Page 1

{Diagnostics}{Production}{He althImaging}

Publication No. 7C8290

28JAN98

HEALTH IMAGING

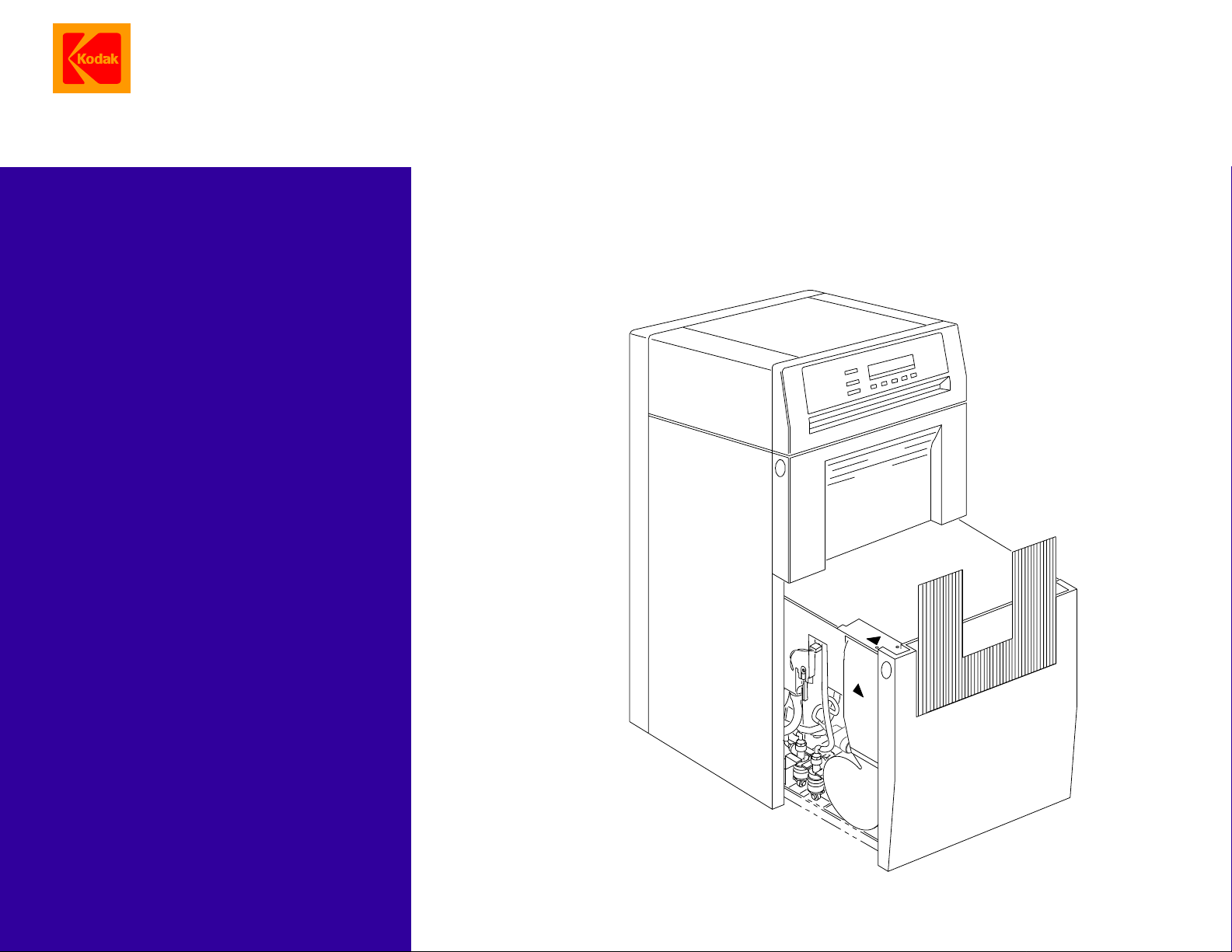

Kodak X-Omat

in a Kodak X-Omat

DIAGNOSTICS

for the

3000 RA INTEGRATED PROCESSOR

MULTILOADER 300 PLUS

© Eastman Kodak Company, 1999

Page 2

PLEASE NOTE The information contained herein is based on the experience and knowledge relating to the

subject matter gained by Eastman Kodak Company prior to publication.

No patent license is granted by this information.

Eastman Kodak Company reserves the right to change this information without notice, and

makes no warranty, express or implied, with respect to this information. Kodak shall not be liable

for any loss or damage, including consequential or special damages, resulting from any use of

this information, even if loss or damage is caused by Kodak’s negligence or other fault.

