KOHLER K-557 Installation Manual

Installation Guide

Three-Port Thermostatic Valve

K-557

M product numbers are for Mexico (i.e. K-12345M)

Los números de productos seguidos de M corresponden a México

(Ej. K-12345M)

Français, page ″Français-1″

Español, página ″Español-1″

1217542-2-B

IMPORTANT INSTRUCTIONS

WARNING: When using electrical products, basic precautions should always be followed,

including the following:

WARNING: Risk of electric shock. Connect only to a circuit protected by a Ground-Fault

Circuit-Interrupter (GFCI)*. Grounding is required. The unit should be installed and grounded by a

qualified service representative.

WARNING: Risk of electric shock. A qualified electrician should route all electrical wiring.

WARNING: Risk of electric shock. Disconnect power before servicing.

WARNING: Unauthorized modification may cause poor performance of the valve. Do not make

modifications to the valve as this could adversely affect the performance of the valve and void the

warranty. Kohler Co. shall not be liable under its warranty or otherwise for personal injury or

damage caused by any such unauthorized modification.

WARNING: Risk of injury or property damage. Please read all instructions thoroughly before

beginning installation.

NOTICE: Follow all plumbing, electrical, and building codes.

NOTICE: Provide generous, unrestricted service access to the valve. Provide access for servicing the

valve and interface. This access must be located immediately next to the valve. Refer to the roughing-in

information.

NOTICE: The valve manufacturer’s minimum flow rate is 1.6 gal/min (6 l/min).

*Outside North America, this device may be known as a Residual Current Device (RCD).

Specifications

Pressures

Maximum Static Pressure 125 psi, 862 kPa, 8.6 bar

Supply Pressure Differential* Max 5 psi, 34.5 kPa, 0.34 bar (Equal pressures recommended.)

Minimum Flow Rate 1.6 gal/min (Less than 72 psi dynamic pressure.)

Temperatures

Programmable Temperature Max 120°F (49°C) Min 86°F (30°C) Full cold may also be selected.

Default Temperature at Start-up 100°F (38°C)

Minimum Mixed Temperature

Differential from Hot Supply

Temperature Stability at Recommended

Supply Conditions

Ambient Temperature Greater than 34°F (1°C), Max 104°F (40°C)

Maximum Relative Humidity 95% non-condensing

Electrical

Electrical Rating 120 V, 15 A, 60 Hz

User Interface Cable Length (supplied) 20 ft (6.1 m)

6 l/min (Less than 500 kPa maintaining pressure.)

2.1 gal/min (Greater than 72 psi dynamic pressure.)

8 l/min (Greater than 500 kPa maintaining pressure.)

3.6°F (2°C)

+/- 1.6°F (1°C)

*In commercial applications where there is a large difference in hot and cold supply pressures or frequent

fluctuation in either supply line is anticipated, it is strongly recommended that pressure regulators be

installed.

1217542-2-B 2 Kohler Co.

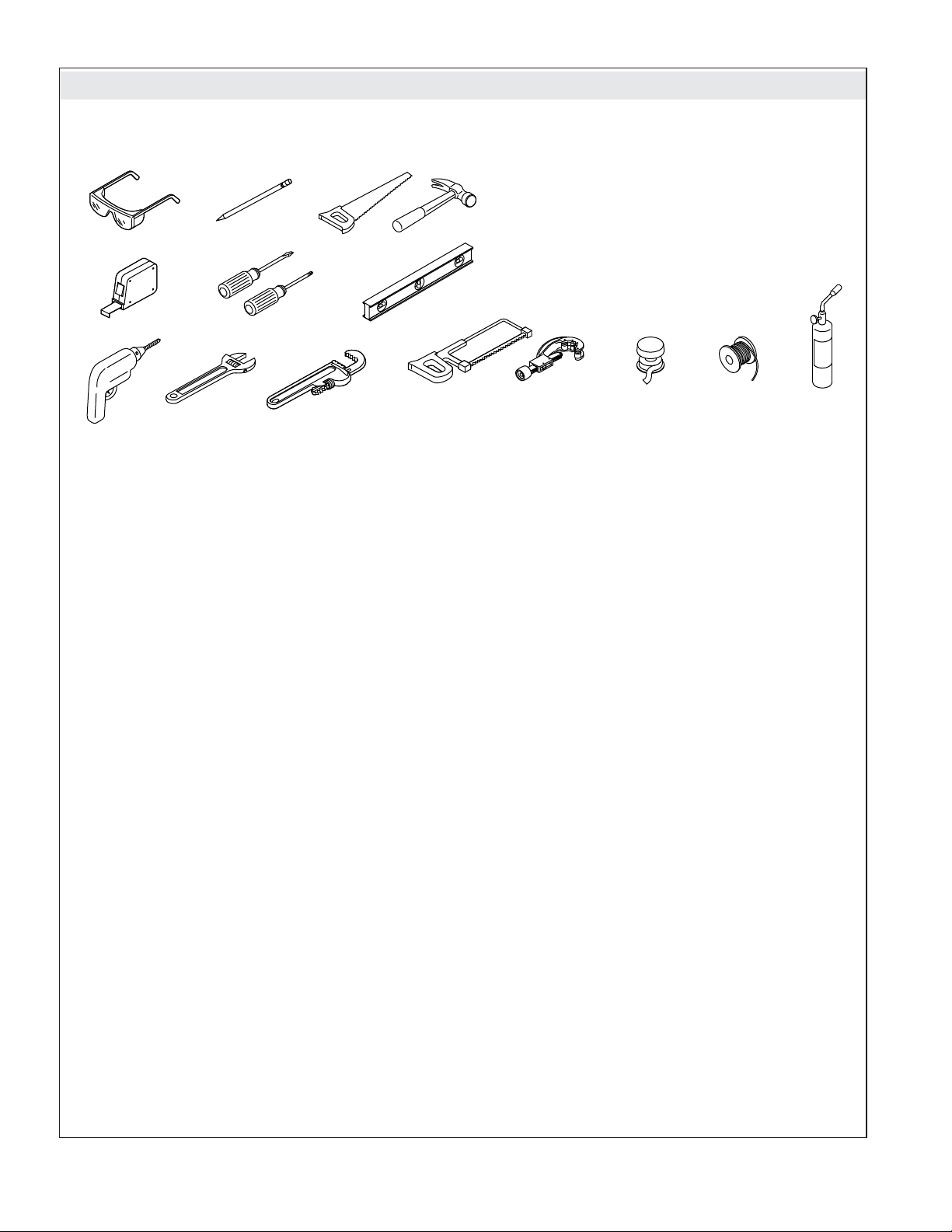

Tools and Materials

Plus:

• (2) 1/2" Union Connectors

• Wood and Framing Materials

• PEX Tubing, Copper Tubing, or PVC

• (2) Water Hammer Arrestors (Recommended)

• (2) Supply Shut-Off Valves

Hacksaw or Tube Cutter Sealant

Tape

Solder Propane

Torch

Kohler Co. 3 1217542-2-B

1-1/2"

(38 mm)

2-11/16"

(68 mm)

12" (305 mm)

15-1/8" (384 mm)

12-1/2"

(318 mm)

9-1/2"

(241 mm)

3-3/8"

(86 mm)

8-1/16" (205 mm)

3/4"

(19 mm)

1-5/16"

(33 mm)

1-3/8"

(35 mm)

2-3/8"

(60 mm)

2-3/8"

(60 mm)

2"

(51 mm)

1-13/16

(46 mm)

1"

(25 mm)

10-5/16" (262 mm)

11-5/8" (295 mm)

13-3/8" (340 mm)

Roughing-In

Before You Begin

NOTICE: Do not install the valve under a whirlpool surround or any location where the temperature may

exceed 104°F (40°C). The valve and its integrated power supply is rated to operate in temperatures up to

104°F (40°C).

NOTICE: Do not apply excessive heat near the valve or apply flux or acids directly onto the valve. This

valve contains plastic and rubber components which will melt if heat is directly applied.

NOTICE: Do not apply petroleum-based lubricants to the valve components. Doing so will damage the

valve components.

NOTICE: Do not use oil-based, non-setting compounds, such as plumbers putty, on the threaded

connections.

NOTICE: Do not remove the check valves from the inlets as this can damage the product.

NOTICE: If the valve will be used for a bath/shower application, the bath fill supply line must be routed

from the #1 outlet port.

Read these instructions and determine the locations of all required components before beginning

installation.

For optimum performance, 1/2″ dedicated water supply lines are recommended.

When possible, install the valve before installing the interface(s).

If possible, flush all piping thoroughly before installing the valve. If the pipes are flushed after the

valve is installed, clean the inlet screens before using the system.

1217542-2-B 4 Kohler Co.

Before You Begin (cont.)

This valve is not intended for single- or dual-outlet use.

A qualified electrician should install a 120 V GFCI electrical outlet, within the stud framing, in close

proximity to the valve.

If possible, install the electrical outlet prior to installing the valve.

