Page 1

Publication No. XP 3239-2

Issue 2

March 1995

HUMIDIFIER SERVICE MANUAL

for all

Kodak MINILOADER'S

M8_FIG10.TIF

Use this Publication for:All Miniloaders fitted with the Humidifier Kit, and Low Voltage Miniloaders Service Codes 3419, 3420 & 3421

HEALTH SCIENCES DIVISION

© Kodak Ltd. 1995

Page 2

XP 3239-2 HUMIDIFIER ASSEMBLY

CAUTION

This equipment includes parts and assemblies sensitive to damage from electrostatic

discharge. Use caution to prevent damage during all service procedures.

© Kodak Ltd.

PLEASE NOTE

The information contained herein is based on the experience and knowledge

relating to the subject matter gained by Kodak Ltd. prior to publication.

No patent licence is granted by this information.

Kodak reserves the right to change this information without notice, and makes no warranty,

express or implied, with respect to this information. Kodak shall not be liable for any loss or

damage, including consequential or special damages, resulting from the use of this information,

even if loss or damage is caused by Kodak's negligence or other fault.

Page XP/2-2

March 1995

Page 3

HUMIDIFIER ASSEMBLY

THEORY GUIDE 4

INSTALLATION INSTRUCTIONS 6

SERVICE 7

XP 3239-2

CONTENTS

PAGE

PCB 208 CIRCUIT 10

PCB 209 CIRCUIT 12

PCB 208 OVERLAY 13

PCB 209 OVERLAY 14

PARTS LIST 15

March 1995

Page XP/2-3

© Kodak Ltd.

Page 4

XP 3239-2 HUMIDIFIER ASSEMBLY

THEORY GUIDE.

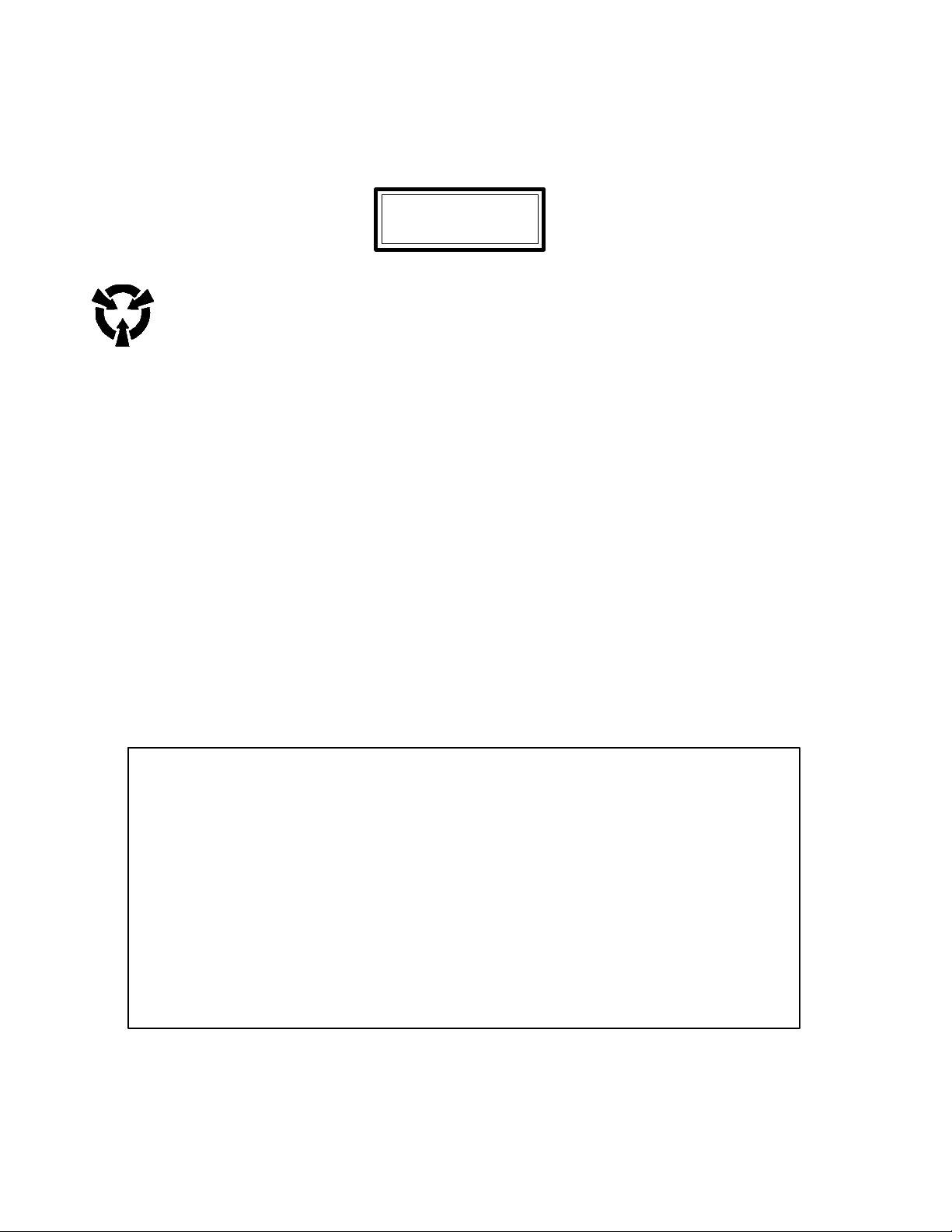

The HUMIDIFIER contains the following parts. See the DIAGRAMS on the opposite page.

1) A water supply MANUAL VALVE - this VALVE incorporates a RESTRICTOR which can be removed

if using a low pressure supply - such as a BOTTLE.

2) A water inlet SOLENOID VALVE which is energised when the HUMIDIFIER requires water.

3) A water level FLOAT SWITCH which controls the water level in the WATER BATH.

4) A WATER BATH to hold water for the PAPER ELEMENT.

5) A PAPER ELEMENT which draws water up in front of the WET FAN.

6) A WET FAN which is switched on when the humidity level inside the MINILOADER is lower than the SET

POINT.

7) A DRY FAN which runs when the WET FAN is switched off to maintain a positive pressure in the

MINILOADER.

8) An OVERFLOW DRAIN which operates if the water level control fails.

9) A SAFETY OVERFLOW CHUTE which prevents water entering the MINILOADER.

10)A MANUAL DRAIN VALVE which allows the drainage of the HUMIDIFIER for service or machine

transport.

11)A DRAIN HEADER which collects all water from the OVERFLOWS and the DRAIN VALVE.

This DRAIN HEADER MUST be connected to a customer drain or a bottle if the water supply is from a

bottle.

12) A HUMIDITY SENSOR which measures the humidity inside the MINILOADER.

13) A MICROPROCESSOR CONTROL PCB which monitors and controls the functions of the

HUMIDIFIER.

14) A two digit DISPLAY which shows the current HUMIDITY inside the MINILOADER.

15) CONTROL SWITCHES which are used to set the desired humidity level.

16) An AIR FILTER to prevent dust entering the HUMIDIFIER.

© Kodak Ltd.

Page XP/2-4

March 1995

Page 5

HUMIDIFIER ASSEMBLY

XP 3239-2

1 2

3

WATER IN

11

DRAIN

8

10

5

7

6

4

WATERFLO.TIF

9

16

15

M8_FIG7.TIF

10

11

14

2

6

5

7

12

1

13

4

9

March 1995

Page XP/2-5

8

3

M8_FIG10.TIF

© Kodak Ltd.

