KOHLER K-682 Installation Manual

Installation Guide

Digital Thermostatic Valve

K-682

M product numbers are for Mexico (i.e. K-12345M)

Los números de productos seguidos de M corresponden a México

(Ej. K-12345M)

Français, page ″Français-1″

Español, página ″Español-1″

1043183-2-E

IMPORTANT INSTRUCTIONS

WARNING: When using electrical products, basic precautions should always be followed,

including the following:

WARNING: Risk of electric shock. A qualified electrician should route all electrical wiring.

WARNING: Risk of electric shock. Disconnect power before servicing.

WARNING: Unauthorized modification may cause poor performance of the valve. Do not make

modifications to the valve as this could adversely affect the performance of the valve and void the

warranty. Kohler Co. shall not be liable under its warranty or otherwise for personal injury or

damage caused by any such unauthorized modification.

WARNING: Risk of injury or property damage. Please read all instructions thoroughly before

beginning installation.

NOTICE: Follow all plumbing, electrical, and building codes.

NOTICE: Some electrical codes require a circuit protected by a Ground-Fault Circuit-Interrupter (GFCI)*.

NOTICE: Provide unrestricted service access to the valve.

*Outside North America, this device may be known as a Residual Current Device (RCD).

___________________________________________________________________________________________________

Operation with DTV, DTV II, or DTV+

DTV: The valve is controlled from one or two user interfaces that connect directly to the valve.

DTV II: To connect the valve to the DTV II system, the K-638 media module is required.

DTV+: To connect one or two valves to the DTV+ system, the K-99695 system controller and

K-97172 data cable(s) are required.

Refer to the appropriate sections in this guide for your system configuration.

Specifications

Pressures

Maximum Static Pressure 125 psi, 862 kPa, 8.6 bar

Supply Pressure Differential* Max 5 psi, 34.5 kPa, 0.34 bar differential Hot pressure should be equal

Minimum Flow Rate 1.6 gal/min (Less than 72 psi dynamic pressure.)

Temperatures

Programmable Temperature Max 120°F (49°C) Min 79°F (26°C) Full cold may also be selected.

Default Temperature at Start-up 102°F (39°C)

Minimum Mixed Temperature

Differential from Hot Supply

Optimum Thermostatic Control Range 86°F (30°C) to 120°F (49°C)

Temperature Stability at Recommended

Supply Conditions

Ambient Temperature Greater than 34°F (1°C), Max 104°F (40°C)

Maximum Relative Humidity 95% non-condensing

Electrical

to or less than cold pressure.

6 l/min (Less than 500 kPa maintaining pressure.)

2.1 gal/min (Greater than 72 psi dynamic pressure.)

8 l/min (Greater than 500 kPa maintaining pressure.)

3.6°F (2°C)

+/- 1.6°F (1°C)

1043183-2-E 2 Kohler Co.

Specifications (cont.)

Pressures

Electrical Rating 100-240 VAC, 50-60 Hz, 1.5 A

User Interface Cable Length (supplied) 30’ (9.14 m)

*In commercial applications where there is a large difference in hot and cold supply pressures or frequent

fluctuation in either supply line is anticipated, it is strongly recommended that pressure regulators be

installed.

Tools and Materials

Plus:

• (2) 3/4" and (6) 1/2" Union Connectors

• Wood and Framing Materials

• PEX Tubing or Copper Tubing

• (2) Water Hammer Arrestors (Recommended)

• (2) Supply Shut-Off Valves

Hacksaw or Tube Cutter Sealant

Tape

Solder Propane

Torch

Kohler Co. 3 1043183-2-E

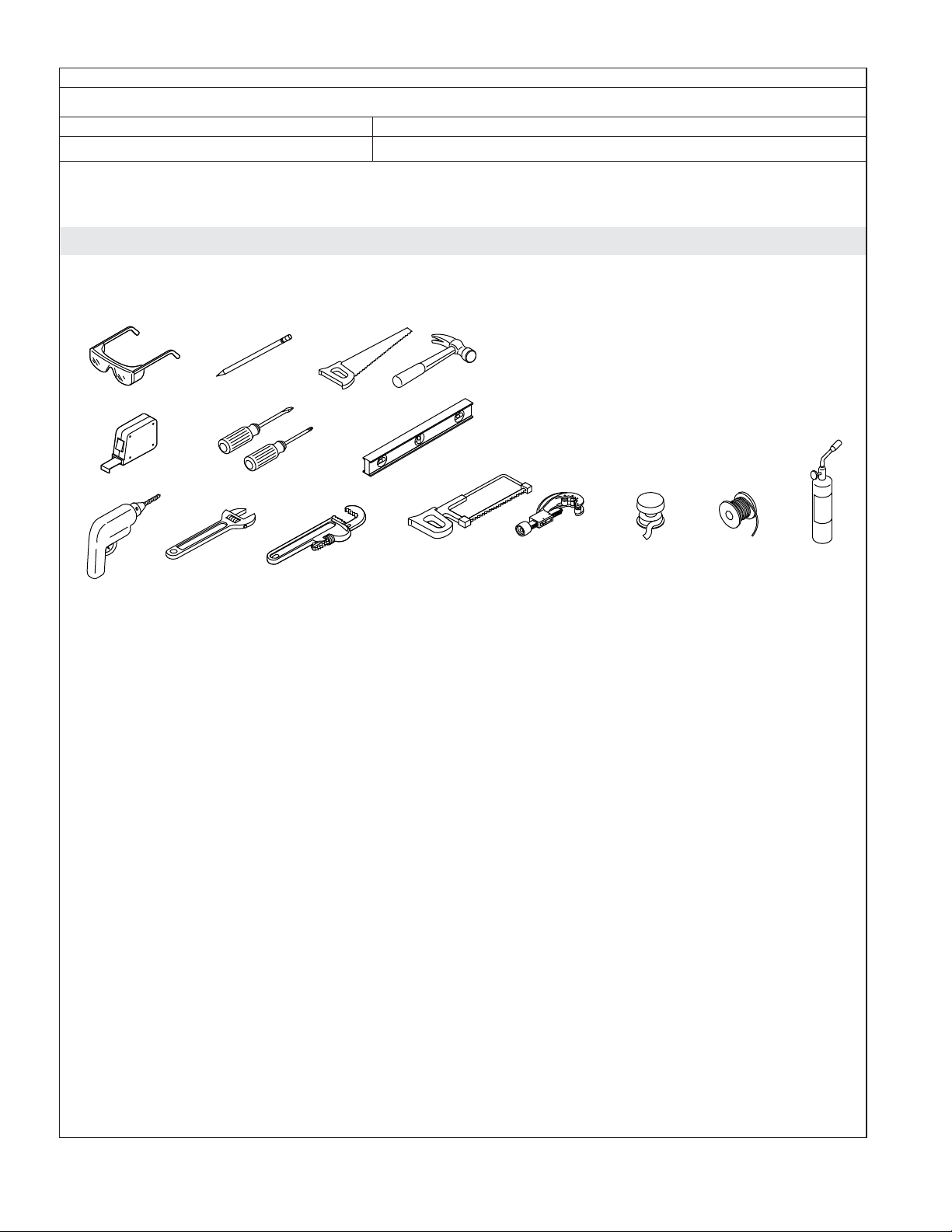

3-3/16"

(81 mm)

30-7/8"

(784 mm)

13' - 1/8"

(3968 mm)

21-5/16" (541 mm)

20-1/8" (511 mm)

2"

(51 mm)

Roughing-In

5-15/16"

(151 mm)

1-5/16" (33 mm)

Cold

3/4" NPT Inlets

2-3/16" (56 mm)

3-1/16" (78 mm)

Hot

1-3/4" (44 mm)

22-1/4" (565 mm)

1/2" NPT Outlets (6)

1-3/4" (44 mm)

1-3/4" (44 mm)

1-3/4" (44 mm)

1-3/4" (44 mm)

3"

(76 mm)

2-1/8"

(54 mm)

7-3/8"

(187 mm)

9-3/16"

(233 mm)

3-5/16"

(84 mm)

Before You Begin

NOTICE: Do not install the valve or power supply under a whirlpool surround or any location where the

temperature may exceed 104°F (40°C). The power supply and valve are rated to operate in temperatures

up to 104°F (40°C).

NOTICE: Do not apply excessive heat near the valve or apply flux or acids directly onto the valve. This

valve contains plastic and rubber components which will melt if heat is directly applied.

NOTICE: Do not apply petroleum-based lubricants to the valve components. Doing so will damage the

valve components.

NOTICE: Do not use oil-based, non-setting compounds, such as plumbers putty, on the threaded inlet

and outlet connections. Use sealant tape or liquid sealant.

NOTICE: Do not allow any outlet to flow more than 10 gal/min (37.9 l/min).

Read these instructions and determine the locations of all required components before beginning

installation.

When possible, install the valve before installing the other components.

If possible, flush all piping thoroughly before installing the valve. If the pipes are flushed after the

valve is installed, clean the inlet screens before using the system.

A qualified electrician should install a 120 V electrical outlet, within the stud framing, in close

proximity to the valve. A GFCI outlet may be required in certain applications.

If possible, install the electrical outlet prior to installing the valve.

1043183-2-E 4 Kohler Co.

Before You Begin (cont.)

For optimum valve performance, the water heater should be set at 120°F (49°C). Hot water pressure

should be equal to or less than the cold water pressure.

This valve complies with UL1951, ASME A112.18.1, ASSE 1016, CSA B125, and CSA C222 No.

218.2-93. This valve is listed with ASSE, CSA, IAPMO/UPC, and UL.

Special Considerations for Large Showering Systems

Showering configurations using large water volumes require supply piping and drain systems that

will sufficiently accommodate the actual total flow rate at any one time.

