Page 1

KD 625/3 - 626/3

WORKSHOP MANUAL

Page 2

- 2 -

CUSE/ATLO

REGISTRATION OF MODIFICATIONS TO THE DOCUMENT

Any modications to this document must be registered by the drafting body, by completing the following table.

Drafting

body

Document

code

Edition Issue date

Review

date

Model

N°

Revision Endorsed

PREFACE

- Every attempt has been made to present within this service manual, accurate and up to date technical information.

However, development on the KOHLER series is continuous.

Therefore, the information within this manual is subject to change without notice and without obligation.

- The information contained within this service manual is the sole property of KOHLER.

As such, no reproduction or replication in whole or part is allowed without the express written permission of

KOHLER.

Information presented within this manual assumes the following:

1 - The person or people performing service work on KOHLER series engines is properly trained and equipped to

safely and professionally perform the subject operation;

2 - The person or people performing service work on KOHLER series engines possesses adequate hand and

KOHLER special tools to safely and professionally perform the subject service operation;

3 - The person or people performing service work on KOHLER series engines has read the pertinent information

regarding the subject service operations and fully understands the operation at hand.

- This manual was written by the manufacturer to provide technical and operating information to authorised KOHLER

after-sales service centres to carry out assembly, disassembly, overhauling, replacement and tuning operations.

- As well as employing good operating techniques and observing the right timing for operations, operators must

read the information very carefully and comply with it scrupulously.

- Time spent reading this information will help to prevent health and safety risks and nancial damage.

Written information is accompanied by illustrations in order to facilitate your understanding of every step of the

operating phases.

02/07/20121° 0

ED0053029350

51261 02/07/2012

KD Workshop Manual_cod. ED0053029350_1° ed_ rev. 00

Page 3

- 3 -

This manual contains the most important information for the repair of KOHLER air cooled, direct injection Diesel

engines type KD 625/3 and 626/3. This information is current upto 02/07/2012

CHAPTER INDEX

CHAPTER INDEX

California emission control warranty statement ................................................................................................................. 6

Your warranty rights and obligations

.................................................................................................................................. 6

GENERAL REMARKS AND SAFETY INFORMATION ........................................................................................... 7

Safety and warning decals ................................................................................................................................................. 7

Limited 3 year kohler® diesel engine warranty .................................................................................................................... 7

General service manual notes

............................................................................................................................................ 7

Glossary and terminology

................................................................................................................................................... 7

Safety regulations ............................................................................................................................................................... 8

General safety during operating phases ............................................................................................................................ 9

Safety and environmental impact ...................................................................................................................................... 9

TECHNICAL INFORMATION .................................................................................................................................. 10

Possible causes and trouble shooting ...............................................................................................................................10

Manufacturer and motor identication data .......................................................................................................................12

The identication plate shown in the gure can be found directly on the engine. .............................................................12

Approval data .....................................................................................................................................................................12

Techinical specications ....................................................................................................................................................13

Performance diagrams ......................................................................................................................................................14

Overall dimensions ............................................................................................................................................................16

MAINTENANCE - PRESCRIBED LUBRICANT - REFILLING ............................................................................. 17

Routine engine maintenance .............................................................................................................................................17

Extraordinary maintenance ...............................................................................................................................................17

Ordinary maintenance .......................................................................................................................................................17

Lubricant ............................................................................................................................................................................18

Prescribed lubricant ...........................................................................................................................................................19

Fuel specications ............................................................................................................................................................ 20

DISASSEMBLY/REASSEMBLY .............................................................................................................................. 22

Recommendations for disassembling and assembling .................................................................................................... 22

Recommendations for overhauls and tuning .................................................................................................................... 22

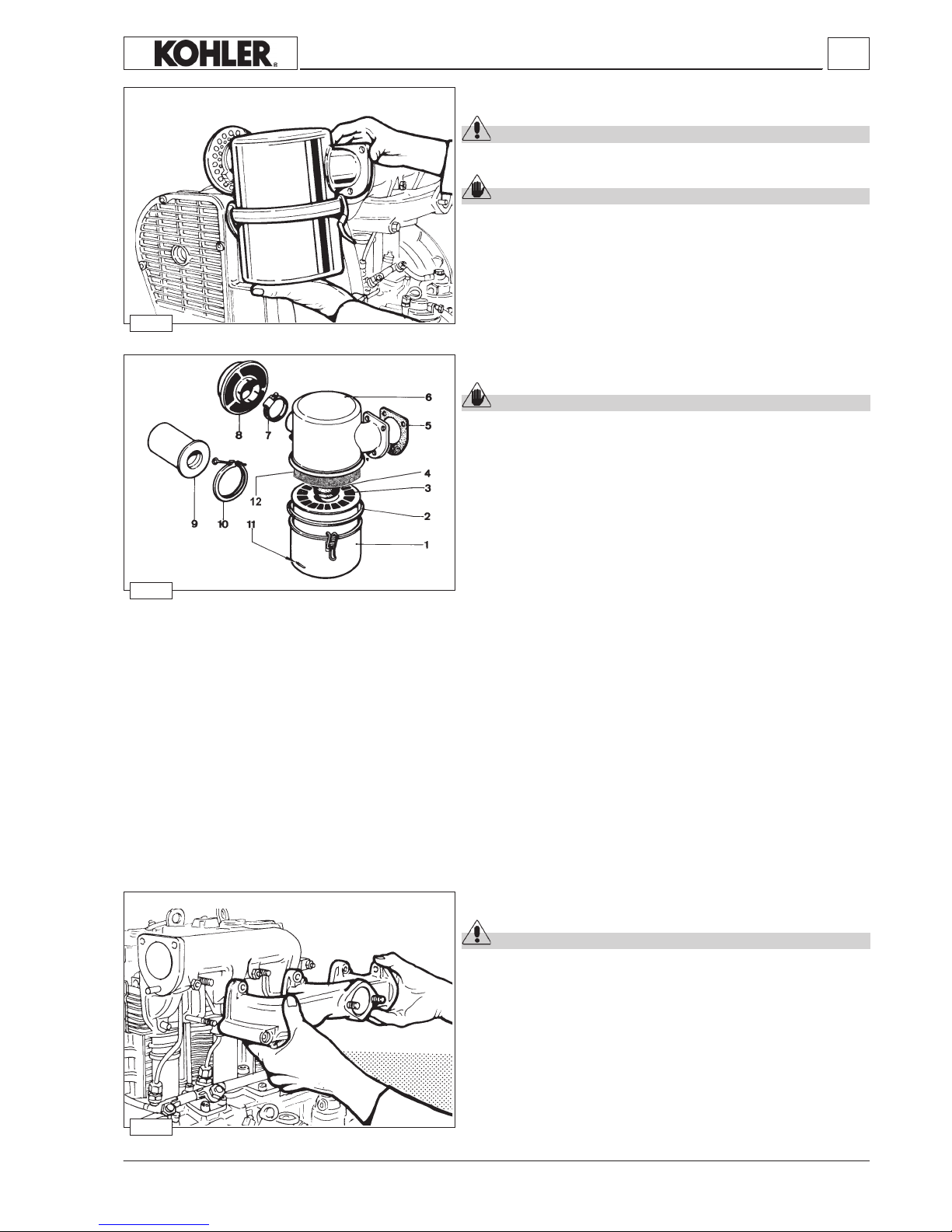

Oil-bath air cleaner ........................................................................................................................................................... 23

Oil-bath air cleaner components ...................................................................................................................................... 23

Exhaust manifold .............................................................................................................................................................. 23

Intake manifold .................................................................................................................................................................. 24

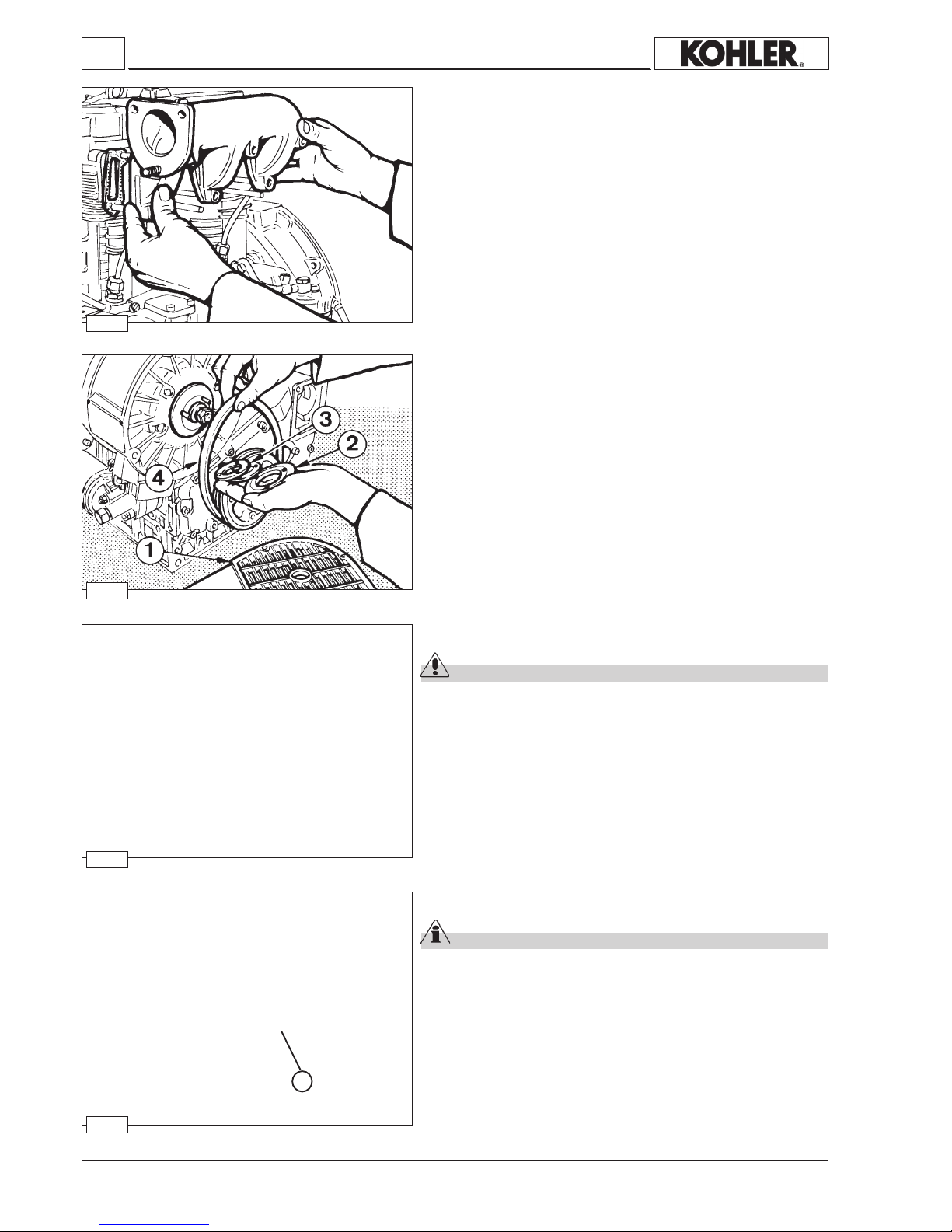

Blower belt alternator ........................................................................................................................................................ 24

