Page 1

INSTALLATION INSTRUCTIONS

for the

Publication No. 246626

September 1991

Kodak RP X-OMAT

Processor, Model M6B

H048_0086DA

Page 2

PLEASE NOTE

The information contained herein is based on the experience and knowledge relating to the subject matter gained by

Eastman Kodak Company prior to publication.

No patent license is granted by this information.

Eastman Kodak Company reserves the right to change this information without notice, and makes no warranty, express

or implied, with respect to this information. Kodak shall not be liable for any loss or damage, including consequential or

special damages, resulting from the use of this information, even if loss or damage is caused by Kodak’s negligence or

other fault.

This equipment includes parts and assemblies sensitive to damage from electrostatic discharge. Use

caution to prevent damage during all service procedures.

Table of Contents

Description Page

Introduction............................................................................................................................................................. 5

Related Publications......................................................................................................................................... 5

Special Tools .................................................................................................................................................... 5

Unpacking the Processor...................................................................................................................................... 6

Removing the Packing Material ........................................................................................................................ 6

Installing the Processor......................................................................................................................................12

Removing the Processor from the Skid ......................................................................................................... 12

Setting a Processor for 50 Hz Operation ....................................................................................................... 14

Installing the Light-Tight Gasket ..................................................................................................................... 17

Installing the Feed Shelf ................................................................................................................................. 18

Installing the Grommets and Replenisher Tubes ........................................................................................... 19

Installing the Developer Filter ......................................................................................................................... 20

Adjusting the Height of the Feed Shelf..........................................................................................................20

Aligning the Film Guide .................................................................................................................................. 21

Moving the Processor Into Position................................................................................................................ 22

Leveling the Processor...................................................................................................................................23

Connecting the Replenishment Tanks............................................................................................................ 26

Connecting the Drains....................................................................................................................................27

Connecting the Wiring to Terminal Strip TB1 ................................................................................................ 28

Connecting the Exhaust.................................................................................................................................. 32

Making the Water Connection........................................................................................................................34

Checking the Drain Valves.............................................................................................................................34

User Selectable Modes ........................................................................................................................................ 35

Flooded Replenishment..................................................................................................................................35

Water Conservation ........................................................................................................................................ 35

Selecting the Replenishment Mode ................................................................................................................ 36

Using the Splash Guard and Drip Tray .......................................................................................................... 37

Filling the Tanks.............................................................................................................................................. 37

Setting the Replenishment Rates ................................................................................................................... 41

Adjusting the Replenishment Rate.................................................................................................................42

2 246626

Page 3

Description Page

Installing the Racks and Crossovers .............................................................................................................. 43

Adjusting the Tension of the Dryer Belt.........................................................................................................45

Installing the Panels and Covers.................................................................................................................... 46

Setting the Dryer Temperature ....................................................................................................................... 46

Checking the Developer Temperature............................................................................................................ 47

Checking the Film Transport .......................................................................................................................... 47

246626 3

Page 4

BLANK PAGE

4 246626

Page 5

Introduction

This publication is part of a series of instruction books that provides technical support information on the

KODAK RP X-OMAT Processor, Model M6B. For ease of referencing and reordering the related publications,

the following chart provides part numbers for each of the X-Omat M6B publications.

Related Publications

COMPLETE

BINDER

246630

OPERATOR

MANUAL

SITE SPECS

2B6835

INSTALLATION

INSTRUCTIONS

246626

SERVICE

MANUAL

246628246627

PARTS LIST

246629

M6B Publications for Processors Having a Serial Number of 15,000 or Above.

COMPLETE

BINDER

635881

OPERATOR’S

CHECKLIST

635886 635885

SITE SPECS

635883

INSTALLATION

INSTRUCTIONS

635884

SERVICE

MANUAL

PARTS LIST

635882

H048_9003BC

H048_9013BC

M6B Publications for Processors Having a Serial Number Below 15,000.

It is recommended that these publications be kept in the binder provided. If an individual document gets

misplaced or destroyed, reorder a copy from your Eastman Kodak Representative.

Use qualified personnel to install the processor.

Special Tools

• Carpenter’s Level - approximately 12 in. Available as TL-1434.

246626 5

Page 6

Unpacking the Processor

If you are unpacking the processor anywhere other than in the final destination, it is

recommended that you keep the internal packing material in place until you move the processor to

the actual installation site. If you do unpack the processor somewhere other than the final

destination, make sure to install any removed parts and pack any loose parts carefully with the

processor for transport.

Make sure that the processor is always upright during transport, storage, and installation.

Removing the Packing Material

[1] Cut the METAL BANDS around the outside of the SHIPPING CARTON.

The processor is not attached to the shipping skid. Use care when moving the processor.

[2] Remove the SHIPPING CARTON from the processor.

[3] Remove the CARDBOARD from the top of the processor.

[4] Remove the TOP COVER from the processor.

[5] Remove the CARDBOARD from between the WASH RACK and the WASH TANK.