Table of Contents

Description Page

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Introduction and Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

All Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Fatal Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Non-Fatal Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Mechanical Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Transport Malfunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Artifacts and Wrong Film Densities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Wet Films . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Solution Levels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2 28JAN98 – 7C8290

Page 3

Error Codes

Section 1: Error Codes

Introduction and Definitions

Introduction • The 500 BOARD monitors the PROCESSOR functions during normal

operations, and continually checksforerrors. When an error occurs,anerror

code is displayed on the DISPLAY PANEL.

• Error codes are displayed by priority.

• The lower the error code number, the higher the priority.

• More than one error code can occur at one time.

• When 2 or more error codes occur, only the error code with the highest

priority will be displayed.

• When a high priority error code is corrected, the next priority error code is

displayed.

• All errors are stored in an error log on the 500 BOARD. Use a PORTABLE

COMPUTER and the correct software for access to the error log. The error

log records the number of times an error occurred.

• There are 3 types of error code: Fatal, Non-Fatal and Warning.

NOTE: When errors occur, the MICROPROCESSOR BOARD might disable

some components.

Use the PORTABLE COMPUTER and the diagnostic tests to analyze the

components.

Fatal Errors A Fatal Error indicates a problem which can cause a dangerous condition if the

PROCESSOR continues to operate. If a sheet of film is being processed when a

fatal error occurs, the film will exit the PROCESSOR. The PROCESSOR will

stop operating and no new films can be inserted into the PROCESSOR. If

additional sheets of film are inserted before the PROCESSOR stops operating,

the film will exit the PROCESSOR, then the PROCESSOR will stop operating

and no films canbe inserted. If aFatalError occurs when thePROCESSOR is in

the standby mode, the PROCESSOR will not operate and no films can be

inserted. The operator cannot correct Fatal Errors. The operator should move

BREAKER CB2, on the PROCESSOR, to the “off” or “O” position and make a

call for service.

Non-Fatal Errors A Non-Fatal Error will not prevent the PROCESSOR from operating. Filmcan be

inserted into the PROCESSOR, but the image quality might decrease. The

operator cannot correct most Non-Fatal errors.The operator should make a call

for service.

Warning Errors A Warning Error indicates a temporary condition or a problem which can be

corrected by the operator. The PROCESSOR will operate and films can be

inserted. Image quality might decrease.

All Errors

Important

When you check an electrical component or BOARD, also check all the:

• connections and CABLES for the component or BOARD

• voltages from the POWER SUPPLY for the component or BOARD

7C8290 – 28JAN98 3

Page 4

DIAGNOSTICS

Fatal Errors

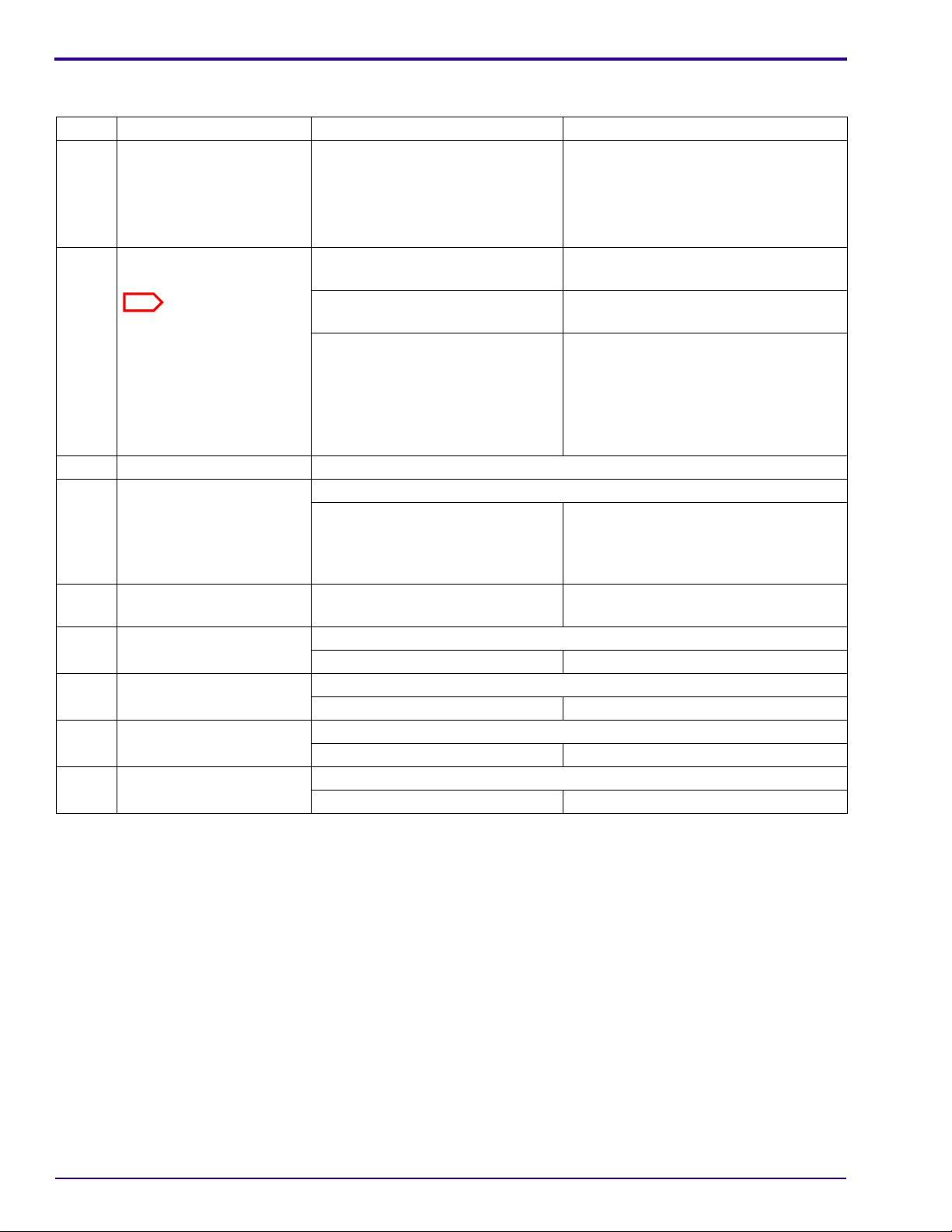

Code Description Possible Malfunction Action

E001 500 BOARD Corrupted software on the 500

BOARD

E002 Dryer over maximum

temperature

Note

Themaximumtemperature

is 79 C (175 F).

Normally, the DRYER DC

OVER-TEMPERATURE

THERMOSTAT opens

beforetheDRYERreaches

this temperature.

E004 Inoperative transport See E041 in the Non-Fatal Errors Table.

E005 Dryer over-temperature

thermostat open

E006 Initialization

communication error

E007 Developer thermistor

failure

E008 Fixer thermistor failure The FIXER HEATER is disabled when this error occurs.

E009 Dryer thermistor failure The DRYER HEATER is disabled when this error occurs.

E010 Analog-to-digital converter

failure

DRYER THERMISTOR Check that the resistance at 25 C

SOLID STATE RELAY U3 that

controls the DRYER HEATER

500 BOARD Install a new BOARD.

When this error occurs, the DRYER HEATER and BLOWER are disabled.

CABLE between PROCESSOR

and MULTILOADER 500 BOARD

The DEVELOPER HEATER is disabled when this error occurs.

DEVELOPER THERMISTOR Install a new THERMISTOR.

FIXER THERMISTOR Install a new THERMISTOR.

DRYER THERMISTOR Install a new THERMISTOR.

All 3 HEATERS are disabled when this error occurs.

500 BOARD Install a new BOARD.

• Load the current software again.

or

• Install new PROMS/EEPROMS:

U17, U19, and U20 on the 500

BOARD.

(77 F) is approximately 10 KW.

Check SSR U3.

Allow THERMOSTAT to reset. If the

THERMOSTAT opens again, determine

the cause of the over-temperature

condition. See E002.

Install a new CABLE. Install a new

BOARD.

