Page 1

Document Scanner 7520

A-61140

Part No. 1E8149

User’ s

Guide

Page 2

Safety Information for Installation Instructions for the Kodak Digital

Scienceääää Document Scanner 7520

IMPORTANT: Equipment shall be installed by qualified

personnel.

WARNING: Dangerous voltage. Disconnect the main

power before installation.

CAUTION: Hot surface, avoid contact

ATTENTION: Eviter le contact, pieces brulantes

VORSICHT: Heisse Oberfläche, Berührung verm eiden

ATTENZIONE: Superficie molto calda, evitare il contatto

ATENÇÃ

ÇÃO: Superfície quente. Evite contato

ÇÃÇÃ

PRECAUCIÓÓÓÓN: Superficie caliente. No T ocar

LET OP: Heet oppervlak, contact vermijden

For the Kodak Digital Science Automatic Document Feeder

CAUTION: Moving parts, avoid contact

ATTENTION: Eviter le contact, pieces en mouvement

VORSICHT: Bewegliche Teile, Berührung vermeiden

ATTENZIONE: Parti in movimento, evitare il contatto

ATENÇÃ

ÇÃO: Partes em movimento. Evite contato

ÇÃÇÃ

PRECAUCIÓÓÓÓN: Piezas móviles. No Tocar

LET OP: Bewegende delen, contact vermijden

Page 3

Acoustic Emission

Maschinenlärminformationsverordnung – 3, GSGV

Der arbeitsplatzbezogene Emissionswert beträgt <70 dB( A) .

[ Machine Noise Information Ordinance – 3, G SG V

– The operator-position noise emission value is <70 dB(A) ].

This equipment was designed for connect ion to IT Power Systems.

ElectroMagnetic Compatibility Statements

United States

NOTE: This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to part 15 of the FCC rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses and can

radiate radio frequency energ y and, if not installed and used in accordance with the

instruction manual, may cause harmful int erference to radio communications.

Operation of this equipm ent in a residential area is likely to cause harmful interference

in which case the user will be required to correct the interference at their own expense.

Taiwan

Japan

Page 4

Congratulations!

You have purchased one of the most productive document scanners on

the market today. Your Kodak Digital Science Document Scanner 7520

has a host of timesaving and productivity enhancing featur es t hat not

only help you get the job done faster, but in more comfort. You should

take proper care of your new scanner as described in this manual. This

will ensure you of many hours of trouble-fr ee operation.

Your new document scanner includes a num ber of features (these vary

depending on the configuration you purchased; optional features

include:

• Bar Code Reader

• Document Printer (fr ont and/or rear)

• Patch Reader

• Footswitch

• Workstation

• Endorser

Please contact Kodak or your scanner vendor for more information

about how these options might fit into your operat ion. If these

accessories are installed, become familiar with their oper at ion as they

will add significant value to your scanning environment.

Page 5

1 Introduction

This manual supports the Kodak Digital Science Document Scanner

7520.

The Kodak Digital Science Document Scanner 7520 is a high-speed,

high-resolution rotary production scanner designed for medium- to highvolume digital capture of business documents. The Document Scanner

captures printed characters, handwritten text, and graphics from

documents of various sizes and thicknesses in an electronic format for

indexing and database storage.

This manual explains how to set-up, operate, maintain and troubleshoot

the Document Scanner 7520.

NOTE: Illustrations in this User’s Guide are shown using the semi-

automatic feeder.

Scanner features The Document Scanner 7520 has the following features:

• Scans up to120 landscape or 90 portrait documents (8 ½ x 11-inch

or 216 x 279 mm) per minute at 200 dpi or 80 landscape or 60

portrait documents per minute at 300 dpi.

• Handles documents of up to 2.5 to 20 in. (64 to 508 mm) long,

2.5 to 12 in. (64 to 305 mm) wide, and 0.014 in. (0.36 mm) thick. The

gap release feature allows thicker documents to be scanned.

• Manual or automatic feeding with positive document separation —

documents can be hand-fed one at a time or stacked up to 1.5

inches (38 mm) or approximately 300 documents of 20-pound stock.

• Self-centering feed tray for easier feeding and enhanced productivity.

• Front and rear scanning (known as “duplex”) allows scanning of one

or two sides of a document in a single pass.

• Easy operation — documents enter and exit the scanner in the

same order.

• Easy-to-reach control panel keys.

• A high-speed document transport system with easy access for

cleaning and removal of paper jams.

• Skew detection and correction, auto-cropping and border reduction.

• Multi-feed detection via length monitoring

A-61140 January 2000 1-1

Page 6

• A two-line, status display which displays image addresses, current

application modes and error and operator messages.

• Full programmability of all 18 application modes with override

capability.

• Audible tones for selected functions such as footswitch, patch

reading, etc.

• English or other language message display.

• An adaptable, modular design for easy addition of accessories.

Scanner options The following optional accessories are available for use with your

scanner:

• A choice of feeders — automatic document feeder or a semi-

automatic document feeder.

• Document printer(s) which provide pre-scan (front) and/or post-scan

(rear) capability of printing information such as date and time of

capture, sequence number, document number and a variety of other

options.

• A bar code reader for decoding data in bar code format.

• A patch reader for automatic document level control.

• A footswitch for document level control.

• A universal stand which has a large, built-in workshelf.

