MAC Series

Operation Manual

Manitowoc Foodservice Walk-In Division

2915 Tennessee Avenue North

Parsons, TN 38363

Phone: 800-225-9916

www.manitowocfoodservice.com

www.manitowocfoodservice.com 800-225-9916 1

P/N 550003765 REV. 5

August, 2014

ECO KPR114586

www.manitowocfoodservice.com 800-225-9916 - 2 -

Table of Contents

Cool Start Guide ……………………………………………………………… 4 - 5

Safety Information ……………………………………………………………. 6

Condensing Unit Specifications …..………………………………….…….. 7

Evaporator Unit Specifications …………………………………………. ….. 8

Receiving Inspection ……………………………………………………. ….. 9

Locating and Mounting Condensing Units ………………………………… 9 – 10

Locating and Mounting Evaporator Coils …………………………………. 11

Condensing Unit and Evaporator Coil Wiring……………………………… 12

Piping …………………………………………………………………………. 12 - 14

Leak Test ……………………………………………………………………… 15

Evacuation ……………………………………………………………………. 16

Refrigerant Charging ………………………………………………………… 17

Compressor Mounts………………………………………………………….. 17

ArcticFox Interface Installation………………..…………………………….. 18 - 19

Operational Start-Up ….……………………………………………………… 20

Compressor Superheat ……………………………………………………… 21

Evaporator Superheat ………………………………………………………. 22

ArcticFox Features…………………………………………………………… 23

ArcticFox Wiring……………………………………………………………… 24

ArcticFox Initialization……………………………………………………….. 25

ArcticFox Button Functions…………………………………………………. 25

ArcticFox Programming……………………………………………………… 26 – 30

ArcticFox Alarm Codes………………………………………………………. 31

Sustaining Mode………………………………………………………………. 31

Data Logging…………………………………………………………………... 32

On Demand Defrost…………………………………………………………… 32

System Defaults………………………………………………………………. 32 – 36

Parts List………………………………………………………………………. 37 - 38

Maintenance ………………………………………………………………….. 39

Warranty Information ………………………………………………………… 40

System Start-Up Data Sheet ………………………………………………… 41

Appendices……. ……………………………………………………………… 42 – 51

A – Sensor Failure Codes……………………………………………. 42 – 43

B – Cooler or Freezer Set Up………………………………………… 44

C – Defrost Set Up…………………………………………………….. 45

D – Condensing Unit Wiring Diagram………………………………… 46 - 47

E – Air Defrost System Wiring Diagram…………………………….. 48

F – Electric Defrost System Wiring Diagram……………………….. 49

G – Standard Exterior Door Section Wiring…………………………. 50

H – Standard Partition Door Section Wiring ……………………….. 51

www.manitowocfoodservice.com 800-225-9916 - 3 -

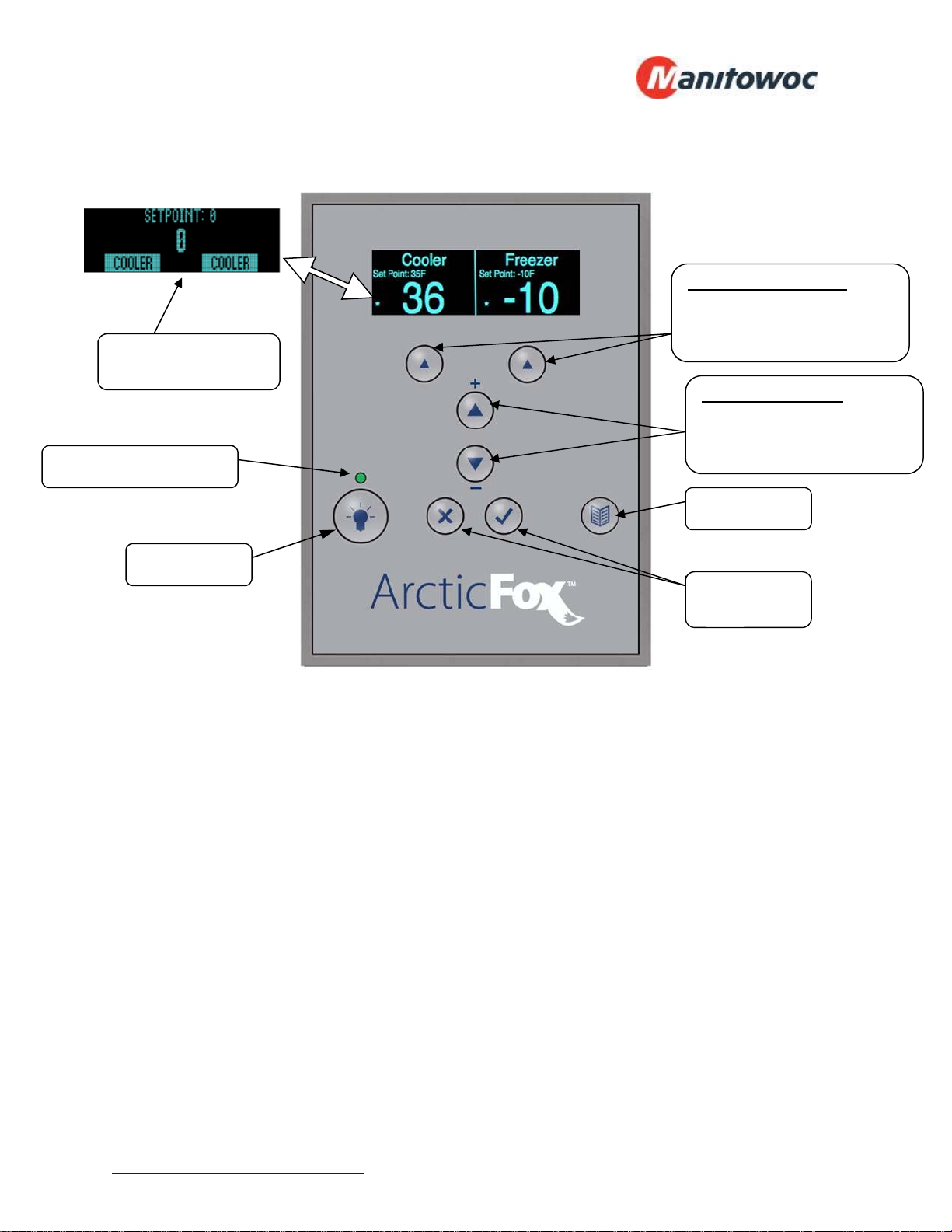

ArcticFox Cool Start Guide:

Alternative Display for

Single Unit

Manual Light Indicator

Soft Buttons (SB1, SB2)

Selects the item highlighted

on the display

Up and Down Arrows

Used to highlight items or

enter values

Menu Button

Light Button

Enter ()

Cancel (X)

Note: Dual control mode shown

General operation of the UI:

SB1 and SB2 perform or select the item that is highlighted above it. In the case

of the picture above pressing SB1 will activate the “Cooler” menu.

The Up and Down arrows are used to select items from a list or adjust the value

of a setting.

The <X> key has the following functionality:

o Cancels entry of current setting

o Silences the Alarm for 5 minutes

o Stops the status scrolling on the top of the display (The enter key also

stops the scrolling). Pressing either the <X> or the <> key will resume

scrolling (there may be a 1-2 second delay for the scrolling to start again.

With the scrolling stopped the Up or Down arrows change the parameter shown.

The light key turns on both the Cooler and Freezer’s lights (if walk-in is so

equipped).

The <Menu> key allows access (with password) to the system parameters and

other service features.

The <> key “enters” or “accepts” a choice while changing settings.