6 246626

Page 7

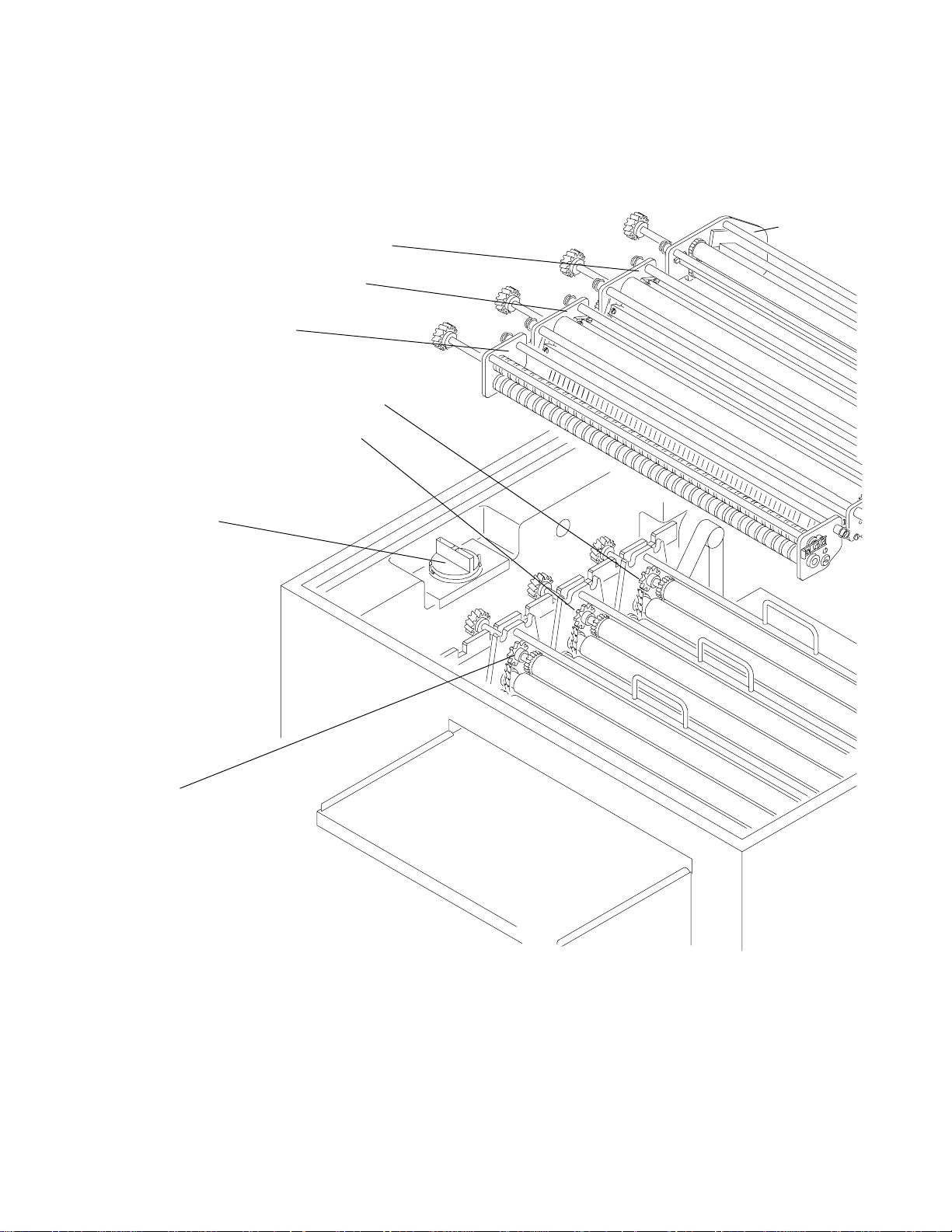

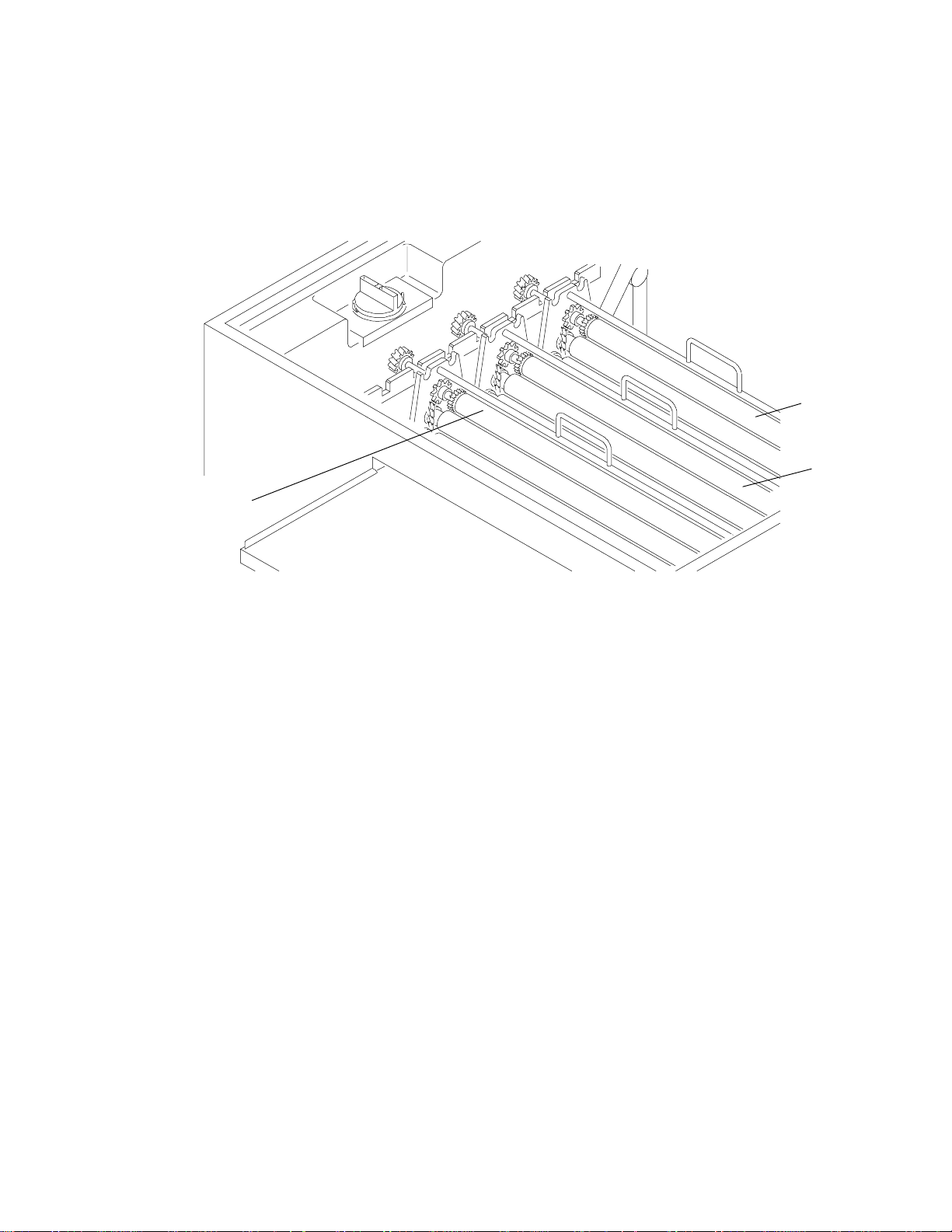

[6] Remove:

• DEVELOPER/FIXER CROSSOVER

• FIXER/WASH CROSSOVER

• DETECTOR CROSSOVER

• SQUEEGEE ASSEMBLY.

FILTER

CANISTER

ASSEMBLY

FIXER/WASH

CROSSOVER

DEVELOPER/FIXER

CROSSOVER

DETECTOR

CROSSOVER

FIXER

RACK

SQUEEGEE

ASSEMBLY

WASH

RACK

DEVELOPER

RACK

H048_0092DCA

H048_0092DA

Figure 1 Crossover Identification

246626 7

Page 8

[7] Remove the PACKING MATERIAL covering the RACK HANDLES.

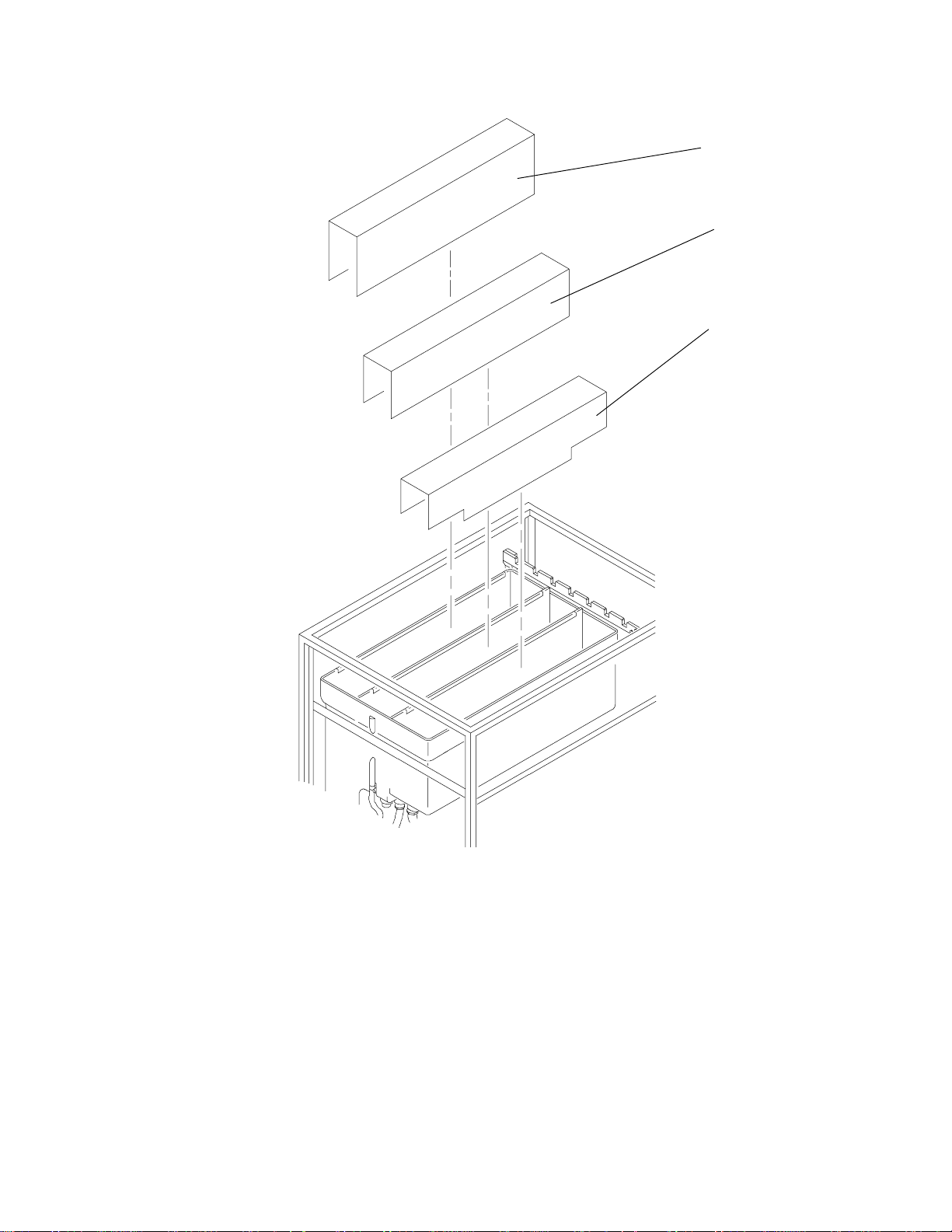

[8] Remove:

• DEVELOPER RACK

• FIXER RACK

• WASH RACK

• CARDBOARD from around each RACK.

DEVELOPER

RACK

WASH

RACK

FIXER

RACK

Figure 2 Rack Identification

H048_0096BCA

H048_0096BA

8 246626

Page 9

[9] Remove the CARDBOARD from inside the bottom of the DEVELOPER, FIXER, and WASH TANKS.

