KOHLER K-1106, K-1112, K-1114, K-1126, K-1131 Installation Manual

...

Installation Guide

Drop-In 120 V Bath Whirlpool

K-1106, K-1112, K-1114,

K-1126, K-1131, K-1139,

K-1144, K-1146, K-1148,

K-1154, K-1157, K-1160,

K-1162, K-1164, K-1192,

K-1194, K-1196, K-1198,

K-1201, K-1209, K-1221,

K-1224, K-1226, K-1231,

K-1239, K-1244, K-1246,

K-1248, K-1257, K-1263,

K-1266, K-1337

M product numbers are for Mexico (i.e. K-12345M)

Los números de productos seguidos de M corresponden a México

(Ej. K-12345M)

Français, page “Français-1”

Español, página “Español-1”

1010564-2-G

Important Information

WARNING: When using electrical products, basic precautions should always be followed, including

the following:

Building materials and wiring should be routed away from the pump body and other heat-producing

components of the unit.

Install to permit access for servicing.

Grounding is required. The unit should be installed by a qualified service representative, and grounded.

WARNING: Risk of electric shock. A licensed electrician should make all electrical connections.

WARNING: Risk of electric shock. Disconnect power before servicing.

WARNING: Risk of injury or property damage. Please read all instructions thoroughly before

beginning installation, including the following requirements.

NOTICE: Follow all local plumbing and electrical codes.

Product Information

Electrical Requirements

The installation must have a Class A Ground-Fault Circuit-Interrupter (GFCI). The GFCI protects against

line-to-ground shock hazard. Use a 120 V, 15 A, 60 Hz dedicated service for the whirlpool.

″H″ models require a separate 120 V, 15 A, 60 Hz dedicated service for the heater.

NOTE: If the pump supply cord is damaged, it must be replaced by the manufacturer, its service agent or

similarly qualified persons in order to avoid a hazard. The heater supply cord cannot be replaced. If the

cord is damaged the heater should be scrapped.

Product Notices

WARNING: Unauthorized modification may cause unsafe operation and poor performance of the

whirlpool. Do not relocate the whirlpool pump, or make other modifications to the whirlpool system,

as this could adversely affect the performance and safe operation of the whirlpool. Kohler Co. shall not

be liable under its warranty or otherwise for personal injury or damage caused by any such

unauthorized modification.

Factory-Assembled Features

Factory installed components include pump with power supply cord and air switch transmitter. No

installation is needed.

″H″ models are also supplied with a factory assembled heater.

An optional timer kit is available for certain models.

The whirlpool pump and piping are factory-assembled.

Connections and Service Access

Before installation, ensure proper access to the final connections.

1010564-2-G 2 Kohler Co.

Important Information (cont.)

NOTICE: Provide unrestricted service access to the pump. You must provide access for servicing the

pump and controls. The access must be located immediately next to the pump. Study the roughing-in

information packed with the whirlpool.

Table of Contents

Important Information .............................................................. 2

Thank You For Choosing Kohler Company .............................................. 4

Tools and Materials ............................................................... 4

Before You Begin ................................................................. 4

Prepare the Site ................................................................. 5

Prepare the Whirlpool ............................................................. 6

Secure the Unit — Models With Support Blocks .......................................... 6

Secure the Whirlpool to the Stud Framing ............................................... 8

Secure the Unit — Models With Whirlpool Base .......................................... 9

Cut the Pump Banding Straps ...................................................... 10

Install the Plumbing .............................................................. 10

Install a Rim-Mounted Faucet ....................................................... 11

Make Electrical Connections ........................................................ 12

Test Run the Whirlpool ............................................................ 13

Complete the Finished Deck ........................................................ 14

Complete the Finished Wall ........................................................ 15

Clean-Up After Installation ......................................................... 15

Confirm Proper Operation .......................................................... 15

Troubleshooting Procedure ......................................................... 17

Kohler Co. 3 1010564-2-G

Thank You For Choosing Kohler Company

We appreciate your commitment to Kohler quality. Please take a few minutes to review this manual before

you start installation. If you encounter any installation or performance problems, please don’t hesitate to

contact us. Our phone numbers and website are listed on the back cover. Thanks again for choosing Kohler

Company.

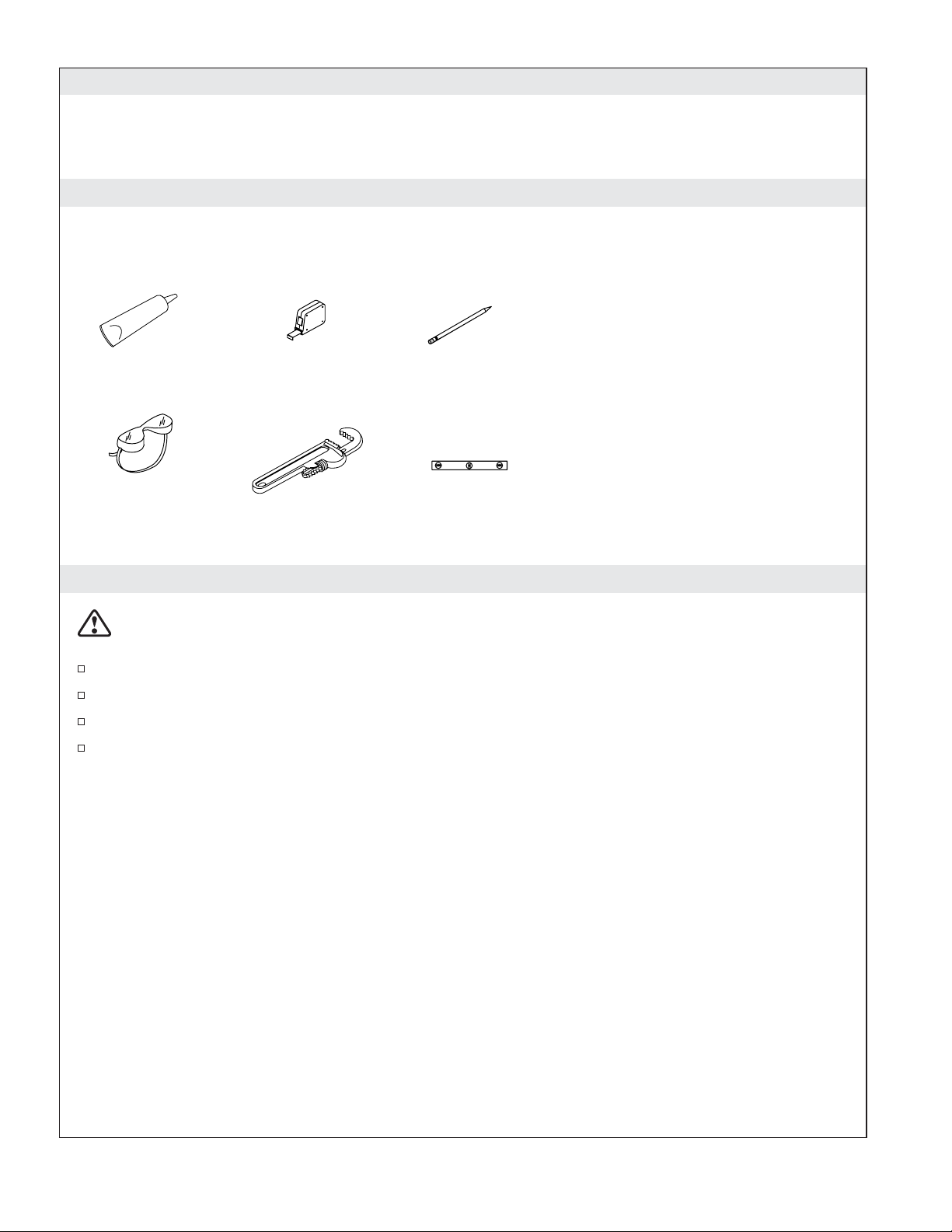

Tools and Materials

Plus:

• Conventional woodworking tools

Sealant

Safety Glasses

Tape Measure

Pipe Wrench

Pencil

Level

and materials

• Drop Cloth

• Construction adhesive (optional)

• Cement or mortar (optional)

• 2x4's or 2x6's

Before You Begin

CAUTION: Risk of product damage. Do not lift the whirlpool by the piping or pump, or use the

piping or pump for structural support of the whirlpool.

We recommend this whirlpool for drop-in installation.

Inspect the whirlpool for damage before you begin installation.

You must install this whirlpool to an adequately supported, level subfloor.

Confirm adequate mounting and connection space for the faucet specified for your installation.

1010564-2-G 4 Kohler Co.

