Page 1

TECHNICAL DATA / COLOR FILM

K OD AK VERICOLOR Slide Film

December 2002 • E-24

—NOTICE—

These films are discontinued.

KODAK VERICOLOR SLIDE FILM / 5072

(Rolls)

KOD AK VERICOLOR Slide Film is intended for producing

same-size positive transparencies from color negati ves or for

making reduced-size transparencies from larger negatives.

You can use this film for professional and photofinishing

applications with contact-printing or copying and

duplicating equipment. You can also use this film to copy

black-and-white line art to make reverse-text slides or crop

negatives to make tighter composition on transparencies.

This film is coated on an acetate base, and is available in

35 mm x 100-foot rolls (5072 Film) and 135-36 rolls

(SO-279 Film). You can mount it in standard 2 x 2-inch slide

mounts or use it uncut as film strips.

Process KODAK VERICOLOR Slide Film in KODAK

FLEXICOLOR Chemicals for Process C-41.

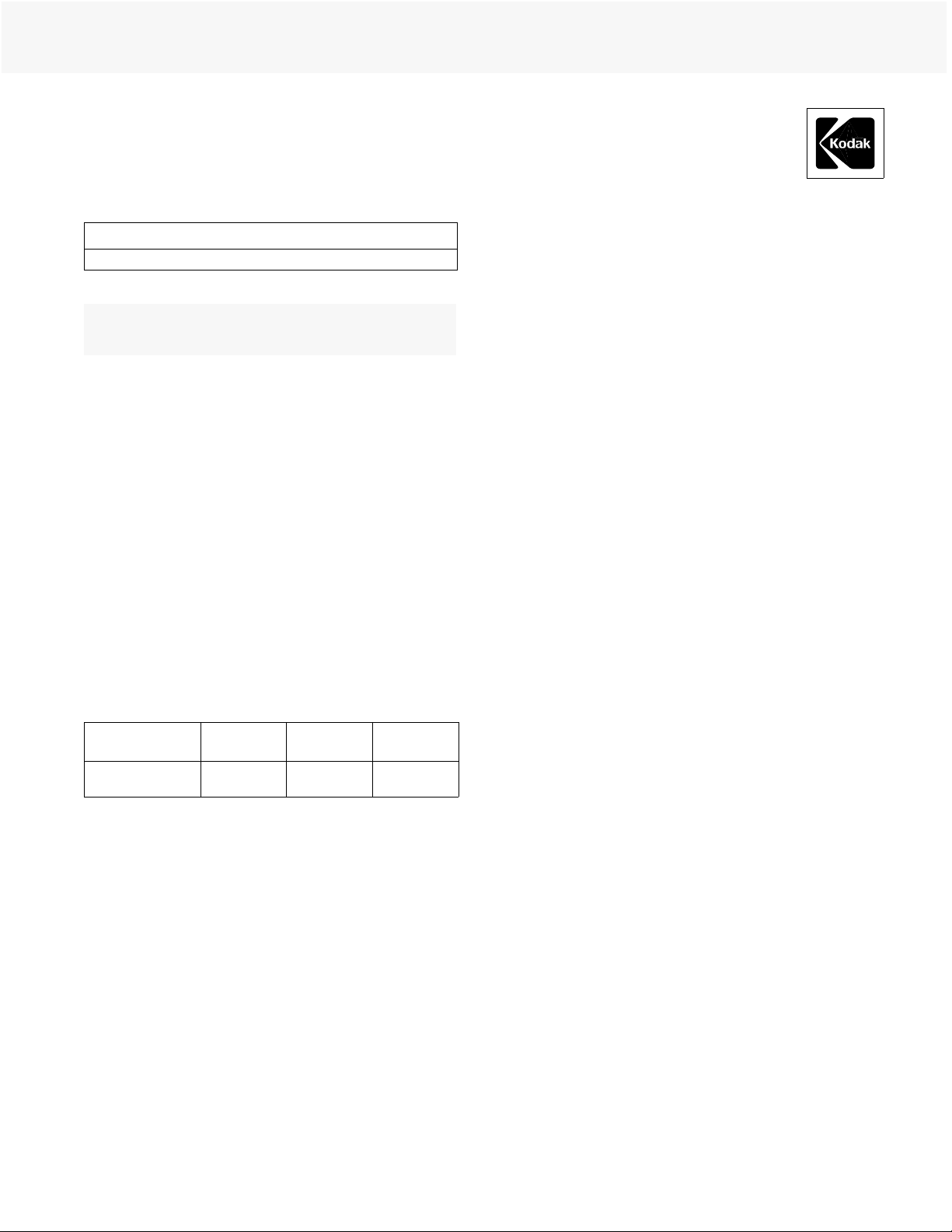

SIZE AVAILABLE

KODAK VERICOLOR Slide Film / 5072

STORAGE AND HANDLING

High temperatures or high humidities may produce

undesirable changes in VERICOLOR Slide Film. Store

unexposed film at 13°C(55°F) or lower in the original

sealed package. To prevent condensation on film that has

been refrigerated, allow the film to warm up to room

temperature before you open the package.

Use the film as soon as possible after purchase, and before

the expiration date. For consistent results, use the same

handling procedures between exposure and processing.

Keep exposed film cool and dry, and process it as soon as

possible after exposure. If processing must be delayed, you

can minimize changes in the latent image of KODAK

VERICOLOR Slide Film by storing it in a moistureproof

container and freezing it before processing. Allow the film to

warm up to room temperature before you process it.

Store processed film at 21°C(70°F) or lower at a relative

humidity below 50 percent. For information on long-term

storage, see KODAK Publication No. E-30, Storage and

Care of KODAK Films and Papers—Before and After

Processing.

Note: When you use KODAK VERICOLOR Slide Film for

reverse-text slides, and exact color reproduction is not

critical, you do not have to freeze the exposed film if you

process it within 7 days.

Rolls (mm x ft) Spec No.