Kohler Co. 5 1217542-2-B

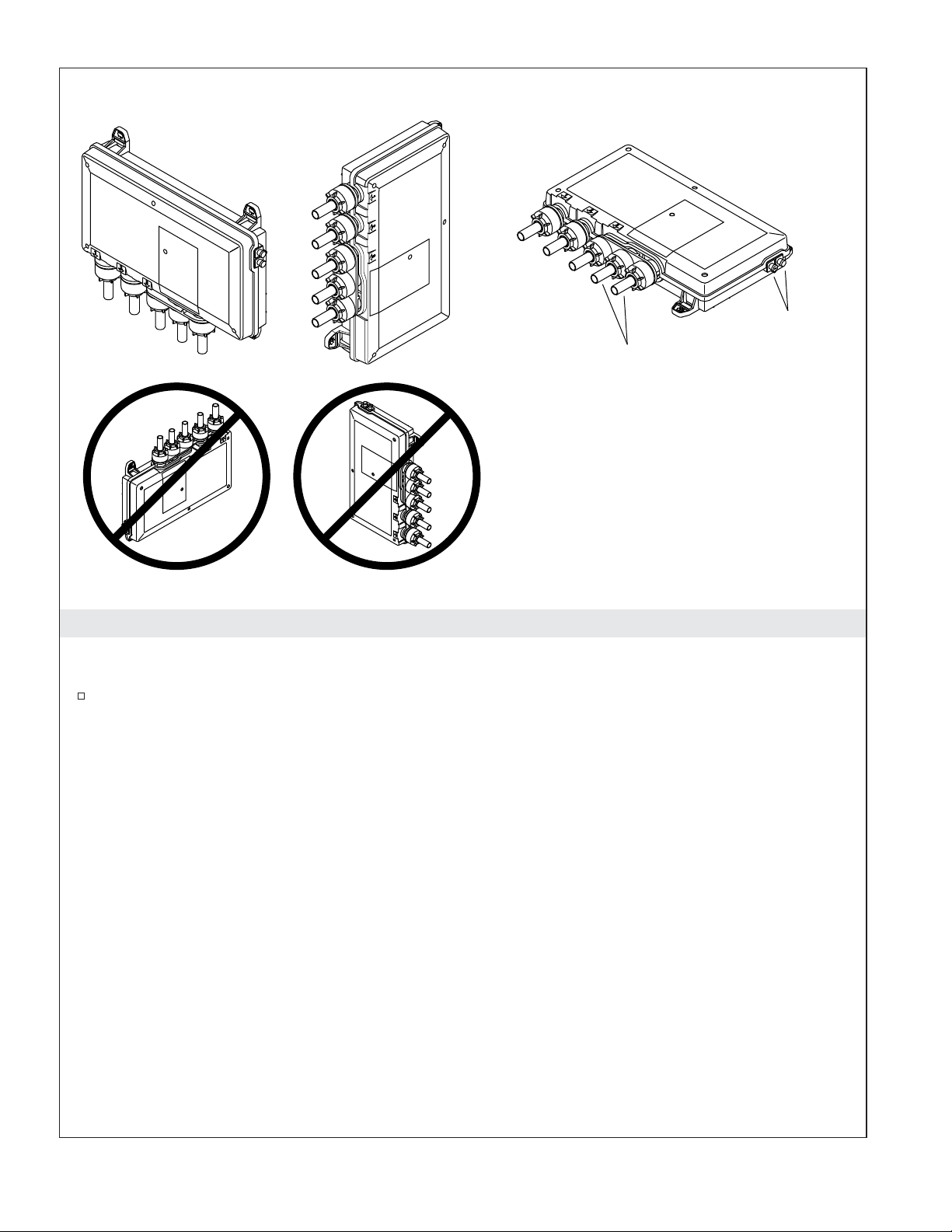

Mounting on a Horizontal SurfaceMounting on a Vertical Surface

Cable

Sockets

Inlets

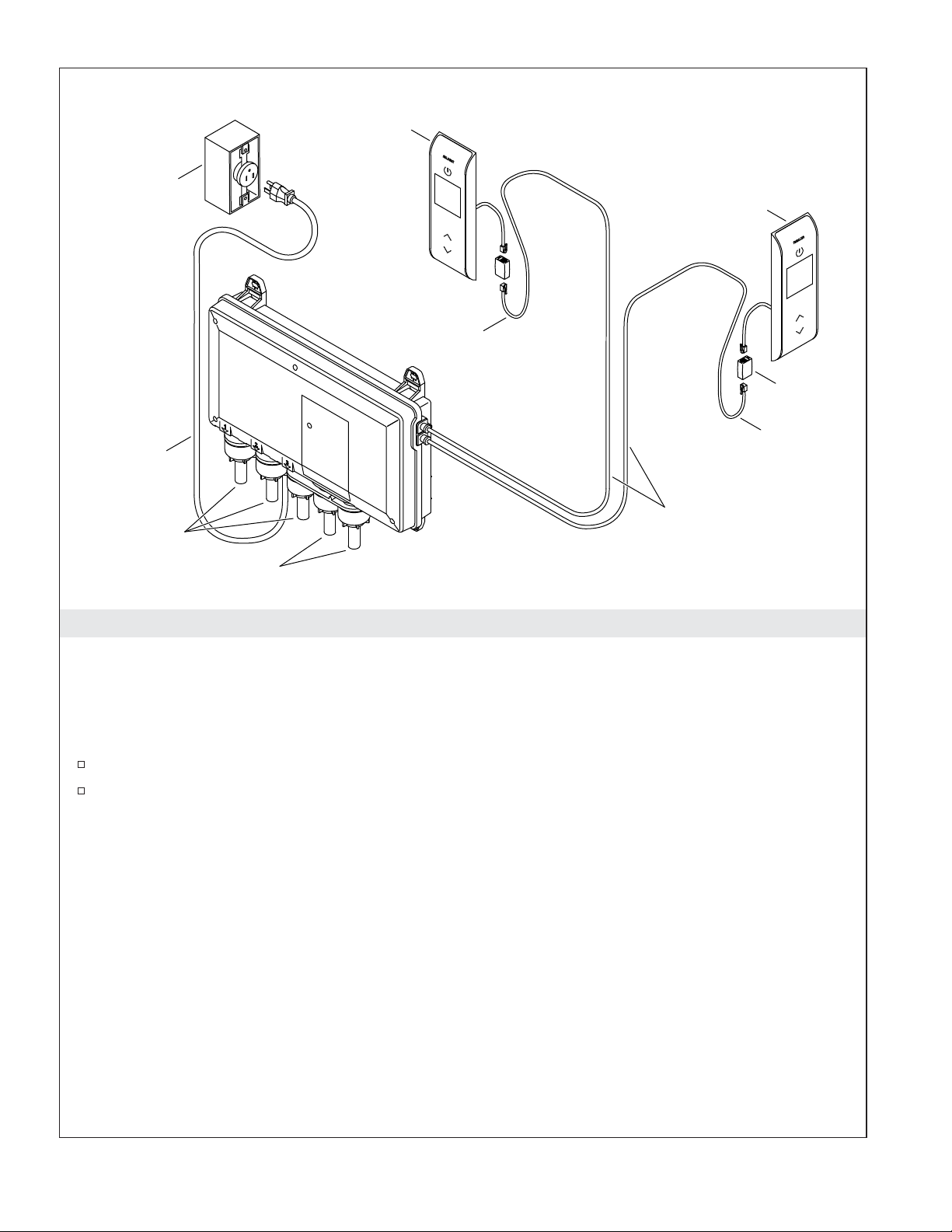

1. Mounting Configurations

NOTICE: Do not mount the valve with the inlets located at the top. Doing so will damage this product.

Vertical and horizontal mounting options are shown above. Do not mount the valve with the inlets

or cable sockets pointing up.

1217542-2-B 6 Kohler Co.

Outlet

Power

Cord

Outlets

Interface

NOTE: Only one interface, installed

inside the shower, is required.

Interface

Drip

Loop

Coupler

Drip Loop

20' (6.1 m) Cables

Supply Inlets

2. Plan the Component Locations

NOTICE: If the valve will be used for a bath/shower application, the bath fill supply line must be routed

from the #1 outlet port.

NOTE: Only one interface is required, located inside the showering enclosure. A second interface can be

installed outside the showering enclosure. The interfaces are identical and either can be used for the

primary and secondary connection.

Determine the locations of all required components before beginning installation.

When routing piping, the numbers marked at each valve outlet must correspond to the appropriate

showering component for pre-programmed or custom showering experiences to function properly.