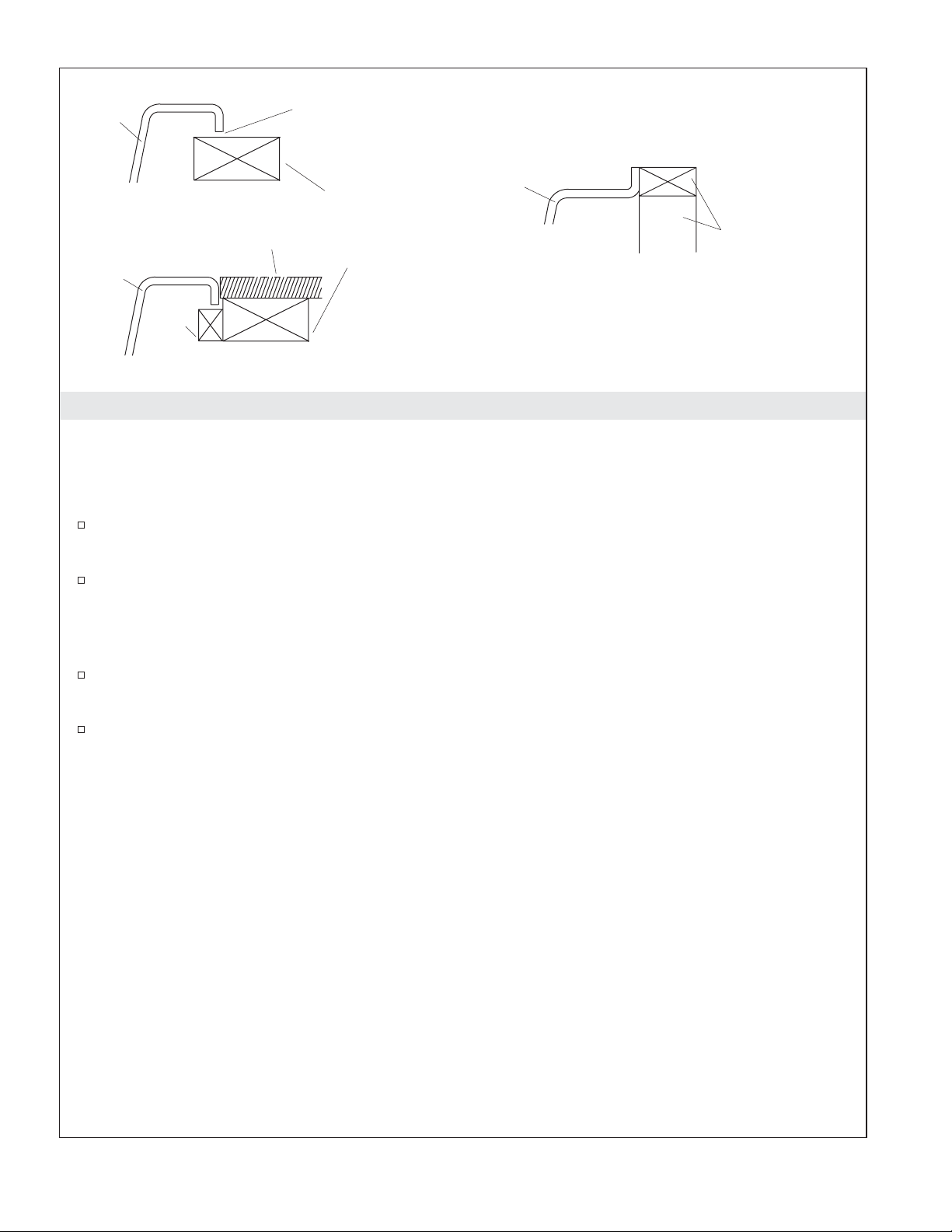

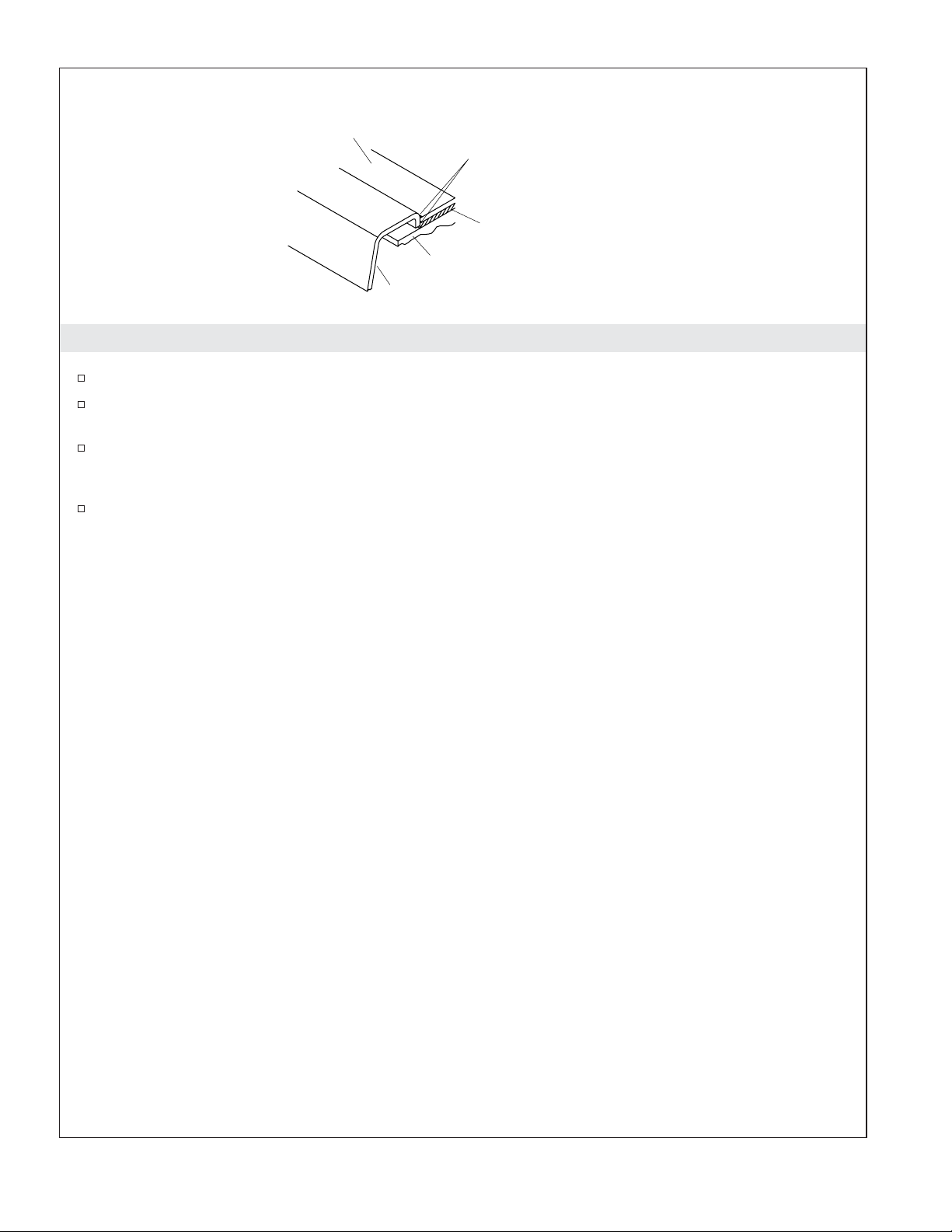

Whirlpool

Rim

Drop-In Installation

Allow for the thickness of

the planned deck material.

Whirlpool

Rim

Wood

Batten

Do not support

the whirlpool

by the rim.

Use the roughing-in

information to

construct the stud

framing.

Whirlpool

Rim

Use the roughing-in

information to

construct the stud

framing.

Flush Installation

Tiled Ledge Installation

1. Prepare the Site

NOTICE: Unless otherwise specified, floor support under the whirlpool must provide for a minimum of

80 lbs/square foot (390 kg/square meter) loading.

NOTICE: Do not support the whirlpool by the rim.

Make sure the flooring offers adequate support for your whirlpool, and verify that the subfloor is

flat and level.

The whirlpool should be installed in a drop-in, flush, or tiled ledge installation. Construct 2x4 or 2x6

stud framing designed for your particular installation. Provide for a 1/16″ (2 mm) gap between the

bottom of the whirlpool rim and the stud framing for drop-in installations. Frame the floor, or

construct a frame for a raised installation in accordance with the roughing-in information packed

with the whirlpool.

Carefully lay out and cut the rough deck material. Use the cut-out template if one is provided, or

refer to the roughing-in cut-out information.

Position the plumbing according to the roughing-in information packed. Cap the supplies, and

check for leaks.

