Page 1

Original Issue Date: 12/04

Model: RDT, HDT, and KSS-J Automatic Transfer Switches

Market: ATS

Subject: Programmable Exerciser Kits GM47597-KA1, -KA2, KA3, -KP1, -KP2,

and -KP3; GM48913; GM48919, and GM64108

(GM38798-KA1, -KA2, KP1, KP2, discontinued*)

TT-1403 4/16c

INSTALLATION INSTRUCTIONS

Introduction

Use the Programmable Exerciser Kit with the following

transfer switch models:

D RDT

D HDT

D KSS-J with Decision-Makerr MPAC 750 Controller

Service kits are also available to replace the exercise

timer on transfer switches equipped with S340 controls.

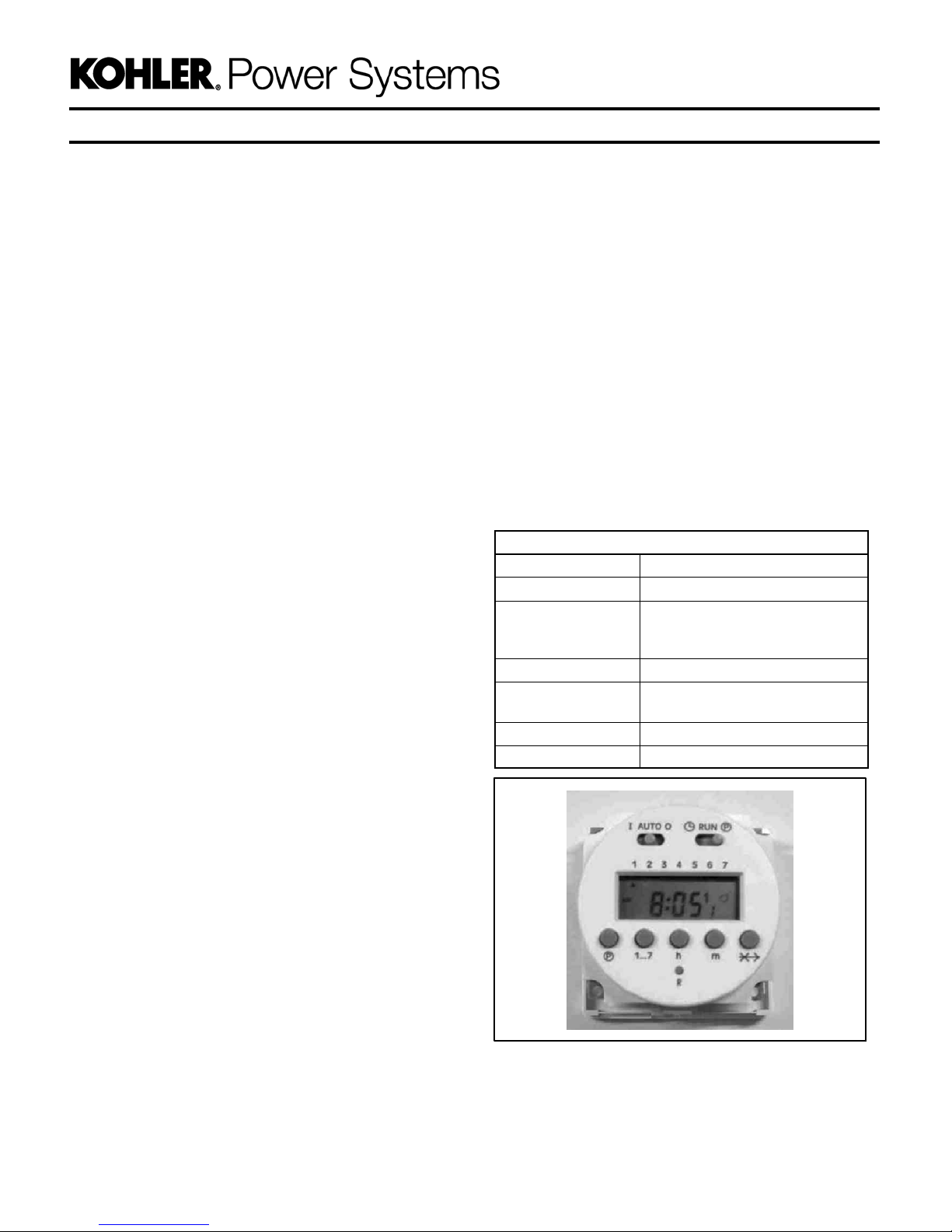

Figure 1 shows the programmable exerciser timer. See

Figure 3 through Figure 5 for illustrations of installed

exerciser timers.

Use the programmable exerciser kit to schedule

generator set exercise runs in addition to the weekly or

biweekly exercise set through the ATS controls. The

programmable exerciser kit can also be used for peak

shaving by scheduling the system to start the generator

set and transfer the load at selected times and days.

Optional Accessory Board GM38796-KA1 or -KP1 is

required for connection and operation of the

programmable exerciser kit on Model RDT transfer

switches.

Timer Features

D 24 hour/7 day timing combined

D 8 on/off operations daily, up to 56 switching (on or off)

cycles per week

D 5 year lithium battery for backup power

D 24 hour display (military time or AM/PM)

D Manual override

D Skip a day feature

Programmable Timer Specifications

Switching SPDT

Switch rating 16 A @ 45C; 10 A @ 55C

Supply voltage 120VAC, 50/60 Hz (GM60427)

Rated power 3.5 VA

Operating

temperature range

Connections 6.3 x 0.8 tab terminals

Shortest switch time 1 minute

240VAC, 50/60 Hz (GM64028)

5-year lithium backup battery

-- 1 0 Cto55C

(--14F to 131F)

The programmable exerciser kits include

programmable timer GM64027 or GM64028, mounting

hardware, and connecting leads as required.

Read the entire installation procedure and compare the

kit parts with the parts list at the end of this publication

before beginning installation. Perform the steps in the

order shown. The installation and wiring must comply

with the National Electrical Code and applicable local

codes.

* Discontinued kits. See page 13 for instructions.

Figure 1 Programmable Exerciser GM64027 (120V)

and GM64028 (240V)

Page 2

Safety Precautions

Observe thefollowing safetyprecautions whileinstalling

the kit.

DANGER

WARNING

Accidental starting.

Can cause severe injury or death.

Disconnect the battery cables before

working on the generator set.

Remove the negative (--) lead first

when disconnecting the battery.

Reconnect the negative (--) lead last

when reconnecting the battery.

Disabling the generator set. Accidental starting can

cause severe injury or death. Before working on the

generator set or connected equipment, disable the generator

set as follows: (1) Move the generator set master switch to the

OFF position. (2) Disconnect thepower to the battery charger.

(3) Remove the battery cables, negative (--) lead first.

Reconnect the negative (--) lead last when reconnecting the

battery. Follow these precautions to prevent starting of the

generator set by an automatic transfer switch, remote

start/stop switch, or engine start command from a remote

computer.

(Decision-Makerr 3+ and 550 Generator Set Controllers)

Disabling the generator set. Accidental starting can

cause severe injury or death. Before working on the

generator set or equipment connected to the set, disable the

generator set as follows: (1) Press the generator set off/reset

button to shut down the generator set. (2) Disconnect the

power to the battery charger, if equipped. (3) Remove the

battery cables, negative (--) lead first. Reconnect the negative

(--) lead last when reconnecting the battery. Follow these

precautions to prevent the starting of the generator set by the

remote start/stop switch.

(RDC, DC, RDC2, DC2, Decision-Makerr 3000, 3500 and

6000 Generator Set Controllers)

DANGER

Hazardous voltage.

Will cause severe injury or death.

Disconnect all power sources before

opening the enclosure.

Hazardous voltage.

Will cause severe injury or death.

