Page 1

Installation Guide

Digital Interface

K-683, K-685 K-684, K-686

M product numbers are for Mexico (i.e. K-12345M)

Los números de productos seguidos de M corresponden a México

(Ej. K-12345M)

Français, page “Français-1”

Español, página “Español-1”

1043184-2-B

Page 2

IMPORTANT INSTRUCTIONS

WARNING: When using electrical products, basic precautions should always be followed, including

the following:

DANGER: Risk of electric shock. Connect only to circuits protected by a Ground-Fault

Circuit-Interrupter (GFCI) or Earth-Leakage Circuit Breaker (ELCB). Grounding is required. The unit

should be installed and grounded by a qualified service representative.

WARNING: Risk of electric shock. A licensed electrician should route all electrical wiring.

WARNING: Risk of electric shock. Disconnect power before servicing.

WARNING: Risk of injury or property damage. Please read all instructions thoroughly before

beginning installation.

NOTICE: Follow all plumbing, electrical, and building codes.

Specifications

Pressures

Maximum Static Pressure 125 psi, 862 kPa, 8.6 bar

Supply Pressure Differential* Max 5 psi, 34.5 kPa, 0.34 bar (Equal pressures recommended.)

Minimum Flow Rate 1.6 gpm (Less than 72 psi dynamic pressure.)

Temperatures

Programmable Temperature Max 120°F (49°C) Min 79°F (26°C) Full cold may also be selected.

Default Temperature at Start-up 102°F (39°C)

Minimum Mixed Temperature

Differential from Hot Supply

Optimum Thermostatic Control Range 86°F (30°C) to 120°F (49°C)

Temperature Stability at Recommended

Supply Conditions

Ambient Temperature Greater than 34°F (1°C), Max 104°F (40°C)

Maximum Relative Humidity 95% non-condensing

Electrical

Electrical Service 100-240 VAC, 50-60 Hz, 1.5 A

User Interface Cable Length (supplied) 30 ft (9.14 m)

6 lpm (Less than 500 kPa maintaining pressure.)

2.1 gpm (Greater than 72 psi dynamic pressure.)

8 lpm (Greater than 500 kPa maintaining pressure.)

3.6°F (2°C)

+/- 1.6°F (1°C)

* In commercial applications where there is a large difference in hot and cold supply pressures or frequent

fluctuation in either supply line is anticipated, it is strongly recommended that pressure regulators be

installed.

1043184-2-B 2 Kohler Co.

Page 3

Thank You For Choosing Kohler Company

We appreciate your commitment to Kohler quality. Please take a few minutes to review this manual before

you start installation. If you encounter any installation or performance problems, please don’t hesitate to

contact us. Our phone numbers and website are listed on the back cover. Thanks again for choosing Kohler

Company.

Tools and Materials

Plus:

• Shims

Screwdrivers

LevelPencil

• Suction Cup (Provided)

Jigsaw/Saber

Saw

Drill

Sealant

Kohler Co. 3 1043184-2-B

Page 4

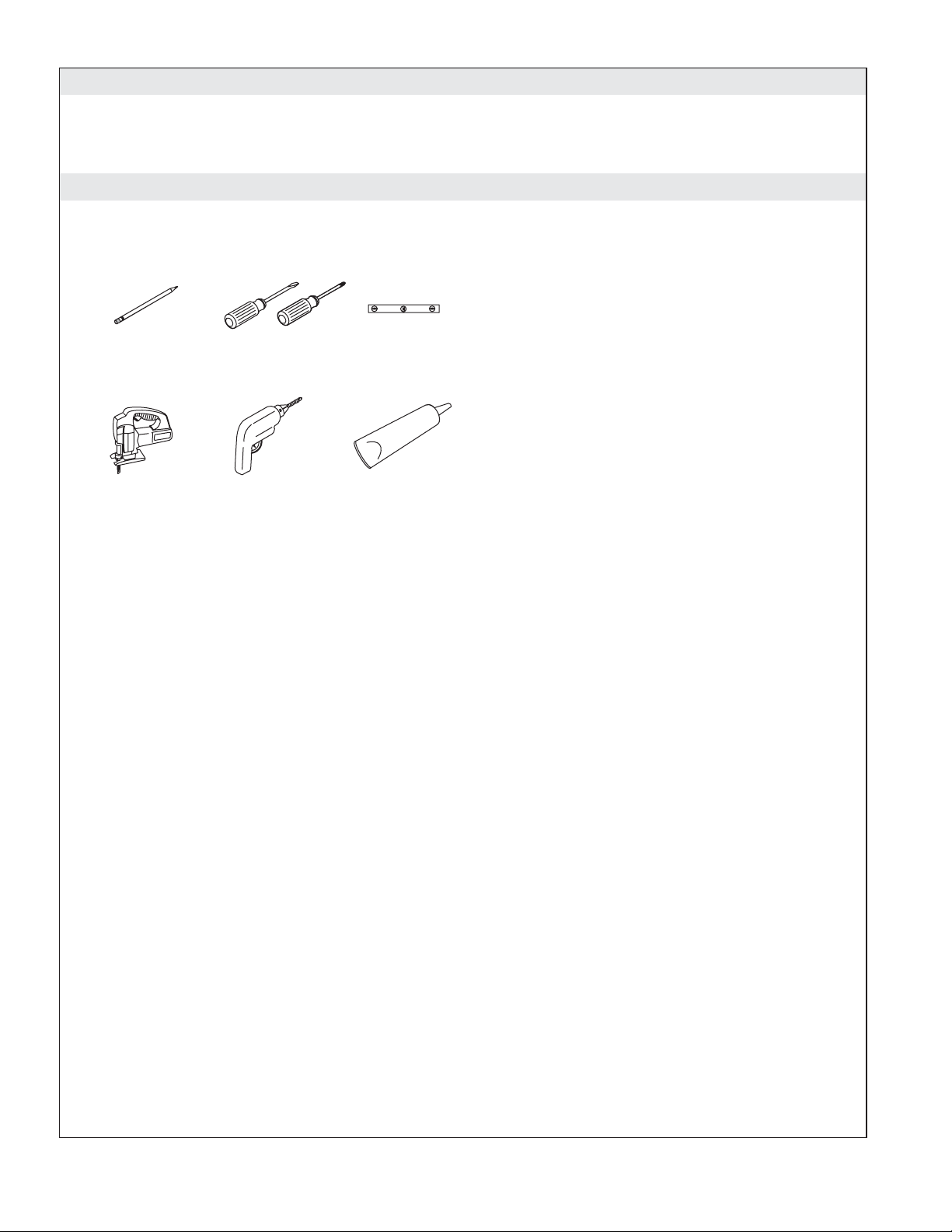

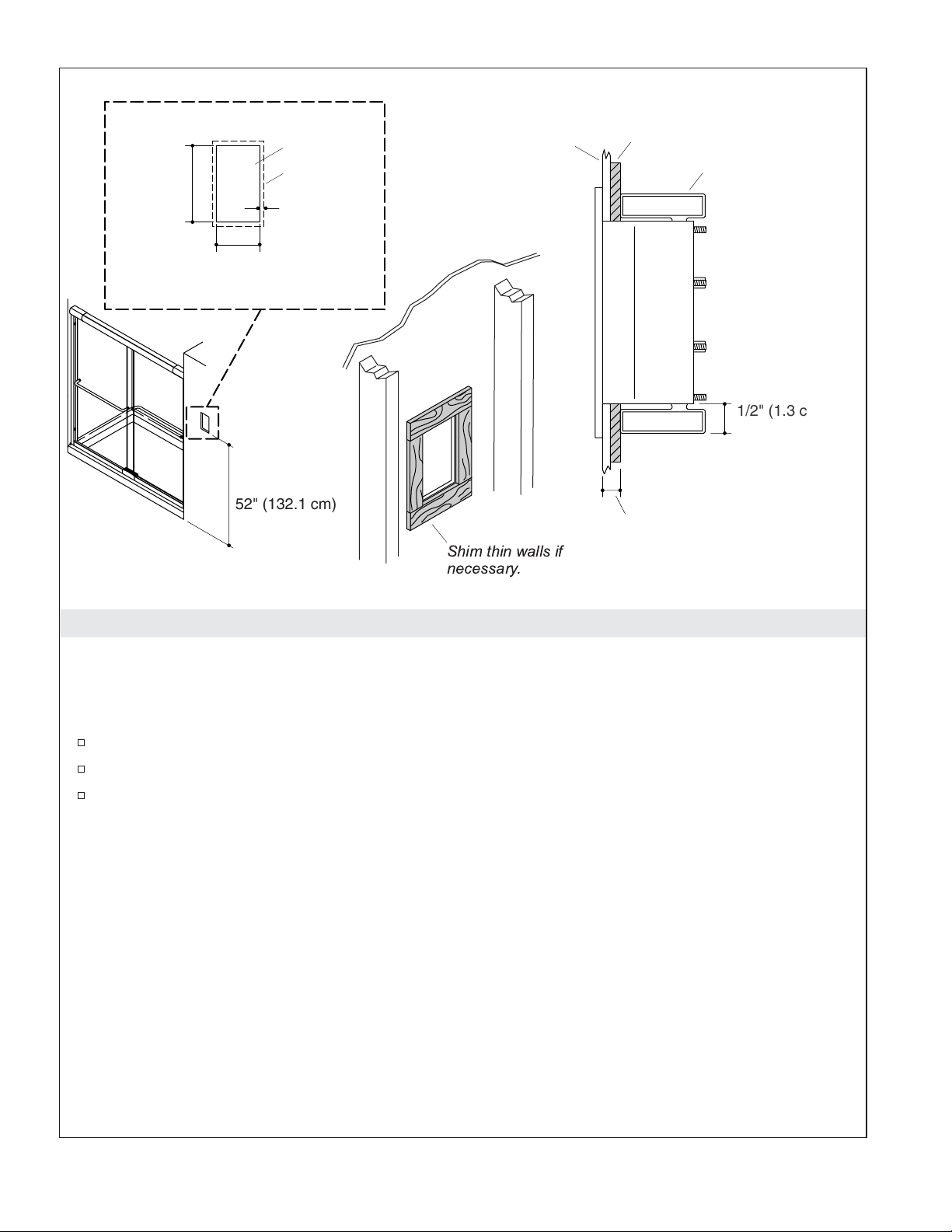

1/2" (1.3 cm) Min Clamp

Arm Clearance

8-1/2"

(21.6 cm)

3-5/8" (9.2 cm)

4-1/2" (11.4 cm)

3/16" (5 mm) Min –

2" (5.1 cm) Max Depth

Clamp Arm

3-5/8" (9.2 cm) –

4-5/8" (11.7 cm)

Wall Cavity

Depth

7-5/8"

(19.4 cm)

7-11/16"

(19.5 cm)

3-11/16" (9.4 cm)

Cutout Detail

8-Pin Interface Cable

30' (9.14 m)

4-Pin Auxiliary Interface Cable

30' (9.14 m)

Cutout

1/4" (6 mm) Min

Interface Lip

Clearance

Roughing-In

Before You Begin

Observe all local plumbing, building, and electrical codes.

