Page 1

Installation Instructions: New A8 Cassette Interface BOARD

Part Number: SP9403701

Due to parts that have become obsolete, the A8 BOARD has been redesigned for use in

the following equipment:

Kodak X-Omat MULTILOADER 300

Kodak X-Omat MULTILOADER 300 PLUS

Kodak X-Omat MULTILOADER 7000

Kodak MINILOADER 2000

Kodak MINILOADER 2000P

* Mounting of the new A8 BOARD is identical to the old style.

* The A3 BOARD is integrated in the new A8 BOARD.

*The new A8 BOARD has firmware installed and can be configured for use with

Multiloaders 300/300PLUS, Multiloader 7000, Miniloaders 2000/2000P.

Important:

than V4.0 installed, it must be upgraded during the installation of the new A8 BOARD.

Mod 52: Part Number 9229220

Multiloader/Miniloader: Must have the following minimum version Operation Software.

XML7000 V1.21 Floppy PN: SP9409351 CD PN: -ML2000/P V2.41 Floppy PN: H9312416 CD PN: 1F2436

XML300Plus V5.22 Floppy PN: H9212526 CD PN: --

XML300 V4.10 Floppy PN: H9214106 CD PN: --

Software: Other sources to obtain and download Multiloader/Miniloader software.

For FE’s in EPMAR: Lotus Notes Database, HIS EPMAR Prof Serv on Great Britain.

For US Distributors: Web site www.kodak.com/go/hidistrib (see your service manager

for a password)

Install the new A8 BOARD as follows:

If a MULTILOADER 300 has operation and bootstrap software that is less

1. Note the current Operation Software installed in the Multiloader/Miniloader.

2. De-energize the equipment.

3. Remove: COVERS AND PANELS

4. Disconnect from existing A8 BOARD: CABLES AND CONNECTORS

5. Remove and discard old A3 + A8 BOARDS.

6. Install new A8 BOARD using existing hardware.

7. Connect to new A8 BOARD: CABLES AND CONNECTORS

12/17/2002

1

Page 2

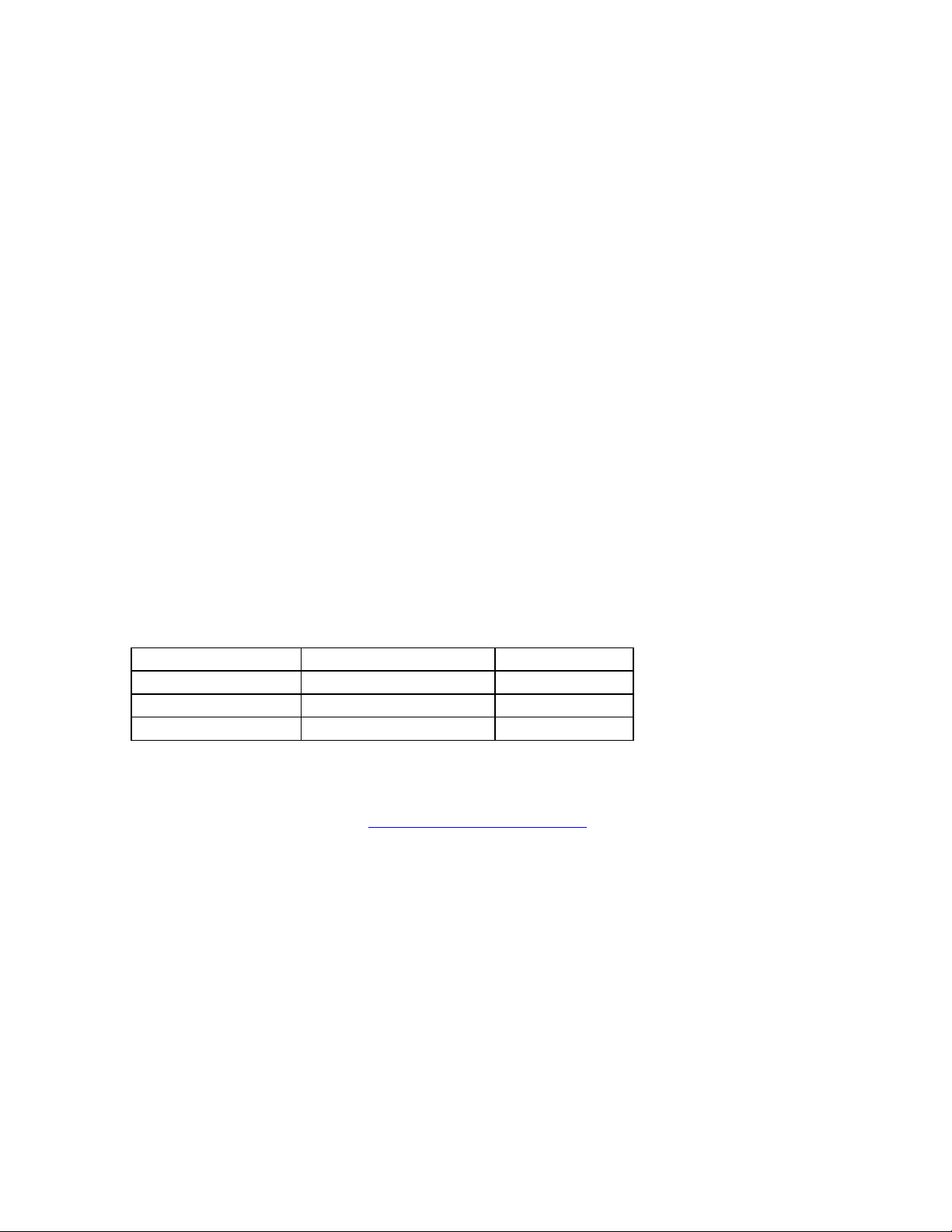

8. Set the S3 DIP SWITCHES on the new A8 BOARD as follows:

Multiloader

Type

XML7000 ON ON ON N.A.

ML2000/2000P OFF ON ON N.A.

XML300 ON OFF ON N.A.

XML300 Plus OFF OFF ON N.A.

9. Set DIP SWITCH S2-3 – OFF (Not Used)

10. For XML7000/(ML2000P SN >6752): Set Jumpers for B20/CPUVO

(B20 with no mirror)

11. For B20 with Mirror, XML300/300Plus/ML2000/(ML2000P SN 6752

and below): Set Jumpers

A8X2 to 1-2

A8X3 to 1-2

A8X50-2 to A8X52-2

12. ML2000P B9/CPI sensor adjustment: test points P1, P21 GNDPE

13. Energize: MULTILOADER/MINILOADER

14. Using LAPTOP COMPUTER download Operating Software noted on

15. Check MULTILOADER/MINILOADER for correct operation.

S3-1 S3-2 S3-3 S3-4

Set DIP SWITCH S2-4—OFF (Not Used)

Set DIP SWITCH S2-1: Same setting as DIP SWITCH 1 of old A8 BOARD

Set DIP SWITCH S2-2: Same setting of DIP SWITCH 2 of old A8 BOARD

A8X2 to 2-3

A8X3 to 2-3

A8X50 (Not Used)

A8X52 (Not Used)

With no film in processor interface adjust R100 to <500mV.

With fresh film blocking B9 sensor voltage should be >3.5VDC. If value

cannot be reached, remove film from B9 sensor and readjust R100 closer to

500mV. Install: COVERS and PANELS

Step 1, Page 1 to the new A8 BOARD. If software version is being

upgraded download new version of Operation Software.