www.manitowocfoodservice.com 800-225-9916 - 4 -

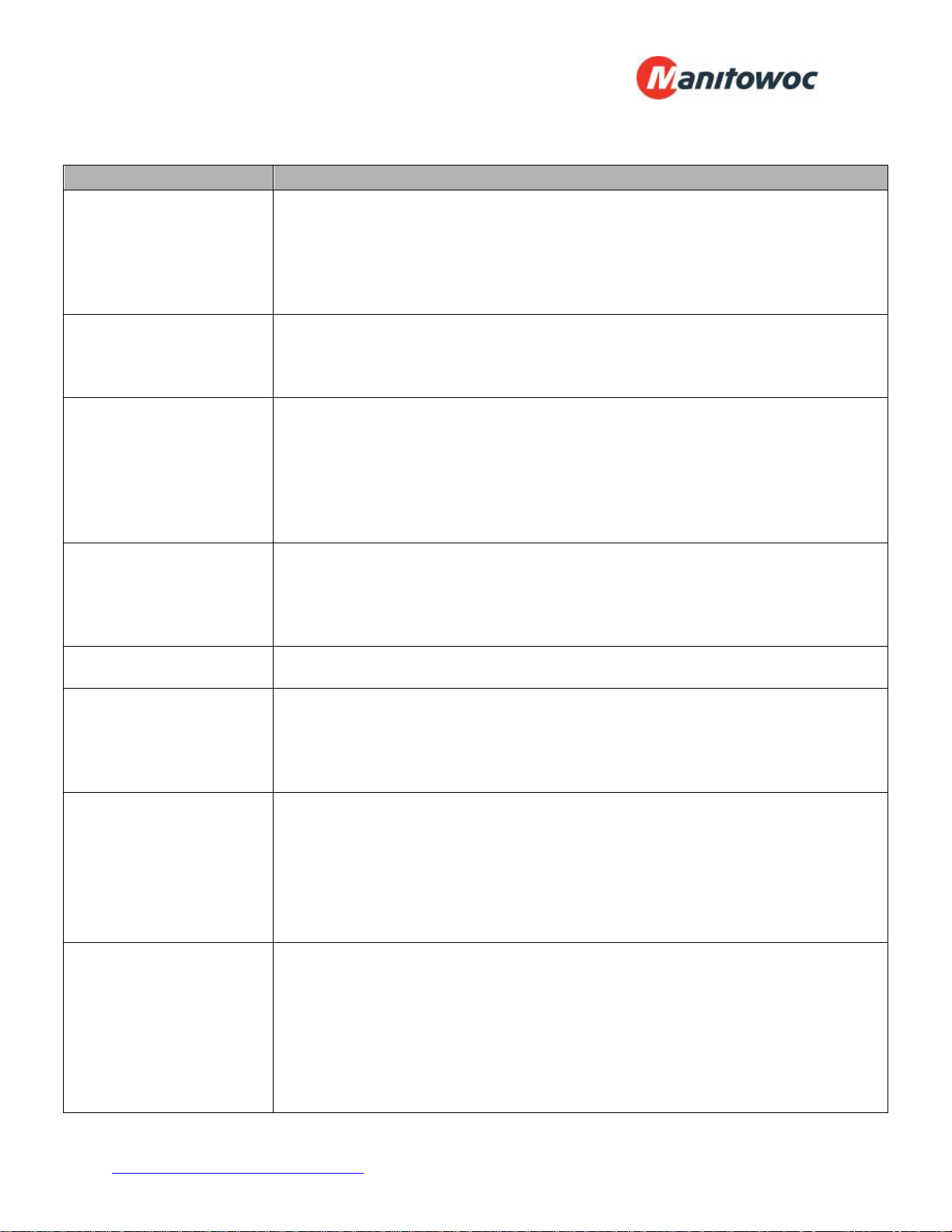

Function Steps

Set Time and Date

Set Temperatures

Set Temperature Alarms

Set Door Alarm Time

Silence Alarms

Clearing Alarms

Set User Password

Set Service Password

1. Press the <Menu> button and enter password (AAAA is default)

2. Enter password, then press <>

3. Press <Down> to scroll to "Set Date & Time", then press <>

4. Press <Up> or <Down> to select the hour, then press <>

5. Press SB2 (under NEXT) to move on to the minute screen.

6. Follow steps until time & date are set, then press < X > to return to main display

1. Press <SB1> or <SB2> and enter password (AAAA is default)

2. Press <Up> or <Down> to change the desired temperature

3. Press <> to enter selection

4. Press <X> to return to main display

1. Press <SB1> or <SB2> and enter password (AAAA is default)

2. Press <SB2> to navigate to "SET COOLER HIGH ALARM"

3. Press <Up> or <Down> to obtain the desired setting

4. Press <SB2> to navigate to "SET COOLER LOW ALARM"

5. Press <Up> or <Down> to obtain the desired setting

6. Press <> to enter selection

7. Press <X> to return to main display

1. Press <SB1> or <SB2> and enter password (AAAA is default)

2. Press <SB2> to navigate to "SET COOLER DOOR ALARM TIME"

3. Press <Up> or <Down> to obtain the desired setting

4. Press <> to enter selection

5. Press <X> to return to main display

Pressing <X> will silence the alarm for 5 minutes

Pressing <X> and <> simultaneously for 3 seconds will permanently silence alarm

1. Press <SB1> or <SB2> and enter password (AAAA is default)

2. Press <SB1> to navigate to "CLEAR COOLER ALARMS"

3. Press <Up> or <Down> to obtain the desired setting

4. Press <> to enter selection

5. Press <X> to return to main display

1. Press the <Menu> button

2. Enter password, then press <>

3. Press <Down> to scroll to "Set User Password", then press <>

4. Enter old password (default is AAAA) and press <>

5. Enter new password and press <>

6. Re-enter new password to confirm and press <>

7. Press <x> twice to return to main display.

1. Press the <Menu> button

2. Enter password, then press <>

3. Press <Down> to scroll to "Service Menu", then press <>

4. Press <Down> to scroll to "Set Service Password", then press <>

5. Enter old password (default is ZZZZ) and press <>

6. Enter new password and press <>

7. Re-enter new password to confirm and press <>

8. Press <x> three times to return to main display.

www.manitowocfoodservice.com 800-225-9916 - 5 -

Note: If the walk-in is a freezer, substitute freezer in place of cooler nomenclature.

General Safety Information:

Read this manual carefully before beginning the installation and operation of the

refrigeration system. Special attention is required to all sections identified with the

following warning and caution notices:

WARNING

Text in a Warning box alerts you to a potential personal injury situation. Read each

Warning statement before proceeding and work carefully.

CAUTION

Text in a Caution box alerts you to a situation in which you could damage the

refrigeration system. Read each Caution statement before proceeding and work

carefully.

Disregarding these special notices may result in personal injury and/or damage to the

refrigeration system.

Safety Notices:

Installation and maintenance/servicing are to be performed only by trained and

qualified personnel familiar with commercial refrigeration systems.

Ensure that all field wiring conforms to the equipment requirements and all

applicable local and national codes.

Disconnect all power sources before installing the controller wiring.

Disconnect all power sources before servicing the refrigeration equipment.

Sheet metal and coil surfaces have sharp edges. Use appropriate protective

gloves to prevent injury.

Use appropriate eye protection during installation and servicing.

www.manitowocfoodservice.com 800-225-9916 - 6 -

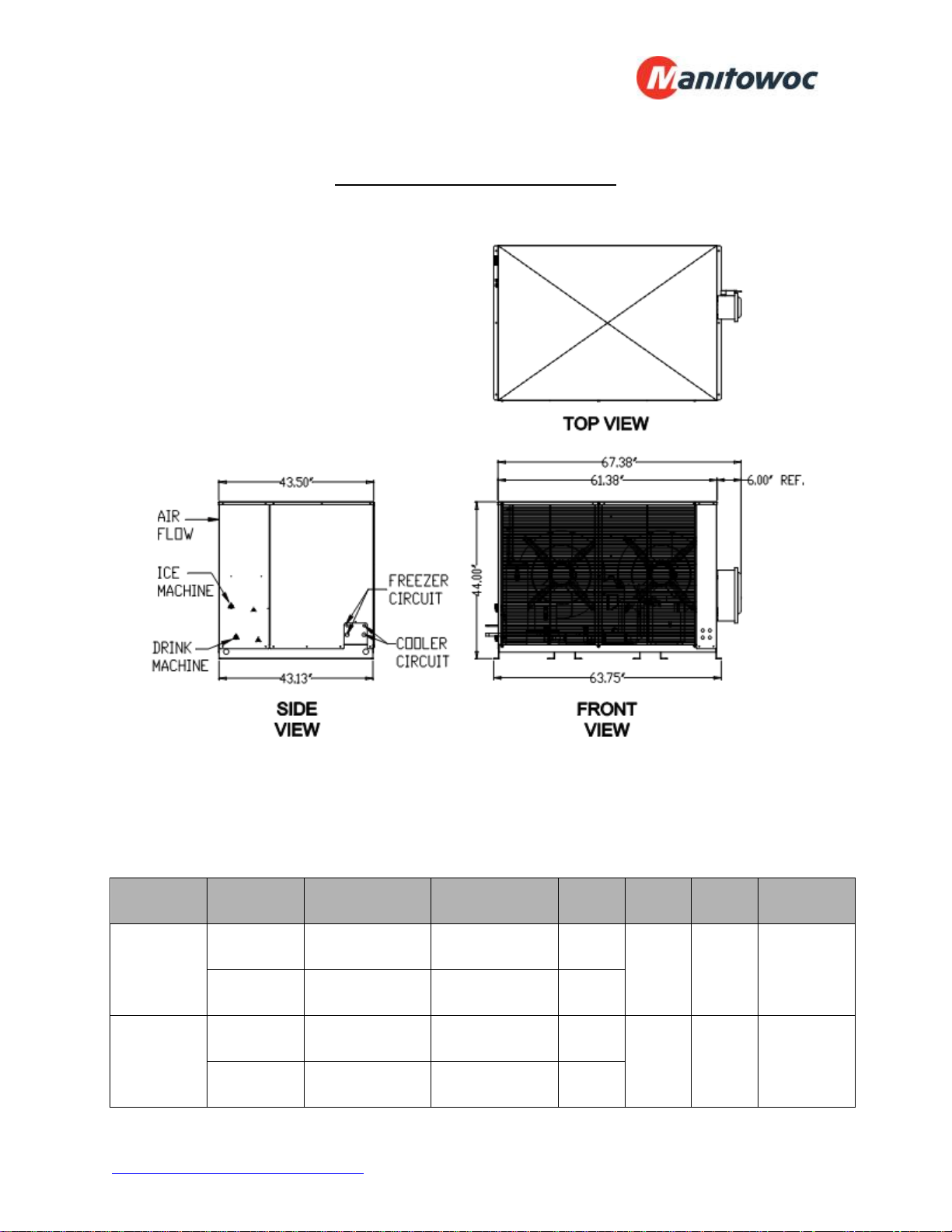

Condensing Unit Specifications

Model Location Compressor Voltage HP MCA MOP

FREEZER ZF13K4E-TF5 208-230/3/60 4.5

MAC 7

COOLER CF04K6E-TF5 208-230/3/60 1.5

FREEZER ZF15K4E-TF5 208-230/3/60 5.5

MAC 8

COOLER CF04K6E-TF5 208-230/3/60 1.5

31.3 40 660 lbs

38.8 50 660 lbs

Approx.

Weight

MCA – Minimum Circuit Ampacity.

MOP – Maximum Overcurrent Protection.

www.manitowocfoodservice.com 800-225-9916 - 7 -

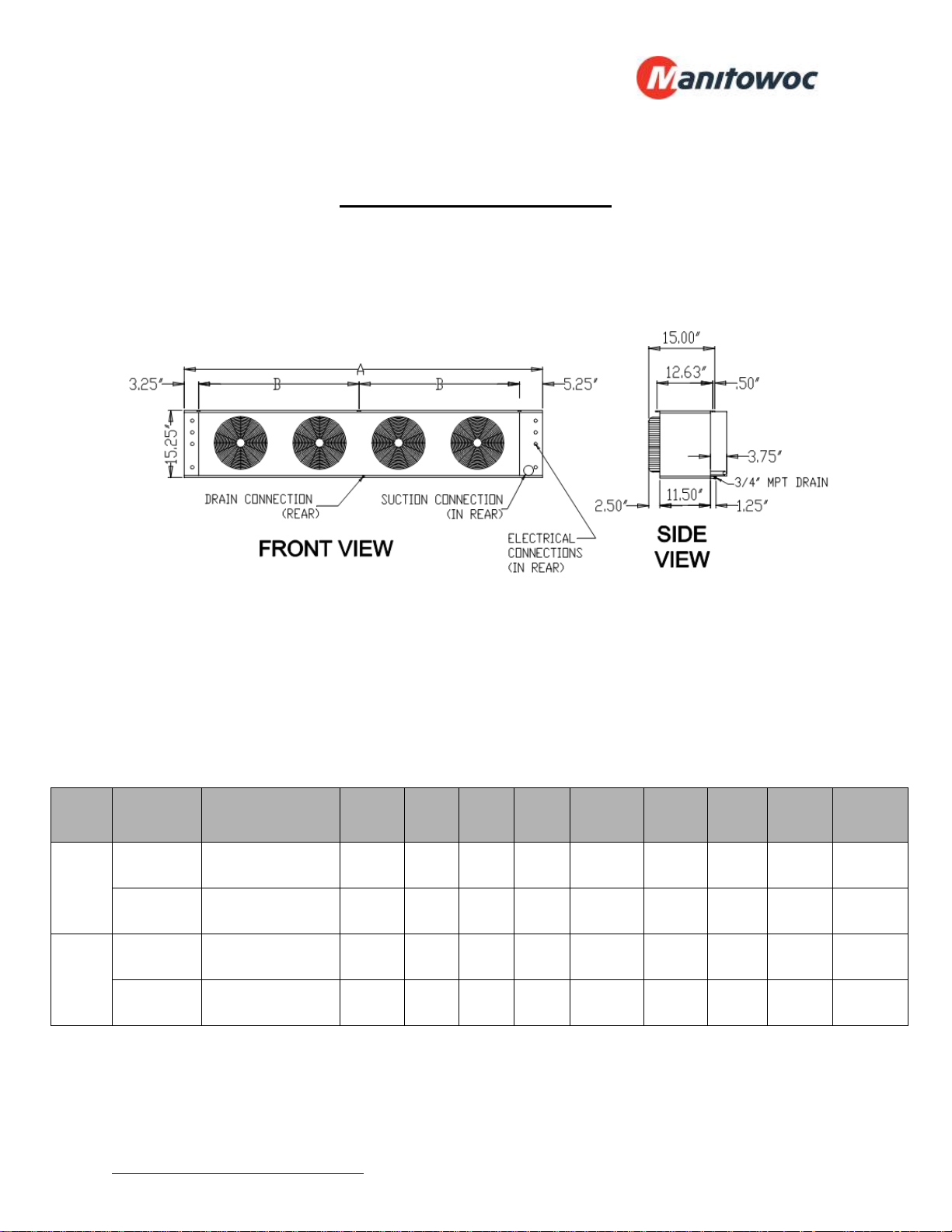

Evaporator Unit Specifications

No.

of

Fans

A B

Suction

OD

Liquid

OD

Motor

Amps

Heater

Amps

Model Location

FREEZER EL36-140-2MAC 14,000 3 63.50 55.00 7/8" 3/8" 1.35 13.00 115 lbs

MAC

7

COOLER AM28-134-2MAC 13,400 2 45.50 37.00 7/8" 3/8" 0.90 n/a 77 lbs

FREEZER EL46-185-2MAC 18,500 4 81.50 36.50 1-1/8" 3/8" 1.80 13.00 155 lbs

MAC

8

COOLER AM28-134-2MAC 13,400 2 45.50 37.00 7/8" 3/8" 0.90 n/a 77 lbs

Evaporator

Model

BTUH

Approx.