Read these instructions and determine all required components along with their installation

locations before beginning this installation.

A licensed electrician should install a 120 V GFCI electrical outlet, within the stud framing, in close

proximity to the electronic valve. The interface(s) is/are powered through the connection(s) with the

valve.

Install the valve prior to installing the interface(s).

Kohler Co. reserves the right to make revisions in the design of faucets without notice, as specified

in the Price Book.

1043184-2-B 4 Kohler Co.

Page 5

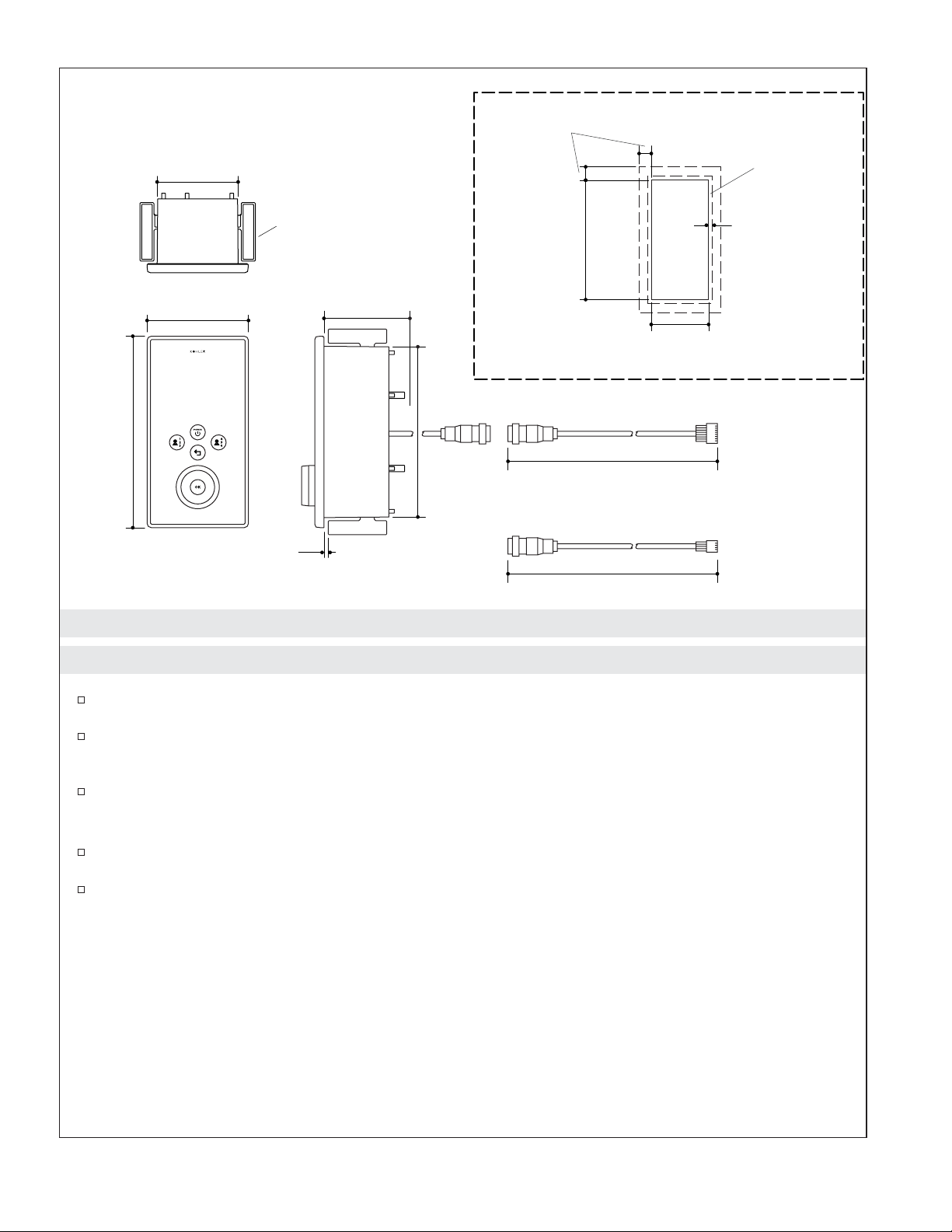

30' (9.14 m) 4-Pin Interface Cable

Primary Interface

(Inside Shower)

Auxiliary Interface

(Outside Shower)

Drip Loop

Connector

Drip Loop

30' (9.14 m) 8-Pin Interface Cable

Drip Loop

Drip Loops

Power Supply

Outlet

1. Preparation

If not already installed, install the digital valve at this time according to the instructions packed

with the product.

NOTE: The optional auxillary interface, with the 4-pin cable, is located outside the showering enclosure,

while the primary interface, with the 8-pin cable, is located inside the showering enclosure.

Determine all required components along with their installation locations before beginning this

installation.

Custom showering experiences other than the preprogrammed options must be programmed into

the interface prior to use. Refer to the ″Digital Interface Homeowners Guide.″

NOTE: The 8-pin cable is used for the primary interface and the 4-pin for the auxillary interface.

Verify that both the primary and auxillary interface are located so the interface cable easily spans

the distance between the valve and interface connection.

Kohler Co. 5 1043184-2-B

Page 6

7-11/16"

(19.5 cm)

3-11/16"

(9.4 cm)

52" (132.1 cm)

Cutout

Interface lip

1/4" (6 mm)

Wall

Shim thin walls if

necessary.

Shim

Clamp Arm

1/2" (1.3 cm) Min

Clamp Arm

Clearance

3/16" (5 mm) Min –

2" (5.1 cm) Max Depth

2. Prepare the Site

NOTE: Portrait interface shown, landscape interface also available.

NOTE: Allow for a 1/4″ (6 mm) overlap for the lip of the wall sleeve and a minimum clearance of 1/2″

(1.3 cm) around the back of the opening to enable the clips to fully engage.

Refer to the rough-in information. With a pencil, mark the cut lines onto the finished wall.

Carefully cut out the opening in the finished wall following the penciled guidelines.

For thin finished wall materials of less than 3/16″ (5 mm), shim around the back of the opening to

provide adequate support for mounting the interface wall sleeve.

1043184-2-B 6 Kohler Co.

Page 7

Apply silicone

sealant.

Insert sleeve and

untuck clamp arms.

Tuck clamp

arms into slots.

Flip clamp arms for

thicker wall material,

1-1/4" (3.2 cm) – 2"

(5.1 cm).

Thinner Wall, 3/16" (5 mm) –

1-1/4" (3.2 cm)

Sleeve

Do not use power

screwdriver.

Interface

Control

Knob

Cable

18"

(45.7 cm)

Min

Secure cable.

Drip Loop

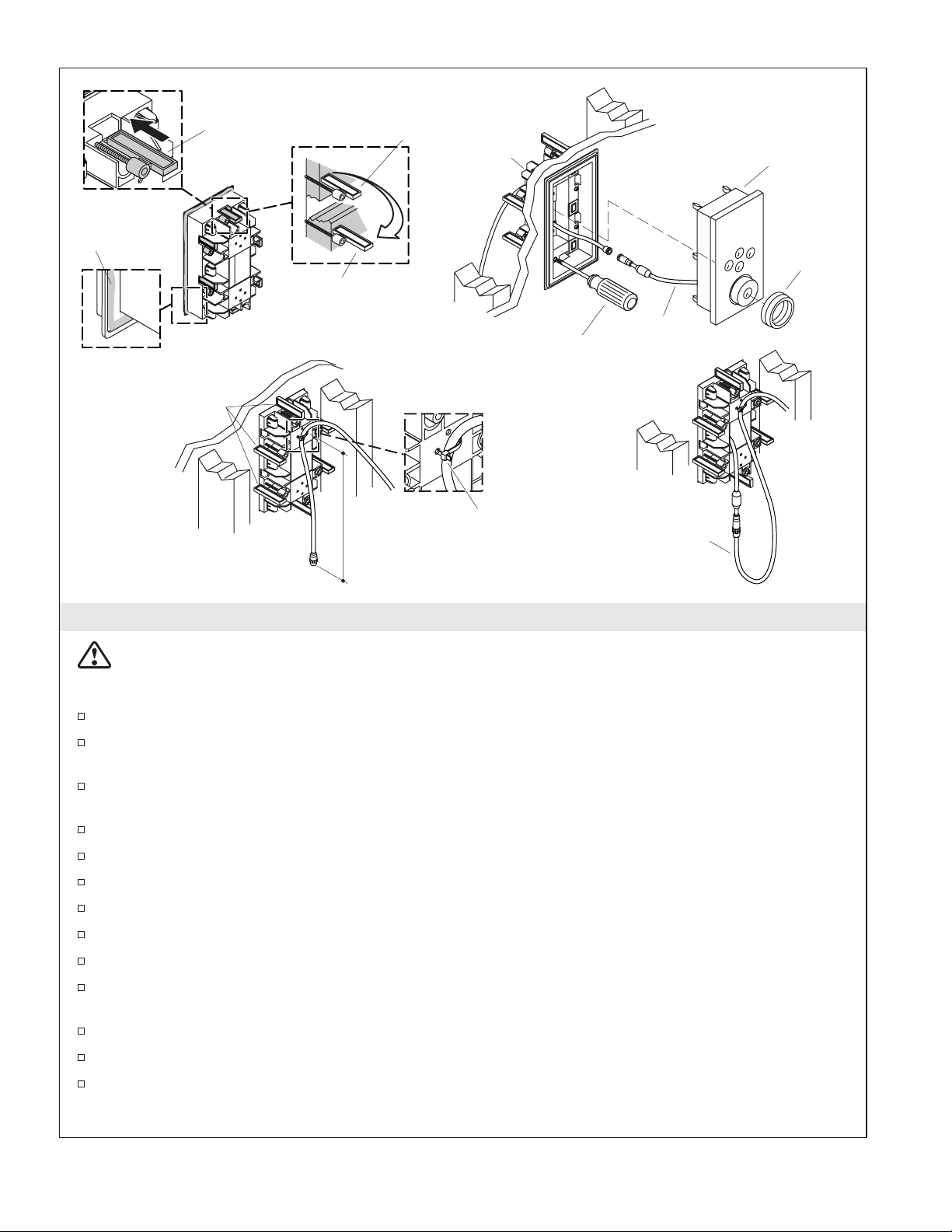

3. Install the Interface

CAUTION: Risk of product damage. Do not use power screwdrivers to install the interface.