Kohler Co. 5 1010564-2-G

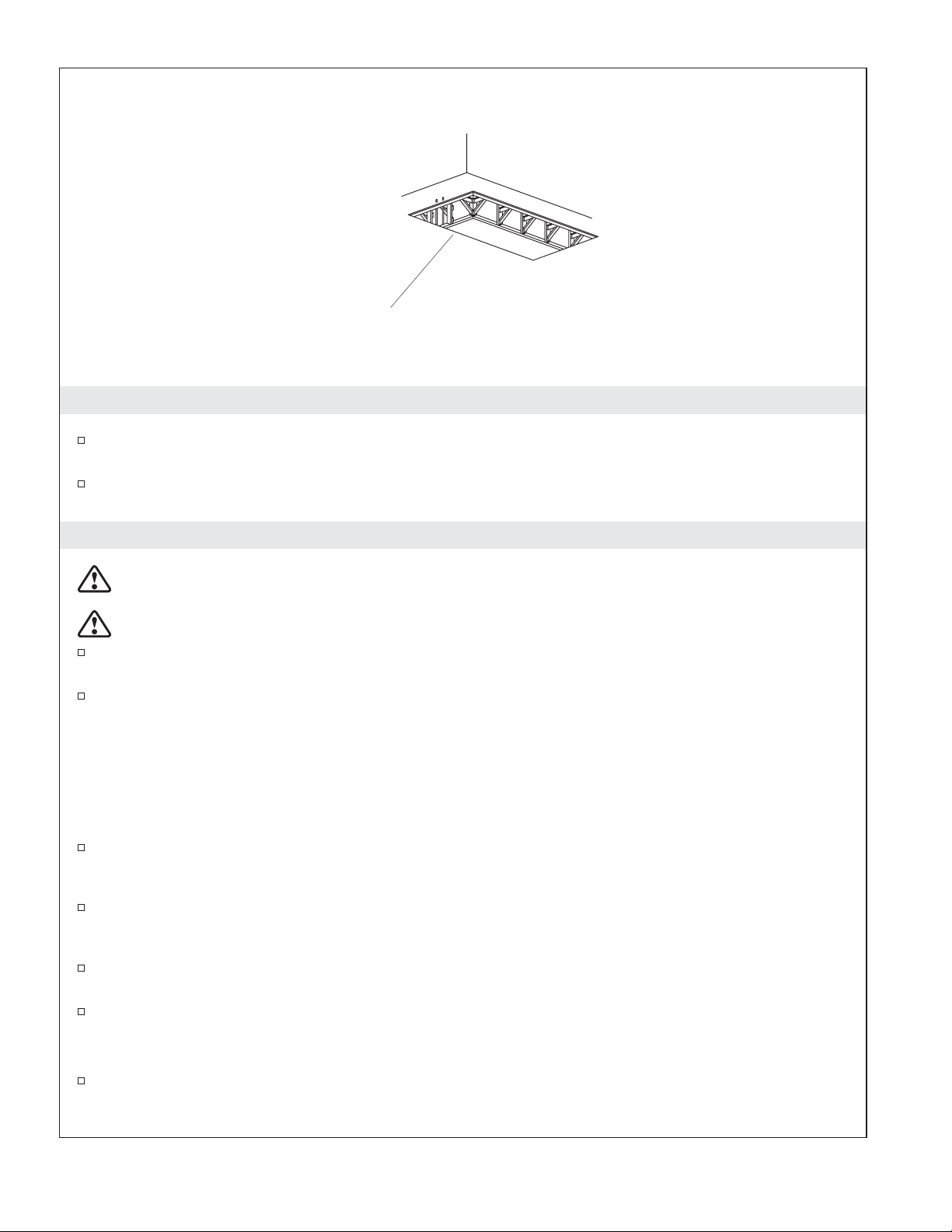

Position the rough

plumbing.

Construct 2x4 or 2x6

stud framing according

to the roughing-in

information.

Provide a 1/16" (2 mm) gap

between the whirlpool rim

and framing.

Frame the floor

according to the

roughing-in information.

Verify that the subfloor

offers adequate support,

and is flat and level.

2. Prepare the Whirlpool

Install the drain to the whirlpool according to the drain manufacturer’s instructions. Do not connect

the trap at this time.

Position a clean drop cloth or similar material in the bottom of the whirlpool. Be careful not to

scratch the surface of the whirlpool.

3. Secure the Unit — Models With Support Blocks

CAUTION: Risk of product damage. Do not lift the whirlpool by the piping or pump, or use the

piping or pump for structural support of the whirlpool.

CAUTION: Risk of product damage. Do not support the whirlpool by the rim.

Choose the installation option that best applies to your particular installation. Follow the

appropriate instructions.

If the subfloor is not level, shim the whirlpool support blocks as necessary.

Option Using a Cement or Mortar Bed

NOTE: Do not use gypsum cement or drywall compound for this application, as they will not provide an

acceptable, durable bond.

NOTE: The pump support bracket (when the pump banding straps are cut) and support blocks must

rest directly on the subfloor.

Spread a 2″ (5.1 cm) thick layer of cement or mortar on the subfloor where the whirlpool will be set.

This will help secure, level, and support the unit. Clear all the material away from the pump

support bracket and support block locations.

Position a piece of plastic drop cloth material on top of the cement or mortar bed. With help,

carefully lift the whirlpool into place, and make sure the pump support bracket and support blocks

do not rest in the bed material.

Insert the drain tailpiece into the trap. Make sure the whirlpool is level and resting on all support

blocks.

Remove the protective tape from the rim. Apply a continuous bead of high-quality silicone sealant

around the entire rim of the whirlpool.

Option Using Construction Adhesive

Apply a generous amount of high-quality construction adhesive to the bottom of the support blocks.

With help, carefully lift the whirlpool into position.

1010564-2-G 6 Kohler Co.

Secure the Unit — Models With Support Blocks (cont.)

Insert the drain tailpiece into the trap. Make sure the whirlpool is level and resting on all support

blocks.

Remove the protective tape from the rim. Apply a continuous bead of high-quality silicone sealant

around the entire rim of the whirlpool.

Option Using Silicone Sealant

With help, carefully lift the whirlpool into position.

Insert the drain tailpiece into the trap. Make sure the whirlpool is level and resting on all support

blocks.

Remove the protective tape from the rim. Apply a continuous bead of high-quality silicone sealant

around the entire rim of the whirlpool.

Kohler Co. 7 1010564-2-G

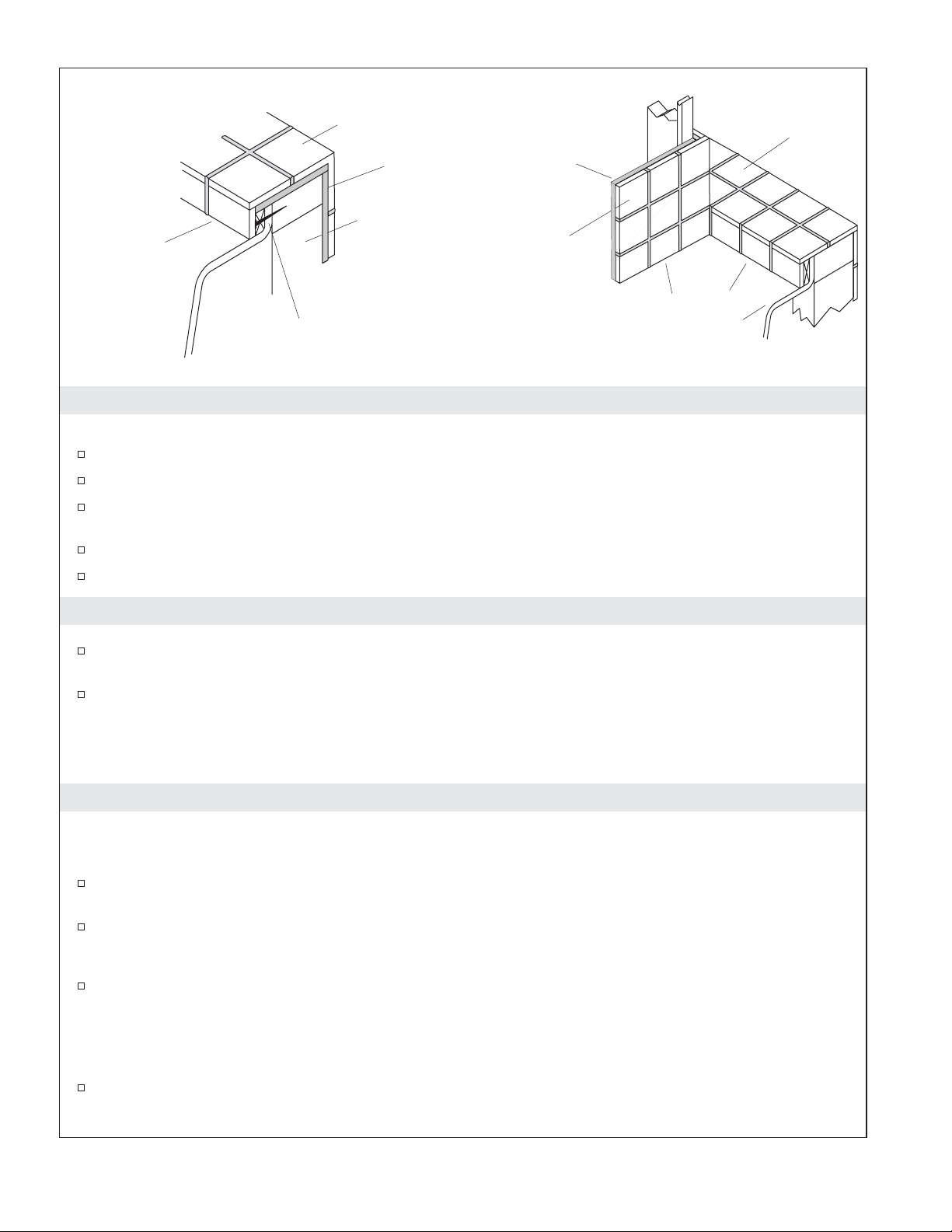

Stud Framing

Nail 1/4" (6 mm) furring

strips to the studs.

Drill a small pilot

hole through the

nailing-in flange.

Use #6 large-head galvanized

nails to secure to the studs.

Install a pressure-treated wood

batten along the nailing-in flange.