1-2 A-61140 January 2000

Page 7

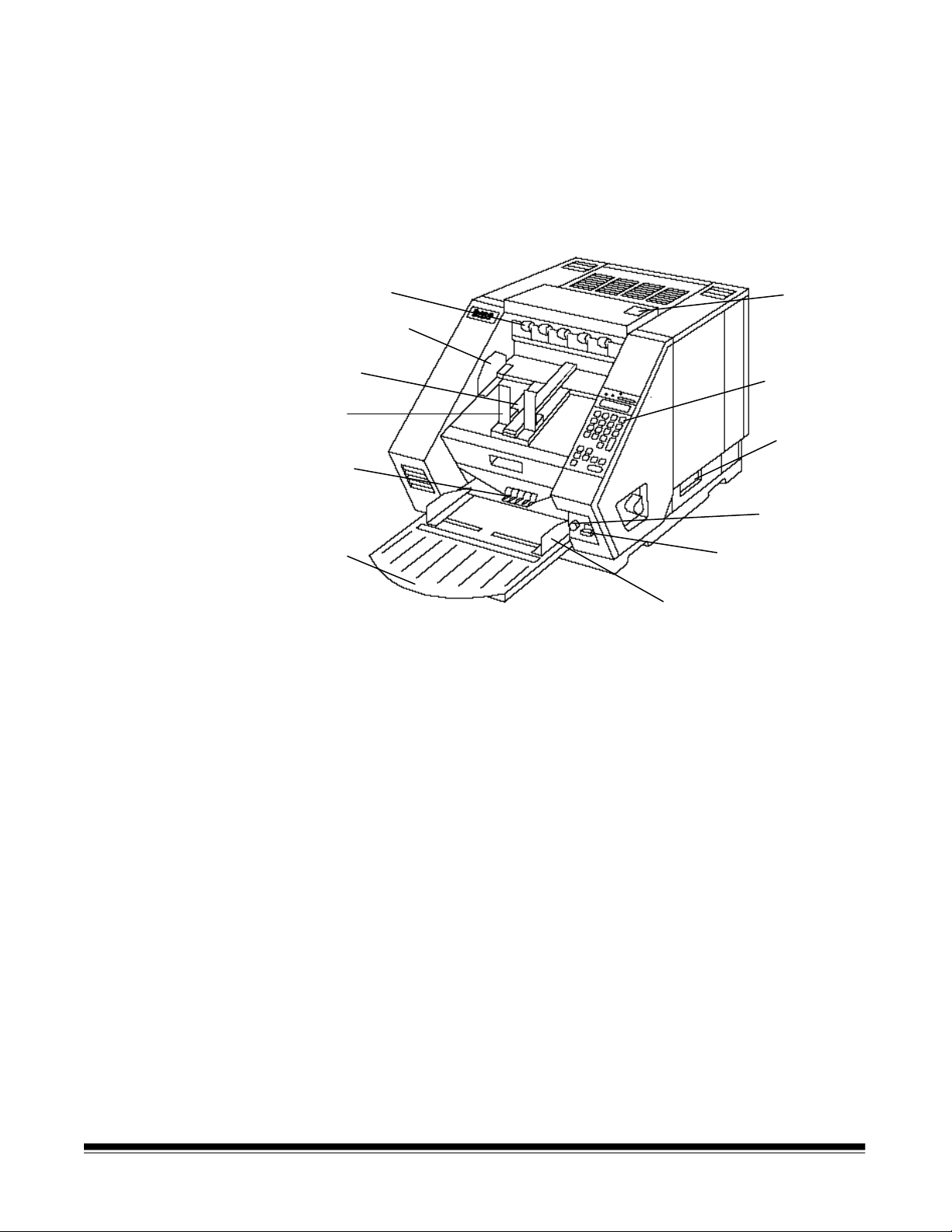

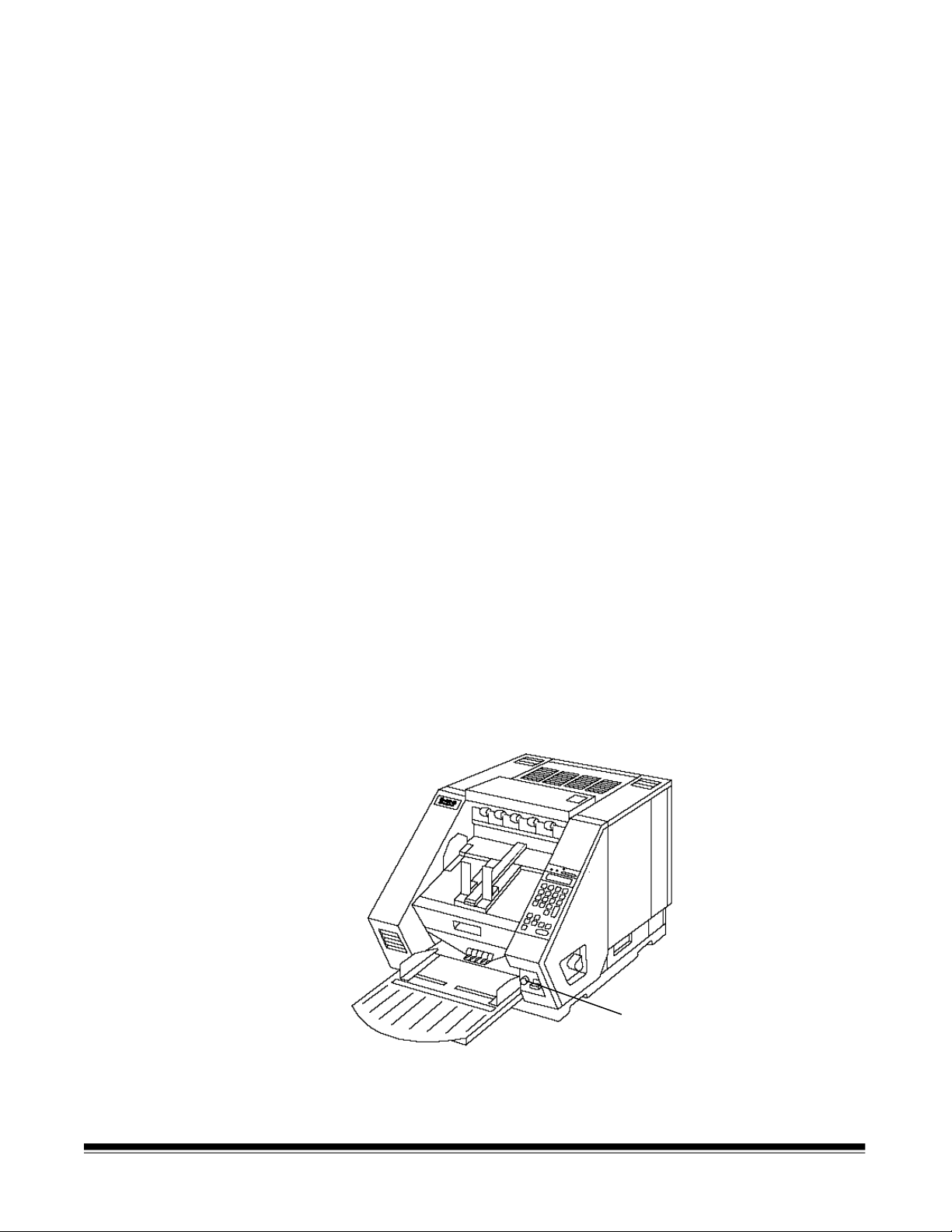

Scanner

handle

components

The following illustrations and descriptions will help you locate and

become familiar with scanner components.

Front View — Document Scanner 7520

(shown with semi-automatic feeder)

Anti-static brush

Exit hopper side guides

Exit hopper

End stop

Feed and separator

rollers

Self-centering

feed tray

Anti-static brush — minimizes the static build-up on the documents

before they are deposited in the exit hopper.

Exit hopper side guides — adjustable to accommodate the size of

your documents to aid in neat and even stacking.

Top cover release

button

Control panel

Side access door

Gap adjustment

knob

Gap release lever

Feed tray side guides

Exit hopper— collects documents after they have been scanned.

End Stop — keeps documents in place as they exit the scanner.