2

Page 3

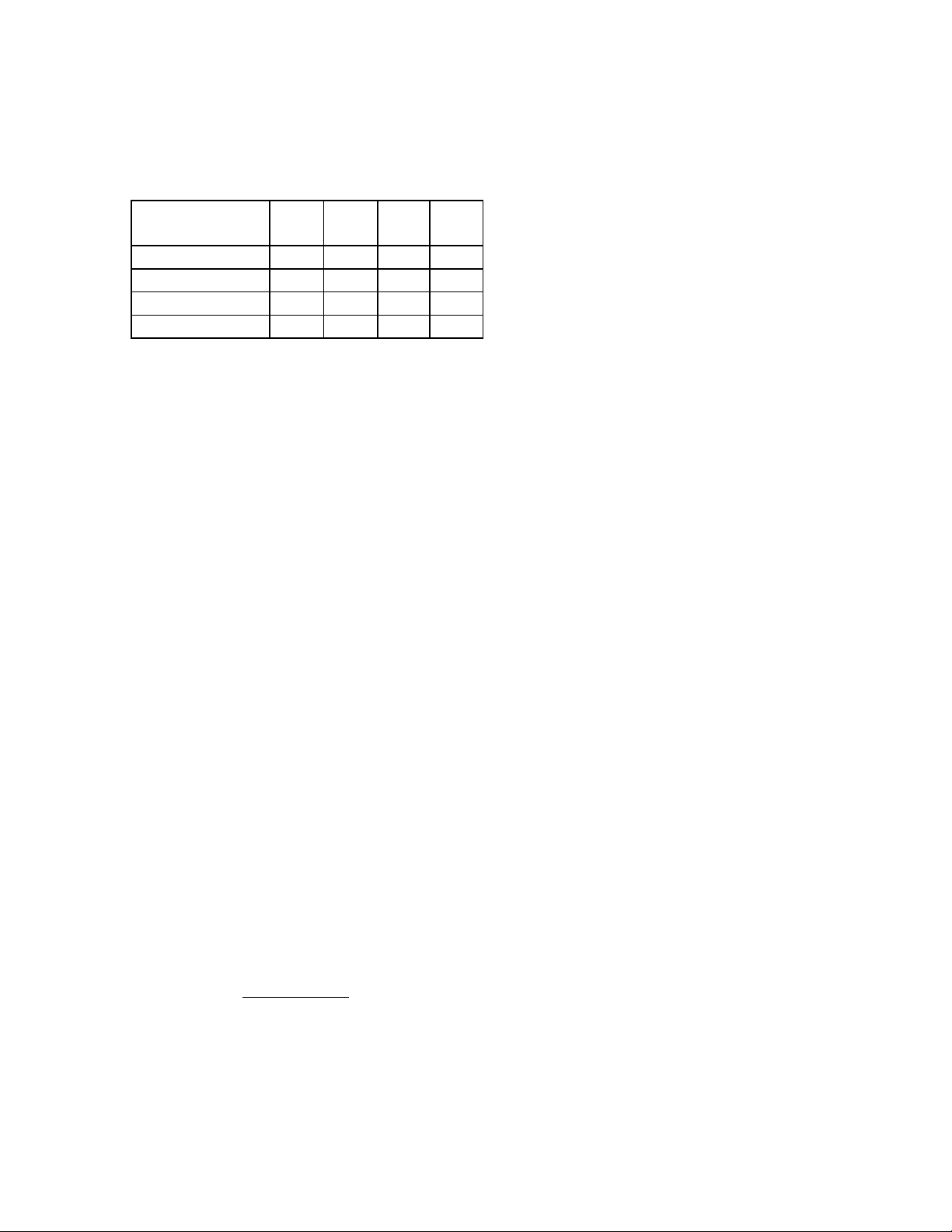

NOTE: When installing new A8 BOARD to a XML300/300 PLUS,

MINILOADER 2000/2000P new test points and circuit board diagram must

be used for service.

