Page 1

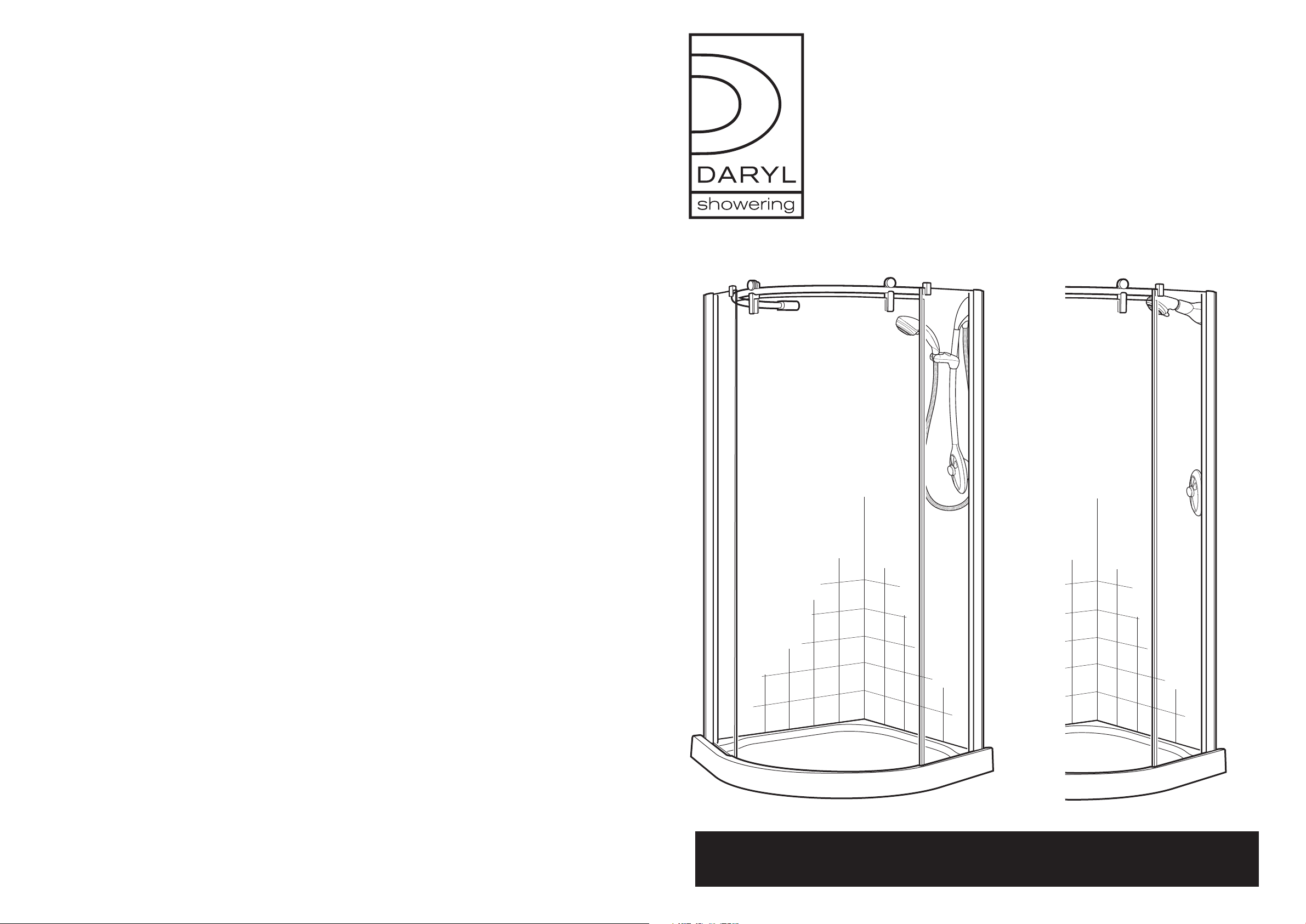

Indigo Quadrant

Enclosure

with integrated

CFI230J

Mira Magna Shower System

(646)

