Page 1

CH260-CH440

Service Manual

IMPORTANT: Read all safety precautions and instructions carefully before operating equipment. Refer to operating

instruction of equipment that this engine powers.

Ensure engine is stopped and level before performing any maintenance or service.

2 Safety

3 Maintenance

5 Specications

18 Tools and Aids

21 Troubleshooting

25 Air Cleaner/Intake

26 Fuel System

30 Governor System

31 Lubrication System

32 Electrical System

39 Starter System

43 Disassembly/Inspection and Service

58 Reassembly

117 690 01 Rev. E KohlerEngines.com

Page 2

Safety

SAFETY PRECAUTIONS

WARNING: A hazard that could result in death, serious injury, or substantial property damage.

CAUTION: A hazard that could result in minor personal injury or property damage.

NOTE: is used to notify people of important installation, operation, or maintenance information.

WARNING

Explosive Fuel can cause

res and severe burns.

Do not ll fuel tank while

engine is hot or running.

Gasoline is extremely ammable

and its vapors can explode if

ignited. Store gasoline only in

approved containers, in well

ventilated, unoccupied buildings,

away from sparks or ames.

Spilled fuel could ignite if it comes

in contact with hot parts or sparks

from ignition. Never use gasoline

as a cleaning agent.

WARNING

Rotating Parts can cause

severe injury.

Stay away while engine

is in operation.

Keep hands, feet, hair, and

clothing away from all moving

parts to prevent injury. Never

operate engine with covers,

shrouds, or guards removed.

WARNING

Carbon Monoxide can

cause severe nausea,

fainting or death.

Avoid inhaling exhaust

fumes.

Engine exhaust gases contain

poisonous carbon monoxide.

Carbon monoxide is odorless,

colorless, and can cause death if

inhaled.

Accidental Starts can

cause severe injury or

death.

Disconnect and ground

spark plug lead(s) before

servicing.

Before working on engine or

equipment, disable engine as

follows: 1) Disconnect spark plug

lead(s). 2) Disconnect negative (–)

battery cable from battery.

Hot Parts can cause

severe burns.

Do not touch engine

while operating or just

after stopping.

Never operate engine with heat

shields or guards removed.

Cleaning Solvents can

cause severe injury or

death.

Use only in well

ventilated areas away

from ignition sources.

Carburetor cleaners and solvents

are extremely ammable. Follow

cleaner manufacturer’s warnings

and instructions on its proper and

safe use. Never use gasoline as a

cleaning agent.

WARNING

WARNING

WARNING

Electrical Shock can

cause injury.

Do not touch wires while

engine is running.

Damaging Crankshaft

and Flywheel can cause

personal injury.

Using improper procedures can

lead to broken fragments. Broken

fragments could be thrown from

engine. Always observe and use

precautions and procedures when

installing ywheel.

Uncoiling Spring can

cause severe injury.

Wear safety goggles or

face protection when

servicing retractable

starter.

Retractable starters contain a

powerful, recoil spring that is

under tension. Always wear safety

goggles when servicing retractable

starters and carefully follow

instructions in Retractable Starter

for relieving spring tension.

CAUTION

CAUTION

WARNING

2

KohlerEngines.com 17 690 01 Rev. E

Page 3

Maintenance

MAINTENANCE INSTRUCTIONS

WARNING

Accidental Starts can cause severe injury or

death.

Disconnect and ground spark plug lead(s)

before servicing.

Normal maintenance, replacement or repair of emission control devices and systems may be performed by any repair

establishment or individual; however, warranty repairs must be performed by a Kohler authorized dealer.

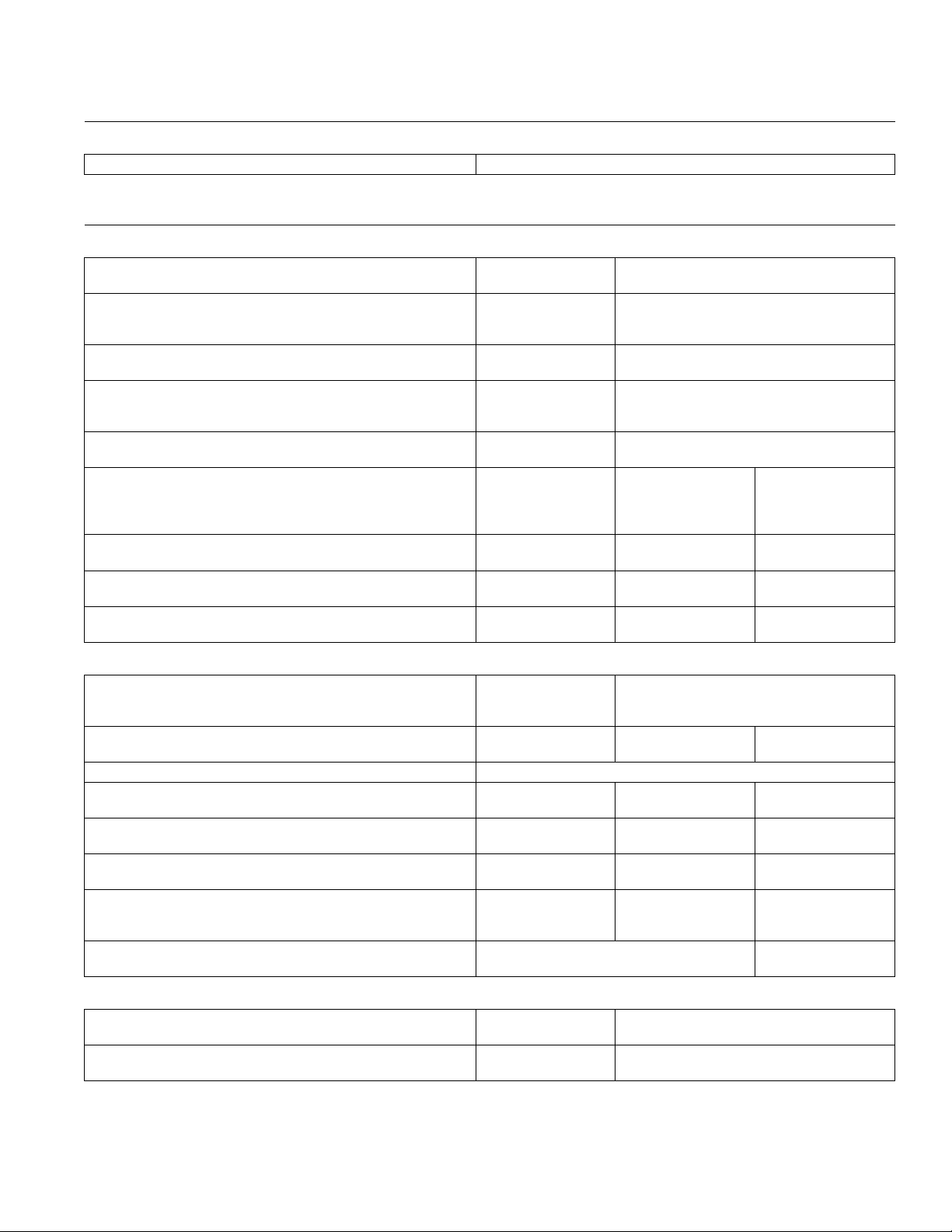

MAINTENANCE SCHEDULE

After rst 5 Hours

● Change oil. Lubrication System

Every 50 Hours or Annually

● Service/replace Quad-Clean

precleaner. Air Cleaner/Intake

™

Every 100 Hours or Annually¹

● Clean low-prole air cleaner element. Air Cleaner/Intake

● Change oil. Lubrication System

● Clean cooling areas. Air Cleaner/Intake

● Replace spark plug and set gap. Electrical System

Before working on engine or equipment, disable engine as

follows: 1) Disconnect spark plug lead(s). 2) Disconnect

negative (–) battery cable from battery.

Every 200 Hours²

● Check and adjust valve clearance when engine is cold. Reassembly

Every 200 Hours

● Replace Quad-Clean

air cleaner element. Air Cleaner/Intake

™

Every 300 Hours

● Replace low-prole air cleaner element. Air Cleaner/Intake

● Check fuel lters (tank outlet lter and in-line lter) clean or replace if needed (if

equipped).

1

Perform these procedures more frequently under severe, dusty, dirty conditions.

2

Have a Kohler authorized dealer perform this service.

Fuel System

REPAIRS/SERVICE PARTS

Kohler genuine service parts can be purchased from Kohler authorized dealers. To nd a local Kohler authorized

dealer visit KohlerEngines.com or call 1-800-544-2444 (U.S. and Canada).

17 690 01 Rev. E KohlerEngines.com

3

Page 4

Maintenance

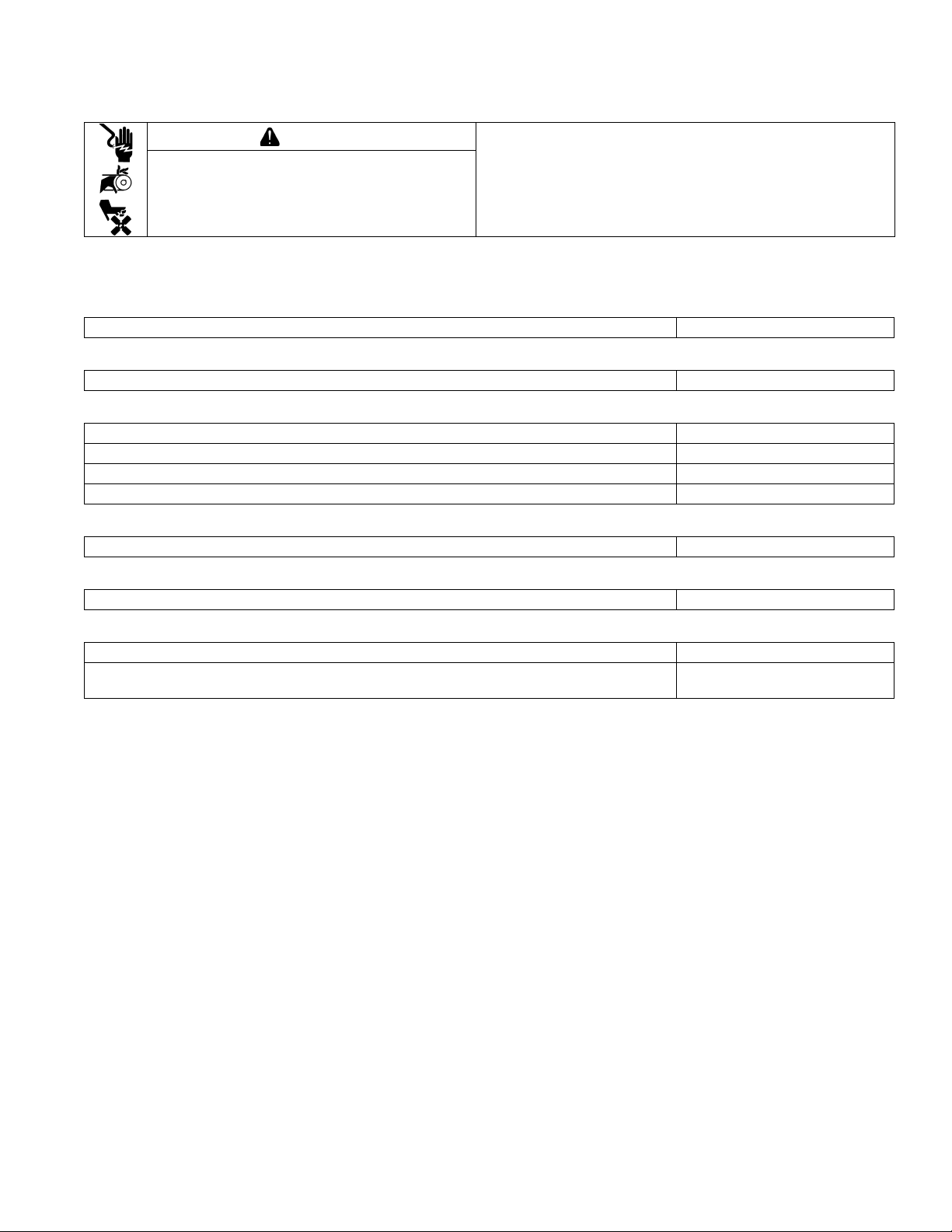

OIL RECOMMENDATIONS

We recommend use of Kohler oils for best performance.

Other high-quality detergent oils (including synthetic)

of API (American Petroleum Institute) service class SJ

or higher are acceptable. Select viscosity based on

air temperature at time of operation as shown in table

below.

FUEL RECOMMENDATIONS

WARNING

Explosive Fuel can cause res and severe

burns.

Do not ll fuel tank while engine is hot or

running.

STORAGE

If engine will be out of service for 2 months or more

follow procedure below.

1. Add Kohler PRO Series fuel treatment or equivalent

to fuel tank. Run engine 2-3 minutes to get stabilized

fuel into fuel system (failures due to untreated fuel

are not warrantable).

2. Change oil while engine is still warm from operation.

Remove spark plug(s) and pour about 1 oz. of

engine oil into cylinder(s). Replace spark plug(s) and

crank engine slowly to distribute oil.

3. Disconnect negative (-) battery cable.

4. Store engine in a clean, dry place.

Gasoline is extremely ammable and its vapors can

explode if ignited. Store gasoline only in approved

containers, in well ventilated, unoccupied buildings,

away from sparks or ames. Spilled fuel could ignite

if it comes in contact with hot parts or sparks from

ignition. Never use gasoline as a cleaning agent.

NOTE: E15, E20 and E85 are NOT approved and

should NOT be used; effects of old, stale or

contaminated fuel are not warrantable.

Fuel must meet these requirements:

● Clean, fresh, unleaded gasoline.

● Octane rating of 87 (R+M)/2 or higher.

● Research Octane Number (RON) 90 octane minimum.

● Gasoline up to 10% ethyl alcohol, 90% unleaded is

acceptable.

● Methyl Tertiary Butyl Ether (MTBE) and unleaded

gasoline blend (max 15% MTBE by volume) are

approved.

● Do not add oil to gasoline.

● Do not overll fuel tank.

● Do not use gasoline older than 30 days.