NOTE: The clamp arms can be removed and turned upside down to allow installation to thicker walls.

Measure the finished wall thickness.

If appropriate, flip the clip arms to accommodate thicker wall materials. Refer to the above

illustration.

Secure the interface cable, from the valve, with a zip tie to the back of the wall sleeve allowing

approximately 18″ (45.7 cm) of cable to hang free.

Insert the free end of the interface cable into the opening of the wall sleeve.

Tuck the clamp arms into the slots of the sleeve.

Apply a bead of silicone sealant into the groove around the backside of the sleeve lip.

Insert the sleeve into the cutout.

Turn the clamp arms so that they are perpendicular to the opening.

Handtighten the screws. Do not overtighten.

Wipe away any excess sealant from around the front of the sleeve. Use care not to get sealant on the

outer surface of the sleeve.

Remove the cap from the interface cables.

Connect the interface to the interface cable.

Carefully feed the connection through the hole in the wall sleeve and into the wall cavity. A drip

loop will automatically be formed in the cable.

Kohler Co. 7 1043184-2-B

Page 8

Install the Interface (cont.)

Verify the gasket is in place on the interface.

Slide the body of the interface into the sleeve.

Firmly press on the interface with the palms of your hands until it snaps into place.

Install the control knob.

1043184-2-B 8 Kohler Co.

Page 9

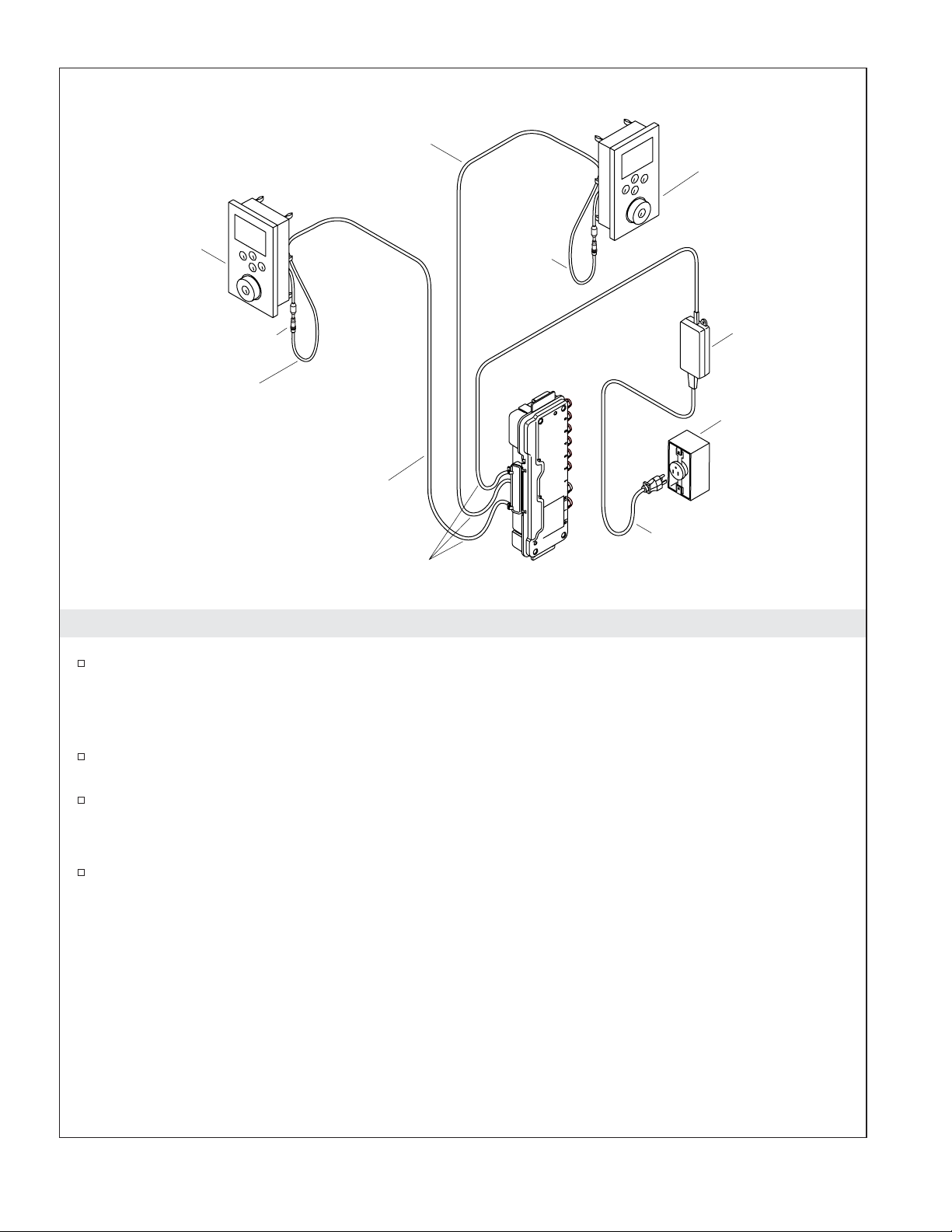

Power Supply

Optional External

Interface Cable

Power Supply

Screws

Molded Grommets

Internal Interface Cable

Drip Loop

Ta b

Clip

Door

Drip Loop

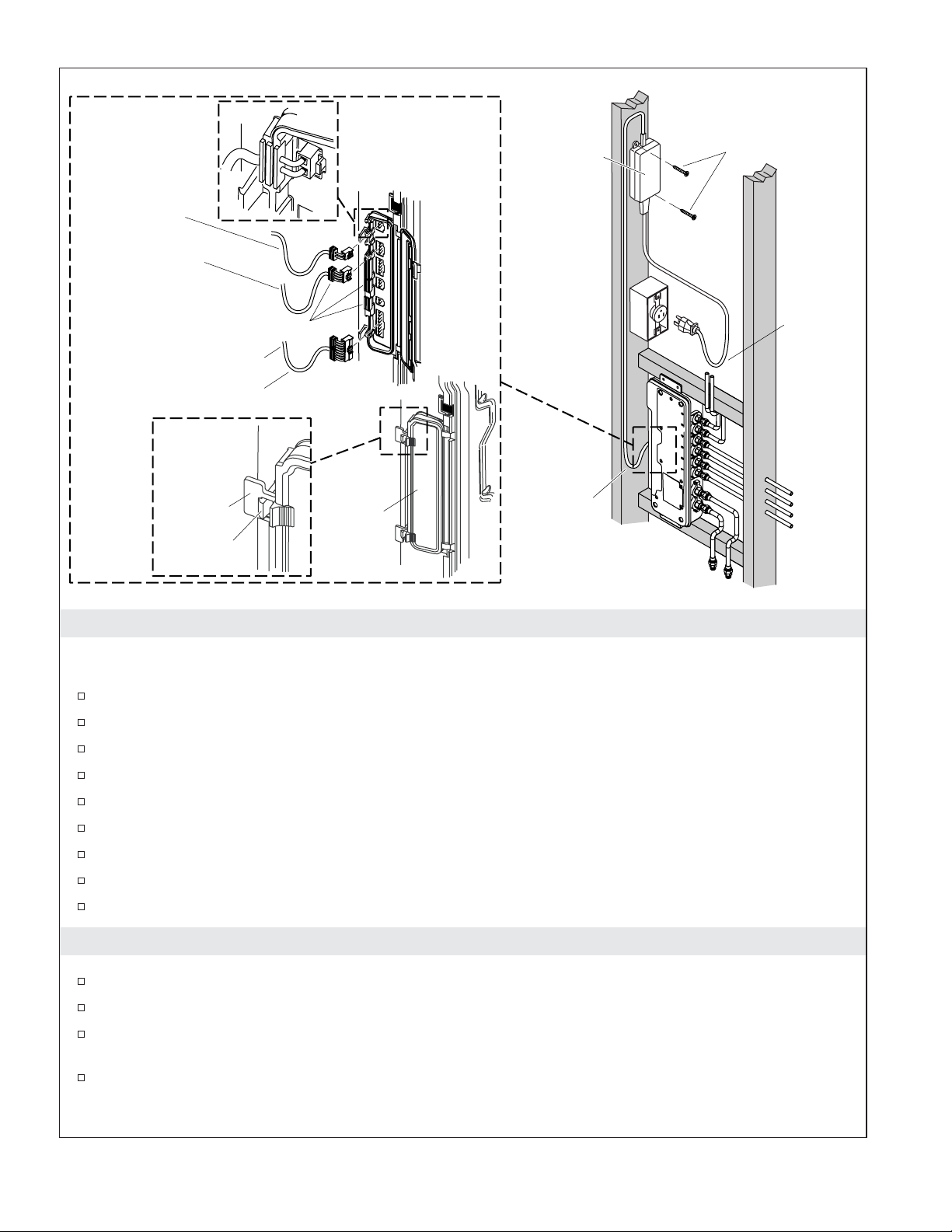

4. Complete the Installation

IMPORTANT! Make drip loops in all cables and cords.