Slide Rail

4

3

2

1

Fixed Head

4

3

2

1

Kohler Daryl Limited

Alfred Road, Wallasey, Wirral, CH44 7HY England

Tel 44 (0)151 606 5000 Fax 44 (0)151 638 0303

www.daryl-showers.co.uk

E-mail Daryl@daryl-showers.co.uk

Fitting + User Instructions

Page 2

Page 3

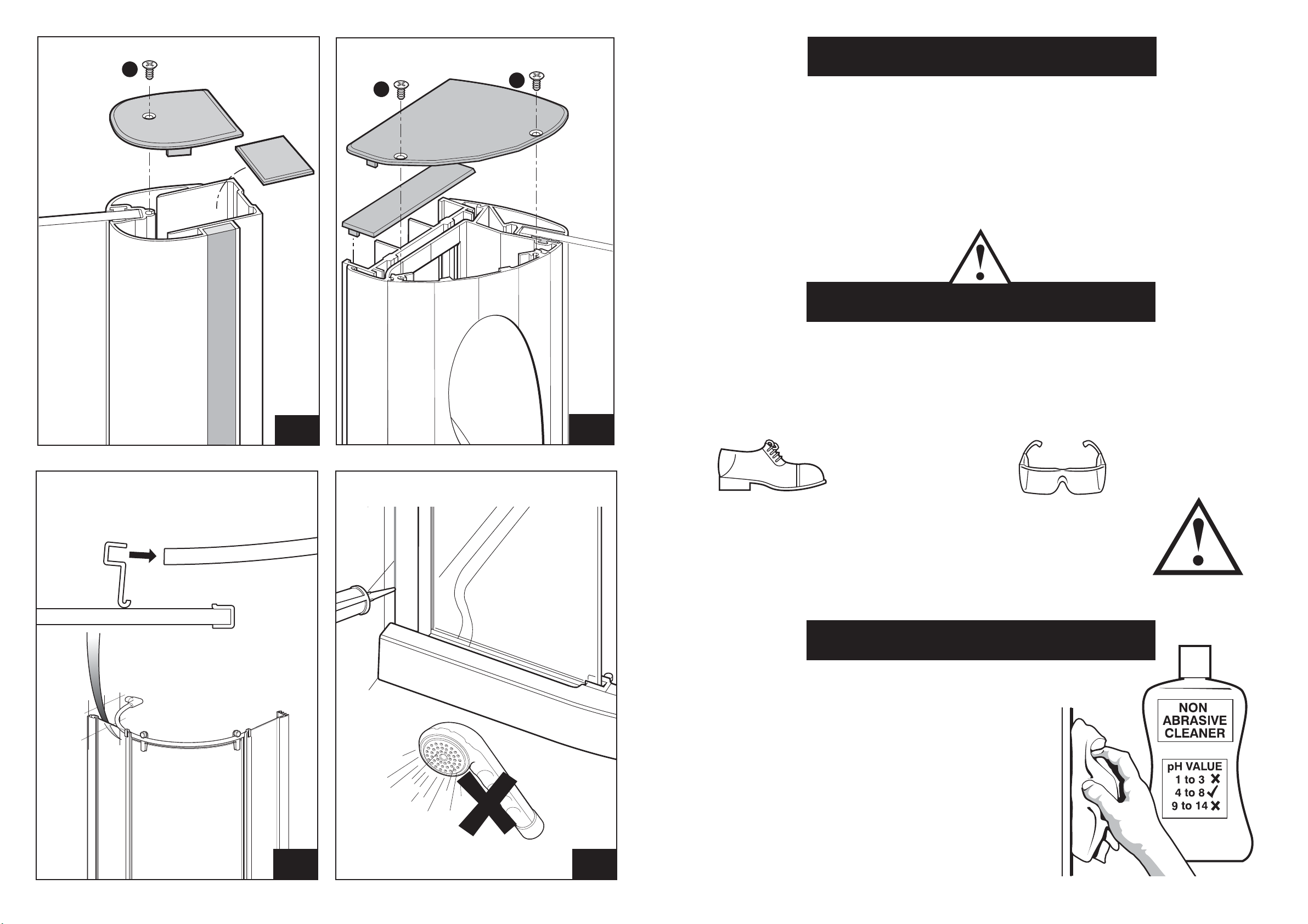

Fit top cap - Non Water delivery side

C

Fit top cap - Water delivery side

C

C

Introduction

The following pages aim to provide comprehensive installation instructions, plus

advice on how to care and maintain your product.

We recommend that the unit is installed by a qualified Plumber or Engineer.

Please retain this document for future reference.

Note: Due to our desire to always improve our products, Daryl reserve the right to

change specification without prior notice

Safety Precautions

Caution: Care should be taken when drilling into walls and floors to avoid any

hidden pipes or wires.

STEP

46

Fit the door seal to the back edge of the door.

When the door is closed the edge of the seal

should touch the side panel along it’s length.

STEP

47

Apply a thin bead of sealant along the outside

edge of the wall channels.

We strongly recommend that all glass panels are moved by a minimum of two

people and that protective packaging along the glass edges is kept in place for

as long as possible to prevent damage before installation

Wear protective

footwear when

lifting panels

People not familiar with the fitting of Daryl Products may require

the assistance from another person at certain stages of the

procedure. We have indicated these points in the process with

the Caution Symbol.

Wear Safety

glasses when

drilling

Caution

Care & Maintenance

The unit should be cleaned regularly.

26

CFI230J

STEP

48

24hrs

Do not use the enclosure for

at least 24 hours.

STEP

49

Use a non abrasive cleaner (ideally with a pH

value of 4 to 8) applied with a soft cloth.