Kohler Co. 7 1217542-2-B

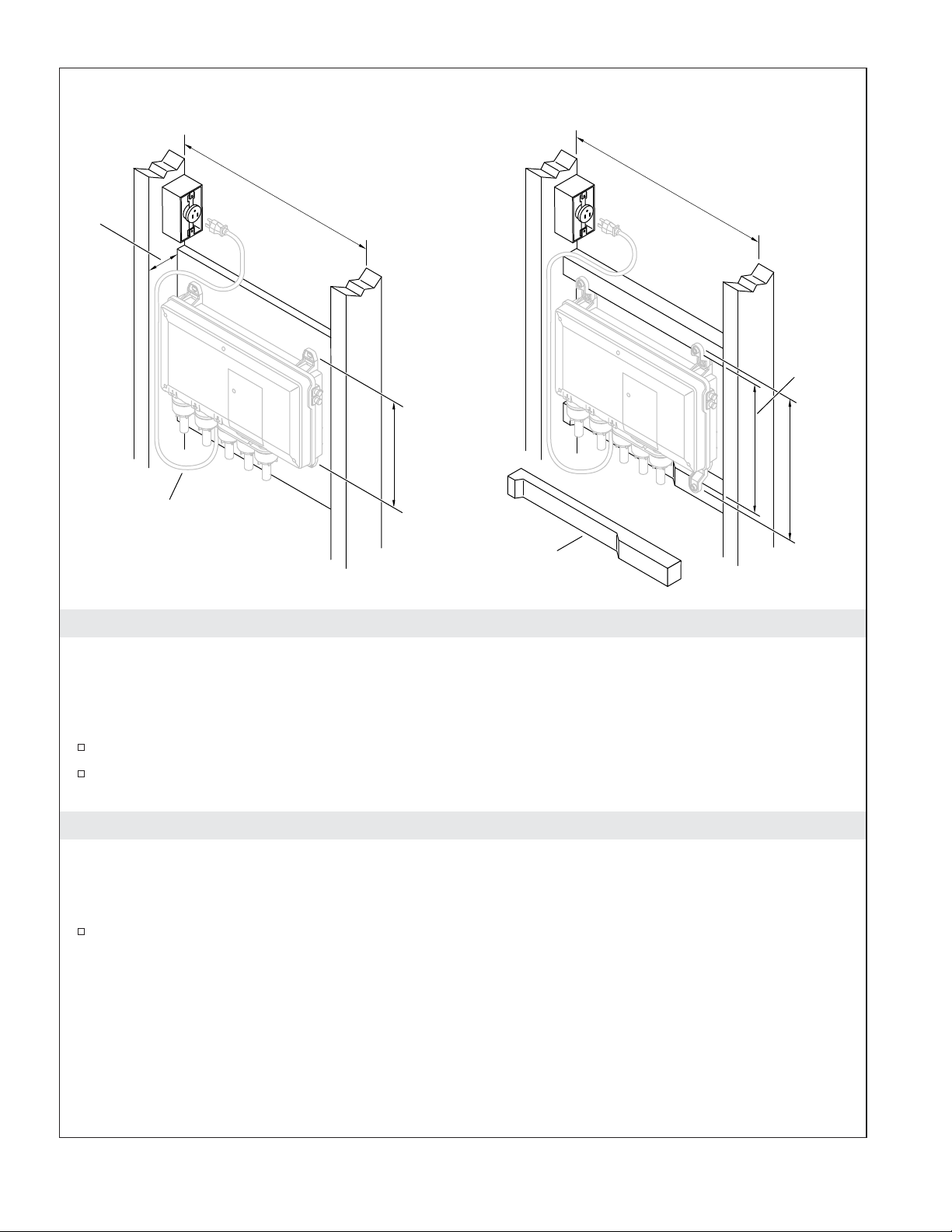

Cross Brace MountBoard Mount

2-3/4"

(70 mm)

Min

Drip Loop

18"

(457 mm) Min

Place the outlet

higher than

the valve.

9-1/2"

(241 mm)

Notch bottom brace.

18"

(457 mm) Min

11-5/8"

(295 mm)

12-1/2"

(318 mm)

3. Prepare the Site

NOTICE: The valve will not fit within a standard stud cavity. A minimum 18″ (457 mm) x 18″ (457 mm)

cavity is required.

NOTE: Horizontal wall installation is shown. The valve can also be wall-mounted vertically or mounted

to a horizontal surface. Refer to the ″Mounting Configurations″ section.

Construct a minimum 18″ (457 mm) wide 2x4 stud cavity.

Install adequate bracing for mounting the valve. Notch the bracing as needed to accommodate the

inlets and outlets.

4. Install the Electrical Outlet

NOTICE: Do not install the valve under a whirlpool surround or any location where the temperature may

exceed 104°F (40°C). The valve and its integrated power supply is rated to operate in temperatures up to

104°F (40°C).

Install a 120 V GFCI electrical outlet within the stud framing, in close proximity to the valve. Locate

the outlet above the valve.

1217542-2-B 8 Kohler Co.