Press the clips to release and open the access door on the valve.

Slide the hinge side of the door in either direction until one side slips free.

Remove the door.

Connect the interface cable(s) to the valve.

Connect the power supply to the valve.

Verify all molded grommets are in place before closing the access cover.

Reinstall the access door.

To close the access door, press on the tabs until the clips snap into place.

Plug the power supply into the outlet.

Drip Loop

5. Installation Checkout

Turn on the water supply to the valve.

Check all connections for leaks and make any adjustments as needed.

Turn on the main power supply. You should hear the valve power up and the power icon on the

user interface will be lit with a green pulsing light.

If not already completed, refer to the ″Digital Interface Homeowners Guide″ to set up the interface.

Kohler Co. 9 1043184-2-B

Page 10

Installation Checkout (cont.)

NOTE: For more information about using the user interface and its menus, refer to the user interface

Homeowners Guide.

At the main menu of the interface select SHOWER > Options > All On. This will select all connected

components and purge the air from the system.

Check for leaks and make any adjustments as needed.

Verify that the water flow is sufficient for your showering needs.

6. Troubleshooting

CAUTION: Risk of personal injury. The valve may contain hot water; be careful when draining any

residual water.

IMPORTANT! Turn off the power and water supply to the valve before performing any maintenance.

It is recommended that any valve maintenance should be performed by an authorized Kohler service

representative.

This troubleshooting guide is for general aid only. For service and installation issues or concerns, call

1-800-4-KOHLER.

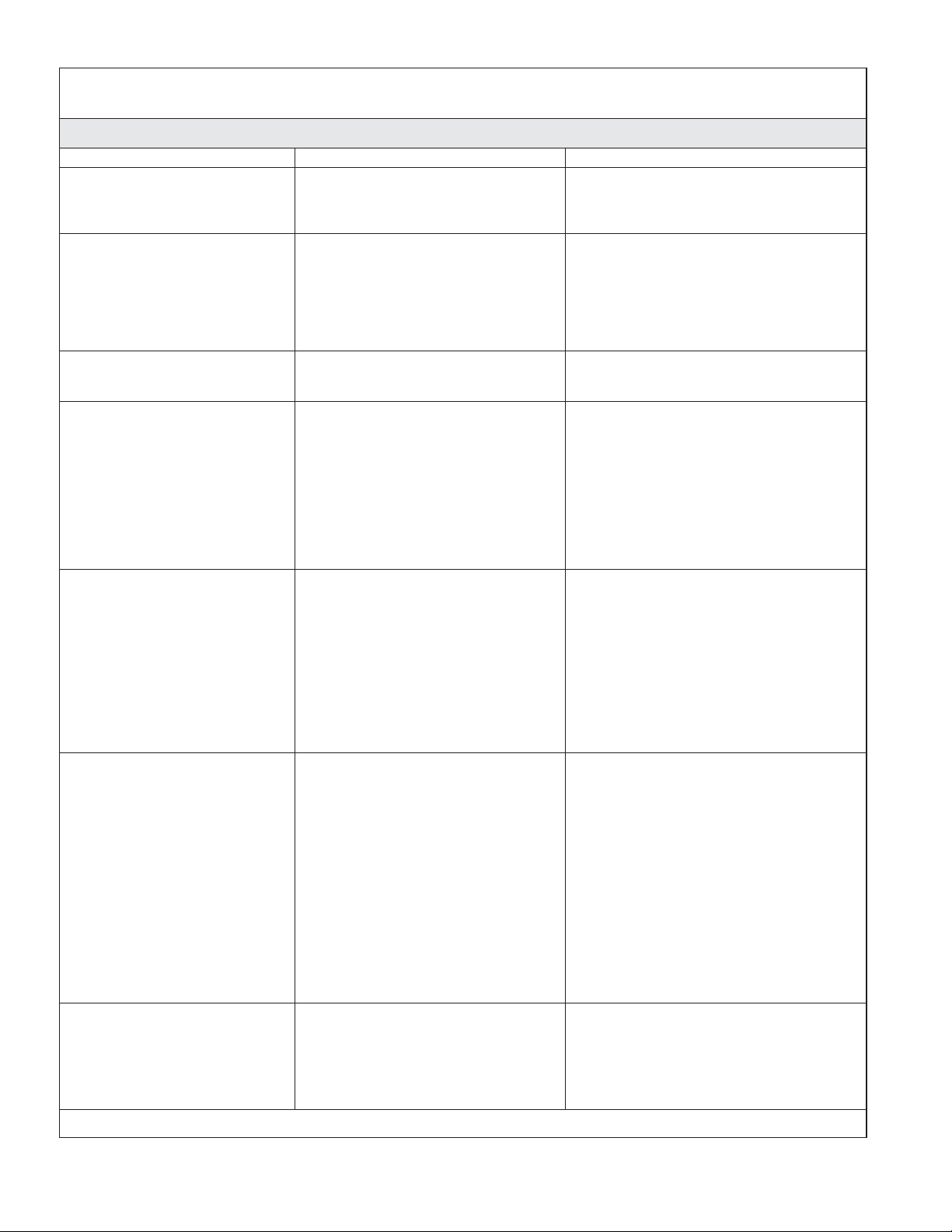

Troubleshooting Table

Symptoms Probable Cause Recommended Action

1. Control panel is not lit. A. Power supply is not plugged

2. The interface power

indicator pulses but does

not turn on.

3. The interface functions

normally but no water

flows from the

components.

into the outlet.

B. Power supply connection to the

valve may be loose or

disconnected.

C. Interface cable connections may

be loose or disconnected.

D. Circuit breaker has been

tripped.

E. The valve memory may require

resetting.

F. If none of the recommended

actions for the above issues

correct the symptom, the valve

or interface requires servicing.

A. Interface cable connections may

be loose or disconnected.

B. If the above recommended

action does not correct the

symptom, the interface or valve

requires servicing.

A. Inlet/outlet fittings may be

blocked.

B. Hot and cold water supplies are

not turned on.

C. The valve memory may require

resetting.

D. System error. D. Check the user interface for an

A. Plug the power supply into the

outlet.

B. Check power supply connections to

the valve and reconnect if needed.

C. Check all interface cable

connections, connect if needed.

D. Reset the circuit breaker.

E. Disconnect and reconnect the

power supply from the valve.

F. Contact your Kohler Co. authorized

service representative.

A. Check all interface cable

connections, connect if needed.

B. Contact your Kohler Co. authorized

service representative.

A. Check the inlets and outlets for

blockage or debris. Clean the inlet

screens. Refer to the ″Clean the

Inlet Screens″ section in the Valve

Homeowners Guide.

B. Turn on the water supply to the

valve.

C. Disconnect and reconnect the

power supply from the valve.

error code. Refer to the

″Diagnostics″ section in the Digital

Interface Homeowners Guide.

1043184-2-B 10 Kohler Co.

Page 11

Troubleshooting (cont.)

Troubleshooting Table

Symptoms Probable Cause Recommended Action

E. If none of the recommended

actions for the above issues

correct the symptom, the valve

requires servicing.

4. Maximum blend

temperature too hot or

too cold.

5. Continuous flow. A. System will not switch off. A. Turn off the water and power

6. Massage mode shuts

down but water continues

to run from

showerhead(s).

7. Only cold water flows

from the outlets.

8. Fluctuating or reduced

flow rate. Valve is

functioning properly.

9. Blend temperature drift or

temperature cycling.

A. Incorrect maximum temperature

setting.

B. If the above recommended

action does not correct the

symptom, the interface or valve

requires servicing.

A. Unequal flow rates between

valve outlets.

B. Fluctuation of inlet pressure. B. Install pressure regulators in the

C. Pressure difference greater than

5 psi (34.5 kPa) between the hot

and cold supply lines.

A. Hot water supply is either not

turned on or not connected to

the valve inlet.

B. Hot water inlet is blocked. B. Check if the hot water inlet screen

C. If none of the recommended

actions for the above issues

correct the symptom, the valve

requires servicing.

A. Inlet/outlet fittings may be

blocked.

B. Water outlet pressure is low. B. Check that the flow rate is at or

C. Fluctuating flow.

D. If none of the recommended

actions for the above issues

correct the symptom, the valve

requires servicing.

A. Fluctuating water temperature. A. Check the inlet temperature

B. Hot water supply temperature

fluctuation.

E. Contact your Kohler Co. authorized

service representative.

A. Refer to the ″Set the Maximum

Temperature″ section in the Digital

Interface Homeowners Guide.

B. Contact your authorized Kohler

service representative.

supply and contact your Kohler Co.

authorized service representative.

A. Verify the installation has one

bodyspray per valve outlet and

uses bodysprays with the same

flow rate. If needed, contact the

installer to revise the installation.

supply lines.

C. Install pressure regulators to bring

the supplies with 5 psi (34.5 kPa)

of each other.

A. Check if the hot water supply is

turned on and connected to the

valve inlet.

for blockage. Clean or replace the

inlet screen. Refer to the Valve

Homeowners Guide.

C. Contact your Kohler Co. authorized

service representative.

A. Check the inlets and outlets for

blockage or debris. Clean the inlet

screens. Refer to the ″Clean the

Inlet Screens″ section.

above the minimum rate required.

Refer to ″Specifications″ section in

the Valve Homeowners Guide.

C. Verify that the dynamic inlet

pressures are within specifications.

Refer to ″Specifications″ section.

D. Contact your Kohler Co. authorized

service representative.

differentials and verify they are

sufficient. Refer to ″Specifications″

section.

B. Check and make adjustments as

needed.

Kohler Co. 11 1043184-2-B

Page 12

Troubleshooting (cont.)

Troubleshooting Table

Symptoms Probable Cause Recommended Action

C. Pressure difference greater than

5 psi (34.5 kPa) between the hot

and cold supply lines.

D. If none of the recommended

actions for the above issues

C. Install pressure regulators to bring

the supplies with 5 psi (34.5 kPa)

of each other.

