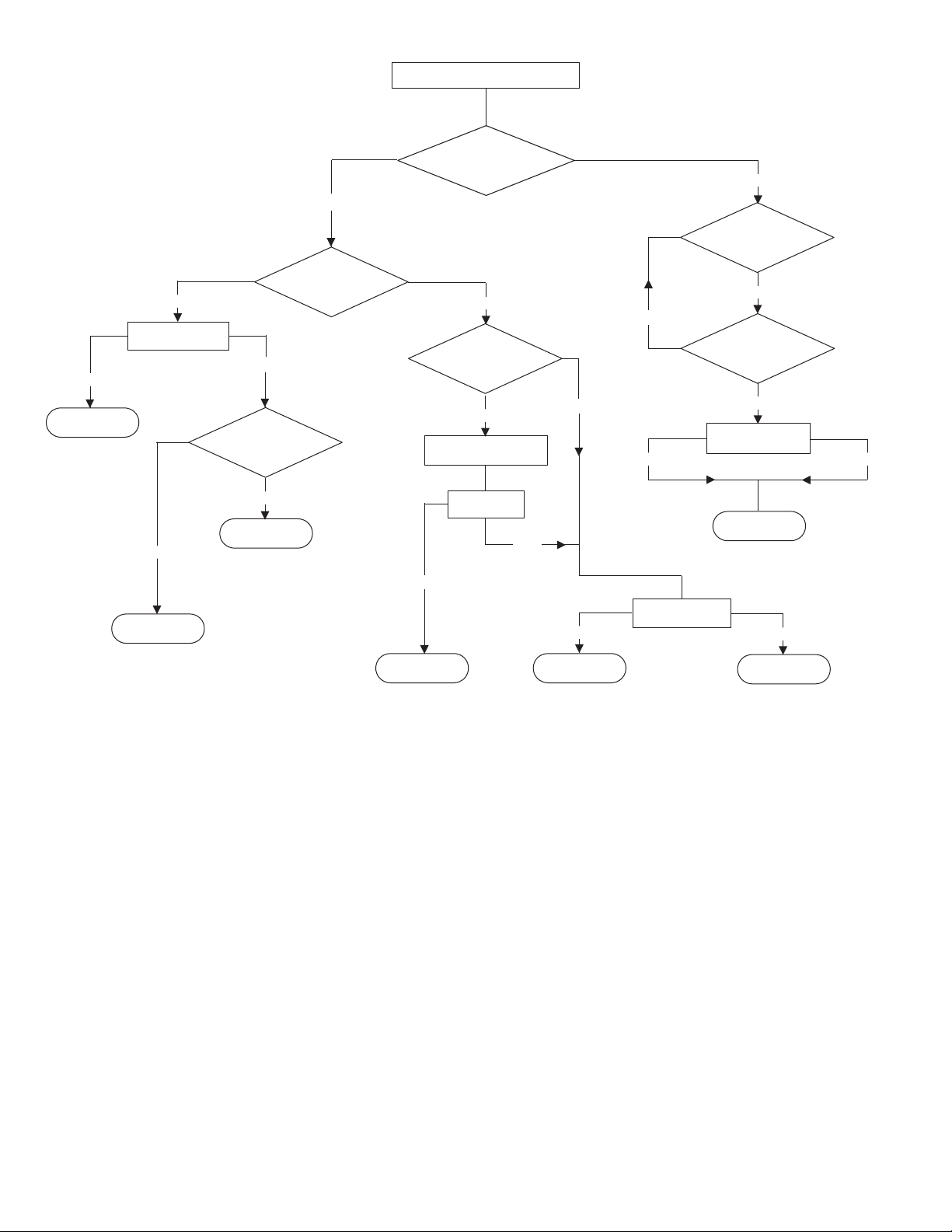

Is it the

correct amp rating for

the application?

YES

Replace

contactor.

NO

Check for voltage at

contactor coil.

Is compressor contactor

NO

Is high or low pressure

control open?

YES

pulled in?

Compressor Will Not Run

Is proper voltage

applied at load side of unit

disconnect switch?

YES

Is compressor

overload tripped?

YES

Allow time for compressor

to cool o.

NO

YES

YES

NO

Are the fuses blown

or breaker tripped in

the disconnect?

NO

Is there power at

line side of unit

disconnect switch?

NO

Check for tripped

breaker in main panel.

NO

NO

Check wiring and

repair as necessary.

YES

Determine cause

and reset.

Bad

Replace the starting

components.

Check starting

components.

Good

Check wiring and

repair as necessary.

Good

Ohm out the

compressor windings.

Replace breaker or

Refer to electrician.

