Single

Cylinder

Engine

K9J,

SERVICE

KJ4J, KJ6J,

MANUAL

K24J, K30J, K32J,

KJBJ,

K34J

CONTENTS

SECTION

SECTION

SECTION

SECTION

SECTION

SECTION

SECTION

1.

General Information

2.

Special Tools

3.

Periodic Maintenance

4.

Troubleshooting

5.

Air Cleaner And Air Intake System

6.

Fuel System And Governor

7.

Retractable Starters

......................................................

................................................

...............................................

....................................................

................................................

..................................

..........................................

.

.

.

II

.

.

II

II

.

.

SECTION

SECTION

SECTION

SECTION

SECTION

8.

Electrical Systems And Components

9.

Automatic Compression Release

10.

Disassembly

11.

Inspection and Repair

12.

Reassembly

.......................................................

..............................................

........................................................

.................................

.....................................

.

.

.

II

.

Ill

Ill

.

GENERAL INFORMATION

SAFETY INFORMATION

For Your Safety!

These safety precautions should

in serious injury to yourself

A

WARNING

and

SECTION 1

be

followed at all times. Failure to follow these safety precautions

others.

A

WARNING

A

WARNING

could

result

~

Explosive Fuel

can cause

burns.

Stop

fuel

WARNING: Explosive Fuel!

Gasoline is extremely flammable

and

its vapors can explode

nited. Store gasoline only in approved containers, in wellventilated,

away from sparks

fill the fuel tank while the engine is

hot

or

could

with

hot

tion. Do

spilled fuel. Never use gasoline as

a cleaning agent.

fires

and severe

engine before filling

tank.

if

ig-

unoccupied

running, since spilled fuel

ignite

if

it

comes in contact

parts

or

sparks from igni-

not

start the engine near

buildings,

or

flames. Do

not

~

Rotating Parts

can cause severe injury.

Stay

away

while

engine

is

operation.

WARNING: Rotating Parts!

Keep hands, feet, hair,

away from

vent injury. Never operate the engine with covers, shrouds,

guards removed.

all moving parts to pre-

in

and

clothing

or

¥Af

Hot Parts

can cause severe burns.

Do

not touch engine

operating or just after stopping.

WARNING: Hot Parts!

Engine components can

tremely

vent severe burns,

these areas while the engine is runningturned off. Never operate the engine

with heat shields

removed.

hot

from operq.tion.

or

immediately after

while

do

or

guards

not

get

To

touch

it

ex-

pre-

is

1.1

A

WARNING

A

WARNING

A

WARNING

~~~

Accidental Starts

can cause severe injury

or

death.

Disconnect

plug

WARNING: Accidental Starts!

Before

equipment, always disconnect the

spark

gine from starting accidentally.

Ground the lead to prevent sparks

that

could

the equipment is in neutral.

A CAUTION: Electrical

.a

Never touch electrical wires

components while the engine is

running. They can

electrical shock.

A WARNING: Overspeed Is

.a

Do

not

setting. Overspeed is hazardous

could

and

A WARNING: Flammable

.a

Carburetor cleaners

are extremely flammable. Keep

sparks, flames,

of

ignition away from the area. Follow the cleaner manufacturer's

warnings

proper

gasoline as

and

ground

lead before servicing.

seNicing

plug

lead to prevent the en-

cause fires. Make sure

tamper with the governor

cause personal injury.

and

instructions

and

safe use. Never use

spark

-

the engine

Shock!

be

sources

Hazardous!

Solvents!

and

and

other sources

or

or

solvents

on

its

a cleaning agent.

of

Carbon Monoxide

can cause severe nausea,

or

fainting

Do

closed

WARNING: Lethal Exhaust Gases!

Engine exhaust gases contain

sonous carbon monoxide. Carbon

monoxide is odorless, colorless,

and

can cause death

Avoid inhaling exhaust fumes,

never run the engine in a closed

building

death.

not

operate engine

or

confined

or

confined area.

area.

in

if

inhaled.

poi-

and

A WARNING: Spring Under

.a

Retractable starters contain a powerful, flat wire recoil spring that is

under tension. Do

center screw from the starter until

the spring tension is released. Removing the center screw before releasing spring tension,

starter disassembly, can cause the

sudden

release

Always wear safety goggles when

seNicing retractable

face protection is recommended.

To

proper

reassembly, follow the procedures

in this section carefully.

and

potentially dangerous

of

the spring.

ensure personal safety

starter disassembly and

Tension!

not

remove the

or

starters-

improper

full

and

~

Sulfuric Acid in batteries

can cause severe injury

or death.

Charge

only

in

well

Keep

sources of ignition

WARNING: Dangerous Acid,

Batteries contain sulfuric acid.

prevent

with skin, eyes,

teries

gas while

vent a fire

teries only in well-ventilated areas.

Keep sparks, open flames,

other sources

the battery at all times. Keep batteries

move all jewelry when

batteries.

Before disconnecting the negative

(-)

switches are

will

minal which

sion

vapors are present.

acid

produce

being

or

out

of

the reach

ground cable, make sure all

occur

at the ground cable ter-

if

hydrogen gas

ventilation.

away.

Explosive Gases!

To

burns, avoid contact

and

clothing. Bat-

explosive hydrogen

charged.

explosion, charge bat-

of

ignition away from

OFF.

If

could

cause an explo-

of

children.

seNicing

ON,

a spark

or

gasoline

To

and

pre-

Re-

1.2

ENGINE IDENTIFICATION NUMBERS

When ordering parts,

involving an engine, always give the

fication and serial

or

number

in any

of

the engine.

communications

model,

speci-

The engine identification

numbers

appear

on a

decal (or decals) affixed to the engine blower housing. Refer to Figure 1-1 . The significance of these

numbers

is shown below:

A'iKOHLERI~[Jjll§lTilrJCcil

MODELNO

__........,..sPEC

B--

I~SERIAlNO

REFER

FOR

INSTRUCTIONS AND

PRECAUTIONS

NO

TO

OWNERS

OPERATION

00

HP

0000

0 0 0 0 0 0

0000000

MANUAl

MAINTENANU

SAFFTY

MODEL

NO

0 0 0 0

;;,:;