Under no circumstances should scourers or

powerful detegents be used as these can damage

the metallic surface of the frame and also tarnish

the glass coating.

If fitted correctly the unit should not require any

maintenance other than cleaning. If problems do

occur contact the Daryl Technical Helpline

Tel: 0151 606 5000

CFI230J

3

Page 4

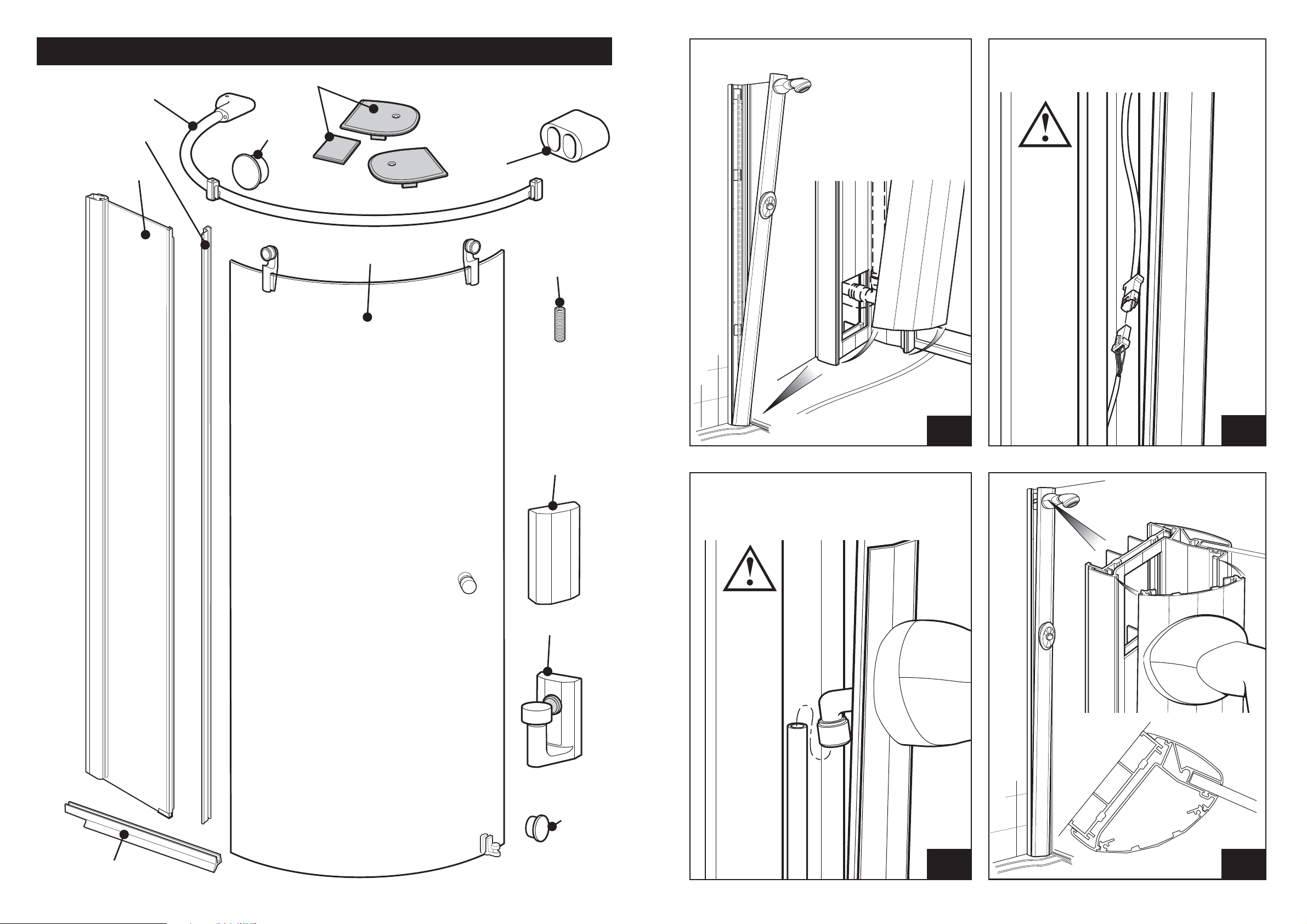

Lintel

Seal

Side Panel

COMPONENTS

Standard Top Caps

Cap

x2

RH

LH

Parking

Block

Fixed Head Water Delivery Only

Carefully lift the Water

Delivery System column

and place the bottom

into the wall jamb

Be very careful not

to scratch or damage

the tray

Support the weight of the column. Plug the

electrical cable into the connector on the cable

from the Water Delivery System

Caution

Door

Nylon Grub

Screw

x2

Blanking

Cap

STEP

42

Support the weight of the column. Connect

the water pipe to the connector from

at the top of the column.

