Publication No. 981088

September 1995

Supersedes 981088

October 1994

INSTALLATION INSTRUCTIONS for the

Kodak X-Omat M43 and M43A PROCESSORS

and the

Kodak X-Omat Clinic 1 PROCESSOR

HEALTH SCIENCES DIVISION

© Eastman Kodak Company

H130_0009DA

PLEASE NOTE The information contained herein is based on the experience and knowledge relating to the

subject matter gained by Eastman Kodak Company prior to publication.

No patent license is granted by this information.

Eastman Kodak Company reserves the right to change this information without notice, and

makes no warranty, express or implied, with respect to this information. Kodak shall not be

liable for any loss or damage, including consequential or special damages, resulting from any

use of this information, even if loss or damage is caused by Kodak’s negligence or other fault.

Warning

To avoid hazardous conditions, keep floors and floor coverings around your Kodak X-Omat Processors and

associated drains clean and dry at all times. Any accumulation of fluids from mixing tanks, drain lines, etc., should

be cleaned up immediately. In the event of an accumulation of liquid due to backup, overflow, or other malfunctions

of the drain associated with your Kodak X-Omat Processor, call a plumber or other contractor to correct any problem

with the drain. Kodak accepts no responsibility or liability whatsoever for the serviceability of any drain connected

to or associated with a Kodak X-Omat Processor. Such drains are the sole responsibility of the customer.

This equipment includes parts and assemblies sensitive to damage from electrostatic

discharge. Use caution to prevent damage during all service procedures.

Important

This manual is intended for use by qualified service personnel only.

2 September 1995 – 981088

Table of Contents

Description Page

Unpacking the PROCESSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installing the PROCESSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Changing the PROCESSOR to 50 or 60 Hz Operation, M43 and M43A Only . . . . . . . . . 32

Processor Setup Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Installing the DRYER PLENUM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Installing the RACKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Leveling the PROCESSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Making the Necessary Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Checking the Electrical Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Connecting the DRAIN LINES and the Water Supply HOSE

for the Table Top or MOUNTING STAND Installations. . . . . . . . . . . . . . . . . . . . 51

Connecting the HOSES from the REPLENISHMENT TANKS

in Table Top or MOUNTING STAND Installations . . . . . . . . . . . . . . . . . . . . . . . 53

Doing the Water Leak Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Setting the Developer Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Checking and Adjusting the Replenishment Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Installing the KNOBS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Installing the FEED TRAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Installing the LIGHTTIGHT FEED TRAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Filling the TANKS with the Developer and Fixer Solutions . . . . . . . . . . . . . . . . . . . . . . . 67

Final Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Moving the PROCESSOR to the Work Area . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installing the PROCESSOR on the MOUNTING STAND . . . . . . . . . . . . . . . . 9

Installing the PROCESSOR on a Table Top . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installing the PROCESSOR Through the Wall . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installing the Alternate SPROCKET on an M43 or M43A PROCESSOR Only 33

Changing the Input CONNECTOR on the DRIVE MOTOR . . . . . . . . . . . . . . 34

Available Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Changing the PROCESSOR Setup Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Identifying the Parts of the PROCESSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Installing the WASH RACK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Installing the FIXER and DEVELOPER RACKS . . . . . . . . . . . . . . . . . . . . . . . 44

Installing the DRYER RACK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Important Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Service Requirements for European Installations of the M43 PROCESSOR . . 49

Making the Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Installing the KNOBS on the DRAIN VALVES . . . . . . . . . . . . . . . . . . . . . . . . 64

Installing the DRYER TEMPERATURE CONTROL KNOB . . . . . . . . . . . . . 65

Mixing the Chemicals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Filling the FIXER TANK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Filling the DEVELOPER TANK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Checking for Correct Operation of the PROCESSOR . . . . . . . . . . . . . . . . . . . . 73

Transport Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Setting the Dryer Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

981088 – September 1995 3

INSTALLATION INSTRUCTIONS

4 September 1995 – 981088

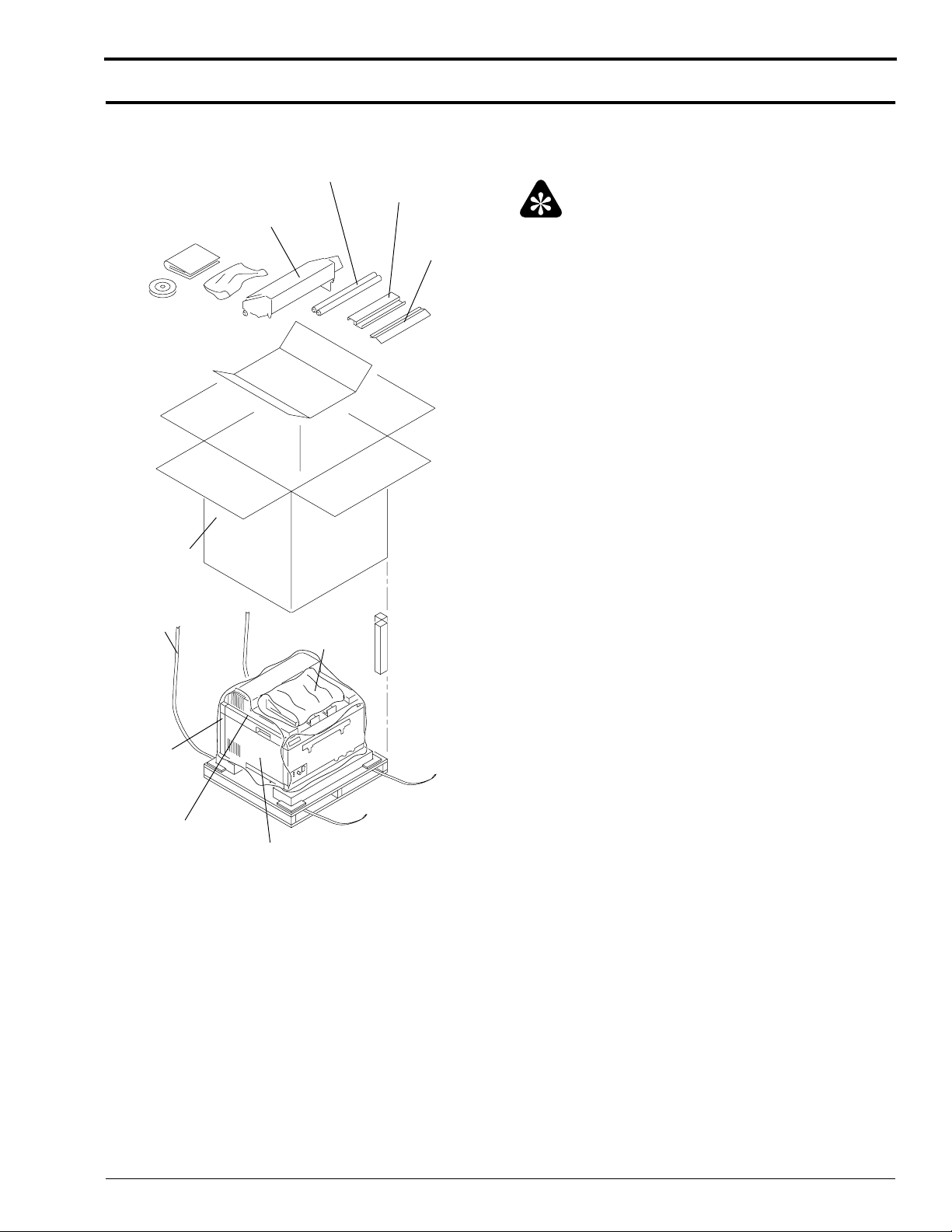

Section 1: Unpacking the PROCESSOR

Unpacking the PROCESSOR

Figure 1 Removing the Components

EXIT ROLLER

ASSEMBLY

DRYER RACK

shipping

carton

metal

bands

FEED

TRAY

EVAPORATION

COVER (2)

SPLASH

GUARD

[1] Cut the metal bands, open the shipping carton, and

remove any packing material.

Important

When removing protective packing material or

wrapping from components, be careful not to cut

through the protective wrapping and damage the

component.

[2] Remove the items packed with the PROCESSOR.

See publication 1C7052 in the front pocket of

your publications binder for a list of the items

packed with your PROCESSOR model.

[3] Remove:

• shipping carton from around the

PROCESSOR

• any other packing materials

• TOP COVER from the PROCESSOR

• EVAPORATION COVERS for the

DEVELOPER and FIXER RACKS

• 2 SIDE ACCESS PANELS and the BACK

ACCESS PANEL by loosening the

2 SCREWS securing each PANEL

• POWER CABLE (provided with the M43A

only)

BACK

ACCESS

PANEL

TOP

COVER

981088 – September 1995 5

SIDE ACCESS

PANEL (2)

H130_0140CCA

H130_0140CA

INSTALLATION INSTRUCTIONS

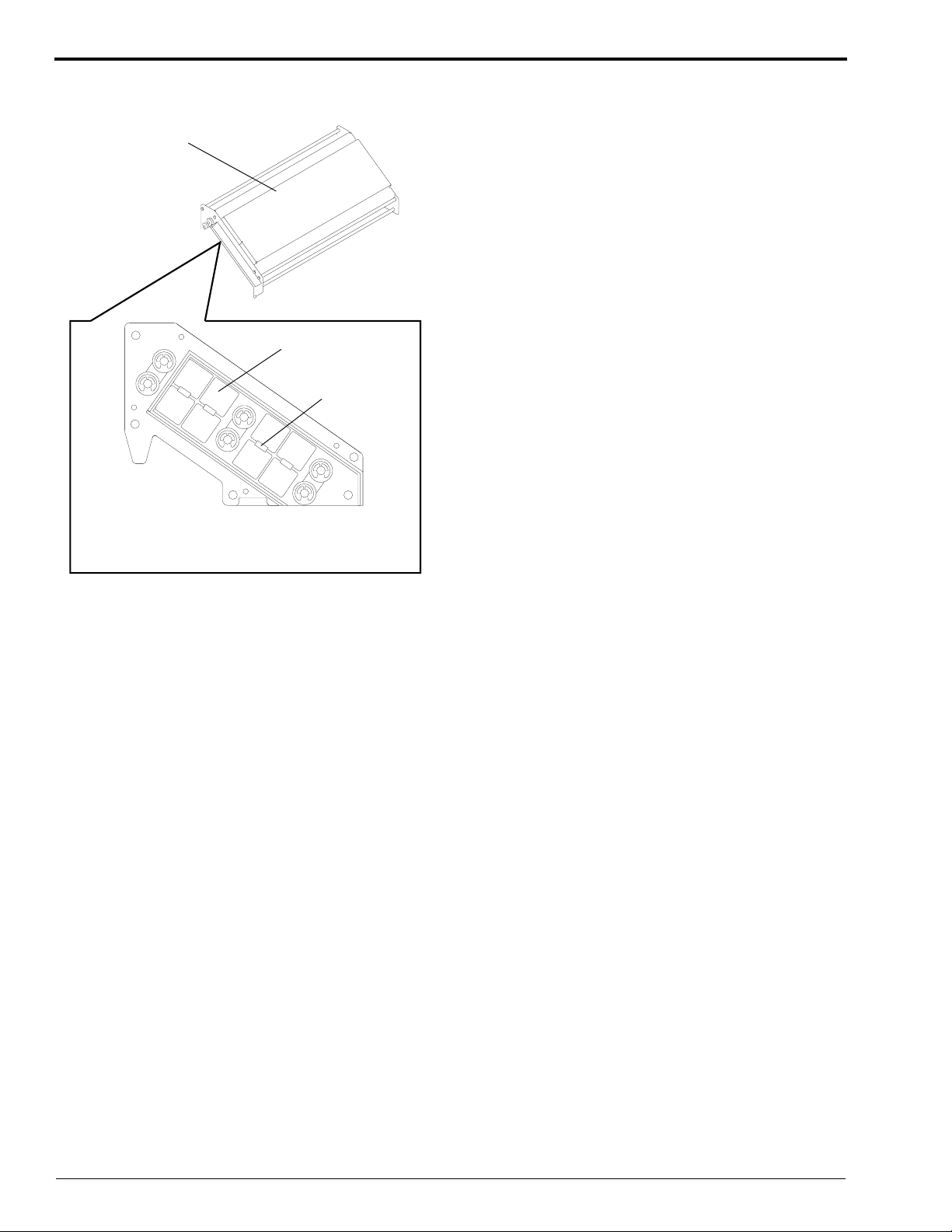

Figure 2 Removing the Tape from the DRYER AIR

TUBES

DRYER RACK

Non-Drive End View

[4] From the DRYER RACK, remove the 8 pieces of

tape holding the DRYER AIR TUBES in position.