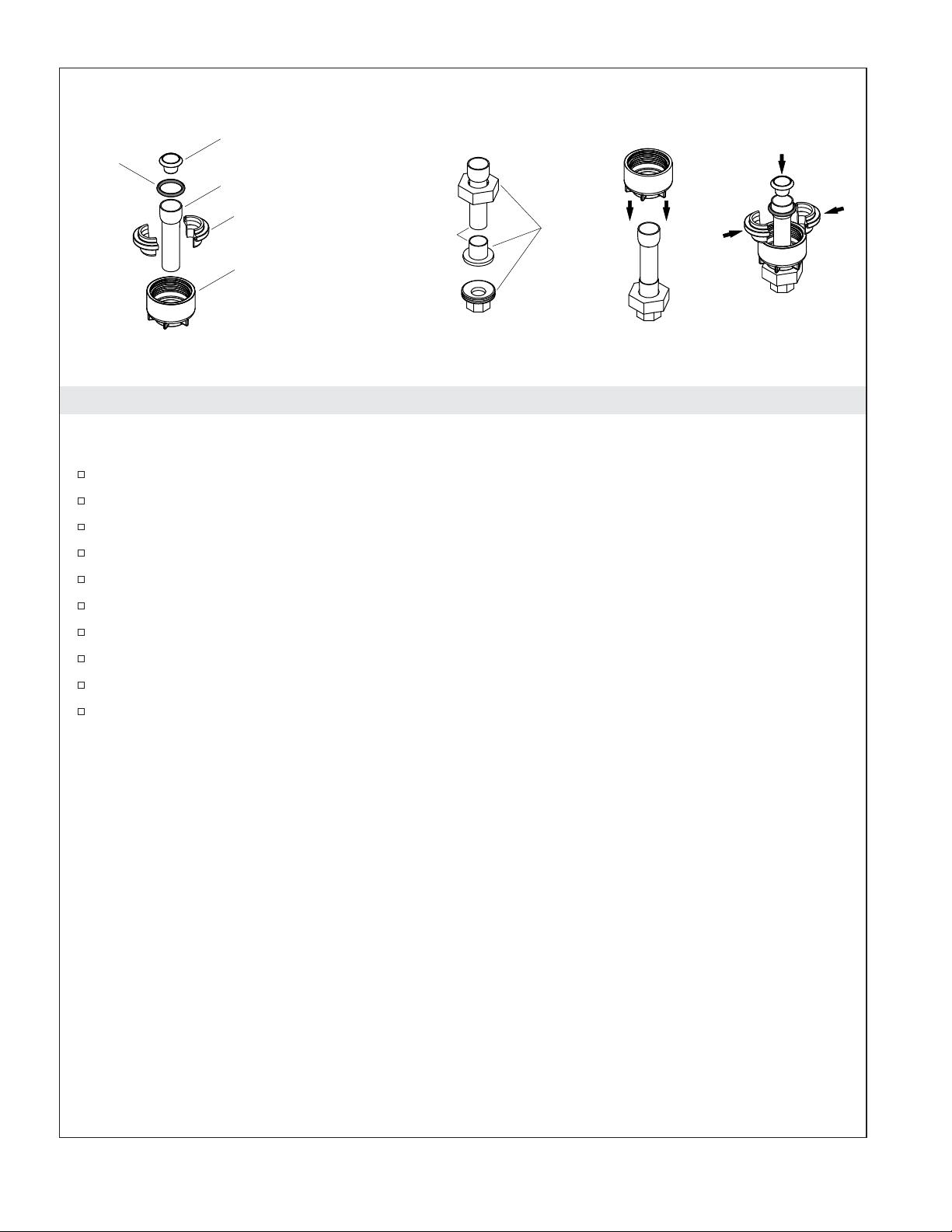

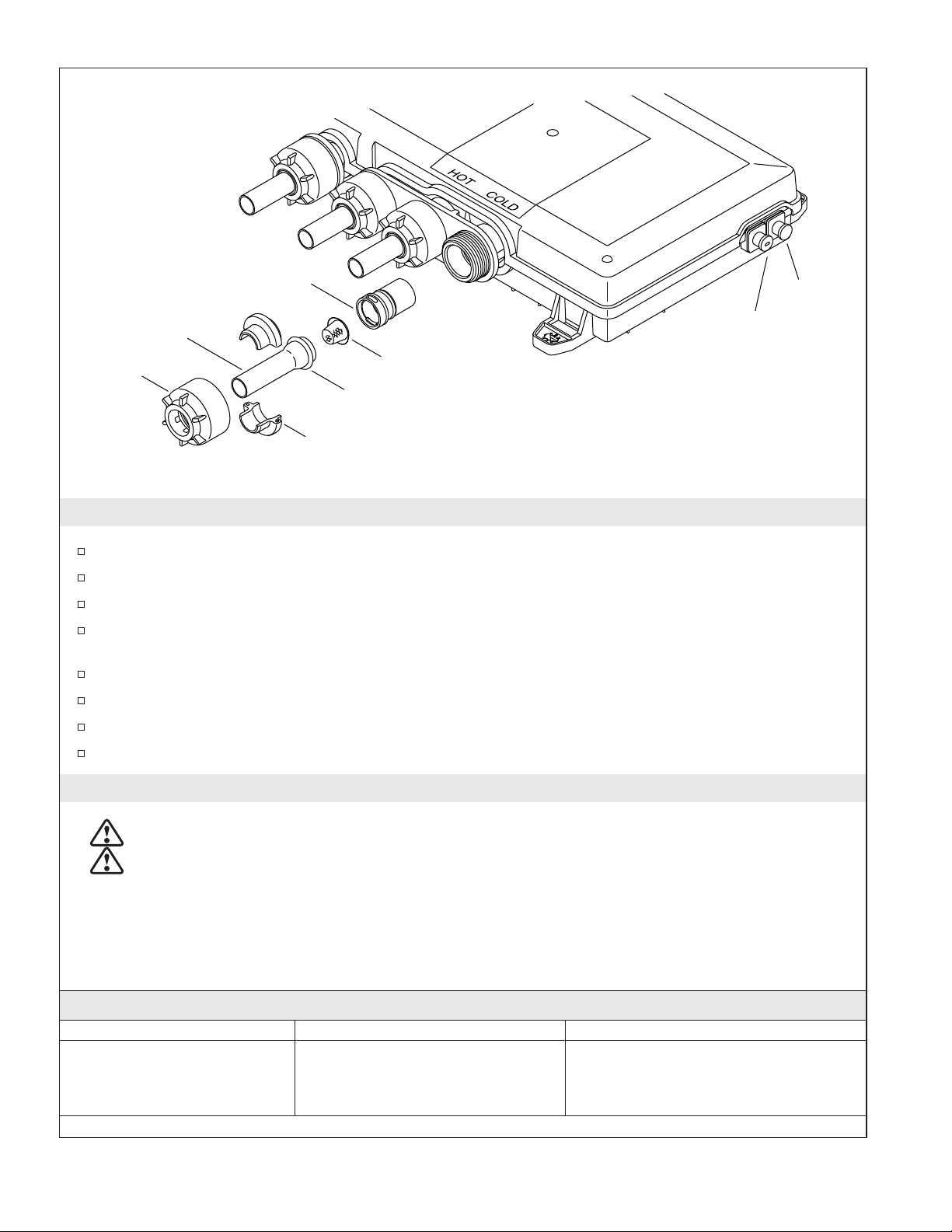

O-Ring

Screen (Inlets Only)

Inlet/Outlet Tube

Adapter Lock

Solder this connection.