STEP

43

Push top of column

into the wall jamb

until it locks in place

4

Splashguard

CFI230J

Fixed Roller

Cap

Caution

STEP

44

STEP

45

CFI230J

25

Page 5

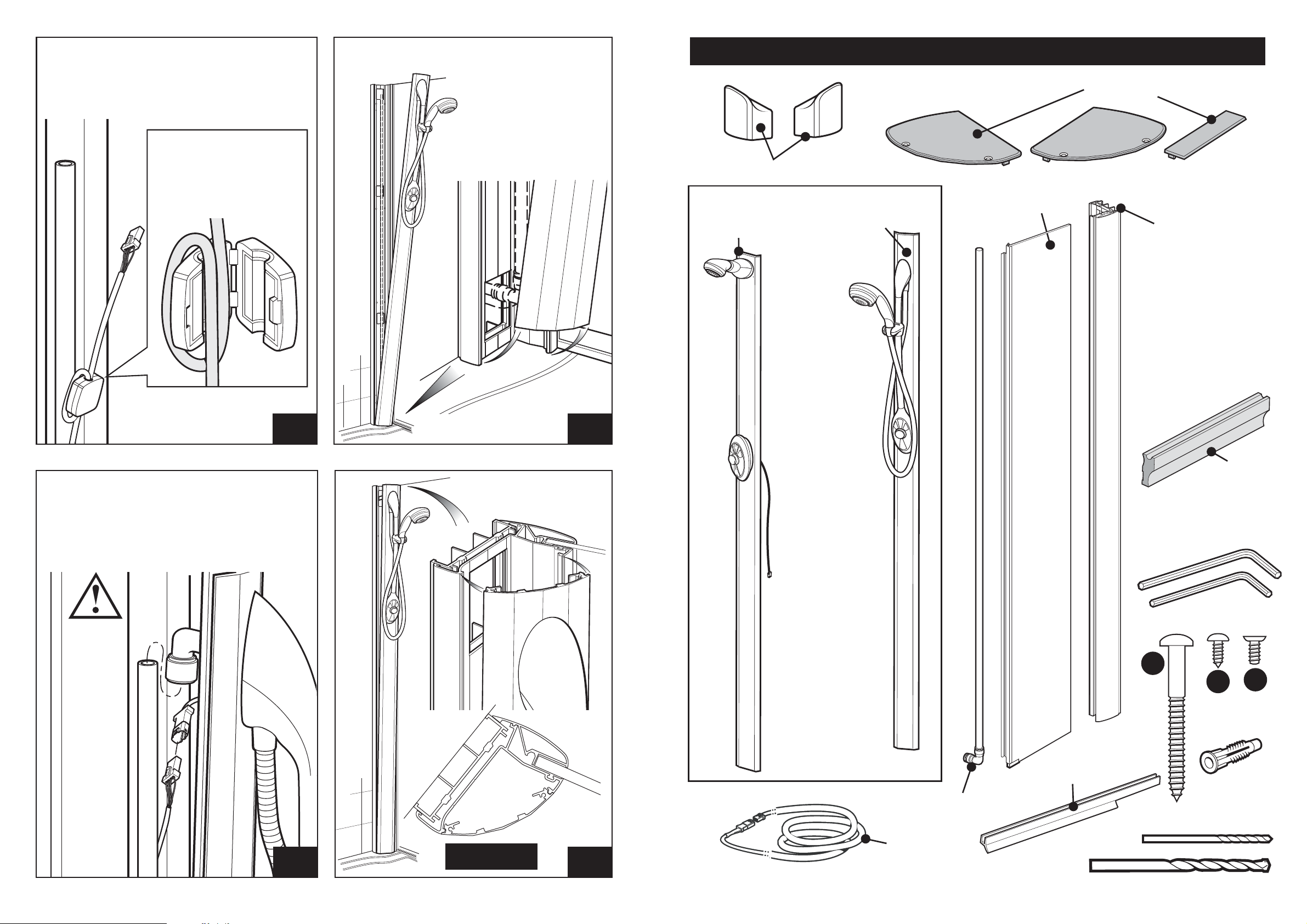

Fit the Suppression Ferrite close to

the Water Delivery connector

Note:

The Suppression Ferrite is packed with the

Digital Mixer

Slide Rail Water Delivery Only

(See Step 42 for the Fixed Head Water Delivery)

Carefully lift the Water

Delivery System column

and place the bottom

into the wall jamb

COMPONENTS

Water Delivery

Top Caps

LH

Place the cable in the

suppression ferrite. Wrap

the cable around the cover

and through the ferrite

again and then close the

cover until it snaps shut

STEP

Support the weight of the column. Connect

the water pipe to the connector from

at the top of the column.