DRYER AIR

TUBES (8)

tape

H130_0142GCA

H130_0142GA

6 September 1995 – 981088

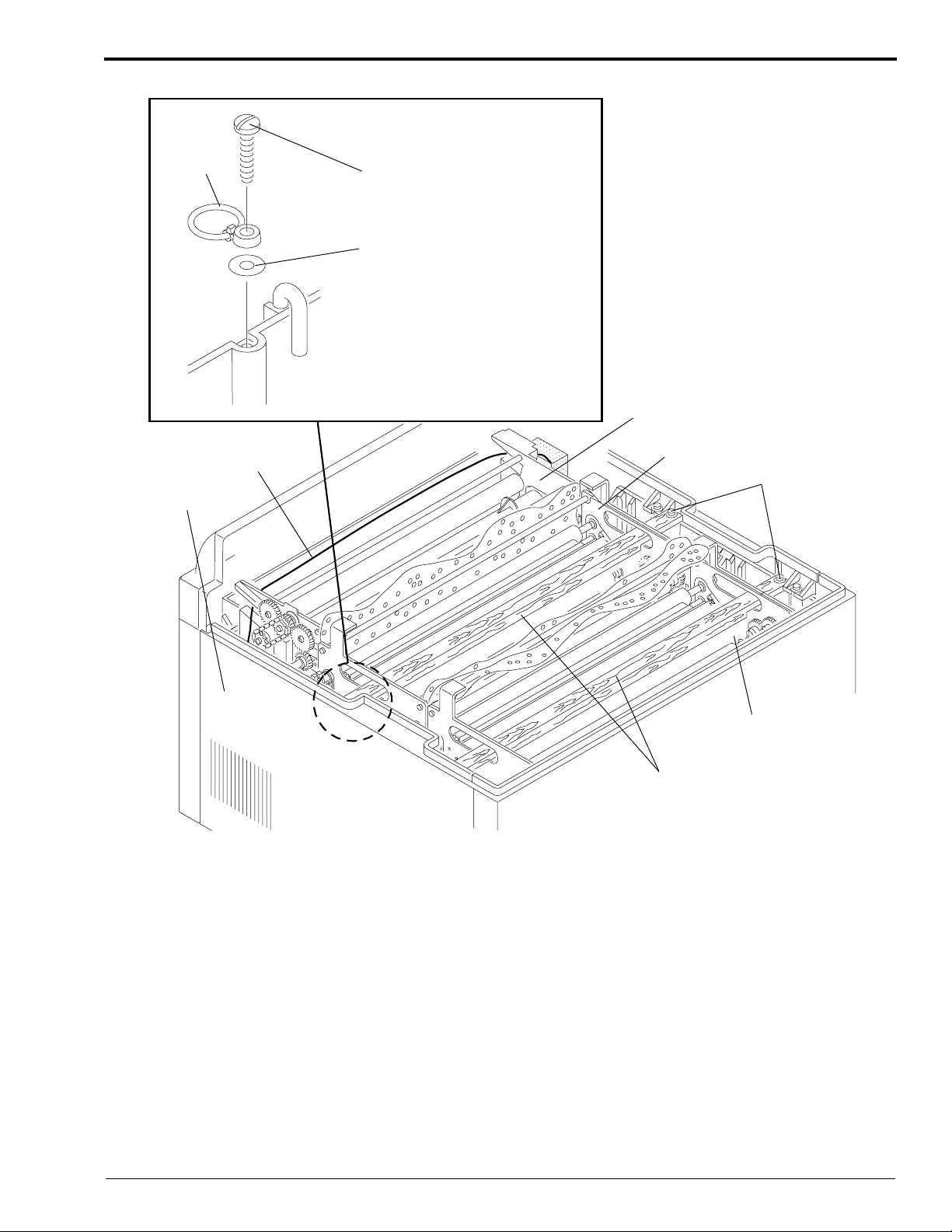

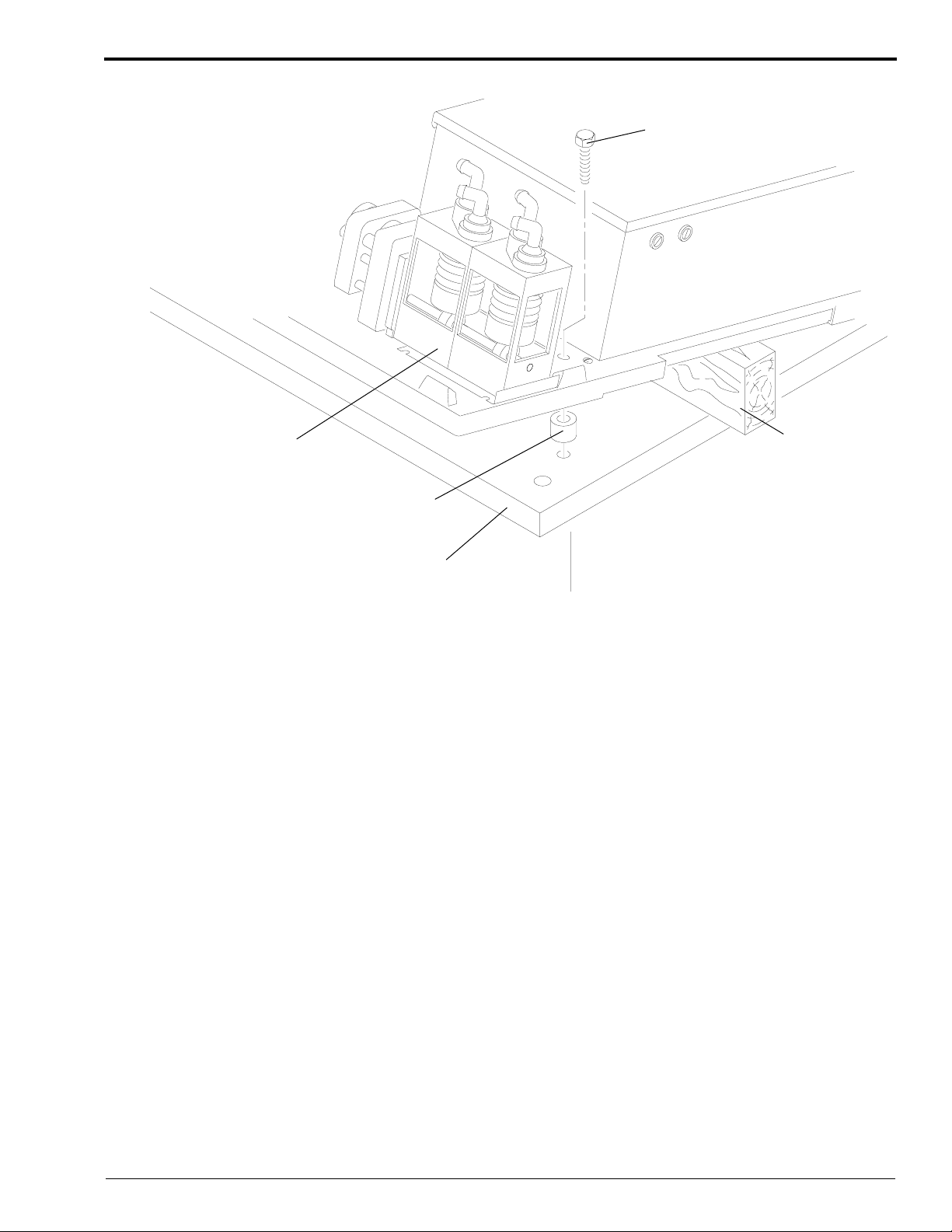

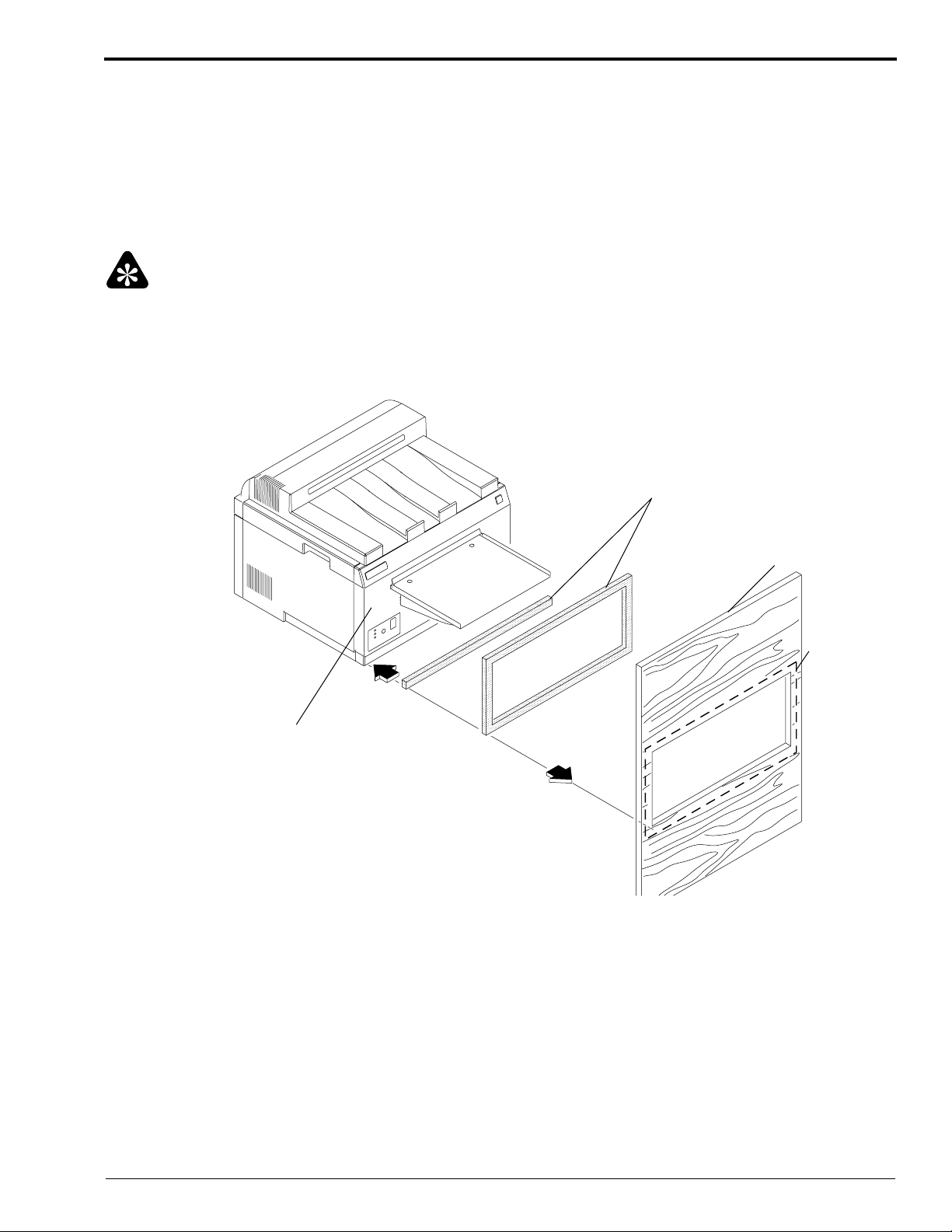

Figure 3 Unpacking the RACKS

Unpacking the PROCESSOR

O-RING

DRIVE

SIDE

ACCESS

PANEL

STRAP

SCREW

WASHER

WASH RACK

FIXER RACK

SCREWS (4)

DEVELOPER

RACK

WOOD RESTRAINTS

H130_0170DCA

H130_0170DA

[5] Remove the 2 SCREWS securing the WOOD RESTRAINT on the DEVELOPER RACK. Remove the WOOD

RESTRAINT from the DEVELOPER RACK.

[6] Remove the 2 SCREWS securing the WOOD RESTRAINT on the FIXER RACK. Remove the WOOD

RESTRAINT from the FIXER RACK.

[7] Locate the SCREW hole on the drive side of the PROCESSOR that was used to secure the WOOD

RESTRAINT onto the FIXER RACK.

[8] Install the O-RING provided into that hole using the SCREW and WASHER provided. The O-RING will be

used in later procedures to enable you to secure the COVER of the ELECTRICAL BOX in the open position.

See the figure.

[9] Remove the DEVELOPER and FIXER RACKS and any protective packing material.

[10] Cut and remove the STRAP securing the WASH RACK in place.

[11] Remove any remaining protective packing material.

981088 – September 1995 7

INSTALLATION INSTRUCTIONS

Section 2: Installing the PROCESSOR

Moving the PROCESSOR to the Work Area

Warning

The unpacked, empty PROCESSOR weighs approximately 84 kg (185 lb). Use 2 people to move it. The PUMPS

are heavy and are located in the back of the PROCESSOR. Rotate the PROCESSOR so that each person supports

1

⁄2 the weight of the PROCESSOR.