Belt tension adjustment .................................................................................................................................................... 24

Half-pulley - Reassembly .................................................................................................................................................. 24

Blower belt alternator - Reassembly

................................................................................................................................. 25

Tension check

................................................................................................................................................................... 25

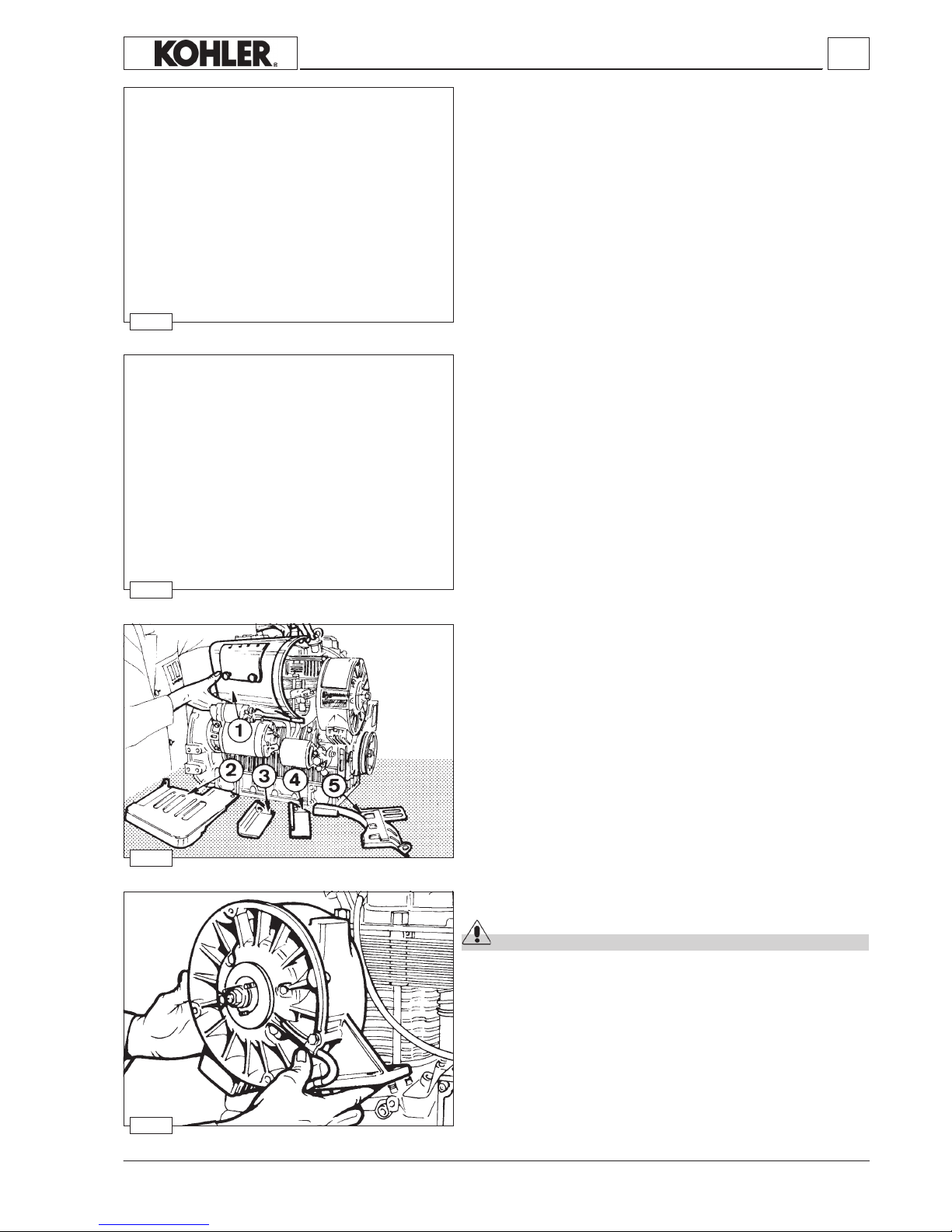

Air shroud and bafes - Disassembly ............................................................................................................................... 25

Blower assembly ............................................................................................................................................................... 25

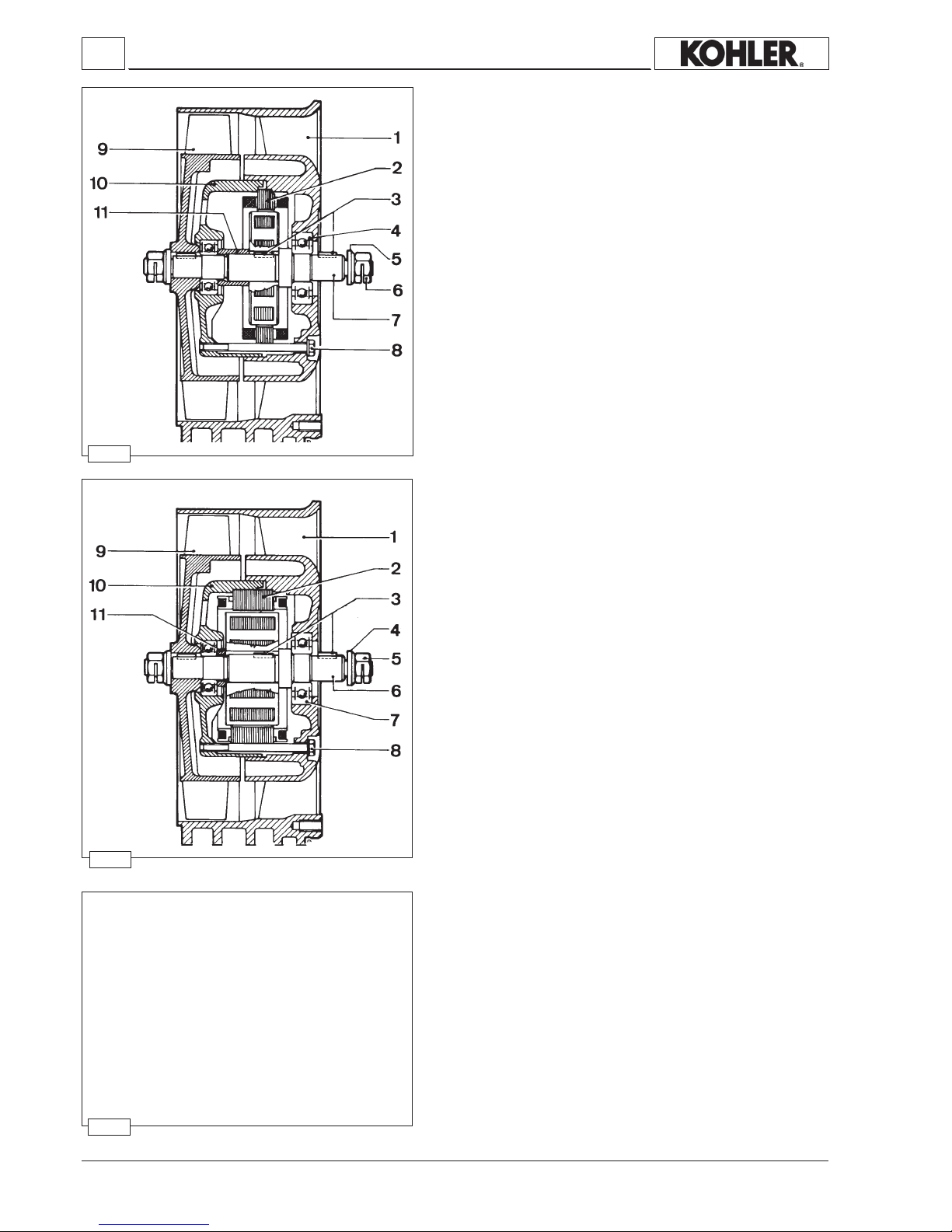

Blower assembly components with 14 A alternator .......................................................................................................... 26

Blower assembly components with 21 A alternator

.......................................................................................................... 26

Blower control pulley - Disassembly

................................................................................................................................ 26

Crankshaft pulley .............................................................................................................................................................. 27

Blower control pulley diameter ......................................................................................................................................... 27

Timing cover ..................................................................................................................................................................... 27

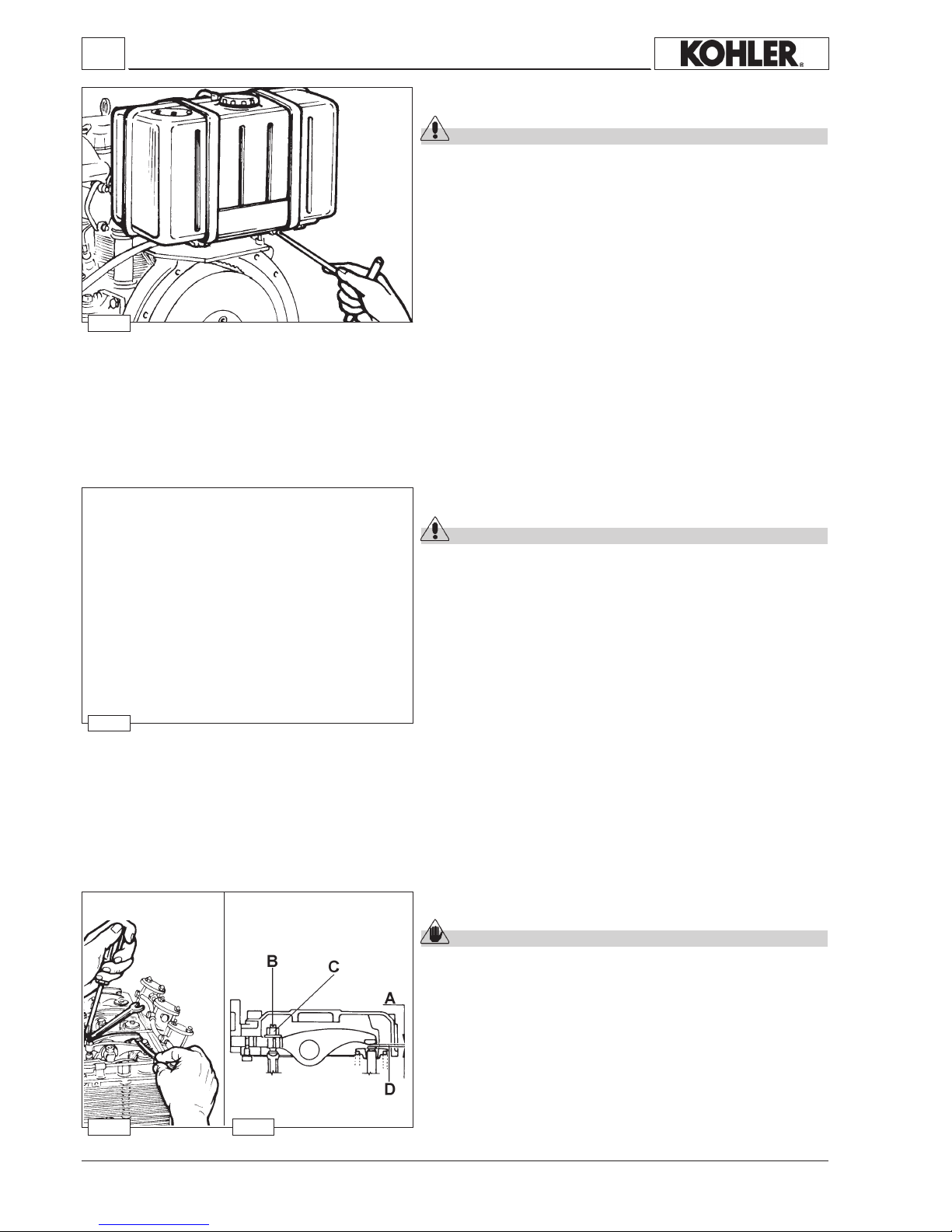

Tank

.................................................................................................................................................................................. 28