Hot water generation: Use a water heating system capable of handling large flow rates. Tankless

(on-demand) water heaters and recirculating pumps may not be adequate for your showering

configuration.

Kohler Co. 5 1043183-2-E

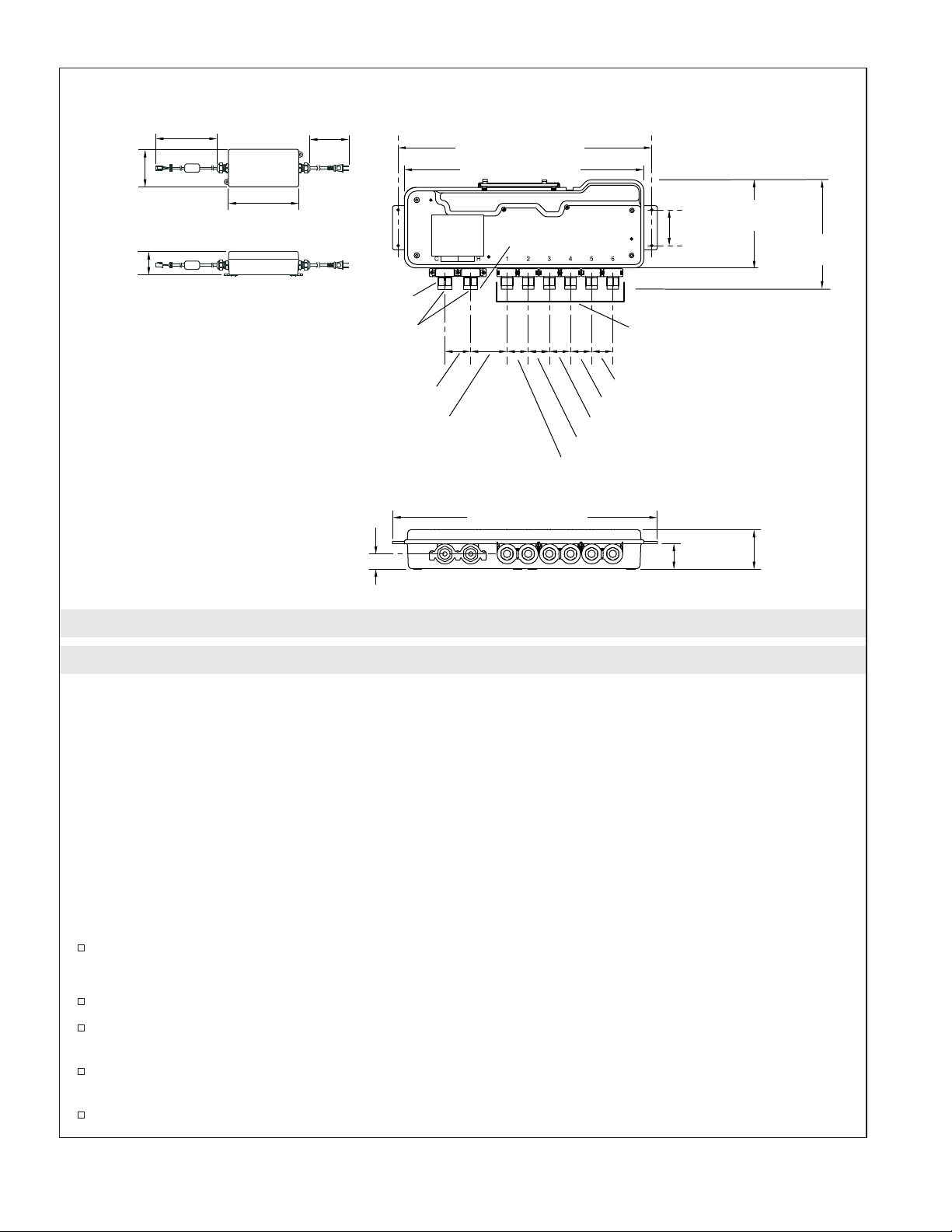

Primary Interface

(Inside Shower)

Connector

30' (9.14 m)

4-Pin Interface Cable

Drip Loop

30' (9.14 m)

8-Pin Interface Cable

Auxiliary Interface

(Outside Shower)

Drip

Loop

Power Supply

Outlet

NOTE: Original DTV

System Shown

Drip Loops

Drip Loop

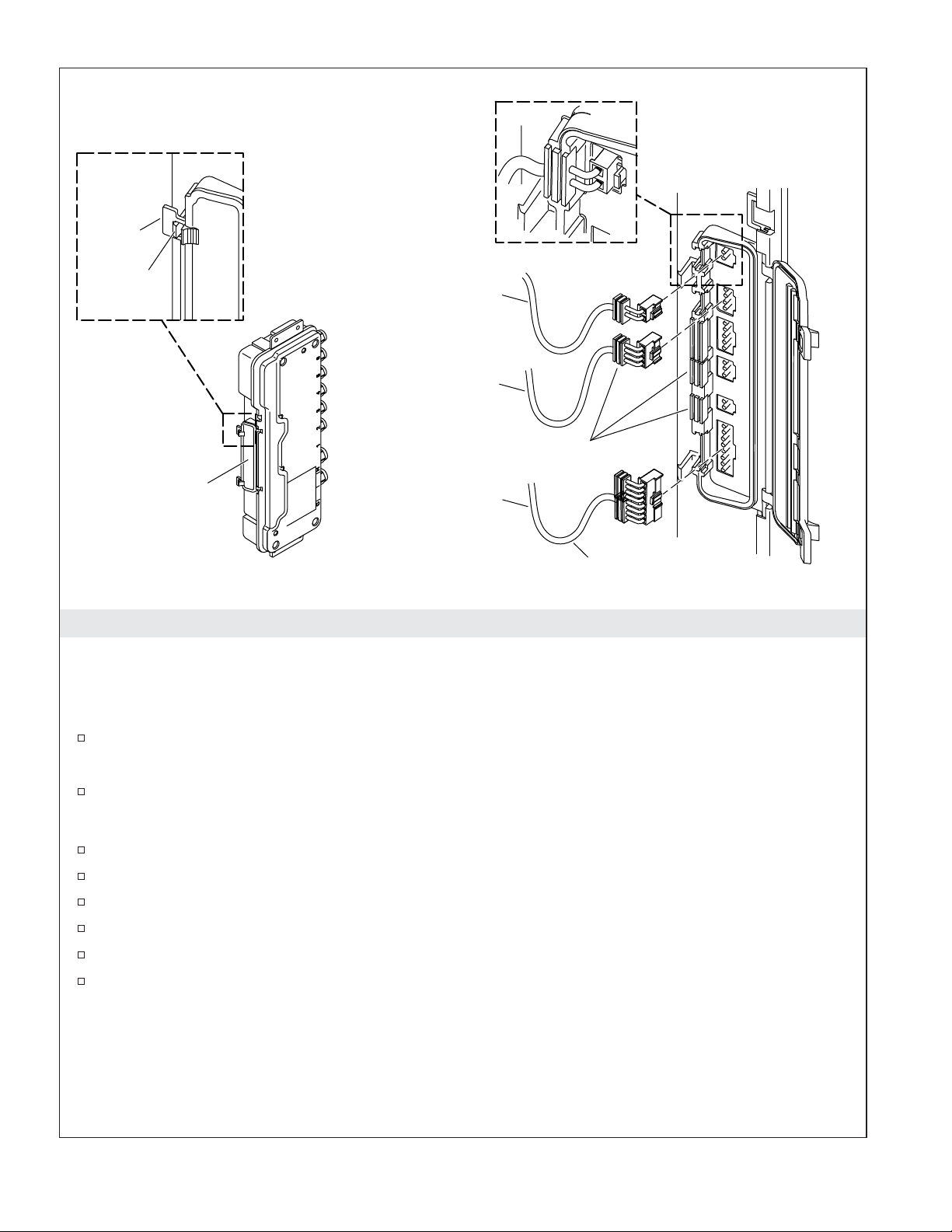

1. Plan the System Layout

NOTE: The original DTV system is shown above. The interface cables do not connect directly to the valve

for DTV II and DTV+.

Determine the locations of all required components before beginning installation.

DTV (shown above): The primary interface, with the 8-pin cable, is located inside the showering

enclosure. An optional auxiliary interface, with the 4-pin cable, can be installed outside the

showering enclosure.

DTV II: Refer to the K-638 media module installation guide for system layout and required

components.

DTV+: Refer to the K-97172 data cable installation guide for system layout and required

components.

When routing piping, the numbers marked at each valve outlet must correspond to the appropriate

shower fitting for pre-programmed or custom showering experiences to function properly.

Custom showering experiences must be programmed into the interface prior to use. Refer to the

″Homeowners Guide″ or ″Users guide″ for the interface or controller for your system.

1043183-2-E 6 Kohler Co.