Adapter Nut

1/2" Union

5. Assemble the Adapters and Unions

NOTICE: Do not apply excessive heat near the valve or apply flux or acids directly onto the valve. This

valve contains plastic and rubber components which will melt if heat is directly applied.

Disassemble the adapter. Ensure all rubber and plastic components are removed.

Slide the union nut onto the inlet/outlet tube.

Solder the inlet/outlet tube to the union. Allow to cool completely.

Assemble the union.

Slide the adapter nut onto the inlet/outlet tube.

Assemble the adapter lock onto the inlet/outet tube and slide the assembly into the adapter nut.

Slide the O-ring onto the inlet/outlet tube.

For inlet tubes only: Insert the screen into the end of the inlet tube.

Reinstall the adapter assembly to the valve.

Repeat for all inlet/outlet tubes as required.

Kohler Co. 9 1217542-2-B

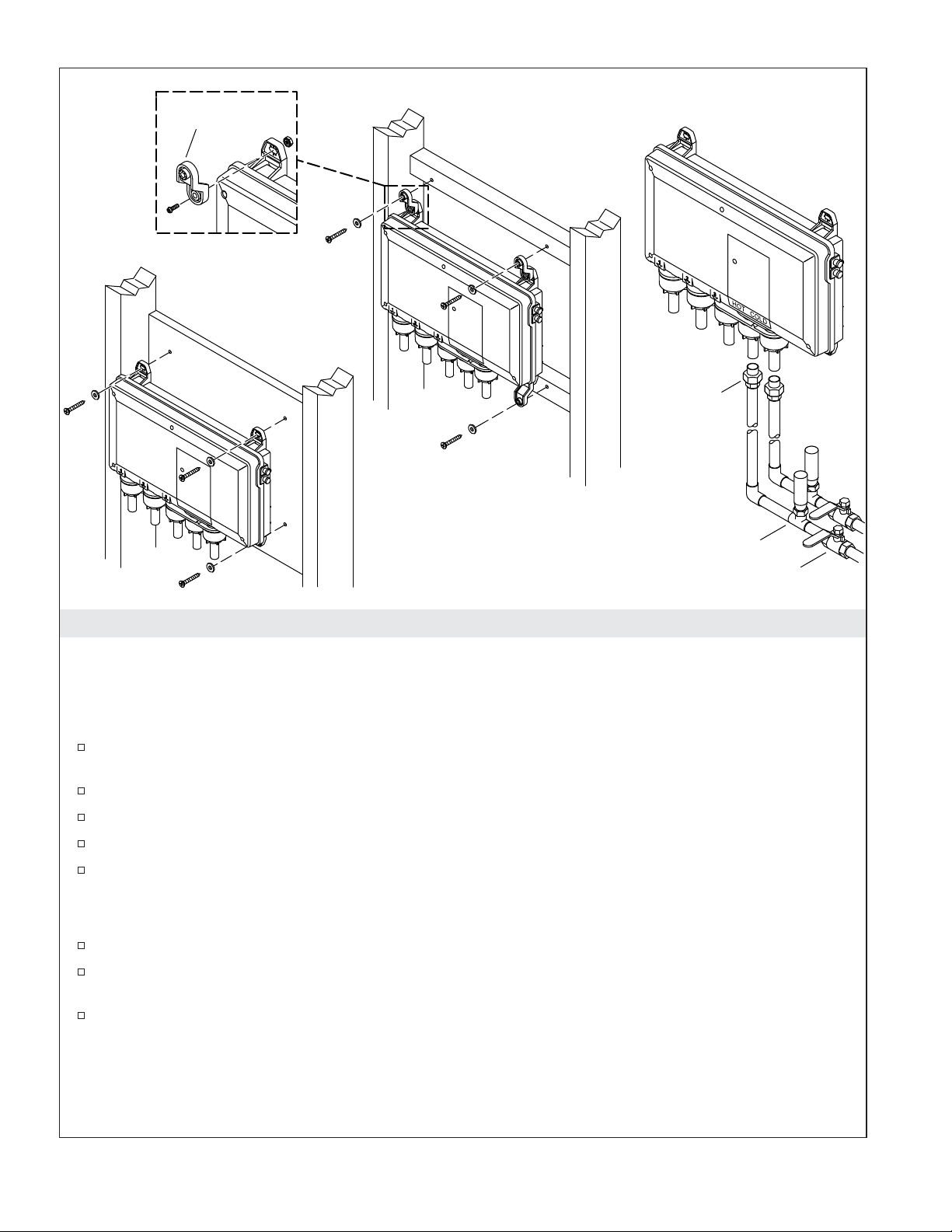

Offset Foot

Board Mount

Cross Brace Mount

1/2" Union

Water Hammer Arrestor

Shut-Off Valve

6. Install the Valve

NOTICE: Do not apply excessive heat near the valve or apply flux or acids directly onto the valve. This

valve contains plastic and rubber components which will melt if heat is directly applied.

IMPORTANT! If your water supply has high amounts of particulates, install wye strainers in the supply

lines.

Route 1/2″ dedicated water supply lines. Use unions to install removable pipe segments to the

valve inlets to allow access for periodic cleaning of the inlet screens.

Install shut-off valves and water hammer arrestors in the supply lines prior to the valve.

Hold the valve up to the installation location. Verify fit and mark the hole locations.

Pre-drill the holes.

Secure the valve with the washers and screws. Do not overtighten.

IMPORTANT! Make sure the shower components are connected to the corresponding numbered outlet(s)

on the valve.

Route the piping from the valve outlets to the appropriate shower components.

Connect the hot and cold supply lines to the appropriate valve inlets. Hot is red and marked with

″HOT,″ cold is blue and marked with ″COLD.″

Secure all piping to the framing.

1217542-2-B 10 Kohler Co.