Flywheel

............................................................................................................................................................................ 28

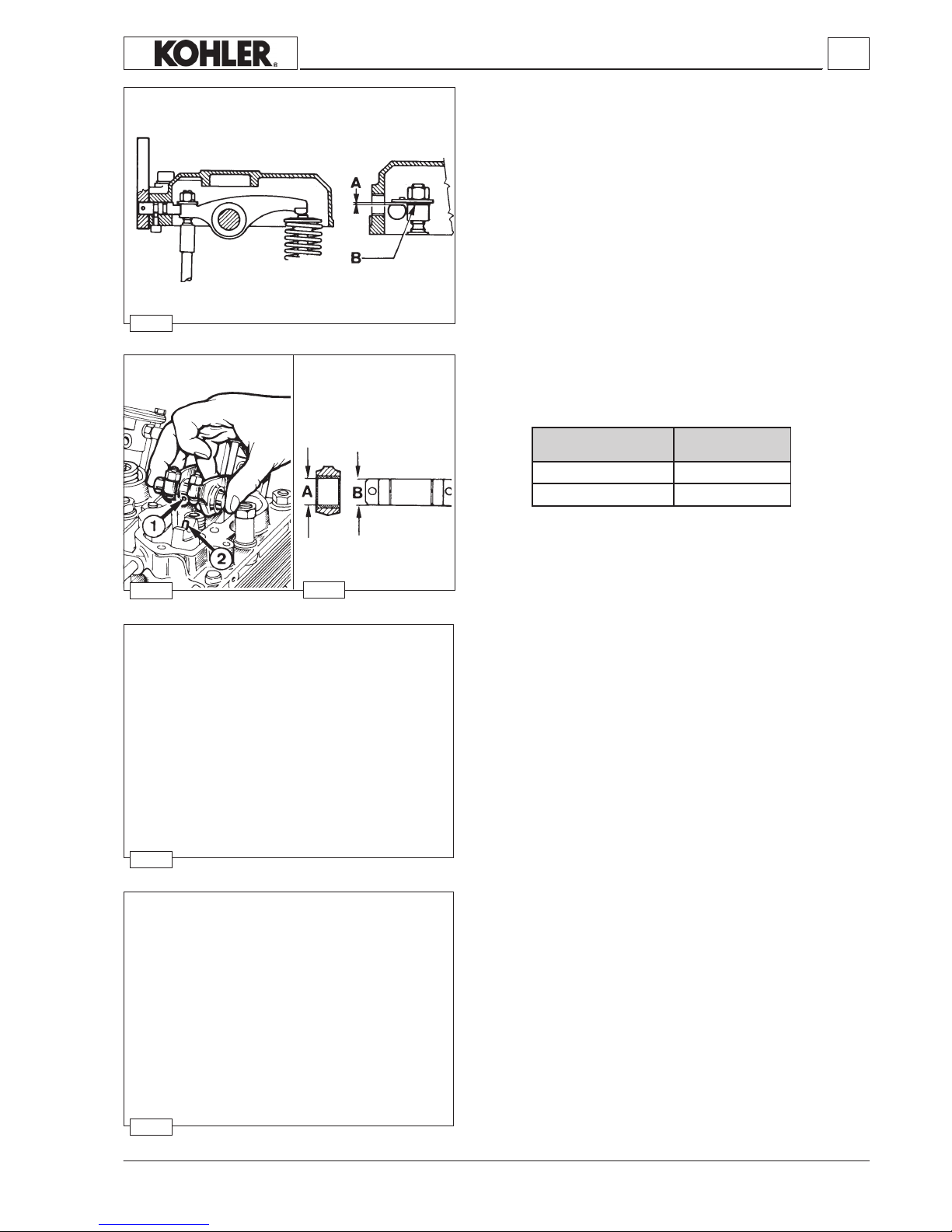

Valve / rocker arm clearance ............................................................................................................................................ 28

Compression release (optional) ........................................................................................................................................ 29

Rocker arm assembly ....................................................................................................................................................... 29

Disassembling size P injector

........................................................................................................................................... 29

Injector protrusion

..............................................................................................................................................................31

KD Workshop Manual_cod. ED0053029350_1° ed_ rev. 00

Page 4

- 4 -

Chapter index

Cylinder Head ....................................................................................................................................................................31

Valves ................................................................................................................................................................................31

Valve stem sealing rings - Reassembly ........................................................................................................................... 32

Valve springs..................................................................................................................................................................... 32

Valve material .................................................................................................................................................................. 32

Valve guides and cylinder head housings ........................................................................................................................ 32

Valve guide insertion ........................................................................................................................................................ 33

Dimensions and clearance between guides and valves ................................................................................................. 33

Valve seats and housings ................................................................................................................................................. 33

Valve seat lapping ............................................................................................................................................................. 33

Pushrod tube spring tting ................................................................................................................................................ 34

Cylinder ............................................................................................................................................................................. 34

Checks and cyiinder roughness ....................................................................................................................................... 34

Piston ................................................................................................................................................................................ 34

Piston weight ..................................................................................................................................................................... 35

Metal snap rings - End gaps ........................................................................................................................................... 35

Metal snap rings - Piston grooves .................................................................................................................................. 35

Metal snap rings - Fitting sequence ................................................................................................................................. 35

Piston - Retting ............................................................................................................................................................... 36

Piston clearance ............................................................................................................................................................... 36

Connecting rod ................................................................................................................................................................. 36

Connecting rod small end bearing and pin ....................................................................................................................... 37

Connecting rod alignment ................................................................................................................................................. 37

Connecting rod weight ...................................................................................................................................................... 37

Connecting rod big end bearing ....................................................................................................................................... 37

Camshaft gear .................................................................................................................................................................. 38

Oil pump gear ................................................................................................................................................................... 38

Timing gear ....................................................................................................................................................................... 38

Main bearing support, gear side ...................................................................................................................................... 38

Main bearing support, ywheel side ................................................................................................................................. 39

Crankshaft ......................................................................................................................................................................... 39

Center main bearing support, locating bolts ..................................................................................................................... 39

Crankshaft removal ........................................................................................................................................................... 39

Crankshaft center main bearing supports ........................................................................................................................ 39

Crankshaft lubrication ducts ............................................................................................................................................. 40

Crankshaft journal radius .................................................................................................................................................. 40

Checking main journals and crank pins ............................................................................................................................ 40

Main journal and crank pin diameter ............................................................................................................................... 40

Diameter of main bearings .................................................................................................................................................41

Main bearing and connecting rod big end bearing inside diameter ..................................................................................41

Clearance between main journals/crank pins and connecting rod bearings ....................................................................41

Main bearing supports .......................................................................................................................................................41

Main bearing housings .......................................................................................................................................................42

Crankshaft end play ...........................................................................................................................................................42

Camshaft ............................................................................................................................................................................42

Camshaft removal ..............................................................................................................................................................42

How to measure camshaft bearing and journal inside diameter .......................................................................................42

Dimensions of camshaft journals and housings ............................................................................................................... 43

Checking intake/exhaust cam height ................................................................................................................................ 43

Intake/exhaust cam height ................................................................................................................................................ 43

Camshaft end play ............................................................................................................................................................ 43

Camshaft timing ................................................................................................................................................................ 44

Valve timing without considering timing marks ................................................................................................................. 44

Valve timing check ............................................................................................................................................................ 44

Hydraulic pump p.t.o. group 1 ........................................................................................................................................... 46

Hydraulic pump 3rd p.t.o., group 2 .................................................................................................................................... 46

Hydraulic pump 4th p.t.o., group 1 ................................................................................................................................... 46

Use of 3rd and 4th p.t.o. ................................................................................................................................................... 46

Mechanical speed governor ..............................................................................................................................................47

Mechanical speed governor components (standard) ........................................................................................................47

Mechanical speed governor operation (standard) .............................................................................................................47

Mechanical speed governor components for special generating sets ............................................................................. 48

Mechanical speed governor setting .................................................................................................................................. 48

Spring for extra fuel supply at starting ............................................................................................................................. 48

KD Workshop Manual_cod. ED0053029350_1° ed_ rev. 00

Page 5

- 5 -

Chapter index

LUBRICATION SYSTEM ......................................................................................................................................... 49

Oil pump ............................................................................................................................................................................ 50

Oil pressure relief valve

.................................................................................................................................................... 50

Oil lter cartridge .............................................................................................................................................................. 50

Oil pressure check ............................................................................................................................................................ 50

Oil pressure curve at idling speed

.....................................................................................................................................51

Oil pressure curve at full speed .........................................................................................................................................51

FUEL SYSTEM ........................................................................................................................................................52

Fuel feeding/injection circuit ............................................................................................................................................. 52

Fuel lter ........................................................................................................................................................................... 52

Fuel feeding pump

............................................................................................................................................................ 52

Injection pump ................................................................................................................................................................. 52

Injection pump only for EPA engines

................................................................................................................................ 53

Injection pump only for standard and 97/68 Ce engines .................................................................................................. 53

Plunger .............................................................................................................................................................................. 54

How to check plunger and barrel for internal leakage

...................................................................................................... 54

How to check injection pump delivery valve sealing ........................................................................................................ 54

Test data for injection pump delivery at the test bench only for EPA engines

................................................................. 55

Test data for injection pump delivery at the test bench for standard and 97 / 68 CE engines ......................................... 55

Injection pump replacement ............................................................................................................................................. 56

Size S injector

................................................................................................................................................................... 56

Size S nozzle

................................................................................................................................................................... 57

Size P injector

................................................................................................................................................................... 57

Size P nozzle

................................................................................................................................................................... 57

Injector setting .................................................................................................................................................................. 58

(Static) Injection timing

..................................................................................................................................................... 58

ELECTRIC SYSTEM ................................................................................................................................................ 62