[1] Move the PROCESSOR to the work area where you plan to install it. When possible move the PROCESSOR

in its upright position.

(a) If the PROCESSOR does not fit through the door opening of the work area, do the steps below.

1. Check that the BACK ACCESS PANEL and DRIVE SIDE ACCESS PANEL are removed. If not,

loosen the 2 SCREWS on each PANEL and remove the PANEL.

2. Check that the FRONT ACCESS PANEL is installed. The FRONT ACCESS will protect the FILM

DETECTOR ASSEMBLY from damage when moving the PROCESSOR through a narrow door

opening.

3. To reduce space requirements, check that the LEVELING FEET are rotated up into the PROCESSOR

as far as possible.

4. Rotate the PROCESSOR so that the non-drive side faces down. See the figure for the dimensions of

the PROCESSOR with the TOP COVER and PANELS removed.

5. To reduce space requirements even more, unscrew the MOUNTING BRACKET for the

INTERLOCK SWITCH and let the INTERLOCK SWITCH hang inside the PROCESSOR.

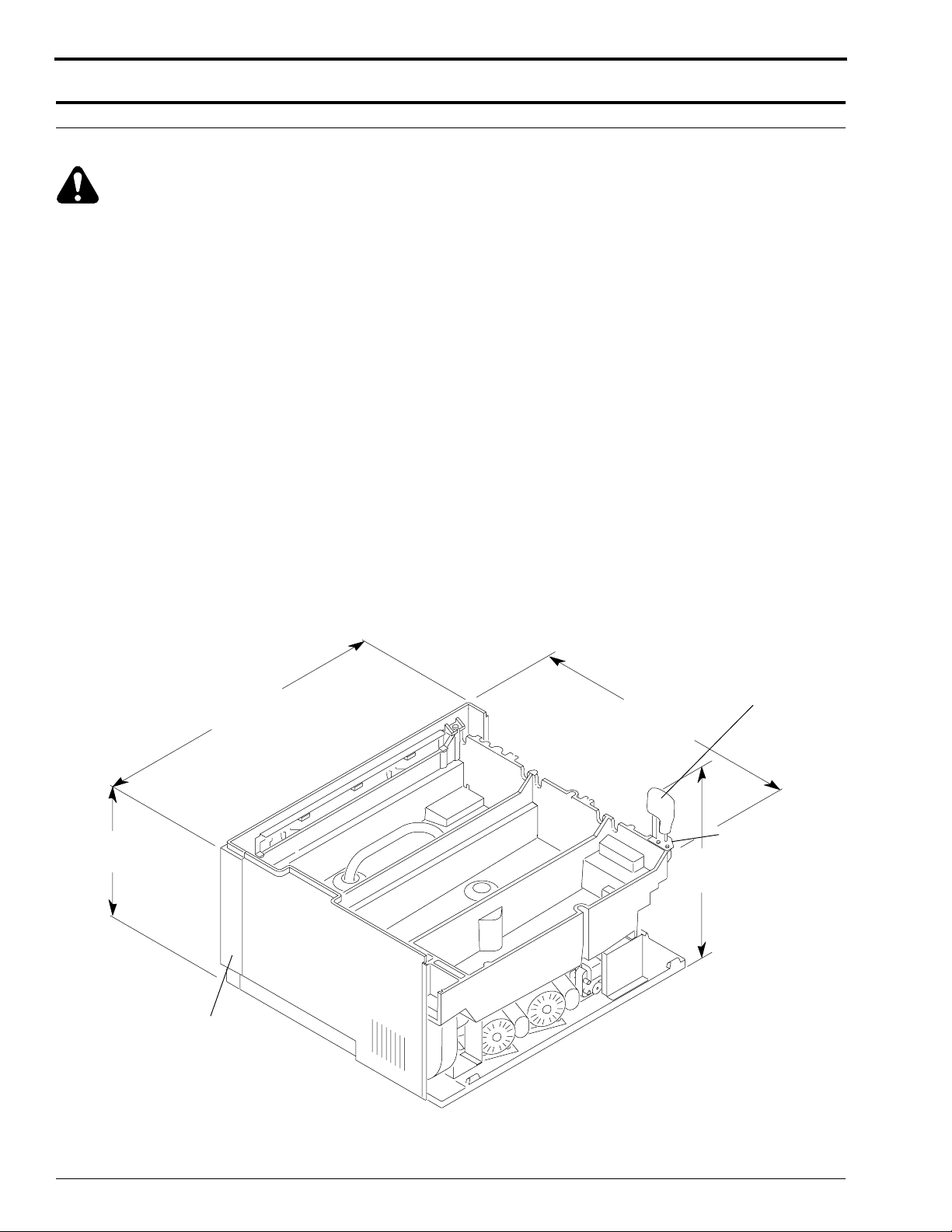

Figure 4 Moving the PROCESSOR through a Narrow Door Opening

69.2 cm

(27 1/4 in.)

34.3 cm

(13 1/2 in.)

FRONT ACCESS

PANEL

non-drive

side

drive

side

66.7 cm

(26 1/4 in.)

41.3 cm

(16 1/4 in.)

INTERLOCK

SWITCH

MOUNTING

BRACKET

H130_0133HCB

H130_0133HA

8 September 1995 – 981088

Installing the PROCESSOR

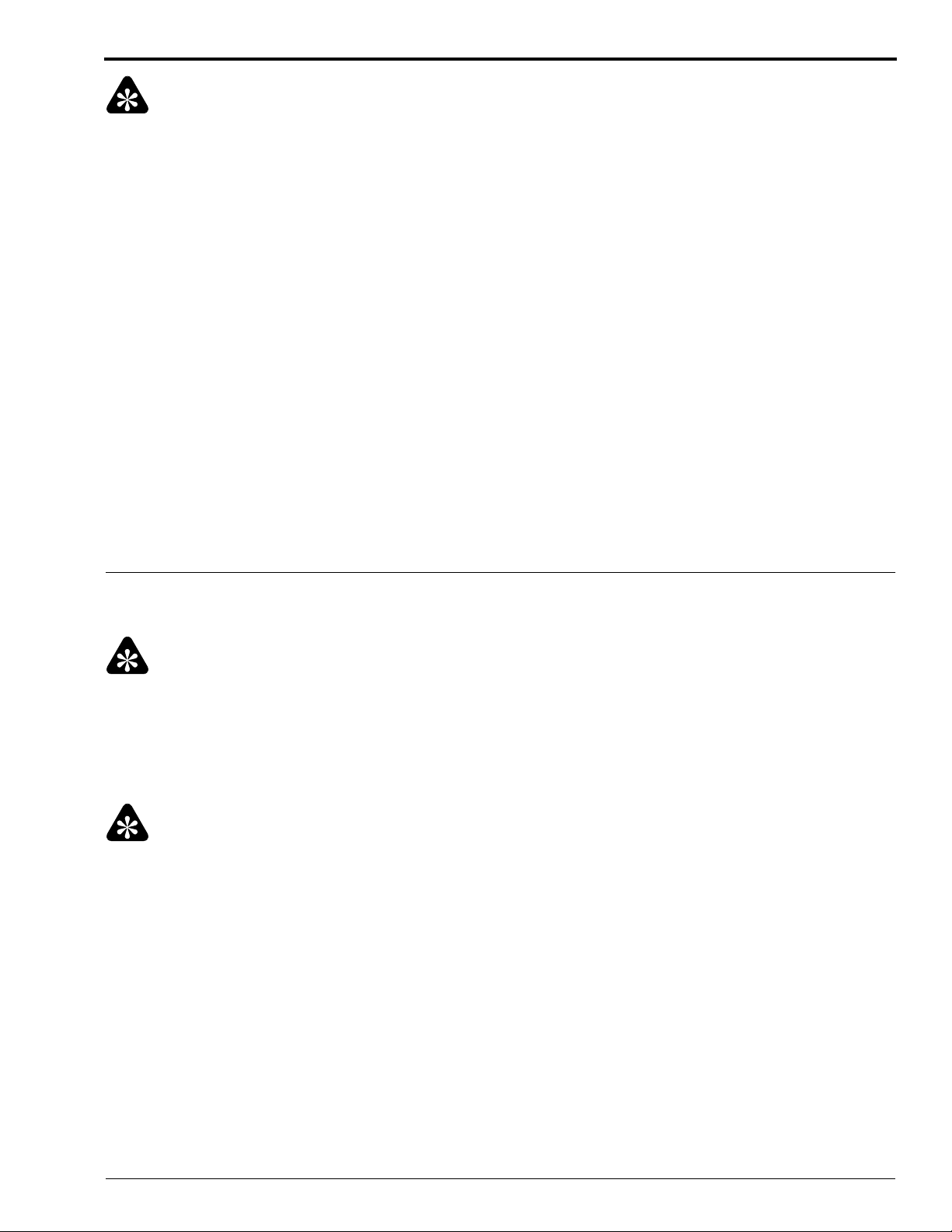

Important

• Servicing and accessing the PROCESSOR is easiest if you position the PROCESSOR on a Kodak

M35, M43, Clinic 1 MOUNTING STAND.

• If you will not be installing the PROCESSOR on the Kodak M35, M43, Clinic 1 MOUNTING

STAND, see “Installing the PROCESSOR on a Table Top” on Page 12.

• If you will be installing the PROCESSOR through the darkroom wall, see “Installing the

PROCESSOR Through the Wall” on Page 13.

[2] Install the PROCESSOR by following 1 of the 3 procedures outlined on the following pages:

• on a Table Top — see Page 12

• through the wall — see Page 13

• on the M35, M43, Clinic 1 MOUNTING STAND — see below

[3] If you removed the INTERLOCK SWITCH in Step 1a, do the steps below.

(a) Install:

• SIDE ACCESS PANELS

• FRONT ACCESS PANEL

• TOP COVER

(b) Push the MOUNTING BRACKET forward until the BLADE of the TOP COVER fully engages the

INTERLOCK SWITCH. Tighten the 2 SCREWS to secure the BRACKET.

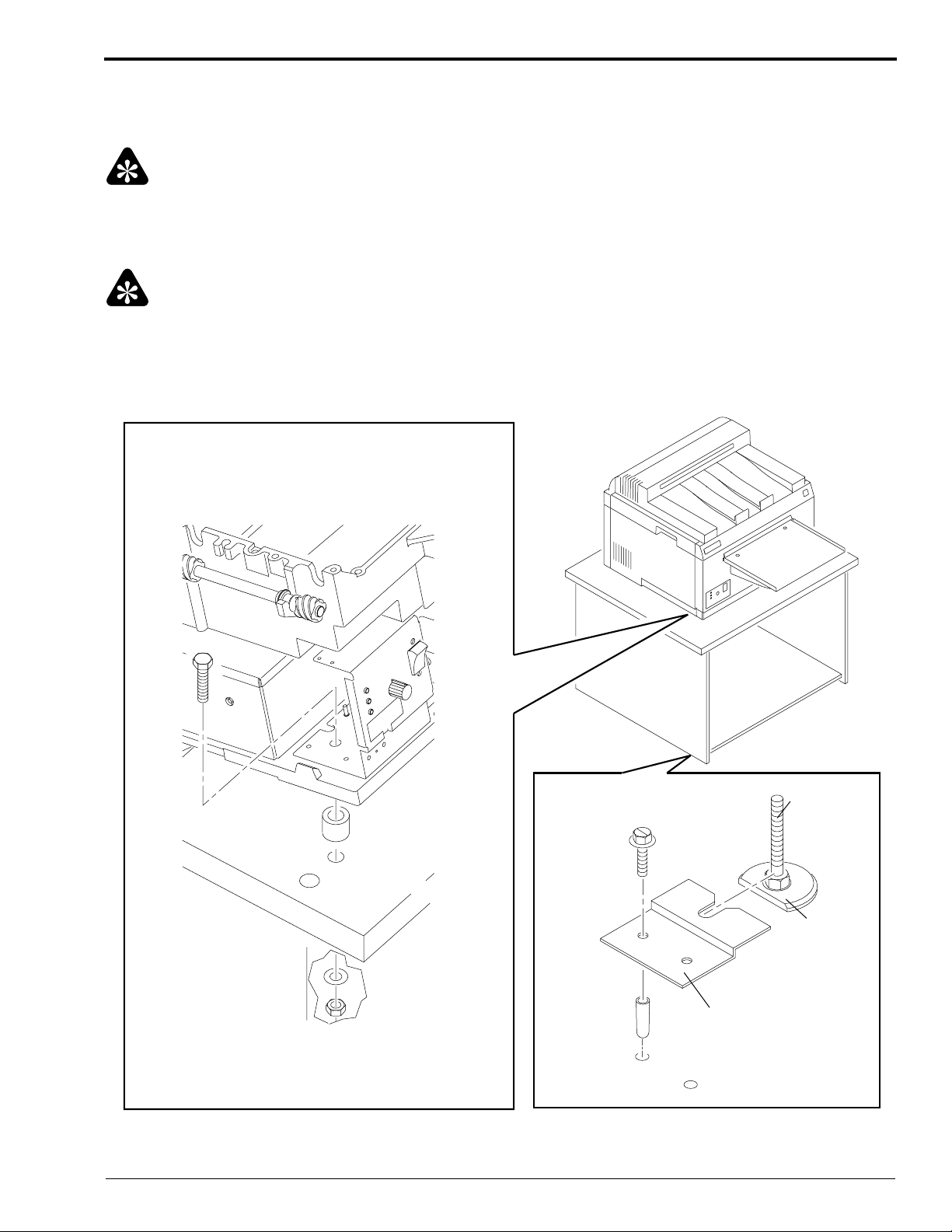

Installing the PROCESSOR on the MOUNTING STAND

[1] Place the PROCESSOR on the MOUNTING STAND with the large holes toward the operator’s work area.