D. Contact your Kohler Co. authorized

service representative.

correct the symptom, the valve

requires servicing.

10. Water leaking from the

valve.

CAUTION: Risk of

personal injury or

product damage. Turn off

the main power and

water supply.

11. Hot water only, the valve

shuts down.

A. Connections are not secure. A. Check all connections. Make

adjustments as needed.

B. Seals are worn or damaged. B. Order a seal service pack and

replace all seals.

C. Internal leak. C. Unit requires overhaul. Contact

your Kohler Co. authorized service

representative.

A. Hot and cold lines are reversed. A. Switch hot and cold water supply

connections. Verify the hot water

supply is connected to the inlet

marked ″H″ and the cold water

supply is connected to the inlet

marked ″C.″

1043184-2-B 12 Kohler Co.

Page 13

Guide d’installation

Interface digitale

Renseignements importants

AVERTISSEMENT : Lors de l’utilisation des produits électriques, des précautions de base devraient

toujours être observées, incluant ce qui suit:

DANGER : Risque d’électrocution. Raccorder uniquement à des circuits protégés par un Disjoncteur

de Fuite de Terre (GFCI) ou à un Disjoncteur de Mise à la Terre (ELCB). Une mise à la terre est

requise. L’unité devrait être installée et mise à la terre par un représentant technicien qualifié.

AVERTISSEMENT : Risque d’électrocution. Tout le câblage électrique devrait être réalisé par un

électricien qualifié.

AVERTISSEMENT : Risque d’électrocution. Débrancher l’alimentation avant de procéder à l’entretien.

AVERTISSEMENT : Risque de blessures ou d’endommagement du matériel. Veuillez lire toutes les

instructions avant de commencer l’installation.

AVIS : Respecter tous les codes de plomberie, d’électricité et de bâtiment.

Spécifications

Pressions

Pression statique maximum 125 psi, 862 kPa, 8,6 bar

Différentiel de pression d’alimentation* Max 5 psi, 34,5 kPa, 0,34 bar (Pressions égales recommandées.)

Calibrage de débit minimum 1,6 gpm (moins de 72 psi de pression dynamique.)

Températures

Température programmable Max 120° F (49°C) Min 79°F (26°C) Froid total peut aussi être

Température de base au démarrage 102°F (39°C)

Différentiel de température mixte

minimum de l’alimentation d’eau chaude

Option de contrôle de portée

thermostatique

Stabilité de température aux conditions

d’alimentation recommandées

Température ambiante Plus que 34° F (1°C) Min 104°F (40°C)

Humidité relative maximum 95% non-condensé

Électrique

Service électrique 100-240 VAC, 50-60 Hz, 1,5 A

Longueur de câble d’interface (fourni) 914,40 cm (9,14 m)

6 lpm (moins de 500 kPa de pression maintenue.)

2,1 gpm (plus de 72 psi de pression dynamique.)

8 lpm (plus de 500 kPa de pression maintenue.)

sélectionné.

3.6°F (2°C)

86°F (30°C) to 120°F (49°C)

+/- 1.6°F (1°C)

* Dans des applications commerciales où il y a une large différence de pressions d’alimentation chaude et

froide ou une fréquente fluctuation dans les lignes d’alimentations est anticipée, il est fortement recommandé

d’installer des régulateurs de pression.

Kohler Co. Français-1 1043184-2-B

Page 14

Merci d’avoir choisi la compagnie Kohler

Nous apprécions votre engagement envers la qualité Kohler. Veuillez prendre s’il vous plaît quelques

minutes pour lire ce manuel avant de commencer l’installation. Ne pas hésiter à nous contacter en cas de

problème d’installation ou de performance. Nos numéros de téléphone et notre adresse du site internet sont

au verso. Merci encore d’avoir choisi la compagnie Kohler.

Outils et matériels

Plus:

• Cales

Tournevis

Niveau à bulleCrayon à papier

• Ventouses (fournies)

Scie sauteuse/

baïonnette

Perceuse

Mastic

1043184-2-B Français-2 Kohler Co.

Page 15

Dégagement minimum du

bras de la pince 1/2" (1,3 cm)

8-1/2"

(21,6 cm)

3-5/8" (9,2 cm)

Bras de la pince

4-1/2" (11,4 cm)

3/16" (5 mm) Min –

Profondeur 2" (5,1 cm) max

Profondeur de

cavité du mur de

3-5/8" (9,2 cm) –

4-5/8" (11,7 cm)

7-5/8"

(19,4 cm)

7-11/16"

(19,5 cm)

3-11/16" (9,4 cm)

Détail de découpe

Câble d'interface à 8 broches

30' (9,14 m)

Câble d'interface à 4 broches auxilliaire

30' (9,14 m)

Dégagement

minimum de la

lèvre de

l'interface de 1/4"

(6 mm)

Découpe

Raccordement

Avant de commencer

Respecter tous les codes électriques, de plomberie et de bâtiment locaux.

Lire ces instructions et déterminer tous les composants requis avec leurs emplacements d’installation

avant de commencer cette installation.

Un électricien agréé devrait installer une prise électrique de 120 V GFCI, aux environs du cadrage

de support, à proximité de la valve électronique. La(les) interface(s) est/sont alimentées à travers

la(les) connexion(s) avec la valve.

Installer la valve avant d’installer la(les) interface(s).

Kohler Co. se réserve le droit d’apporter toutes modifications au design des robinets et ceci sans

préavis, comme spécifié dans le catalogue des prix.

Kohler Co. Français-3 1043184-2-B

Page 16

Interface primaire

(intérieur de la

douche)

Connecteur

Anneau d'écoulement

Câble d'interface à

4 broches de 30' (9.14 m)

Câble d'interface à

8 broches de 30' (9.14 m)

Interface auxilliaire

(extérieur de la

douche)

Anneau

d'écoulement

Alimentation

électrique

Sortie

Anneau d'écoulement

Anneaux d'écoulement

1. Préparation

Installer l’ensemble la valve digitale si celà n’a pas déjà été fait à ce moment selon les instructions

emballées avec le produit.

REMARQUE : L’interface auxilliaire optionnelle, avec un câbleà4broches, est localisé à l’extérieur de la

cabine de douche, alors que l’interface primaire, avec le câbleà8broches, est localisé à l’intérieur de la

cabine de douche.

Déterminer tous les composants requis avec leurs emplacements d’installation avant de commencer

cette installation.

Les expériences personnalisées de douche autres que les options préalablement programmées

doivent être programmées dans l’interface avant l’utilisation. Se référer au ″guide du propriétaire de

l’interface digitale.″

REMARQUE : Le câbleà8broches est utilisé pour l’interface primaire et celui de 4 pour l’interface

auxilliaire.

Vérifier que l’interface primaire et auxilliaire sont localisées de manière à ce que le câble d’interface

s’adapte facilement à la distance entre la valve et la connexion de l’interface.

1043184-2-B Français-4 Kohler Co.

Page 17

7-11/16"

(19,5 cm)

3-11/16"

(9,4 cm)

52" (132,1 cm)

Découpe

Lèvre de

l'interface

1/4" (6 mm)

Mur

Cale

Bras de la pince

Dégagement

minimum du bras

de la pince 1/2"

(1,3 cm)

3/16" (5 mm) Min –

Profondeur 2" (5,1 cm) max

2. Préparer le site

REMARQUE : L’interface portrait est illustrée, l’interface panorama aussi disponible.

REMARQUE : Permettre un chevauchement de 1/4″ (6 mm) de la lèvre du manchon du mur et un

dégagement minimum de 1/2″ (1,3 cm) autour de l’arrière de l’ouverture pour permettre aux clips de

s’engager entièrement.

Se référer à l’information de raccordement. Avec un crayon, marquer les lignes de découpe sur le

mur fini.

Découper l’ouverture dans le mur fini en suivant les guides au crayon.

Pour des matériaux de mur fini de moins de 3/16″ (5 mm), le rebord autour de l’arrière de

l’ouverture pour fournir un support adéquat pour le montage du manchon du mur d’interface.

Kohler Co. Français-5 1043184-2-B

Page 18

Appliquer du

mastic à la

silicone.

Insérer le manchon

et déployer les bras

de la pince.

Engager les

bras de la pince

dans les

rainures.

Pivoter les bras de la

pince pour un matériau

de mur plus épais, 1-1/4"

(3,2 cm) – 2" (5,1 cm).

Mur plus fin, 3/16" (5 mm) – 11/4" (3,2 cm)

Manchon

Ne pas utiliser de

tournevis électrique.

Interface

Bouton

de

contrôle

Câble

18"

(45,7 cm)

Min

Sécuriser

le câble.

Anneau

d'écoulement

3. Installer l’interface

ATTENTION : Risque d’endommagement du produit. Ne pas utiliser de tournevis électriques pour

installer l’interface.

REMARQUE : Les bras de pince peuvent être retirés et retournés pour permettre l’installation sur des

murs plus épais.

Mesurer l’épaisseur du mur fini.

Si approprié, retourner les bras du clip pour accommoder les matériaux de mur plus épais. Se

référer à l’illustration ci-dessus.

Sécuriser le câble d’interface, à partir de la valve, avec un serre fils à l’arrière du manchon du mur

permettant approximativement à 18″ (45,7 cm) de câble de se suspendre librement.

Insérer l’extrémité libre du câble d’interface dans l’ouverture du manchon du mur.

Engager les bras de pince dans les rainures du manchon.

Appliquer un ruban de mastic à la silicone dans la rainure autour de l’arrière de la lèvre du

manchon.

Insérer le manchon dans la découpe.

Pivoter les bras de pince de manière à ce qu’ils soient perpendiculaires à l’ouverture.

Serrer les vis à la main. Ne pas trop serrer.

Nettoyer tout excès de mastic de l’avant du manchon. Faire attention de ne pas mettre de mastic sur

la surface extérieure du manchon.

Retirer le capuchon des câbles de l’interface.

Connecter l’interface au câble d’interface.

1043184-2-B Français-6 Kohler Co.

Page 19

Installer l’interface (cont.)