Standard electric equipment ............................................................................................................................................. 62

Electric starting layout without battery charging light

....................................................................................................... 62

Electrical starting layout with battery charging Iight ......................................................................................................... 62

12,5 V, 14 A Alternator

...................................................................................................................................................... 62

Alternator battery charger curve (12.5 V, 14A)

................................................................................................................. 63

12 V, 21 A Alternator

......................................................................................................................................................... 63

Alternator battery charger curve (12 V, 21 A)

................................................................................................................... 63

Magnetization checking tool (Part No. 7000-9727-001) ................................................................................................... 64

Checking for cable continuity

........................................................................................................................................... 64

Voltage regulator

............................................................................................................................................................... 64

How to check voltage regulator for proper operation

....................................................................................................... 65

Alternator type Bosch G1 14 V, 33 A

................................................................................................................................ 66

Alternator type Bosch Gil 14 V, 33 A layout ...................................................................................................................... 66

14 V, 33 A Bosch G1 alternator battery charger curve

..................................................................................................... 66

Starting motor type Bosch JF (R) 12 V, class 2.5 ............................................................................................................. 67

Characteristic curves for starting motor type Bosch JF (R) 12 V

..................................................................................... 67

Starting motor layout ......................................................................................................................................................... 67

SETTINGS ............................................................................................................................................................... 68

Settings ............................................................................................................................................................................. 68

Injection pump delivery setting ......................................................................................................................................... 68

Stop setting

....................................................................................................................................................................... 68

APPENDIX FOR ENGINE WITH ADVANCE VARIATOR ..................................................................................... 71

ADVANCE VARIATOR OPERATING PRINCIPLE ................................................................................................. 72

Injection timing device operation ...................................................................................................................................... 72

KD Workshop Manual_cod. ED0053029350_1° ed_ rev. 00

Page 6

- 6 -

CALIFORNIA EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS

The California Air Resources Board and Kohler Co. are pleased to explain the emission control system warranty on your 2012 engine. In

California, new heavy-duty off-road engines must be designed, built and equipped to meet the State’s stringent anti-smog standards. Kohler Co.

must warrant the emission control system on your engine for the time period listed below provided there has been no abuse, neglect or improper

maintenance of your engine.

Your emission control system may include parts such as the fuel-injection system and the air induction system. Also included may be hoses,

connectors and other emission related assemblies.

Where a warrantable condition exists, Kohler Co. will repair your heavy-duty off-road engine at no cost to you including diagnosis, parts and labor.

MANUFACTURER’S WARRANTY COVERAGE:

Your off-road, diesel engine emission control system is covered under warranty for a period of ve (5) years or 3,000 hours, whichever occurs rst,

beginning on the date the engine or equipment is delivered to an ultimate purchaser for all constant speed engines with maximum power 19≤kW<37

and rated speed less than 3,000 rpm, all variable speed engines with maximum power 19≤kW<37, and all variable or constant speed engines with

maximum power greater than 37 kW. Your off-road, diesel engine emission control system on variable or constant-speed engines with maximum

power less than 19 kW, and for constant speed engines with maximum power 19≤kW<37 and rated speed equal to or greater than 3,000 rpm is

covered under warranty for a period of two (2) years or 1,500 hours, whichever

occurs rst. If any emission related part on your engine is defective, the part will be repaired or replaced by Kohler Co.

OWNER’S WARRANTY RESPONSIBILITIES:

As the heavy-duty off-road engine owner, you are responsible for the performance of the required maintenance listed in your Kohler Co.

owner’s manual. Kohler Co. recommends that you retain all receipts covering maintenance on your heavy-duty off-road engine, but Kohler Co.

cannot deny warranty solely for the lack of receipts or for your failure to ensure the performance of all recommended scheduled maintenance.

As the heavy-duty off-road engine owner, you should however be aware that Kohler Co. may deny you warranty coverage if your heavy-duty offroad engine or emission control related component has failed due to abuse, neglect, improper maintenance or unapproved modications.

Your engine is designed to operate on commercial diesel fuel (No. 1 or No. 2 low sulfur or ultra low sulfur diesel fuel) only. Use of any other fuel

may result in your engine no longer operating in compliance with California’s emissions requirements.

You are responsible for initiating the warranty process. The Air Resources Board suggests that you present your heavy-duty off-road engine to a

Kohler Co. dealer as soon as a problem exists. The warranty repairs should be completed by the dealer as expeditiously as possible.

Please review the document titled, “Kohler Co. Federal and California Emission Control Systems Limited Warranty Off-Road Diesel Engines”, for

complete details of your heavy-duty off-road engine warranty. If you have any questions regarding your warranty rights and responsibilities or the

location of the nearest Kohler Co. authorized service location, you should contact Kohler Co. at 1-800-544-2444 or access our website at www.

kohlerengines.com.

Chapter index

DISASSEMBLY/REASSEMBLY .............................................................................................................................. 74

Solenoid valve assembly diagram .....................................................................................................................................74

Speed sensor and variator assembly diagram

................................................................................................................. 78

Blower belt alternator - Disassembly ................................................................................................................................ 80

Blower control pulley - Disassembly .................................................................................................................................81

Angular position sensor and AC pump assembly diagram

.............................................................................................. 88

Phase sensor assembly diagram ..................................................................................................................................... 90

Resetting the dial indicator

............................................................................................................................................... 92

Sensor test ........................................................................................................................................................................ 92

Resetting the dial indicator ............................................................................................................................................... 93

Measuring the depth between the sensor support and the camshaft

............................................................................. 93

Air gap adjustment ............................................................................................................................................................ 93

Example of adhesive plate on the control panel

............................................................................................................... 98

STORAGE ............................................................................................................................................................. 100

Storage ........................................................................................................................................................................... 100

External engine protection:

............................................................................................................................................. 100

Injection systems protection: .......................................................................................................................................... 100

External engine protection:

............................................................................................................................................. 100

Procedures to be carried out before start the engine ......................................................................................................101

MAIN TORQUE SPECIFICATIONS AND USE OF SEALANTS .......................................................................... 102

Main torque specications ...............................................................................................................................................102

Use of sealants only for engines with variator

.................................................................................................................103

Table of tightening torques for standard screws (coarse thread)

................................................................................... 104

Table of tightening torques for standard screws (ne thread)

........................................................................................ 104

SPECIAL TOOLS .................................................................................................................................................. 105

KD Workshop Manual_cod. ED0053029350_1° ed_ rev. 00

Page 7

- 7 -

1

GENERAL REMARKS AND SAFETY INFORMATION

WARRANTY CERTIFICATE

GLOSSARY AND TERMINOLOGY

For clarity, here are the denitions of a number of terms used

recurrently in the manual.

- Cylinder number one: is the piston timing belt side «viewed

from the ywheel side of the engine».

- Rotation direction: anticlockwise «viewed from the ywheel

side of the engine».

GENERAL SERVICE MANUAL NOTES

1

- Use only genuine Kohler repair parts.

Failure to use genuine Kohler parts could result in sub-

standard performance and low longevity.

2

- All data presented are in metric format. That is, dimensions

are presented in millimeters (mm), torque is presented in

Newton-meters (Nm), weight is presented in kilograms

(Kg), volume is presented in liters or cubic centimeters (cc)

and pressure is presented in barometric units (bar).

LIMITED 3 YEAR KOHLER® DIESEL ENGINE WARRANTY

Kohler Co. warrants to the original retail consumer that each new KOHLER Diesel engine sold by Kohler Co. will be free from manufacturing

defects in materials or workmanship in normal service for a period of three (3) years or 2000 hours whichever occurs rst from the date of

purchase, provided it is operated and maintained in accordance with Kohler Co.’s instructions and manuals. If no hour meter is installed as original

equipment then 8 hours of use per day and 5 days per week will be used to calculate hours used.

Our obligation under this warranty is expressly limited, at our option, to the replacement or repair at Kohler Co., Kohler, Wisconsin 53044, or at a

service facility designated by us of such parts as inspection shall disclose to have been defective.

This warranty does not apply to defects caused by unreasonable use, including faulty repairs by others and failure to provide reasonable and

necessary maintenance.

The following items are not covered by this warranty:

Engine accessories such as fuel tanks, clutches, transmissions, power-drive assemblies and batteries, unless supplied or installed by Kohler Co.

These are subject to the warranties, if any, of their manufacturers.

KOHLER CO. AND/OR THE SELLER SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTIAL OR CONSEQUENTIAL DAMAGES

OF ANY KIND, including but not limited to labor costs or transportation charges in connection with the repair or replacement of defective parts.

IMPLIED OR STATUTORY WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE,

ARE EXPRESSLY LIMITED TO THE DURATION OF THIS WRITTEN WARRANTY. We make no other express warranty, nor is any one authorized

to make any on our behalf.

Some states do not allow limitations on how long an implied warranty lasts, or the exclusion or limitation of incidental or consequential damages,

so the above limitation or exclusion may not apply to you.

This warranty gives you specic legal rights, and you may also have other rights, which vary from state to state.

To obtain warranty service

Purchaser must bring the engine to an authorized Kohler service facility. To locate the nearest facility, visit our website, www.kohlerengines.com,

and use the locator function, consult your Yellow Pages or telephone 1-800-544-2444.

ENGINE DIVISION, KOHLER CO., KOHLER, WISCONSIN 53044

- Important remarks and features of the text are highlighted

using symbols, which are explained below:

Danger – Attention

This indicates situations of grave danger which, if ignored,

may seriously threaten the health and safety of individuals.

SAFETY AND WARNING DECALS

Caution – Warning

This indicates that it is necessary to take proper precautions

to prevent any risk to the health and safety of individuals

and avoid nancial damage.

Important

This indicates particularly important technical information

that should not be ignored.

KD Workshop Manual_cod. ED0053029350_1° ed_ rev. 00

Page 8

- 8 -

1

GENERAL NOTES

.

Kohler engines are built to provide safe and longlasting

performances, but in order to obtain these results it is

essential that the maintenance requirements described in

the manual are observed along with the following safety

recommendations.

. The engine has been built to the specications of a

machine manufacturer, and it is his responsibility to ensure

that all necessary action is taken to meet the essential

and legally prescribed health and safety requirements.

Any use of the machine other than that described cannot

be considered as complying with its intended purpose

as specied by Kohler, which therefore declines all

responsibility for accidents caused by such operations.

. The following instructions are intended for the user of the

machine in order to reduce or eliminate risks, especially

those concerning the operation and standard maintenance

of the engine.

. The user should read these instructions carefully and get

to know the operations described. By not doing so he may

place at risk his own health and safety and that of anyone

else in the vicinity of the machine.

. The engine may be used or mounted on a machine only

by personnel suitably trained in its operation and aware of

the dangers involved. This is particularly true for standard

and, above all, special maintenance work. For special

maintenance contact personnel trained specically by

Kohler. This work should be carried out in accordance with

existing literature.