Page 6

XP 3239-2 HUMIDIFIER ASSEMBLY

INSTALLATION INSTRUCTIONS.

WATER SUPPLY

The incoming water supply specification is:-

PRESSURE RANGE 0.3 to 5 Bar. Install a REGULATOR if required.

TEMPERATURE 4 to 29 oC Tempered water required if temperature of incoming water is below 4 oC.

VOLUME APPROX. 1Lite per 24 hours approximately (depending on room humidity).

A 50 micron WATER FILTER should be provided by the customer.

Connect the water supply to the WATER INLET. If a BOTTLE is being used to supply the inlet water, the

RESTRICTOR should be removed. If the water supply is at mains pressure, the RESTRICTOR MUST be fitted,

otherwise water can splash inside the MINILOADER when the SOLENOID VALVE opens.

The drain must be connected. Normally water only flows from the unit when the HUMIDIFIER is drained for service

purposes or if the MINILOADER is to be moved, but in the event of a failure of the SOLENOID VALVE the drain is

required to have a capacity of 1 Litre/minute.If the water supply is at mains, the drain should be connected to a fixed

customer drain.

If the water supply is from a BOTTLE, a larger size collecting BOTTLE than the inlet BOTTLE should be used.

IMPORTANT:- If the MINILOADER is in a mobile unit, or is mounted on a movable STAND, the customer

must be informed that the water must be turned off and the HUMIDIFIER drained using the DRAIN VALVE,

before the MINILOADER is moved. If the MINILOADER is not going to be used for some time, it is advisable

to drain the HUMIDIFIER of water to prevent bacterial growth in the PAPER ELEMENT.

When the MINILOADER is switched on, the HUMIDIFIER is also turned on. The DISPLAY will show the current

humidity inside the MINILOADER. If the humidity inside the MINILOADER is greater than the preset value, only the

DRY FAN will run. If the humidity is below the preset value, the SOLENOID VALVE opens, the DRY FAN stops and

the WET FAN starts to increase the humidity.

If the humidity inside the MINILOADER is different (either higher or lower) from the preset value after 10 minutes, the

figures on the DISPLAY will flash. If the humidity inside is higher than the preset value nothing can be done, but if the

humidity is lower, check the water supply, FLOAT VALVE and the PAPER ELEMENT.

The speed of the WET and DRY FANS (and therefore the noise made by them) can be controlled.

For LOW VOLTAGE machines the speed is contolled by POTENTIOMETERS on PCB 207. The recomended setting

is R730 (for the DRY FAN) turn fully clockwise then back 5 turns anf R728 (for the WET FAN) turn fully clockwise

then back 3 turns.

For KIT HUMIDIFIERS the speed of both FANS are adjusted at the same time by a POTENTIOMETER mounted on

the FAN ASSEMBLY. See the drawing on PAGE XP/2-26.

© Kodak Ltd.