4

KohlerEngines.com 17 690 01 Rev. E

Page 5

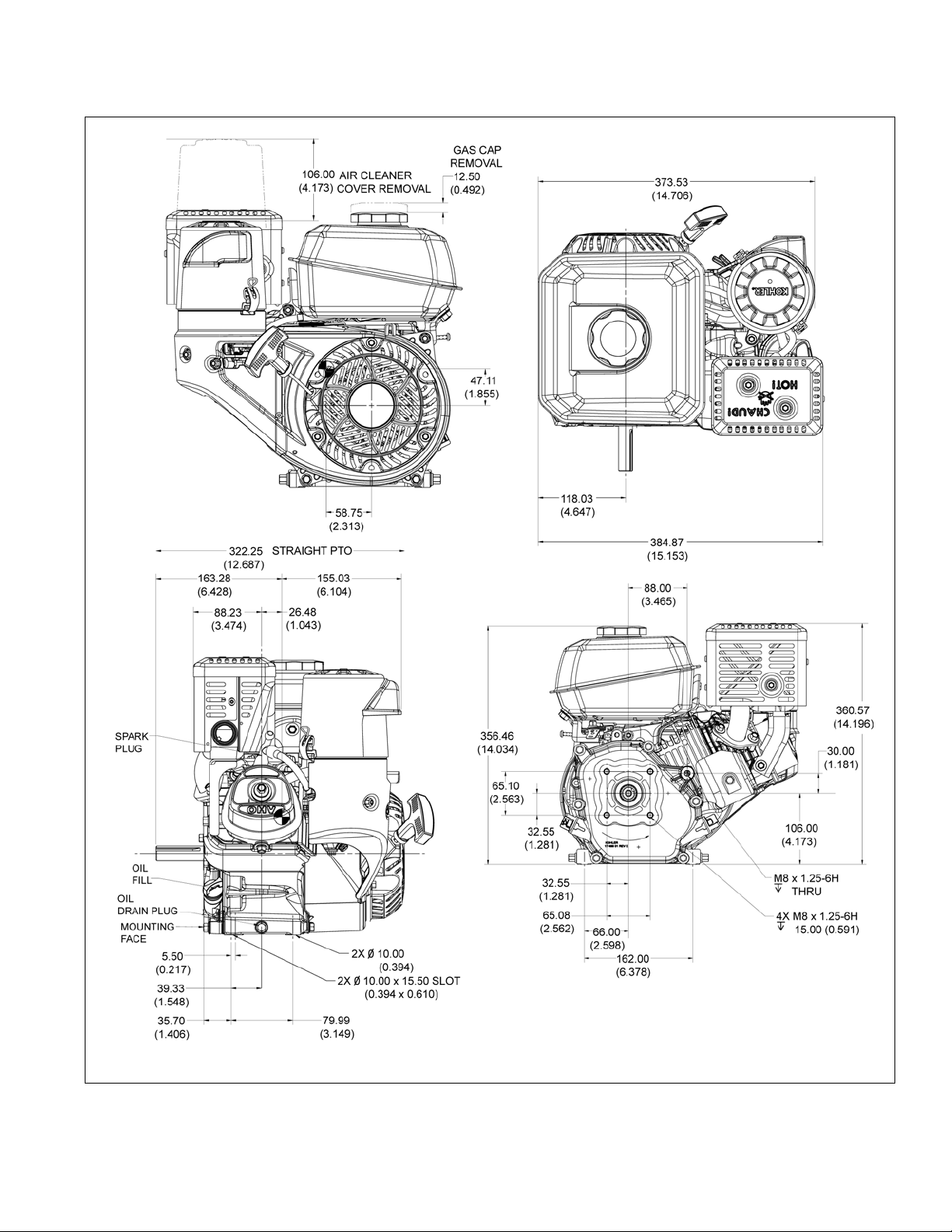

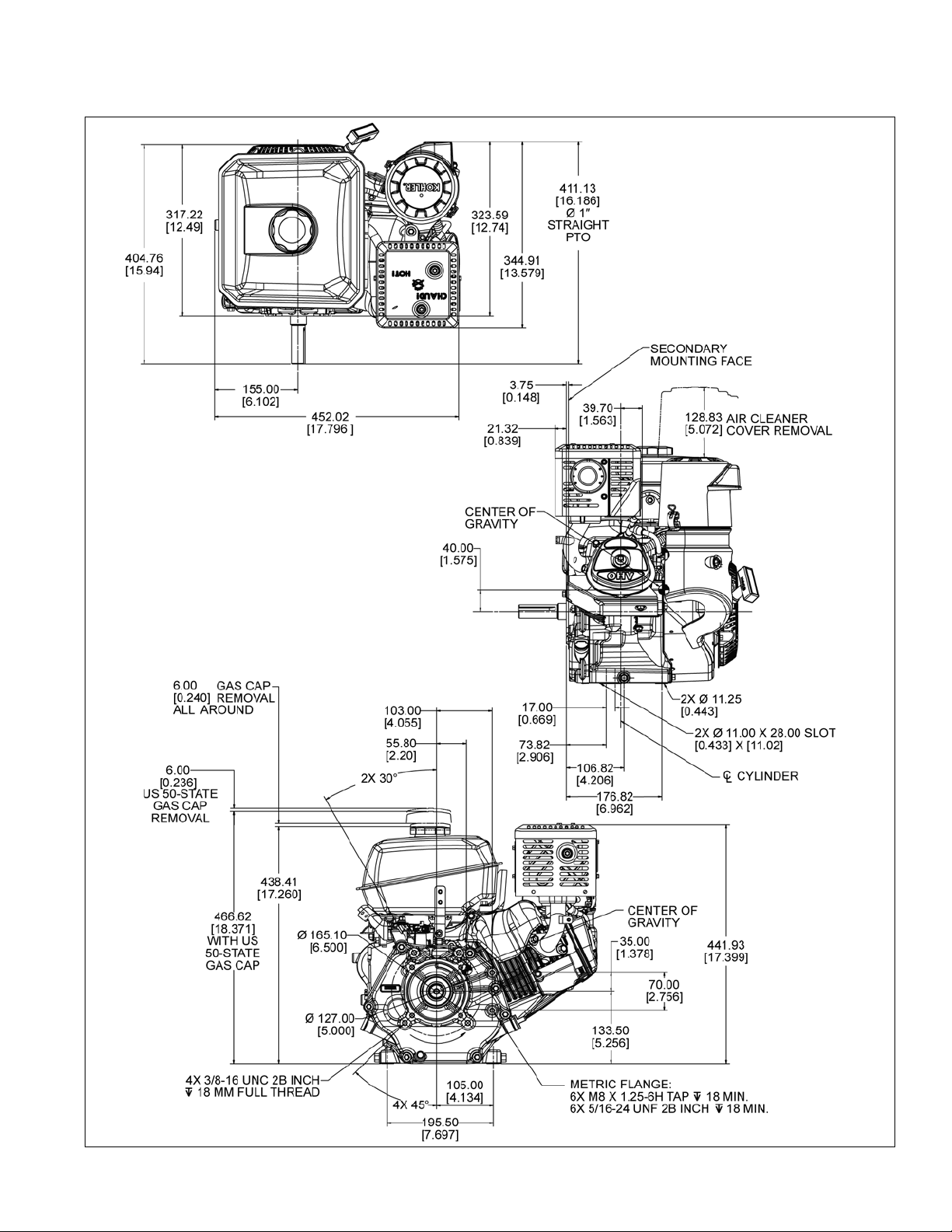

CH260/CH270 Engine Dimensions

Specications

Dimensions in millimeters.

Inch equivalents shown in [ ].

17 690 01 Rev. E KohlerEngines.com

5

Page 6

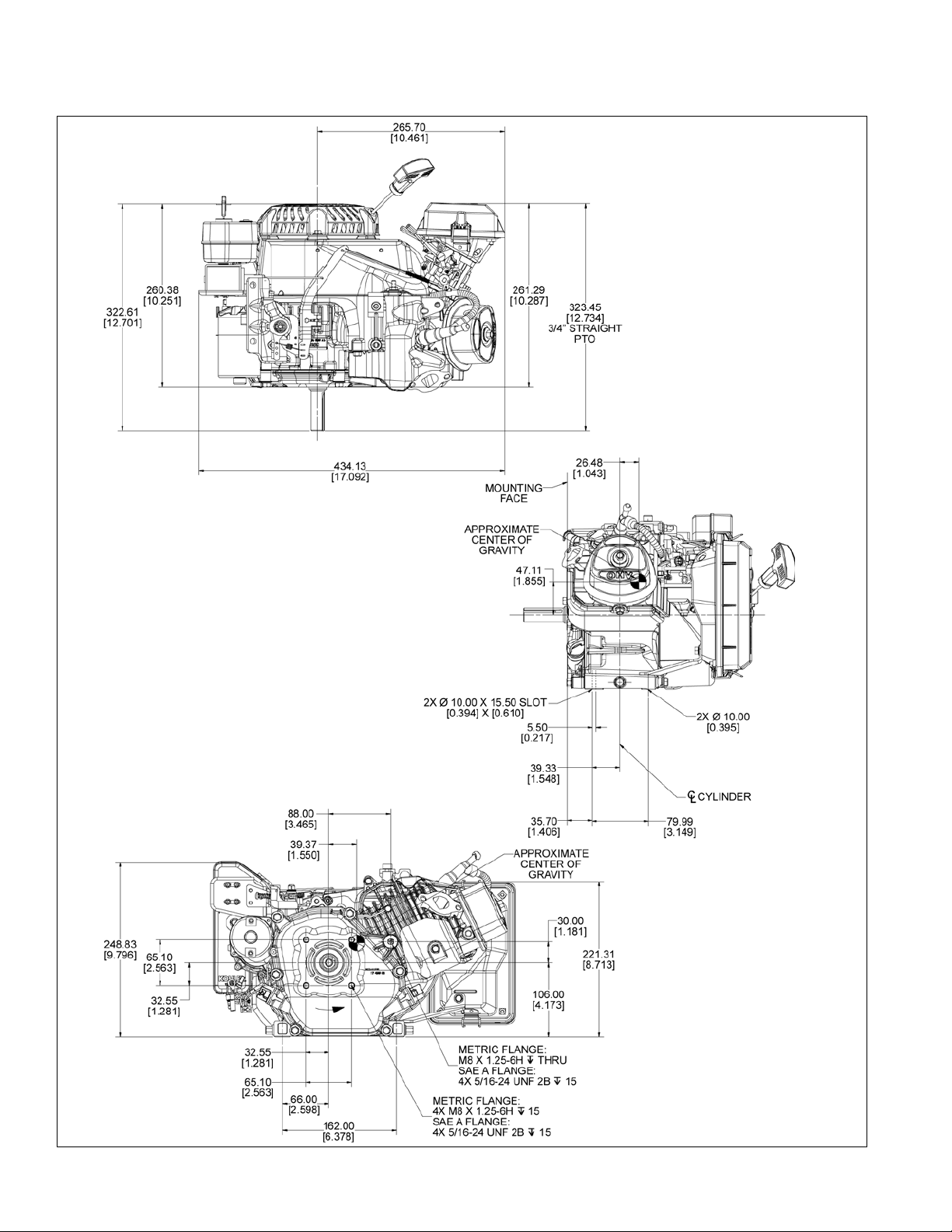

Specications

CH260/CH270 Engine Dimensions

Dimensions in millimeters.

Inch equivalents shown in [ ].

6

KohlerEngines.com 17 690 01 Rev. E

Page 7

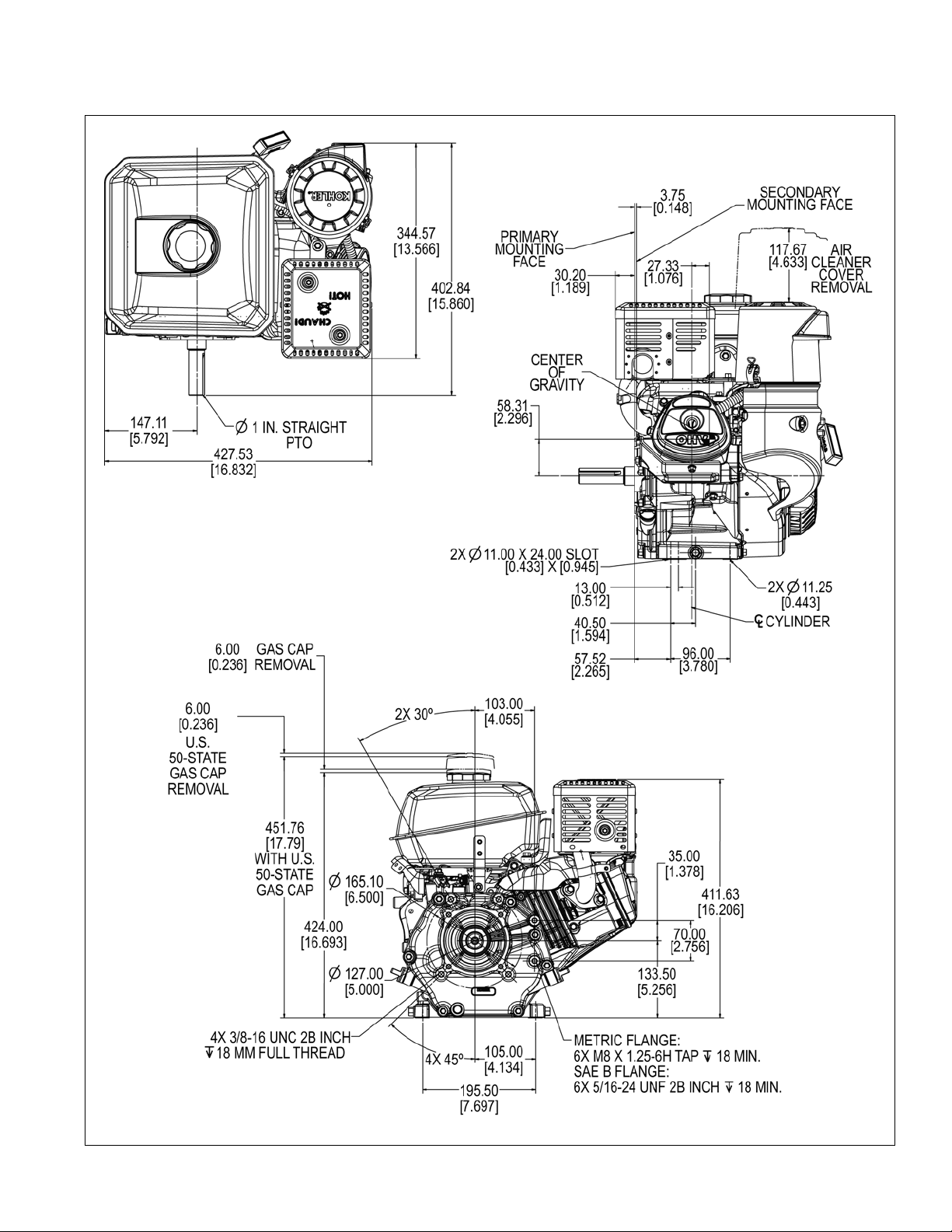

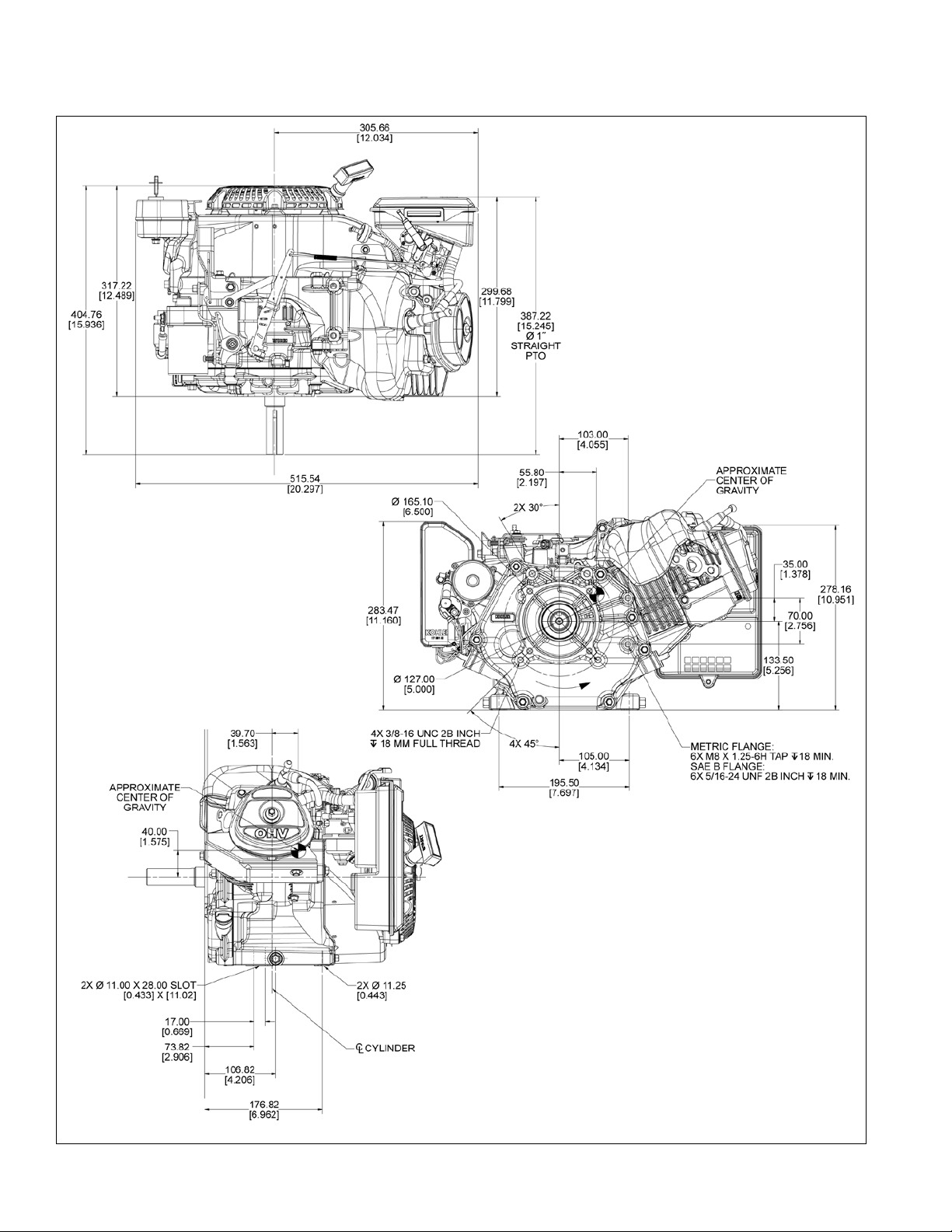

CH395 Engine Dimensions

Specications

Dimensions in millimeters.