Only authorized personnel should

open the enclosure.

Short circuits. Hazardous voltage/current can cause

severe injury or death. Short circuits can cause bodily injury

and/or equipment damage. Do not contact electrical

connections with tools or jewelry while making adjustments or

repairs. Remove all jewelry before servicing the equipment.

NOTICE

Foreign material contamination. Cover the transfer switch

during installation to keep dirt, grit, metal drill chips, and other

debris out of the components. Cover the solenoid mechanism

during installation. After installation, use the manual operating

handle tocycle thecontactor toverify that it operates freely. Do

not use a screwdriver to force the contactor mechanism.

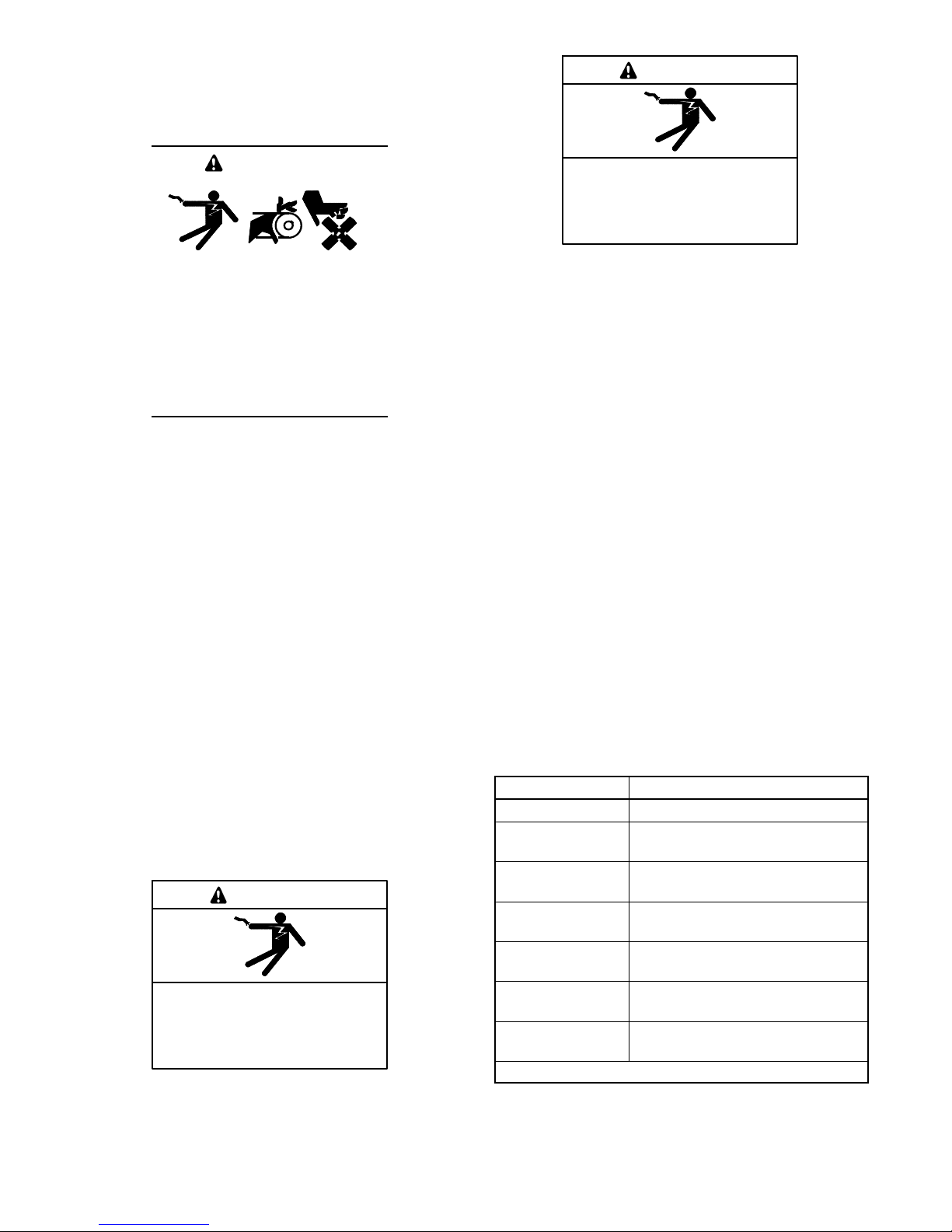

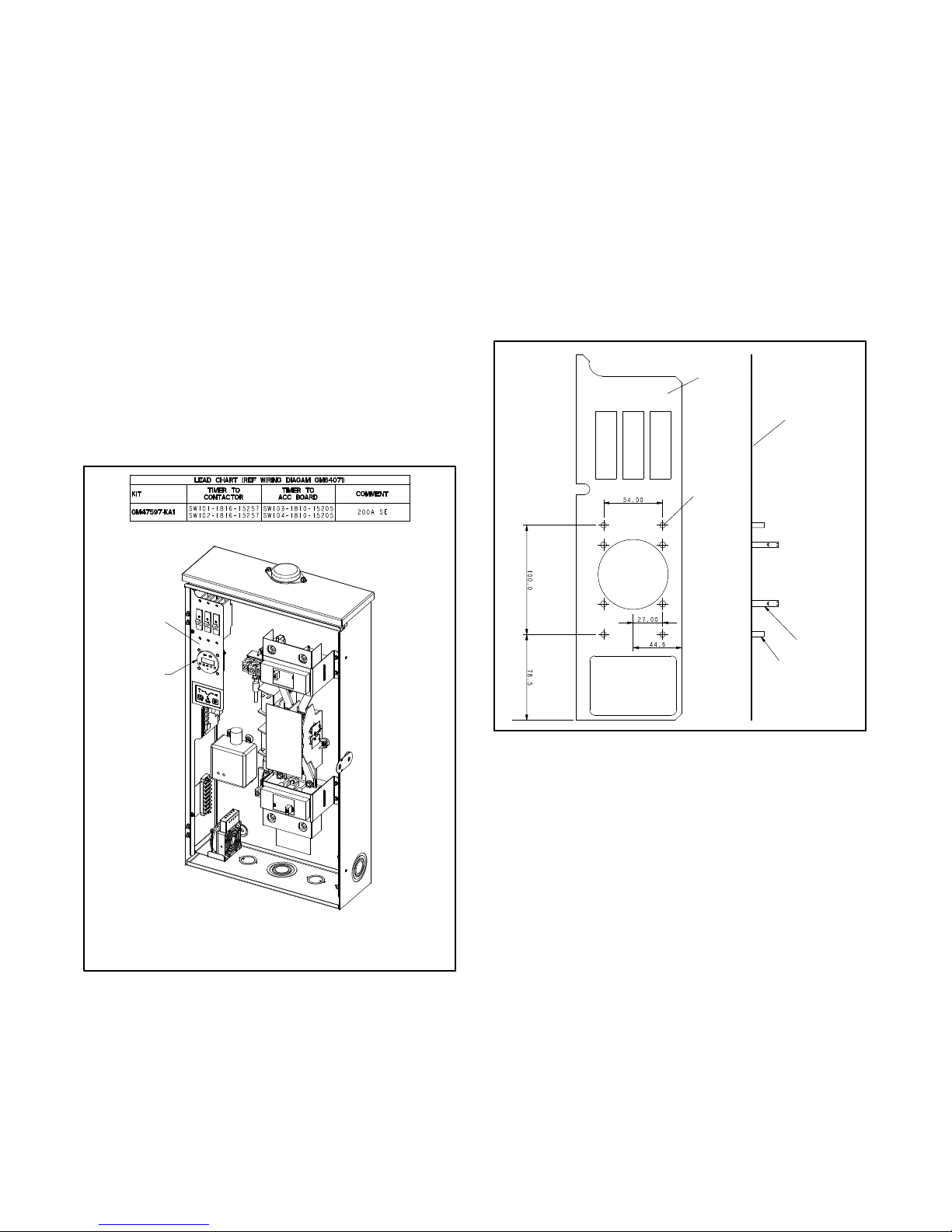

1 Kit Application Notes

Figure 2 lists the available programmable exerciser kits

and their applications. Kits include the programmable

exerciser timer and mounting hardware.