Page XP/2-6

March 1995

Page 7

HUMIDIFIER ASSEMBLY

XP 3239-2

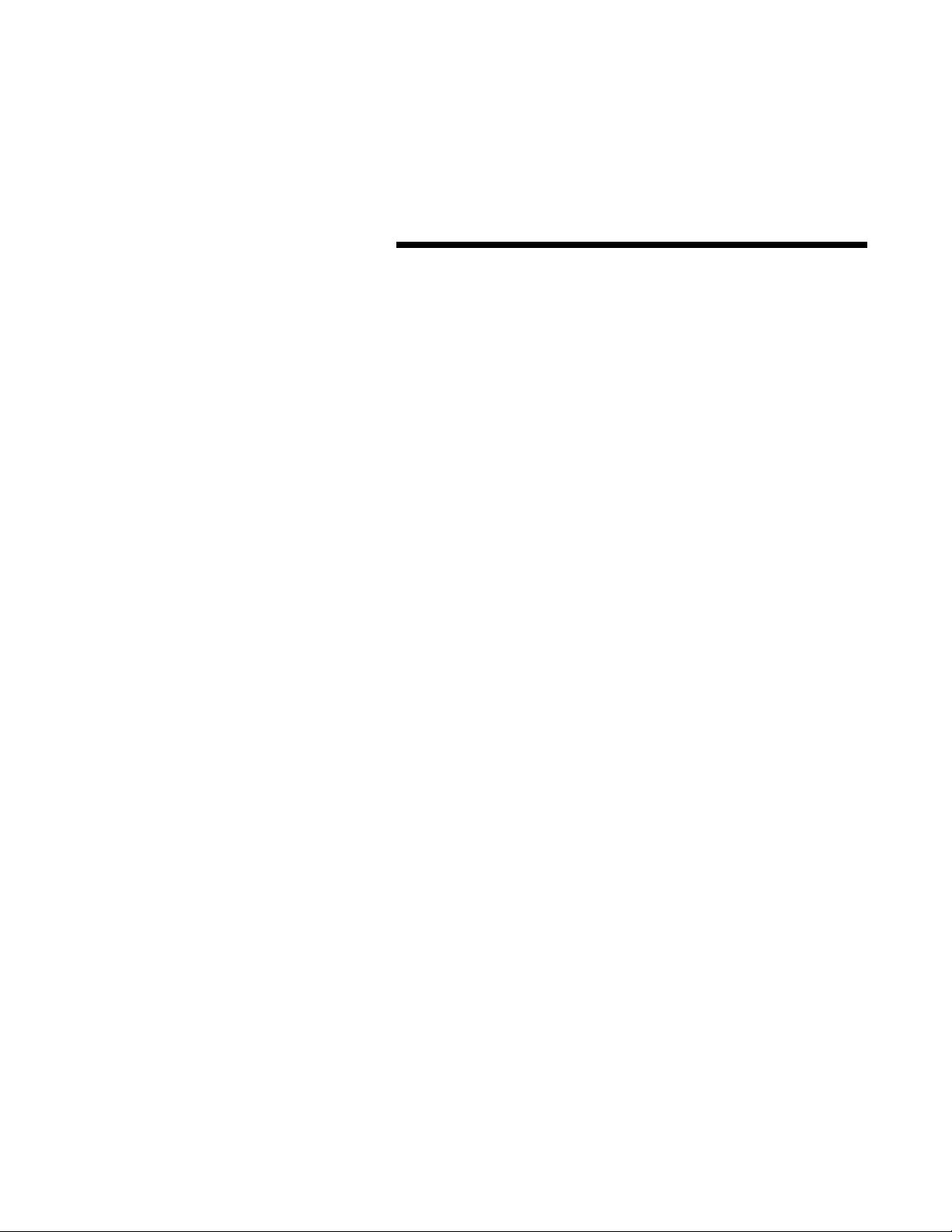

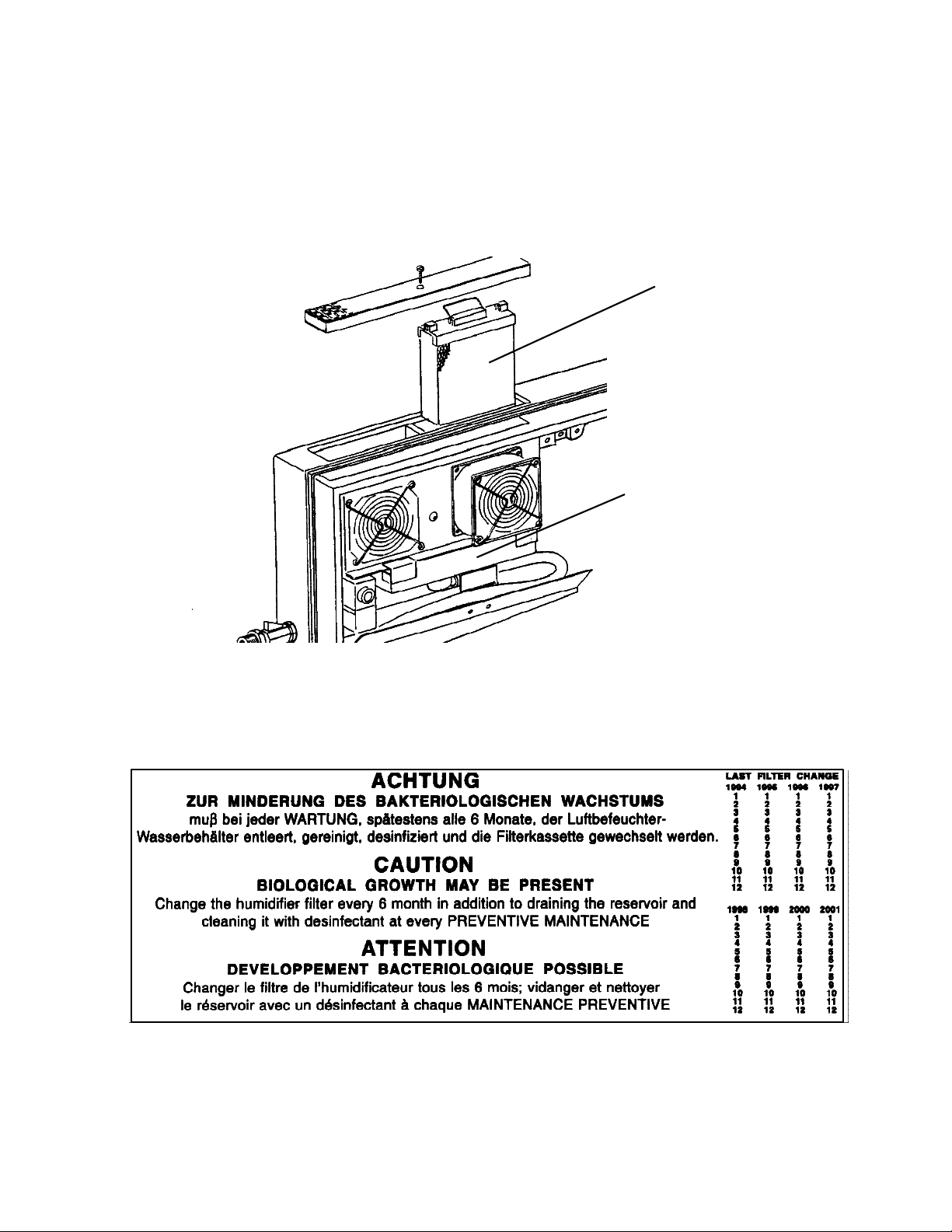

SERVICE

Routine service of the HUMIDIFIER requires that the unit is thoroughly cleaned out when a PM (Preventative

Maintenance) CALL is carried out. Disinfectant or bleach should be used. The PAPER ELEMENT should be changed

if necessary, and must be changed if it is more than six months old. The LABEL inside the HUMIDIFIER should be checked

with the date of the ELEMENT change.

Replace ELEMENT

Clean out WATER BATH

M8_FIG10.TIF

LABEL.TIF

March 1995

Page XP/2-7

© Kodak Ltd.