Weight

www.manitowocfoodservice.com 800-225-9916 - 8 -

Receiving Inspection

Check the shipment carefully and compare to the bill of lading. Account for all items

listed and inspect each container for damage. Carefully inspect for any concealed

damage. Report any shortages or damages to the carrier, note on the bill of lading, and

file a freight claim.

Damaged material cannot be returned to the manufacturer without prior approval. A

Return Material Authorization (RMA) must be obtained. Contact a sales representative

at 800-826-7036.

Locating and Mounting Condensing Unit

General Guidelines:

Check the selected installation location to ensure that racks, braces, flooring,

foundations, etc. are adequate to support the condensing unit weight.

The installation location is clean, dry, and level.

Locate away from corrosive and noise sensitive atmospheres.

Use the condensing unit skid and base when moving the unit. Do not remove

unit from skid until the unit is moved to the mounting location.

Mount the condensing unit base to pads or structural rails using properly sized

bolts through the unit base.

WARNING

Do not lift the condensing unit by the refrigerant tubing or components. These features

will not support the condensing unit weight. Injury and unit damage may occur!

CAUTION

Do not leave the condensing unit mounted to the wooden skid. This prevents all of the

unit supports from contacting the mounting surface. Excessive vibration and premature

equipment failure can occur.

www.manitowocfoodservice.com 800-225-9916 - 9 -

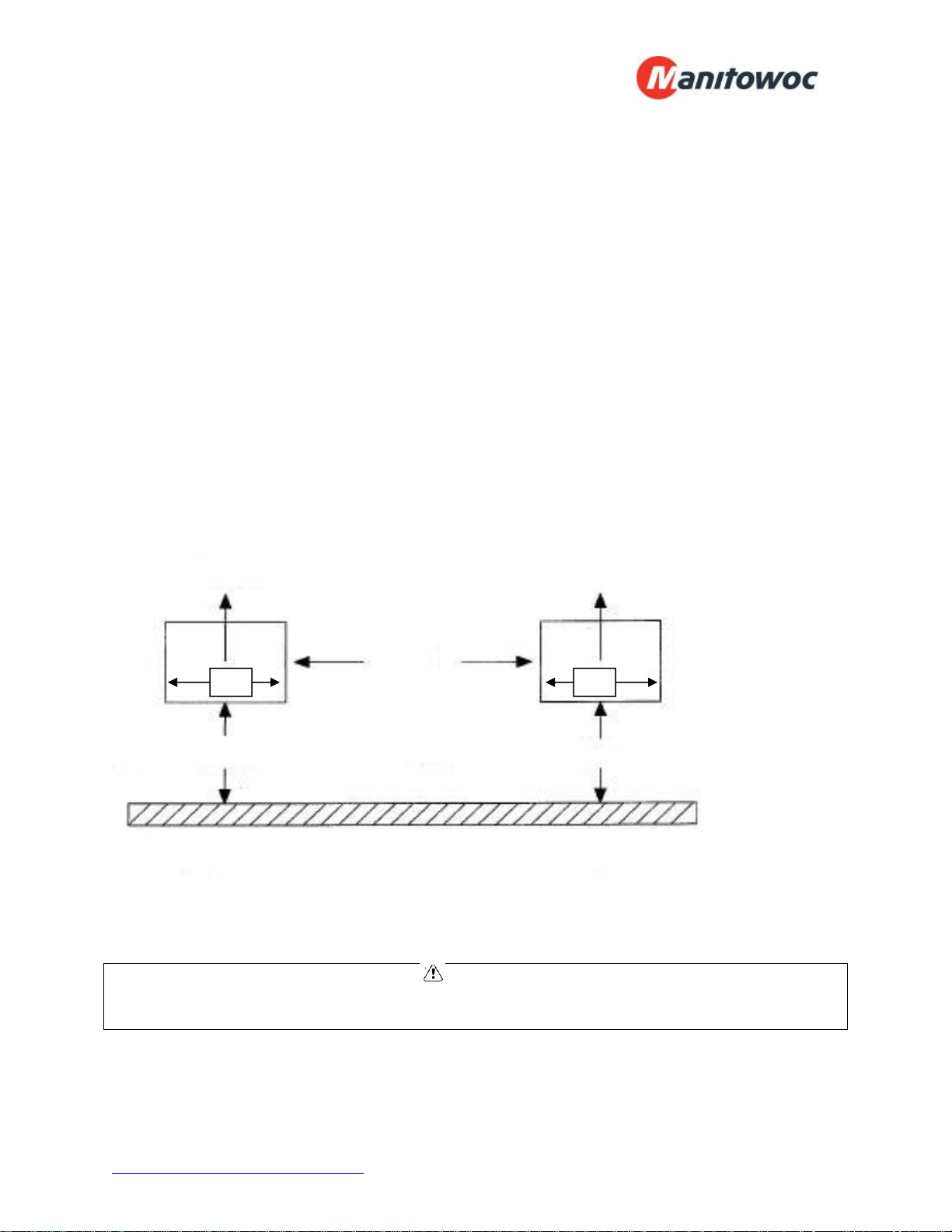

Clearance Requirements:

Locate where there is a sufficient and unrestricted supply of clean ambient air.

Locate where there is adequate space for the removal of the heated discharged

air from the condensing unit area.

Do not position multiple units so that discharge air from one unit is blowing into

the condenser inlet air of the other unit.

All sides of the unit should be positioned a minimum distance equal to the total

width of the condensing unit away from any other unit, wall, or obstruction.

Example of Multiple Units with Horizontal Airflow

AIR

FLOW

AIR

FLOW

MINIMUM

DISTANCE

24”

INTAKE AIR

MINIMUM DISTANCE 24”

(VIEWED FROM ABOVE)

24”

BUILDING WALL

24”

INTAKE AIR

MINIMUM DISTANCE 24”

CAUTION

Failure to observe clearance and air flow requirements will result in poor system

performance and premature equipment failure!

www.manitowocfoodservice.com 800-225-9916 - 10 -

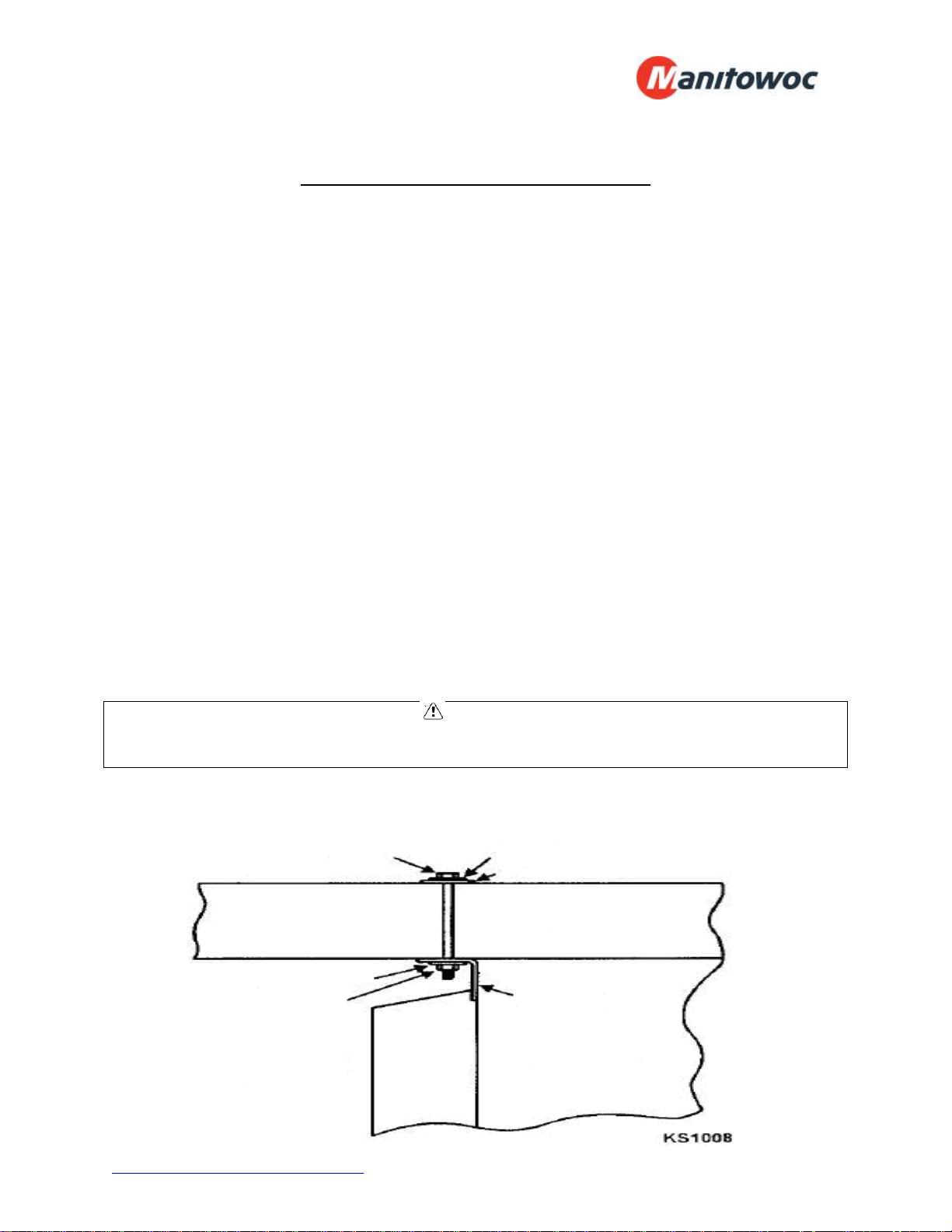

Locating and Mounting Evaporator Coil

General Guidelines:

Do not place the evaporator above or close to door openings. This will help

prevent potential icing problems.

Allow a minimum clearance equal to or greater than the coil height on all sides of

the coil for proper air flow and service access. This does not apply to fan side.

Use the evaporator coil for a template to locate and drill the mounting holes (1/2”

diameter).

Place a 1” and a 1-5/8” washer on each nylon bolt and insert through the drilled

mounting holes.

Lift the evaporator coil until the nylon bolts extend through the mounting

brackets.

Install washers and secure with nuts. Tighten until the coil is firm against the

ceiling. The evaporator coil must be level.

Additional information is available in the installation manual supplied with the

evaporator.

CAUTION

Failure to observe clearance and air flow requirements will result in poor system

performance and premature equipment failure!