To replace the older style timer GM39330 on the

200 Amp service entrance rated model RDT, service kit

GM64108 is required. The service kit includes a retrofit

mounting panel that is required for timer replacement on

the 200 Amp service entrance rated Model RDT only.

Service kitsare also availablefor exerciser replacement

on transfer switches equipped with S340 controls.

Kit Number Application

GM47597-KP2 100--200 Amp Model RDT

GM47597-KP1 400 Amp Model RDT;

GM47597--KP3

GM48913 Service Kit for S340 Controls,

GM48919 Service Kit for S340 Controls,

GM64108 Service Kit for 200 Amp RDT SE *

GM38798-KA1,

-KA2, -KP1, -KP2

* SE = Service Entrance Model

200 and 400 Amp Model RDT SE *

Model KSS-J with Decision-Makerr

MPAC 750 Controller

120 VAC

240 VAC

(replaces timer GM39330)

Kits with timer GM39330.

Discontinued; see page 13.

2 TT-1403 4/16

Figure 2 Programmable Exerciser Kit Application

Page 3

2 Installation Procedure

2.1 Mounting, 100--200 Amp Model RDT

Note: For factory-installed exerciser kits, proceed to

section 5.

1. Disable the generator set to prevent accidental

starting:

a. Shutdown the generator set by either moving

the generator set master switch to OFF or by

pressing the OFF/RESET button on the

generator set controller.

b. Disconnect power to the battery charger, if

equipped.

c. Disconnect the generator set engine starting

battery, negative (--) lead first.

2. Disconnect power to the transfer switch before

opening the ATS enclosure.

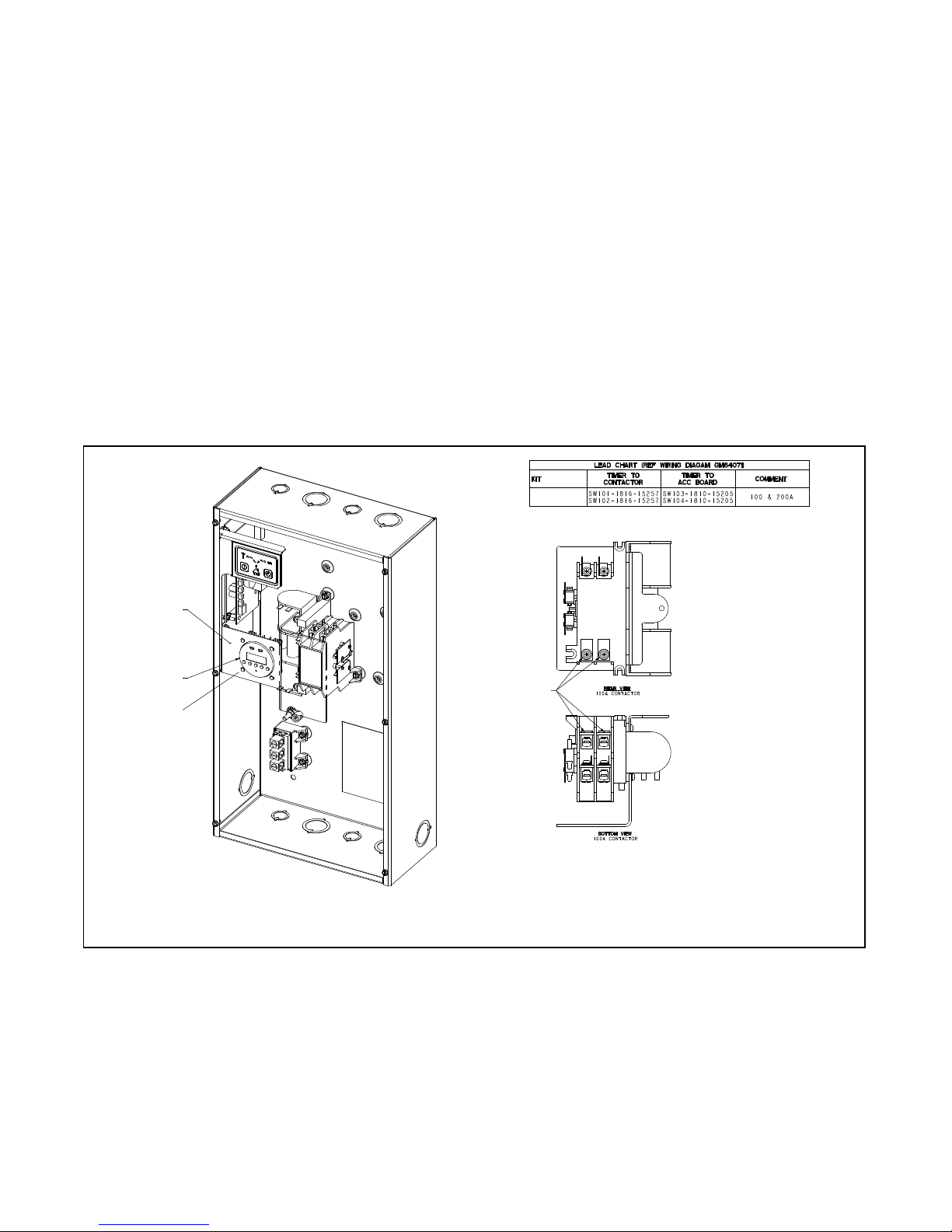

SeeFigure3.

1. Install timer mounting bracket GM64057 over the

controller bracket as shown in Figure 3. Use the

existing controller bracket nuts to secure the timer

mounting bracket to the bottom 2 studs.

2. Insert the timer through the opening in the bracket.

Secure the timer to the four standoffs using four

mounting screws X-49-2 provided with the kit.

3. Proceed to the Wiring Section for timer

connections.

Note: For 100 Amp models: Insert the lead ring

terminals through the slot under the bus and

under the flat washer on the load lug. See

Figure 3.