Inch equivalents shown in [ ].

17 690 01 Rev. E KohlerEngines.com

7

Page 8

Specications

CH395 Engine Dimensions

Dimensions in millimeters.

Inch equivalents shown in [ ].

8

KohlerEngines.com 17 690 01 Rev. E

Page 9

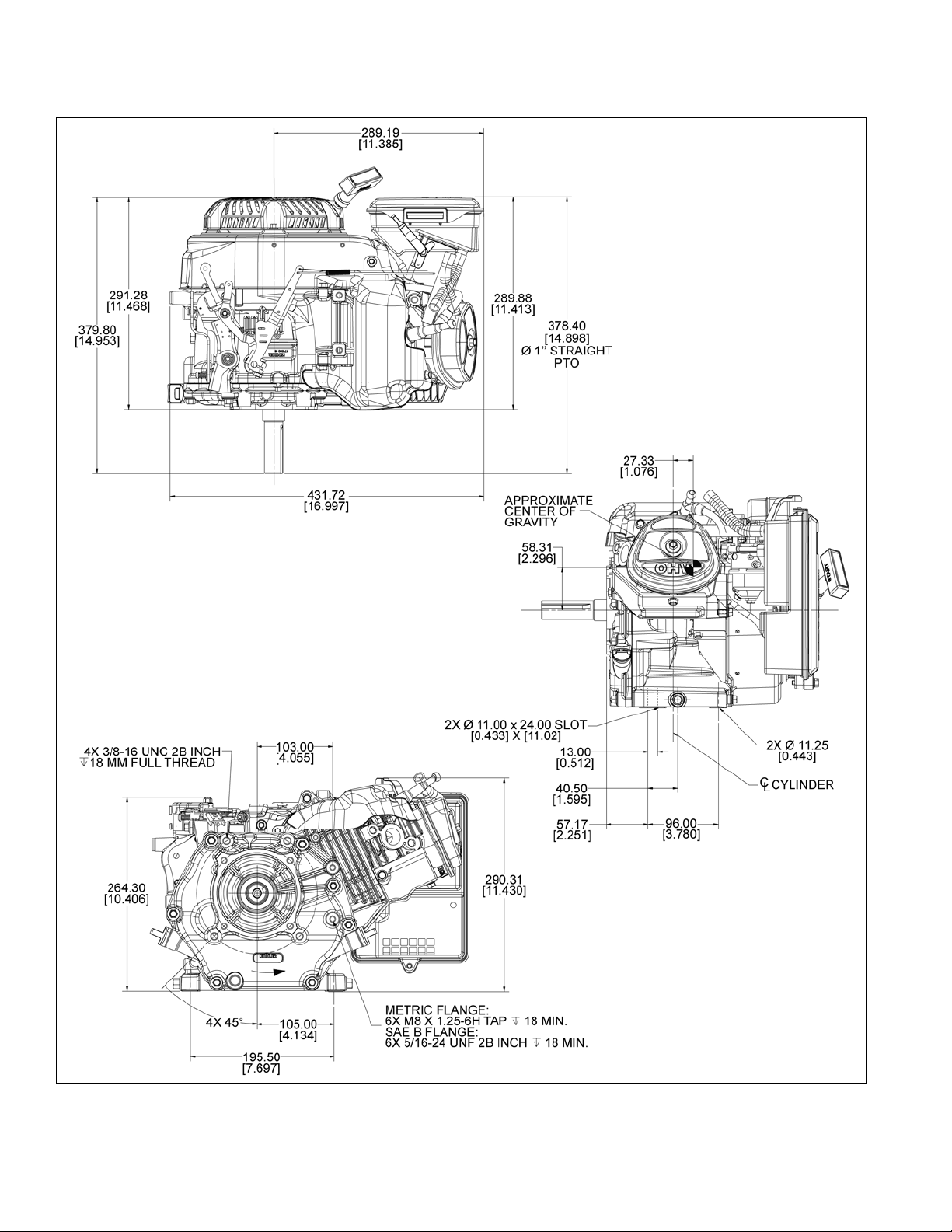

CH440 Engine Dimensions

Specications

Dimensions in millimeters.

Inch equivalents shown in [ ].

17 690 01 Rev. E KohlerEngines.com

9

Page 10

Specications

CH440 Engine Dimensions

Dimensions in millimeters.

Inch equivalents shown in [ ].

10

KohlerEngines.com 17 690 01 Rev. E

Page 11

Specications

ENGINE IDENTIFICATION NUMBERS

Kohler engine identication numbers (model, specication and serial) should be referenced for efcient repair,

ordering correct parts, and engine replacement.

Model . . . . . . . . . . . . . . . . . . . . . CH260

Command Engine

Horizontal Shaft

Numerical Designation

Specication . . . . . . . . . . . . . . . CH260-0001

Serial . . . . . . . . . . . . . . . . . . . . . 3923500328

Year Manufactured Code Factory Code

Code Year

39 2009

40 2010

41 2011

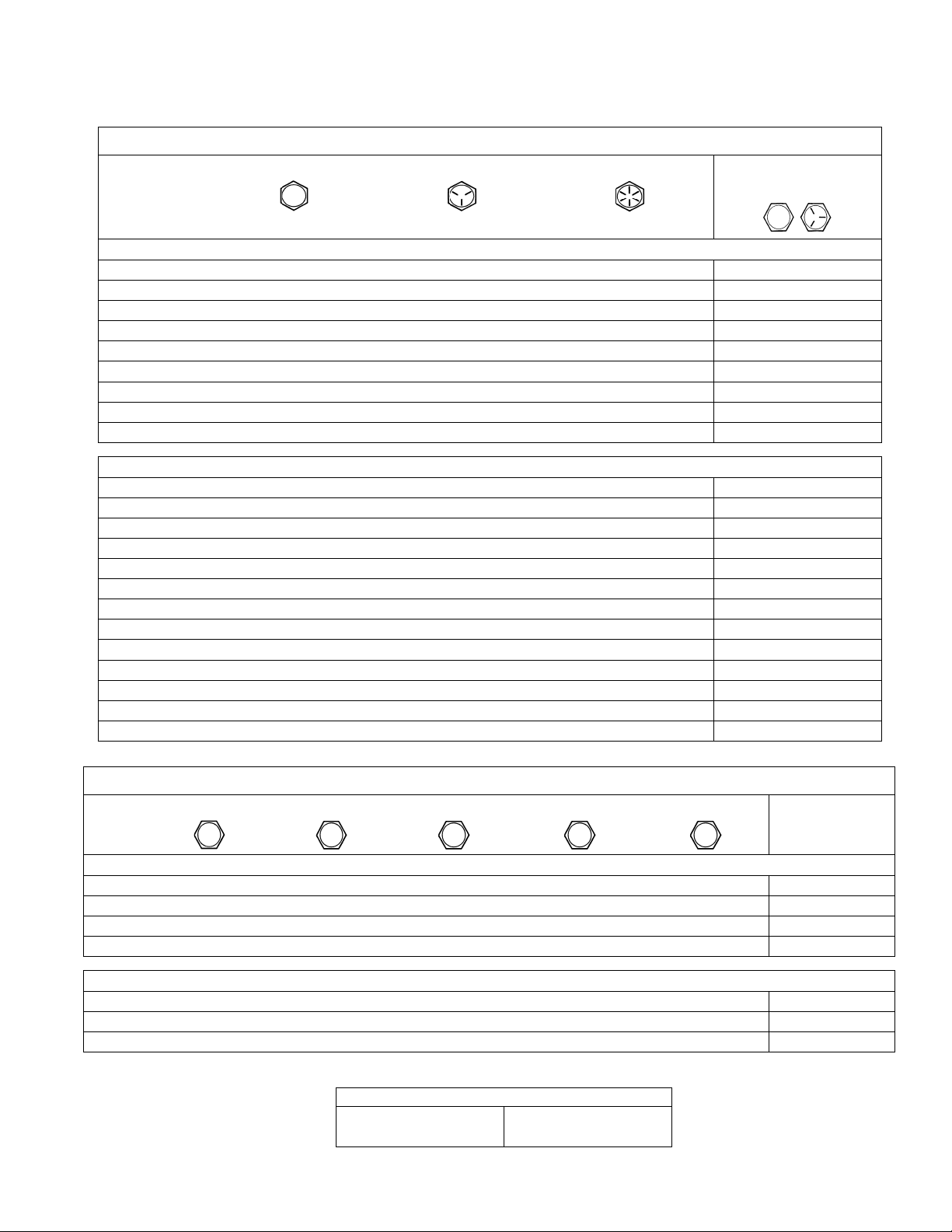

GENERAL SPECIFICATIONS

3,6

CH260/CH270 CH395 CH440

Bore 70 mm (2.8 in.) 78 mm (3.1 in.) 89 mm (3.5 in.)

Stroke 54 mm (2.1 in.) 58 mm (2.3 in.) 69 mm (2.7 in.)

Displacement 208 cc

(12.7 cu. in.)

Oil Capacity (rell) 0.6 L

(0.63 U.S. qt.)

Maximum Angle of Operation (@ full oil level)

TORQUE SPECIFICATIONS

3,5

4

CH260/CH270 CH395 CH440

277 cc

(16.9 cu. in.)

1.1 L

(1.16 U.S. qt.)

25°

429 cc

(24.7 cu. in.)

1.3 L

(1.37 U.S. qt.)

Air Cleaner

Quad-Clean

Air Cleaner Base Mounting Screw 8.0 N·m (71 in. lb.)

™

Low-Prole Air Cleaner Base Mounting Screw 6.7 N·m (59 in. lb.)

Blower Housing and Sheet Metal

M6 Screw 10 N·m (89 in. lb.)

M6 Nut 8.0 N·m (71 in. lb.)

Carburetor

Stud 10 N·m (89 in. lb.)

Primary Nut 8 N·m (71 in. lb.)

Intake Cover Nut 4 N·m (35 in. lb.)

Intake Cover Screw 1.3 N·m (12 in. lb.)

Connecting Rod

Cap Fastener (torque in increments) 12 N·m

20 N·m (177 in. lb.)

(106 in. lb.)

3

Values are in Metric units. Values in parentheses are English equivalents.

4

Exceeding maximum angle of operation may cause engine damage from insufcient lubrication.

5

Lubricate threads with engine oil prior to assembly.

6

Any and all horsepower (hp) references by Kohler are Certied Power Ratings and per SAE J1940 & J1995 hp

standards. Details on Certied Power Ratings can be found at KohlerEngines.com.

17 690 01 Rev. E KohlerEngines.com

11

Page 12

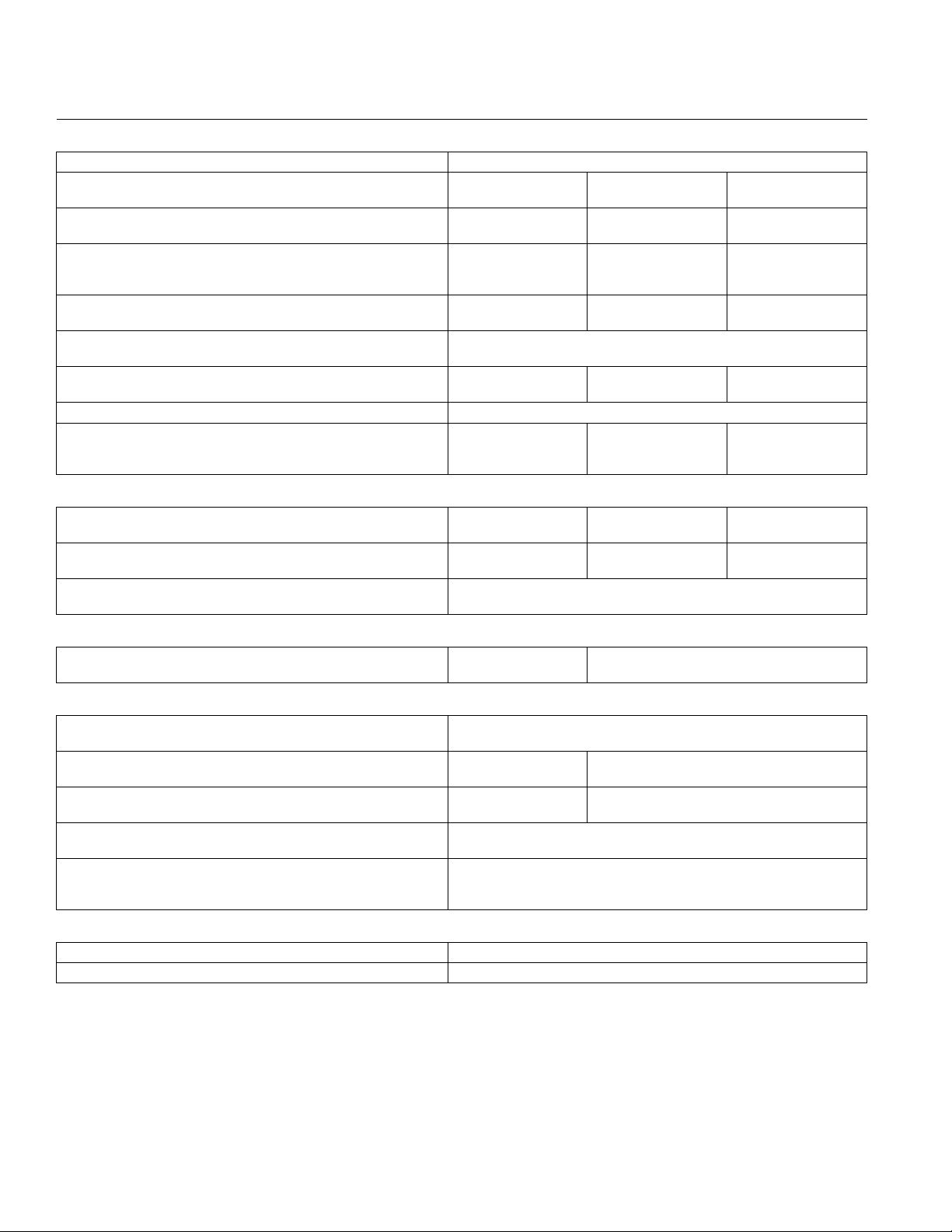

Specications

TORQUE SPECIFICATIONS

3,5

CH260/CH270 CH395 CH440

Crankcase

Oil Drain Plug 18 N·m (13 ft. lb.)

Closure Plate Screw 24 N·m (212 in. lb.)

Cylinder Head

Fastener (torque in 2 increments) First to 12 N·m

(106 in. lb.)

First to 18 N·m (159 in. lb.)

Finally to 36 N·m (319 in. lb.)

Finally to 24 N·m

(212 in. lb.)

Electric Starter

Mounting Screw 24 N·m (212 in. lb.)

Flywheel

Retaining Nut 74 N·m

113 N·m (1000 in. lb.)

(655 in. lb.)

Fuel Tank

Mounting Nut 24 N·m (212 in. lb.)

Mounting Screw 24 N·m (212 in. lb.)

Inlet Fitting 1.5 N·m (13 in. lb.)

Governor

Lever Nut 12 N·m (106 in. lb.)

Throttle Control Lever Nut 9 N·m (80 in. lb.)

Ignition

Spark Plug 27 N·m (20 ft. lb.)

Module Fastener 10 N·m (89 in. lb.)

Oil Sentry

Oil Sentry

Oil Sentry

Float Switch Screw 8 N·m (71 in. lb.)

