Page 1

TECHNICAL DATA /

COLOR PAPER

K OD AK EKTA CHR OME

RADIANCE III HC Copy P aper

SIZES AVAILABLE

—NOTICE—

KODAK PROFESSIONAL EKTACHROME

RADIANCE III Papers and Materials and

KODAK EKTACHROME R-3 Chemicals

Alternative options for image capture and out put have

gradually eliminated the need for PROFESSIONAL

EKTACHROME RADIANCE III Papers and Materials as well

as chemicals for Process R-3. Therefore, dependent on

individual country an d m arket requirements, Kodak will

discontinue these products as inventor ies ar e exhausted

Technology has made the option of scanning, man i pulating,

and outputting images directly to traditional color paper very

popular, and photographers are increasingly using color

negative film and digital cameras for image capture. Producing

positive prints, even from transparencies, for image display no

longer requires the use of RADI ANC E Papers and Materials.

Information on Kodak Professional Modular Digital Workflow

Products (Equipment an d Sof tware) is available at

www.kodak.com/go/digitalprolab

Thank you for using KODAK PROFESSIONAL Products.

Discontinuance of

Use this resin-coated color reversal paper to make direct

color copies when you need high-contrast reproduction of

line-copy originals such as drawings, maps, documents,

blueprints, and layouts. EKTACHROME RADIANCE III

HC Copy Paper has higher contrast and D-max than

KODAK EKTACHROME RADIANCE III Copy Paper.

The “HC” stands for high contras t.

This paper is available in both rolls and sheets with F

(glossy) and N (semi-matt) surfaces. You can process it with

KODAK EKTACHROME R-3 Chemicals.