GM47597-- KP2

GM47597

1

2

3

1. Mounting bracket GM64057

2. Timer GM64028

Figure 3 Mounting, 100--200 Amp Model RDT

4

GM38798

3. Screws X-49-2 (qty. 4)

4. Load lugs. See step 3 and note, above.

TT-1403 4/16 3

Page 4

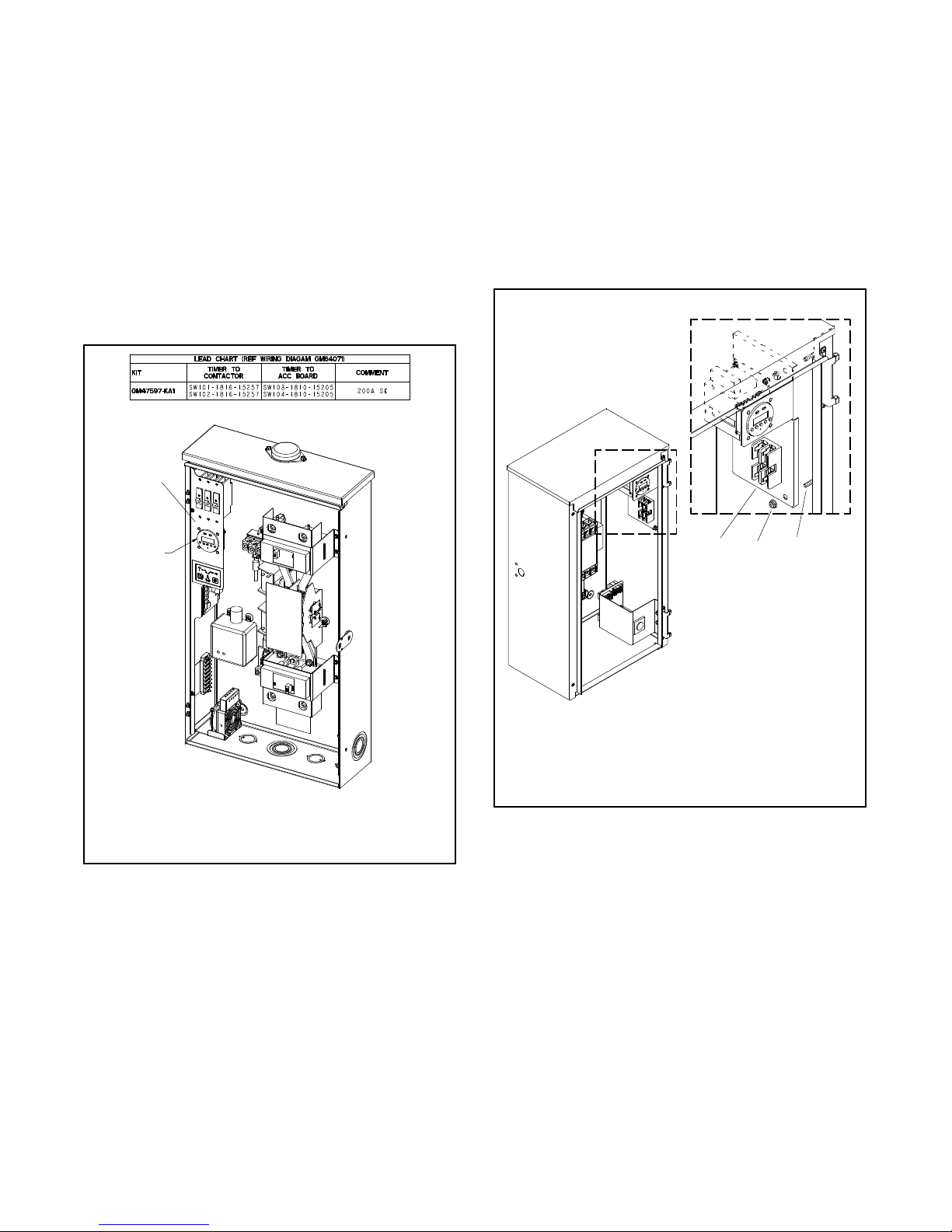

2.2 Mounting, 400 Amp Model RDT,

Service Entrance Rated 200 Amp or

400 Amp Model RDT

SeeFigure4.

1. Replace the existing mounting bracketwith bracket

GM64055 provided with the kit. See Figure 4.

2. Insert the timer through the opening in the bracket.

Secure the timer to the four standoffs using four

mounting screws X-49-2 provided with the kit.

3. Proceed to the Wiring Section for timer

connections.

1

2.3 Mounting, Models KSS-J with

Decision-Makerr MPAC 750 Controller

1. Align the mounting holes on the timer bracket

GM89060 with the two mounting studs on the

inside of the transfer switch box. See Figure 5.

1. Secure the timer kit to the studs with the two

X-6210-2 nuts provided with the kit. See Figure 5.

2. Proceed to the Wiring Section 3.2 for timer

connections.

2

GM47597

1. Bracket GM64055

2. Timer GM64028 with screws X-49-2 (qty. 4)

Figure 4 Mounting, 400 Amp Model RDT or 200

Amp and 400 Amp Service Entrance Rated

Model RDT

1

2

1. Bracket GM89060

2. Nut X-6210-2 (qty. 2)

3. Mounting Stud

Figure 5 Mounting, Models KSS-J with

Decision-Makerr MPAC 750

3

GM46745

4 TT-1403 4/16

Page 5

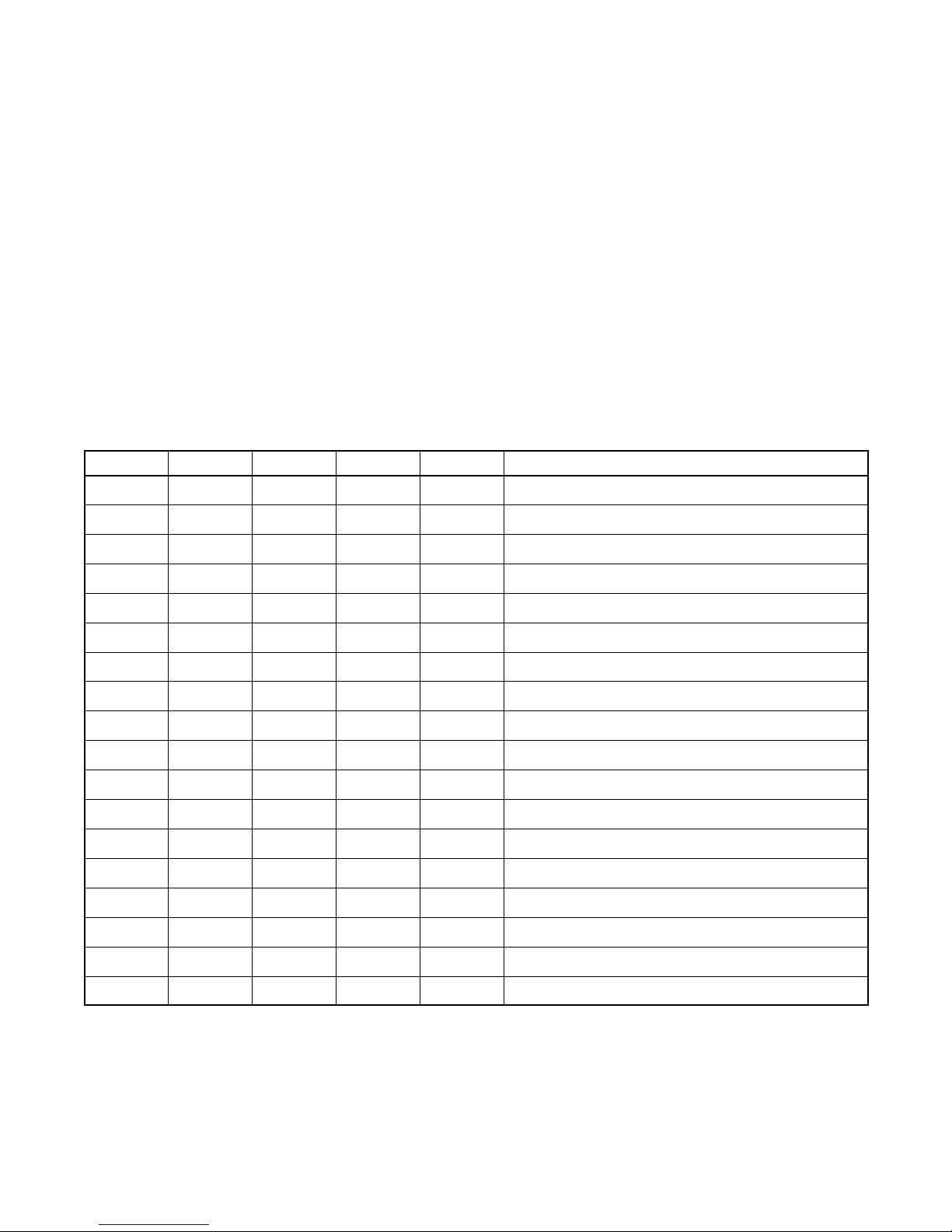

2.4 Service Kit GM64108, Retrofit Timer

Replacement Kit for the Service

Entrance Rated 200 Amp Model RDT

See Figure 6 and Figure 7. Use Service Kit GM64108 to

replace an old style timer GM39330 with timer

GM64028. The service kit includes retrofit mounting

panel GM64074.

from metal drill chips. Drill four 1/4 inch diameter

holes through the existing mounting bracket at the

marked locations.