Feed and separator rollers — provides smooth document feeding of

various sizes and textures.

Self-centering feed tray — centers documents in the transport for

reduced skew and cropping control.

Control panel — contains the status display, indicators, and operating

keys used to control the scanner.

Gap adjustment knob — allows you to manually adjust the space

between the feed and separator rollers for documents of varying

thicknesses.

Gap release lever — allows you to open the feed gap to allow thicker

documents to be fed into the transport.

Feed tray sides guides — holds documents prior to feeding.

A-61140 January 2000 1-3

Page 8

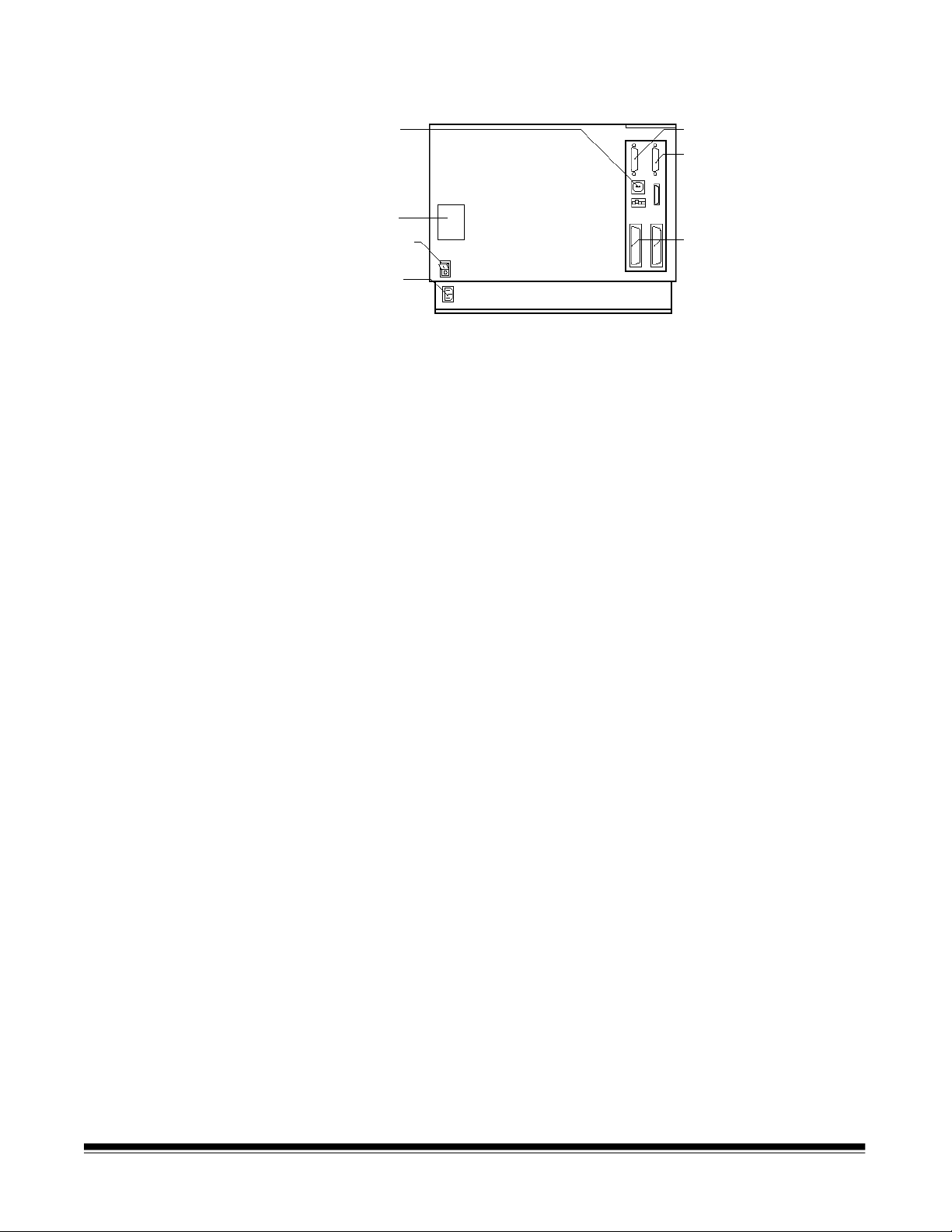

Rear View — Document Scanner 7520

Serial #

Power switch

Footswitch

connector

Power cord

connector

COIN 1/3

COIN 2

SCSI connectors

Footswitch connector — allows you to plug in the optional Footswitch

accessory.

