Page 1

Document Scanner/

Microimager 990

A-61096

Part No. 1E8015

User’s

Guide

Page 2

1 Introduction

The

Kodak Digital Science

microfilm and electronically scan documents simultaneously. The

scanner/microimager is designed for productive throughput in mediumto high-volume applications accommodating a variety of document

sizes.

Each mode can be configured to film and scan documents

simultaneously or film documents only (no scan). In addition, certain

modes may be configured to scan documents only (no film). Details of

the no film/no scan mode are provided in this manual.

Document Scanner/Microimager 990 can

Scanner features

The Document Scanner/Microimager 990 has the following features:

• A high-speed document transport system.

• Automatic exposure control, which calculates proper microfilm

exposure settings.

• Excellent image quality, with a choice of 24X, 40X, or 50X

reduction ratios.

• A two-line 80-character display for status information and operator

messages.

• Easy-to-reach control panel keys, identified by graphic symbols.

• Full programmability of 18 application modes, with override

capability.

• Linked modes may be used to carry over the image address from

one mode to another.

• Programmable keys to perform commonly-used functions.

• Transport-on functions, which allow some function codes to be

executed while the transport is running.

• Film cassettes with memory capability; one or two cassettes may

be used, according to user requirements.

A-61096 June 1999 1-1

• Custom image mark sizing.

• Audible tones for selected functions, such as the footswitch, patch

reading, etc.

• English or other language message display.

• A large, built-in workshelf.

• An adaptable, modular design for easy addition of accessories.

Page 3

Scanner/microimager

options

The following options are available for use with the scanner/

microimager:

• A choice of feeders, including a semi-automatic feeder or a check

feeder.

• A choice of exit hoppers, including a standard hopper or a check

stacker.

• A Footswitch for document level control.

• An Endorser for stamping information on documents.

• A 600 dpi, 12-character ink-jet printer which supports black and

magenta ink colors.

• A Patch Reader for automatic document level control.

• End-fed patch capability.

• A Bar Code Reader for decoding encoded information.

• A skew/length monitor.

• A film writing module for writing information on film next to

document images.

• A custom-designed chair (ergonomic design).

• A workstation console, left or right position.

1-2 A-61096 June 1999

Page 4

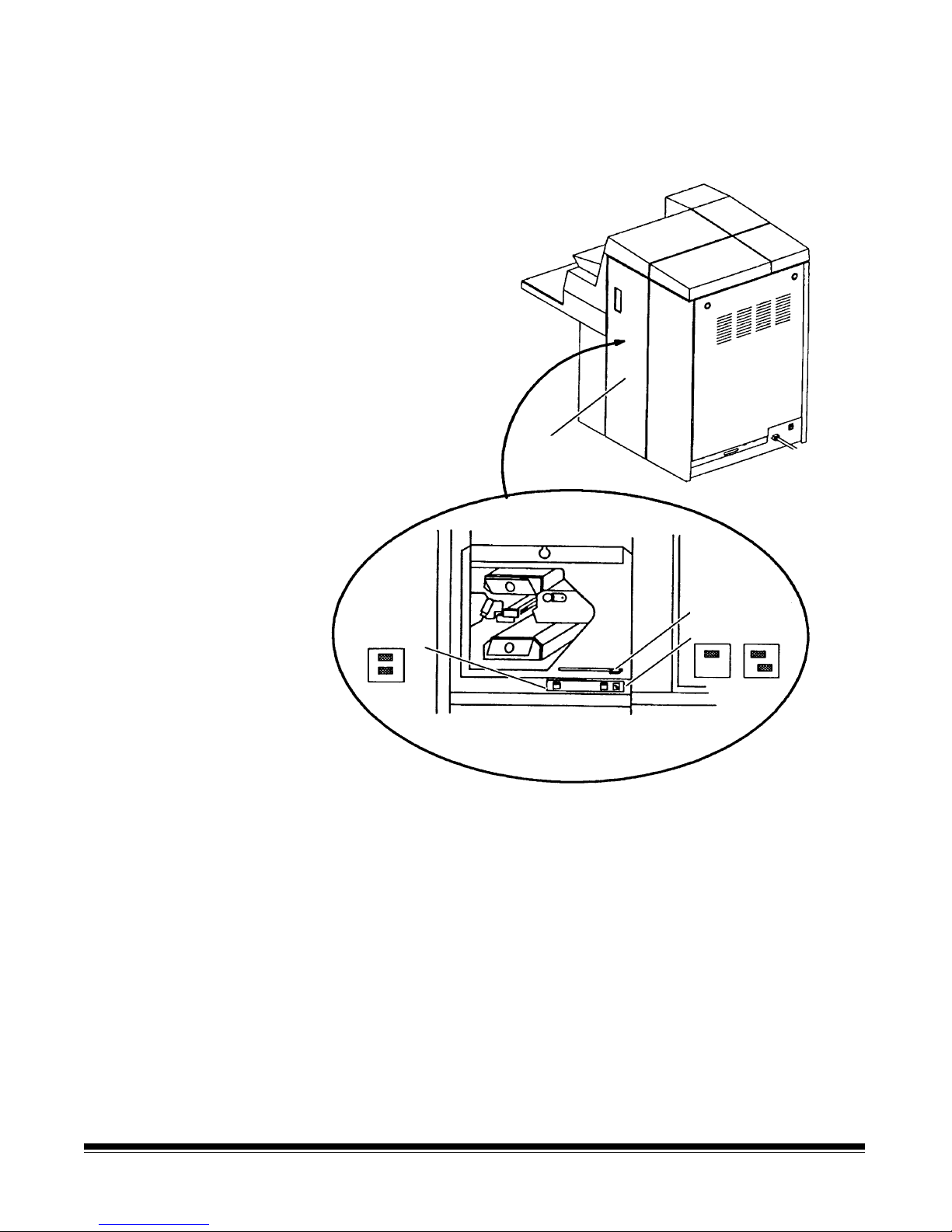

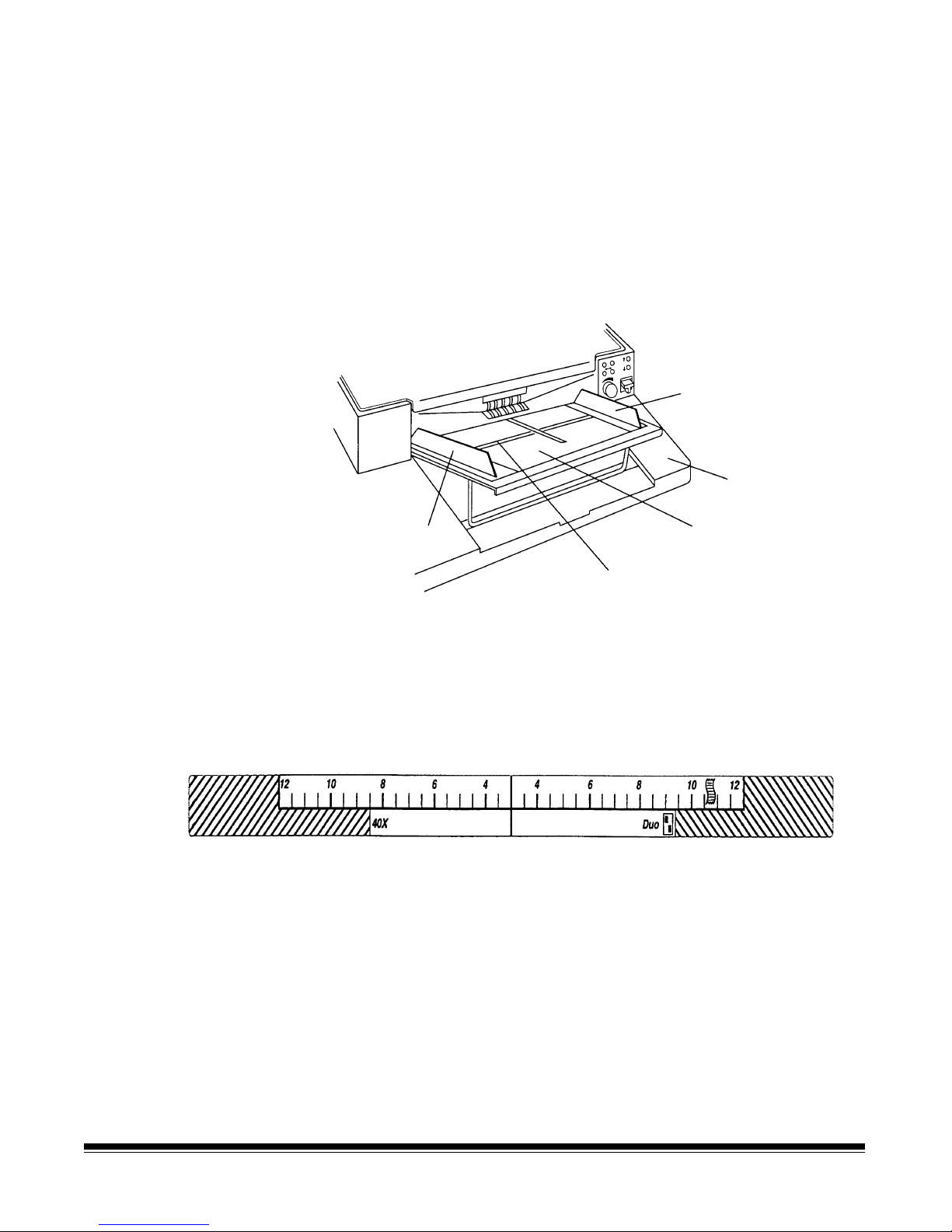

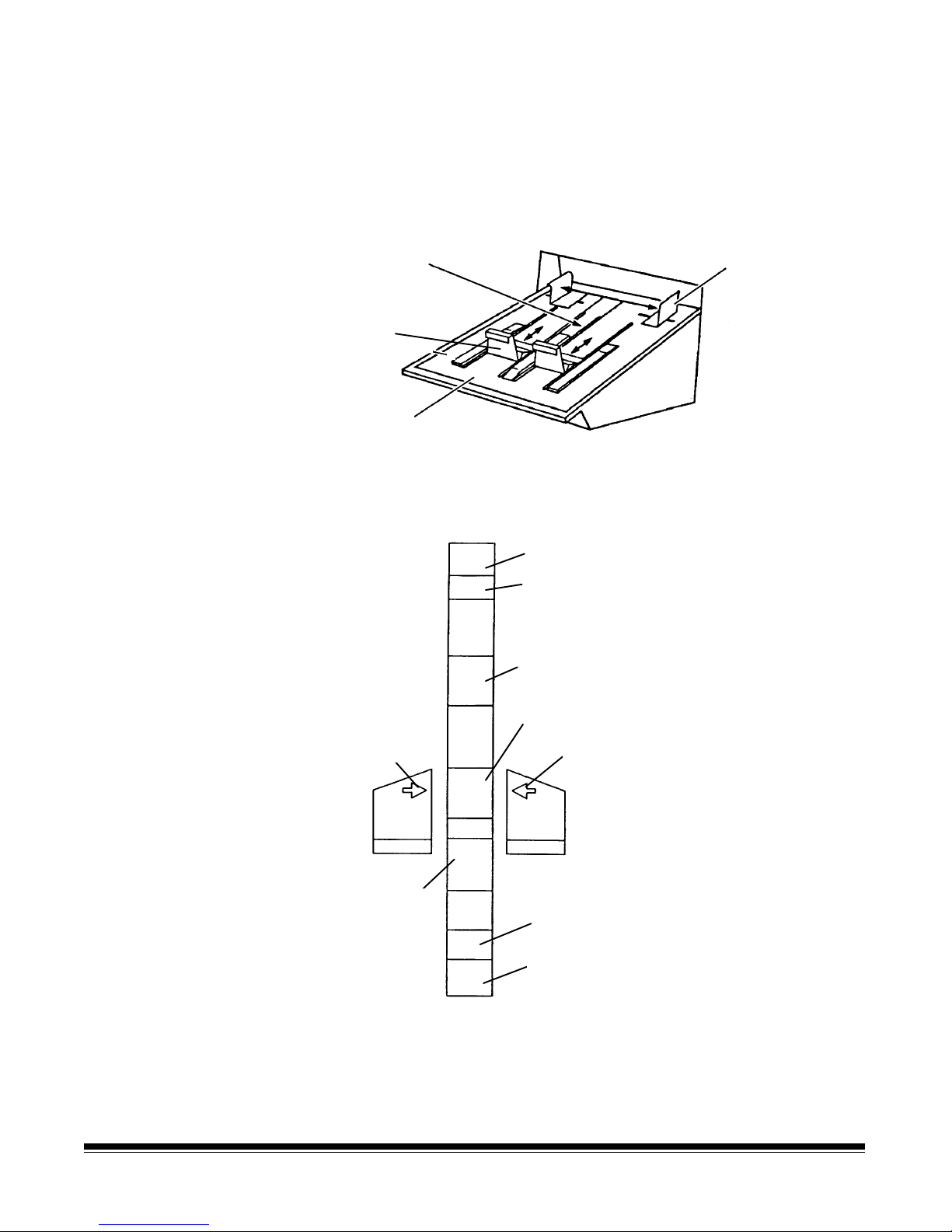

Scanner/microimager

components

The following illustrations and descriptions will help you locate and

become familiar with scanner/microimager components.

NOTE: The illustrations in this manual depict the scanner/microimager

990D, with the feeder/horizontal transport area brought

forward from the control panel.

Left-side access

Door (not shown)

Cassette

access door

Control panel

Feed and

separator

rollers

Feed tray

Left-side access door — provides access to the lens holder

assembly, mirrors, and other components.

Cassette access door — provides access to the film cassette

compartment.

Top cover

Exit hopper

Right-side access door

Side pane l switch

Gap release lever

Gap adjustment knob

Control panel — contains the status display, indicators, and operating

keys used to control the scanner/microimager.

Feed and separator rollers — provides smooth feeding of documents

of various sizes and textures.

Feed tray — holds documents prior to feeding.

Top cover — provides access behind the transport area

.

Exit hopper — collects documents after they have been scanned.

Right-side access door — provides access to the optical system,

transport system components and other components.

Side panel switch — allows you to turn the transport system on and

off.

Gap release lever — allows you to open the feed gap to allow thicker

documents to be fed into the transport.

Gap adjustment knob — allows you to manually adjust the space

between the feed and separator rollers for documents of varying

thicknesses.

A-61096 June 1999 1-3

Page 5

Rear view

Computer

interface 1

(COIN 1)

Computer

interface 2

(COIN 2)

J30 J31 J45 J32 J33 J46

Computer

interface 3

(COIN 3)

SCSI ports

Not Used

Power

cord

Main power switch

ON

OFF

Computer interface 1 (COIN1) — service/diagnostic interface.

Configures the scanner/microimager and runs diagnostics.

Computer interface 2 (COIN2) — OCR command/bar code interface.

Transfers commands between the scanner/microimager and external

devices/subsystems.

Computer interface 3 (COIN3) — SCSI diagnostic port interface.

System debugging and monitoring SCSI-host computer

communications.

SCSI ports — SCSI interface connection for the scanner/microimager.

Power cord — plugs into an appropriate power outlet.

Main power switch — turns main power to the scanner/microimager

on and off .