™

Module Screw 3.5 N·m (31 in. lb.)

™

Wire Lead Nut 10 N·m (89 in. lb.)

™

Mufer

Exhaust Screw

M8

M10

24 N·m (212 in. lb.)

---

---

35 N·m (310 in. lb.)

Mufer Shield Screw

M6 8 N·m (71 in. lb.)

M4 2 N·m (18 in. lb.) 3.5 N·m (31 in. lb.)

Spark Arrestor Screw M5 3.5 N·m (31 in. lb.)

Retractable Starter

Cover Screw 5.4 N·m (48 in. lb.)

Center Screw 10 N·m (89 in. lb.)

Rocker Arm

Stud 13.6 N·m (120 in. lb.)

Pivot Jam Nut 10 N·m (89 in. lb.)

3

Values are in Metric units. Values in parentheses are English equivalents.

5

Lubricate threads with engine oil prior to assembly.

12

KohlerEngines.com 17 690 01 Rev. E

Page 13

Specications

TORQUE SPECIFICATIONS

3,5

CH260/CH270 CH395 CH440

Valve Cover

Fastener 10 N·m (89 in. lb.)

CLEARANCE SPECIFICATIONS

3

CH260/CH270 CH395 CH440

Camshaft

Running Clearance 0.007/0.043 mm

(0.0003/0.0017 in.)

0.016/0.052 mm

(0.0006/0.0020 in.)

Bore I.D.

New 13.991/14.009 mm

16.000/16.018 mm (0.6300/0.6310 in.)

(0.5508/0.5515 in.)

Max. Wear Limit 14.018 mm

16.068 mm (0.6289 in.)

(0.5519 in.)

Camshaft Bearing Surface O.D.

New 13.975 mm

15.975 mm (0.63 in.)

(0.55 in.)

Max. Wear Limit 13.90 mm

15.90 mm (0.626 in.)

(0.547 in.)

Cam Lobe Prole (minimum dimension, measured from

base circle to top of lobe)

Intake - New 31.966 mm

(1.259 in.)

Max. Wear Limit 31.72 mm

(1.249 in.)

Exhaust - New 31.966 mm

(1.259 in.)

Max. Wear Limit 31.72 mm

(1.249 in.)

32.544 mm

(1.281 in.)

32.11 mm

(1.264 in.)

32.256 mm

(1.270 in.)

31.79 mm

(1.252 in.)

33.266 mm

(1.310 in.)

32.26 mm

(1.270 in.)

32.642 mm

(1.285 in.)

31.61 mm

(1.245 in.)

Connecting Rod

Crankpin End I.D. @ 21°C (70°F)

New 30.021/30.026 mm

(1.1819/1.1821 in.)

Max. Wear Limit 30.08 mm

(1.184 in.)

33.020/33.030 mm

(1.3000/1.3004 in.)

33.07 mm

(1.302 in.)

37.08 mm

(1.460 in.)

Connecting Rod-to-Crankpin Side Clearance

New 0.58/0.60 mm

(0.023/0.024 in.)

Max. Wear Limit 1.10 mm

(0.043 in.)

Connecting Rod-to-Piston Pin Running Clearance 0.008/0.025 mm

(0.0003/0.0010 in.)

0.73 mm

(0.029 in.)

1.36 mm

(0.054 in.)

0.006/0.028 mm

(0.0002/0.0011 in.)

0.56 mm

(0.022 in.)

1.06 mm

(0.042 in.)

0.008/0.025 mm

(0.0003/0.0010 in.)

Piston Pin End I.D. @ 21°C (70°F)

New 18.010/18.015 mm

(0.7091/0.7093 in.)

18.004/18.020 mm

(0.7088/0.7094 in.)

20.000/20.008 mm

(0.7874/0.7874 in.)

Max. Wear Limit 18.08 mm (0.712 in.) 20.05 mm

(0.789 in.)

Crankcase

Governor Cross Shaft Bore I.D.

New

Max. Wear Limit 6.037 mm

6.000/6.024 mm

(0.2362/0.2372 in.)

8.000/8.024 mm (0.3150/0.3159 in.)

8.074 mm (0.7118 in.)

(0.2377 in.)

3

Values are in Metric units. Values in parentheses are English equivalents.

17 690 01 Rev. E KohlerEngines.com

13

Page 14

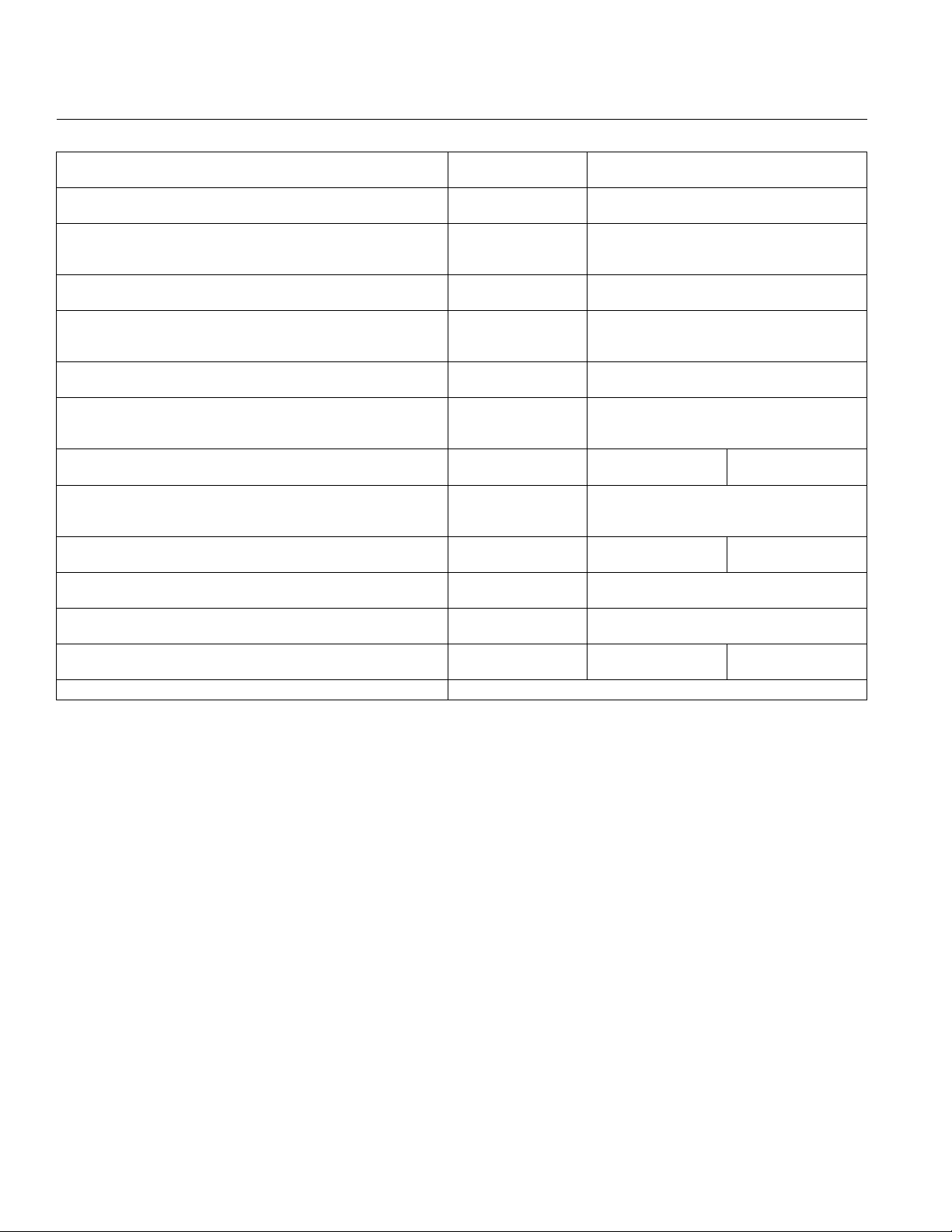

Specications

CLEARANCE SPECIFICATIONS

3

CH260/CH270 CH395 CH440

Crankshaft

End Play (free) 0.0508/0.254 mm (0.002/0.010 in.)

Ball Bearing Internal Clearance 0.003/0.025 mm

(0.0001/0.0010 in.)

Crankshaft O.D. (new) 24.975/24.989 mm

(0.9833/0.9838 in.)

0.005/0.020 mm

(0.0002/0.0008 in.)

29.975/29.989 mm

(1.1801/1.1807 in.)

0.006/0.020 mm

(0.0002/0.0008 in.)

34.975/34.989 mm

(1.3770/1.3775 in.)

Connecting Rod Journal O.D.

New 30.020/30.030 mm

(1.1819/1.1823 in.)

Max. Wear Limit 30.08 mm

(1.1842 in.)

Max. Taper

Max. Out-of-Round

Width 24.5/24.9 mm

(0.9646/0.9803 in.)

32.975/32.985 mm

(1.2982/1.2986 in.)

32.92 mm

(1.2961 in.)

2.5 microns (0.0001 in.)

12.7 microns (0.0005 in.)

30.30/30.36 mm

(1.1930/1.1953 in.)

36.975/36.985 mm

(1.4557/1.4561 in.)

28.30/28.36 mm

(1.1142/1.1165 in.)

Runout (either end) 0.025 mm (0.001 in.)

Main Bearing I.D. (Crankcase/Closure Plate)

New (installed) 24.992/25.000 mm

(0.9839/0.9842 in.)

29.990/30.000 mm

1.1807/1.1811 in.)

34.990/35.000 mm

(1.3776/1.3780 in.)

Cylinder Bore

Bore I.D.

New

Max. Wear Limit 70.200 mm

Max. Out-of-Round

Max. Taper

70.027/70.035 mm

(2.757/2.757 in.)

(2.764 in.)

77.98/78.02 mm

(3.0701/3.0717 in.)

78.185 mm

(3.0781 in.)

12.7 microns (0.0005 in.)

12.7 microns (0.0005 in.)

89.00/89.02 mm

(3.5039/3.5045 in.)

36.92 mm

(1.4535 in.)

89.185 mm

(3.5112 in.)

Cylinder Head

Max. Out-of-Flatness 0.08 mm

0.1 mm (0.004 in.)

(0.003 in.)

Governor

Governor Cross Shaft -to-Crankcase Running

0.020/0.069 mm (0.0008/0.0027 in.)

Clearance

Governor Cross Shaft O.D.

New

Max. Wear Limit 5.942 mm

5.955/5.980 mm

(0.2344/0.2354 in.)

7.955/7.980 mm

(0.3132/0.3142 in.)

7.900 mm (0.3110 in.)

(0.2339 in.)

Governor Gear Shaft -to-Governor Gear Running

0.022/0.134 mm (0.0009/0.0053 in.)

Clearance

Governor Gear Shaft O.D.

New

Max. Wear Limit

6.016/6.028 mm (0.2368/0.2373 in.)

6.003 mm (0.2363 in.)

Ignition

Spark Plug Gap 0.76 mm (0.030 in.)

Module Air Gap 0.254 mm (0.010 in.)

3

Values are in Metric units. Values in parentheses are English equivalents.

14

KohlerEngines.com 17 690 01 Rev. E

Page 15

Specications

CLEARANCE SPECIFICATIONS

3

CH260/CH270 CH395 CH440

Piston, Piston Rings, and Piston Pin

Piston-to-Piston Pin Running Clearance 0.009/0.016 mm

0.002/0.016 mm (0.0001/0.0006 in.)

(0.0003/0.0006 in.)

Piston Pin Bore I.D.

New 18.004/18.005 mm

(0.7088/0.7089 in.)

18.000/18.008 mm

(0.7087/0.7090 in.)

20.000/20.008 mm

(0.7874/0.7877 in.)

Max. Wear Limit 18.05 mm (0.7106 in.) 20.05 mm

(0.7894 in.)

Piston Pin O.D.

New 17.992/17.995 mm (0.7083/0.7084 in.)

19.992/19.998 mm

(0.7871/0.7873 in.)

Max. Wear Limit 17.95 mm (0.7067 in.) 19.95 mm

(0.7854 in.)

Top and Center Compression Ring Side Clearance

New Bore 0.04 mm

(0.002 in.)

Used Bore (Max.) 0.15 mm

(0.006 in.)

Top Compression Ring End Gap

New Bore

0.325/0.400 mm

(0.013/0.016 in.)

0.07 mm

(0.003 in.)

0.11 mm

(0.004 in.)

0.045 mm

(0.0018 in.)

0.10 mm

(0.004 in.)

0.250/0.400 mm (0.010/0.016 in.)

Used Bore (Max.) 1.00 mm (0.039 in.)

Center Compression Ring End Gap

New Bore

Used Bore (Max.) 1.00 mm

0.325/0.400 mm

(0.013/0.016 in.)

0.650/0.800 mm

(0.026/0.032 in.)

1.50 mm (0.059 in.)

0.640/0.800 mm

(0.025/0.032 in.)

(0.039 in.)

Oil Control Ring-to-Groove Side Clearance 0.05/0.19 mm (0.0019/0.0075 in.) 0.09/0.15 mm

(0.0035/0.0059 in.)

Piston Thrust Face O.D.

New 69.970/69.960 mm

(2.755/2.754 in.)

Max. Wear Limit 69.82 mm

(2.749 in.)

Piston Thrust Face-to-Cylinder Bore Running

Clearance

0.057/0.075 mm

(0.002/0.003 in.)

77.955/77.975 mm

7

(3.071/3.070 in.)

77.82 mm

(3.064 in.)

0.033/0.067 mm

7

(0.001/0.003 in.)

88.955/88.975 mm

8

(3.502/3.503 in.)

88.82 mm

(3.497 in.)

0.025/0.060 mm

8

(0.001/0.002 in.)

9

9

3

Values are in Metric units. Values in parentheses are English equivalents.

7

Measure 21.8-22.2 mm (0.8583-0.8740 in.) above bottom of piston skirt at right angles to piston pin.

8

Measure 17.8-18.2 mm (0.7008-0.7165 in.) above bottom of piston skirt at right angles to piston pin.

9

Measure 29.8-30.2 mm (1.1732-1.1890 in.) above bottom of piston skirt at right angles to piston pin.

17 690 01 Rev. E KohlerEngines.com

15

Page 16

Specications

CLEARANCE SPECIFICATIONS

3

CH260/CH270 CH395 CH440

Valves and Valve Lifters

Intake Valve Stem-to-Valve Guide Running Clearance 0.038/0.065 mm

0.025/0.055 mm (0.0010/0.0022 in.)

(0.0015/0.0026 in.)

Exhaust Valve Stem-to-Valve Guide Running Clearance 0.085/0.112 mm

0.040/0.07 mm (0.0016/0.0026 in.)

(0.0033/0.0044 in.)

Intake Valve Stem O.D.

New

5.50 mm

(0.217 in.)

Max. Wear Limit 5.34 mm

(0.210 in.)

Exhaust Valve Stem O.D.

New 5.438 mm

(0.214 in.)

Max. Wear Limit 5.28 mm

(0.208 in.)

Intake Valve Stem to Guide

New 0.024/0.039 mm

0.025/0.055 mm (0.0010/0.0022 in.)

(0.0009/0.0015 in.)

Max. Wear Limit 0.10 mm

(0.0039 in.)

0.13 mm

(0.0051 in.)

Exhaust Valve Stem to Guide

New 0.098/0.112 mm

0.040/0.070 mm (0.0016/0.0028 in.)

(0.0038/0.0044 in.)

Max. Wear Limit 0.12 mm

(0.0047 in.)

Valve Guide Reamer Size

Standard Intake

5.524 mm (0.2175

in.)

0.10 mm

(0.0039 in.)

Standard Exhaust 5.536 mm (0.2179

in.)

Valve Seat Width 0.80 mm (0.0315

1.10 mm (0.0433

in.)

Nominal Valve Face Angle 45°

6.57 mm (0.259 in.)

6.40 mm (0.252 in.)

6.55 mm (0.258 in.)

6.41 mm (0.252 in.)

0.14 mm

(0.0055 in.)

0.11 mm

(0.0043 in.)

6.608 mm (0.2602 in.)