. Kohler declines all responsibility for accidents or for failure

to comply with the requirements of law if changes are made

to the engine’s functional parameters or to the fuel ow rate

adjustments and speed of rotation, if seals are removed,

or if parts not described in the operating and maintenance

manual are removed and reassembled by unauthorized

personnel.

WARNING

. In addition to all other machine specications, ensure that

the engine is in a near horizontal position when starting. lf

starting manually, ensure that the necessary operations

can be performed without any risk of striking against walls

or dangerous objects. Rope starting (except for recoil rope

starting) is not permitted even in emergencies.

. Check that the machine is stable so that there is no risk of it

overturning.

. Get to know the engine speed adjustment and machine

stop operations.

. Do not start the machine in closed or poorly ventilated

environments. The internal combustion process generates

carbon monoxide, an odourless and highly toxic gas, so

spending too long a time in an environment where the

engine discharges its exhaust products freely can lead to

loss of consciousness and even death.

. The engine may not be used in environments containing

ammable materials, explosive atmospheres or easily

combustible powders, unless adequate and specic

precautions have been taken and are clearly stated and

certied for the machine.

. To prevent the risk of re, keep the machine at a distance of

at least one metre from buildings or other machines.

SAFETY REGULATIONS

.

Children and animals must be kept at a sufcient distance

from the machine to prevent any danger resulting from its

operation.

. Fuel is ammable, so the tank must be lled only when the

engine is turned off. Dry carefully any fuel that may have

spilled, remove the fuel container and any cloths soaked

in fuel or oil, check that any sound-absorbing panels made

of porous material are not soaked with fuel or oil, and make

sure that the ground on which the machine is located has not

absorbed fuel or oil.

. Before starting, remove any tools that have been used for

carrying out maintenance work to the engine and/or the

machine and check that any guards removed have been

replaced. In cold climates it is possible to mix kerosene with

the diesel fuel to make the engine easier to start. The liquids

must be mixed in the tank by pouring in rst the kerosene

and then the diesel fuel. Consult Kohler technical ofce for

mixture proportions. Petrol may not be used because of the

risk of it forming ammable vapours.

. During operation the surface of the engine reaches

temperatures that may be dangerous. Avoid in particular all

contact with the exhaust system.

. The liquid cooling circuit is under pressure. Do not carry out

any checks before the engine has cooled down, and even

then open the radiator cap or the expansion tank cautiously.

Wear protective clothing and glasses. lf there is an electric

fan, do not approach the engine while it is still hot as the fan

may come on even when the engine is not running. Clean the

cooling system with the engine turned off.

. While cleaning the oil bath air lter, check that the oil is

disposed of in such a way as not to harm the environment.

Any ltering sponges in the oil bath air lter should not be

soaked with oil. The cyclone pre-lter cup must not be lled

with oil.

. Since the oil must be emptied out while the engine is still hot

(approx. 80°C), particular care should be taken in order to

avoid burns. In any case make sure that oil does not come

into contact with your skin because of the health hazards

involved.

. Fuel vapours are highly toxic, so ll up only in the open air or

in well ventilated environments.

. During operations which involve access to moving parts of

the engine and/or removal of the rotary guards, disconnect

and insulate the positive cable of the battery so as to prevent

accidental short circuits and activation of the starter motor.

. Check the belt tension only when the engine is turned off.

IMPORTANT

.

To start the engine follow the specic instructions provided

in the engine and/or machine operating manual. Do not

use auxiliary starting devices not originally installed on the

machine (e.g. Startpilot systems which utilise ether etc.)

. Before carrying out any work on the engine, turn it off and

allow it to cool down. Do not perform any operation while the

engine is running.

.

Check that the discharged oil, the oil lter and the oil

contained in the oil lter are disposed of in such a way as not

to harm the environment.

.

Close the fuel tank ller cap carefully after each fílling

operation. Do not ll the tank right up to the top, but leave

sufcient space to allow for any expansion of the fuel.

.

Do not smoke or use naked ames while lling.

General remarks and safety information

KD Workshop Manual_cod. ED0053029350_1° ed_ rev. 00

Page 9

- 9 -

1

GENERAL SAFETY DURING OPERATING PHASES

– The procedures contained in this manual have been

tested and selected by the manufacturer’s technical

experts, and hence are to be recognised as authorised

operating methods.

– Some tools are normal workshop ones, while others are

special tools designed by the Manufacturer of the engine.

– All tools must be in good working condition so that engine

components are not damaged and that operations are

carried out properly and safely.

– It is important to wear the personal safety devices

prescribed by work safety laws and also by the standards

of this manual.

– Holes must be lined up methodically and with the aid of

suitable equipment. Do not use your ngers to carry out

this operation to avoid the risk of amputation.

SAFETY AND ENVIRONMENTAL IMPACT

Every organisation has a duty to implement procedures to

identify, assess and monitor the inuence of its own activities

(products, services, etc.) on the environment.

Procedures for identifying the extent of the impact on the environment must consider the following factors:

- Liquid waste;

- Waste management;

- Soil contamination;

- Atmospheric emissions;

- Use of raw materials and natural resources;

- Regulations and directives regarding environmental impact.

In order to minimise the impact on the environment, the manufacturer now provides a number of indications to be followed by all

persons handling the engine, for any reason, during its expected

lifetime.

- All packaging components must be disposed of in accordance

with the laws of the country in which disposal is taking place.

- Keep the fuel and engine control systems and the exhaust

pipes in efcient working order to limit environmental and noise

pollution.

- When discontinuing use of the engine, select all components

according to their chemical characteristics and dispose of them

separately.

– Some phases may require the assistance of more than

one operator. If so, it is important to inform and train them

regarding the type of activity they will be performing in

order to prevent risks to the health and safety of all persons

involved.

– Do not use ammable liquids (petrol, diesel, etc.) to

degrease or wash components. Use special products.

– Use the oils and greases recommended by the manufacturer.

Do not mix different brands or combine oils with different

characteristics.

– Discontinue use of the engine if any irregularities arise,

particularly in the case of unusual vibrations.

– Do not tamper with any devices to alter the level of

performance guaranteed by the manufacturer.

.

Take care when removing the oil lter as it may be hot.

. The operations of checking, lling up and replacing the

cooling liquid must be carried out with the engine turned off

and cold. Take particular care if liquids containing nitrites

are mixed with others not containing these compounds

as this may give rise to the formation of nitrosamines

which are a health hazard. The cooling liquid is polluting,

so dispose of in a manner that does not damage the

environment.

. In order to move the engine simultaneously use the

eyebolts tted for this purpose by Kohler. These lifting

points are however not suitable for the entire machine, so

in this case use the eyebolts tted by the manufacturer.

General remarks and safety information

KD Workshop Manual_cod. ED0053029350_1° ed_ rev. 00

Page 10

- 10 -

2

FUEL

CIRCUIT

POSSIBLE CAUSE

ELECTRIC

SYSTEM

MAINTENANCE

SETTINGS REPAIRS

In adequat e

performance

High noise

level

Overheats

TROUBLE

Engine does

not start

Engine starts

but stops

No acceleration

Non -unif orm

speed

Black smoke

White smoke

Too low oil

pressure

Excessive oil

consumption

Obstructed fuel line

Fuel lter clogged

Air or water leaks in fuel system

The tank cap vent hole is clogged

No fuel

Discharged battery

Cable connection uncertain or incorrect

Faulty starting switch

Faulty starting motor

Clogged air lter

Excessive idle operation

Incomplete run-in

Overloaded engine

Non-conforming engine oil

Incorrect governor linkage adjustment

Governor spring broken or unhooked

Low idle speed

Rings worn or sticking

Worn cylinder

Worn main con rod-rocker arm

bearings

Badly sealed intake valve

Head tightening nuts loose

Damaged cylinder head gasket

Excessive valve-rocker arm clearance

No clearance between valves and rocker arms

Valves sticking

Defective timing system

Bent rods

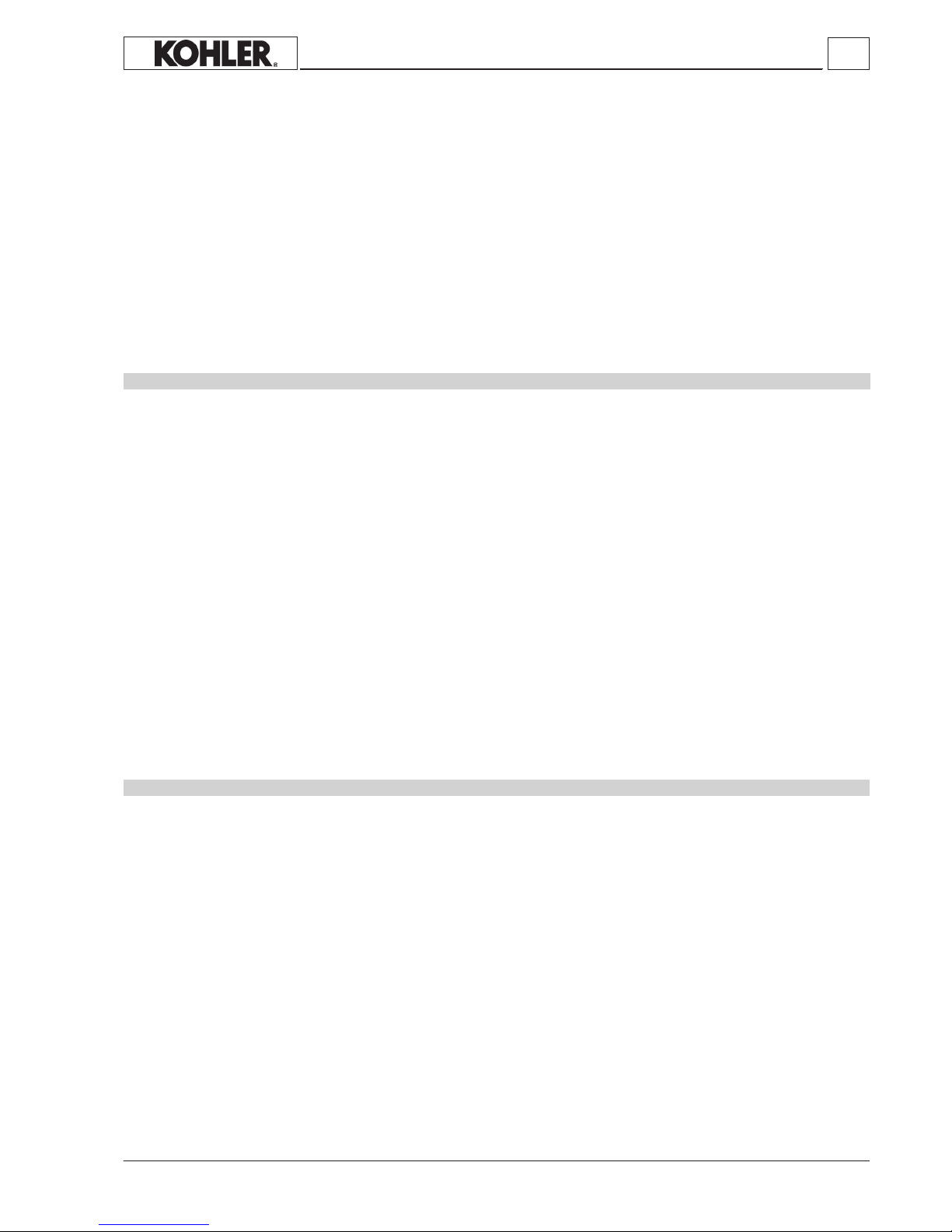

POSSIBLE CAUSES AND TROUBLE SHOOTING

THE ENGINE MUST BE STOPPED IMMEDIATELY WHEN:

1) - The engine rpms suddenly increase and decrease

2) - A sudden and unusual noise is heard

3) - The colour of the exhaust fumes suddenly darkens

4) - The oil pressure indicator light turns on while running.