2. Align and insert the mounting studs on the retrofit

mounting bracket through the newly drilled holes

on the existing mounting bracket. Thread nuts

X-6210-1 onto the mounting studs to secure. See

Figure 6 and Figure 7.

Tools Required:

D Electric drill with 1/4 in. chuck (minimum)

D 1/4 inch dia. drill bit

NOTICE

Foreign material contamination. Cover the transfer switch

during installation to keep dirt, grit, metal drill chips, and other

debris out of the components. Cover the solenoid mechanism

during installation. After installation, use the manual operating

handle tocycle thecontactor toverify that it operates freely. Do

not use a screwdriver to force the contactor mechanism.

2

1

3. Secure the timer tothe four standoffsusing the four

mounting screws X-49-2 provided with the kit.

4. Proceed to the Wiring Section for timer

connections.

1

1

2

3

2

Figure 7 Retrofit Mounting Panel GM64074

GM47597

1. Timer GM64028 with screws X-49-2 (qty. 4)

2. Mounting bracket GM64074 with nuts X-6210-1 (qty. 4)

Figure 6 Retrofit Timer Replacement Service Kit

GM64108 for Service Entrance-Rated 200

Amp Model RDT

1. Using the dimensions in Figure 7 or retrofit panel

GM64074 as a guide, mark four holes on the

existing mounting bracket at the locations of the

four studs on the retrofit panel. Cover the

components inside the enclosure to protect them

TT-1403 4/16 5

Page 6

3 Wiring

3.1 RDT Models

DANGER

Hazardous voltage.

Will cause severe injury or death.

Disconnect all power sources before

opening the enclosure.

Short circuits. Hazardous voltage/current can cause

severe injury or death. Short circuits can cause bodily injury

and/or equipment damage. Do not contact electrical

connections with tools or jewelry while making adjustments or

repairs. Remove all jewelry before servicing the equipment.

Wiring must comply with the National Electrical Code

and applicable local codes.

Note: Check that the supply voltage matches the

voltage marked on the unit. Wiring to incorrect

voltage will void the warranty.

1

1. Verify that power has been disconnected as

described in Section 2, Installation Procedure.

2. Use the leads supplied with the kit to connect the

timer according to the wiring diagrams. See

Figure 8.

Note: For 100 Amp models: Insert the lead ring

terminals through the slot under the bus and

under the flat washer on the load lug. See

Figure 3.

2

1. Accessory Board

2. DIP - Switches

3. Timer

4. Contactor (200Amp Shown)

Figure 8 Wiring Diagram for RDT Models

3

4

GM64071

6 TT-1403 4/16

Page 7

3.2 KSS-J Models with Decision-Makerr

MPAC 750 Controllers

1. Verify that power has been disconnected as

described in Section 2, Installation Procedure.

2. Use harness leads GM91325,supplied, to connect

the exercise kit according to the wiring diagram in

Figure 10. Connect the timer to the controller

(leads 103 and 104) and connect the fuse block to

the contactor (leads LA and LC). Use piggyback

terminals 233704 at the contactor if needed.

3. Connect the transformer to supply the correct

voltage to the timer. Configure the primary and

secondary transformer connections for the

corresponding system voltage. See Figure 9 and

Figure 11.

Transformer Connections

System Voltage

208 H1, H2 X1, X4

220--240 H1, H2 X1, X3

380--416 H1, H3 X1, X3

480 H1, H4 X1, X3

Primary Secondary

Figure 9 Transformer Wiring Configuration Chart

2

3

1

1. Decision- Makerr MPAC 750 Controller

2. Harness GM91325

3. Timer GM64027

4. Fuse blocks X-6129-2 and X-6129-4

5. Contactor

6. Transformer GM40071

4

5

6

Figure 10 Wiring Diagram for KSS-J Models with Decision-makerr MPAC 750 Controller

2

GM91312

1

1. Primary Transformer

Connections

2. Secondary Transformer

Connections

Figure 11 Diagram Detail, Transformer Wiring Configuration (208 V shown; see Figure 9 for other voltages)

TT-1403 4/16 7

GM91312

Page 8

4 Service Kits GM48913 and

GM48919

Use the service kit GM48913 (120VAC) or

GM48919 (240VAC) to replace failedexercise timerson

transfer switches equipped with S340 controls. The

service kits include the exercise timer GM64027, timer

enclosure GM64054, and a DIN rail for timer mounting.

See Figure 12 and Figure 13.

GM64027

Figure 12 Timer with Enclosure

5 Setup

After connecting the wiring leads, the controllers must

be set for loaded or unloaded exercise. Follow the

specific instructions below for either the RDT or KSS-J

model transfer switches.

Note: Changing the type of exercise (loaded or

unloaded) that is run by the exercise timer does

not affect the type of exercise that is set by the

transfer switch controller.

5.1 Setup for RDT Models

On RDT model transfer switches, the exercise timer

must be set manually to run either loaded or unloaded

exercises. Set DIP switch #2 on the Accessory Board to

select loadedor unloaded exercise runs. SeeFigure 14.

See Figure 8 for the location of the DIP switches on the

accessory board.

D Set DIP switch #2 to the OFF position to run the

generator set without transferring the load, or

D Set DIP switch #2 to the ON position to start the

generator set and transfer the load during exercise

runs. For peak shave applications, set the DIP switch

to the ON position.

OFF

DIP Switch

2 Loaded Exercise Unloaded Loaded

(open)

ON

(closed)

1 2

GM64087

1. To power source:

120 VAC (GM64027 timer)

240 VAC (GM64028 timer

2. Engine start connection

Figure 13 Wiring Diagram for Service Kits GM48913

and GM48919

Figure 14 Accessory Board DIP Switch Setting

1

2

1. Accessory

Board

2. DIP

Switches

GM64027

Figure 15 Detail, Dip Switch Location

8 TT-1403 4/16

Page 9

5.2 Setup for KSS-J with Decision-Makerr

MPAC 750

On KSS-J model transfer switches, use SiteTecht

software to change the default setting (unloaded) for

exercises that are run by the exercise timer. Kohler

SiteTech is available to Kohler authorized distributors

and dealers. For detailed information on using SiteTech

software, see the SiteTech operation manual, TP-6701.

Note: On the MPAC 750 controller, the default setting

for the exercise timer will be unloaded.

Note: The exerciser timer uses the remote test feature

to provide the exerciser timer functionality. If

necessary, an exercise started by the

programmable exerciser can be stopped locally

by pressing and holding the TEST button on the

MPAC 750 controller for about two seconds.

1. Reconnect power as described in Section 6.

2. Use a USB cable to connect the Decision-Makerr

MPAC 750 controller to your personal computer.

3. Launch the SiteTech software.

4. Select Prog. Inputs at the top of the screen.

5. For Mainboard Input 1, select Remote Test from

the drop-down menu. See Figure 16.

6. Select Parameters at the top of the screen.

7. Scroll down to Accessory Setup A1 and click on

the arrow to expand the menu. See Figure 17.

8. Find Accessory Setup A1 Remote Test Load in

the list and select either Loaded orUnloaded from

the drop-down menu in the second column.

9. Select Apply Changes from the top menu to set

the changes and complete the procedure.

Figure 17 SiteTech Software, Programming Exercise

Timer

Figure 16 SiteTech Software, Programming Exercise

Timer

TT-1403 4/16 9

Page 10

6 Reconnect Power

7.1 Setting the timer

DANGER

Hazardous voltage.

Will cause severe injury or death.

Only authorized personnel should

open the enclosure.