Evaporator Coil Mounting Diagram

Nylon Bolt 1” O.D. washer

1-5/8” O.D. washer

1” O.D. washer

Nut

Note: Fasteners are

supplied in the

mounting kit.

Evaporator

Mounting

Bracket

www.manitowocfoodservice.com 800-225-9916 - 11 -

Wiring

All electrical connections and routing must comply with local and national codes. Do not

modify the factory installed wiring without written factory approval. The field wiring must

enter through the knockouts provided. Refer to the nameplate on the condensing or

evaporator coil to determine the proper electrical power supply. Wire type should be of

copper conductor only and properly sized to handle the electrical load. The unit and coil

must be properly grounded. Condensing unit wiring diagrams are attached inside the

electrical box cover. Evaporator coil wiring diagrams are located inside the evaporator

end panel. Copies of the wiring diagrams are also available in the back of this manual.

WARNING

All wiring must comply with local and national codes. Wiring must be performed only by

a refrigeration technician or certified electrician. Failure to follow these guidelines may

result in injury!

CAUTION

Check all wiring connections, including factory terminals, before operation. Connections

can become loose during shipment and installation.

Piping

General Requirements:

All refrigeration piping and components are to be installed in accordance with applicable

local and national codes and in conformance with industry refrigeration guidelines to

ensure proper operation of the refrigeration system. Only refrigeration grade copper

tubing should be used. Long radius elbows should be used. Short radius elbows have

points of excessive stress concentration and are subject to breaking at these points, do

www.manitowocfoodservice.com 800-225-9916 - 12 -

not use short radius elbows. Suction lines must be insulated with a minimum 1” thick

armaflex to reduce heat pick-up.

Cleanliness:

Condensing units and evaporator coils are cleaned and dehydrated at the factory. The

condensing unit must remain closed and pressurized until the piping is complete and

final connections are ready to be made.

CAUTION

The maximum air exposure for dehydrated condensing units is 15 minutes. Systems

exposed longer than 15 minutes must have the compressor oil and drier filter replaced.

Leaving a system exposed to the atmosphere for more than 15 minutes can result in

premature system failure.

Note: PC model condensing units are supplied with a refrigerant charge. PR model

condensing units are supplied with a dry holding charge.

Do not remove system tubing covers until work is ready to be performed. Ensure that

all refrigeration tubing is clean and dry prior to installation. Use only tubing cutters when

trimming tubing to the proper length. Do not use saws to cut tubing.

CAUTION

The use of saws to cut tubing can contaminate the system with copper chips causing

premature system failure.

Brazing joints require a dry inert gas, typically nitrogen, be passed through the lines at a

low pressure to prevent scaling and oxidation. Use only silver solder brazing alloys.

Minimize the amount of flux to prevent internal contamination. Flux only the male

portion of the joint. Thoroughly clean fluxed joints after brazing.

CAUTION

Dry inert gas must be passed through the system while brazing to prevent scaling and

oxidation. Scaling and oxides can clog refrigeration components resulting in system

failure.

Pipe Supports:

All tubing should be supported in a least two locations (near the end of each tubing run).

Long runs will require additional support. As a guide, support 3/8” to 7/8” pipe every five

feet, 1-1/8” to 1-3/8” every seven feet, and 1-5/8” to 2-1/8” every ten feet. Do not leave

a corner unsupported when changing directions. Place supports within 2 feet of each

direction change. Piping that is attached to a vibrating object (such as a compressor or

www.manitowocfoodservice.com 800-225-9916 - 13 -

compressor base) must be supported in a manner that will not restrict the movement of

the vibrating object. Rigid mounting will fatigue the tubing causing refrigerant leaks.

Oil Traps:

To ensure proper oil return to the compressor, a P-type oil trap should be installed at

the base of each suction riser of four feet or more. The suction trap must be the same

size as the suction line. Additional traps are necessary for long vertical risers. Add a

trap for each length of pipe (approximately 20 feet) to insure proper oil return. Suction

lines must slope ¼” per 10 feet toward the compressor. Install a suction line trap at the

evaporator outlet if the suction line rises to a point higher than the connection on the

evaporator.

CAUTION

Failure to properly install oil traps can prevent sufficient oil return to the compressor

resulting in premature compressor failure.

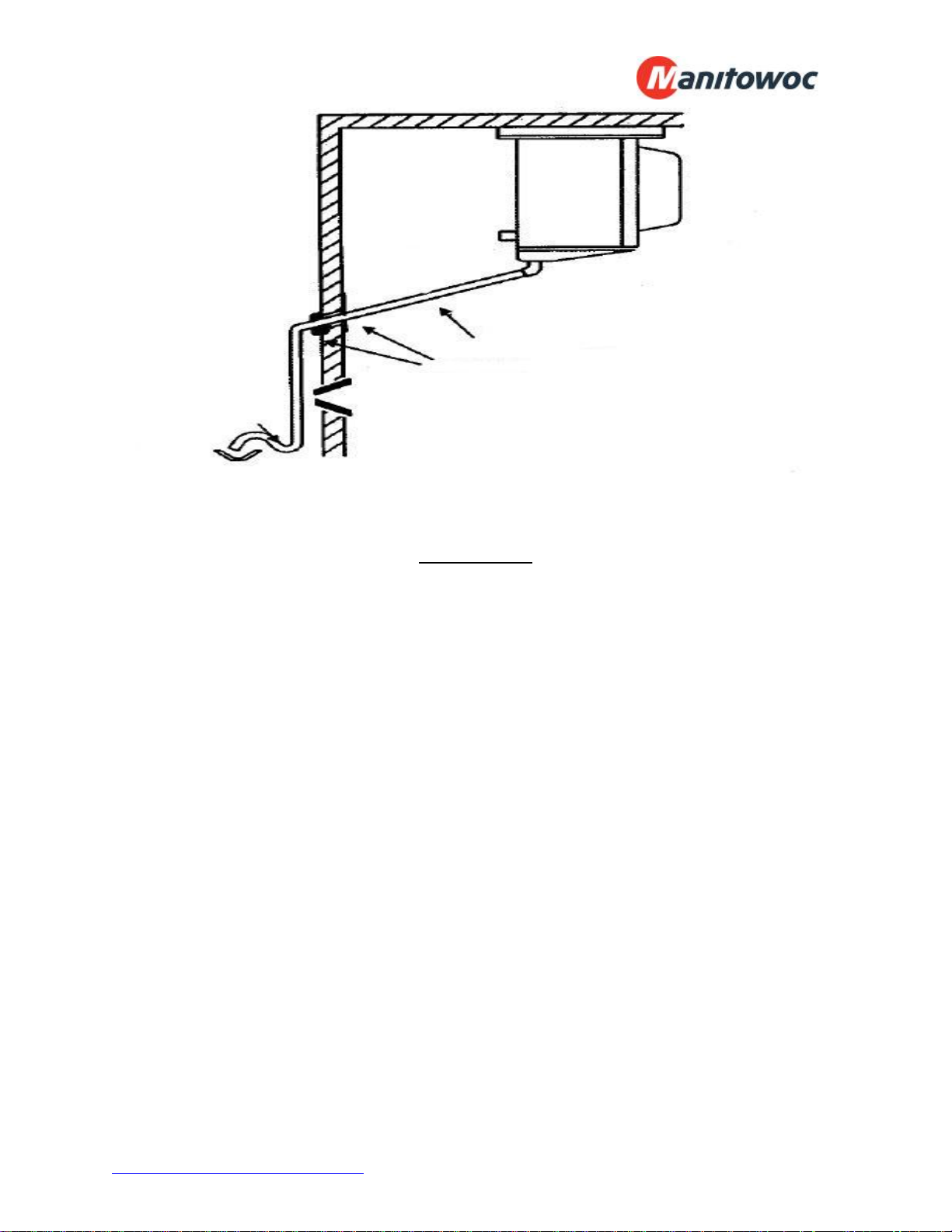

Drain Lines:

Evaporator coil drain lines should be pitched a minimum of ½” per foot to allow proper

drainage and exit the walk-in as quickly as possible. Insulate and seal the drain line

where it passes through the wall. Copper drain line is required. If the refrigerated

space is 33°F or lower, drain line insulation and heat tape are required. Drain lines

must be insulated with minimum ½” thick armaflex. The drain line heat tape must be

wrapped around the copper drain line. Do not locate bends, elbows, or drain traps

within the refrigerated space. Do not reduce the drain line size. Locate a drain line Ptrap outside of the refrigerated space. Any traps exposed to low ambient temperatures

should be wrapped with a drain line heater (provide 20 watts of heat per foot of drain

line at 0°F, 30 watts per foot at -20°F.

www.manitowocfoodservice.com 800-225-9916 - 14 -

Pitch drain line

½” per foot

Seal and

Insulate

Typical Drain Installation

P-Trap

Leak Testing

After all connections are complete the refrigeration system must be tested for leaks.

Failure to perform a leak test can result in unsatisfactory system performance,

additional servicing and service costs, and possible system failure. Leak test should be

performed using an electronic leak detector. All joints and components, both factory

and field installed, should be thoroughly inspected for leaks. The system installation

must be leak free!

Leak Testing “PR” model systems:

Open both the liquid and suction service valves.

Ensure the solenoid valve is energized and open.

Add 50 psi refrigerant, then pressurize with dry nitrogen to the low side test

pressure identified on the unit rating label.

Allow thirty minutes for refrigerant to reach all parts of the system.

Check all joints and components with an electronic leak detector.

Leak Testing “PC” model systems:

Leave the service valves closed, the condensing unit is charged with refrigerant.

Ensure the solenoid valve is energized and open.

www.manitowocfoodservice.com 800-225-9916 - 15 -

Add 50 psi refrigerant, then pressurize with dry nitrogen to the low side test

pressure identified on the unit rating label.

Allow thirty minutes for refrigerant to reach all parts of the system.

Check all joints and components with an electronic leak detector.

If a leak is detected, relieve the pressure and/or reclaim the refrigerant and repair the

leak. If additional brazing is required, pass a dry inert gas (nitrogen) through the system

to prevent contamination. Retest the system as outlined above until no leaks are

detected.

CAUTION

If a braze joint is detected leaking, dry inert gas must be passed through the system

while repairing the joint to prevent scaling and oxidation. Scaling and oxides can clog

refrigeration components resulting in system failure.

CAUTION

Always use the system specified refrigerant when pressuring to perform a leak test.

System Evacuation

Evacuation of the refrigeration system is necessary to remove all air and moisture from

the system. A reliable rotary vacuum pump with an accurate deep vacuum gauge is

recommended. Do not use the system compressor as a vacuum pump and do not

operate the compressor while the system is under vacuum.

Evacuation of “PR” model systems:

Open both the liquid and suction service valves.

Ensure the solenoid valve is energized and open.

Connect vacuum pump to the liquid and suction service valves.

Evacuate the system to 250 microns and maintain for a minimum of 4 hours.

Perform a vacuum decay test for a minimum of ten minutes to ensure the system

is leak free and dry.

Evacuation of “PC” model systems:

Leave the service valves closed, the condensing unit has been evacuated and is

charged with refrigerant.

Ensure the solenoid valve is energized and open.

www.manitowocfoodservice.com 800-225-9916 - 16 -

Connect vacuum pump to the liquid and suction service valves.

Evacuate the system to 250 microns and maintain for a minimum of 4 hours.