Stud Framing

4. Secure the Whirlpool to the Stud Framing

Option for Integral Flange Models

Drill a small pilot hole through the nailing-in flange at each stud. Add shims between the nailing-in

flange and the studs as needed to eliminate gaps.

Nail 1/4” (6 mm) thick furring strips to the studs to shim out to the edge of the nailing-in flange.

Use #6 large-head galvanized nails to secure the nailing-in flange to the studs.

For tile ledge installations, size and install a pressure-treated wood batten along the nailing-in

flange. Pre-drill nail holes through the wood batten and nailing-in flange before securing with

galvanized nails.

1010564-2-G 8 Kohler Co.

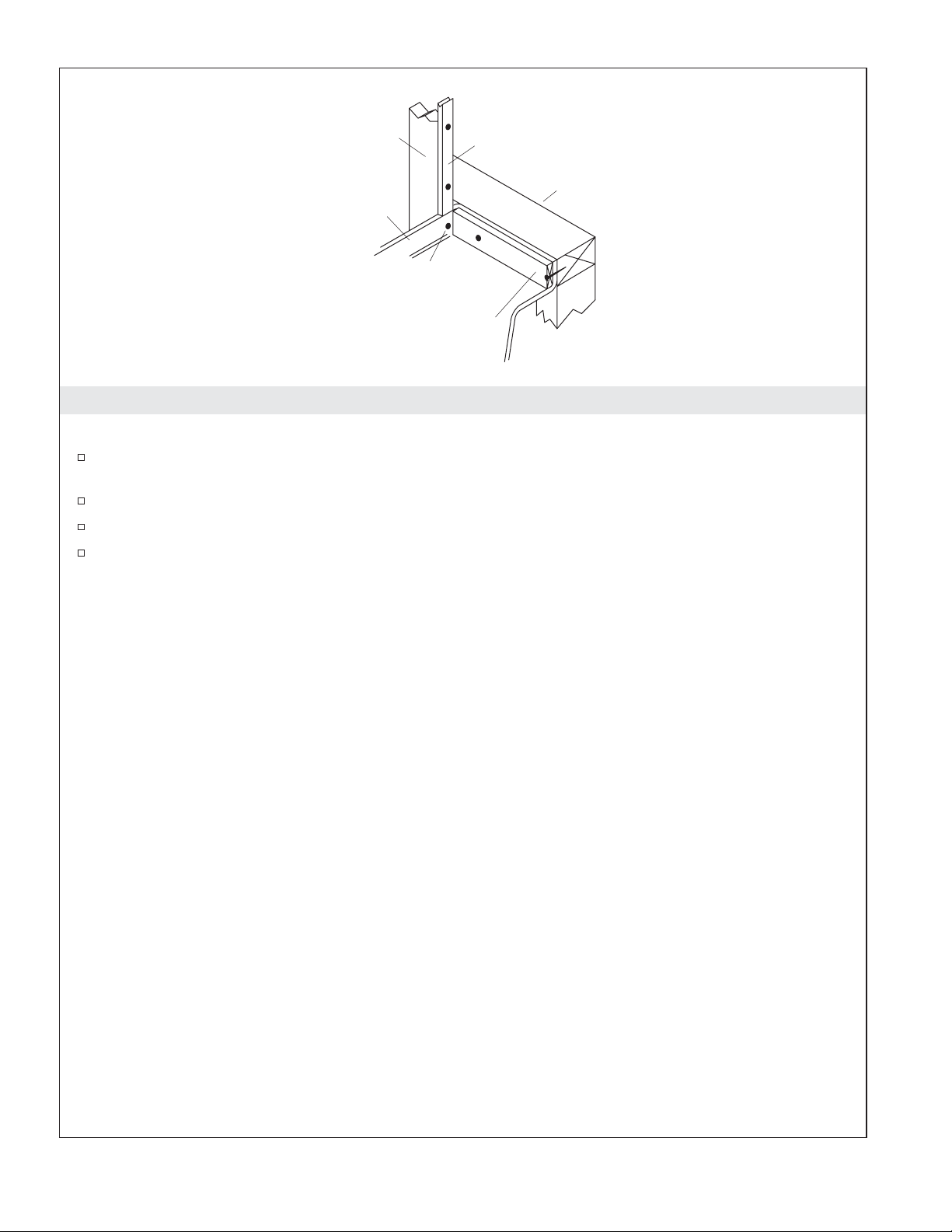

Spread a 2" (5.1 cm) layer of

cement or mortar bed material.

Apply a bead of

silicone sealant

around the entire

rim.

or

Apply construction

adhesive to the

whirlpool base.

5. Secure the Unit — Models With Whirlpool Base

CAUTION: Risk of product damage. Do not lift the whirlpool by the piping or pump, or use the

piping or pump for structural support of the whirlpool.

CAUTION: Risk of product damage. Do not support the whirlpool by the rim.

Choose the installation option that best applies to your particular installation. Follow the

appropriate instructions.

If the subfloor is not level, shim the whirlpool base as necessary.

Option Using a Cement or Mortar Bed

NOTE: Do not use gypsum cement or drywall compound for this application, as they will not provide an

acceptable, durable bond.

Spread a 2″ (5.1 cm) thick layer of cement or mortar on the subfloor where the whirlpool will be set.

This will help secure, level, and support the unit.

Position a piece of plastic drop cloth material on top of the cement or mortar bed. With help,

carefully lift the whirlpool into place.

Insert the drain tailpiece into the trap. Make sure the whirlpool is level. Use screws or lag bolts to

secure the whirlpool base to the floor. Drill small pilot holes through the whirlpool base as needed.

Remove the protective tape from the rim. Apply a continuous bead of high-quality silicone sealant

around the entire rim of the whirlpool.

Option Using Construction Adhesive

Apply a generous amount of high-quality construction adhesive to the bottom of the whirlpool base.

With help, carefully lift the whirlpool into position.

Insert the drain tailpiece into the trap. Make sure the whirlpool is level. Use screws or lag bolts to

secure the whirlpool base to the floor. Drill small pilot holes through the whirlpool base as needed.

Remove the protective tape from the rim. Apply a continuous bead of high-quality silicone sealant

around the entire rim of the whirlpool.

Option Using Silicone Sealant

With help, carefully lift the whirlpool into position.

Insert the drain tailpiece into the trap. Make sure the whirlpool is level. Use screws or lag bolts to

secure the whirlpool base to the floor. Drill small pilot holes through the whirlpool base as needed.

Remove the protective tape from the rim. Apply a continuous bead of high-quality silicone sealant

around the entire rim of the whirlpool.

Kohler Co. 9 1010564-2-G

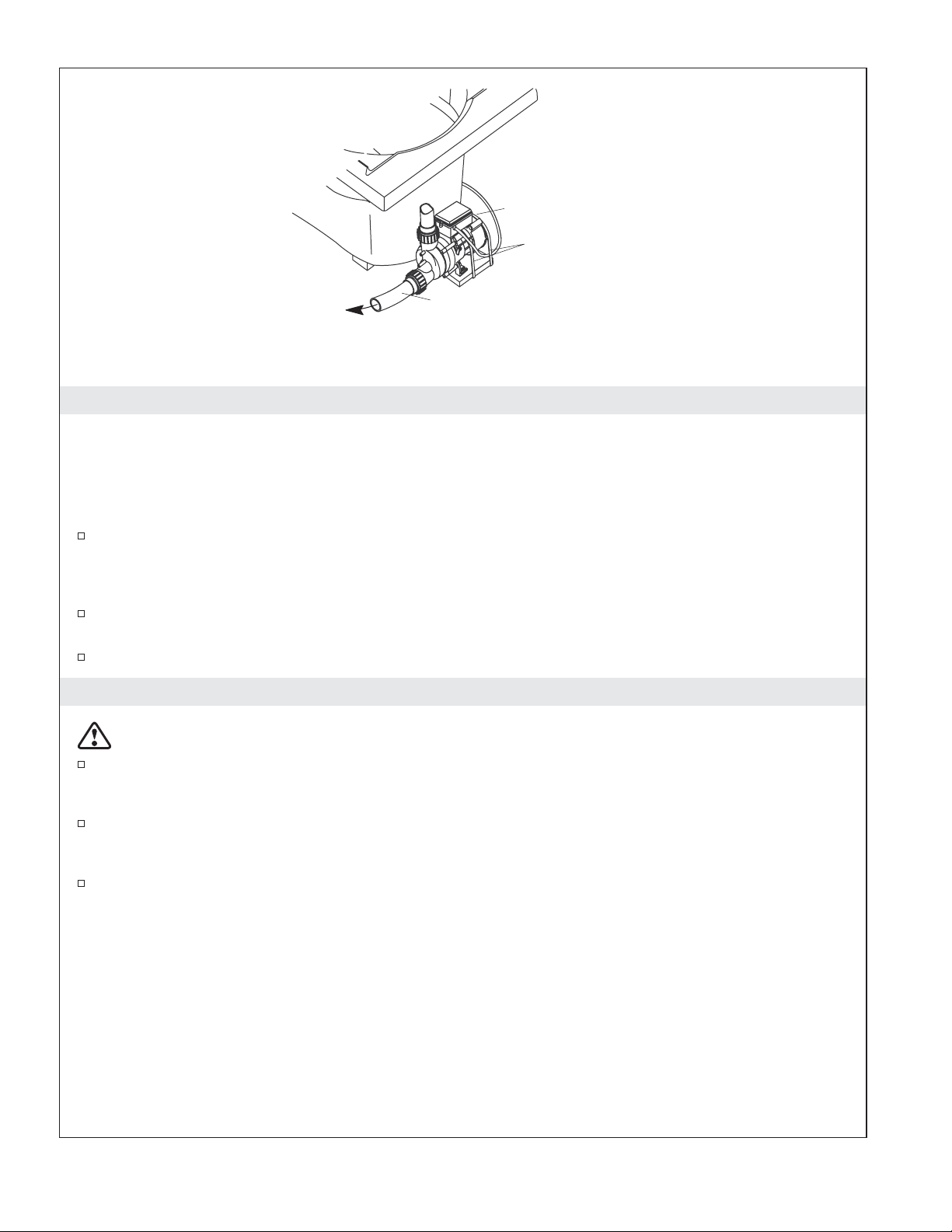

Pump

Cut the pump

banding straps.