1-4 A-61096 June 1999

Page 6

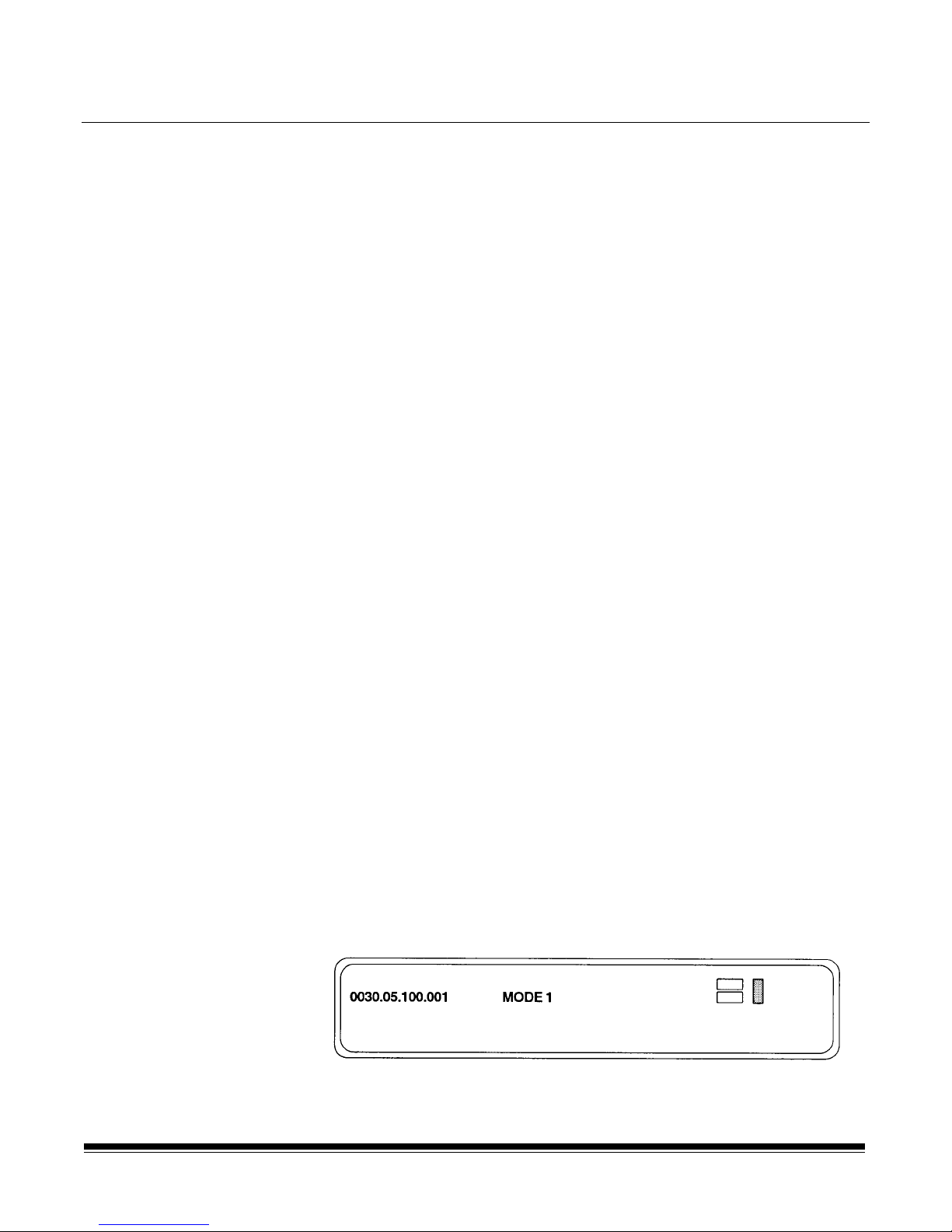

Status display — indicates the image address, scan mode, document

level and operator messages.

Two line status display

Image

address

Mode name/

number

Operator message

Lens

reduction

Film mode

indicator

Document

level

indicator

A-61096 June 1999 1-5

Page 7

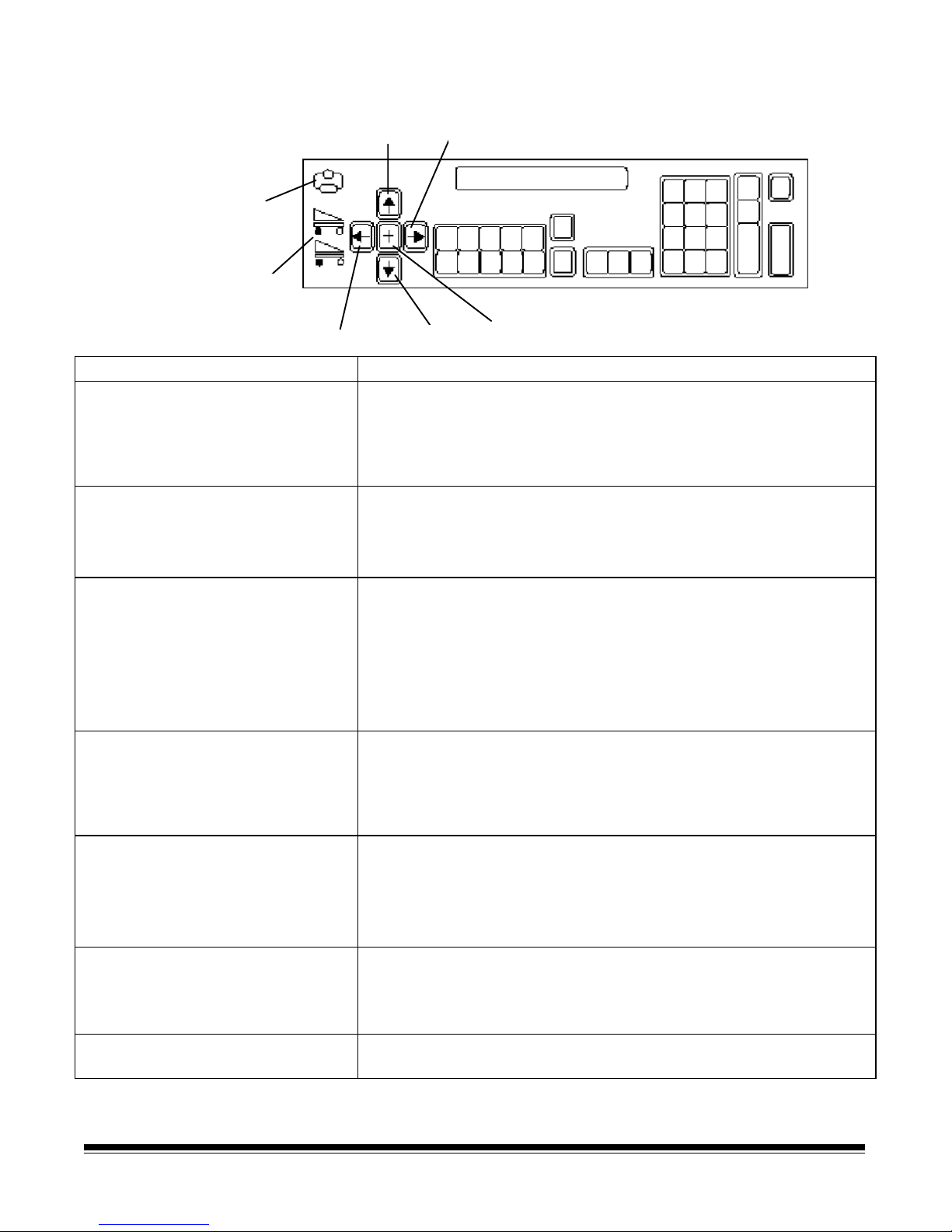

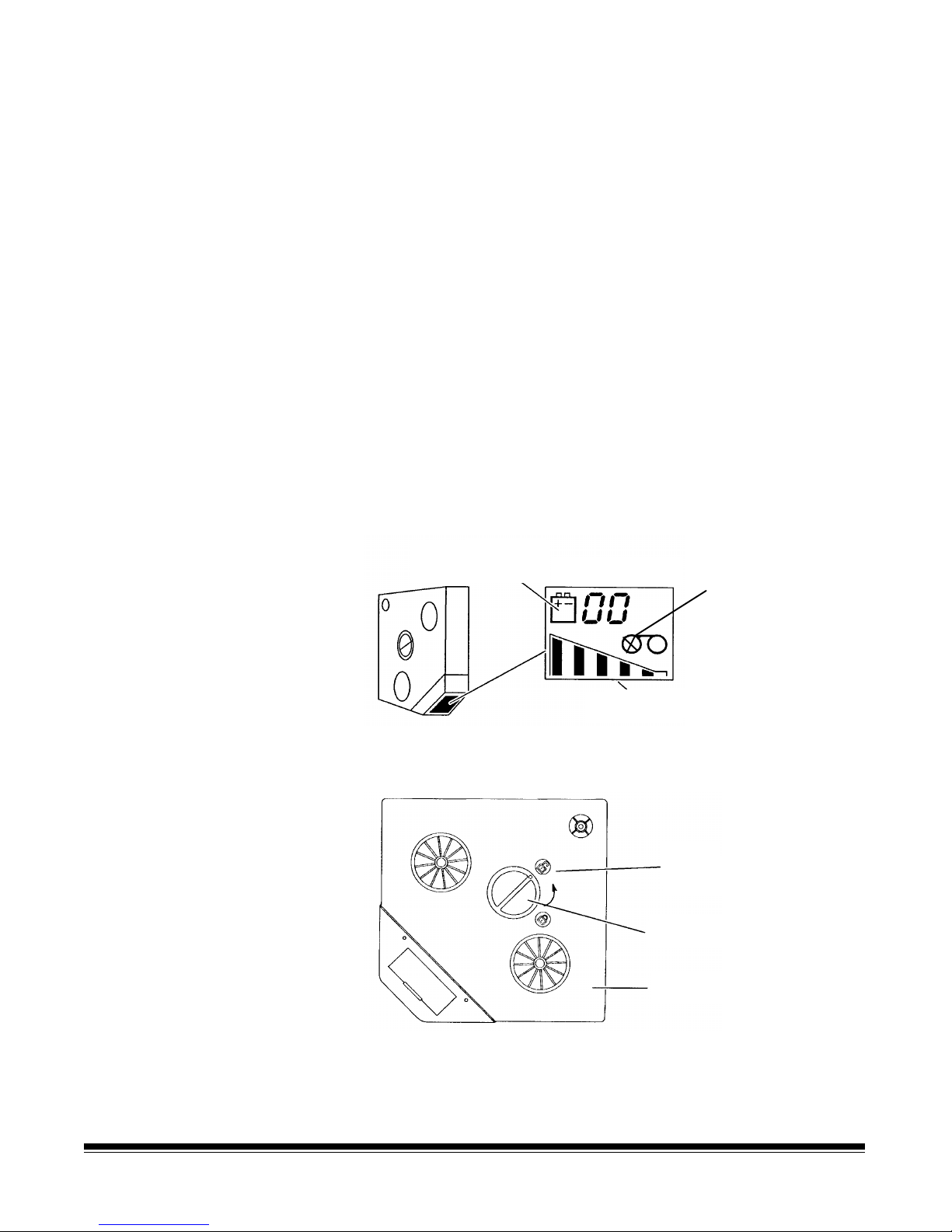

Operating keys and indicators

Right arrow

Plus key

Visual tone

display

Film supply

indicators

Left arrow

Up arrow

Downarrow

Key/Indicator Function

Visual tone display The upper and lower lights a re both illuminated whenever an

audio tone is issued. When using a Footswitch, the lower light is

illuminated and an audio tone is issued whenever the Footswitch

is pressed; while the upper light is illuminated (but no audio tone

is issued) when the Footswitch is released.

Up arrow (↑)

TheUparrowallowsyouto:

• Increment values at a faster rate.

• Increase a data value when used with certain functions.

• Enter an alpha character in the image address fixed field.

Right arrow (→)

The Right arrow allows you to:

• Increment values at a slower rate.

• Display additional messages in the status display. A blinking

cursor over the arrow in the display indicates there are

additional messages. Press the Right arrow key to display

these messages.

• Enter an alphanumeric character in the image address.

Film supply indicators Indicates how much film is available: A full cassette is indicated

by all lights in the display. An empty cassette is indicated by no

lights in the display. The upper indicator represents the film

supply in the upper cassette while the lower indicator represents

the film supply in the lower cassette.

Left arrow (←)

The Left arrow allows you to:

• Decrement values at a slower rate.

• Backspace, delete the last keystroke, or clear messages in

the status display.

• Enter an alphanumeric character in the image address.

Down arrow (↓)

TheDownarrowallowsyouto:

• Decrement values at a faster rate.

• Decrease a data value when used with certain functions.

• Enter an alpha character in the image address fixed field.

Plus key (+) Inputs a value for the image address. When pressed, it allows a

field to remain unchanged.

1-6 A-61096 June 1999

Page 8

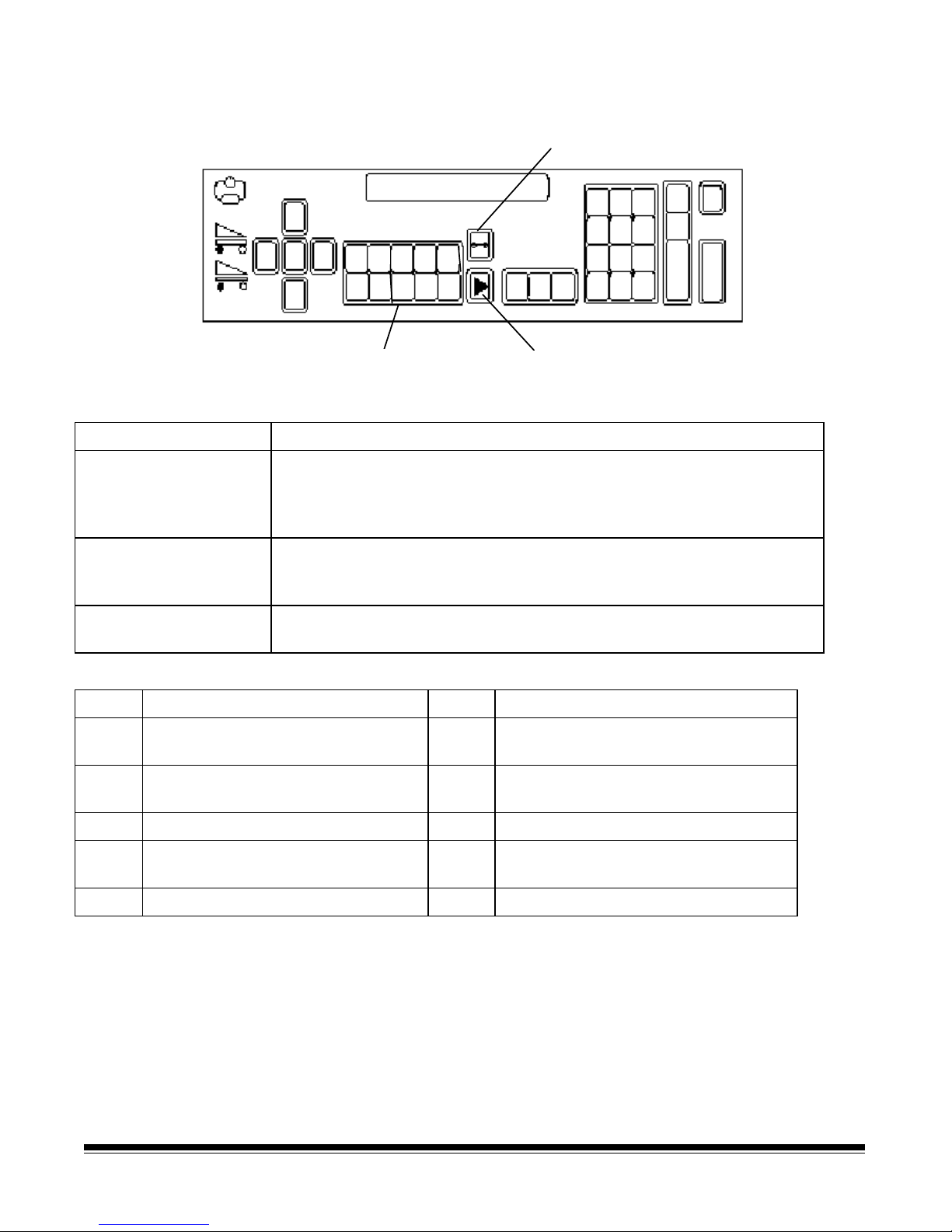

Operating keys and indicators

3

5

Film advance

P1 P2

P7 P8

P6

Programmable keys

P

(P keys)

P4

P

P10

Jog key

Keys/Indicators Function

Film advance Advances film without making an exposure. Provides blank film

between images or at the end of a roll of film. Film is advanced as

long as the key is pressed (2.5 inches per second; or 0.5 inches if key

is pressed f or less than one second).

Programmable keys

(P keys)

Perform specific functions. The P keys have default values; any or all

of the defaults may be overridden/reprogrammed at installation. Use

the table below to record the functions performed by the P keys.

Jog Momentarily turns on (jogs) the transport system to help document

jams.