Perform a vacuum decay test for a minimum of ten minutes to ensure the system

is leak free and dry.

CAUTION

Do not use the system compressor to evacuate the system. Do not start the

compressor while the system is under vacuum. This may damage the compressor and

cause premature system failure.

Refrigerant Charging

The refrigerant charge should be added to the system through the liquid line service

valve. Do not charge liquid refrigerant into the suction service valve! The initial charge

should be determined by weight and sight glass indication. Start the system. If the

condensing temperature is 105° F or greater, charge the system until the sight glass

clears. If the condensing unit temperature is below 105° F, reduce the condenser face

surface area to raise the discharge pressures above 105° F and proceed to charge to a

clear sight glass. Return to a full condenser face area when charging is complete.

CAUTION

Do not charge liquid refrigerant into the suction service valve. Do not overcharge the

system. These conditions can permit liquid refrigerant to enter the compressor and

cause damage to internal components resulting in premature system failure.

Note: PC model condensers are charged at the factory with 17 lbs. (freezer) and 8-1/2

lbs (cooler) of R404A refrigerant. Due to site variances, an additional charge may be

required.

Operational Start-Up

The first 2 – 4 hours of operation after initial start-up is a critical time. Do not just start

the system and leave. Pressure values, compressor and evaporator superheat, and

inspecting for excessive vibrations and loose connections are some of checks that must

be performed prior to leaving the system.

Pre-Start Checks:

Verify that all service valves are fully open.

Ensure that all refrigerant and electrical connections are tight.

www.manitowocfoodservice.com 800-225-9916 - 17 -

Verify that the wiring and piping is properly routed and secured.

The compressor mounting bolts are properly adjusted.

All fan motors and mounting brackets are tight.

The condensing unit base and evaporator coil are properly secured.

ArcticFox User Interface is properly installed and mounted.

Compressor Mounts:

Check the compressor mounting bolts to ensure the nuts have not become loose during

shipment.

CAUTION

Failure to ensure the compressor mounts are properly tightened can result in fatigue to

the system piping causing leaks and poor system performance.

ArcticFox User Interface Installation and Initialization:

The user interface is designed to sit on the manager’s desk, but can be field modified to

mount directly to the walk-in or wall. The User Interface has a port on top for a CAT5e

cable.

To mount the user interface to a vertical surface using the UI Wall Mounting Assembly:

Select mounting location (allow 12” min. clearance for UI away from high traffic

areas and protected from direct contact with liquids).

Remove the backing from the (2) 2-1/2” long lengths of double sided tape located

on the back of the assembly.

Press the assembly onto the pre-selected mounting location surface ensuring the

assembly is level and plumb.

Secure the assembly to the vertical surface using (4) 10-16 x ½” self tapping

screws.

Once the user interface is secured in its stationary location, connect the CAT5e cable

from VFD-UI indicated on the evaporator coil to the UI ensuring the CAT5e cable is

securely fastened to adjacent surfaces.

Once unit is powered up, the UI will begin the initialization process.

At initialization the Start-up screen is shown, followed by an Initialization screen,

followed by the Main screen. The Start-up screen will flow directly into the main screen

without user interaction.

www.manitowocfoodservice.com 800-225-9916 - 18 -

The status bar is located at the top of the display and will continuously alternate through

the status of the key parts of the system. These include:

Unit State – (Idle, Idle-W, Cooling, Defrost)

Door Status – (Open, Closed). Unit will read ‘closed’ if the door functionality is

not utilized.

Light Status – (On, Off). Unit will read ‘off’ if the light functionality is not utilized.

Temperature set point – (35° F for coolers, -10° F for freezers).

Alarms – Any alarm condition results in an audible alarm and visual alarm.

CAUTION

If a cooler/freezer combo is operating from a single UI, connect additional factory

supplied CAT5e cable from Optional Modules at the freezer evaporator to the Optional

Modules at the cooler evaportor.

Set the time and date:

Press the <Menu> button and enter password (default is AAAA)

Enter password, then press <√>.

Press <Down> to scroll to “Set Date & Time”, then press <√>.

Press<Up> or <Down> to select the hour, then press <√>

Press SB2 (under next) to move on to the minute screen.

Follow the steps above until the time and date are set, then press <√> to return

to the Menu screen.

Press <X> twice to return to main display.

Set the Manager Password:

Press the <Menu> button

Enter password, then press <√>.

Press <Down> to scroll to “Set User Password”, then press <√>.

Enter old password (default is AAAA) and press <√>

Enter new password and press <√>

Re-enter new password and press <√>

www.manitowocfoodservice.com 800-225-9916 - 19 -

Press <X> twice to return to main display

Set the Service Password:

Press the <Menu> button

Enter password, then press <√>.

Press <Down> to scroll to “Service Menu”, then press <√>.

Press <Down> to scroll to “Set Service Password”, then press <√>.

Enter old password (default is ZZZZ) and press <√>

Enter new password and press <√>

Re-enter new password and press <√>

Press <X> three times to return to main display

Start-Up Procedure:

CAUTION

Do not start the system while in a vacuum. Do not leave the system unattended until

normal operating conditions are achieved.

Operate the system for a minimum of two hours and perform checks of the following:

Check the compressor discharge and suction pressures to ensure they are in the

normal operating range.

Check the liquid line sight glass for proper refrigerant charge.

Check the voltage and amperage at the compressor terminals. Voltage must be

within +10% or -5% of the rating indicted on the condensing unit name plate. On

three phase compressors, verify there is a balanced load.

Check all fans on the evaporator coil and condensing unit to be sure they are

operational and turning in the correct direction.

Check the piping and electrical connections for vibration. Add supports and

strapping if needed.

Check the crankcase heater operation (if equipped).

The defrost times and settings are pre-set and controlled by ArcticFox.

Set temperature is pre-set and controlled by ArcticFox.

www.manitowocfoodservice.com 800-225-9916 - 20 -

Check the compressor and evaporator superheat (pages 21-22). Superheat is

pre-set and controlled by ArcticFox.

After all system checks have been checked, properly adjusted, and verified, replace all

Schrader caps, service valve caps, electrical box covers, housings, etc. File a copy of

this manual for future reference.

Compressor Superheat:

CAUTION

Failure to check and properly adjust compressor superheat can result in premature

system failure.

Compressor superheat is a critical value that must be checked. Check the compressor

superheat as follows:

Determine the suction pressure at the suction service valve of the compressor.

Determine the saturation temperature at the observed suction pressure using

refrigeration pressure temperature tables.

Measure the suction line temperature 6 -10 inches away from the compressor.

Subtract the saturation temperature (step 2) from the measured temperature

(step 3). The difference is the superheat of suction gas.

A low suction superheat can cause liquid to return to the compressor. This will cause

dilution of the oil and eventual failure of the bearings, rings and valves. A high suction

superheat will cause excessive discharge temperatures, which cause a breakdown of

the oil. This causes piston ring wear, and piston and cylinder wall damage. System

capacity decreases as the suction superheat increases. For maximum system capacity,

keep the suction superheat as low as practical. Copeland requires a minimum

compressor superheat of 20°F; however, to improve compressor life, 25°F to 40°F is

www.manitowocfoodservice.com 800-225-9916 - 21 -

preferred. Adjust the superheat using the ArcticFox controller. Refer to “Evaporator

Superheat” on the next page for more information.

Evaporator Superheat:

Check the evaporator superheat once the walk-in has reached the desired temperature.

Generally, systems with a design temperature drop of 10°F should have an evaporator

superheat value of 6° - 10°F on freezers and 8° - 12°F on coolers for maximum

efficiency. The evaporator superheat is pre-set for 8°F at the factory.

To determine the evaporator superheat:

1. Measure the suction pressure at the evaporator outlet.

2. Convert the pressure to saturation temperature referencing a temperature-pressure

chart.

3. Measure the temperature of the suction line near the EEV sensor. Do not remove

the insulation from around the sensor.

4. Subtract the saturation temperature reading (step 2) from the measured temperature

(step 3). The difference is the evaporator superheat.

www.manitowocfoodservice.com 800-225-9916 - 22 -

Temperature minus

pressure converted

to temperature

equals superheat

Pressure

Temperature

Determining Evaporator Superheat

CAUTION

Minimum compressor superheat of 20°F may override these recommendations on

systems with short line runs.

CAUTION

The condensing unit must have the discharge pressure above the equivalent 105°F

condensing pressure (reference refrigerant charging on page 17).

CAUTION

Correct location and full contact of the EEV sensor is extremely important for proper

system performance. EEV sensor is premounted and insulated before shipment.

www.manitowocfoodservice.com 800-225-9916 - 23 -

ArcticFoxFeatures

Alternative Display for

Single Unit

Manual Light Indicator

Light Button

Soft Buttons (SB1, SB2)

Selects the item highlighted

on the display

Up and Down Arrows

Used to highlight items or

enter values

Menu Button

Enter ()

Cancel (X)

Note: Dual control mode shown

The ArcticFox Control System consists of a User Interface Control (Desk or wall

mounted) and one or two evaporator coil assemblies with a factory mounted Smart

Relay Board in each coil. The Smart Relay Board is factory configured to match the coil

application (cooler or freezer). The User Interface Control is also referred to as the UI.

The standard features are shown below:

Monitoring of the complete refrigeration system

Programmable Operating Parameters

Vacuum Fluorescence Display which shows:

o Box temperature(s)

o Set Point(s)

o Alarm Conditions

Data Logging (Flash Drive)

Demand Defrost

Audible Alarm

Password Protection

www.manitowocfoodservice.com 800-225-9916 - 24 -

Wiring:

All low voltage wiring must be run separate from line voltage:

User Interface Wiring

The ArcticFox User Interface does not require an external power source. The only

connection to it is a CAT-5e cable that originates at the Evaporator Coil Assembly.

Evaporator Coil Wiring

The ArcticFox Smart Relay Board is mounted in each Evaporator Coil Assembly and

controls:

Refrigeration System

Electric Expansion Valve

Walk-In Cooler/Freezer Interior Light(s) - optional

Walk-In Cooler/Freezer Door Heater(s) - optional

Walk-In Cooler/Freezer Alarms

There are three terminal boards located in the Evaporator Coil Assembly used for field

wiring:

Power Supply Terminal Block

The Power Supply Terminal Block must be supplied with 208-230/60/1 field connected

power with ground. (See wiring diagram, Appendix E/F)

Terminal Block TB3, Low Voltage Wiring

Low voltage wiring is brought to terminal Block TB3 when optional Door Sensor

Switches are used. It is recommended that 18 gauge wire be used. (See wiring

diagram, Appendix E/F)

Terminal Block TB4 Wiring

When Door Heaters and/or Lights are to be controlled by ArcticFox, they must be wired

to Terminal Block 4. (See wiring diagram, Appendix E/F)

www.manitowocfoodservice.com 800-225-9916 - 25 -

Initialization of ArcticFox Control System:

When power is first applied to the ArcticFox User Interface, it checks the configuration

of the system to which it is connected. If a Cooler/Freezer combo box is wired to it, the

controller automatically connects. If the configuration is not a Cooler/Freezer combo

box, refer to “set up” section for instructions to manually configure controller. This

configuration can consist of the following options:

One “Cooler” evaporator

One “Freezer” evaporator

One “Cooler/Freezer” combo, separate compartments

It is recommended (but not required) that the refrigeration system be operational before

attaching the ArcticFox User Interface.

