Page 1

Puolication

io.

XP3111-13

Kodak

Service

for

Ektachem

Publication

the

DTSC

MODULE

Page 2

The

information

contained

herein

is

based

PLEASE

on

the

experience

NOTE

and

knowledge

relating

to

the

subject

matter

gained

No

Eastman

Warranty,

including

15

by

Eastman

patent

caused

license

Kodak

express

consequential

by

Kodak's

Kodak

is

granted

Company

or

implied,

Company

by

reserves

with

or

special

negligence

prior

this

information.

the

respect

damages.

or

other

to

publication

right

to

to

this

information.

resulting

fault

change

from

this

Kodak

the

use

information

shall

of

this

without

not

be

liable

information,

notice.

for

even

and

any

loss

if

loss

makes

or

damage.

or

damage

no

a

\

i

YA

J

This

damage

damage

equipment

from

during

electrostatic

includes

all

service

+

CAUTION

parts

discharge.

procedures.

and

+

assemolies

Use

sensitive

caution

to

to

prevent

©

|

© ©

0

0

0

0

o

o

©

aa

|

0 0

0

0 0 0

0

(6

0

(6

Page 3

Contents

of

the

Service

Publication

Section

Section

General

Normal

Information

Contents

Special

Labels

Operation

Slide

Slide

Slide

Transport

Identification

Spotting

Tools

System

System

System

Publication

XP3111-1

XP3111-2

No.

Section

Section

7.

8.

CANCELLED.

For

publication

CANCELLED.

For

publication

site

installation

specifications,

for the

for

see

Kodak

instructions,

the

Kodak

Publication

the

Ektachem

see the

Ektachem

service

DT60

DT60

No.

ANALYZER

service

ANALYZER

Section

Section

HALL

CANCELLED.

For

publication

Diagnostics

Diagnosing

Error

EFFECT

information

and

Code

Tables

BOARD

for

Repairing

on

the

options,

Kedak

see

Ektachem

Malfunctions

the

service

DT60

XP3111-4

ANALYZER

Section

Section

Section

9.

10.

11.

Special

Parts/Removals

CANCELLED.

Procedures

Correction

DR

Computer

For

Procedures

the

Factors

Interface

glossary,

see

the

XP3111-9

XP3111-19

service

Section

Section

Error

Checkout

Diagrams XP3111-5

Adjustments

FLASH

SLIDE

SPOT

BAR

TIP

Conditions

Procedures

LAMP

TRANSPORT

DETECCTOR

CODE

-

Height

READER

-

Illumination

BELT

SENSOR

-

-

Tension

-

Voltage

XP3111-6

Voltage

Section

Section

Section

12.

13.

14.

publication

CANCELLED.

For

publication

Newsletters

Notes

for the

modifications,

for the

Kodak

see the

Kodak

Ektachem

service

Ektachem

DT60

DT60

ANALYZER

ANALYZER

XP3111-13

2/89

To

for

To

XP3111-13

order

the

order

a

complete

Service

the

complete

set

Publication,

of

service

Tabs,

use

publication,

the

publication

Title

Page,

no.

use

and

XP3111-13.

PK3111.

Contents

page

2/89

Page 4

Publication

No.

XP3111-1

4/86

Kodak

DTSC

General

Ektachem

MODULE

Information

The

information

Company

No patent

Eastman

with

resulting

prior

license

Kodak

respect

from

Section

contained

to

publication

is

granted

Company

to

this

information.

the

use

herein

reserves

of

this

is

based

by

this

tha

Kodak

information.

on

the

exparience

information

right

to

change

shall

not

be

even

if

loss

PLEASE

and

this

information

lisble

for

or

damage

NOTE

knowiedge

any

is

relating

without

loss

or

caused

notice.

by

Kodak's

to

the

subject

and

makes

damage.

including

negligence

1

matter

no

consequential

gained

warranty.

or

other

by

Eastman

express

or

special

fault

or

damages.

Kodak

implied,

©

Eastman

Kodak

Company,

1986

Page 5

Table

of

Contents

Figure

No.

Contents

Configuration

Special

of

Tools

the

of

Service

the

DTSC

Publication......,.............sssese

MODULE..............

sn

ne

al

2-9

XP3111-1,

4/86

~

Page 6

Contents

of

the

The

service

General

Normal

Options

Diagrams

Diagnostics

Adjustments

Site

Installation

publication

Information

Operation

Specifications

includes

Instructions

the

Service

following

Publication

sections:

The

and

addition

parts

installation

Special

Parts

Glossary

Modifications

Newsletters

Notes

Comment

and

to

removals

removals,

Procedures

and

Removals

Card

instructions

section

illustrated

includes

for

some

parts,

adjustment

of

the

and

specifications

assemblies,

numerical

and

alphabetical

indexes.

Figure

XP3111-1,

1

4/86

XP3111-1,

4/86

1.2

Page 7

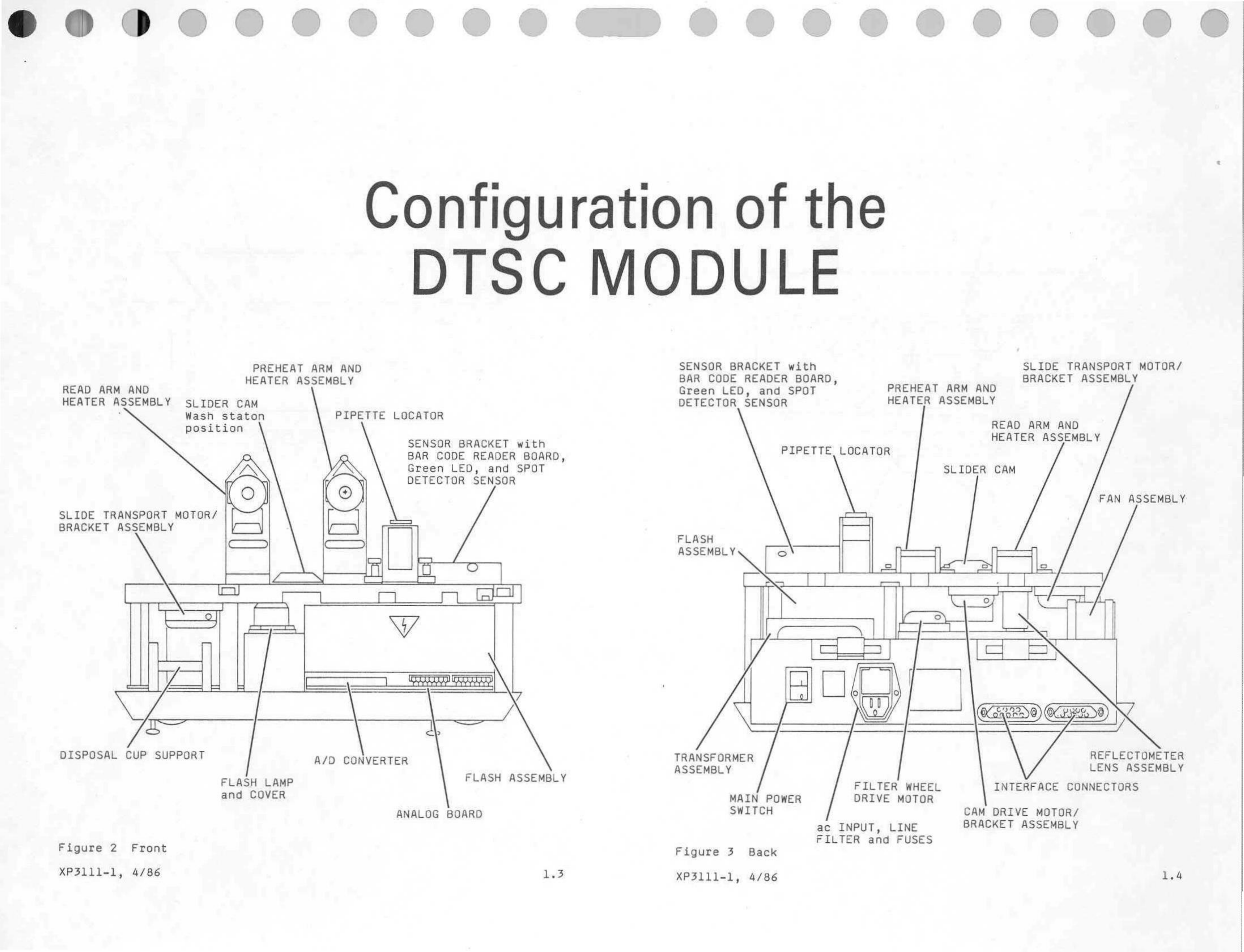

READ

ARM AND

PREHEAT

HEATER

ARM AND

ASSEMBLY

Configuration

DTSC

MODULE

SENSOR

BAR

Green

CODE

of

BRACKET

READER

LED,

and

the

with

BOARD,

SPOT

PREHEAT

ARM

AND

SLIDE

BRACKET

TRANSPORT

ASSEMBLY

MOTOR/

HEATER

SLIDE

BRACKET

ASSEMBLY

TRANSPORT

ASSEMBLY

SLIDER

Wash

position

MOTOR/

CAM

staton

PIPETTE

LOCATOR

SENSOR

BAR

Green

DETECTOR

BRACKET

CODE

LED,

READER

and

SENSOR

with

BOARD,

SPOT

DETECTOR

FLASH

ASSEMBLY

SENSOR

A

o

PIPETTE,

LOCATOR

HEATER

ASSEMBLY

SLIDER

READ

HEATER

CAM

ARM AND

ASSEMBLY

FAN

ASSEMBLY

Ns

|

(

I

[

TOM

Lol

Y

=

)

