Page 1

SERVICE CODES: 3211, 3212, 3234 & 3235

NEWSLETTER MINILOADER 1 & 1M

CES TECHNICAL NEWSLETTER MINILOADER 1 & 1M

Health Sciences Products

FOR KODAK PERSONNEL USE ONLY

ISSUE: No 4/DECEMBER/1992

TABLE OF CONTENTS PAGE

25. MODIFICATION M33 (MINILOADER 1) 2

26. MODIFICATION M34 (MINILOADER 1) 2

27. MODIFICATION M01 (MINILOADER 1M) 2

28. PHOTOCELL FC8 IN VER TICAL INTERFACE 3

29. CAM MOTOR AND SPROCKET 3

30. USING MINILOADER 1 MAGAZINES IN MINILOADER 1M 4

31. MAKING PRINTOUTS USING THE DICONIX 180Si 5

32. NEW SOFTW ARE FOR MINILOADER 1M 5

33. LANGUAGE ERRORS 6

34. CASSETTE P ATCHING 7

35. CHECKING CAPACITOR ON PCB 301

(MINILOADER 1M ONL Y) 8

36. MODIFICATION M02 (MINILOADER 1M) 9

© KODAK Ltd. England

1

No. 4/DECEMBER/1992

Page 2

NEWSLETTER MINILOADER 1 & 1M

25. MODIFICATION M33 (MINILOADER 1)

The PRINTED CIRCUIT BOARD PCB 101B, has been replaced with a new PCB 101C to further improve

the reliability of the MINILOADER. The new PCB has a SOLID STATE RELAY to replace TIMER T6.

This modification is to prevent the CONVEYOR BELT from running in reverse at the end of a cycle. It

replaces modification M28.

When the new PCB 101C is fitted, the old PCB must be returned, otherwise your country will be charged for

the modification.

TYPE 1 SELECTIVE. PART NUMBER 3090033 AVAILABLE NOW.

SERIAL NUMBERS AFFECTED :-

1162 - 1412 PLUS 1101 - 1161 with a serial number suffix M.

26. MODIFICATION M34 (MINILOADER 1)

This modification changes the speed of the CAM MOTOR to stop CAM SYSTEM MALFUNCTIONS, to

prevent damage to the CAM SYSTEM RELAYS, and lengthen the life of the CAM MOTOR. The CAM

MOTOR is run at a slower speed, and the cycle time is maintained by changing the gearing of the CAM

SYSTEM.

TYPE 1 SELECTIVE PART NUMBER 30090034 AVAILABLE NOW

SERIAL NUMBERS AFFECTED :-

ALL MINILOADER 1's

27. MODIFICATION M01 (MINILOADER 1M)

This modification changes the speed of the CAM MOTOR to stop CAM SYSTEM MALFUNCTIONS, to

prevent damage to the CAM SYSTEM RELAYS, and lengthen the life of the CAM MOTOR. FILM handling is also improved. This modification will also prevent spurious blowing of the CAM MOTOR FUSE.

No parts are required to carry out this modification, the MODIFICATION INSTRUCTIONS are available as

PUBLICATION MA3234-M01.

TYPE 1 REQUIRED PART NUMBER - NO PARTS REQUIRED AVAILABLE NOW

SERIAL NUMBERS AFFECTED :-

1500 - 1530

1700 - 1718

No. 4/DECEMBER/1992

2

© KODAK Ltd. England

Page 3

NEWSLETTER MINILOADER 1 & 1M

28. PHOTOCELL FC 9 IN VER TICAL INTERFACE.

On MINILOADER 1, the PHOTOCELL FC9 ( FILM jammed at the bottom of the VERTICAL INTERFACE CHUTE ) had 4 WIRES connected to it, as the RECEIVER part was in series with PHOTOCELL

FC7.

On MINILOADER 1M, the PHOTOCELL FC9 has its own SOCKET on PCB 303. Therefore the PHOTOCELL has only 3 CONNECTIONS, as the common part of the SENDER and RECEIVER are connected

together like all other PHOTOCELLS.