~~~w~'~

,0M~N~?,

FOR

OPERATION

INSTRUCTIONS AND

PRECAUTIONS

~~~~~~~:~;~~~~~~~

MAINHNANCE

SAFETY

._....,..__

'JS,~

c

SERIAL

NO

IIIIIIIIIIIIIIIIIIIIIIIIIII~WIIIIII111

000000000

1

A

B

c

Identification

Decal

A. MODEL NO.

K 32 1 PT

K-Serles

Engine

Approximate

Displacement

(Cu.

ln.)

Single

Cylinder

Figure

1-1.

Version

A - Special Oil Pan

C - Clutch Model

G -

Generator

P - Pump Model

Q - Quiet Model

R - Reduction

S - Electric

T - Retractable

ST - Electric

Retractable

EP

- Electric Plant

Location

of

Identification

Code

Application

Gear

Start

Start

Start

And

Start

Engine

Decal.

B.

SPEC NO.

C.

SERIAL NO.

E - 1 7 2 4 5 2

u

A

Letter

1965

A

1966

B

c 1967

D 1968

E 1969

Engine

~

26, 27,

Model

31

28

29

30

46

47

60

71

9076430

LJ

First Two Digits I If

Seven

Digit Number

10-19 1969

20-29 1970

30-39

40-49

50-59

60-69

70-72 1975

73-79

80-89 1977

90-94

95-99 1979

1971

1972

1973

1974

1976

1978

Remaining digits are a

Code

M.2.d..!tl

K91

K161

K141

K181

K241

K301

K321

K341

60

1248

l

Variation

Basic

1 0 0 2 6 6 9 2

L__j

First Three Digits I If

Eight Digit Number

100-109 1980

110-119

120-129

130-139

140-149

150-159

factory

1981

1982

1983

1984

1985

code.

of

Engine

1 5 0 1 8 9 7 5 9 1

LJ

First

Two Digits I

Digit Number

15

16 1986

17

18

19

20

21

22

23

24

25

1985

1987

1988

1989

1990

1991

1992

1993

1994

1995

If

Ten

Figure

1-2.

Engine

Identification

Decals.

1.3

OIL

RECOMMENDATIONS

Using

the

proper

crankcase

ly

important,

regularly.

oil

dirty

Oil

Use

troleum

the viscosity

time

causes

Type

high-quality

Institute)

of

operation

and in

Failure

type

the

as is

premature

detergent

Service

based

as shown in

and weight

gear

checking

to

use the

on

the

of

oil in

the

reduction unit is

oil daily and changing oil

correct

engine

oil

of

Class

air

temperature

the

wear

API

SF

table.

oil

(American

or

extreme-

or

using

and failure.

SG.

Select

at

the

engine

Pe-

NOTE: Using

or

extending oil

recommended

which is

A

logo

or

symbol

service

class and SAE

other

not

than

covered

on oil

Service

change

could

cause

by

containers

viscosity

Class

SF

intervals

the

grade.

longer

engine

engine warranty.

identifies

or

SG

than

damage

the

API

oil

Recommended

Straight

and 1 OW-40

(0°C).

consumption

30-weight

are

Using

these

and

Shoulder of flange

SAE

Viscosity

oil is

preferred.

not

recommended

oils substantially

combustion

SAE 1 OW-30

above

chamber

Grades

32 °F

increases

deposits.

oil

Check

Check

Check

drain

should be up

level

the

drain

plug.

NOTE: Do not

Oil

Level

oil lever

gear

reduction uniot oil level by

plug on

is low,

cover,

plug hole, and

add

below

the

dipstick.

remove

BEFORE

the

lower

to

the

oil until it

operate

the

"L"

EACH USE.

part

bottom

the

vented

reaches

replace

the

mark

removing

of

the

cover.

of

the

plug hole.

plug at

the

drain plug and vented

engine

or

over

with

the

Oil

the

bottom

the

oil level

"F"

top

of the

mark

Bayonet

the

level

If

oil

of

on

Remove from block

Place

Read level

Figure

1.4

on

shoulder

1-3.

Dipsticks And

Oil

Fill Tubes.

Push down on tube

level

Read

Change

For a new engine,

hours

operation

For an overhauled engine

shortblock

Service Class

operation. Change the oil

period. Refill with Service Class

specified in

ing hours

Oil

of

operation.

thereafter.

or

the

thereafter.

change

Change oil

miniblock, use straight

SF

or

SG

table. Change oil

oil

aft~r

or

one rebuilt with a new

oil

for

after

FUEL RECOMMENDATIONS

the first 5

every

the first 5 hours

25 hours

30-weight

this initial

SF

or

SG

every

run-in

oil as

25

operat-

of

of

Do

not use gasoline left over

gum

son, to minimize

and to insure easy starting.

Do

not add oil to the gasoline.

Do

not overfill the fuel tank. Leave

fuel to expand.

deposits

from

the previous sea-

in

your fuel system

room

tor

the

Fuel Type

For best results, use only clean, fresh, unleaded

gasoline with a

higher.

should be 90

In

pump

sticker

countries using the Research

octane

minimum.

octane

rating

of

87

method,

or

it

£ WARNING: Explosive Fuel!

Gasoline may

system. Gasoline is extremely flammable and it can

explode

other sources

connect and ground the spark

the possibility

General Recommendations

Purchase gasoline

clean, approved containers. A container with a ca-

pacity of 2 gallons

recommended.

and

helps eliminate spoilage during refueling.

be

present in the carburetor and fuel

if

ignited. Keep sparks, open flames, and

of

ignition away from the engine. Dis-

plug

lead to prevent

of

sparks from the ignition system.

in

small quantities and store

or

less with a pouring spout

Such a container

is

easier to handle

in

is

Unleaded gasoline

less combustion

line

may

be used

available and exhaust emissions are not regulated.

Be

aware however, that the cylinder head will re-

quire

more

frequent

is

recommended,

chamber

in

deposits. Leaded gaso-

areas where unleaded is not

service.

as it leaves

Gasoline/ Alcohol blends

Gasohol (up

gasoline by volume) is approved as a fuel

engines.

proved.

to

10% ethyl alcohol, 90% unleaded

for

Kohler

Other gasoline/alcohol blends are not ap-

Gasoline/Ether blends

Methyl Tertiary Butyl Ether (MTBE) and unleaded

gasoline blends (up to a

volume) are approved as a

Other

gasoline/ether

maximum

blends are not approved.

fuel

of

15%

for

Kohler engines.

MTBE

by

OIL REFILL QUANTITIES (U.S. STANDARD QUARTS)

K91

1/2

Quart 1 Quart

*

A-type

level,

K141, K161,

(After

oil pan

then

capacity

add oil as necessary

K181

refilling, always

varies

K241, K301, K321,

2 Quarts

check

from 1 to

to

1-3/4

bring up

Figure

K341 K241

oil level --DO

quarts.

to

full level.

On

1-4.

A,

K301

1 Quart*

NOT

OVERFILL)

these add 1 quart

A,

of

K321

oil,

A,

K341

check

A

1.5

HORSEPOWER

GENERAL

BALANCE

GEAR

CAMSHAFT

CONNECTING

ROD

CRANKSHAFT

CYLINDER

BORE

CYLINDER

IGNITION

cv-•

=z--,:;;.

0

./

--""

PISTON

®:..:~.~~

PISTON

~

®-}raJJ

"""'!:

PISTON

PIN

VALVES

(Maximum

En

ine

Model

Displacement

Max. Operating

Shalt

0.0.

Sleeve

Small

PTO

Flywheel

M

End

A R

I Max. Taper (Sleeve)

N

Running

S Clearance

-(Sieevef

c

:f---M-a_x

~~-~M=ax~.~O~u~l~of~R~o~u~nd-~.........:_~oo=0~5-+~.o~o=o5~-t-~.o~oo~5=--~.........:.~oo~o=5.........:+~.o~o=o5~-t-~.0~00~5:_~.........:~.o~oo=5.........:~

ff--~~~~~~~.........:~:_-t-~~-t--~=---j--~~--jL_~~-~~~-t-~~--~

N

Max.

Max.

HD.

Spark

Plug

T~e

Gap

Nominal Point

Service Replacement Sizes

Thrust Face

o.D.(J)

Ring

End

Max. Ring Side Clearance

Service Replacement Sizes

Thrust Face

0.0.®

Ring hNr.:e;:;;w"Bo;:;re;;o":--tt-----+------t---·0_1_0i_.0_23_t-----+-·-01..,0.,..i.0:--2_0-t-·0_1_0i_.0_20_+-_.0_10,...i.-:-02_0--l

End

Max.

Outside Diameter .5623/.5625

Guide Reamer

c!appet

··r~~f~ce

MiTmum

(Zero Lash)

Minimum

Valve Stem

0.0.

Nominal

Guide

w~::l~~Wmlf---Ex-h-

RPM)

Bore x Stroke

Cu.

.~axlmum

W&arlimil

End

Play

1.0.

Installed

End

Play

End

1.0.

(New)

&

Maximum

0.0.

wear

~~~-

~~~~e~el

Ma~~r:,um

f----'l~<L-...f--.....:::_--jf--.........:=--+-=--t-.....:::_--jf--.........:=--+-=--t--==-----1

wear

New

Ste1~v~a'l~~ring

New

__

~w~e~ar_L_im-il-~~.~93~5~0~~~1.~18~5~0~+--1~.1-8-50~-r-1~.4-99-0~~-1.-49_9_0_+--1-.4-9-90--r-1-.4-9-90-~

Max.

Taper

End

Play .004/.023 .002/.023 .002/.023 .003/.020 .003/.020 .003/.020 .003/.020

Oul

ol

Round

Max.

Taper

Oul

of

Flatness

Type®

BaHery

Magneto

Gaseous

f--="cc:ew=---11--"2~.3~71:...:/2:...:.3~6~9

::::mr~,

New

Used

Gap

f--o..;;M;;cc";;'=;m=:'"""n--ll--.........:_=---+---=_=----t.::c=2=.9.::c31=+-~_=---+==3:.:.3...:6.:.:7=-t.::c=3::..4::.92=-=+=-"3.::_74:..:.4:....:.:.