Short circuits. Hazardous voltage/current can cause

severe injury or death. Short circuits can cause bodily injury

and/or equipment damage. Do not contact electrical

connections with tools or jewelry while making adjustments or

repairs. Remove all jewelry before servicing the equipment.

Reconnect power to the system.

1. Install the transfer switch enclosure door(s).

2. Reconnect power to the transfer switch.

3. Reconnect the generator set engine starting

battery, negative (--) lead last.

4. Reconnect power to the battery charger, if

equipped.

7 Programming and Operation

The timer provides flexible timing for daily and/or weekly

programming. The single-channel timer combines

24 hour/7 day timing.

Each exerciseperiod requiresseparate programming of

the ON and OFF time. Up to 8 on/off operations are

allowed for each day for a total of up to 56 switching

cycles per week.

Be sure to program an off cycle after every on cycle.

The minimum time setting is 1 minute.

Setting the current time and day

1. Slide RUN switch to left symbol of clock face.

2. Press the 1.7 button until the arrow points to

current day (1=Monday, 2=Tuesday, etc.). Press

the h (hour) and m (minute) buttons to set the

current time. Pay attention to the AM/PM indicator.

The PM indicator shows from noon to 11:59 p.m.

3. Slide the RUN switch to run. The clock colon

between the hours and minutes blinks when the

clock is running.

1

14

2

3

DANGER

Hazardous voltage.

Will cause severe injury or death.

Only authorized personnel should

open the enclosure.

Short circuits. Hazardous voltage/current can cause

severe injury or death. Short circuits can cause bodily injury

and/or equipment damage. Do not contact electrical

connections with tools or jewelry while making adjustments or

repairs. Remove all jewelry before servicing the equipment.

Remove the transfer switch enclosure door(s)to access

the programmable exerciser. Do not contact electrical

connections when programming the exerciser.

Note: A lithium battery provides 5 year backup power.

The timer can be programmed after installation

before reconnecting power to the transfer switch.

13

12

1. AUTO switch

2. RUN switch

3. Number 1 indicates

single channel timer

4. Switch on indicator

(light bulb symbol)

5. Cycle number indicator

6. Skip indicator

7. Skip a day button

10

8. Minutes button, m

9. Hour button, h

10. Reset button

11. 1...7 day selection

button

12. Program button

13. AM/PM indicators

14. Day 1--7 indicators

Figure 18 Timer Switches and Display

4

5

6

tt1403

78911

10 TT-1403 4/16

Page 11

7.2 Programming the Exercise Cycles

Use the procedures in the following sections to program

up to 8 on/off events for each day of the week.

Note: After each ON cycle, be sure to program a

corresponding OFF cycle for the same days of

the week.

After all exercise cycles have been programmed, slide

the RUN switch to the RUNposition. The clock colon will

blink.

7.2.1 Day Selection

For each on or off cycle, you will need to set the day or

days of the week. To save time you can set up each

on/off cycle for one day, Monday through Friday,

weekends only, all days except Sunday, or the entire

week. This can save a lotof time when programming the

on and off cycles.

1. Slide the RUN switch to P.

2. Press the 17 button seven times and notice a

single arrow will move in steps below the 1--7

numbers, indicating the individual days of the week

3. Press the 17 button again to see days 1 to 5

highlighted with arrows (Monday through Friday).

4. Press 17 againto seearrows highlighting 6 and 7

(weekends).

5. Press 17 again to see arrows highlighting all

days except Sunday.

6. Press 17 again to see arrows highlighting all

days of the week.

7.2.2 Programming an ON cycle

1. Slide the RUN switch to P. The lower number 1

indicates thisis the first switch cycleand a bulb icon

indicates a switch on condition (circuit closes).

Note: Odd numbers indicate a switch-on cycle.

7.2.3 Programming an OFF cycle

1. Slide the RUN switch to P. Press the P button. The

switch cycle number changes to 2 and the bulb

blinks, indicating switch-off (circuit opens).

Note: Even numbers indicate a switch-off cycle.

2. Press the 1...7 button until the arrows point to the

selected day(s) you want this OFF cycle to occur.

3. Press h and m buttons to select the switch-off time.

To program another exercise cycle, press the lower P

button to advance to the next cycle and return to step 2

of Section 7.2.2.

After programming the on and off cycles, slide the RUN

switch to the RUN position. The clock colon will blink.

7.2.4 Setting error

If EEE appears, a setting error exists. The switch cycle

number in error is shown.

1. Slide set switch to P.

2. Press P button until the cycle with the error is

shown. Review this and the nextsetting andcorrect

the error.

3. Slide the set switch to RUN.

7.2.5 Clear any setting

1. Slide the RUN switch to P.

2. Press the lower P button to move to the switch on

cycle you want to clear.

2. Press the 1....7 button until arrowspoint to selected

day(s) youwant thisON cycleto occur. See Section

7.2.1, Day Selection, for instructions to choose

days of the week.

3. Press the h and m buttons to show the desired

switch-on time, noting the AM/PM indicator.

TT-1403 4/16 11

3. Press the P and X—> (skip) buttons

simultaneously and hold until the time display

shows 00:00. Repeat for the corresponding switch

off cycle. This on/off cycle is now inactive.

7.2.6 Clear all settings

To erase all settings, press R.

Page 12

7.3 Operation

Note: Setting the override to ON ( I ) will signal the

generator set to run continuously.

7.3.1 Autorun mode

1. Set the time and day and desired switch cycles.

2. Slide set switch to RUN and mode switch to AUTO.

Switching will begin with the next switch-on set

time.

7.3.3 To switch the override OFF

Slide the mode switch to 0. The switch remains off

indefinitely ( circuit open).

Note: The generator set will not exercise on schedule if

the override is set to OFF (0).

7.3.2 To switch the override ON

Slide mode switch to I. The switch remains on

indefinitely (circuit closed).

7.3.4 Skip a cycle

In automatic run mode, press the X—> button to skip the

next program.

8 Programming Worksheet

Use the following worksheet to plan on and off switching cycles for each exercise run. Program an off cycle after each

on cycle.

Cycle

Ex. 1 On AM 7 20 1--5

Ex. 2 Off AM 7 50 1--5

1

2

3

4

5

6

7

8

9

10

11

12

13

On/Off AM/PM h m Day(s)

14

15

16

12 TT-1403 4/16

Page 13

9 Exerciser GM39330

The older styleprogrammable timer GM39330 shown in

Figure 19 is no longer available. Instructions for the

GM39330 timer are provided in this section for

reference.

9.1 Installation Procedure,

Exerciser GM39330

For installed kits (GM38798-KA1 and -KA2), start with

the ATS Setup section and then proceed to the

programming instructions.

1. Disable the generator set to prevent accidental

starting:

a. Disconnect power to the battery charger, if

equipped.

b. Disconnect the generator set engine starting

battery, negative (--) lead first.

2. Disconnect power to the transfer switch before

opening the ATS enclosure.

9.1.1 Mounting

Figure 19 Programmable Exerciser GM39330

(no longer available)

Programmable Exerciser Specifications

Output 1 SPDT relay with dry contacts

Switch rating 16A 277VAC resistive

Supply voltage 208/240VAC, 50/60Hz ;

Power required 4VA

Ambient temperature

range

Connection 1/4 in. quick connects

Accuracy 4 minutes per year

Shortest switch time 1 minute

100 hour capacitor backup of

memory and display

-- 2 8 Cto60C

(--20F to 140F)

10 -- 24 AWG

Figure 20 GM39330 Specifications

The Programmable Exerciser is programmable for

24-hour or 7-day schedules. Follow the instructions in

this document to install (if not factory-installed) and

program the exerciser.

Mount the programmable exerciser on the bracket

provided with the kit as shown in Figure 22.

