Page 1

•

s~~

s.

M.

No.

1-1490

A

I[@)(dlm~

.'.

• •

•

• .,',

••

R

1/4.5

UI·rOR

JOJmm

SIX-20

LENS

CAMERA

Page 2

I

I

I

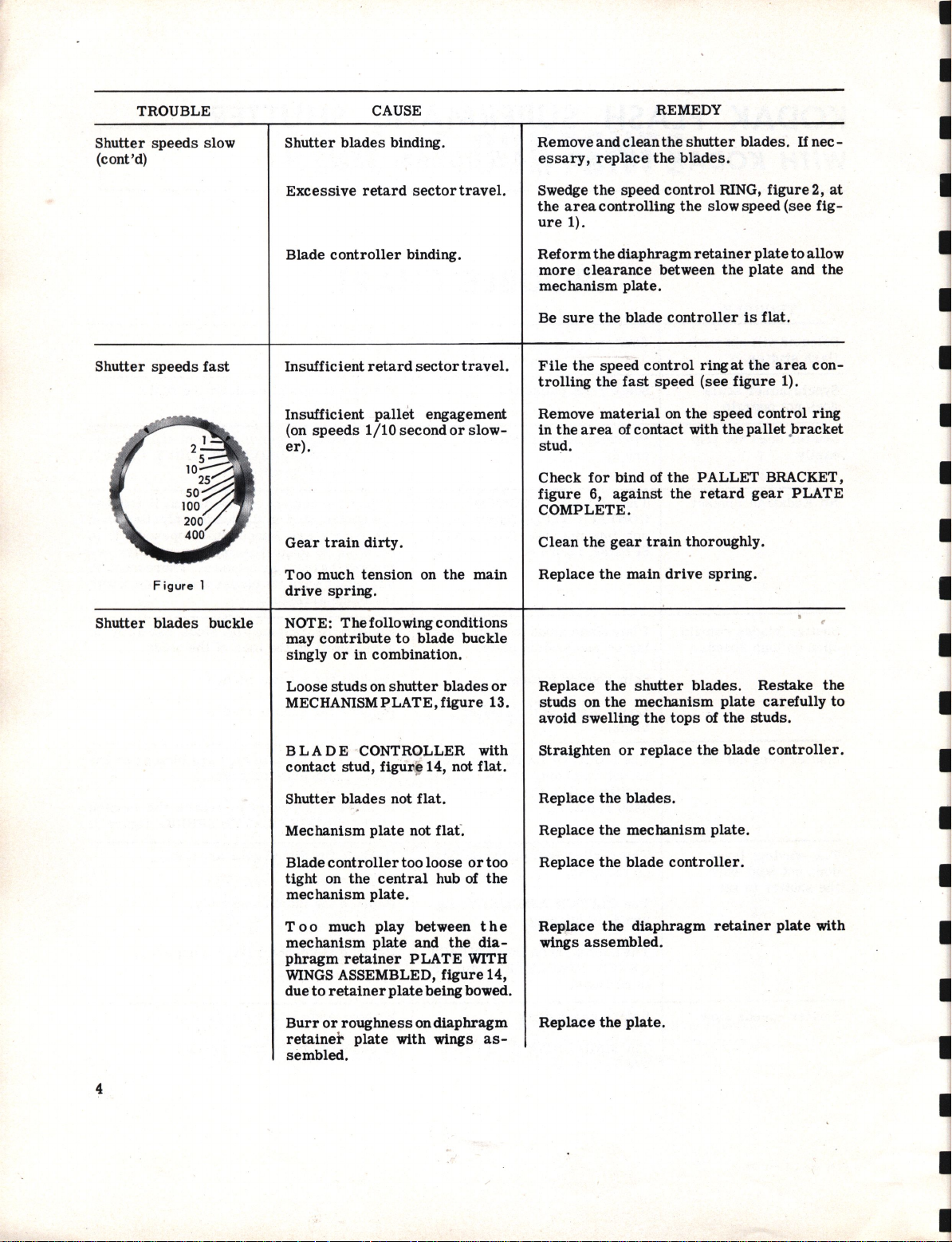

TABLE

Kodak

TROUBLE CHART

DISASSEMBLY AND REASSEMBLY

Speed

Control

Winding

Cover

Winding

:rrigger,

Retard

Main

Flash

Flash

Flash

Shutter

Lever

Complete

Gear,

Assembly

Assembly

Gear

Drive

Contact

Synchronization

Shutter

Blades

.......

Ring

. . . . . . . .

......

Clutch

..............

Time

Lever

....

Train

Assembly.

Parts

Contact

. . . . . . . . . . .

OF

Flash

Kodak

. . . . . .

. .

Ektar f /4.5

Assembly,

Assembly,

. . . . . . .

.......

. . .' , , . .

Conversion

CONTENTS

Supermatic

.

.

and

and

Kit

101mm

Star

Bulb

.

.

Shutter

Wheel

Lever

with

Lens

.

"

Page

No.

10

11

11

13

3

7

'7

7

8

8

8

9

9

I

I

I

I

,

I

I

I

Kodak

Flash

Kodak

Monitor

TROUBLE

DISASSEMBLY AND REASSEMBLY

Speed

Winding

Cover

Winding

Trigger

Retard

Main

Flash

Flash

Flash

'

Shutter

Capitalized

tions.

be

found

CHART . . . . .

Control

Complete

Assembly

Gear

Drive

Contact

Synchronization

Shutter

Such

on

the

Ring . . . . . .

Lever

Gear,

Clutch

Assembly

Blades

nomenciature,

.............

Train

Assembly.

Parts

Contact

words

figure

. : . . . . . .

. . . . . . .

Assembly

and

Bulb

Lever

. .

. . . . . . .

.......

. . . . . . .

Conversion

. . . . . . . . . . .

in

the

text

indicate

when

indicated

not

in

Supermatic

Six-20

and

Star

Assembly

.

Kit

.

nomenclature

followed

the

last

preceding

Shutter

Camera

Wheel

.

by a

for

which

direct

figure

appears

figure

reference,

references.

on

illustra-

will

15

18

18

18

18

19

19

20

20

21

21

22

23

I

Page 3

KODAK

FLASH

SUPERMATIC

SH

UTTER_---.

WITH KODAK

TROUBLE

scale

not

contact

r-

remain

speeds

work

trip

Solenoid will not

flash

shutter

Synchronizer

does

not

operate

Shutter

easily

No

Shutt'

open on high

Kodatron

I

er

does

blades

EKTAR

1/4.5

TROUBLE

CAUSE

Shutter

Scale

Possible

ure

The

CONTACT STUD,

not

SPRING,

Plate

ing on

is

not

rivet

burr

5.

BLADE

touching

figure

blade

mechanism

designed

pulled

on TRIGGER ,

the

studs

JOJmm

CHART

for

use

out.

fig-

CONTROLLER

figure

CONTACT

8.

loose

plate.

or

16,

miss-

LENS

with a solenoid.

Fit

new

Burnish

tacts

the

when

~

is

in a set

Adjust

the

contact

the

blades

possible

movingthefront

no

contact

the

blade

Replace

avoid

swelling

REMEDY

rivet

and

readjust

the

trigger

MAIN DRIVE ASSEMBLY,

the

contact

stud

are

to

make

when

arrestor.

or

restake

at

position.

spri~

on

the

almost

the

lens

the

blades

the

tops

the

the

point

so

that

blade

controller

fully opened.

adjustment

mount.

the

are

studs

of

There

the

scale.

-

where

it

con-

figure

7,

-

it

touches

when

It

must

is

re-

be

to

after

held open with

carefully

studs.

-

•

Shutter

The

winding

does

not hold when

the

shutter

Shutter

does

is

.

speeds

not

lever

set

slow

set

5,

8,

Replace

Replace

The

speed

It

on

Replace

Replace

Replace

Remove

Replace

Split

shutter

Loose

blades

TheTRIGGER

is

-

not

position

been

released.

The

winding

on

the

The

CLUTCH ASSEMBLY,

ure

4,

The

latch

LEVER

is

damaged.

Retard

The

MAIN

ure

7,

blades.

studs

on

the

.

LATCH,

returning

after

the

gear

gear.

is

slipping .

point on

COMPLETE,

gears

dirty.

DRIVE SPRING,

is

weak.

shutter

to

its

shutter

pinion

the

CONTACT

figure

proper

is

loose

fig-

figure

has

fig-

the

shutter

the

shutter

trigger

may

the

latch

index

plate

be

necessary

TRIGGER LATCH SPRING,

the

pinion

the

clutch

the

contact

and

clean

the

main

blades.

blades.

is

bent

or

cover.

to

gear

assembly.

lever

the

retard

drive

and binding on

reduce

assembly.

spring.

the

complete.

gears

figure

,

the

tension

3.

3

'T.M. Reg. U.S. Pat. Off.