FEATURES BENEFITS

• Improved color reproduction • More accurate colors

• Extremely low minimum

density

• Elimination of thermal

yellowing

• Cleaner, whiter whites

• Longer print life under

dark-storage conditions

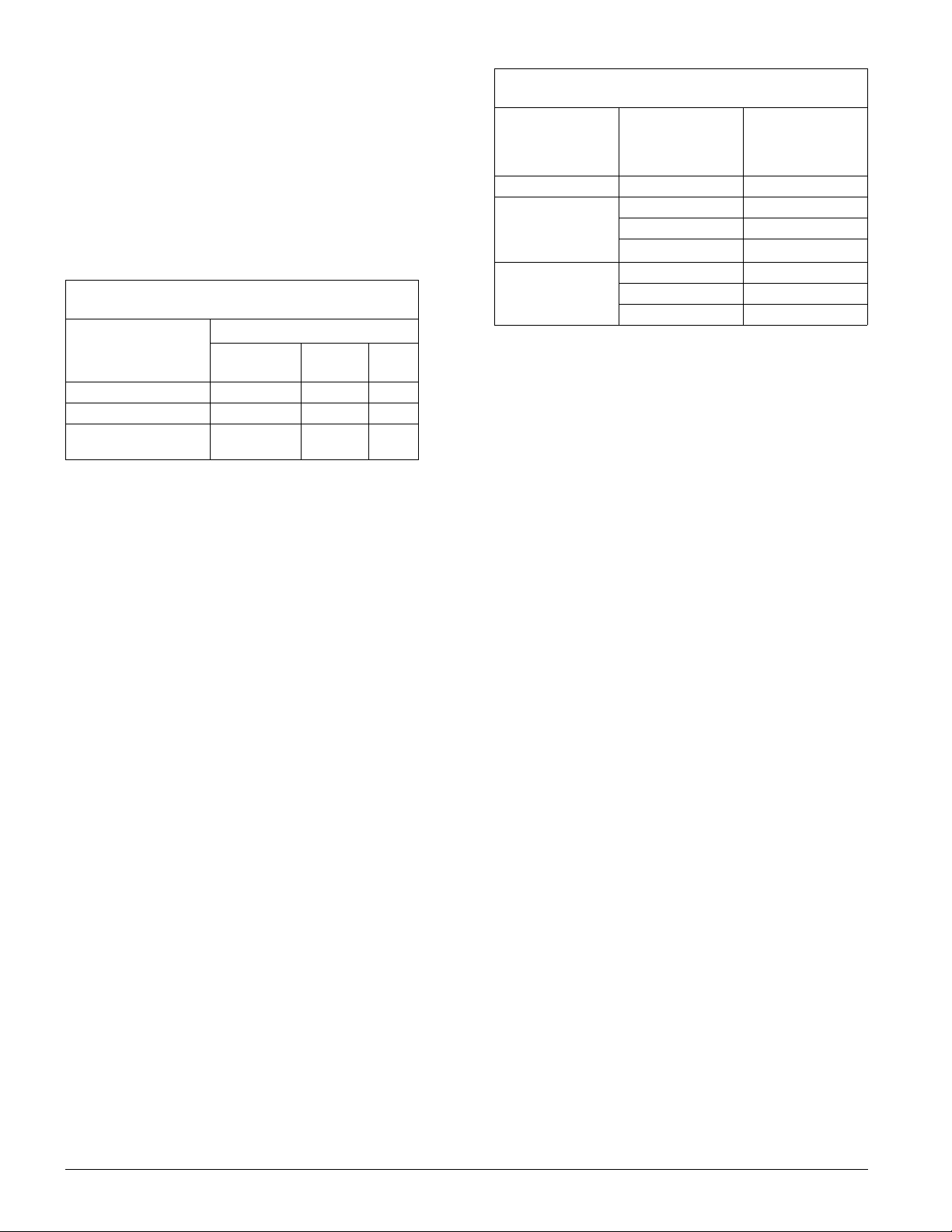

Sizes and catalog numbers may differ from country to

country. See your dealer who supplies KODAK

PROFESSIONAL Products. The following sizes are

available in the U.S. and Canada.

Sheets

Size

in. x in. /

cm x cm

8.5 x 11 /

21.6 x 27.9

11 x 14 /

27.9 x 35.6

11 x 14 /

27.9 x 35.6

16 x 20 /

40.6 x 50.8

20 x 24 /

50.8 x 61

20 x 24 /

50.8 x 61

Rolls

Rolls

in. x ft /

cm x m

11 x 200 /

27.9 x 61

11 x 200 /

27.9 x 61

11.7 x 200 /

29.7 x 61

11.7 x 200 /

29.7 x 61

20 x 200 /

50.8 x 61

24 x 200 /

61 x 61

30 x 100 /

76.2 x 30.5

50 x 100 /

127 x 30.5

50 x 100 /

127 x 30.5

50 x 100 /

127 x 30.5

50 x 100 /

127 x 30.5

February 2003 • E-2411

Sheets Per

Package

100 N 508 6673

50 F 508 6756

50 N 508 6699

50 N 508 6707

50 F 508 6715

50 N 508 6657

Spec No. Surface CAT No.

193 F 508 6897

193 N 508 6830

193 N 5086764

193 F 508 6848

223 N 5086822

223 F 508 6855

223 N 5211461

223 F 508 7036

223 N 5086814

224 F 508 6871

224 N 5086806

Surface CAT No.

©Eastman Kodak Company, 1999

Page 2

STORAGE AND HANDLING

Store unexposed paper at 13°C(55°F) or lower. High

temperatures or high humidity may produce unwanted

quality change s. To avoid moisture condensation on paper

that has been refrigerated, allow it to completely warm up to

room temperature before opening the package. For best

results, remove the paper from cold storage the day before

printing, or use the warm-up times in the following table. For

more storage information, see KODAK Publication No.

E-30, Storage and Care of KODAK Photographic

Materials — Before and After Processing.

Warm-Up Times (in Hours) to Reach

Room Temperature of 24 °C (75°F)

From a Storage Temperature of

Size

50-sheet box 3 2 2

100-sheet box 4 3 2

Rolls wider

than 11 in. (28 cm)

-18°C

(0°F)

12 9 6

2°C

(36°F)

10°C

(50°F)

These times are based on a single package, positioned to

allow free air circulation. After you remove the paper you

need, re-wrap the package and reseal it with tape to restore

the moisture barrier.

Handle this paper very carefully by the edges to avoid

creases and fingerprints. This high-speed p aper is extremely

sensitive to light; store and transport it in lighttight boxes.

DARKROOM RECOMMENDATIONS

Do not use a safelight; handle unprocessed paper in total

darkness. Be sure that your darkroom is lighttight. Eliminate

stray light from the repro camera lamps, timer s, digital

displays, etc.; even indicator lights and fluorescent tape can

fog the paper.

EXPOSURE

You can expose EKTACHR OME RADIANCE III HC Copy

Paper from opaque originals in a pro cess or repro camera b y

using subtractive, tricolor-additive, or semi-additive

methods. Although this paper is balanced for exposure with

a light source of 3200 K, you can use any of the following:

pulsed xenon, incandescent, flood, or halogen lamps. Do not

use fluorescent lamps or electronic flash.