1. Install the mounting bracket as shown inFigure 22.

2. Insert the exerciser through the opening in the

bracket. With a screwdriver, press down and turn

the outer screws until the flanges are in position to

fasten the unit in the bracket, then release.

3. Insert plugs into the unused holes. See Figure 21.

1

2

1. Outer screws 2. Holes

2

1

Figure 21 Mounting Flanges

TT-1403 4/16 13

Page 14

ACCESSORY BOARD LOCATION

TIMER GM39330

Figure 22 Mounting

DIP SWITCHES

Figure 23 Wiring Diagram

GM38798

(200 A SHOWN)

GM39331

14 TT-1403 4/16

Page 15

9.1.2 Wiring

Wiring must comply with the National Electrical Code

and applicable local codes.

Note: Check that the supply voltage matches the

voltage marked on the unit. Wiring to incorrect

voltage will void the warranty.

9.3 Operating Instructions,

Exerciser GM39330

DANGER

1. Verify that power has been disconnected as

described above.

2. Use the leads supplied with the kit to connect the

exerciser according to the wiring diagram in

Figure 23.

9.2 ATS Setup,

Exerciser GM39330

Set DIP switch #2 on the Accessory Board to select

loaded or unloaded programmed exercise runs. See

Figure 22 and Figure 23 for the location of the DIP

switches on the accessory board.

D Set DIP switch #2 to the OFF position to run the

generator set without transferring the load. See

Figure 24, or

D Set DIP switch #2 to the ON position to start the

generator set and transfer the load during

programmed exercise runs. For peak shave

applications, set the DIP switch to the ON position.

DIP switch #2 does not affect the exercise period that is

set by pressing the Exercise button on the ATS

controller.

Hazardous voltage.

Will cause severe injury or death.

Only authorized personnel should

open the enclosure.

Short circuits. Hazardous voltage/current can cause

severe injury or death. Short circuits can cause bodily injury

and/or equipment damage. Do not contact electrical

connections with tools or jewelry while making adjustments or

repairs. Remove all jewelry before servicing the equipment.

The programmable exerciser must have power

connected in order to set the time and program the unit.

1. Install the transfer switch enclosure door(s).

2. Reconnect power to the transfer switch.

3. Reconnect the generator set engine starting

battery, negative (--) lead last.

4. Reconnect power to the battery charger, if

equipped.

5. Remove the transfer switch enclosure door(s) to

access the programmable exerciser. Do not

contact electrical connections when programming

the exerciser.

OFF

DIP Switch

2 Loaded Exercise Unloaded Loaded

(open)

ON

(closed)

Figure 24 Accessory Board DIP Switch Setting

TT-1403 4/16 15

Page 16

9.3.1 Key Description

See Figure 19 for key locations and Figure 25 for

descriptions of the keys.

Key Description

Setting the Time/Automatic Run Mode Prog.

Prog. Program Mode

Res.* Reset: Clears all programs and time

Select ON or OFF in Prog. Mode, Manual Override in

Run Mode

Select ON or OFF in Prog. Mode, Manual Override in

Run Mode

1h* Manual Daylight Change Key

h Setting the Hour (12:-- -- AM)

m Setting the M inute (12:01 AM)

Day Set Day(s) for time and programs

* Recessed keys; use a pen point to press.

Figure 25 Key Description

9.3.2 LCD Display Elements

The LCD incorporatesa number of different elements to

display various data and information. See Figure 26.

Figure 27 Time Display

9.3.4 Setting the Time

Note: If the h and m keys are held down longer than

2 seconds, the numbers will advance rapidly.

Press and hold the

daylight savings time is in effect, press 1h first).

1. Press h to advance to the current hour (while

holding down the

2. Press m to advance to the current minute (while

holding down the

3. Press Day repeatedly to advance to current day

(while holding down the

key during the following: (If

key).

key).

key).

Figure 26 LCD Display

9.3.3 Selecting AM/PM or Military Time

Note: Before proceeding with setting the time and

programming theunit, press thereset key to clear

all data from the memory.

After pressing reset, the display may show AM (right).

The numberedday symbols willbe flashing onand off. If

the display does not show AM, it is in military time mode

(00:00 to 23:59). To change to AM/PM mode, press and

hold the h key and press the 1h key once. AM will

appear in display. If display is in AM mode and military

mode is desired, press and hold the h key, pressthe 1h

key once.

9.3.5 Manual Daylight Time Changeover

Each year, in the Spring, press 1h to advance the time

an hour. In the Fall, press 1h to set back an hour.

9.4 Programs,

Exerciser GM39330

The Programmable Exerciser will accept up to 20

programs. A program consists of:

D An ON or OFF command

D Time of day (hour and minute)

D Single day or multiple days

Each exercise period requires two programs: one ON

command tostart the generator set, anda separateOFF

command to stop the generator set.

Note: Do not program an ON command without also

programming an OFF command.

A programmed OFF command will not transfer the load

or shut down the generator set if the utility (normal)

power is not available.

16 TT-1403 4/16

Page 17

Multiple on or off events may be programmed. For

example, Program 1 may turn the generator set ON at

10:00 PM Mon.--Fri. Program 2 may turn the generator

set OFF at 10:30 PM Mon.--Fri.

Loaded/unloaded exercise: The setting of DIP switch

#2 onthe Accessory Board determines whetherthe load

is transferred to the generator set during the

programmed exercise r uns. See ATS Setup.

Note: An exercise period that is scheduled by pressing

the Exercise button on the ATS controller is not

affected by the programmable exerciser or the

DIP switch setting.

Programming Notes

D If the days are flashing, it indicates the day of the

week was not set when setting the time. The timer

cannot be programmed unless the day of the week is

entered.

D If the programmed ON time is earlier in the day than

the current time, press

once to turn the timer on.

The timer does not look back to determine if it should

be on or off after programming.

D If 24 hour time control (same schedule every day of

the week) is desired, ignore the the Day key.

When programming is complete, snap the clear plastic

cover over the exerciser. Replace the transfer switch

enclosure door(s).

9.4.1 Programming 24 Hour or 7 Day

Schedules

It is helpful to write out the program schedules before

beginning. See Figure 28 on page 17.

The current time of day and day of week must be set

before programming. See Setting the Time.

Prog On/Off h m Day(s)

1 On 7am 20 Mon., Tue., Wed., Thurs., Fri.

D If anON or OFF symbol isnot entered, the ON symbol

will flash, and the program will not be accepted.

9.4.2 Day Key Selections

Press Day Key Display Shows Days

0times 1234567 Every day

1time 123456 Monday--Saturday

2times 12345 Monday--Friday

3times 67 Saturday and Sunday

4times 1 Monday

5times 2 Tuesday

6times 3 Wednesday

7times 4 Thursday

8times 5 Friday

9times 6 Saturday

10 times 7 Sunday

Figure 28 Programming Worksheet, Timer GM39330

TT-1403 4/16 17

Page 18

EXAMPLE

9.4.4 Changing A Program

The following example demonstrates how to program

different on and off times. Typically, the generator set

should be exercised once a week.

Program 1: ON at 1:00 AM Monday thru Saturday

Program 2: OFF at 1:30 AM Monday thru Friday

Program 3: OFF at 2:00 AM Saturday

Three programs need to be entered.

Press the Prog. key only once. The display appears as

shown in Figure 29.

Figure 29 Display after Prog. KeyisPressed

Program 1 (ON at 1:00 AM Monday thru Saturday):

Press

Press h key to 01AM

Press m key once to 00

Press Day keyonce 123456isdisplayed

Press Prog. key to enter

key once ON symbol appears

Select the program to be changed with the Prog. key. A

new setof days maybe selected with the Day key just as

in initialprogramming. Hour andminute canbe changed

with the h and m keys. Press Prog.or

new program.

key tostore the

9.4.5 Deleting A Program

To delete only one or a few programs:

1. Press Prog. key until the desired program is

displayed.