'-

Page 4

I

I

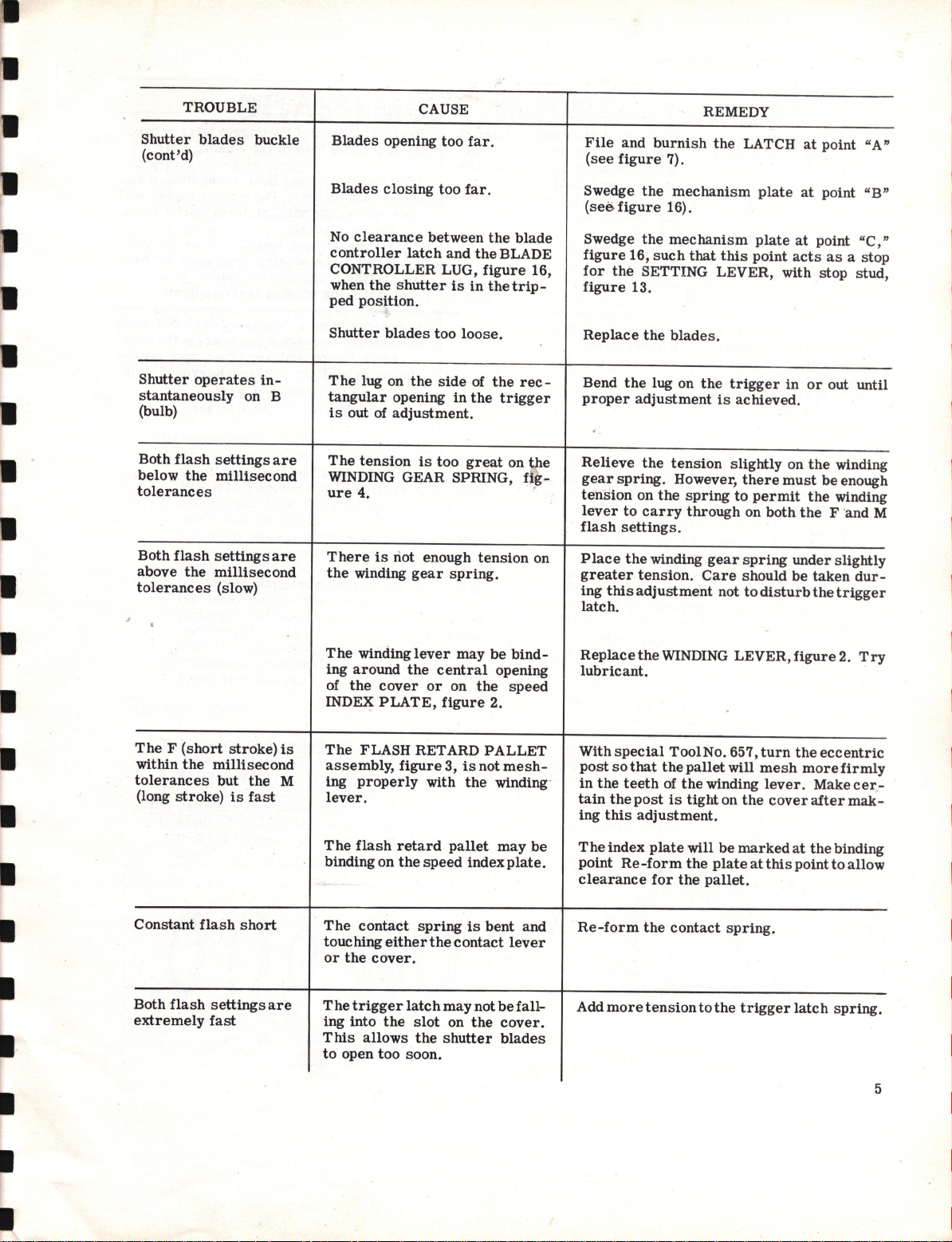

TROUBLE

Shutter

(c

ont '

d)

Shutter

speeds

speeds

slow

fast

Shutter

Excessive

Blade

Insufficient

Insufficient

(on

er)

Gear

blades

controller

speeds

.

train

CAUSE

binding.

retard

retard

pallet

1/10

dirty.

sector

binding.

sector

engagement

second

travel.

travel.

or

slow-

Remove and

essary,

Swedge

the

ure

Reform

more

mechanism

Be

File

trolling

Remove

in

stud.

Check

figure

COMPLETE.

Clean

area

1).

clearance

sure

the

the

area

the

replace

the

controlling

the

diaphragm

the

speed

the

material

of contact with

for

bind

6,

against

gear

clean

the

speed

plate.

blade

control

fast

of

train

REMEDY

the

shutter

blades.

control

the

between

controller

speed (see

on

the

the

the

thoroughly.

blades.

RING,

slow speed (see

retainer

the

plate

is

ringat

PALLET BRACKET,

retard

the

figure

speed

the

pallet .bracket

figure

plate

flat.

area

1).

control

gear

If

nec-

2,

at

fig-

to

allow

and

the

con-

ring

PLATE

I

I

I

I

I

Shutter

Figure

blades

1

buckle

Too much

drive

NOTE:

may

singly

Loose

MECHANISMPLATE,figure 13.

LAD

B

contact stud,

Shutter

Mechanism

Blade

tight on

mechanism

Too

mechanism

phragm

WINGS

to

due

Burr

retainei-plate

sembled.

tension

spring.

The

contribute

following conditions

or

in combination.

studs

on

E CONTROLLER with

blades

plate

controller

the

plate

much

plate

retainer

ASSEMBLED,

retainer

or

roughness

on

to

blade buckle

shutter

figu~

e

not

flat.

not flat".

too

central

.

play

between

and

PLATE

plate

on

with wings

the

blades

14, not flat.

loose

hub of

the

figure

being bowed.

diaphragm

main

or

or

too

the

the

dia-

WITH

14,

as-

Replace

Replace

studs

avoid swelling

Straighten

Replace

Replace

Replace

Replace

wings

Replace

the

main

the

on

the

or

the

blades.

the

mechanism

the

blade

the

diaphragm

assembled.

the

plate.

drive

shutter

mechanism

the

replace

blades.

tops

of

the

controller

spring.

plate

the

studs.

blade

plate.

.

retainer

Restake

carefully

controller.

plate

the

to

with

4

I

Page 5

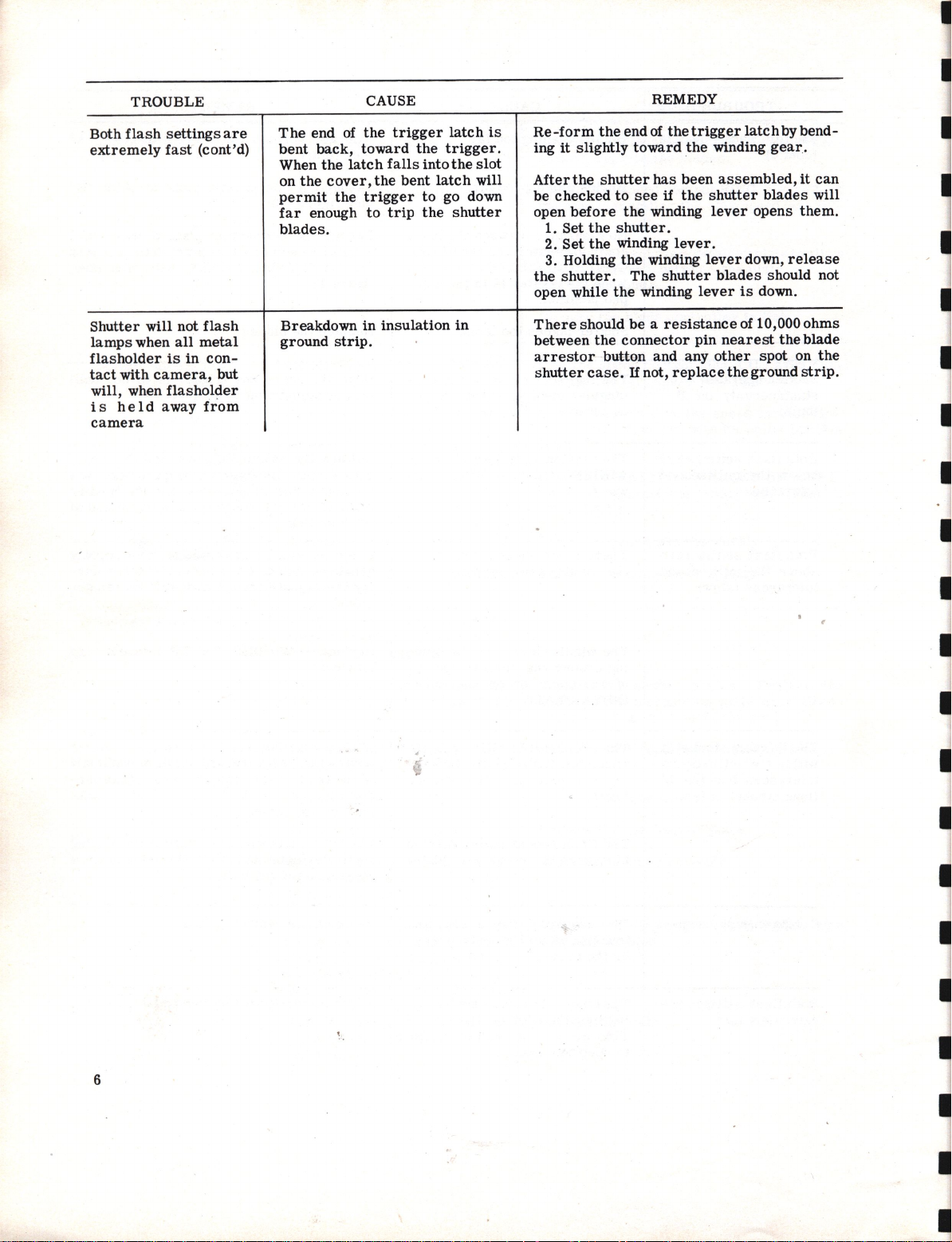

TROUBLE

CAUSE

REMEDY

Shutter

(cont'd)