35 x 100 ft, perf VS 663

©Eastman Kodak Company, 2000

Acetate

Base

5-mil

(0.13 mm)

CAT No.

122 1217

DARKROOM RECOMMENDATIONS

Do not use a safelight. Handle unprocessed film in total

darkness.

Page 2

EXPOSURE

Equipment

Expose this film with optical- or contact-printing equipment.

For large-scale production, you can use printers and copying

equipment modified for production applications.

Use exposing equipment that has a tungsten-halogen

(3200 K) light source, a heat-absorbing glass, an ultraviolet

absorber (such as a KODAK WRATTEN Gelatin Filter

No. 2B or a KODAK Color Printing Filter CP2B), and

built-in dichroic filters.

Printing Color Negatives and Internegatives

KODAK VERICOLOR Slide Film is intended for exposure

times of

at the exposure plane to 16 footcandles (172 lux) without a

negative or filters in the light beam. Use an initial exposure

time between 1 and 4 seconds.

VERICOLOR Slide Film, use a starting filter pack of

20M + 30Y. Negatives made on daylight-balanced films

exposed with tungsten light will require more yellow

filtration.

VERICOLOR Slide Film. See the film carton for

supplementary information on each emulsion. This

information includes starting filter-pack and aperture

adjustments. The aperture adjustment includes the exposure

adjustment required for the filters.

internegatives from different types of transparency films,

make tests to determine the best filter pack for printing

internegatives onto KODAK VERICOLOR Slide Film. Start

with a filter pack that produces successful results in printing

original camera negatives and adjust filtration and exposure

as required.

Making Reverse-Text Slides

You can use KODAK VERICOLOR Slide Film to produce

reverse-text slides with white or near-white letters on a dark

or colored background. To make a reverse-text slide,

photograph dark letters on white background with color

compensating filters over the lens. For backgrounds of

various colors, use the filters and exposures given in the

tables below.

and lens aperture for exposure, use an incident-light meter

set at the exposure index indicated below. When you add the

filters in front of the camera lens, increase the exposure as

shown in the tables. Make an exposure series of at least

±1 stop in

between 1 and 8 seconds.