Serial number — provides the serial number and agency approvals.

Power switch — toggle this switch to turn the power on (|) or off (O).

Power cord connector — plugs into an appropriate power outlet.

COIN 1/3 — service/diagnostic interface . Configures the scanner and

runs diagnostics.

COIN 2 — not for customer use.

SCSI connectors — SCSI connection for the scanner.

For European units only:

WARNING: Communications between the Scanner 7520 and the

host computer including both the SCSI cable (TDK:

HF70RH26X29X13) and RS-232 cable

(TDK: HF70RH12X15X7.3) must have ferrite cores.

These ferrite-cored cables are used for radio

frequency interference suppression.

A-61140 January 2000 1-5

Page 9

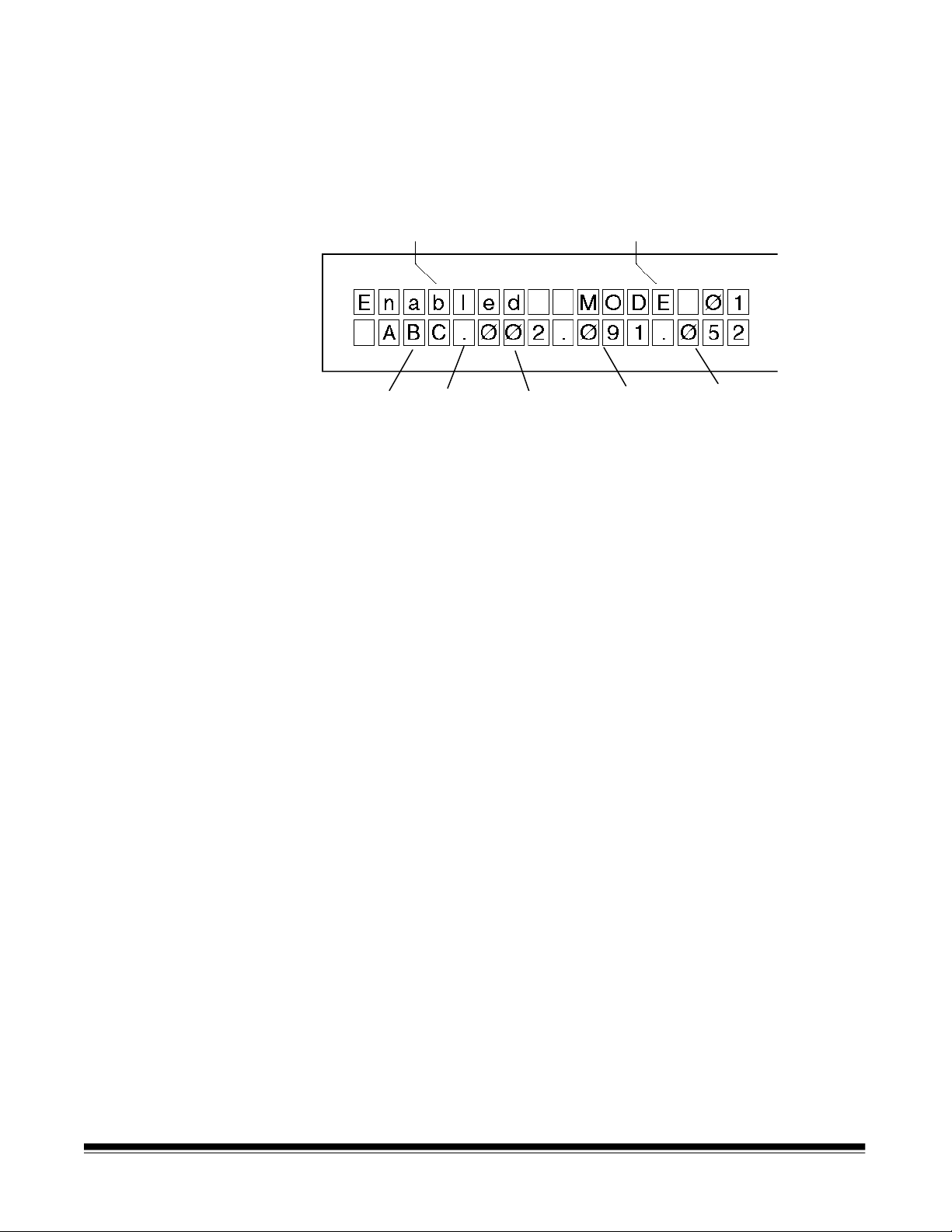

Control panel The control panel consists of the status display and the operation keys

Scanner status

Mode number

Level III

and indicators.

Status display

The status display indicates the image address, current application

mode and error messages.

Fixed

field

Delimiter

Level II Level I

Scanner Status — displays if the scanner is enabled or disabled.

Mode Number — displays the current mode number or name.

Fixed field — an alphanumeric field containing fixed information, i.e.,

the date, application ID, etc.

Delimiters — used to separate the levels in an image address.

Delimiters can be displayed in different locations (as shown above)

based upon system configuration.

Level I* — identifies the Level 1 sequence (commonly the page

number)

Level II* — identifies the Level 2 sequence (commonly the document

number)

Level III* — identifies the Level 3 sequence (commonly a batch

number)

*Depending on your application design, you may see a variety of

different number and level schemes. See your application design person

for more information.