38

Be very careful not

to scratch or damage

the tray

Push top of column

into wall jamb

until it locks in place

STEP

39

Roller Securing Caps

Fixed Head

Water Delivery

System

OR

(419)

Slide Rail

Water Delivery

System

RH

Glass Panel

Water Delivery Wall

Jamb, Wall Channel

& Glass Clamp

Door

Stop Vinyl

(except 800)

Plug the electrical cable into the connector

from the Water Delivery System at the top

of the column.

Caution

STEP

40

PROCEED TO

STEP 47

STEP

41

NOTE:

The Water Delivery

System is supplied

attached to the

Wall Jamb

2m Pipe and

Connector

Electrical

Cable

Splashguard

6mm

5mm

x9(+4)

A

3mm

3mm

x4(+1)

B

x3

C

x13

24

CFI230J

CFI230J

5

Page 6

ENCLOSURE INSTALLATION

Fit roller securing caps to both top roller brackets.

Caps will ‘click’ and lock in place

Lift bottom roller up and tighten the fixing

screw with a 3mm allen key.

Non Water Delivery Side only

Loosely fit wall channel into glass panel jamb

Carefully lift the assembly onto the tray. The end

of the glass panel fits into slot ‘A’ on the tray.

The wall channel end sits on the flat section of

the tray ‘B’

B

A

Fit the cap to cover the screw

STEP

1

Adjust wall jamb until glass is parallel to the

edge of the tray ‘A’. When jamb is vertical mark

edge of wall channel on the wall ‘B’.

B

B

±0mm

Remove wall channel from jamb and place

against mark on wall

STEP

2

Cut the 2 metre pipe

to size. Measure from

the centre line of the

connector.

Bottom Entry

‘A’ = 1750mm

Top Entry

‘A’ = 320mm

STEP

34

Connect pipework

Bottom Entry Top Entry

STEP

35

A

6

CFI230J

A

STEP

3

STEP

4

STEP

36

STEP

37

CFI230J

23

Page 7

Loosen the screw fixing the bottom roller to

the glass with a 3mm allen key

Locate other side of glass door panel between

the roller and plastic glass guide

Check the wall channel is vertical and mark

through the 3 holes ‘A’

Drill 3 x 6mm holes

Fit the splash guard to the bottom of the panel.

Note: lip faces to the outside of Enclosure

and cutout is towards the wall end of the glass

STEP

30

Caution

STEP

31

A

Seal behind channel

and tighten screws

Fit plugs

Loosely fit screws

A

STEP

5

STEP

6

Whilst supporting the weight of the door slide

the bottom roller into the bottom track

Caution

Lift the glass door up and slide the rollers onto

the lintel

Caution

Slide glass panel into slot in tray “A’ and fit

jamb onto wall channel ‘B’

B

On the inside of the enclosure. pull the rubber

strip away from the wall jamb

22

CFI230J

STEP

32

STEP

33

A

STEP

7

STEP

8

CFI230J

7

Page 8

Ensure glass panel is vertical

±0mm

Drill 4 x 3mm holes

through jamb into wall

channel

Check glass is vertical. If not

remove screws, re-drill and

re-fit as required.

Re-fit rubber strip over

screws

Fit the fixed roller to the tray on the same side as

lintel wall fixing, applying sealant on the edges.

Note: The seal ‘A’ on the glass panel will need

to be pulled away, to allow the roller to be fitted,

and re-fitted afterwards.

Push the roller onto the slot in the tray until it

locks in place ensuring the plastic glass

guide is retained inside the roller body

A

Fit the blanking cap on the other side

of the tray.

Note: The seal ‘A’ on the glass panel will need

to be pulled away, to allow the cover to be fitted,

and re-fitted afterwards.

Fit 4 x screws

STEP

9

Carefully remove the Water Delivery System

from the Water Delivery Wall Jamb.

B

B

STEP

10

Slacken screws ‘A’. Push the glass panel between

the wall jamb and the glass clamp. The glass

should be 2mm lower than the top of the wall

jamb. Tighten screws ‘A’ when the glass is in

the correct position

STEP

11

STEP

Push the door stop vinyl into the track and

against the fixed roller (except 800)

26

STEP

27

Carefully lift door into the enclosure

Important: Requires a minimum of 2 people

8

CFI230J

STEP

12

A

STEP

13

STEP

28

Caution

STEP

29

CFI230J

21

Page 9

Remove the lintel from glass and remove the parking block

1. Match parking block

to mark on wall

2. Spot drill hole positions

3. Drill holes with 6mm drill

Carefully lift the assembly onto the tray. The end

of the glass panel fits into slot ‘A’ on the tray.

The wall channel end sits on the flat section of

the tray ‘B’

Adjust wall jamb until glass is parallel to the

edge of the tray ‘A’ and vertical at ‘B’.