~~~~:C~".'':.t&~

Gap

Use~::""

Ring

Side Clearance _ _

Size

f--~'"=ak=e--~~·0:.:05:...:/.=00~9--j.........:·=00~6~/.0:.:0:::8-+~·0:.:0::.6/~.0=08:_~~-U=08~/.::.01...:0--j~·::.00~8~/.0~1::.0-+~·0:.:0::.8/~.0~10:_~·=00:.:8/~.0~1=0®~

Exhaus•

f----'"'_ak_e

E•haust

Intake

r------+---~r----~-------t-----r-------t-----t------i

Exhaust

Angle

Valve

1.0.

Intake

2.375x2.000

RPM

New

New

limit

Fuel:

Gap

M

New

ln.

li

I.D.

Bore

Bore

'·

8.86

4000

.005/.020

.001/.0025

.003

.0007/.0008

.5630/.5633

.9841/.9844

.9841

11

ro

.9360/.9355

.001

2.3755/2.3745 2.9380/2.9370 2.9380/2.9370

2.378

.003 .003 .003

.003 .003

.003

RCJ-8

.025

.025

.018

.020

-+=2~.9.::c29:..:.7..::/2.:.:.9.::c28:..:1+='2.-"92:.:9.:c7/.::c2

2.366 2.925

.0035/.006 .007/.010

.007/.017 .007/.017

.027 .027

.006 .006

- -

- -

_ _

.250

.0111.o15

__

~--~-2"'o3~5---+-~·.::c27~1=8---t--~·2:..:.7:...:18~-tc--~·3:..:.1~8--+---=·3_18~-t--~·c:.31~8---+--~·3~1=8--~

.1768 .2482

.2478

.2458

Seat 45' 45' 45' 45' 45' 45' 45'

.. -..

.005

---+--~.o=o"'7---+----":o~o7~~---:...:oo~7---+---:o~o...:8

2.938x2.500

16.94

.005/.010

.001/.002

.0025

.0006/.0011

.6255/.6258

1.1811/1.1814

1.1811

1.186011.1855

2.941 2.941

RCJ-8 RCJ-8

.62471.6249

.3125 .3125 .3125 .3125 .3125 .3125

.o17I.019 .o17I.019

.3103

.3088

2.938x2.750

3600

.005/.010

.001/.002

.0006/.0011

.6255/.6258

1.1811/1.1814

1.1811

_ _ _ _ _ _

1.186011.1855

.001 .001 .001 .001 .001 .001

.003 .003 .003

.025 .025 .035

.025 .025 .025 .025

.018

.020 .020 .020 .020 .020 .020

.007/.010

.007/.017

2.9329/2.9336

.0034/.0051

.62471.6249

005 005 006

3.251x2.875

18.64

3600

.4998/.5001

.002/.010

.005/.010

.0025

.003 .002 .002 .002

.018

2.925

.027 .030

.006

.032

.006

.2482

.3103

.3088

.001/.002

.0003/.0008

.8596/.8599

1.5745/1.5749

1.5745

1.5000/1.4995

3.251513.2505

·..:c92:.:8c..1

+'3:...:.2:.:4..:c32:...:/3:...:.2:.:4:...:13+"'3.-=-36~8-=/3.:.:.3..:c65

3.238 3.363

.007/.010 .007/.010 .007/.010

.010/.020 .010/.020 .010/.020

.8591/.8593

.o111.o19

3.375x3.250

23.85

3600

.4996

.0025

3.254

RH-10

.018 .018

.006

.318 .318 .318

.3103 .3103 .3103 .3103

.3074

.4998/.5001

.002/.010

.005/.010

.001/.002

.0003/.0008

.8757/.8760

1.5745/1.5749

1.5745

1.500011.4995 1.500011.4995 1.500011.4995

3.375513.3745

.003

- 3.3700/3.3693 3.4945/3.4938 3.7465/3.7455

- .0045/.0062

_

_

3.378 3.503

RH-10

.003

-

.003-

.8752/.8754 .8752/.8754 .8752/.8754

.o17I.019 .o17I.019

.3074

__

-r--~:o...:oa--~--_...::o"'o8~-t---:=oo~8--~

3.500x3.250

29.07

3600

.4996

.0025

.003

.003

.035

.010 -.020 -.030

.030

.006

.010-

.030 .030

.006

006

31.27

3600

.4998/.5001

.4996

.002/.010

.005/.010

.001/.002

.0025

.0003/.0008

.8757/.8760

1.5745/1.5749

1.5745

3.5005/3.4995 3.7505/3.7495

.003

.003

RH-10 RH-10

.035

.025

.018

-=-3.'-'49:.:4..::1/-=-3.~49:.:2c:.5

4

.020-

.0050/.0067

+'3:..:..

3.491

.030

.006

.030

.006 .006

.3074 .3074

006 006

3.

750x3.250

35.90

3600

.4998/.5001

.4996

.002/.010

.005/.010

.001/.002

.0025

.0003/.0008

.8757/.8760

1.5745/1.5749

1.5745

3.753

.003

.002

.003

.035

.025

.018

7:...:42:.:5...:/3:...:.

74.:..c1:.:0®

4

3.738®

.007/.010®

.010/.020

.030

.006

4

.0030/.0050

.030

.o111.o19

.318

CD

Maximum limits combination of

0.0.

measurements

®Ball

bearing 1.3779/1.3784, Maximum Wear 1.3779

(])Ball

bearing 1.7716/1.7721, Maximum Wear 1.7716

•

Includes

K141

1.0.

and

Figure

1.6

® Pre Series

®

BaH

bearing .002/.023

® Champion spark plugs or equivalent

(J)

Measure just below oil ring groove and

at right angles

1-5.

Engine

II

1.3733/1.3738, Maximum Wear 1.3728

to

piston pin

Specifications

And

Tolerances.

® 1800 RPM generator sets .005/.007

® Measure W' above the bottom

of the piston skirt.

~

Top

and center compression rings.

HORSEPOWER

CONNECTING

RODSCD

SPARK

CYLINDER

HEADCD

FLYWHEEL

RETAINING

GOVERNOR

GRASS

SCREEN

OIL

PAN

MANIFOLD

CAMSHAFT

NON

METALLIC

MOUNTING

(Max.

RPM)

Engine

Model

Posi-lock®

Capscrew@

PLUGS

NUT

SCREW

BUSHING

Metal

Plastic

Aluminum

Cast

Iron

Sheet

Metal®

SCREW/NUT

NUT

FUEL

PUMP

SCREWS

~

-

140

ln.lbs.

18·22 ft. lbs.

ps

((J1

~

K91

200 ln. lbs.

~4

2 a

0

40·50 ft. lbs.

250 in. lbs.

70-90 in. lbs.

-

-

-

250 in. lbs.

-

-

-

-

~

9}

X,

1

New 140 ln. lba.

-

Used 100 ln. lbs.

200 ln. lbs.

18·22

fl.

lbs.

p,

0'

~)

K161,

K181

~

15-20

fl.lbs.

3 0

\,_25

(QJ2

85-90 fl.

lbs.®

-

130·150 in. lbs.

70-140

in. lbs.

-

-

Grade

5-250

Grade 8--350 in. lbs.

in. lbs.

-

-

-

37·45 in. lbs.

K321

(ll6

K301

New 260 ln. lbs.

Used 200 ln. lbs.

2851n. lbs.

18-22 ft. lbs.

([jl I

50·60

fl.

lbs.

22-27

ft.

100-120 in. lbs.

70·140

in. lbs.

20·30 in. lbs.

IXI%1~

~IQJ

8

(QJ 4 (QJ

.

IQJ

01

I K241, 9

rQJ

K301,

25-30 ft. lbs.

6

3

l_SdJs

(ji2

-

35

fl.lbs.

200 in. lbs.

-

-

37·45 in. lbs.

K321

(7

(Q!a

(QJ

I

(QJ

I 9 25-30 ft. lbs.

·~~·,,}

25

(QJ2

lbs.

~

1

1o(Ql,

(ji6

K341

IQJ9

USE STANDARD TORQUE SETTINGS WHEN

SPECIFIC VALUES ARE NOT SPECIFIED.

CD

Lubricate with engine

®

DO

NOT overtorque

NEW-

Component directly from stock.

USED-

Component that was

Cast Iron or Steel

Grade 2

Size

0

----=-=

20

32

32

150

260

300

35ft.

45ft.

50

70ft.

75ft.

100ft.

110ft.

140ft.

150ft.

200ft.

in. lb.

in. lb.