9

2

으

一

č

5

一

더

-

で

ちち

DISPOSAL

Figure

XP3111-1,

2

CUP

Front

4/86

SUPPORT

FLASH

and

COVER

LAMP

A/D

CONVERTER

ANALOG

FLASH

BOARD

ASSEMBLY

LZ

TRANSFORMER

ASSEMBLY

MAIN

SWITCH

Figure

XP3111-1,

3

Back

4/86

POWER

FILTER

WHEEL

INTERFACE

ac

FILTER

INPUT,

DRIVE

and

MOTOR

LINE

FUSES

CAM

BRACKET

DRIVE

MOTOR/

ASSEMBLY

REFLECTOMETER

LENS

CONNECTORS

ASSEMBLY

Page 8

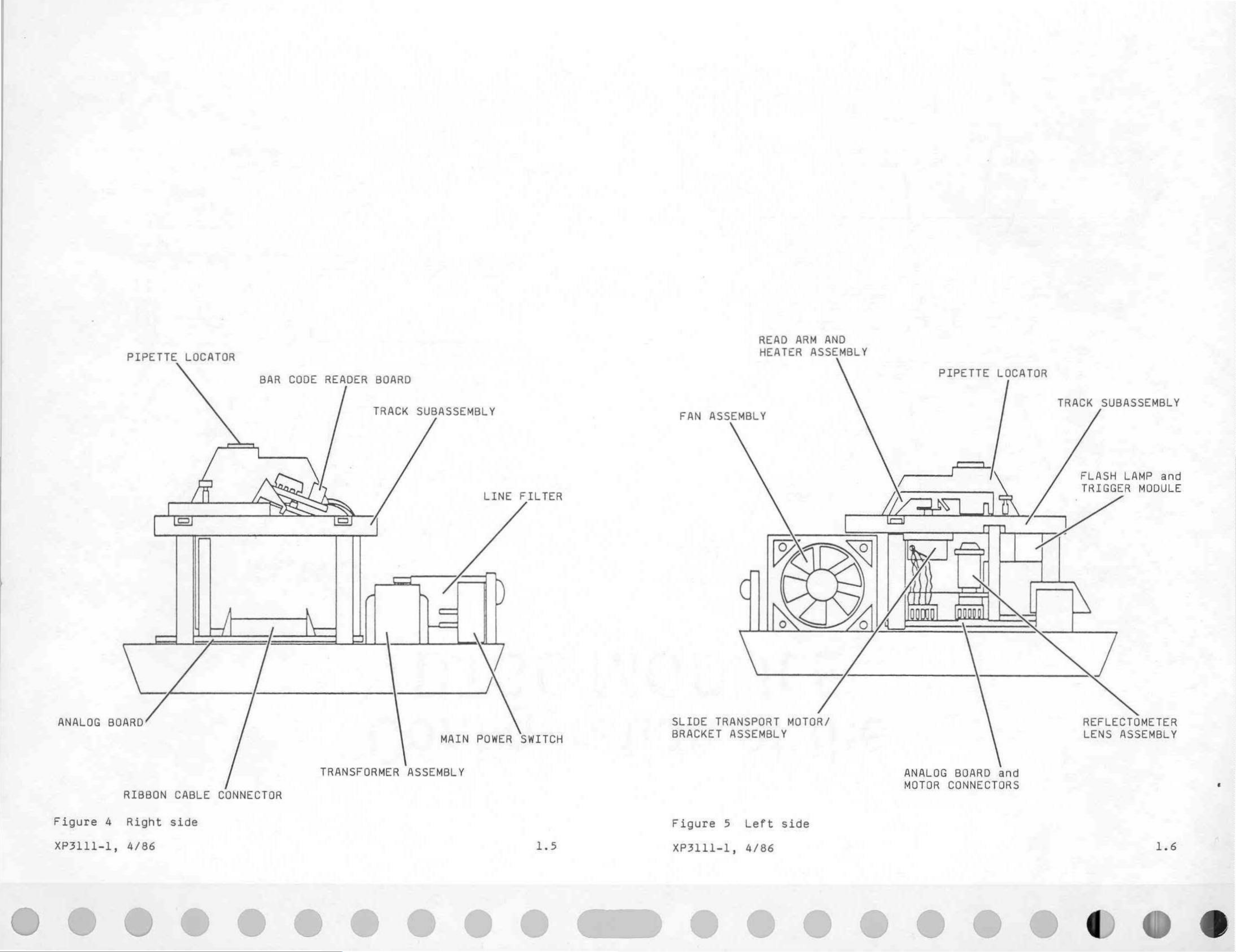

READ

ARM

AND

PIPETTE LOCATOR

BAR

CODE

READER

BOARD

TRACK

SUBASSEMBLY

LINE

FILTER

FAN

ASSEMBLY

HEATER

ASSEMBLY

PIPETTE

LOCATOR

TRACK

FLASH

TRIGGER

SUBASSEMBLY

LAMP

MODULE

and

ANALOG

Figure

XP3111-1,

BOARD

4

RIBBON

Right

4/86

CABLE

side

CONNECTOR

TRANSFORMER

MAIN

ASSEMBLY

POWER

SWITCH

1.5

SLIDE

BRACKET

Figure

XP3111-1,

TRANSPORT

ASSEMBLY

5

Left

4/86

MOTOR/

side

ANALOG

MOTOR

BOARD

CONNECTORS

and

REFLECTOMETER

LENS

ASSEMBLY

1.6

>DO0

@

Page 9

0000009090

COMME

Net

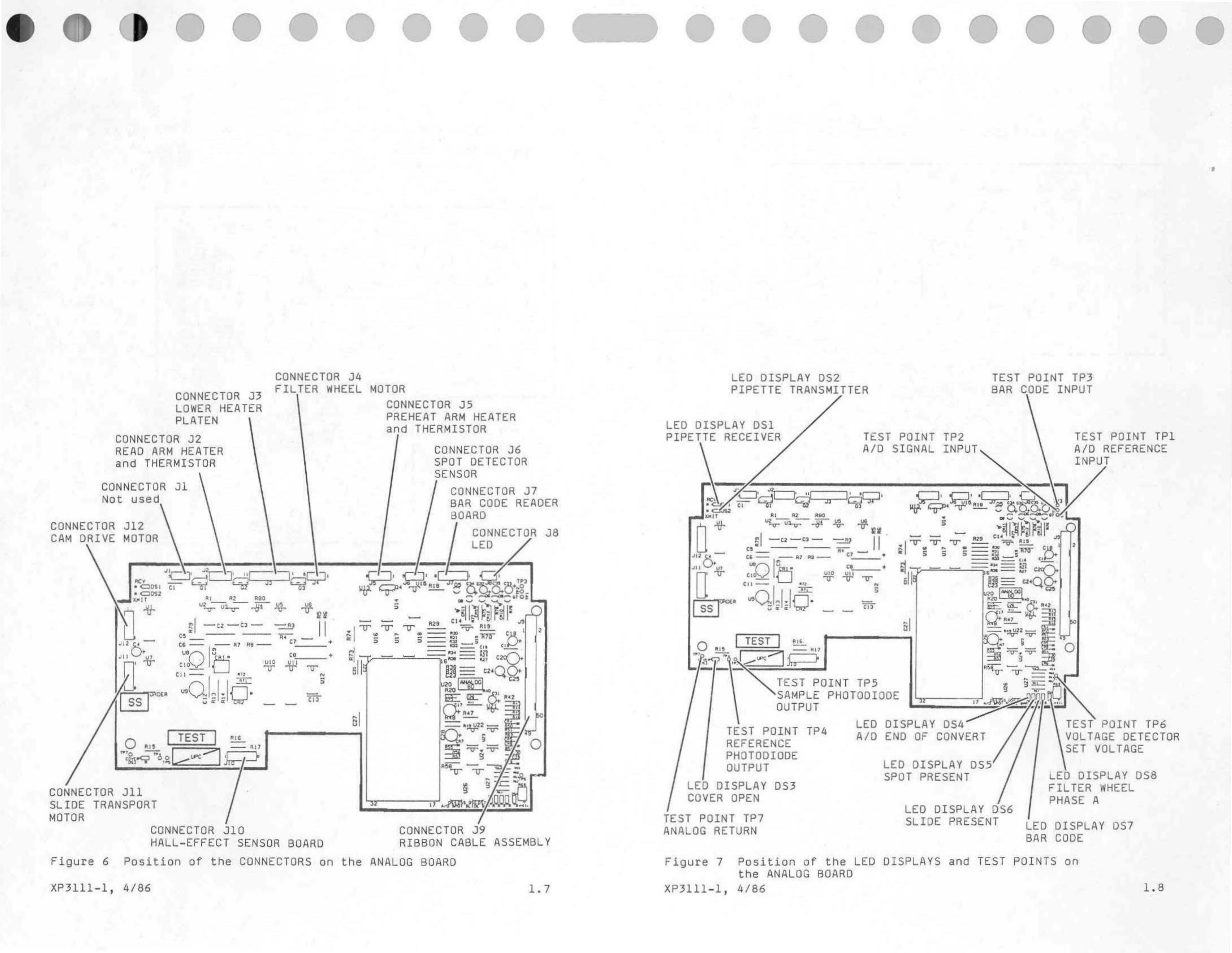

CONNECTOR

CAM

DRIVE

CONNECTOR

READ

and

ARM

THERMISTOR

TOR

-

J12

MOTOR

CONNECTOR

LOWER

PLATEN

J2

HEATER

HEATER

«QE

33

CONNECTOR

FILTER

J4

WHEEL

MOTOR

CONNECTOR

PREHEAT

and

J5

ARM

THERMISTOR

CONNECTOR

SPOT

DETECTOR

SENSOR

CONNECTOR

BAR

BOARD

CONNECTOR

HEATER

J6

CODE

37

READER

38

LED

PIPETTE

DISPLAY

LED

PIPETTE

RECEIVER

DISPLAY

DS1

DS2

TRANSMITTER

TEST

A/D

POINT

SIGNAL

TP2

INPUT

TEST

BAR

POINT

CODE

TP3

INPUT

TEST

A/D

POINT

REFERENCE

TPL

CONNECTOR

SLTDE

MOTOR

TRANSPORT

Oo:

J11

È

DI

Ti

CONNECTOR

HALL-EFFECT

+

т

AL

me

J10

SENSOR

Reo

BOARD

CONNECTOR

RIBBON

CABLE

J9

ASSEMBLY

LED

COVER

TEST

ANALOG

TEST

REFERENCE

PHOTODIODE

OUTPUT

DISPLAY

POINT

RETURN

OPEN

TP7

a

SAMPLE

OUTPUT

POINT

DS3

POINT

PHOTODIODE

TP4

TP5

LED

A/D

DISPLAY

END

LED

SPOT

OF

DISPLAY

PRESENT

LED

SLIDE

DS4

CONVERT

DS5

DISPLAY

PRESENT

DS6

LED

BAR

a

TEST

VOLTAGE

SET

LED

FILTER

PHASE

DISPLAY

CODE

DISPLAY

POINT

DETECTOR

VOLTAGE

WHEEL

A

DS7

TP6

DS8

Figure

XP3111-1,

6

Position

4/86

of

the

CONNECTORS

on

the

ANALOG

BOARD

1.7

Figure

XP3111-1,

7

Position

the

4/86

ANALOG

of

BOARD

the LED

DISPLAYS

and

TEST

POINTS

on

1.8

Page 10

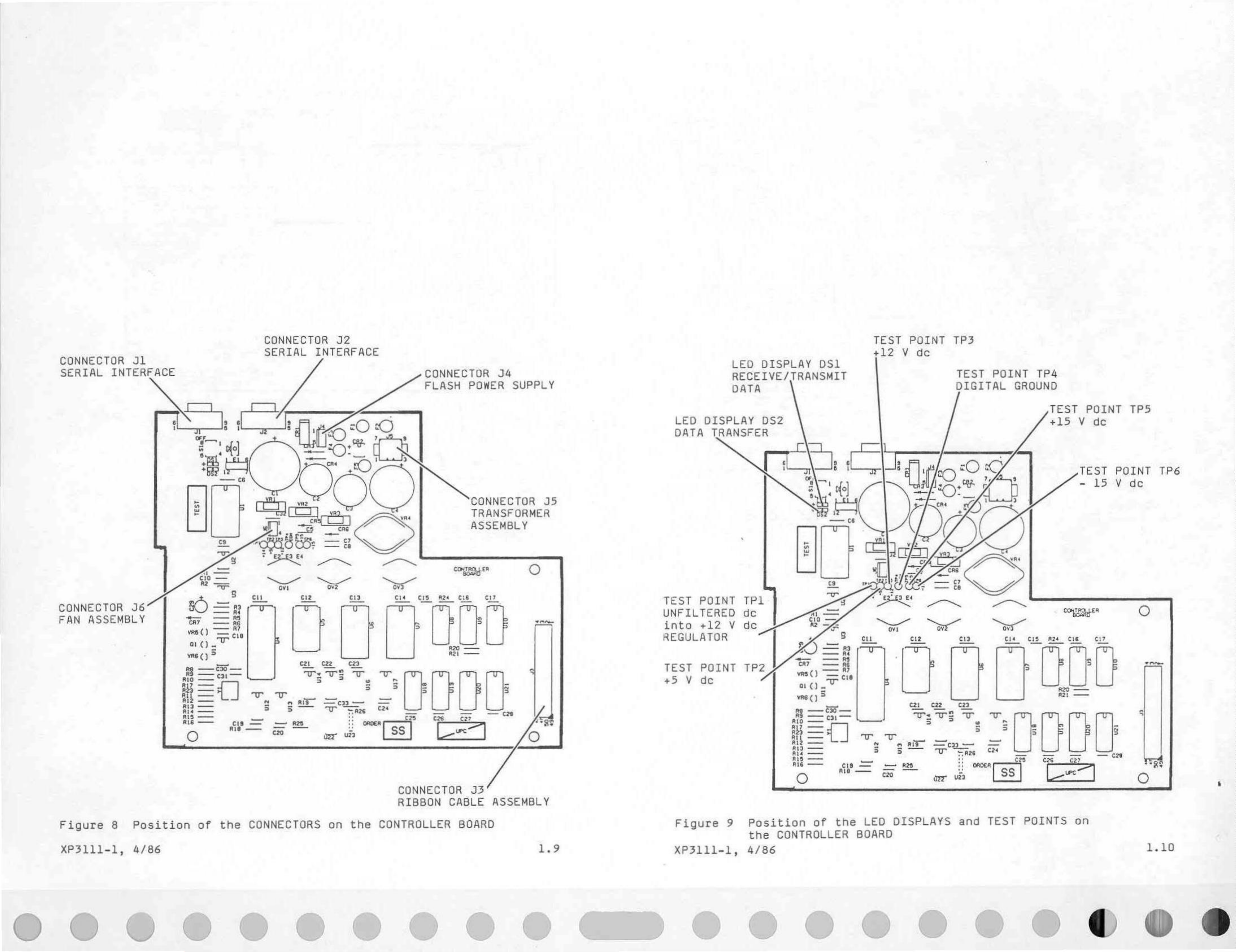

CONNECTOR

J2

TEST

POINT

TP3

CONNECTOR

SERIAL

Jl

INTERFACE

SERIAL

INTERFACE

CONNECTOR

FLASH

POWER

CONNECTOR

TRANSFORMER

J4

SUPPLY

J5

LED

DATA

LED

RECEIVE/TRANSMIT

DATA

DISPLAY

TRANSFER

DISPLAY

DS2

DS1

+12

Y

de

TEST

DIGITAL

POINT

TP4

GROUND

TEST

+15

POINT

V

de

TEST

-

15

TP5

POINT

V

de

TP6

CONNECTOR

FAN

ASSEMBLY

J6

ASSEMBLY

TEST

UNFILTERED

into

REGULATOR

TEST

+5

V

POINT

+12

POINT

de

V

TPE

de

de

TPZ

Figure

XP3111-1,

8

Position

4/86

of

the

CONNECTORS

on

the

CONNECTOR

RIBBON

CONTROLLER

J3

CABLE

BOARD

ASSEMBLY

1.9

Figure

XP3111-1,

9

Position

the

4/86

CONTROLLER

of

the

LED

BOARD

DISPLAYS

and

TEST

POINTS

on

1.10

O

©

©

Ч

)

W

L

|

>

tk

Page 11

q

PUSH-PULL

SCALE

TL-1079

LOGIC

PEN

TL-3008

BAR

SLIDE

CODE

as

READE!

WHITE

SLIDE

REFERENCE

TL-3575

SERIAL

CONNECTOR

Figure

XP3111-1,

10

4/86

LOOPBACK

TL-3225

TIP

GAUGE

HEIGHT

TL-3446

ADJUSTMENT

1.11

XP3111-1,

BLACK

SLIDE

4/86

REFERENCE

TL-3576

3900/A390

BOARD

TL-3577

TEST

1.12

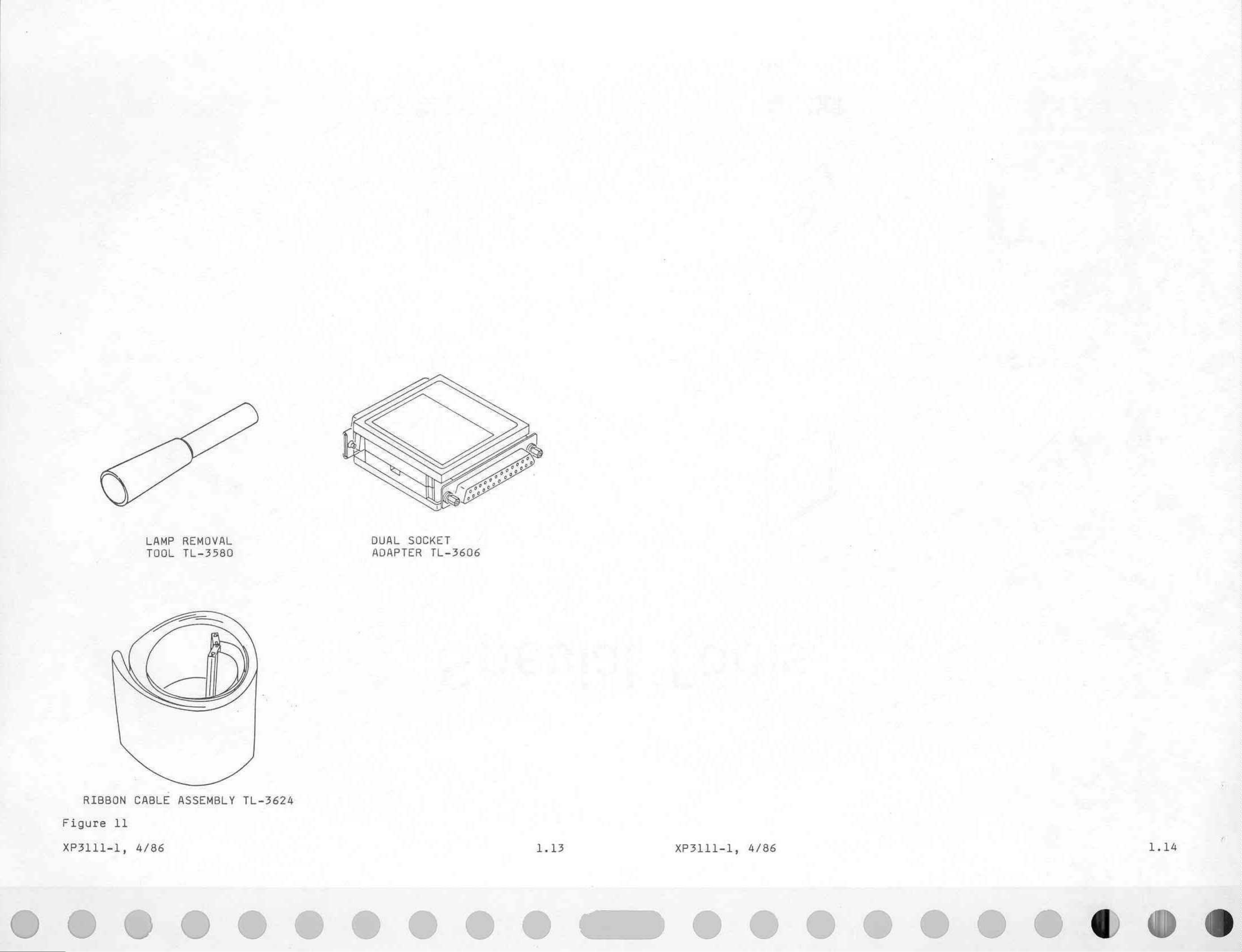

Page 12

LAMP

REMOVAL

DUAL

SOCKET

TOOL

SIE

TL-3580 ADAPTER

TL-3606

RIBBON

Figure

XP3111-1,

11

CABLE

4/86

0000090

ASSEMBLY

TL-3624

1.13

|

XP3111-1,

4/86 1.14

0292900060

Page 13

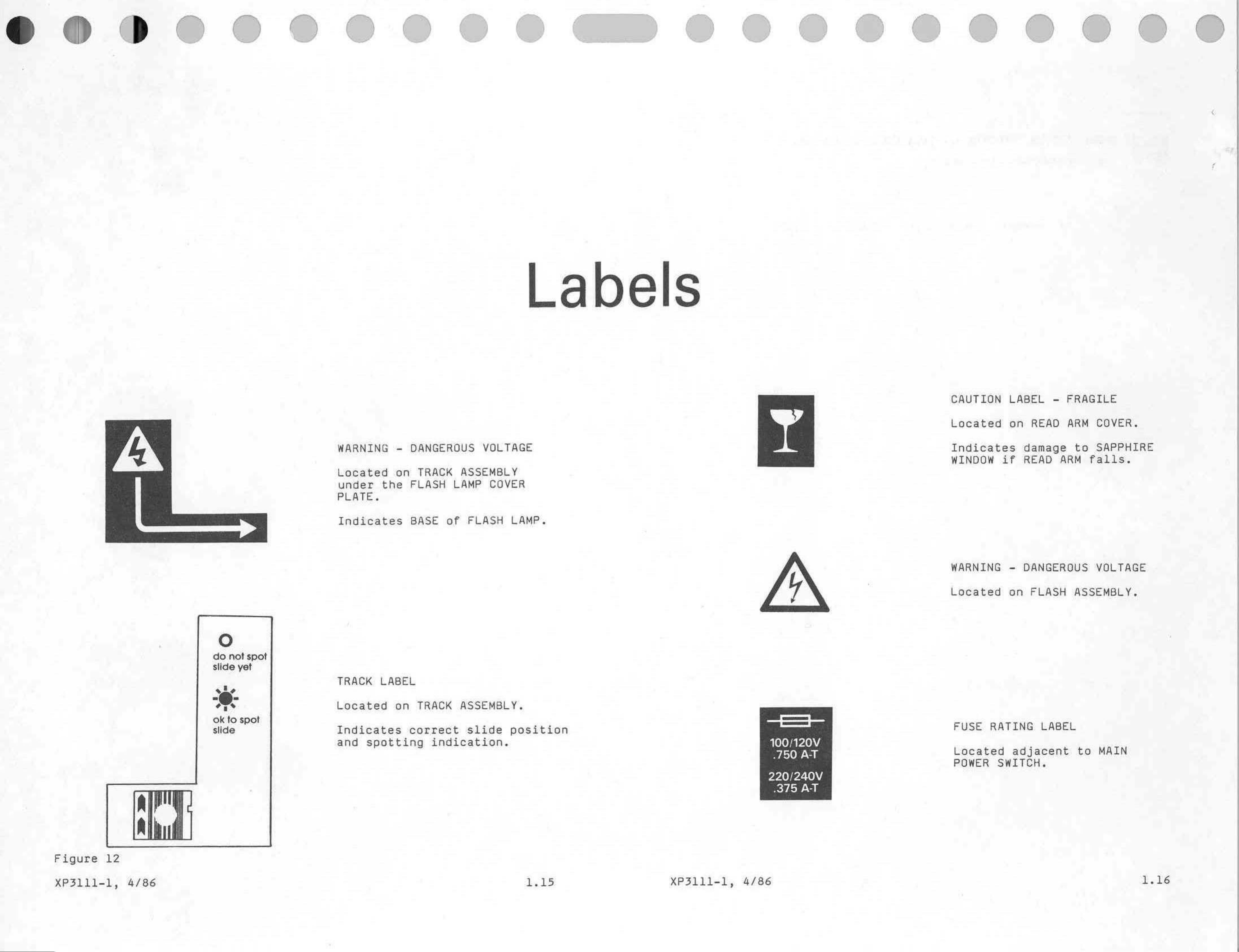

Labels

WARNING

Located

under

PLATE.