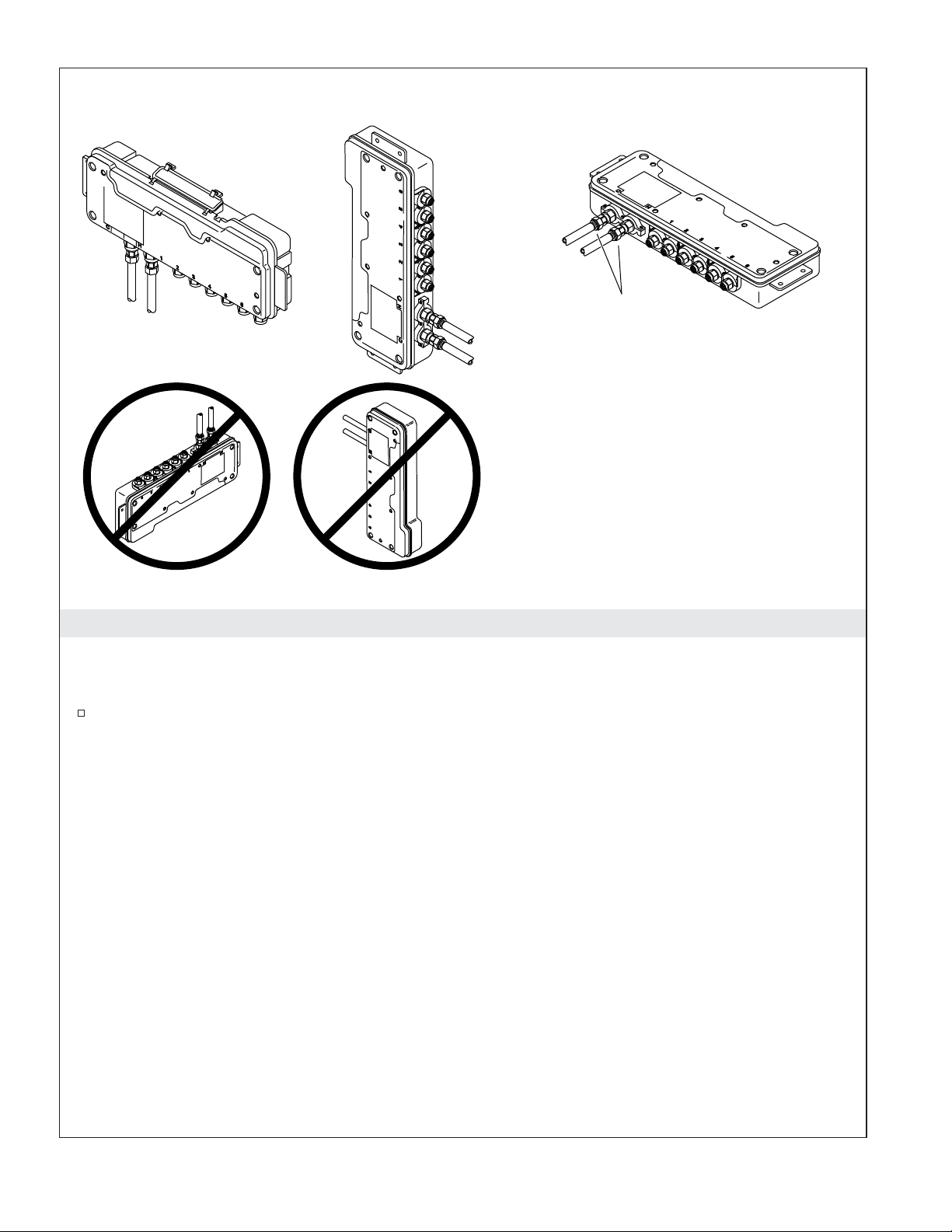

Mounting on a Horizontal SurfaceMounting on a Vertical Surface

Inlets

2. Mounting Configurations

NOTICE: Do not mount the valve with the inlets pointing up or positioned above the outlet ports. Doing

so will damage this product.

Vertical and horizontal mounting options are shown above.

Kohler Co. 7 1043183-2-E

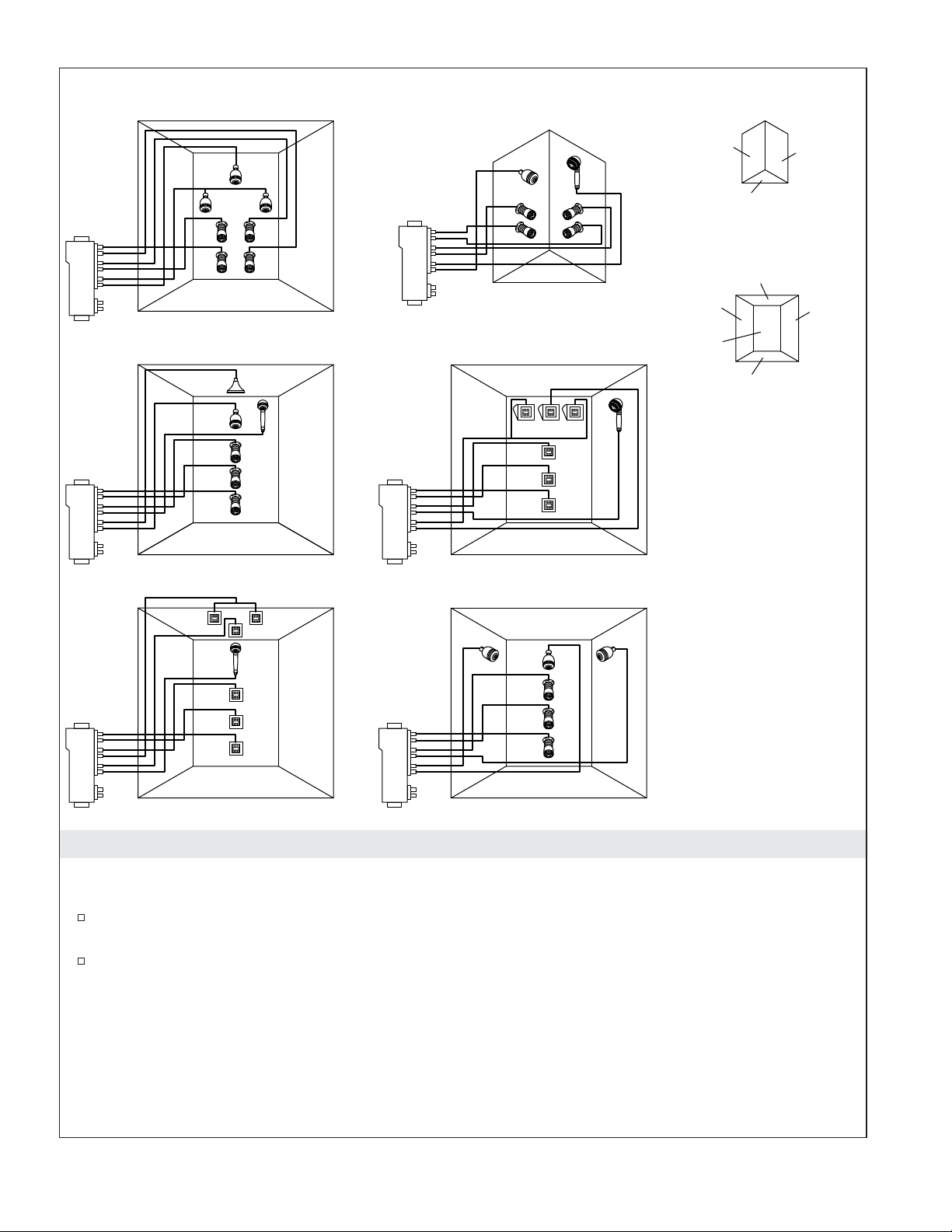

Frontage Envelop

CH 12 34 56 CH 12 34 56

1

22

34

1

34

65

65

CH 12 34 56

Unwind Linear

2

*

1

3

4

5

6

CH 12 34 56

2

12

4

5

6

Downpour Surround

3

3

2

*

1

2

*

1

Wall 1

Wall 2

2

Floor

Ceiling

Wall 1

Wall 3

Wall 2

Floor

3

If bodysprays, watertiles

*

or watertile showerheads

are present in these

outlets, they will not cycle.

3

*

4

5

6

CH 12 34 56

4

5

6

CH 12 34 56

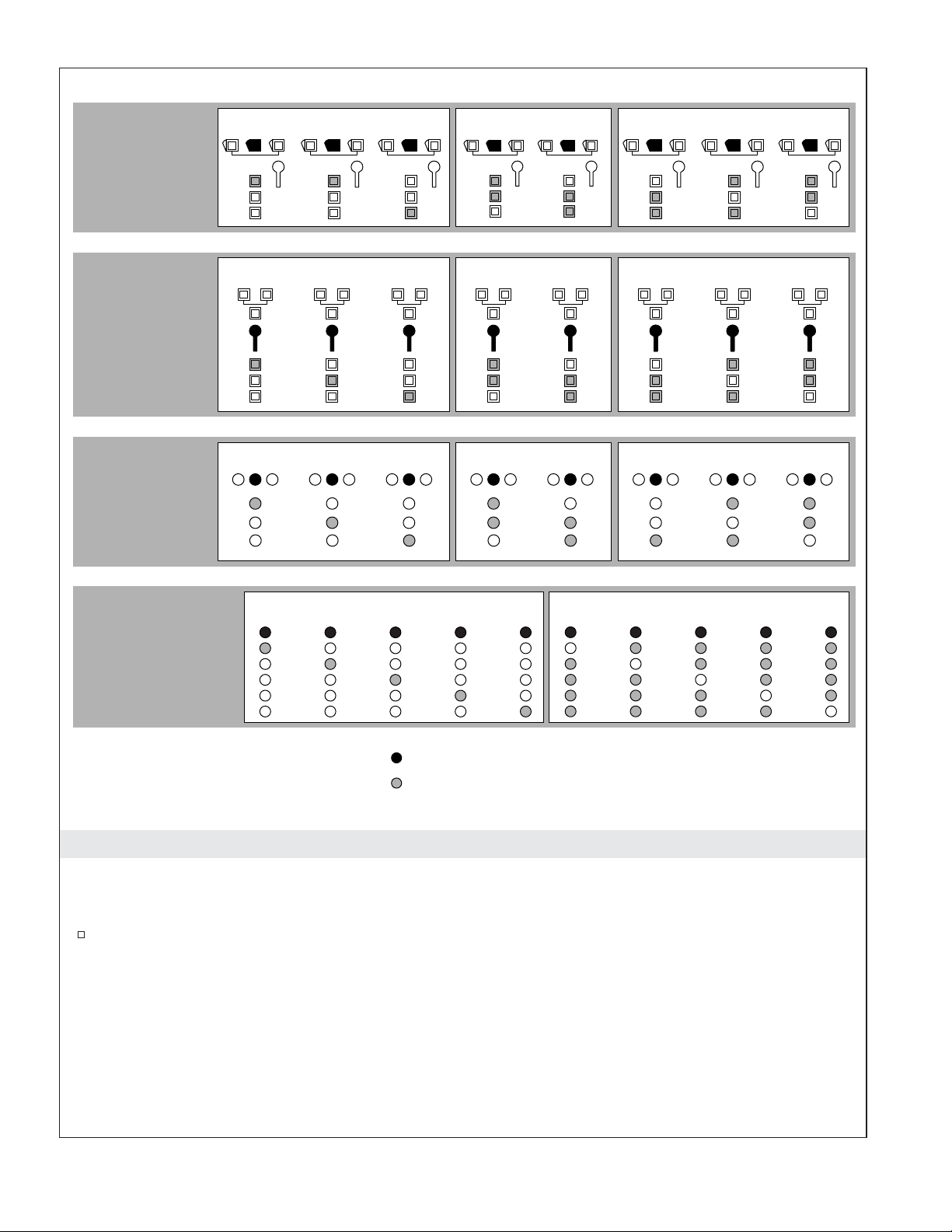

3. Shower Configurations (DTV and DTV II)

NOTE: Pre-programmed shower configurations are shown; other options are possible. Configurations

other than the pre-programmed options will LIMIT the pre-programmed massage functions.