1-6 A-61140 January 2000

Page 10

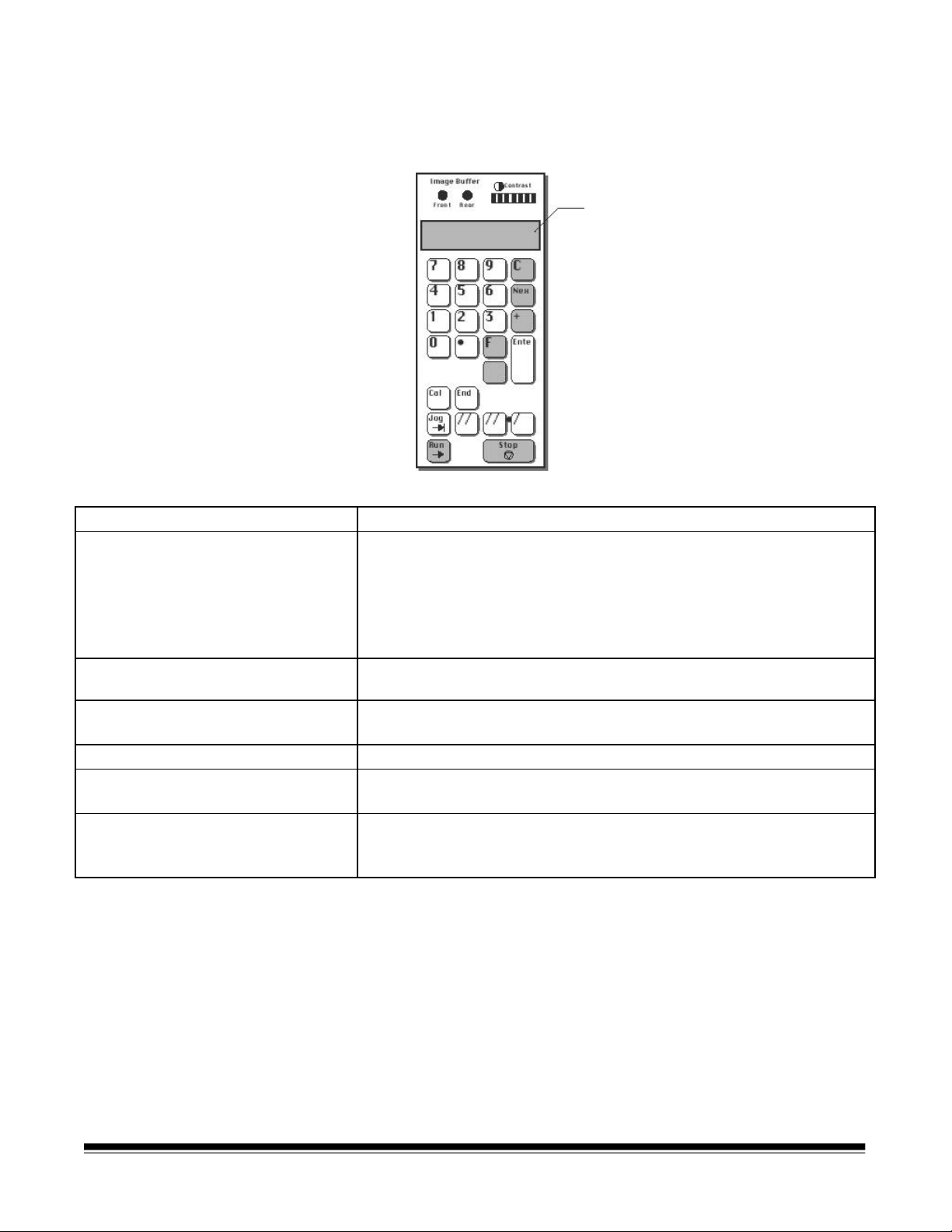

Operating keys and indicators

Following is an illustration and a description of the operating keys and

indicators.

Two-line status display

Key/Indicator Function

Image buffer status Front — green indicates the front side image buffer is available for

scanning; red indicates the buffer is not available and the feeder is

off (for simplex- and duplex-defined application modes).

Back — green indicates the rear side image buffer is available for

scanning; red indicates the buffer is not available and the feeder is

off (for duplex-defined application modes only).

Contrast thumbwheel Allows you to adjust the display contrast between the characters

and the background in the display.

Numeric keys (0-9) Used with the Enter key to enter numeric data such as an image

address or function code.

Decimal key Allows you to insert a field separator in an image address.

F key Selects one of the available functions when used with the numeric

keys.

C Clear or Cancel. Allows you to cancel a function without changing

the preset value(s). Also used to clear error messages from the

status display.