Indicates

the

-

DANGEROUS

on

TRACK

FLASH

BASE

ASSEMBLY

LAMP

of

FLASH

VOLTAGE

COVER

LAMP.

CAUTION

Located

Indicates

WINDOW

LABEL

on

if

-

READ

damage

READ

FRAGILE

ARM

to

ARM

falls.

COVER.

SAPPHIRE

o

do

not

slide

ok

to

slide

spot

yet

spot

TRACK

Located

Indicates

and

LABEL

spotting

on

TRACK

correct

ASSEMBLY.

slide

indication.

position

==

100/120V

-750

AT

WARNING

Located

FUSE

Located

POWER

RATING

-

DANGEROUS

on

adjacent

SWITCH.

FLASH

LABEL

VOLTAGE

ASSEMBLY.

to

MAIN

Figure

XP3111-1,

12

4/86

1,15

XP3111-1,

4/86

220/240V

„375

AT

1.16

Page 14

Kodak,

Ektachem,

and

DTSC

are

trademarks.

4/86

XP3111-1

EASTMAN

KODAK

COMPANY

Customer

©

ROCHESTER,

Equipment

Services

N.Y.

Division

14650

Printed

in

USA

Page 15

Publication

No.

XP3111-2

3/86

Slide

Slide

Slide

HALL

Kodak

Ektachem

Normal

Transport

Identification

Spotting

EFFECT

System....................

System..............

System......................

SENSORS.....................

DTSC

Section

Operation

Index

MODULE

2

Page

2.01

2.14

2.19

2.23

ANALOG

Temperature

Flash

Slide

Reading

Power

Initialization

The

information

gained

by

Eastman

No patent

Eastman

warranty,

including

is

license

Kodak

express

cohsequential

caused

by

Kodak's

and

CONTROLLER

Control

System

and

Light

Distribution

contained

Company

or

herein

Kodak

Company

is

granted

by

reserves

implied.

with

or

special

negligence

is

based

prior

this

information.

the right

respect

damages,

or

other

Path

*

To

be

PLEASE

NOTE

on

the

experience

to

publication.

to

change

to

this

information.

resulting

from

fault.

BOARD

provided

and

knowledge

this

information

Kodak

shall

the

use

of

in a revision.

relating

to

without

notice,

not

be

liable

for

this

information,

even

*

*

*

=

*

品

the

subject

and

any

loss

if

loss

matter

makes

or

damage,

or

damage

no

©

Eastman

Kodak

Company,

1986

Page 16

tion

2.

N

|

ration

+

Slide

Transport

tem

The

Slide

chemistry

Many

is

MODULE.

the

Slide

The

operations

only

a

operations

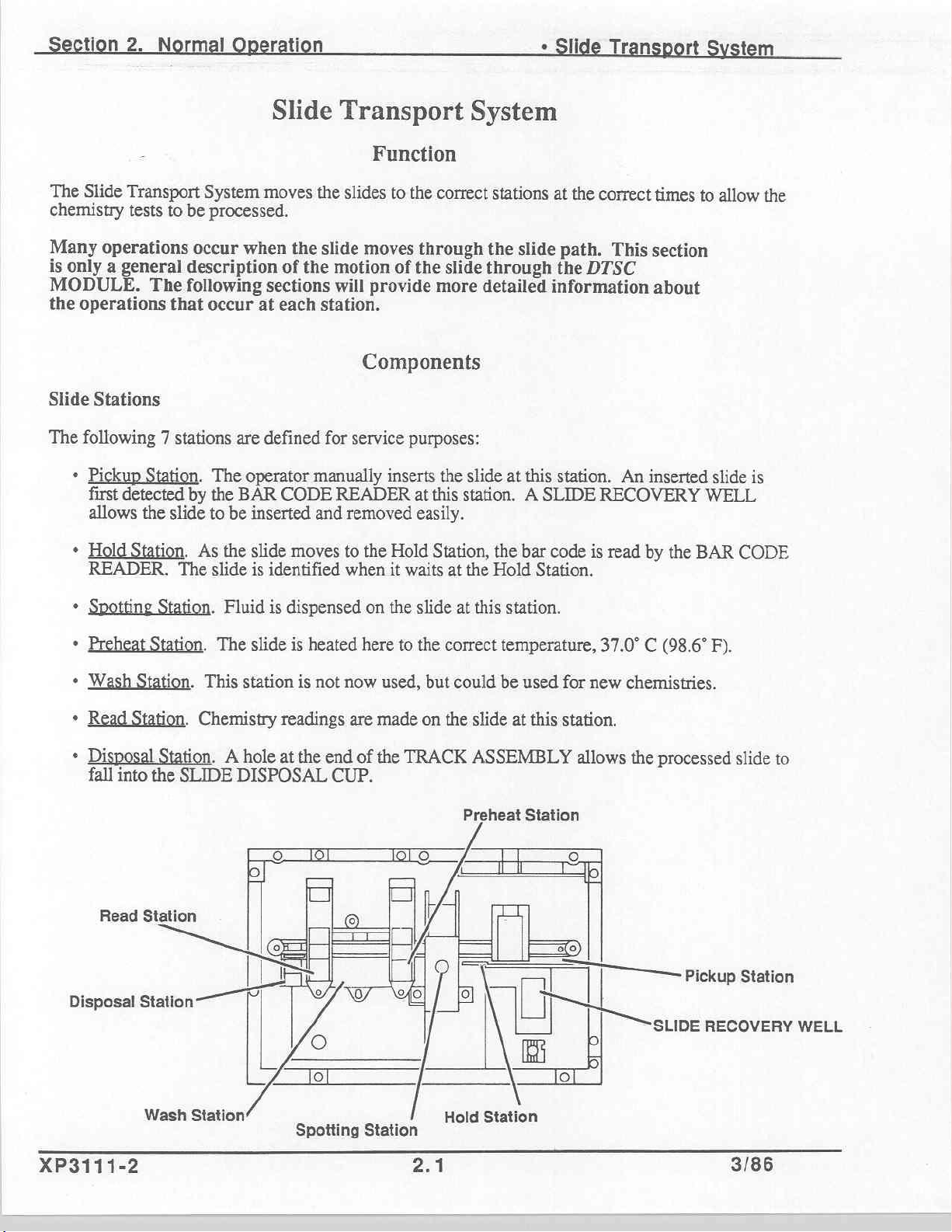

Stations

following

ㆍ

Pickup

first

allows

*

Hold

READER.

Transport

be

to

tests

occur

general

detected

Station.

description

The

following

that

7

stations

Station.

by

the

slide

The

System

processed.

occur

The

the

to

As

slide

moves

when

sections

at

are

defined

operator

BAR

be

inserted

the

slide

is

identified

Slide

the

of

each

CODE

moves

Transport

the

slide

the

motion

will

station.

for

manually

READER

and

Function

slides

to

the

moves

provide

through

of

the

Components

service

removed

to

when

inserts

the

Hold

it

purposes:

at

easily.

waits

System

correct

slide

more

the

this

Station,

stations

the

through

detailed

slide

station.

the

at

the

Hold

at

slide

path.

the

information

at

this

station.

A

SLIDE

bar

code

Station.

the

correct

This

DTSC

RECOVERY

is

read

times

section

about

An

inserted

by

the

to

allow

slide

WELL

BAR

the

is

CODE

+

Spotting

«

Preheat

+

Wash

*

Read

*

Disposal

Station.

Station.

Disposal

fall

into

Read

Station

Station.

Station.

Station. A hole

the

Station

Fluid

The

This

Chemistry

SLIDE

DISPOSAL

station

İLE

—

İİ

{AOE

is

dispensed

slide

is

readings

at

AAN

heated

is

not

the

end

CUP.

fT

0

here

now

are

of

on

the

used,

made

the

slide

to

the

but

on

TRACK

|

le

[e

at

this

correct

could

the

temperature,

be

slide

ASSEMBLY

Preheat

station.

used

for

at

this

station.

Station

-

EO)

[Pickup

Li

o]

37.0* C (98.6*

new

chemistries.

allows

the

ο]

의

|

|

—

sune

b

F).

processed

slide

RECOVERY

to

Station

WELL

XP3111-2

Wash

Station

Spotting

Station

2.1

Hold

Station

3/86

Page 17

i

rmal

ration

*

Slide

Transport

tem

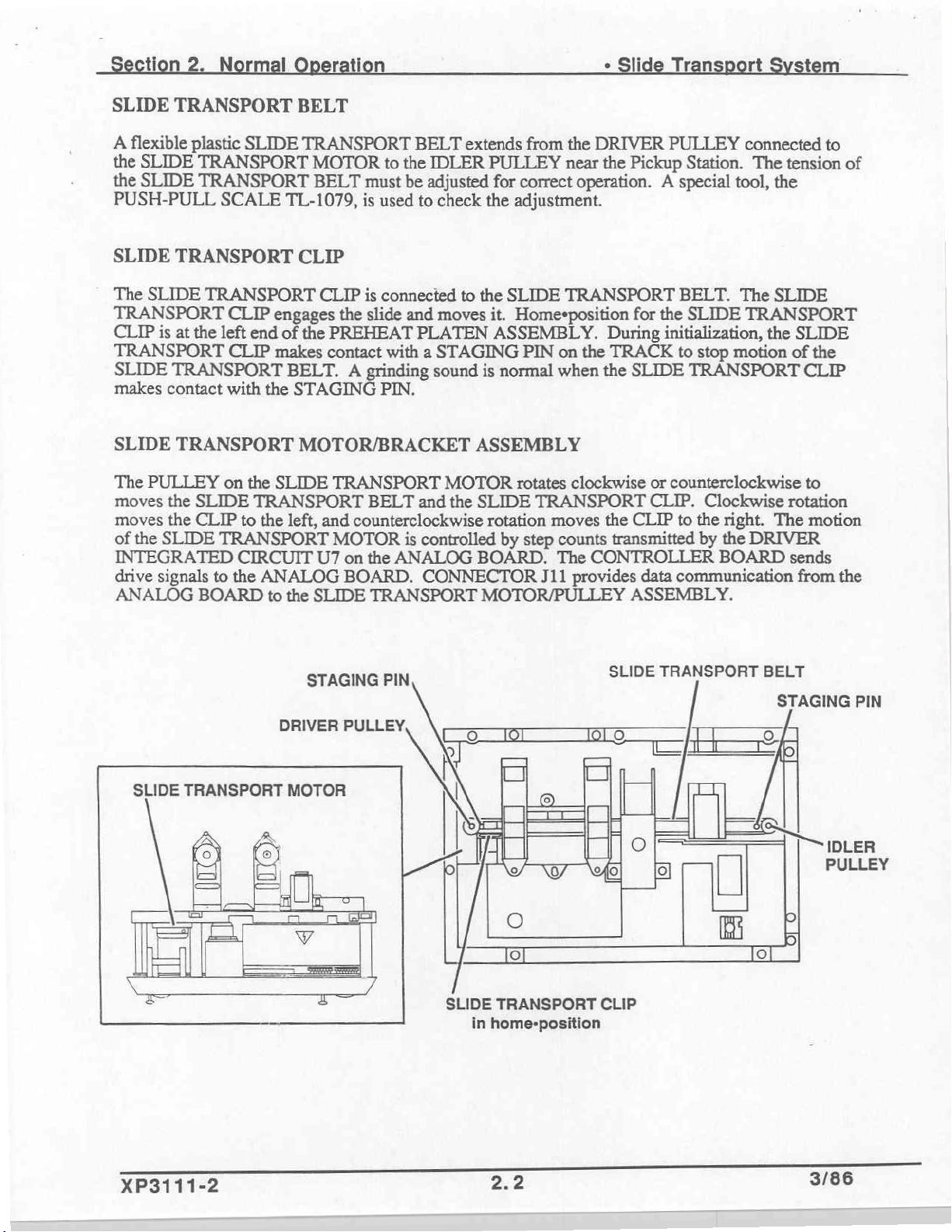

SLIDE

A

the

the

PUSH-PULL

SLIDE

The

TRANSPORT

CLIP

TRANSPORT

SLIDE

makes

SLIDE

The

moves

moves

of

INTEGRATED

drive

ANALOG

TRANSPORT

flexible

SLIDE

SLIDE

the

plastic

TRANSPORT

SLIDE

is

at

TRANSPORT

contact

TRANSPORT

PULLEY

the

the

SLIDE

signals

SLIDE

TRANSPORT

TRANSPORT

SCALE

TRANSPORT

CLIP

the

left

end

CLIP

with

the

on

the

SLIDE

CLIP

BOARD

TRANSPORT

to

the

TRANSPORT

CIRCUIT

to

the

ANALOG

to

BELT

TRANSPORT

MOTOR

BELT

TL-1079,

CLIP

CLIP

engages

of

the

PREHEAT

makes

SLIDE

contact

BELT. A grinding

STAGING

MOTOR/BRACKET

TRANSPORT

left,

and

MOTOR

U7

the

SLIDE

to

the

must

be

is

used

is

connected

the

slide

and

with a STAGING

PIN.

BELT

counterclockwise

is

on

the

ANALOG

BOARD.

TRANSPORT

BELT

to

PLATEN

and

extends

IDLER

adjusted

check

moves

sound

controlled

CONNECTOR

PULLEY

for

the

to

the

it.

ASSEMBLY.

is

normal

ASSEMBLY

MOTOR

the

SLIDE

rotation

BOARD.

MOTOR/PULLEY

from

the

DRIVER

near

the

correct

adjustment.

SLIDE

Homesposition

PIN

rotates

by

step

operation.

TRANSPORT

on

the

when

the

clockwise

TRANSPORT

moves

counts

The

CONTROLLER

J11

provides

PULLEY

Pickup

for

During

TRACK

SLIDE

the

CLIP

transmitted

ASSEMBLY.

Station.

A special

BELT.

the

SLIDE

initialization,

to

stop

TRANSPORT

or

counterclockwise

CLIP.

to

the

data

communication

connected

The

tool,

The

TRANSPORT

motion

Clockwise

right.

by

the

DRIVER

BOARD

tension

the

SLIDE

the

SLIDE

of

CLIP

to

rotation

The

motion

sends

from

to

of

the

the

SLIDE

TRANSPORT

DRIVER

MOTOR

A

©

>

STAGING

PULLEY,

PIN

LERİ

SLIDE

TRANSPORT

in

home-position

SLIDE

CLIP

TRANSPORT

i

BELT

STAGING

Ll

PIN

IDLER

PULLEY

XP3111-2

2.2

3/86

Page 18

tion

2.