Important

If you will be securing the MOUNTING STAND with SEISMIC BRACKETS, ensure that the MOUNTING

STAND, on its LEVELING FEET, is no more than 2.5 cm (1 in.) above the floor.

[2] Install the 4 LEVELING FEET and 4 LOCK NUTS on the MOUNTING STAND.

(a) Rotate the LEVELING FEET until the MOUNTING STAND is approximately 2.5 - 3.75 cm

1

(1 - 1

⁄2in.) above the FLOOR.

Important

If you will be securing the MOUNTING STAND with SEISMIC BRACKETS, use the FLOOR PLATES provided

with the SEISMIC BRACKET KIT 261413.

[3] Install the FLOOR PLATES under each of the 4 LEVELING FEET of the MOUNTING STAND.

[4] Move the MOUNTING STAND as close to its final position as possible while still maintaining clearance on

all sides of the PROCESSOR for access to components.

[5] Check that the MOUNTING STAND is level both front-to-back and side-to-side.

[6] Once the MOUNTING STAND is level, tighten the 4 LOCK NUTS against the base of the MOUNTING

STAND to secure its height.

981088 – September 1995 9

INSTALLATION INSTRUCTIONS

Caution

The empty PROCESSOR weighs approximately 84 kg (185 lb).

[7] Position the PROCESSOR on the MOUNTING STAND. Do not allow the LEVELING FEET to fall into the

holes in the TOP of the MOUNTING STAND.

Figure 5 Using the MOUNTING STAND

holes for

LEVELING FEET

holes for

LEVELING FEET

H130_0204BCA

H130_0204BA

[8] Raise and support the non-feed end of the PROCESSOR to gain access to 2 LEVELING FEET. Use a 5 x 10 cm

(2 x 4 in.) piece of wood that is 1 m (3 ft.) long to support the PROCESSOR.

(a) Position the piece of wood so that:

• it supports the entire width of the PROCESSOR (drive side to non-drive side)

• it is closer to the center of the PROCESSOR than to the back

[9] Remove the NUT from each of the 2 non-feed end LEVELING FEET. Keep the NUTS for later installation.

[10] Remove and discard the LEVELING FOOT on the drive side of the PROCESSOR near the

REPLENISHMENT PUMP.

1

[11] Install the 7.6 cm (3

⁄2 in.) LEVELING FOOT (packed with the PROCESSOR) in its place. See Figure 6.

[12] Rotate these 2 LEVELING FEET clockwise until they are fully extended. Use a SOCKET or WRENCH to

ensure that the LEVELING FEET are tight.

[13] Position a SPACER on the TOP of the MOUNTING STAND under each of the 2 LEVELING FEET.

Note

The SPACERS are packed with the MOUNTING STAND.

[14] Lower the raised end of the PROCESSOR by removing the piece of wood supporting it.

[15] Check that the LEVELING FEET are lowered into the SPACERS.

[16] Align the 2 LEVELING FEET and SPACERS with the holes in the TOP of the MOUNTING STAND. Insert

the LEVELING FEET through the holes.

10 September 1995 – 981088

Figure 6 Installing the SPACERS on the Non-Feed End of the PROCESSOR

non-feed

end

Installing the PROCESSOR

LEVELING

FOOT (2)

REPLENISHMENT PUMP

SPACER (2)

drive side

MOUNTING STAND

wood

support

H130_0182HCA

H130_0182HA

[17] Repeat Steps 8, 9, and 12 through 16 for other end, the feed end, of the PROCESSOR.

[18] Check that the PROCESSOR is level.

[19] Install the following parts onto the 4 LEVELING FEET by reaching under the TOP of the MOUNTING

STAND:

• 4 WASHERS, provided with the MOUNTING STAND

• 4 NUTS - removed in Step 9

[20] Advance to the appropriate section as outlined below.

(a) If you are installing an M43A or Clinic 1 PROCESSOR for 60 Hz operation, advance to the section

“PROCESSOR Setup Options” on Page 35.

(b) If you are installing an M43A PROCESSOR for 50 Hz operation, advance to the section “Changing the

PROCESSOR to 50 or 60 Hz Operation” on Page 32.

981088 – September 1995 11

INSTALLATION INSTRUCTIONS

Installing the PROCESSOR on a Table Top

Warning

The unpacked, empty PROCESSOR weighs approximately 84 kg (185 lb). Use 2 people to move it. The PUMPS

are heavy and are located in the back of the PROCESSOR. Rotate the PROCESSOR so that each person supports

1

⁄2 the weight of the PROCESSOR.

[1] Check that the work surface is capable of supporting a minimum of 113 kg (250 lb).

[2] Place the PROCESSOR on the work surface with the FRONT ACCESS PANEL facing the operator’s work

area.

(a) Check that all 4 LEVELING FEET are supported.

(b) Refer to the Site Specifications, Publication Number 981087, to check that you have room to access:

• the front of the PROCESSOR

• the ELECTRICAL BOX on the drive side of the PROCESSOR

[3] Locate the 4 FLOOR PLATES packed with the PROCESSOR.

[4] Insert the 4 FLOOR PLATES under the 4 LEVELING FEET of the PROCESSOR.

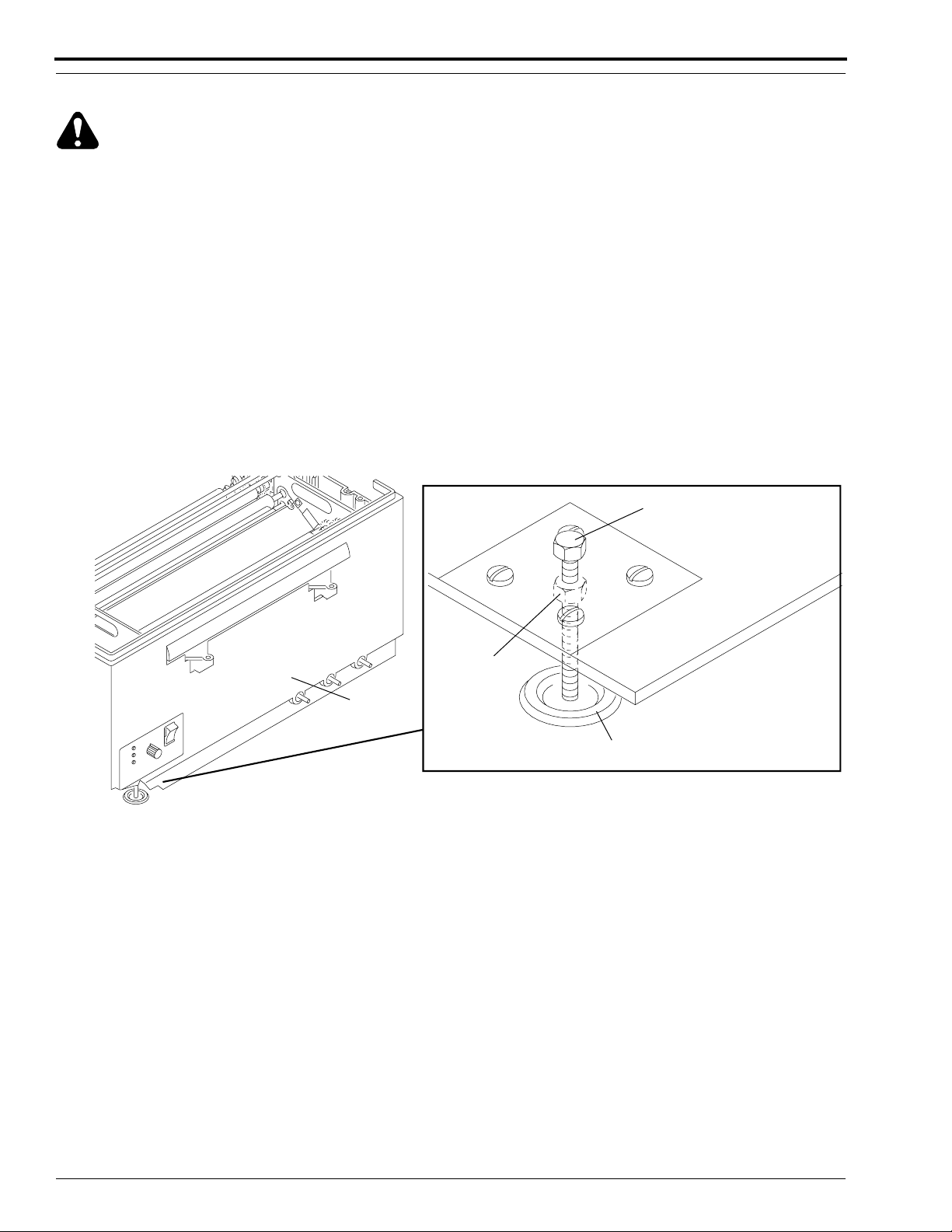

Figure 7 Installing the FLOOR PLATES

LEVELING FOOT (4)

NUT (4)

FRONT

ACCESS

PANEL

FLOOR PLATE (4)

[5] Advance to the appropriate section as outlined below.

(a) If you are installing an M43A or Clinic 1 PROCESSOR for 60 Hz operation, advance to the section

“PROCESSOR Setup Options” on Page 35.

(b) If you are installing an M43A PROCESSOR for 50 Hz operation, advance to the section “Changing the

PROCESSOR to 50 or 60 Hz Operation” on Page 32.

H130_0147BCA

H130_0147BA

12 September 1995 – 981088

Installing the PROCESSOR

Installing the PROCESSOR Through the Wall

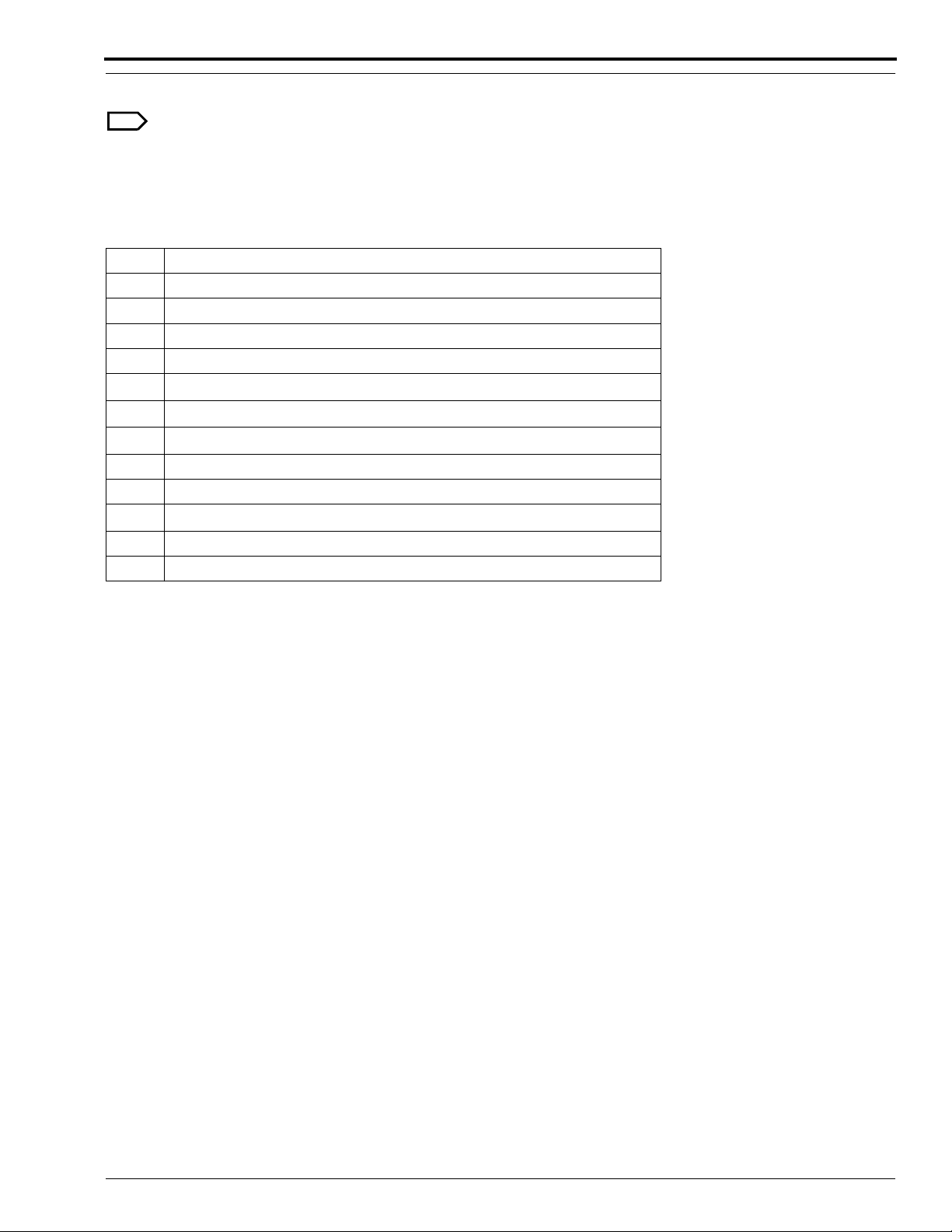

Note

• These instructions assume that you are setting the PROCESSOR on a Kodak M35, M43, and Clinic 1

MOUNTING STAND.