Button Functions:

Light (☼) – This is used to turn on all of the lights that are wired into the Smart

Relay Board(s). The Led indicator light reflects the status of the light button – not

necessarily the actual light condition. Pushing the light button while the lights are

on will shut them off (after the time delay expires). This does not apply when the

lights are not controlled by the ArcticFox controller.

System Selection Arrow (▲) – This is used to select the system to be

programmed.

Up, Down Arrows (▲, ▼) – These buttons are used to scroll through menus,

parameters and settings.

Cancel (X) – Depressing this button cancels the immediately preceding input.

Enter (√) – Depressing this button “accepts” the immediately preceding input.

Menu ( ) – Depressing this button brings up the main menu after the user

enters and accepts the password.

www.manitowocfoodservice.com 800-225-9916 - 26 -

Programming ArcticFox Control System:

Initial Set-Up:

The Smart Relay Board located in the Evaporator Coil Assembly is factory configured

to match the Evaporator application (Cooler or Freezer). The UI is factory configured

for a Cooler/Freezer combo box so no changes are required for this application.

To make a program change:

Select the appropriate application (Cooler or Freezer) by pressing the (▲) button below it.

Enter password by scrolling (▲,▼arrows), selecting (▲), then entering (√)

Set box temperature

Set high temp alarm

Set low temp alarm

Set door alarm time (1 minute to 60 minutes)

Clear alarms

Additional Program Changes:

To make additional changes or to view current settings available through different

menus, press the menu button. Multiple pushes allow scrolling through the menu

layers.

www.manitowocfoodservice.com 800-225-9916 - 27 -

Program Changes:

Main Menu (Manager’s Menu)

Information Menu

UI (VFD) Info

o BT (Boot Table)

o SW (Software Version)

o BLD (Build Date)

o VFD (Temperature)

o DT (Current Date)

o TM (Current Time)

Cooler Evaporator Info

o BT (Boot Table)

o SW (Software Version)

o HW (Hardware Version)

o MB (Modbus Version)

Freezer Evaporator Info (If Installed)

Set Date and Time

Set User Password

Service Menu

Cooler Service Menu

o Cooler Setup

Set Cooler Superheat – 4F to 20F

Set Cooler Hysterisis – 1F to 5F

Set Cooler Off Hysterisis – 1F to 5F

Cooler Door Sensor Enabled

- None

- Doors 1 or 2

- Doors 1 and 2

- Cooler Door Heater On Time – 0hr to 23hr 45 min.

- Cooler Door Heater Off Time – 0hr to 23hr 45 min

www.manitowocfoodservice.com 800-225-9916 - 28 -

Program Changes Continued:

Set Light Max. On Time – 15min. to 120min.

Set Light Delay After Door Close – 0min. to 120 min.

Set Light Delay After Manual Off – 0min. to 120 min.

Cooler Light Opera Mode – On/Off

Cooler Enable Logging – Yes/No

Cooler Initial Cool Down – On/Off

Cooler Disable Temp Alarms – 1hr to 24hr

o Cooler Defrost Setup

Start Cooler Defrost – Yes/No

Select Cooler Defrost Mode – Electric/Air

Cooler Defrost Threshold – 0% to 99%

Cooler Defrost Calculation Start Temp – 0F to 20F

Cooler Defrost Timer Mode – Max Time No Defrost

Compressor Run Time

Cooler Compressor Run Time Until Defrost – 100 min

to 2880 min

Cooler Defrost Drip Time – 0 min to 5 min

Cooler Defrost Heater Delay – 0 min to 5 min

Cooler Fan Delay After Defrost – 0 min to 15 min

Cooler Defrost Max Temp – 40F to 70F

Cooler Max Defrost Time – 15 min to 120 min

Cooler Defrost Alarm Hold Off – 2 min to 120 min

Freezer Service Menu (Not Available if no Freezer)

o Freezer Setup

Set Freezer Superheat – 4F to 20F

Set Freezer Hysterisis – 1F to 5F

Set Freezer Off Hysterisis – 1F to 5F

www.manitowocfoodservice.com 800-225-9916 - 29 -

Program Changes Continued:

Freezer Door Sensor Enabled

- None

- Doors 1 or 2

- Doors 1 and 2

- Cooler Door Heater On Time – 0hr to 23hr 45 min.

- Cooler Door Heater Off Time – 0hr to 23hr 45 min

Set Light Max. On Time – 15min. to 120min.

Set Light Delay After Door Close – 0min. to 120 min.

Set Light Delay After Manual Off – 0min. to 120 min.

Freezer Light Opera Mode – On/Off

Freezer Enable Logging – Yes/No

Freezer Initial Cool Down – On/Off

Freezer Disable Temp Alarms – 1hr to 24hr

o Freezer Defrost Setup

Start Freezer Defrost – Yes/No

Select Freezer Defrost Mode – Electric/Air

Freezer Defrost Threshold – 0% to 99%

Freezer Defrost Calculation Start Temp – 0F to 20F

Freezer Defrost Timer Mode – Max Time No Defrost

Compressor Run Time

Freezer Compressor Run Time Until Defrost – 100

min to 2880 min

Freezer Defrost Drip Time – 0 min to 5 min

Freezer Defrost Heater Delay – 0 min to 5 min

Freezer Fan Delay After Defrost – 0 min to 15 min

Freezer Defrost Max Temp – 40F to 70F

Freezer Max Defrost Time – 15 min to 120 min

Freezer Defrost Alarm Hold Off – 2 min to 120 min

www.manitowocfoodservice.com 800-225-9916 - 30 -

Program Changes Continued:

VFD Tests

o All Pixels On

o All Pixels Off

o Sound Alarm – Initiates Audible Alarm

o Silence Alarm – Silences Alarm

USB Menu

o Load VFD Firmware

Select VFD Firmware

o Load Cooler Evap Firmware

Select SRB Firmware

o Load Freezer Evap Firmware

Select SRB Firmware

Installed Modules

o Is Cooler Evap Installed – Yes/No

o Is Freezer Evap Installed – Yes/No

Set Service Password

o Enter Old Service Password

o Enter New Password

CAUTION

Firmware updates are supplied via zip drive from the factory. The zip drive containing

the firmware must be connected to the UI usb port in order to ‘Select Firmware’.

www.manitowocfoodservice.com 800-225-9916 - 31 -

Alarm Codes:

If the ArcticFox User Interface sounds an audible alarm, it will display the visual alarm code in a

shaded box above the box temperature display. Four types of alarms can be present:

Sensor Failure – The audible alarm will sound when a sensor fails and the display will

flash showing a 4 digit code that can be disseminated through the use of the table in

Appendix A.

Door Alarm – The audible alarm will sound if a freezer or cooler door is left open longer

than the alarm delay setting.

High Temp Alarm – The audible alarm will sound if the box temperature exceeds the

alarm set point.

Low Temp Alarm – The audible alarm will sound if the box temperature falls below the

alarm set point.

The audible alarm can be silenced by pressing the (X) and (√) buttons

simultaneously for three seconds. After alarm is silenced, it will beep every 30

seconds until alarm conditioned is cleared.

Sustaining Mode:

In the event of a sensor failure, the refrigeration system will revert to an automatically

controlled sustaining mode. In this mode, the refrigeration system will continue to

operate to keep the box at or near the temperature set point. This allows the user

adequate time to obtain service to resolve the problem. Sensor failures must be

addressed by an authorized service agent within 24 hours.

The audible alarm will sound and the display will flash a 4 digit code (see Appendix A).

The system detects if a defrost is needed and may go into defrost mode displayed L-

Defrost. When the system comes out of defrost mode and starts cooling, L-Cooling is

displayed. When cooling stops, system goes into idle mode. L-Idle is displayed. This

cycle is repeated while in sustaining mode. ‘L’ in front of mode is a quick indicator that

system is operating in sustaining mode for ‘limited operation’ and authorized service

agent must be contacted.

www.manitowocfoodservice.com 800-225-9916 - 32 -

Data Logging:

The ArcticFox User Interface logs data when a flash stick is inserted into the USB port

on the top of the control. Two types of data are logged, events and sensors. Events

are logged when they occur and sensor data is logged every minute. This data is

compiled and can be downloaded from the flash drive.

On Demand Defrost:

Through the use of a proprietary operating system, the ArcticFox Control continuously

monitors the refrigeration system performance to determine the need for defrost. When

the system performance drops below a predetermined efficiency, the ArcticFox Control

initiates a defrost cycle. When the ArcticFox Control determines the coil is free of frost,

defrost is terminated.

The ArcticFox Control can also be programmed to defrost at timed intervals and has a

settable feature to allow for timed safety defrosts. This feature is available through the

cooler or freezer “Defrost Setup” menu.

Anti-Short Cycle:

The ArcticFox control also has a built in feature to prevent short cycling. Once the

compressor shuts down, the compressor can not come back on for 3 minutes.

System Defaults:

The following table lists the factory default settings for the ArcticFox Control. All of

these settings are programmable through the ArcticFox User Interface.

www.manitowocfoodservice.com 800-225-9916 - 33 -

Default

Parameter

FREEZER

Operator Password Screen AAAA

Set Freezer Temperature

Set Freezer High Temp Alarm

Set Freezer Low Temp Alarm

Set Freezer Door Alarm Time

Clear Freezer Alarms

Setting Brief Functionality Description

Screen where user password is entered in order to access

the parameters available in the Manager's menu. The

password contains 4 alpha characters. The selection range

on each character is A thru Z.

Temperature set point from which Hysteresis determines CI

-10°F

+10°F

-20°F

60 minutes

No

and CO Temps (Target Walk-in temperature set point)

High temperature alarm set point. Temperature at which the

alarm initiates (after delay time has been satisfied)

Low temperature alarm set point. Temperature at which the

alarm initiates (after delay time has been satisfied)

Door Open Alarm time delay set point. A door open alarm

is initiated if the walk-in door remains open for longer than

set point duration.

Silences audible alarm and clears all visual alarms

COOLER

Operator Password Screen AAAA

Set Cooler Temperature

Set Cooler High Temp Alarm

Set Cooler Low Temp Alarm

Set Cooler Door Alarm Time

Clear Cooler Alarms

FREEZER

Service Menu

Service Password Screen

Freezer Service Menu

Freezer Setup

Set Freezer Superheat

Set Freezer On Hyst

Set Freezer Off Hyst

+35°F

+40°F

+30°F

60 minutes

No

ZZZZ

8°

Pre-Set

Pre-Set

Screen where user password is entered in order to access

the parameters available in the Manager's menu. The

password contains 4 alpha characters. The selection range

on each character is A thru Z.

Temperature set point from which Hysteresis determines CI

and CO Temps (Target Walk-in temperature set point)

High temperature alarm set point. Temperature at which the

alarm initiates (after delay time has been satisfied)

Low temperature alarm set point. Temperature at which the

alarm initiates (after delay time has been satisfied)

Door Open Alarm time delay set point. A door open alarm

is initiated if the walk-in door remains open for longer than

set point duration.

Silences audible alarm and clears all visual alarms

Screen where user password is entered in order to access

the parameters available in the Service menu. The

password contains 4 alpha characters. The selection range

on each character is A thru Z.

Set point for the desired evaporator operating superheat

Number of degrees above Freezer Temperature set point at

which cooling cycle begins

Number of degrees below Freezer Temperature set point at

witch cooling cycle ends

www.manitowocfoodservice.com 800-225-9916 - 34 -

Determines which door sensors are enabled for monitoring.