Normal

ration

:

Sli

ran

t

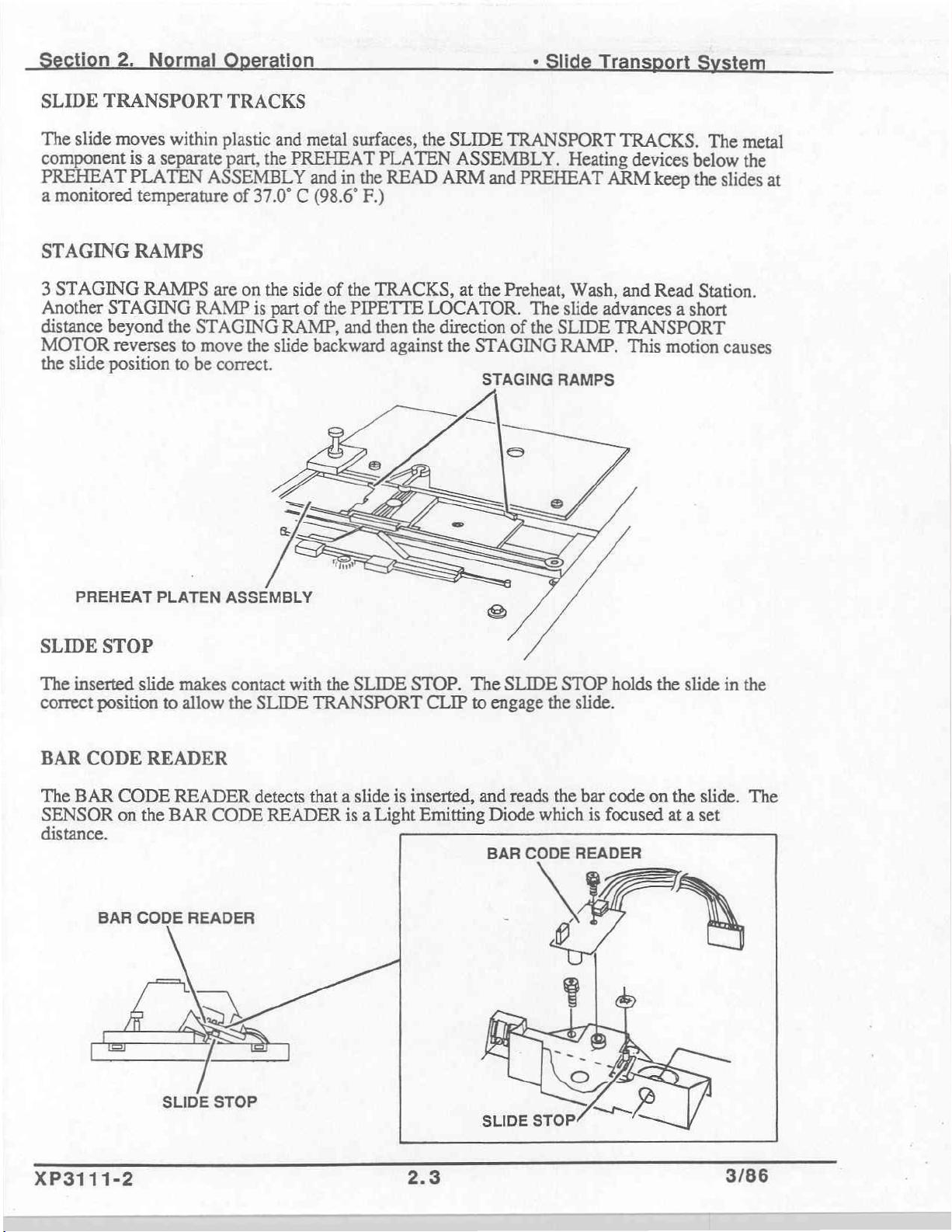

SLIDE

The

component

PREHEAT

a

monitored

STAGING

3

STAGING

Another

distance

MOTOR

the

TRANSPORT

slide

moves

STAGING

beyond

reverses

slide

position

within

is

a

separate

PLATEN

temperature

RAMPS

RAMPS

RAMP

the

STAGING

to

move

to

be

ASSEMBLY

TRACKS

plastic

part,

are

correct.

and

the

of

37.0° C (98.6°

on

the

is

part

RAMP,

the

slide

metal

PREHEAT

and

in

side

of

the

of

the

PIPETTE

and

backward

surfaces,

the

F.)

the

PLATEN

READ

TRACKS,

LOCATOR.

then

the

against

SLIDE

ASSEMBLY.

ARM

direction

the

and

at

the

STAGING

STAGING

TRANSPORT

PREHEAT

Preheat,

of

The

the

TRACKS.

Heating

Wash,

slide

SLIDE

RAMP.

RAMPS

devices

ARM

and

advances a short

TRANSPORT

This

keep

Read

motion

The

metal

below

the

the

slides

Station.

causes

at

PREHEAT

SLIDE

The

correct

BAR

The

SENSOR

distance.

STOP

inserted

position

CODE

BAR

CODE

on

BAR

PLATEN

slide

makes

to

READER

READER

the

BAR

CODE

allow

CODE

READER

ASSEMBLY

contact

the

with

SLIDE

detects

READER

the

SLIDE

TRANSPORT

that a slide

is a Light

STOP.

CLIP

is

inserted,

Emitting

The

to

engage

and

Diode

SLIDE

the

reads

which

STOP

slide.

the

holds

bar

code

is

focused

the

on

the

at a set

slide

in

slide.

the

The

XP3111-2

SLIDE

STOP

2.3

3/86

Page 19

n2

m

Ti

+

Slide

T

ri

t

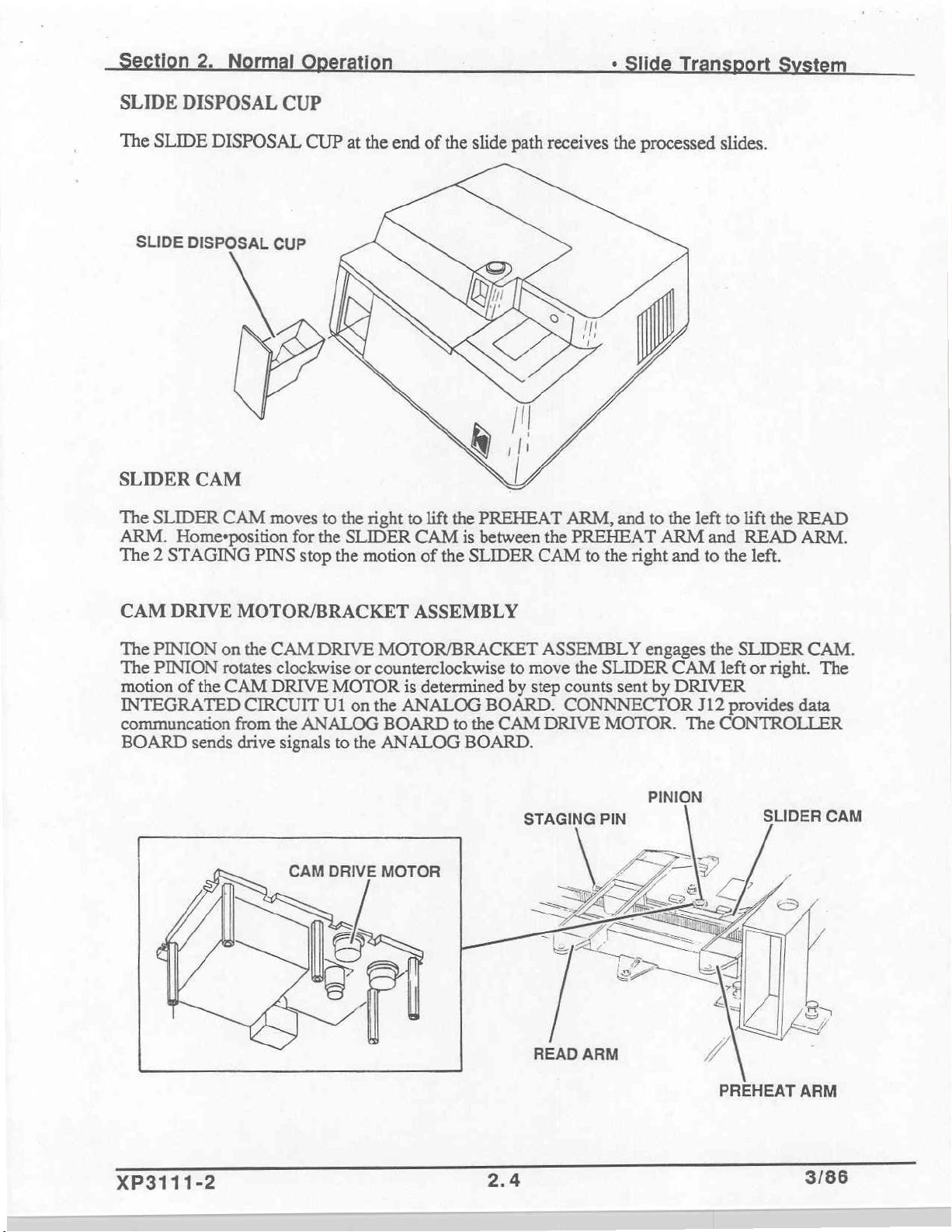

SLIDE

The

SLIDER

The

ARM.

The 2 STAGING

DISPOSAL

SLIDE

SLIDE

DISPOSAL

DISPOSAL

CAM

SLIDER

Home+position

CAM

CUP

CUP

moves

PINS

CUP

to

the

for the

stop

the

at

the

end

right

SLIDER

motion

of

to

CAM

of

the

lift

the

the

slide

PREHEAT

is

between

SLIDER

path

the

CAM

receives

the

ARM,

and

PREHEAT

to

the

processed

to

the

left

ARM

right

and

slides.

to

lift

and

READ

to

the

the

left.

READ

ARM.

CAM

The

The

motion

INTEGRATED

communcation

BOARD

DRIVE

PINION

PINION

of

the

sends

on

rotates

CAM

——

MOTOR/BRACKET

the

CAM

DRIVE

clockwise

DRIVE

CIRCUIT

from

the

drive

signals

U1

ANALOG

CAM

DRIVE

MOTOR

on

to

ASSEMBLY

MOTOR/BRACKET

or

counterclockwise

is

determined

the

ANALOG

the

BOARD

ANALOG

MOTOR

to

the

BOARD.

to

move

by

step

BOARD.

CAM

STAGING

READ

ASSEMBLY

the

SLIDER

counts

CONNNECTOR

DRIVE

MOTOR.

PIN

ARM

engages

sent

PINION

CAM

by

DRIVER

the

SLIDER

left

J12

provides

The

CONTROLLER

PREHEAT

or

right.

SLIDER

CAM.

The

data

CAM

ARM

XP3111-2

2.4

3/86

Page 20

Section

2.

Normal

Operation

*

Slide

Transport

System

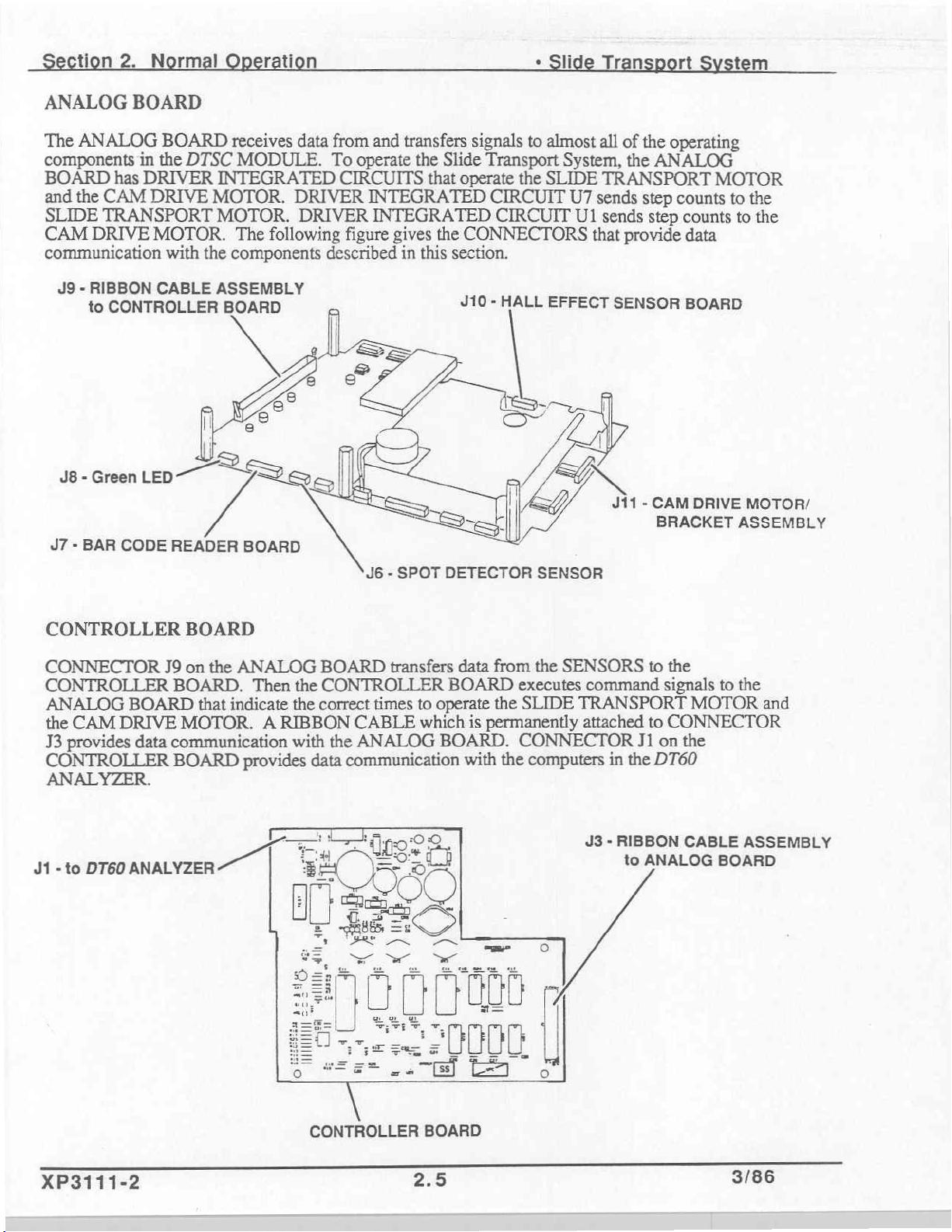

ANALOG

The

ANALOG

components

BOARD

and

the

SLIDE

CAM

communication

J9 - RIBBON

BOARD

in

has

DRIVER

CAM

TRANSPORT

DRIVE

to

DRIVE

MOTOR.

CONTROLLER

BOARD

the

CABLE

J8-GreenLED

47 - BAR

CODE

DTSC

with

receives

MODULE.

INTEGRATED

MOTOR.

MOTOR.

The following

the

components

ASSEMBLY

BOARD

data

from

To

CIRCUITS

DRIVER

DRIVER

figure

described

operate

D

y

READER

BOARD

and

transfers

the

Slide

that

INTEGRATED

INTEGRATED

gives

the

in

this

section.

J6 - SPOT

DETECTOR

signals

operate

CONNECTORS

J10 - HALL

to

almost

Transport

the

SLIDE

CIRCUIT

CIRCUIT

SENSOR

System,

U7

U1

EFFECT

all

of

the

the

TRANSPORT

sends

step

sends

step

that

provide

SENSOR

J11 - CAM

operating

ANALOG

counts

counts

data

BOARD

DRIVE

BRACKET

MOTOR

to

to

MOTOR/

ASSEMBLY

the

the

CONTROLLER

CONNECTOR

CONTROLLER

ANALOG

the

CAM

J3

provides

CONTROLLER

ANALYZER.

