Page 1

KODAK DRYVIEW 5800 Laser Imager

CARESTREAM DRYVIEW 5850 Laser Imager

User’s Guide

Page 2

Page 3

Table of Contents

1. Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-1

DRYVIEW 5800 and 5850 Laser Imagers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-1

Intended Use - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-1

How the Laser Imager Works - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-2

System Components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-3

Print Sequence - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-4

Automatic Image Quality Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-5

Agency Compliance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-5

User Guide Conventions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1 -5

2. Using and Maintaining the Imager - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-1

Operator Control of the Imager - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-1

Turning the Imager Power ON and OFF - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-1

Local Panel and Display Screen - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-2

Local Panel / Display Screen - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-2

Display Screen Icons - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-3

Web Portal - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-5

Levels of User Access - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-5

Accessing the Web Portal - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-6

Operations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-7

Unloading and loading the Film Tray - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-7

Inserting the Film Saver and Removing the Film Tray - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-10

Removing Print Jobs From the Unprintable Jobs Queue - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-10

Calibration Prints - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-11

Running a Calibration Print - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-11

Calibration Failure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-11

Working with Quality Test Prints - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-12

Requesting a Test Print at the Imager - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-12

Requesting a Test Print at the Web Portal - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-12

Operator Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-13

Changing the Charcoal Filter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-13

3. Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-1

Error and Alarm Indications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-1

DICOM Printer Status Messages - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-1

Printer Status Messages - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-2

Film Tray Status Messages - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-3

Job Manager Status Messages - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-5

Condition Codes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-6

2011-09-09 2G0733 i

Page 4

Table of Contents

Clearing Film Jams - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-13

Film Jam - Code 2x-116 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-14

Film Jam - Code 2x126 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-17

Film Jam - Code 26325 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-19

Film Jam - Codes 26326 or 26543 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-19

Film Jam - Code 26544 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-21

Calling for Support - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-22

4. Film Technical Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-1

General Description - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-1

Spectral Sensitivity - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-1

Image Quality - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-1

Environmental Impact - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-2

Storing and Handling Undeveloped Film - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-2

Handling Developed Film - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-2

Archiving Developed Film - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-3

Exposing to Moisture - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-3

Dissipating Odor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-3

Dissipating Heat - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-3

Recycling Film - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-3

5. Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-1

Location - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-1

Equipment Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-1

Operating Space Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-1

Other Location Considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2

Environmental Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-3

Temperature - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-3

Relative Humidity - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-3

Altitude - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-3

Surface Condition - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-3

Environmental Effects - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-3

Laser Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-3

Power Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-4

Network Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-4

Film - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-4

Film Types - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-4

Film Sizes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-5

Film Storage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-5

Glossary - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -G-1

ii 2G0733 2011-09-09

Page 5

1 Overview

DRYVIEW 5800 and 5850 Laser Imagers

The laser imager is a continuous-tone laser imager with an internal

photothermographic film processor. Heat, rather than photo chemicals,

is used to develop the film. The laser imager receives digital images

from medical image source devices (modalities) over a network. The

format that the imager accepts is DICOM.

The laser imager prints images on laser imaging film. Each film

package contains 100 sheets of film. The imager can accept any type

and size of film as described in Chapter 5 of this manual.

Intended Use The KODAK DRYVIEW 5800 Laser Imager provides high quality hard

copy film output from digital imaging source modalities for use in

medical imaging diagnosis and referral. Electronic image information

signals are managed and transformed optically to expose KODAK

DRYVIEW media. The system is intended for use with a variety of

digital modalities including, but not limited to, CT (Computerized

Tomography), MR (Magnetic Resonance) and CR (Computed

Radiology) for diagnostic use by medical radiologists and

communications to referring physicians and their patients.

The CARESTREAM DRYVIEW 5850 Laser Imager is intended to

provide high-resolution hard copy images from digital imaging source

output signals. The device is intended for use with KODAK DRYVIEW

media including DVM (DRYVIEW Mammography Films). The imager

will interface with a variety of digital modalities, including, but not

limited to, CR (Computed Radiology), DR (Digital Radiology), CT

(Computerized Tomography), MRI (Magnetic Resonance Imaging), and

FFDM (Full Field Digital Mammography). The images are to be used

for medical diagnosis and referral to physicians and their patients.

2011-09-09 2G0733 1-1

Page 6

Overview

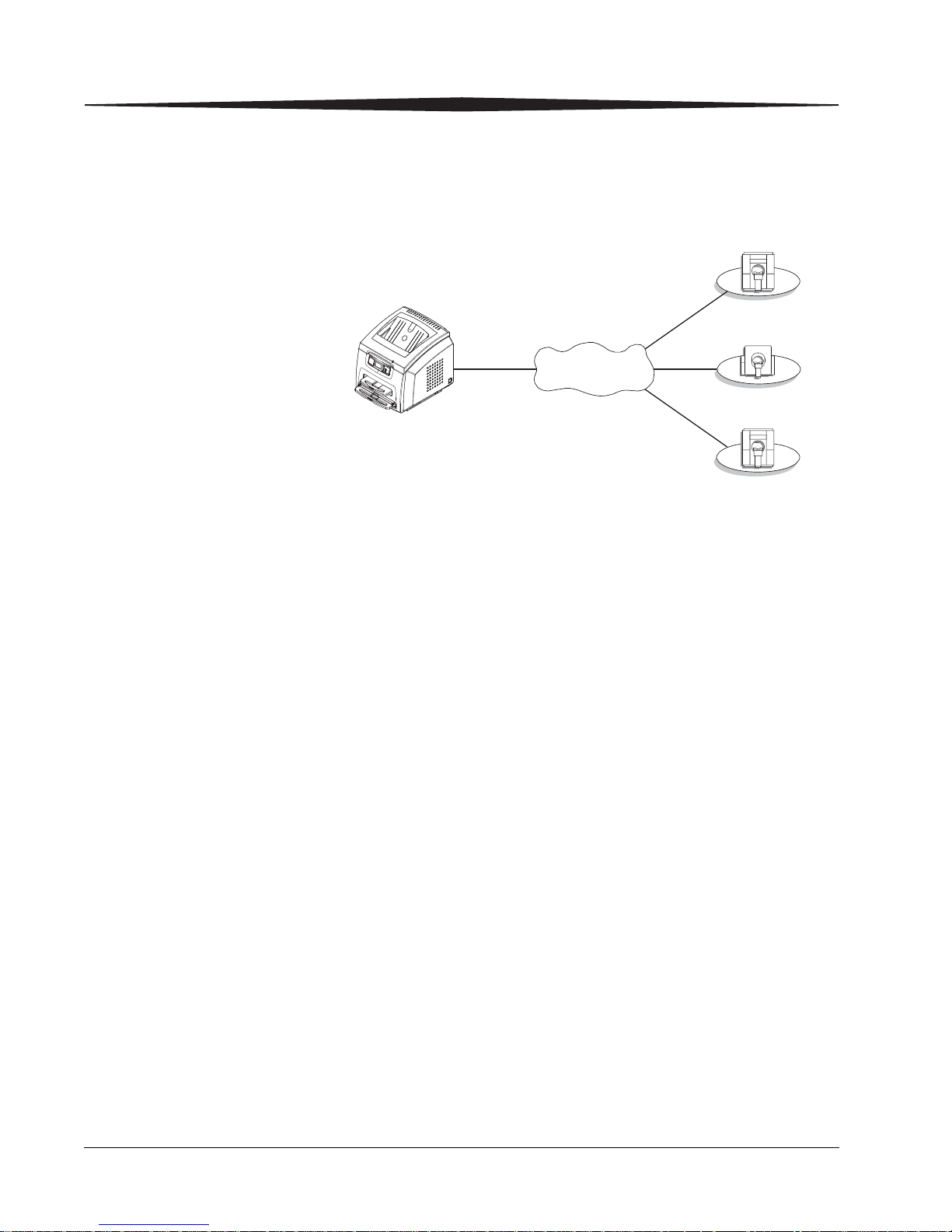

Laser Imager

Network

Modality

Modality

Modality

How the Laser Imager Works

The imager is a network printer connected on a network along with one or

more medical imaging devices. It prints images sent over the network from

medical imaging devices or workstations sending images concurrently.

The imager has hard-disk storage for a large number of digital images. As

images arrive, they are stored on the hard disk and placed in a print queue

(sequenced for printing) based on time of receipt and priority. Because the

imager can store images, it can continue to accept incoming print jobs even

when the film cartridge is empty or the imager is temporarily unable to

print. Images that require a different film size or film type than is currently

in the imager are placed in a separate “waiting for media” queue and a code

on the local panel reminds the operator to change film.

During normal operation, the imager requires very little operator attention.

The imager prints automatically in response to print requests from the

associated image devices. Information sent along with print requests, such

as film size, density and priority, control the print operations. Main operator

responsibilities include loading film and monitoring for malfunctions.

1-2 2G0733 2011-09-09

Page 7

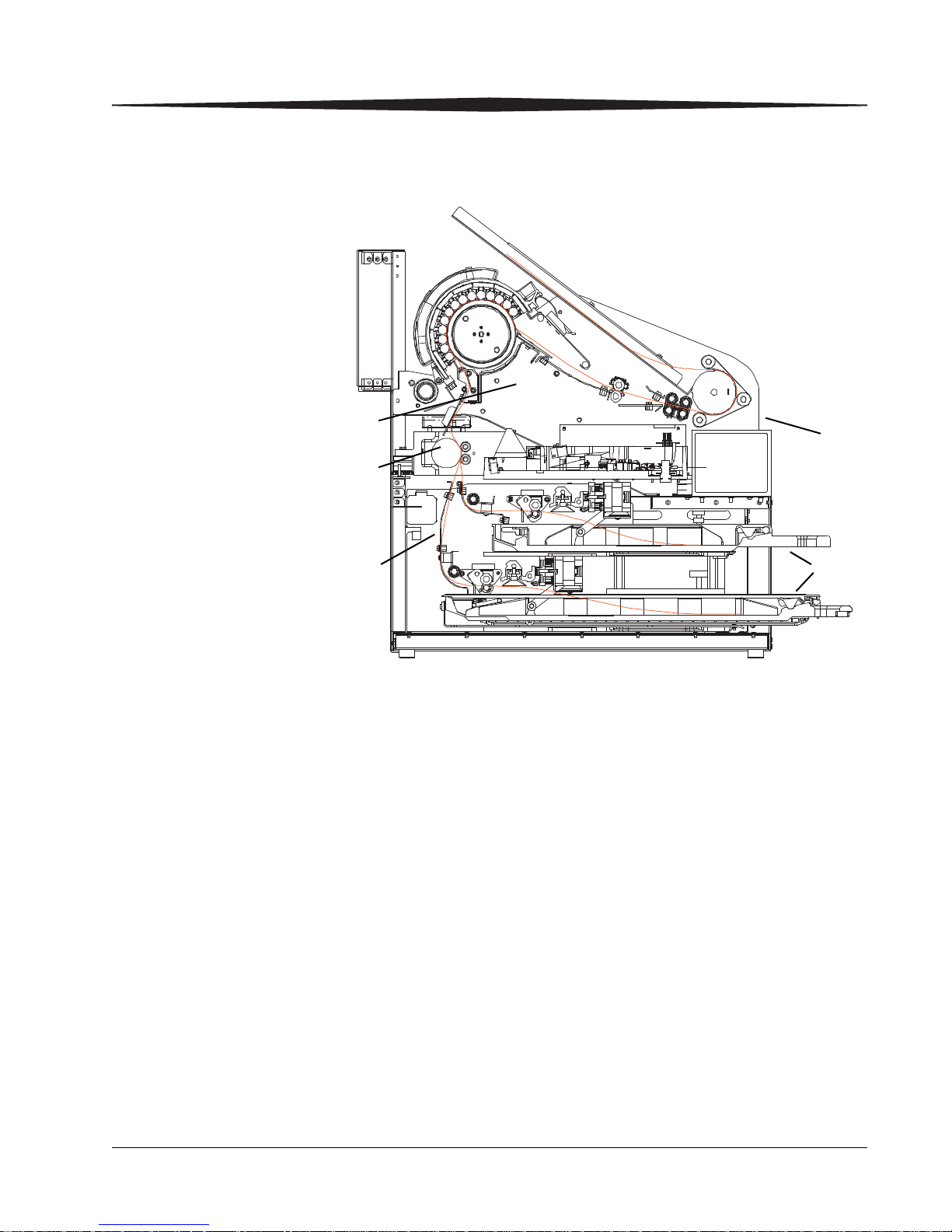

System Components

1

2

3

4

5

Overview

1 Film trays. Your imager is configured with two film trays. Each

film tray holds a different size of film. Both film trays must be

installed in order for the imager to operate.