5. Screw parking block to wall

A

6. Re-fit lintel to glass

and push wall mount

on to the parking block

4. Plug holes

7. Secure the lintel to

parking block by

tightening allen

screw ‘A’

A

STEP

24

A

B

Take care not to

damage pipe and

cable protruding

from wall

STEP

14

±0mm

B

A

STEP

15

Check the lintel is level.

If adjustment is required turn screw ‘A’

on the panel clamps to lift or lower the rail.

Note: If the lintel cannot be made level by

adjusting the clamps remove the grub screws

and fit the longer ones supplied in the parts pack.

When the lintel is level tighten screw ‘B’ on

each panel clamp until it grips the glass.

IMPORTANT - DO NOT OVER TIGHTEN

Fit caps to lintel ‘C’

C

B

A

Spot drill through 4 fixing holes in the

wall jamb and mark the wall. Only 4 of the

8 holes are using alternate sides ‘A’.

Carefully remove the panel from the tray

Drill 4 x 8mm holes

Fit plugs

B

A

mm0±

Carefully lift the panel

back into postion

Loosely fit

4 x screws

A

A

Seal behind

the wall channel

and tighten

screws

20

CFI230J

STEP

25

STEP

16

STEP

17

CFI230J

9

Page 10

Check the wall channel and jamb is vertical.

Loosen screws ‘A’ to adjust from side to side.

Re-tighten screws

The edge of the glass should fit against the end

of the slot in the tray ‘B’. To adjust the glass

loosen the 4 screws ‘C’ and move the panel until

it is the correct postion. Re-tighten screws

Loosely fit the parking block into the wall mount ‘A’. Lift the lintel onto the glass. The panel clamps

fit over the top edge of the glass and should be equally spaced on each panel

A

A

STEP

18

If the any further adjustment is required to make

the glass panel vertical turn the 4 screws ‘D’

until the panel is in the correct position

C

Check end of

glass is vertical

B

Measure the distance of the glass between

the wall jamb and the tray ‘A’. Cut the

splashguard to size cutting at the wall jamb end.

Fit the splashguard to the bottom of the glass

STEP

19

Note:

The lintel is supplied as a RH unit.

For LH versions loosen the panel clamps

and turn them through 180

Ensure glass panels

Check top rail is level. Draw around parking block

are parallel to each other

o

STEP

22

10

CFI230J

D

STEP

20

mm0±

A

STEP

21

STEP

23

CFI230J

19

Page 11

The Daryl Care Programme

Keeping your enclosure beautiful throughout its lifetime is easy with

products from the Daryl care programme

Using state of the art bespoke machinery combined with the

latest technology, all Daryl doors and panels are coated with

a glass protector in highly controlled factory conditions.

The protector acts as an invisible barrier on the glass to

prevent build up of limescale, soap scum, stains and dirt.

The factory applied protector will last from months to years

depending on use and the hardness of water in your area.

It will never crack, peel, discolour or build up. Coated

surfaces are kept clean simply by rinsing or wiping with a

damp cloth and regular use of Daryl Glass Cleaner.

There are two separate elements to caring for your Daryl

shower door, enclosure or bath screen.

Regular cleaning

• Mildew thrives in damp, unventilated areas. It is, therefore,

important to always wipe down, with a soft cloth or towel,

the glass and metal sections inside the shower every time

it is used

• Do not allow water to remain on glass and metal sections

for long periods of time

• Every week or two, use Daryl Glass Cleaner to polish the

enclosure (including metal sections) ensuring all surfaces

are wiped down

USER INSTRUCTIONS

Hint - these User Instruction pages can be separated from the Fitting Instruction pages if desired

Low, Medium or High Flow Button

- Buttons glow BLUE when pressed

Temperature

Control Knob

1 Daryl Glass Cleaner for the regular cleaning of your

shower door, enclosure or screen

2 Daryl Care Kit comprising of Glass Treatment and

Glass Protector suitable for use where glass protector

has not already been applied or for topping up factory

coated protector

Daryl Glass Cleaner

For occasional cleaning of glass treated with Daryl Glass

Protector or for more regular maintenance of untreated

surfaces, we recommend using Daryl Glass Cleaner. The

Cleaner cleans and polishes without smearing or streaking

and rejuvenates the Glass Protector.

Daryl Glass Treatment and Daryl Glass Protector

Available in one care kit, the Treatment and Protector are

used on new or existing shower installations where

Protector has not already been applied and for topping up

factory coated glass after a reasonable length of time. The

Treatment must always be used on existing shower

installations to prepare for the Protector. The Treatment is a

cleaning material that is applied to the glass to ensure it is in

the cleanest condition possible prior to application of the

Protector. If this process is not undertaken, there is the

likelihood of locking in dust, dirt and stains under the

Protector.

Daryl Protector acts as an invisible barrier on the glass to

prevent the build up of lime scale, soap scum, stains and

dirt. Applied like a polish, one application will last from

months to years depending on use and the hardness of

water in your area. It will never crack, peel, discolour or build

up. Coated surfaces are kept clean simply by rinsing or

wiping with a damp cloth and regular use of Daryl Glass

Cleaner.