Shutter

stantaneously

(bulb)

Both

below

tolerances

Both

above

tolerances

blades

operates

flash

the

flash

the

settings

millisecond

settings

millisecond

(slow)

buckle

in-

on B

are

are

Blades

Blades

No

controller

CONTROLLER LUG,

when

ped

Shutter

The

tangular

is

The

WINDING GEAR SPRING,

ure

There

the

opening

closing

clearance

the

position.

blades

lug on

out

of

tension

4. .

is

winding

too

too

between

latch

and

shutter

opening

adjustment.

riot enough

the

is

gear

is

too

side

in

too

spring.

loose.

far.

far.

the

the

figure

in

the

of

the

great

tension

BLADE

the

trigger

blade

16,

trip-

rec-

on t e

fig-

on

File

and

(see

figure

Swedge

(ses

figure

Swedge

figure

16,

for

the

figure

Replace

Bend

the

proper

Relieve

gear

spring.

tension

lever

to

flash

settings.

Place

the

greater

ing

this

latch.

burnish

the

the

such

SETTING LEVER, with stop stud,

13.

the

lug on

adjustment

the

on

the

carry

winding

tension.

adjustment

the

7).

mechanism

16).

mechanism

that

this

blades.

the

is

tension

However,

spring

through

gear

Care

not

LATCH

plate

plate

at

point

acts

trigger

achieved.

slightly on

to

there

permit

on

both

spring

should

to

disturb

in

must

under

be

at

point "A"

at

point "B"

point "C

as

or

out until

the

winding

be

the

winding

the

F 'and M

slightly

taken

the

a stop

enough

dur-

trigger

,"

I

The F (short

within

the

millisecond

tolerances

(long

stroke)

Constant

Both

extremely

flash

flash

settings

fast

stroke)

but

is

short

the

fast

is

M

are

The

winding

ing

around

of

the

cover

INDEX

The

assembly,

ing

lever.

The

binding on

The

touching

or

T he

ing into

This

to

PLATE,

FLASH RETARD

figure

properly

flash

retard

the

contact

either

the

cover.

trigger

the

allows

open

too

lever

the

or

with

speed

spring

latch

slot

the

soon.

may

central

on

figure

3,

is

pallet

the

contact

may

on

shutter

be

opening

the

2.

PALLET

not

the

winding'

may

index

is

bent

not

be

the

bind-

speed

mesh-

be

plate.

and

lever

fallcover.

blades

Replace

lubricant

With

post

in

tain

ing

T he index

point

clearance

Re-form

Add

spec

so

the

teeth

the

this

Re-form

more

that

the

post

adjustment.

WINDING LEVER,

.

ial

Tool

No. 657,

the

pallet

will

of

the

winding

is

tight

on

the

plate

will

be

plate

pallet.

spring.

tothe

marked

trigger

for

the

the

contact

tension

the

turn

mesh

lever.

at

this

figure

the

cover

at

point

latch

ecc

more

Make

after

the

2.

Try

entric

firmly

cer-

mak-

binding

to

allow

spring.

5

•

Page 6

TROUBLE

CAUSE

I

I

REMEDY

flash

Both

extremely

Shutter

lamps

flasholder

tact

will, when

is

camera

will not

when

with

held

settings

fast

(cont'd)

all

metal

is

in

camera,

flasholder

away

are

flash

con-

but

from

The

end

back,

the

the

cover,

enough

of

the

strip.

bent

When

on

permit

far

blades.

Breakdown

ground

the

toward

latch

the

trigger

to

in

trigger

the

falls

into

bent

latch

to

trip

the

insulation

latch

is

trigger.

the

slot

will

go down

shutter

in

Re-form

ing

After

be

open

1.

2.

3. Holding

the

open while

There

between

arrestor

shutter

the

it

slightly

the

checked

before

Set

the

Set

the

shutter.

should be a

the

case.

end of

the

trigger

toward

shutter

to

see

the

shutter.

winding

the

The

the

connector

button and any

If

has

been

if

the

winding

lever.

winding

shutter

winding

resistance

not,

replace

the

pin

winding

assembled,

shutter

lever

lever

blades

lever

is

of 10,000

nearest

other

the

latch

by

gear.

blades

opens

down,

should not

down.

the

spot on

ground

bend-

it

can

will

them.

release

ohms

blade

the

strip.

I

I

6

Page 7

•

I

SPEED

The

sequence

1.

Front

2.

Diaphragm

3.

Set

4. Speed and

ing

projections

the

central

5. Speed

The

sequence

1.

Speed

position.

BULB LEVER ASSEMBLY,

on

ure

assembly

of

neath

2. Speed and

the

plate

the

until

3.

Diaphragm

4.

Front

WINDING

The

sequence

1.

Speed

2. Winding

DISASSEMBLY

CONTROL RING

of

disassembly

lens

mount,

pointer

the

synchronizer

diaphragm

the

plate

counterclockwise

in

three

cutouts

collar.

control

CAUTION:

VER

is

disturbed,

ing will have

of

reassembly

control

Be

sure

the

retarding

6,and

the

are

the

speed

control

the

ring.

diaphragm

three

projections

with

the

central

LEVER

it

is

lens

control

lever.

collar.

properly

pOinter

mount.

of

disassembly

using

the

center

on

RING.

If

the

to

be

ring,

the

SECTOR WITH STUD,

PALLET

resting

three

ring,

is

Tool

TIP,

figure

scale

at

INDEX

the

WINDING

the

adjusted.

with

ring

cutouts

Turn

positioned.

tip.

paragraphs

PLATE

of

the

outside

flash

is

as

shutter

projecting

figure

BRACKET with

against

and

index

plate

in

the

on

the

is

as

follows:

No. 501-0.

2.

"M.»

by

until

the

plate

edge of

LE-

tim-

follows:

in

lug on

5,

the

the

tnside

are

not

by lining up

cehter

the

outside

plate

clockwise

as

follows:

1-5,

AND

turnthree

fit

into

the

tripped

the

studs

fig-

stud

edge

under-

of

the

of

above.

REASSEMBLY

2. Set

the

shutter.

3. Winding lever, with

from

. ,

the

left

GEAR,

SPRING

quarter

and

second

mate

the

ing

the

of

cover.

the

Check

and

attachment.

tact

the

blades.

the

is

slot

return

there

spring,

latch

4. Speed

figure

in

tension

strokes

replacing

strokes.

setting

shutter.

CAUTION:

TRIGGER LATCH,

may

release

spring

tension.

T

rip

the

lever

cover.

the

slot

latch

resting

After

shutter

down

As

latch

should

If

it

TRIGGER LATCH SPRING,

for

a bind

the

TRIGGER,

the

trigger

in

the

After

should

on

in

the

cover.

the

trigger

to

its

is

too

much

it

will

and

the

control

the

meshed

4.

Place

by giving two and

to

the

the

lever

This

for

the

flash

Do

not

figure

the

winding

and lightly hold

around

the

shutter

fall

does

not, add

between

figure

The

winding

latch,

cover,

the

shutter

return

the

ledge

is

proper

trigger.

tend

ring,

pOl?ition

tension

to

paragraphs

sixth

with

the

winding

after

should

synchronization

touch

the

central

is

into

the

5,

lever

push

and

open

ha,s

to a position

just

depressed,

on

retard

or

seventh

the

WINDING

WINDING

betheapproxi-

5,

as

gear

tripped,

the

more

trigger

at

the

been

above

very

the

the

lever,

the

first

the

it

the

collar

slot

tension

figure

the

point of

should

latch

the

tripped,

where

the

allow

slowly.

trigger

action

1-4,

GEAR

lifting

wind-

the

on

shutter

above.

tooth

one-

and

of

on

end

the

on

3.

latch

con-

out of

it

small

it

to

If

latch

of

the

I

I

I

The

sequenc~

1.

Apply a

RCX169

lever.