Drainage

NOTE:

Pump model illustrated may differ from your

actual product.

Suction Line

6. Cut the Pump Banding Straps

NOTE: If your pump model does not have banding straps, proceed to the next section.

IMPORTANT! This step is necessary to make your Kohler whirlpool operate more quietly.

NOTE: Do not raise the pump higher than it was before you cut the pump banding straps. If the pump is

raised too high, it will not prime properly.

Use tin snips to cut the two pump banding straps. When the banding straps are cut, the pump

support bracket and pump will drop about 1/2″ (1.3 cm) until they rest on the subfloor. If the pump

drops more than 1/2″ (1.3 cm), shim under the pump support bracket so there is a 1/2″ (1.3 cm)

gap between the pump and bracket to allow for proper drainage.

To minimize whirlpool noise and vibration, be sure the pump is not in direct contact with the

shipping bracket after the pump banding straps are cut.

Secure the pump support bracket to the subfloor with screws or lag bolts (not provided).

7. Install the Plumbing

CAUTION: Risk of property damage. Ensure a watertight seal on the whirlpool drain.

Connect the drain to the trap according to the drain manufacturer’s instructions.

NOTICE: An access panel will simplify future maintenance.

Install the faucet valving according to the faucet manufacturer’s instructions. Do not install the

faucet trim until instructed. Open the hot and cold water supplies, and check the supply

connections for leakage.

Run water into the whirlpool, and check the drain connections for leakage.

1010564-2-G 10 Kohler Co.

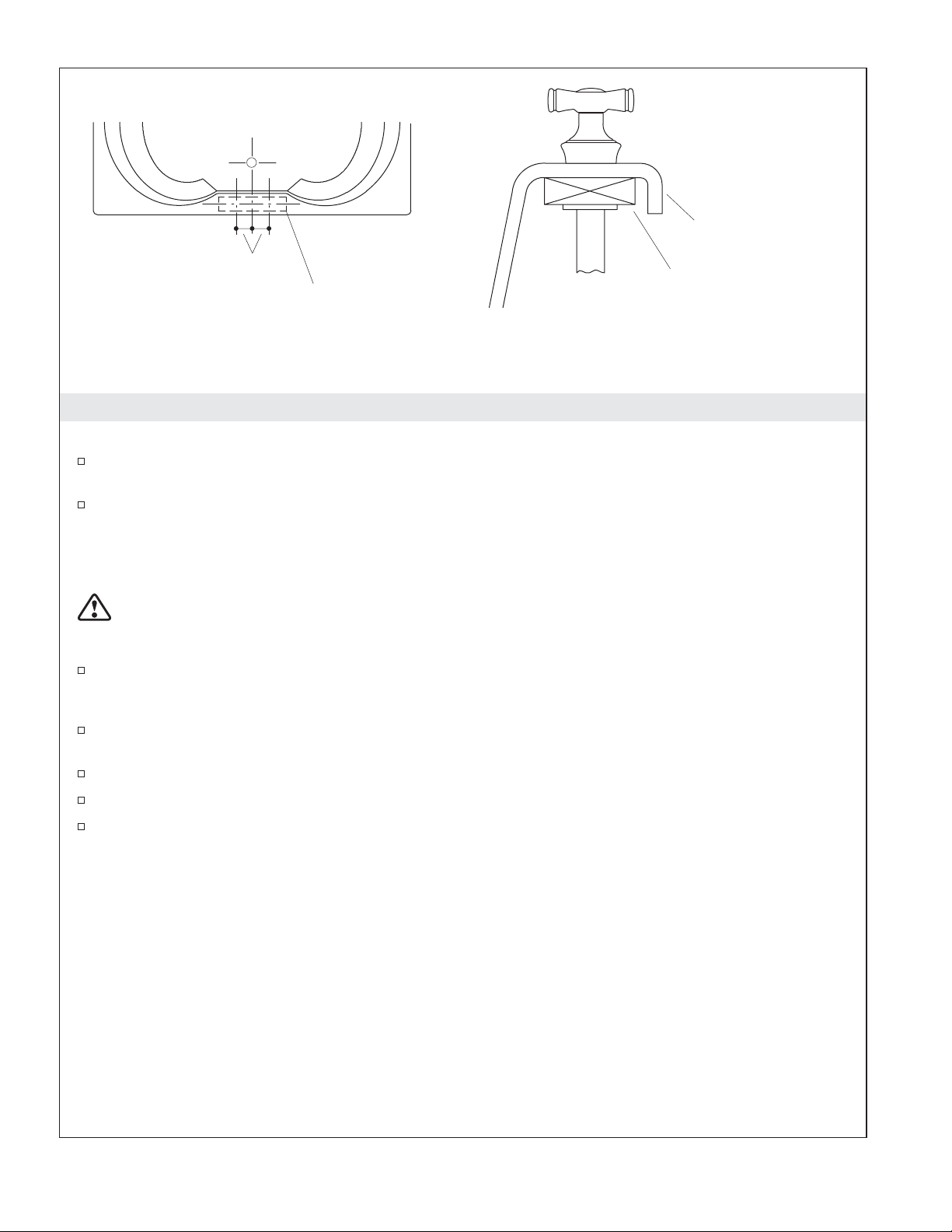

Whirlpool Rim

4" (10.2 cm)

Measure, cut, and drill a piece of 1/2" exterior

grade plywood 4" (10.2 cm) x 11-1/2" (29.2 cm) for

Install the faucet to the rim and

plywood according to the faucet

manufacturer's instructions.

the K-1226, or 4" (10.2 cm) x 15-1/2" (39.4 cm) for

the K-1331.

8. Install a Rim-Mounted Faucet

K-1226 and K-1231 Only

Measure and cut a piece of 1/2″ exterior grade plywood 4″ (10.2 cm) x 11-1/2″ (29.2 cm) for the

K-1226, or 4″ (10.2 cm) x 15-1/2″ (39.4 cm) for the K-1231.

The faucet should be located in the center of the flat area of the rim. Refer to the faucet

manufacturer’s instructions. Use a pencil to mark the faucet centerlines for drilling.

NOTE: The K-1226 will accept faucets with 4″ (10.2 cm) centers, and the K-1231 will accept faucets with 4″

(10.2 cm) or 6″ (15.2 cm) centers.

CAUTION: Risk of product damage. Position a thin piece of cardboard on the finished surface of the

whirlpool before clamping the plywood in place. Make sure the clamps do not make direct contact

with the finished surface of the whirlpool.

Set a thin piece of cardboard on the finished surface of the whirlpool rim. Position the plywood on

the bottom of the rim, and carefully clamp the plywood in place. Make sure the clamps are in

contact with the cardboard, not the finished surface of the whirlpool.

Carefully drill the faucet holes to the size required by the faucet manufacturer. Remove the clamps

and cardboard.

Install the faucet to the rim and plywood according to the faucet manufacturer’s instructions.

Open the hot and cold water supplies, and check the supply connections for leakage.

Run water into the whirlpool, and check the drain connections for leakage.