2 Film feed transport. The film feed transport orients and centers

the film while moving the film from the film tray to the imaging

portion of the imager.

3 Film imaging. The optics module writes the image onto the film

while the film is moved through the exposure transport area.

4 Film processor. The film processor uses heat to develop the

image written onto the film by the laser in the optics module.

5 Local panel. The local panel contains the display screen.

2011-09-09 2G0733 1-3

Page 8

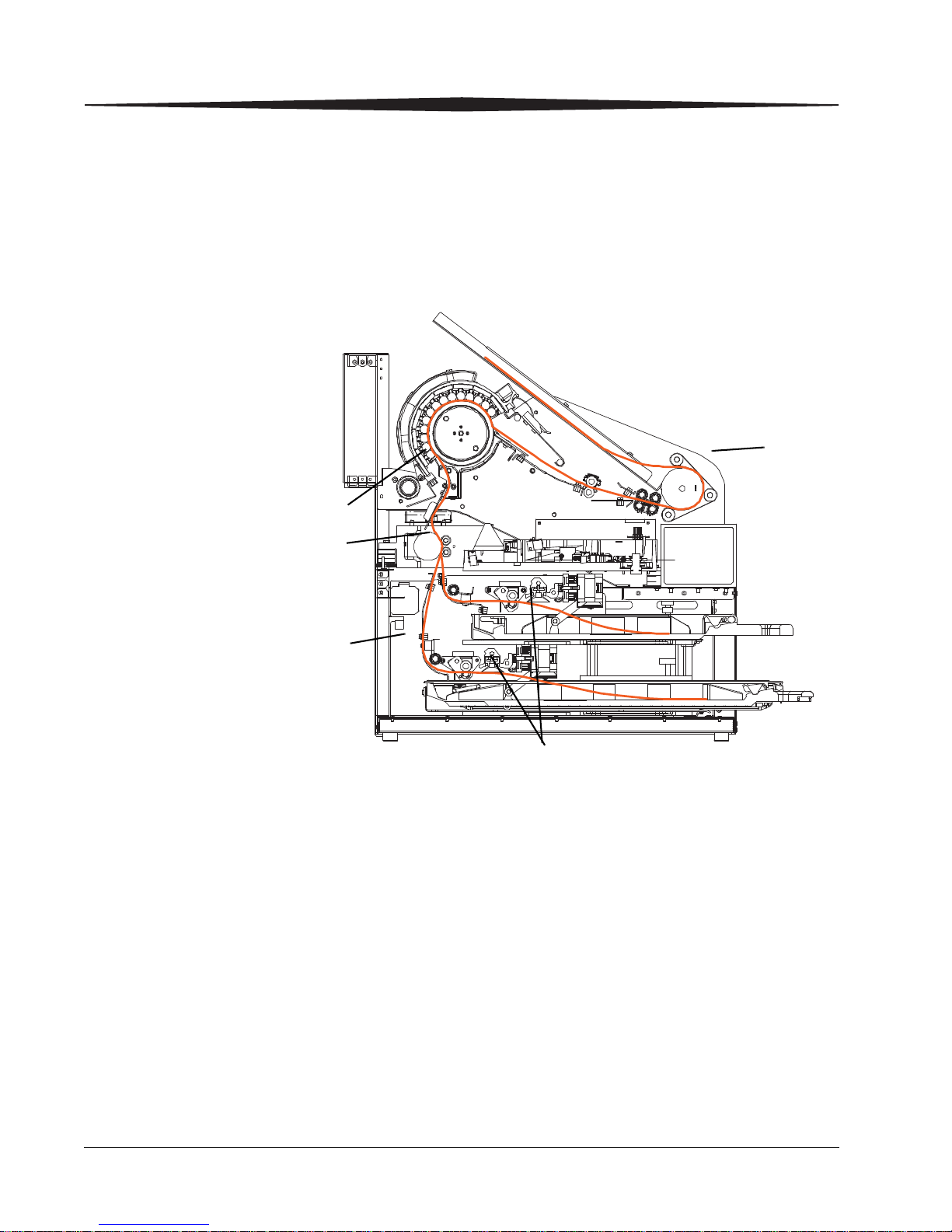

Overview

1

2

3

4

5

Print Sequence

When the imager receives a print request, it determines the requested film

size and type and then it selects the appropriate film tray.

Each time the imager receives a print request, the following print sequence

occurs:

1-4 2G0733 2011-09-09

1. Suction cups in the pickup area lift a single sheet of film out of the

tray and feed the film into the transport rollers.

2. The transport rollers move the film up into the registration transport

area, where film registration takes place.

3. As the film moves through the exposure transport, the optics module

writes the image onto the film, then moves the film into the film

processor.

4. As the film passes over the processor drum, the heat generated by the

drum develops the film.

5. The film transport rollers move the exposed film to the exit area.

Page 9

Automatic Image Quality Control

CAUTION:

LASER WARNING:

An internal densitometer is a key element in the Automatic Image Quality

Control (AIQC) process. The densitometer enables the imager to

automatically adjust image processing parameters to produce the best image.

The imager adjusts these parameters each time it prints a calibration film.

A calibration film is printed when:

• The film tray is inserted in the imager with film of a new lot number.

• A calibration film is requested from the local panel or web portal.

• A film tray is inserted into the imager for which a current calibration

is not stored.

Agency Compliance

See the Safety Manual.

Overview

User Guide Conventions

The following special messages emphasize information or indicate potential

risks to personnel or equipment.

NOTE: Notes provide additional information, such as expanded

explanations, hints, or reminders.

IMPORTANT: Important notes highlight critical policy information that

Cautions point out procedures that you must follow precisely to

avoid damage to the system or any of its components, loss of data,

or corruption of files in software applications.

DANGER: Danger identifies procedures that you must follow

Laser warnings warn personnel that access to laser radiation is

possible and all personnel must avoid direct exposure to the beam.

affects how you use this guide and this product.

precisely to avoid injury to yourself or others.

2011-09-09 2G0733 1-5

Page 10

Page 11

2 Using and Maintaining the

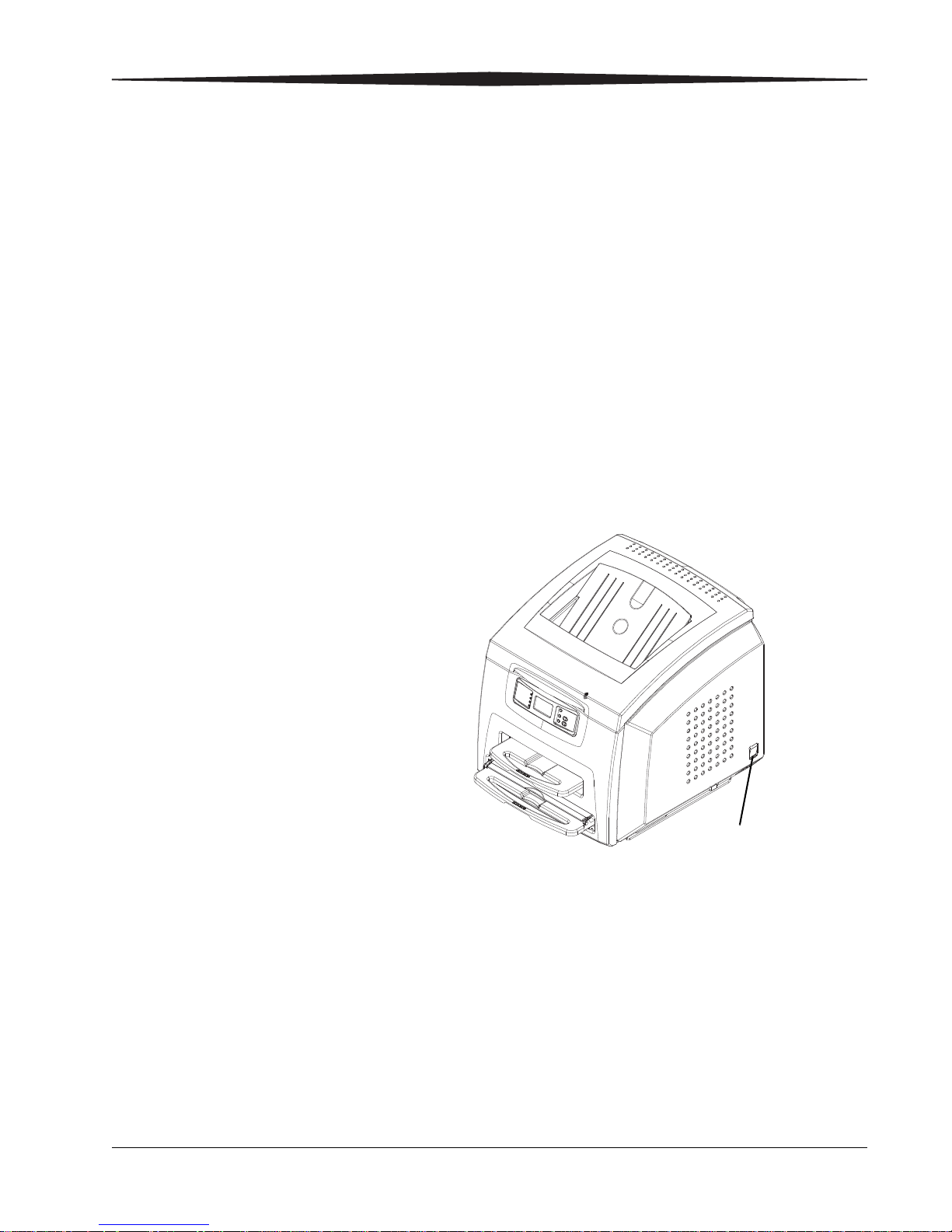

Power switch

Imager

Operator Control of the Imager

During normal operation, the imager receives and automatically prints

images sent by modalities over a network. Very little operator control is

required. The main responsibilities of the operator are described in the

following section, along with overview information about using the

imager.