Note: Reverse-text slides exposed with KODAK

WRATTEN Gelatin Filters usually have more saturated

colors than slides made with KODAK Color Compensating

Filters.

1

⁄

second to 8 seconds. Set the illumination level

4

To print negatives made on Kodak color films onto

The filter pack is based on average emulsions of KODAK

Because of the variables involved in producing

Use a 3200 K light source. To determine the shutter speed

1

⁄

-stop increments. Keep the exposure time

2

Using KODAK WRATTEN Gelatin Filters

Use an Exposure Index (EI) of 8 with no filters over the light

source. Place the WRATTEN Gelatin Filter over the lens.

Background

Color in Slide

Red-brown None 0

Purple

Dark blue

Cyan

Dark green

Red

Orange

Dark Yellow

Magenta

* Y ou can increase exposure by extending the exposure time, as long as

it does not exceed 8 seconds.

KODAK WRATTEN

Gelatin Filter No.

12

(deep yellow)

12 + 85B

(deep yellow + amber)

29

(deep red tricolor)

34A

(violet)

38A

(blue)

44

(light blue-green)

47

(blue tricolor)

61

(deep green tricolor)

Exposure

Adjustment

2 stops

2 stops

4 stops

4 stops

4 stops

4 stops

4 stops

4 stops

*

Using Color Compensating Filters

Use an Exposure Index (EI) of 2 with a filter pack of

CP60R + CP50 over the light source. Place the

color-compensating filters over the lens.

Background

Color in Slide

Magenta 75G 1 stop

Blue 50R + 50Y 1

Cyan 70R + 05Y 0

Dark green 50M 1 stop

Yellow-orange 90B + 40C 2 stops

Dark red

* You can increase exposure by extending the exposure time, as

long as it does not exceed 8 seconds.

KODAK Color

Compensating

Filter

Remove the CP

filter pack from

the light source.

Add 90C + 20G in

front of the lens.

Exposure

Adjustment

1

⁄

stops

2

0

*

PROCESSING

Process KODAK VERICOLOR Slide Film in KODAK

FLEXICOLOR Chemicals for Process C-41. Do not process

this film in washless minilab process cycles, i.e., Process

C-41B and C-41RA. This film is of an older design that

requires a stabilizing agent for image stability. Process this

film only in a processor that uses KODAK FLEXICOLOR

Stabilizer III and Replenisher.

For information on processing, see KODAK Publication

No. Z-131, Using KODAK FLEXICOLOR Chemicals.

2 KODAK VERICOLOR Slide Film • E-24

Page 3

KODAK VERICOLOR PRINT FILM / 4111

(Sheets)

KODAK VERICOLOR Print Film is intended for producing

positive transparencies from color negatives and

internegatives for displays or photo mechanical

reproduction. This film has a dimensionally stable 7-mil

ESTAR Thick Base with a retouching surface on both sides.