Massage functions that correspond with custom configurations can be programmed. Refer to the

″Digital Interface Homeowners Guide.″

The bodyspray to valve outlet ratio must be 1:1. All bodysprays must have equal flow rates;

unequal flow rates will cause the massage mode to shut down. See examples below:

Correct: Four bodysprays using four outlets, one per bodyspray (1:1). See the ″Envelop″ configuration above.

Incorrect: Four bodysprays using three outlets; two bodysprays each installed to one valve outlet (1:1), and

the other two bodysprays installed to one valve outlet (2:1).

1043183-2-E 8 Kohler Co.

Ceiling

12 34 56

CH

Wall 1

Wall 2

Wall 1

Wall 3

Floor

Wall 2

Floor

CH 12 34 56

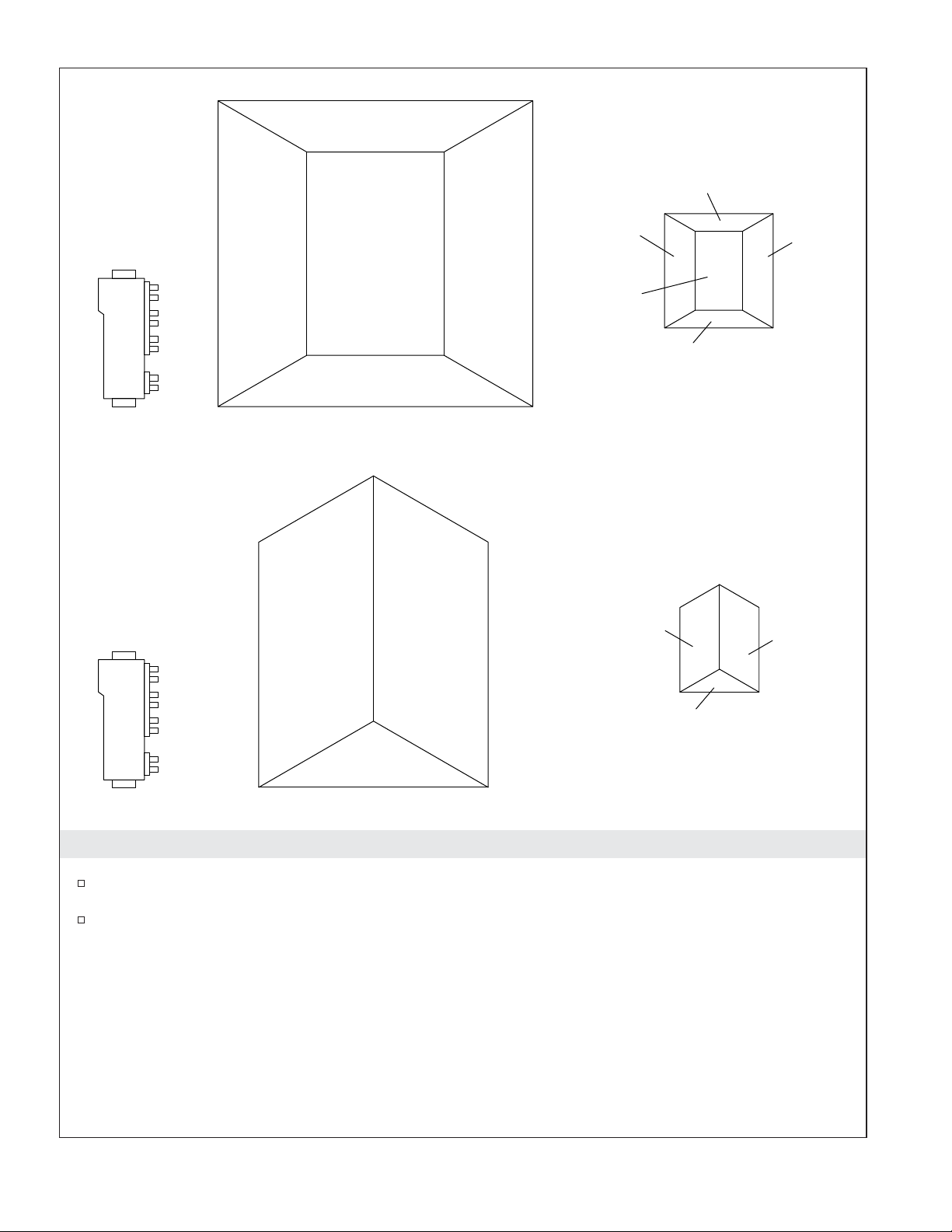

4. Custom Shower Configurations (DTV and DTV II)

Draw in the fittings for your custom shower.

Draw lines from the valve to each fitting. Be aware that:

•

Outlet 1 should be the primary showerhead.

•

The installer must determine the desired sequence for Single mode and plumb the ports to the

bodysprays accordingly.

•

Custom mode will allow the user to select a different water outlet as the primary showerhead, but it

is not recommended.

•

In Custom mode, the bodysprays will cycle up the solenoid bank regardless of which port is the

primary outlet.

Kohler Co. 9 1043183-2-E

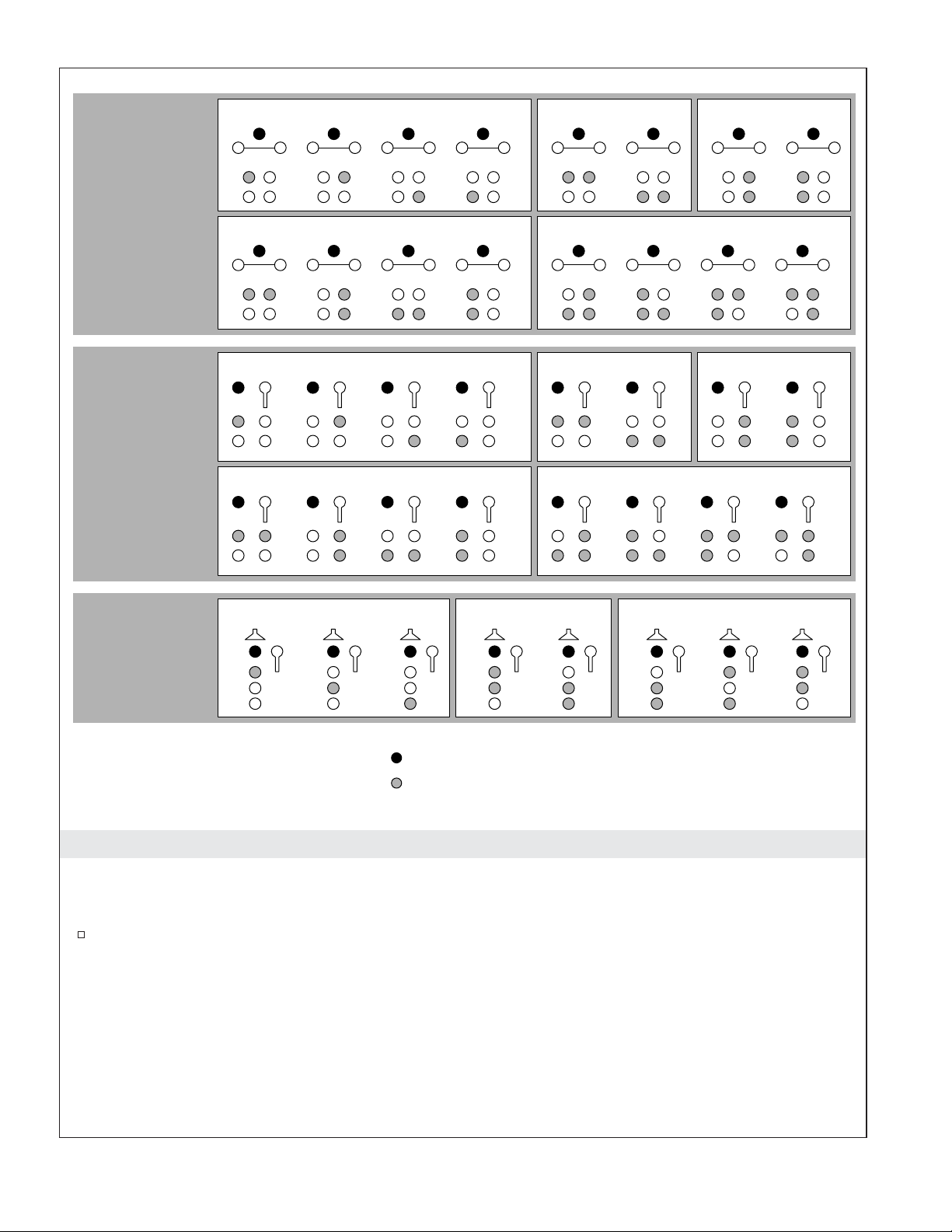

Frontage

Configuration 1

Single

Dual 1 Dual 2

Envelop

Configuration 2

Unwind

Configuration 3

Dual 3

Single

Dual 3

Single Dual Wave

Wave

Dual 1

Wave

Dual 2

= Constant on

= On while cycling

5. Massage Cycling Configurations (DTV and DTV II)

NOTE: Primary outlets and any outlets designated as handshowers will not be included in the cycling

pattern. For installations that include both bodysprays and watertiles, the outlets designated as watertiles

will not cycle.