Turning the Imager Power ON and OFF

2011-09-09 2G0733 2-1

There is a power switch located at the back right of the imager:

• "|" = Power ON

• "O" = Power OFF

In the event of a power loss, the imager shuts down. Films in process

will not be completed and will remain where they are located in the

imager.

The imager will restart after power is restored. After self-test, the

imager clears any films in process and automatically reprints any films

that were in process when power was interrupted.

Page 12

Using and Maintaining the Imager

1

2

3

4

567

8

Local Panel and Display Screen

Local Panel /

Display Screen

1 Ready LED. When steady on, the LED indicates that the imager is ready for printing.

When flashing, the imager is processing and printing films. When unlit, the imager is not

ready to print.

2 Error LED. When lit, this LED indicates that the imager has an error. An error code

appears on the display screen.

3 Attention LED. When lit, this LED indicates a condition that requires attention, such as

out of film. The imager can still process and print films from unaffected film trays.

4 Warming LED. When lit, this LED indicates that the imager is warming up. A timer is

also shown on the display screen indicating the amount of time, in minutes, before the

imager reaches operating temperature.

5 Display screen. Displays codes and icons that indicate the status and operating condition

of the imager.

6 Menu Selection button. In Menu Selection Mode, you can work with menus on the

display screen, and the functionality of buttons on the right side of the local panel

change. To enter Menu Selection Mode, press and hold the Menu Selection button (6 on

the graphic above) for five seconds. The following screens are available:

• Test Print screen: Select a test print (only SMPTE is available for 5800 Laser

Imager)(Prints are available for mammography quality control for the 5850 Laser

Imager).

• Maintenance Reset screen: Reset maintenance items such as reset print counts,

jobs to delete

7 Unlock buttons. Used to unlock the film trays. Note that the trays will not unlock unless

a film saver is installed in trays that have film.

{

NOTE: These buttons are used to select or cancel when in Menu Selection Mode. See

the Icons table on page 2-4.

8 Calibration buttons. Initiate a manual film calibration for upper and lower film trays.

NOTE: These buttons are used to move up or down in a menu when in Menu

Selection Mode. See the Icons table on page 2-4.

2-2 2G0733 2011-09-09

Page 13

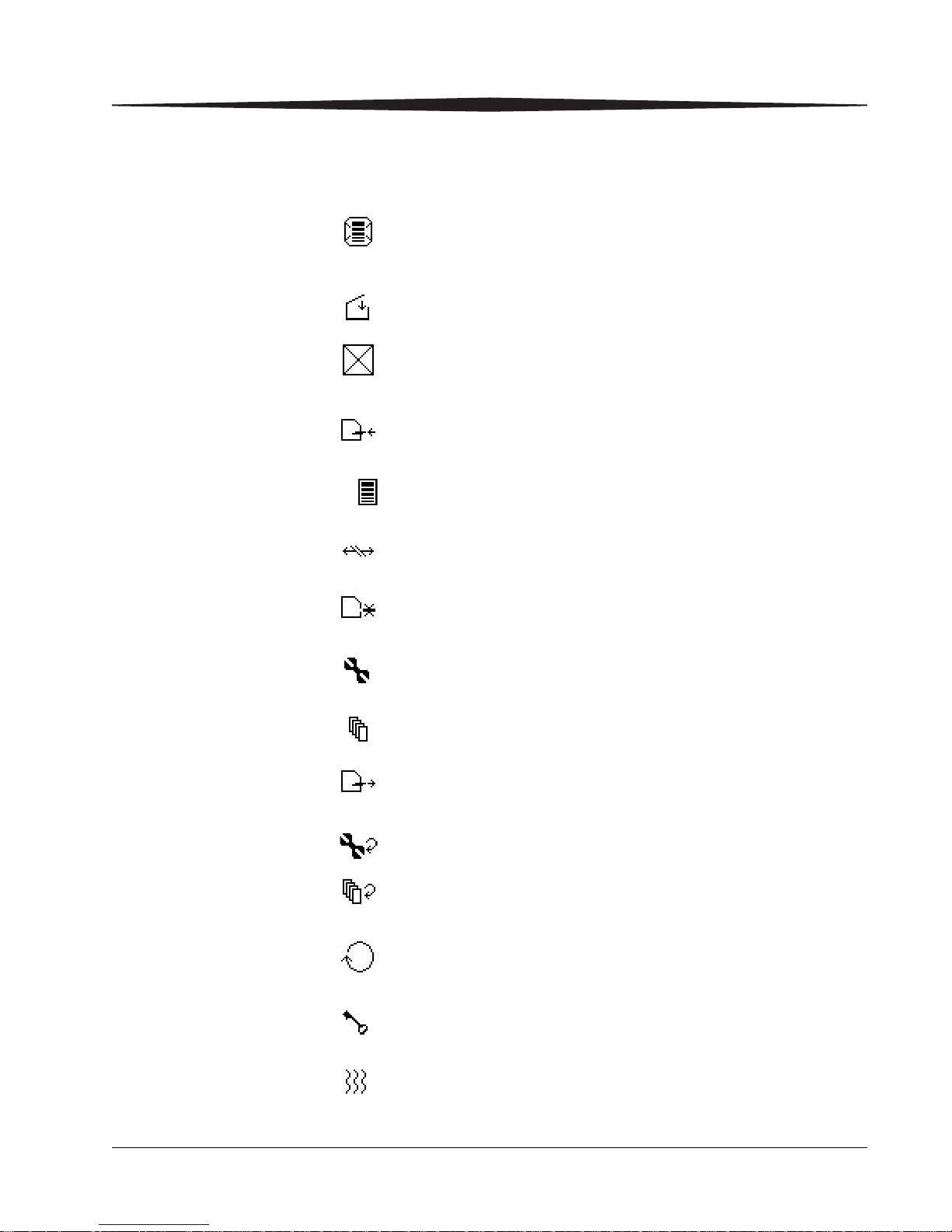

Display Screen Icons

Using and Maintaining the Imager

Icon Description

This icon indicates that film calibration is required. The imager is

unable to print jobs from this tray until a successful calibration

occurs.

This icon indicates that a door is open on the imager.

This icon indicates an error with the film tray. An error code will

also be shown on the display screen. The film tray cannot be used

until the error is corrected.

This icon indicates that you should insert the film saver into the

film tray.

This icon appears when the film fails the calibration and indicates

that the imager has been placed in manual mode.

This icon indicates that the DICOM network connection to the

imager is offline.

This icon indicates that a film tray is not installed. Both film trays

must be installed in order for the imager to operate.

This icon indicates that preventive maintenance is due.

This icon indicates that one or more jobs are present in the

Unprintable Job Queue.

This icon indicates that the film saver must be removed from the

film tray.

This icon indicates that a reset of the print counts to preventive

maintenance is due.

This icon indicates there are prints in the queue that are waiting to

be deleted.

This icon indicates that a user-initiated system restart is in process.

2011-09-09 2G0733 2-3

This icon indicates that the imager has been placed in service

mode.

This icon indicates that the imager is warming up. The amount of

time remaining until the imager reaches the operating temperature

is also shown on the display screen.

Page 14

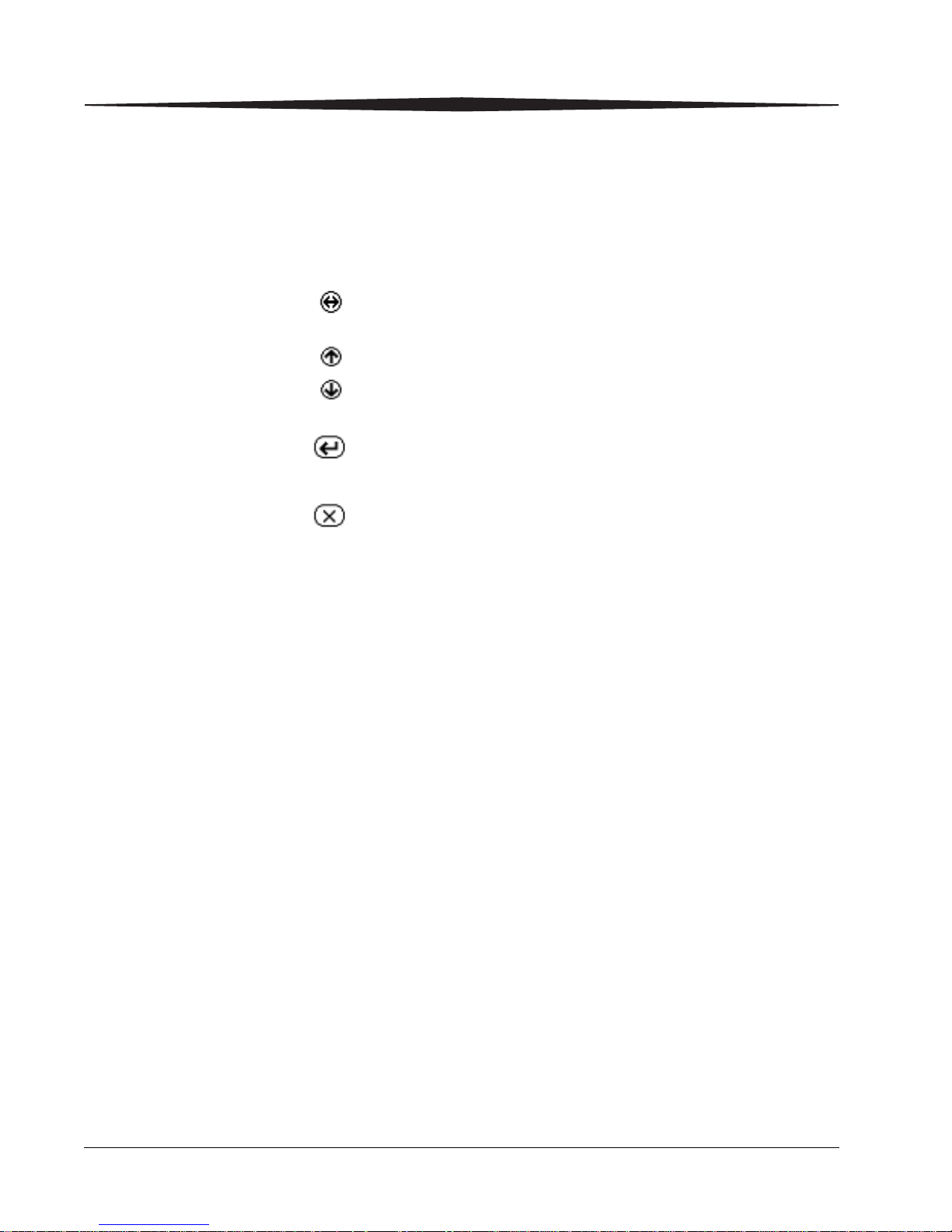

Using and Maintaining the Imager

Icons in Menu Selection Mode

Icon Description

The following icons appear on the display screen when you are in

Menu Selection Mode. These icons represent the changed

functionality of the buttons on the right side of the local panel.

While in Menu Selection Mode, press the button (6 in the graphic

on page 2-2) to display the Test Print or Maintenance Reset screen.

These icons indicate that the buttons shown by 8 in the graphic on

page 2-2 have changed functionality. Rather than being used as

Calibration buttons, you now use these buttons to move up or down

in the menu on the displays screen.

This icon indicates that the button shown by the upper 7 in the

graphic on page 2-2 is no longer an Unlock button. Instead, use the

button to select the currently highlighted menu item.