All MINILOADERS left the factory with a VERTICAL INTERFACE with the correct type of FC9 CABLE

included. However, some VERTICAL INTERFACES have been mixed up in country stock, so it is possible

that you may receive an INTERFACE with the wrong CABLE.

For MINILOADER 1, the CABLE (4 WIRE) for PHOTOCELL FC9 is 30016320

For MINILOADER 1M, the CABLE (3 WIRE) for PHOTOCELL FC9 is 30016324

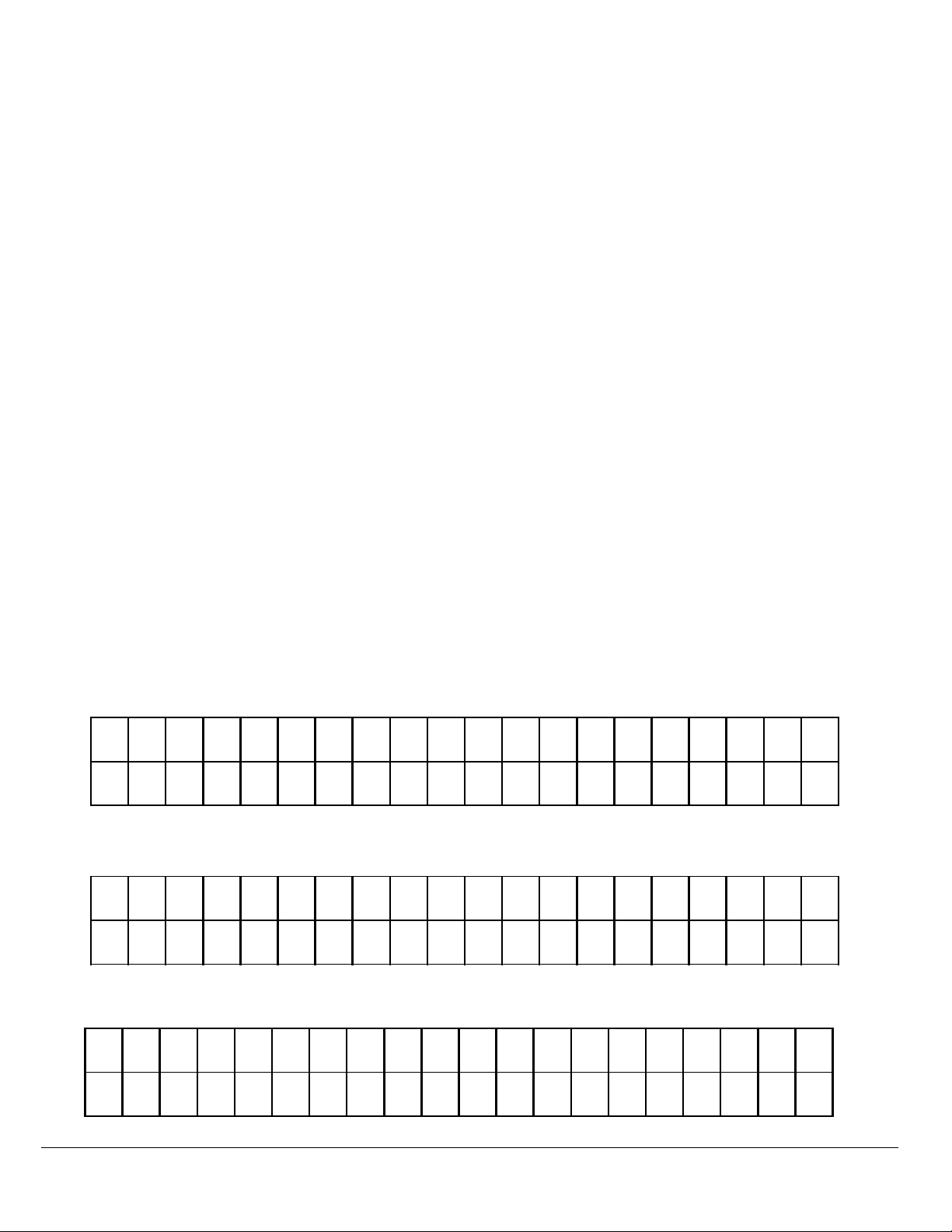

The connections of the PHOTOCELL LEADS to the PLUGS, after the LEADS have been passed through the

STRAIN RELIEF BUSH, are as shown below for the two types of MINILOADER.