For massage cycling configurations for DTV+, refer to the guide found on the K-99695 controller

product page at www.us.kohler.com.

1043183-2-E 10 Kohler Co.

Linear

Configuration 4

Single

Dual

Wave

Downpour

Configuration 5

Surround

Configuration 6

Custom

WaveDualSingle

DualSingle Wave

WaveSingle

= Constant on

= On while cycling

6. Massage Cycling Configurations (DTV and DTV II)

NOTE: Primary outlets and any outlets designated as handshowers will not be included in the cycling

pattern. For installations that include both bodysprays and watertiles, the outlets designated as watertiles

will not cycle.

For massage cycling configurations for DTV+, refer to the guide found on the K-99695 controller

product page at www.us.kohler.com.

Kohler Co. 11 1043183-2-E

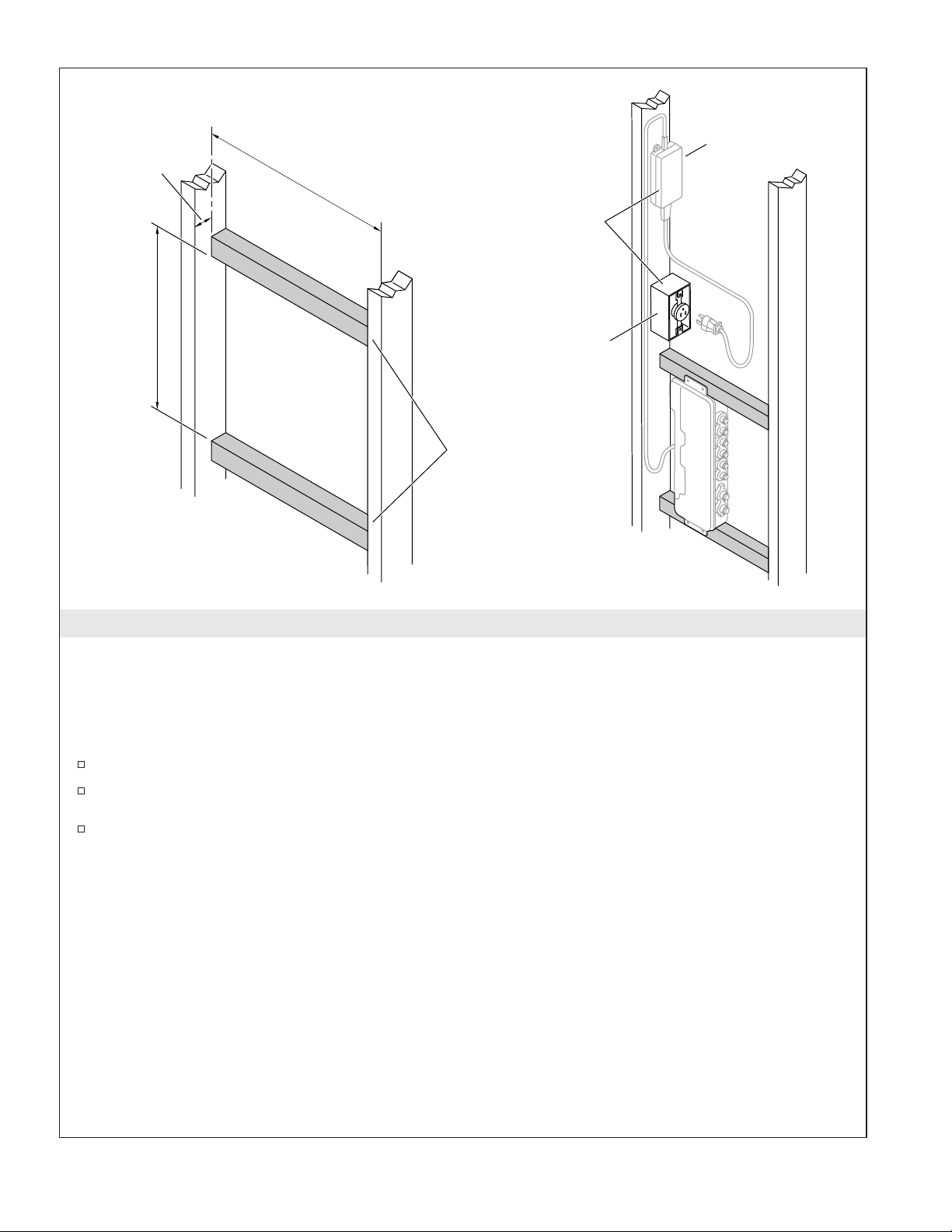

1-1/4"

(32 mm)

20-3/16"

(513 mm)

21"

(533 mm) Min

Power Supply

Position higher

than the valve.

Outlet

Install

bracing.

7. Prepare the Site

NOTICE: Do not install the power supply under a whirlpool surround or any location where the

temperature may exceed 104°F (40°C). The power supply is rated to operate in temperatures up to 104°F

(40°C).

NOTE: Vertical installation within a stud cavity is shown. The valve can also be mounted to a horizontal

surface. Refer to the ″Mounting Configurations″ section.

This product is designed to fit within a minimum 21″ (533 mm) 2x4 stud cavity.

Install adequate bracing for mounting the valve.

Install a 120 V electrical outlet within the stud framing, in close proximity to the valve. Locate the

outlet above the valve, allowing space to mount the power supply close to the outlet. A GFCI outlet

may be required in some applications.

1043183-2-E 12 Kohler Co.

6"

(152 mm)

1/2" NPT Outlets

Washer

Screw

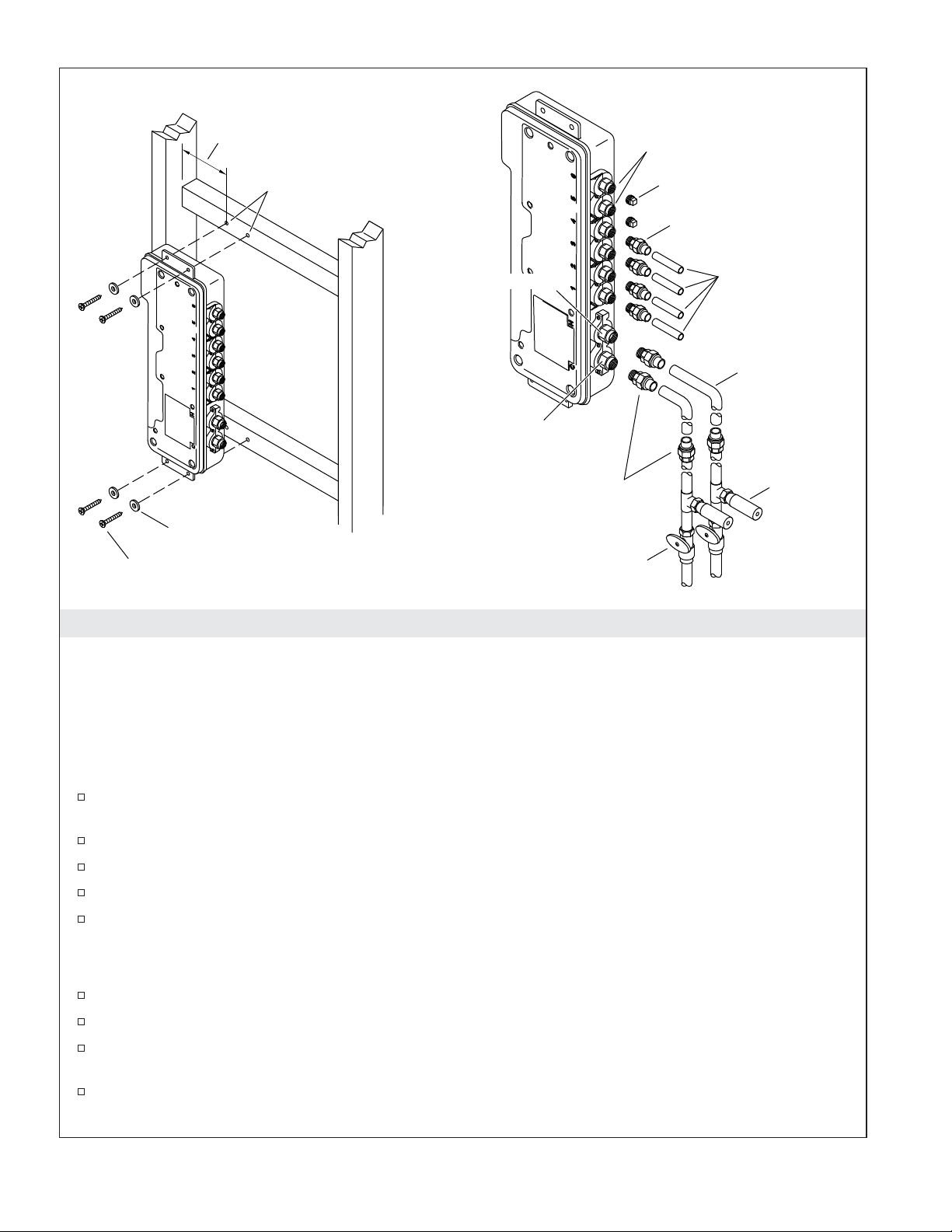

8. Install the Valve

Mark the holes.

