Page 1

BEFORE YOU BEGINBEFORE YOU BEGIN

MINIMA

INSTALLATION INSTRUCTIONS

SLIDING, 1 DOOR 1 PANEL

8mm K-45803T-L-SHP

10mm K-45806T-L-SHP

·

Before you install your shower door, please read

these instructions carefully to familiarize yourself

with the required tools, materials, and installation

sequences. Follow the sections that pertain to your

particular installation. This will help you avoid costly

mistakes. In addition to proper installation, read all

operating and safety instructions.

All information is based on the latest product

·

information available at the time of publication.

Kohler China Ltd. reserves the right to make

changes in product characteristics, packaging, or

availability at any time without notice.

These instructions contain important care, cleaning,

·

and warranty information-

instructions for the consumer.

Make sure that the bath and the finished wall

·

material are completely and correctly installed prior

to installing your shower door. Prepare waterproof

layer to wall and floor of the showering area. It is not

allowed for any presence of electric switches and

sockets. Make sure the floor drain runs smoothly.

Before starting the door installation, lay out and

·

identify all the parts. Use the exploded view

illustrated on page 2 for reference.

For the installation method of customized shower

·

with different dimensions, please refer to this

instructions.

CAUTION: Risk of injury or product damage.

Tempered glass cannot be cut, drilled or knocked

by hard object. Make sure corner area of the

glass refraining from knocking so as to cause

personal injury due to broken glass.

ATTENTION:

receptors or curbs. (Not included). If the curb is not

Kohler-branded, please note its top width should be

more than 80mm.

IMPORTANT:

finished wall. The squareness of the wall is

recommended no more than 3 mm/m. KOHLER

Company won't take responsibility of the installation

quality.

Please install this door on Kohler

The shower door requires a flat vertical

please leave these

·

·

·

·

·

2

·

(

) 80mm

3mm/m

1198141-T01-B

-1-

13-1 528437

, 2014

Copyright Kohler China Ltd., 2014

Page 2

ROUGHING-IN

H

B

PARTS IDENTIFICATIONPARTS IDENTIFICATION

IMPORTANT

Unit: mm

SKU B H

K-45803T

K-45806T

1200-1600 1850-2000

Before installation check that all components are

correctly supplied.

If any parts are missing please ring the helpline.