Using a Process (Repro) Camera

For a 1:1 ratio in a Klimsch Super M3 Repro Camera

equipped with a halogen light source, use these

trial-exposure conditions:

T rial Exposure Using a Process (Repro) Camera to Expose

KODAK EKTACHROME RADIANCE III HC Copy Paper

Exposure Time (in

Printing Method Filters

Subtractive CC10Y 4.4

Tric olor -a ddit ive

(with KODAK

WRATTEN Gelatin

Filters)

Semi-additive (with

KODAK WRATTEN

Gelatin Filters)

No. 29 Red 4.5

No. 61 Green 12

No.47B Blue 9.2

White Ligh t 2.3

No. 29 Red 1.5

No. 61 Green 4.5

Seconds) for an

Aperture Setting

of f/22

Because exposure times and filtration will differ with the

equipment, the light source, the original, your process

control, etc., use the tables as a guide.

To maintain high image quality, control flare as much as

possible. Flare consists of stray ambient light and scattered

image light that might reach the paper during exposure.

Follow these procedures to control flare:

• Keep the lens surfaces, mirrors, filters, and copyboard

glass clean and free of scratches.

• Keep the interior of the camera clean.

• Use the additive or semi-additive printing method

whenever possible to minimize the number of filters in

the optical path.

• Adjust the copyboard lights and room lights so that

neither the lights nor reflections from the copyboard

glass fall on the camera lens.

• Mask the areas surrounding the original with black

material.

Adjustment for Long or Short Exposures

Y ou will not notice a change in the speed or in the contrast of

RADIANCE III HC Copy Paper at exposure times from

0.5 second to 100 seconds with tungsten, haloge n, or

pulsed-xenon light sources. We do not recommend using

flash to expose this paper. The short flash exposure times

will affect the quality of the prints.

LATENT-IMAGE KEEPING

You should n ot s ee any shifts in the latent image with

different keeping times between exposure and processing.

Therefore, you do not need to change your printing

procedures to compensate for latent-image shifts under

normal temperature and handling conditions.

2 KODAK EKTACHROME RADIANCE III HC Copy Paper • E-2411

Page 3

PROCESSING

Use KOD AK EKTACHROME R-3 or R -3 LU Chemicals to

process this paper in continuous or roller-transport

processors. For specific processing instructions, see

KODAK Pu bl i cat io n No. Z-129B, Using KODAK

EKTACHROME R-3 Chemicals in Continuous and

Roller-Transport Processors, available on our website at

www.kodak.com/go/professional.

DRYING

Do not ferrotype this paper.

Remove excess water from the surface of the paper before

drying. Dry the prints using dust-free air. The temperature of

the air will depend on the design of the dryer, the air-flow

rate, and the total drying time. The ideal drying temperature

is between 50 and 70°C (122 and 158°F). If the temp erature

is too high, the paper may curl. If the temperature is too low,

the surface gloss of the paper is reduced, and the risk of the

paper sticking is increased.

VIEWING

Evaluate prints und er l ight of t he same col or an d bri g ht ness

that you will use to view the final prints. A good average

viewing condition is a light source with a color temperature

of 4000 ±1000 K, a Color Rendering Index (CRI) of 85 to

100, and an illuminance of a least 538 lux (50 foo tcand les).

Fluorescent lamps such as the cool white delux e fluores cent

lamp (made by several manufacturers) meet these

conditions. You can also use a mixture of incandescent and

fluorescent lamps. For each pair of 40-watt cool white delux e

fluorescent lamps, use a 75-watt frosted tungsen bulb.

MOUNTING

From cpotter@node1 Thu Dec 12 17:18:27 1996

Date: Thu, 12 Dec 96 17:21:57 EST

You can mount p ri nts with KODAK Dry Mounting Tissue,

Type 2. The temperature across the heating platen of the

mounting press should be between 82 and 99°C (180 and

From: cpotter@node1 (Chris Potter)

To: dpenazek@caps

Subject: Illustration Update

inns:

any

210°F). T emperatures above 110°C (230°F) or high pressure

may cause physical and color changes in prints. Preheat the

cover sheet that you use o ver the face of the print to remov e

moisture. Apply pressure for 30 seconds or longer for a thick

mount.

DISPLAYING

Photographic dyes, like all dyes, can chang e with time and

exposure to sunlight, ultraviolet radiation, excessive heat,

and high humidi ty. To h elp p re vent changes in photographic

dyes, follow these guidelines:

• Illuminate prints with tungsten light whenever possible.

• Display prints in the lowest lig ht level consistent with

your viewing needs.