None = No doors are enabled

1 = Door 1 sensor is enabled

2 = Door 2 sensor is enabled

Freezer Door Sensor Enables

1 & 2

1 & 2 = Both Door 1 and Door 2 sensors are enabled

Freezer Door Heater On Time

Freezer Door Heater Off Time

Set Light Max On Time (optional)

Set Light Delay After DC

(optional)

Set Light DLY After Man Off

(optional)

Freezer Enable Logging

COOLER

Service Password Screen

Cooler Service Menu

Cooler Setup

0:15

0:15

120

minutes

15 minutes

15 minutes

Yes

ZZZZ

Time of day the door heater will turn On

Time of day the door heater will turn Off. NOTE: If equal to

Door Heater On Time the heater will always be on.

Maximum time the interior lights will remain ON continuously

regardless of the current door open/closed status and

regardless if the light has been turned on manually.

The time setting for the length of time the interior lights will

remain ON (when lights have been activated ON by opening

the door) after the door has been closed.

The time setting for the length of time the interior lights will

remain ON (when lights have been activated ON manually

via the UI) after the lights have been manually turned off.

When selected YES, data logging thru USB port on the UI

will occur (if USB flash drive has been inserted).

Set Cooler Superheat

Set Cooler On Hyst

Set Cooler Off Hyst

Cooler Door Sensor Enables

Cooler Door Heater On Time

Cooler Door Heater Off Time

Set Light Max On Time (optional)

Set Light Delay After DC

(optional)

Set Light DLY After Man Off

(optional)

Cooler Enable Logging

8°

Pre-Set

Pre-Set

1

0:15

0:15

120

minutes

15 minutes

15 minutes

Yes

Set point for the desired evaporator operating superheat

Number of degrees above Freezer Temperature set point at

which cooling cycle begins

Number of degrees below Freezer Temperature set point at

witch cooling cycle ends

Determines which door sensors are enabled for monitoring.

None = No doors are enabled

1 = Door 1 sensor is enabled

2 = Door 2 sensor is enabled

1 & 2 = Both Door 1 and Door 2 sensors are enabled

Time of day the door heater will turn On

Time of day the door heater will turn Off. NOTE: If equal to

Door Heater On Time the heater will always be on.

Maximum time the interior lights will remain ON continuously

regardless of the current door open/closed status and

regardless if the light has been turned on manually.

The time setting for the length of time the interior lights will

remain ON (when lights have been activated ON by opening

the door) after the door has been closed.

The time setting for the length of time the interior lights will

remain ON (when lights have been activated ON manually

via the UI) after the lights have been manually turned off.

When selected YES, data logging thru USB port on the UI

will occur if USB flash drive has been inserted.

www.manitowocfoodservice.com 800-225-9916 - 35 -

FREEZER

Freezer Defrost Setup

Start Freezer Defrost Now

Select Freezer Defrost Mode

Freezer Defrost Threshold

Freezer Defrost Calc Temp Start

Freezer Defrost Timer Mode

Freezer Comp Run Time Till

Defrost

Freezer Defrost Drip Time

Freezer Defrost Heater Delay

Freezer Fan Delay After Defrost

Freezer Defrost Max Temp

Freezer Max Defrost Time

Freezer Defrost Alarm Hold Off

No

Electric

Pre-Set

Pre-Set

CCRT

Pre-Set

Pre-Set

Pre-Set

Pre-Set

Pre-Set

Pre-Set

Pre-Set

When YES is user selected, a manual defrost is initiated.

This function operates independently of any other defrost

functionality settings and only works one time per command.

Determines the type defrost system that the unit cooler

utilizes. For a freezer application, the only setting available

is Electric.

Defrost Effectiveness Threshold (DET) .This setting value

represents the percentage (%) the evaporator effectiveness

will decline before a "demand defrost" is triggered to initiate.

(the higher the DET % value the more frost that will be

allowed to accumulate on the evaporator coil)

This setting value is added to the temperature set point

value and the sum is the temperature (during the

compressor ON cycle) used to dictate whether the

effectiveness calculations are being calculated or not being

calculated. If the evap Air IN temperature is above the sum

value, the effectiveness calculations stop calculating. If the

evap Air IN temperature is at or below the sum value, the

effectiveness calculations start calculating.

Max Continuous Compressor Run Time. (CCRT) This

setting determines the safety defrost activation mode.

This setting value is only active if the "Continuous

Compressor Run Time" mode has been selected for the

Safety Defrost operation. If the compressor runs

continuously for the time that has been set, the system will

automatically go into a defrost.

This is the delay time for water to drip from the evap coil.

When the defrost heaters turn off, the delay time starts and

when the delay time expires the compressor will turn on.

This is the delay time after a defrost has been triggered to

activate before the defrost heaters will be turned on. (allows

time for the compressor to pump down and shut off before

the heaters come on)

This is the delay time after the drip time has expired before

the evaporator fans turn ON. (the compressor starts to run

at the beginning of this delay period) Any residual moisture

that is left on the evap coil surface after the drip time period

will be frozen before the evap fans come on.

This is the temperature at which a defrost cycle will be

terminated by temperature.

This is the length of time after which a defrost cycle will be

terminated by time if the defrost cycle has not already been

terminated on temperature.

NOTE: The unit cooler also employs a fixed setting

mechanical Heater Safety thermostat that can terminate

the defrost cycle if for some reason the defrost cycle is

not terminated on temperature or time via the ArcticFox

controller.

The delay time in minutes after a defrost cycle has ended

before a high temp alarm can occur.

www.manitowocfoodservice.com 800-225-9916 - 36 -

COOLER

Cooler Defrost Setup

Start Cooler Defrost Now

Select Cooler Defrost Mode

Cooler Defrost Threshold

Cooler Defrost Calc Temp Start

Cooler Defrost Timer Mode

Cooler Comp Run Time Till

Defrost

No

Air

Pre-Set

Pre-Set

CCRT

Pre-Set

When YES is user selected, a manual defrost is initiated.

This function operates independently of any other defrost

functionality settings and only works one time per command.

Determines the type defrost system that the unit utilizes.

NOTE: Defrost termination for "Air Defrost Mode" is always

terminated based on time. Defrost termination for "Electric

Defrost Mode" is by temp. or time on a first achieved basis.

Defrost Effectiveness Threshold (DET). This setting value

represents the percentage (%) the evaporator effectiveness

will decline before a "demand defrost" is triggered to initiate.

(the higher the DET % value the more frost that will be

allowed to accumulate on the evaporator coil)

This setting value is added to the temperature set point

value and the sum is the temperature (during the

compressor ON cycle) used to dictate whether the

effectiveness calculations are being calculated or not being

calculated. If the evap Air IN temperature is above the sum

value, the effectiveness calculations stop calculating. If the

evap Air IN temperature is at or below the sum value, the

effectiveness calculations start calculating.

Max Continuous Compressor Run Time. (CCRT) This

setting determines the safety defrost activation mode.

This setting value is only active if the "Continuous

Compressor Run Time" mode has been selected for the

Safety Defrost operation. If the compressor runs

continuously for the time that has been set, the system will

automatically go into a defrost.

Cooler Defrost Drip Time

Cooler Defrost Heater Delay

Cooler Fan Delay After Defrost

Cooler Defrost Max Temp

Cooler Max Defrost Time

Pre-Set

Pre-Set

Pre-Set

Pre-Set

Pre-Set

This is the delay time for water to drip from the evap coil.

When the defrost heaters turn off, the delay time starts and

when the delay time expires the compressor will turn on.

Only active if electric defrost mode has been selected.

This is the delay time after a defrost has been triggered to

activate before the defrost heaters will be turned on. (allows

time for the compressor to pump down and shut off before

the heaters come on). Only active if electric defrost.

This is the delay time after the drip time has expired before

the evaporator fans turn ON. (the compressor starts to run

at the beginning of this delay period) Any residual moisture

that is left on the evap coil surface after the drip time period

will be frozen before the evap fans come on. NOTE: Only

active if electric defrost mode has been selected.

This is the temperature at which a defrost cycle will be

terminated by temperature. Only active if electric defrost.

This is the length of time after which a defrost cycle will be

terminated by time if the defrost cycle has not already been

terminated on temperature. In Air Defrost Mode, the Off

cycle air defrost will always terminate on time.

NOTE: The unit cooler (electric defrost model only) also

employs a fixed setting mechanical Heater Safety

thermostat that can terminate the defrost cycle if for

some reason the defrost cycle is not terminated on

temperature or time via the ArcticFox controller.

www.manitowocfoodservice.com 800-225-9916 - 37 -

The delay time in minutes after a defrost cycle has ended

Cooler Defrost Alarm Hold Off

Pre-Set

before a high temp alarm can occur.

Parts List:

The following is the parts list of items that can be serviced. The user interface is not

serviceable and if damaged, must be replaced as a unit. If the Smart Relay Board must

be replaced, proper ESD handling procedures must be followed.

Evaporator Part Description Part Number

Wall Mounting Bracket 550003550

User Interface 550002636

Smart Relay Boards

Cooler - 550002640-SRB-MAC-C

Freezer - 550002640-SRB-MAC-F

Electric Expansion Valve 550002639

Electric Expansion Valve Cable 10’

with connector 550003062

Terminal Block, 32 position 550002641

Transformer 550002642

Wire Harness, 78” Transformer 550002650

Wire Harness, 132” Transformer 550003044

Wire Harness, 24” Temp Sensor 550002643

Wire Harness, 72” Temp Sensor 550002644

Wire Harness, 132” Temp Sensor 550002645

Pressure Transducer 550002646

Fuse, .250A, 250V 550002655

Cable, CAT-5e (2’) Extension 550003057

Bracket, CAT-5e connecter 550003060

Fuse Holder 550002656

CAT5E Cable (50’) 550002651

CAT5E Cable (100’) 550003182

CAT5E Cable (200’) 550003783

CAT5E Cable (300’) 550003784

Wire Harness, 72” Transducer 550002647

Wire Harness, 132” Transducer 550002658

Wire Harness, 168” Transducer 550002659

www.manitowocfoodservice.com 800-225-9916 - 38 -

MAC 7 & MAC 8 Condensing Units

Condensing Unit Part Description Part Number

Compressor CF04K6E-TF5

208-230/3/60 (MAC 7 & 8, CLR) 550002804

Compressor ZF13K4E-TF5

208-230/3/60 (MAC 7, FZR) 030000978

Compressor ZF15K4E-TF5

208-230/3/60 (MAC 8, FZR) 030001789

Low Pressure Switch

(MAC 7 & 8, CLR) 030001344

High Pressure Switch 030001347

Low Pressure Control

(MAC 7 & 8, FZR) 550003572

3/8 Check Valve

(MAC 7 & 8, CLR) 550004787

½ Check Valve

(MAC 7 & 8, FZR) 550004788

Compressor Contractor 11167R

Defrost Lockout Relay

(MAC 7 & 8, FZR) 550003755

Pump Down Relay

(MAC 7 & 8, FZR) 550003755

Head Pressure Control Valve

(MAC 7 & 8, CLR) 550003791

Head Pressure Control Valve

(MAC 7 & 8, FZR) 550003793

Fan Contactor R1, R2, R3, R4 12164C

Condenser Fan Motor 550003547

Condenser Fan Motor Capacitor 550003548

Condenser Fan Blade 550003573

Condenser Fan Motor

Mounting Bracket 550002621

Wire Grille 550003790

www.manitowocfoodservice.com 800-225-9916 - 39 -

Maintenance

Maintenance Chart

Area Task Frequency

Evaporator Check for proper defrosting Monthly

Clean the coil and drain pan Every 6 months

Check for proper drainage

Condenser Inspect /clean the coil if the air supply is near polluting sources

(such as cooking appliances)

Clean the coil surface Every 3 months

General Check/tighten all electrical connections Every 6 months

Check all wiring and insulators

Check contactor for proper operation and contact point deterioration

Check all fan motors

Tighten fan set screws, and motor mount nuts and bolts

Check the operation of the control system

Make certain all safety controls are operating properly

Check operation of the drain line heater and examine for cuts and

abrasions

Check/tighten all mechanical/flare connections

Monthly

CAUTION

Failure to keep the condenser coil clean will result in reduced airflow through the

condenser, resulting in poor system performance and premature compressor failure.