P Key Function (defaults indicated) P Key Function (defaults indicated)

P1

P2

F04, F02 Toggle Count Only

Mode

F45 Print Test

P6

P7

F30 Display Amount of Film

Remaining

F44 Omit Printing on Next

Document Only

P3

P4

F09 Total Document Count

F08 Display Last Image

P8

P9

F46 Print Position

F07 Level 0

Address

P5

F37 Calibrate

P10

A-61096 June 1999 1-7

F98, F38 Stop and End-of-job

Page 9

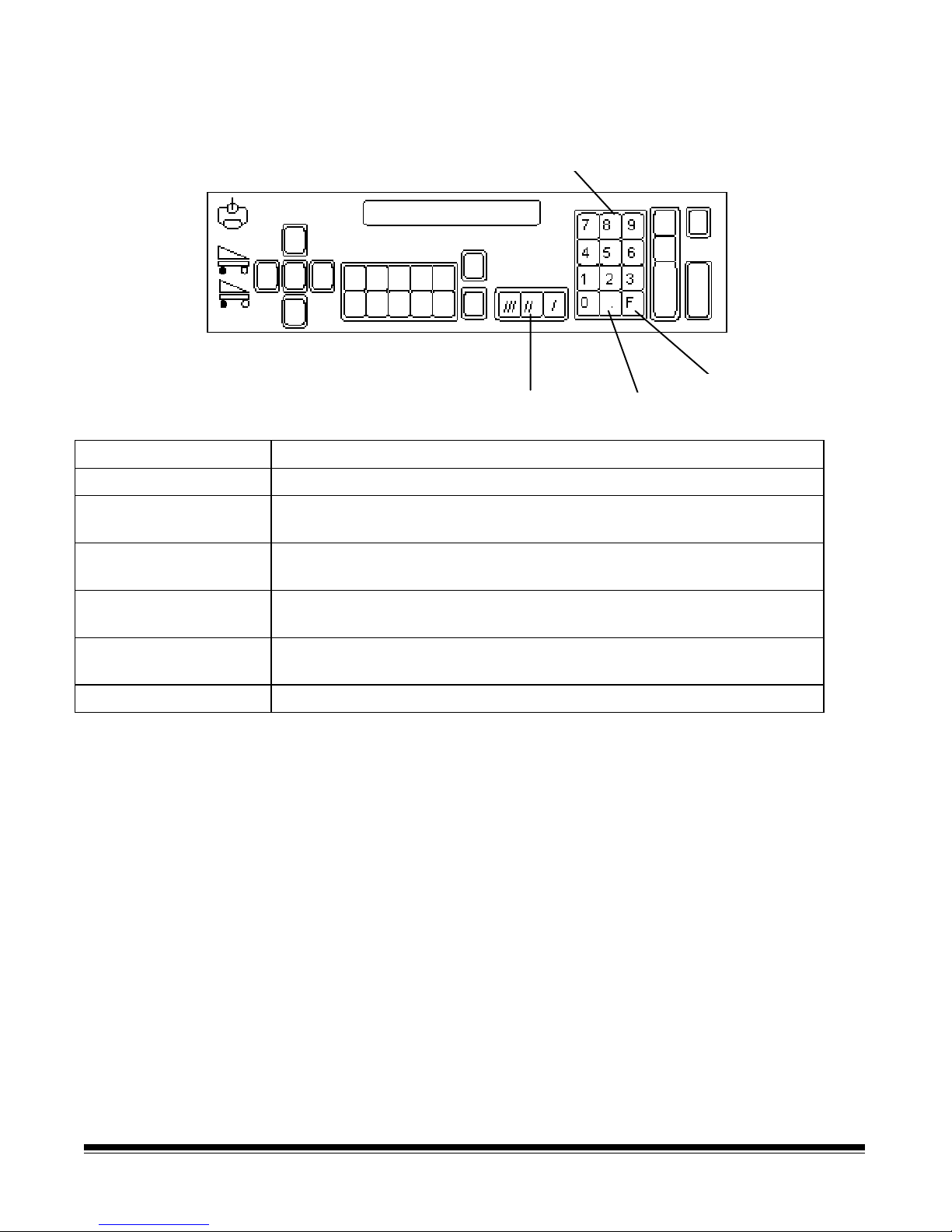

Operating keys and indicators

Numeric keys

Fkey

Level keys Decimal key

Keys/Indicators Function

Numeric keys (0-9) Enter numeric data such as an image address or function code.

F key Selects one of the available functions, when used with the numeric

keys.

Level 3 key Identifies the next document f ed into the scanner/microimager as a

level 3 document.

Level 2 key Identifies the next document f ed into the scanner/microimager as a

level 2 document.

Level 1 key Identifies the next document f ed into the scanner/microimager as a

level 1 document.

Decimal key Inserts a field separator in an image address.

1-8 A-61096 June 1999

Page 10

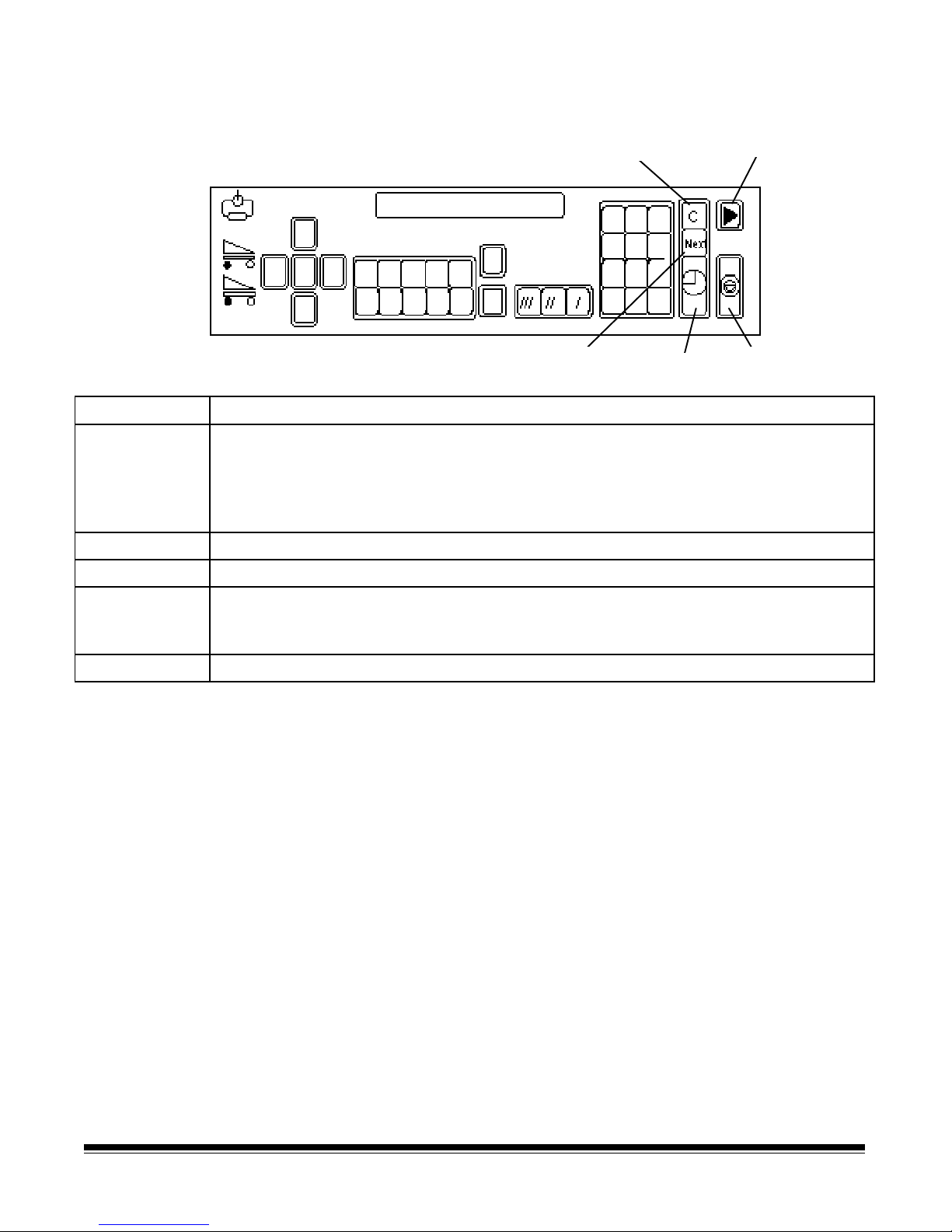

Operating keys and indicators

r

Clear/Cancel

Next

Key/Indicator Function

Clear/Cancel The C key allows you to:

• Cancel a function without changing the preset values.

• Clear the status display after executing specified function codes.

•

• Clear an operator message f rom the status display.

• •

Run Turns on the feeder and transport system.

NEXT Allows you to enter the next document image address.

Ente

Run

Stop

Stop Stops the feeder and transport system. Documents still in the transport system will

be scanned or microfilmed and placed in the exit hopper before the transport system

stops.

Enter Enters data for a f unction code or an image address change.

A-61096 June 1999 1-9

Page 11

2 Getting Started

The following steps are necessary to prepare the scanner/microimager

for operation. Procedures on how to perform these steps are described

in this chapter.

1. Turn on the main power switch.

2. Turn on the side panel switch.

3. Select the language display.

4. Load the f ilm into the cassette(s).

5. Load the cassette(s) into the scanner/microimager.

6. Change the lens holder position.

7. Select the mask.

8. Calibrate the scanner/microimager (if applicable).

9. Adjust the feed and separator roller gap.

10. Adjust the feed shelf position.

11. Adjust the feed shelf side guides.

Turning on the

scanner/microimager

12. Adjust the feed shelf side extension (if applicable).

13. Adjust the exit hopper side guides and end stop.

14. Change the deflector (if required).

15. Run an Exposure Step Test (if required).

16. Prepare the documents for filming/scanning.

Follow the steps below to turn the power on to the scanner/

microimager.

1. Turn on the main power switch (located at the rear of the machine).

NOTE: It is not necessary to turn off the main power switch during

normal daily operations.

2. Turn on the side panel switch.

Wait until the status d isplay indicators are lit and an operating display

appears before continuing.

40X

A-61096 June 1999 2-1

Page 12

Selecting the language

display

The scanner/microimager may have been configured at installation to

allow use of a second language in the status display. The language

used (French, German, Italian, Spanish, or other) is defined during

installation. If available, the alternate language display may be

accessed using function code F19.

Loading film into the

cassette(s)

IMPORTANT:

Always load and unload film in subdued indirect light to

help prevent “fogging”.

The following steps are required to load film into the cassette(s):

1. Select the correct film for your application(s)and appropriate

cassette(s).

2. Check the cassette display bef ore loading a new roll of film. Verify

that:

• The film supply indicator shows the cassette is empty.

•

• There is not a low battery symbol. If a low battery symbol

• •

appears, or the display is not visible, replace the battery (refer

to Chapter 5,

Maintenance

, “Replacing the film cassette

battery”).

Low battery symbol

appears here

Cassette display

Empty film

supply indicator

Film supply i ndicator

3. Place the cassette on a flat surface, with the top cover side up (as

shown).

Unlocked

symbol

Cover latch

Top cover

4. Press down on the cover latch and turn counterclockwise to unlock

the top cover.

2-2 A-61096 June 1999

Page 13

5. Remove the top cover and set it aside.

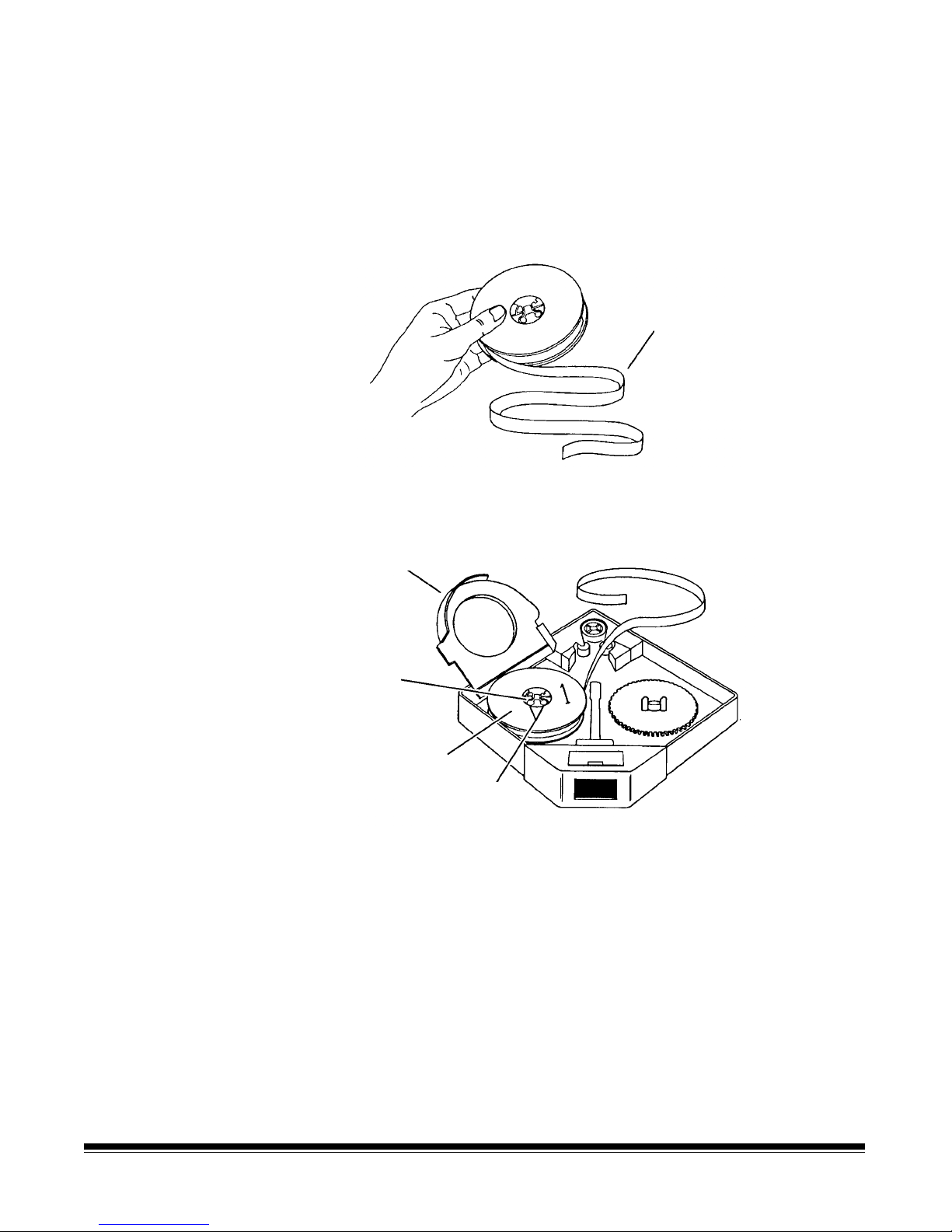

6. Open a new box of microfilm and remove the spool of film.

NOTE: Save the empty box to store the exposed film prior to

processing and f or storing the f ilm following processing.

7. Peeloff the paper band from around the spool.

8. Unwind approximately 18 in. (46 cm) of film.

18 in. (46 cm)

9. Lift the light guard and place the spool of film on the supply

spindle, with the number 1 side up.

Light guard

Lug

New spool

of film

Holes

10. Slowly rotate the spool until the two round holes on the spool

engage the lugs on the spindle.