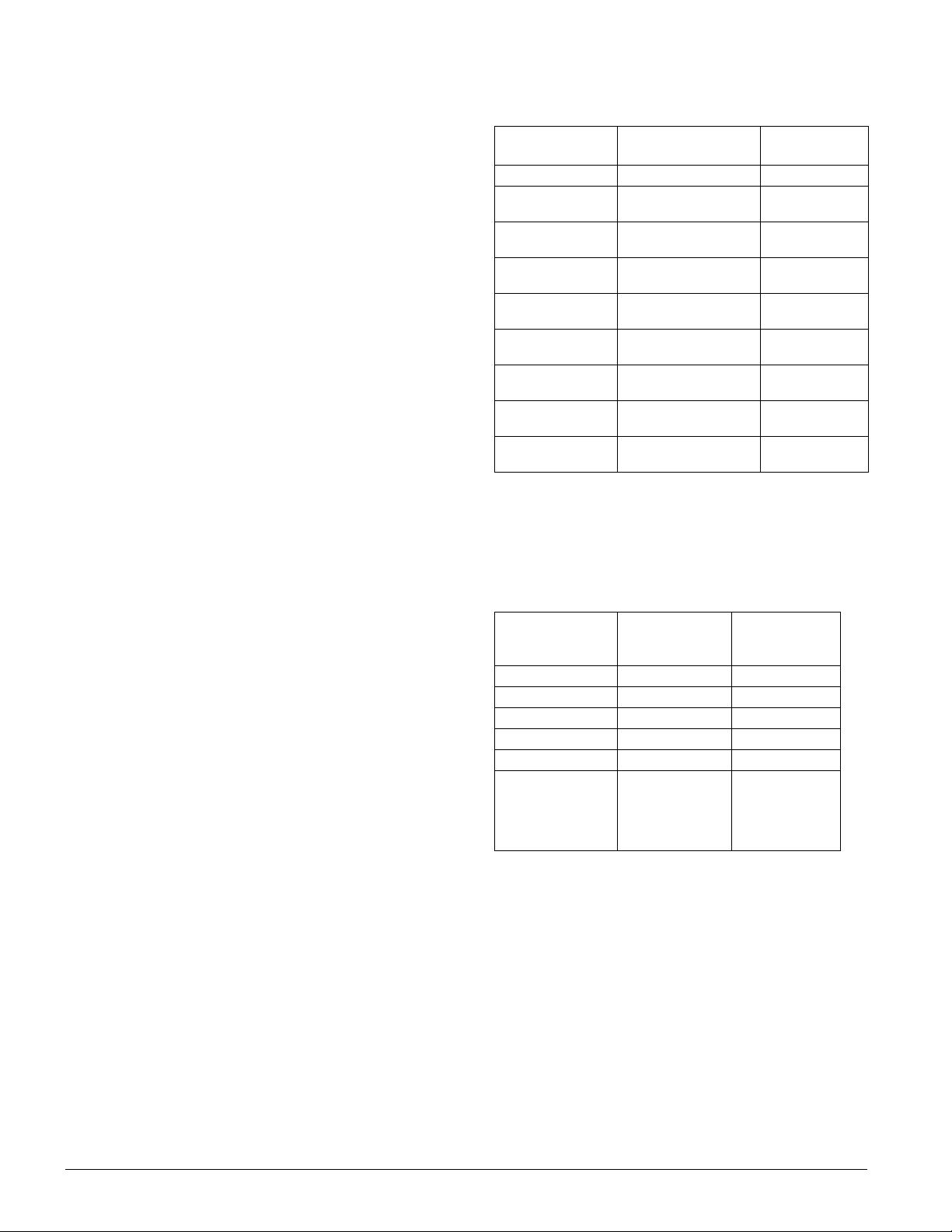

SIZES AVAILABLE

Note: You can freeze exposed KODAK VERICOLOR Print

Film to minimize changes. If you cannot process this film

within 4 hours after exposing it, store it in a moistureproof

container and freeze it to avoid changes in the latent image.

Allow the film to warm up to room temperature before you

process it.

DARKROOM RECOMMEDATIONS

Do not use a safelight. Handle unprocessed film in total

darkness.

KODAK VERICOLOR Print Film / 4111

Rolls (in. x ft) Spec No.

40 x 100

50 x 100 122 2249

Sheets

10 4 x 5

10 8 x 10 122 1373

50 8 x 10 122 1399

50 10 x 10 122 1415

10 11 x 14 122 1431

10 20 x 24 122 1472

351

Size

(Inches)

EST AR Thick

Base

7-mil

(0.18 mm)

EST AR Thick

Base

7-mil

(0.18 mm)

CAT No.

122 2223

CAT No.

122 1357

STORAGE AND HANDLING

High temperatures or high humidities may produce

undesirable changes in these films. Store unexposed film at

13°C(55°F) or lower in the original sealed package. To

prevent condensation on film that has been refrigerated,

allow the film to warm up to room temperature before you

open the package.