A-61140 January 2000 1-7

Page 11

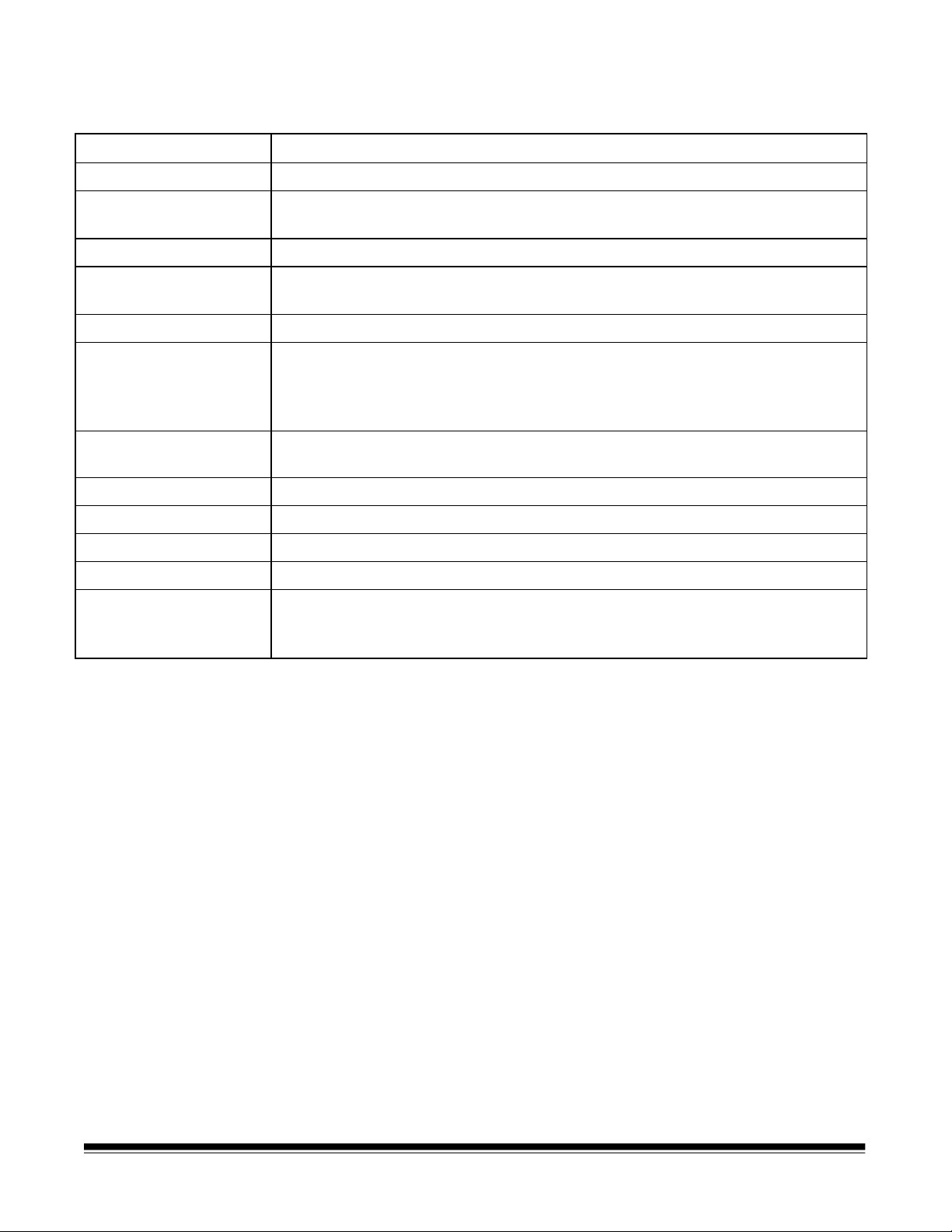

Operating keys and indicators

Keys/Indicators Function

Next Allows you to enter the next document image address.

+ Allows you to enter a new value for the image address. When pressed, it

allows a field to remain unchanged.

Enter Used to enter numeric data for a function code or an image address change.

Back Used to move the cursor back one space during numeric data input (the last

data input is erased).

CAL Starts the calibration process.

End Press End to stop the feeder and transport system at the end of a batch or

job and alert the host computer that the batch or job has ended. When

pressed, the documents in the transport system will be scanned and

stacked faced down in the exit hopper before the transport is disabled.

Jog Momentarily turns on (jogs) the transport system to help clear document

jams.

Level 3 key Identifies the next document fed into the scanner as a Level 3 document.

Level 2 key Identifies the next document fed into the scanner as a Level 2 document.

Level 1 key Identifies the next document fed into the scanner as a Level 1 document.

Run Turns on the feeder and transport system.

Stop Stops the feeder and transport system. When Stop is pressed, documents

in the transport system will be scanned and placed in the exit hopper before

the transport system stops.

Confirmation tone/alarm

The confirmation tone/alarm is located under the control panel and

sounds when one of the following conditions occur:

• Run is pressed (one long tone).

• Stop or End is pressed (many short tones followed by a long tone).

• Feeder clutch engages/disengages (one short tone).

• Incorrect key is pressed (three short tones).

• Document skew is greater than what is setup in the skew parameter,

or when a document is shorter or longer than the specified length

parameters (one short tone).

• A bar code is detected (if the accessory is enabled and the

confirmation tone is enabled).

• A patch code is detected (if the accessory is enabled and the

confirmation tone is enabled).

• The Footswitch is detected (if the accessory is enabled and the

confirmation tone is enabled — one short tone).

1-8 A-61140 January 2000

Page 12

2 Getting Started

The following steps are necessary to prepare the scanner for operation.

Procedures on how to perform these steps are described in this

chapter.

1. Turn on the power to the scanner.

2. Select the language display.

3. Calibrate the scanner.

4. Prepare the documents for scanning.

5. Adjust the feed and separator roller gap, if required (semi-automatic

feeder).

6. Adjust the feed shelf position.

7. Adjust the feed shelf side guides.

8. Adjust the exit hopper side guides and end stop.

9. Select the desired application mode and image level, or the Count

Only function.

10. Start the scanner from the host computer. (This step is not

necessary for the Count Only function.)

Turning on the scanner

11. Press Run.

12. Feed the documents into the scanner.

13. Press Stop or End, depending on whether the batch or job has been

completed.

NOTE:After you press Stop, Run can be pressed again and more

documents can be fed into the scanner. After pressing End,

you must enable the scanner from the host computer before

scanning again.

Follow the steps below to turn on the power to the scanner.

1. Turn on the power switch (located at the rear of the machine).

NOTE: Several initialization messages will appear in the status

display. If you cannot see any messages, try adjusting the

contrast.

2. Send the Scan command from the host computer to the scanner.

The message Enabled will appear in the status display. The current

application mode and next image address will also be displayed.

IMPORTANT: Do not use the operating keys until the Warming Up

Completed message has been displayed. Entries

made before this message is displayed will not be

recognized by the scanner.

A-61140 January 2000 2-1

Page 13

Selecting the language display

The scanner may have been configured at installation to allow use of a

second language in the status display. The language used (French,

German, Italian, Spanish, or other) is defined during installation. If

available, the alternate language display may be accessed using

function code F19.

Calibrating the scanner

Calibration sets the intensity of the lamps, which contribute to the overall

quality of the scanned document image.