For MINILOADER 1

Red

Blue

White

Screen

For MINILOADER 1M

Screen

White

Red

29. CAM MOTOR AND SPROCKET.

Please not that the part number of the CAM MOTOR for all MINILOADERS is 30015658. This MOTOR

includes the SHAFT extension and the CLUTCH.

The MOTOR 30015513 does not include these parts, it is used for the CONVEYOR BELT drive.

Please amend page PL21 of your PARTS LIST PL3211/3212 (August 91) accordingly.

Make sure you use the correct SPROCKET on the CAM MOTOR.

MINILOADER 1M 30013132 SPROCKET (10 TEETH)

MINILOADER 1 (AFTER MOD M34) 30013391 SPROCKET (14 TEETH)

© KODAK Ltd. England

3

No. 4/DECEMBER/1992

Page 4

NEWSLETTER MINILOADER 1 & 1M

30. USING MINILOADER 1 MAGAZINES IN MINILOADER 1M.

If an existing MINILOADER RECEIVING MAGAZINE is to be used in a MINILOADER 1M as a SERIAL

UNLOADING MAGAZINE, a REFLECTOR (use 3 x 91194551) needs to be added to the MAGAZINE lid

as shown below. This change is necessary as the MINILOADER 1M detects a SERIAL MAGAZINE by the

means of this REFLECTOR, and will not start SERIAL MODE unless the REFLECTOR is detected.

Also, to take advantage of the MAGAZINE OPEN detection capability of MINILOADER 1M, a second

REFLECTOR 30023195 should be fitted as shown on the side of the MAGAZINE. If any supply MAGAZINES, originally from a MINILOADER 1 are being used on MINILOADER 1M, this MAGAZINE OPEN

REFLECTOR should also be fitted to the old MAGAZINES.

Reflector 30023195

for magazine open

Reflector

3 x 9194551

No. 4/DECEMBER/1992

4

© KODAK Ltd. England

Page 5

NEWSLETTER MINILOADER 1 & 1M

31. MAKING PRINTOUTS WITH THE DICONIX 180Si.

For the Kodak DICONIX 180 Si printer set the configuration as shown below.

If these settings are used, the printer will operate with MULTILOADER 2, MINILOADER 1M, 2 and 2

PLUS.

New Printer Settings

(1) Emulation = EPSON FX-85

(2) Page Length Not important

(3) Perforation Skip = Off

(4) Character Set = USA or UK

(5) Character Default Not important

(6) Carriage Return = CR

(7) Line Feed = LF+CR

(8) Graphic Print Dir Not important

(9) LF/Graphic/Pitch Mode = Normal

(10) Protocol = RDY/BSY

(11) Parity = None

(12) Data Length = 7 bits

(13) Baud Rates (Stop Bits) = 1200(1)

32. NEW SOFTWARE FOR MINILOADER 1M.

A new EPROM is available for MINILOADER 1M. The new software corrects some errors in the program.

(1) A CASSETTE which failed to open is now ejected immediately.

(2) After a TILT SYSTEM malfunction, the MINILOADER can now be reset without powering down.

(3) The SERIAL BUTTON has no effect on the STAND-ALONE MINILOADER.

(4) Message "SUPPLY MAGAZINE NEARLY EMPTY" no longer occurs when in SERIAL MODE.

(5) When the film has been removed after a FILM jam in the CHUTE, the message can now be cleared

without powering down.

(6) An incorrect spelling of EMPTY has been corrected.

(7) All designed languages are now present.

(8) Several errors on the PRINTOUT and in SERVICE MODE have been corrected.

The SOFTWARE is available in two VARIANTS :-

PART NO.