This icon indicates that the button shown by the lower 7 in the

graphic on page 2-2 is no longer an Unlock button. Instead, use the

button to cancel the selection.

2-4 2G0733 2011-09-09

Page 15

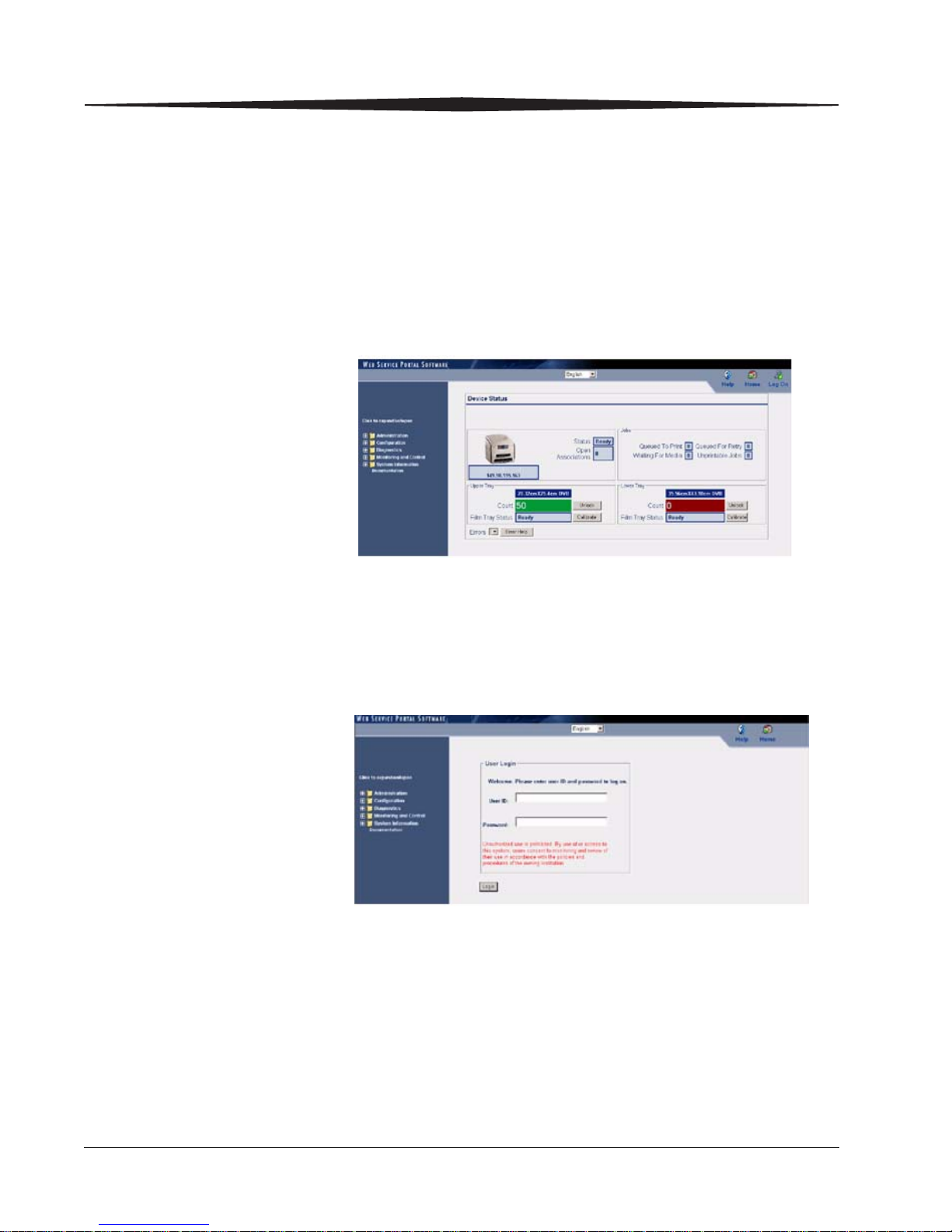

Web Portal

Using and Maintaining the Imager

The Web Portal is your interface to additional functions on the imager. In

the Web Portal, you can view and manage the imager's connections over the

network, configure features, and view and correct error messages and

general status.

After you have accessed the Web Portal, you can check the status of the

imager and check the media and status of the film trays.

With a user account, you can log on to the Web Portal to perform more

advanced functions such as:

• Setting up and working with network configuration for the imager

and connected image sources

• Retrieving logs, statistics, and system status

• Performing diagnostic utilities, including backup and restore

Levels of User

Access

IMPORTANT: For information about creating user accounts, refer to the

Web Portal Help system.

There are four levels of user access to the imager.

Level 1: Operator - Activities include printing, clearing some errors,

removing film jams, and deleting jobs. A password is not required

for this level of access.

Level 2: Key Operator - Activities include printing, clearing some errors,

removing film jams, performing minor setup, and deleting jobs.

Access to Level 2 requires a Level 2 ID and password.

Level 3: Local Service - Local Service providers are trained and certified

self-maintenance customers. Level 3 First Call Service provides

access to all Level 1 and 2 features and functions. Access to Level 3

requires a Level 3 ID and password.

Level 4: Full Service - Full Service providers are Field Engineers and

Technical Support staff. Full Service providers have access to all

Level 1, 2, and 3 service features. The providers can also access the

imager through a service computer or through a remote computer

connected to the network. Access to Level 4 requires a Service ID

and password.

2011-09-09 2G0733 2-5

Page 16

Using and Maintaining the Imager

Accessing the Web

Portal

To access the Web Portal, you will need a desktop or laptop computer that is

connected to the network.

1. On a desktop or laptop computer, start MICROSOFT INTERNET

EXPLORER.

2. In the address field, type: http://<IP address>

NOTE: <IP address> is the IP address of the imager.

3. Click Go.

The main window for the Web Portal appears.

The center panel displays the screens where you view and perform

tasks. Online Help is available by selecting Documentation from the

left panel. The left panel displays links to all other screens.

To log on to the Web Portal as a Level 2 or Level 3 user, do the following.

1. Click the Log On icon. The following window appears.

2. Enter your User ID and password.

NOTE: The imager comes with a default User ID and password for

Level 2 and Level 3 users.

• Level 2: User ID = KeyOperator; Password = DV5800

• Level 3: User ID = LocalService; Password = DV5800

3. Click Login.

The items on the left side of the display will differ according to your

level of access.

2-6 2G0733 2011-09-09

Page 17

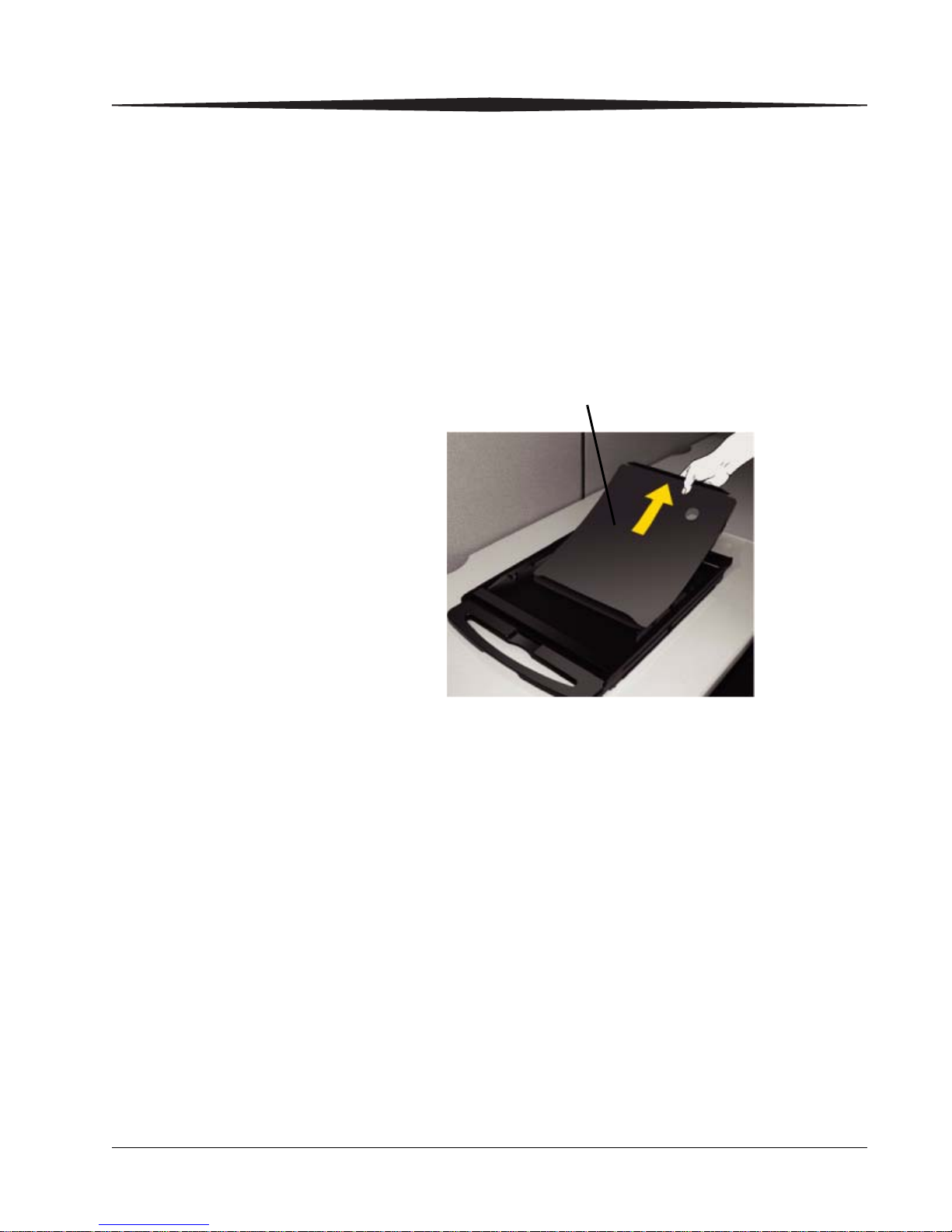

Operations

Film insert

Using and Maintaining the Imager

Unloading and

loading the Film Tray

IMPORTANT: Leave the imager powered on while loading or unloading

the film tray.

When 100 sheets of film have been used, a 0 film count appears on the

display screen.

1. Press the unlock button on the local panel to release the film tray.

2. Remove the film tray from the imager.

3. Remove the old film insert from the tray, and discard in a manner

suitable to local ordinances.

NOTE: Before loading a new package of film, clean any particles from the

inside surface of the film tray, including the ramp and top edge of

the tray.