J1

-to

DT60

BOARD

DRIVE

data

BOARD

J9

on

the

ANALOG

BOARD.

that

MOTOR.

communication

BOARD

Then

indicate

A

provides

ο,

BOARD

the

CONTROLLER

the

correct

RIBBON

with

the

data

:

transfers

times

CABLE

ANALOG

communication

data

BOARD

to

operate

which

BOARD.

with

from

the

executes

the

SLIDE

is

permanently

CONNECTOR

the

computers

SENSORS

command

TRANSPORT

attached

in

the

J3 - RIBBON

to

to

the

signals

to

CONNECTOR

J1

on

the

DT60

CABLE

ANALOG

to

MOTOR

BOARD

the

and

ASSEMBLY

XP3111-2

CONTROLLER

BOARD

2.5

3/86

Page 21

n

2.

|

tion

e

Sli

n:

ti

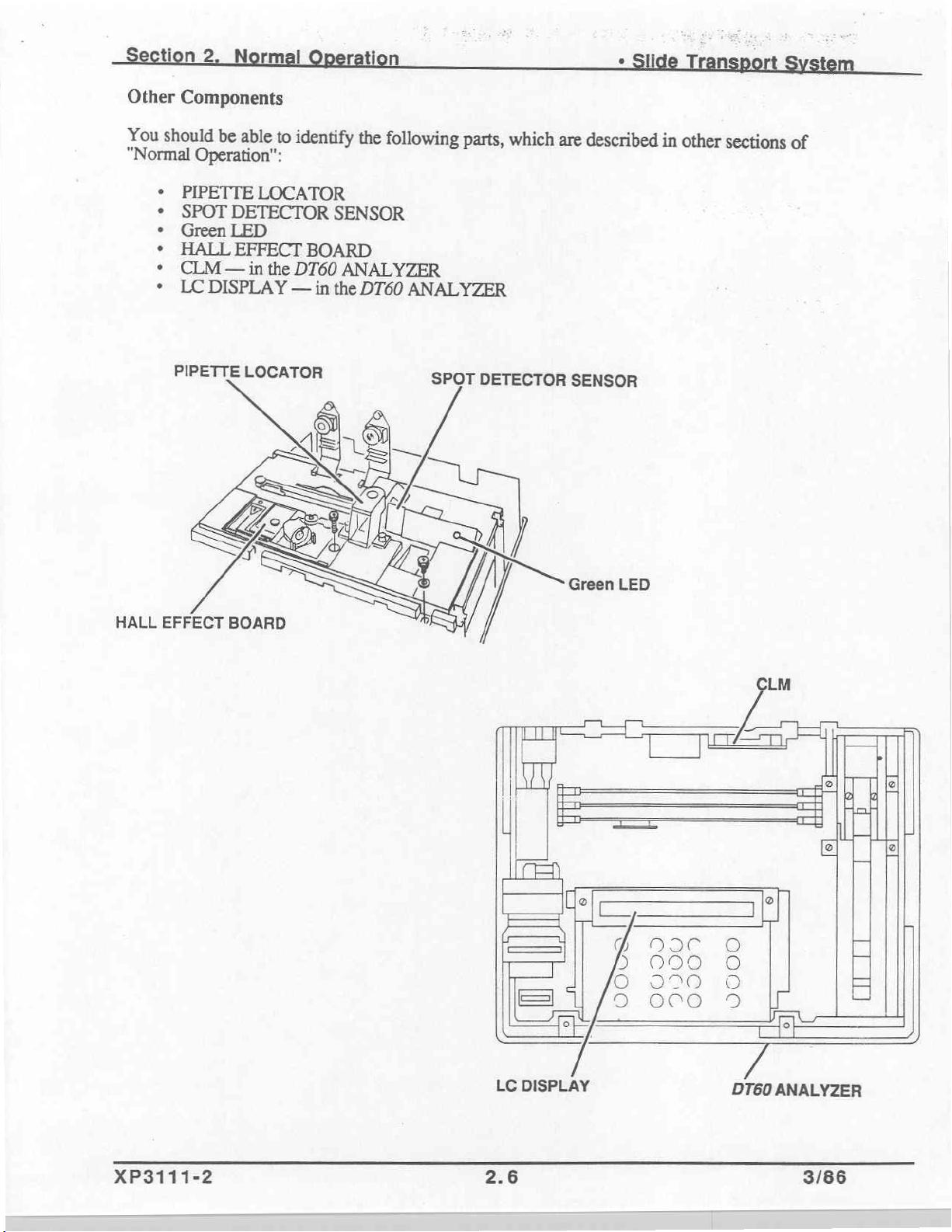

Other

You

"Normal

Components

should

PIPETTE

SPOT

Green

HALL

CLM — in

“ec...

LC

PIPETTE

be

able

to

Operation":

LOCATOR

DETECTOR

LED

EFFECT

the

DT60

DISPLAY

—

LOCATOR

identify

BOARD

in

the

SENSOR

ANALYZER

the

DT60

following

ANALYZER

parts,

SPOT

which

DETECTOR

are

described

SENSOR

in

other

sections

of

HALL

EFFECT

BOARD

XP3111-2

LC

2.6

DISPLAY

DT60

ANALYZER

3/86

Page 22

ti

rati

n

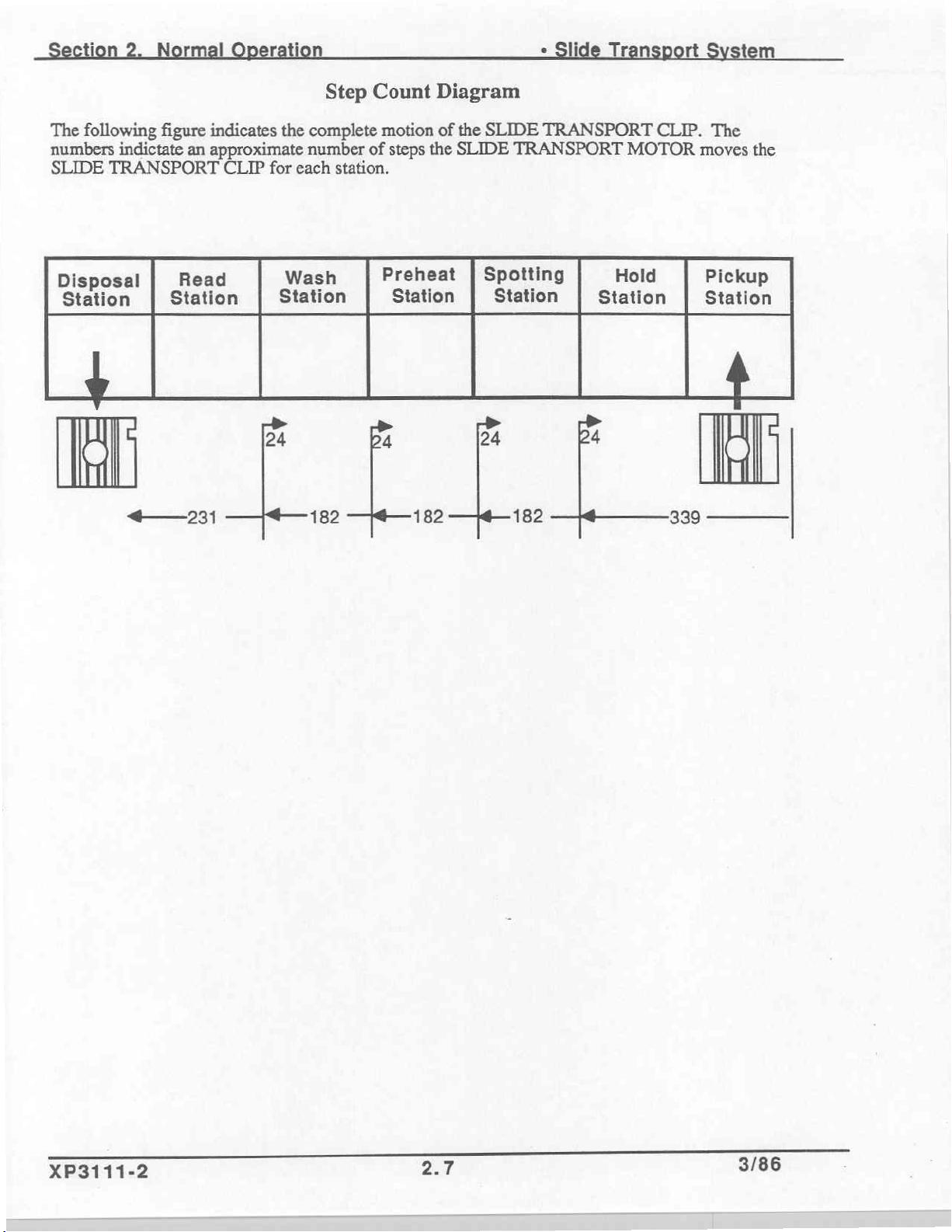

The

following

numbers

SLIDE

Disposal

Station

|

TRANSPORT

ῃ

figure

indictate

|

Station

자

indicates

an

approximate

CLIP

Read

231

the

complete

number

for

each

Wash

Station

=>

24

182

Step

Count

motion

of

station.

Preheat

Station

Ba

steps

the

182

Diagram

of

the

SLIDE

SLIDE

Spotting

|

Station

>

24

TRANSPORT

TRANSPORT

Station

[を

24

182

MOTOR

Hold

CLIP.

339

The

moves

Pickup

Station

le

the

|

XP3111-2

2.7

3/86

Page 23

ti

1.

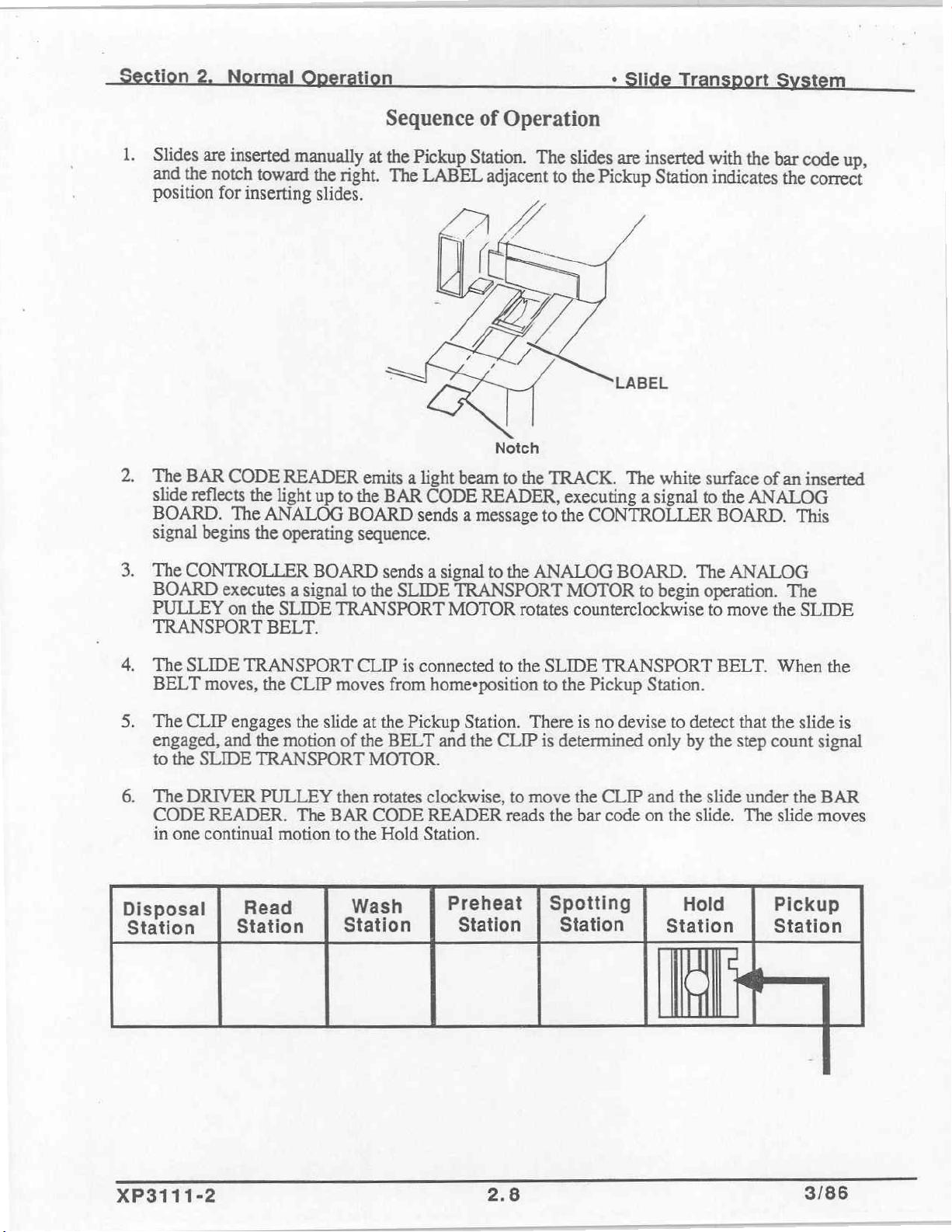

Slides

and

position

2.

The

slide

BOARD.

signal

are

inserted

the

notch

for

inserting

BAR

CODE

reflects

begins

the

The

manually

toward

READER

light

ANALOG

the

operating

i

at

the

right.

slides.

emits

up

to

the

BOARD

sequence.

Sequence

the

Pickup

The

LABEL

Station.

Operation

of

The

adjacent

slides

to

the

‧

are

inserted

Pickup

Station

rt

with

the

bar

indicates

the

m

code

up,

correct

AL

Notch

a

light

beam

to

the

BAR

CODE

sends

READER,

a

message

TRACK.

executing

the

to

The

white

a

signal

CONTROLLER

surface

to

the

ANALOG

BOARD.

of

an

inserted

This

3.

The

BOARD

PULLEY

TRANSPORT

4,

The

BELT

5.

The

engaged,

to

6.

The

CODE

in

Disposal

Station

CONTROLLER

executes a signal

on

SLIDE

CLIP

the

DRIVER

one

TRANSPORT

moves,

engages

and

SLIDE

READER.

continual

Read

Station

BOARD

the

SLIDE

BELT.

the

CLIP

the

slide

the

motion

TRANSPORT

PULLEY

The

BAR

motion

sends a signal

to

the

SLIDE

TRANSPORT

CLIP

is

moves

of

then

to

Wash

Station

from

at

the

the

BELT

MOTOR.

rotates

CODE

the

Hold

Pickup

to

the

TRANSPORT

MOTOR

connected

homesposition

Station.

and

the

clockwise,

READER

Station.

Preheat

Station

rotates

to

the

CLIP

to

reads

|

ANALOG

MOTOR

SLIDE

to

the

There

is

determined

move

the

Spotting

Station

BOARD.

counterclockwise

TRANSPORT

Pickup

is

no

devise

the

CLIP

bar

code

The

to

begin

operation.

Station.

to

detect

only

by

and

the

on

the

slide.

Hold

Station

li

ANALOG

to

move

BELT.

that

the

step

slide

the

When

the

count

under

The

slide

Pickup

Station

The

SLIDE

slide

signal

the

moves

the

is

BAR

XP3111-2

2.8

3/86

Page 24

tion

7.

The

transfers

8.

The

the

MODULE.

9.

For

decoded.

SELECT

2.

Normal

bar

code

the

bar

code

status

the

of

slide

If

TEST"

data

is

sent

data

to

the

data

is

the

chemistry.

to

be

successfully

the

bar

code

is

displayed.

ration

to

the

DT60

ANALYZER

compared

The

is

partially

CONTROLLER

with

data

stored

DT60

ANALYZER

identified

The

as a rate

decoded,

operator

BOARD.

for

identification.

in

the

CDM

then

slide,

at

the

message

must

manually

+

Slide

Transport

The

CONTROLLER

in

the

DT60

sends a response

least the

"SLIDE

select

ANALYZER

first 3 bars

NOT

IDENTIFIED

the

test

on

to

BOARD

the

DTSC

must

the

KEYBOARD.

to

be

tem

check

/

10.

Data

is

in

the

CLM.

calibrated

11.

Ifthe

chemistry

the

slide,

sends a message

Station.

12.

If

the

chemistry

ANALYZER

name

of

13.