11. Lower the light guard.

A-61096 June 1999 2-3

Page 14

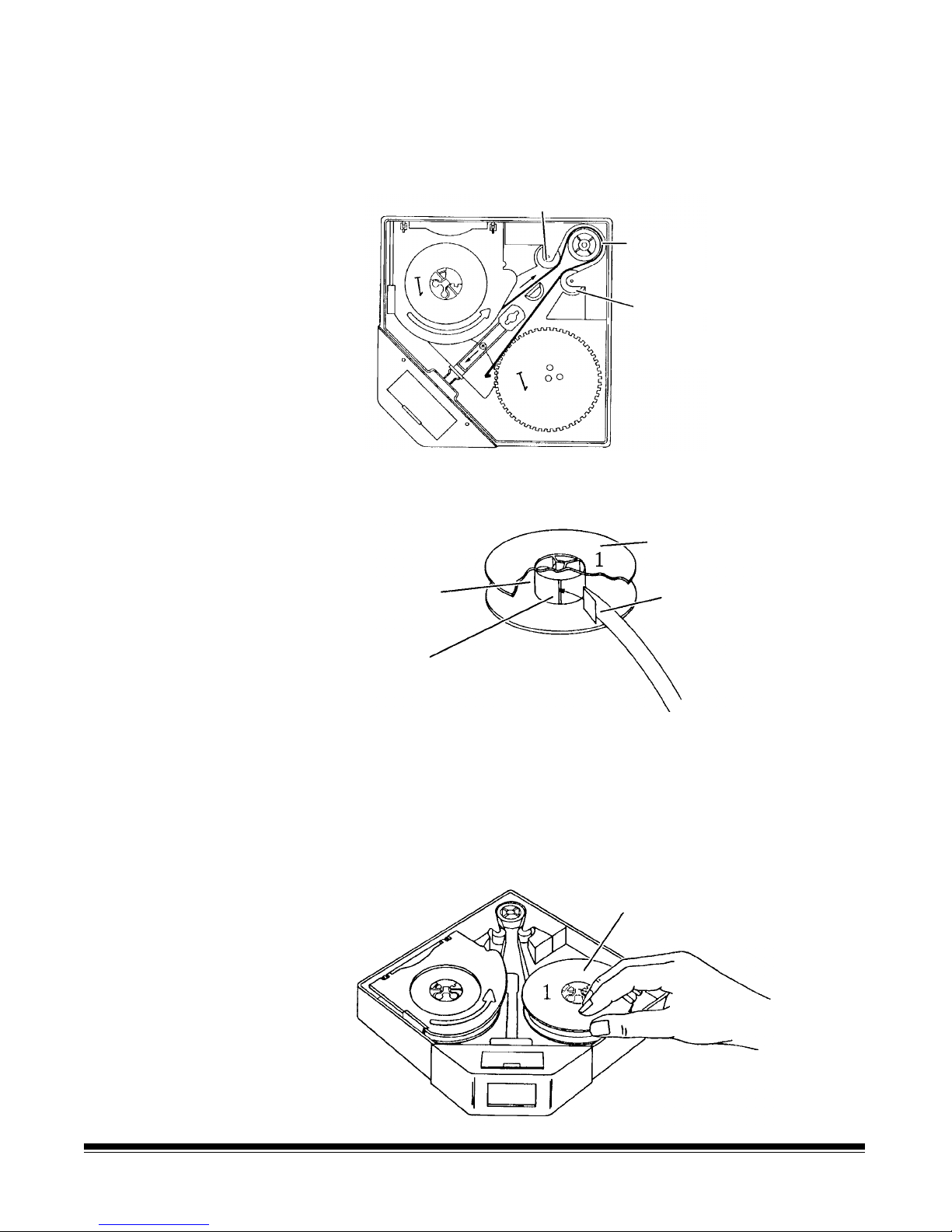

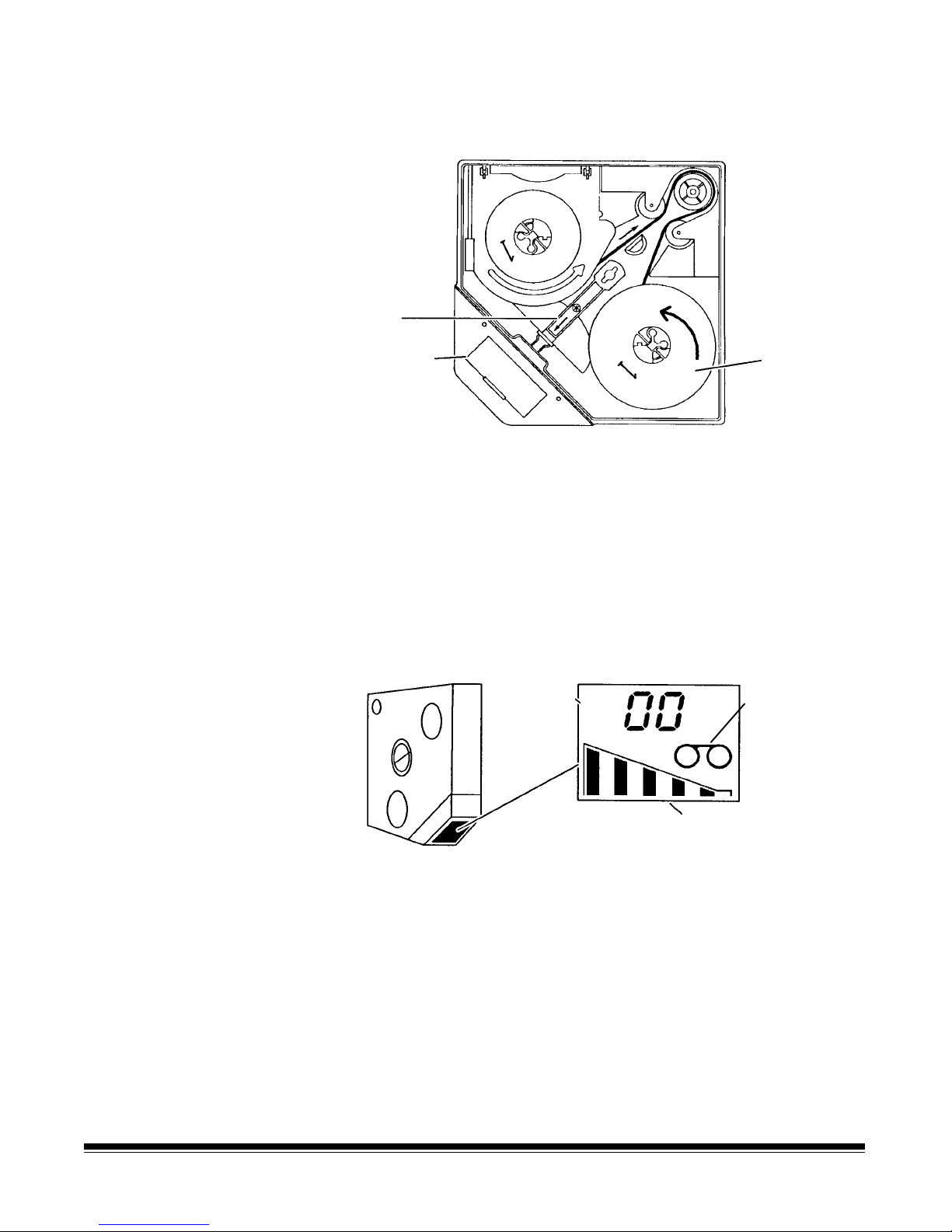

12. Thread the film around the guide roller, drive roller and idler roller,

following the path indicated by the threading arrows inside the film

cassette.

Guideroller

Drive

roller

Idler

roller

13. Fold back approximately ½ in. (1 cm) at the end of the film.

Take-up spool

Spool core

Slot

Fold film back

½-inch (1 cm)

14. Pick up the take-up spool and hold it with the number 1 side up.

15. Insert the folded end of the film into the slot in the take-up spool

core.

16. Rotate the spool counterclockwise to secure the film on the spool.

17. Place the take-up spool over the take-up spindle lugs.

Take-up spool

2-4 A-61096 June 1999

Page 15

18. Slide the release lever toward the battery compartment and hold it

g

in this position.

Release

lever

Battery

compartment

Take-up

spool

19. Slowly rotate the take-up spool counterclockwise 3 complete turns

to secure the film onto the spool. Allow the release lever to return

to its normal position.

20. Replace the top cover on the cassette. Press down on the cover

latch and turn it clockwise to lock the top cover in place.

NOTE: If the film has been loaded correctly, the film supply

indicator changes to show the cassette is full.

Cassette display

Film spool

loaded

A-61096 June 1999 2-5

Full roll of film / cassette not inserted

into scanner/microima

er

Page 16

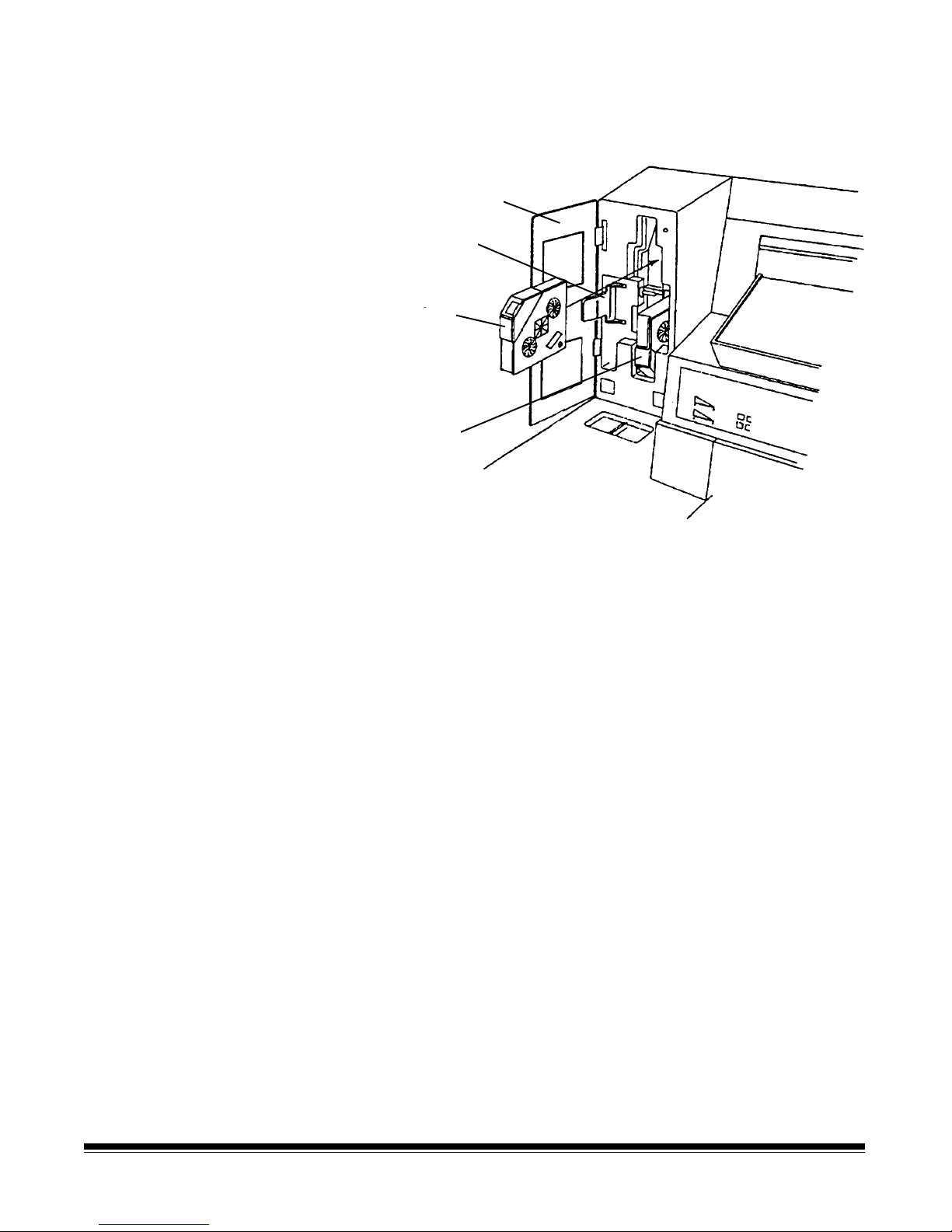

Loading cassette(s) into

r

the scanner/microimager

A film cassette may be loaded into either the upper or lower film slot.

Cassette

access doo

Drive release

lever

Upper cassette

Lower cassette

(in place)

1. Open the cassette access door.

2. Swing the drive release level (green handle) out.

3. Insert the film ca ssette(s).

NOTE: Refer to the label on the inside of the cassette access door

for cassette orientation. The display on the film cassette is

oriented dif f erently depending upon the film slot being

used.

4. Swing the drive release lever back into place.

5. Close the cassette access door.

Whenever a new or partial roll of film is loaded into the scanner/

microimager, a leader is automatically made when the cassette access

door is closed and the side panel switch is turned on.

A

Please Wait…

message appears in the status display while the film

leader is advanced. Once a normal operating display appears,

indicating the leader has been advanced, check the film supply

indicators on the control panel to verify that a f ull roll of film is

indicated.

2-6 A-61096 June 1999

Page 17

Entering a cassette ID

r

number

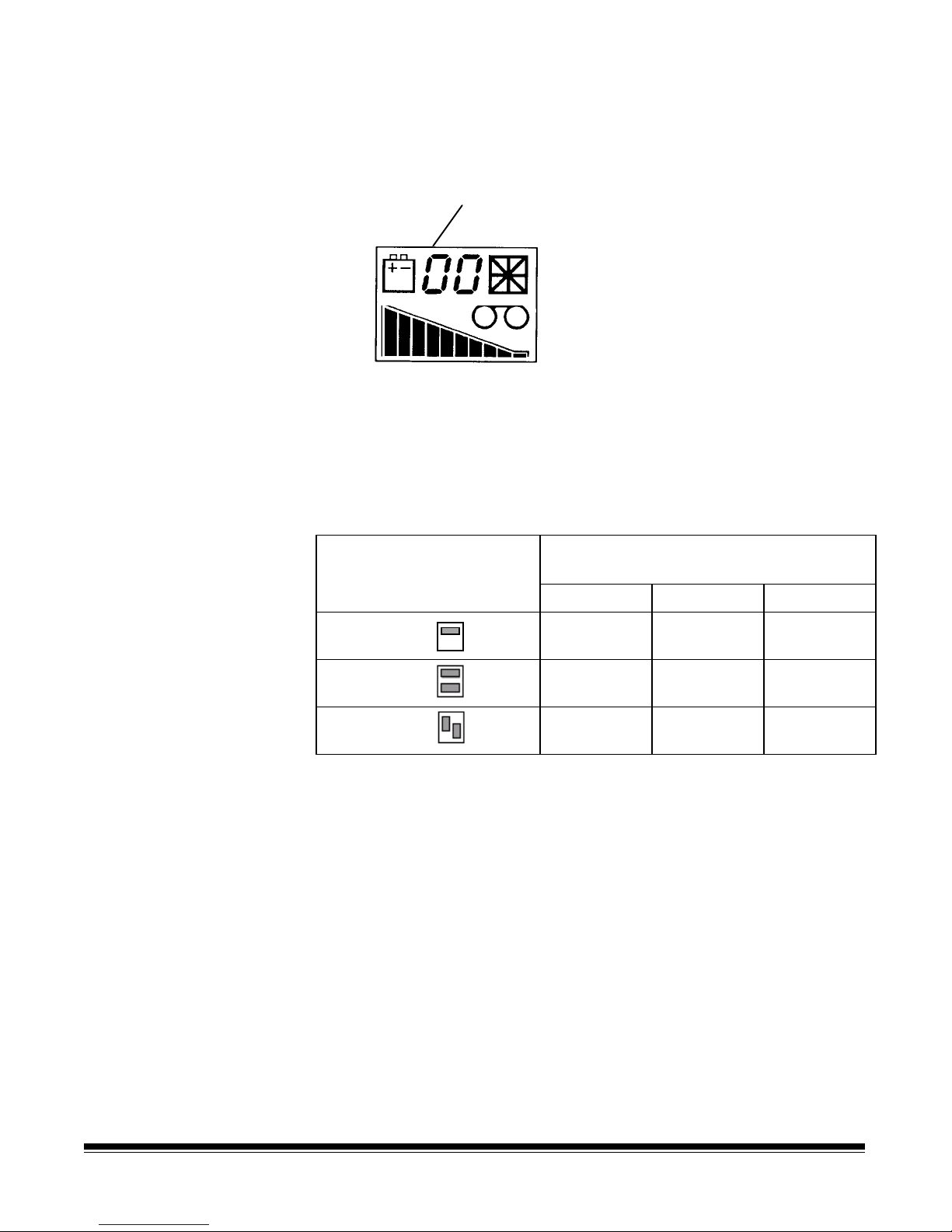

The cassette ID number that appears in the cassette display may be

entered or changed using function code F36.

Cassette ID numbe

Selecting the lens

reduction

A lens reduction must be selected so the filmed images are exposed

correctly on the film.

The lens reduction selected is based on the film mode used and the

width of the documents to be filmed:

Maximum Document Width using

Lens Reduction

Film Mode 24X 40X 50X

Simplex

Duplex

Duo

12 in

30 cm

not allowed 10.2 in

not allowed 8.9 in

10.2 in

25.5 cm

25.5 cm

22.25 cm

12 in

30 cm

12 in

30 cm

10.2 in

25.5 cm

A-61096 June 1999 2-7

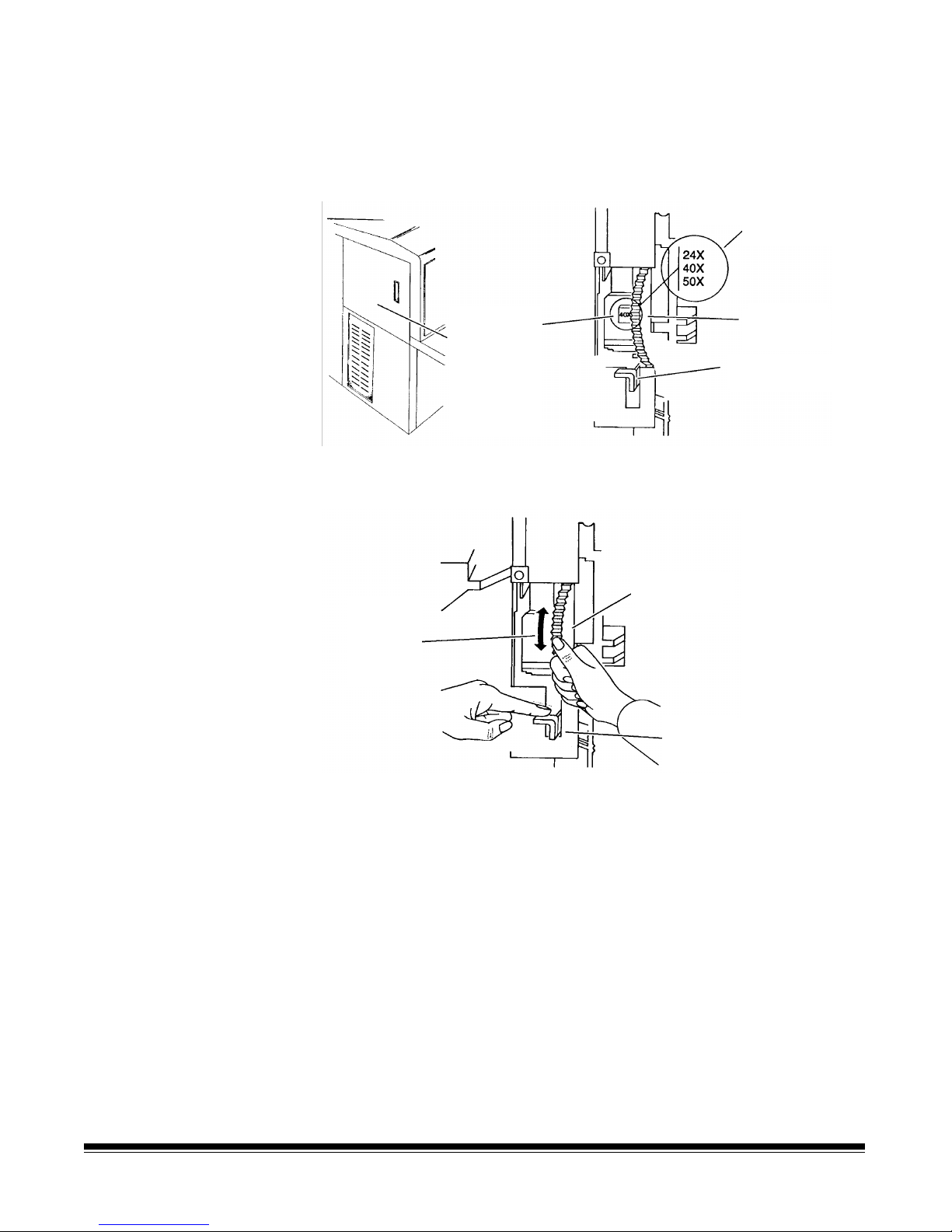

Page 18

Changing the lens holder

position

Once the proper lens reduction has been selected, change the lens

holder position to reflect the desired lens reduction.