2011-09-09 2G0733 2-7

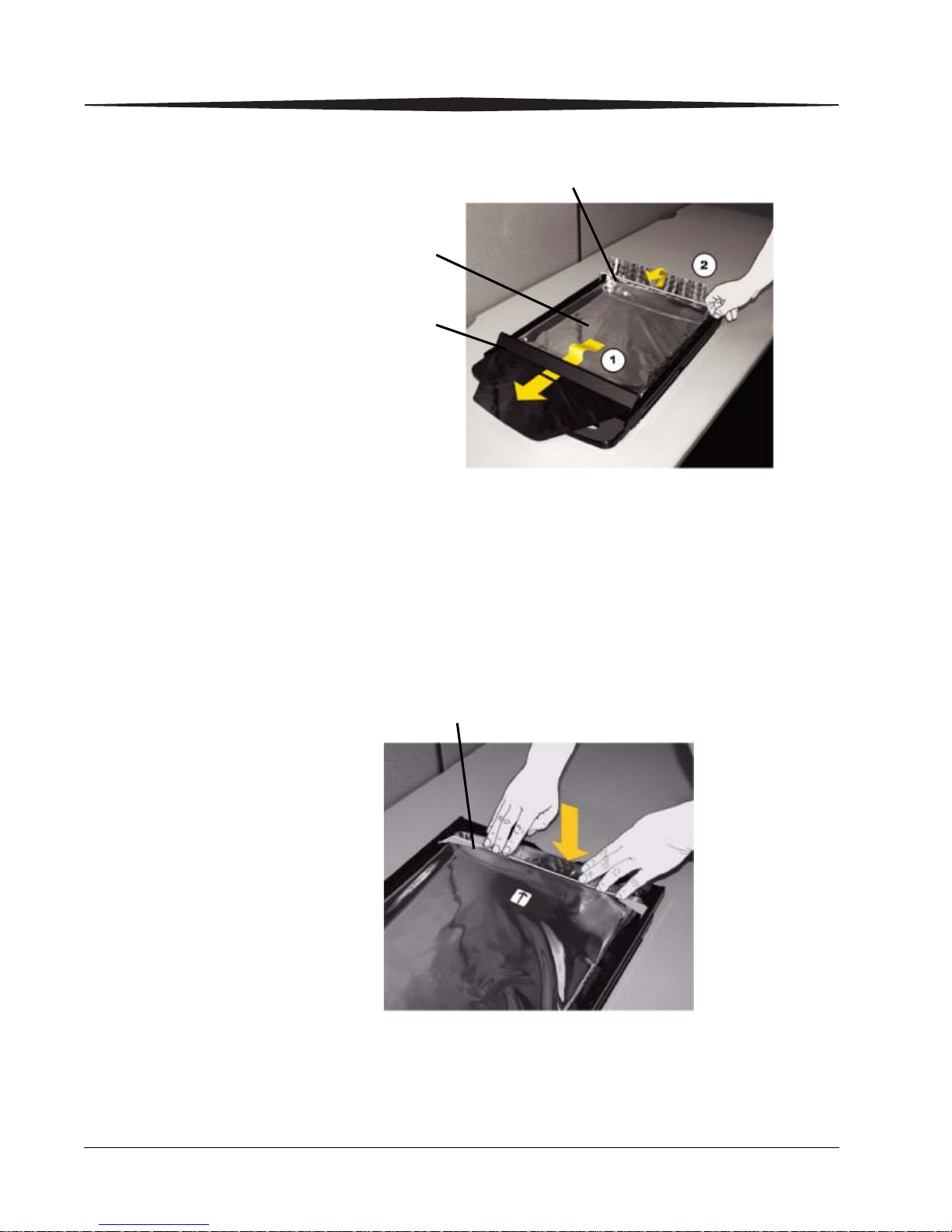

Page 18

Using and Maintaining the Imager

Bag holder

Diverter

Film

package

Bag holder

4. Pull the diverter (plastic bar) and bag holder (silver bar) into the up

position.

5. Press the new film package down in the tray with the label facing up.

6. Pull the front flap of the film package forward, and place it under the

diverter (1).

7. Set the back end of the film package under the bag holder (2).

8. Press down firmly using both hands so the film package sits flat

against the bottom of the tray.

9. Swing the bag holder of the film tray back in place.

2-8 2G0733 2011-09-09

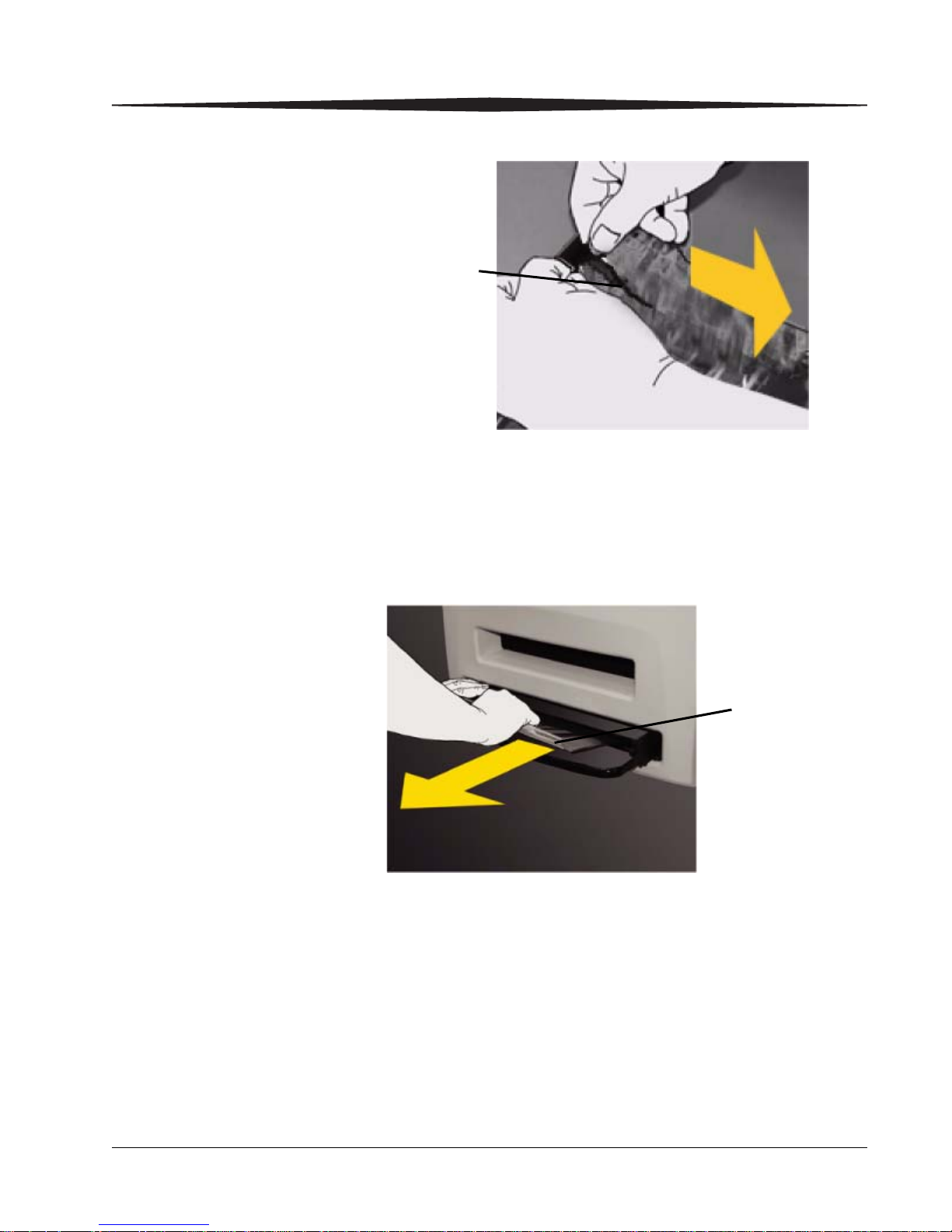

Page 19

Using and Maintaining the Imager

Tear strip

Plastic bag

10. Remove the tear strip from the plastic bag.

11. Swing the diverter of the film tray back in place.

IMPORTANT:Do not install the film saver onto the film tray.

12. Slide the tray back into the imager slot.

13. To remove the plastic bag so the imager can access the film, pull the

plastic bag tail firmly and smoothly. The entire film bag will slide

out.

2011-09-09 2G0733 2-9

Page 20

Using and Maintaining the Imager

H221_0002BC

Inserting the Film

Saver and Removing

the Film Tray

A film saver must be inserted into a film tray before:

• The hood is opened.

• Any panel on the imager is removed.

• Film tray with film in it is removed.

1. Insert the film saver as shown below.

2. If the film tray has not been unlocked, press the unlock button on the

local panel.

NOTE: The film tray must be removed within 30 seconds after pressing

the unlock button. Otherwise, the film tray will re-lock

automatically.

3. Remove the film tray as shown below.

Removing Print Jobs

From the Unprintable

Jobs Queue

Inserting the Film Saver

NOTE: The film saver can be stored under the film tray until required.

When there are jobs in the unprintable jobs queue that can not be printed,

condition code 20703 and an icon show on the display screen. To remove

these jobs from the print queue, do the following.

1. Press and hold the Menu Selection button for 5 seconds. Release the

button and the Test Print Menu displays.

2. Press and release the Menu Selection button again to display the Error

Reset Menu.

3. Check that the 20703 error is highlighted on the display screen, then

press the Enter button.

The icon and condition code are cleared, and the display screen returns to

normal operation.

2-10 2G0733 2011-09-09

Page 21

Using and Maintaining the Imager

Calibration Prints imager calibration is performed by printing a calibration print. A calibration

print has a step wedge pattern with a series of 26 stripes of increasing

optical density. The only purpose of a calibration print is to calibrate the

imager. The imager prints a calibration print when:

• A manual film calibration is requested.

• A film tray containing film with new sensitometric characteristics

(speed, contrast) is loaded.

• A film tray for which a current calibration is not stored is inserted into

the imager.

You can discard all calibration prints.

Running a

Calibration Print

You may occasionally have to request that the imager print a calibration

print to calibrate the imager. You may be asked to do this if you call for

service. You should also run a calibration print if a "Not Calibrated" status

message appears on the Web Portal Home screen, or if a calibration error

code (2x-624, 2x-631, or 2x-632) appears on the display screen.

To request a calibration print from the local panel, press the calibration

button for the applicable film tray (see “Local Panel / Display Screen”).

To request a calibration print from the Web Portal:

1. Access the Web Portal (see “Accessing the Web Portal”).

2. Click Calibrate, for the applicable film tray.

Calibration Failure Occasionally, the imager may fail calibration and will notify the operator

with an error code on the display screen and a code and message on the Web

Portal. The most common cause is a film-related problem. Depending on the

cause, the imager may be able to continue operating but would display the

manual mode icon.

2011-09-09 2G0733 2-11

Page 22

Using and Maintaining the Imager

Working with Quality

Test Prints

Requesting a Test Print

at the Imager

Requesting a Test Print

at the Web Portal

The imager can print an internally generated density test print with a

SMPTE pattern. Density test prints can be used as a quality assurance tool to

verify the uniformity of films printed by the imager. The 5850 Laser Imager

provides additional test images that can be used for mammography quality

control.

You can request a test print at the imager or from the Web Portal.

1. At the imager, press the Setup button for approximately 5 seconds.

The Test Print menu displays.

2. Select the desired test print, and press the Enter button to initiate the

test print.

3. Select Cancel to exit from the Test Print menu.

1. Access the Web Portal (see “Accessing the Web Portal”).

2. Select Diagnostics>Test Print.

3. For “Select Test,” use the drop-down list to select the desired test. For

example, for the SMPTE pattern, select Density Test.

4. Enter an optional label to be printed on the test film.

5. Enter the desired density (0.1 to 3.2).

6. Use the drop-down list to select the film tray.

7. Select the number of copies to be printed.

8. Click Run.

2-12 2G0733 2011-09-09

Page 23

Operator Maintenance

CAUTION:

Hood

Front panel

Charcoal filter

Changing the

Charcoal Filter

In the U.S., exhausted charcoal filters are considered to be

non-hazardous waste according to the U.S . Envi ro nme nta l

Protection Agency Resource Conservation Recovery Act (RCRA).