1n.

in.

ln.

ln.

ln.

in. lb.

in. lb.

ft.

8-3~

10-24

10-32

1/4-20 70

1/4-28 85

5/16-18

5/16-24 165

3/8-t6

3/8-24

7/t6-14

7/16-20

1/2-13

1/2-20

9/16-12

9/16-18

5/8-11

5/8-18

3/4-10

3/4-16

Conversions

oil

-loosen

-and

in

Grade s•

Q

i--=-

--

lb.

115

lb.

140

lb.

lb.

250

270

lb.

lb.

lb.

lb.

lb.

105ft.

125ft.

lb.

t65

lb.

180ft.

lb.

230ft.

lb.

245ft.

lb.

325ft.

lb.

in. lbs. x .083 =ft. lbs.

ft. lbs. x

ft.lbs.

ft.

lbs. x 1.3558 ~ N m

retorque the hex nuts on Pos1-Lock connecting rods.

a running engine.

25

ln.

lb.

40

ln.

lb.

40

ln.

lb.

ln.

lb

ln.

lb

1n.

lb.

1n.

lb

35ft.

lb.

40ft.

lb

55ft

lb.

75ft.

lb.

80ft.

lb.

lb.

lb.

ft.

lb.

lb.

lb.

lb.

lb.

12

~in.

x

.1383~kgm

Grade 8

@

165

ln.

200

ln.

350

ln.

30ft.

50

ft.

60ft.

80ft.

105ft.

115ft.

165ft.

~75ft.

230ft.

260ft.

330ft.

350ft.

470ft.

lbs.

lb.

lb.

lb.

lb.

lb.

lb.

lb.

lb.

lb.

lb.

lb.

lb.

lb.

lb.

lb.

lb.

OIL

DRAIN

at

150

180

20 ft. lbs.

25 ft. lbs.

20·25

PLUGS

Assembly)

Tightening

in. lb.

in.

lb.

ft. lbs.

Torque

Aluminum

100

120

13 ft.lbs.

16

20·25

Pans

in.

lb.

in.

lb.

ft.

lbs.

ft.

lbs.

(Oil

~

1/4"

3/8"

1/2"

3/4"

X-708-1@

® Overtorque 20%, loosen below torque value and retorque to

®Torque

twice with minimum of one minute interval

<ID

3/8~16

thread with hex head nut and fibre gasket

® Pnor

to

Ser.

#23209832 45-55 ~-lbs.

Cast Iron Pans

f1nal

torque value

•

Includes

K141

Figure

1-6.

Torque

Values &

Sequences

For Fasteners.

1.7

SECTION 2

SPECIAL TOOLS

SPECIAL SERVICE TOOL KIT

These quality tools are designed

form

specific

procedures. By using tools designed

you can service engines easier, faster and safer!

In

addition, you·

customer

and

time.

down

The Special Service Tool Kit No.

ordered

tools can be

Kohler Engine Distributor

disassembly, repair and reassembly

II

increase

satisfaction by decreasing engine

complete

as shown

ordered

your

individually. Contact

for

NO.

3211-A

to

help you per-

for

the

job,

service capabilities

3211-A

in

Figure 2-1

price and availability.

can be

or

the

your

Figure

2-1.

Special Service Tool Kit

2.1

VALVE

SERVICE

TOOLS

TOOL NO. &

VALVE SEAT PULLERS Removal

11726

11913

FORCING SCREW Used

11915

ADAPTER

11918

VALVE SEAT INSTALLER

11811 seats. Use

11812

SLIDE

3222

11799

Weight

12244

Slide

3268 VALVE GUIDE REMOVAL KIT

11838

Stud 3 1/2"

12100

Stud 2 1/2"

11800

Adapter

0917

Nut

12008

Nut

NAME

HAMMER

Bolt

adapter, 3222

forcing

pullers

Used

to

Used

Provides

and

Used

slide

screw

with

11726 & 11913

to

connect

slide

hammer

to

install

guide

to

pull

hammer

APPLICATION

of

valve seats, Use 11918

slide

hammer

valve seat

valve seat

intake

with

pulling

removal. Use 4747

valve

and

exhaust

4747

handle

force for valve seat

guides

with

& 11915

pullers

handle.

3222

ILLUSTRATION

~

Ct==tP

©

~

~

~

~

(

llB~ii

:~~~

3224 VALVE GUIDE INSTALLER KIT

12325 Driver

11763 Driver

11770Gage

11771 Gage

REAMERS (Valve Guide)

11843 5/16"

11844 1/4"

SEAL

3223 SEAL INSTALLER KIT Used

11782 Seal

11783 Seal

11784 Seal

11785 Seal

11786 Seal

11787 Seal

11790 Seal

11791 Seal

11792 Seal

11793 Seal

11795

Installer

Installer

Installer

Installer

Installer

Installer

Installer

Installer

Installer

Installer

Handle

Used

proper

11770 & 11771

To ream valve

AND

damage

11795

to

install

valve

depth.

Use 11763

depth

guides

BEARING

to

install

seals

and

to

proper

handle

with

installers

guides

gages

to

driver

with

INSTALLERS

without

depth.

Use

~

~

cw

c(

(])

v

X:1~

2.2

SEAL

AND

BEARING

INSTALLERS

TOOL NO. & NAME

3242 SEAL PROTECTOR SLEEVE KIT

12021

12020

12022

12127 1.50 12128 1.44

3241

12014 Ins. (Crank

12015 Ins. (Cam Bushing)

12016, 12017, 12018 & 12109

.75"

1.25 12126 1.12

BEARING INSTALLING KIT

Brg.

Installers

1.00

Bushing)

Used on

seals

Used

bearings

OTHER

3226 FLYWHEEL PULLER KIT

12485 Puller

5108

12505

12504

12506 Storage Bag

FLYWHEEL STRAP WRENCH Used

10357

Bolt

BoltBolt-

w/forcing

- 1/4"

w/washer

10-24

3/8"

w/washer

screw

(3)

w/washer

(2)

(2)

Used

bearing

removal

APPLICATION

crankshaft

to

prevent

to

install

and

bushings

when

damage

& remove

installing

engine

APPLICATIONS

to

remove

plates

to

hold

flywheels

from

engine

flywheel for nut

and

ILLUSTRATION

a

@

<(((

((

r

~~

~

~~

J J

)

~

OFFSET

11797 Wrench 1/2"

4923

FEELER GAGE

11767

TIMING GAGE

10355

SCRAPER

11762

HANDLE

4747

TOOL BOARD AND HOOK SET

12033

WRENCH

Wrench

Timing

Handle

9/16"

Gage

Used

to

remove &

barrel

retaining

to

Used

backlash

Used

position

Used

without

Used

hammer, and valve seat

Used

set

on

to

hold

when

to

scrape

damage

with

to

store and

bearing

install

nuts

oil

pump

twin

cylinder

balance

assembling

machined

installers,

identify

drive gear

gears in

cylinder

engine

timed

engine

surfaces

slide

installers

tools

n

~-

~

I

~

SEE FRONT PAGE

:=J

o)

2.3

KIT

3222

3268 Valve

NO.

VALVE TOOLS

11726 Valve Seat

11913 Valve Seat

11915

Forcing

11918

Adapter

11811 Valve Seat

11812 Valve Seat

Slide

12325 Valve

11763 Valve

11770 Valve

11771 Valve

11843 Valve

11844 Valve

3211

PART NO & NAME

Screw

Hammer

Guide

Guide

Guide

Guide

Guide

Guide

Guide

1

KT19

-A

Puller

Puller

Installer

Installer

Removal Kit

Driver

Driver (depth)

Depth

Gage

Depth

Gage

Reamer

Reamer

engines

5/16"

1/4"

prior

to

TOOL

......

......

co

0)

...... ......

~

~

•

•

•

•

•

•

•

•

• •

•

•

•

• •

•

• • •

• • • •

•

Series

II

USAGE

MODEL("

...... ...... ......

..,.

co

~

~

~

• •

•

•

•

• •

......

N

0

M M

C?

~ ~

•

•

•

•

• •

•

• •

•

K"

• • • • •

•

•

• •

• •

(Spec

No.

CHART

SERIES)

.....

......

..,:..

~

0)

......

..,:..

~

......

..,.