4 28JAN98 – 7C8290

Page 5

Non-Fatal Errors

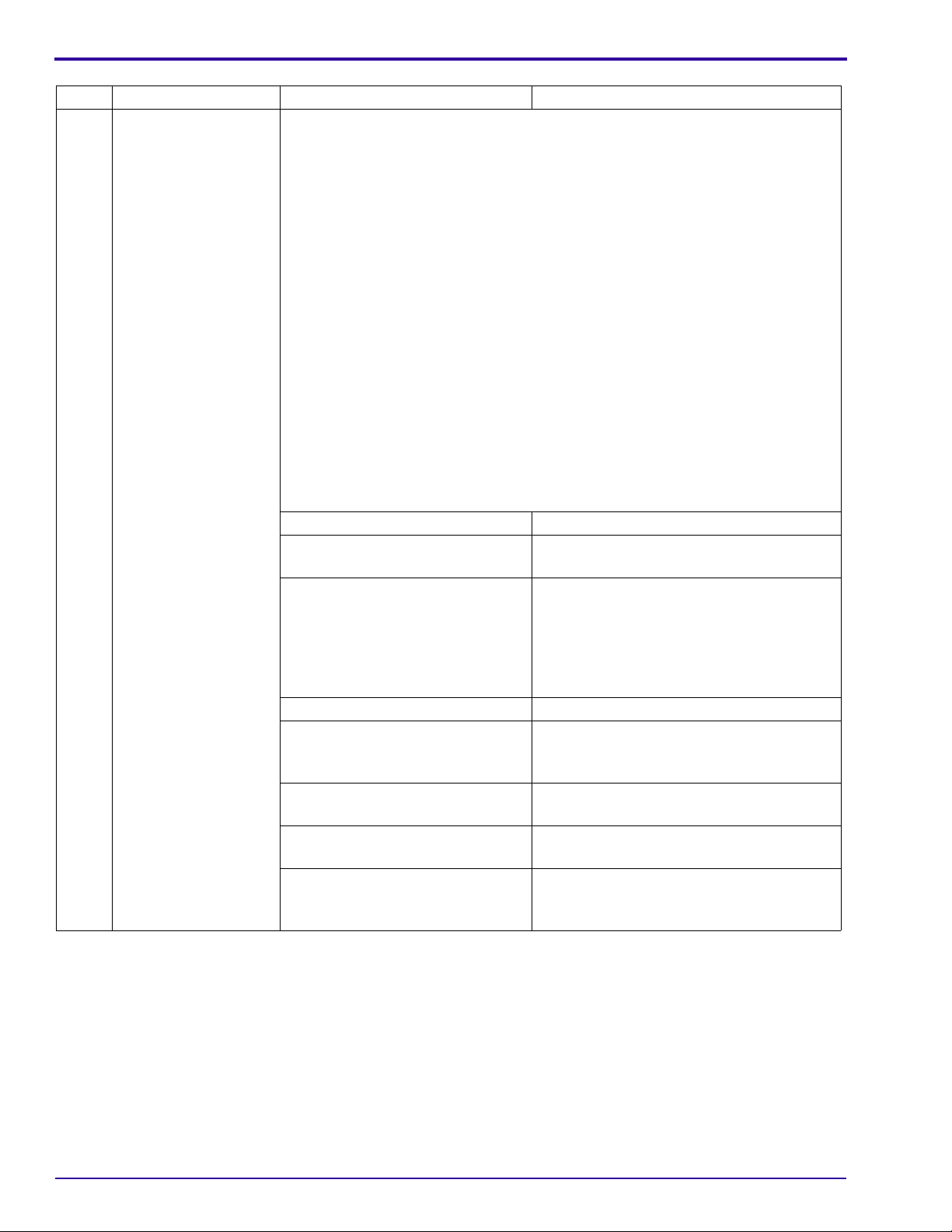

Code Description Possible Malfunction Action

E032 Developer tank fill

error

This error will occur if the:

• DEVELOPER TANK:

– does not fill in 4 minutes in normal operation.

– does not fill in 15 minutes in the Tank Fill Mode.

– is empty and the operator does not select the Tank Fill Mode.

• REPLENISHER TANK is empty.

• REPLENISHMENT HOSE has an obstruction.

• TANKS of the PROCESSOR are filledwithwaterduringthe initial installation.

The following parts will be disabled:

• DEVELOPER REPLENISHMENT PUMP

• RECIRCULATION PUMP

• Temperature control for the fixer and developer

To prevent the error from occurring during the initial installation:

• add 240 mL (8 fl oz) of developer to the DEVELOPER TANK before you fill

the PROCESSOR with water.

• energize the RECIRCULATION PUMP to move the developer and remove

any air bubbles. Use the diagnostics to energize the PUMP.

LEVEL PROBES Clean and check the PROBES.

The solution level in the

REPLENISHER TANK is low.

Solution does not flow through the

HOSES between the

REPLENISHMENT TANK and the

REPLENISHMENT PUMP.

The DEVELOPER DRAIN VALVE

is open.

SOLID STATE RELAY SSR U2

that controls the DEVELOPER

REPLENISHMENT PUMP

POPPET VALVES in the

DEVELOPER REPLENISHMENT

PUMP

DEVELOPER REPLENISHMENT

PUMP

The500BOARDdoesnotenergize

the SOLID STATE RELAY

SSR U2.

Mix new developer solution.

Check:

• HOSE CLAMPS are tight

• HOSES:

– are round and opened

– have no obstructions or air bubbles

Close the VALVE.

Check SSR U2.

Clean and check the VALVES.

Check FUSE F1 and the

REPLENISHMENT PUMP MOTOR B3.

If necessary, install a new BOARD.

Error Codes

7C8290 – 28JAN98 5

Page 6

DIAGNOSTICS

Code Description Possible Malfunction Action

E033 Fixer tank fill error This error will occur if the:

• FIXER TANK

– does not fill in 4 minutes in normal operation.

– does not fill in 15 minutes in the Tank Fill Mode.

– is empty and the operator does not select the Tank Fill Mode.

• REPLENISHMENT TANK is empty.

• REPLENISHMENT HOSE has an obstruction.

• TANKS of the PROCESSORarefilled with water during theinitialinstallation.

The following parts will be disabled:

• FIXER REPLENISHMENT PUMP

• RECIRCULATION PUMP

• Temperature control for the fixer and developer

To prevent the error from occurring during the initial installation:

• add 240 mL (8 fl oz) of fixer to the FIXER TANK before you fill the

PROCESSOR with water.