Alimenter avec précaution la connexion à travers l’orifice du manchon du mur et dans la cavité. Un

anneau d’écoulement se formera automatiquement dans le câble.

Vérifier que le joint est en place sur l’interface.

Glisser le corps de l’interface dans le manchon.

Presser fermement sur l’interface avec les paumes des mains jusqu’à engager en place.

Installer le boutons de contrôle.

Kohler Co. Français-7 1043184-2-B

Page 20

Alimentation

électrique

Câble d'interface

extérieur optionnel

Oeillets moulés

Câble d'interface intérieur

Anneau d'écoulement

Languette

Clip

Por te

Alimentation

électrique

Anneau

écoulement

Vis

Anneau

écoulement

4. Compléter l’installation

IMPORTANT ! Former des anneaux d’écoulement dans tous les câbles et cordons.

Presser les clips pour libérer et ouvrir la porte d’accès sur la valve.

Glisser le côté charnière de la porte dans une des directions jusqu’à ce qu’un côté se libère.

Retirer la porte.

Connecter le(s) câble(s) d’interface de la valve.

Connecter l’alimentation électrique à la valve.

Vérifier que tous les oeillets moulés sont en place avant de fermer le couvercle d’accès.

Réinstaller la porte d’accès.

Pour fermer la porte d’accès, presser les languettes jusqu’à ce que les clips se mettent en place.

Brancher l’alimentation électrique dans la prise.

5. Vérification de l’installation

Ouvrir l’alimentation d’eau à la valve.

Vérifier s’il y a des fuites dans les connexions et faire tous les réglages au besoin.

Ouvrir l’alimentation électrique principale. Le son de mise sous tension de la valve devrait être

entendu et l’icône d’alimentation de l’interface de l’utilisateur clignotera en vert.

Si ce n’est pas déjà fait, se référer au ″Guide du propriétaire de l’interface digitale″ pour initialiser

l’interface.

1043184-2-B Français-8 Kohler Co.

Page 21

Vérification de l’installation (cont.)

REMARQUE : Pour plus d’information sur l’interface de l’utilisateur et ses menus, se référer au guide du

propriétaire de l’interface de l’utilisateur.

Au menu principal de l’interface, sélectionner DOUCHE>Options>Marche tous. Ceci sélectionnera

tous les composants connectés et purgera l’air du système.

Vérifier s’il y a des fuites et faire tous les réglages selon le besoin.

Vérifier que le débit d’eau est suffisant pour les besoins de douche.

6. Dépannage

ATTENTION : Risque de blessures corporelles. La valve peut contenir de l’eau chaude; faire attention

lors de la purge de toute eau résiduelle.

IMPORTANT ! Couper le courant et l’alimentation d’eau à la valve avant de procéder à toute

maintenance.

Il est recommandé que toute maintenance de valve devrait être effectuée par un technicien représentant de

Kohler.

Ce guide de dépannage est seulement destiné à une aide générale. Pour des problèmes ou questions

concernant le dépannage et l’installation, composer le 1-800-4-KOHLER.

Tableau de dépannage

Symptômes Cause probable Action recommandée

1. Le pannel de contrôle

n’est pas allumé.

2. L’indicateur de courant de

l’interface clignote mais

ne s’allume pas.

3. L’interface fonctionne

normalement mais il n’y a

pas de débit d’eau des

composants.

A. L’alimentation n’est pas branché

dans la prise.

B. La connexion de l’alimentation à

la valve peut être desserrée ou

déconnectée.

C. Les connexions de câble

d’interface sont peut être

desserrés ou déconnectés.

D. Le disjoncteur a été déclenché. D. Réinitialiser le disjoncteur.

E. La mémoire de la valve

nécessite une réinitialisation.

F. Si aucune de ces actions

recommandées ne rectifient le

symptôme, la valve ou

l’interface nécessitent un

dépannage.

A. Les connexions de câble

d’interface sont peut être

desserrés ou déconnectés.

B. Si l’action recommandée

ci-dessus ne rectifie pas le

problème, l’interface ou la valve

nécessitent un dépannage.

A. Les raccords entrée/sortie sont

peut-être bouchés.

B. Les alimentations d’eau chaude

et froide ne sont pas ouvertes.

C. La mémoire de la valve

nécessite une réinitialisation.

A. Brancher l’alimentation électrique

dans la prise.

B. Vérifier les connexions

d’alimentation en courant à la

valve et reconnecter si besoin.

C. Vérifier toutes les connexions de

câble d’interface, connecter si

besoin.

E. Déconnecter et reconnecter

l’alimentation électrique de la

valve.

F. Contacter un représentant de

service autorisé Kohler Co.

A. Vérifier toutes les connexions de

câble d’interface, connecter si

besoin.

B. Contacter un représentant de

service autorisé Kohler Co.

A. Vérifier les entrées et sorties de

tout blocage ou débris. Nettoyer les

grilles d’entrée. Se référer à la

section ″Nettoyer les grilles

d’entrée″ du guide du propriétaire

de la valve.

B. Ouvrir l’alimentation d’eau à la

valve.

C. Déconnecter et reconnecter

l’alimentation électrique de la

valve.

Kohler Co. Français-9 1043184-2-B

Page 22

Dépannage (cont.)

Tableau de dépannage

Symptômes Cause probable Action recommandée

D. Erreur de système. D. Vérifier l’interface de tout code

E. Si aucune de ces actions

recommandées ne rectifient le

symptôme, la valve nécessite un

dépannage.

4. La température maximale

de mélange est trop

chaude ou trop froide.

5. Débit continu. A. Le système ne s’éteint pas. A. Couper l’alimentation d’eau et

6. Le mode massage s’arrête

mais l’eau continue à

couler des pommes de

douches.

7. Seule de l’eau froide

émane des sorties.

8. Fluctuation ou réduction

du débit. La valve

fonctionne correctement.

A. Réglage de température

maximum incorrect.

B. Si l’action recommandée

ci-dessus ne rectifie pas le

problème, l’interface ou la valve

nécessitent un dépannage.

A. Calibrages inégaux de débit

entre les sorties de valve.

B. Fluctuation de pression d’entrée. B. Installer les régulateurs de pression

C. Différence de pression plus

grande que 5 psi (34,5 kPa)

entre les lignes d’alimentation

chaude et froide.

A. Soit l’alimentation d’eau chaude

n’est pas ouverte, soit elle n’est

pas connectée à l’entrée de la

valve.

B. L’entrée d’eau chaude est

bloquée.

C. Si aucune de ces actions

recommandées ne rectifient le

symptôme, la valve nécessite un

dépannage.

A. Les raccords entrée/sortie sont

peut-être bouchés.

B. La pression d’eau est faible.

d’erreur. Se référer à la section

″Diagnostics″ du guide du

propriétaire de l’interface digitale.

E. Contacter un représentant de

service autorisé Kohler Co.

A. Se référer à la section ″Régler la

température maximum″ du guide

du propriétaire de l’interface

digitale.

B. Contacter un représentant de

service autorisé Kohler.

électrique et contacter le

représentant autorisé de service

Kohler Co.

A. Vérifier que l’installation comprend

un jet pour corps par sortie de

valve et utilise des jets pour le

corps de même débit. Si besoin,

contacter l’installateur pour réviser

l’installation.

dans les lignes d’alimentation.

C. Installer les régulateurs de pression

pour amener les alimentations à 5

psi (34,5 kPa) l’un de l’autre.

A. Vérifier si l’alimentation d’eau

chaude est ouverte et connectée à

l’entrée de la valve.

B. Vérifier si la grille d’entrée d’eau

chaude est obstruée. Nettoyer ou

remplacer la grille d’entrée. Se

référer au guide du propriétaire de

la valve.

C. Contacter un représentant de

service autorisé Kohler Co.

A. Vérifier les entrées et sorties de

tout blocage ou débris. Nettoyer les

grilles d’entrée. Se référer à la

section ″Nettoyer les grilles

d’entrée″.

B. Vérifier que le calibrage de débit

est au minimum ou plus de celui

requis. Se référer à la section

″Spécifications″ du guide du

propriétaire de la valve.

1043184-2-B Français-10 Kohler Co.

Page 23

Dépannage (cont.)

Tableau de dépannage

Symptômes Cause probable Action recommandée

C. Débit fluctuant. C. Vérifier que les pressions d’entrée

dynamiques sont conformes aux

spécifications. Se référer à la section

″Spécifications″.

D. Si aucune de ces actions

recommandées ne rectifient le

D. Contacter un représentant de

service autorisé Kohler Co.

symptôme, la valve nécessite un

dépannage.

9. Dérive de température

mixte ou cycle de

température.

A. Fluctuation de température

d’eau.

A. Vérifier que les différentiels de

température d’entrée soient

suffisants. Se référer à la section

″Spécifications″.

B. Fluctuation de température

d’alimentation d’eau chaude.

C. Différence de pression plus

grande que 5 psi (34,5 kPa)

entre les lignes d’alimentation

B. Vérifier et faire les ajustements si

nécessaire.

C. Installer les régulateurs de pression

pour amener les alimentations à 5

psi (34,5 kPa) l’un de l’autre.

chaude et froide.

D. Si aucune de ces actions

recommandées ne rectifient le

D. Contacter un représentant de

service autorisé Kohler Co.

symptôme, la valve nécessite un

dépannage.

10. Fuite d’eau du corps de la

valve.

ATTENTION: Risque de

blessure corporelle ou

d’endommagement du

produit. Couper le

courant principal et

l’alimentation d’eau.

11. Eau chaude uniquement,

la valve s’arrête.

A. Les connexions ne sont pas

sécurisées.

B. Les joints sont usés ou

endommagés.

A. Vérifier toutes les connexions. Faire

les réglages.

B. Commander un paquet de joint de

dépannage et remplacer tous les

joints.

C. Fuite interne. C. L’unité nécessite une révision.

Contacter un représentant de

service autorisé Kohler Co.

A. Les lignes d’eau chaude et

froide sont inversées.

A. Permuter les connexions

d’alimentation d’eau chaude et

froide. Vérifier que l’alimentation

d’eau chaude est connectée à

l’entrée marquée ″H″ et que

l’alimentation d’eau froide est

connectée à l’entrée marquée ″C″.