• In hard water areas, do not allow lime scale to build up.

Stubborn deposits of lime scale can usually be removed

by using a 50:50 solution of vinegar and water, which

should be rinsed off thoroughly and dried after use

• Regular cleaning is required to remove the small

amounts of residue that are not repelled by the Protector

Everyday Care

Wipe down the glass and metal sections with a soft cloth or

towel and warm water after each time the shower is used.

Do not allow water to remain on glass and metal sections

for long periods, do not allow the build up of lime scale and

do not use caustic cleaners or abrasives.

Daryl showers trays

If you have a Daryl shower tray scuffs and marks on acrylic

trays can often be removed by the light use of a mildly

abrasive cleaner applied with a damp cloth and polished off.

Other cleaning materials

Ensure that if you use a non-Daryl cleaning product, it has a

pH level between 4 & 8 and is non-abrasive. Prolonged use

of cleaners with a pH level outside the specified range can

cause damage to metal sections and possibly affect the

safe operation of your Daryl Shower. All cleaning material

(including Daryl’s) must be wiped down after application.

Do not use ‘spray and leave’ cleaning products on the metal

surface as these may cause damage to your door or

enclosure.

Warm Up/Stop Button

- glows BLUE

when powered

Warm Up Function (Optional)

St

1. Press the Warm Up push-button.

2. The unit delays turning on to allow you to get out

of the shower.

3. The Warm Up push-button flashes for a number of

seconds until water comes out of the handset at the desired temperature.

4. When the water is at the desired temperature the unit turns off waiting for you to shower.

To Operate the Shower

1. Press the Low, Medium or High flow push-button.

2. Water will come out of the handset at the desired temperature.

3. To alter the showering temperature, turn the temperature control knob. Whilst the showering temperature

stabilises, the selected flow push-button will flash.

4. Press the Stop push-button at the end of your shower.

Caution!

Anyone who may have difficulty understanding or operating the controls of any shower should be attended

whilst showering. Particular consideration should be given to:

• the young

• the elderly

• the infirm

• the disabled

• anyone who suffers from a medical condition that can result in temporary incapacity (e.g. epilepsy or

blackouts).

• anyone inexperienced in the correct operation of the controls.

18

CFI230J

CFI230J

11

Page 12

Spray Settings

The handset has three different spray actions: Start, Soothe and Massage and an Eco setting. To adjust the

spray setting turn the spray plate as follows:

1. Start - Water flows from the outer set of holes.

To select the Start setting, turn the spray plate

anticlockwise from the full clockwise position

until it clicks once.

Spray Plate

2. Soothe - Water flows from the middle set of holes.

CLEANING

The unit should be cleaned regularly.

Use a non abrasive cleaner (ideally with a pH value of 4 to 8)

applied with a soft cloth.

Under no circumstances should scourers or powerful

detegents be used as these can damage the metallic

surface of the frame and also tarnish the glass coating.

To select the Soothe setting, turn the spray plate

anticlockwise from the full clockwise position until it

clicks twice.

3. Massage - Water flows from the inner set of holes.

To select the Massage setting, turn the spray plate

anticlockwise from the full clockwise position until

it clicks three times.

4. Eco - Water flows from the outer set of holes at a

reduced flow rate.

To select the Economy setting, turn the spray

plate fully clockwise.

To avoid limescale, use your thumb or a soft cloth

to wipe any limescale from the soft rubber nozzles

and the front face of the showerhead.

CUSTOMER SERVICE

Kohler Daryl and Kohler Mira

We take the question of customer service seriously. Consequently, there is one initial point of contact – Daryl

Showering Technical Services (0151-606-5000). This team will ensure that the quality of support you require is

provided by specialists appropriate to that field; i.e. for matters relating to the shower enclosure, you will be

aided by Daryl Showering and for the shower system (including the Digital Mixer), your call will be supported by

Mira Showers personnel.

Your contact for all queries is Daryl Showering Customer Services (0151-606-5000)

If, when you first use your shower it does not function correctly, first contact your installer to check that

installation and commissioning are satisfactory and in accordance with the instructions in this manual.

12

CFI230J

If, over time, the performance of your shower declines, consult this manual to see whether simple home

maintenance is required. Please call our Technical Services Department to talk the difficulty through, request

service under guarantees (if applicable) or take advantage of our after-sales service.

CFI230J

17

Page 13

TROUBLESHOOTING

1

2

3

4

The information below gives details on what you can do as a user should you encounter difficulties whilst

operating the shower.

If there is a problem with the shower control some of the push buttons will flash very fast.