~

• • • •

•

•

• •

•

• •

•

•

• • •

•

•

• •

(1)

•

•

•

•

49199

and

N N

M

co

LO

U?

~

~

•

•

•

•

•

•

•

•

•

• •

•

•

lower).

BEARING

12014

Installer-

12015

Installer-

12016

Installer-

12017

Installer12018

Installer-

12019

Installer11782

Installer

11783

Installer-

11784

Installer

11785

Installer

11786

Installer-

11787

Installer

11790

Installer-

11791

Installer

11792

Installer-

11793

Installer-

11795

Handle-

12020 Seal Sleeve

12021 Seal Sleeve

12022 Seal Sleeve

12126 Seal Sleeve

12127 Seal Sleeve

12128 Seal Sleeve

- Seal (PTO)

- Seal (PTO)

- Seal (PTO)

- Seal (PTO)

- Seal (PTO)

Crank

Cam

Bushing

Bearing

Bearing

Bearing

Bearing

Seal

(Flywheel)

Seal

(Flywheel)

Seal

(Flywheel)

Seal

(Flywheel)

Seal

(Flywheel)

Installer

AND

Bushing

(PTO)

Seal

SEAL

INSTALLERS

•

•

•

•

•

•

•

•

•

•

•

•

• • • •

• • •

• • •

• •

•

•

USE AS REQUIRED

USE AS REQUIRED

USE AS REQUIRED

USE AS REQUIRED

USE AS REQUIRED

USE AS REQUIRED

•

•

• •

• •

• •

• •

•

•

•

•

•

•

• •

•

•

10357

Flywheel

11797

Offset

4923

Offset

11767

Feeler

10355

Timing

11762

Scraper

4747 Drive

3226

Flywheel

NOTE: K141

2.4

Strap

Wrench

Wrench

Gauge-Crank(OII

Tool

Handle

Puller

requires

MISCELLANEOUS

Wrench

'/2'

9/16"

(Balance

Kit

same

1/2"

• •

Pump)

Gear)

•

•

•

•

• •

tools as K161.

• • • • •

• • • • •

•

•

TOOLS

•

•

•

• •

•

• •

•

• •

•

•

•

•

•

•

• •

•

•

•

•

• •

•

•

•

• •

•

•

•

•

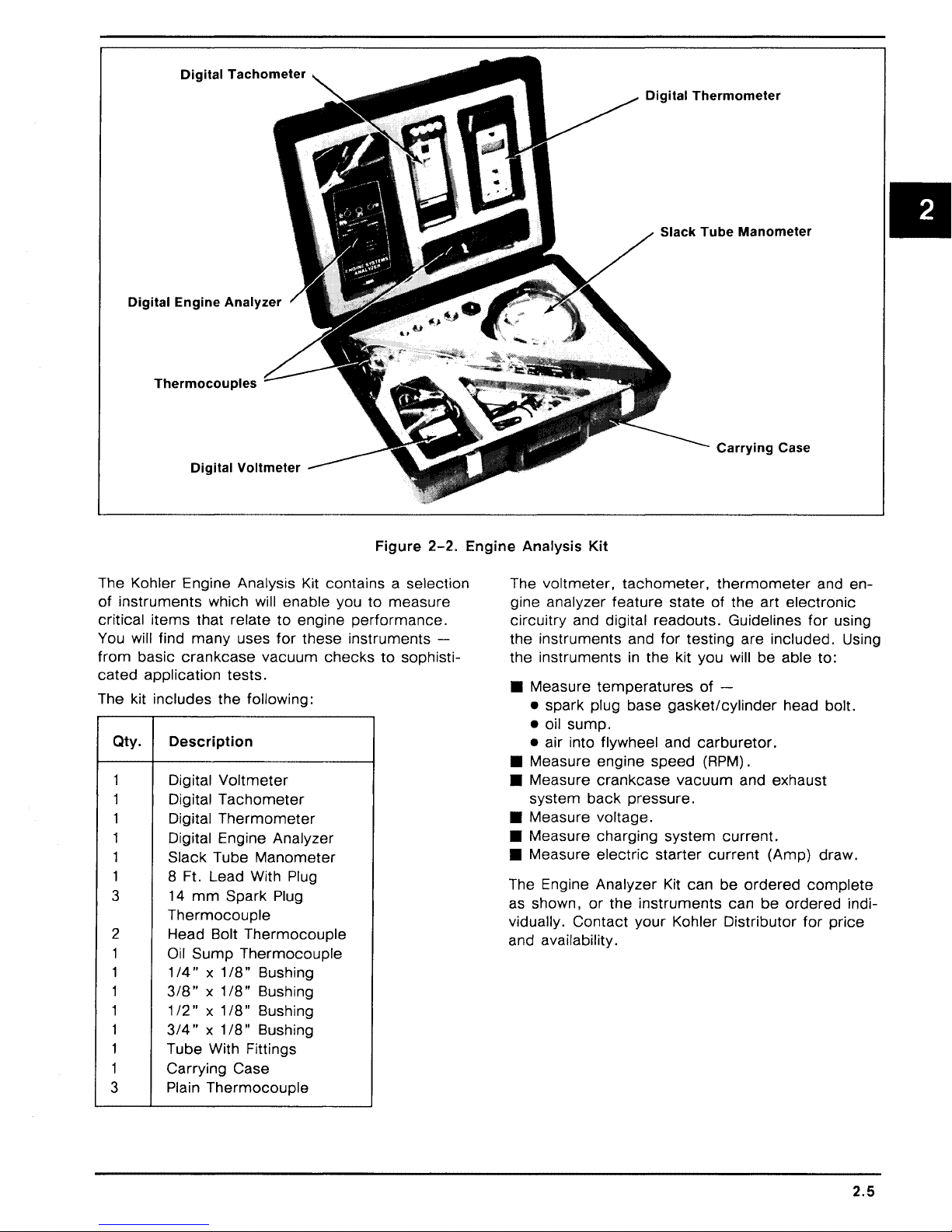

Digital

Digital

Engine

Thermocouples

Tachometer

Analyzer

Digital

Slack

Thermometer

Tube

Manometer

Digital

Voltmeter

Figure

2-2.

The Kohler Engine Analysis Kit contains a selection

of

instruments

critical

items

You will find

from

basic

cated

application

The kit includes

Qty.

1

1

1 Digital

1

1

1

3

which will enable you

that relate

many

crankcase

uses

vacuum

to

for

engine

these

checks

tests.

the

following:

Description

Digital

Digital

Voltmeter

Tachometer

Thermometer

Digital Engine Analyzer

Slack Tube

Manometer

8 Ft. Lead With Plug

mm

14

Spark Plug

to

measure

performance.

instruments

to

sophisti-

-

Thermocouple

2 Head Bolt

1 Oil

1 1

1

1

1

1

Sump

/4"

318" x 1

1/2" X 1/8"

3/4" X 1/8"

Tube With Fittings

1 Carrying

3

Plain

Thermocouple

Thermocouple

x 1

/8"

Bushing

/8"

Bushing

Bushing

Bushing

Case

Thermocouple

Engine

Analysis

The

Kit

voltmeter,

gine analyzer

circuitry

the

and digital readouts. Guidelines

instruments

feature

the instruments

• Measure

temperatures

• spark plug base

• oil

sump.

• air into flywheel and

• Measure engine

• Measure

system

crankcase

back

• Measure voltage.

• Measure charging

• Measure

electric

The Engine Analyzer Kit can

as shown,

vidually.

or

the

Contact

and availability.

tachometer,

state

and

for

testing

in

the kit you will

gasket/cylinder

carburetor.

speed

vacuum

pressure.

system

starter

instruments

your

Kohler Distributor

Carrying

thermometer

of

the

art

are

be

of

-

(RPM) .

and exhaust

current.

current

be

ordered

can

be

Case

and

en-

electronic

for

using

included. Using

able to:

head bolt.

(Amp}

draw.

complete

ordered

for

indi-

price

2.5

SECTION 3

PERIODIC MAINTENANCE

REQUIRED

These required maintenance procedures should be

MAINTENANCE

Required Maintenance

Check

Clean

Clean/Replace Fuel Filter

Clean Foam Precleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 Hours*

Change

Check Optional Reduction

Gear Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 Hours

Clean Cooling Fins and

External Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 Hours*

Clean Paper Air

Cleaner Element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 00 Hours*

Check Spark Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 00 Hours

Check

Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500 Hours

Clean Cylinder Head and

Combustion

Service Starter

Motor Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Annually

• Perform these maintenance procedures

Oil

Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Daily

Grass Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Daily*

..........................................