3/4" NPT Hot Inlet

3/4" NPT

Cold Inlet

3/4" Union

Shut-Off Valve

Plug unused outlets

1/2" Union

1/2" Tubing

3/4" Tubing

Water

Hammer

Arrester

.

NOTICE: Do not apply excessive heat near the valve or apply flux or acids directly onto the valve. This

valve contains plastic and rubber components which will melt if heat is directly applied.

NOTICE: Do not use oil-based, non-setting compounds, such as plumbers putty, on the threaded

connections. Use sealant tape or liquid sealant on threaded inlet and outlet connections.

IMPORTANT! If your water supply has high amounts of particulates, install wye strainers in the supply

lines.

Route the water supply lines. Use unions to install removable pipe segments to the valve inlets to

allow access for periodic cleaning of the inlet screens.

Install shut-off valves and water hammer arrestors in the supply lines prior to the valve.

Hold the valve up to the installation location. Verify fit and mark the hole locations.

Pre-drill the holes.

Secure the valve with the washers and screws. Do not overtighten.

IMPORTANT! Make sure the shower fittings are connected to the corresponding numbered outlet(s) on

the valve for your configuration. Refer to the ″Shower Configurations″ section.

Route the piping from the valve outlets to the appropriate shower fitting.

If utilizing a custom configuration, plug any unused outlets.

Connect the hot and cold supply lines to the appropriate valve inlets. Hot is red and marked with

an ″H,″ cold is blue and marked with a ″C.″

Secure all piping to the framing.

Kohler Co. 13 1043183-2-E

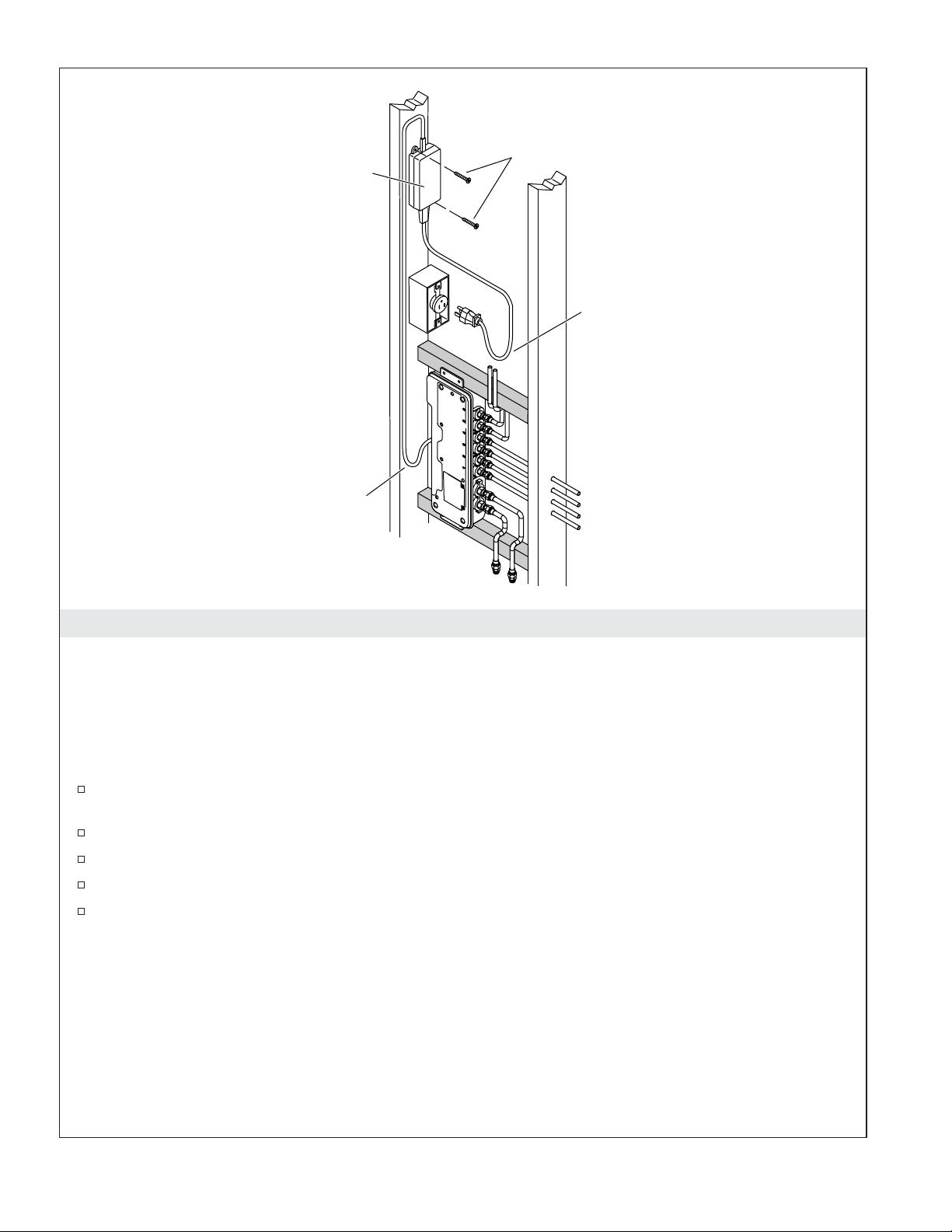

Power Supply

Drip Loop

Screws

Drip Loop

9. Install the Power Supply

NOTICE: Do not install the power supply under a whirlpool surround or any location where the

temperature may exceed 104°F (40°C). The power supply is rated to operate in temperatures up to 104°F

(40°C).

NOTICE: Do not plug in the power supply until all interface cables are connected.

NOTE: Make drip loops in all cables and cords.

Hold the power supply up to the installation location and verify the cord will reach the electrical

outlet.

Mark the hole locations.

Pre-drill the holes.

Secure the power supply with the screws.

Do not plug the power supply into the electrical outlet at this time.

1043183-2-E 14 Kohler Co.

Tab

Clip

Door

Power Supply

Optional External

Interface Cable

Grommets

Internal

Interface Cable

Drip Loop

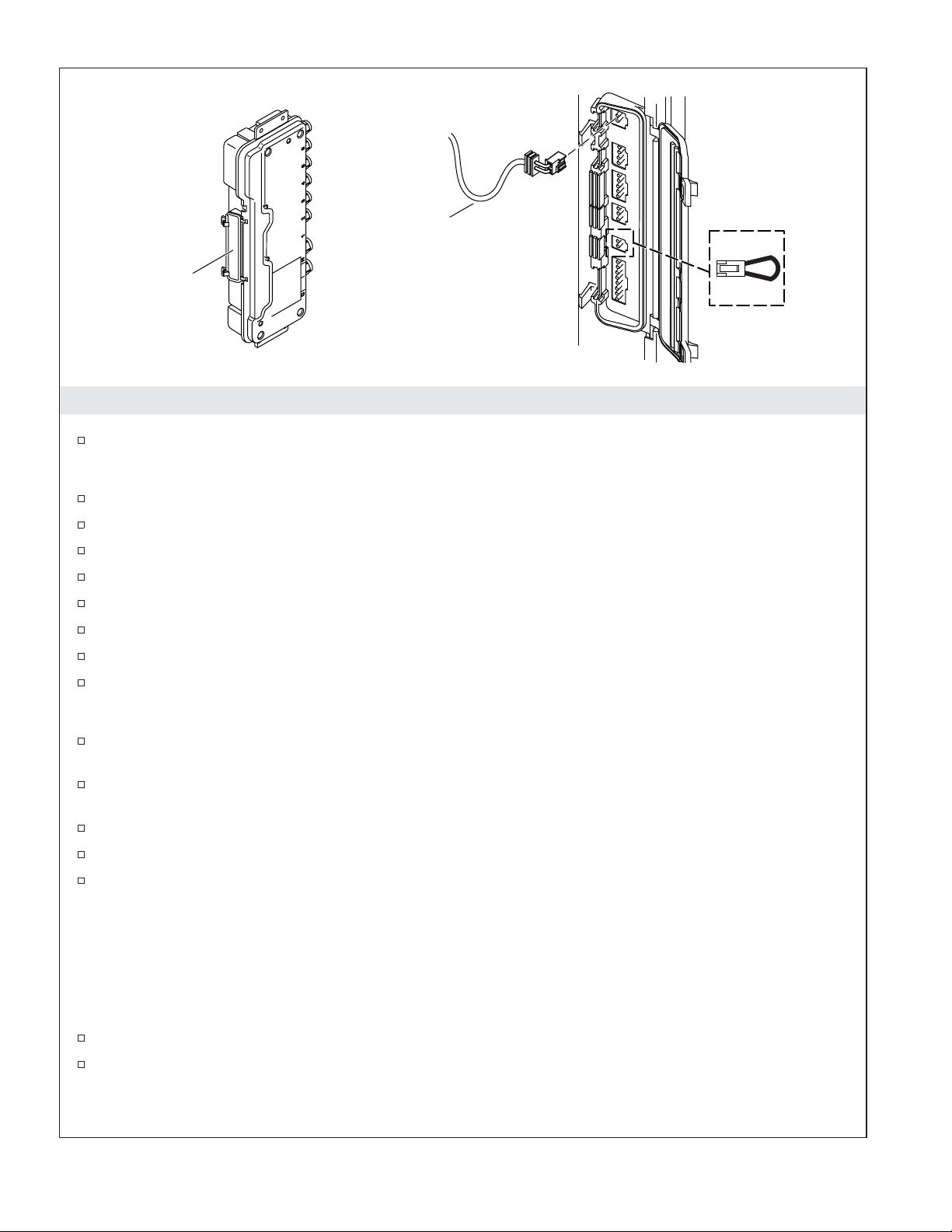

10. Complete the Installation

If an interface is not available, proceed to the ″Installation Checkout″ section, and ″Test for Leaks without an

Interface.″

NOTE: Make drip loops in all cables and cords.