6.608 mm (0.2602 in.)

1.20 mm (0.0472

in.)

in.)

3

Values are in Metric units. Values in parentheses are English equivalents.

16

KohlerEngines.com 17 690 01 Rev. E

Page 17

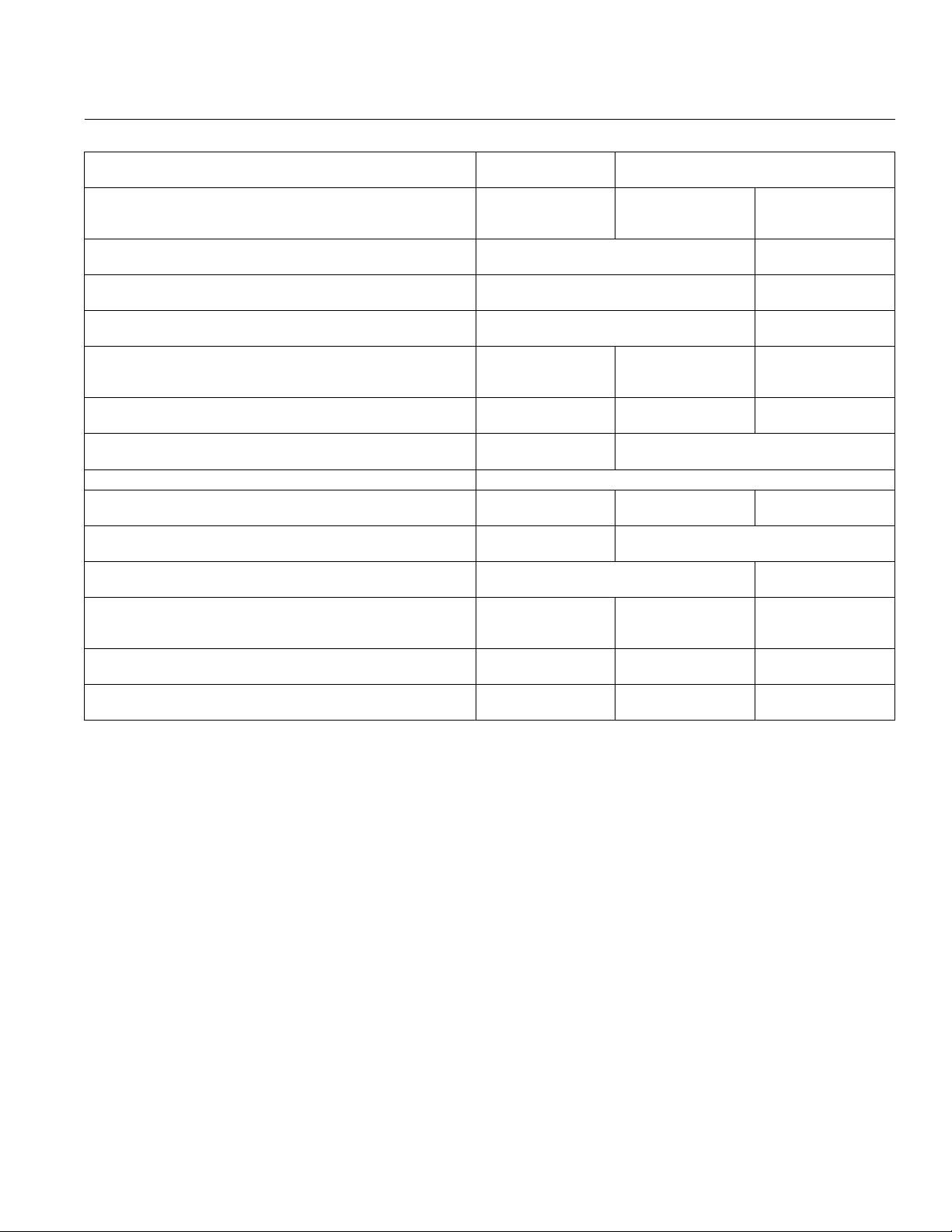

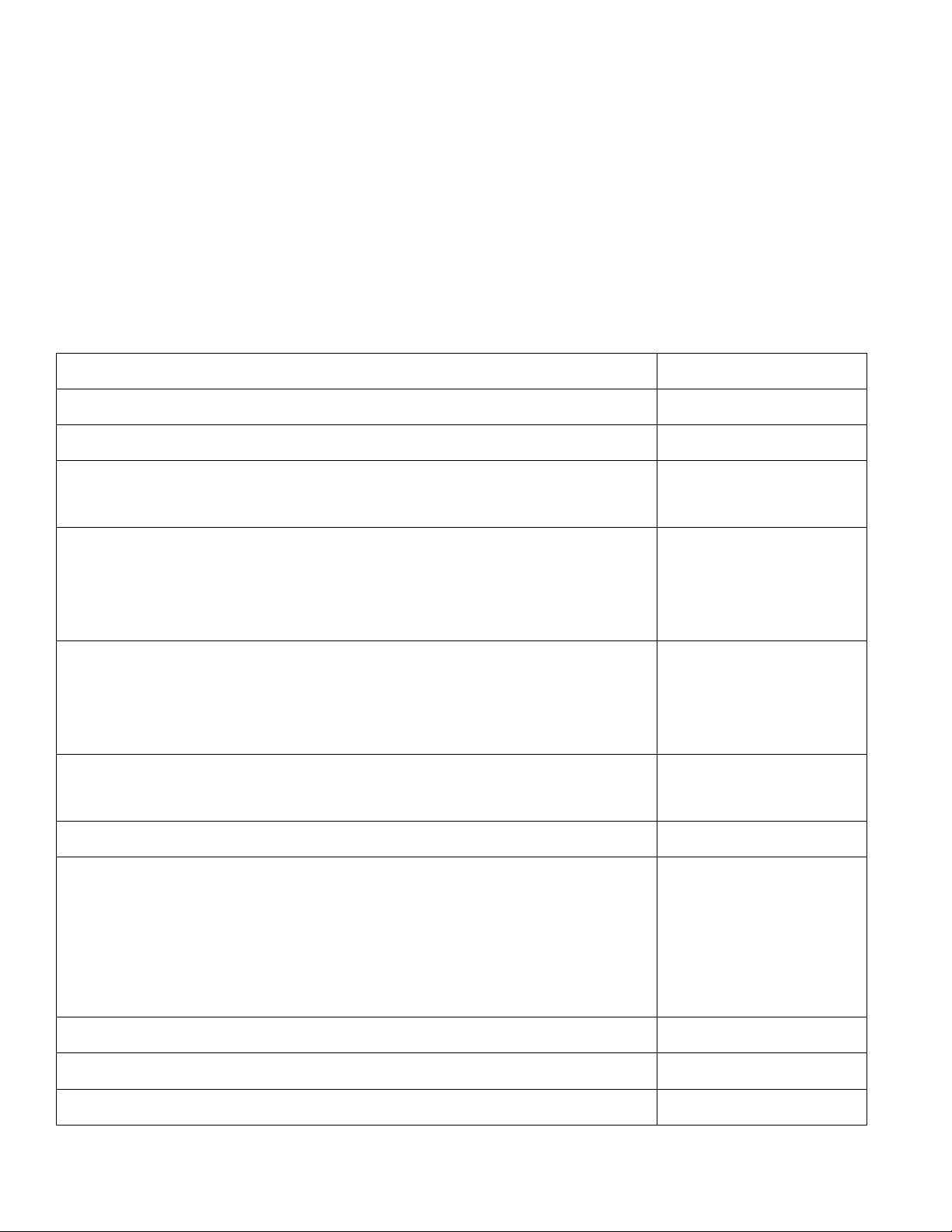

GENERAL TORQUE VALUES

English Fastener Torque Recommendations for Standard Applications

Bolts, Screws, Nuts and Fasteners Assembled Into Cast Iron or Steel

Grade 2 or 5 Fasteners

Size Grade 2 Grade 5 Grade 8

Tightening Torque: N·m (in. lb.) ± 20%

8-32 2.3 (20) 2.8 (25) — 2.3 (20)

10-24 3.6 (32) 4.5 (40) — 3.6 (32)

10-32 3.6 (32) 4.5 (40) — —

1/4-20 7.9 (70) 13.0 (115) 18.7 (165) 7.9 (70)

1/4-28 9.6 (85) 15.8 (140) 22.6 (200) —

5/16-18 17.0 (150) 28.3 (250) 39.6 (350) 17.0 (150)

5/16-24 18.7 (165) 30.5 (270) — —

3/8-16 29.4 (260) — — —

3/8-24 33.9 (300) — — —

Tightening Torque: N·m (ft. lb.) ± 20%

5/16-24 — — 40.7 (30) —

3/8-16 — 47.5 (35) 67.8 (50) —

3/8-24 — 54.2 (40) 81.4 (60) —

7/16-14 47.5 (35) 74.6 (55) 108.5 (80) —

7/16-20 61.0 (45) 101.7 (75) 142.5 (105) —

1/2-13 67.8 (50) 108.5 (80) 155.9 (115) —

1/2-20 94.9 (70) 142.4 (105) 223.7 (165) —

9/16-12 101.7 (75) 169.5 (125) 237.3 (175) —

9/16-18 135.6 (100) 223.7 (165) 311.9 (230) —

5/8-11 149.5 (110) 244.1 (180) 352.6 (260) —

5/8-18 189.8 (140) 311.9 (230) 447.5 (330) —

3/4-10 199.3 (147) 332.2 (245) 474.6 (350) —

3/4-16 271.2 (200) 440.7 (325) 637.3 (470) —

Specications

Into Aluminum

Metric Fastener Torque Recommendations for Standard Applications

Size

4.8

5.8

Property Class

8.8

10.9 12.9

Noncritical

Fasteners

Into Aluminum

Tightening Torque: N·m (in. lb.) ± 10%

M4 1.2 (11) 1.7 (15) 2.9 (26) 4.1 (36) 5.0 (44) 2.0 (18)

M5 2.5 (22) 3.2 (28) 5.8 (51) 8.1 (72) 9.7 (86) 4.0 (35)

M6 4.3 (38) 5.7 (50) 9.9 (88) 14.0 (124) 16.5 (146) 6.8 (60)

M8 10.5 (93) 13.6 (120) 24.4 (216) 33.9 (300) 40.7 (360) 17.0 (150)

Tightening Torque: N·m (ft. lb.) ± 10%

M10 21.7 (16) 27.1 (20) 47.5 (35) 66.4 (49) 81.4 (60) 33.9 (25)

M12 36.6 (27) 47.5 (35) 82.7 (61) 116.6 (86) 139.7 (103) 61.0 (45)

M14 58.3 (43) 76.4 (56) 131.5 (97) 184.4 (136) 219.7 (162) 94.9 (70)

Torque Conversions

N·m = in. lb. x 0.113 in. lb. = N·m x 8.85

N·m = ft. lb. x 1.356 ft. lb. = N·m x 0.737

17 690 01 Rev. E KohlerEngines.com

17

Page 18

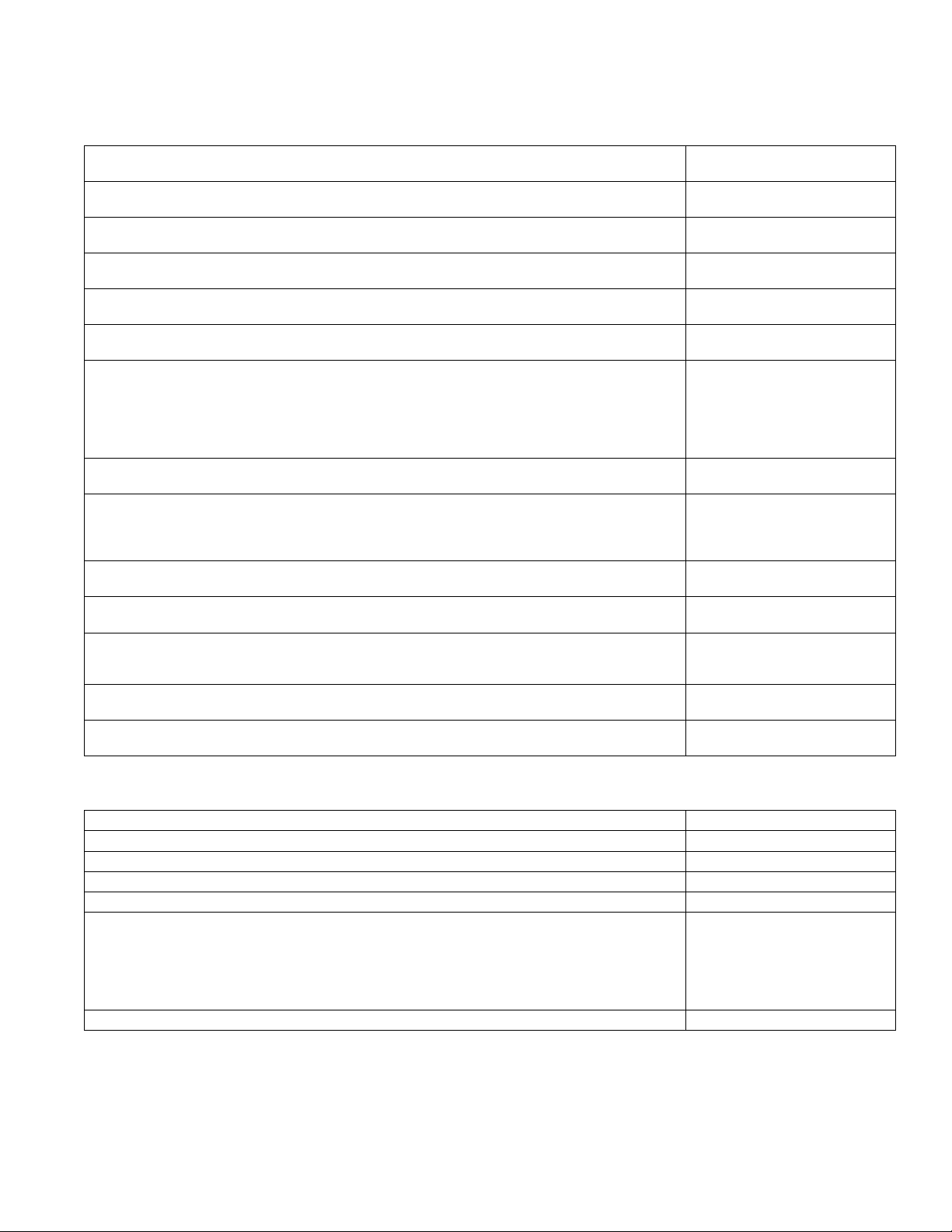

Tools and Aids

Certain quality tools are designed to help you perform specic disassembly, repair, and reassembly procedures. By

using these tools, you can properly service engines easier, faster, and safer! In addition, you’ll increase your service

capabilities and customer satisfaction by decreasing engine downtime.

Here is a list of tools and their source.

SEPARATE TOOL SUPPLIERS

Kohler Tools

Contact your local Kohler source of

supply.

TOOLS

Description Source/Part No.

Alcohol Content Tester

For testing alcohol content (%) in reformulated/oxygenated fuels.

Camshaft Endplay Plate

For checking camshaft endplay.

Camshaft Seal Protector (Aegis)

For protecting seal during camshaft installation.

Cylinder Leakdown Tester

For checking combustion retention and if cylinder, piston, rings, or valves are worn.

Individual component available:

Adapter 12 mm x 14 mm (Required for leakdown test on XT-6 engines)

Dealer Tool Kit (Domestic)

Complete kit of Kohler required tools.

Components of 25 761 39-S

Ignition System Tester

Cylinder Leakdown Tester

Oil Pressure Test Kit

Rectier-Regulator Tester (120 V AC/60Hz)

Dealer Tool Kit (International)

Complete kit of Kohler required tools.

Components of 25 761 42-S

Ignition System Tester

Cylinder Leakdown Tester

Oil Pressure Test Kit

Rectier-Regulator Tester (240 V AC/50Hz)

Digital Vacuum/Pressure Tester

For checking crankcase vacuum.

Individual component available:

Rubber Adapter Plug

Electronic Fuel Injection (EFI) Diagnostic Software

For Laptop or Desktop PC.