Kohler Co. 11 1010564-2-G

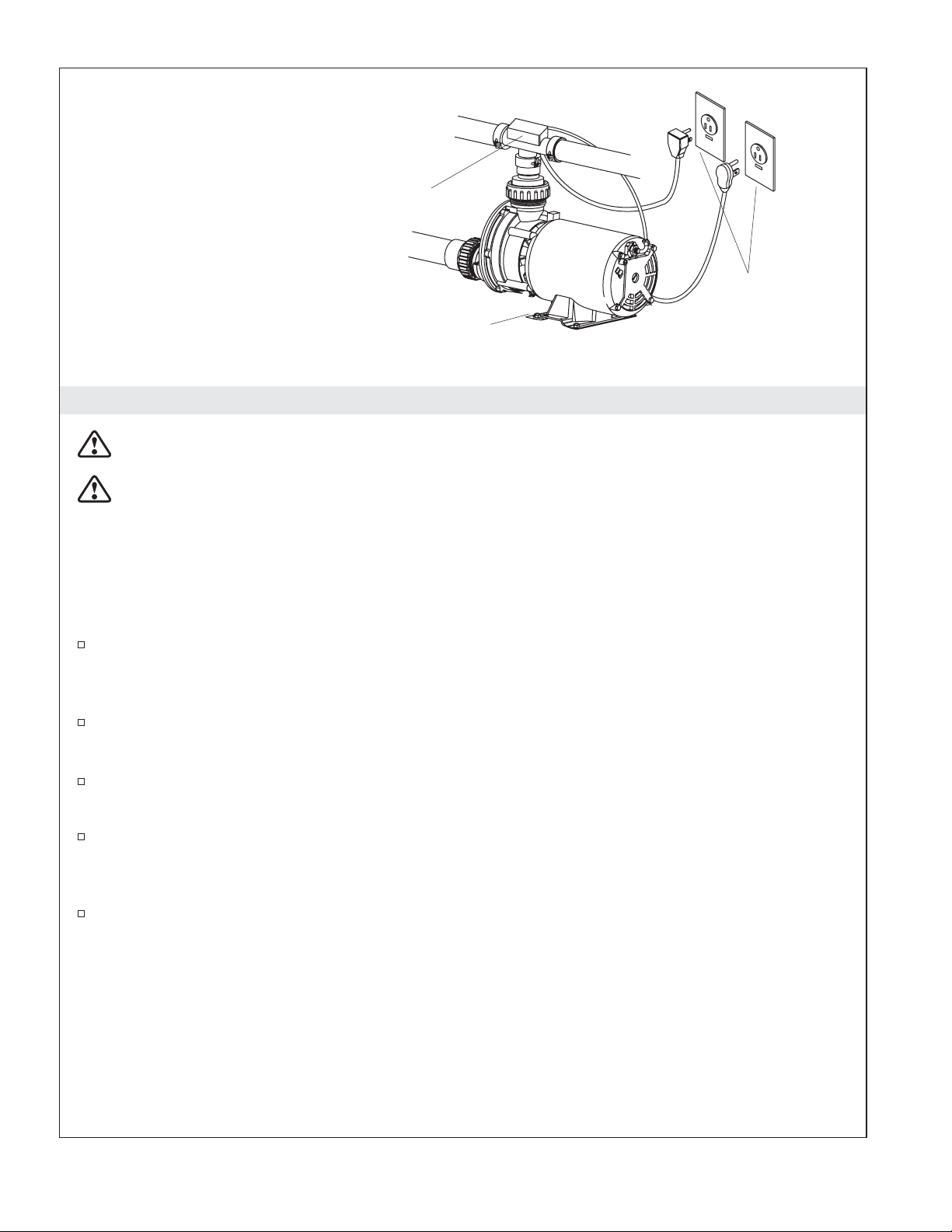

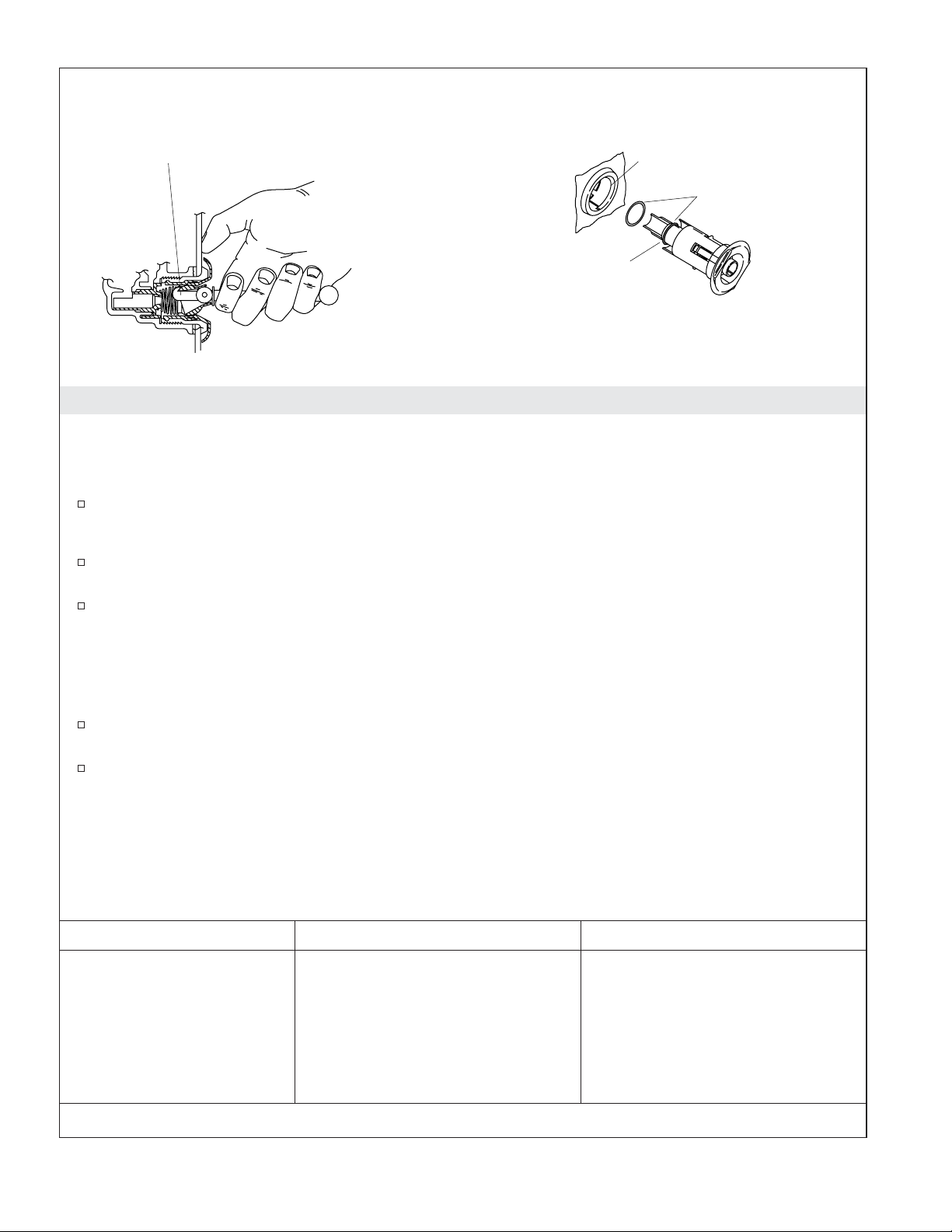

Install a GFCI-protected 120 V, 15 A grounded outlet. Install a second GFCI-protected

outlet for "H" models for the heater.

Optional Heater (models may vary)

either T-style (shown) or water intake

(not shown).

Make sure the air actuator tubing is

securely attached to the pump.

Bond in accordance with applicable codes.

NOTE:

Pump model illustrated may differ from your actual product.

Plug pump and

heater into these

outlets.

9. Make Electrical Connections

WARNING: Risk of electric shock. Make sure the power has been disconnected before performing the

following procedures.

WARNING: Risk of electric shock. To reduce the risk of electrical shock, connect the pump and in-line

heater (if heater option included) to properly grounded, grounding-type receptacles protected by

Ground-Fault Circuit-Interrupters (GFCI’s). Do not remove the plugs’ grounding pins. Do not use

grounding adapters.

Pump Wiring

NOTE: The whirlpool model number is printed on a label near the whirlpool pump. This label also

identifies the electrical rating of the whirlpool.

Your Kohler whirlpool bath is equipped with a cord and plug. All wiring of the pump and control

has been completed at the factory. A licensed electrician must install a GFCI-protected, 120 V, 15 A,

grounded outlet. No other load should be on this circuit. Locate the outlet behind the whirlpool,

and within 24″ (61 cm) of the pump.

Plug the pump into this outlet.

NOTE: Make sure the air actuator tubing is securely attached to the pump, and is not kinked or damaged.

If a K-1639 Timer Kit will be used, install it now according to the instructions packed.

In-line Heater Wiring

″H″ Models: The heater is equipped with a cord and plug. All wiring of the heater has been

completed at the factory. A licensed electrician must install a GFCI-protected, 120 V, 15 A, grounded

outlet. No other load should be on this circuit. Locate the outlet behind the whirlpool, and within

24″ (61 cm) of the heater.

Plug the heater into this outlet.

1010564-2-G 12 Kohler Co.