Route the interface cable(s) in the wall from the valve location to the interface installation

location(s).

If not already installed, install the interface(s) according to the instructions packed with the product.

Connect the Cables

Press the clips to release and open the door on the valve.

To remove the door, slide the hinge side of the door in either direction until it slips free.

Connect the interface cable(s) to the valve.

Connect the power supply to the valve.

Verify all grommets are in place, then reinstall the door.

To close the door, press on the tabs until the clips snap in place.

Kohler Co. 15 1043183-2-E

Power

Supply

Door

11. Installation Checkout

Turn on the water supply to the valve.

Test for Leaks without an Interface or Controller

Disconnect the power from the valve.

Open the access door on the valve.

Verify the power supply cord is connected to the appropriate socket.

Connect the jumper to the valve, then reconnect the power.

Wait 10 seconds for the valve to initialize; the outlets will activate.

Check all connections for leaks.

Disconnect the power, then remove the jumper.

Close the access door, then reconnect the power to the valve.

Jumper

Test for Proper Operation (Requires an Installed Interface or Controller)

Turn on the main power supply. You should hear the valve power up and the user interface will be

lit.

If not already completed, set up the interface. Refer to the ″Homeowners Guide″ or ″Users Guide″

for the interface or controller for your system.

Use the interface to turn on the water outlets.

Check for leaks and make any adjustments as needed.

Verify that the water flow is sufficient for your showering needs.

Exercise the Valve (Requires an Installed Interface)

NOTE: Valves which have been recently installed, or have not been used for some time should be

exercised before running tests or setting the maximum temperature.

NOTE: The maximum water temperature to the outlets is limited to 120°F (49°C). The valve will

automatically shut down if the temperature exceeds 120°F (49°C).

Verify that the hot and cold water supply lines are connected to appropriate valve inlets.

Using the interface, adjust the temperature from cold to hot and back to cold several times, pausing

for 30 seconds at each extreme.

Check Component Functions

1043183-2-E 16 Kohler Co.

Installation Checkout (cont.)

Using the interface, turn on each component separately to verify that the selected component

matches the component running. Make any corrections or adjustments as needed.

Turn off the system.

Kohler Co. 17 1043183-2-E

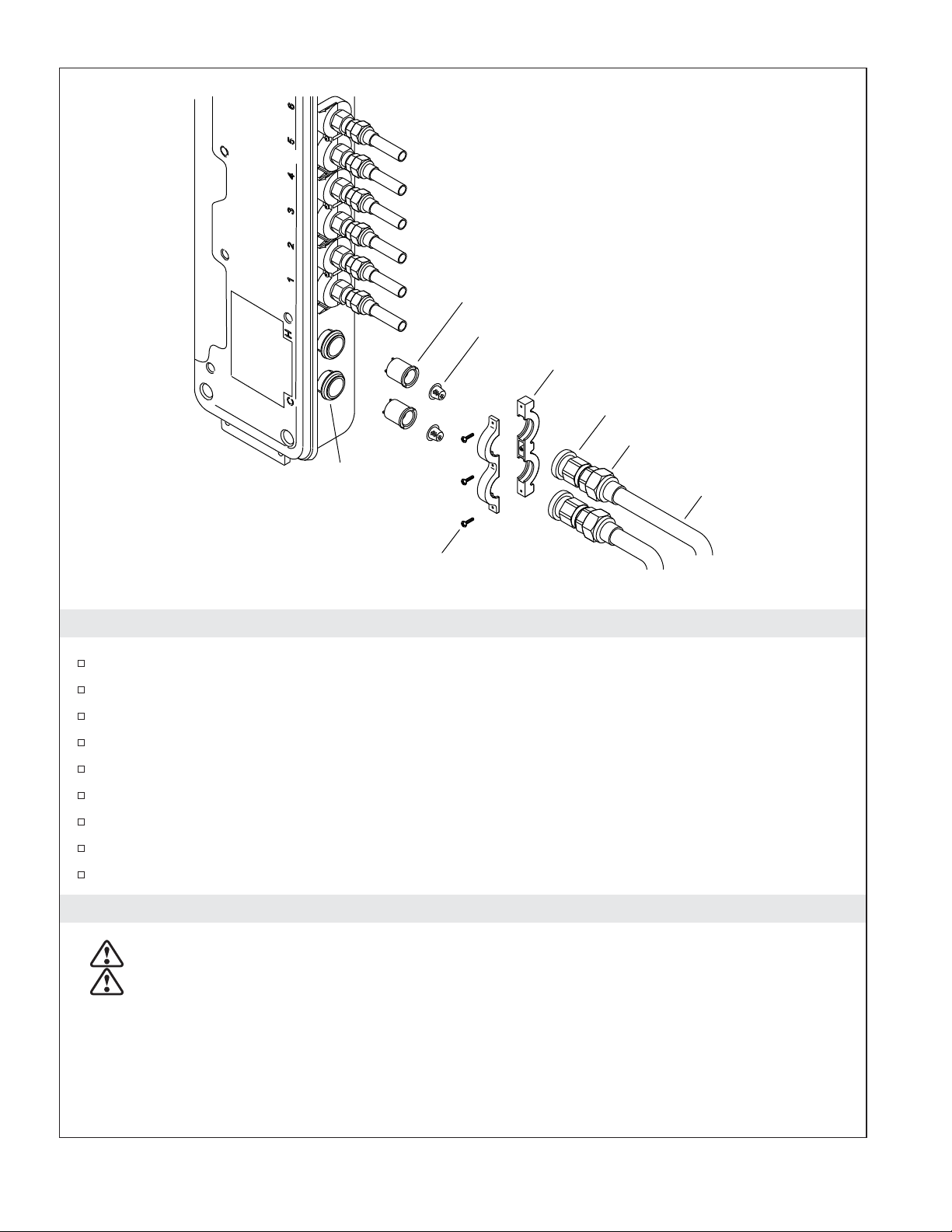

Check Valve

Screen

Inlet Clamp

Adapter

Union Connection

O-Ring

Screw

12. Clean the Inlet Screens

Disconnect the power and turn off the water supply.

Disconnect the removable pipe segment.

Remove the screws and inlet clamp.

Remove the adapters from the valve inlets.

Gently pull the check valves from the valve inlets.

Remove the screens from the check valves.

Clean the screens to remove any dirt or debris.

Rinse or replace the check valves and screens.

Reassemble the inlet connections.

Troubleshooting

Removable

Pipe Segment

WARNING: Risk of electric shock. Disconnect power before servicing.

CAUTION: Risk of personal injury. The valve may contain hot water; be careful when draining

any residual water.

NOTICE: Valve maintenance should be performed by a KOHLER Authorized Service Representative.

NOTE: For service parts information, visit your product page at www.kohler.com/serviceparts.

This troubleshooting guide is for general aid only. For service and installation issues or concerns, call

1-800-4KOHLER.

1043183-2-E 18 Kohler Co.

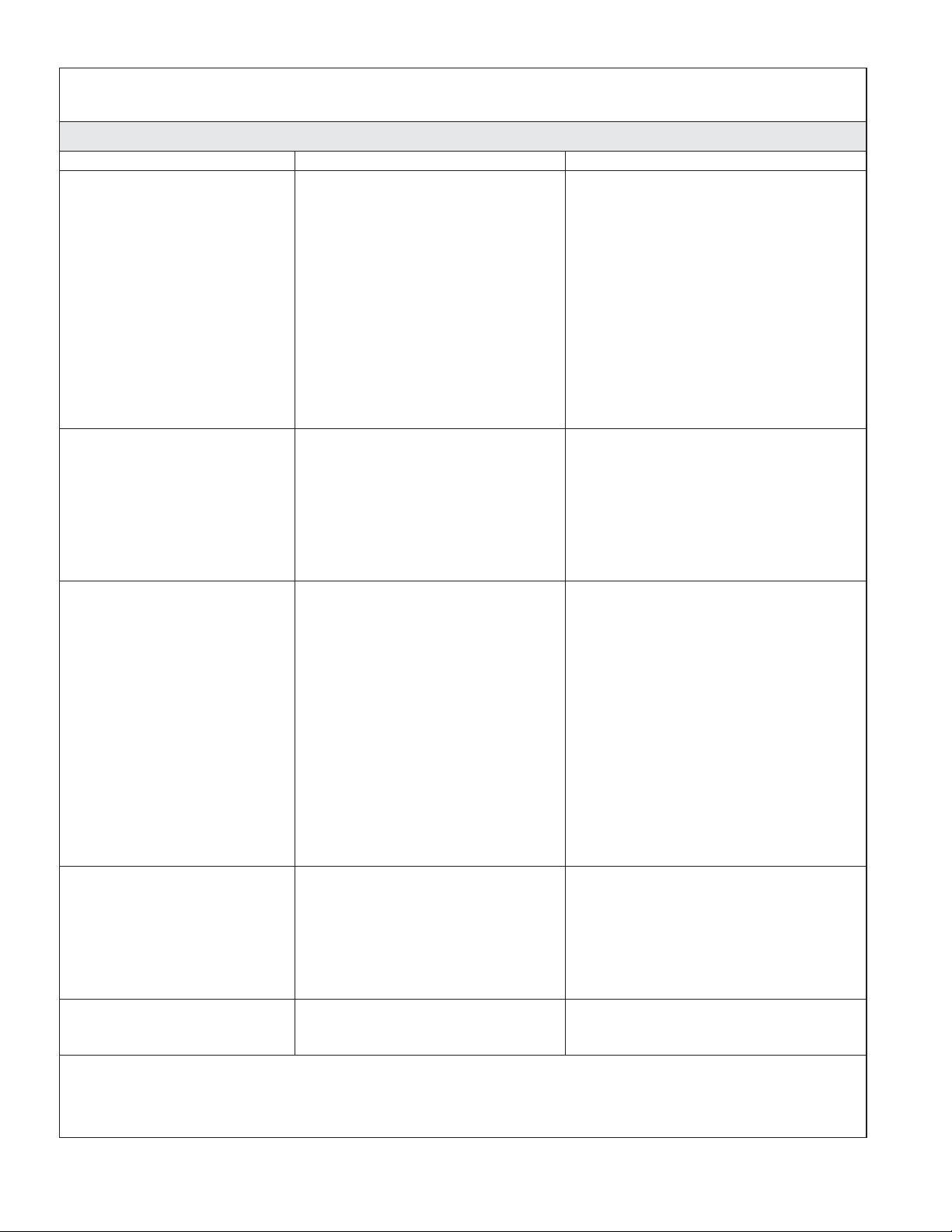

Troubleshooting (cont.)