• If a print is exposed to direct or indirect sunlight or

fluorescent light, use an ultraviolet-absorbing filter

between the light source and the print.

• Keep the temperature and humidity as low as possible.

KODAK EKTACHROME RADIANCE III HC Copy Paper • E-2411 3

Page 4

CURVES

4.0

3.0

2.0

DENSITY

1.0

0.0

0.0

F002_0777AC

Characteristic Curves

Exposure:

Process:

Densitometry:

1/2 second

R-3

1.0

LOG EXPOSURE (lux-seconds)

Status A, Reflection

B

G

R

2.0

3.0

2.5

2.0

1.5

1.0

DIFFUSE SPECTRAL DENSITY

0.5

0.0

4.0

400

F002_0779AC

Spectral-Sensitivity Curves

Spectral-Dye-Density Curves

Process:

R-3

Yellow

Magenta

500

WAVELENGTH (nm)

600

Cyan

700

2.0

1.0

*

0.0

LOG SENSITIVITY

1.0

2.0

Yellow-

Forming

Layer

Magenta-

Forming

Layer

Cyan-

Forming

Layer

700 750650600550500450400350300250

WAVELENGTH (nm)

*Sensitivity = reciprocal of exposure (erg/cm ) required

to produce specified density

F002_0778AC

2

NOTICE: The sensitometric curves and data in this publication represent prod uct tested

under the conditions of exposure and processing specified. They are representative of

production coatings, and therefore do not apply directly to a particular box or roll of

photographic material. They do not represent standards or specifications that must be met

by Eastman Kodak Company. The company reserves the right to change and improve

product characteristics at any time.

4 KODAK EKTACHROME RADIANCE III HC Copy Paper • E-2411

Page 5

MORE INFORMATION

Kodak has many publications to assist you with information

on Kodak products, equipment, and materials.

The following publications are available from dealers who

sell Kodak products, or you can contact Kodak in your

country for more information.

E-30 Storage and Care of KODAK Photographic

Materials—Before and After Proce ssin g

E-1766 KODAK EKTACHROME RADIANCE III Paper

E-1767 KODAK EKTACHROME RADIANCE III SELECT

Material

E-67 Finishing Prints on KODAK Water-Resistant Papers

E-70 Retouching Prints on KODAK EKTACOLOR and

EKTACHROME Papers

E-2410 KODAK EKTACHROME RADIANCE III Copy Pap er

E-2412A KODAK EKTACHROME RADIANCE III Overhead

Material

E-2412B KODAK EKTACHROME RADIANCE III Clear

Display Material

E-2413 KOD AK EKTACHROME RADIANCE III T r anslucent

Display Material

Z-129 Using KODAK EKTACHROME R-3 Chemicals,

Sixth Edition

Z-129A KODAK EKTACHROME R-3 and R -3 000

Chemicals

Z-129B Using KODAK EKTACHROME R-3 Chemicals in

Continuous and Roller-Transport Processors

Z-129C Using KODAK EKTACHROME R-3000 and

R-3 Chemicals in Batch-Type Processors

Z-129E Monitoring and Troubleshooting Processes Using

KODAK EKTACHROME R-3 and R-3000

Chemicals

Z-129G Recovering Silver from Processes Using KODAK

EKTACHROME R-3 Chemicals

Z-129H Using KODAK EKTACHROME R-3 LU Chemicals

in Roller-Transport Processors

For the latest version of technical supp or t publicat ions for

KODAK PROFESSIONAL Prod uct s, visit Koda k on-line at:

http://www.kodak.com/go/professional

If you have questions about KODAK PROFESSIONAL

Products, call Kodak.

In the U.S.A.:

1-800-242-2424, Ext. 19, M onday–Friday

9 a.m.–7 p.m. (Eastern time)

In Canada:

1-800-465-6325, M onday–Friday

8 a.m.–5 p.m. (Eastern time)

Note: The Kodak materials described in this publication for

use with KODAK EKTACHROME RADIANCE III HC Copy

Paper are available from dealers who supply KODAK

PROFESSIONAL Products. You can use other materials, but

you may not obtain similar results.

KODAK EKTACHROME RADIANCE III HC Copy Paper • E-2411 5

Page 6

KODAK EKTACHROME RADIANCE III HC Copy Paper

KODAK EKTACHROME

RADIANCE III HC Copy Paper

KODAK Publication No. E-2411

Kodak, Kodak Professional, Ektachrome, Ekt aco l or,

Radiance, an d Wratten are trademarks

Minor Revision 2-03

Printed in U.S.A.

Loading...

Loading...