800-820-2628

Top Lintel

Inline Panel

Wall Channel

C

Glass Clamp

800-820-2628

Door Panel

1198141-T01-B

Threshold

Splashguard

-2-

Wall Channel

Cover Seal

Page 3

4mm Allen key

4mm

Top Roller Clamps

Mid-support Clamp

X6

A

B

2.5mm Allen Key

2.5mm

X4

C

Screw Covers

X7

Screw Covers

X4

Support Strip

X2

X2

Bottom Guide

End Socket

Door Closing Guide

Plastic Guides

Frame Cap,LH Frame Cap,RH

X4

Wall Plugs

X7

X2

Wedge

ED

Handle

1198141-T01-B

-3-

Page 4

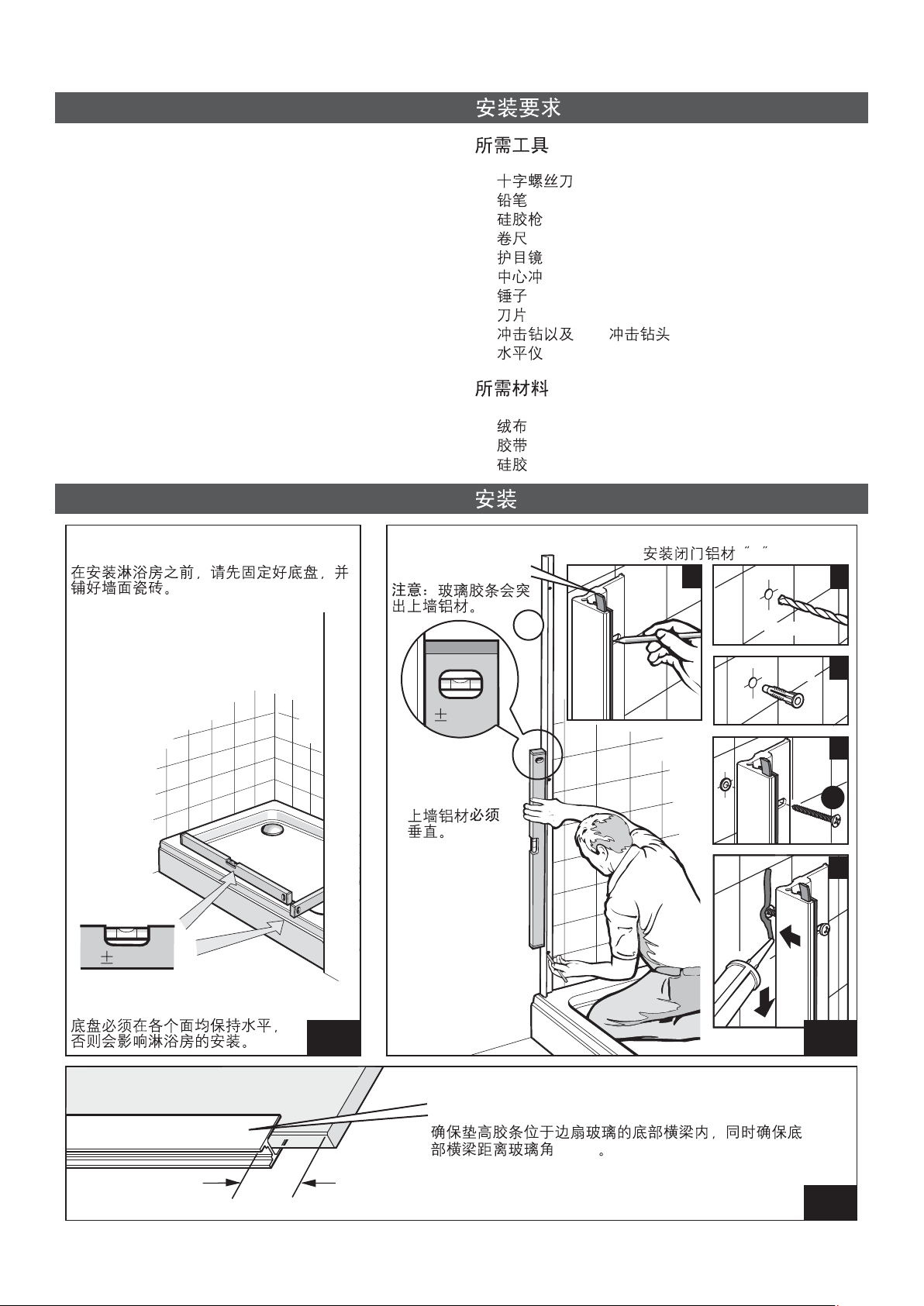

INSTALLATION REQUIREMENTSINSTALLATION REQUIREMENTS

Tools Required

·

Phillips Screwdriver

·

Pencil

·

Caulk Gun

·

Measuring Tape

·

Safety Glasses

·

Center Punch

·

Hammer

·

Knife

·

Masonry Drill & 6mm Drilll Bit

·

Level

Materials Required

·

Drop Cloth

Tape

·

Silicone Sealant

·

INSTALLATION

Fit tray and then tile walls before fitting

the unit.

·

·

·

·

·

·

·

·

·

·

·

·

·

NOTE: Glass seal will

extend out of wall

channel.

A

6mm

Fit Wall Channel 'A'

A

1

X3

6mm

X3

2

0mm

Tray MUST be level in all planes or the

unit will not install properly.

STEP

3

X3

0mm

4

Wall channels

MUST

plumb.

be

A

X3

5

STEP

1

Ensure the support strips are still on the bottom edge

of the inline panel, inside the H section, and that the H

section is 53mm from the corner of the glass.

2

1198141-T01-B

53mm

53mm

STEP

3

-4-

Page 5

Bottom channel fits under

seal.

Caution

Rest panel against

seal of wall channel

'A' .

Support glass

panel until glass

clamp is fitted

A

Check that bottom

channel is parallel to

edge of tray.

.

Glass needs to be at least 8mm

into wall channel

8mm

8mm minimum

8mm

STEP

4

Fit glass clamp and turn screw until it

lightly grips glass.

Glass should

protrude out

of bottom

channel by

53mm.

53mm

0mm

Glass panel

be plumb.

When glass is in

correct position

fully tighten clamp

glass screws.

must

1198141-T01-B

C

X4

STEP

5

STEP

6

-5-

Page 6

Cut seals exposed at top with a sharp knife.

53mm

Mark hole position, remove temporarily the bottom

guide and drill hole into the tray.

Top view

STEP

7

STEP

8

Lay a bead of sealant in bottom guide as shown, then

slide it under glass.

STEP

10

Locate one end of threshold under the bottom guide.

1198141-T01-B

6mm

STEP

9

2

1

STEP

11

-6-

Page 7

Remove

=

=

cover vinyl.

Lay sealant on

bottom of door

closing guide.

Place door

closing guide

under wall

channel.

Keep threshold position parallel to tray edge.

Fit the second wall channel.

X3

0mm

Wall channel

MUST

plumb.

be

X3

A

STEP

12

6mm

X3

STEP

13

Push cover vinyl Into place.

2

3

4

5

1198141-T01-B

Channel fits over

threshold.

STEP

14

-7-

STEP

15

Page 8

Screw bottom

guide to tray.

Position support clamps and sockets on top lintel.

Top view

B

B

STEP

16

1

Turn with allen key to

lightly grip the top lintel.

Fully tighten mid support clamp '2' & loosely fit end sockets '1' & '3'.

213

2

1

2

E

Screw mid support clamp to

lintel.

Turn with allen key to lightly

grip the top lintel.

3

3

Slide lintel and sockets to position.

Place the end socket1&3ontopofglass and wall channels.

13

1

1198141-T01-B

STEP

17

2

3

STEP

18

-8-

Page 9

Screw into wall channel.

X2

D

Place mid support clamp.

Screw mid support clamp

firmly to glass.

Screw 2nd socket to wall

channel then tighten the allen

screws on both sides.

Allen screw

D

STEP

19

Carefully turn door

panel on its edge

and support.

STEP

20

10mm

Fit splashguard to

bottom of door 10mm

from the closing

edge.

1198141-T01-B

STEP

21

10mm

STEP

22

-9-

Page 10

Fit door panel.

Place support spacer.

Lower the door panel into bottom

guide and rest on spacer support

and strip.

1

Place support strip.

2

Caution

3

Fit rollers clamps to top lintel and

door panel.

Front

STEP

23

Lift door panel slightly and remove

support strip.

Ensure screws are securely tightened.

1198141-T01-B

X2

STEP

24

Slide door open and remove support spacer.

STEP

25

-10-

Page 11

Fit plastic guides into bottom guide.

Carefully apply silicone

sealant along the back

face to fix the plastic

guide in place.

Notched seal

Inline

panel

Fit seals on:

Back edge

Door

panel

STEP

26

Closing edge

Door

panel

1198141-T01-B

STEP

27

-11-

Page 12

Fix handle.

Fix cap.

Lay a thin bead of sealant.

STEP

28

STEP

29

Allow at least 24 hours before using shower to allow

sealant to cure.

24

24hrs

1198141-T01-B

STEP

30

STEP

31

-12-

Loading...

Loading...