1. Open the left-side access door.

Available lens

reductions

Current lens

reduction

(inside leftside access

door

Press to unlock

2. Press down and hold the lens holder lock as shown.

Lens holder

Lens

reduction

label

location

Lens

holder lock

Lens holder

2-8 A-61096 June 1999

3. Rotate the lens holder up or down until the lens reduction selected

is displayed facing you.

4. Release the lens holder lock. Releasing the lock causes a groove

in the lens holder to be engaged, ensuring that it does not rotate

freely.

5. Close the left-side access door.

NOTE: A double-asterisk (**) appears in the first line of the status

display if the lens holder position is not set properly (i.e., if

the lens holder is positioned between lens reductions).

Page 19

Selecting the mask

r

Select the film mask that corresponds to the film mode used.

1. Open the right-side access door.

Right-side

access door

Film mask leve

Duplex setting

Simplex or Duo

2. Slide the film mask lever to the left when using the duplex film

mode, or to the right when using the simplex or duo film mode.

3. Close the right-side access door.

A-61096 June 1999 2-9

Page 20

Calibrating the

scanner/microimager

NOTE: Disregard this section if the current mode configuration is

filming only.

Calibration sets the intensity of the lamps, which contributes to the

overall quality of the scanned document image.

The scanner/microimager should be calibrated:

• At least once a day when the scanner/microimager is turned on

using the side panel switch — prior to scanning documents.

• Any time the scanner/microimager is turned on using the main

power switch.

• If image quality is poor.

• After changing a Document Scanning Array lamp.

Calibrate the scanner/microimager using a calibration target (sheet of

paper) that is:

• Blank

• Clean

• Matte finish (not glossy)

• White or the same color as the background color of the documents

to be scanned. If you are scanning a variety of colored documents,

use a white calibration target.

• Wider than the documents you are going to scan (i.e., to scan

8 1/2 x 11 inch (215.9 x 279.4 mm) documents, the calibration

target should be wider than 8 1/2 inches (215.9 mm). The

recommended width for the calibration target is 12 inches (300

mm).

2-10 A-61096 June 1999

Page 21

To calibrate the scanner/microimager:

1. Verify the main power and side panel switches are on. A normal

operating status display should appear.

2. Press P5 or enter function code F37 to start the calibration

sequence.

3. Insert the calibration target into the feeder.

Calibration

target

NOTE:When using a Document Scanner/Microimager 990S, you

are prompted to enter the calibration target once. When

using a Document Scanner/Microimager 990D, you are

prompted to enter the calibration target twice.

Unsuccessful calibration

When calibration is successful, the status display returns to a normal

operating display.

If calibration is not successful, a message appears in the status

display.

You may need to:

• Verify you are using a clean, blank sheet of paper as a calibration

target.

• Verify there is not a document already in the document path. (Refer

to the section entitled, “Clearing the document path” in Chapter 7.)

• Clean the Document Scanning Array. (Refer to the section entitled,

“Cleaning the Document Scanning Array” in Chapter 5.)

• Calibrate the scanner/microimager again. If calibration fails again,

change the lamps. (Refer to the section entitled, “Replacing the

exposure lamps” in Chapter 5.)

If you have done all of the above and calibration still fails, contact your

service representative.

A-61096 June 1999 2-11

Page 22

Adjusting t he feed and

separator roller gap

IMPORTANT:

Before adjusting the feed and separator roller gap, be

sure the feed and separator rollers are clean. Cleaning

the feed and separator rollers will frequently resolve

document feeding problems.

The adjustment procedure should only be done when

feeding and separating problems continue after the

feed and separator rollers have been cleaned . For

procedures on cleaning rollers, see Chapter 5,

Maintenance.

The gap adjustment knob on the control panel increases or decreases

the space between the feed and separator rollers. The gap must be

adjusted properly for smooth transportation of documents without

document overlap.

When documents of different thicknesses are fed in a group, adjust the

gap using the thinnest document in the group.

The feed and separator roller gap may have to be adjusted to

compensate for:

• Very thin documents (onion skin, tracing paper, etc.).

• Very thick documents (card stock, punch cards, cover stock).

• Some coated documents (photographic paper, plastic-coated

paper).

If the gap is not adjusted properly:

• More than one document at a time may be drawn into the transport

system at the same time; not all of the documents will be

scanned/filmed.

• Documents may be drawn into the transport too quickly; documents

may overlap or be spaced too closely (causing an error display).

• Documents may become skewed during transport; jamming may

occur.

NOTE:Priorto performing the adjustment procedure, the

scanner/microimager must be calibrated and enabled.

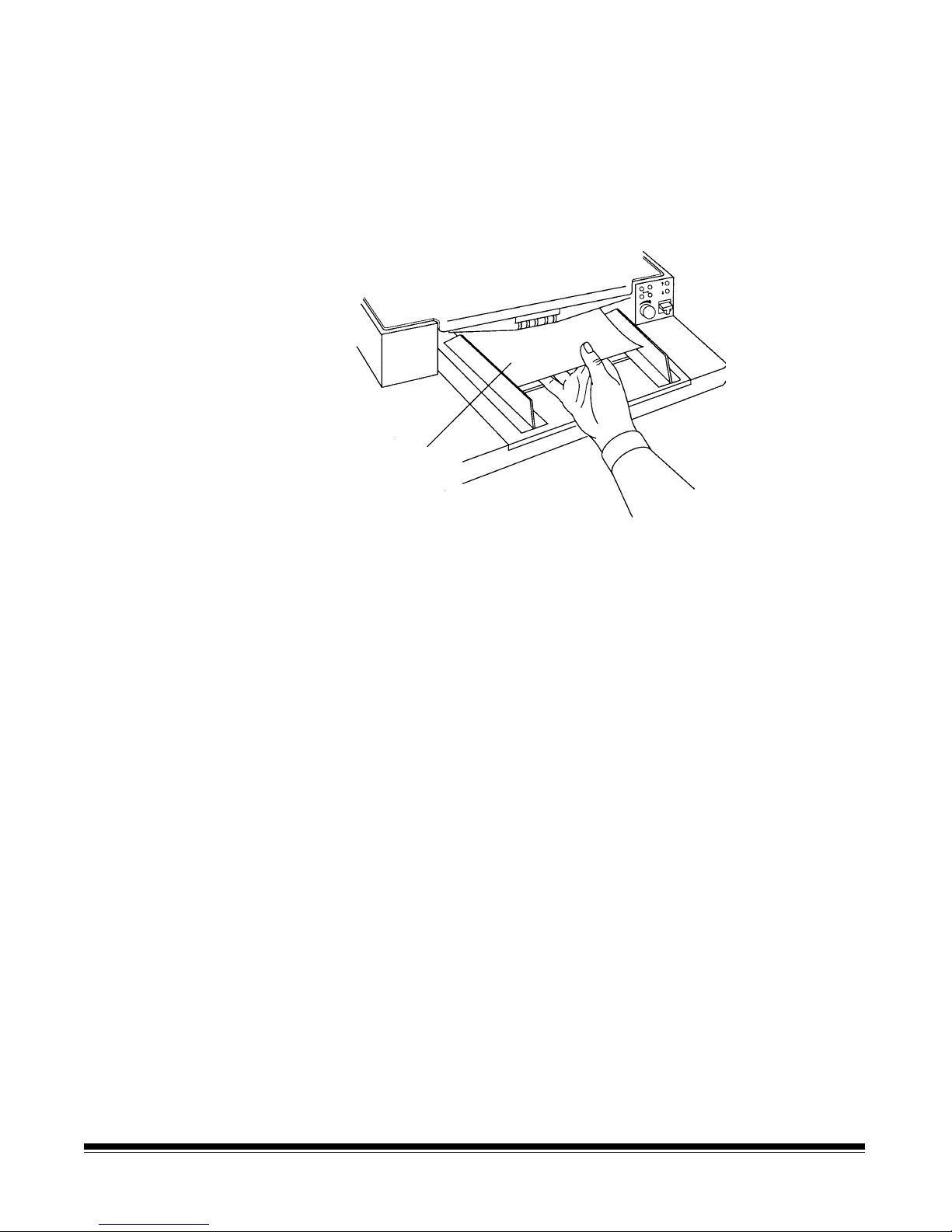

To adjust the feed and separator roller gap:

1. Turn on the side panel switch.

2. Enterfunction code F04 and enable counting-only.

3. Press Enter.

4. Press Run.

IMPORTANT:

Do not make a gap adjustment w hile documents are in

the feeder or transport system; doing so will produce an

inaccurate adjustment

.

2-12 A-61096 June 1999

5. Turn the gap adjustment knob clockwise three complete turns, or

until it stops, to open the gap between the feed and separator

rollers.

Page 23

6. Turn the gap adjustment knob counterclockwise 2 1/2 turns.

7. Select two documents of the same size, texture and thickness,

similar to the types of documents you will be processing.

8. Place one document on top of the other. Hold the documents firmly

by their trailing edges. Insert them into the gap approximately 1/8

in. (3 mm).

Gap adjustment knob

Feed rollers

Separated

document

Trailing edge of top

document

If the documents separate, repeat the following steps until the

documents do not separate:

• Turn the gap adjustment knob clockwise 1/2 turn.

• Insert the documents again.

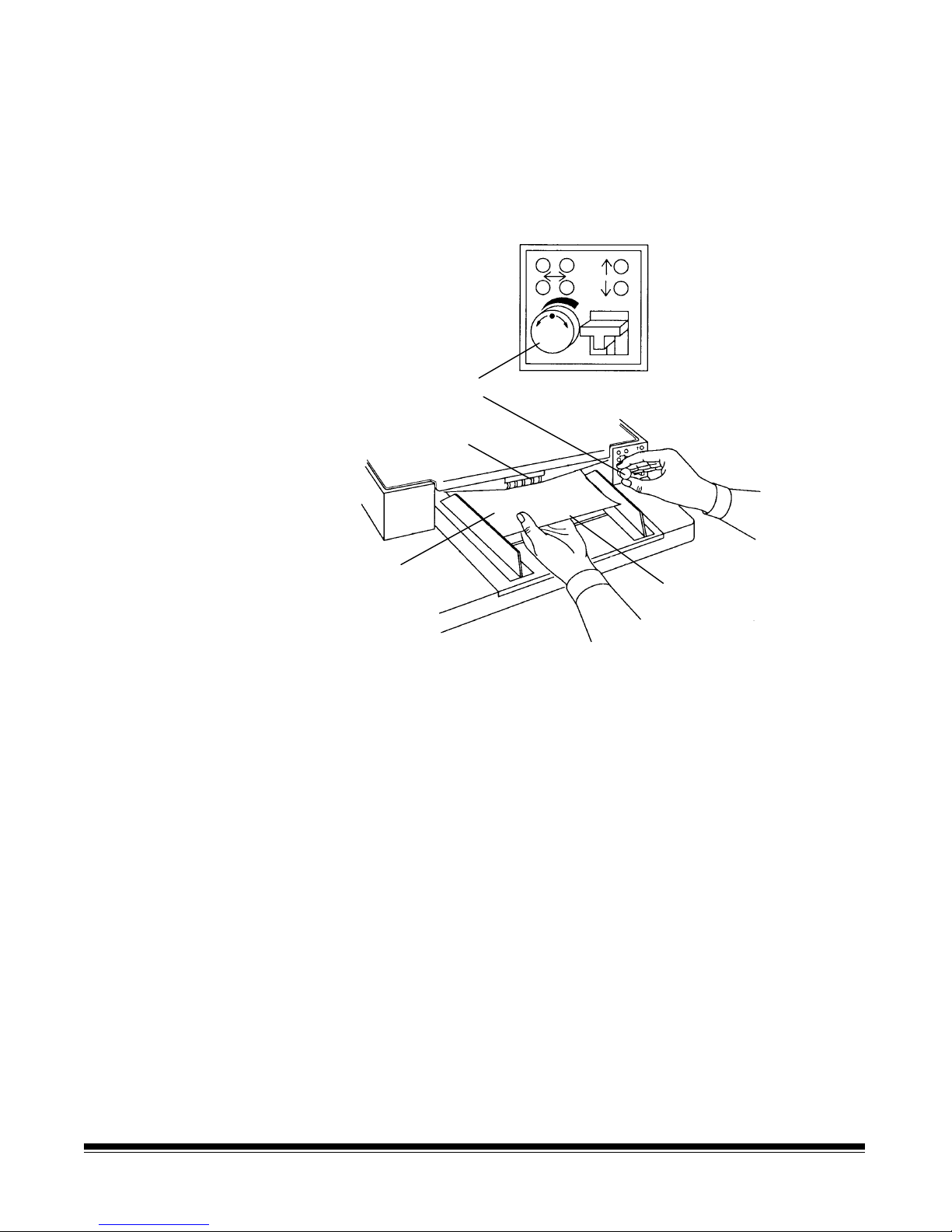

If the documents do not separate, proceed with Step 9.

9. Rotate the gap adjustment knob counterclockwise 1 or 2 clicks.

10. Hold the trailing edges of the documents firmly. Insert them into

the gap.

• If the bottom document is not separating from the top

document, remove the documents and repeat Steps 9 and 10

until the bottom document separates from the top document by

approximately 1 in. (25.4 mm).

• If the bottom document is separating from the top document,

proceed with Step 11.

A-61096 June 1999 2-13

Page 24

11. W hen you have adjusted the gap so the bottom document

separates consistently from the top document, rotate the gap

adjustment knob counterclockwise another 1 or 2 clicks to

complete the adjustment.

12. Feed a stack of 50 to 100 documents twice through the transport

system. Verify the final count reflects the total number of

documents that were fed and that the counter shows the same

amount each time the documents are counted.

If the count is not the same, the gap is not adjusted correctly.

Rotate the gap adjustment knob counterclockwise another 1 or 2

clicks and repeat Step 12. Repeat until corrected.