CARDBOARD from

DEVELOPER TANK

CARDBOARD from

FIXER TANK

CARDBOARD from

WASH TANK

H108_0136DCA

H108_0136DA

Figure 3 Removing Cardboard from the Processor Tanks

246626 9

Page 10

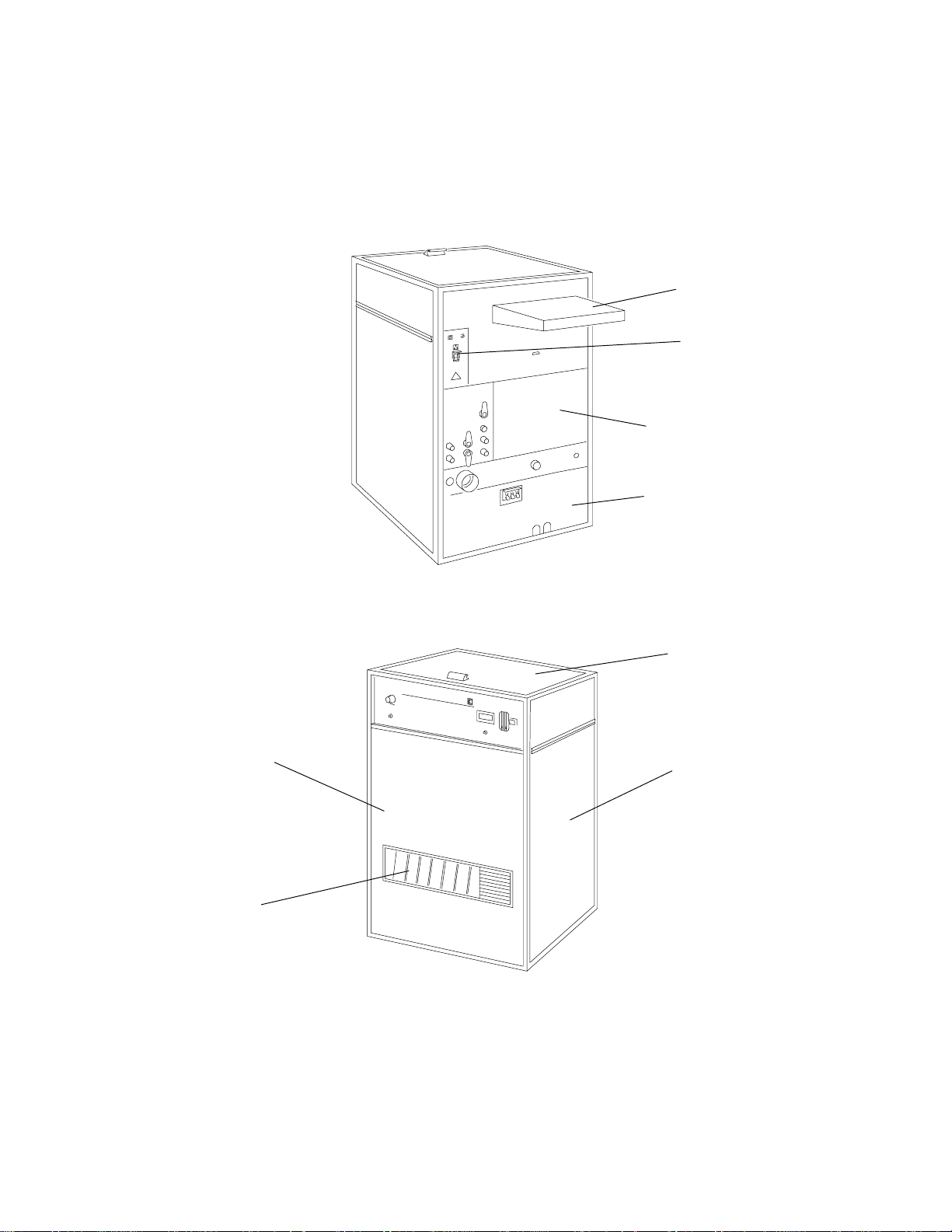

[10] Remove the RECEIVING-END ACCESS PANEL from the processor.

[11] Remove the 3 DRAIN HOSES from the RECEIVING BIN.

[12] Remove and keep the WRAPPED ITEMS from inside the front of the processor.

NOTE

On later models of the processor, some wrapped items may be found on top of the processor.

FEED-END MIDDLE

ACCESS PANEL

FEED-END LOWER

ACCESS PANEL

FEED TRAY

CONTROL

PANEL

RECEIVING-END

ACCESS PANEL

RECEIVING

BIN

Figure 4 Feed-End View of the Processor

TOP COVER

DRIVE SIDE

ACCESS PANEL

H048_0085BCA

H048_0085BA

H108_0003BCA

H048_0086BA

Figure 5 Receiving-End View of the Processor

10 246626

Page 11

[13] Remove the 10 OUTER AIR TUBES and remove the PACKING MATERIAL around the SHAFTS of the

ROLLERS.

[14] Install the 10 OUTER DRYER AIR TUBES with the AIR SLOTS facing the film path.

PACKING

MATERIAL

DRYER

AIR

TUBES

CARDBOARD

Figure 6 Removing Cardboard from around the Roller Shafts

H048_0113BCA

H048_0113BA

246626 11

Page 12

Installing the Processor

H048_0108CA

PROCESSOR

H048_0108CCA

SKID

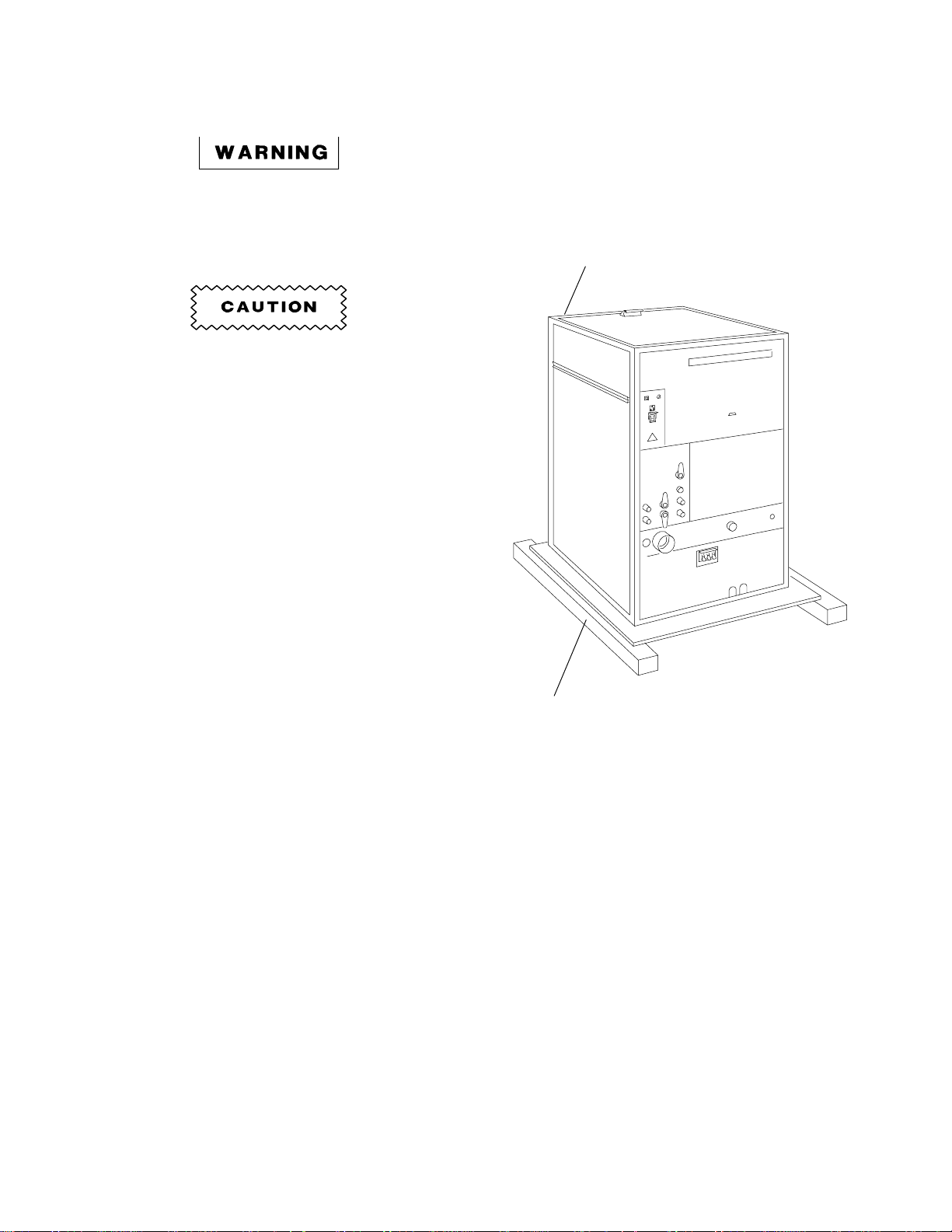

Removing the Processor from the Skid

The processor weighs over 200 kg

(442 lb), therefore use 2 people when

installing the LEVELING SCREWS and

moving the processor into position.

The processor is not attached to the

SKID. Use care when moving the

SKID.

[1] Move the processor, on the SKID, as close as

possible to the processor’s final destination.

Figure 7 Processor Mounted on Skid

12 246626

Page 13

[2] Remove the FEED-END, LOWER ACCESS

H048_0141AC

2.5 cm (1 in.)

LEVELING

SCREW

FLOOR

PLATE

HEAD

H048_0141ACA

PANEL and the 2 SIDE PANELS from the

processor for easier access.

[3] Remove the processor from the SKID.