TABLE OF LIKELY ANOMALIES AND THEIR SYMPTOMS

The following table contains the possible causes of some failures which may occur during operation.

Always perform these simple checks before removing or replacing any part.

TECHNICAL INFORMATION

KD Workshop Manual_cod. ED0053029350_1° ed_ rev. 00

Page 11

- 11 -

2

INJECTION

LUBRICATION

CIRCUIT

COOLING

CIRCUIT

Damaged injector

Injection pump valve damaged

Injector not adjusted

Faulty fuel feeding pump

Hardened pump control rod

Broken or loose supplementary start-

up spring

Worn or damaged pumping element

Incorrect tuning of injection components

(delivery balancing advance)

Extra fuel control level sticking

Oil level too high

Oil level low

Oil pressure valve blocked or dirty

Oil pressure regulator not adjusted

Worm oil pump

Oil sump suction line clogged

Faulty pressure gauge or pressure switch

Blocked draining pipe

Worn or broken blower belt

Cooling circuit clogged

POSSIBLE CAUSE

In adequat e

performance

High noise

level

Overheats

TROUBLE

Engine does

not start

Engine starts

but stops

No acceleration

Non -unif orm

speed

Black smoke

White smoke

Too low oil

pressure

Excessive oil

consumption

Technical information

KD Workshop Manual_cod. ED0053029350_1° ed_ rev. 00

Page 12

- 12 -

2

Technical information

EPA Label Shown on the Recoil Starter or on Air Shroud

MANUFACTURER AND MOTOR IDENTIFICATION DATA

The identication plate shown in the gure can be found directly on the engine.

It contains the following information:

A) Manufacturer’s identity

B) Engine type

C) Engine serial number

D) Maximum operating speed

E) Number of the customer version (form K)

F) Approval data

Approval data

The approval reference directives EC are on the engine plate (F).

s/n

MADE IN ITALY

rpm

XX XX XXXX

XX XX XXXX

XXXX

XXXXXX

e9 • 97/68/CE • 00/000xx • xxxx •xx

Xx

0.00

xxx xxx xx

Model

Spec.

C

A

F

D

E

B

KD Workshop Manual_cod. ED0053029350_1° ed_ rev. 00

Page 13

- 13 -

2

ENGINE TYPE

Only for 97/68 CE and EPA approved engines

* Referred to max. NB power

** At NA power

*** Depending on the application

Technical information

TECHINICAL SPECIFICATIONS

KD Workshop Manual_cod. ED0053029350_1° ed_ rev. 00

3

95

88

1870

17:1

3000

28/38

26/35,4

24/32,7

104/10,6

@2000

13/17,7

7,98/10,8

190/258.5

15

0,017

5

170

2400

38000

300

35°

25°

****

1 - 3 - 2

N.

mm

mm

Cm³

kW/CV

kW/CV

kW/CV

Nm/kgm

kW/CV

kW/CV

g/CV.h - g/kW.h

l.

kg/h

l.

kg

l./min'

l./min'

kg

α

α

α

Number of cylinders

Bore

Stroke

Displacement

Compression ratio

R.P.M.

N (80/1269/CEE) ISO 1585

Power kW/HP NB ISO 3046 IFN

NA ISO 3046 ICXN

Max. torque

Max. torque at 3rd p.t.o. at 3200 r.p.m.

Max. torque at 4th p.t.o. at 3200 r.p.m.

Specic fuel consumption *

Tank capacity

Oil consumption **

Oil sump capacity

Dry weight

Combustion air volume at 3000 r.p.m.

Cooling air volume at 3000 r.p.m.

Max. permissible driving shaft axial load in

both directions

momentary

Max. inclination lasting up to 1 h.

permanent

Firing Order

KD

625-3

Page 14

- 14 -

2

Technical information

PERFORMANCE DIAGRAMS

KD 625-3 @ 3000 r.p.m.KD 626-3 @ 3000 r.p.m.

KD 626-3 NR @ 3000 r.p.m. KD 626-3 B2 NR @ 2800 r.p.m.

KD Workshop Manual_cod. ED0053029350_1° ed_ rev. 00

Page 15

- 15 -

2

Technical information

N (80/1269/EEC - ISO 1585) - AUTOMOTIVE RATING: Intermittent operation with variable speed and variable load.

NB (ISO 3046 - 1 IFN) - RATING WITH NO OWERLOAD CAPABILITY: continuos ligth duty operation with constant speed and

variable load.

NA (ISO 3046 - 1 ICXN) - CONTINUOS RATING WITH OVERLOAD CAPABILITY: continuos heavy duty with constant speed

and constant load.

MN Torque at N power.

MB (NB curve)

MA (NA curve).

C Specic fuel consumption at NB power.

The above power values refer to an engine tted with air cleaner and standard mufer, after testing and at the environmental

conditions of 20°C and 1 bar.

Max. power tolerance is 5%. Power decreases by approximately 1% every 100 m di altitude and by 2% every 5°C above

25°C.

Important

Non-approval by KOHLER for any modications releases the company from any damages incurred by the engine.

Note: Consult KOHLER for power, torque curves and specic consumptions at rates differing from those given above.

KD 625 - 3 / 626 - 3 EPA

@ 2400 r.p.m. @ 2600 r.p.m.

KD Workshop Manual_cod. ED0053029350_1° ed_ rev. 00

Page 16

- 16 -

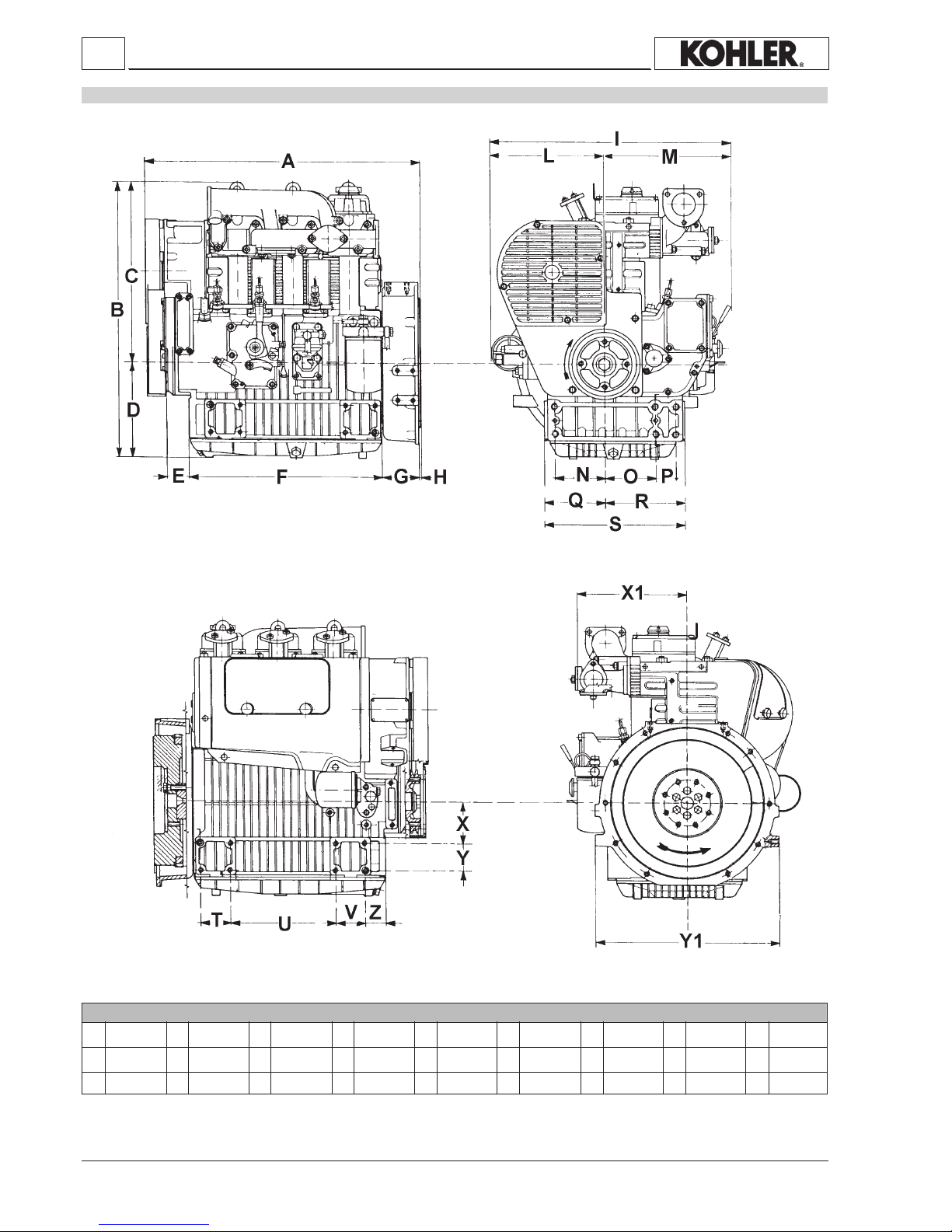

2

A

B

C

D

E

F

601

612

400

DIMENSIONI mm - MESURES mm - DIMENSION mm - EINBAUMAßE mm - DIMENSIONE mm - DIMENÇÕES (mm)