PS1.1 4/6/92 VARIANT 1 (ENGLISH/ITALIAN/NORWEGIAN) 30015959

PS1.1 4/6/92 VARIANT 2 (ENGLISH/SPANISH/PORTUGUESE) 30015960

The new SOFTWARE is needed on SERIAL NUMBERS 1500 - 1524 & 1700 - 1711

© KODAK Ltd. England

5

No. 4/DECEMBER/1992

Page 6

NEWSLETTER MINILOADER 1 & 1M

33. LANGUAGE ERRORS.

Please report any language errors to your country specialist by giving:-

a) The correct translation.

b) The existing incorrect translation with the errors highlighted.

c) If possible give the English version of the message.

Please use a copy of the FORM below to report any errors. Use a separate copy for every incorrect message.

VERSION NUMBER OF THE SOFTWARE :-

VARIANT NUMBER OF THE SOFTWARE :-

DATE REPORT IS MADE :-

YOUR NAME :-

YOUR ADDRESS :-

Send the FORM via your COUNTRY SPECIALIST to :-

W F CRICHTON, KODAK LTD, C/O DEPT. A3M, KODAK HOUSE, PO BOX 66, HEMEL HEMPSTEAD, HP1 1JU, ENGLAND.

Correct translation

Incorrect translation

English version of message

No. 4/DECEMBER/1992

6

© KODAK Ltd. England

Page 7

NEWSLETTER MINILOADER 1 & 1M

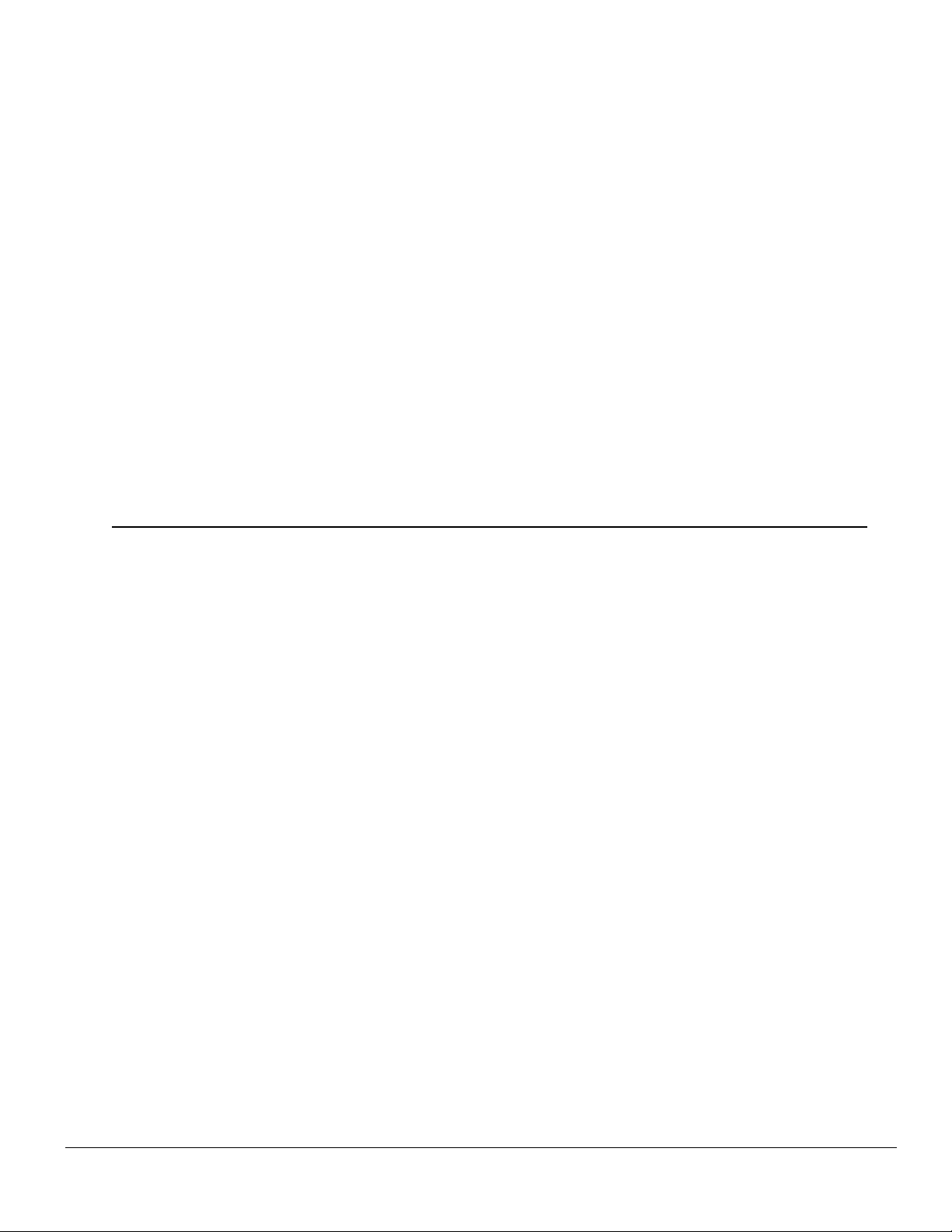

34. CASSETTE P ATCHING.

All MINILOADER CASSETTES must be patched correctly otherwise reliable operation is impossible. The

CASSETTES should be fitted with 3 PATCHES as shown below using TOOLS 9194531 & 9194511. The

correct PATCHES are PART NUMBER 9194551, REFLECTIVE FOIL 8 x 15 mm.

It is advisable to replace the PATCHES on the OUTSIDE of the CASSETTE on every PM visit. It is also

advisable to supply your customer with a small quantity of the PATCHES, and train them how to replace the

exterior PATCHES if the CASSETTE is repeatedly ejected.

PATCH 1

PATCH 2

PATCH 3

© KODAK Ltd. England

7

No. 4/DECEMBER/1992

Page 8

NEWSLETTER MINILOADER 1 & 1M