EFI Service Kit

For troubleshooting and setting up an EFI engine.

Components of 24 761 01-S

Fuel Pressure Tester

Noid Light

90° Adapter

In-line "T" Fitting

Code Plug, Red Wire

Code Plug, Blue Wire

Shrader Valve Adapter Hose

Flywheel Holding Tool (CS)

For holding ywheel of CS series engines.

Flywheel Puller

For properly removing ywheel from engine.

Flywheel Strap Wrench

For holding ywheel during removal.

SE Tools

415 Howard St.

Lapeer, MI 48446

Phone 810-664-2981

Toll Free 800-664-2981

Fax 810-664-8181

Design Technology Inc.

768 Burr Oak Drive

Westmont, IL 60559

Phone 630-920-1300

Fax 630-920-0011

Kohler 25 455 11-S

SE Tools KLR-82405

SE Tools KLR-82417

Kohler 25 761 05-S

Design Technology Inc.

DTI-731-03

Kohler 25 761 39-S

Kohler 25 455 01-S

Kohler 25 761 05-S

Kohler 25 761 06-S

Kohler 25 761 20-S

Kohler 25 761 42-S

Kohler 25 455 01-S

Kohler 25 761 05-S

Kohler 25 761 06-S

Kohler 25 761 41-S

Design Technology Inc.

DTI-721-01

Design Technology Inc.

DTI-721-10

Kohler 25 761 23-S

Kohler 24 761 01-S

Design Technology Inc.

DTI-019

DTI-021

DTI-023

DTI-035

DTI-027

DTI-029

DTI-037

SE Tools KLR-82407

SE Tools KLR-82408

SE Tools KLR-82409

18 17 690 01 Rev. EKohlerEngines.com

Page 19

Tools and Aids

TOOLS

Description Source/Part No.

Hydraulic Valve Lifter Tool

For removing and installing hydraulic lifters.

Ignition System Tester

For testing output on all systems, including CD.

Inductive Tachometer (Digital)

For checking operating speed (RPM) of an engine.

Offset Wrench (K and M Series)

For removing and reinstalling cylinder barrel retaining nuts.

Oil Pressure Test Kit

For testing/verifying oil pressure on pressure lubricated engines.

Radiator Tester

For pressure testing radiator and cap on Aegis liquid-cooled engines.

Rectier-Regulator Tester (120 volt current)

Rectier-Regulator Tester (240 volt current)

For testing rectier-regulators.

Components of 25 761 20-S and 25 761 41-S

CS-PRO Regulator Test Harness

Special Regulator Test Harness with Diode

Spark Advance Module (SAM) Tester

For testing SAM (ASAM and DSAM) on engines with SMART-SPARK

.

™

Starter Servicing Kit (All Starters)

For removing and reinstalling drive retaining rings and brushes.

Individual component available:

Starter Brush Holding Tool (Solenoid Shift)

Triad/OHC Timing Tool Set

For holding cam gears and crankshaft in timed position while installing timing belt.

Valve Guide Reamer (K and M Series)

For properly sizing valve guides after installation.

Valve Guide Reamer O.S. (Command Series)

For reaming worn valve guides to accept replacement oversize valves. Can be used

in low-speed drill press or with handle below for hand reaming.

Reamer Handle

For hand reaming using Kohler 25 455 12-S reamer.

Valve Guide Service Kit (Courage, Aegis, Command, OHC)

For servicing worn valve guides.

Kohler 25 761 38-S

Kohler 25 455 01-S

Design Technology Inc.

DTI-110

Kohler 52 455 04-S

Kohler 25 761 06-S

Kohler 25 455 10-S

Kohler 25 761 20-S

Kohler 25 761 41-S

Design Technology Inc.

DTI-031

DTI-033

Kohler 25 761 40-S

SE Tools KLR-82411

SE Tools KLR-82416

Kohler 28 761 01-S

Design Technology Inc.

DTI-K828

Kohler 25 455 12-S

Design Technology Inc.

DTI-K830

SE Tools KLR-82415

AIDS

Description Source/Part No.

Camshaft Lubricant (Valspar ZZ613) Kohler 25 357 14-S

Dielectric Grease (GE/Novaguard G661) Kohler 25 357 11-S

Dielectric Grease Loctite

®

51360

Kohler Electric Starter Drive Lubricant (Inertia Drive) Kohler 52 357 01-S

Kohler Electric Starter Drive Lubricant (Solenoid Shift) Kohler 52 357 02-S

RTV Silicone Sealant

Loctite

Only oxime-based, oil resistant RTV sealants, such as those listed, are approved

®

5900® Heavy Body in 4 oz. aerosol dispenser.

for use. Loctite® Nos. 5900® or 5910® are recommended for best sealing

characteristics.

Kohler 25 597 07-S

Loctite® 5910

®

Loctite® Ultra Black 598™

Loctite® Ultra Blue 587™

Loctite® Ultra Copper 5920™

Spline Drive Lubricant Kohler 25 357 12-S

1917 690 01 Rev. E KohlerEngines.com

Page 20

Tools and Aids

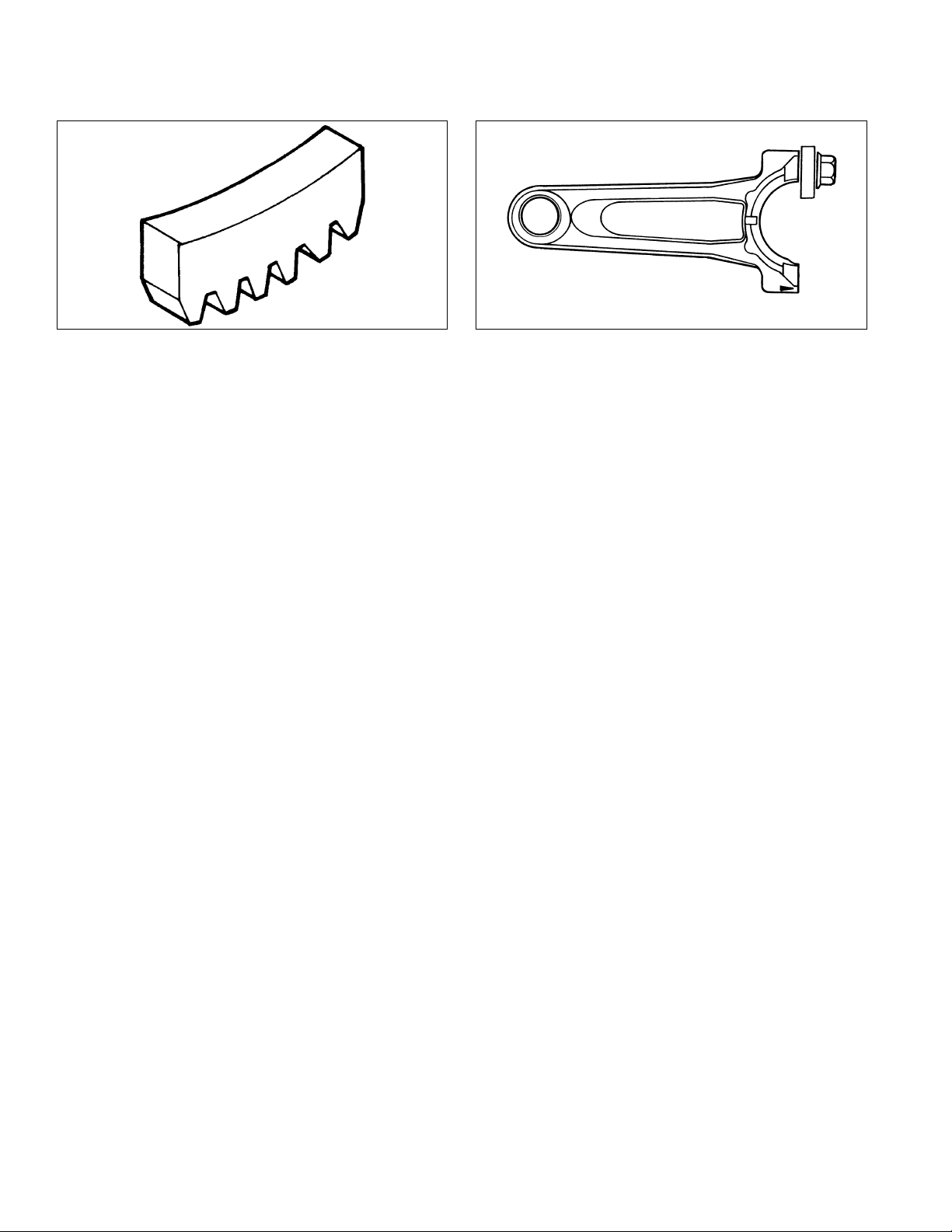

FLYWHEEL HOLDING TOOL ROCKER ARM/CRANKSHAFT TOOL

A ywheel holding tool can be made out of an old junk

ywheel ring gear and used in place of a strap wrench.

1. Using an abrasive cut-off wheel, cut out a six tooth

segment of ring gear as shown.

2. Grind off any burrs or sharp edges.

3. Invert segment and place it between ignition bosses

on crankcase so tool teeth engage ywheel ring

gear teeth. Bosses will lock tool and ywheel in

position for loosening, tightening, or removing with a

puller.

A spanner wrench to lift rocker arms or turn crankshaft

may be made out of an old junk connecting rod.

1. Find a used connecting rod from a 10 HP or larger

engine. Remove and discard rod cap.

2. Remove studs of a Posi-Lock rod or grind off

aligning steps of a Command rod, so joint surface is

at.

3. Find a 1 in. long capscrew with correct thread size to

match threads in connecting rod.

4. Use a at washer with correct I.D. to slip on

capscrew and approximately 1 in. O.D. Assemble

capscrew and washer to joint surface of rod.

20 17 690 01 Rev. EKohlerEngines.com

Page 21

Troubleshooting

TROUBLESHOOTING GUIDE

When troubles occur, be sure to check simple causes which, at rst, may seem too obvious to be considered. For

example, a starting problem could be caused by an empty fuel tank.

Some general common causes of engine troubles are listed below and vary by engine specication. Use these to

locate causing factors.

Engine Cranks But Will Not Start

● Battery connected backwards.

● Blown fuse.

● Carburetor solenoid malfunction.

● Choke not closing.

● Clogged fuel line or fuel lter.

● Diode in wiring harness failed in open circuit mode.

● DSAI or DSAM malfunction.

● Empty fuel tank.

● Faulty electronic control unit.

● Faulty ignition coil(s).

● Faulty spark plug(s).

● Fuel pump malfunction-vacuum hose clogged or

leaking.

● Fuel shut-off valve closed.

● Ignition module(s) faulty or improperly gapped.

● Insufcient voltage to electronic control unit.

● Interlock switch is engaged or faulty.

● Key switch or kill switch in OFF position.

● Low oil level.

● Quality of fuel (dirt, water, stale, mixture).

● SMART-SPARKTM malfunction.

● Spark plug lead(s) disconnected.

Engine Starts But Does Not Keep Running

● Faulty carburetor.

● Faulty cylinder head gasket.

● Faulty or misadjusted choke or throttle controls.

● Fuel pump malfunction-vacuum hose clogged or

leaking.

● Intake system leak.

● Loose wires or connections that intermittently ground

ignition kill circuit.

● Quality of fuel (dirt, water, stale, mixture).

● Restricted fuel tank cap vent.

Engine Starts Hard

● Clogged fuel line or fuel lter.

● Engine overheated.

● Faulty ACR mechanism.

● Faulty or misadjusted choke or throttle controls.

● Faulty spark plug(s).

● Flywheel key sheared.

● Fuel pump malfunction-vacuum hose clogged or

leaking.

● Interlock switch is engaged or faulty.

● Loose wires or connections that intermittently ground

ignition kill circuit.

● Low compression.

● Quality of fuel (dirt, water, stale, mixture).

● Weak spark.

Engine Will Not Crank

● Battery is discharged.

● Faulty electric starter or solenoid.

● Faulty key switch or ignition switch.

● Interlock switch is engaged or faulty.

● Loose wires or connections that intermittently ground

ignition kill circuit.

● Pawls not engaging in drive cup.

● Seized internal engine components.

Engine Runs But Misses

● Carburetor adjusted incorrectly.

● Engine overheated.

● Faulty spark plug(s).

● Ignition module(s) faulty or improperly gapped.

● Incorrect crankshaft position sensor air gap.

● Interlock switch is engaged or faulty.

● Loose wires or connections that intermittently ground

ignition kill circuit.

● Quality of fuel (dirt, water, stale, mixture).

● Spark plug lead(s) disconnected.

● Spark plug lead boot loose on plug.

● Spark plug lead loose.

Engine Will Not Idle

● Engine overheated.

● Faulty spark plug(s).

● Idle fuel adjusting needle(s) improperly set.

● Idle speed adjusting screw improperly set.

● Inadequate fuel supply.

● Low compression.

● Quality of fuel (dirt, water, stale, mixture).

● Restricted fuel tank cap vent.

Engine Overheats

● Cooling fan broken.

● Excessive engine load.

● Fan belt failed/off.

● Faulty carburetor.

● High crankcase oil level.

● Lean fuel mixture.

● Low cooling system uid level.

● Low crankcase oil level.

● Radiator, and/or cooling system components clogged,

restricted, or leaking.

● Water pump belt failed/broken.

● Water pump malfunction.

Engine Knocks

● Excessive engine load.

● Hydraulic lifter malfunction.

● Incorrect oil viscosity/type.

● Internal wear or damage.

● Low crankcase oil level.

● Quality of fuel (dirt, water, stale, mixture).

2117 690 01 Rev. E KohlerEngines.com

Page 22

Troubleshooting

Engine Loses Power

● Dirty air cleaner element.

● Engine overheated.

● Excessive engine load.

● Restricted exhaust.

● Faulty spark plug(s).

● High crankcase oil level.

● Incorrect governor setting.

● Low battery.

● Low compression.

● Low crankcase oil level.

● Quality of fuel (dirt, water, stale, mixture).

Engine Uses Excessive Amount of Oil

● Loose or improperly torqued fasteners.

● Blown head gasket/overheated.

● Breather reed broken.

● Clogged, broken, or inoperative crankcase breather.

● Crankcase overlled.

● Incorrect oil viscosity/type.

● Worn cylinder bore.

● Worn or broken piston rings.

● Worn valve stems/valve guides.

Oil Leaks from Oil Seals, Gaskets

● Breather reed broken.

● Clogged, broken, or inoperative crankcase breather.

● Loose or improperly torqued fasteners.

● Piston blow by, or leaky valves.

● Restricted exhaust.

EXTERNAL ENGINE INSPECTION

NOTE: It is good practice to drain oil at a location away

from workbench. Be sure to allow ample time for

complete drainage.

Before cleaning or disassembling engine, make a

thorough inspection of its external appearance and

condition. This inspection can give clues to what

might be found inside engines (and cause) when it is

disassembled.

● Check for buildup of dirt and debris on crankcase,

cooling ns, grass screen, and other external surfaces.

Dirt or debris on these areas can cause overheating.

● Check for obvious fuel and oil leaks, and damaged

components. Excessive oil leakage can indicate a

clogged or inoperative breather, worn or damaged

seals or gaskets, or loose fasteners.

● Check air cleaner cover and base for damage or

indications of improper t and seal.

● Check air cleaner element. Look for holes, tears,

cracked or damaged sealing surfaces, or other

damage that could allow unltered air into engine. A

dirty or clogged element could indicate insufcient or

improper maintenance.

● Check carburetor throat for dirt. Dirt in throat is further

indication that air cleaner was not functioning properly.

● Check if oil level is within operating range on dipstick.

If it is above, sniff for gasoline odor.

● Check condition of oil. Drain oil into a container; it

should ow freely. Check for metal chips and other

foreign particles.

Sludge is a natural by-product of combustion; a small

accumulation is normal. Excessive sludge formation

could indicate over rich fuel settings, weak ignition,

overextended oil change interval or wrong weight or

type of oil was used.

CLEANING ENGINE

WARNING

Cleaning Solvents can cause severe injury or

death.