Municipality owned and licensed solid waste management facilities

are an appropriate disposal option. Contact your local or state

solid waste authorities to determine if additional disposal

requirements apply. In other regions, contact local or regional

solid waste authorities for proper disposal guidance.

The preventive maintenance filter must be changed every 7,500 films. When

it is time to replace the filter, condition code 20449 and an icon show on the

display screen.

1. Remove the film trays (see “Inserting the Film Saver and Removing

the Film Tray”).

2. Turn the imager OFF (O).

Using and Maintaining the Imager

2011-09-09 2G0733 2-13

Page 24

Using and Maintaining the Imager

3. Raise the hood.

4. Pull the front panel forward.

5. Remove the charcoal filter by lifting it up and pulling it forward.

6. Install a new charcoal filter.

7. Close the front panel.

8. Close the hood.

9. Install the film trays.

10. Remove the film savers.

11. Turn the imager ON (|).

12. Wait for the imager to complete the start-up routine.

13. Clear the preventive maintenance icon and condition code.

a. Press and hold the Menu Selection button for five seconds.

Release the button, and the Test Print menu displays.

b. Press and release the Menu Selection button again to display the

Error Reset menu.

c. Check that the 20449 error is highlighted on the display screen,

and press the Enter button.

The icon and condition code are cleared, and the display screen

returns to normal operation.

2-14 2G0733 2011-09-09

Page 25

3 Troubleshooting

Error and Alarm Indications

The imager can detect errors and other conditions that require operator

action. These errors or abnormal conditions are reported on the display

screen and on the Web Portal in the form of condition codes and

messages.

DICOM Printer Status Messages

In response to a DICOM printer N-GET status request from a modality,

a printer status message and a printer status message are returned to the

requesting SCU. Every error has an associated printer status info

message. If more than one error exists when a printer N-GET request is

received, a status message is sent in response according to an

established priority. The following table shows the DICOM printer

status and printer status.

Table 3-1: DICOM Printer Status Messages

Printer

Status

FAILURE ELEC DOWN

Printer Status Printer Status Printer Status

PRINTER DOWN

PROC DOWN

WARNING BAD SUPPLY MGZ

CALIBRATION ERR

CHECK PRINTER

COVER OPEN

EMPTY MEDIASZ

MEDIATP

FILM JAM

FILM TRANS ERR

PRINTER BUSY

PROC INIT

PRINTER INIT

PRINTER OFFLINE

2011-09-09 2G0733 3-1

Page 26

Troubleshooting

Printer Status Messages

The following table describes how the local panel and Web Portal indicate

printer status to the user.

Table 3-2: Printer Status Messages

Printer

Status

Any Film

Supply Open

Door Open • Ready LED off

Failed • Ready LED off

Imager

Unlock

Requested

Offline • Ready LED off

Local Panel

• Ready LED off

• Display is blanked

for open tray

• Status code: 20702

• Attention LED on

• Status code: 20701

• Error LED on

• Error code shown

• Ready LED off

• Unlock LED

flashing for the

requested film tray

• Attention LED on

• Status code: 20704

Web Portal

Display

Not Ready WARNING /

Hood Open WARNING /

Failed See Condition

Not Ready n/a The printer will complete

Printing

Disabled

DICOM Status Description

At least one of the film

COVER OPEN

COVER OPEN

Code

WARNING /

PRINTER

OFFLINE

trays is not inserted and

latched into place.

The imager hood is open or

one of the side panels may

be off. The imager is not

“Ready.”

An error has occurred that

prevents printing.

any prints in progress prior

to unlocking a film tray for

removal.

The printer has been

disabled and does not have

a network connection.

Printing • Ready LED

flashing

Ready • Ready LED on

display shows

count, type, and

size for each film

tray

Self-test • Ready LED off

• the Display shows

the Carestream logo

Service

Mode

3-2 2G0733 2011-09-09

• Ready LED off

• Attention LED on

Status code: 20700

Printing NORMAL The imager is currently

printing films.

Ready NORMAL The imager is online and

the Processor has reached

operating temperature.

Self-test WARNING /

PRINTER INIT

Service Mode WARNING /

PRINTER

OFFLINE

This occurs when power is

first applied to the imager.

The service switch is

enabled. The imager is not

“Ready.”

Page 27

Table 3-2: Printer Status Messages (Continued)

Troubleshooting

Printer

Status

Warming • Ready LED off

Local Panel

• Warming LED on

• Number of minutes

until warm shown

Web Portal

Display

Warming=xx WARNING /

Film Tray Status Messages

The following table describes how the local panel and Web Portal indicate

film tray status to the user.

Table 3-3: Film Tray Status Messages

Film Tray

State

Failed • Attention LED on

• Status code: 21000 (upper),

23000 (lower)

• Unlock button LED on

• Cal button LED flashing

• Tray info area displays icon

for this state

Local Panel

DICOM Status Description

The Processor is warming

PROC INIT

Web Portal

Display

Failed An error has occurred that

up and will not be ready to

print for xx minutes.

Description

affects normal operation. This

film tray is currently not useable

and requires user intervention.

Calibrating • Attention LED on

• Status code: 21001 (upper),

23001 (lower)

• Unlock button LED on

• Cal button LED off

• Tray info area displays film

type, size, and count

Film Covered • Attention LED on

• Status code: 21003 (upper),

23003 (lower)

Film Tray

Empty

• Unlock button LED on

• Cal button LED off

• Tray info area displays film

type, size, and count

Calibrating A calibration is in progress for

this film tray.

Film is Covered Either the film bag or film saver

is still on and must be removed

before the film tray can be used.

Empty and/or

sheet count of 0

A film tray is inserted, but the

sheet count is 0.

2011-09-09 2G0733 3-3

Page 28

Troubleshooting

Table 3-3: Film Tray Status Messages (Continued)

Film Tray

State

Local Panel

Manual Mode • Attention LED on

• Status code: 21002 (upper),

23002 (lower)

• Unlock button LED on

• Cal button LED off

• Tray info area displays film

type, size, and count

No Film Tray • Unlock button LED on

• Cal button LED off

• Tray info area displays icon

for this state

Ready • Unlock button LED on

• Cal button LED off

• Tray info area displays film

type, size, and count

Requires

Calibration

• Attention LED on

• Status code: 21001 (upper),

23001 (lower)

• Unlock button LED on

• Cal button LED off

• Tray info area displays film

type, size, and count

Web Portal

Display

Description

The film in this film tray does

not meet AIQC standards.

However, the user has selected

“Manual Mode,” so it will be

used as if it is “Ready.”

Invalid Film Tray There is a film tray in the film

supply but it does not contain a

liner/RF tag.

Normal Tray Info The film tray is ready for use.

Requires

Calibration

The film tray must be calibrated

before the imager can print from

it.

Supply Open • Ready LED off

• Unlock button LED off

• Cal button LED off

No Film Tray There is no film tray inserted.

Both trays must be inserted in

order for the imager to operate.

• Tray info area blank

Unlock Pending • Ready LED off (or blinking if

active print)

• Cal LED off (or blinking if

active calibration)

• Unlock button LED blinking

• If the film tray requires a

cover, the status code is:

Status code: 21004 (upper),

23004 (lower)

Unlock

Requested

An “Unlock” has been requested

but has not started because of

one of the following:

• films are still moving through

the imager

• the film tray contains film but

has not been covered with a

film saver

Once the conditions for unlock

is met, film tray can be removed.

3-4 2G0733 2011-09-09

Page 29

Job Manager Status Messages

The following table describes how the local panel and Web Portal indicate

job status to the user.

Table 3-4: Job Manager Status Messages

Troubleshooting

Job Manager

Status

Active n/a Shows how many

No Media • Attention LED on

Offline • Ready LED on

Unprintable

jobs queued

Display Screen

• Required media

size is displayed

• Status code:

20704

• Status code:

20703

Web Portal

Display

jobs having this

status are queued

Shows how many

jobs having this

status are queued

Imager Offline The imager will not accept any DICOM job

Shows how many

jobs having this

status are queued

Description

The imager is accepting DICOM job

requests and film is available for all current

jobs.

The imager is accepting DICOM job

requests but film of the correct size and type

is not available for at least one current job.

requests.

The imager has queued jobs that can never

be printed and should be deleted by the user.

2011-09-09 2G0733 3-5

Page 30

Troubleshooting

Condition Codes

Condition codes are shown on the display screen in the order in which they

are generated. If there is more than one code associated with the current

condition of the imager, the first code is shown on the display screen for six

seconds, while other codes in the list are displayed for three seconds as the

list is cycled. The LEDs on the left side of the local panel will be on

whenever there is a condition code of that type.

Table 3-5: Condition Codes

Code Web Portal Message User Action

01004 MIM Core: Internal Software

Error

04200 MIM Core: Disk Full 1. Delete jobs in the "Unprintable jobs" queue.

06400 MIM Core: Image Page Error 1. Delete jobs in the "Unprintable jobs" queue.

06410 MIM Core: Image Rendering

Error

06411 MIM Core: Image Data Error 1. Delete jobs in the "Unprintable jobs" queue.

06420 MIM Core: Internal Software

Error

1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

2. Load requested film type for jobs in the "Waiting

for media" queue.

3. If the error persists, call for service.

2. Resend the print job from the image source.

3. If the error persists, call for service.

1. Delete jobs in the "Unprintable jobs" queue.

2. Resend the print job from the image source.

3. If the error persists, call for service.

2. Resend the print job from the image source.

3. If the error persists, call for service.

1. Delete jobs in the "Unprintable jobs" queue.

2. Resend the print job from the image source.

3. If the error persists, call for service.

06430 MIM Core: Internal Software

Error

10001 MIS: Internal Software Error 1. Shut down the imager, then start the imager.

3-6 2G0733 2011-09-09

1. Delete jobs in the "Unprintable jobs" queue.

2. Resend the print job from the image source.

3. If the error persists, call for service.

2. If the error persists, call for service.

Page 31

Troubleshooting

Table 3-5: Condition Codes (Continued)

Code Web Portal Message User Action

10003 MIS: Image Buffer Error 1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

10015 MIS: Database Error 1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

10910 MIS: MCS Communication

Failure

1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

20004 USB Failure 1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

20154 MCS: Internal Communications

Failure

20155 Incompatible MCS Printer

Configuration for hardware

20156 Incompatible Software Versions

Installed

20209 Laser Imager Opened During

Self Test

1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

1. Close the hood or the open cover.

2. Shut down the imager, then start the imager.

3. If the error persists, call for service.

20449 none 1. Change the charcoal filter.

2. Press and hold the Menu Selection button for five

seconds. Release the button and the Test Print

menu displays.

3. Press and release the Menu Selection button again

to display the Error Reset menu.

4. Check that the 20449 error is highlighted on the

display screen, and press the Enter button.

The icon and condition code are cleared, and the

display screen returns to normal operation.

20701 none 1. Close the hood or the open cover.

20702 none 1. Install the missing film tray.

2011-09-09 2G0733 3-7

Page 32

Troubleshooting

Table 3-5: Condition Codes (Continued)

Code Web Portal Message User Action

20703 none 1. Press and hold the Menu Selection button for five

seconds.

2. Press and release the Menu Selection button again

to display the Error Reset menu. Delete the jobs in

the Unprintable Jobs Queue.