Polyol Ester (POE) Lubricants:

Polyol Ester (POE) lubricants quickly absorb moisture from the ambient surroundings.

POE lubricants absorb moisture more rapidly and in greater quantity than conventional

mineral oils. Because moisture levels greater than 100 PPM will result in system

corrosion and component failure, it is essential that system exposure to ambient

conditions be kept to a minimum.

If a system is left open to the atmosphere for more than 15 minutes, the liquid line drier

and compressor oil must be replaced. Drain at least 95% of the oil from the compressor

suction port. Measure the amount of removed oil, and replace it with exactly the same

amount of new POE oil.

Mobil EAL™ ARCTIC 22 CC is the preferred Polyol Ester lubricant because of its

particular additives. ICI Emkarate RL 32S is an acceptable alternative when the Mobil

is not available. These POE lubricants must be used with HFC refrigerants. Lubricants

are packaged in specially designed, sealed containers. Once opened, use the lubricant

immediately. Properly dispose of any unused lubricant.

www.manitowocfoodservice.com 800-225-9916 - 40 -

Notes:

Warranty Information

For information regarding warranty guidelines, claim form, product registration, warranty

verification, or locating a service provider please visit our website at

www.manitowocfoodservice.com or call 1-800-225-9916.

www.manitowocfoodservice.com 800-225-9916 - 41 -

System Start-Up Data Sheet

A permanent data sheet must be prepared on each installation. A completed copy should be retained

with this manual.

System Reference Data

The following information should be filled out and signed by Refrigeration Installation Contractor:

Date System Installed: / /

Installer and Address:

Phone Number: ( ) -

Service Agency:

Phone Number: ( ) -

Condensing Unit: Model Number:

Serial Number:

Compressor Model Number: Compressor Model Number:

Compressor Serial Number: Compressor Serial Number:

Electrical: Volts: Phase:

Voltage at Compressor: L1: L2: L3:

Amperage at Compressor: L1: L2: L3:

Evaporator(s): Quantity:

Evaporator Model Number: Evaporator Model Number:

Evaporator Serial Number: Evaporator Serial Number:

Electrical: Volts: Phase:

Expansion Valve Manufacturer/Model Number:

Ambient at Start-Up: °F

Design Box Temperature: °F °F

Operating Box Temperature: °F °F

Thermostat Setting: °F °F

Defrost Settings: /day minutes failsafe /day minutes failsafe

Compressor Discharge Pressure: PSIG PSIG

Compressor Suction Pressure: PSIG PSIG

Suction Line Temperature at Compressor: °F °F

Discharge Line Temperature at Compressor: °F °F

Superheat at Compressor: °F °F

Suction Line Temperature at Evaporator: °F °F

Superheat at Evaporator: °F °F

Evacuation: # Times Final Micron # Times Final Micron

Evaporator Drain Line Trapped Outside of Box: Yes No

www.manitowocfoodservice.com 800-225-9916 - 42 -

Appendix A – Sensor Failure Codes:

UI Error Code

Value

0001

0002

0004

0008

0010

0003

0005

0006

0007

0009

000A

000B

000C

000D

000E

000F

0011

0012

0013

SENSOR FAILURE SCENARIOS

Evap Out (suct. Line) Temp Sensor Failure

Defrost Termination Sensor Failure

Evap Out (suct. Line) Temp Sensor Failure

Evap Out (suct. Line) Temp Sensor Failure

Evap Out (suct. Line) Temp Sensor Failure

Evap Out (suct. Line) Temp Sensor Failure

Evap Out (suct. Line) Temp Sensor Failure

Evap Out (suct. Line) Temp Sensor Failure

Evap Out (suct. Line) Temp Sensor Failure

Defrost Termination Sensor Failure

Defrost Termination Sensor Failure

Defrost Termination Sensor Failure

ARCTICFOX

Pressure Sensor Failure

Coil Air In Sensor Failure

Coil Air Out Sensor Failure

Pressure Sensor Failure

Coil Air In Sensor Failure

Pressure Sensor Failure

Coil Air Out Sensor Failure

Coil Air In Sensor Failure

Coil Air Out Sensor Failure

Pressure Sensor Failure

Coil Air In Sensor Failure

Coil Air Out Sensor Failure

Pressure Sensor Failure

Coil Air In Sensor Failure

Pressure Sensor Failure

Coil Air In Sensor Failure

Coil Air Out Sensor Failure

Pressure Sensor Failure

Coil Air Out Sensor Failure

Coil Air In Sensor Failure

Coil Air Out Sensor Failure

Pressure Sensor Failure

Coil Air In Sensor Failure

Coil Air Out Sensor Failure

Pressure Sensor Failure

Coil Air In Sensor Failure

Pressure Sensor Failure

Coil Air In Sensor Failure

- 43 -

Appendix A – Sensor Failure Codes Continued:

UI Error Code

Value

0014

0015

0016

0017

0018

0019

001A

001B

001C

001D

001E

001F

SENSOR FAILURE SCENARIOS

Coil Air Out Sensor Failure

Defrost Termination Sensor Failure

Coil Air Out Sensor Failure

Defrost Termination Sensor Failure

Coil Air Out Sensor Failure

Defrost Termination Sensor Failure

Defrost Termination Sensor Failure

Coil Air Out Sensor Failure

Evap Out (suct. Line) Temp Sensor Failure

Defrost Termination Sensor Failure

Evap Out (suct. Line) Temp Sensor Failure

Defrost Termination Sensor Failure

Evap Out (suct. Line) Temp Sensor Failure

Defrost Termination Sensor Failure

Evap Out (suct. Line) Temp Sensor Failure

Defrost Termination Sensor Failure

Coil Air Out Sensor Failure

Evap Out (suct. Line) Temp Sensor Failure

Defrost Termination Sensor Failure

Coil Air Out Sensor Failure

Evap Out (suct. Line) Temp Sensor Failure

Defrost Termination Sensor Failure

Coil Air Out Sensor Failure

Evap Out (suct. Line) Temp Sensor Failure

Defrost Termination Sensor Failure

Coil Air Out Sensor Failure

Evap Out (suct. Line) Temp Sensor Failure

Defrost Termination Sensor Failure

ARCTICFOX

Coil Air In Sensor Failure

Pressure Sensor Failure

Coil Air In Sensor Failure

Pressure Sensor Failure

Coil Air In Sensor Failure

Pressure Sensor Failure

Coil Air In Sensor Failure

Pressure Sensor Failure

Coil Air In Sensor Failure

Pressure Sensor Failure

Coil Air In Sensor Failure

- 44 -

Appendix B - Cooler or Freezer Setup:

The table below lists the items contained in the SETUP menu and their use.

Item Name Range

Increment

Superheat 4F – 20F Sets the target Superheat for the unit

On Hysteresis Pre-Set

Off Hysteresis Pre-Set

Door Heater On

Time

Door Heater Off

Time

Set Light on

Max time

Set Light off

Delay After

Door Close

Set Light Off

Delay After

Manual Off

Set Light Opera

Mode

Logging

Enabled

0hr – 23:45hr

(15min steps)

0hr – 23:45hr

(15min steps)

15-120 min

(1 min steps)

0-120 min

(1 min steps)

0-120 min

(1 min steps)

On/Off

YES/NO

Number of degrees above the set point where the

cooling cycle will re-start

Number of degrees below the set point where the

cooling cycle will end

The Time-Of-Day the door heater will turn on

The Time-Of-Day the door heater will turn off (If

equal to Door Heater On Time then the heater is

always on)

Maximum time the inside lights will be on regardless

of manual or door status

Length of time to wait after the door closed before

turning off the lights

Length of time to wait after the Manual Light is

turned off before turning the lights off.

Flash lights 5 times 1 minute before turning them off

to give fair warning to anyone inside the unit. Must

be off if fl. lights are used

Enables logging ONLY IF a USB flash drive is

inserted

Contents

Note: Light functionality is only available if the lights are controlled by ArcticFox controller.

- 45 -

Appendix C - Defrost Setup:

The Table below lists the configurable parameters associated with the Defrost for either the Cooler

or Freezer.

Item Name Range/

Contents

Increment

Start Defrost

(manual)

No/Yes

Start a cooler defrost cycle outside of the normally

scheduled/calculated defrost

Defrost Mode Electric/Air Air or Electric

Defrost

Threshold (%)

Defrost Safety

Timer Mode

0 – 99 %

(1% steps)

Pre-Set

This number set the threshold (%) that must occur before

the demand defrost will activate. Higher number mean

more frost will accumulate

There are two modes for the safety timer.

1) Time between defrosts

2) Continuous Compressor Run Time

There are two meanings for this time and the meaning is

selected by the Defrost Safety Timer Mode (See above)

1) Maximum number of minutes between defrosts.

After a manual defrost or Demand defrost the

Defrost Safety

Timer

Pre-Set

counter starts at zero.

2) Maximum number of minutes of continuous

compressor run time before the system is forced to

defrost. The counter is cleared when a cooling

cycle ends

Defrost Drip

Time

Defrost Fan On

delay

Defrost Max

Temp

Defrost Max

Time

Defrost Heater

Delay

Defrost Calc

start Temp

Defrost Alarm

Hold-off

Pre-Set

Pre-Set

Pre-Set

Pre-Set

Pre-Set

Pre-Set

Pre-Set

Number of minutes to wait after heaters turn off before

compressor turns on.

Number of minutes to wait after the drip time ends before

allowing the fans to restart.

This is the temperature at which the defrost cycle is

terminated

This is the maximum number of minutes the defrost cycle

will run

Delay between the start of the defrost and the time the

electric heater is started. This allows the compressor to

pump-down

This value determines when the demand defrost

calculation is started during the cooling cycle. Higher

values start the calculation earlier but may cause false

defrosts

Hold time after defrost before a high temp alarm can

occur. This allows the cooling cycle to cool the evaporator

before testing for high temperature violations

- 46 -

Appendix D – Condensing Unit Wiring Diagram:

- 47 -

Appendix D – Condensing Unit Wiring Diagram -Continued:

- 48 -

Appendix E – Air Defrost Wiring Diagram:

- 49 -

Appendix F – Electric Defrost Wiring Diagram:

- 50 -

Appendix G – Standard Exterior Door Section Wiring:

- 51 -

Appendix H – Standard Partition Door Section Wiring:

- 52 -

- 53 -

Loading...

Loading...