Use only in well ventilated areas away from

ignition sources.

Carburetor cleaners and solvents are extremely

ammable. Follow cleaner manufacturer’s warnings

and instructions on its proper and safe use. Never use

gasoline as a cleaning agent.

After inspecting external condition of engine, clean

engine thoroughly before disassembly. Clean individual

components as engine is disassembled. Only clean

parts can be accurately inspected and gauged for wear

or damage. There are many commercially available

cleaners that will quickly remove grease, oil, and grime

from engine parts. When such a cleaner is used, follow

manufacturer’s instructions and safety precautions

carefully.

Make sure all traces of cleaner are removed before

engine is reassembled and placed into operation. Even

small amounts of these cleaners can quickly break down

lubricating properties of engine oil.

22 17 690 01 Rev. EKohlerEngines.com

Page 23

CRANKCASE VACUUM TEST

Troubleshooting

WARNING

Carbon Monoxide can cause severe nausea,

fainting or death.

Avoid inhaling exhaust fumes.

Engine exhaust gases contain poisonous carbon

monoxide. Carbon monoxide is odorless, colorless,

and can cause death if inhaled.

A partial vacuum should be present in crankcase when engine is operating. Pressure in crankcase (normally caused

by a clogged or improperly assembled breather) can cause oil to be forced out at oil seals, gaskets, or other available

spots.

Crankcase vacuum is best measured with either a water manometer or a vacuum gauge. Complete instructions are

provided in kits.

To test crankcase vacuum with manometer:

1. Insert rubber stopper into oil ll hole. Be sure pinch

clamp is installed on hose and use tapered adapters

to connect hose between stopper and one

manometer tube. Leave other tube open to

atmosphere. Check that water level in manometer is

at 0 line. Make sure pinch clamp is closed.

2. Start engine and run no-load high speed.

3. Open clamp and note water level in tube.

Level in engine side should be a minimum of 10.2

cm (4 in.) above level in open side.

If level in engine side is less than specied (low/no

vacuum), or level in engine side is lower than level in

open side (pressure), check for conditions in table

below.

4. Close pinch clamp before stopping engine.

Keep hands, feet, hair, and clothing away from all

moving parts to prevent injury. Never operate engine

with covers, shrouds, or guards removed.

To test crankcase vacuum with vacuum/pressure gauge:

1. Remove dipstick or oil ll plug/cap.

2. Install adapter into oil ll//dipstick tube opening,

3. Run engine and observe gauge reading.

Analog tester–needle movement to left of 0 is a

Digital tester–depress test button on top of tester.

Crankcase vacuum should be a minimum of 10.2 cm

Rotating Parts can cause severe injury.

Stay away while engine is in operation.

upside down over end of a small diameter dipstick

tube, or directly into engine if a tube is not used.

Insert barbed gauge tting into hole in stopper.

vacuum, and movement to right indicates a pressure.

(4 in.) of water. If reading is below specication, or if

pressure is present, check table below for possible

causes and conclusions.

WARNING

Condition Conclusion

Crankcase breather clogged or inoperative. NOTE: If breather is integral part of valve cover and

cannot be serviced separately, replace valve

cover and recheck pressure.

Disassemble breather, clean parts thoroughly, check

sealing surfaces for atness, reassemble, and recheck

pressure.

Seals and/or gaskets leaking. Loose or improperly torque

fasteners.

Piston blow by or leaky valves (conrm by inspecting

components).

Restricted exhaust. Check exhaust screen/spark arrestor (if equipped). Clean

Replace all worn or damaged seals and gaskets. Make

sure all fasteners are tightened securely. Use appropriate

torque valves and sequences when necessary.

Recondition piston, rings, cylinder bore, valves and

valves guides.

or replace as needed. Repair or replace any other

damaged/restricted mufer or exhaust system parts.

2317 690 01 Rev. E KohlerEngines.com

Page 24

Troubleshooting

COMPRESSION TEST

For Command Twins:

A compression test is best performed on a warm engine. Clean any dirt or debris away from base of spark plug(s)

before removing them. Be sure choke is off, and throttle is wide open during test. Compression should be at least 160

psi and should not vary more than 15% between cylinders.

All other models:

These engines are equipped with an automatic compression release (ACR) mechanism. It is difcult to obtain an

accurate compression reading because of ACR mechanism. As an alternative, use cylinder leakdown test described

below.

CYLINDER LEAKDOWN TEST

A cylinder leakdown test can be a valuable alternative to a compression test. By pressurizing combustion chamber

from an external air source you can determine if valves or rings are leaking, and how badly.

Cylinder leakdown tester is a relatively simple, inexpensive leakdown tester for small engines. This tester includes a

quick-connect for attaching adapter hose and a holding tool.

1. Run engine for 3-5 minutes to warm it up.

2. Remove spark plug(s) and air lter from engine.

3. Rotate crankshaft until piston (of cylinder being tested) is at top dead center (TDC) of compression stroke. Hold

engine in this position while testing. Holding tool supplied with tester can be used if PTO end of crankshaft is

accessible. Lock holding tool onto crankshaft. Install a 3/8 in. breaker bar into hole/slot of holding tool, so it is

perpendicular to both holding tool and crankshaft PTO.

If ywheel end is more accessible, use a breaker bar and socket on ywheel nut/screw to hold it in position. An

assistant may be needed to hold breaker bar during testing. If engine is mounted in a piece of equipment, it may

be possible to hold it by clamping or wedging a driven component. Just be certain that engine cannot rotate off of

TDC in either direction.

4. Install adapter into spark plug hole, but do not attach it to tester at this time.

5. Turn regulator knob completely counterclockwise.

6. Connect an air source of at least 50 psi to tester.

7. Turn regulator knob clockwise (increase direction) until gauge needle is in yellow set area at low end of scale.

8. Connect tester quick-connect to adapter hose. While rmly holding engine at TDC, gradually open tester valve.

Note gauge reading and listen for escaping air at combustion air intake, exhaust outlet, and crankcase breather.

Condition Conclusion

Air escaping from crankcase breather. Ring or cylinder worn.

Air escaping from exhaust system. Defective exhaust valve/improper seating.

Air escaping from intake. Defective intake valve/improper seating.

Gauge reading in low (green) zone. Piston rings and cylinder in good condition.

Gauge reading in moderate (yellow) zone. Engine is still usable, but there is some wear present.

Customer should start planning for overhaul or

replacement.

Gauge reading in high (red) zone. Rings and/or cylinder have considerable wear. Engine

should be reconditioned or replaced.

24 17 690 01 Rev. EKohlerEngines.com

Page 25

Air Cleaner/Intake

AIR CLEANER

These systems are CARB/EPA certied and components

should not be altered or modied in any way.

Quad-Clean

Air Cleaner Components

™

A

B

B

C

D

E

A Air Cleaner Cover B Bail

C Precleaner D Paper Element

E Air Cleaner Base

Low-Prole Air Cleaner Components

I

H

G

F

F Screw G Air Cleaner Cover

H Foam Element I Air Cleaner Base

NOTE: Running engine with cover positioned for cold

weather operation in normal conditions can

damage engine.

NOTE: Operating engine with loose or damaged air

cleaner components could cause premature

wear and failure. Replace all bent or damaged

components.

NOTE: Paper element cannot be blown out with

compressed air.

Quad-Clean

™

Move bails on air cleaner cover down; remove latches

from under tabs on base; remove cover.

Precleaner

1. Remove precleaner from paper element.

2. Replace or wash precleaner in warm water with

detergent. Rinse and allow to air dry.

3. Lightly oil precleaner with new engine oil; squeeze

out excess oil.

4. Reinstall precleaner over paper element.

Paper Element

1. Separate precleaner from element; service

precleaner and replace paper element.

2. Install new paper element on base; install precleaner

over paper element.

Position air cleaner cover for normal operation (sun

decal out) or cold weather operation (snowake decal

out); place latches under tabs on base; lift up bails to

secure cover.

Low-Prole

1. Remove screw and air cleaner cover.

2. Remove foam element from base.

3. Wash foam element in warm water with detergent.

Rinse and allow to air dry.

4. Lightly oil foam element with new engine oil;

squeeze out excess oil.

5. Reinstall foam element into base.

6. Reinstall cover and secure with screw.

BREATHER TUBE

Ensure both ends of breather tube are properly

connected.

AIR COOLING

WARNING

Hot Parts can cause severe burns.

Do not touch engine while operating or just

after stopping.

Never operate engine with heat shields or guards

removed.

Proper cooling is essential. To prevent over heating,

clean screens, cooling ns, and other external surfaces

of engine. Avoid spraying water at wiring harness or any

electrical components. Refer to Maintenance Schedule.

17 690 01 Rev. E KohlerEngines.com

25

Page 26

Fuel System

Typical carbureted fuel system and related components

include:

● Fuel tank.

● Fuel lines.

● In-line fuel lter.

● Fuel tank lter.

● Carburetor.

● Fuel strainer screen in carburetor.

FUEL RECOMMENDATIONS

Refer to Maintenance.

FUEL LINE

Low permeation fuel line must be installed on carbureted

Kohler Co. engines to maintain EPA and CARB

regulatory compliance.

FUEL FILTER

Fuel Tank Filter (if equipped)

A serviceable fuel tank lter is located under fuel tank

cap, in ller neck.

Daily or as required clean lter of any accumulation as

follows:

1. Remove fuel tank cap and lter.

2. Clean lter with solvent, replace if damaged.

3. Wipe lter and insert it.

4. Tighten fuel tank cap securely.

FUEL SYSTEM TESTS

When engine starts hard, or turns over but will not start, fuel system might be causing problems. Test fuel system by

performing following test.

1. Check for fuel in combustion chamber.

a. Disconnect and ground spark plug lead.

b. Close choke on carburetor.

c. Crank engine several times.

d. Remove spark plug and check for fuel at tip.

2. Check for fuel ow from tank to carburetor.

a. Remove fuel line from inlet tting of carburetor.

Fuel Valve

WARNING

Explosive Fuel can cause res and severe

burns.

Do not ll fuel tank while engine is hot or

running.

Gasoline is extremely ammable and its vapors can

explode if ignited. Store gasoline only in approved

containers, in well ventilated, unoccupied buildings,

away from sparks or ames. Spilled fuel could ignite

if it comes in contact with hot parts or sparks from

ignition. Never use gasoline as a cleaning agent.

NOTE: Models with a low-prole air cleaner do not have

fuel valve.

1. Stop engine.

2. Remove securing hardware and carburetor cover

panel.

3. Turn fuel valve lever to OFF position.

4. Remove fuel valve cup.

5. Clean fuel valve cup with solvent and wipe it off.

6. Check O-ring, replace if damaged. Check screen for

blockage or damage, replace if necessary. New

screen must be located on pick-up tube.

7. Place O-ring on screen followed by fuel valve cup.

Rotate fuel valve cup until it is nger tight. Turn with

a wrench 1/2 to 3/4 turn.

8. Turn fuel valve to ON position and check for leaks. If

fuel valve cup leaks repeat step 7.

9. Reinstall carburetor cover panel, using hardware

removed in step 2 to secure.

b. Use an approved fuel container to catch fuel, and

hold line below bottom of tank to observe fuel

ow.

3. Check operation of fuel shut-off valve.

a. Remove fuel sediment bowl under inlet tting of

carburetor.

b. Turn fuel shut-off valve ON and OFF and observe

operation.

Condition Conclusion

Fuel at tip of spark plug. Fuel is reaching combustion chamber.

No fuel at tip of spark plug. Check fuel ow from fuel tank (step 2).

Fuel ows from fuel line. Check operation of fuel shut-off valve (step 3).

No fuel ow from fuel line. Check fuel tank vent, in-line lter threaded into tank, and

fuel line. Correct any observed problem and reconnect

line.

Fuel ows from valve. Check for dirt and water in sediment bowl and screen.

Clean bowl and screen as needed. Check for faulty

carburetor, refer to Carburetor.

No fuel ows from valve. Check for a restriction in fuel shut-off valve or inlet elbow.

26

KohlerEngines.com 17 690 01 Rev. E

Page 27

CARBURETOR

Fuel System

WARNING

Explosive Fuel can cause res and severe

burns.

Do not ll fuel tank while engine is hot or

running.

Typical One-Barrel Carburetor Components

A

B

C

F

I

K

D

E

G

H

J

L

M

Gasoline is extremely ammable and its vapors can

explode if ignited. Store gasoline only in approved

containers, in well ventilated, unoccupied buildings, away

from sparks or ames. Spilled fuel could ignite if it comes

in contact with hot parts or sparks from ignition. Never use

gasoline as a cleaning agent.

These engines are equipped with a xed main jet

carburetor. Carburetor is designed to deliver correct fuelto-air mixture to engine under all operating conditions.

Idle mixture is set at factory and cannot be adjusted.

Troubleshooting Checklist

When engine starts hard, runs rough, or stalls at low

idle speed, check these areas before adjusting or

disassembling carburetor.

1. Make sure fuel tank is lled with clean, fresh

gasoline.

2. Make sure fuel tank cap vent is not blocked and is

operating properly.

3. Make sure fuel is reaching carburetor. This includes

checking fuel shut-off valve, fuel tank lter screen,

in-line fuel lter, fuel lines and fuel pump for

restrictions or faulty components as necessary.

4. Make sure air cleaner base and carburetor are

securely fastened to engine using gaskets in good

condition.

5. Make sure air cleaner element (including precleaner

if equipped) is clean and all air cleaner components

are fastened securely.

6. Make sure ignition system, governor system,

exhaust system, and throttle and choke controls are

operating properly.

N

O

P

A Fuel Shut-Off B Wave Washer

C Fuel Shut-Off Valve D

E Idle Jet F Fuel Shut-Off Gasket

G Main Nozzle Tube H Main Jet

I Bowl Gasket J Fuel Inlet Needle

K Spring L Hinge Pin

M Float N Fuel Bowl

Bowl Retaining Screw

O

17 690 01 Rev. E KohlerEngines.com

Gasket

P Bowl Retaining Screw

Low Idle Speed

Adjusting Screw

27

Page 28

Fuel System

Troubleshooting-Carburetor Related Causes

Condition Possible Cause Conclusion

Engine starts hard, runs rough, or

stalls at idle speed.

Engine runs rich (indicated by

black, sooty exhaust smoke,

misring, loss of speed and power,

governor hunting, or excessive

throttle opening).

Engine runs lean (indicated by

misring, loss of speed and power,

governor hunting, or excessive

throttle opening).

Fuel leaks from carburetor. Float damaged. Submerge oat to check for leaks.

Low idle fuel mixture (some models)/

speed improperly adjusted.

Clogged air cleaner. Clean or replace air cleaner.

Choke partially closed during

operation.

Dirt under fuel inlet needle. Remove needle; clean needle and seat

Bowl vent or air bleeds plugged. Clean vent, ports, and air bleeds. Blow

Leaky, cracked, or damaged oat. Submerge oat to check for leaks.

Intake air leak. Check if carburetor is loose or one of

Idle holes plugged; dirt in fuel delivery

channels.

Dirt under fuel inlet needle. Remove needle; clean needle and seat

Bowl vents plugged. Blow out with compressed air.

Carburetor bowl gasket leaks. Replace gasket.

Adjust idle speed screw or clean

carburetor.

Check choke lever/linkage to ensure

choke is operating properly.

and blow with compressed air.

out all passages with compressed air.

intake gaskets is leaking.

Clean main fuel jet and all passages;

blow out with compressed air.

Replace oat.

and blow with compressed air.

Carburetor Circuits

Float

Fuel level in bowl is maintained by oat and fuel inlet

needle. Buoyant force of oat stops fuel ow when

engine is at rest. When fuel is being consumed, oat will

drop and fuel pressure will push inlet needle away from

seat, allowing more fuel to enter bowl. When demand

ceases, buoyant force of oat will again overcome fuel

pressure, rising to predetermined setting and stop ow.

Slow and Mid-Range

At low speeds engine operates only on slow circuit. As

a metered amount of air is drawn through slow air bleed

jets, fuel is drawn through main jet and further metered

through slow jet. Air and fuel are mixed in body of slow

jet and exit to idle progression (transfer port) chamber.