G

H

I

212

47

421

L

M

N

82

4

525

O

P

Q

247

278

110

R

S

T

110

45

132

U

V

Z

173

305

65

X

Y

230

65

46

X1

Y1

94

60

237

400

OVERALL DIMENSIONS

Note : Dimensions shown in mm

Technical information

KD Workshop Manual_cod. ED0053029350_1° ed_ rev. 00

Page 17

- 17 -

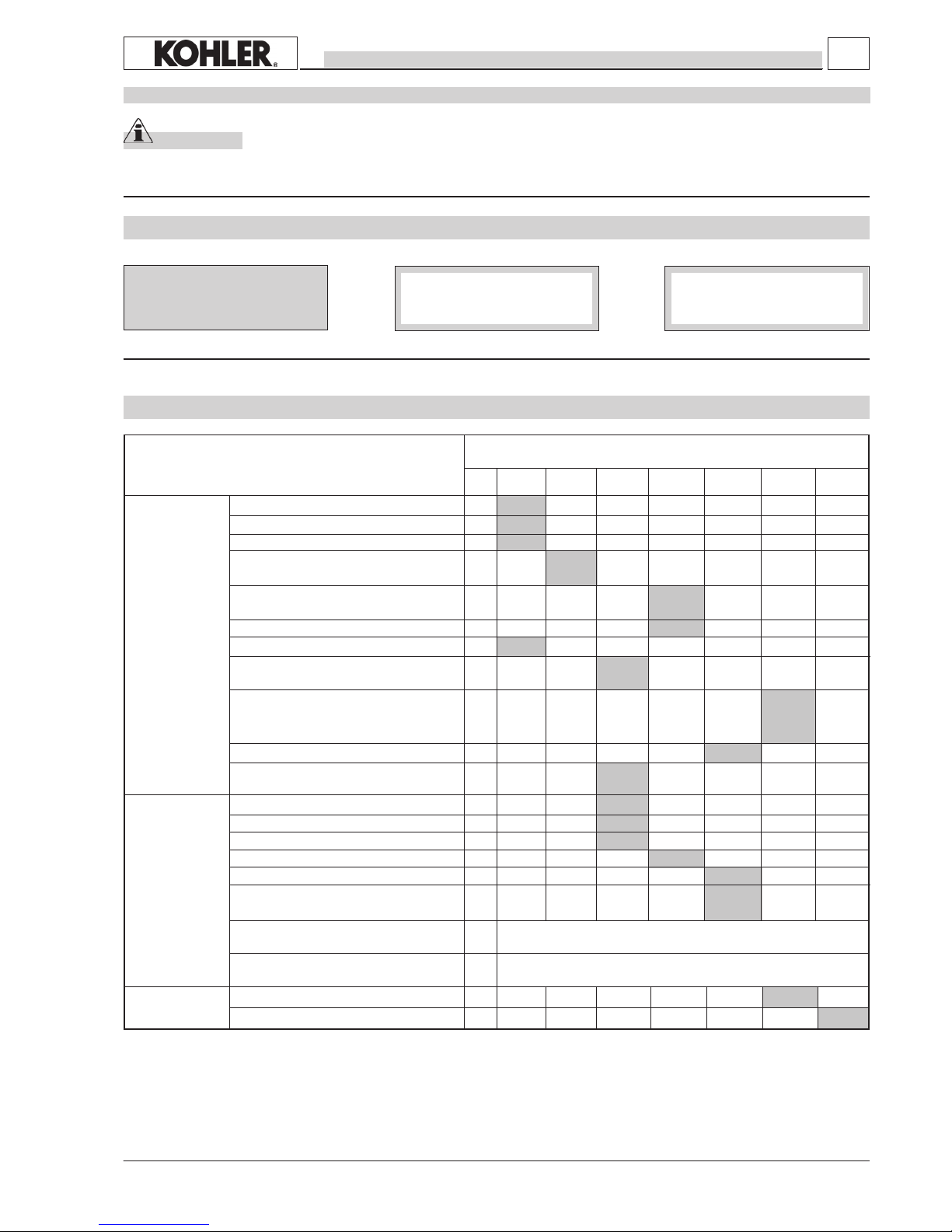

10 125 250 500 1000 2500 5000

(***)

(*)

(*)

(*)

(**)

(**)

(***)

(***)

3

MAINTENANCE - PRESCRIBED LUBRICANT - REFILLING

Engine oilreplacement.

Oil lter replacement.

OPERATION DESCRIPTION

FREQUENCY x HOURS

LEVEL ENGINE LUBRICANT

DRY AIR CLEANER

OIL BATH AIR CLEANER

BLOWER BELT TENSION

VALV E/R OC KER A RM S CLE ARA NC E

ADJUSTMENT

SETTING AND INJECTORS CLEANING

FUEL PIPES

RUBBER INTAKE HOSE (AIR FILTER – IN-

TAKE MANIFOLD)

ENGINE OIL RADIATOR CLEANING (IN THE

APPLICATIONS WHERE IT IS PRESENT)

FUEL TANK CLEANING

COOLING SYSTEM CLEANING

ENGINE LUBRICANT

OIL FILTER

FUEL FILTER

BLOWER BELT

FUEL PIPES

RUBBER INTAKE HOSE (AIR FILTER – IN-

TAKE MANIFOLD)

DRY AIR CLEANER EXTERNAL CAR-

TRIDGE

DRY AIR CLEANER INTERNAL CARTRID-

GE

PARTIAL OVERHAUL

TOTAL OVERHAUL

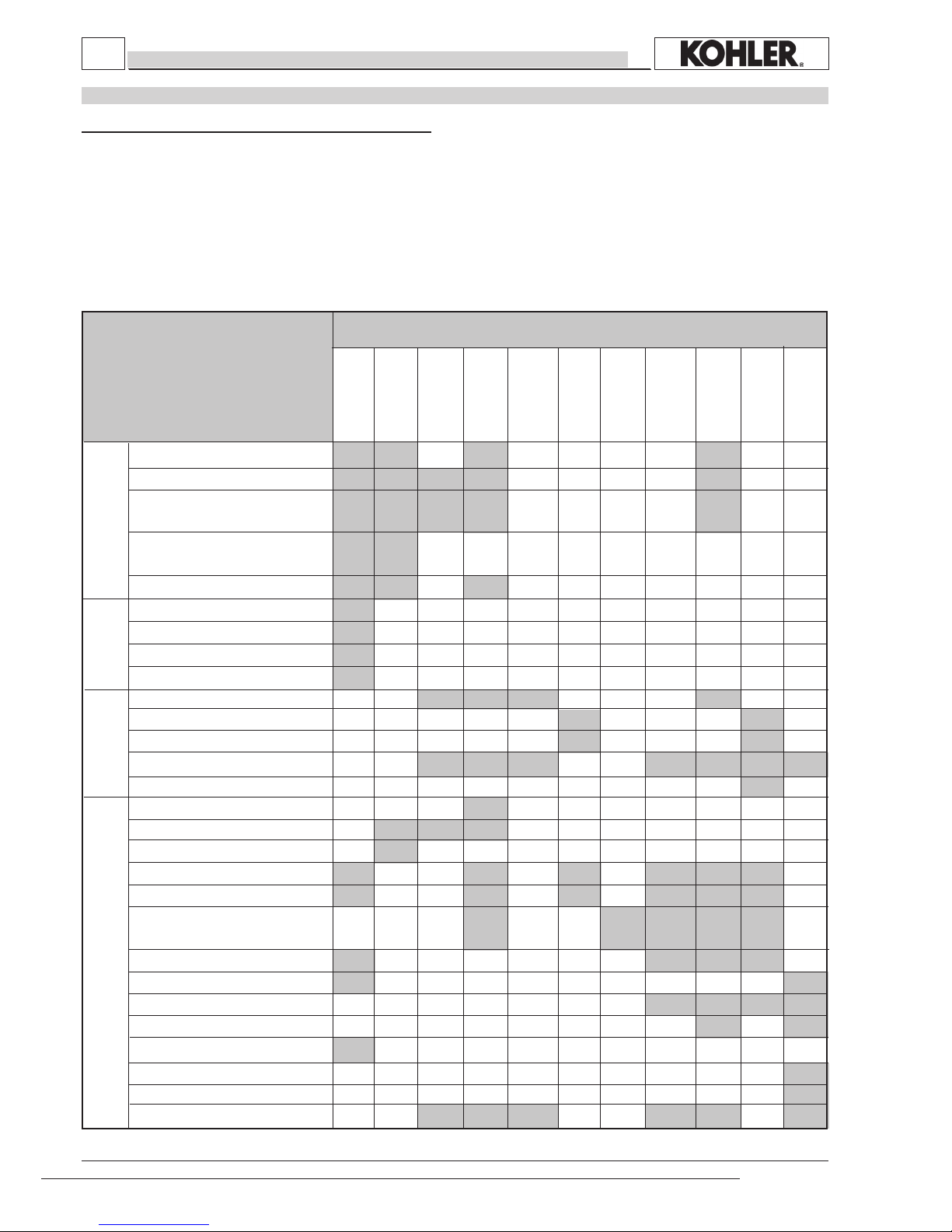

Important

Failure to carry out the operations described in the table may lead to technical damage to the machine and/or system

AFTER THE FIRST 50 WORKING

HOURS

CHECK

REPLACEMENT

OVERHAUL

INSPECTION

(*) - In case of low use: every year.

(**) - In case of low use: every 2 years.

(***) - The period of time that must elapse before cleaning or replacing the lter element depends on the environment in which the

engine operates. The air lter must be cleaned and replaced more frequently in very dusty conditions.