P1 (green) R100 Adj sensor input B22/CT2L

P2 (green) sensor input B17/CPUEF

P3 (green) sensor input B18/CPUER

P4 (green) R101 Adj sensor input B22/CT2R

P5 (green) sensor input B20/CPUVO

P6 (red) VµP

P7 (red) VCC (+5 Vdc) micro process voltage

P8 (green) _RESET

P9 (red) Vpe10 (+10 Vdc) Unreg

P10 (red) Vpe30 (+30 Vdc) Unreg

P11 (red) Vpe31 (+24 Vdc) Reg

P12 (green) FPGA PA0

P13 (red) Vpe11 (+5 Vdc) Reg

P14 (green) R70 ADUST

P21 (black square) GNDpe peripheral ground

P22 (black) GNDuP micro controller voltage ground 12/17/2002

3

Page 4

DIAGRAMS

CASSETTE INTERFACE BOARD A8

21 34

21 34

21 34

21 34

21 34

21 34

21 34

X7

X27 X28

X21 X22 X25

X26

X9X10 X11 X14 X15

X17 X18 X19 X12 X13

X16

21 34

21 34

21 34

21 34

21 34

21 34

21 34

21 34

21 34

21 34

21 34

21 34

21 34

21 34

21 34

21 34

21 34

21 34

+5Vdc

+5Vdc

+5Vdc

+5Vdc

+5Vdc

+5Vdc

+5Vdc

+5Vdc

+5Vdc

+5Vdc

+5Vdc

+5Vdc

+5Vdc

+5Vdc

+5Vdc

+5Vdc

+5Vdc

+5Vdc

B22

Off

B20

Vacuum

Tilt

B19

Suckerbar

B18

Film Pick up

Endsw. Rear

B17

Film Pick Up

Endsw. Front

B16

B12

B10

B7

B5

B3

H186_0019EC_

Film Type 2

Detection Right

21 34

21 34

Cassette

Really Open

Cassette

Centered Right

Endsw. Open

Centering Bars

Cassette In

Endsw. Right

Cassette In

Endsw. Left

Endsw. Open

Cass. Input Flap

B21

Film Type 2

21 34

21 34

B15

Cass. Opener

B11

Cassette

B9

Centering Bars

B6

Cassette In

B4

Cass. Input Flap

B2

Cassette

21 34

Detection Left

21 34

Endsw. Open

21 34

Centered Left

21 34

Closed Endsw.

21 34

Endsw. Middle

21 34

Endsw. Closed

21 34

Registration

7

56

912 11 13 14 15

1718 19 20 10

34

2

8

16

1

X55

-

+

-

+

-

+

-

+

-

+

-

+

-

+

GndPE

-

+

-

+

-

+

-

+

-

+

-

+

-

+

-

+

+

-

GndPE

GndPE

GndPE

GndPE

GndPE

GndPE

GndPE

GndPE

GndPE

GndPE

GndPE

GndPE

GndPE

GndPE

GndPE

GndPE

+

-

GndPE

P8

V1

U29

B24

+24Vdc

Cassette

X6

S1

RESET

BOOT

RED

-

+

+5Vdc

X23

4

4

Registration 2

TO A10/1

42134

X5

+5Vdc

X2

P12

2

1

3

S3

OFF ON

P5 B20

P4 R101 ADJUST

P3 B18

P2 B17

P1 R100 ADJUST

P6

P7

GndPE

X33

213456789

213

213

TO A10/2

+5Vdc

213

4

213

X8

+5Vdc

432

1

A16X1

SENSOR

TO HUMIDITY

TO A10/3

1

U31

4

2

4

1

3

S2

OFF ON

R101

P4

1

X53

P12 PA0

P11 VPE31 (+24Vdc) Reg.

P10 VPE30 (+30Vdc) Unreg.

P9 VPE10 +10Vdc) Unreg.

P8 RESET

P7 VCC (+5Vdc) Micro Processor Voltage

P6 V

P22

P10

P11

RS232

X49

4

A1 X1

FROM

FROM

120 VAC

POWER

P5

P22 GND

P21 GNDPE

P14 R70 ADJUST

P13 VPE11 (+5Vdc) Reg..

P13

P9

120VAC

213

X3

B23

SUPPLY

AND TO A4 X28

432

P14

P1

Top Cover

Interlock Switch

X3

TO HUMIDIFIER

1

4

X36

A16X2

+5Vdc

R70

R100

1

P3

P2

X50 X52

P21

BLK

-

+

+5Vdc

X31

213

4

TO A9 X1

213

11

GndPE

X34

4

X35

2

+5Vdc

213

TO A9 X3

1

21

+24Vdc

X37

21

+24Vdc

X38

+30Vdc

X39

21 21

+30Vdc

X40

120VAC

21 321 3

X44

120VAC

X48

120VAC

21 321 3 21 3

X47

120VAC

X46

120VAC

X45

{

X300

FROM

Y3

34

21

14

13

X55

X40

X60

SUPPLY

POWER

Blowing

Cassette

Y5

Sucking

Cassette

Y7

Suckerbar

21

X39

Y4

Cassette

21

76 8345

21 3 21 3 21 3

Tilting

Opener

Y6

M1 M3 M4 M6 M7

Cassette

Sucker Venting

M7

Motor

Roller

M6

Cassette

Film Pick Up

CASSETTE INTERFACE BOARD A8

M4

Cassette

Centering

M3

Finger

Holding

M1

Cassette

Input Flap

18 12OCT01 – 3H9265

Loading...

Loading...