• energize the RECIRCULATION PUMP tomove the fixer and removeany air

bubbles. Use the diagnostics to energize the PUMP.

LEVEL PROBES Clean and check the PROBES.

The solution level in the

Mix new fixer solution.

REPLENISHER TANK is low.

Solution does not flow through the

HOSES between the

REPLENISHMENT TANK and the

Check:

• HOSE CLAMPS are tight

• HOSES:

REPLENISHMENT PUMP.

– are round and opened

– have no obstructions or air bubbles

The FIXER DRAIN VALVE is open. Close the VALVE.

SOLID STATE RELAY SSR U4

Check SSR U4.

that controls the FIXER

REPLENISHMENT PUMP

POPPET VALVES in the FIXER

Clean and check the VALVES.

REPLENISHMENT PUMP

FIXER REPLENISHMENT PUMP Check FUSE F1 and the

REPLENISHMENT PUMP MOTOR B4.

The500BOARDdoesnotenergize

If necessary, install a new BOARD.

the SOLID STATE RELAY

SSR U4.

6 28JAN98 – 7C8290

Page 7

Code Description Possible Malfunction Action

E034 Unable to determine

developer temperature

The DEVELOPER HEATER and the DEVELOPER COOLING SOLENOID is

disabled when this error occurs.

DEVELOPER THERMISTOR:

• open•circuit or short•circuit

• Resistance not correct

• Check that the resistance at 25 C

(77 F) is approximately 10k ohms.

• If necessary, install a new

DEVELOPER THERMISTOR

500 BOARD:

Install a new 500 BOARD.

• A/D CONVERSION

ELECTRONICS malfunction

• PRECISION RESISTOR test

failure

Ambient temperature is below

15 C (59 F).

Increase the ambient temperature, or deenergize and then energize the

PROCESSOR.

See EO37 for additional actions.

E035 Unable to determine

fixer temperature

The FIXER HEATER is disabled when this error occurs.

FIXER THERMISTOR:

• open•circuit or short•circuit

• Resistance not correct

• Check that the resistance at 25 C

(77 F) is approximately 10k ohms.

• If necessary, install a new FIXER

THERMISTOR.

500 BOARD:

Install a new 500 BOARD.

• A/D CONVERSION

ELECTRONICS malfunction

• PRECISION RESISTOR test

failure

Ambient temperature is below

15 C (59 F).

Increase the ambient temperature, or deenergize and then energize the

PROCESSOR.

See EO39 for additional actions.

Error Codes

Code Description Possible Malfunction Action

E036 Unable to determine

DRYER temperature

The DRYER HEATER is disabled when this error occurs.

DRYER THERMISTOR:

• open•circuit or short•circuit

• Resistance not correct

• Check that the resistance at 25 C

(77 F) is approximately 10k ohms.

• If necessary, install a new DRYER

THERMISTOR

500 BOARD:

Install a new 500 BOARD.

• A/D CONVERSION

ELECTRONICS malfunction

• PRECISION RESISTOR test

failure

See EO40 for additional actions.

7C8290 – 28JAN98 7

Page 8

DIAGNOSTICS

Code Description Possible Malfunction Action

E037 Loss of developer heating

ability

DEVELOPER HEATER HR1 has an internal OVERTEMPATURE

THERMOSTAT. When the HEATER is too hot, the OVERTEMPERATURE

THERMOSTAT opens. Wait for the HEATER to cool and allow the

THERMOSTAT to reset before you measure the resistance.

SOLID STATE RELAY

U1(controls the DEVELOPER

HEATER)

DEVELOPER HEATER HR1:

• open•circuit

• Incorrect resistance

Check for correct operation of SOLID

STATE RELAY U1. If necessary, install a

new RELAY U1.

• Check FUSE F2.

• Check that the resistance at 25 C

(77 F) is approximately 50 ohms.

• Install a new DEVELOPER HEATER

HR1.

500 BOARD does not energize

Install a new 500 BOARD.

the SOLID STATERELAY U1:

Malfunction of RELAY K504A

DEVELOPER COOLING

SOLENOID L2

• Check that DEVELOPER COOLING

SOLENOID L2 stops the developer flow

through the HEAT EXCHANGER.

• If necessary, install anew DEVELOPER

COOLING SOLENOID L2.

RECIRCULATION PUMP • Check FUSE F1.

• Check for the correct operation of

MOTOR B5.

• If necessary, install a new

RECIRCULATION PUMP.

See EO34 for additional actions.

8 28JAN98 – 7C8290

Page 9

Code Description Possible Malfunction Action

E038 Loss of developer

cooling ability

Water does not enter the WASH

TANK.

Check:

• that water is supplied to the

PROCESSOR.

– The water supply is turned on.

– The FILTER is clean.

• WASH WATER SOLENOID L1

– The operation is correct.

– The SCREEN has no obstructions.