35. CHECKING CAP ACITOR ON PCB 301 (MINILOADER 1M ONLY)

On some PCB 301's (Microprocessor PCB), CAPACITOR C112 has been incorrectly inserted. The overlay

on the PCB is incorrect, the CAPACITOR should be inserted as shown below.

CAPACITOR C112 is part of the MICROPROCESSOR POWER SUPPLY, and if the CAPACITOR is

fitted incorrectly, the machine will be susceptible to mains voltage transients and noise.

On the next SERVICE CALL to a MINILOADER 1M, please check the orientation of this CAPACITOR

and correct if necessary.

CAPACITOR C112 should be inserted with the POSITIVE end as shown here.

No. 4/DECEMBER/1992

8

© KODAK Ltd. England

Page 9

NEWSLETTER MINILOADER 1 & 1M

36. MODIFICATION M02 (MINILOADER 1M)

Modification M02 is a modification to reduce the speed of the TILT MOTOR by fitting a different GEARBOX. The new GEARBOX has a ratio of 80:1 compared to the 40:1 ratio of the old GEARBOX. At present

the tilt speed control POTENTIOMETER setting is critical. If the speed is set too low, the TILT MOTOR

can stall and give ERROR CODE *23*. If the speed is set too high the TILT MOTOR can over-run and

cause the FILM to be caught on the edge of the MAGAZINE or on the MULTIPLE FILM DETECTOR. On

some units, it was impossible to obtain a satisfactory setting.

TYPE 1 PART NUMBER 30092102 AVAILABLE JANUARY 92

THE OLD TILT MOTOR ASSEMBLY MUST BE RETURNED TO STUTTGART, OTHERWISE YOUR

COUNTRY WILL BE CHARGED DM 500 FOR THE KIT.

SERIAL NUMBERS AFFECTED :-

1500 - 1531 and 1700 - 1718

Send Newsletter Articles to:

Bill Crichton

Kodak Ltd.

Customer Equipment Services

c/o Dept. A3m

PO Box 66

Kodak House

Hemel Hempstead

HP1 1JU

ENGLAND

© KODAK Ltd. England

9

No. 4/DECEMBER/1992

Page 10

© CUSTOMER EQUIPMENT SERVICES, KODAK LTD., ENGLAND

Loading...

Loading...