Page 8

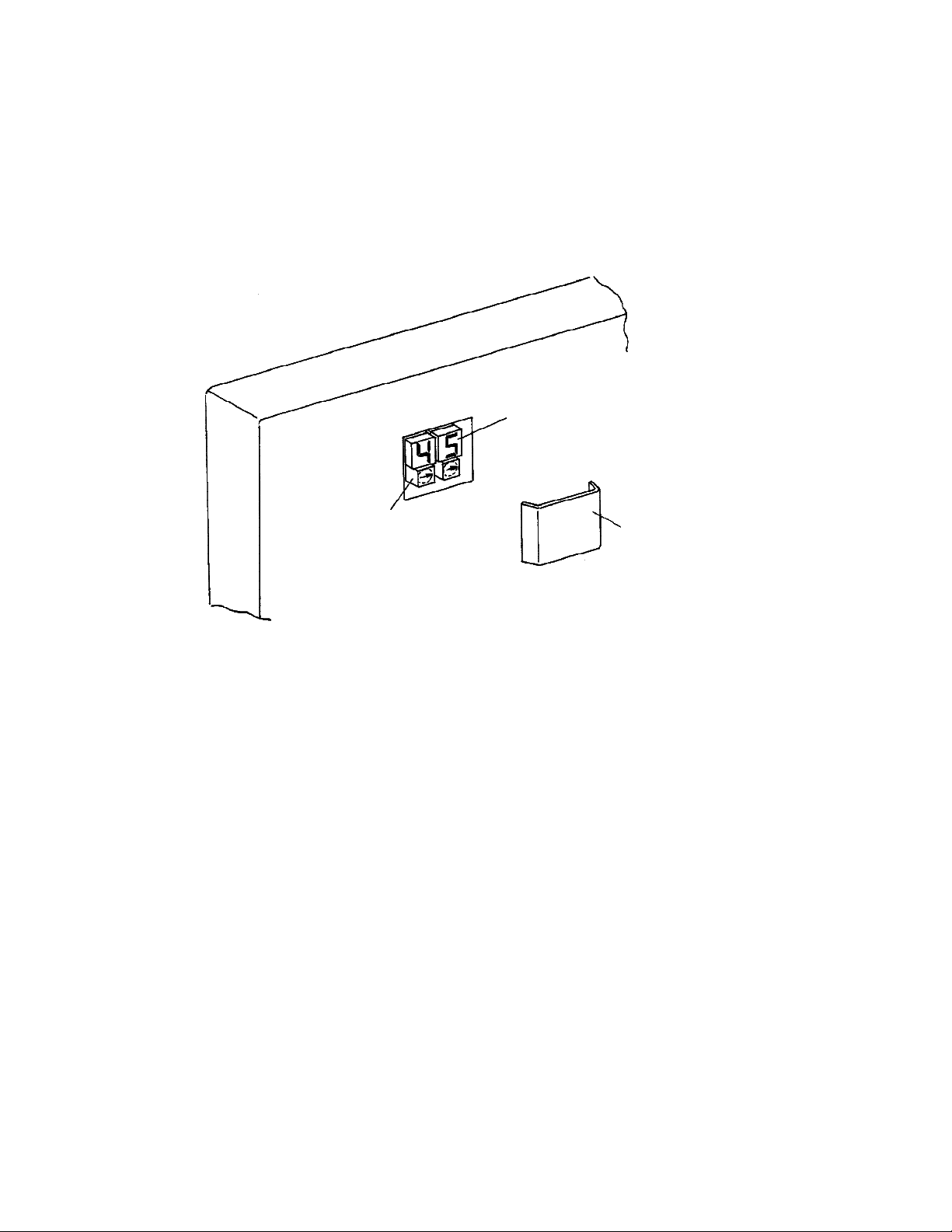

XP 3239-2 HUMIDIFIER ASSEMBLY

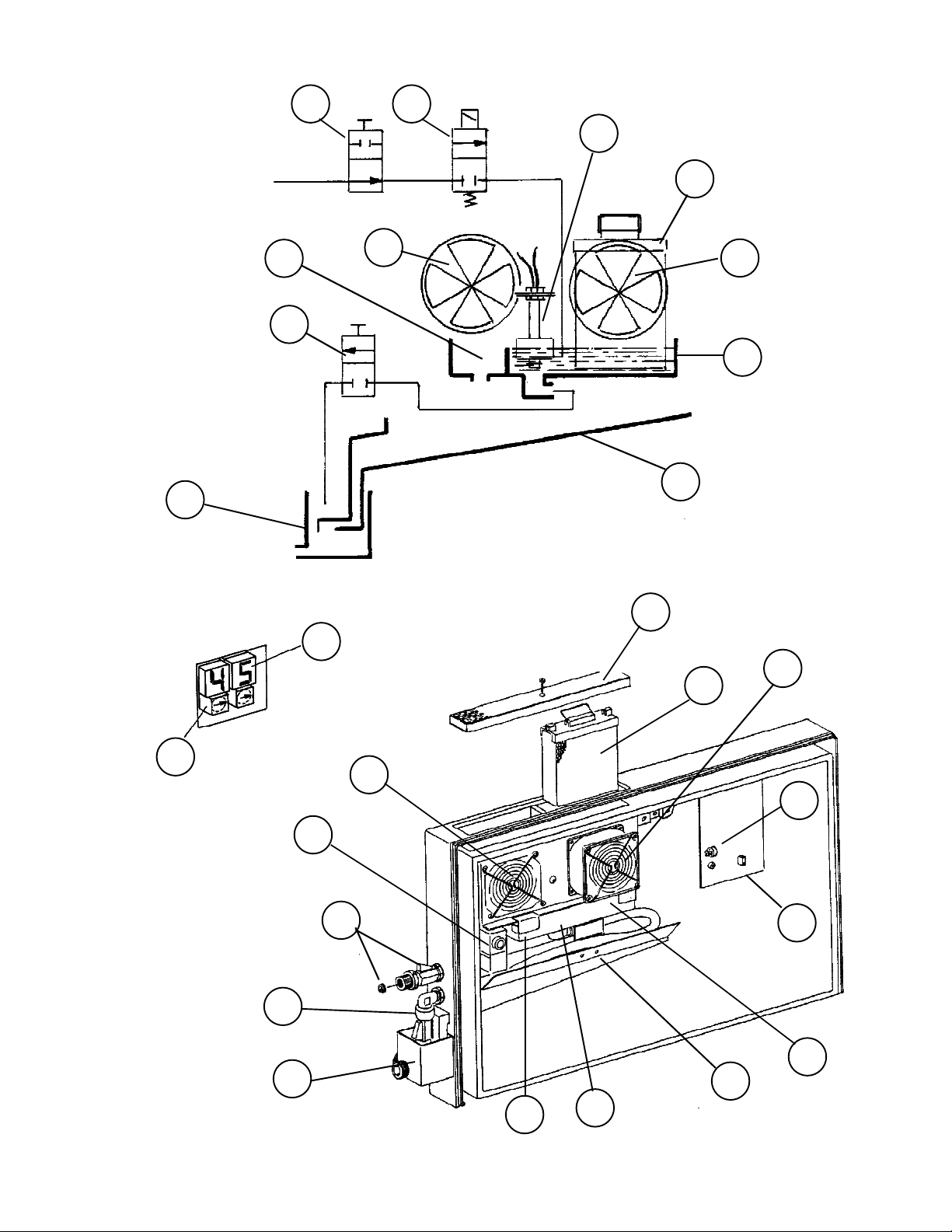

IMPORTANT. If the HUMIDIFIER supplied with a new LOW VOLTAGE MINILOADER, the

PCB will be PCB 208. If the HUMIDIFIER was fitted as a modification, the PCB will be PCB 209.

The two PCB's are NOT interchangable.

To alter the humidity setting, remove the clear plastic COVER and set the SELECTOR SWITCHES to the desired

humidity. The recommended preset is 45% RH. Replace the COVER.

DISPLAY

SELECTOR SWITCHES

COVER

M8_FIG7.TIF

When the MINILOADER is powered up, the HUMIDIFIER will switch on automatically. If the humidity inside the

MINILOADER is greater than the preset value, only the DRY FAN will run. If the humidity is below the preset value,

the INLET WATER VALVE opens, the DRY FAN stops and the WET FAN starts to increase the humidity inside the

MINILOADER.

IMPORTANT :- If the humidity inside the MINILOADER is different (either higher or lower) from the preset value after

10 minutes, the figures on the DISPLAY will flash. If the humidity is higher than the preset nothing can be done, but if

the humidity is lower, check the water supply, FLOAT VALVE and the FILTER ELEMENT.

The calibration of the HUMIDITY SENSOR is factory set, but if a HUMIDITY METER (29050132) is available the

calibration of the DISPLAY can be adjusted. After the unit has stabilised (after 30 minutes), measure the humidity inside

the MINILOADER by inserting the PROBE of the HUMIDITY METER through the ENTRY SLOT. Compare the

reading on the HUMIDITY METER with the HUMIDIFIER DISPLAY. If necessary the HUMIDIFIER DISPLAY

reading can be adjusted by POTENTIOMETER R11 on the HUMIDIFIER PCB 209. See FIGURE 9.

IMPORTANT - DO NOT TOUCH THE VARIABLE CAPACITOR OR YOU WILL ALTER THE FACTORY

SETTING.

© Kodak Ltd.