• DEVELOPER COOLING SOLENOID

L2

• QUICK DISCONNECT

The temperature of the water

entering the WASH TANK is too

hot.

Decrease the temperature of the water

supply. The wash water must be a

minimum of 5.5 C (10 F) below the

set•point of the developer.

HEAT EXCHANGER in the WASH

TANK

The 500 BOARD does not energize

SOLENOIDS L1 or L2

Remove any obstructions from the

EXCHANGER.

Check for 24 V DC at TERMINALS 1 and 2

on the:

• WASH WATER SOLENOID L1

• DEVELOPER COOLING SOLENOID

L2

If necessary, install a new BOARD.

RECIRCULATION PUMP Check the RECIRCULATION PUMP

MOTOR B5. If necessary, install a new

PUMP.

The WASH TANK CLIP is not fully

seated or is not installed.

Check that the CLIP is fully seated. If

necessary, install the CLIP.

Error Codes

7C8290 – 28JAN98 9

Page 10

DIAGNOSTICS

Code Description Possible Malfunction Action

E039 Loss of fixer heating ability FIXER HEATER HR2 has an internal OVERTEMPATURE THERMOSTAT.

When the HEATER is too hot, the OVERTEMPERATURE THERMOSTAT

opens. Wait for the HEATER to cool and allow the THERMOSTAT to reset

before you measure the resistance.

SOLID STATE RELAY U5

(controls the FIXER HEATER)

Check for correct operation of SOLID

STATE RELAY U5. If necessary, install a

new RELAY U5.

FIXER HEATER HR2:

• open•circuit

• Incorrect resistance

• Check FUSE F2.

• Check that the resistance at 25 C

(77 F) is approximately 50 ohms.

• Install a new FIXER HEATER HR2.

500 BOARD does not energize

Install a new 500 BOARD.

the SOLID STATERELAY U5:

Malfunction of RELAY K504B

RECIRCULATION PUMP • Check FUSE F1.

• Check for the correct operation of

MOTOR B5.

• If necessary, install a new

RECIRCULATION PUMP.

See EO35 for additional actions.

Code Description Possible Malfunction Action

E040 Loss of dryer heating ability A PANEL or DRYER RACK is

Install the part.

not installed.

SOLID STATE RELAYU3 that

Check SSR U3.

controls the DRYER HEATER

RELAY K1 that enables the

Check K1.

DRYER HEATER

No continuity for the DRYER

HEATER

DRYER

OVER-TEMPERATURE

THERMOSTAT

Check that the resistance at 25 C (77 F) is

approximately 16 W.

Allow the THERMOSTAT to reset. If the

THERMOSTAT opens again, determine the

cause of the high temperature. If you cannot

determine the causeof the problem, installa

new THERMOSTAT.

No continuity for the DRYER

HEATER THERMAL CUTOFF

500 BOARD:

Check that the DRYER BLOWER operates

correctly. Install a new CUTOFF.

If necessary, install a new BOARD.

• The 500 BOARD does not

energize the SOLID

STATE RELAY SSR U3.

• The RELAY K501

malfunctions.

10 28JAN98 – 7C8290

Page 11

Code Description Possible Malfunction Action

E041 Loss oftransportspeedcontrol

Note

This error occurs when the

transport speed is set for 10

seconds and the speed is not

within 7.6 cm/min (3 in./min) of

the set•point.

When the PROCESSOR operates normally:

• The supply voltage from the QUAD POWER SUPPLY through the

7000 BOARD to the DRIVE MOTOR CONTROLLER is 24 V DC at

PIN 3 on the DRIVE MOTOR CONTROLLER.

• The control voltage at Test Point 10 on the 500 BOARD is

approximately:

1.0 V DC for the Extended Speed

1.9 V DC for the Standard Speed

2.6 V DC for the Rapid Speed

3.4 V DC for the K/RA Speed

Note

There might be large variations in control voltages between

PROCESSORS.

Feedback pulses from the DRIVE MOTOR CONTROLLER at Test Point

8 on the 500 BOARD indicate the speed of the DRIVE MOTOR.

Error Codes

If the transport operates slower than the set speed, the

MICROPROCESSOR increases the control voltage approximately 25

mV every second at Test Point 8 on the 500 BOARD. When the voltage

reaches 5 V DC, the MICROPROCESSOR stops increasing the voltage.

500 BOARD If the control voltage is not correct at TP 10

on the 500 BOARD, install a new BOARD.

7000 BOARD Install the PROCESSOR in the

MULTILOADER and check for the following

voltages on the 7000 BOARD:

• 24 V DC between PINS 1 and 10 of

PJ7003

• 5 V DC between PINS 4 and 10 of

PJ7003

DC DRIVE MOTOR B6 or

DRIVE MOTOR

CONTROLLER

E042 Loss of accessory data link Loose connections Check all connections between any

500 BOARD Install a new BOARD.

2000 BOARD Install a new BOARD.

E045 Display data link error CABLES between the

3000 and 500 BOARD

If B6 operates, but no pulses occur at Test

Point 8 on the 500 BOARD, check:

• B6

• CONTROLLER

accessory and the PROCESSOR.