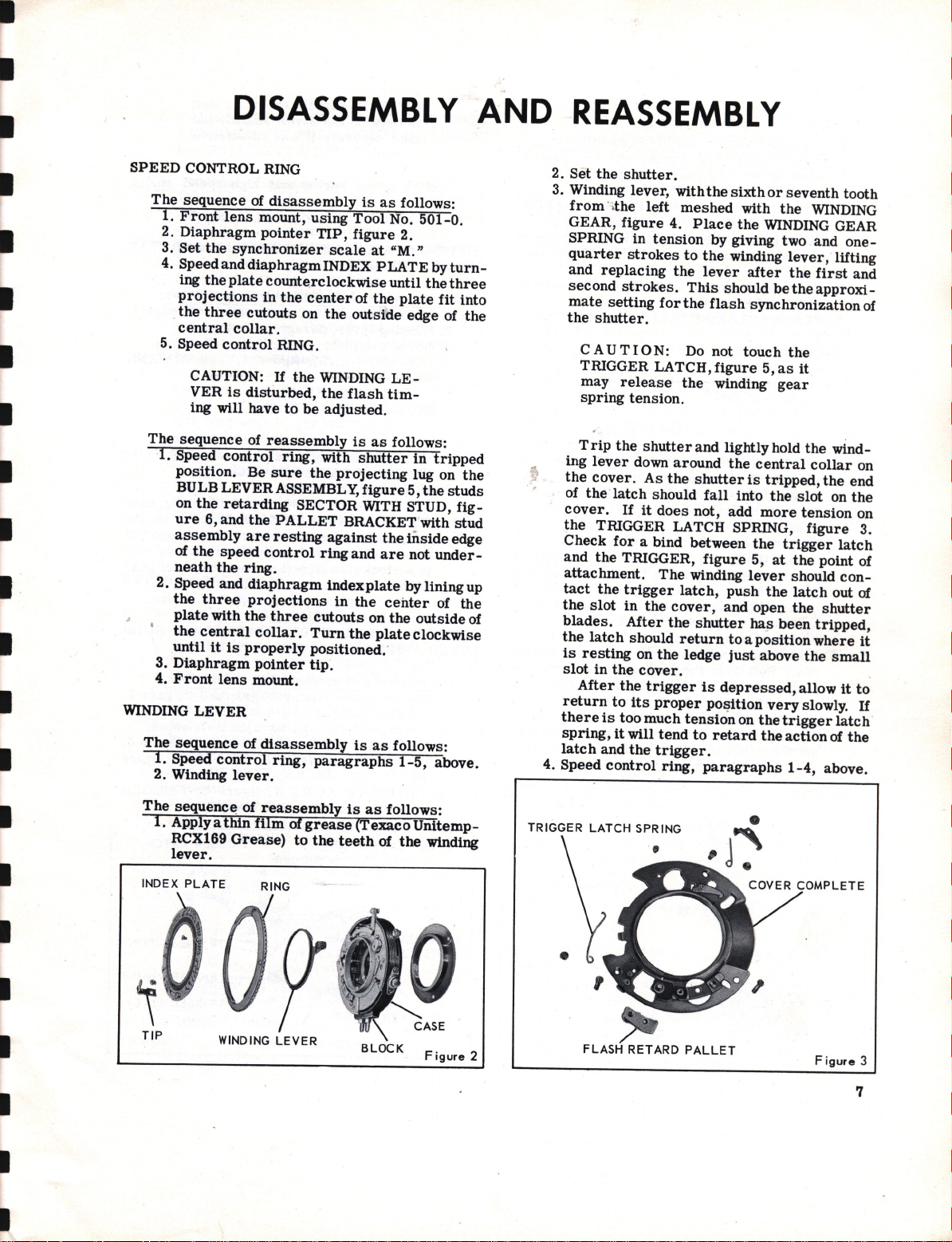

INDEX

PLATE

TIP

of

reassembly

thin

film

Grease)

RING

WINDING

Of

grease

to

LEVER

the

is

as

(Texaco

teeth

BLOCK

follows:

Unitemp-

of

the

winding

Figure

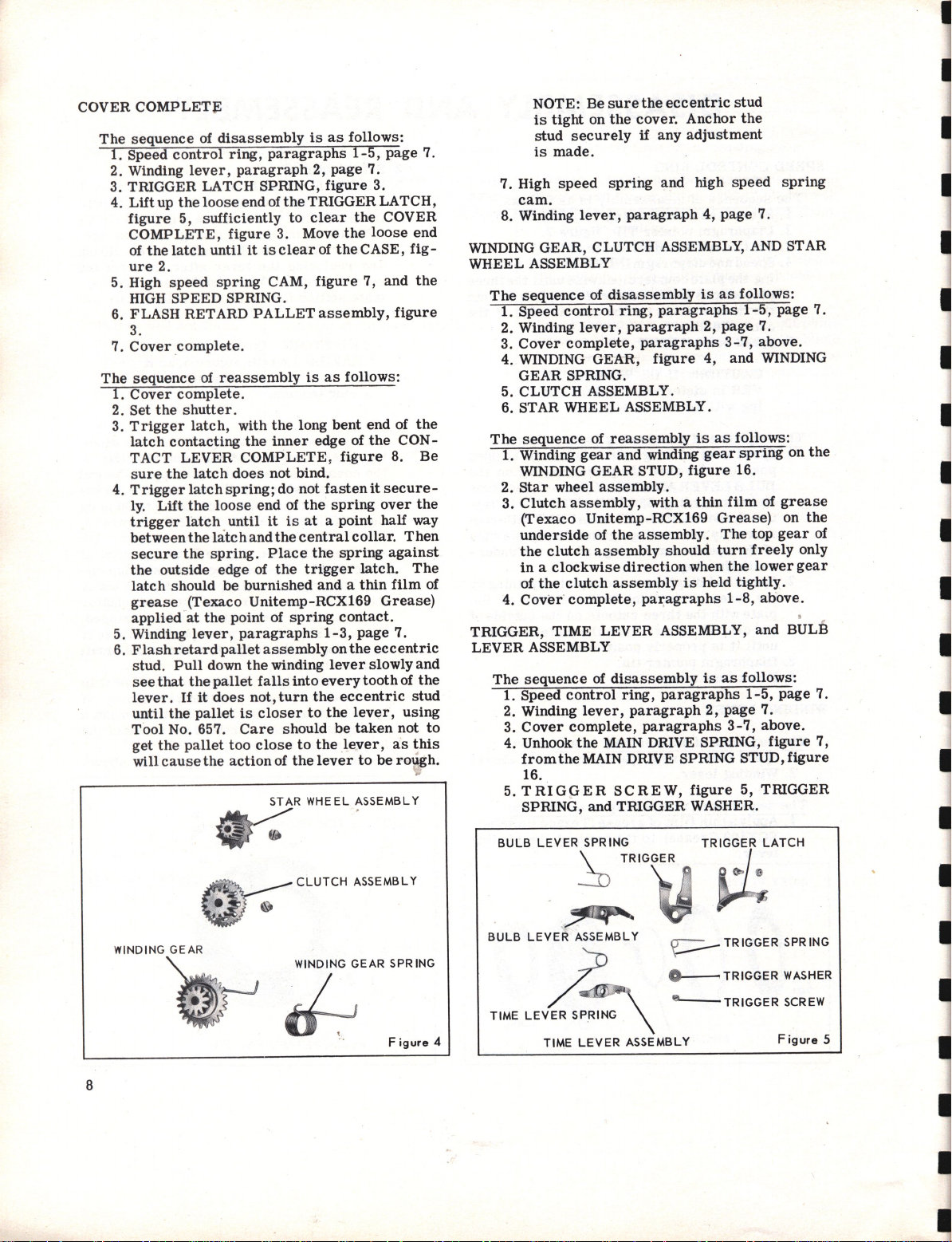

TRIGGER

2

LATCH

SPRING

LETE

Figure

3

7

Page 8

COVER

COMPLET~

The

sequence

1.

Speed

2. Winding

3. TRIGGER LATCH SPRING,

Lift

4.

figure

COMPLETE,

of

the

ure

5. High

HIGH

6. FLASH RETARD

of

disassembly

control

up

the

5,

latch

2.

speed

SPEED

ring,

lever, paragraph

loose

sufficiently

figure

until

spring

SPRING .

end

it

3.

7.

Cover

.complete.

The

sequence

1.

Cover

Set

2.

3.

Trigger

latch

TACT

sure

4.

Trigger

ly. Lift

trigger

between

secure

the

latch

grease

applied -at

5. Winding

Flash

6.

stud. Pull

see

lever.

until

Tool

get

will

of

complete

the

shutter.

latch, with

contacting

LEVER

the

latch

latch

the

latch

the

the

outside

should

(Texaco

the

lever,

retard

down

that

the

If

it

the

pallet

No. 657.

the pallet

cause

the

reassembly

.

the

COMPLETE,

does

spring;

loose

until

latch

and

spring.

edge

be

burnished

Unitemp-RCX169

point

paragraphs

pallet

the

pallet

does

not,

is

Care

too

action

•

is

paragraphs

2,

figure

ofthe

TRIGGER LATCH,

to

clear

3. Move

is

clear

of

CAM,

PALLET

not

end

it

Place

of

of

assembly

winding

falls

closer

close

ST

figure

assembly,

is

as

the

long

inner

edge

bind.

do not

fasten

of

the

is

at a point

the

central

the

the

trigger

and a thin

spring

1-3,

lever

into

every

turn

the

to

the

should

to

the

of

the

lever

AR

WHE

CLUTCH ASSEMBL Y

as

follows:

1-5,

page

page

7.