Page XP/2-8

March 1995

Page 9

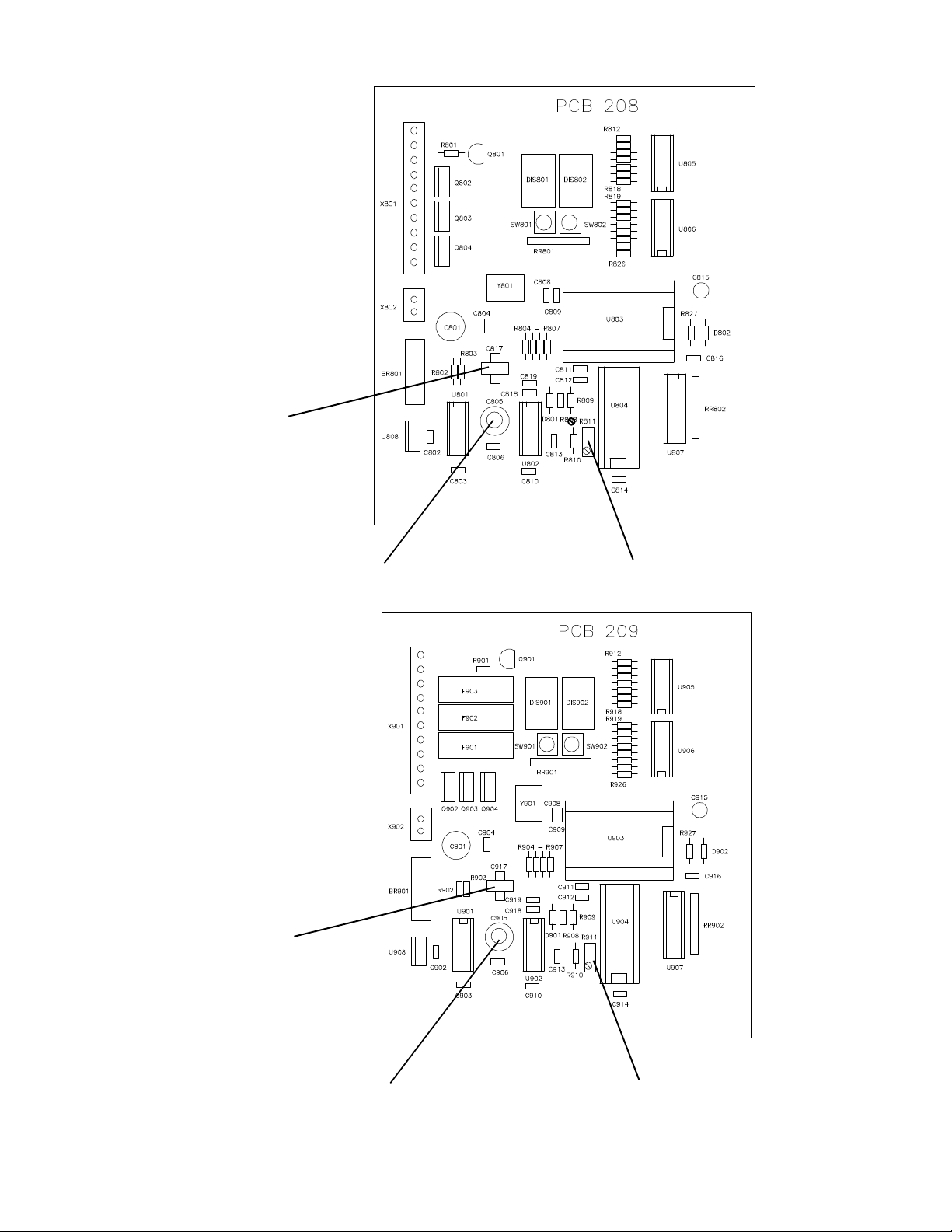

HUMIDIFIER ASSEMBLY

PCB 208

LOW VOLTAGE

MACHINES ONLY

HUMIDITY SENSOR

XP 3239-2

PCB208.PIC

CALIBRATION - DO NOT TOUCH - FACTORY SET

PCB 209

KIT HUMIDIFIERS

ONLY

HUMIDITY SENSOR

DISPLAY ADJUSTMENT

PCB209.PIC

March 1995

CALIBRATION - DO NOT TOUCH - FACTORY SET

Page XP/2-9

DISPLAY ADJUSTMENT

© Kodak Ltd.