The scanner should be calibrated:

• at least once a day

• if image quality is poor

• after changing lamps

Calibrate the scanner using a calibration target (sheet of paper) that is:

• Blank

• Clean

• Matte finish (not glossy)

• White or the same color as the background color of the documents

to be scanned. When using a duplex-defined application mode,

make sure that both front and rear colors of the calibration target

correspond with the front and rear colors of the documents to be

scanned. If you are scanning a variety of colored documents, use a

white calibration target.

• Wider than the documents you are going to scan (i.e., to scan 8.5 x

11 inch (216 x 279 mm) portrait orientation documents, the

calibration target should be wider than 8.5 inches (216 mm). The

recommended width for the calibration target is 12 inches

(300 mm).

To scan 11 x 17-inch (280 x 432) documents, the calibration target

should be wider than 11 inches (279 mm) but not wider than 12

inches (305 mm).

• Between 12 and 25.5 inches (305 and 648 mm) long.

For your convenience, 12 x 12-inch calibration targets

(Part # 986527) are supplied with the scanner and are also available

from Parts Services, 1 800 431-7278.

To calibrate the scanner:

1. Verify the power switch is on and a normal operating status display

is displayed.

2. Press CAL on the control panel. A message will be displayed

prompting you to feed the calibration target.

3. Insert the calibration target into the feeder.

When calibration is successful, the status display returns to a normal

operating display.

2-2 A-61140 January 2000

Page 14

Unsuccessful calibration

If calibration is not successful, a message appears in the status display.

You may need to:

• Verify you are using a clean, blank sheet of paper (at least 12 inches

in length) as a calibration target. The paper must be wider than the

documents being scanned and at least 8 1/2 inches long.

• Verify there is not a document already in the document path. (Refer

to the section entitled, “Clearing the document path” in Chapter 7.)

• Clean the imaging guides. (Refer to the section entitled “Cleaning the

imaging guides” in Chapter 5.)

• Calibrate the scanner again. If calibration fails again, change the

lamps. (Refer to the section entitled, “Replacing the exposure

lamps” in Chapter 5.)

If you have done all of the above and calibration still fails, contact your

service representative.

Preparing documents for scanning

Document orientation

Document sizes

Before you begin processing documents, make certain the documents

may be fed through the scanner easily:

• Remove any staples, rubber bands, loose mending tape, or paper

clips from the documents to be processed.

• Straighten wrinkled edges and tape any torn documents.

• Trim ragged edges.

When using the semi-automatic feeder, make certain all documents are

of similar size, texture, thickness and weight, and the leading edges of

all documents are aligned.

Before scanning, position all documents the way you want them to be

displayed on the host computer. Feed the documents so the text or

graphic appears to be facing in the same direction.

The following document sizes can be scanned:

Length 2 ½ x 17 inches (64 x 432 mm). Documents between 17

and 30 inches (508 mm) long can be scanned by adjusting

the exit hopper end stops.

Width 2 ½ x 12 inches (64 x 305 mm)

Minimum document thickness: onion skin (0.0015-inch / 0.04 mm)

Maximum document thickness: index card (0.014 inch / 0.36 mm)

index card (0.040 inch / 1.00 mm)

A-61140 January 2000 2-3

Page 15

Adjusting the feed

and separator roller

gap (semi-automatic

feeder)

The gap adjustment knob on the control panel increases or decreases

the space between the feed and separator rollers. The gap must be

adjusted properly for smooth transportation of documents without

document overlap.

When documents of different thicknesses are fed in a group, adjust the

gap using the thinnest document in the group.

The feed and separator roller gap may have to be adjusted to

compensate for:

• Very thin documents (onion skin, tracing paper, etc.).

• Very thick documents (card stock, punch cards, cover stock).

• Some coated documents (photographic paper, plastic-coated

paper).

If the gap is not adjusted properly:

• More than one document at a time may be drawn into the transport

system at the same time; not all of the documents will be scanned.

• Documents may be drawn into the transport too quickly; documents

may overlap or be spaced too closely (causing an error display).

• Documents may become skewed during transport; jamming may

occur.

NOTE:Prior to performing the adjustment procedure, the scanner

must be calibrated and enabled.