3.

the

COVER

the

loose

the

CASE,

7,

and

figure

follows:

bent

end of

of

the

CON-

figure

spring

spring

contact.

on

eccentric

be

lever,

EL ASSEMBL Y

it

collar.

latch.

page

the

eccentric

slowly

tooth

lever,

taken

to

be

8.

secureover

half

Then

against

film

Grease)

7.

of

using

not

as

rough.

7.

end

fig-

the

the

Be

the

way

The

of

and

the

stud

to

this

NOTE: Be

is

tight

stud

is

made.

7. High

8. Winding

WINDING GEAR , CLUTCH ASSEMBLY, AND STAR

WHEEL

The

1.

2. Winding

3.

4. WINDING GEAR,

5. CLUTCH ASSEMBLY.

6. STAR

The

1.

2.

3.

4.

TRIGGER,

LEVER

The

1.

2. Winding

3.

4. Unhook

5.

BULB LEVER SPRING

speed

cam.

ASSEMBLY

sequence

Speed

Cover

G EAR SPRING.

sequence

Winding

WINDING GEAR STUD,

Star

wheel

Clutch

(Texaco

underside

the

clutch

in a clockwise

of

the

Cover

TIME

ASSEMBLY

sequence

Speed

Cover

from

the

16 . .

TRIGGER

SPRING,

sure

the

eccentric

on

the

cover.

securely

lever,

of

control

lever,

complete,

WHEEL

of

gear

assembly,

Unitemp-RCX169

clutch

complete,

of

control

lever,

complete,

the

MAIN DRIVE SPRING STUD,

and

if

any

spring

disassembly

reassembly

assembly.

of

the

assembly

assembly

LEVER

disassembly

MAIN DRIVE SPRING,

SCREW,

TRIGGER

and

paragraph

ring,

paragraphs

paragraph

paragraphs

figure

ASSEMBLY.

and

winding

with a thin

assembly.

should

direction

ring,

paragraph

TRIGGER

is

paragraphs

ASSEMBLY,

paragraphs

paragraphs

figure

when

figure

WASHER .

stud

Anchor

adjustment

high

speed

4,

page

is

as

2,

page

3-7,

4,

and

is

as

follows:

gear

spring

16.

film

Grease)

The

turn

the

held

tightly.

1-8,

is

as

2,

page

3-7,

5, TRIGGER

the

spring

7.

follows:

1-5,

page

7.

above.

WINDING

of

grease

on

top

gear

freely

lower

above.

and

BULB

follows:

1-5,

page

7.

above.

figure

figure

on

only

gear

7.

the

the

of

7.

7,

I

I

8

WINDING

GEAR

WINDING

~

GEAR SPR

Figure

ING

BULB LEVER ASSEMBLY

TIME

LEVER SPRING

4

TIME

LEVER ASSEMBLY

~

TR

IGGER SPR

o TRIGGER

~TRIGGER

WASHER

SCREW

Figure

ING

5

Page 9

•

•

6. TRIGGER,

LEVER

and

The

sequence

1.

With

the

trigger

the

bulb

trigger.

the

time

trigger

bly,

three

of

tweezers

holes.

lever

and

the

TIME

The

gainst

2.

Trigger

screw.

the

end

rest

3. Hook

onto

4.

Cover

RET

ARD GEAR TRAIN

•

The

sequence

'

I.

Speed

2. Winding

Cover

3.

4. Unhook

SPRING,

5.

Retard

6.

Retard

7.

RetardGEAR

8.

RetardGEAR

9. ESCAPEMENT

assembly.

Retard

10.

11.

PALLET

the

pallet

SECTOR SPRING GEAR

ECTOR

TIME

SPRING, BULB

BULB

of

the

bulb

lever

Place

lever

and

with

the

parts

With

springs

the

short

levers,

AND BULB

long

ends

the

case.

washer,

Lift

of

it

against

the

loose

the

main

complete,

of

control

lever,

complete,

the

figure

GEAR

gear

PALLET.

BRACKET

bracket

SCREW

j " _

LEVER

LEVER

reassembly

lever

with

the

assembly

the

spring

the

top

spring

by

inserting

down

through

the

long

turned

ends

resting

guide

LEVER

of

the

trigger

the

long end of

the

main

the

end of

drive

paragraphs

disassembly

ripg,

paragraph

paragraphs,

retard

6. .

PLATE

PLATE

WITH

WITH

WHEEL

. .

spring.

PLATE

ASSEMBLY,

LEVER

SPRING.

is

as

spring

oval

time

of

ends

the

stud.

spring

paragraphs

PALLET

NO.2

NO.3

underneath,

hole up

in

the

lever

between

the

bulb

facing

in a clockwise

springs

drive

the

COMPLETE.

with

up.

one

prong

the

of

the

against

parts

STUD,

spring,

the

spring

main

stud.

is

as

2,

page

SCREWS.

PINION

PINION

with

stud

SCREW

down

~

PLATE

ASSEMBLY,

follows:

and

opening

assembly

the

top

lever

assem-

Grasp

of a

center

time

and

direction

the

lugs

over

figure

should

1-8,

3-7,

assembly

rest

and

trigger

spring

stud,

drive

spring

page

follows:

1-5,

page

7.

page

BRACKET

assembly.

assembly.

No.3

pinion

Figure

COMPLETE

TIME

hold

insert

on

the

and

of

the

all

pair

of

the

bulb

on

the

16.

a-

over

and

8.

7.

8.

and

NOTE:

dirty,

ing

and

thoroughly

12.

Retarding

tarding

Set

13.

14.

The

10.

11.

12.

13.

6

14.

the

Retarding

sector

sequence

1.

Retarding

sector

at

the

Retarding

2.

3.

Place

inner

SPR,ING BUSHING,

4. With

down,

et

with

the

spring

Place

spring

STUD,

should

5.

Retard

6.

Escapement

bly.

7.

Retard

Retard

8.

9.

Retard

the

gear

Retard

bracket.

Lift

the

teeth

pass

tarding

are

meshed

be

approximately

case.

Remaining

Put

the

plaCing

inside

complete

Cover

If

the

clean

holes

all

the

•

SECTOR SCREW. Unhook

SECTOR SPRING.

shutter.

sector

spring.

of

sector

spring,

top

.

sector

the

long end of

side

the

short

place

stud

the

pallet

on

the

figure

rest

pallet.

gear

gear

gear

faCing

gear

up

the

of

freely

sector

pallet

the

long

edge

. .

complete,

retard

the

retard

in

the

mechanism pla

parts

.

with

reassembly

with

with

screw.

of

the

blade

end of

the

spring

assembly.

to

extend

bracket

PALLET

16.

The

against

wheel

with

NO.3

with No. 2

plate

complete

the

plate

gear

end

the

retarding

under

so

that

the

outer

1/8

retard

of

bracket

the

gear

end

lug on

paragraphs

of

the

the

the

figure

the

inside

out,

the

with

shutter

screw

of'

the

edge

inch

of

gears

gear

stud

stud

long end of

pallet

Allow

and

BRACKET SPRING

long end of

case.

No.4

pinion

pinion

the

gear. Place

when

plate

spring

the

the

are

bear-

gear

train

and

the

is

as follows:

and

the

spring

controller

7.

bracket

the

the

toward

the

pallet

pinion

assembly

assembly.

, with

blades.

near

gear

sector

the

of

the sector

from

screw.

in

spring

retard

1-8,

against

pallet

the

the

the

tension

against

te

the re-

retarding

retarding

the

spring

LATCH

spring

brack

long end of

the

case.

bracket

the

spring

assem-

teeth

pall

plate

with

the

gear

shutter

gear

plate

page

the

-

.

of

e t

until

stud

re-

teeth

will

by

the

8.

•

•

\l

GEAR WITH NO.

GEAR WITH

NO.3

ESCAPEMENT WHEEL

•

PALLET

SECTOR WITH STUD

'~N

!

PINION

BRACKET

PALLET

BRACKET

SPRING

MAIN DRIVE ASSEMBLY

The

sequence

1. Speed

2. Winding

Cover

3.

4. Unhook

the

control

lever,

complete,

the

main

of

disassembly

ring,

paragraph

paragraphs

LATCH SPRING,

drive

LATCH.

is

as

paragraphs

2,

page

follows:

1-5,

3- 7,

figure

page

7.

page

7,

7.