Malfunction Cause Remedy

Push buttons are

flashing on the shower

control and / or the

shower will not operate

Water supply isolated

Damaged or broken cable

connection

Check water supply

Check cable connections

B

A

No flow or low flow rate

from the Shower Fittings

Drip from spray plate

assembly on handset

Electrical supply isolated

or fuse blown

Digital Mixer Valve

breakdown

Spray plate assembly

blocked

Hose blocked or twisted

Digital Mixer Valve malfunction

A small amount of water

may be retained in the

shower fitting after the

shower control has been

turned off. This may drain

over a few minutes

Digital Mixer Valve

malfunction

Check electrical supply

Isolate product and turn

back on after 30 seconds

If the problem still

persists note the

sequence of the flashing

push buttons and

contact Customer

Services

Refer to Cleaning

Clear blockage or

release twist in hose

Contact Customer Services

This is quite normal.

Changing the angle of

the shower fitting may

vary the draining time

Solenoid fault. May

require cleaning or

replacement. Contact

Customer Services

Handset Adjustment

To adjust the height of the handset press

the release button ‘A’ and slide the clamp

bracket assembly up or down to the

desired position.

The handset can be moved both vertically

and horizontally until the desired position

is reached ‘B’. A friction mechanism in the

clamp bracket will hold the handset in

place.

Fixed Head Adjustment

Move the spray head to the required

position. The spray head is adjustable in

both the horizontal and vertical

directions.

16

CFI230J

Incorrect shower

temperature

Maximum temperature

incorrectly set

Digital Mixer Valve incorrectly

fitted

Refer to Commissioning,

Maximum temperature

setting

Make sure that the hot

and cold water supplies

are connected correctly

CFI230J

13

Page 14

COMMISSIONING/SETTING

1. General

1.1. Turn on the water supply to the Digital Mixer.

1.2. Check for leaks over the complete system.

1.3. Turn on the electrical supply to the Digital Mixer.

For the Pumped Version with the Slide Rail System, pump priming can be helped by removing the handset

and lowering the end of the hose into the shower tray.

2. Set the Maximum Temperature

Note! The maximum temperature of the unit can only be set when the unit has not been used for a period of

10 minutes or after switching the unit’s electrical supply OFF and ON.

2.1. Temperature Selection - Set the temperature control knob to the desired position, as per the table

below.

Temperature Control Temperature Selection °C

Knob Position

1 Factory Set 45°C

Setting Option 1

Operate the shower and set the desired flow and temperature, then press and momentarily hold the

Warm Up/Stop and Medium push-buttons at the same time. The Medium push-button will flash and

beep three times to confirm the selection is successful.

The mixer is locked to your selected temperature and flow. Pressing any flow push-button turns the

mixer ON. Pressing the Warm Up/Stop push-button turns the mixer OFF.

Caution! If the temperature control knob is altered while the mixer is in standby mode or while

the shower is in operation, the water temperature settings will be changed to the new setting next time

the shower is used.

Note! Selecting the Warm Up/Stop and Medium push-buttons at the same time again, cancels the

lock mode option set. The Medium push-button will flash and beep three times

Setting Otion 2

Note! This can only be set when the mixer has not been used for a period of 10 minutes. Switching the

unit’s electrical supply OFF and ON cancels the lock mode.

Press and momentarily hold the Warm Up/Stop and Medium push-buttons at the same time. The

Medium push-button will flash and beep three times to confirm the selection is successful. The

interfaces are locked.

Note! Selecting the Warm Up/Stop and Medium push-buttons at the same time again, cancels the

lock mode option set. The Medium push-button will flash and beep three times

2 45°C

3 36°C

4 38°C

5 40°C

6 42°C

7 45°C

8 47°C

9 48°C

2.2. Enabling - Press and momentarily hold the Warm Up/Stop and High push-buttons at the same time.

Release the push-buttons and press them again within 2 seconds. The High push-button will flash and beep

three times to confirm the selection is successful.

4. Timeout

Note! Timeout allows you to run the shower for a set period of time before it automatically shuts off. This can

only be set when the unit has not been used for a period of 30 minutes or after switching the unit‘s electrical

supply OFF and ON.

4.1. Timeout Selection - Set the temperature control knob to the desired position, as per the table below.

Temperature Control Timeout (Minutes)

Knob Position

1 30

2 30

3 3

4 4

5 5

3. Lock Mode

Note! Allows you to lock the unit during operation.

3.1. There are two Safety Lock Modes

Option 1 - Locks the mixer to your flow and temperature settings.

Option 2 - Locks the interface so no push-buttons can be used.

Note! The Warm Up/Stop push-button will be illuminated on the interface used to set the lock mode, no

other interface will be illuminated.

CFI230J

14

6 6

7 7

8 8

9 9

4.2. Enabling - Press and momentarily hold the Warm Up/Stop and Low push-buttons at the same

time. The Low push-button will flash and beep three times to confirm the selection is successful.

CFI230J

15

Loading...

Loading...