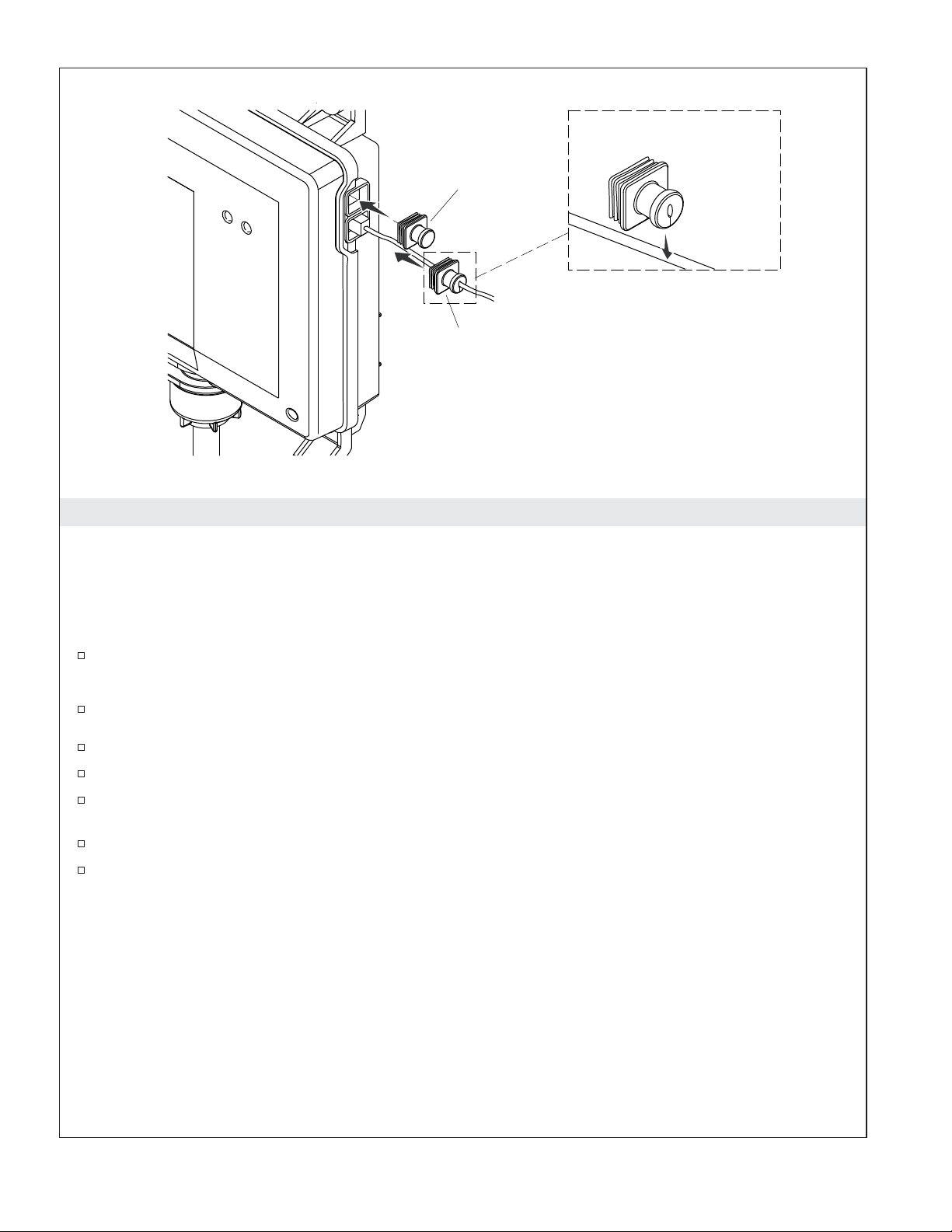

Slide the split boot onto the

interface cable.

Solid Boot

Split Boot

7. Complete the Installation

If an interface is not available, proceed to the ″Installation Checkout″ section, and ″Test for Leaks without an

Interface.″

NOTICE: Do not plug in the power cord until all interface cables are connected.

NOTE: Make drip loops in all cables and cords.

Route the interface cable(s) in the wall from the valve location to the interface installation

location(s).

If not already installed, install the interface(s) according to the instructions packed with the product.

Attach a split boot to each interface cable.

Connect the interface cable(s) to the valve.

Press the boot over the connection and into the valve socket. If only one interface is installed, insert

a solid boot into the unused socket.

Verify there is power to the 120 V GFCI electrical outlet.

Plug the power cord into the outlet.

Kohler Co. 11 1217542-2-B

8. Installation Checkout

Turn on the water supply to the valve.

Test for Leaks without an Interface

Disconnect the power from the valve.

Connect the jumper to the valve, then reconnect the power.

Wait 10 seconds for the valve to initialize; the outlets will activate.

Check all connections for leaks.

Disconnect the power, then remove the jumper.

Reconnect the power to the valve.

Jumper

Test for Proper Operation (Requires an Installed Interface)

Press the power icon on the user interface. The interface screen should be lit.

If not already completed, refer to the ″Digital Interface Homeowners Guide″ to set up the interface.

NOTE: For more information about using the interface, refer to the ″Digital Interface Homeowners

Guide.″

Use the interface to turn on the water outlets.

Check for leaks and make any adjustments as needed.

Verify that the water flow is sufficient for your showering needs.

Exercise the Valve (Requires an Installed Interface)

NOTE: Valves which have been recently installed, or have not been used for some time should be

exercised before running tests or setting the maximum temperature.

NOTE: The maximum water temperature to the outlets is limited to 120°F (49°C). The valve will

automatically shut down if the temperature exceeds 120°F (49°C).

Verify that the hot and cold water supply lines are connected to appropriate valve inlets.

Using the up and down arrow icons on the user interface, adjust the temperature from cold to hot

and back to cold several times, pausing for 30 seconds at each extreme.

1217542-2-B 12 Kohler Co.

Check Valve

Boot

Copper Tube

Nut

Seal

Screen

O-Ring

Clean the Inlet Screens

Disconnect the power and turn off the water supply.

Unthread the plastic nuts from the hot and cold inlets.

Remove the copper tubes. The O-ring and screen may be attached to the end of the tube.