20705 none 1. Press and hold the Menu Selection button for five

seconds. Release the button and the Test Print

Menu displays.

2. Press and release the Menu Selection button again

to display the Error Reset Menu.

3. Check that the 20703 error is highlighted on the

display screen, then press the Enter button.

20706 none 1. Turn the imager power OFF.

20915 Internal Image Data Transfer

Failed

20919 Internal Image Data Render

Failed

21000 or

none None. The film tray requires attention due to an error.

23000

21001 or

none None. The film tray needs calibration before it can be

23001

21002 or

none None. The film tray is operating in “manual mode,”

23002

21003 or

none Remove the film saver or the film bag.

23003

21004 or

none Install a film saver before removing the film tray.

23004

21116 or

23116

Film Jam in Area 1: xxxxx

Supply

1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

The specific error is reflected by a separate code.

used.

which means the image quality is not within the normal

range.

See “Film Jam - Code 2x-116”.

21118 or

23118

xxxxx Supply: Internal

Hardware Failure

3-8 2G0733 2011-09-09

1. Cover the film tray with the film saver. Remove the

tray from the imager.

2. Re-insert the film tray and remove the film saver.

3. If the error persists, call for service.

Page 33

Table 3-5: Condition Codes (Continued)

Code Web Portal Message User Action

Troubleshooting

21119 or

23119

21122 or

23122

21125 or

23125

21126 or

23126

xxxxx Supply: Internal

Hardware Failure

xxxxx Supply: Internal

Hardware Failure

xxxxx Supply: Internal

Hardware Failure

Film Jam in Area 1: xxxxx

Supply

1. Cover the film tray with the film saver. Remove the

tray from the imager.

2. Re-insert the film tray and remove the film saver.

3. If the error persists, call for service.

1. Cover the film tray with the film saver. Remove the

tray from the imager.

2. Take the film tray to a dark room and remove the

film saver. Verify that the film is lying flat. Replace

the film saver.

3. Re-insert the film tray and remove the film saver.

4. If this error repeats, try a new film pack.

5. If the error persists, call for service.

1. Cover the film tray with the film saver. Remove the

tray from the imager.

2. Re-insert the film tray and remove the film saver.

3. If the error persists, call for service.

See “Film Jam - Code 2x126”.

21130 or

23130

21131 or

23131

21139 or

23139

21145 or

23145

xxxxx Supply: Internal

Hardware Failure

xxxxx Supply: Internal

Hardware Failure

xxxxx Supply: Unable to

Identify Film Pack

xxxxx Supply: Unsupported

Film Type

1. Cover the film tray with the film saver. Remove the

tray from the imager.

2. Re-insert the film tray and remove the film saver.

3. If the error persists, call for service.

1. Cover the film tray with the film saver. Remove the

tray from the imager.

2. Re-insert the film tray and remove the film saver.

3. If the error repeats, shut down the imager, then st art

the imager.

4. If the error persists, call for service.

1. Try a different film pack.

2. If the error persists, call for service.

1. The imager has not been configured to use this film

type.

2. Try a different film type or reconfigure the imager.

3. If the error persists, call for service.

2011-09-09 2G0733 3-9

Page 34

Troubleshooting

Table 3-5: Condition Codes (Continued)

Code Web Portal Message User Action

21146 or

23146

21624 or

23624

21631 or

23631

21632 or

23632

xxxxx Supply: Unsupported

Film Size

xxxxx Supply: Film Calibration

Failure

xxxxx Supply: Film Calibration

Failure - Dmin Outside Target

xxxxx Supply: Film Calibration

Failure - Dmax Outside Ta rget

1. The imager has not been configured to use this film

size.

2. Try a different film size or reconfigure the imager.

3. If the error persists, call for service.

1. Try calibration again, or try a different film pack.

2. If the error repeats, shut down the imager, then start

the imager.

3. If the error persists, call for service.

1. The minimum density of the film is too high.

Calibration results for this film are outside the

normal range, but will still be used.

2. If you do not wish to use these calibration results,

perform a new calibration on this film or try

another film pack.

1. The maximum density of the film is lower than the

target density. Calibration results for this film are

outside the normal range, but will still be used.

2. If you do not wish to use these calibration results,

perform a new calibration on this film or try

another film pack.

25922 RF Tag: Internal Diagnostic

Failure

25931 RF Tag: Internal

Communications Failure

1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

26325 Film Jam in Area 2 See “Film Jam - Code 26325”.

26326 Film Jam in Area 2 or 3 See “Film Jam - Codes 26326 or 26543”.

26543 Film Jam in Area 3 See “Film Jam - Codes 26326 or 26543”.

26544 Film Jam in Area 3 See “Film Jam - Code 26544”.

26931 Film Transport: Internal

Communications Failure

26933 Film Transport: Internal

Communications Failure

1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

3-10 2G0733 2011-09-09

Page 35

Table 3-5: Condition Codes (Continued)

Code Web Portal Message User Action

Troubleshooting

27123 Optics: Internal Hardware

Failure

1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

27601 Optics: Calibration Failed 1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

27604 Optics: Calibration Failed 1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

27607 Optics: Calibration Failed 1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

27611 Optics: Internal Hardware

Failure

27646 Optics: Internal Hardware

Failure

27650 Optics: Internal Hardware

Failure

27931 Optics: Internal Communications

Failure

1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

28154 Processor: Internal

Communications Failure

28155 Processor: Internal

Communications Failure

28501 Processor: Internal Hardware

Failure

1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

28509 Processor Warm-up Failure 1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

28510 Processor: Internal Hardware

Failure

1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

28551 Processor Heater Failure 1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

28554 Processor Over Temperature 1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

2011-09-09 2G0733 3-11

Page 36

Troubleshooting

Table 3-5: Condition Codes (Continued)

Code Web Portal Message User Action

28931 Processor: Internal

Communications Failure

29154 Densitometer: Internal

Communications Failure

29924 Densitometer: Internal

Diagnostic Failure

29925 Densitometer: Internal

Diagnostic Failure

29926 Densitometer: Internal

Diagnostic Failure

29927 Densitometer: Internal

Diagnostic Failure

29931 Densitometer: Internal

Communications Failure

36931 Local Panel: Internal

Communications Failure

1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

36935 Local Panel: No

Communications from MCS

1. Shut down the imager, then start the imager.

2. If the error persists, call for service.

3-12 2G0733 2011-09-09

Page 37

Clearing Film Jams

CAUTION:

Troubleshooting

Shutting off power to clear a film jam is not required.

3

2

1

Jam Areas and Film Path

1

2011-09-09 2G0733 3-13

Page 38

Troubleshooting

Film tray slots

Film Jam - Code

2x-116

1. Remove the film trays (see “Inserting the Film Saver and Removing

the Film Tray”).

2. Remove any misplaced films from Area 1. This area can be accessed

through the film trays slots.

NOTE: If the film is not accessible from the front of the imager, continue

with Step 3.

3-14 2G0733 2011-09-09

Page 39

Troubleshooting

Hood

Left panel

2 thumb screws

3. Open the hood.

4. Loosen the 2 thumb screws and remove the left panel.

2011-09-09 2G0733 3-15

Page 40

Troubleshooting

Pickup access areas

5. Remove any misplaced films seen in the pickup access areas.

6. If Area 1 did not contain misplaced films, take the film trays to a dark

room and remove the film saver. Remove any misplaced films and

cover the tray with the film saver.

7. Set the left panel in place and tighten the 2 thumb screws.

8. Close the hood.

3-16 2G0733 2011-09-09

Page 41

Troubleshooting

Film tray slots

Film Jam - Code

2x126

1. Remove the film trays (see “Inserting the Film Saver and Removing

the Film Tray”).

2. Remove any misplaced films from Area 1. This area can be accessed

through the film trays slots.

3. If Area 1 did not contain misplaced films, take the film trays to a dark

room and remove the film saver. Remove any misplaced films and

replace the film saver.

4. If misplaced films were not found in the tray, open and close the

imager hood. Wait two minutes for misplaced films to emerge from

the imager.

If misplaced films were never located and this error recurs on the next

film, continue with Step 5.

2011-09-09 2G0733 3-17

Page 42

Troubleshooting

Hood

Left panel

2 thumb screws

Pickup access areas

5. Open the hood.

6. Loosen the 2 thumb screws and remove the left panel.

3-18 2G0733 2011-09-09

Page 43

Troubleshooting

CAUTION:

Hood

Drum cover latches

Drum cover

7. Remove any misplaced films seen in the pickup access areas.

8. Set the left panel in place and tighten the 2 thumb screws.

9. Close the hood.

Film Jam - Code

26325

Film Jam - Codes

26326 or 26543

IMPORTANT: If this error occurred at the same time as 2x-126, follow the

instructions for “Film Jam - Code 2x126”.

1. If this error occurred alone, open and close the hood to clear the error.

2. If this error repeats, restart the imager.

2011-09-09 2G0733 3-19

1. Open the hood.

2. Remove any misplaced films.

Hot surface.

3. Undo the drum cover latches and lift the drum cover.

Page 44

Troubleshooting

Hood

Left panel

2 thumb screws

4. Carefully remove any films found in the drum area.

5. Close the drum cover and secure the cover latches.

If the film was not found in the drum area, continue with Step 6.

6. Open the hood.

7. Loosen the 2 thumb screws and remove the left panel.

3-20 2G0733 2011-09-09

Page 45

Troubleshooting

Film advance knob

Film Jam - Code

26544

8. Use the manual advance knob to move the film through the processor.

9. Set the left panel in place and tighten the 2 thumb screws.

10. Close the hood.

If film was not previously removed, the misplaced films will emerge

from the imager within two minutes.

1. Remove any films jammed in the imager film exit.

2. Open the hood and remove any films in Area 2.

3. Close the hood.

2011-09-09 2G0733 3-21

Page 46

Troubleshooting

Calling for Support

If you cannot correct a condition and need help, call for support. Have the

following information ready when you call:

• Model Number

• Serial Number or K-Number

• Condition code and message if they are shown on the display screen

and Web Portal

3-22 2G0733 2011-09-09

Page 47

4 Film Technical Information

0 0.5 1 1.5 2 2.5 3

0

0.5

1

1.5

2

2.5

3

3.5

General Description

This section describes the characteristics of laser imaging film, not the

operation of the laser imager. The laser imaging film is a

high-resolution, infrared-sensitive, photothermo graphic film designed

specifically for the laser imager. The laser imaging film is packaged in

daylight-load packages and is available in blue, clear, and

mammography film types.

Spectral Sensitivity The laser imaging film is infrared sensitive and has been sensitized to

the infrared laser diode of the imager. When handled according to

instructions on the daylight-load film package, safelights are not

needed. If you remove undeveloped film from the daylight-load

package, you will need a darkroom setting and a green safelight.

Image Quality The laser imaging film delivers diagnostic-quality, continuous-tone

2011-09-09 2G0733 4-1

Relative Log Exposure (Example)

images along with sharp alphanumerics and optimum contrast. This

high-quality, silver-based film provides health care providers with the

same diagnostic information they are accustomed to

viewing—including the spatial resolution, contrast, and gray levels.

Because it is a totally dry imaging process, there is no image quality

variability due to wet chemistry.