Bad

Replace

compressor.

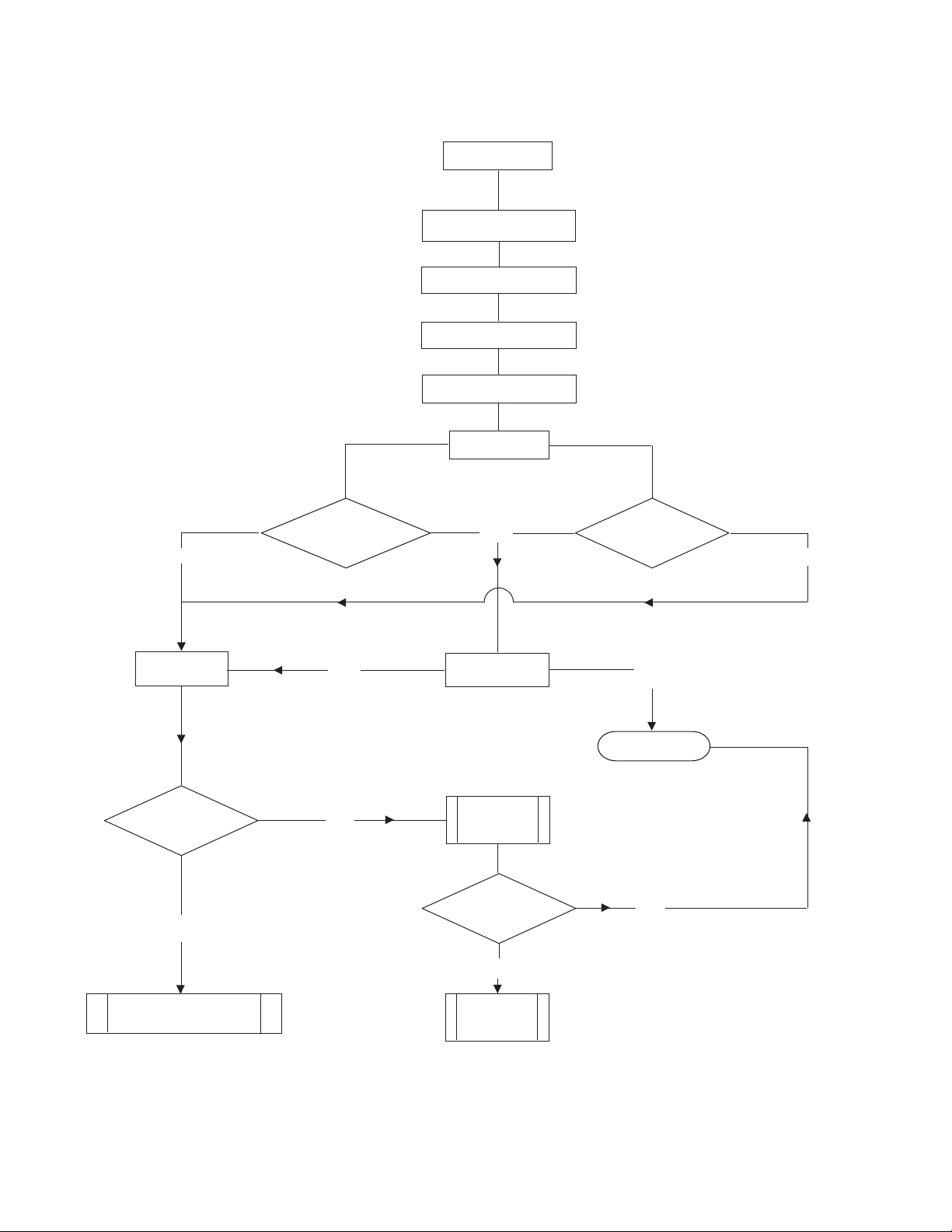

Note: The procedures described below require the skills of a competent, EPA certied refrigeration technician.

Also required are a manifold gauge set, digital thermometer with thermocouple type probe,

pressure-temperature chart and various hand tools (wrenches, service valve rachet, etc.)

Refrigeration

Install manifold gauge set onto

suction and high side service valves.

Record suction line temperature,

4" from compressor.

Record discharge line temperature,

4 to 6" from compressor.

Record liquid line temperature

before lter drier.

Compare super heat

and sub cooling.

YES

Not a refrigeration

system problem.

Is the evaporator ice covered?

YES

Is super heat within factory

specs of 10 – 12° F for freezers or

6 – 8° F for coolers?

OK

NO

NO

Check and verify

refrigerant charge.

See refrigerant

charging

procedure.

Charge OK?