2. Press m key to :59 and press once more to blank

out.

3. Press h key to 11PM and press once more to blank

out.

4. Press

and then enter the Run Mode.

Note: Using the reset key will delete ALL programs, the

time of day, and day of the week.

key. Display will flash for several seconds

9.5 Manual Override,

Exerciser GM39330

Program 2 (OFF at 1:30 AM Monday thru Friday):

Press

Press h key to 01AM

Press m key to 30

Press Day keytwotimes 12345isdisplayed

Press Prog. key to enter

Program 3 (OFF at 2:00 AM Saturday):

Press

Press h key to 02AM

Press m key once to 00

Press Day key 9 times until only 6 is displayed

Press Prog. key to enter

Press

key twice OFFsymbol appears

key twice OFFsymbol appears

key to enter

9.4.3 Reviewing Programs

To review the programs at any time, press Prog. key.

Programs willappear inthe order they were enteredwith

repeated presses of the Prog. key. After all programs

have been reviewed, the blank display will appear to

allow entering another program. Another press of the

Prog. key will display the number of free programs

available, such as Fr 16 if 4 programs have been

entered.

9.5.1 Temporary Override

While in the Run Mode, pressing the key once will

reverse the output; ON to OFF or OFF to ON. The

symbol appears in the display to indicate a temporary

override. At the next scheduled switching time,

automatic control resumes, eliminating the override.

Pressing the override key will turn the generator set on

at unprogrammed times. Be sure to press the override

key again to turn the generator set off.

Note: If the override key is not pressed a second time to

turn the unit off, the generator set will run until the

next programmed OFF event.

18 TT-1403 4/16

Page 19

9.5.2 Continuous Override

While in the Run Mode:

D Pressing the key twice will turn the output to ON

permanently.

D Pressing the key three times will turn the output

OFF permanently.

D To terminate a continuous override, press the key

until

appears in the display.

symbol appears in display.

symbol appears in display.

9.6 Troubleshooting,

Exerciser GM39330

PROBLEM: Days are flashing, pressing key turns

output ON and OFF, and pressing any other key does

nothing.

SOLUTION: Time of Day and Day of Week have not

been set. See Setting the Time.

This is the condition after a reset. If the timer is found in

this condition after it has been installed, programmed

and operating for a while, it may indicate that electrical

noise or voltage transients have disrupted the

microprocessor causing a loss of program information.

Contact the factory if the problem persists.

A second but unlikely cause of program loss is a power

failure with the backup capacitor low or dead. Check by

disconnecting power and monitoring how long the

capacitor keeps the time of day in the display. Typically,

the capacitor will maintain the time and programs for 4

days, but not more than 5 days.

PROBLEM: Time of day was set while holding the

key down, but days are still flashing.

SOLUTION: Current day of week was not set while

holding down the

key. See Setting the Time.

PROBLEM: It is 10:00 AM and an ON program for

8:00 AM was entered, but the output is not ON. Display

shows the

and symbols.

SOLUTION: After programming, the timer does not look

back to determine if it should be ON. Press the

key

(temporary override) to turn the output ON;

appears in display. The timer will assume automatic

operation at the next programmed event.

PROBLEM: A program for 8:00 AM Monday thru Friday

was entered, but it will not accept it and

SOLUTION: ON

or OFF was not entered as part

is flashing.

of the program. ON or OFF must be selected.

9.7 Parts Lists, Exerciser GM39330

(no longer available)

Exerciser, Programmable 100A

Kit: GM38798-KA1, -KP1

Qty. Description Part Number

1 Timer GM39330

2 Terminal, ATS Lug Sensing GM31593

1 Bracket, Timer Mounting GM38801

1 Diagram, Wiring GM39331

1 Lead SW101--1816--5757

1 Lead SW102--1816--5757

1 Lead SW103--1808--5705

1 Lead SW104--1808--5705

Exerciser, Programmable 200A

Kit: GM38798-KA2, -KP2

Qty. Description Part Number

1 Timer GM39330

1 Bracket, Timer Mounting GM38801

1 Diagram, Wiring GM39331

1 Lead SW101--1816--5757

1 Lead SW102--1816--5757

1 Lead SW103--1808--5705

1 Lead SW104--1808--5705

TT-1403 4/16 19

Page 20

KOHLER CO., Kohler, Wisconsin 53044 USA

A

Phone 920-457-4441, Fax 920-459-1646

For the nearest sales and service outlet in the

US and Canada, phone 1-800-544-2444

KOHLERPower.com

Kohler Power Systems

Asia Pacific Headquarters

7 Jurong Pier Road

Singapore 619159

Phone (65) 6264-6422, Fax (65) 6264-6455

10 Parts Lists

Exerciser, Programmable, 100--200 Amp RDT

Kit: GM47597-KP2

Qty. Description Part Number

1 Dwg, Assy Programmable

Exerciser

1 Timer, Exercise, 240V GM64028

1 Bracket, Exerciser 100-200A GM64057

1 Diagram, Wiring GM64071

1 Lead SW101-1816-15257

1 Lead SW102-1816-15257

1 Lead SW103-1810-15205

1 Lead SW104-1810-15205

4 Screw, Machine X-49-2

Exerciser, Programmable, 400 Amp RDT,

200 Amp RDT SE, 400 Amp RDT SE

Kit: GM47597-KP1

Qty. Description Part Number

1 Control, Time Electronic

240VAC

1 Bracket, Timer Mounting GM64055

1 Diagram, Wiring GM64071

1 Lead SW101 --1816-15257

1 Lead SW102 --1816--15257

1 Lead SW103 --1810--15205

1 Lead SW104 --1810--15205

4 Screw X-49-2

Exerciser, Programmable, 200 Amp RDT SE

Service Kit

Kit: GM64108

Qty. Description Part Number

1 Control, Time Electronic 240

VAC

1 Panel GM64074

1 Diagram, Wiring GM64071

1 Lead SW101 --1816-15257

1 Lead SW102 --1816--15257

1 Lead SW103 --1816--15205

1 Lead SW104 --1816--15205

4 Screw X-49-2

4 Nut X-6210-1

GM47597

GM64028

GM64028

Exerciser, Programmable, Model KSS-J with

Decision-Makerr MPAC 750

Kit: GM47597-KP3

Qty. Description Part Number

2 Terminal, piggyback, male 233704

1 Transformer GM40071

1 Timer, Exercise, 120V GM64027

1 Bracket, Exerciser GM89060

1 Harness, Programmable

Exerciser Leads

4 Screw, Machine X-49-2

1 Fuse block X-6129-2

2 Fuse block X-6129-9

2 Fuse, 1 Amp, 600 V X-6135-1

2 Nut, flange spiralock, 1/4-20 X-6210-2

6 Screw, hex washer,

thread-forming

GM91325

X-67-113

Exerciser, Programmable, 120 VAC Service Kit

Kit: GM48913

Qty. Description Part Number

1 Rail, DIN GM48806

1 Control, Time Electronic 120

VAC

1 Enclosure, Timer GM64054

1 Diagram, Wiring GM64087

2 Screw X-67-113

GM64027

Exerciser, Programmable, 240 VAC Service Kit

Kit: GM48919

Qty. Description Part Number

1 Rail, DIN GM48806

1 Control, Time Electronic 240

VAC

1 Enclosure, Timer GM64054

1 Diagram, Wiring GM64087

2 Screw X-67-113

GM64028

vailability is subject to change without notice. Kohler Co. reserves the

right to change the design or specifications without notice and without any

obligation or liability whatsoever. Contact your local Kohlerr generator

set distributor for availability.

2014, 2016 by Kohler Co. All rights reserved.

20 TT-1403 4/16

Loading...

Loading...