13. Press Stop.

14. Enter function code F04 and disable Counting-only.

15. Press Enter.

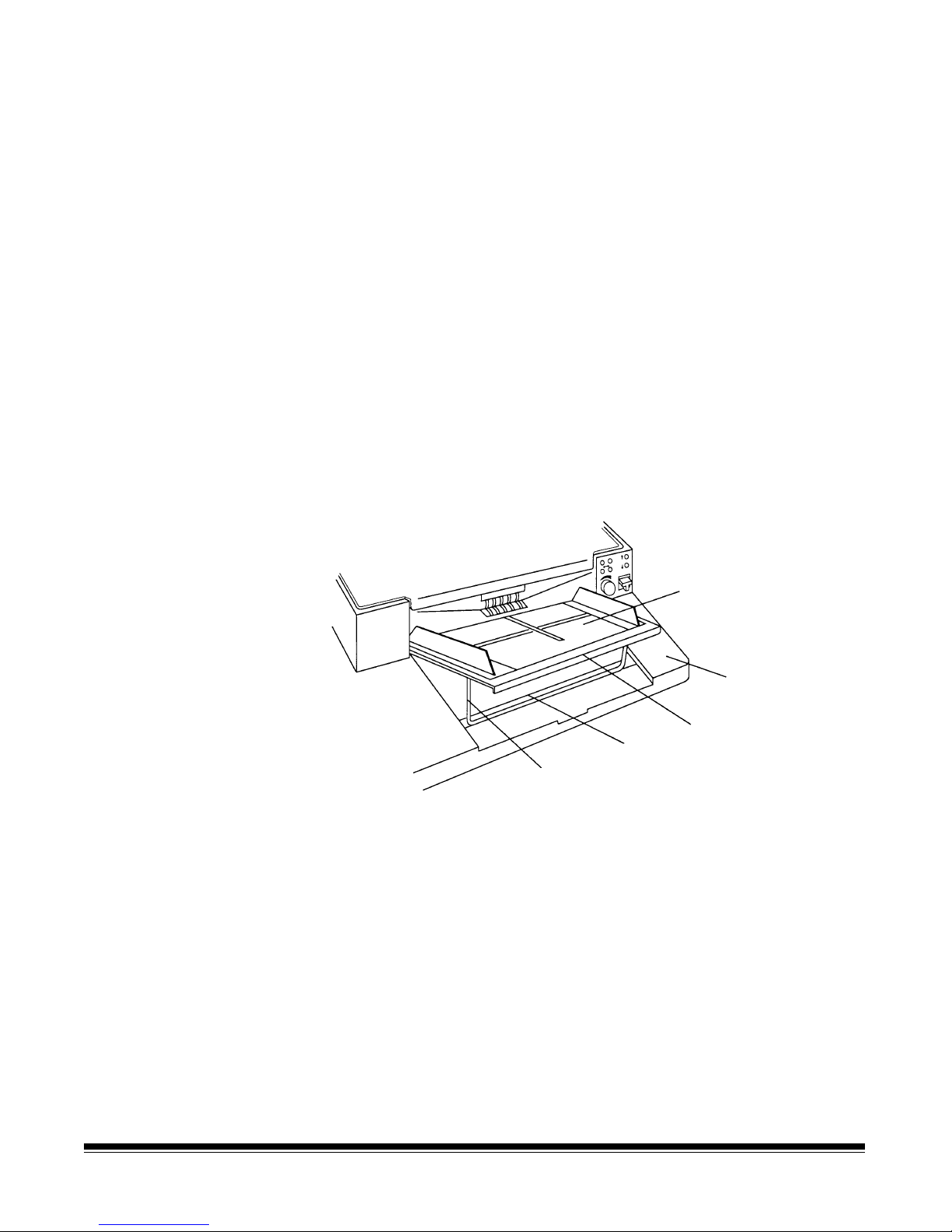

Adjusting t he feed shelf

position

Before you begin feeding documents into the scanner/microimager,

adjust the position of the feed shelf.

Feed shelf

Work shelf

Groove

Height

adjustment arm

Front edge of

feed shelf

To semi-automatically feed multiple documents, the feed shelf should

be in the raised position (as shown above).

To raise the feed shelf:

2-14 A-61096 June 1999

1. Grasp the front of the feed shelf and lift it up.

2. Swing the height adjustment arm out and insert it into the groove

on the work shelf.

To hand-feed documents (one at a time), the feed shelf should be in

the down position (not shown).

Page 25

To lower the feed shelf:

1. Grasp the front of the feed shelf and lift it up until the height

adjustment arm is no longer resting in the groove on the work shelf.

2. Push the height adjustment arm forward and gently lower the feed

shelf into position, level with the work shelf.

Adjusting t he feed shelf

length

NOTE: This section should be disregarded when using a

scanner/microimager 990S.

The feed shelf length may be adjusted to accommodate non-standard

size documents.

To adjust the feed shelf length:

• Grasp the front edge of the feed shelf and pull the feed shelf

extension toward you.

Feed shelf

Feed shelf

extension

Front edge of

feed shelf

To retract the feed shelf length:

• Push the feed shelf extension gently back into its original position.

A-61096 June 1999 2-15

Page 26

Adjusting t he feed shelf

side guides

Before you begin processing documents, adjust the side guides on the

feed shelf to accommodate the documents being processed.

If you are scanning and filming:

• Slide the feed shelf side guides apart, leaving approximately 1/16

in. (2 mm) clearance on each side of the documents. The

documents are automatically centered across the width of the

transport. You may adjust the side guides to feed documents offcenter by holding one of the side guides in place and then sliding

the second side guide into the desired position.

Side guide

Work shelf

Side guide

Feed shelf label

Front edge of

feed shelf

If you are filming only (no scan):

1. Determine the lens reduction and film mode you are using

(simplex, duplex, or duo).

2. Slide apart the side guides on the feed shelf until the feed shelf

label is visible.

3. Use the examples on the following page(s) to determine where to

set the side guides. Leave approximately 1/16 in. (2 mm) clearance

on each side of the documents so they feed properly.

IMPORTANT:

Microfilming documents which exceed the maximum

document size can result in loss of document

information on the microfilm.

2-16 A-61096 June 1999

If the documents are smaller than the area shown on the feed shelf

label, center the documents within the label boundaries on the feed

shelf. Readjust the side guides to fit the documents, allowing 1/16 in.

(2 mm) on either side of the document.

Page 27

If the documents are larger than the area shown on the feed shelf

label, and do not fit between the side guides, rotate and reposition the

documents within the side guides. If the documents still do not fit within

the label boundaries and extend past the side guides, you may have

selected an incorrect lens reduction and/or film mode for the size of

your documents. Refer to the section entitled, “Selecting a lens

reduction” earlier in this chapter. This section lists the maximum

document size allowed by each lens reduction and microfilming mode.

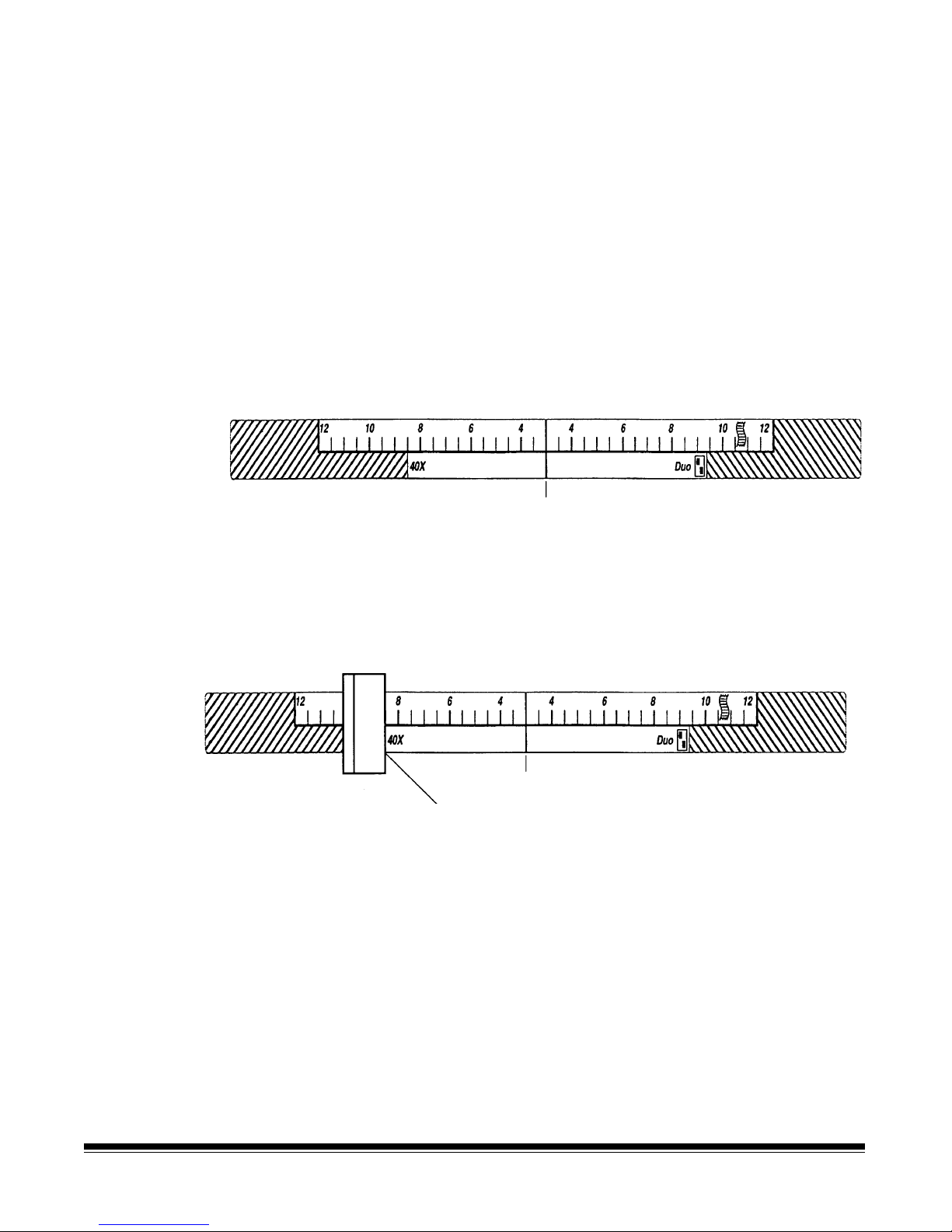

The following examples show the correct placement of the feed shelf

side guides for each possible combination of lens reduction and film

mode:

24X reduction ratio; simplex film mode

50X reduction ratio; simplex film mode

Center Line

Center the documents, allowing approximately 1/16 in. (2 mm)

clearance on each side of the documents so they feed properly.

40X reduction ratio; simplex film mode

Center Line

Left feeder side guide should be aligned here

Set the left feed shelf guide side shelf where indicated.

Set the right feed shelf side guide dependent upon the width of the

document, allowing approximately 1/16 in. (2 mm) clearance on each

side of the documents so they feed properly.

A-61096 June 1999 2-17

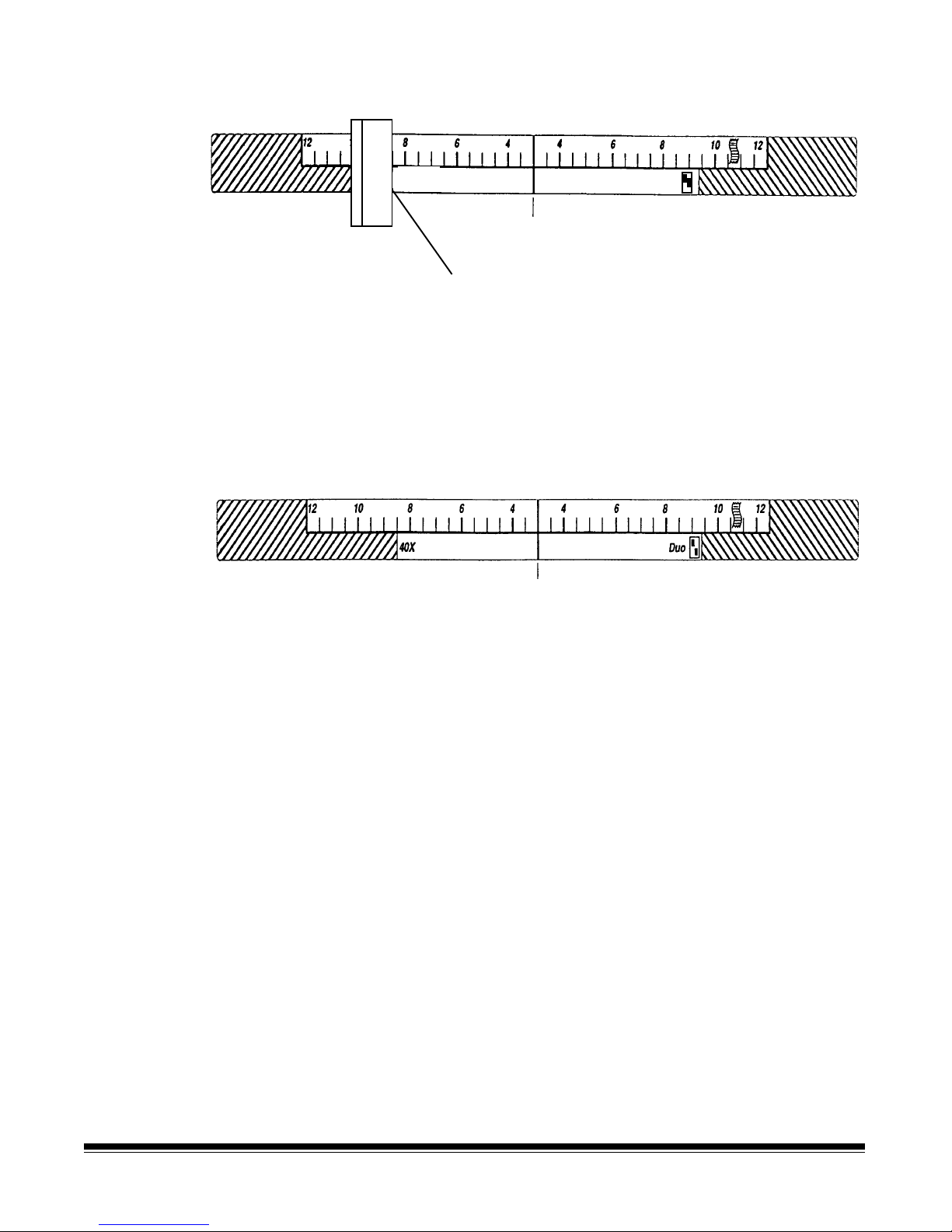

Page 28

40X reduction ratio; duplex film mode

40X

Center Line

Left feed shelf side guide should be aligned here

Duo

Set the left feed shelf side guide where indicated. Set the right feed

shelf side guide dependent upon the width of the document, allowing

approximately 1/16 in. (2 mm) clearance on each side of the

documents so they feed properly.

50X reduction ratio; duplex film mode

Center Line

Center the documents, allowing approximately 1/16 in. (2 mm)

clearance on each side of the documents so they feed properly.

2-18 A-61096 June 1999

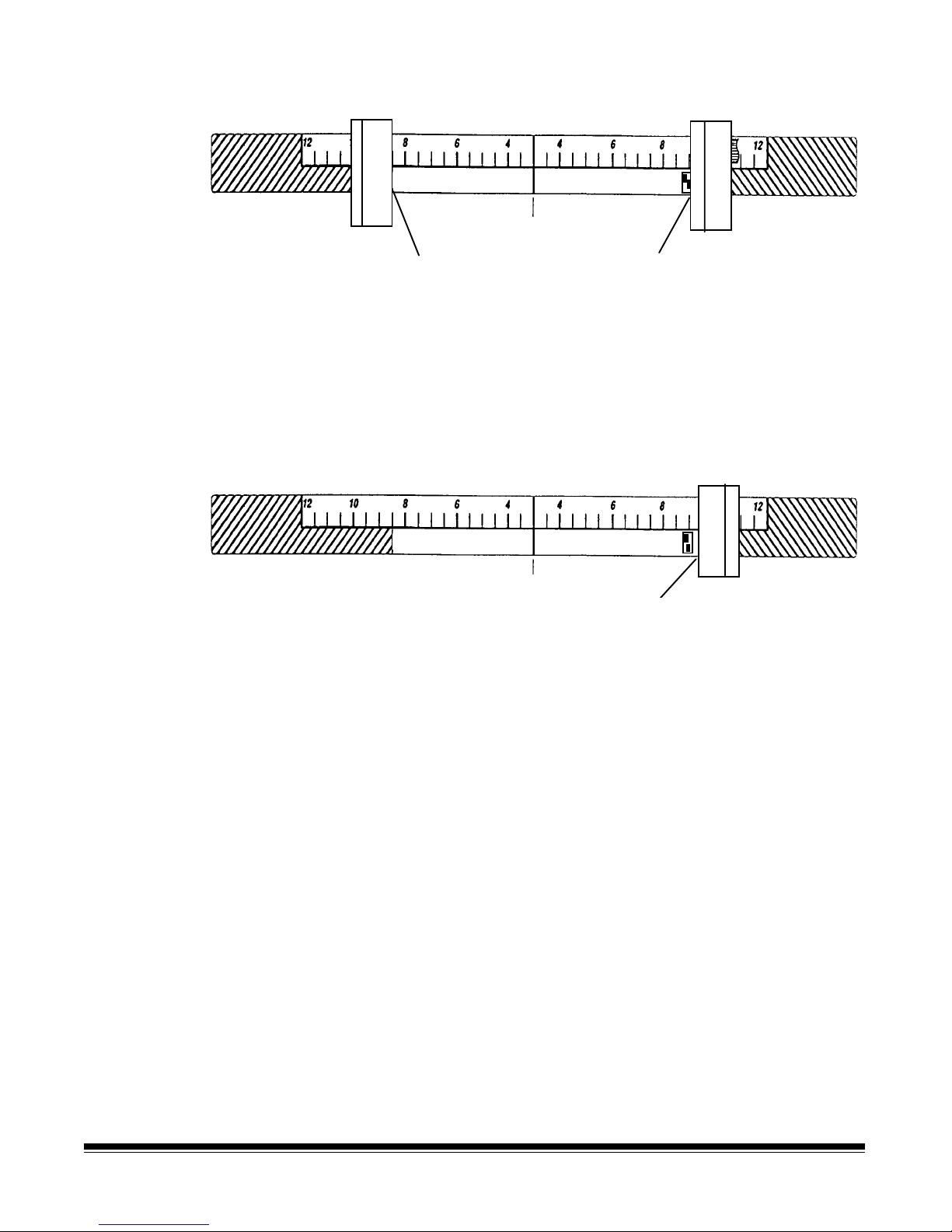

Page 29

40X reduction ratio; duo film mode

40X

Left feed shelf side guide should be aligned here

Set the left and right feed shelf side guides where indicated. Allow

approximately 1/16 in. (2 mm) clearance on each side of the

documents so they feed properly.