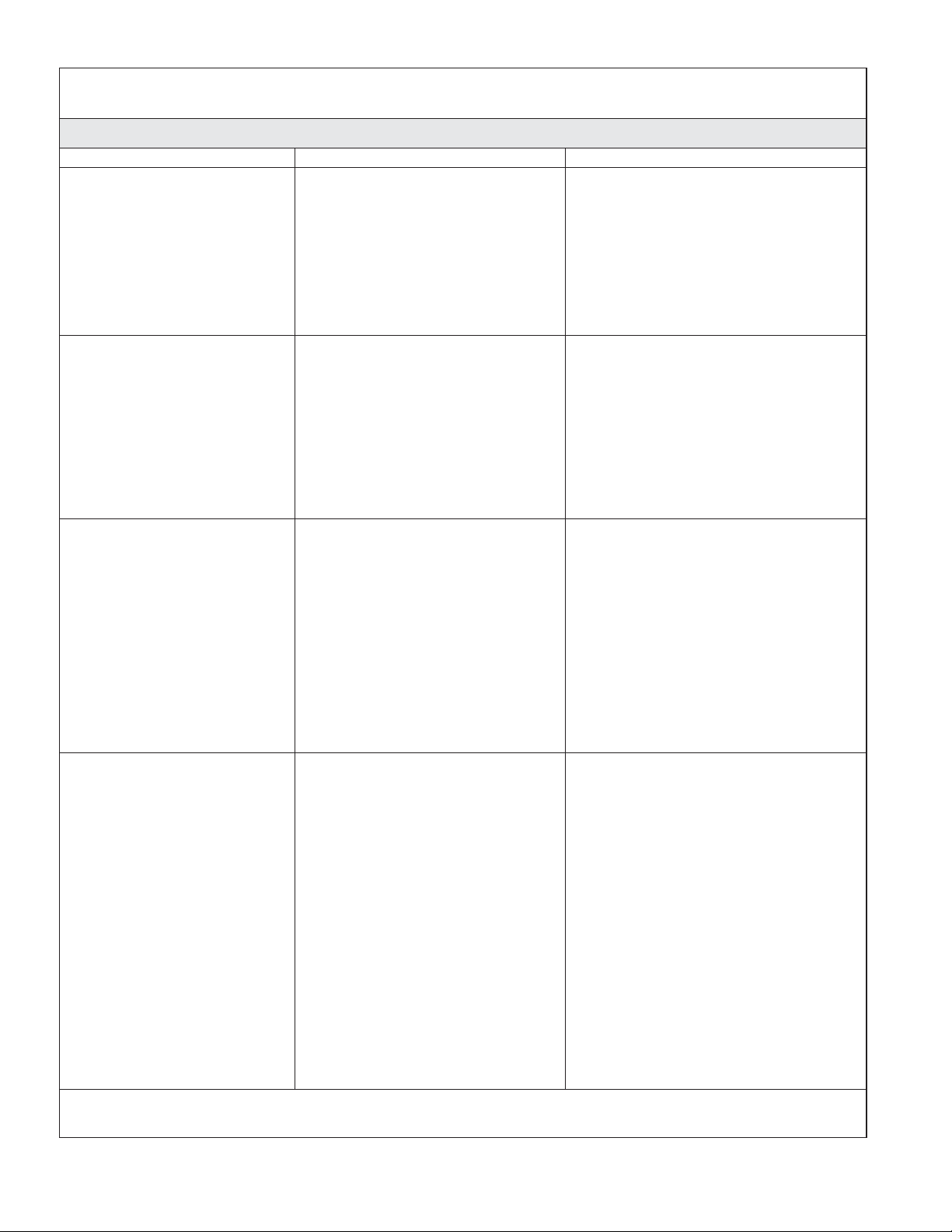

Troubleshooting Table

Symptoms Probable Cause Recommended Action

1. Valve will not turn on. A. Power supply is not plugged

2. The interface power

indicator is lit but the

system does not turn on.

3. The interface functions

normally but no water

flows from the

components.

4. Maximum blend

temperature too hot or

too cold.

5. Continuous flow. A. System will not switch off. A. Turn off the water and power

into the outlet.

B. Power supply connection to the

valve may be loose or

disconnected.

C. Interface/data cable connections

may be loose or disconnected.

D. Circuit breaker has been

tripped.

E. The valve memory may require

resetting.

F. If none of the recommended

actions for the above issues

correct the symptom, the valve

or interface requires servicing.

A. Interface cable connections may

be loose.

B. The interface cable or coupler is

damaged.

C. If the above recommended

action does not correct the

symptom, the interface or valve

requires servicing.

A. Inlet/outlet fittings may be

blocked.

B. Hot and cold water supplies are

not turned on.

C. The valve memory may require

resetting.

D. System error. D. Check the user interface or

E. If none of the recommended

actions for the above issues

correct the symptom, the valve

requires servicing.

A. Incorrect maximum temperature

setting.

B. If the above recommended

action does not correct the

symptom, the interface or valve

requires servicing.

A. Plug the power supply into the

outlet.

B. Check power supply connections to

the valve and reconnect if needed.

C. Check interface/data cable

connections, connect if needed.

D. Reset the circuit breaker.

E. Disconnect and reconnect the

power supply from the valve.

F. Contact your Kohler Co. authorized

service representative.

A. Check all interface cable

connections.

B. Replace the cable or coupler.

C. Contact your Kohler Co. authorized

service representative.

A. Check the inlets and outlets for

blockage or debris. Clean the inlet

screens. Refer to the ″Clean the

Inlet Screens″ section.

B. Turn on the water supply to the

valve.

C. Disconnect and reconnect the

power supply from the valve.

controller for an error code. Refer

to the interface/controller

Homeowners Guide or Users

Guide.

E. Contact your Kohler Co. authorized

service representative.

A. Set the maximum temperature.

Refer to the interface/controller

Homeowners Guide or Users

Guide.

B. Contact your authorized Kohler

service representative.

supply and contact your Kohler Co.

authorized service representative.

Kohler Co. 19 1043183-2-E

Troubleshooting (cont.)

Troubleshooting Table

Symptoms Probable Cause Recommended Action

6. Massage mode shuts

down but water continues

to run from

showerhead(s).

7. Only cold water flows

from the outlets.

8. Fluctuating or reduced

flow rate. Valve is

functioning properly.

9. Blend temperature drift or

temperature cycling.

A. Unequal flow rates between

valve outlets.

B. Fluctuation of inlet pressure. B. Install pressure regulators in the

C. Pressure difference greater than

5 psi (34.5 kPa) between the hot

and cold supply lines.

A. Hot water supply is either not

turned on or not connected to

the valve inlet.

B. Hot water inlet is blocked. B. Check the hot water inlet screen for

C. If none of the recommended

actions for the above issues

correct the symptom, the valve

requires servicing.

A. Inlet/outlet fittings may be

blocked.

B. Water outlet pressure is low. B. Check that the flow rate is at or

C. Fluctuating flow. C. Verify that the dynamic inlet

D. If none of the recommended

actions for the above issues

correct the symptom, the valve

requires servicing.

A. Inlet temperature differential is

too great.

B. Hot water pressure too high. B. Install pressure-reducing check

C. Pressure difference greater than

5 psi (34.5 kPa) between the hot

and cold supply lines.

D. Flow rate too low.

E. If none of the recommended

actions for the above issues

correct the symptom, the valve

requires servicing.

A. Verify the installation has one

bodyspray per valve outlet and

uses bodysprays with the same

flow rate. If needed, contact the

installer to revise the installation.

supply lines.

C. Install pressure regulators to bring

the supplies within 5 psi (34.5 kPa)

of each other.

A. Check if the hot water supply is

turned on and connected to the

valve inlet.

blockage. Clean or replace the inlet

screen. Refer to the Valve

Homeowners Guide.

C. Contact your Kohler Co. authorized

service representative.

A. Check the inlets and outlets for

blockage or debris. Clean the inlet

screens. Refer to the ″Clean the

Inlet Screens″ section.

above the minimum rate required.

Refer to ″Specifications″ section.

pressures are within specifications.

Refer to ″Specifications″ section.

D. Contact your Kohler Co. authorized

service representative.

A. Lower the hot water temperature to

120°F (49°C). Maximum

temperature difference between hot

and cold should be 70°F (21°C) or

less.

valve on the hot supply to achieve

equal or slight less pressure than

the cold supply.

C. Install pressure regulators to bring

the supplies within 5 psi (34.5 kPa)

of each other.

D. Check the inlets and outlets for

blockage or debris. Clean the inlet

screens. Refer to the ″Clean the

Inlet Screens″ section.

E. Contact your Kohler Co. authorized

service representative.

1043183-2-E 20 Kohler Co.

Loading...

Loading...