The

slide

BELT

BELT

device

read

from

the

The

chemistry

for

the

generation

is

not

the

message

to

the

is

included

sends

all

the

chemistry

advances a short

reverses

is

determined

to

check

to

move

that

the slide

only

CLM

that

of

number

included

"SLIDE

DISC

in

data

necessary

is

displayed.

distance

the

slide

by

step

ЩИ

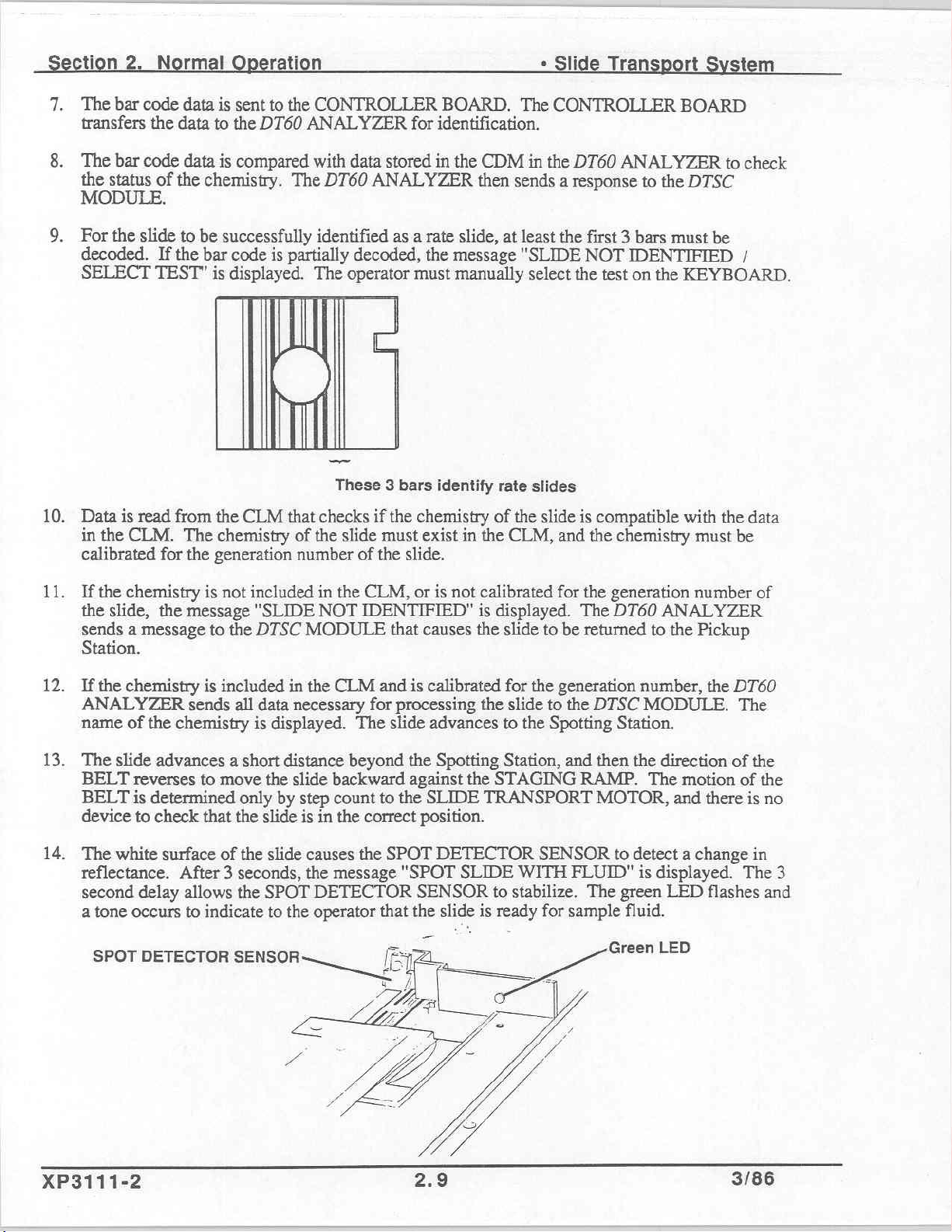

These 3 bars

checks

the

slide

of

in

the

NOT

MODULE

the

CLM

The

beyond

backward

count

is

in

the

=

identify

if

the

chemistry

must

exist

the

slide.

CLM,

IDENTIFIED"

correct

or

that

causes

and

is

for

processing

slide

the

against

to

the

SLIDE

position.

is

not

calibrated

advances

Spotting

rate

slides

of

the

in

the

CLM,

calibrated

is

displayed.

the

slide

for the

the

slide

to

the

Station,

the

STAGING

TRANSPORT

slide

is

compatible

and

the

for

the

The

to

be

returned

generation

to

the

DISC

Spotting

and

then

RAMP.

MOTOR,

with

chemistry

generation

DT60

number,

MODULE.

Station.

the

must

number

ANALYZER

to

the

Pickup

direction

The

motion

and

the

be

the

DT60

The

of

of

there

is

data

of

the

the

no

14.

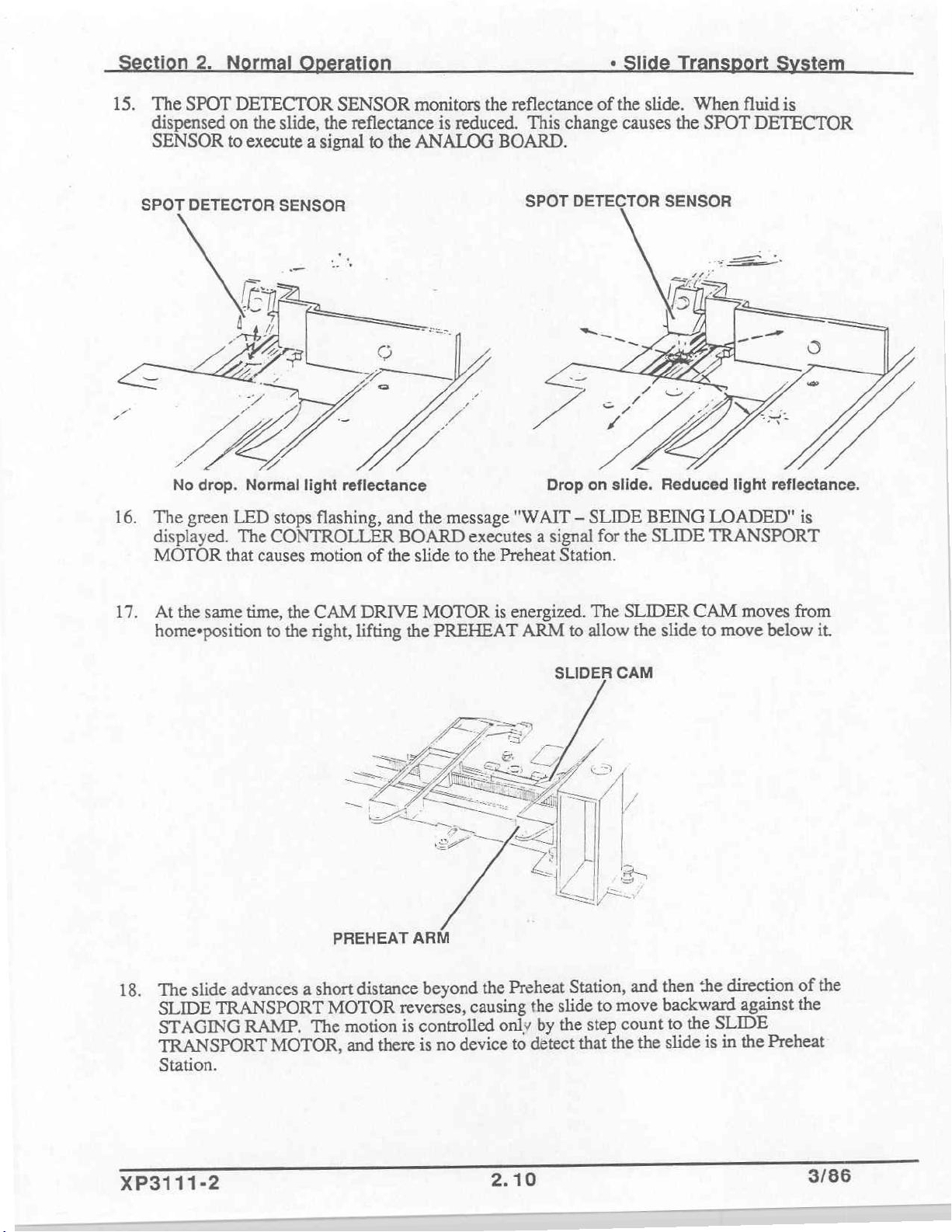

The

white

surface

reflectance. After 3 seconds,

second

a

tone

SPOT

delay

occurs

DETECTOR

of

allows

to

indicate

XP3111-2

the

the

slide

SPOT

to

the

causes

the

the

message

DETECTOR

operator

Zz

SPOT

"SPOT

that

re

DETECTOR

SENSOR

the

slide

SLIDE

デン

WITH

to

stabilize.

is

ready

ディ

SENSOR

FLUID"

The

for

sample

to

detect a change

is

displayed.

green

Green

LED

fluid.

LED

in

The

3

flashes and

3786

Page 25

15.

tion

2.

The

SPOT

dispensed

SENSOR

N

rati

DETECTOR

on

the

slide,

the

to

execute a signal

SENSOR

reflectance

to

the

monitors

the

is

reduced.

ANALOG

reflectance

This

change

BOARD.

+

Slide

of

the

slide.

causes

Ti

When

the

SPOT

t t

fluid

is

DETECTOR

SPOT

16.

No

The

DETECTOR

green

displayed.

MOTOR

17.

Atthe

homesposition

drop.

LED

The

that

same

SENSOR

Normal

light

stops

CONTROLLER

causes

time,

the

to

the

reflectance

flashing,

motion

CAM

right,

and

of

DRIVE

lifting the

the

message

BOARD

the

slide

to

MOTOR

PREHEAT ARM

SPOT

DETECTOR

"WAIT — SLIDE

executes a signal

the

Preheat

is

energized.

for

Station.

The

to

allow

SENSOR

BEING

the

SLIDE

SLIDER

the

slide

LOADED"

TRANSPORT

CAM

to

moves

move

is

from

below

it.

18.

slide

The

SLIDE

TRANSPORT

STAGING

TRANSPORT

Station.

advances

a

RAMP.

MOTOR,

PREHEAT

short

MOTOR

motion

The

distance

reverses,

is

there

and

ARM

beyond

the

causing

controlled

device

no

is

Preheat

the

by

only

detect

to

SLIDER

Station,

to

slide

step

the

that

CAM

and

move

count

the

the

direction

:he

then

backward

SLIDE

the

to

in

is

slide

of

against

the

the

Preheat

the

XP3111-2

2.10

3/86

Page 26

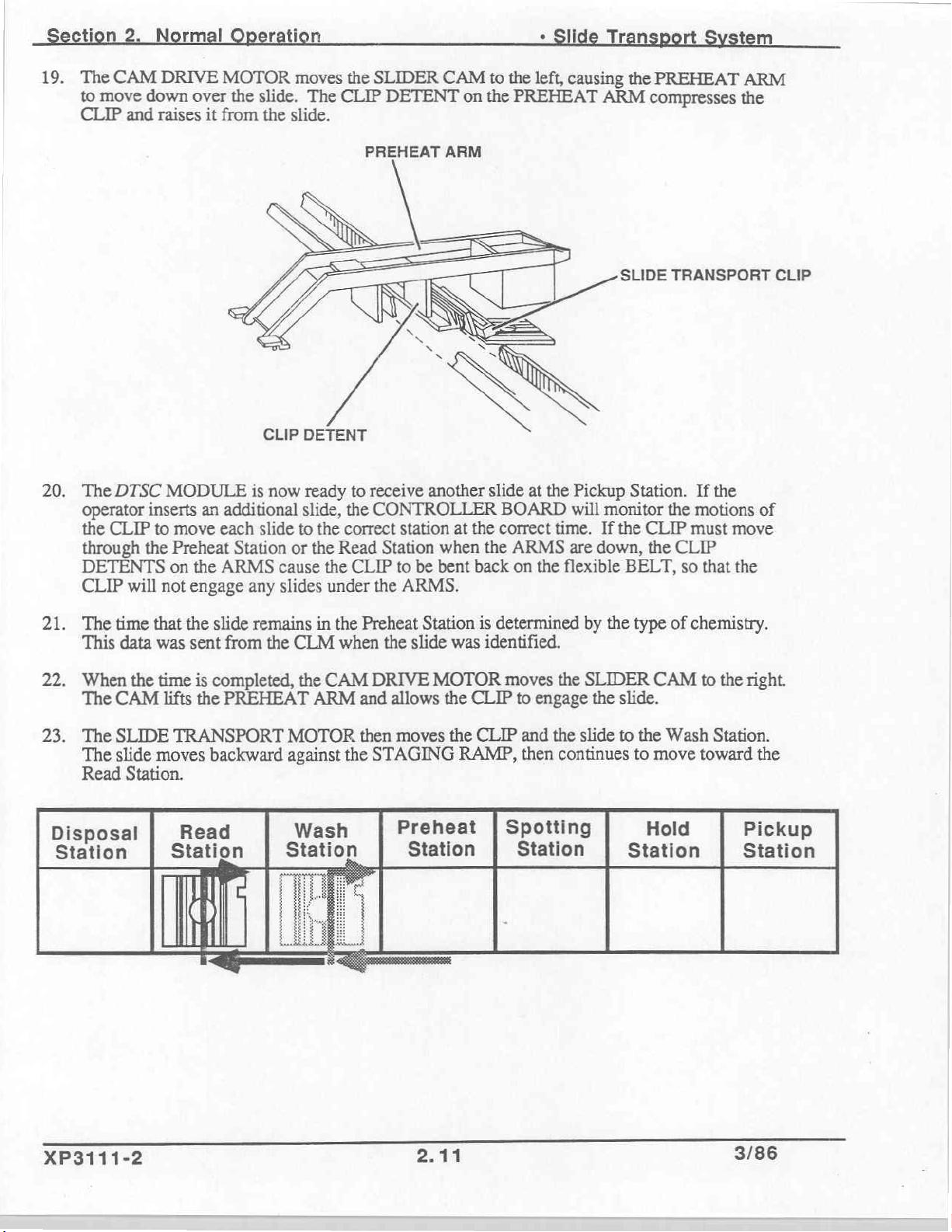

19.

ti

The

CAM

to

move down

CLIP

and

Normal

DRIVE

over

raises

it

MOTOR

the

slide.

from

ration

moves

The

the

slide.

the

SLIDER

CLIP

DETENT

CAM

on

to

the

the

PREHEAT

left,

causing

ri

ARM

the

PREHEAT

compresses

tem

ARM

the

20.

The

DTSC

operator

the

through

DETENTS

CLIP

inserts

CLIP

the

will

MODULE

to

move

Preheat

on

the

not

engage

CLIP

is

now

an

additional

each

slide

Station

ARMS

any

DETENT

ready

slide,

to

the

or

the

cause

slides

PREHEAT

to

the

correct

Read

the

CLIP

under

ARM

receive

CONTROLLER

Station

the

another

station

to

ARMS.

be

at

when

bent

slide

BOARD

the

correct

the

back

at

ARMS

on

the

the

Pickup

will

time.

are

flexible

SLIDE

Station.

monitor

If

the

CLIP

down,

the

BELT,

TRANSPORT

If

the

the

motions

must

CLIP

so

that

CLIP

of

move

the

21.

The

This

22.

When

The

23.

The

The

Read

Disposal

Station

time

that

data

was

the

time

CAM

SLIDE

slide

lifts

TRANSPORT

moves

Station.

]|

Station

the

slide

sent

from

is

completed,

the

PREHEAT ARM

backward

Read

remains

the

CLM

the

MOTOR

against

Wash

Station

in

CAM

the

Preheat

when

and

then

the

Station

the

slide

DRIVE

STAGING

MOTOR

allows

moves

Preheat

Station

is

determined

was

identified.

the

CLIP

the

CLIP

RAMP,

|

by

moves

to

engage

and

then

the

the

SLIDER

the

slide

continues

Spotting

Station

the

type

slide.

to

the

to

Station

of

chemistry.

CAM

Wash

move

Hold

to

the

right.