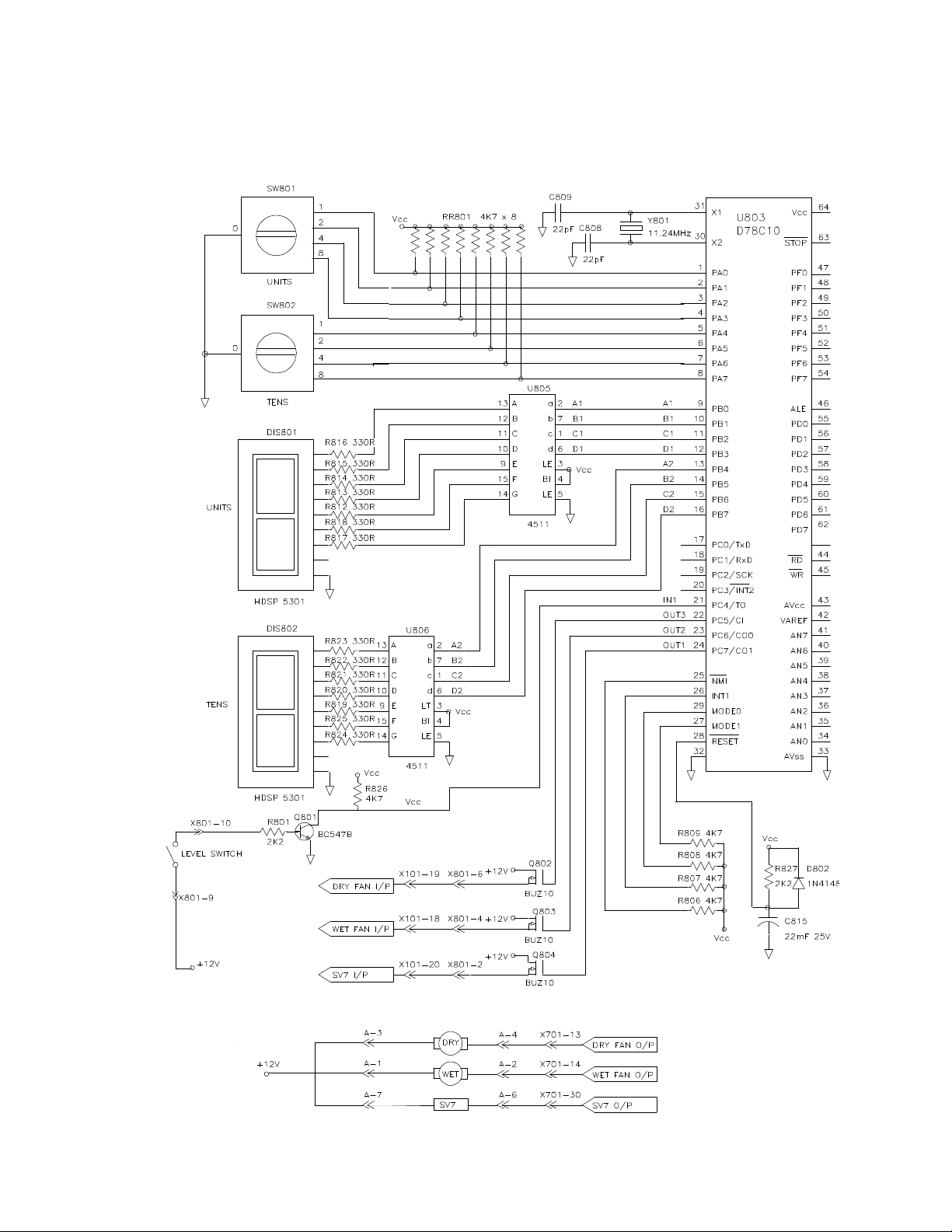

Page 10

XP 3239-2 HUMIDIFIER ASSEMBLY

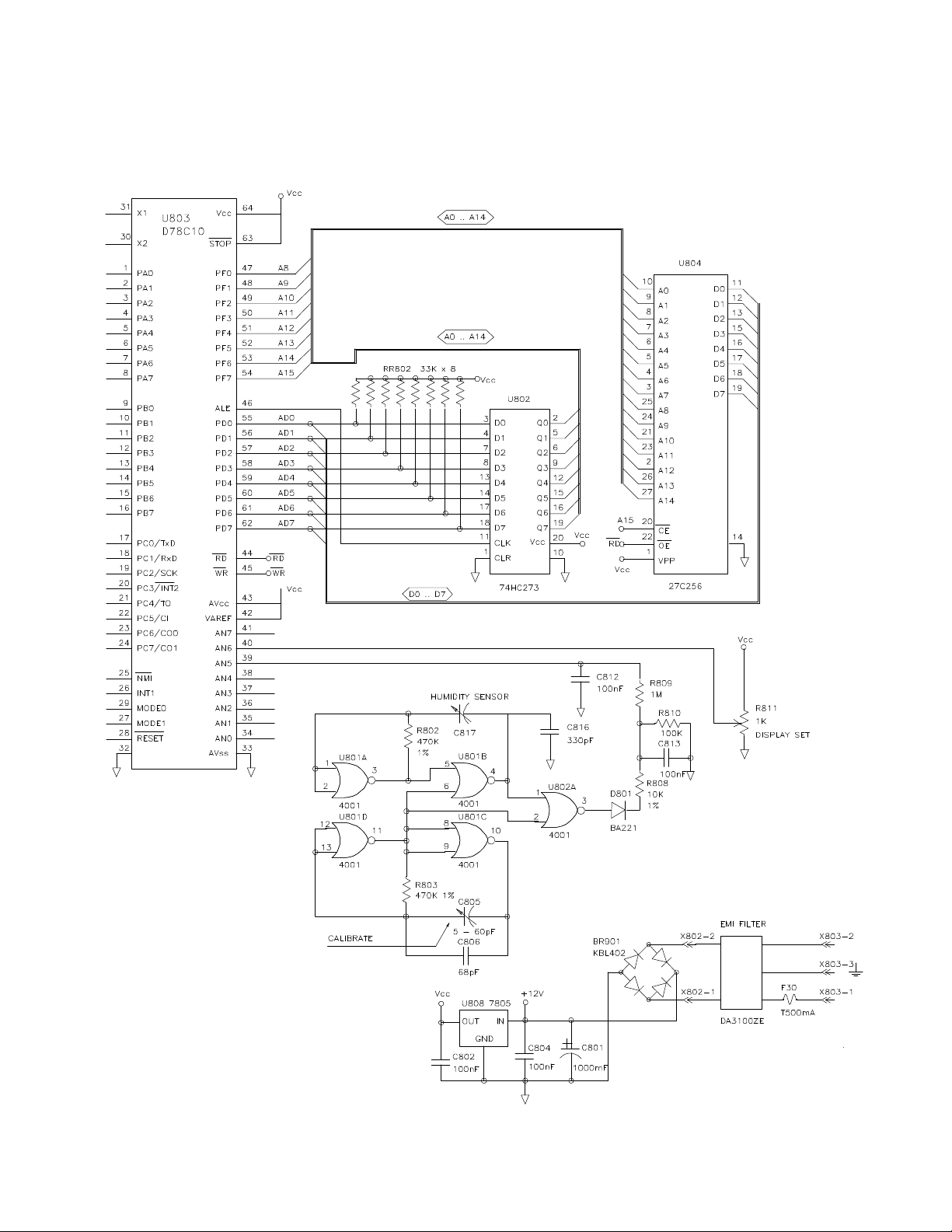

PCB 208 (LOW VOLTAGE MACHINE HUMIDIFIERS ONLY)

PCB208L.PIC

© Kodak Ltd.

Page XP/2-10

March 1995

Page 11

HUMIDIFIER ASSEMBLY

XP 3239-2

PCB 208 (LOW VOLTAGE MACHINE HUMIDIFIERS ONLY)

March 1995

Page XP/2-11

PCB208R.PIC

© Kodak Ltd.

Page 12

XP 3239-2 HUMIDIFIER ASSEMBLY

PCB 209 (KIT HUMIDIFIERS ONLY)

© Kodak Ltd.

Page XP/2-12

PCB209L.PIC

March 1995

Page 13

HUMIDIFIER ASSEMBLY

PCB 209 (KIT HUMIDIFIERS ONLY)

XP 3239-2

March 1995

Page XP/2-13

PCB209R.PIC

© Kodak Ltd.

Page 14

XP 3239-2 HUMIDIFIER ASSEMBLY

PCB 208 (LOW VOLTAGE MACHINE HUMIDIFIERS ONLY)

COMPONENT OVERLAY

© Kodak Ltd.

Page XP/2-14

PCB208.PIC

March 1995

Page 15

HUMIDIFIER ASSEMBLY

XP 3239-2

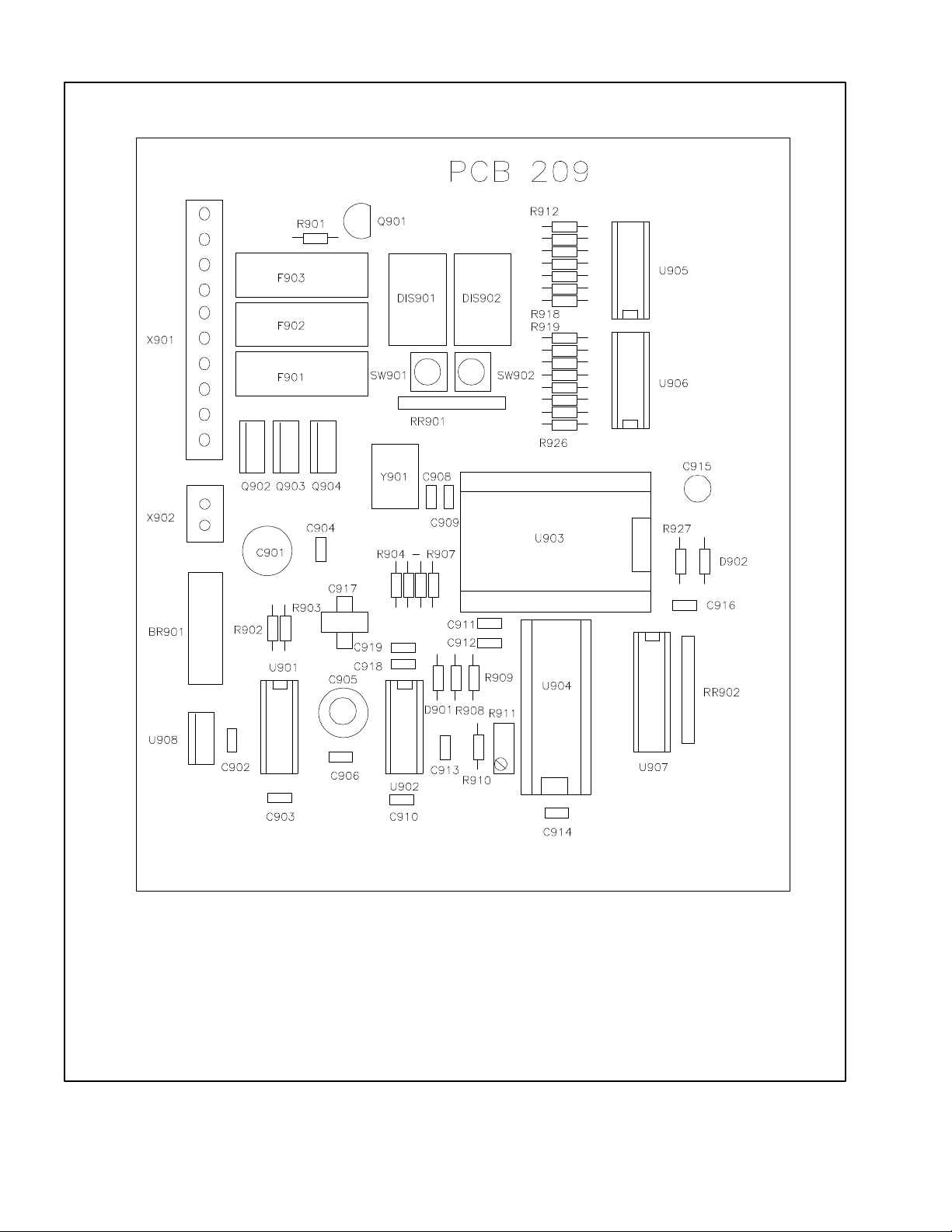

PCB 209 (KIT HUMIDIFIERS ONLY)

COMPONENT OVERLAY

March 1995

Page XP/2-15

PCB209.PIC

© Kodak Ltd.

Page 16

XP 3239-2 HUMIDIFIER ASSEMBLY

1

19

6

7

5

4

2

3

8

9

18

16

17

15

HUMIDIFIER ASSEMBLY

FIG A

© Kodak Ltd.