• The Kodak X-Omat M43 Through-the-Wall Kit, CAT No. 871-3109, is available and includes:

Qty Item

1 FOAM BLOCK, LIGHT LOCK

2 FOAM GASKET, LIGHT LOCK

6 HOSE CLAMPS #12 for DRAINS

4 HOSE CLAMPS #2 for REPLENISHMENT HOSES

2

HOSE, Opaque,

3

HOSE, Opaque,

2

FITTING, Barbed,

2 EYEBOLTS

2 NUTS for EYEBOLTS

3

FITTING, Barbed,

2 WASHERS for LEVELING FEET

2 WASHERS for EYEBOLTS

3

⁄8 in. ID, 3 ft., for REPLENISHMENT HOSES

3

⁄4 in. ID, 4 ft., for DRAINS

3

⁄8 in., for REPLENISHMENT HOSES

3

⁄4 in., for DRAINS

Planning the Site

[1] Check that the dimensions and location of the hole in the wall match the WALL OPENING in Figure 8 on

Page 14.

[2] Determine the other requirements of your site, such as the location of these items:

• FLOOR DRAIN

• REPLENISHMENT TANKS

– If the REPLENISHMENT TANKS are to be located outside the darkroom, decide whether you will

locate them inside the MOUNTING STAND or outside the MOUNTING STAND.

• main water supply VALVE

• main power supply CIRCUIT BREAKER, which should be located:

– outside of the darkroom

– within sight of the PROCESSOR and be accessible by the operators and service personnel

981088 – September 1995 13

INSTALLATION INSTRUCTIONS

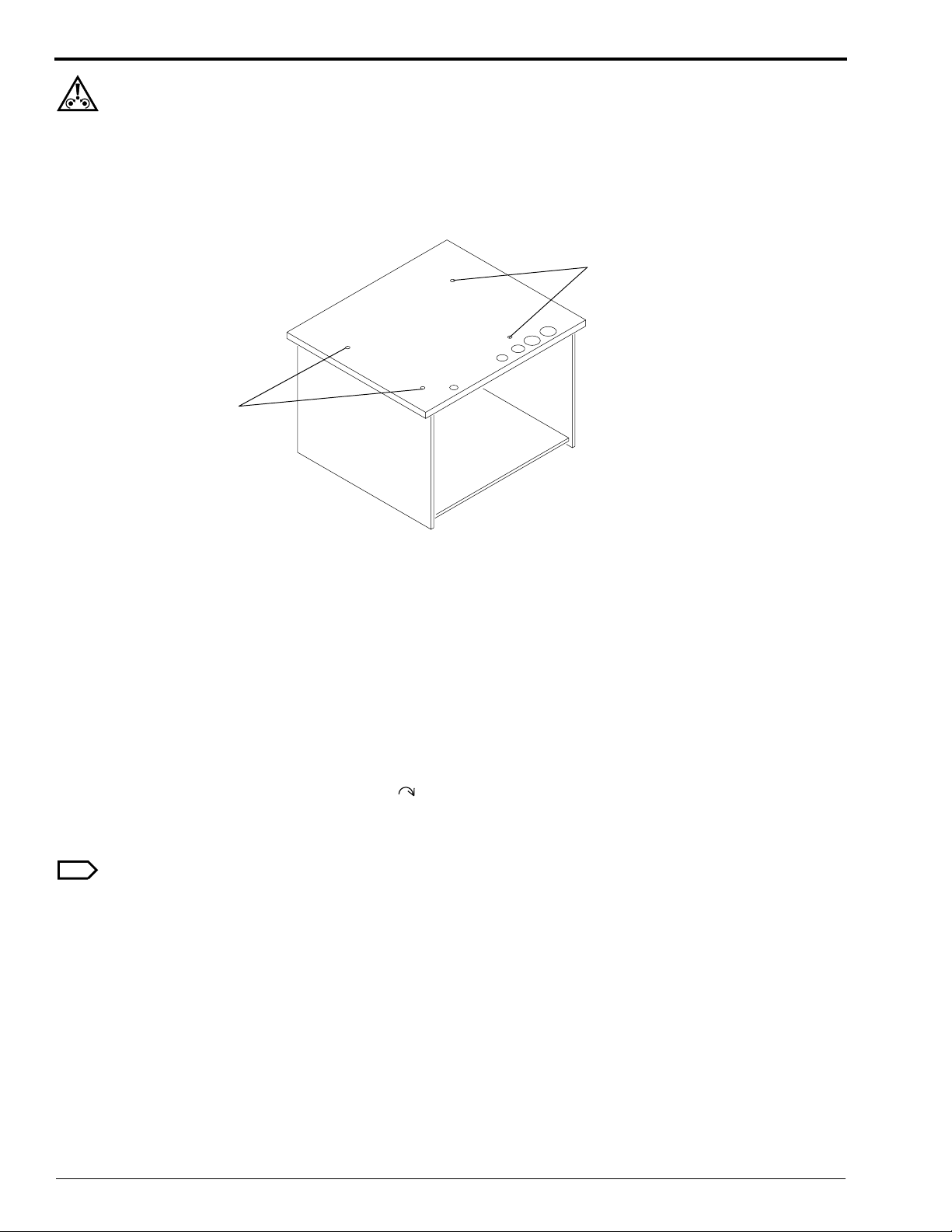

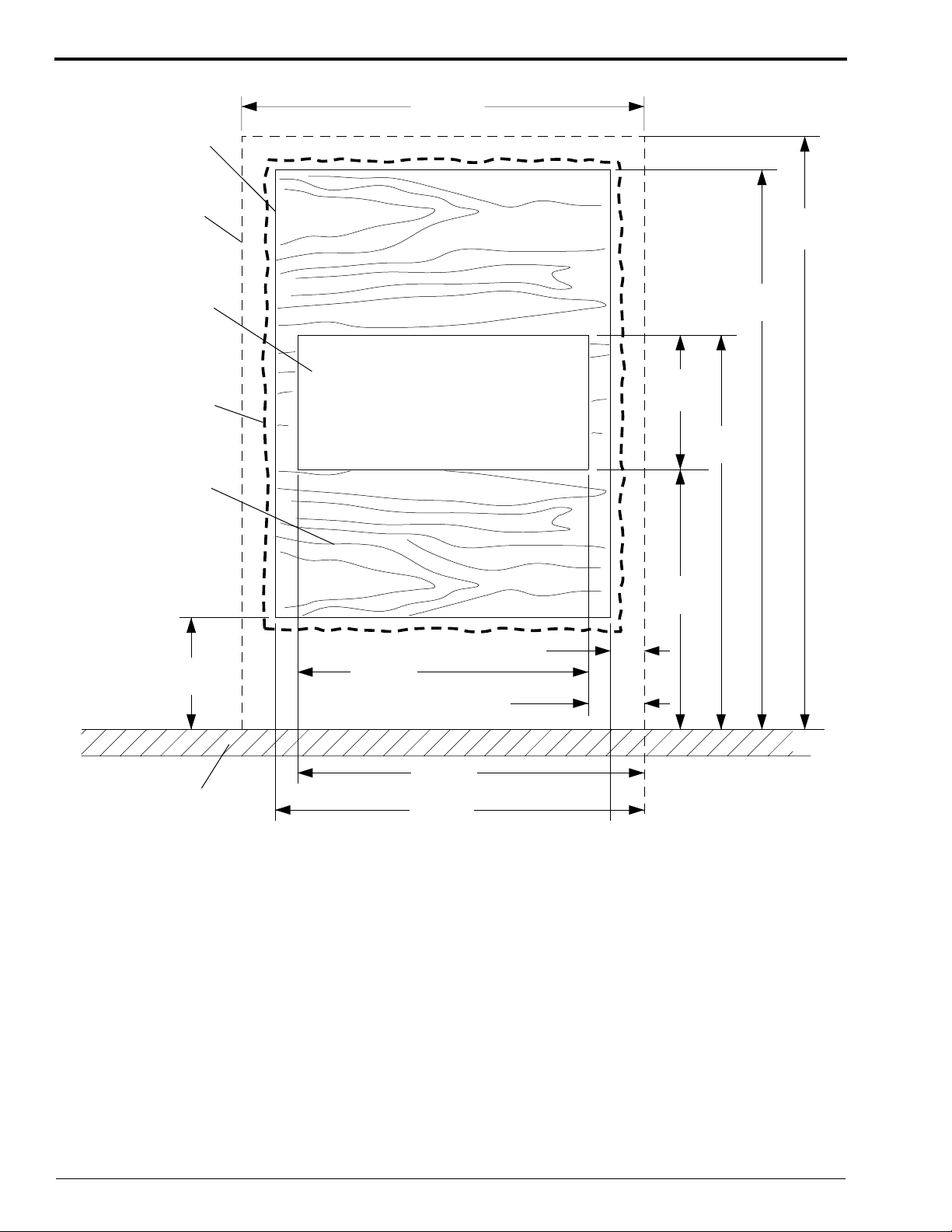

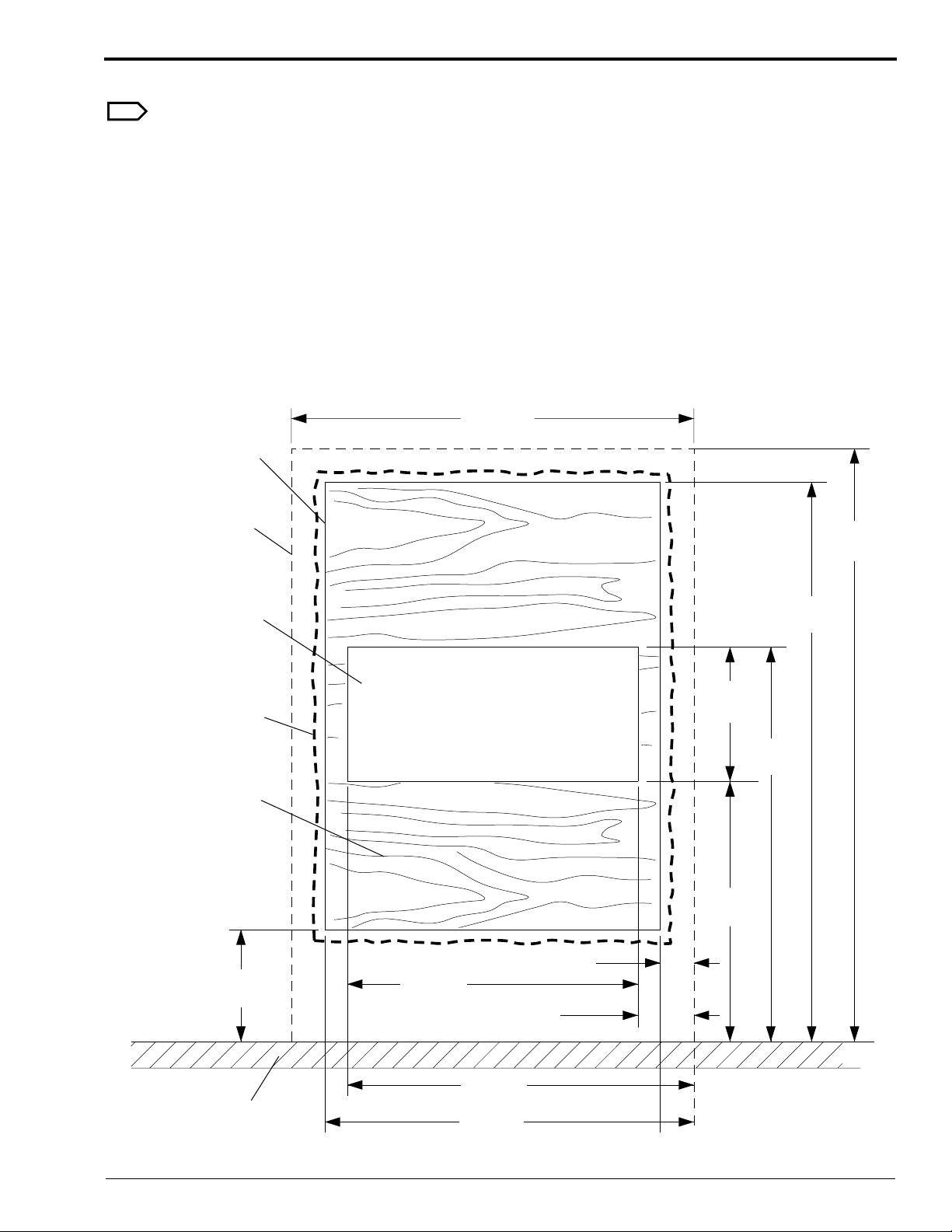

Figure 8 Checking the Dimensions of the Hole in the Wall, as viewed from the darkroom side

91.4 cm

(36 in.)