Station.

toward

the

Pickup

Station

XP3111-2

2-11 3/86

Page 27

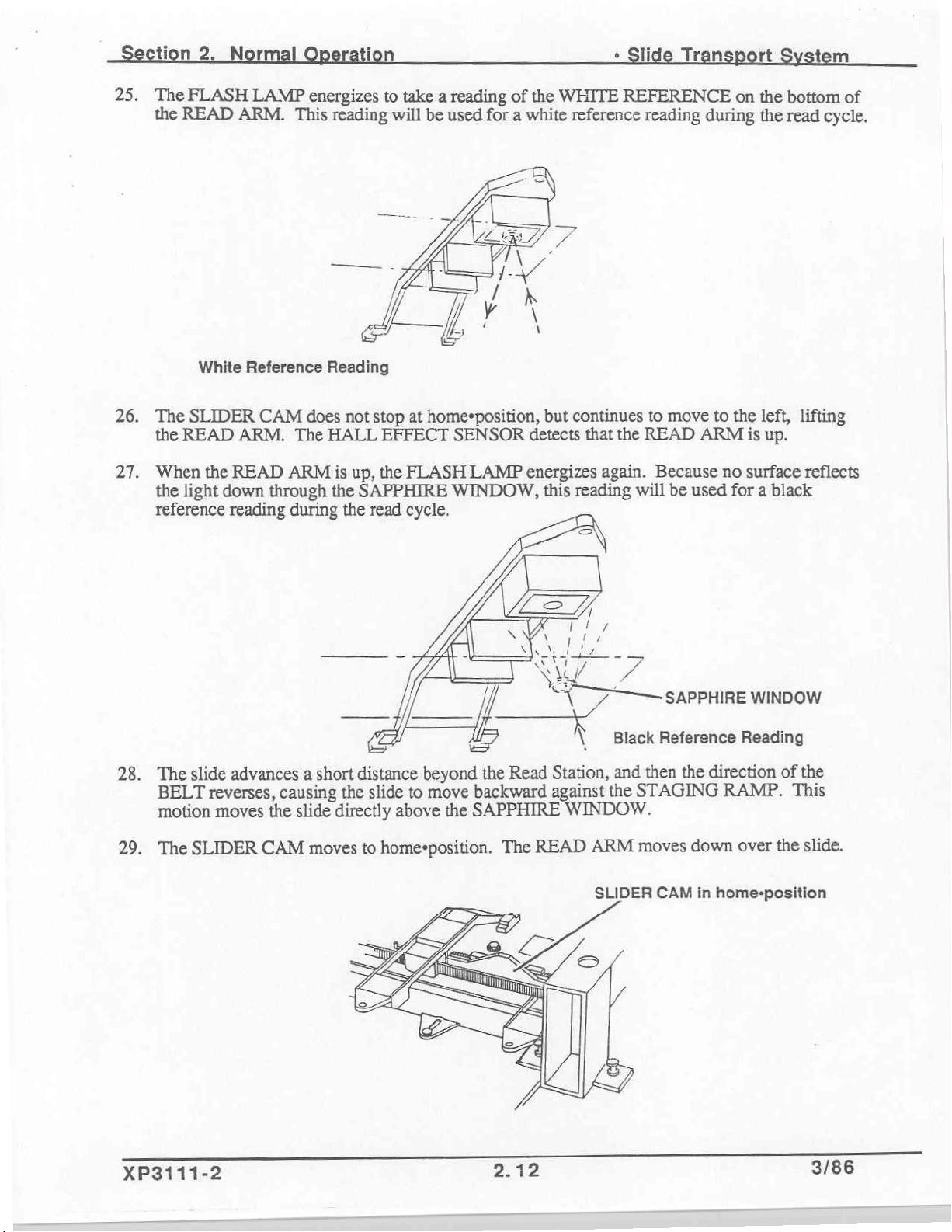

25.

tion

The

the

2

FLASH

READ

LAMP

ARM.

energizes

This

reading

to

take a reading

will

be

used

of

the

WHITE

for a white

+

Slide

REFERENCE

reference

reading

Tr

during

rt m

on

the

bottom

the

read

of

cycle.

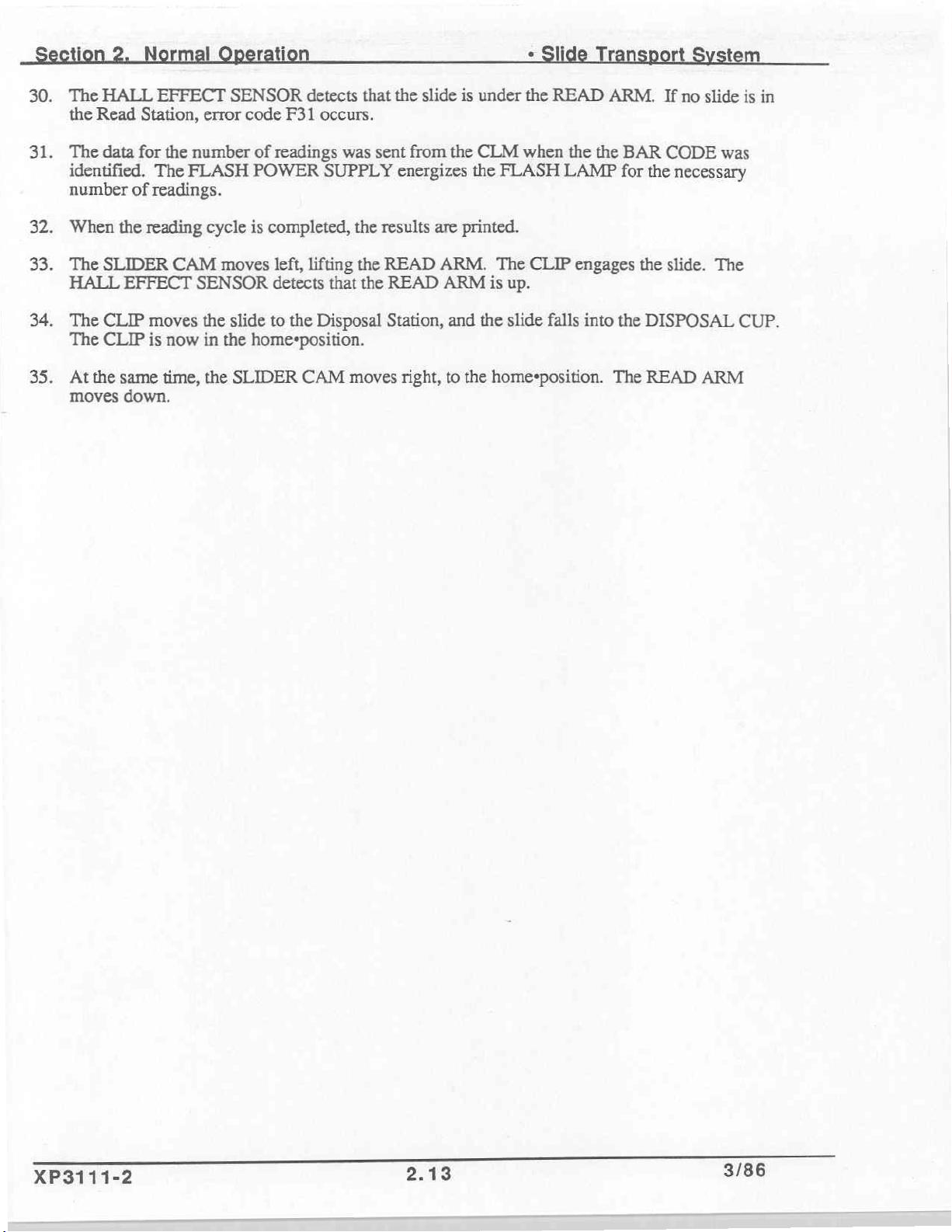

26.

27.

28.

The

When

White

SLIDER

the

READ

the

READ

the

light

down

reference

The

BELT

motion

reading

slide

advances a short

reverses,

moves

Reference

CAM

ARM.

The

ARM

through

during

causing

the

Reading

does

HALL

is

the

slide

directly

not

stop

at

EFFECT

up, the

SAPPHIRE

the

read

FLASH

cycle.

77

distance

the slide

to

above

home+position,

SENSOR

LAMP

WINDOW,

but

detects

energizes

this

Ne

;

beyond

move

the

backward

the

SAPPHIRE

Read

continues

that

the

again.

reading

Wo

X

Station,

against

WINDOW.

7

\

7

。

—

Black

and

the

to

move

READ

Because

will

be

used

SAPPHIRE

Reference

then

the

STAGING

to

the

left,

ARM

is

up.

no

surface

for a black

WINDOW

Reading

direction

RAMP.

lifting

reflects

of

the

This

The

29.

XP3111-2

SLIDER

CAM

moves

home+position.

to

The

2.12

READ

ARM

SLIDER

moves

CAM

down

over

in

home-position

the

slide.

3/86

Page 28

Section

30.

The

HALL

the

Read

31.

The

data

identified.

number

32.

When

33.

The

SLIDER

HALL

34.

The

CLIP

The

CLIP

35.

At

the

moves

2.

Normal

Station,

for

of

the

reading

EFFECT

moves

is

same

down.

Operation

EFFECT

the

The

readings.

CAM

now

time,

SENSOR

error

number

FLASH

cycle

moves

SENSOR

the

slide

in

the

the

SLIDER

detects

code

F31

of

readings

POWER

is

completed,

left,

lifting

detects

to

the

that

occurs.

was

SUPPLY

the

the

that

the

Disposal

home+position.

CAM

moves

the

slide

sent

from

energizes

results

READ

READ

Station,

right,

だ

is

under

the

CLM

the

are

printed.

ARM.

ARM

and

the

to

the

だ

xsSlideTransportSvstem

the

READ

when

FLASH

The

CLIP

is

up.

slide

falls

home+position.

the

the

LAMP

engages

into

ARM.

BAR

for

the

the

The

If

no

CODE

the

necessary

slide.

DISPOSAL

READ

slide

was

The

CUP.

ARM

is

_

in

XP3111-2

2.13

3/86

Page 29

Norm

ti

«Slide

Identification

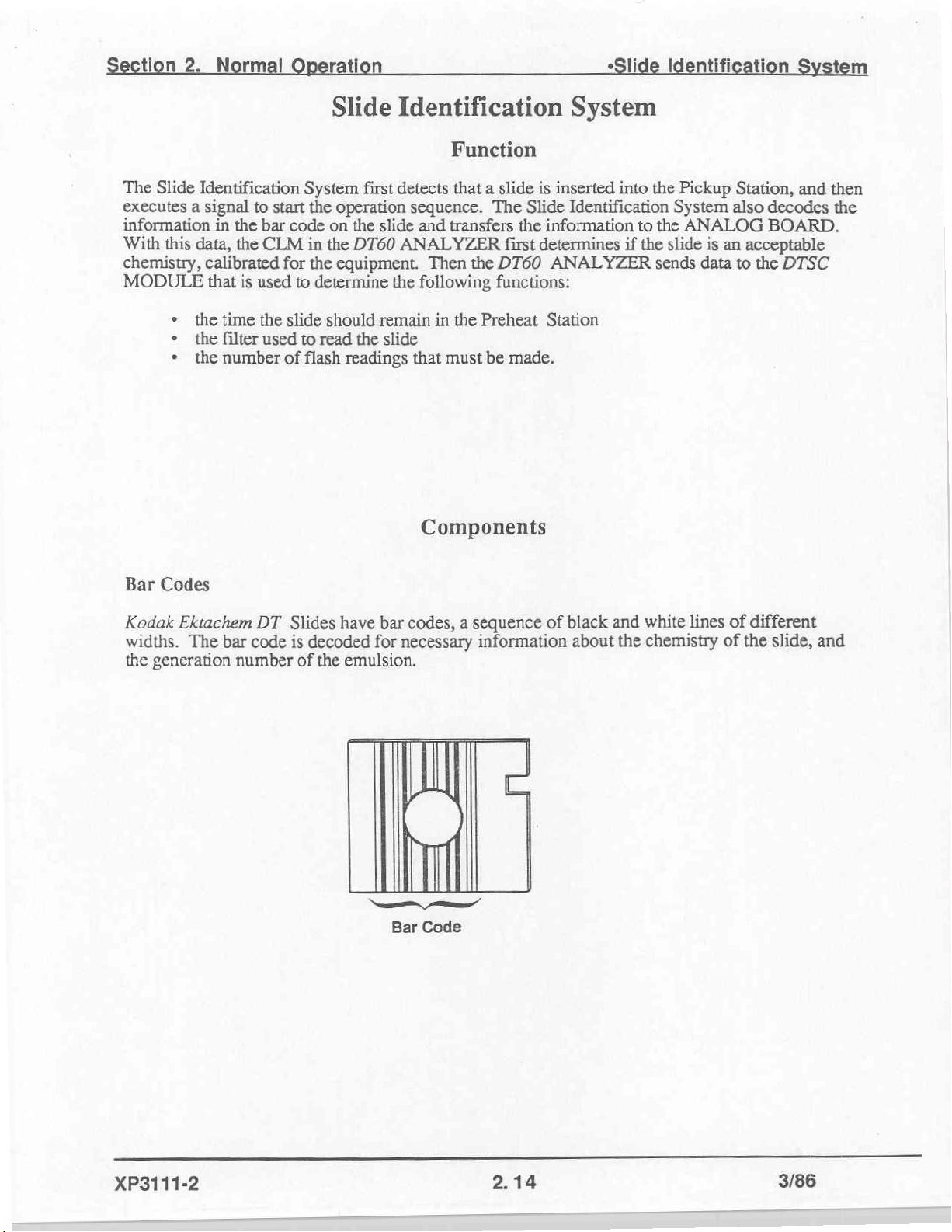

The

Slide

Identification

executes a signal

information

With

this

data,

chemistry,

MODULE

calibrated

+

the

・

the

+

the

in

the

the

that

is

time

filter

number

to

used

System

start

the

bar

code

on

CLM

in

the

for

the

to

determine

the slide

used

to

of

flash

should

read

Slide

operation

equipment.

readings

Identification

first

detects

sequence.

the

slide

DT60

ANALYZER

the

remain

the

slide

that

Function

that a slide

The

and

transfers

first

Then

the

DT60

following

in

must

Components

functions:

the

Preheat

be

made.

System

is

inserted

Slide

Identification

the

information

determines

ANALYZER

Station

into

to

if

the

the

Pickup

System

the

ANALOG

slide

sends

Station,

also

is

an

acceptable

data

to

and

decodes

BOARD.

the

DTSC

then

the

Bar

Codes

Kodak

widths.

the

Ektachem

generation

The

DT

bar

code

number

Slides

is

have

decoded

of

the

bar

codes, a sequence

for

necessary

emulsion.

Bar

Code

information

of

black

about

and

white

the

chemistry

lines

of

of

different

the

slide,

and

XP3111-2

2.14

3/86

Page 30

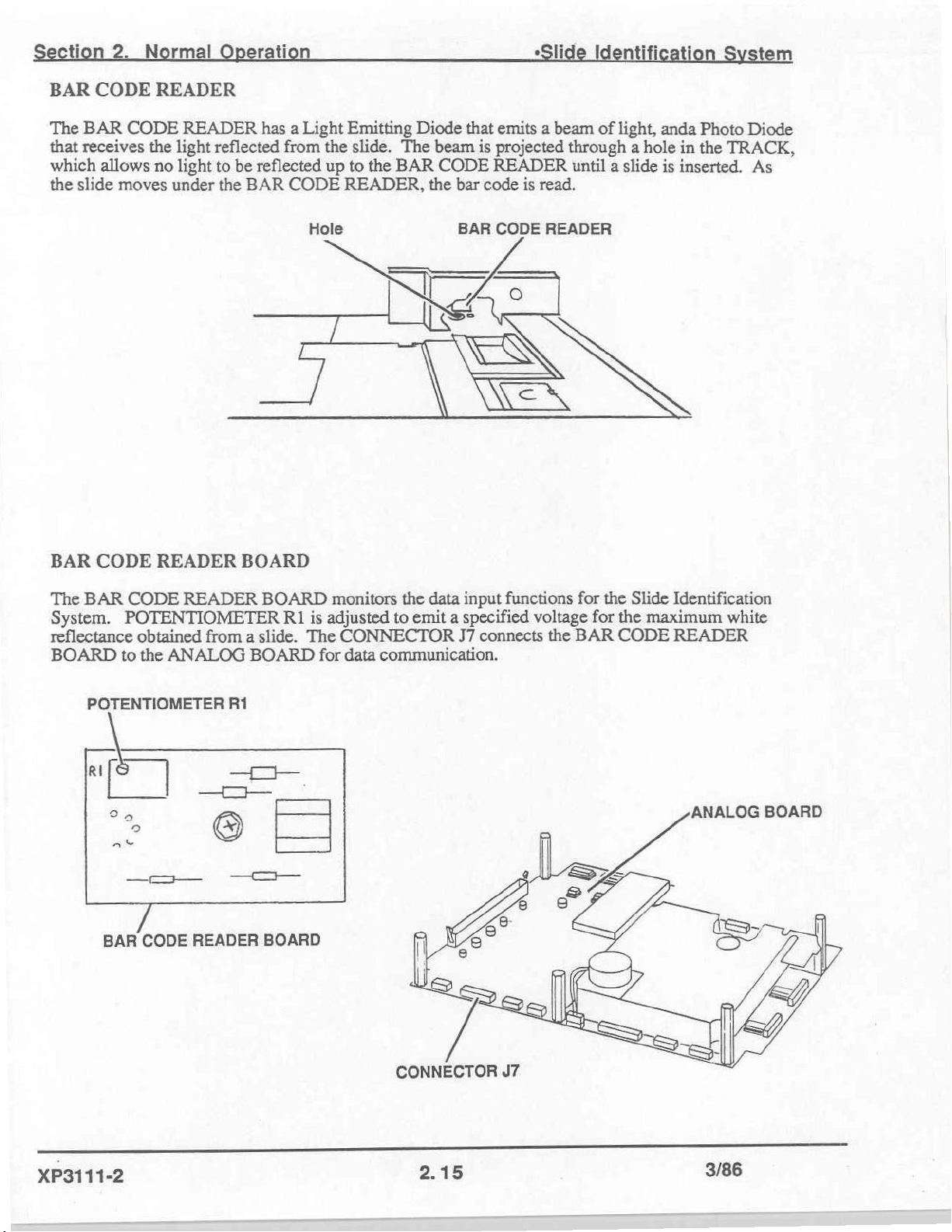

tion

BAR

The

BAR

that

receives

which

the

slide

2.