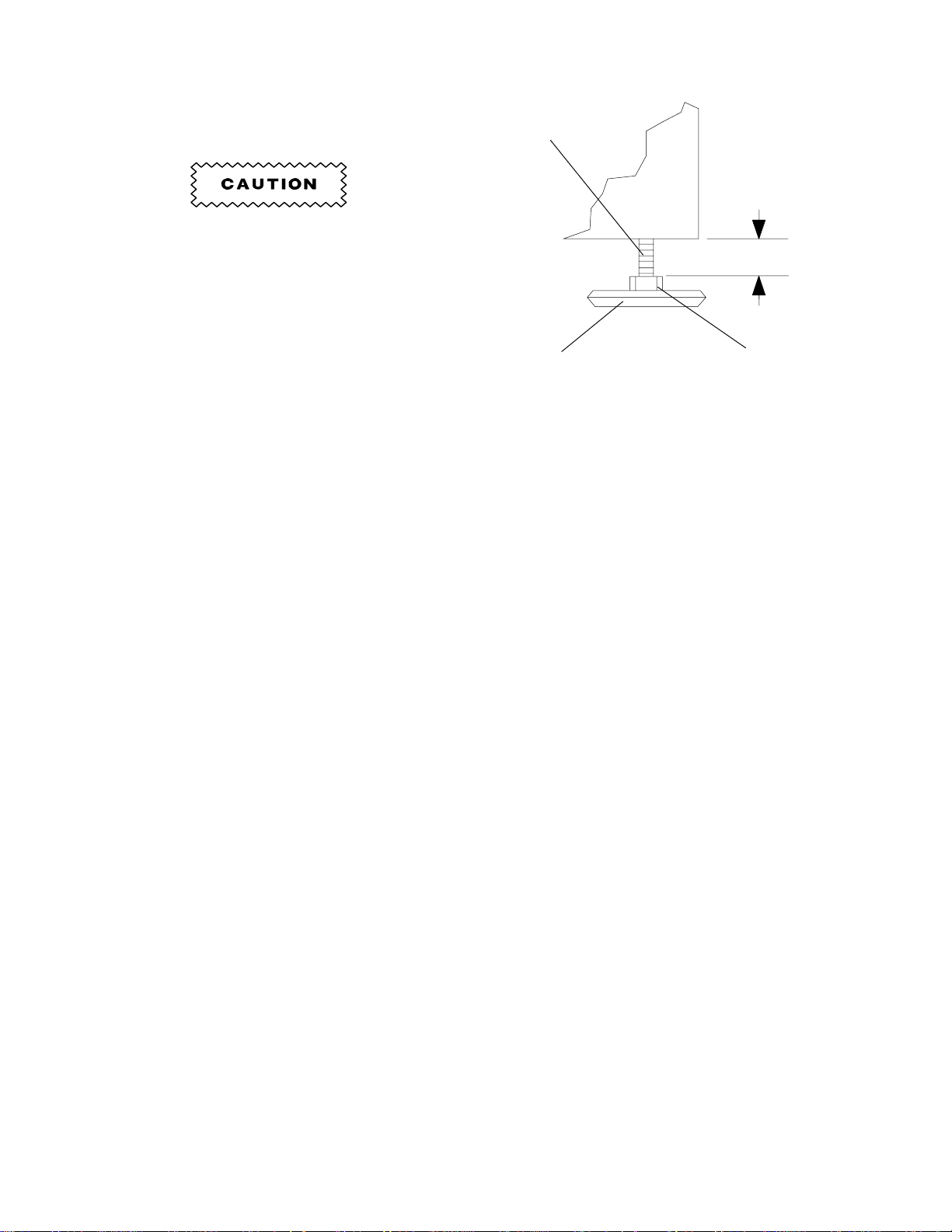

To prevent damage to the LEVELING

SCREWS and the processor, do not

allow more than a 25 mm (1 in.)

clearance between the bottom of the

processor and the HEAD of the

LEVELING SCREW.

[4] Install the 4 LEVELING SCREWS.

NOTE

For processors being used on 60 HZ

power, skip the next section on 50 Hz

Operation, and continue with the

section, ‘‘Installing the Light-Tight

Gasket’’ on page 17.

Figure 8 Installing the Leveling Screws

246626 13

Page 14

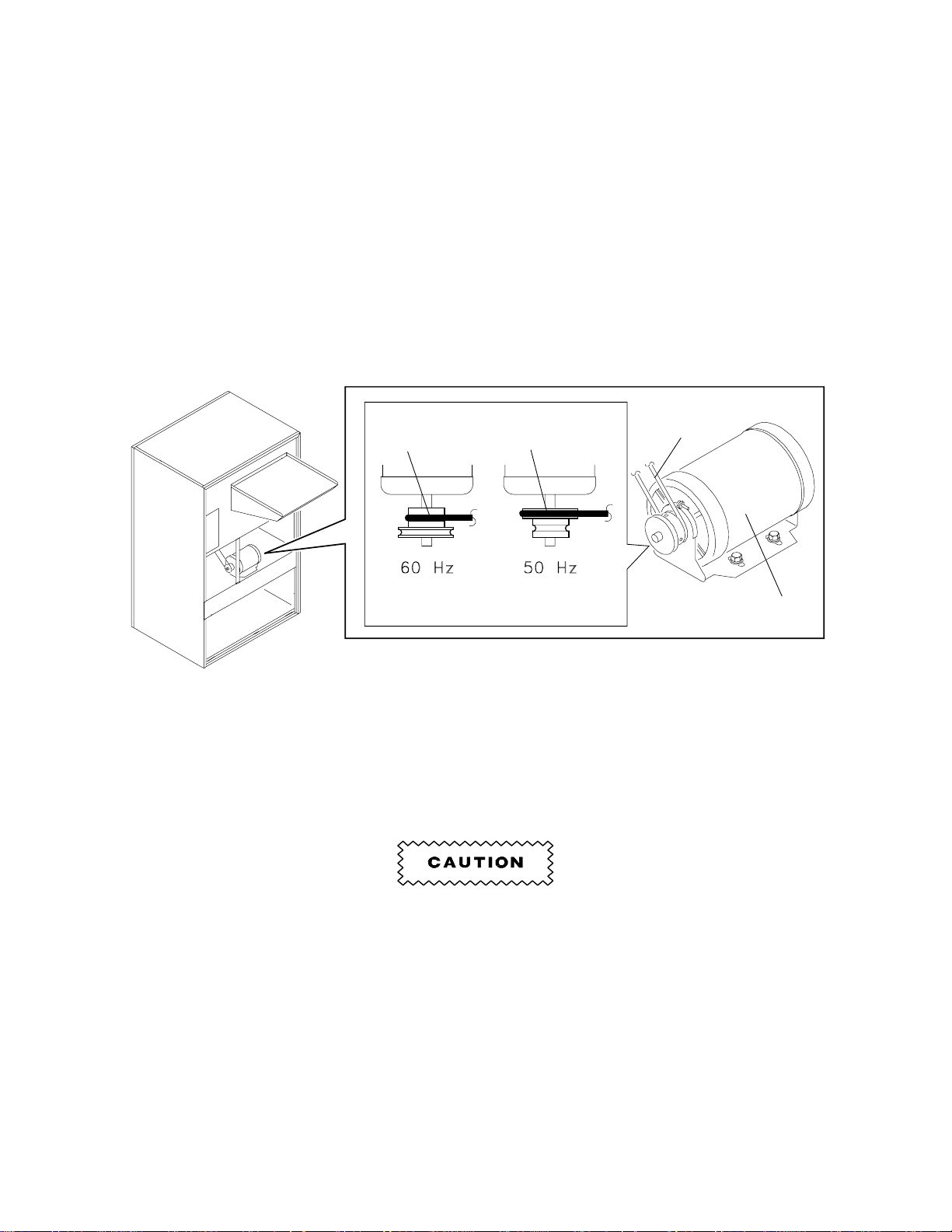

Setting a Processor for 50 Hz Operation

For processors being used on 50 Hz power, do the following:

[1] Remove the BLOWER MOTOR COVER.

[2] Move the BLOWER MOTOR to the inner set of mounting holes, located on the frame of the processor.

[3] Remove the BLOWER MOTOR PULLEY.

[4] Turn the BLOWER MOTOR PULLEY around and install the PULLEY making sure that the larger

diameter end of the PULLEY is mounted toward the BLOWER MOTOR MOUNTING FRAME. See

Figure 9.

[5] Move the DRIVE BELT to the larger diameter part of the BLOWER MOTOR PULLEY.

[6] Adjust the position of the BLOWER MOTOR to obtain the correct tension of the BLOWER DRIVE BELT.

See the Service Manual for the correct procedure.