WALL OPENING

edge of the

WOOD FRAME

FRAME OPENING

for the

PROCESSOR

CAULK

WOOD FRAME

25.4 cm

(10 in.)

66.0 cm

(26 in.)

134.6 cm

(53 in.)

127.0 cm

(50 in.)

30.5 cm

(12 in.)

89.5 cm

(35 1/4 in.)

59.1 cm

(23 1/4 in.)

7.6 cm

(3 in.)

12.7 cm

(5 in.)

78.7 cm

floor

(31 in.)

83.8 cm

(33 in.)

H130_0177DCB

H130_0177DA

14 September 1995 – 981088

Installing the PROCESSOR

Preparing the MOUNTING STAND

[3] Install on the MOUNTING STAND the 4 LEVELING FEET and 4 LOCK NUTS that were packed with the

MOUNTING STAND.

Important

If you will be securing the MOUNTING STAND with SEISMIC BRACKETS, ensure that the LEVELING FEET

extend past the bottom of the MOUNTING STAND by no more than 2.5 cm (1 in.).

1

[4] Rotate the LEVELING FEET until the FEET extend past the MOUNTING STAND by 3.75 cm (1

⁄2in.).

Important

If you will be securing the MOUNTING STAND with SEISMIC BRACKETS, place the 4 FLOOR PLATES

provided with the SEISMIC BRACKET KIT 261413 under the 4 LEVELING FEET of the MOUNTING STAND.

[5] Install the 4 FLOOR PLATES under the 4 LEVELING FEET of the MOUNTING STAND.

Figure 9 Installing FLOOR PLATES under the MOUNTING STAND

LEVELING

FOOT (4)

FLOOR

PLATE (4)

SEISMIC BRACKET (4)

for the MOUNTING

STAND

H130_0091DCC

H130_0091DA

981088 – September 1995 15

INSTALLATION INSTRUCTIONS

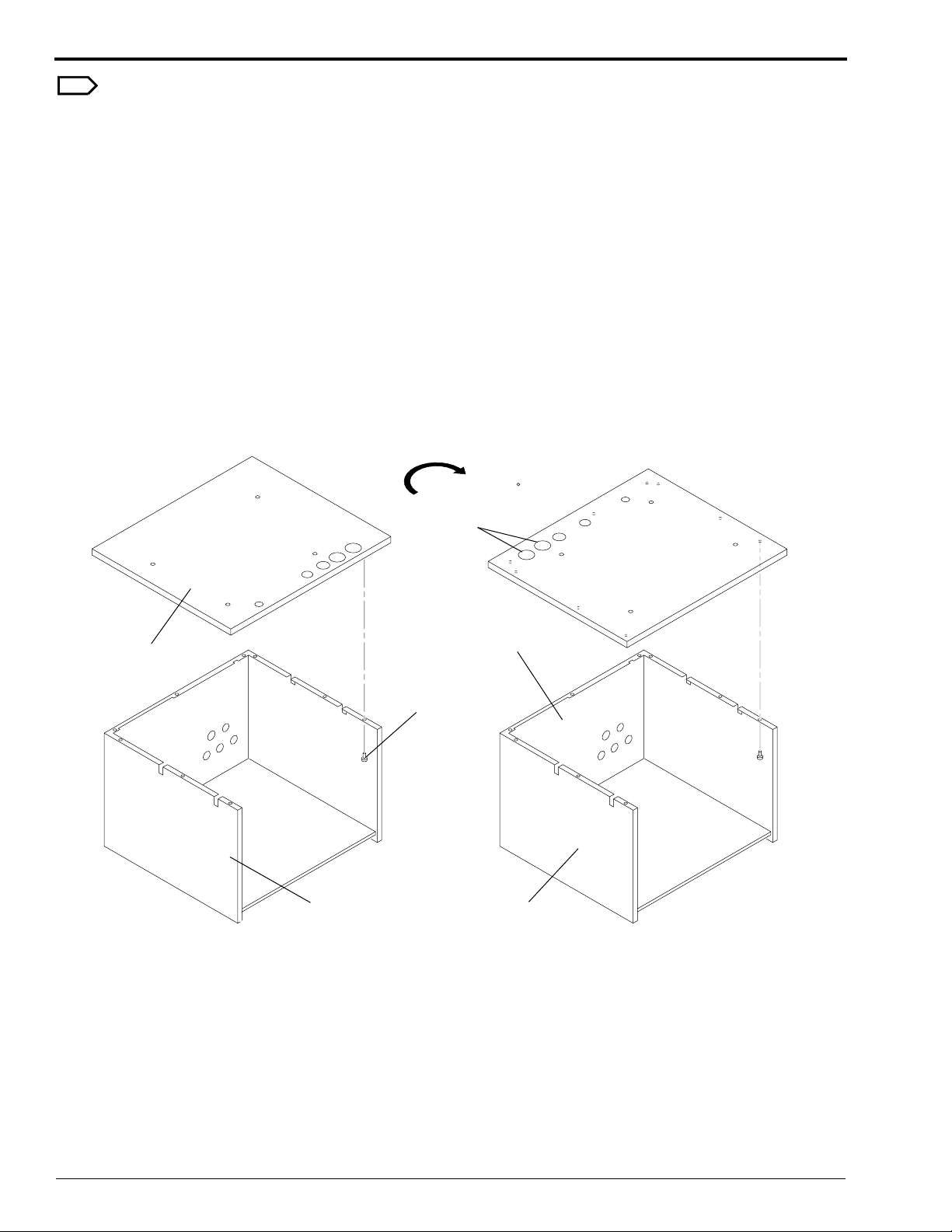

Note

The TOP of the MOUNTING STAND has holes cut in one end to allow for the routing of HOSES and the POWER

CABLE. In through-the-wall installations, these holes must be positioned against the wall. If the

REPLENISHMENT TANKS will be stored inside the MOUNTING STAND, you must remove the TOP of the

MOUNTING STAND and rotate it 180°, as described in Step 6 below. In all other cases, you can use the

MOUNTING STAND as it was shipped.

[6] Check that the TOP of the MOUNTING STAND is positioned correctly to allow for the routing of the HOSES

and the POWER CABLE. If the REPLENISHMENT TANKS will be stored inside the MOUNTING STAND,

do the following steps.

(a) Remove the 9 SCREWS securing the TOP of the MOUNTING STAND.

(b) Rotate the TOP 180° so that the holes are at the closed end of the MOUNTING STAND.

(c) Check that the TOP of the MOUNTING STAND is flush with the closed end of the MOUNTING

STAND.

(d) Install the 9 SCREWS in the second set of pre-drilled holes on the under side of the TOP of the

MOUNTING STAND.

Figure 10 Rotating the TOP of the MOUNTING STAND

ROTATE 180

TOP

MOUNTING

STAND

holes

closed

SCREW (9)

end

side

wall

H130_0205HCA

H130_0205HA

16 September 1995 – 981088

Installing the PROCESSOR

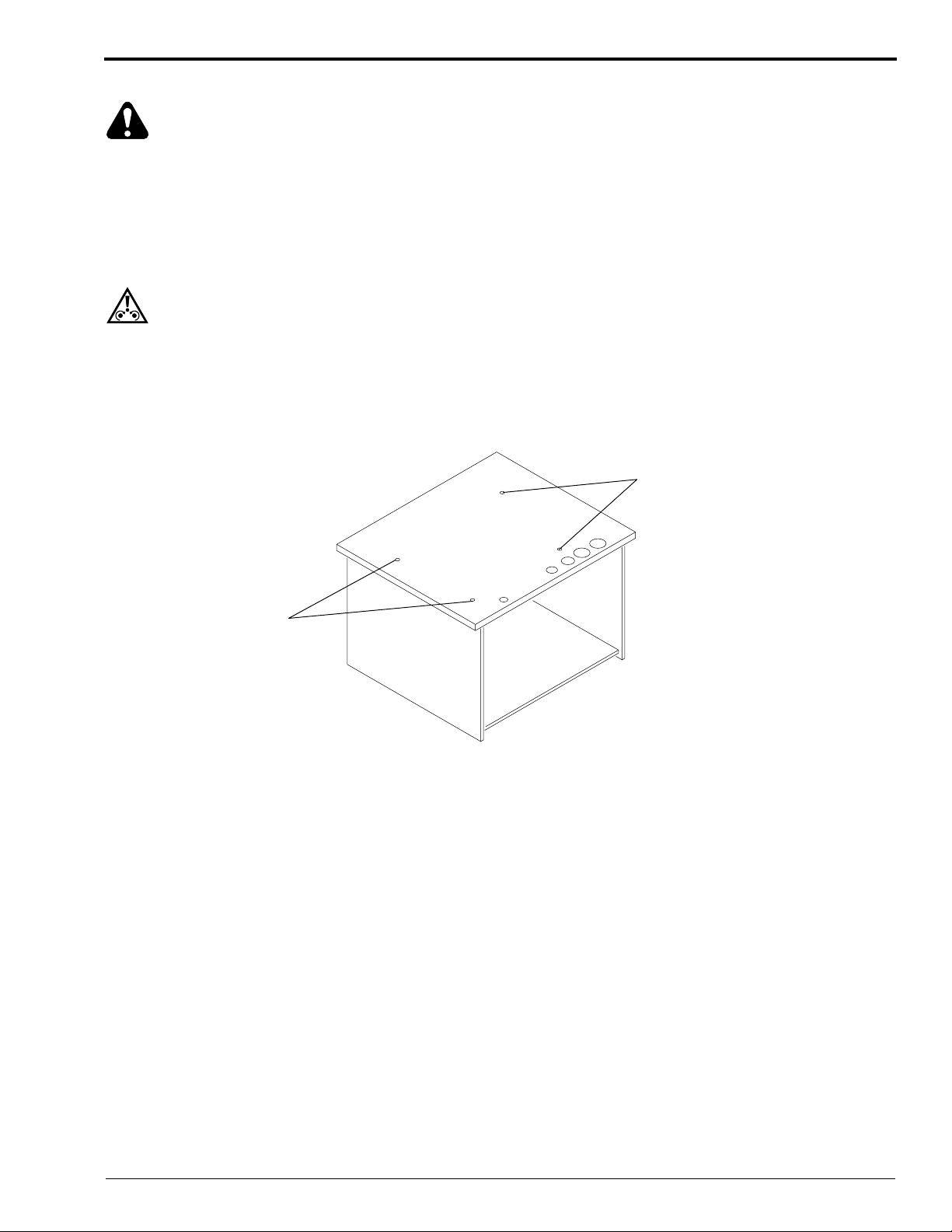

Positioning the PROCESSOR on the MOUNTING STAND

Warning

The unpacked, empty PROCESSOR weighs approximately 84 kg (185 lb). Use 2 people to move it. The PUMPS

are heavy and are located in the back of the PROCESSOR. Rotate the PROCESSOR so that each person supports

1

⁄2 the weight of the PROCESSOR.

[7] Move the MOUNTING STAND near the wall while still maintaining clearance on all 4 sides of the

PROCESSOR for access to components.

(a) Check that the MOUNTING STAND is positioned so that the large holes in the top are toward the wall.