Use the film as soon as possible after purchase, and before

the expiration date. For consistent results, use the same

handling procedures between exposure and processing.

Keep exposed film cool and dry, and process it as soon as

possible after exposure.

Store processed film at 21°C(70°F) or lower at a relative

humidity below 50 percent. For information on long-term

storage, see KODAK Publication No. E-30, Storage and

Care of KODAK Films and Papers—Before and After

Processing.

EXPOSURE

Equipment

Use exposing equipment that has a tungten-halogen

(3200 K) light source, a heat-absorbing glass, and

untraviolet-absorbing filter (such as a KODAK WRATTEN

Gelatin Filter No. 2B or a KODAK Color Printing Filter

CP2B), and built-in dichroic filters.

Printing Color Negatives and Internegatives

KODAK VERICOLOR Print Film is intended for exposures

times of 1 to 20 seconds. Set the illumination at the exposure

plane at 2 footcandles (22 lux) without a negative or filters in

the light beam. Use an initial exposure time between 1 and

15 seconds.

To print negatives made on Kodak color films onto

VERICOLOR Print Film, use a starting filter pack of

20M + 30Y. Negatives made on daylight-balanced films

exposed with tungsten light will require more yellow

filtration. Push processed negatives may require a different

filter pack.

These filter packs are based on average emulsions of

VERICOLOR Print Film. See the film carton for

supplementary information on each emulsion. The

information lists filter and includes aperture adjustments for

times of 10 and 120 seconds. The aperture adjustment

includes the exposure adjustment required for the filters.

Use these recommendations as a guide for making trial

exposures. For best tone rendering and color balance, make

a test transparency from each type of film negative. View the

test tranparencies on a illuminator that has the same color

quality and brightness as the illuminator you will use to

display or view the finished transparencies.

Because of the variables involved in producing

internegatives from different types of transparency films,

make test to determine the best filter pack for printing

internegatives onto KODAK VERICOLOR Print Film. Start

with a filter pack that produces successful results in printing

original camera negatives and adjust filtration and exposu re

as required.

KODAK VERICOLOR Slide Film • E-24 3

Page 4

KODAK VERICOLOR Slide Film

PROCESSING

Process KODAK VERICOLOR Print Film in KODAK

FLEXICOLOR Chemicals for Process C-41. Do not process

this film in washless minilab process cycles, i.e., Process

C-41B and C-41RA. This film is of an older design that

requires a stabilizing agent for image stability. Process this

film only in a processor that uses KODAK FLEXICOLOR

Stabilizer III and Replenisher.

For information on processing, see KODAK Publication

No. Z-131, Using KODAK FLEXICOLOR Chemicals at

www.kodak.com/go/photochemicals.

RETOUCHING

Use KODAK E-6 Transparency Retouching Dyes or

KODAK Liquid Retouching Colors to retouch

transparencies made on KODAK VERICOLOR Print Film.

Note: Although both types of dyes will produce a good

visual match, neither will perfectly match the image dyes of

KODAK VERICOLOR Print Film; therefore, you may

notice a slight mismatch in photomechanical reproductions

of the transparencies. Also, when retouched transparencies

are used in displays for an extended period of time, the

retouching dyes and image dyes may not change a the same

rate.

MORE INFORMATION

Kodak has many publications to assist you with information

on Kodak products, equipment, and materials.

The following publications are available from Kodak

customer service, or from dealers who sell Kodak products,

or you can contact Kodak in your country for more

information.

E-30 Storage and Handling of KODAK Films and Papers—

Before and After Processing

Z-131 Using KODAK FLEXICOLOR Chemicals

Note: The Kodak materials described in this publication for

use with KODAK VERICOLOR Films are available from

dealers who supply KODAK PROFESSIONAL Products.

You can use other materials, but you may not obtain similar

results.

KODAK VERICOLOR Slide Film

KODAK Publication No. E-24

CAT 000 0000

Kodak, Estar, Flexicolor, Vericolor, and Wratten are trademarks.

Minor Revision 12-02

Printed in U.S.A.

Loading...

Loading...