SMALL

DIAMETER

LARGE

DIAMETER

DRIVE

BELT

BLOWER

MOTOR

H108_0015BCA

H108_0015BA

Figure 9 Positioning the Blower Motor and Drive Belt

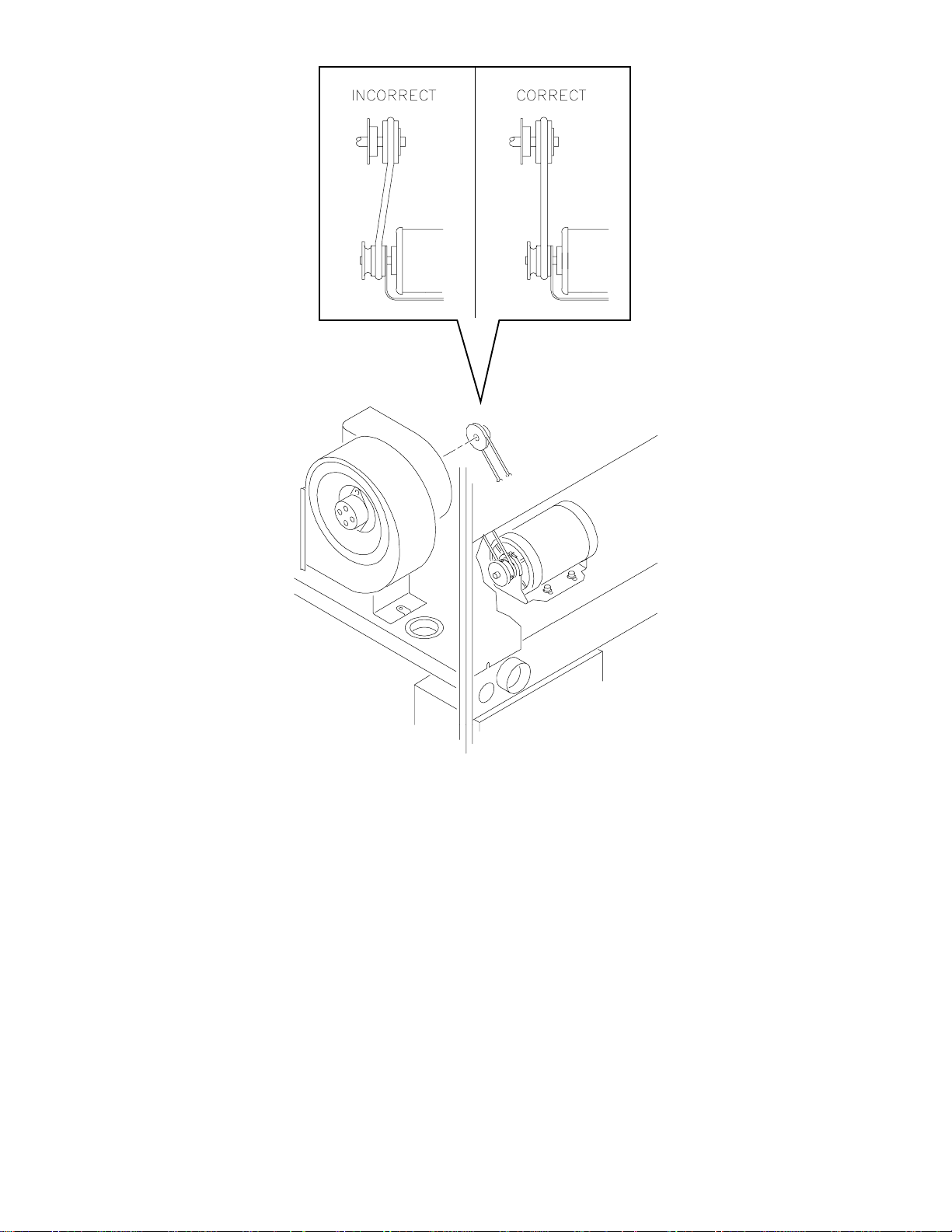

[7] Check the alignment of the DRIVE BELT. Adjust the PULLEY as necessary. When the processor is

operating, check that this alignment is correct. See Figure 10 on page 15.

[8] Deenergize the processor by moving the MAIN CIRCUIT BREAKER, CB1, to the ‘‘O’’ position.

Do not place hands or fingers near the moving parts.

[9] Install the BLOWER MOTOR COVER.

14 246626

Page 15

H048_0115CA

Figure 10 Aligning the Blower Motor Pulley

246626 15

Page 16

[10] Remove the SPLASH GUARD and the CHAIN GUARD from the MAIN DRIVE MOTOR.

[11] Loosen the MOTOR-MOUNTING BRACKET.

[12] Remove the CHAIN and the SPROCKET from the MAIN DRIVE MOTOR.

[13] Install from the prepack carton:

• Chain Segment

• 24-Tooth Sprocket

[14] Install the CHAIN.

[15] Move the MOTOR to adjust the CHAIN for the correct tension allowing a deflection of 3.2 to 6.4 mm

(1/8 - 1/4 in.).

CHAIN GUARD

MAIN DRIVE

MOTOR

MOTOR

SPROCKET

CHAIN

MOTOR MOUNT

BRACKET SCREW

H048_0114DCA

H048_0114DA

Figure 11 Exposing the Chain Drive

16 246626

Page 17

Installing the Light-Tight Gasket

H048_0107AA

H048_0107ACA

LIGHT-TIGHT

GASKET

(from Prepack)

LIGHT-TIGHT

GASKET

(INSTALLED)

[1] Install the LIGHT-TIGHT GASKET. See the

figure.

Do not stretch the GASKET.

Figure 12 Installing the Light-Tight Gasket

246626 17

Page 18

Installing the Feed Shelf

[1] Install the FEED SHELF using the 5 SCREWS, 5 WASHERS, and 5 LOCK WASHERS.

NOTE

Do not tighten the SCREWS.

WING NUT (3)

FEED SHELF

SCREW (5)

AUXILIARY

RUN SWITCH

CONNECTOR

RECEPTACLE

WASHER (5)

LOCK WASHER (5)

SCREW (5)

Figure 13 Installing the Feed Shelf

[2] Install the FILM GUIDE onto the FEED SHELF using the 3 WING NUTS and 3 WASHERS.

NOTE

Do not tighten the WING NUTS.

H048_0071BCC

H048_0071BA

[3] Plug the AUXILIARY/RUN SWITCH CONNECTOR into the RECEPTACLE.

18 246626

Page 19

Installing the Grommets and Replenisher Tubes

NOTE

For alternate installation of the

REPLENISHER TUBES, insert them

through the HOLES in the bottom of

the processor, see Figures 14 and 15,

or see the Site Specifications.

[1] Install the 2 GROMMETS. Remove a section

of the GROMMET if necessary.

[2] Install the REPLENISHER TUBES through the

GROMMETS.

SLOTS

SECTION

Figure 14 Alternate Method for

Installing Replenisher Tubes

H048_0006CA

GROMMETS

H108_0016CCA

H048_0109CA

Figure 15 Installing the Replenisher Tubes

Through the Processor Slots

246626 19

Page 20

Installing the Developer Filter

H108_0068AA

FILTER

CAP

DEVELOPER

FILTER

H108_0068ACA

[1] Install the DEVELOPER FILTER.

[2] Moisten the O-RING for the FILTER CAP with

water.

[3] Install the FILTER CAP.

Adjusting the Height of the Feed Shelf

Figure 16 Installing the Developer Filter

[1] Install the DEVELOPER RACK ASSEMBLY and the DETECTOR CROSSOVER ASSEMBLY, and check

that they are positioned correctly.

DEVELOPER/FIXER

CROSSOVER ASSEMBLY

FIXER/WASH

CROSSOVER

ASSEMBLY

SQUEEGEE

ASSEMBLY

ENTRANCE

DETECTOR

ASSEMBLY

H048_0097BCA

H048_0097BA

Figure 17 Installing the Detector Crossover Assembly

20 246626

Page 21

[2] Adjust the position of the FEED SHELF so

H108_0038AA

H108_0038ACB

5 SCREWS

NIP

ROLLERS

ENTRANCE

CROSSOVER

DETECTOR

3 WING NUTS

1 mm (1/16 in.)

Approximately

that it is approximately 1 mm (1/16 in.) lower

than the NIP of the DETECTOR

CROSSOVER ROLLERS.

[3] When the height is adjusted correctly, tighten

the 5 SCREWS.

NOTE

Do not tighten the WING NUTS.

Aligning the Film Guide

[1] Insert a 35 x 43 cm (14 x 17 in.) film.

Figure 18 Installing the Feed Shelf

[2] Use the edges of the film to align the FILM GUIDE with the DETECTOR CROSSOVER ASSEMBLY for

[3] Tighten the 3 WING NUTS.

SCREW (5)

squareness.

WING NUT (3)

FEED SHELF

FILM

GUIDE

Figure 19 Installing the Film Guide Assembly

DETECTOR

CROSSOVER

ASSEMBLY

H108_0034BCA

H108_0034BA

246626 21

Page 22

Moving the Processor Into Position

H108_0030AA

PROCESSOR

WALL

H108_0030ACA

H048_0141AC

2.5 cm (1 in.)

LEVELING

SCREW

FLOOR

PLATE

HEAD

H048_0141ACA

The processor weighs over 200 kg

(442 lb), therefore use 2 people when

installing the LEVELING SCREWS and

moving the processor into position.

[1] Move the processor within approximately

2.5 cm (1 in.) of the wall.

[2] Install the FLOOR PLATES.

[3] Move the processor against the wall.

[4] Check that the LIGHT-TIGHT GASKET is tight

against the wall. Compress the LIGHT-TIGHT

GASKET to approximately 10 mm (3/8 in.).

Figure 20 Positioning the Processor

22 246626

Figure 21 Installing the Floor Plates

Page 23

Leveling the Processor

To prevent damaging the LEVELING SCREWS and the processor, do not allow more than a

25 mm (1 in.) clearance between the bottom of the processor and the HEAD of the LEVELING

SCREW.