Check the CABLES.

7C8290 – 28JAN98 11

Page 12

DIAGNOSTICS

Warnings

Error

Code Error Description Possible Malfunction Action

E128 PROCESSOR is not

engaged in the

MULTILOADER

E129 Tanks currently being

filled

E130 Replenish pumps

disabled

E132 Developer under set

temperature

E133 Developer over set

temperature

E134 Dryer under set

temperature

E141 Low developer tank

level

E142 Low fixer tank level When this error occurs,

When this error occurs,

• the following function is disabled:

– film transport

• the following parts are disabled:

– DRYER HEATER

– BLOWER

PROCESSOR is extended. Engage the PROCESSOR in the MULTOLOADER.

INTERLOCK SWITCH S4 Check S4. If necessary, install a new S4.

7000 BOARD Install a new BOARD.

When this error occurs,

• the following function is disabled:

– film transport

• the following parts are disabled:

– RECIRCULATION PUMP

– 3 HEATERS

– DRYER BLOWER

None None. This message will clear automatically.

None Use the KEYPAD to select either Automatic or

Flooded Replenishment to enable the PUMPS.

None None. This message will clear automatically when

the developer reaches the set•point temperature.

None None. This message will clear automatically when

the developer reaches the set•point temperature.

None None. This message will clear automatically when

the DRYER reaches the set•point temperature.

When this error occurs,

• the RECIRCULATION PUMP is disabled.

• the temperature control for the fixer and developer is disabled.

None This error will clear automatically when the

developer solution reaches the correct level.

• the RECIRCULATION PUMP is disabled.

• the temperature control for the fixer and developer is disabled.

None This error clears automatically when the fixer

solution reaches the correct level.

12 28JAN98 – 7C8290

Page 13

Section 2: Mechanical Diagnostics

Transport Malfunction

Possible Cause Check

RACK and CROSSOVER

ASSEMBLIES

ROLLER ASSEMBLIES ROLLERS

DRYER AIR TUBE BAFFLES

RACK and CROSSOVER ASSEMBLIES:correct positionsseated

correctly

• squareness

– SeeADJUSTMENTSandREPLACEMENTS, Publication

No. 7C8285, RACKS and CROSSOVERS. Adjusting the

Squareness of the CROSSOVERS

Adjusting the Squareness of the RACKS

• cleaned completely

– SeethePREVENTIVEMAINTENANCE, Publication

No. 7C8289.

CROSSOVER TROUGHS

correct positions

WASH RESERVOIR

installed correctly

• correct positions

• rotate freely

• GUDGEONS

– no damage

– If necessary, install new ROLLERS.

GEARS, SPROCKETS, and IDLERS

• engage correctly

• not broken or worn

BEARINGS

no wear

SPRINGS and E-RINGS

not broken or missing

RACK ASSEMBLY

• DRIVE CHAIN

– tension

installed

Temperature setting of the DRYER

lowest possible setting to provide the best image quality

DRYER RACK

seated correctly

LOCKING TABS

correct positions

DRIVE GEAR on the DRYER RACK

no damage

Mechanical Diagnostics

7C8290 – 28JAN98 13

Page 14

DIAGNOSTICS

Artifacts and Wrong Film Densities

Possible Cause Check

Replenishment system Replenishment rates

correct setting

HOSES

• opened and round

• no obstructions

or air bubbles

HOSE CLAMPS

• tight

REPLENISHMENT PUMP

• operation

• calibration

Replenishment chemicals

• Change any chemicals that are:

– not mixed correctly

– exhausted

– contaminated

Note

When you mix chemicals:

• Mix a maximum of a 2-week supply of the DEVELOPER

RELENISHER.

• Follow all directions for mixing chemicals and solutions.

• Use a SPLASH GUARD and DRIP TRAY when you remove the

FIXER RACK from thePROCESSOR to prevent contamination ofthe

developer.

DEVELOPER and FIXER TANKS

• DRAIN VALVES

– completely closed

Recirculation system DEVELOPER and RECIRCULATION HOSES

• ORIFICES

– no obstructions

DEVELOPER FILTER

If necessary, install a new FILTER.

Movement of the solutions at the surface of the PROCESSOR TANKS

when you energize the PROCESSOR and the TANKS are full.

• If the solutions do not move, check:

– HOSES have no obstructions or air bubbles in the recirculation

system.

– RECIRCULATION PUMP operates.

– DEVELOPER FILTER is clean and in the correct position.