Kohler Co. Français-11 1043184-2-B

Page 24

Guía de instalación

Interface digital

INSTRUCCIONES IMPORTANTES

ADVERTENCIA: Al usar aparatos eléctricos, siga siempre las precauciones básicas, incluyendo las

siguientes:

PELIGRO: Riesgo de descarga eléctrica. Conecte la unidad solamente a circuitos protegidos por un

interruptor de circuito con pérdida a tierra (GFCI) o disyuntor de fuga a tierra (ELCB). La conexión a

tierra es un requisito. Un representante de servicio autorizado debe instalar esta unidad y conectarla a

tierra.

ADVERTENCIA: Riesgo de descarga eléctrica. Un electricista calificado debe realizar todo el cableado

eléctrico.

ADVERTENCIA: Riesgo de descarga eléctrica. Desconecte el suministro eléctrico antes de dar servicio.

ADVERTENCIA: Riesgo de lesiones personales o daños a la propiedad. Por favor, lea atentamente

todas las instrucciones antes de comenzar la instalación.

AVISO: Cumpla con todos los códigos de plomería, eléctricos y de construcción.

Especificaciones

Presiones

Presión estática máxima 125 psi, 862 kPa, 8,6 bar

Diferencial de presión del suministro* 5 psi, 34,5 kPa, 0,34 bar máx. (Se recomiendan presiones iguales.)

Caudal mínimo 1,6 gpm (presión dinámica menor que 72 psi.)

Temperaturas

Temperatura programable Máx 120°F (49°C) Mín 79°F (26°C) También se puede seleccionar

Temperatura preseleccionada en el

encendido

Diferencial de temperatura mínimo de la

mezcla a partir del suministro caliente

Rango de control termostático óptimo 86°F (30°C) a 120°F (49°C)

Estabilidad de la temperatura en

condiciones recomendadas del suministro

Temperatura ambiental Mayor que 34°F (1°C), Máx 104°F (40°C)

Humedad relativa máxima 95% sin condensación

Eléctricas

Circuito eléctrico 100-240 VCA, 50-60 Hz, 1,5 A

Longitud del cable de la interface del

usuario (provisto)

6 lpm (presión sostenible menor que 500 kPa.)

2,1 gpm (presión dinámica mayor que 72 psi.)

8 lpm (presión sostenible mayor que 500 kPa.)

completamente fría.

102°F (39°C)

3.6°F (2°C)

+/- 1.6°F (1°C)

30 pies (9,14 m)

* En aplicaciones comerciales donde existe una gran diferencia en las presiones del suministro de agua

caliente y fría, o se anticipa una fluctuación frecuente en alguna de las líneas de suministro, se recomienda

enfáticamente la instalación de reguladores de presión.

Kohler Co. Español-1 1043184-2-B

Page 25

Gracias por elegir los productos de Kohler

Le agradecemos que haya elegido la calidad de Kohler. Dedique unos minutos para leer este manual antes

de comenzar la instalación. En caso de problemas de instalación o de funcionamiento, no dude en

contactarnos. Nuestros números de teléfono y nuestro sitio web se encuentran en la cubierta posterior de esta

guía. Gracias nuevamente por escoger a Kohler.

Herramientas y materiales

Más:

• Cuñas

Destornilladores

NivelLápiz

• Ventosa (provista)

Sierra de vaivén o

caladora eléctrica

Taladro

Sellador

Kohler Co. Español-2 1043184-2-B

Page 26

Espacio para el brazo de la

abrazadera 1/2" (1,3 cm) Mín.

8-1/2"

(21,6 cm)

3-5/8" (9,2 cm)

Brazo de abrazadera

3-5/8" (9,2 cm) 4-5/8" (11,7 cm) de

4-1/2" (11,4 cm)

3/16" (5 mm) Mín 2" (5,1 cm) Máx. de profundidad

profundidad de la

cavidad de pared

7-5/8"

(19,4 cm)

Abertura

7-11/16"

(19,5 cm)

3-11/16" (9,4 cm)

Detalle de la abertura

Cable de interface de 8 clavijas

30' (9,14 m)

Cable de interface auxiliar de 4 clavijas

30' (9,14 m)

Espacio para el

labio de la

interface de 1/4"

(6 mm) Mín.

Diagrama de instalación

Antes de comenzar

Cumpla con todos los códigos locales de plomería, de construcción y de electricidad.

Lea estas instrucciones y determine cuáles son los componentes requeridos y sus lugares de

instalación, antes de comenzar la instalación.

Un electricista calificado debe instalar un tomacorriente eléctrico GFCI de 120 V, en la estructura de

postes de madera, cerca de la válvula electrónica. La interface o interfaces reciben alimentación

eléctrica a través de las conexiones con la válvula.

Instale la válvula antes de instalar la interface o interfaces.

Kohler Co. se reserva el derecho de modificar el diseño de la grifería sin previo aviso, tal como se

especifica en la lista de precios.

1043184-2-B Español-3 Kohler Co.

Page 27

Cable de interface de

4 clavijas de 30' (9,14 m)

Interface auxiliar

(exterior de la

ducha)

Interface primaria

(interior de la ducha)

Conector

Lazo de goteo

Cable de interface de

8 clavijas de 30' (9,14 m)

Lazos de goteo

Lazo

de goteo

Lazo de goteo

1. Preparación

Si aún no se ha instalado, instale la válvula digital en este momento según las instrucciones

provistas con el producto.

Fuente de

alimentación

eléctrica

Salida

NOTA: La interface auxiliar opcional, con el cable de 4 clavijas, se ubica fuera de la mampara de ducha,

mientras que la interface primaria, con el cable de 8 clavijas, se ubica dentro de la mampara de ducha.

Determine cuáles son los componentes requeridos y los lugares de instalación, antes de comenzar la

instalación.

Las experiencias de duchas personalizadas que no sean las opciones preprogramadas, se tienen que

programar en la interface antes de usar. Consulte la ″Guía del usuario de la interface digital″.

NOTA: El cable de 8 clavijas se utiliza para la interface primaria y el de 4 clavijas para la interface auxiliar.

Verifique que ambas interfaces, la primaria y la auxiliar, se ubiquen de manera que el cable de la

interface alcance fácilmente la distancia entre la válvula y la conexión de la interface.

Kohler Co. Español-4 1043184-2-B

Page 28

7-11/16"

(19,5 cm)

3-11/16"

(9,4 cm)

52" (132,1 cm)

Abertura

Labio de la

interface

1/4" (6 mm)

Pared

Cuña

Brazo de abrazadera

Espacio para el

brazo de la

abrazadera 1/2"

(1,3 cm) Mín.

3/16" (5 mm) Mín 2" (5,1 cm) Máx. de profundidad

2. Prepare el sitio

NOTA: Se muestra la interface vertical, la interface horizontal también está disponible.

NOTA: Prevea para un empalme de 1/4″ (6 mm) del labio de la manga de pared y una separación mínima

de 1/2″ (1,3 cm) alrededor de la parte posterior de la abertura para permitir que los clips enganchen

completamente.

Consulte el diagrama de instalación. Con un lápiz, marque la líneas de corte en la pared acabada.

Con cuidado corte la abertura en la pared acabada siguiendo la línea trazada con lápiz.

Para materiales delgados de acabado de la pared de menos de 3/16″ (5 mm), utilice cuñas alrededor

de la parte posterior de la abertura para proveer el soporte adecuado para montar la manga de

pared de la interface.

1043184-2-B Español-5 Kohler Co.

Page 29

Aplique

sellador de

silicona.

Inserte la manga y

saque los brazos de

la abrazadera.

Meta los brazos

de la abrazadera

en las ranuras.

Voltee los brazos de la

abrazadera para paredes

de mayor espesor, 1-1/4"

(3,2 cm) - 2" (5,1 cm).

Pared más delgada,

3/16" (5 mm) 1-1/4" (3,2 cm)

Manga

Interface

Perilla de

control

Cable

No use un

destornillador

eléctrico.

18"

(45,7 cm)

Mín

Fije el cable.

Lazo de goteo

3. Instale la interface

PRECAUCIÓN: Riesgo de daños al producto. No utilice destornilladores eléctricos para instalar la

interface.

NOTA: Los brazos de la abrazadera se pueden quitar y voltear para permitir la instalar en paredes de

mayor espesor.

Mida el espesor de la pared acabada.

Si corresponde, voltee los brazos del clip para permitir materiales de pared de mayor espesor.

Consulte la ilustración mostrada arriba.

Fije el cable de la interface, desde la válvula, con una atadura a la parte posterior de la manga de

pared dejando aproximadamente 18″ (45,7 cm) de cable colgando libremente.

Inserte el extremo libre del cable de la interface en la abertura de la manga de pared.

Meta los brazos de la abrazadera en las ranuras de la manga.

Aplique una tira de sellador de silicona en la ranura alrededor de la parte posterior del labio de la

manga.

Inserte la manga en la abertura.

Gire los brazos de la abrazadera de modo que estén perpendiculares con la abertura.

Apriete a mano los tornillos. No apriete demasiado.

Limpie el exceso de sellador de alrededor del frente de la manga. Tenga cuidado de no ensuciar de

sellador la superficie exterior de la manga.

Retire el tapón de los cables de la interface.

Conecte la interface al cable de la interface.

Kohler Co. Español-6 1043184-2-B

Page 30

Instale la interface (cont.)

Con cuidado pase la conexión a través del orificio en la manga de pared y dentro de la cavidad de

la pared. Un lazo de goteo se formará automáticamente en el cable.

Verifique que el empaque esté en su lugar en la interface.

Deslice el cuerpo de la interface en la manga.

Presione con firmeza la interface con las palmas de sus manos hasta que encaje en su lugar.

Instale la perilla de control.

1043184-2-B Español-7 Kohler Co.

Page 31

Fuente de

alimentación

eléctrica

Cable de interface

exterior opcional

Fuente de

alimentación

eléctrica

Tornillos

Ojales moldeados

Cable de interface interior

Lazo de goteo

Lengüeta

Clip

Puerta

Lazo de

goteo

4. Termine la instalación

¡IMPORTANTE! Forme lazos de goteo en todos los cables y cordones.