YES

Is liquid sub cooling

within factory specs

of 10 – 15° F?

NOT

OK

Find and repair leak

and recharge system.

NO

YES

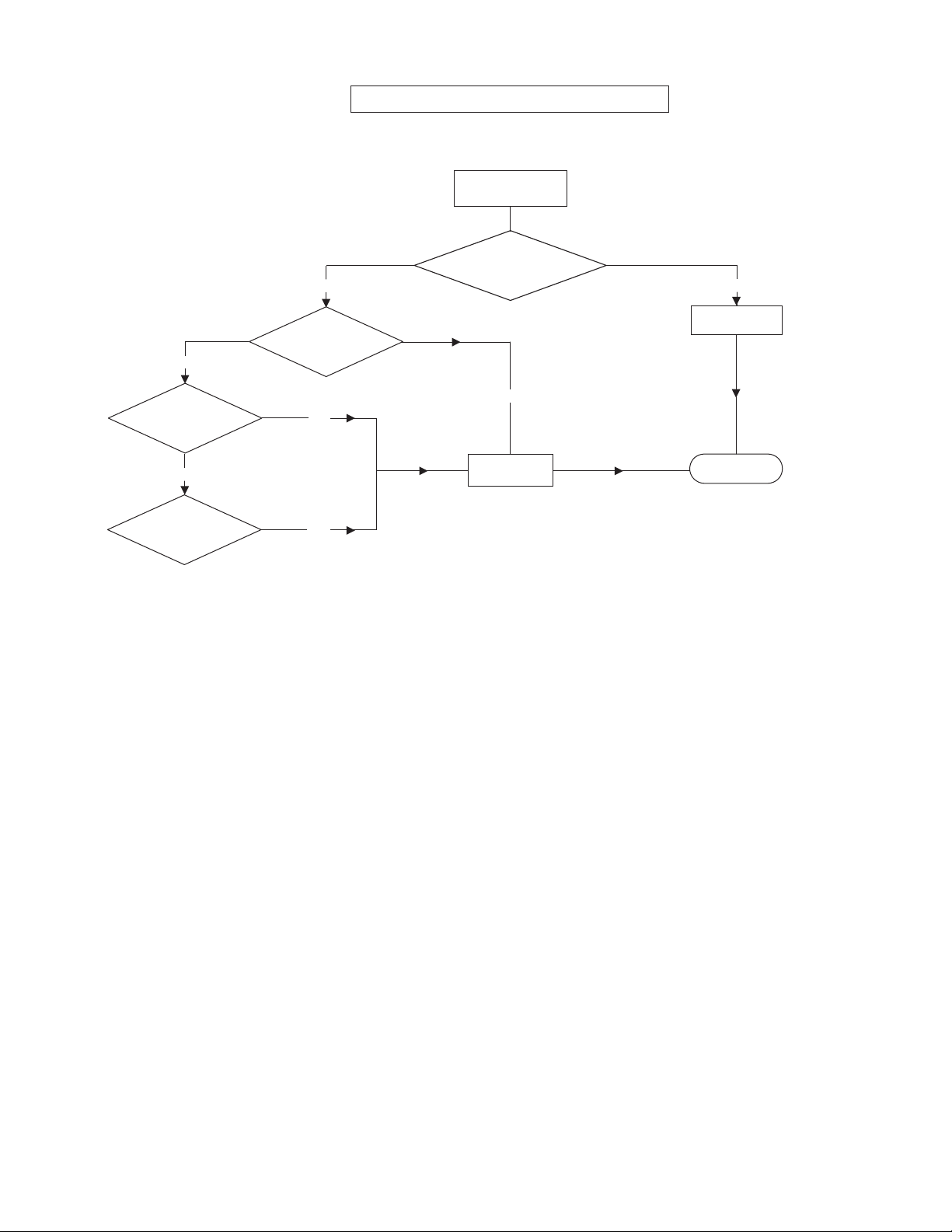

“Walk-in Cooler or Freezer is Too Cold”

See

See TXV

diagnostics.

YES

Is the valve

stuck closed?

YES

The TXV is correct

for the application?

YES

Thermostatic Expansion Valve (TXV ) Diagnostics

TXV is hunting and

will not hold setting.

Is the TXV sensing bulb

mounted securely to the suction

line before the “P” trap?

NO

NO

Remount sensing

valve properly.

NO

Is the valve

stuck open?

Replace TXV

and drier.

YES

Note: To check expansion valves for proper operation, immerse the sensing bulb in a

pan of warm water. DO NOT spray sensing bulb with refrigerant of any kind.

Check system for

proper operation.

Loading...

Loading...