[1] Install and seat the DEVELOPER, FIXER, and WASH RACK ASSEMBLIES.

DEVELOPER

RACK

WASH

RACK

FIXER

RACK

H048_0096BCA

H048_0096BA

Figure 22 Installing the Rack Assemblies

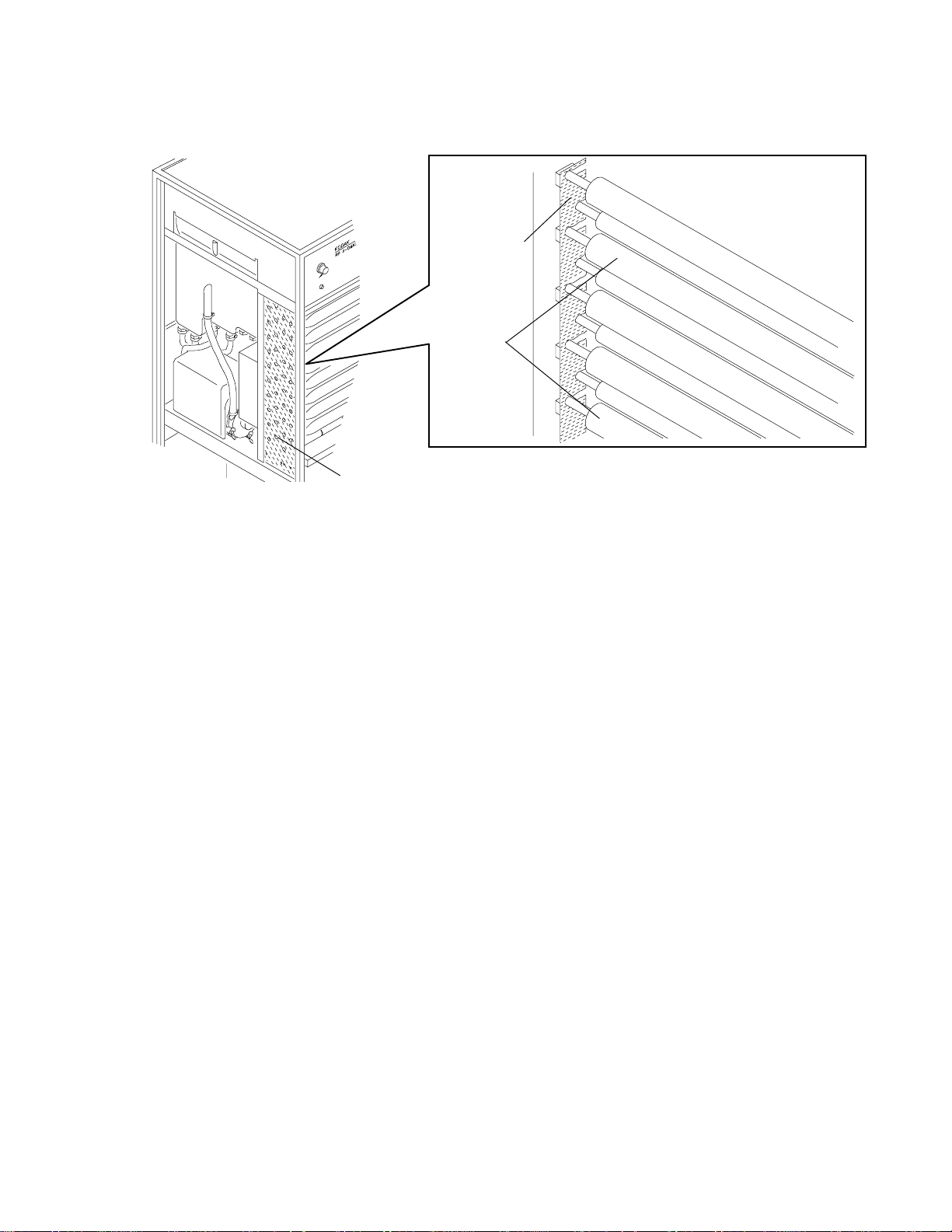

[2] Check that the RACKS are in their correct positions and that the GEARS of the RACK ASSEMBLIES

engage with the GEARS of the MAIN DRIVE SHAFT.

RACK

ASSEMBLY

GEAR

MAIN

DRIVE

SHAFT

GEAR

H108_0063BCA

H048_0101BA

Figure 23 Positioning the Racks and Gears

246626 23

Page 24

The edge of the LEVEL could cause damage to the surface of the ROLLER.

[3] Place a LEVEL as shown in the figure. Adjust the LEVELING SCREWS to level the processor from side

to side.

LEVEL

H048_0102BCA

H048_0102BA

Figure 24 Leveling the Processor Side to Side

[4] Place a LEVEL as shown in the figure. Adjust the LEVELING SCREWS to level the processor from front

to back.

LEVEL

ROLLERS

H108_0058BCA

H108_0058BA

Figure 25 Leveling the Processor Front to Back

24 246626

Page 25

[5] Install the Seismic Kit, if required.

LEVELING

SCREW (4)

LEVELING SCREW (4)

WASHER (8)

FLOOR PLATE (4)

SLOT

BRACKET (4)

Figure 26 Installing the Seismic Kit

BOLT (8)

H108_0193DCA

H108_0193DA

246626 25

Page 26

Connecting the Replenishment Tanks

[1] Install the STRAINERS.

[2] Connect the 10 mm (3/8 in.) TUBING (not supplied) from the inlets of the REPLENISHMENT PUMP

ASSEMBLY to the DEVELOPER and FIXER REPLENISHMENT TANKS.

To prevent contamination of the processor solutions, check that the DEVELOPER and FIXER

REPLENISHMENT TUBES are connected to the correct tanks.

REPLENISHMENT

REPLENISHMENT

TANKS

PUMP ASSEMBLY

STRAINERS

Figure 27 Connecting Replenishment Tubing

H048_0110BCA

H048_0110BA

26 246626

Page 27

Connecting the Drains

H048_0112CA

WASH

DRAIN

VALVE

WASH

OVERFLOW/DRAIN

FIXER

OVERFLOW/DRAIN

DEVELOPER

OVERFLOW/DRAIN

WATER

INLET

DEVELOPER

DRAIN

VALVE

DEVELOPER

AUXILIARY

DRAIN

FIXER

AUXILIARY

DRAIN

FIXER

DRAIN

VALVE

H048_0112CCA

The processor is equipped to accommodate the

separation of DEVELOPER, FIXER, and WATER

effluent liquid. The processor is shipped from the

factory with a separate FIXER OVERFLOW/TANK

DRAIN, AUXILIARY FIXER TANK DRAIN,

DEVELOPER OVERFLOW/TANK DRAIN,

AUXILIARY DEVELOPER TANK DRAIN, and a

common WASH WATER OVERFLOW/TANK DRAIN.

To prevent severe corrosion, do not

use brass or copper piping.

[1] Connect the three 1.9 cm ( ⁄

3

in.) tubes

4

provided, on the FEED-END of the processor.

Route the tubing as required. Drain service

must comply with local codes. Do not make a

solid connection at the floor drain.

Figure 28 Connecting the Drains

246626 27

Page 28

Connecting the Wiring to Terminal Strip TB1

[1] Remove the LOWER ACCESS PANEL from the FEED-END of the processor.

[2] Open the TRANSFORMER BOX DOOR.

[3] Determine the supply voltage being applied to the processor.

[4] Connect the main input power wires to TERMINAL STRIP TB1.

[5] Take the appropriate ELECTRIC SERVICE LABEL from the PREPACK CARTON. Install the ELECTRIC

SERVICE LABEL on the DATA PLATE which is located on the REPLENISHER CHECK TUBE

BRACKET.

[6] Connect the JUMPERS from the PREPACK CARTON to TERMINAL STRIP TB2. See the figure.

[7] Dress the JUMPER wires neatly to prevent damage to the wires due to pinching or scraping by the panel

edge.

[8] Close the TRANSFORMER BOX DOOR.

TERMINAL

STRIP TB1

TRANSFORMER

BOX DOOR

TERMINAL

STRIP TB2

H048_0083DCC

H048_0083DA

Figure 29 Accessing Terminal Strip TB1 and Installing the Electric Service Label

28 246626

Page 29

BUILDING

POWER SYSTEM

3 Phase Neutral

120V.L-N/208V.L-L

127V.L-N/220V.L-L

3 WIRE

OR

L1

N

L2

NOMINAL SUPPLY

VOLTAGE

120/208

MEASURED SUPPLY

VOLTAGE

104/180-127/220

FREQUENCY

(Hz)

60

CONNECTION

DIAGRAM

A

L3

1

PROCESSOR

1

PROCESSOR

Single Phase Neutral

100V.L-N/200V.L-L

120V.L-N/240V.L-L

23

TB1

220V.L-L

OR

240V.L-L

L1

32

TB1

3 WIRE

OR

L1

4

2 WIRESingle Phase

L2

4

N

127/220

220

240

120/200

115/199-123/213

124/215-140/242

198-216

217-242

226-254

90-98

99-110

50

50

50/60

50/60

B

C

D

E

F

G

H

L2

1

23

TB1

PROCESSOR

3 Phase Neutral

220V.L-N/380V.L-L

OR

240V.L-N/415V.L-L

L1

L3

1

TB1

PROCESSOR

(LOAD SPLITTING)

4

4 WIRE

120/240

230/380

104/208-127/254

207/357-233/403

60

50

SPLIT LOAD

N

L2

4

32

240/415

225/390-254/440

50

SPLIT LOAD

J

K

L

H108_9020EC

Figure 30 Wiring Diagrams

246626 29

Page 30

TB2

A

TB2

B

TB2

C

N

12

4

3

5

H1

H2

H3

H5

H4

X1

X2

X3

X4

7

30

ADD WIRE JUMPERS: 12 TO 4 ADD WIRE JUMPERS: N TO H1

SOLS., SF.