If the screen remains in the check valve, use a small bladed screwdriver to gently pull the check

valve from the valve inlet.

Remove the screens from the copper tubes or check valves.

Clean the screens to remove any dirt or debris.

Rinse or replace the check valves and screens.

Reassemble the inlet connections.

Split

Boot

Troubleshooting

WARNING: Risk of electric shock. Disconnect power before servicing.

CAUTION: Risk of personal injury. The valve may contain hot water; be careful when draining

any residual water.

NOTICE: Valve maintenance should be performed by a KOHLER Authorized Service Representative.

NOTE: For service parts information, visit your product page at www.kohler.com.

This troubleshooting guide is for general aid only. For service and installation issues or concerns, call

1-800-4KOHLER.

Troubleshooting Table

Symptoms Probable Cause Recommended Action

1. Valve will not turn on. A. Valve is not plugged into the

outlet.

B. Interface cable connections may

be loose or disconnected.

Kohler Co. 13 1217542-2-B

A. Plug the valve into an outlet.

B. Check all interface cable

connections, connect if needed.

Troubleshooting (cont.)

Troubleshooting Table

Symptoms Probable Cause Recommended Action

C. Circuit breaker has been

tripped.

D. The valve memory may require

resetting.

E. A ″straight-through″ cable or

coupler was used to connect the

interface to the valve.

F. If none of the recommended

actions for the above issues

correct the symptom, the valve

or interface requires servicing.

2. The interface power

indicator is lit, but the

system will not turn on.

3. The interface functions

normally but no water

flows from the

components.

4. Maximum blend

temperature too hot or

too cold.

5. Continuous flow. A. System will not switch off. A. Turn off the water and power

6. Only cold water flows

from the outlets.

A. Interface cable connections may

be loose.

B. If the above recommended

action does not correct the

symptom, the interface or valve

requires servicing.

A. Valve outlets may be blocked. A. Check the valve outlets for

B. Fittings/Spray faces may be

blocked.

C. Hot and cold water supplies are

not turned on.

D. The valve memory may require

resetting.

E. System error. E. Check the user interface for an

F. If none of the recommended

actions for the above issues

correct the symptom, the valve

requires servicing.

A. Incorrect maximum temperature

setting.

B. If the above recommended

action does not correct the

symptom, the interface or valve

requires servicing.

B. Flow rate exceeds 10 gal/min

(45.5 l/min) from one outlet.

A. Hot water supply is either not

turned on or not connected to

the valve inlet.

B. Hot water inlet is blocked. B. Check the hot water inlet screen for

C. Reset the circuit breaker.

D. Disconnect and reconnect the valve

power cord from the electrical

outlet.

E. Connect the interface to the valve

using a ″cross-over″ cable and

coupler.

F. Contact your Kohler Co.

Authorized Service Representative.

A. Check all interface cable

connections, connect if needed.

B. Contact your Kohler Co.

Authorized Service Representative.

blockage or debris. Clean the outlet

screens.

B. Clean the spray faces and any

screens in your fittings.

C. Turn on the water supply to the

valve.

D. Disconnect and reconnect the valve

power cord from the electrical

outlet.

error code. Refer to the ″Error Code

Diagnosis″ section in the Digital

Interface Homeowners Guide.

F. Contact your Kohler Co.

Authorized Service Representative.

A. Refer to the ″

Maximum″ section in the Digital

Interface Homeowners Guide.

B. Contact your Kohler Co.

Authorized Service Representative.

supply and contact your Kohler Co.

Authorized Service Representative.

B. Ensure flow restrictors are installed

in both outlets.

A. Check if the hot water supply is

turned on and connected to the

valve inlet.

blockage. Clean or replace the inlet

screen.

Temperature – Set the

1217542-2-B 14 Kohler Co.

Troubleshooting (cont.)

Troubleshooting Table

Symptoms Probable Cause Recommended Action

7. Fluctuating or reduced

flow rate. Valve is

functioning properly.

8. Blend temperature drift or

temperature cycling.

9. Water leaking from the

valve.

CAUTION: Risk of

personal injury or

product damage. Turn off

the main power and

water supply.

10. Hot water only, the valve

shuts down.

C. The hot water supply is

exhausted.

D. If none of the recommended

actions for the above issues

correct the symptom, the valve

requires servicing.

A. Valve inlets may be blocked. A. Check the valve inlets for blockage

B. Fittings/Spray faces may be

blocked.

C. Water outlet pressure is low. C. Check that the flow rate is at or

D. Fluctuating supply pressure. D. Verify that the dynamic inlet

E. Water supply temperatures are

not within the recommended

range.

A. Fluctuating water supply

temperature.

B. Pressure difference greater than

5 psi (34.5 kPa) between the hot

and cold supply lines.

C. If none of the recommended

actions for the above issues

correct the symptom, the valve

requires servicing.

A. Connections are not secure. A. Check all connections. Make

B. Seals are worn or damaged. B. Order a seal service pack and

C. Internal leak. C. Unit requires overhaul. Contact

A. Hot and cold lines are reversed. A. Switch hot and cold water supply

C. Allow time for the water heater to

come up to temperature.

D. Contact your Kohler Co.

Authorized Service Representative.

or debris. Clean the inlet screens.

Refer to the ″Clean the Inlet

Screens″ section.

B. Clean the spray faces and any

screens in your fittings.

above the minimum rate required.

Refer to ″Specifications″ section.

pressures are within specifications.

Refer to ″Specifications″ section.

E. Check if inlet water temperatures

are within the recommended range.

A. Check the inlet temperature

differentials and verify they are

sufficient. Refer to ″Specifications″

section.

B. Install pressure regulators to bring

the supplies within 5 psi (34.5 kPa)

of each other.

C. Contact your Kohler Co.

Authorized Service Representative.

adjustments as needed.

replace all seals.

your Kohler Co. Authorized Service

Representative.

connections. Verify the hot water

supply is connected to the ″Hot″

inlet and the cold water supply is

connected to the ″Cold″ inlet.

Kohler Co. 15 1217542-2-B

Loading...

Loading...