8.

from

9

Page 10

I

I

5. Unhook

MAIN DRIVE SPRING STUD,

6. Set

7. MAIN DRIVE ASSEMBLY,

is

The

sequence

1. Apply a

RCX169

assembly

the

DRIVE STUD,

ure

SPRING, and on

the

This

before

2. Main

being

in

3.

Close

toward

cutout

around

latch

tip

4. Main

Cover

5.

~

LASH

CONTACT PARTS

The

sequence

1.

Speed

2. Winding

3.

Cover

4.

Retard

5. Winding

graphs 4 and

6. CONNECTOR PINS,

635.

Connector

7.

8.

Ground

SCREW,

9.

Disengage

nism

CAM

the

MAIN DRIVE SPRING

the

shutter

attached

thin

SETTING

7,

at

RETARDING SECTOR STUD,

area

applying

drive

sure

the

assembly.

the

the

part

the

spring

of

the

drive

complete,

control

complete,

gear

plate.

LATCH

.

the

main

of

reassembly

film

Grease)

where

LEVER,figure

figure

the

point

of

the

the

assembly

to

fit

shutter

BLADE CONTROLLER LUG.

of

the

lug.

against

latch.

sp:ring.

.

of

disassembly

ring,

lever,

paragraph

train,

gear

and

5,

page

BLOCK,

CONTACT

figure

SPRING BUSHING

the

RESISTOR

8.

figure

drive

spring

of

to

it

of

the

latch

the

Place

paragraphs

paragraphs

is

grease

the

engages

blades. Push

latch

paragraphs

c.1utch

figure

(Texaco

slot

on

16; on

contact

latch

where

should

lubricant.

on

the

setting

will

the

the

vertical

is

paragraphs

2,

assembly, para-

8.

figure

8,

2.

STRIP

from

~

from

figure

as

the

13;

the

with

main

lever

loose

1-8,

as

page

3-7, page

using

16.

7,

to

.

follows:

Unitemp-

the

main

stop

stud

ontheMAIN

LATCH,

the

LATCH

it

contacts

figure

be

burnished

drive

stop

the

come

to

end of

lug

on

page

follows:

1-5, page

7.

4-11,

page

Tool

CONNECT6R

the

mecha-

F i

the

which

drive

on

fig-

16.

stud,

stud

latch

The

rest

the

the

8.

7.

8.

9.

No.

gure

10. Holding

262,

using

screw

11. CONTACT SPRING,

GROUND

Remove

the

12. CONTACT

13.

Shutters

assembled

remove

the

move

plunger

sulating

SPRING

the

The

sequence

1.

If

the

on

long end of

the

the

tact

spring

tact

LEVER

Bend

spring

2.

Contact

LEVER

contact

the

spring

tenSion,

CONTACT

7

LEVER

the

remove

Tool

.

CON:!'

the

case

INSULATOR.

of

the

end

of

the

assembly,

SLEEVE.

and

CONTACT

a new

contact

contact

the

contact

long end of

outside

lever

around

lever

SPRING on

the

last

clockwise

lever

STUD,

lever

shutter

in a clockwise

and

LEVERSPR

~

~

.-

BUSHING

CONTACT

the

No. 503L.

ACT STRIP

case

LEVER

the

flash

as

follows: Using

TERMINAL NUT,

the

PLUNGER ASSEMBLY.

ca~e

INSULATOR WASHER.

the

LEVER

of

reassembly

LEVER

LEVER

the

the

edge

latch.

the

tail.

1/8

complete

figure

spring

blades.

rest

EVER

CONTACT

CONTACT S;REW

SCREWwithTool

CONTACT SCREW NUT ,

Remove

to

which

INSULATOR WASHER and

COMPLETE.

receptacle

and

the

Remove

case

INSULATOR. Remove

COMPLETE.

lever

spring

of

Form

Then

inch

at

it

ING

LATCH

is

is

LATCH SPRING,

BUSHING, with

at

spring

the

spring

the

vertical

place

the

contact

of

the

least

on

16.

should

Tur

'n

the

direction

in

the

groove

SPRING

LEVER

the

is

fastened

and

the

type

Tool

figure

terminal

the

CONTACT

as

follows:

to

be

used,

the

bottom.

and

rest

lug on

short

end of

part

of

the

CONTACT

lever

long end of

15

degrees

the

CONTACT,

The

ends

face

in,

long end

to

place

in

COMPLETE

CONTACT

CONNEC/TOR

No.

contact

the

resistor.

are

dis-

No. 503J,

9, on

Re-

the

boayin-

place

figure

8,

the

Lift

it

against

the

con-

the

the

con-

bushing.

the

.

of

the

toward

of

the

it

in

the

case

Figure

STRIP

SCREW

I

.

8

10

HI

GH

MAIN

SPE

ED

DRIVE

~

SPRING

o

ASSEMBLY

/

\-

~

•

"'

~

MAIN

LATCH

---LATCH

A

DRIV~

SPRING

SPRING

CONT ACT

ONT ACT SPRING

INSULATOR

--0

K

/ INSULATOR WASHER

SCREW

NUT CONNECTOR PIN

GROUND

CONTACT

H

STRIP

Page 11

I

I

I

I

~

~

)V~.,/

"

SLEEVE

INSULATOR

TERMINAL

Form

the

vertical

CAUTION:

is

burnished

that

condition.

3.

Contact

washer

tact

end

contact

placing

screw

nut.

tact

screw

nut with

4. Ground

5.

Connector

6.

Connector

7.

Secure

8.

Winding

graphs

Retard

9.

10.

If

the

the

assembled

of

the

spring

push

sembly

Fasten

the

opening

shu

the

plunger

the

plunger

plunger

terminal

Place

"

insulator.

and

11.

Trip

its

gainst

CONTACT

----I

---0

NUT"

short

part

of

The

spring.

between

of

the

screw.

the

case

To

with

Tool

No. 503L.

contact

block.

pins.

the

resistor.

gear

1 and 3,

gear

train,

tt

e r

type,

insert

assembly

body

insulating

case

Position

over

the

the

threaded

through

the

plunger

shutter

action

shutter

LEVER

~

end

of

the

contact

contact

and

must

Place

the

shutter

contact

Secure

insulator

tighten

Tool

strip

and

clutch

page

paragraphs

is

of

in

parts

insulator

assembly.

opening

the

with

and

at

by placing one

SETTING LEVER,

COMPLETE

~

---

PLUNGER ASSEMBLY

~

INSULATOR

CONTACT SPRING

the

spring

lever

lever

remain

the

case

spring

the

and

the

nut, hold

No. 262 and

connector

assembly,

8.

the

flash

the

threaded

the

collar

sleeve.

in

the

washer

Replace

the

end

in

the

end

of

opening

the

the

same

around

tail.

tail

in

case

and

and

insert

spring

the

screw.

4-13,

receptacle

end of

end of

Then

body

terminal.

on

of

the

shutter

the

plunger

tit

the

terminal

time

Figure

9

WASHER

the

insulator

the

con-

the

by

re-

contact

the

con-

turn

the

para-

page 9.

the

the

insert

the

end

the

case

contact

base

as-

spring.

nut.

retard

finder

a-

figure

13.

Observe

LER

CONTACT

slight

before

spring

of

the

12.

Cover

FLASH SYNCHRONIZATION

After

the

shutter

ed

to

see

if

shutter

slowly.

lease

must

trip

The

blades

in

the

the

shutter

winding

the

trigger.

whUe

do, '

refer

extremely

Check

latch.

must

shutter

must

position

The

with

reliable

ances

chronization

F

M (long

*From

fil'st

begin

FLASH SHUTTER CONTACT CONVERSION KIT

A

more

been

achieved

contact

discarded

replaced

Contact

Parts

OLD-STYLE FLASH CONTACT PARTS

The

1.

2. Winding

3. CONNECTOR PINS,

the

blades

Set

the

the

winding

the

shutter

will open while

cover

plate.

and

lever

the

winding

to

the

fast;"

the

When

the

be locked

has

been

return

fully and

.

flash

settings

of

(short

List

shutter

the

delayed

with

stroke)*

stroke)*

instant

to

satisfactory

parts.

are

by

the

Conversion

No. 1-1490A.

sequence

Retard

graphs 4 and

No. 635.

whether

contact

the

b 1 a

does

not

spring

operation

toward

complete,

is

winding

when

the

shutter

lever

shutter

must

be

To

the

winding lever. While holding

in

the

fully wound

The

shutter

lever

"TroubleChart-Bothflashsettings

see

page

shutter

in

the

actuated

on

testing

the

of

contact

show light.

by a

change

The

old-style

no

longer

parts

furnished

Kit No. 121349 - Supplement

of

disassembly

gear

train,

gear

5, page 8. .

the

BLADE CONTROL-

STU

D,

with

des

touch

paragraphs

assembled,

lever

trigger

and

very

blades.

checked

the

check

is

being held down.