Presione los clips para liberar y abrir la puerta de acceso de la válvula.

Deslice el lado de bisagra de la puerta en cualquier dirección hasta liberar un lado.

Retire la puerta.

Conecte el cable o cables de interface a la válvula.

Conecte la fuente de alimentación eléctrica a la válvula.

Verifique que todos los ojales moldeados estén en sus lugares antes de cerrar la tapa de acceso.

Vuelva a instalar la puerta de acceso.

Para cerrar la puerta de acceso, presione las lengüetas hasta que los clips encajen en su lugar.

Enchufe la fuente de alimentación al tomacorriente.

Lazo de

goteo

5. Verificación de la instalación

Abra el suministro de agua a la válvula.

Revise todas las conexiones para asegurarse que no haya fugas y ajuste según sea necesario.

Active el suministro eléctrico principal. Debe escuchar que la válvula enciende y el icono de

encendido/apagado de la interface del usuario se encenderá con una luz intermitente color verde.

Para configurar la interface, consulte la ″Guía del usuario de la interface digital″, si aún no se ha

realizado.

Kohler Co. Español-8 1043184-2-B

Page 32

Verificación de la instalación (cont.)

NOTA: Para obtener más información sobre el uso de la interface del usuario y sus menús, consulte la

Guía del usuario de la interface del usuario.

En el menú principal de la interface, seleccione DUCHA > Opciones > Todos abiertos. Esto

seleccionará todos los componentes conectados y purgará el aire del sistema.

Revise que no haya fugas y ajuste según sea necesario.

Verifique que el flujo de agua sea suficiente para las necesidades de su ducha.

6. Procedimiento para resolver problemas

PRECAUCIÓN: Riesgo de lesiones personales. La válvula puede tener agua caliente, tenga cuidado al

drenar el agua residual.

¡IMPORTANTE! Cierre el suministro de agua y desconecte el suministro eléctrico a la válvula antes de

realizar el mantenimiento.

Se recomienda que un representante de servicio autorizado de Kohler realice todo el mantenimiento de la

válvula.

Esta guía para resolver problemas está diseñada únicamente como ayuda general. Para preguntas de servicio

o instalación, llame al 1-800-4-KOHLER.

Tabla para resolver problemas

Síntomas Causa probable Acción recomendada

1. El panel de control no se

ilumina.

2. El indicador de encendido

de la interface pulsa pero

no se enciende.

3. La interface funciona

normalmente pero no

fluye agua de los

componentes.

A. La fuente de alimentación

eléctrica no está enchufada en el

tomacorriente.

B. La conexión de la fuente de

alimentación eléctrica puede

estar floja o desconectada.

C. Las conexiones del cable de la

interface pueden estar flojas o

desconectadas.

D. El interruptor de circuito se ha

disparado.

E. Puede ser necesario restablecer

la memoria de la válvula.

F. Si ninguna de las acciones

recomendadas para los

problemas anteriores corrige el

síntoma, la válvula o la interface

requiere servicio.

A. Las conexiones del cable de la

interface pueden estar flojas o

desconectadas.

B. Si la acción recomendada

anteriormente no corrige el

síntoma, la interface o la válvula

requiere servicio.

A. Las conexiones de

entrada/salida pueden estar

obstruidas.

B. Los suministros del agua fría y

caliente no están abiertos.

A. Enchufe la fuente de alimentación

al tomacorriente.

B. Revise todas las conexiones

eléctricas a la válvula y vuelva a

conectar si es necesario.

C. Revise todas las conexiones del

cable de la interface, conecte si es

necesario.

D. Restablezca la corriente eléctrica

(reset) del interruptor de circuito.

E. Desconecte y vuelva a conectar la

fuente de alimentación eléctrica de

la válvula.

F. Consulte a un representante de

servicio autorizado de Kohler Co.

A. Revise todas las conexiones del

cable de la interface, conecte si es

necesario.

B. Consulte a un representante de

servicio autorizado de Kohler Co.

A. Verifique que no haya suciedad u

obstrucciones en las entradas y las

salidas. Limpie las rejillas de

entrada. Consulte la sección

″Limpie las rejillas de entrada″ de

la Guía del usuario de la válvula.

B. Abra el suministro de agua a la

válvula.

1043184-2-B Español-9 Kohler Co.

Page 33

Procedimiento para resolver problemas (cont.)

Tabla para resolver problemas

Síntomas Causa probable Acción recomendada

C. Puede ser necesario restablecer

la memoria de la válvula.

D. Error del sistema. D. Vea si la interface del usuario tiene

E. Si ninguna de las acciones

recomendadas para los

problemas anteriores corrige el

síntoma, la válvula requiere

servicio.

4. La temperatura máxima

de la mezcla está muy

caliente o muy fría.

5. Flujo continuo. A. El sistema no se apaga. A. Cierre el suministro de agua y

6. El modo de masaje se

apaga pero el agua

continúa fluyendo de la

cabeza o cabezas de

ducha.

7. Sólo agua fría fluye de las

salidas.

8. Caudal reducido o

fluctuante. La válvula

funciona correctamente.

A. Valor de temperatura máxima

incorrecto.

B. Si la acción recomendada

anteriormente no corrige el

síntoma, la interface o la válvula

requiere servicio.

A. Caudales disparejos entre las

salidas de la válvula.

B. Fluctuación de la presión de

entrada.

C. Diferencia de presión mayor

que 5 psi (34,5 kPa) entre los

suministros de agua caliente y

fría.

A. El suministro de agua caliente

no está abierto o no está

conectado a la entrada de la

válvula.

B. La entrada de agua caliente está

obstruida.

C. Si ninguna de las acciones

recomendadas para los

problemas anteriores corrige el

síntoma, la válvula requiere

servicio.

A. Las conexiones de

entrada/salida pueden estar

obstruidas.

C. Desconecte y vuelva a conectar la

fuente de alimentación eléctrica de

la válvula.

un código de error. Consulte la

sección ″Diagnóstico″ en la Guía

del usuario de la interface digital.

E. Consulte a un representante de

servicio autorizado de Kohler Co.

A. Consulte la sección ″Fijar la

temperatura máxima″ en la Guía

del usuario de la interface digital.

B. Consulte a un representante de

servicio autorizado de Kohler.

desconecte el suministro eléctrico, y

comuníquese con su representante

de servicio autorizado de Kohler

Co.

A. Verifique que la instalación tenga

un jet - cuerpo por salida de

válvula y que utilice jets - cuerpo

de la misma capacidad de flujo. Si

es necesario, comuníquese con el

instalador para verificar la

instalación.

B. Instale reguladores de presión en

las líneas de suministro.

C. Instale reguladores de presión para

que los suministros esténa5psi

(34,5 kPa) uno del otro.

A. Verifique que el suministro de agua

caliente esté abierto y conectado a

la entrada de la válvula.

B. Verifique que la rejilla de entrada

del agua caliente no tenga

obstrucciones. Limpie o reemplace

la rejilla de entrada. Consulte la

Guía del usuario de la válvula.

C. Consulte a un representante de

servicio autorizado de Kohler Co.

A. Verifique que no haya suciedad u

obstrucciones en las entradas y las

salidas. Limpie las rejillas de

entrada. Consulte la sección

″Limpie las rejillas de entrada″.

Kohler Co. Español-10 1043184-2-B

Page 34

Procedimiento para resolver problemas (cont.)

Tabla para resolver problemas

Síntomas Causa probable Acción recomendada

9. Cambio o altibajas en la

temperatura de mezcla.

10. Fuga de agua en la

válvula.

PRECAUCIÓN: Riesgo

de lesiones personales o

daños al producto.

Desconecte la energía

eléctrica principal y cierre

el suministro de agua.

11. Sólo sale agua caliente, la

válvula se apaga.

B. La presión de salida de agua es

baja.

C. Flujo fluctuante. C. Verifique que las presiones

D. Si ninguna de las acciones

recomendadas para los

problemas anteriores corrige el

síntoma, la válvula requiere

servicio.

A. La temperatura del agua

fluctua.

B. Fluctuación de la temperatura

del suministro de agua caliente.

C. Diferencia de presión mayor

que 5 psi (34,5 kPa) entre los

suministros de agua caliente y

fría.

D. Si ninguna de las acciones

recomendadas para los

problemas anteriores corrige el

síntoma, la válvula requiere

servicio.

A. Las conexiones no están

aseguradas.

B. Los sellos están gastados o

dañados.

C. Fuga interna. C. La unidad requiere reconstrucción.

A. Las líneas de agua fría y

caliente están invertidas.

B. Verifique que el caudal esté al

mínimo requerido o más alto.

Consulte la sección

″Especificaciones″ en la Guía del

usuario de la válvula.

dinámicas de entrada estén dentro

de las especificaciones. Consulte la

sección ″Especificaciones″.

D. Consulte a un representante de

servicio autorizado de Kohler Co.

A. Verifique que los diferenciales de

temperatura de entrada sean

suficientes. Consulte la sección

″Especificaciones″.

B. Verifique y haga los ajustes

necesarios.

C. Instale reguladores de presión para

que los suministros esténa5psi

(34,5 kPa) uno del otro.

D. Consulte a un representante de

servicio autorizado de Kohler Co.

A. Revise todas las conexiones. Realice

los ajustes necesarios.

B. Adquiera el paquete de sellos de

servicio y cambie todos los sellos.

Consulte a un representante de

servicio autorizado de Kohler Co.

A. Intercambie las conexiones de los

suministros del agua fría y caliente.

Verifique que el suministro de agua

caliente esté conectado a la entrada

identificada con la letra ″H″ y que

el suministro de agua fría esté

conectado a la entrada identificada

con la letra ″C.″

1043184-2-B Español-11 Kohler Co.

Page 35

1043184-2-B

Page 36

USA: 1-800-4-KOHLER

Canada: 1-800-964-5590

México: 001-877-680-1310

kohler.com

©2006 Kohler Co.

1043184-2-B

Loading...

Loading...