From idle progression chamber, air fuel mixture is

metered through idle port passage. At low idle air/fuel

mixture is controlled by setting of idle fuel adjusting

screws. This mixture is then mixed with main body of

air and delivered to engine. As throttle plate opening

increases, greater amounts of air/fuel mixture are drawn

in through xed and metered idle progression holes.

As throttle plate opens further, vacuum signal becomes

great enough at venturi so main circuit begins to work.

Main (high-speed)

At high speeds/loads engine operates on main circuit.

As a metered amount of air is drawn through air jet,

fuel is drawn through main jet. Air and fuel are mixed

in main nozzles then enters main body of airow where

further mixing of fuel and air occurs. This mixture is then

delivered to combustion chamber. Carburetor has a xed

main circuit; no adjustment is possible.

Carburetor Adjustments

NOTE: Carburetor adjustments should be made only

after engine has warmed up.

Carburetor is designed to deliver correct fuel-to-air

mixture to engine under all operating conditions. Main

fuel jet is calibrated at factory and is not adjustable. Idle

fuel adjusting needles are also set at factory and are not

adjustable.

Low Idle Speed (RPM) Adjustment

NOTE: Actual low idle speed depends on application.

Refer to equipment manufacturer’s

recommendations. Low idle speed for basic

engines is 1800 RPM.

1. Place throttle control into idle or slow position. Turn

low idle speed adjusting screw in or out to obtain

allow idle speed of 1800 RPM (± 75 RPM).

Carburetor Servicing

WARNING

Accidental Starts can cause severe injury or

death.

Disconnect and ground spark plug lead(s)

before servicing.

Before working on engine or equipment, disable

engine as follows: 1) Disconnect spark plug lead(s). 2)

Disconnect negative (–) battery cable from battery.

28

NOTE: Main and slow jets are xed and size specic

and can be removed if required. Fixed jets for

high altitudes are available.

KohlerEngines.com 17 690 01 Rev. E

Page 29

● Inspect carburetor body for cracks, holes, and other

wear or damage.

● Inspect oat for cracks, holes, and missing or

damaged oat tabs. Check oat hinge and shaft for

wear or damage.

● Inspect fuel inlet needle and seat for wear or damage.

1. Perform removal procedures for appropriate air

cleaner and carburetor outlined in Disassembly.

2. Clean exterior surfaces of dirt or foreign material

before disassembling carburetor. Remove bowl

retaining screws, and carefully separate fuel bowl

from carburetor. Do not damage fuel bowl O-rings.

Transfer any remaining fuel into an approved

container. Save all parts. Fuel can also be drained

prior to bowl removal by loosening/removing bowl

drain screw.

3. Remove oat pin and inlet needle. Seat for inlet

needle is not serviceable and should not be

removed.

4. Clean carburetor bowl and inlet seat areas as

required.

5. Carefully remove main jet from carburetor. After

main jet is removed, main nozzles can be removed

through bottom of main towers. Note orientation/

direction of nozzles. End with 2 raised shoulders

should be out/down adjacent to main jets.

6. Save parts for cleaning and reuse unless a jet kit is

also being installed. Clean slow jets using

compressed air or carburetor cleaner, do not use

wire.

NOTE: There are 2 O-rings on body of idle jet.

Carburetor is now disassembled for appropriate cleaning

and installation of parts in overhaul kit. See instructions

provided with repair kits for more detailed information.

Fuel System

High Altitude Operation

Engines may require a high altitude carburetor kit to

ensure correct engine operation at altitudes above

1219 meters (4000 ft.). To obtain high altitude kit

information or to nd a Kohler authorized dealer visit

KohlerEngines.com or call1-800-544-2444 (U.S. and

Canada).

This engine should be operated in its original

conguration below 1219 meters (4000 ft.) as damage

may occur if high altitude carburetor kit is installed and

operated below 1219 meters (4000 ft.).

17 690 01 Rev. E KohlerEngines.com

29

Page 30

Governor System

GOVERNOR

Governor Components

A

B

A

C

F

D

E

C

A Flyweight B Regulating Pin

C Cross Shaft D Governor Lever

E Throttle Linkage F Throttle Lever

● When engine is at rest, and throttle is in fast position,

tension of governor spring holds throttle plate open.

When engine is operating, governor gear assembly is

rotating. Force applied by regulating pin against cross

shaft tends to close throttle plate. Governor spring

tension and force applied by regulating pin balance

each other during operation, to maintain engine

speed.

● When load is applied and engine speed and governor

gear speed decreases, governor spring tension moves

governor arm to open throttle plate wider. This allows

more fuel into engine, increasing engine speed. As

speed reaches governed setting, governor spring

tension and force applied by regulating pin will again

offset each other to hold a steady engine speed.

Governor Adjustments

NOTE: Make sure carburetor is mounted and secured in

place when adjustment is being made/checked.

Initial Adjustment Procedure

Make this initial adjustment whenever governor lever

is loosened or removed from cross shaft. To ensure

proper setting, make sure throttle linkage is connected to

governor lever and to carburetor throttle lever.

1. Close fuel shut-off valve.

2. Remove air cleaner outer cover. Then either

reposition fuel tank to access governor cross shaft

and lever joint, or disconnect fuel line and remove

tank from engine.

3. Loosen governor lever mounting nut.

4. CH260, CH270: Move governor lever clockwise until

it stops. Rotate governor cross shaft clockwise until

it stops.

CH395, CH440: Move governor lever

counterclockwise until it stops. Rotate governor

cross shaft counterclockwise until it stops.

5. Hold both in this position and torque governor lever

nut to 12 N·m (106 in. lb.).

Governed speed setting is determined by position of

throttle control. It can be variable or constant, depending

on engine application.

Governor is designed to hold engine speed constant

under changing load conditions. Most engines are

equipped with a centrifugal yweight mechanical

governor. Governor gear/yweight mechanism of

mechanical governor is mounted inside crankcase and is

driven off gear on camshaft.

This governor design works as follows:

● Centrifugal force acting on rotating governor gear

assembly causes yweights to move outward as

speed increases. Governor spring tension moves

them inward as speed decreases.

● As yweights move outward, they cause regulating pin

to move outward.

● Regulating pin contacts tab on cross shaft causing

shaft to rotate.

● One end of cross shaft protrudes through crankcase.

Rotating action of cross shaft is transmitted to throttle

lever of carburetor through external throttle linkage.

30

KohlerEngines.com 17 690 01 Rev. E

Page 31

Lubrication System

These engines use a splash lubrication system, supplying necessary lubrication to the crankshaft, camshaft,

connecting rod and valve train components.

Lubrication Components

A

C

C

B

A Dipstick B Oil Fill Plug C Oil Drain Plug

OIL RECOMMENDATIONS

Refer to Maintenance.

CHECK OIL LEVEL

NOTE: To prevent extensive engine wear or damage,

never run engine with oil level below or above

operating range indicator on dipstick.

Ensure engine is cool. Clean oil ll/dipstick areas of any

debris.

1. Remove dipstick; wipe oil off.

2. Reinsert dipstick into tube; rest on oil ll neck; turn

counterclockwise until cap drops down to lowest

point of thread leads; do not thread cap onto tube.

a. Remove dipstick; check oil level. Level should be

at top of indicator on dipstick.

or

b. Remove oil ll plug. Level should be up to point of

overowing ller neck.

3. If oil is low, add oil up to point of overowing ller

neck.

CHANGE OIL

Change oil while engine is warm.

1. Clean area around oil ll plug/dipstick and drain

plug.

2. Remove drain plug and oil ll plug/dipstick. Drain oil

completely.

3. Reinstall drain plug. Torque to 18 N·m (13 ft. lb.).

4. Fill crankcase with new oil, up to point of overowing

ller neck.

5. Reinstall oil ll plug/dipstick and tighten securely.

6. Dispose of used oil in accordance with local

ordinances.

OIL SENTRY

(if equipped)

™

This switch is designed to prevent engine from starting

in a low oil or no oil condition. Oil Sentry™ may not shut

down a running engine before damage occurs. In some

applications this switch may activate a warning signal.

Read your equipment manuals for more information. For

testing procedures refer to Electronic Ignition Systems

and Oil Sentry™ Tests.

4. Reinstall dipstick or oil ll plug and tighten securely.

17 690 01 Rev. E KohlerEngines.com

31

Page 32

Electrical System

SPARK PLUGS

CAUTION

Electrical Shock can cause injury.

Do not touch wires while engine is running.

Spark Plug Component and Details

A

B

C

Inspection

Inspect each spark plug as it is removed from cylinder

head. Deposits on tip are an indication of general

condition of piston rings, valves, and carburetor.

Normal and fouled plugs are shown in following photos:

Normal

Plug taken from an engine operating under normal

conditions will have light tan or gray colored deposits. If

center electrode is not worn, plug can be set to proper

gap and reused.

Worn

D

A Wire Gauge B Spark Plug

C Ground Electrode D Gap

NOTE: Do not clean spark plug in a machine using

abrasive grit. Some grit could remain in spark

plug and enter engine causing extensive wear

and damage.

Engine misre or starting problems are often caused

by a spark plug that has improper gap or is in poor

condition.

Engine is equipped with following spark plugs:

Gap 0.76 mm (0.03 in.)

Thread Size 14 mm

Reach 19.1 mm (3/4 in.)

Hex Size 15.9 mm (5/8 in.)

Refer to Maintenance for Repairs/Service Parts.

Service

Clean out spark plug recess. Remove plug and replace.

1. Check gap using wire feeler gauge. Adjust gap to

0.76 mm (0.03 in.).

2. Install plug into cylinder head.

3. Torque plug to 27 N·m (20 ft. lb.).

On a worn plug, center electrode will be rounded and

gap will be greater than specied gap. Replace a worn

spark plug immediately.

Wet Fouled

A wet plug is caused by excess fuel or oil in combustion

chamber. Excess fuel could be caused by a restricted air

cleaner, a carburetor problem, or operating engine with

too much choke. Oil in combustion chamber is usually

caused by a restricted air cleaner, a breather problem,

worn piston rings, or valve guides.

32

KohlerEngines.com 17 690 01 Rev. E

Page 33

Electrical System

Carbon Fouled

Soft, sooty, black deposits indicate incomplete

combustion caused by a restricted air cleaner, over rich

carburetion, weak ignition, or poor compression.

Overheated

Chalky, white deposits indicate very high combustion

temperatures. This condition is usually accompanied

by excessive gap erosion. Lean carburetor settings,

an intake air leak, or incorrect spark timing are normal

causes for high combustion temperatures.

BATTERY

A 12 volt battery (not furnished) with a minimum current

rating of 230 cold cranking amps/18 amp hours should

be sufcient for cranking most electric start engine

models. Actual cold cranking requirement depends on

engine size, application, and starting temperatures.

Cranking requirements increase as temperatures

decrease and battery capacity shrinks. Refer to

equipment's operating instructions for specic battery

requirements.

If battery charge is insufcient to turn over engine,

recharge battery.

Battery Maintenance

Regular maintenance is necessary to prolong battery

life.

Battery Test

To test battery, follow manufacturer's instructions.

ELECTRONIC IGNITION SYSTEM

Inductive Discharge Ignition System

H

G

C

D

A Ignition Module B Magnet

Air Gap 0.252 mm

C

E Flywheel F

G Spark Plug H Spark Plug Boot

I Spark Plug Terminal J Lamination

K Kill Terminal

These engines are equipped with a dependable

magneto breakerless ignition. In such a system,

electrical energy is generated by cutting of magnetic ux

lines generated from ignition magnet on engine ywheel

via prescribed air gap as it passes ignition module.

This energy is transferred through ignition module

laminations and is then converted in module electronics

and stored in module primary coil, as a current. Stored

energy is transferred at correct moment by triggering a

semiconductor switch inside module. Electrical break

by switch initiates energy transfer by causing collapse

of magnetic eld at coil primary. This includes a voltage

at coil primary that is amplied via transformer action at

coil secondary. Amplitude of voltage at coil secondary

is sufcient to jump gap at spark plug, igniting fuel air

mixture in gap and initiating combustion. Note that by

design, these modules only will provide proper function if

mounted in correct orientation.

This ignition system is designed to be trouble free for

life of engine. Other than periodically checking/replacing

spark plugs, no maintenance or timing adjustments

are necessary or possible. Mechanical systems do

occasionally fail or break down. Refer to Troubleshooting

to determine root of a reported problem.

Reported ignition problems are most often due to poor

connections. Before beginning test procedure, check

all external wiring. Be certain all ignition-related wires

are connected, including spark plug leads. Be certain all

terminal connections t snugly. Make sure ignition switch

is in run position.

(0.010 in.)

A

B

E

F

K

Kill Switch/Off

D

Position of Key

Switch

Ignition Module

(Enlarged View)

I

J

17 690 01 Rev. E KohlerEngines.com

33

Page 34

Electrical System

Electronic Ignition Systems and Oil Sentry™ Tests

1. Disconnect cap from spark plug and attach it to

terminal end of spark tester. Attach tester spring clip

to a good ground, not to spark plug. Turn ignition/key

switch ON and crank engine while observing ring

tip of tester.

Condition Conclusion

Tester is ring. Ignition system is good.

Install a new spark plug

and try to start engine. If it

still will not start, check

other possible causes

(fuel, compression, etc.).

Tester doesn't re. Go to step 2.

2. On electric start engines, remove starter cover

panel. Locate black/white kill lead coming from

ignition module inside blower housing. Disconnect

bullet connector where kill lead plugs into harness.

Repeat spark test (step 1).

Condition Conclusion

Spark is now present. Check for a shorted lead

in kill circuit or a faulty

switch (step 7).

Still no spark. Go to step 3.

3. Disconnect bullet connector where Oil Sentry

control module joins lead from Oil Sentry™ oat

™

switch (yellow leads). Repeat spark test again.

Condition Conclusion

Spark is now present. Control module or oat

switch is faulty. Test

control module (step 4) and

oat switch (step 5). If there

is still no spark, test

ignition module (step 6).

4. Set an ohmmeter to Rx1 scale and zero meter.

Connect black ohmmeter lead to yellow Oil Sentry

control module lead and touch red ohmmeter lead to

black wire.

Condition Conclusion

Continuity should be

indicated.

Replace Oil Sentry

control module for any

™

other results.

5. Set an ohmmeter to Rx1 scale and zero meter.

Connect one ohmmeter lead to Oil Sentry

switch lead (yellow with green sleeve) and touch

oat

™

other lead to a bare spot on crankcase (ground).

Drain oil from crankcase and repeat test.

With oil at proper level, no continuity should have

been indicated. After oil was drained, continuity

should have been indicated.

Condition Conclusion

No continuity indicated. Remove closure plate

from engine and remove

oat switch for further

testing (steps 5a and 5b).

a. If continuity was indicated with and without oil

above, check if insulation has been scraped off

oat switch lead.

Condition Conclusion

Lead wire is bare. Allowing it to short, repair

with electrical tape or

replace oat switch.

b. With oat switch removed, connect one

ohmmeter lead to oat switch lead terminal and

connect other lead to mounting bracket. Test

resistance with switch in normal position and

inverted. Repeat test 2 or 3 times in each

direction.

Condition Conclusion

Switch continuity should

If not, replace it.

be as indicated.

6. Set an ohmmeter to Rx1K or Rx10K scale and zero.

Connect one ohmmeter lead to kill lead (black/white)

terminal and connect other lead into spark plug cap.

a. Remove cap from spark plug lead and test

resistance of cap alone.

™

blower housing and remove ignition module. With

b. If resistances are other than specied, remove

kill lead and spark plug cap removed, test

resistance from small spade terminal to core of

spark plug lead wire. If resistance is not in this

range, replace module.

Resistance Chart

Ignition Module 13.5-18.0 K ohms

Cap 4-6 K ohms

Spade Terminal to Spark

9.5-12.9 K ohms

Plug Lead Wire

34

KohlerEngines.com 17 690 01 Rev. E

Page 35

Electrical System

7. Set an ohmmeter to Rx1 scale and zero meter. Test

ignition/key switch as follows.

a. Trace two black leads from on/off switch and

separate them from any connections. Connect