AFTER 6 CHECKS WITH CLEANING

AFTER 3 CHECKS WITH CLEANING

ROUTINE ENGINE MAINTENANCE

EXTRAORDINARY MAINTENANCE

ORDINARY MAINTENANCE

KD Workshop Manual_cod. ED0053029350_1° ed_ rev. 00

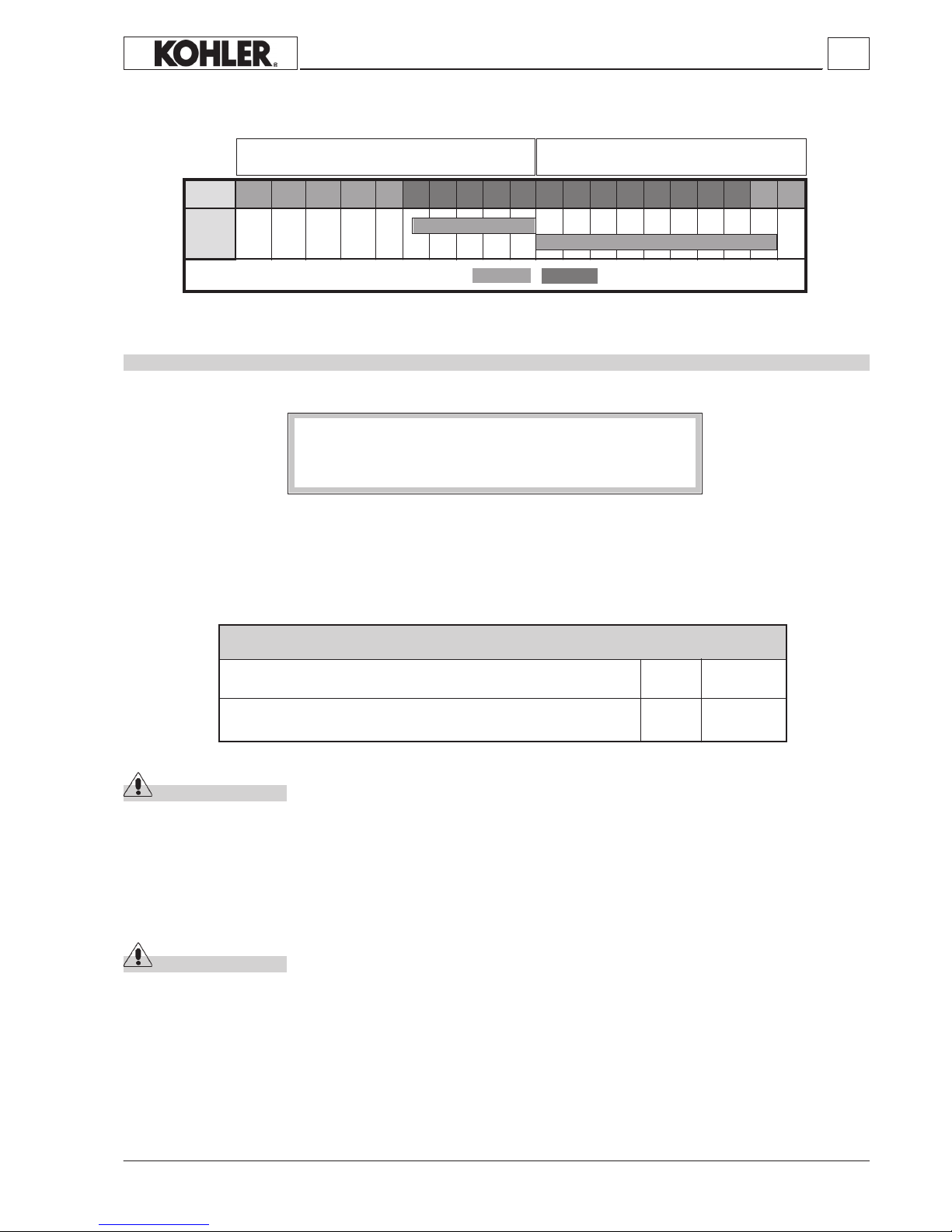

Page 18

- 18 -

3

SAE 20W*

SAE 30*

SAE 40*

SAE 10W-30**

SAE 10W-40**

SAE 10W-60**

SAE 15W-40 **

SAE 15W-40 **

SAE 20W-60 **

SAE 5W-30 ***

SAE 0W-30 ***

-30-2520

-

15

-105

0+5+10+15+20

+

25

+30+

35

+40+

45

SAE 10W*

+

50

-35-

40

SAE 5W-40 ***

Maintenance - Prescribed lubricant - Relling

International specications

They dene testing performances and procedures that the lubricants need to successfully respond to in several engine testing and

laboratory analysis so as to be considered qualied and in conformity to the regulations set for each lubrication kind.

A.P.I : ( American Petroleum Institute )

MIL : Engine oil U.S. military specications released for logistic reasons

ACEA : European Automobile Manufacturers Association

Tables shown are of useful reference when buying a kind of oil.

Codes are usually printed-out on the oil container and the understanding of their meaning is useful for comparing different brands

and choosing the kind with the right characteristics.

Usually a specication showing a following letter or number is preferable to one with a preceding letter or number.

An SF oil, for instance, is more performing than a SE oil but less performing than a SG one.

PETROL

A1 = Low-viscosity, for frictions reduction

A2 = Standard

A3 = High performances

LIGHT DUTY DIESEL ENGINES

B1 = Low-viscosity, for frictions reduction

B2 = Standard

B3 =High performances (indirect injection)

B4 = High quality (direct injection)

HEAVY DUTY DIESEL ENGINES

E1 = OBSOLETE

E2 = Standard

E3 = Heavy conditions (Euro 1 - Euro 2 engines )

E4 = Heavy conditions (Euro 1 - Euro 2 - Euro 3 engines )

E5 = High performances in heavy conditions (Euro 1 - Euro 2 -

Euro 3 engines )

ACEA Regualtions - ACEA Sequences

LUBRICANT

SAE Classication

In the SAE classication, oils differ on the basis of their

viscosity, and no other qualitative characteristic is taken

into account.

The rst number refers to the viscosity when the engine

is cold (symbol W = winter), while the second considers

viscosity with the engine at régime.

The criteria for choosing must consider, during winter, the

lowest outside temperature to which the engine will be

subject and the highest functioning temperature during

summer.

Single-degree oils are normally used when the running

temperature varies scarcely.

Multi-degree oil is less sensitive to temperature changes.

* Mineral base

** Semi-synthetic base

*** Synthetic base

SAE- Grade

KD Workshop Manual_cod. ED0053029350_1° ed_ rev. 00

Page 19

- 19 -

CF CE CD CC CB CA SA SB SC SD SE SF SG

L - 2104 D / E

L - 46152 B / C / D / E

SH

API

SJ

SLCH-4 CG-4 CF-4 CF-2

MIL

5,5

5

DIESEL

AGIP SUPERDIE-

SEL

MULTIGRADE

15W40

API CF 4

ACEA B2 - E2

MIL - L-2104 D/E

3

Maintenance - Prescribed lubricant - Relling

Litres

Litres

API / MIL Sequences

OBSOLETE

PETROL

CURRENT

specications

PRESCRIBED LUBRICANT

In the countries where AGIP products are not available, use oil API SJ/CF for Diesel engines or oil corresponding to the military

specication MIL-L-2104 D/E.

For a temperature of -10°C an oil with a 5W40 viscosity is recommended. For a temperature of -15°C an oil with a 0W30 viscosity is recommended.

OIL VOLUME AT MAX LEVEL (OIL FILTER INCLUDED)

OIL VOLUME AT MAX LEVEL (WITHOUT OIL FILTER)

Danger – Attention

- The engine may be damaged if operated with insufcient lube oil.

- It is also dangerous to supply too much lube oil to the engine because a sudden increase in engine rpm could be caused

by its combustion.

- Use proper lube oil preserve your engine.

Good quality or poor quality of the lubricating oil has an affect on engine performance and life.

- If inferior oil is used, or if your engine oil is not changed regularly, the risk of piston seizure, piston ring sticking, and

accelerated wear of the cylinder liner, bearing and other moving components increases signicantly.

- Always use oil with the right viscosity for the ambient temperature in which your engine is being operated.

Danger – Attention

- The used engine oil can cause skin-cancer if kept frequently in contact for prolonged periods.

- If contact with oil cannot be avoided, wash carefully your hands with water and soap as soon as possible.

- Do not disperse the oil in the ambient, as it has a high pollution power.

KD Workshop Manual_cod. ED0053029350_1° ed_ rev. 00

Page 20

- 20 -

15

3

API CF4 - CG4

API CF - CD - CE

Fuels for low temperatures

It is possible to run the engine at temperatures below 0°C using special winter fuels.

These fuels reduce the formation of parafn in diesel at low temperatures.

If parafn forms in the diesel, the fuel lter becomes blocked interrupting the ow of fuel.

Fuel can be: - Summer up to 0°C

- Winter up to -10°C

- Alpine up to -20°C

- Arctic up to -30°C

For all fuel types, the cetane number cannot be lower than 51.

Aviation kerosene and RME fuels (biofuels)

The only Aviation fuels that may be used in this engine are: JP5, JP4, JP8 and JET-A if 5% oil is added.

For more information on Aviation fuels and Biofuels (RME, RSME) please contact the KOHLER applications department.

Capacities standard fuel tank

Litres

Maintenance - Prescribed lubricant - Relling

Fuel with low sulphur content

Fuel with high sulphur content

PRESCRIBED LUBRICANT

FUEL SPECIFICATIONS

Danger – Attention

- To avoid explosions or re outbreaks, do not smoke or use naked ames during the operations.

- Fuel vapours are highly toxic. Only carry out the operations outdoors or in a well ventilated place.

- Keep your face well away from the plug to prevent harmful vapours from being inhaled.

- Dispose of fuel in the correct way and do not litter as it is highly polluting.

To achieve optimum performance of the engine, use good quality fuel with certain characteristics:

Cetane number (minimum 51): indicates the ignition quality.

A fuel with a low cetane number may cause problems when starting from cold and have a negative

effect on combustion.

Viscosity

(2.0/4.5 centistokes at 40°C): this is the resistance to ow and performance may decline if not within the limits.

Density (0.835/0.855 Kg/litre): a low density reduces the power of the engine, and density that is too high increases performance

and opacity of the exhaust

Distillation (85% at 350°): this is an indication of the mixture of different hydrocarbons in the fuel.

A high ratio of light hydrocarbons may have a negative effect on combustion.

Sulphur (maximum 0.05% of the weight): high sulphur content may cause engine wear.

In those countries where diesel has a high sulphur content, it is advisable to lubricate the

engine with a high alkaline oil or alternatively to replace the lubricating oil recommended

by the manufacturer more frequently.

The countries in which diesel normally has a low sulphur content are: Europe, North America and Australia.

As for lters, tanks and special crankcases please refer to KOHLER instructions.

KD Workshop Manual_cod. ED0053029350_1° ed_ rev. 00

Page 21

- 21 -

3

........................................................................................................................................................

........................................................................................................................................................

........................................................................................................................................................

........................................................................................................................................................

........................................................................................................................................................

........................................................................................................................................................

........................................................................................................................................................

........................................................................................................................................................

........................................................................................................................................................

........................................................................................................................................................

........................................................................................................................................................

........................................................................................................................................................

........................................................................................................................................................

........................................................................................................................................................

........................................................................................................................................................

........................................................................................................................................................

........................................................................................................................................................

........................................................................................................................................................

........................................................................................................................................................

........................................................................................................................................................

........................................................................................................................................................

........................................................................................................................................................

........................................................................................................................................................

........................................................................................................................................................

........................................................................................................................................................

........................................................................................................................................................

........................................................................................................................................................

........................................................................................................................................................

KD Workshop Manual_cod. ED0053029350_1° ed_ rev. 00

Page 22

- 22 -

4

RECOMMENDATIONS FOR OVERHAULS AND TUNING

Important

To locate specic topics, the reader should refer to the index.

– Before any intervention, the operator should lay out all equipment and tools in such a way as to enable him to carry out ope-

rations correctly and safely.

– The operator must comply with the specic measures described in order to avoid errors that might cause damage to the engine.

– Before carrying out any operation, clean the assemblies and/or components thoroughly and eliminate any deposits or residual

material.

– Wash the components with special detergent and do not use steam or hot water.

– Do not use ammable products (petrol, diesel, etc.) to degrease or wash components. Use special products.

– Dry all washed surfaces and components thoroughly with a jet of air or special cloths before reassembling them.

– Apply a layer of lubricant over all surfaces to protect them against oxidation.

– Check all components for intactness, wear and tear, seizure, cracks and/or faults to be sure that the engine is in good working

condition.

– Some mechanical parts must be replaced en bloc, together with their coupled parts (e.g. valve guide/valve etc.) as specied

in the spare parts catalogue.

Danger - Attention

During repair operations, when using compressed air, wear eye protection.

RECOMMENDATIONS FOR DISASSEMBLING AND ASSEMBLING

DISASSEMBLY/REASSEMBLY

Important

To locate specic topics, the reader should refer to the index.

– Besides disassembly and reassembly operations this chapter also includes checking and setting specications, dimensions,

repair and operating instructions.