Caution

The empty PROCESSOR weighs approximately 84 kg (185 lb).

[8] Position the PROCESSOR on the MOUNTING STAND with the feed-end towards the wall. Do not allow the

LEVELING FEET to fall into the holes in the TOP of the MOUNTING STAND.

Figure 11 Positioning the PROCESSOR on the MOUNTING STAND

holes for

LEVELING FEET

holes for

LEVELING FEET

H130_0204BCA

H130_0204BA

[9] Check that the following parts are removed from the PROCESSOR.

• TOP COVER

• BACK ACCESS PANEL

• FRONT ACCESS PANEL

• DRIVE SIDE ACCESS PANEL

• NON-DRIVE SIDE ACCESS PANEL

[10] Raise and support the non-feed end of the PROCESSOR to gain access to the 2 LEVELING FEET. Use a 5 x

10 cm (2 x 4 in.) piece of wood that is 1 m (3 ft.) long to support the PROCESSOR.

(a) Position the piece of wood so that:

• it supports the entire width of the PROCESSOR (drive side to non-drive side)

• it is closer to the center of the PROCESSOR than to the back

[11] Remove the NUT from each of the 2 non-feed end LEVELING FEET. Keep the NUTS for later installation.

[12] Remove and discard the LEVELING FOOT on the drive side of the PROCESSOR near the

REPLENISHMENT PUMP. See the Figure 11.

1

[13] Install the 7.6 cm (3

⁄2 in.) LEVELING FOOT provided with the PROCESSOR.

981088 – September 1995 17

INSTALLATION INSTRUCTIONS

[14] Rotate these 2 LEVELING FEET clockwise until they are fully extended. Use a SOCKET or WRENCH to

ensure that the LEVELING FEET are tight.

[15] Position a SPACER, provided with the MOUNTING STAND, on the TOP of the MOUNTING STAND under

each of the 2 LEVELING FEET.

[16] Lower the raised end of the PROCESSOR by removing the piece of wood supporting it.

[17] Check that the LEVELING FEET are lowered into the SPACERS.

[18] Align the 2 LEVELING FEET and SPACERS with the holes in the TOP of the MOUNTING STAND. Position

the LEVELING FEET through the holes.

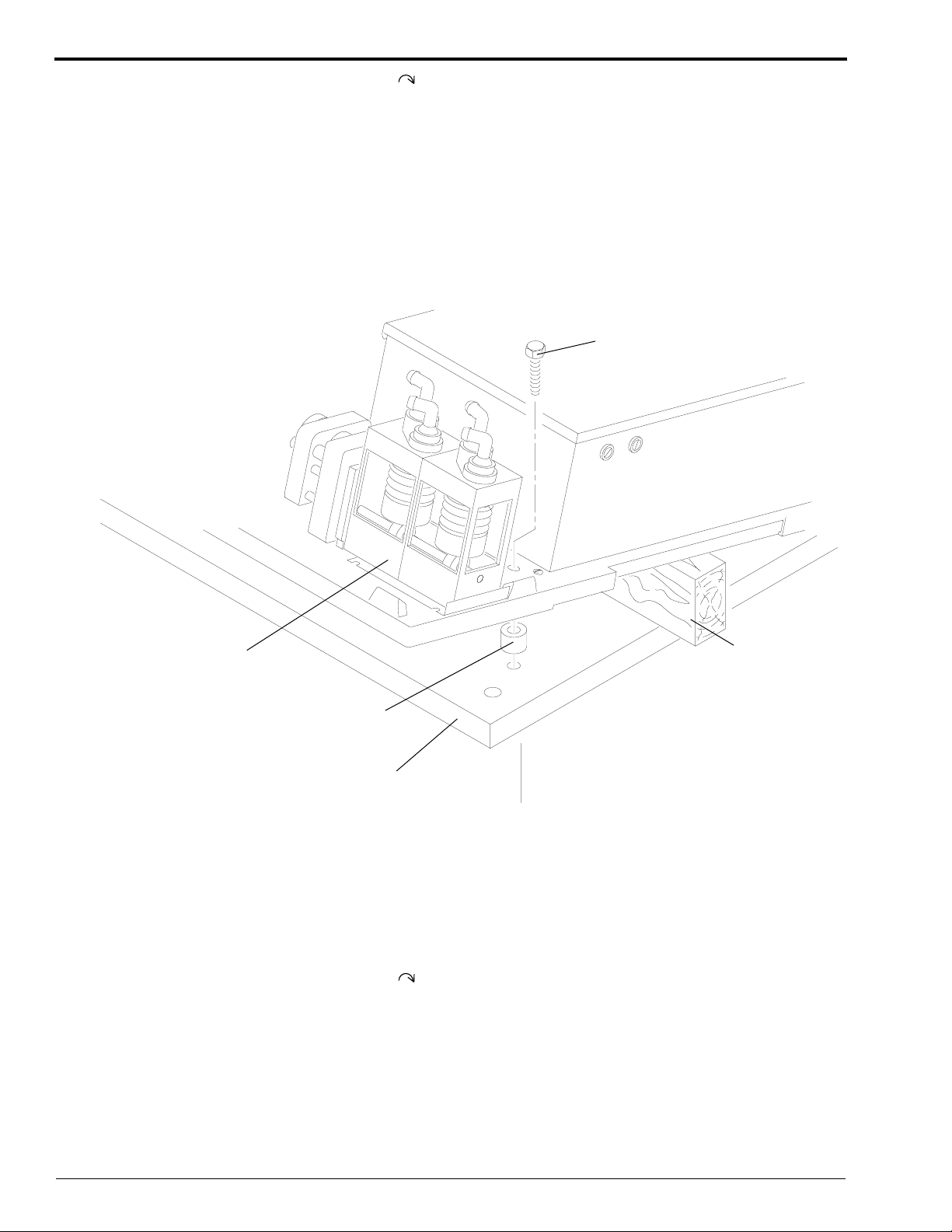

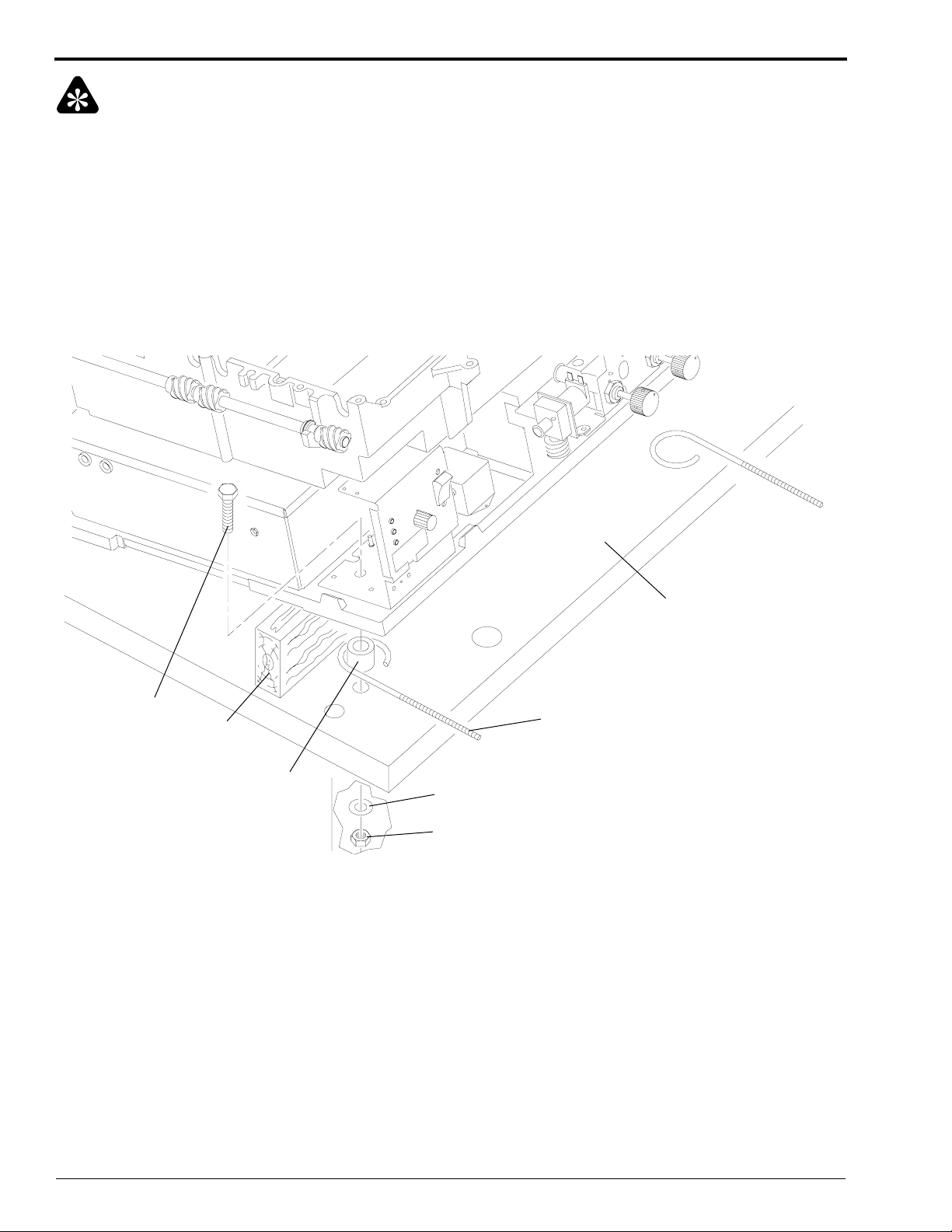

Figure 12 Installing the SPACERS and Replacing one LEVELING FOOT on the Non-Feed End of the

PROCESSOR

LEVELING

FOOT (2)

non-feed

end

REPLENISHMENT PUMP

SPACER (2)

drive side

MOUNTING STAND

wood

support

H130_0182HCA

H130_0182HA

[19] Raise and support the feed end of the PROCESSOR to gain access to the other 2 LEVELING FEET. Use a 5

x 10 cm (2 x 4 in.) piece of wood that is 1 m (3 ft.) long to support the PROCESSOR.

(a) Position the piece of wood so that:

• it supports the entire width of the PROCESSOR (drive side to non-drive side)

• it is closer to the center of the PROCESSOR than to the front

[20] Remove the NUT from each of the 2 feed-end LEVELING FEET. Keep the NUTS for later installation.

[21] Rotate these 2 LEVELING FEET clockwise until they are fully extended. Use a SOCKET or WRENCH to

ensure that the LEVELING FEET are tight.

[22] Insert the HOSES listed below through the holes in the TOP of the MOUNTING STAND:

• 3 DRAIN HOSES

- Use black, opaque DRAIN HOSES if they are going through the wall

- Use clear DRAIN HOSES if draining outside of the darkroom

• a HOSE from the main water supply, not provided

18 September 1995 – 981088

Installing the PROCESSOR

[23] Connect the 3 DRAIN HOSES to the 3 DRAIN VALVE FITTINGS.

(a) Position the CLAMPS, provided in the prepack, so that you can access the SCREWS by inserting a

SCREWDRIVER through the notches in the BRACKET.

(b) Insert the 3 DRAIN HOSES under the 3 NARROW BAND CLAMPS and tighten the 3 SCREWS of the

CLAMPS.