Oil

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 Hours

Valve-

extremely dusty and dirty conditions.

To-

Tappet

Chamber*

..............................................

performed

more

frequently when engine is operated under

at the

frequency

stated

As Required

or

in

the table:

Frequency

500

Hours**

500 Hours

*

• 250 Hours when leaded gasoline is used.

~

WARNING: Accidental Starts!

Before

remove the spark

starting accidentally. Ground the lead to prevent

sparks that

CHECK

The

proper oil

phasized. Check oil

seNicing

OIL

importance

the engine

plug

to prevent the engine from

could

cause fires.

LEVEL

of checking and maintaining the

level in crankcase cannot be

BEFORE

or

equipment, always

EACH

USE

overem-

as follows:

1. Make sure the engine is stopped, level, and is

cool so the oil has had

sump.

2.

Clean the area around oil fill

fore removing

etc.,

out of the engine.

3. Remove

sert dipstick and push it

tube. Remove dipstick and

4.

On

engines with threaded

shoulder plug on

oil fill

to

keep dirt, grass clippings,

cap/dipstick;

top

time

to

drain into the

cap/dipstick

wipe oil off. Rein-

all the way down into

of

check

type

hole

the level.

plug dipstick,

to

observe level.

be-

3.1

The oil level should

"F"

mark

on

the

dipstick. Refer

be

up to, but not over, the

to

Figure

3-1.

Precleaner

If

so

equipped,

every

tremely

25 operating hours

dusty,

wash and reoil

(more

dirty

conditions).

the

precleaner

often

under

ex-

Figure

5. Add the

Always

adding

CAUTION:

CHANGE

For a new engine,

hours

of

thereafter.

hours

those rebuilt with a

use straight

for

the first 5 hours

after

this initial

hours

thereafter.

warm

from

carry

away

proper

check

more

oil.

Never

operate

below

stick.

"L"

OIL

operation. Change oil

For an overhauled engine

30-weight

run-in

Drain oil while the engine is still

operation. The oil will flow freely and

more

impurities. Change oil as follows:

t

Operating

Range

__l_

L

3-1.

Oil Level Range.

type

of

oil if the level is low.

the level with dipstick

the engine with the oil level

mark

or

over

"F"

change

new

of

oil

after

the first 5

every

shortblock

Service Class

operation. Change the oil

period. Change oil

or

SF

before

mark

on

dip-

25 operating

or

miniblock,

or

SG

oil

every

25

1 . Remove

the

2.

Rinse

detergent

water (do not wring).

dry.

3. Saturate

Squeeze out excess oil.

4. Reinstall

precleaner

precleaner

precleaner

are eliminated. Squeeze out excess

precleaner

precleaner

from

paper

in warm

thoroughly until all

water

Allow

precleaner

in

clean, fresh engine oil.

over

paper

element.

with

element.

detergent.

traces

to

Paper Element

Every 100

tremely

element. Replace the element as necessary.

1.

Remove the precleaner (if so equipped), element

cover, and paper element.

2.

Replace a dirty, bent,

a genuine Kohler element. Handle new elements

faces are bent

NOTE:

Reinstall the paper element.

3.

4.

Install the precleaner (cleaned and oiled) over

the

hours

dusty

carefully; do not use of the sealing sur-

Do

not wash the paper element

pressed air as this will

paper

of operation

or

dirty conditions),

or

or

damaged.

element.

(more

damaged

damage

often under ex-

check

the paper

element with

or

element.

use

Wash

of

air

com-

1. Remove

engine

better

2.

Reinstall

ened securely.

Fill with new oil

3.

mark

on dipstick

the engine is

oil.

SERVICE

K-Series

paper

also

are

which surrounds the

ure

3-2.

the

oil drain plug and dipstick. Tilt the

slightly towards the drain hole to obtain

drainage.

the

drain plug. Make sure it is tight-

of

the

on

the

AIR

engines are

air

cleaner

equipped

proper

dipstick. Always

before

adding

level when filling and checking

CLEANER

equipped

element.

with an oiled

paper

Some

element.

type

check

more

with a

specifications

foam

3.2

to the

oil. Make sure

high-density

precleaner

Refer

"F"

the level

to

Fig-

5.

Install the air cleaner

en wing nut. Make sure element is sealed tightly against air cleaner base.

cover

and wing nut. Tight-

Inspect Air Cleaner Components

Whenever the air cleaner

icing the element

components:

Air

Cleaner Base - Make sure it

carburetor

Element

New Look

is not bent

nut

is

cleaner base and

50 in. lb. torque.

Breather

cleaner base and breather

and is not

Cover

~ngines

or

secured tightly to seal

Tube

or

and

only,

damaged.

element

- Make sure it

cover

precleaner,

bent

or

Element

make

Check

element

cover. Tighten nut to

cover.

is

removed,

check

is

damaged.

Cover

sure

that element cover

is

sealed tightly

the following

secured tightly to

Nut -On

element

between air

or

serv-

K181

cover

in

air

"'--

PRECLEANER

(OPTION)

Figure

NOTE:

ponents could allow unfiltered air into the engine

causing

damaged

Damaged, worn,

premature

or

wear and failure. Replace all

worn components.

or

loose air cleaner

3-2.

Air Cleaner Components.

com-

CLEAN AIR INTAKE/COOLING AREAS

To ensure

screen, cooling fins, and other external surfaces

of engine are kept clean at

operating hours

dusty, dirty conditions), remove the blower housing and

fins and external surfaces as necessary. Make

sure the cooling shrouds are reinstalled. Refer to

the

"Disassembly"

cooling shroud removal and installation proce-

dures.

NOTE:

screen, dirty

ing shrouds removed

due to overheating.

proper

other

Operating the engine with a blocked grass

cooling, make sure the grass

all times. Every 50

(more

cooling shrouds. Clean the cooling

or

plugged cooling fins,

often under extremely

and "Reassembly" sections

and/or

will cause engine damage

cool-

CHECK SPARK PLUG

for

Ground Electrode

Figure

1 . Before removing spark plug, clean the area

around the base of plug to keep dirt and debris out of engine.

3-3.

Servicing Spark Plug.

Every 1 00 operating hours, remove the spark plug,

check

new plug as necessary. Refer

its condition, and reset gap

to

or

replace with

Figure

3-3.

2. Remove the plug and

place the plug if worn

able.

check

or

its condition.

if reuse is question-

Re-

3.3

NOTE: Do not clean the spark plug

using abrasive grit.

spark plug and

wear and

3.

Check

gap by

enter

damage.

gap

using a wire feeler gauge. Adjust

carefully bending the ground electrode.

Some

grit could remain

the engine causing extensive

in

a machine

in

4. Reinstall

plug

spark

to

18/22 ft. lb.

plug into cylinder head. Torque

SERVICE OPTIONAL REDUCTION GEAR

UNIT

On

engines

check

hours. Refer

equipped

the oil level

to

Figure

with a reduction

in

unit

every

3-4.

gear

50 operating

unit,

Figure

3-5.

In-line

Fuel Filter.

SERVICE STARTER MOTOR DRIVE

Every 500 operating hours

occurs

of

1. Remove

2. Remove dust

first) , clean and lubricate the drive splines

the Bendix-drive

starter

propriate

spacer, spring, dust

pinion.

electric

from

"Disassembly"

cover,

or

annually (whichever

starter

crankcase. (Refer

stop nut, stop gear

cover

motor.

section.)

spacer, and drive

to

ap-

Drain Plug

(Oil Level

Figure

1 . Remove the plug on the lower part of

cover.

to the

2.

To add oil,

of

top

used

3.

Reinstall and tighten the plugs securely.

3-4.

Reduction Gear Unit.

With engine level, the oil should be up

bottom

the unit. Use the

in

of

the plug hole.

remove

the engine crankcase.

the vented fill plug at the

same

type of oil as

Check)

gear

unit

CHECK FUEL FILTER

Some

filter. Visually

to

engines are equipped with

inspect the filter periodically. Re-

place when dirty with a genuine Kohler filter. Refer

Figure

3-5.

an

in-line

fuel

3.