5.

of

is

not

unwound position.

with

become

the

action

flash

3t -5t

12

until

operation

in

available.

paragraphs

and

clutch

figure

the

contact

are

fully open.

the

stud,

the

stud.

it

will

is

the

winding lever.

slowly.

to

see

latch

is

for

this

position,

blades

the

shutter

should not open

winding

set,

the

the

winding

locked

should

equipment.

in

the

shutter

bulbs

are

milliseconds

- 16

milliseconds

the

of

the

design

parts

in

the

is

assembly,

figure

1-8,

must

always

released

still

condition,

winding

in

shutter

the

which

They

Flash

as

10,

16,

spring

bend

page

be

The

if

the

in

lever

After

the

be

The

as

shutter

of

the

are

are

follows:

4-11,

using

makes

If

the

check-

trip

very

lever

shutter

the

depress

If

safety

lever

lever,

unwound

timed

toler-

for

syn-

follows:

blades

flash

to

to

Shutter

page

para-

Tool

just

the

end

8.

the

Re-

slot

set

the

they

the

it

.

has

be

be

to

9.

I

I

11

Page 12

4.

Disengage

nism

5. CONTACT

6.

Connector

7. Ground CONTACT STRIP

SCREW,

8. Holding

with

SCREW

the

contact

ER,

INSULATOR.

contact

9. DETENT SPRING AND

DETENT SPRING

and

SEMBLY.

10. CONTACT ESCAPEMENT WHEEL.

11. SHUTTERS

TYPE

Tool

figure

SEMBLY.

WASHER,

minal

tact

the

CONTACT. SCREW NUT,

503L.

tact

the

TACT

NEW-STYLE FLASH CONTACT PARTS

The

sequence

1.

Place

figure

with

and

DETENT

SPRING AND

the

RESISTOR

plate.

LEVER

BLOCK,

figure

the

CONTACT SCREW,

Tool

No. 262,

NUT,

screw,

the

CONTACT SPRING,

spring.

the

DETENT SPRING

OF

are

disassembled

No. 503J,

11, on

Remove

the

body

insulating

end

of

the

Remove

spring,

case

the

facing

case

INSULATOR. Remove

LEVER

of

assembly

the

contact

8, on

long

the

COMPLETE.

figure

8.

remove

using

Tool

the

Remove

AND

THE

remove

the

end

plunger

CONTACT SPRING,

the

CONTACT SCREW,

INSULATOR WASHER,

COMPLETE.

LEVER

the

contact

end

of

the

shutter

ROLLER

from

2.

CONNECTOR

the

No. 503L.

case

insulator

and

the

resistor

ROLLER

ROLLER

AND

ROLLERAS-

FLASH

of

the

assembly,

SLEEVE.

RECEPTACLE

as

follows:

the

TERMINAL NUT,

the

PLUNGER AS-

case

INSULATOR

and

using

is

as

follows:

LATCH SPRING,

LEVER

spring

blades.

WASHER

at

Lift

'o~

DETENT

ROLLER

CONT ACT ESCAPEMENT WHEEL

CONT

COMPLETE

CONTACT

SPRING

ASSEMBLY AI\

ACT

LEVER

~

CONT ACT

WASHER

INSULATOR

SCREW

--0

--0

~

SCREW

AND

~

----w-

~ENT

ROLLER

t)

~ 0 ~

~

Sl~~\

II 0

~

NUT

.,

\

f}

, CONNECTOR

CONNEIi:TOR PIN

CONTACT

CONTACT

"

SPRING

the

mecha-

figure

CONTACT

Remove

WASH-

the

case

from

BUSffiNG,

WASHER,

Using

the

ter-

On

the

con-

remove

Tool

con-

the

CON-

BUSHING,

the

bottom

the

long

Figur

SPRING AND

- BUSHING

STRIP

SCREW

10,

the

No.

and

e 10

'lr

end of

the

spring

and

rest

it

against

side

edge of

lever

latch.

around

tail.

T hen

SPRING on

the

last

clockwise

2.

Contact

LEVER

contact

the

shutter

spring

tension,

Form

the

vertical

CAUTION:

is

burnished

that

Contact

3.

washer

tact

end of

contact

4.

Contact

the

screw

5.

Ground

6. New

7.

8.

9. Winding

10.

11. SHUTTERS

Figure

connector

Connector

Secure

the

mechanism

of

the

graphs

Retard

TYPE

are

the

contact

as

described

Insert

insulating

bled

parts

case

insulator

of

the

11

INSULATOR--;~

/'

CONTACT

SCREW

the

spring

Form

the

vertical

1/8

at

lever

STUD,

lever

in a clockwise

and

short

part

condition.

spring

between

the

screw.

screw

in

contact

pins.

the

looped

resistor

gear

1-3,

gear

reassembled

lever

the

collar

sleeve.

in

plunger

'"

q:--

~

~

the

place

the

the

contact

inch

of

least

15

complete

figure

spring

blades.

rest

it

end of

of

the

Thecontactlevertail

and

by

placing

the

contact

nut,

using

position

strip

block.

wire

plate

to

the

and

page

8.

train,

OF

THE FLASH

spring

in

paragraphs 1 and

end of

the

terminal

washer

assembly.

CONTACT

CONT ACT

/

/

INSULATOR

NUT

lug

on

short

part

the

Turn

in

contact

must

shutter

'.

clutch

paragraphs

Then

end of

of

the

CON T ACT

lever

bushing. Bend

long end

degrees.

on

the

16.

The

should

the

connector

LEVER

CONTACT

face

the

direction

groove

the

spring

lever

remain

the

case

spring

Tool

with

No. 503L. Hold

Tool

end of

Solder

ground

assembly,

RECEPTACLE

as

follows:

and

the

the

insert

body.

on

the

Replace

COMPLETE

SCREW

long end of

~

WASHER

PLUNGER ASSEMBLY ·

the

the

the

contact

LEVER

ofthe

CONTACT

ends

in,

to

place

in

the

around

tail.

in

case

insulator

and

the

and

insert

No. 262.

screw.

the

resistor

the

other

contact

4-13,

Replace

contact

2 above.

terminal

the

assem-

Replace

threaded

the

SPRING

TE?NA

out-

contact

spring

lever

spring

of

the

toward

the

it

in

case.

the

con-

the

to

end

st'rip

para-

page

9.

lever

body

the

'end

con-

.L NUT

~

I

I

I

I

12

Page 13

tact

12.

spring,

plunger

spring.

nut. On

replace

end

facing

washer

case.

spring

tact

screw

the

washer.

using

Tool

in

position

Trip

the

its

opening

gainst

13.

Observe

LER

CONTACT

slight

contact

fore

the

does

not

spring

Place

against

the

with

the

extending

Secure

the

the

over

in

the

contact

case

out.

Replace

the

opening on

the

the

the

Replace

through

spring

end of

insulator

contact

washer

opening

the

No. 503L while holding

with

Tool

No. 262.

shutter

blades

touch

toward

action

shutter

whether

with

are

the

the

and

at

by

placing

SETTING

the

ST

U D,

the

contact

fully open.

spring,

stud.

the

threaded

the

end of

and

contact

BLADE CONTROL-

bend

13. STAR WHEEL ASSEMBLY,

14.

Replace

the

cover

complete

lever.

15.

Cock

the

release

the

winding

trigger

cover

with a

check

for

trigger

•

the

cover

crease

A

slight

desirable.

.005

-inch

tail

and

engages

in

contact.

is

excessive

controlled

in

or

out.

Allow

position.

see

that

they

close,

tail

toward

driver

shutter;

the

latch

a bind

latch

complete.

the

tension

downward

clearance

that

the'tail.

If

by bending

the

winding

Depress

the

hold

the

blade

then

shutter.

lever

to

must

distinct

between

or

between

on

pressure

There

part

of

The

there

is

clearance,

the

flash

contacts

the

shutter

against

press

At

the

prevent

drop

into

snap.

the

the

If

no bind

the

trigger

must

between

the

trigger

contact

no

clearance

the

the

lever

trigger,

end

of

case,

the

vertical

end of

the

opening

with

the

the

contact

with

the

case

the

inside

the

insert

in

the

spring

screw

the

same

time

one

finger

LEVER,

figure

16,

spring

If

the

end

figure

and

the

same

its

the

If

it

4.

the

trigger

time

return.

slot

does

trigger

trigger

exists,

latch

on

the

be

approximately

the

contact

latch

points

or

spacing

contact

to

go

to

lever

the

and

do not

the

close.

contact

place a screw-

portion

the

in

the

terminal

spring,

collar

insulator

of

the

contact

the

con-

and

nut,

screw

retard

a-

figure

makes

just

be-

the

stud

of

the

winding

to

hold

The

on

the

not,

and

the

latch

and

in-

spring.

spring

is

lever

which

must

be

if

there

may

be

tail

at

rest

watch

to

If

lever

of

the

contact

stud

., and apply

blades

With

prOximately

contact

the

contact

sure

of

at

this

the

lever

the

lever

point.

shutter

.005

latch

lever.

contact

wheel.