LT. 120V

DEV. HTR.

DRY

240V

MTRS. ETC.

4 TO H4

5 TO H1

X4 TO 7

240V

HTRS.

T1

NN

12

4

3

5

H1

H2

H3

H5

H4

X1

X2

X3

X4

7

30

REMOVE METAL STRAP H2-H3

SOLS., SF.

LT. 120V

DRY

HTRS.

240V

T1

D

DEV. HTR.

MTRS. ETC.

240V

H1 TO H3

12 TO 4

4 TO H2

H2 TO H4

X3 TO 7

SOLS., SF.

12

4

3

5

H1

H2

H3

H5

H4

X1

X2

X3

X4

T1

7

30

REMOVE METAL STRAP H2-H3

ADD WIRE JUMPERS: N TO H1

E

LT. 120V

DRY

HTRS.

240V

H1 TO H3

12 TO H2

H2 TO H4

4 TO X2

X2 TO 7

DEV. HTR.

MTRS. ETC.

240V

F

TB2

NN

12

4

3

5

H1

H2

H3

H5

H4

X1

X2

X3

X4

T1

7

30

ADD WIRE JUMPERS: N TO 3

SOLS., SF.

LT. 120V

DRY

HTRS.

240V

3 TO H1

12 TO H5

4 TO H4

X3 TO 7

DEV. HTR.

MTRS. ETC.

240V

TB2

SOLS., SF.

12

4

3

5

H1

H2

H3

H5

H4

X1

X2

X3

X4

T1

7

30

ADD WIRE JUMPERS: N TO 3

LT. 120V

DRY

HTRS.

240V

3 TO H1

12 TO H2

4 TO H4

H4 TO 7 X1 TO 7

DEV. HTR.

MTRS. ETC.

240V

TB2

N

12

4

3

5

H1

H2

H3

H5

H4

X1

X2

X3

X4

7

30

ADD WIRE JUMPERS: N TO 3

SOLS., SF.

LT. 120V

DRY

HTRS.

240V

T1

3 TO H1

12 TO H2

4 TO X2

DEV. HTR.

MTRS. ETC.

240V

H108_9021EC

Figure 31 Wiring Diagrams (Cont.)

30 246626

Page 31

TB2

G

TB2

H

J

TB2

N

12

4

3

5

H1

H2

H3

H5

H4

X1

X2

X3

X4

7

30

REMOVE METAL STRAP H2-H3

ADD WIRE JUMPERS: N TO H1

SOLS., SF.

LT. 120V

DRY

HTRS.

240V

T1

DEV. HTR.

MTRS. ETC.

H1 TO H3

12 TO X4

X4 TO 7

4 TO H2

H2 TO H4

240V

NN

12

4

3

5

H1

H2

H3

H5

H4

X1

X2

X3

X4

7

30

REMOVE METAL STRAP H2-H3

ADD WIRE JUMPERS: N TO H1

K

SOLS., SF.

LT. 120V

DEV. HTR.

DRY

240V

MTRS. ETC.

240V

H1 TO H3

12 TO X3

X3 TO 7

4 TO H2

H2 TO H4

HTRS.

T1

12

4

3

5

H1

H2

H3

H5

H4

X1

X2

X3

X4

7

30

ADD WIRE JUMPERS: 12 TO 4

SOLS., SF.

LT. 120V

DEV. HTR.

DRY

240V

4 TO 7

MTRS. ETC.

240V

HTRS.

T1

L

TB2

NN

12

4

3

5

H1

H2

H3

H5

H4

X1

X2

X3

X4

T1

7

30

REMOVE METAL STRAP 3-5 REMOVE METAL STRAP 3-5

ADD WIRE JUMPERS: N TO H1

SOLS., SF.

LT. 120V

DRY

HTRS.

240V

H1 TO 7

12 TO H5

4 TO 3

3 TO 3

3 TO X2

DEV. HTR.

MTRS. ETC.

240V

TB2

SOLS., SF.

12

4

3

5

H1

H2

H3

H5

H4

X1

X2

X3

X4

T1

7

30

ADD WIRE JUMPERS: N TO H1

LT. 120V

DRY

HTRS.

240V

H1 TO 7

12 TO H2

4 TO X2

3 TO H4

DEV. HTR.

MTRS. ETC.

240V

H108_9022EC

Figure 32 Wiring Diagrams (Cont.)

246626 31

Page 32

Connecting the Exhaust

[1] Connect 7.6 cm (3 in.) ELBOWS and rigid DUCT or flexible EXHAUST HOSE between the processor

EXHAUST PORT and the BUILDING EXHAUST DUCT.

NOTE

Do not make a solid connection at the BUILDING END. Do not connect the EXHAUST DUCT to

the processor at this time.

[2] Measure the static pressure in the DUCT using a modified J TUBE (CHECK TUBE 592380) and AIR

METER TL-2431. Make the measurement 30.5 cm (12 in.) from the end of the DUCT to be connected

to the processor.

AIR FLOW

30 cm

(12 in.)

AIR METER

EXHAUST HOSE

Figure 33 Measuring the Static Pressure

RUBBER HOSE or

MODIFIED J TUBE

TAPE (3 places)

HOSE SUPPORT

CENTER CONNECTOR

H048_0118BCA

H048_0118BA

32 246626

Page 33

[3] To obtain the correct static pressure, as shown in Table 1, adjust the clearance at the BUILDING END of

the DUCT as illustrated.

Table 1 Static Pressures

Negative Static Pressure, (Water Head)

Duct Diameter MIN MAX

76 mm (3 in.) 0.76 mm (0.03 in.) 1.02 mm (0.04 in.)

102 mm (4 in.) 0.25 mm (0.01 in.) 0.51 mm (0.02 in.)

[4] Connect the DUCT to the building exhaust.

Adjust clearance to obtain

required static pressure in duct.

Adjust clearance to obtain

Do not make solid connection.

required static pressure in duct.

Duct

from

Processor

Do not make solid connection.

5.1 cm (2.0 in.)

maximum

Figure 34 Connecting the Processor Exhaust to the Building Exhaust

[5] Connect the DUCT to the processor.

H108_0008BAA

H108_0008BA

246626 33

Page 34

Making the Water Connection

Before connecting the water line to the processor, flush the line to remove any debris or rust

particles in the line.

See the Site Specifications, and install the plumbing to the water connection, using an adapter if necessary.

Checking the Drain Valves

Check that the 3 DRAIN VALVES are closed. All VALVE HANDLES should be in the vertical position.

CHECK

VALVE

MIXING

VALVE

SHUTOFF

VALVES

COLD WATER

SUPPLY

CIRCUIT

BREAKER

COLD WATER

SUPPLY

HOT WATER

SUPPLY

H048_0089DCA

H048_0089DA

Figure 35 Connecting the Water Inlet Plumbing

34 246626

Page 35

User Selectable Modes

Flooded Replenishment

Factory set to ‘‘OFF’’ (Left) position.

This feature is designed for low film usage. When in the ‘‘ON’’ (Right) position, it allows for replenishment of

the developer and fixer solutions each time the processor comes out of standby.

Water Conservation

Factory set to ‘‘ON’’ (Right) position.

[1] When water conservation is ‘‘ON’’, and the processor cycles into standby, no water flows to the

processor except when water is needed for developer cooling. As film is processed, water flows into the

wash tank.

NOTE

When the processor is not in use, it will continue to cycle in and out of standby without water

flowing to the wash tank.

[2] When water conservation is ‘‘OFF’’, water continually flows to the wash tank as long as the processor is

out of standby.

246626 35

Page 36

Selecting the Replenishment Mode

[1] To access SWITCH U20 on the 100 CIRCUIT BOARD, open the ELECTRICAL BOX DOOR.

[2] If the customer requires FLOODED REPLENISHMENT, set the SWITCH U20-1 to the right (ON).

[3] If the customer requires no WATER CONSERVATION, set the SWITCH U20-2 to the left (OFF).

[4] U20-3 must be set to the right (ON) position.

[5] U20-4 must be set to the left (OFF) position.

ELECTRICAL

BOX DOOR

100 CIRCUIT BOARD

U20

SWITCHES

Figure 36 Setting Switch U20 on the 100 Circuit Board

H048_0099DCA

H048_0099DA

36 246626

Page 37

Using the Splash Guard and Drip Tray

[1] Install a SPLASH GUARD before removing or installing a RACK ASSEMBLY.