Clean the drive shaft splines with solvent. Dry

solvent thoroughly.

4.

Apply a small

drive

lubricant (Part No.

NOTE: Kohler

357 01) must be used on all Kohler

drives. The use

drive to stick

5.

Apply a small

stop nut threads. Assemble drive parts

verse

6. Reinstall

order

160 in. lb.

priate

"Reassembly"

amount

starter

of

other

or

bind.

amount

of

removal. Torque stop nut

starter

to

of

Kohler

52

drive lubricant (Part No.

lubricants can cause the

of

Loctite®

crankcase. (Refer

section.)

electric

357 01)

electric

No.

to

splines.

271

in

to

starter

52

starter

to

re-

to

appro-

CLEAN CYLINDER HEAD AND COMBUSTION CHAMBER

Every 500 operating hours (250 hours when leaded

gasoline is used) ,

combustion

remove

chamber.

cylinder head and clean

Refer to Figure

3-6.

3.4

~1

Figure

1 . Remove the cylinder head baffle and cylinder

head.

2. Clean away

wooden

3. Reinstall the cylinder head using a new gasket.

Torque the cylinder head fasteners

quence

CHECK

Every 500 operating hours,

cover

flat feeler gauge. Refer to Figure

must

1 . Remove the air cleaner assembly, carburetor,

and

"Disassembly"

2.

Position the crankshaft so the piston

of

tappets).

3-6.

Cleaning Cylinder Head And

Combustion Chamber.

combustion

or

plastic scraper.

to

the values specified

VALVE-

and

check

be cold when checking this clearance.

breather

compression

TO-

valve-to-tappet

assembly. (Refer

section.)

stroke

deposits using a

TAPPET

remove

(cam

has no

in

se-

in

Figure

CLEARANCE

breather/valve

clearance with a

3-8.

The engine

to

appropriate

is

effect

3-7.

at top

on

K161, K181 •

15-20

0)2

7©8Q)14(Q)

Q)

©

3

Q5

K241,

K301, K321

25-30

ft. lbs.

9

©

ft. lbs.

~6

Figure

3-8.

Measuring ValveClearance.

To-

Tappet

Q)

3

g5

* Includes

Figure

3-7.

K341

25-30

ft. lbs.

g2

K141

Cylinder Head Fastener

Tightening Sequence.

3. Measure

valve-to-tappet

clearance with a flat

feeler gauge.

On

Model

clearance is too small,

grind the valve

K91, K141, K161,

remove the valves and

stems

until the

K181

correct

-If

the

clearance is obtained. Make sure valve stems are

ground perfectly flat and smooth.

Model Intake Valve Exhaust Valve

K91

K161,K181

K241,

K321,

If

K301

K341

clearance is too large, replace the valves and

Figure

.005" I .009"

.006" I .008"

.008" I .01

3-9.

0"

Valve Clearances

.011

"/.015"

.017"/.019"

.017"/.019"

recheck clearance.

NOTE:

grinding the valves

the

for

On

Large clearances can also be reduced by

and/or

valve seats. Refer to

"Inspection And Repair/Reconditioning" section

valve specifications.

Models

K241, K301, K321,

K341

- Adjust the

clearance by turning the adjusting screw on tappets. Refer to Figure

3-9.

STORAGE

If the engine will be out

mately two months

storage procedure.

1 . Change the oil when engine is still warm from

operation. Refer to "Change

2. Change the oil

equipped. Refill with the

engine crankcase

fer

to "Service Optional Reduction Gear Unit. "

Run

engine

for

clean oil throughout engine.

3. Drain the

fuel tank and fuel system (or run

engine until fuel tank and fuel system are

empty).

4. Remove the spark plug. Add one tablespoon

of engine oil into the spark plug hole. Install

by do not connect plug lead. Crank the

plug,

engine two

or

5. Remove the spark plug. Cover the spark plug

with

hole

thumb

piston is at the top of its stroke (pressure

against thumb is greatest).

do not connect plug lead.

of

service

or

more,

use the following

Oil."

in

reduction

gear

same

for

season of operation. Re-

a few minutes

to

three revolutions.

and turn engine

Reinstall plug, but

for

approxi-

unit, if so

oil as used

distribute

over

until the

in

Figure

3-10.

Clearance Through

Adjusting

K341.

Valve-

Models

To-

Tappet

K241

6. Clean the exterior surfaces of engine. Spread

a light film of oil over any exposed metal surfaces of engine to prevent rust.

7. Store the engine

in

a clean, dry place.

3.6

SECTION 4

TROUBLESHOOTING

TROUBLESHOOTING

When trouble occurs, be sure to

causes which, at first,

be considered. For example, a starting problem

could be caused

Some

listed below. Use this as a guide to locate trouble

causing factors.

Engine Cranks But

1 . Empty fuel tank.

2. Fuel shutoff valve closed.

3. Clogged fuel line.

4. Spark plug lead disconnected.

5. Keyswitch

6. Faulty spark

7. Faulty ignition.

8. Dirt

Engine

1 . Restricted

2. Dirt

3. Faulty choke

4. Loose wires

5. Carburetor improperly adjusted.

6. Faulty cylinder head gasket.

7. Faulty fuel pump.

Engine

1 . Hydrostatic transmission not

2. Loose wires

3. Dirt

4.

5. Faulty choke

6. Faulty spark plug.

7. Carburetor improperly adjusted.

8.

9. Low compression.

10. Faulty

Engine Will Not Crank

1 . Hydrostatic transmission is not

common

or

water

Starts

or

water

ground.

Starts Hard

drive is engaged.

or

water

Clogged

Incorrect

ACR

drive is engaged.

by

causes

or

kill switch

plug.

in

But

Does Not Keep Running

fuel tank vent.

in

or

or

or

in

or

restricted fuel lines.

or

valve-to-tappet

mechanism.

GUIDE

check

may

seem too obvious to

an

empty

of

Will Not Start

fuel system.

fuel system.

throttle controls/cables.

connections shorting ignition to

connections.

fuel system.

throttle controls/cables.

fuel tank.

engine troubles are

in

"off"

in

clearance.

the simple

position.

neutrai/PTO

in

neutrai/PTO

2. Battery is discharged.

3. Safety interlock switch is

or

4. Loose

5. Faulty keyswitch

6. Faulty electric starter/starter solenoid.

7. Retractable starter not engaging

8. Seized internal engine components.

Engine Runs

1 . Dirt

2. Spark plug lead loose.

3. Loose wires

ing ignition to ground.

4. Carburetor improperly adjusted.

5. Engine overheating.

6.

Incorrect

Engine Will Not Idle

1 . Idle speed adjusting screw improperly set.

2. Dirt

3. Idle fuel adjusting screw improperly set.

Fuel tank vent restricted.

4.

5. Faulty spark

6. Incorrect

7. Low compression.

Engine Overheats

1 . Grass screen, cooling fins

clogged.

2. Excessive engine

3. Low crankcase oil level.

4. High crankcase oil level.

5. Carburetor improperly adjusted.

Engine Knocks

1 . Low crankcase

2. Excessive engine load.

Engine Loses Power

1 . Low crankcase oil level.

2. High crankcase oil level.

3. Restricted air cleaner element.

4. Dirt

5. Excessive engine load.

6. Engine overheating.

7. Faulty spark

8. Carburetor improperly adjusted.

faulty wires

But

or

water

valve-to-tappet

or

water

valve-to-tappet

or

water

plug.

or

Misses

in

fuel system.

or

connections intermittently short-

in

fuel system.

plug.

load.

oil level.

in

fuel system.

"engaged"

or

connections.

ignition switch.

in

clearance.

clearance.

or

shrouding

.

drive cup.

II

4.1

9. Low compression.

Engine Uses Excessive Amount of Oil

1. Incorrect oil viscosity

or

2. Clogged

system.

3. Worn

4. Worn cylinder bore.

5. Worn valve

improperly assembled breather

or

broken piston rings.

stems

or

and/or

type.

guides.

EXTERNAL ENGINE INSPECTION

0 Before cleaning

check

This inspection can give clues to what might

be found inside the engine (and the cause)

once

its external appearance and condition.

it is disassembled.

or

disassembling the engine,

CLEANING THE ENGINE

After inspecting the external condition of the engine, clean it thoroughly before disassembling.