Page 48

Film Technical Information

Environmental

Impact

Wet (Silver Halide) Film Dry Film

Developer Fixer Wash Film Film

Product Regulations

OSHA MSDS Required Required Not required Not required Provided

DOT Hazardous Hazardous No limits No limits No limits

Use permits Local Local None None None

Disposal* Regulations

EPA Hazardous Hazardous No No No

DOT Hazardous Hazardous No No No

NOTE: There is no SUPERFUND liability with dry laser imaging film.

* State and local laws vary. Consult appropriate regulations or authorities prior to disposal.

Storing and Handling

Undeveloped Film

Tests show that the laser imaging film is not considered hazardous to the

environment. As a result, you can develop, recycle, and dispose of film with

less impact on the environment than if you were using wet-developed silver

halide films.

L

aser Imaging Film

US Environmental Regulations Comparison

To achieve consistent results up to the expiration date indicated on the film

package, the laser imaging film must be stored in a cool, dry place, 5–25 °C

(41–77 °F), and protected from radiation and chemistry fumes.

Handling Developed

Film

The film can withstand short-term temperature spikes, up to 35 °C (95 °F),

for several hours during transit without any significant effect on film quality

or performance. Transit temperatures above 35 °C (95 °F) will gradually

diminish shelf life.

Handling the laser imaging film requires reasonable care. Spills, humidity,

and other moisture typically have no significant effect on developed films.

However, prolonged exposure to intense light or excessive heat,

above 54 °C (130 °F), for more than three hours may cause some gradual

darkening of images. Leaving films in vehicles in hot climates for extended

periods of time is not recommended.

For best results, store film in sleeves when not being reviewed. The laser

imaging film can be left on a light box for more than 24 hours. In extreme

cases in which light boxes are exceptionally hot, above 49 °C (120° F),

remove the film from them prior to eight hours of continuous exposure.

Take care when using spotlight viewing for more than 30 seconds because

temperatures near the light source may exceed 82 °C (180 °F). Use in slide

projectors is not recommended due to the high temperatures generally found

in these devices.

With dry technology, a small amount of final development occurs when the

film exits the Laser Imager and is initially exposed to ambient or view-box

4-2 2G0733 2011-09-09

Page 49

Film Technical Information

lighting. This is virtually undetectable and has no effect on image quality

(typically 0.02 change in density). This small density increase is uniform

and permanent upon full exposure of the film under normal handling

conditions (room light or view box).

Archiving Developed

Film

The laser imaging film has been tested and can be archived for more than

100 years when stored at American National Standards Institute (ANSI)

recommended storage conditions at 25 °C (77 °F). Developed films may be

stored at higher temperatures; however, that may reduce the number of years

the film can be stored. For example, storing films at a constant elevated

temperature of 32 °C (90 °F) may reduce archive capability to 30 years.

Exposing to Moisture The laser imaging films typically withstand humidity, spills and other forms

of water without any significant effect on image quality or film integrity. If

needed, film can be cleaned with a clean, damp cloth.

Dissipating Odor Dry technology eliminates virtually all unpleasant odors. While some

low-level odors are produced during the development process, they pose no

known adverse health risks. Processing odor levels are furthe r reduced by a

non-hazardous, recyclable filter in the Laser Imager. This filter traps most

low-level odors and prevents them from dissipating into the work

environment. To help maintain optimum performance, the filter requires

periodic replacement. The laser imager requires no special venting.

Dissipating Heat The laser imager uses controlled heat to develop the laser imaging film. The

heat has virtually no effect on the air temperature of the work area. The

amount of heat dissipated into an area during a day is typically less than the

heat generated by two to four 100 W light bulbs.

Recycling Film According to the Environmental Protection Agency (EPA) standards, the

laser imaging film is not considered hazardous and requires no special

disposal procedures. However, the film does contain silver and polyester

that may be recovered by using one of several recycling processes.

2011-09-09 2G0733 4-3

Page 50

Page 51

5 Specifications

8cm

(3 in.)

13 cm

(5 in.)

66 cm

(26 in.)

62 cm

(24 in.)

76 cm

(30 in.)

141 cm

(55 in.)

8cm

(3 in.)

62 cm

(24 in.)

Location

Equipment

Specifications

Height 62 cm (24 in.) 95 cm (37 in.)

Width 62 cm (24 in.) 81 cm (32 in.)

Unpacked Packed

Operating Space

Requirements

Depth 66 cm (26 in.) without film trays

76 cm (30 in.) with film trays

Weight 70 kg (155 lb) 147.4 kg (325.0 lb)

The following is the minimum space required around the imager to

perform normal operator functions. Service functions will require more

space.

106 cm (42 in.)

2011-09-09 2G0733 5-1

Page 52

Specifications

CAUTION:

1.83 m (6.00 ft)

Other Location

Considerations

Additional factors that influence where the imager is located include

proximity to patients, flammable materials, liquids, and other equipment.

This equipment is not contained in a sealed cabinet. Do not use this

equipment in locations where it can come in contact with liquids,

including body fluids.

IMPORTANT:

• This equipment is intended to connect to other medical devices. Only

an authorized service provider may install this equipment.

• Do not locate the imager within 2.0 m (6.6 ft) of where a cell phone

will be used, even if the cell phone is separated from the equipment

by a wall.

• Do not locate the imager within 4.0 m (13.1 ft) of a microwave oven.

Electromagnetic radiation from a microwave oven is only an issue if,

after the oven door is closed and latched, the seal does not maintain

an electromagnetic tight fit between the oven door and the oven main

housing. Determining if the seal has an electromagnetic tight fit

requires special detection equipment.

• Do not locate the imager in the presence of flammable anesthetics,

oxygen, or nitrous oxide. The imager does not have a gas-sealed

electronics enclosure and could ignite any flammable or explosive

gases present in the imager’s environment.

• Do not locate the imager in close contact with MRI devices due to

possible high magnetic fields near an MRI unit. The magnetic field in

the area where the imager is installed must be less than 50 Gauss.

5-2 2G0733 2011-09-09

• Do not locate the imager closer than 1.83 m (6.00 ft) from a patient

bed or chair.

• Do not locate the imager in a room that is in direct sunlight.

• Do not substitute or modify any part of the imager.

Page 53

Specifications

Environmental Requirements

Temperature • Operating: 15–33 °C (59–91 °F)

• Storage: From –40 through 60 °C (From –40 through 140 °F)

Relative Humidity • Operating: 20–80 % RH, noncondensing

• Storage: 10–90 % RH, noncondensing

Altitude 30 m (100 ft) below sea level to 2438 m (8000 ft) above sea level

Surface Condition The surface must be a level (must be level within 1 °) table top or counter

capable of supporting the weight of the imager. For the imager to operate

with no image degradation, surface vibration levels cannot exceed the

following:

2

G

-7

1 x 10

-5

6 x 10

-6

5 x 10

-6

1 x 10

Environmental Effects

• Heat Dissipation: total heat dissipation for the imager is

883 BTU/hour

• Acoustical Noise:

– Less than or equal to 75 dB-A at 1 m during a sound burst of 1 sec

– Less than or equal to 65 dB-A at 1 m during normal operation

– Less than or equal to 50 dB-A at 1 m during idle mode

Laser Specifications

• Wavelength : Minimum 800 nm, nomi nal 810 nm, maximum 820 nm

• Laser Beam Divergence: Maximum 32 degrees, minimum 6.8 degrees

• Laser Maximum Power: 120 mW

/Hz

Freq. Range Direction

1–50 Hz Vertical or horizontal

50–200 Hz Vertical or horizontal

200–650 Hz Vertical or horizontal

650–1000 Hz Vertical or horizontal

or less

2011-09-09 2G0733 5-3

• Radiation class: Class 3B invisible laser radiation

• Type: Diode

Page 54

Specifications

Power Requirements

The imager power supply has an auto-sensing and auto-switching feature for

both voltage and frequency. The current draw is 10 A at 120 V (AC), and

the power consumption is a maximum of 1275 W.

One of the following single-phase, 15 A power sources, with grounding ,

must be provided within 2.5 m (8.2 ft) of the imager.

North America 120 V (AC) From +6 through -10%, 60 Hz ±3 Hz

Europe 240 V (AC) ±10 %, 50 Hz ±3 Hz

China 220 V (AC) ±10 %, 50 Hz ±3 Hz

The wire must be insulation-rated for 600 V. A dedicated line is

recommended.

Network Requirements

Area Power

The imager receives digital images from medical imaging devices

(modalities) over a 10Base-T or 100Base-T Ethernet Network. A single

CAT 5 UTP cable is provided in the accessories package for the imager:

2.0 m (6.6 ft).

Film

Prior to installation, you must order and have on hand the appropriate film.

See the publications cover page for more information on film types that can

be used in this laser imager. Contact your sales representative if you have

questions.

Film Types The imager accommodates the following film types:

• KODAK DRYVIEW DVB Laser Imaging Film

• KODAK DRYVIEW DVC Laser Imaging Film

• KODAK DRYVIEW DVB+ Laser Imaging Film

• KODAK DRYVIEW DVB+ Premium Laser Imaging Film

• 5850 Laser Imager only: KODAK DRYVIEW Mammography

Laser Imaging Film and KODAK DRYVIEW DVM+ Mammography

Laser Imaging Film

NOTE: Not all film types are available in every country.

5-4 2G0733 2011-09-09

Page 55

Specifications

Film Sizes The imager accommodates the following film sizes:

• 20 x 25 cm (8 x 10 in.)

• 25 x 30 cm (10 x 12 in.)

• 28 x 35 cm (11 x 14 in .)

• 35 x 35 cm (14 x 14 in .)

• 35 x 43 cm (14 x 17 in .)

Film Storage Film must be stored at 5–25 °C (41–77 °F) and 85 % RH or less.

2011-09-09 2G0733 5-5

Page 56

Page 57

Glossary

CR Computed Radiography, the process of creating digital radiographic

images.

CT Computed Tomography, the process of creating digital tomographic

images.

Cycle power Cycle power means to shut down and power up the Laser Imager.

DICOM Digital Imaging and Communications in Medicine. A TCP/IP-based

protocol for transmitting and receiving medical imaging and related data

over a network.

Dmax Dmax means maximum density. Dmax is the density of an area on the

film that has received maximum exposure.

Dmin Dmin means minimum density. Dmin is the density of an unex posed

area on the film.

DR Digital Radiography, the process of creating digital radiographic

images.

GSDF Grayscale Standard Display Function.

GSM Gray Scale Manager.

Film model The film model defines the print characteristics for a particular lot of

film.

Key operator The person(s) designated by the department manager to receive

applications training and allowed access to password-protected areas to

make system changes.

LED Light Emitting Diode.

Media An alternate term for film.

Modality Medical equipment that actually generates medical images (for

example, an MRI).

Monotonic Continuously increasing. When a calibration sheet, which consists of

strips of increasing density (Dmin) to maximum density (Dmax), is read

by the densitometer, the density values must be monotonic

(continuously increasing). If they are not, an error message is generated.

MPDB Modality Preferences Database.

MR Magnetic Resonance.

N/A Not Available or Not Applicable.

PLUT Presentation Look-Up Table.

Service image An image used by service personnel for troubleshooting.

Shutdown The process of exiting current tasks and applications and turning the

power OFF.

SMPTE test pattern A Society of Motion Picture and Television Engineering monitor test

pattern that is used for analyzing image-quality problems.

2011-09-09 2G0733 G-1

Page 58

Glossary

Test type The type of test film that will be printed. Two film test types are

available: a density test film (SMPTE pattern) and a calibration film.