[2] Set the RACK ASSEMBLY into the DRIP TRAY.

SPLASH

GUARD

DRIP

TRAY

H048_0119BCA

H048_0119BA

Figure 37 Installing the Splash Guard

Filling the Tanks

• Before filling the tanks with chemicals, it is recommended that you fill the tanks with water and

check the plumbing system for leakage with the processor energized.

• All adjustable metal band clamps used on tubing connections must be checked for tightness at the

time of the processor installation.

• Although a clamp may be properly tightened at the time of installation, cold-flow (shrinkage) of the

plastic tubing will take place beneath the clamp, thus the clamp may require further tightening within 2

to 4 weeks.

• Always check the tightness of the clamp after installing replacement tubing.

[1] Remove all the RACKS.

[2] Install the SPLASH GUARD. See Figure 37.

NOTE

246626 37

Page 38

[3] Fill the FIXER TANK to the FIXER FILL LINE. See the figure.

DRIVE

SIDE

NON-DRIVE

SIDE

FIXER

FILL LINE

DEVELOPER

FILL LINE

H048_0094BCA

H048_0094BA

Figure 38 Tank Fill Lines

[4] Clean any FIXER spills.

[5] Clean the SPLASH GUARD.

[6] Install the SPLASH GUARD to allow filling of the DEVELOPER TANK.

[7] Fill the DEVELOPER TANK to the DEVELOPER FILL LINE.

[8] Open the WATER SUPPLY VALVE to provide water to the processor. (The tank will not fill until the

processor is energized in a later step.)

38 246626

Page 39

[9] Unlock the DRYER TEMPERATURE CONTROL KNOB by rotating the LOCKING RING

counter-clockwise approximately ⁄

1

turn.

4

[10] Rotate the DRYER TEMPERATURE CONTROL KNOB counter-clockwise as far as it will turn.

[11] Lock the DRYER TEMPERATURE CONTROL KNOB by rotating the LOCKING RING clockwise

approximately ⁄

1

4

turn.

NOTE

This will keep the DRYER at minimum heat to provide the correct temperature for adjusting the

tension of the DRYER BELT.

LOCKING

RING

SETSCREW

DRYER TEMPERATURE

CONTROL KNOB

REPL

SWITCH

H048_0105BCA

H048_0105BA

Figure 39 Adjusting the Dryer Temperature Control Knob

246626 39

Page 40

If the processor is to be operated at

H048_0106CA

CIRCUIT

BREAKER

H048_0106CCA

50 Hz, make sure that the processor is

set for operation at 50 Hz. See the

procedure ‘‘Setting a Processor for

50 Hz Operation’’ on page 14.

[12] Move the CIRCUIT BREAKER to the ‘‘I’’, or

energized position

[13] Check that the RECIRCULATION PUMPS are

operating by observing motion on the surface

of the solution TANKS.

[14] Allow the wash water to overflow for

5 minutes or longer.

[15] Clean the WASH TANK, if necessary.

[16] Check the processor for leaks.

IMPORTANT

After the processor has been in regular

use for one or 2 days, once again

check the processor for leaks.

Figure 40 Control Panel of the Processor

40 246626

Page 41

Setting the Replenishment Rates

NOTE

Refer to the manufacturer’s specifications for the film and chemicals being used, for operating

temperatures and replenishment rates. The KODAK

No. 30 is available from your Kodak Representative or Marketing Technical Group, Health

Sciences Division, Eastman Kodak Company, Rochester, New York 14650.

NOTE

Contact a qualified operator, service personnel, or authorized dealer representative to perform the

following adjustments.

[1] Remove the RECEIVING-END ACCESS PANEL and the DRIVE SIDE ACCESS PANEL from the

processor. Run the REPLENISHMENT PUMP to purge air from the system.

[2] With the 2 GRADUATED CYLINDERS under the REPLENISHMENT CHECK TUBES, turn the VALVES

on and press the ‘‘REPL’’ SWITCH. See Figure 39 on page 39, if necessary. Run the PUMP to purge

air from the system.

[3] With the GRADUATED CYLINDER under the DEVELOPER CHECK TUBE, turn the VALVE on and

press the ‘‘REPL’’ SWITCH for 13 seconds.

NOTE

RP

X-OMAT Processor Service Bulletin

This is the amount of time film, 14 inches in length, causes the replenishment pump to operate.

[4] Compare the average of 2 or more measurements with the film and chemical specifications of the

manufacturer.

[5] If necessary, adjust the developer replenishment rate following the instructions on page 42.

[6] Repeat for FIXER REPLENISHMENT rate.

246626 41

Page 42

Adjusting the Replenishment Rate

Do not adjust the SETSCREW or LOCK NUT.

[1] Remove the outside PUMP COVER by loosening the 2 SCREWS on the top of the PUMP, and lifting the

COVER off.

[2] Rotate the CRANK by hand to gain access to the ADJUSTING SCREW.

[3] Rotate the appropriate fixer or developer ADJUSTING SCREW to provide the correct replenishment

rates.

[4] Install the PUMP COVER.

CRANK

ADJUSTING SCREW

OUTPUT

DECREASE

INCREASE

STROKE INDICATOR

STROKE SCALE

SET SCREW

(DO NOT ADJUST)

SCREW (2)

PUMP

COVER

Figure 41 Setting the Replenishment Rate

H048_0104BCA

H048_0104BA

42 246626

Page 43

Installing the Racks and Crossovers

[1] Carefully, install the RACKS. Use the SPLASH GUARD.

[2] Install the CROSSOVERS.

FILTER

CANISTER

ASSEMBLY

FIXER/WASH

CROSSOVER

DEVELOPER/FIXER

CROSSOVER

DETECTOR

CROSSOVER

FIXER

RACK

SQUEEGEE

ASSEMBLY

WASH

RACK

DEVELOPER

RACK

H048_0092DCA

H048_0092DA

Figure 42 Installing the Racks and Crossovers

246626 43

Page 44

[3] Install the EVAPORATION COVERS.

Figure 43 Installing the Evaporation Cover

EVAPORATION

COVERS

H048_0103BCA

H048_0103BA

44 246626

Page 45

Adjusting the Tension of the Dryer Belt

Parts are moving within the processor. Keep hands and loose clothing out of the processor.

[1] With the processor operating, the DRYER TEMPERATURE CONTROL rotated to the full

counter-clockwise position, and the dryer cool, adjust the tension of the DRYER BELT as follows:

[2] Loosen the LOCKING SCREW.

[3] Rotate the ADJUSTING SCREW KNOB to tighten the BELT until the ROLLERS just begin to rotate.

[4] Rotate the ADJUSTING SCREW KNOB an additional 1 rotation.

[5] Tighten the LOCKING SCREW.

[6] Tighten the ADJUSTING SCREW LOCK NUT.

BELT

AIR

TUBE

LOCKING

SCREW

ADJUSTING

SCREW LOCKNUT

ADJUSTING

ROLLER

SCREW KNOB

ASSEMBLY

Figure 44 Locating the Dryer Belt and Adjuster

H048_0093BCA

H048_0093BA

246626 45

Page 46

Installing the Panels and Covers

Install all PANELS and COVERS.

When required by local code, install panel-locking devices. Parts and instructions are included in

the PREPACK.

Setting the Dryer Temperature

NOTE

[1] Unlock the DRYER TEMPERATURE CONTROL KNOB by rotating the LOCKING RING

counter-clockwise approximately ⁄

1

turn.

4

[2] Set the DRYER TEMPERATURE CONTROL KNOB to the minimum setting required to dry film.

[3] Lock the DRYER TEMPERATURE CONTROL KNOB by rotating the LOCKING RING clockwise

approximately ⁄

1

4

turn.

LOCKING

RING

SETSCREW

DRYER TEMPERATURE

CONTROL KNOB

H048_0105BCA

H048_0105BA

REPL

SWITCH

Figure 45 Adjusting the Dryer Temperature Control Knob

46 246626

Page 47

Checking the Developer Temperature

[1] When the DEVELOPER LAMP begins to flash, remove the TOP COVER.

[2] Insert a THERMOMETER of known accuracy into the DEVELOPER TANK.

[3] Install the TOP COVER.

[4] Operate the processor for 15 minutes to stabilize the temperature.

[5] Check that the temperature on the DEVELOPER TEMPERATURE METER is the same as on the

THERMOMETER (35°C [95°F] set at the factory).

NOTE

See the Service Manual for the adjustment procedure.

THERMOMETER

H048_0098BCA

H048_0098BA

Figure 46 Placing the Thermometer

[6] Check that the following are installed:

• RACKS

• CROSSOVERS

• COVERS

[7] Check that the LIGHT-TIGHT GASKET is tight against the wall.

Checking the Film Transport

[1] Feed three 35 x 43 cm (14 x 17 in.) films into the processor. Check that the RACKS move the film

through the processor correctly.

246626 47

Page 48

3040ii_a.txt

EASTMAN KODAK COMPANY • ROCHESTER, N.Y. 14650Printed in USA

Kodak

and

X-Omat

are trademarks.

Customer Equipment Services Division

Loading...

Loading...