While

watch

close

lever

too

If

stoned

must

pressing

the

contacts

at

any

tail

on

far

and

necessary,

at

point

be

square.

time.

the

should

the

"A,"

SHUTTER BLADES

The

sequence

1. Speed

2.

Winding

3.

Cover

4. Winding

wheel

5.

Trigger

bulb

of

control

lever,

complete,

gear,

assembly,

assembly,

lever

assembly,

disassembly

ring,

paragraph

clutch

8.

6.

Retard

7. Main

gear

drive

train,

assembly,

9 .

8.

Flash

contact

parts,

10.

9.

Rear

lens

mount.

10.

Blade

controller

figure 7 and

11. MECHANISM

Diaphragm

12.

the

PLATE,

retainer

ASSEMBLED.

13.

Shutter

blades.

14. BLADE CONTROLLER,

The

sequence

1.

If

necessary,

oughly. Hold

of

reassembly

clean

the

tail

near

the

pressure

tripped,

inch

clearance

spring

This

is

lever

the

trigger

to

make

If

they

contact

be

moved

winding

figure

paragraphs

paragraphs

assembly,

paragraphs

time

paragraphs

paragraphs

paragraphs

paragrapqs

toward

there

lug

to

assure

latch

sure

close,

lever

lever

12.

is

as

2,

lever

contact

and

into

has

back

follows:

1-5,

page

3-7,

4-6,

assembly,

4-14,

lever

the

shutter

must

be

ap-

between

the

side

full

pres-

the

star

down fully,

they

do not

the

contact

been

bent

slightly.

should

Corner

"B"

page

7.

page

8.

and

star

page

8.

4-6,

page

page 9.

4-7,

page

4-13,

page

LATCH SPRING BUSillNG,

LATCH SPRING.

figure

PLATE

the

blades

figure

is

as

shutter

carefully

13.

WITH

14.

follows:

blades

to

WINGS

thoravoid

the

of

be

7.

and

A

Figure

12

PLATE

WITH

WINGS

SETTING

ASSEMBLED

LEVER

SPRING

Figure

13

13

Page 14

them

and

clean

their

bending

a

cause

2.

Blade

soft

-cloth.

corrosion.

controller.

Fingerprints

on

the

surfaces

blades

3. BLADE WITH DOUBLE BLADE BUSHING

and stu(l,

over

LUG,

4.

Proceeding

BLADES WITH STUD,

the

row

5. BLADE

bushing

plate

6.

Diaphragm

bled,

the

mechanism

stud

plate

operate

7. Open

wings and

b I a

mechanism

phragm

9.

The

POINTER and

oughly

(T

exac

recess

lever.

clean

Diaphragm

9.

the

figure

the

stud

figure

14, with

near

17, on

counterclockwise,

wide end of

end of

should

over

and

each

the

preceding

the

stud.

appear

retainer

with

the

cutout

retainer

assembly,

is

plate

for

secured,

the

figure

freely.

the

de

shutter

around

run

blades.

the

the

plate.

wings-

to

shutter

CAS

setting

cleaned.

0 Unitemp-RCX169

in

the

case

Then

wipe

cloth.

pOinter.

projecting

arm

the

hole

the

BLADE CONTROLLER

the

mechanism

in

replace

figure

blade

to

overlap

14, allowing

blade. .

blade

with double

The

back

of

the

mechanism

as

shown

in

plate

with wings

slot

in

the

outer

over

the

PALLET

the

shutter

side

central

This

the

maximum

E,

figure

lever

Apply a

opening

BRACKET with

6.

After

the

blades

Close

the

diaphragm

of a screwdriver

opening

will

open

aperture.

13,

diaphragm

should

thin

film

Grease)

occupied

this

Turn

is

near

by

area

lightly with a

the

pointer

the

cable

the

the

blade

plate.

the

blade

figure

assem-

edge

in

retainer

should

'1

nth

the

be

thor-

of

grease

to

setting

release

until

socket.

10. Setting

LEVER

loose

side

11.

Mechanismplate.

jections

are

After

ring,

should

of

12. Blade

13.

Flash

lever,

end of

of

the

in

position

the

the

operate

the

setting

controller

contact

with one end of

SPRING

attached

the

shutter

on

the

ends

in

plate

is

setting

lever, and

freely.

lever

parts,

spring

case.

See

that

of

the

secured,

spring

latch

paragraphs

to

the

resting

the

the

diaphragm

slots

the

Secure

to

and

latch

the

SETTING

lever

and

against

circularpI'o-

in

tbe

pointer.

the

diaphragm

shutter

the

loose

the

case

spring.

1-11,

wings

blades

stud.

page

10.

14. Main

drive

assembly,

paragraphs

1-4,

page

9.

15.

16.

Retard

Trigger

bulb

gear

assembly,

lever

train,

paragraphs

time

assembly,

1-13,

lever

assembly,

paragraphs

1-3,

page

page

8.

17. Winding

wheel

18.

Rear

gear,

assembly,

lens

mount.

clutch

assemb,ly,

paragraphs

1':'4,

and

page

star

8.

with

will

four

nar-

15.

of

the

dia-

the

the

the

~

end

9.

and

I

PLATE

WITH

WINGS

ASSEMBLED

BLADE

BLADE CONTROLLER

e

RETARDING SECTOR STUD

MAIN

WITH

STUD

BLADE

BLADE BUSHING

BLADE CONTROLLER

DRIVE STUD

BLADE CONTROLLER

CONTACT STUD

WITH

DOUBLE

Figure

Figure

LUG

Figure

14

15

I

16

14

Page 15

KODAK

FLASH

SUPERMATIC

SHUTTER

__

FOR

Shutter

easily

Shutter

open on high

Shutter

KODAK

TROUBLE

does

blades

does

not

remain

speeds

not

set

trip

MONITOR

TROUBLE

TROUBLE

Possible

SEMBLY,

Split

Loose

blades.

Plate

ing on

The

21,

position

been

burr

on TRIGGER AS-

figure

shutter

blade

TRIGGER LATCH,

is

not

released.

blades.

studs

on

the

studs

mechanism

returning

after

the

SIX-20

21.

shutter

loose

or

miss-

plate.

figure

to

its

proper

shutter

CAMERA

CHART

Burnish

the

point

ASSEMBLY,

ReplaCE}

Replace

Replace

avoid swelling

The

trigger

speed

has

It

on

may

the

REMEDY

the

trigger

where

figure

the

shutter

the

shutter

or

restake

latch

index

plate

be

necessary

TRIGGER LATCH

and

it

contacts

24, when

blades.

blades.

the

the

top

of

is

bent and binding on

or

cover.

to

collar

reduce

assembly

the

MAIN

in a set

studs

the

studs.

SPRING,figure

DRIVE

position.

carefully

the

tension

at

to

the

19.

The

winding

not hold when

ter

is

set

Shutter

Shutter

speeds

Figure

speeds

lever

the

slow

17

fast

does

shut-

The

winding

on

the

The

CLUTCH ASSEMBLY,

ure

20,

The

latch

LEVER

is

damaged.

Retard

The

MAIN DRIVE SPRING,

ure

23,

Shutter

Excessive

Insufficient

InsuffiCient

(on

speeds

gear

gear.

is

slipping.

point on

COMPLETE,

gears

dirty.

is

weak.

blades

binding.

retard

retard

pallet

1/10

pj.nion

is

the

CONTACT

figure

sector

sector

engagement

or

slower).

loose

fig-

24,

fig-

travel.

travel.

Replace

Replace

Replace

Remove

Replace

Remove

Swedge

at

the

area

figure

File

the

the

fast

Remove

in

the

area

stud.

the

the

clutch

the

and

the

and

the

speed

cQntrolling

17.)

speed

speed.

material

of

pinion

contact

clean

main

drive

replace

ring

(See

contact

gear

assembly.

assembly.

lever

complete.

the

retard

spring.

the

shutter

control

the

at

the

figure

on

the

speed

with

the

gears.

RING,

slow

area

17.)

pallet

blades.

figure

speed.

control

(See

controlling

ring

bracket

18,

15

Page 16

TROUBLE

Shutter

(cont'd) -

speeds

fast

Gear

train

CAUSE

dirty.

Check

fo'r bind of

figure

COMPLETE.

Clean

22,

the

against

gear

REMEDY

the

the

train

thoroughly.

PALLET

retard

BRACKET,

gear

PLATE

Shutter

blades

buckle

Too

much

drive

spring.

NOTE:

to

Loose

or

27.

B

contact

Shutter

Mechanism

Blade

too

the

Too

mechanism

phragm

WINGS

due

bowed.

Burr

retainer

bled.

The

blade

buckle,

studs

MECHANISM

LAD

E CONTROLLER with

stud,

blades

controller

tight

on

mechanism

muc h play

retainer

ASSEMBLED,

to

retainer

or

roughness

plate

tension

following

singly

on

shutter

PLATE,figure

figure

nof

plate

not

too

the

central

plate.

plate

PLATE

plate's

with wings

on

the

conditions

or

28, not

flat.

flat.

loose

between

and

the

figure

on

diaphragm

assem-

main