50X reduction ratio; duo film mode

40X

Duo

Center Line

Right feeder si de guide should be aligned here

Duo

Center Line

Right feed shelf side guide

should be aligned here

Set the right feed shelf side guide where indicated. Set the left f eed

shelf side guide dependent upon the width of the document, allowing

approximately 1/16 in. (2 mm) clearance on each side of the

documents so they feed properly.

A-61096 June 1999 2-19

Page 30

Adjusting the exit

)

hopper side guides and

end stop

The exit hopper side guides and end stop must be adjusted so

documents are stacked properly after processing.

1. Adjust the side guides on the exit hopper to match the adjustment

of the side guides on the feed shelf.

Exit hopper

label

End

stop

Exit hopper

Side guides

(arrows depict

correct placement

of side guides)

2. Adjust the end stop of the exit hopper by determining the longest

document to be processed. Slide the end stop until the arrows

point to where the length of the longest document is shown on the

exit hopper label.

Checks

IBM cards

5-inch

8½-inch(A5

ArrowArrow

11-inch (A4)

14-inch (B3)

17-inch with

adapter (A3)

2-20 A-61096 June 1999

Page 31

Changing the deflector

The scanner/microimager comes with two deflectors (stored in the

pocket located inside the right-side access door), designed to help

stack the documents as they exit the transport sy stem and enter the

exit hopper.

Use the short deflector for documents less than 5 in. (13 cm) and the

long deflector for documents longer than 5 in. (13 cm) as well as for

mixed sizes.

Short document deflector

Attachment

pins

Long document deflector

Holding clip

Deflector

Front cover

(does not have to

be open to attach

deflectors)

(Swings to right)

1. Grasp the deflector near the attachment pin (as shown).

Lip of exit hopper

Deflector

(black side must be down)

2. Guide the def lector into the exit hopper, just below the lip of the

hopper, to insert the attachment pin in the holding clip.

3. Pull the deflector toward you until it clicks into place.

A-61096 June 1999 2-21

Page 32

Running an exposure

step test

An Exposure Step Test is run to determine the proper AEC illumination

level.

Perform an Exposure Step Test whenever one (or more) of the

following conditions is true:

• After changing exposure lamps.

• Before using a diff erent type of microfilm.

• Before using a different microfilm processing lab.

• After a change in processing lab results are noticed.

Before running an Exposure Step Test, clean all mirrors and imaging

guides. Refer to Chapter 7,

Maintenance

.

The following procedure outlines how to generate a step test filmstrip.

After the test is completed, the film should be unloaded and

processed. It is recommended that no filming take place until the

results of the test are evaluated and the proper AEC illumination level

is determined.

1. Prepare 10 plain white forms numbering them from 0 through 9.

The numbers should be at least 1 in. (25 mm) high.

2. Insert two film cassettes, loaded with the same type of microfilm to

be used during normal operation.

NOTE: If you do not have two f ilm cassettes, insert a single film

cassette in the upper slot, run the Exposure Step Test,

change to the lower slot, and rerun the Exposure Step

Test.

3. Enterfunction code F24. Verify that the AEC is turned on. If it is not

on, press 1 and then Enter to turn it on.

4. Enterfunction code F25.

• Use the left arrow key to change the base illumination level to 0

(the lightest setting). Press Enter and then Run. Select the

plain white form with the number 0 printed on it. Feed the

document into the transport two or three times.

• Use the right arrow key to change the base illumination level to

the next highest setting. Press Enter and then Run. Select the

plain white f orm with the next highest number on it. Feed the

document into the transport two or three times.

• Repeat this process until all 10 forms have been f ilmed.

5. Press the C key.

6. Enterfunction code F24.Press0 and then Enter to turn the AEC

off.

2-22 A-61096 June 1999

Page 33

7. Enterfunction code F26.

• Use the left arrow key to change the base illumination level to 0

(the lightest setting). Press Enter and then Run. Select the

plain white form with the number 0 printed on it. Feed the

document into the transport two or three times.

• Use the right arrow key to change the base illumination level to

the next highest setting. Press Enter and then press Run.

Select the plain white form with the next highest number on it.

Feed the document into the transport two or three times.

• Repeat this process until all 10 forms have been filmed.

8. Press the C key.

9. Enterfunction code F27 to advance the film 2 to 3 f eet.

NOTE: It is recommended that you create a 6-foot leader by

entering function code F28. The advanced film protects the

images f rom exposure to roomlight.

10. Remove the film from the cassettes using the steps outlined in

Chapter 3,

Operating the Scanner/microimager.

11. Place each filmstrip in separate boxes and label each box with the

following information:

Preparing documents for

scanning

• Exposure Step Test

• Date of Test

• Upper or lower cassette used

• Type of microfilm used

• Machine used f or test (if more than one machine is on-site)

12. Send the f ilm for processing. For consistency, use the same

processing lab that processes your regular production work.

13. W hen the film is returned, evaluate it to determine which settings

produced the best images. Use a microfilmreader for the initial

evaluation; in addition, view the images via a reader/printer, or

however the end user see it.

Before you begin processing documents, be sure the documents will

feed through the scanner/microimager easily:

• Remove any staples, rubber bands, loose mending tape, or paper

clips from the documents to be processed.

• Straighten wrinkled edges and tape any torn documents.

• Trim ragged edges.

When using the automatic feeder, make certain all documents are of

similar size, texture, thickness and weight; and that the leading edges

of all documents are aligned.

A-61096 June 1999 2-23

Page 34

Document orientation

Documents appear on film in the same order and orientation in which

they are fed into the scanner/microimager. It is important to place the

documents in the desired order and orientation before feeding them

into the transport.

The documents may be either Cine or Comic orientation.

Cine Comic

2-24 A-61096 June 1999

Page 35

3 Operating the Scanner/Microimager

Overview

The scanning process consists of the following steps:

1. Prepare the scanner/microimager for operation (refer to Chapter 2,

Getting Started

2. Enable the scanner/microimager from the host system.

3. Select a mode for the application. Typically the host computer

performs this step, but it may also be performed by the operator.

4. Select temporary operating values (if required).

5. Check the film supply to verify there is enough film to complete the

job or batch.

6. Press Run.

7. Feed the documents into the transport.

• The scanner/microimager assigns a sequential ID number (for

digital image storage), the document image level and image

address.

• The document is scanned.

• The document is recorded on f ilm, along with the appropriate

image mark.

for more information).

• The document image header is created.

• The host computer initiates transfer of the document image

header and document image to the host system for storage on

magnetic or optical disk media.

• Documents are deposited in the exit hopper, face down, in the

order in which they were fed into the transport.

8. Press Stop.

9. Enterfunction code F38 to indicate end-of-job.

10. Unload the film cassette(s).

11. Turn off the side panel switch.

NOTE: If the scanner/microimager will not be used for 8 hours or

more, turn of f the main power switch.

A-61096 June 1999 3-1

Page 36

Selecting a mode

The scanner/microimager offers 18 modes that may be programmed

for a particular application or group of applications.

The modes are programmed at the time of installation and stored for

easy access and use.

Typically, the mode is selected via the host system, using a scannerunique command. However, you may manually select a mode.

To select a mode, either:

• Enter function code F01 (Select Mode) or F91 (Select Linked

Mode).

or

• Check with yo ur system administrator to see if one or more of the P

keys has been preprogrammed to perform specific functions.

Temporary operating

values

Each of the 18 modes programmed at the time of installation contain

definitions that affect the output of the scanner/microimager. Each

mode is programmed to conform to the output requirements of a

particular application or group of applications.

There may be instances, however, when a particular application

requires some variation of an existing mode. In such instances, mode

definitions may be changed using available function codes. See

Chapter 4,

function codes.

NOTE: Changes to mode def initions remain in effect until another

Example:

If Mode 15 contains definitions that allow you to use the

Imagelink

from the leading edge of the document the endorsement is printed) is

programmed to be ½-inch.

Function Codes,

mode is selected or the side panel switch is turned off . The

original mode definition is only affected by these changes if

the mode overrides are saved (the mode override option may

be selected at installation and if selected, a plus sign (+)

appears in the first line of the status display).

for a listing and description of the available

Kodak

Endorser, the starting print position (which defines how f ar

3-2 A-61096 June 1999

If there is a special application that requires the endorsement be

printed 1 inch from the leading edge of the document, you may use

function code F59 to temporarily change the starting print position.

Page 37

Setting the automatic

exposure control

Automatic Exposure Control (AEC) provides optimal film quality by

helping to ensure that filmed documents are exposed at the proper

level.

Before filming documents, determine whether the AEC should be

turned on or off.

When AEC is turned on, it automatically adjusts for variations in

contrast, color, etc. Typically, AEC is turned on for average or normal

documents.

When AEC is turned off, it is fixed at a particular level f or documents

which have large areas of dense shading, etc.). Typically AEC is

turned off f or filming special documents such as transparencies, onion

skin documents or highly reflective documents.

NOTE: It is assumed that an Exposure Step Test has been

performed to determine the proper illumination level. Refer to

Chapter 2

To verify the mode selected specifies that AEC is on:

• Enter function code F24 (AEC On/Off).

The display shows: Automatic Exposure Control OFF (or ON)

− If the AEC is OFF, enter 1 to turn it on.

− If the AEC is ON, p ress the C key.

• Enter function code F25 (AEC Auto Adjust) to adjust the base

illumination level.

, Getting Started

for more information.

− Use the arrow keys to lighten or darken the base illumination

level (where 0 is the lightest and 9 is the darkest).

− Press Enter when the level has been adjusted correctly.

To verify the mode selected specifies that AEC is off:

• Enter function code F24 (AEC On/Off).

The display shows: Automatic Exposure Control OFF (or ON)

− If the AEC is ON, enter 0 to turn it off.

− If the AEC is OFF, press the C key.

• Enter function code F26 (AEC Fixed Adjust) to adjust the fixed

illumination level.

− Use the arrow keys to lighten or darken the fixed illumination

level (where 0 is the lightest and 9 is the darkest).

− Press Enter when the level has been adjusted correctly.

A-61096 June 1999 3-3

Page 38

Checking the film

r

supply

The film supply indicators, located on the left side of the control panel,

are used to determine whether or not there is enough film to complete

the job. The indicator has 10 vertical bars, each representing 10% of a

full roll of film (i.e., if all 10 bars are displayed, a full roll of film is

available; if 8 bars are displayed 80% of the roll is available, and so

on). A warning message appears when the film supply is down to

10%.

Upper cassette indicator

10%

Lower cassette indicato

10%

NOTE: You can also enter f unction code F30 to determine how much

film remains. The amount of film remaining in both the upper

and lower cassettes is displayed. In addition, the approximate

number of documents which can be filmed on the remainder

of the roll(s) is displayed.

3-4 A-61096 June 1999

Page 39

Feeding documents

After the scanner/microimager has been prepared for operation, and

the desired mode and any temporary operating values have been

defined, you are ready to feed documents into the transport.

1. Verify the side panel switch is on and all proper adjustments have

been made (feeder side guides, exit hopper side guides, etc.).

2. Press Run.

3. Select a stack of documents that is no more than a ½-inch (1 cm)

thick.

4. Fan the stack of documents so the leading edge of the top

document engages the feed/separator rollers as shown:

5. Place the stack of f anned documents into the feeder so the leading

edge of the top document contacts the feed/separator rollers. The

documents are drawn into the transport, with the top document

being fed first. The documents are deposited in the exit hopper

face down, in the order in which they were fed into the transport.

6. Repeat Steps 3 through 5 until all of the application documents

have been fed into the transport.

7. Press Stop after all documents have been deposited in the exit

hopper.

NOTE: When using simplex or duplex mode, the f ully or partially

exposed roll(s) of f ilm can be unloaded when the

application is completed. When using duo mode, refer to

the section “Using duo mode” later in this chapter.

A-61096 June 1999 3-5

Page 40

Feeding thick

documents

The gap release lever is used to feed thick documents such as card

stock or cover stock. The lever is located on the front panel of the

scanner/microimager, next to the gap adjustment knob.

Gap adjustment knob Gap release lever

1. Press down and hold the gap release lever. This opens the gap

between the feed and separator rollers, allowing thick documents

to pass between them. You will be able to see the gap open as the

lever is pushed down.

2. Insert the document past the rollers until it is taken into the

transport.

NOTE: If more than one thick document is to be scanned/filmed,

feed them into the transport one at a time.

Gap release l ever

(hold down)

3. After the thick document(s) have been scanned/filmed, release the

gap release lever. It will return to its original position. The feed and

separator rollers will return to the previously adjusted positions.

3-6 A-61096 June 1999

Page 41

Using duo mode

Duo mode allows you to double the number of single-sided documents

exposed on a single roll of film. This is done by rotating the cassette(s)

after the first side of the film has been fully exposed. Documents are

first exposed down one side of the film (channel A), until the end of the

roll is reached. Then, the cassette(s) are rotated and documents are

exposed down the other side of the film (channel B).

Due to the way in which documents are exposed when using duo

mode, the following recommendations are made:

• Do not mix duo mode microfilming with simplex or duplex mode

microfilming using the same roll of film.

• Do not unload a partially exposed roll of film created using duo

mode.

The following steps illustrate the use of duo mode:

1. Feed documents into the transport as described in the section

entitled, “Feeding documents”.

2. A message appears in the status display when the first side of the

film has been fully exposed:

E212 End of side 1, flip cassette

.

3. Open the cassette access door.

4. Swing the drive release lever (green handle) out.

5. Remove the cassette from the upper f ilm slot.

6. Rotate the cassette so the side two symbol (

) faces the control

panel (as shown). Refer to the labels inside the cassette access

door for proper orientation.

Cassette access door

Side two

symbol

Drive release

lever

Control panel

7. Reinsert the cassette into the upper film slot.

8. Repeat Steps 5 through 7 for the cassette in the lower f ilm slot.

A-61096 June 1999 3-7

9. Continue feeding documents. A message appears in the status

display when the second side of the f ilm has been exposed. Refer

to the section “Unloading a fully exposed roll of film” later in this

chapter.

Page 42

Unloading film

cassette(s)

You may unload a fully or partially exposed roll of film.

IMPORTANT:

Always load and unload film in subdued, indirect light

to help prevent "fogging.”

Unloading a fully

exposed roll of film

Use the following steps to unload a fully exposed roll of film (simplex,

duplex, or duo format).

It is assumed that all documents have been deposited in the exit

hopper and Stop has been pressed.

1. Perform function code F29 (Advance Film to End of Roll).

2. Open the cassette access door.

3. Swing the drive release lever (green handle) out.

4. Remove the film cassette(s).

5. Place the cassette on a flat surface, with the top cover side up.

6. Press down on the cover latch and turn it counterclockwise to

unlock the cover.

7. Remove the top cover and set it aside.

8. Place a finger over the take-up spool flange to prevent the film

from unwinding and lift up to remove the spool of f ilm.

9. Place the spool into the film box. Allow approximately 2 to 3 in.

(5 to 8 cm) of the film to protrude from under the lid of the box (as

shown). Close the top of the box securely.

2to3inches

(5to8cm)

10. W rite identification data (i.e., subject, title, date, job number, etc.)

on the film box label. The film is now ready for processing.

NOTE: Replace the top cover back on the cassette(s), regardless

of whether or not you immediately reload the cassette.

This helps to extend battery life.

3-8 A-61096 June 1999

Page 43

Unloading a partially

exposed roll of film

Follow the steps below to unload a partially exposed roll of film

(simplex or duplex format).

IMPORTANT:

Do not unload a partially exposed roll of film when using

duo mode. Images will be lost if a partial roll is

unloaded.

It is assumed that all documents have been deposited in the exit

hopper and Stop has been pressed.

1. Enterfunction code F28 (Film Advance).

2. Open the cassette access door.

3. Swing the drive release lever (green handle) out.

4. Remove the film cassette(s).

5. Place the cassette on a flat surface, with the top cover side up.

6. Press down on the cover latch and turn it counterclockwise to

unlock the cover.

7. Remove the top cover and set it aside.

Guideroller

Drive roller

Idlerroller

Release

lever

Battery compartment Take-up

spool

8. Slide the release lever toward the battery compartment and hold it

in this position.

A-61096 June 1999 3-9

Page 44

9. Place a finger over the take-up spool flange to prevent the film

10. Cut the film with a pair of scissors as indicated in the illustration

Supply spool

from unwinding.