CODE

CODE

allows

moves

Normal

READER

READER

the

light

no

light

under

rati “Sli

has a Light

reflected

to

be

the

from

reflected

BAR

CODE

Emitting

the

slide.

up

to

the

READER,

Diode

The

BAR

beam

CODE

the

that

is

bar

code

emits a beam

projected

READER

through a hole

until a slide

is

read.

of

light,

11

anda

in

is

inserted.

Photo

the

TRACK,

m

Diode

As

BAR

CODE

The

BAR

CODE

System.

reflectance

BOARD

POTENTIOMETER

obtained

to

the

READER

READER

from a slide.

ANALOG

BOARD

BOARD

Hole

BOARD

RI

monitors

is

adjusted

The

CONNECTOR

for

data

BAR

Ww

the

data

input

to

emit a specified

J7

connects

communication.

CODE

READER

functions

voltage

the

for

the

for the

BAR

Slide

maximum

CODE

Identification

white

READER

POTENTIOMETER

η

Sia;

aX

一

BAR

XP3111-2

CODE

R1

ーー

©

—=—

READER

BOARD

ANALOG

BOARD

CONNECTOR

2.15

J7

3/86

Page 31

tion

Norma

rati

*Slide

Identificati

tem

1.

When

the

2

The

signal

CONTROLLER

the

DTSC

TRACK.

white

surface

to

the

MODULE

The

hole

of

ANALOG

BOARD.

Sequence

allows

an

inserted

BOARD.

of

is

initialized,

almost

This

no

Hole

slide

reflects

The

ANALOG

signal

Operation

the

BAR

light

to

light

begins

the

CODE

be

reflected

BAR

CODE

to

the

BAR

BOARD

operation

READER

up

to

the

READER

CODE

sends

a

message

seguence.

projects

BAR

READER,

a

CODE

to

light

READER.

which

the

to

a

hole

causes

in

a

3.

4.

5.

6.

The

CONTROLLER

BOARD

The

SLIDE

to

the

Pickup

The

CLIP

As

the

slide

read.

sends a

signal

TRANSPORT

Station

moves

the

moves

BOARD

to

to

engage

slide

under

sends a signal

the

SLIDE

MOTOR

the

to

the

Hold

the

BAR

CODE

TRANSPORT

moves

slide.

Station,

READER,

to

the

the

SLIDE

in

ANALOG

MOTOR

one

continual

the light

BOARD.

to

begin

TRANSPORT

motion.

reflected

The

ANALOG

operation.

CLIP

from

from

the

bar

home+position

code

is

XP3111-2

2.16

3/86

Page 32

Section

7.

The

light

the

uniform

thickness

The

you

CODE

2.

Normal

BAR

CODE

reflected

black

following

understand

READER.

from

lines

do

negative

of

the

figure

Operation

READER

the

white

not.

The

electrical

lines.

is a graphic

these

fundamentals,

BOARD

and

adjustment

value

makes a series

black

to

the

description

you

lines

in

the

procedure

white

lines.

of a bar

will

be

of

bar

for the

The

code

able

to

“Slide

electrical

code.

BAR

length

understand

signals

The

CODE

of

conversion

Identification

that

correspond

white

lines

reflect

READER

the

signals

to

the

correspond

an

electrical

adjustment

light,

gives

signal.

for the

to

a

the

and

to

BAR

tem

the

If

8.

Because

READER

9.

The

The

DT60

10.

If

Station.

of

BAR

signal

ANALYZER.

no

bar

code

Readings

the

position

BOARD

CODE

is

transferred

READER

data

reverses

was

Voltage

Reflectance

of

the

inserted

the

data

BOARD

to

the

CONTROLLER

sent,

error

code

LT

|------

signal

Li

for

sp.

slide,

the

bar

to

the

correct

sends a pulsing

BOARD,

F32

occurs

bar

code:

Black

Reading

ss

No

slide

-

White

code

sequence.

digital

to

indicate a possible

Reading = -5

is

read

backward.

signal

and

then a bus

to

the

ANALOG

to

-7 V de

The

BAR

message

slide

jam

CODE

BOARD.

is

sent

at

the

to

the

Pickup

11.

The

"SLIDE

select

XP3111-2

first 3 bars

NOT

IDENTIFIED / SELECT

the

test

on

identify

the

the

KEYBOARD.

slide

as a rate

slide.

TEST“

If

is

These 3 bars

21T

only

these

bars

а

|

identify

rate

are

decoded,

The

operator

slides.

the

must

manually

message

3/86

Page 33

tion

12.

If

the

a

message

13.

Data

the

CLM.

calibrated

14.

If

the

ANALYZER

name

15

If

the

slide,

message

2.

slide

is

was

to

read

The

for

mal

the

from

the

chemistry

sends

of

the

chemistry

chemistry

the

message

to

the

DTSC

rati

not

inserted

DTSC

chemistry

the

MODULE

CLM

generation

is

included

all

data

is

displayed.

is

not

included

"SLIDE

MODULE

correctly,

that

that

checks

of

the

slide

number

in

the

CLM

necessary

in

the

NOT

VALID"

that

error

causes

if

the

must

exist

of

the

slide.

and

for

processing

The

slide

CLM,

is

causes

code

L19

will

the

slide

chemistry

in

the

is

calibrated

the

advances

or

is

not

calibrated

displayed.

the

slide

to

occur.

to

be

of

the

CLM,

for

slide

to

The

be

the

*Slide

The

returned

slide

is

and

the

the

generation

to

the

DTSC

Spotting

for

the

DT60

returned

ANALYZER

to

Identificati

DT60

to

compatible

chemistry must

ANALYZER

the

Pickup

with

number,

MODULE.

Station.

generation

number

sends

the

Pickup

Station.

t

sends

Station.

the

data

be

the

DT60

The

of

the

a

in

XP3111-2

2.18

3/66.

Page 34

This

section

on a slide.

describes

the

Slide

operation

of

Spotting

Function

the

SPOT

Components

DETECTOR

System

SENSOR

when

fluid

is

dispensed

SPOT

The

BAR

projects a focused

the

the

CONNECTOR

ANALOG

The

a

continue

continually,

in

POTENTIOMETER

DETECTOR

DETECTOR

SPOT

CODE

Spotting

light

reflected

function

drop

of

the

the

Spotting

DETECTOR

READER

Station,

from

P6

BOARD.

of

the

fluid

is

dispensed

processing

but

the

Station

SENSOR.

SENSOR

BOARD.

beam

the

the

provides

SPOT

cycle

reading

and

R68

CONNECTOR

ГУ

/

A

LI

SENSOR

of

light,

light

is

projected

surface

data

DETECTOR

on a slide.

of

the

from

ready

on

the

ANALOG

P6

is

fastened

The

SPOT

and a Photo

of

the

communication

SENSOR

The

slide.

the

SPOT

to

be

spotted.

to

DETECTOR

Diode

to

the

center

slide.

SPOT

The

SPOT

DETECTOR

BOARD

the

SENSOR

that

detects

of

from

the

is

to

detect

DETECTOR

DETECTOR

adjusts

BRACKET,

SENSOR

the

slide,

SPOT

the

SENSOR

the light

has a Light

reflected

and

DETECTOR

change

SENSOR

light.

the

SPOT

of

then

SENSOR

is

taken

output

POTENTIOMETER

which

reflectance

of

also

holds

Emitting

When a slide

DETECTOR

SENSOR

executes a signal

is

energized

only

when

the

Diode

to

caused

the

SPOT

R68

the

that

is

in

reads

the

when

slide

to

is

SPOT

DETECTOR

XP3111-2

SENSOR

SENSOR

BRACKET

CONNECTOR

2.19

J6

3/86

Page 35

ection

PIPETTE

A

the

ANALYZER.

PIPETTE"

2.

PIPETTE

DTSC

rmal

with

MODULE

The

have

more

rati

disposable

is

Operator's

information

the

TIPS

same

is

used

PIPETTE

Manual,

about

to

provided

and

the

the

aspirate

videotape

function

and

in

and

+

dispense

Modification

"Kodak

correct

fluids.

Ektachem

operation

^

PIPETTE

No. 2 for the

Slide

Spotti

The

DT

of

PIPETTE

DT60

and

DTE

PIPETTES.

tem

used

with

PIPETTE

PIPETTE

The

dispensed

dispense

with

the

LOCATOR

LOCATOR

precision.

mL

10

PIPETTE

The

of

drop

LOCATOR

holds

TIP

fluid

inserted

the

SEAT

correct

the

in

PIPETTE

the

in

position

in

PIPETTE

on

correct

the

LOCATOR

slide.

the

position

must

so

be

TIP

can

fluid

adjusted

SEAT

correctly

be

to

XP3111-2

2.

20

3/86

Page 36

N

ti

ㆍ

li

ttin

m

Green

The

PIPETTE.

CONNECTOR

LED

green

LED

blinks

The

CLIPLITE

J8

on

to

indicate

the

ANALOG

hold

Green

to

the

LED

the

operator

LED.

BOARD

when

CONNECTOR

to

the

LED.

the

slide

P8

provides

CLIPLITE

is

ready

to

data

CONNECTOR

receive

communication

P8

the

fluid

from

to

the

TIP

HEIGHT

The TIP

the

side

dispensed

adjustment

TIP.

of

the

HEIGHT

If

the

TIP

on

procedure

ADJUSTMENT

ADJUSTMENT

distance

and

the

center

not

has

is

be

of

TIP

GAUGE

GAUGE

too

short,

the

dispensed

the

slide.

more

information

HEIGHT

ADJUSTMENT

CONNECTOR

TL-3446

TL-3446

TIP

could

on

the

slide.

This

tool

about

J8

is

also

is

damage

If

the

used

using

GAUGE

used

to

check

the

slide,

distance

with

this

is

the

tool.

TL-3446

the

or

the

too

long,

DT60

ANALOG

distance

drop

the

ANALYZER.

BOARD

from

could

drop

the

adhere

might

The

slide

to

the

not

be

to

XP3111-2

2.21

3/86

Page 37

1.

Before

2.

The

motion

TRANSPORT

when a slide

reflectance

DETECTOR

3.

After

stabilize.

DETECTOR

4.

The

green

spotted.

5.

When

ANALOG

the

the

the

slide

of

the

MOTOR.

enters

from

does

drive

signal

Then

SENSOR.

LED

drop

is

BOARD.

enters

the

blinks

the

slide

to

the

Spotting

the

surface

not

execute a signal.

is

sent,

ANALOG

and a tone

dispensed,

The

Sequence

Spotting

the

Spotting

The

SPOT

Station.

of

the

slide

a 3

second

BOARD

occurs

the

reduced

slide

is

ready

of

Station,

DETECTOR

the

Station

When a slide

is

detected

delay

begins

to

indicate

reflection

to

advance

Operation

green

LED

is

determined

is

energized

enters

by

the

occurs

to

to

allow

monitor

to

the

to

SPOT

to

the

is

not

by step

continually,

the

Spotting

SPOT

the

operator

Wash

DETECTOR,

the

reading

DETECTOR

Station.

energized.

count

SPOT

that

signals

but

Station,

DETECTOR

from

the

the

slide

causes a signal

to

does

but

SPOT

is

ready

the

not

the

the

SLIDE

monitor

SPOT

to

to

be

to

the

>

#

V

XP3111-2

2522

3/86

Page 38

tion

2.

ti

‧

EE

EN

The

"Hall Effect"

of

conductors

distance

function

HALL

2

HALL

EFFECT

EFFECT

HALL

The

the

CONNECTOR

the

from a magnet,

of

EFFECT

EFFECT

SENSORS

SENSOR

EFFECT

HALL

signals

HALL

was

in a magnetic

HALL

EFFECT

to

EFFECT

the

J10

ANALOG

EFFECT

SENSORS

SENSORS

monitors

BOARD

on

BOARD.

first

described

field. A HALL

and

to

SENSORS

are

monitors

BOARD

the

the

the

BOARD.

ANALOG

HALL

by

convert

position

monitors

the

located

position

the

CONNECTOR

BOARD.

EFFECT

Function

the

physicist

EFFECT

distance

in

the

Components

on

the

of

of

the

signals

to

DTSC

HALL

the

OPERATOR

READ

of

The

SENSORS

Edwin

SENSOR

an

analog

MODULE.

EFFECT

ARM.

the

HALL

P10

provides

COVER

H. Hall.

is

able

signal.

BOARD.

ACCESS

EFFECT

data

PLATE

It

is a

description

to

measure a short

This

section

One

of

COVER.

SENSORS

communication

must

be

removed

COVER

will

the

HALL

The

and

PLATE

of

the

action

change

describe

other

HALL

transfers

to

for

access

in

the

to

HALL

for

HALL

EFFECT

for

COVER

EFFECT

READ

ARM

Ро

SENSOR

HALL

SENSOR

EFFECT

BOARD

XP3111-2

2.23

3/86

Page 39

MAGNETS

2

permanent

OPERATOR

operation,

MAGNET

Install

OPERATOR

ACCESS

COVER

the

falls

anew

MAGNETS

ACCESS

correct

READ

out

poles

of

ARM

are

used

COVER.

of

the

the

component,

or a new

with

the

The

other

MAGNETS

do

not

OPERATOR

HALL

MAGNET

EFFECT

must

be

install

it

ACCESS

MAGNI

READ

if

Operation

SENSORS.

is

in

the

toward

you

cannot

COVER

E

a

ARM:

end

of

the

HALL

determine

for

ky

A

=

One

MAGNET

the

READ

EFFECT

the

replacement

A

À

ES

|

is

ARM.

original

For

SENSORS.

position.

parts.

in

the

correct

If

a

OPERATOR

When

MAGNET,

dei

READ

The

EFFECT

measurement,

MAGNET.

Error

Read

Option

the

OPERATOR

that

unction.

ARM

operation

SENSOR

*

when

7.0

to

when

*

6.5

to

when

+

code

Station

109

the

ACCESS

ACCESS

and

executes a signal.

COVER

for the

the

The

the

READ

HALL

READ

and

HALL

is

the

EFFECT

EFFECT

ARM

11.5 V de

the

READ

ARM

11.0 V de

READ

the

occurs

F31

at

the

checks

ARM

when

correct

operation

the

COVER

down

ARM

MAGNET

is

is

is

the

time.

COVER

Error

code

when a test

is

more

is

measured

SENSOR

SENSOR

down

and

a

and

down

the

up,

fully

the

EFFECT

HALL

HALL

of

is

down,

L27

is

being

complex.

can

should

no

slide

slide

is

voltage

EFFECT

the

HALL

occurs

processed.

Any

as

an

detect

short

detect 3 positions

is

at

the

the

in

output

SENSOR

SENSOR

EFFECT

if

the

HALL

Option

change

exponential

Read

Read

in

changes

Station,

Station,

should

not

does

SENSOR

EFFECT

70

distance

change.

in

distance

for the

the

the

4.5

be

indicate

the

for

SENSOR

cancels

between

Because

READ

voltage

voltage

V

8.0

to

that

READ

detects

the

monitoring

the

of

from

the

ARM:

output

output

dc.

slide

a

ARM.

the

does

HALL

this

should

should

the

in

is

not

be

be

XP3111-2

2.24

3/86

Page 40

Publication

No.

XP3111-4

2/86

Kodak

DTSC

Section

Ektachem

MODULE

4

Diagnostics

PLEASE

NOTE

tha

snlormation contained

‘nad

by

Eastman

Na

patent

hse i granted

Fatman

Koch

rn,

nars

Including

conesquertal

le

cmd

by

Kodak

Company

or

or

Kodak

nagigunes

herein

bese

Company

by

reserves

wt

pacs

onthe

prior

to

tia

eration

ho

right

мона о thi

damage.

renting

er

cer

but

eerie

pue

an

t9

change

ti

information

formation

Kodak

hom

tha

ue

Блонди

ое

without

sal

nt

be

lable or

of

th

formation,

ve

maci mana

etic

and

ay

osa

eve

ie

matin

10

ox

damage.

cr

damage

©

Eastman

Ce

Y

Kodak

equipment

This

damage

damage

Company,

electrostatic

from

during

1986

includes

all

service

assemblies

and

parts

discharge.

procedures.

Use

sensitive

caution

prevent

to

to

Page 41

Diagnosing

€rror

Error

Error

Contents

Using

Malfunctions