14

13

Page XP/2-16

10

11

12

PARTS1.TIF

March 1995

Page 17

HUMIDIFIER ASSEMBLY

KEY P AR T NO DESCRIPTION

1 30027208 ELBOW

2 30027129 FITTING, INLET

3 30027213 SEAL, "O" RING

4 30027217 NUT , M20

5 30027200 SOLENOID VAL VE, WA TER INLET, 12 VOL T

6 30015592 ELBOW , 1/8"

7 30015590 TUBE, RIGID, 5 x 3 mm

8 30015563 NUT , M3

XP 3239-2

9 30025818 WASHER, M4 x 12

10 30027130 FITTING, OUTLET

11 30027122 DRAIN HEADER

12 30027221 SCREW, CROSS HEAD, M3 x 25

13 30027215 PLUG, 3/8"

14 30027209 PIPE, 10 x 14 mm

15 30027216 ADAPTOR, 3/4" x 15 mm

16 30027206 VAL VE, DRAIN

17 30027126 RESTRICTOR

18 30027204 REDUCER, 3/4" M x 3/8" F

19 30027205 VAL VE, WATER INLET

March 1995

Page XP/2-17

HUMIDIFIER ASSEMBLY

FIG A

© Kodak Ltd.

Page 18

XP 3239-2 HUMIDIFIER ASSEMBLY

2

1

3

4

5

15

14

13

6

7

8

9

10

11

12

HUMIDIFIER ASSEMBLY

FIG B

© Kodak Ltd.

Page XP/2-18

PARTS2.TIF

March 1995

Page 19

HUMIDIFIER ASSEMBLY

KEY P AR T NO DESCRIPTION

1 30027221 SCREW, CROSS-HEADED, M3 x 25

2 30027112 COVER, FILTER

3 30027113 FIL TER, AIR

4 3002711 1 SUPPOR T , FILTER

5 30025818 WASHER, M4 INTERNAL, M12 EXTERNAL

6 30015611 SCREW , HEX-HEADED, M3 x 6

7 30027128 COVER, DISPLAY

8 30027141 GUARD, PCB 208/209

XP 3239-2

9 30025813 SCREW, HEX-HEADED, M4 x 6

10 30015685 STUD, M4 x 10

11 30015564 NUT, M4

12 30027140 SUPPOR T, PCB, MINI 2 & 2 PLUS ONL Y

30027139 SUPPOR T, PCB, MINI 1 & 1M ONL Y

13 30015682 SCREW, HEX-HEADED, M3 x 8

14 30027103 HOUSING - MODEL M35-M ONLY

30027104 HOUSING - MINI 2 & 2 PLUS MODEL SA & 480RA

30027105 HOUSING - MINILOADER 1 & 1M ONLY

15 30027202 FILTER CARTRIDGE

IMPORTANT - MAKE SURE YOU ORDER THE CORRECT PARTS FOR THE VERSION

OF HUMIDIFIER THAT IS FITTED TO THE MINILOADER

March 1995

Page XP/2-19

HUMIDIFIER ASSEMBLY

FIG B

© Kodak Ltd.

Page 20

XP 3239-2 HUMIDIFIER ASSEMBLY

4

2

3

5

6

1

8

7

12

9

13

4

14

23

15

22

9

21

HUMIDIFIER ASSEMBLY

FIG C

20

19

18

17

16

10

11

PARTS3.TIF

© Kodak Ltd.

Page XP/2-20

March 1995

Page 21

HUMIDIFIER ASSEMBLY

KEY P AR T NO DESCRIPTION

1 30015557 SCREW, CROSS-HEAD, COUNTERSUNK, M3 x 10

2 30027210 CONNECTOR, HOSE

3 30027211 ADAPTOR

4 30015556 SCREW , CROSS-HEAD COUNTERSUNK, M3 x 6

5 30027222 SCREW , SELF-TAPPING, 3.5 x 6.5 mm

6 30025851 SCREW , CROSS-HEAD, SELF-TAPPING, 3.9 x 13 mm

7 30027110 SUPPORT, VERSION M35-M ONL Y

8 30015568 WASHER, FLAT , M3

XP 3239-2

9 30015563 NUT , M3

10 30026615 PCB 208 (LOW VOLTAGE MINILOADER ONL Y)

30027132 PCB 209 (FOR ALL KIT HUMIDIFIERS)

11 30027142 PROTECTION, PCB 208/209

12 30015956 CONNECTOR, FEMALE, 9 PIN

13 30027146 BRACKET , CONNECT OR SUPPORT

14 30015955 CONNECTOR, MALE, 9 PIN

15 30027137 BRACKET , ELEMENT SUPPORT

16 30025818 WASHER, M4 INTERNAL, M12 EXTERNAL

17 30015564 NUT, M4

18 30027107 SUPPOR T

19 30027127 NIPPLE

20 30027201 SENSOR, WA TER LEVEL

21 30027207 NUT, M17

22 30015569 WASHER M4

23 30027147 INLET , WATER

March 1995

Page XP/2-21

HUMIDIFIER ASSEMBLY

FIG C

© Kodak Ltd.

Page 22

XP 3239-2 HUMIDIFIER ASSEMBLY

4

5

3

1

6

2

7

8

8

9

9

8

16

15

3

10

1

11

11

14

13

12

9

10

HUMIDIFIER ASSEMBLY

FIG D

© Kodak Ltd.

Page XP/2-22

PARTS4.TIF

PARTS4A.TIF

March 1995

Page 23

HUMIDIFIER ASSEMBLY

XP 3239-2

KEY P AR T NO DESCRIPTION

1 30027203 F AN, 12 VOLT

2 30015557 SCREW , CROSS-HEADED, COUNTERSUNK, M3 x 10

3 30015556 SCREW , CROSS-HEADED, COUNTERSUNK, M3 x 6

4 30027120 GUIDE, FILTER

5 30027106 SUPPORT, FAN

6 30025851 SCREW , SELF TAPPING, 3.9 x 13

7 30027116 FIXING, TRA Y, RIGHT

8 30015563 NUT , M3

9 30015568 WASHER, FLAT , M3

10 30025106 SCREW, HEX-HEADED, M3 x 14

11 30015523 GRID, F AN

12 30015552 SCREW, CROSS-HEAD, M3 x 16

13 30015682 SCREW, HEX-HEAD, M3 x 8

14 30027218 CONNECTOR BLOCK

15 30027214 GROMMET, 7 mm

16 300271 17 FIXING, TRA Y, LEFT

March 1995

Page XP/2-23

HUMIDIFIER ASSEMBLY

FIG D

© Kodak Ltd.

Page 24

XP 3239-2 HUMIDIFIER ASSEMBLY

20

19

21

4

2

3

5

6

7

8

1

9

10

12

11

10

13

7

18

16

17

HUMIDIFIER ASSEMBLY

FIG E

© Kodak Ltd.