(between the idler roller and the take-up spool).

Cut here

Take-up spool

flange

Place finger here

to prevent film from

unwinding

11. Lift the take-up spool out of the cassette.

12. Place the spool into the film box. Allow approximately 2 to 3 in.

(5 to 8 cm) of the film to protrude from under the lid of the box.

13. Close the top of the box securely.

14. W rite identification data (i.e., subject, title, date, job number, etc.)

on the film box label. The film is now ready for processing.

To continue filming using the unexposed portion of the roll of film:

1. Obtain an empty take-up spool.

2. Unwind approximately 18 in. (46 cm) of film.

3. Fold back approximately 1/2 in. (1 cm) at the end of the film.

4. Pick up the take-up spool and hold it with the Number 1 side up.

5. Insert the folded end of the f ilm into the slot in the take-up spool

core.

Take-up spool

Spool core

Fold film back

½-inch (1 cm)

3-10 A-61096 June 1999

Slot

Page 45

6. Rotate the spool counterclockwise to secure the film on the spool.

7. Place the take-up spool over the take-up spindle lugs.

8. Slide the release lever toward the battery compartment and hold it

in this position.

9. Slowly rotate the take-up spool counterclockwise 3 full turns to

secure the film on the spool. Allow the release lever to return to its

normal position.

Release

lever

Battery

compartment

Take-up

spool

10. Replace the top cover on the cassette. Press down on the cover

latch and turn it clockwise to lock the cover in place.

NOTE: The cassette may now be inserted into the

scanner/microimager and filming may continue.

A-61096 June 1999 3-11

Page 46

4 Function Codes

Using function

codes

There are a variety of functions available which may be used to

temporarily change operating conditions and values, and to obtain

system and accessory status information.

These functions are listed in the Function Code Summary later in this

chapter. Following are the procedures for using f unction codes:

1. Press the F key.

2. Press the numeric keys which correspond to the desired function

code.

3. Press Enter.

If the function is used to enable or disable an operation (turn an option

on or off):

1. Press 1 to turn the option On, or 0 to turn the option Off.

2. Press Enter.

If the function requires numeric input:

1. Press the numeric key(s) required.

2. Press Enter.

If the function is used to increment or decrement a measurement:

• Press the arrow keys to increment or decrement as follows:

− Press the Up arrow to increment the measurement by

1 inch (25 mm) or 1 value adjustment, or

− Press the Down arrow to decrement the measurement by

1 inch (25 mm) or 1 value adjustment, or

− Press the Right arrow to increment the measurement by

1/8-inch (3 mm), or

− Press the Left arrow to decrement the measurement by

1/8-inch (3 mm).

• Press Enter.

To cancel a function (before pressing Enter) or clear the status display

after executing a function code:

• Press C (Clear/Cancel).

A-61096 June 1999 4-1

Page 47

Function code

summary

Following is a summary of the functions and their corresponding

function code:

Status

Accessory Status*..............................................................F05

Date and Time Display* .....................................................F23

Elapsed Time*....................................................................F17

Counters

Level 0 Count* ...................................................................F10

Level 1 Count* ...................................................................F11

Level 2 Count* ...................................................................F12

Level 3 Count* ...................................................................F13

Total Document Count*......................................................F09

Reset Level Counts ............................................................F14

Setup

Action/Confirmation Tone ..................................................F93

Alarm Tone ........................................................................F16

Alarm Volume..................................................................... F15

Change Date .....................................................................F22

Change Time .....................................................................F21

Display Contrast.................................................................F18

Display Language ..............................................................F19

Measurement System ........................................................F20

Cassette ID Number...........................................................F35

Operator ID........................................................................F34

Calibration..........................................................................F37

Mode

Select Mode.......................................................................F01

Select Linked Mode............................................................F91

Counting Only....................................................................F04

Filming Only Mode .............................................................F03

Restore Mode.....................................................................F02

Index/Image Address

Last Image Address*..........................................................F08

Level 0*..............................................................................F07

Level 1*..............................................................................F94

Level 2*..............................................................................F95

Level 3*..............................................................................F96

Fixed Field..........................................................................F92

Next Image Address...........................................................F97

* May be executed while transport is running.

4-2 A-61096 June 1999

Page 48

Scanning†

Scanner/Microimager Calibration.......................................F37

Latched Scanning Flag*.....................................................F73

Momentary Scanning Flag*................................................F74

Scanner/Microimager End-of-Job.......................................F38

Filming

Filming Only.......................................................................F03

Cassette ID Number...........................................................F35

Roll Number.......................................................................F33

AEC On/Off........................................................................F24

AEC Auto Adjust ................................................................F25

AEC Fixed Adjust...............................................................F26

Display Film Remaining*....................................................F30

Film Advance*....................................................................F27

Film Leader*.......................................................................F28

Lead End Code..................................................................F31

Trail End Code...................................................................F32

Advance Film to End of Roll...............................................F29

Operation

Run ....................................................................................F99

Terminate Batch* ...............................................................F06

Stop*..................................................................................F98

Endorser

Endorser On/Off.................................................................F57

Endorser Mode...................................................................F58

Endorser Print Position ......................................................F59

Footswitch

Footswitch Confirmation Tone ...........................................F75

Bar Code

Bar Code Reading On/Off..................................................F60

Partial Bar Code Reading On/Off.......................................F66

Bar Code Reading Confirmation Tone...............................F63

Bar Code/Patch Reading Confirmation Tone.....................F62

Bar Code Test....................................................................F65

Omit Bar Code Reading on Next Document*.....................F64

* May be executed while transport is running.

† Will result in an E104 error if you attempt to use this function when the current mode

configuration is Film Only (no scan).

A-61096 June 1999 4-3

Page 49

Document Controller

Length Checking On/Off ....................................................F70

Omit Length Checking on Next Document Only*...............F71

Skew Detection..................................................................F72

Document Printers

All Document Printers On/Off.............................................F40

Primary Document Printer 1 On/Off ...................................F41

Secondary Document Printer 1 On/Off .............................F42

Document Printer 12 On/Off ...............................................F43

Omit Printing on Next Document........................................F44

Print Position......................................................................F46

Print Test............................................................................F45

Printer Character Shift........................................................F39

Printer Open Jet Test.........................................................F56

Purge Frequency................................................................F49

Purge Print Head*..............................................................F48

Super12 Document Printer

Print Contrast.....................................................................F39

Print Head Position............................................................F40

Print Test............................................................................F45

Automatic Purge Print Head...............................................F48

Align Print Image................................................................F49

Print Cartridge Status.........................................................F56

NOTE: Function codes F43, F44 and F46 work the same on a

Super12 Document Printer.

Document Sorter‡

Document Sorter On/Off ....................................................F80

Sort Next Document Only into Specified Bin* ....................F81

Sort All Documents into Specified Bin................................F82

Patch Reader

Patch Reader 1 On/Off ......................................................F50

End-fed Patch Reading On/Of f ..........................................F52

Patch Reading Confirmation Tone.....................................F53

Omit Patch Reading on Next Document*...........................F54

* May be executed while transport is running.

‡ This functionality is scheduled for future available and will be available only on a

limited basis as an alteration.

4-4 A-61096 June 1999

Page 50

Function code listing

Following is a listing of the function codes and descriptions.

Code Function Code Name Description

F01 Select Mode Allows you to select one of the predefined application

modes. Enter a value from 1 to 18 and press Enter.

F02 Restore Mode Allows you to restore the current application mode to its

default status, provided mode overrides are not saved.

F03 Filming Only

Allows you to film documents, with no level counting,

endorsing, patch reading, etc. Enter 1 to turn Filming

Only on or 0 to turn Filming Only off and press Enter.

F04 Counting Only

Allows you to count the number of documents entering

the scanner/microimager without scanning. Enter 1 to

turn Counting Only o n or 0 to turn Counting Only of f and

press Enter.

F05 Accessory Status Displays the current status of each accessory installed.

Press the Down arrow to view the status of the next

accessory, or press the Up arrow to view the status of the

previous accessory.

F06 Terminate Batch Allows you to prematurely end a batch.

F07 Level 0 Allows you to def ine the next document scanned as a

Level 0 document.

F08 Last Image Address Allows you to display the image address of the last

document scanned.

F09 Total Document Count

Allows you to display the total number of documents that

entered the feeder (Level 3, Level 2, Level 1 or Level 0).

Press 0 to reset the counter and then press Enter.

F10 Level 0 Count Allows you to display the total number of documents that

have entered the feeder as Level 0 documents. Press 0

to reset the counter and then press Enter.

F11 Level 1 Count Allows you to display the total number of documents that

have entered the feeder as Level 1 documents. Press 0

to reset the counter and then press Enter.

F12 Level 2 Count Allows you to display the total number of documents that

have entered the feeder as Level 2 documents. Press 0

to reset the counter and then press Enter.

F13 Level 3 Count Allows you to display the total number of documents that

have entered the feeder as Level 3 documents. Press 0

to reset the counter and then press Enter.

F14 Reset Level Counts

Allows you to reset all the level counters (Level 0, Level

1, Level 2, and Level 3) to 0.

A-61096 June 1999 4-5

Page 51

Code Function Code Name Description

F15 Alarm Volume Allows you to adjust the volume of the alarm. Press the

Up arrow to increase the volume or press the Down

arrow to decrease the volume, then press Enter.

F16 Alarm Tone Allows you to adjust the pitch of the alarm tone. Press the

Up arrow to increase the pitch or press the Down arrow

to decrease the pitch, then press Enter.

F17 Elapsed Time Allows you to display the number of hours the motor,

transport and main power have been running, in addition

to the non-resettable document count. Press the Right

arrow to view the meters.

Meter A — displays motor-on hours

Meter B — displays transport-on hours

Meter C — displays main power-on hours

Meter D — displays document count

F18 Display Contrast Allows you to adjust the contrast of the status display.

Press the Up arrow to increase the contrast or press the

Down arrow to decrease the contrast, then press Enter.

F19 Display Language Allows you to choose your preferred language. Press the

arrow key to toggle between two available options.

F20 Measurement System Allows you to choose your preferred measurement

system. Press the arrow key to toggle between two

available options.

F21 Change Time Allows you to change the time. Enter the new time in the

format illustrated and press Enter.

F22 Change Date Allows you to change the date. Enter the new date in the

format illustrated and press Enter.

F23 Time and Date Display Allows you to view the current time and date.

F24 AEC On/Off Allows you to turn the Automatic Exposure Control on or

off. Turning AEC on places the AEC in Auto mode;

turning AEC off places the AEC in Fixed mode. Enter 1 to

turn AEC on, or 0 to turn AEC off and press Enter.

F25 AEC Auto Adjust Allows you to adjust the AEC setting when the AEC is in

Auto mode. Press the Left arrow to decrease the

exposure level (to a minimum level of 0) or press the

Right arrow to increase the exposure level (to a

maximum level of 9), then press Enter.

F26 AEC Fixed Adjust Allows you to adjust the AEC setting when the AEC is in

Fixed mode. Press the Left arrow to decrease the

exposure level (to a minimum level of 0) or press the

Right arrow to increase the exposure level (to a

maximum level of 9), then press Enter.

F27 Film Advance Allows you to advance the film in 6-inch (150 mm)

4-6 A-61096 June 1999

increments or by entering a specific amount. Enter the

amount of inches to advance the f ilm then press Enter.

Page 52

Code Function Code Name Description

F28 Film Leader Allows you to create a film leader which is 6 feet (1.8

meters) of blank film.

F29 Advance Film to End of

Roll

Allows you to advance the film to the end of the roll. Use

F29 prior to unloading a film cassette. A low film warning

will be displayed after the film has been advanced.

F30 Display Film Remaining Allows you to display the amount of film remaining (in

inches or meters) in each film cassette. It also displays

the approximate number of documents which can be

filmed using the remaining amount of film. Press C to

return to a normal operating display.

F31 Lead End Code Allows you to create a lead end code for retrieval

purposes. Enter the following values.

• Roll number

• Operator ID

• Next Image Address

Press Enter af ter each value is entered.

F32 Trail End Code Allows you to create a trail end code for retrieval

purposes. Trail end code is only used when using Duo

mode.

F33 Roll Number Allows you to display the current roll number or change to

a new roll number. To enter a new roll number, enter the

desired roll number and press Enter.

F34 Operator ID Number Allows you to display the operator ID number or change

to a new operator ID number. Enter a new operator ID

(up to 3 digits) and press Enter.

F35 Cassette ID Number Allows you to display or change the cassette ID number.

Enter a new cassette ID number (up to 2 digits) and

press Enter.

F37 Calibration Allows you to initiate the calibration process required

before scanning documents. To do this, feed a calibration

target into the scanner/microimager.

F38 End-of-Job Allows you to signal the host computer that the last

document of the job has been fed into the transport.

F39 Printer Character Shift

(for Document Printers)

Allows you to select which set of ink jets will be used to

print each character. Enter 1 to select the left set of ink

jets, enter 2 to select the center set of ink jets, or enter 3

to select the right set of ink jets, then press Enter.

F39 Print Contrast

(for Super12 Document

Printer)

Allows you to increase or decrease the amount of ink put

on the document. Press the Up arrow for more ink and

press the Down arrow for less ink. Incremental values

are: 12, 25, 37, 50, 62, 75, 87 and 100%.

A-61096 June 1999 4-7

Page 53

Code Function Code Name Description

F40 All Document Printers

On/Off

(for Document Printers)

F40 Print Head Position

(for Super12 Document

Printer)

Allows you to turn all Document Printers (primary DP1,

secondary DP1 and DP12) on or off. Enter 1 to turn on or

0 to turn of f, then press Enter.

Allows you to change the print heads or clean the printer.

This function can only be performed when the transport is

off. Enter 1 to Change Heads or 2 to Clean Printer, then

press Enter.

F41 Primary DP1 On/Off Allows you to turn the primary Document Printer 1 on or

off. Enter 1 to turn on or 0 to turn off, then press Enter.

NOTE:If the Super12 Document Printer is installed, a

message indicating “Unassigned Function” will be

displayed.

F42 Secondary DP1 On/Off Allows you to turn the secondary Document Printer 1 on

or off. Enter 1 to turn on or 0 to turn off, then press

Enter.

NOTE:If the Super12 Document Printer is installed, a

message indicating “Unassigned Function” will be

displayed.

F43 Document Printer 12/

Super12 On/Off

Allows you to turn the Document Printer 12 or Super12

Document Printer on or off. Enter 1 to turn on or 0 to turn

off, then press Enter.

F44 Omit Printing on the Next

Document Only

Allows you to specify no information be printed on the

next document scanned. Printing will resume on

subsequent documents. Enter 1 to omit printing on the

next document, or 0 to print on the next document then

press Enter.

NOTE: If you enter F44 and then F45, the Omit Printing

Status on Next Document will be cleared.

F45 Print Test

(for Document Printers)

Allows you to test the position and print quality of all

Document Printers installed. Enter the number of the print

test you want to perform.

1=Print IA test 3=Shift test

2=Prime test 4=Standard test

This function can be done when the transport is off.

F45 Print Test

(for Super12 Document

Printer)

Allows you to test the position and print quality of the

Super12 Document Printer. Enter the number of the print

test you want to perform.

1=Mode Image — will print the current image for the level

and mode you are in.

2=Test Pattern — will print a preloaded test image.

This function can be done when the transport is off.

4-8 A-61096 June 1999

Page 54

Code Function Code Name Description

F46 Print Position Allows you to specify how far from the leading edge of

the document printed information will appear. Press the

Up arrow to increment the starting print position by 1 inch

(25 mm), press the Down arrow to decrement the starting

print position by 1 inch (25 mm). Press the Right arrow to

increment the starting print position by 0.125-inch (3 mm),

or press the Left arrow to decrement the starting print

position by 0.125-inch (3 mm), then press Enter.

F48 Purge Print Head

Allows you to initiate an immediate priming ink spurt.

(for Document Printers)

F48 Print Purge Pattern

(for Super12 Document

Printer)

F49 Purge Frequency

(for Document Printers)

Allows you to initiate an automatic purging of the print

heads.

This function can be done when the transport is off.

Allows you to specify how often, in terms of the number

of documents fed into the transport, a priming ink spurt is

initiated. Enter the number of documents, up to 50,000

and press Enter.

F49 Align Print Image

(for Super12 Document

Printer)

Allows you to specify how far to move the left half of an

image up or down (in increments of one line) on the

document so it will align with the right half of the image.

F50 Patch Reader 1 On/Off Allows you to turn the primary Patch Reader on or of f.

Enter 1 to turn on or 0 to turn of f, then press Enter.

F51 Patch Reader 2 On/Off Allows you to turn the secondary Patch Reader on or off.

Enter 1 to turn on or 0 to turn of f, then press Enter.

F52 End-fed Patch Reading

On/Off

Turn End-fed Patch Reading on if you expect the patch