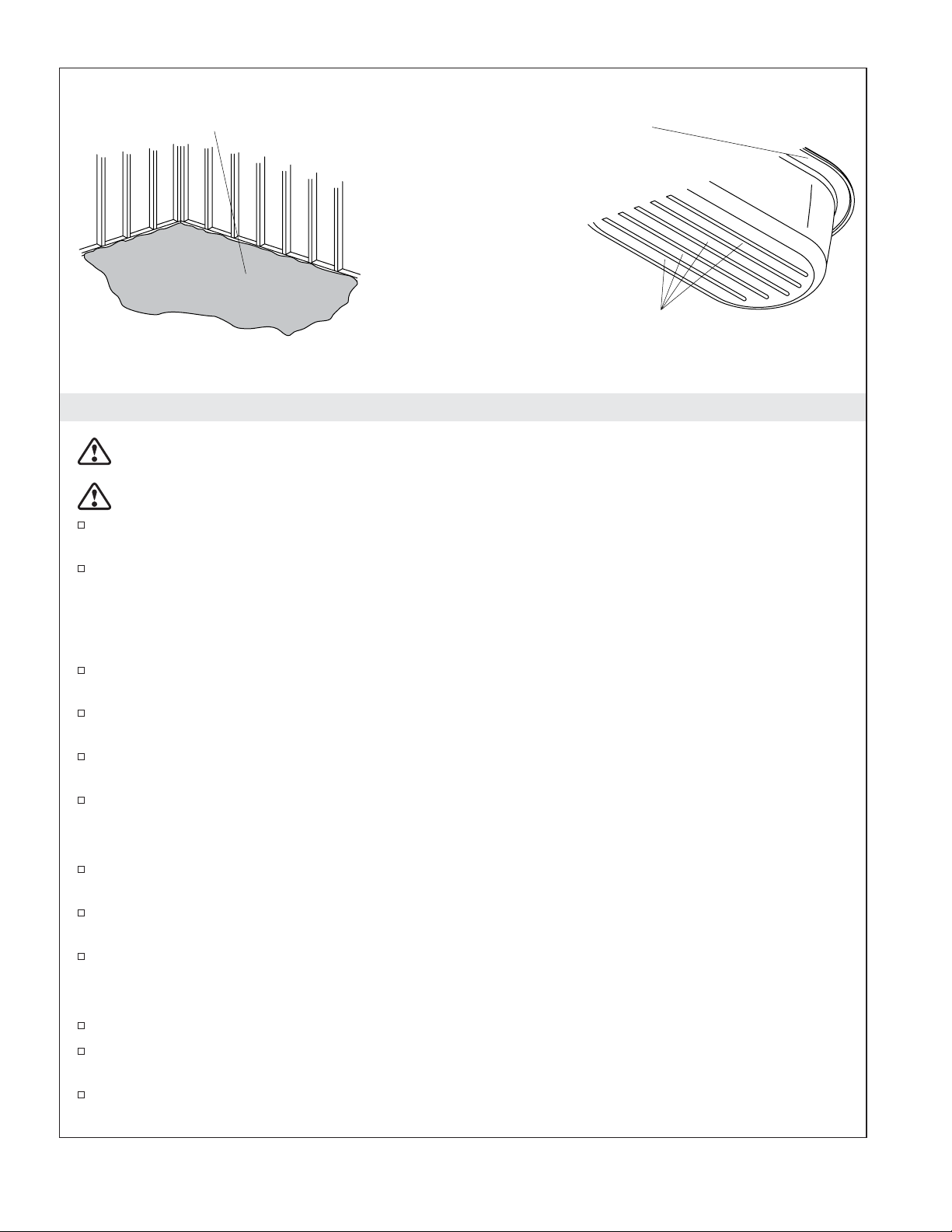

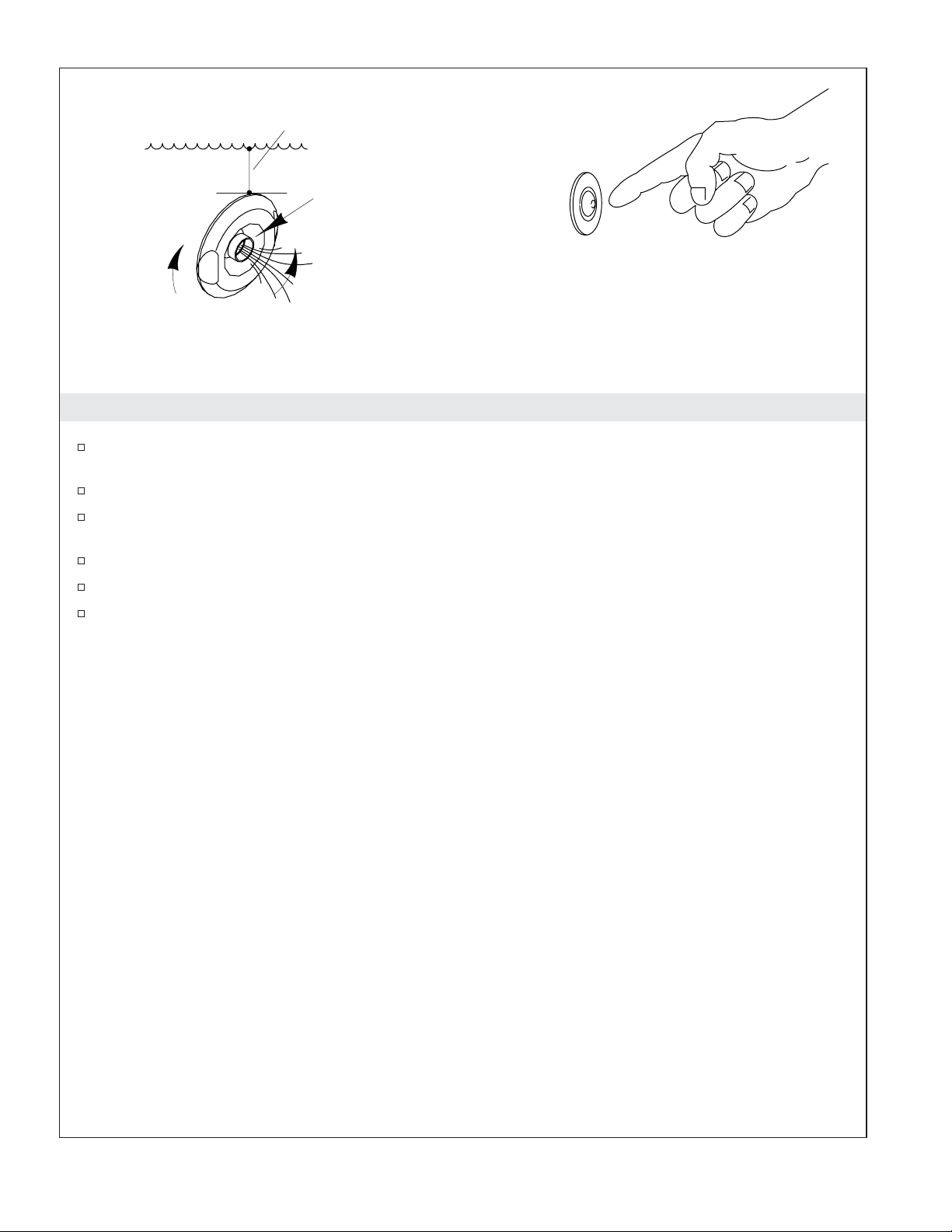

Fill with water 2" (5.1 cm)

above the highest jet.

Turn the jet trim ring

clockwise to

decrease the flow.

Turn the jet trim ring counterclockwise

to increase the flow.

Position the jet

nozzles to direct

the water flow as

desired.

Press the air actuator to turn

the whirlpool on or off.

10. Test Run the Whirlpool

Check all electrical connections, and make sure the electrical power to the whirlpool and heater (if

equipped) is on.

Make sure all union connections to the pump and heater are securely hand tightened.

Verify that the pump banding straps have been cut (if applicable), and that the pump is resting

directly on the subfloor or whirlpool base.

Fill the whirlpool to a level at least 2″ (5.1 cm) above the top of the highest jet.

Operate the whirlpool for 5 minutes, and check all whirlpool piping connections for leaks.

For additional information on whirlpool operation, refer to ″Confirm Proper Operation.″

Kohler Co. 13 1010564-2-G

Finished Deck

Material

Whirlpool

Apply silicone sealant to the

edges of the water-resistant

deck material and the

finished deck

Water-Resistant

Deck Material

Framing

11. Complete the Finished Deck

If you have not already done so, carefully remove the protective tape from the whirlpool rim.

Cover the framing with water-resistant deck material. Seal the joints between the whirlpool rim

edge and the water-resistant deck material with silicone sealant.

Tape and mud the water-resistant deck material. Install the finished deck to the water-resistant deck

material. Seal the joints between the whirlpool rim and the finished deck material with silicone

sealant.

Install the faucet trim according to the trim manufacturer’s instructions.

1010564-2-G 14 Kohler Co.

Install the finished

ledge material.

First install water-resistant

wall material.

Framing

Finished

Ledge

Apply silicone

sealant to the

joint between the

finished wall and

the whirlpool rim.

Whirlpool Flange

Install the finished

wall material.

Apply silicone sealant to the

joint between the finished

wall and the whirlpool rim.

12. Complete the Finished Wall

Tiled Ledge Installation

If you have not already done so, carefully remove the protective tape from the whirlpool rim.

Cover the framing with water-resistant wall material.

Tape and mud the water-resistant wall material. Install the finished wall to the water-resistant wall

material.

Seal the joints between the whirlpool rim and the finished wall material with silicone sealant.

Install the faucet trim according to the instructions packed with the trim.

13. Clean-Up After Installation

When cleaning up after installation, do not use abrasive cleansers, as they may scratch and dull the

whirlpool surface. Use warm water and a liquid detergent to clean the surface.

Remove stubborn stains, paint, or tar with turpentine or paint thinner. Do not allow cleaners

containing petroleum distillates to remain in contact with any whirlpool surfaces for long periods

of time. Remove plaster by carefully scraping with a wood edge. Do not use metal scrapers, wire

brushes, or other metal tools. Use a powder-type detergent on a damp cloth to provide mild

abrasive action to any residual plaster.

14. Confirm Proper Operation

Fill the Whirlpool

NOTE: Please read these steps carefully before you operate your whirlpool.