15

11

Page XP/2-24

14

24

22

23

PARTS5.TIF

March 1995

Page 25

HUMIDIFIER ASSEMBLY

KEY P AR T NO DESCRIPTION

1 30027109 TRA Y, WATER

2 30027125 FITTING

3 30027123 FITTING

4 30027148 PROTECTION PLATE

5 30027131 LABEL, HUMIDIFIER

6 30015682 SCREW, HEX-HEADED, M3 x 8

7 30015568 WASHER, FLAT , M3

8 30027115 BRACKET

9 30027119 BRACKET

XP 3239-2

10 30015563 NUT, M3

11 30015537 SCREW, HEX-HEADED, M4 x 10

12 30027108 OVERFLOW TRAY

13 30025812 SCREW, HEX-HEADED, M3 x 20

14 30015564 NUT , M4

15 30027145 STOP, LIGHT PROTECTION (KIT HUMIDIFIER ONLY)

16 30027149 PROTECTION, METAL PANEL HUMIDIFIERS ONL Y

17 30027150 PROTECTION, METAL P ANEL HUMIDIFIERS ONLY

18 30027143 BLOCK, RUBBER (KIT HUMIDIFIER ONLY)

19 30027144 BRACKET (KIT HUMIDIFIER ONLY)

20 30027209 TUBE, 10 x 14

21 30027212 SEAL, "O" RING

22 300271 18 ADAPTOR PLATE, MODEL M35-M ONL Y

23 30015565 NUT , M5

24 30025825 SCREW, CROSS HEADED, COUNTERSUNK, M5 x 10

March 1995

Page XP/2-25

HUMIDIFIER ASSEMBLY

FIG E

© Kodak Ltd.

Page 26

XP 3239-2 HUMIDIFIER ASSEMBLY

HUMIDIFIER

PARTS6A.TIF

11

10

1

12

2

PCB 208

3

4

5

6

9

LOW VOLTAGE MACHINE ONLY

8

7

13

HUMIDIFIER

9

PARTS6B.TIF

HUMIDIFIER ASSEMBLY

FIG F

3

PCB 209

4

5

14

7

8

HUMIDIFIER KITS ONLY

© Kodak Ltd.

Page XP/2-26

March 1995

Page 27

HUMIDIFIER ASSEMBLY

XP 3239-2

KEY P AR T NO DESCRIPTION

1 30027135 CABLE, PCB 208 TO 207 - LOW VOL T AGE MACHINE ONLY

2 30026615 PCB 208 - LOW VOL T AGE MACHINE ONLY

3 30027227 FIL TER, EMI, ARCOTRONICS

4 30027226 FIL TER/FUSE ASSEMBLY COMPLETE

5 30027224 FUSEHOLDER, OMEGA K1010

6 30027225 FUSE, T500 mAMP , 5 x 20 mm

7 30027229 PLUG, MALE, 4 POLE

8 30027228 PLUG, FEMALE, 4 POLE

9 30027133 CABLE, TRANSFORMER TO EMI FILTER

10 30027136 CABLE, PCB 207 TO HUMIDIFIER - LOW VOLT AGE

MACHINE ONLY

11 30027223 POTENTIOMETER 47 R, 5 WA TT - KIT HUMIDIFIER ONLY

12 30027134 CABLE PCB 209 TO HUMIDIFIER - KIT HUMIDIFIER ONLY

13 30027132 PCB 209 - KIT HUMIDIFIER ONLY

14 30025644 FUSE, T2 AMP, 5 x 20 mm

IMPORTANT - MAKE SURE YOU ORDER THE CORRECT PARTS FOR THE VERSION

OF HUMIDIFIER THAT IS FITTED TO THE MINILOADER

March 1995

Page XP/2-27

HUMIDIFIER ASSEMBLY

FIG F

© Kodak Ltd.

Page 28

XP 3239-2 HUMIDIFIER ASSEMBLY

HUMIDIFIER ASSEMBLY

FIG G

© Kodak Ltd.

Page XP/2-28

PCB208.PIC

March 1995

Page 29

HUMIDIFIER ASSEMBLY

KEY P AR T NO DESCRIPTION

PCB 208 30026615 PCB 208 - LOW VOLT AGE MACHINE ONLY

BR801 30026630 DIODE BRIDGE, KBU604

C805 30026649 CAPACITOR, VARIABLE, 3 - 60 pF

C817 30026647 SENSOR, HUMIDITY, PHILLIPS

DIS801, 802 30026656 DISPLAY, COMMON CATHODE

Q801 30025520 TRANSISTOR, NPN, BC547

Q802, 3, 4 30026626 TRANSISTOR. MOSFET, BUZ10

XP 3239-2

U801, 802 30026642 INTEGRATED CIRCUIT , 4001, QUAD 2 INPUT NOR

U803 30025505 INTEGRATED CIRCUIT , MICROPROCESSOR , 78C10

U804 30027220 INTEGRATED CIRCUIT , EPROM, V. HUMIDIFIER 01

U805, 806 30026643 INTEGRATED CIRCUIT , 4511, BCD TO 7 SEG DRIVER

U807 30025508 INTEGRATED CIRCUIT , BUFFER, 74HC373

U808 30025523 INTEGRATED CIRCUIT , 7805, VOLT AGE REG.

IMPORTANT - MAKE SURE YOU ORDER THE CORRECT PARTS FOR THE VERSION

OF HUMIDIFIER THAT IS FITTED TO THE MINILOADER

March 1995

Page XP/2-29

HUMIDIFIER ASSEMBLY

FIG G

© Kodak Ltd.

Page 30

XP 3239-2 HUMIDIFIER ASSEMBLY

HUMIDIFIER ASSEMBLY

FIG H

© Kodak Ltd.

Page XP/2-30

PCB209.PIC

March 1995

Page 31

HUMIDIFIER ASSEMBLY

KEY P AR T NO DESCRIPTION

PCB 209 30027132 PCB 209 - HUMIDIFIER KITS ONLY

BR901 30026630 DIODE BRIDGE, KBU604

C905 30026649 CAPACITOR, VARIABLE, 3 - 60 pF

C917 30026647 SENSOR, HUMIDITY, PHILLIPS

DIS901, 902 30026656 DISPLAY, COMMON CATHODE

F901, 2, 3 30025642 FUSE, 5 x 20 mm, T1A

30025591 FUSEHOLDER, PCB TYPE

Q901 30025520 TRANSISTOR, NPN, BC547

XP 3239-2

Q902, 3, 4 30026626 TRANSISTOR. MOSFET, BUZ10

U901, 902 30026642 INTEGRATED CIRCUIT , 4001, QUAD 2 INPUT NOR

U903 30025505 INTEGRATED CIRCUIT , MICROPROCESSOR , 78C10

U904 30027220 INTEGRATED CIRCUIT , EPROM, V. HUMIDIFIER 01

U905, 906 30026643 INTEGRATED CIRCUIT , 4511, BCD TO 7 SEG DRIVER

U907 30025508 INTEGRATED CIRCUIT , BUFFER, 74HC373

U908 30025523 INTEGRATED CIRCUIT , 7805, VOLT AGE REG.

IMPORTANT - MAKE SURE YOU ORDER THE CORRECT PARTS FOR THE VERSION

OF HUMIDIFIER THAT IS FITTED TO THE MINILOADER

March 1995

Page XP/2-31

HUMIDIFIER ASSEMBLY

FIG H

© Kodak Ltd.

Page 32

XP 3239-2 HUMIDIFIER ASSEMBLY

THIS PAGE IS INTENTIONALY LEFT BLANK

© Kodak Ltd.

Page XP/2-32

March 1995

Page 33

HUMIDIFIER ASSEMBLY

Rev. Date PCN No. Pub.No. Affected Pages Description

XP 3239-2

October 94

November 94

1 300800xx 9, 14,15, 28, &

30

26,27

Corrected drawings of PCB 208 & 209

overlays.

Added POTENTIOMETER to drawing

and text.

March 1995

Page XP/2-33

© Kodak Ltd.

Page 34

HEAL TH SCIENCES DIVISION

© Kodak Ltd., Customer Equipment Services Division, Swallowdale Lane, Hemel Hempstead, Hertfordshire, England.

Loading...

Loading...