Also clean individual components as the engine is

disassembled.

inspected and gauged

There are many commercially available cleaners

that quickly remove grease, oil and grime from

engine parts. When such a cleaner is used, follow

the

manufacturer's

sure all traces of the cleaner are removed before

the engine is reassembled and placed

tion. Even small amounts of these cleaners quickly

break down the lubricating properties of engine oil.

BASIC ENGINE

Only clean parts can be accurately

for

wear

or

damage.

instructions carefully. Make

in

opera-

TESTS

for

0 Check

crankcase, cooling fins, grass screen and

other external surfaces. Dirt or debris

areas are causes of overheating.

0 Check

aged components. Excessive oil leakage can

indicate a clogged

breather, worn

or

loose

0 Check the air cleaner cover, element cover

and air cleaner base

of improper fit

0 Check the air cleaner element. Look for holes,

tears, cracked

other damage that could allow dirt to enter the

engine. Also note if the element is clogged

restricted. These conditions could indicate that

the air cleaner has been underserviced.

0 Check the carburetor throat for dirt. Dirt

throat is further indication that the air cleaner

is not functioning properly.

0 Check the oil level. Note if the oil level

within the operating range

it is low

0 Check the condition

into a container - it should flow freely. Check

for

metal chips and other foreign particles.

NOTE:

away from the workbench.

time

Sludge is a natural

small accumu_lation

formation could indicate that the oil has not been

changed as

weight

settings

It

for

of

buildup of dirt and debris on the

in

these

for

obvious fuel and oil leaks and

or

improperly assembled

or

damaged seals and gaskets

or

improperly torqued fasteners.

for

damage

or

seal.

or

damaged sealing surfaces or

on

or

overfilled.

of

the oil. Drain the oil

is good practice to drain oil at a location

Be

sure to allow ample

complete

oil has been used,

or

weak ignition, to name a few.

drainage.

by-product

is

normal. Excessive sludge

recommended,

of combustion; a

an

over-rich

or

the dipstick,

incorrect type or

dam-

indications

in

is

or

carburetor

or

the

Fuel System Test

To

determine if fuel is getting

disconnect the fuel line at inlet to carburetor - if

fuel does not flow out of line,

to tank

cap, blocked filter screen, faulty fuel pump, etc.

fuel is getting as far as the carburetor, remove

the spark plug, crank engine and

inside combustion chamber.

here, check

for

clogged lines, wrong (unvented) filler

for

faulty carburetor.

to

the carburetor,

check

If

system back

check

no fuel is present

for

If

fuel

Ignition System Test

To determine if the ignition system is good, re-

move the spark plug and place plug with side

electrode against cylinder head then crank engine

at sufficient speed to produce a good spark.

sharp, snappy spark is noted, this eliminates the

ignition system components as the cause, al-

though the ignition timing could be off.

If

no spark

the ignition system further. If points are pitted,

don't

bad shape. Dirty points may be cleaned. A bad

condenser will cause premature failure of points.

if

Check the breaker push rod

ing

or

can be tested on commercial

manufacturer's instructions. Check ignition coil

coil tester for continuity.

or

a weak spark is produced,

attempt

sticking - replace as needed. Condenser

to service them - replace points

for

evidence of bind-

tester

per tester

If

check

a

in

on

Crankcase Vacuum

A partial vacuum should exist

when the engine is operating at normal temperatures. Pressure

by a clogged or improperly assembled breather)

can cause oil to be forced out at oil seals, gaskets

or

other available spots.

Crankcase vacuum is best measured with a slack

tube manometer. The

in

the crankcase (usually caused

manometer

in

the crankcase

included

in

the

4.2

Kohler Engine Analysis Kit is

to

the

"Special

tion.

Tools"

section

Crankcase Vacuum Test

recommended.

for

more

informa-

Refer

side.

If

there

side is the

pressure

engine side)

following table.

same

(level

check

is no

vacuum

as in open side)

in

open side is higher than

for

(level

the conditions

in

engine

or

a positive

in

in

the

To

test

crankcase

1. Insert the

Leave the

to

the

atmosphere.

clamp

2.

Start the engine and run at high speed (3200

to 3600

3.

Open the

the

be 5

1.

Crankcase

2.

Seals

improperly

3.

Piston

inspecting

is closed.

RPM)

tube.

to

1 0 inches above the level

and/or

blowby

vacuum

stopper

other

vent

.

clamp

The level

and note the water level

Possible Cause

breather

gaskets leaking. Loose

torqued

or

leaky valves.

components.)

with the

hose into the oil fill hole.

of

the

manometer

Make sure the shutoff

in

the engine side should

NO

CRANKCASE VACUUM/PRESSURE

clogged

fasteners.

or

manometer:

in

inoperative.

or

(Confirm

open

in

the open

by

4. Close the shutoff

engine.

clamp

before

Compression Test

Because these engines are

matic

compression release

difficult

ing.

To

and related

crankcase

1.

Disassemble breather, clean parts

reassemble, and recheck pressure.

2.

Replace all

Make sure fasteners are

appropriate

necessary.

3.

Recondition

and valve guides.

to

check

obtain an

the condition

mechanisms,

vacuum

IN

CRANKCASE

worn

torque

piston, rings,

accurate

test

Solution

or

damaged

values and sequences when

equipped

mechanism

of

the

physical inspection and a

are

recommended.

tightened

cylinder

shutting

with an auto-

compression

combustion

thoroughly,

seals and gaskets.

securely. Use

bore, valves,

off

(ACR), it is

read-

chamber

the

II

4.

Restricted exhaust.

MEASURE

BETWEEN

DIFFERENCE

COLUMNS

Figure

4.

Replace restricted

4-1.

muffler/exhaust

system.

Figure

4-2.

"U"

Tube

Manometer

4.3

SECTION 5

AIR CLEANER AND AIR INTAKE SYSTEM

K series engines are equipped with a

paper air

fications are also equipped with

precleaner that surrounds the paper element. Re-

fer

cleaner

to Figure

5-1.

element.

Engines of

high-density

an

oiled foam

some

speci-

AIR CLEANER DISASSEMBLY

1 . Remove the wing nut and air cleaner cover.

2.

Remove the precleaner (if so

per

element

3. Remove the base screws, air cleaner base,

gasket and hose.

and seal.

equipped),

pa-

AIR CLEANER SERVICE

Precleaner

If

so equipped, wash and

every 25 operating hours

tremely

1 . Wash the precleaner

2. Rinse the precleaner thoroughly

3. Saturate the precleaner with

4. Reinstall the precleaner

dusty

or

dirty conditions).

gent.

detergent

of

cess water (do not wring).

dry.

gine

oil. Squeeze out excess oil.

ment.

are eliminated. Squeeze out ex-

re-oil

the precleaner

(more

in

often under ex-

warm water and

Allow precleaner to

clean, fresh en-

over

the

deter-

until all traces

paper

ele-

II

Figure

5-1.

Air

Cleaner

"'------

Assembly

PRECLEANER

- Exploded View.

(OPTION)

5.1

Paper Element

Inspect Air Cleaner Components

Every 1 00 operating hours

tremely

element. Replace

1 . Remove the precleaner (if so equipped), ele-

2.

NOTE:

compressed

3. Reinstall the

4.

5.

dusty

or

dirty conditions)

the

ment

cover

ment.

Replace a dirty, bent

new genuine Kohler

elements carefully;

bent

or

Do not wash the paper element or use

Install the precleaner (cleaned and oiled) over

the paper element.

Install the air cleaner

Tighten wing nut. Make sure element

tightly against air cleaner base.

nut, element cover and paper ele-

damaged.

air as this will damage the element.

paper

(more

element

or

element.

do

not use if surfaces are

element.

cover

often under ex-

check

as follows:

damaged

Handle new

and wing nut.

element with a

the

is

paper

sealed

Whenever the air cleaner

when servicing the paper element

check

1 .

2.

3. Breather

NOTE:

tain specifications, the element

the breather tube, making it impossible

crankcase vacuum.

the end of the breather tube that protrudes

through the air cleaner base at approximately a 45

degree angle.

the following components:

Air

Cleaner Base - Make sure it is secured

tightly to carburetor and is not bent

aged.

Element

K181

ment

that element

seal element between air cleaner base and

element cover. Tighten nut

torque. Refer to Figure