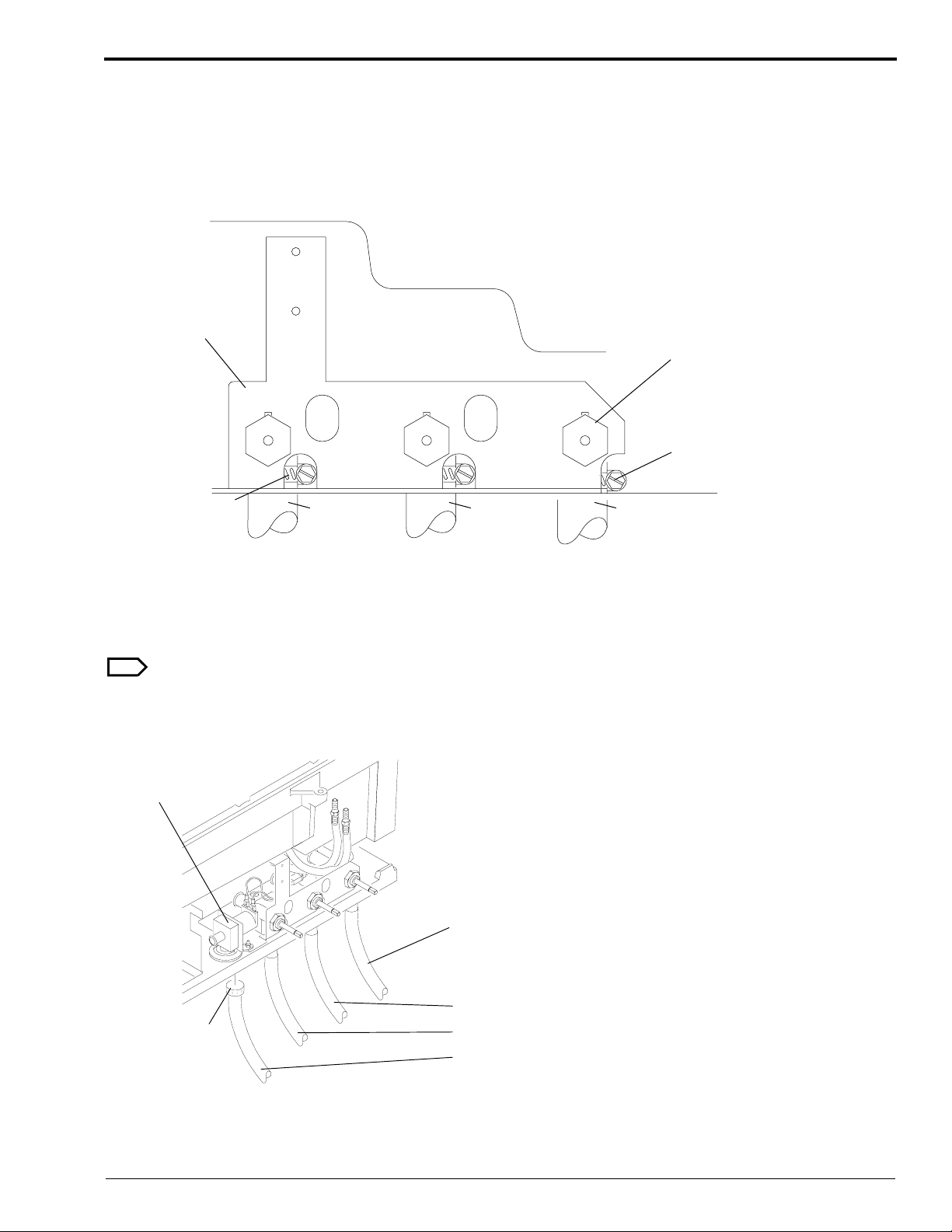

Figure 13 Connecting the DRAIN HOSES

BRACKET

DRAIN VALVE

FITTING (3)

SCREW (3)

NARROW BAND

CLAMP (3)

wash

DRAIN

HOSE

fixer

DRAIN

HOSE

developer

DRAIN

HOSE

H130_0187BCA

H130_0187BA

[24] For an M43 PROCESSOR only, install the HOSE ADAPTER and WASHER packed with the PROCESSOR

to the bottom of the WATER INPUT SOLENOID.

[25] Use a standard 5/8 in. NHT HOSE BIB FITTING to connect the HOSE from the main water supply to the under

side of the WATER INPUT SOLENOID.

Note

If you are routing a water supply HOSE under the PROCESSOR, you will need a 90° fitting, not provided, at the

WATER INPUT SOLENOID connection.

Figure 14 Connecting the DRAIN HOSES and the HOSE from the Main Water Supply

WATER INPUT

SOLENOID

developer DRAIN HOSE

fixer DRAIN HOSE

BIB FITTING

wash DRAIN HOSE

water supply HOSE

H130_0026BCB

H130_0026BA

981088 – September 1995 19

INSTALLATION INSTRUCTIONS

Important

Read the following steps carefully. Determine whether you need to route the REPLENISHMENT HOSES and the

POWER CABLE through the darkroom wall. Do only the steps that are appropriate for your installation

requirements. It is not recommended to route the POWER CABLE through the wall.

[26] Route the developer REPLENISHMENT HOSE, identified by the red WIRE TIE, through the hole under the

developer DRAIN VALVE.

[27] Route the fixer REPLENISHMENT HOSE, identified by the blue WIRE TIE, through the hole under the fixer

DRAIN VALVE.

[28] Position a SPACER on the TOP of the MOUNTING STAND under each of the 2 LEVELING FEET.

[29] Position a EYEBOLT over each SPACER. See the figure for the correct orientation of the EYEBOLTS.

Figure 15 Installing the EYEBOLTS

MOUNTING

STAND

LEVELING

FOOT (2)

wood

support

SPACER (2)

WASHER (4)

NUT (4)

EYEBOLT (2)

H130_0183HCA

H130_0183HA

[30] Lower the raised end of the PROCESSOR by removing the piece of wood supporting it.

[31] Check that the LEVELING FEET are lowered into the SPACERS.

[32] Align the 2 LEVELING FEET and SPACERS with the holes in the TOP of the MOUNTING STAND. Position

the LEVELING FEET through the holes.

[33] Install the following parts onto the 4 LEVELING FEET by reaching under the TOP of the MOUNTING

STAND:

• 4 WASHERS, provided with the MOUNTING STAND

• 4 NUTS, removed in Steps 11 and 20

20 September 1995 – 981088

Installing the PROCESSOR

Preparing the WOOD FRAME

Note

This procedure may be easier to do if you mount the WOOD FRAME to the wall before you cut the opening and drill

the holes. However, if you wish, you may cut the opening and drill the holes before you mount the WOOD FRAME

to the wall.

[34] Check that the dimensions and location of the opening cut in the wall are correct. See the figure below for the

correct dimensions.

[35] Apply lighttight CAULK to the wall around the WALL OPENING on the outside of the darkroom.

[36] Mount the WOOD FRAME securely to the wall.

[37] Cut an opening in the WOOD FRAME for the PROCESSOR. See the figure for the correct dimensions of the

hole.

[38] If there is no need for connections through the WOOD FRAME, go to section “Installing the GASKET on the

WOOD FRAME” on Page 23.

Figure 16 Preparing the WOOD FRAME, as viewed from the darkroom side

91.4 cm

WALL OPENING

(36 in.)

edge of the

WOOD FRAME

FRAME OPENING

for the

PROCESSOR

CAULK

WOOD FRAME

25.4 cm

(10 in.)

66.0 cm

(26 in.)

134.6 cm

(53 in.)

127.0 cm

(50 in.)

30.5 cm

(12 in.)

89.5 cm

(35 1/4 in.)

59.1 cm

(23 1/4 in.)

7.6 cm

(3 in.)

12.7 cm

(5 in.)

78.7 cm

floor

(31 in.)

83.8 cm

(33 in.)

H130_0177DCB

H130_0177DA

981088 – September 1995 21

INSTALLATION INSTRUCTIONS

[39] If you need to make connections through the WOOD FRAME, mark the location of the necessary holes on the

WOOD FRAME. Depending on how you plan to route the HOSES and CABLE, you will need to cut some or

all of the following holes in the WOOD FRAME. See the figure below for the correct locations of the holes.

[40] Drill the necessary holes in the WOOD FRAME.

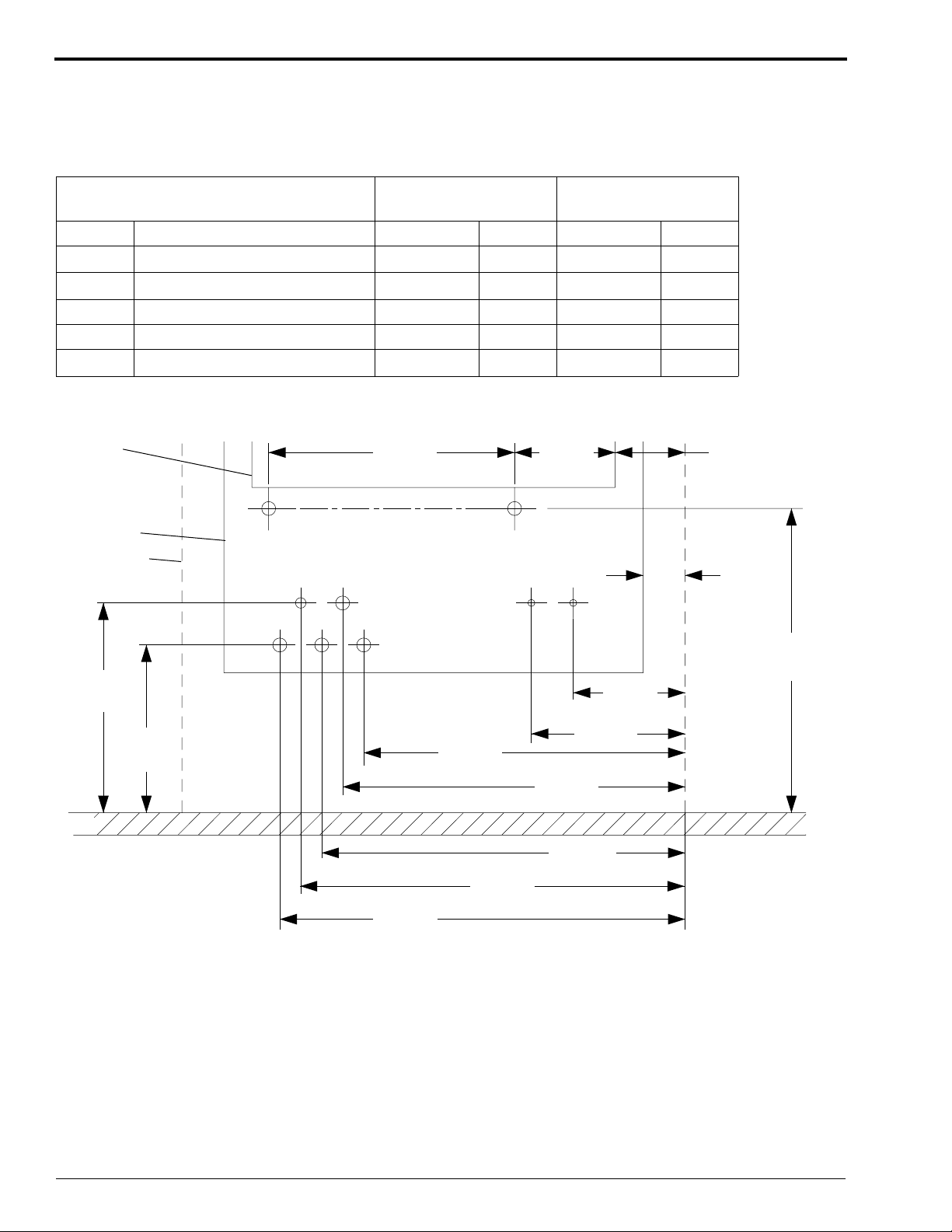

Tanks Inside

Darkroom

Tanks Outside

Darkroom

Hole Description Diameter Quantity Diameter

A DRAIN HOSES 1 in. 3

B REPLENISHMENT HOSES

1

⁄2 in.

2——

1

⁄8 in.

1

C POWER CABLE* As Needed 1 As Needed 1

D WATER INPUT HOSE As Needed 1 As Needed 1

E EYEBOLTS

1

⁄4 in.

2

1

⁄4 in.

* Routing the POWER CABLE through the wall is not the recommended installation.

Figure 17 Preparing the Holes in the WOOD FRAME, as viewed from the darkroom side

Frame

Opening

for the

Processor

Wall

Opening

Edge of

Wood

Frame

38.1 cm

(15 in.)

E

C

30.5 cm

(12 in.)

44.7 cm

(17 5/8 in.)

D

AAA

58.4 cm

(23 in.)

18.3 cm

(7 3/16 in.)

E

BB

20.3 cm

(8 in.)

27.9 cm

(11 in.)

62.2 cm

(24 1/2 in.)

3

2

12.7 cm

(5 in.)

7.6 cm

(3 in.)

55.2 cm

(21 3/4 in.)

66.0 cm

(26 in.)

69.9 cm

(27 1/2 in.)

73.7 cm

(29 in.)

H130_0178HCA

H130_0178HA

22 September 1995 – 981088

Installing the PROCESSOR

Installing the GASKET on the WOOD FRAME

[41] Cut the foam GASKET to fit around the edges of the hole cut in the WOOD FRAME for the PROCESSOR.

[42] Install the GASKET on the PROCESSOR side of the WOOD FRAME around the perimeter of the hole. See

the figure for the correct location of the GASKET.

[43] Check that there are no gaps in the GASKET.

[44] Cut another piece of GASKET the dimension of the front of the PROCESSOR.

[45] Install the GASKET on the PROCESSOR along the bottom edge of the FRONT ACCESS PANEL.

Important

Additional GASKETS may be necessary in some installations:

• where the wall is not plumb

• if using a LIGHTTIGHT FEED TRAY

Figure 18 Installing the GASKETS

GASKETS

FRONT ACCESS

PANEL

WOOD FRAME

Position

of

GASKET

when

installed

H130_0197HCA

H130_0197HA

981088 – September 1995 23

Loading...

Loading...