Position the jet nozzles so they face down toward the basin. Turn the jet trim rings fully

counterclockwise.

Fill the whirlpool to a water level at least 2″ (5.1 cm) above the top of the highest jet.

NOTE: The water temperature in the whirlpool should not exceed 104°F (40°C).

To service orifices insert a pencil into the end of the jet nozzle and push the orifice out. After

removing any blockage, check the orifice to make sure it is clear and press it into the jet housing.

NOTE: Orifices are only installed in whirlpool jets when there are six or more jets in the whirlpool system.

Operating Sequence

Press the air actuator to turn on the whirlpool jets.

Kohler Co. 15 1010564-2-G

Confirm Proper Operation (cont.)

Adjust each jet for optimum air/water mixture. Turn the trim ring clockwise to reduce the air flow,

and counterclockwise to increase the air flow.

If equipped with a heater, the heater will engage automatically when the pump is turned on and

will disengage when the pump is turned off. The heater will not turn on if the water temperature

exceeds 104°F (40°C).

Press the air actuator a second time to turn off the whirlpool.

1010564-2-G 16 Kohler Co.

Remove the Jets

Reinstall the Jets

Insert the tool hook as shown and pull the jet out of the

housing. The jet should be facing up when this is done.

Housing

Inspect and

lubricate the O-ring.

Slide the O-ring

onto the first

shoulder of the jet.

Insert the jet into the housing, and lightly

push and rotate until it snaps in position.

15. Troubleshooting Procedure

Remove the Factory Installed Jets

NOTE: A special tool is provided with the replacement jets that will allow you to remove the jets from the

whirlpool. This tool is also supplied with each trim kit.

Position the jet ball nozzle so it is pointing upward.

NOTE: The nozzle must remain pointed up or the tool will slip off.

Insert the removal tool, hooked end up, into the opening of the jet and hook the inside top of the

nozzle.

Grasp the tool firmly and place your thumb against the whirlpool wall. Pull steadily on the tool

until the jet assembly pulls free of the hole. Be careful not to lose the O-ring.

Reinstall the Jets

NOTE: The jet O-ring must be correctly positioned, must be lubricated, and must be in good condition to

permit easy rotation and proper operation of the jet.

Install the O-ring onto the first shoulder of the jet. Lubricate the O-ring with silicone lubricant to

prevent noisy operation of the jet.

Carefully insert the jet into the housing, and lightly push and rotate the jet until it snaps into

position. Do not force the jet.

NOTE: When installed correctly, the jet should turn smoothly both clockwise and counterclockwise.

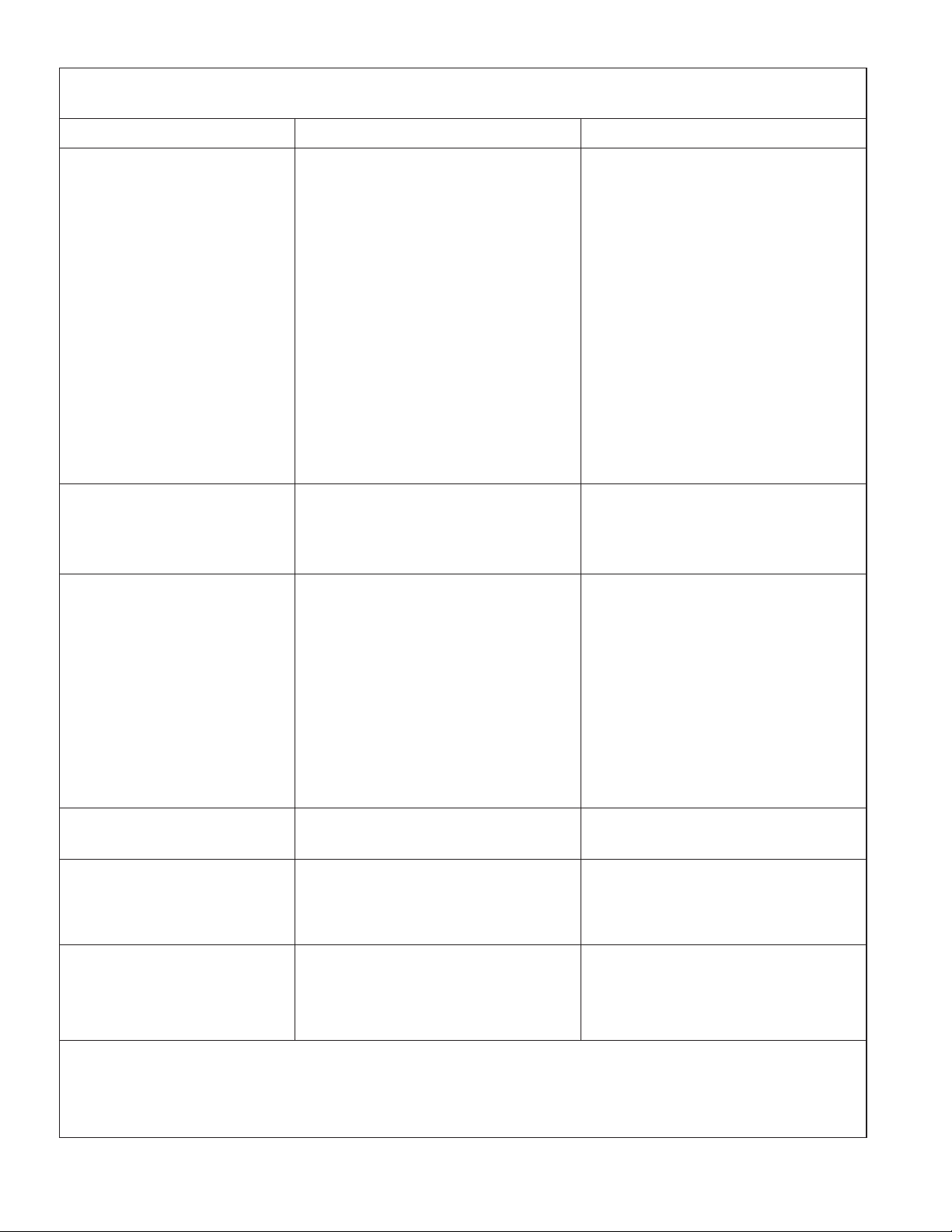

Troubleshooting Guide

This troubleshooting guide is for general aid only. A Kohler Authorized Service Representative or qualified

electrician should correct any electrical problems. For warranty service, contact your dealer or wholesale

distributor.

Symptoms Probable Causes Recommended Action

1. Whirlpool does not start

or stop.

A. No power to motor. A. Check that the pump and heater

are plugged in and that the GFCI

or ELCB is switched to the

correct position. Plug in or reset

the GFCI/ELCB as needed.

B. Air hose is loose or disconnected. B. Check that the hose is connected

at both the receiver/pump end

and to the air switch. Reconnect

if needed.

Kohler Co. 17 1010564-2-G

Troubleshooting Procedure (cont.)

Symptoms Probable Causes Recommended Action

C. Air hose is pinched or kinked. C. Adjust hose to clear the

D. Part(s) of the push button

assembly is/are damaged.

E. Push button has grease in the

bleed area.

F. Air hose is not properly installed

to the optional timer kit, or the

pump is in the ″off″ position.

G. Air hose is damaged. G. Replace the air hose.

H. Motor/pump does not work. H. Rebuild or replace motor/pump.

2. Motor starts, not all jets

are functioning.

3. Whirlpool stops

automatically before 18

minutes.

4. Pump does not prime.

(Models with support

blocks only.)

5. Noisy operation. A. Pump banding straps have not

6. Heater does not operate.

(“H” models only)

A. Jet is closed. A. Rotate jet trim ring

B. Jet not installed correctly. B. Reinstall jet; check for O-ring

C. Jets are blocked. C. Remove blockage.

A. The GFCI or ELCB trips. A. Identify source of fault, and

B. Suction blocked. B. Remove obstruction.

C. Jets are blocked. C. Remove blockage.

D. Motor overheated and protection

device activated.

A. Pump shimmed too high. A. Lower pump support bracket.

been cut. (Models with support

blocks only.)

B. Jet O-ring dislodged. B. Remove jet, replace and lubricate

A. No power to heater. A.

B. Water temperature exceeds 104°F

(40°C).

C. Heater does not work. C. Replace heater.

pinched/kinked area. If the

tubing is pinched/kinked and

cannot be readjusted, or no

noticeable pinch/kink is

apparent, poke a small hole in

the tubing with a tack and try

the system again.

D. Replace the push button

assembly.

E. Disassemble the push button

assembly and wipe away any

excess grease. Reassemble the

button and retry the system.

F. Refer to the timer kit installation

instructions to check the timer kit

installation. Contact the

installer/dealer.

counterclockwise to open.

damage.

correct.

D. Check for blockage at motor

vents. Remove blockage and

allow motor to cool.

Check for suction blockage.

Remove blockage and allow

motor to cool.

Check for jet blockage. Remove

blockage and allow motor to

cool.

A. Cut pump banding straps with

tin snips.

O-ring, and reinstall jet.

Reset the GFCI or ELCB.

B. Allow water to cool and heater

will reengage.

1010564-2-G 18 Kohler Co.

Loading...

Loading...