14 28JAN98 – 7C8290

Page 15

Possible Cause Check

RACK and CROSSOVER

ASSEMBLIES

RACKS and CROSSOVERS

• correct positions

• seated correctly

• cleaned completely

– SeethePREVENTIVEMAINTENANCE, Publication

No. 7C8289.

CROSSOVER TROUGHS and EVAPORATION COVERS

• correct positions

• TROUGHS

– clean

• TROUGH DRAINS

– no obstructions

WASH RESERVOIR

installed correctly

ROLLERS ROLLERS

• clean and not scratched

• correct positions

• rotate freely

• GUDGEONS

– no damage

– If necessary, install new ROLLERS.

DETECTOR ROLLERS

clean

GEARS, SPROCKETS, and IDLERS

• engage correctly

• no wear

BEARINGS

no wear

SPRINGS and E-RINGS

not broken or missing

DEVELOPER and FIXER RACK ASSEMBLIES

• DRIVE CHAINS

– correct adjustment of the tension

Drying system DRYER AIR TUBES

• clean

– If necessary, use a BOTTLE BRUSH and water to clean the

TUBES and SLOTS in the TUBES.

• BAFFLES

– installed

Temperature setting of the DRYER

• lowest possible setting to provide the best image quality

• exhaust for the PROCESSOR

– meets the specifications

– See the MULTILOADER 300 PLUS SITE SPECIFICATIONS.

Mechanical Diagnostics

7C8290 – 28JAN98 15

Page 16

DIAGNOSTICS

Possible Cause Check

Wrong water temperature Temperature of the water

Should be: 6.7 C (12 F) below the developer set point

Wash water Water flows through the WASH RACK

Holes in the WASH RESERVOIR

• clean

Ventilation system Exhaust for the PROCESSOR

• meets specifications

• See the MULTILOADER 300 PLUS SITE SPECIFICATIONS.

External EXHAUST HOSE

connected to the AIR EXHAUST

Internal EXHAUST HOSE

connected to the AIR EXHAUST

Wet Films

Possible Cause Check

Film and chemicals are not

compatible

Replenishment system Replenishment rates

Film

• compatible with selected system

• correct setting

HOSES

• opened and round

• no obstructions

HOSE CLAMPS

• tight

REPLENISHMENT PUMP

• operation

• calibration

Replenishment chemicals

• Change any chemicals that are:

– not mixed correctly

– exhausted

– contaminated

Note

When you mix chemicals:

• Mix a maximum of a 2-week supply of the DEVELOPER

RELENISHER.

• Follow all directions for mixing chemicals and solutions.

• Use a SPLASH GUARD and DRIP TRAY when you remove the

FIXER RACK from thePROCESSOR to prevent contamination ofthe

developer.

DEVELOPER and FIXER TANKS

• DRAIN VALVES

– completely closed

16 28JAN98 – 7C8290

Page 17

Mechanical Diagnostics

Possible Cause Check

Recirculation system Movement of the solutions at the surface of the PROCESSOR TANKS

when you energize the PROCESSOR and the TANKS are full.

• If the solutions do not move, check:

– HOSES have no obstructions or air bubbles in the recirculation

system

– RECIRCULATION PUMP operates

– DEVELOPER FILTER is clean and in the correct position

Drying system DRYER AIR TUBES

• clean

– If necessary, use a BOTTLE BRUSH and water to clean the

TUBES and SLOTS in the TUBES.

• BAFFLES

– installed

DRYER

• lowest possible setting to provide the best image quality

DRYER AIR EXHAUST

• no obstructions

• installed correctly

– See the Installation Instructions, Publication No. 5B9330.

DRYER HEATER

• operates correctly

DRYER RACK

• seated correctly

Wash water Water flows through the WASH RACK

Holes in the WASH RESERVOIR

• opened

– If necessary, clean theholes to prevent an overflowof water from

the TROUGHS into the DEVELOPER and FIXER TANKS.

7C8290 – 28JAN98 17

Page 18

Solution Levels

Possible Cause Check

Replenishment system Replenishment rates

• correct setting

HOSES

• opened and round

• no obstructions

REPLENISHMENT PUMP

• operation

• calibration

REPLENISHMENT TANKS

• quantity of solution

POPPET VALVES

• clean

• no damage

DEVELOPER and FIXER TANKS

• DRAIN VALVES

– no leakage

CROSSOVER TROUGHS

• correct position

• TROUGHS

– clean

• TROUGH DRAINS

– no obstructions

Mechanical Diagnostics

Publication History

Affected

Print Date Pub No. ECO No.

Jan. 98 7C8290 N/A All dg3488_1_28jan98.fm First Printing.

Pages File Name Notes

Kodak

and

X-Omat

are trademarks.

Printed in U.S.A. • dg3488_1.fm

EASTMAN KODAK COMPANY

Rochester, NY 14650

HEALTH IMAGING

Loading...

Loading...