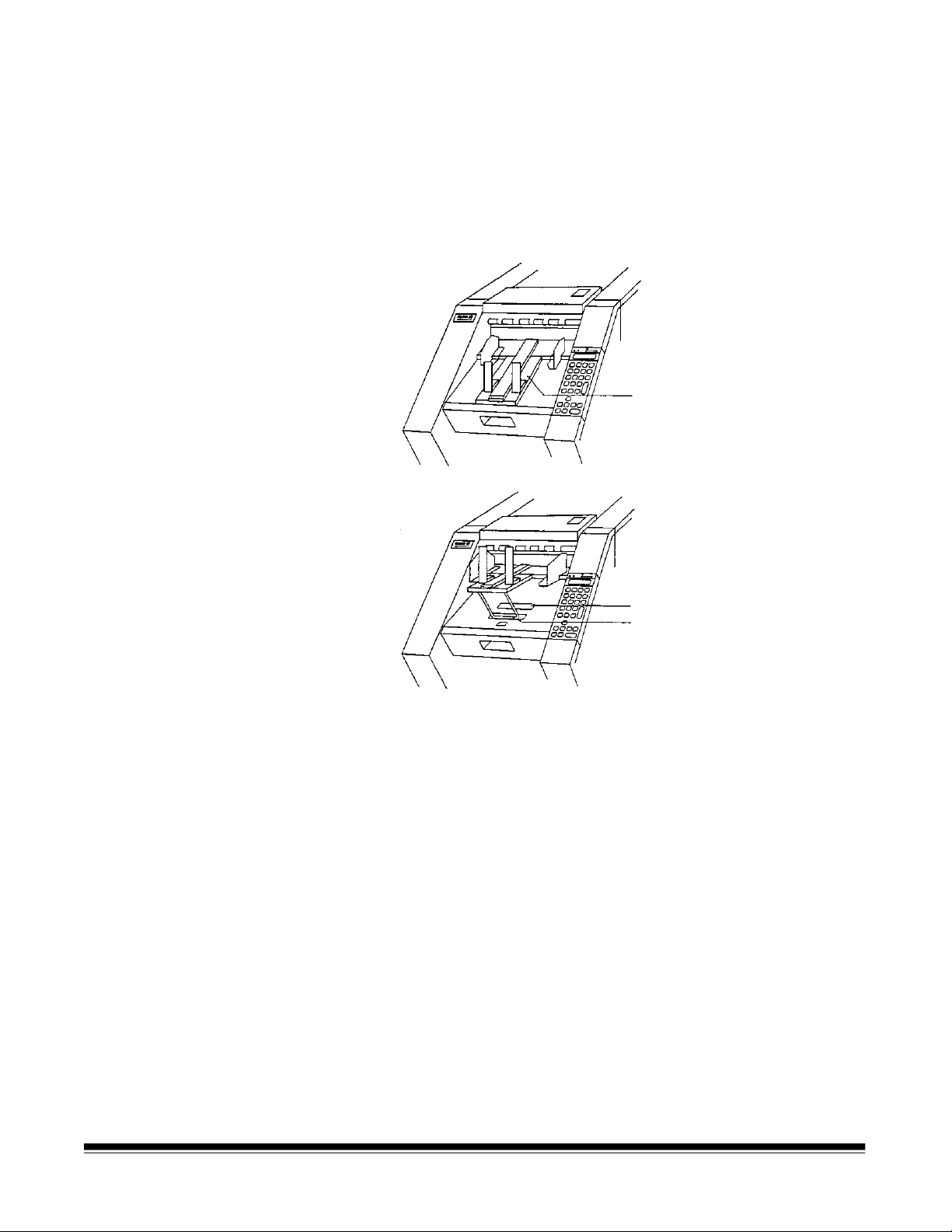

To adjust the feed and separator roller gap:

1. Verify that the power switch is on.

2. Turn the gap adjustment knob clockwise three complete turns to

open the gap between the feed roller and separator roller.

Gap adjustment knob

3. Enter F04 and enable Counting Only.

2-4 A-61140 January 2000

Page 16

4. Press Run.

5. Select two documents of the same size, texture and thickness,

similar to the types of documents you will be scanning.

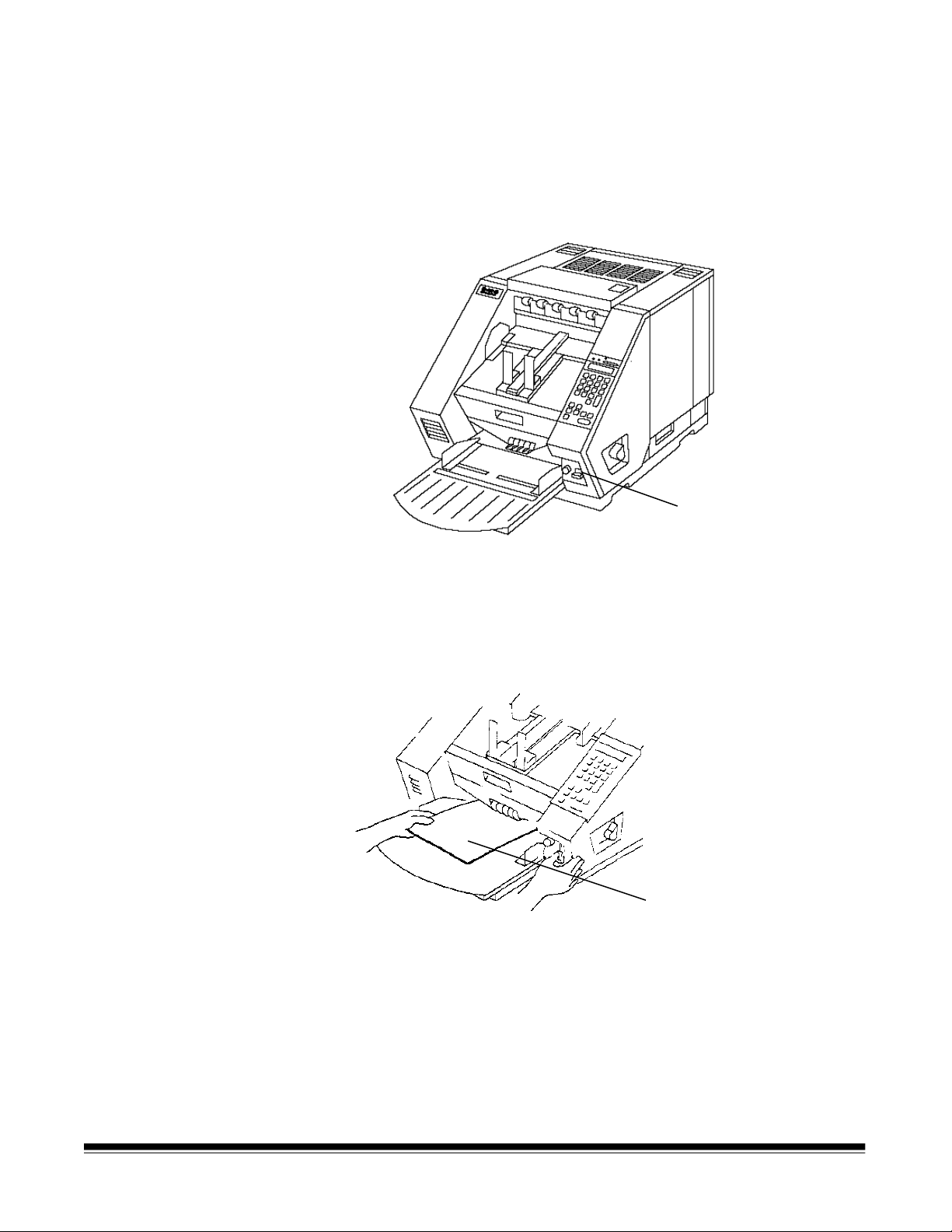

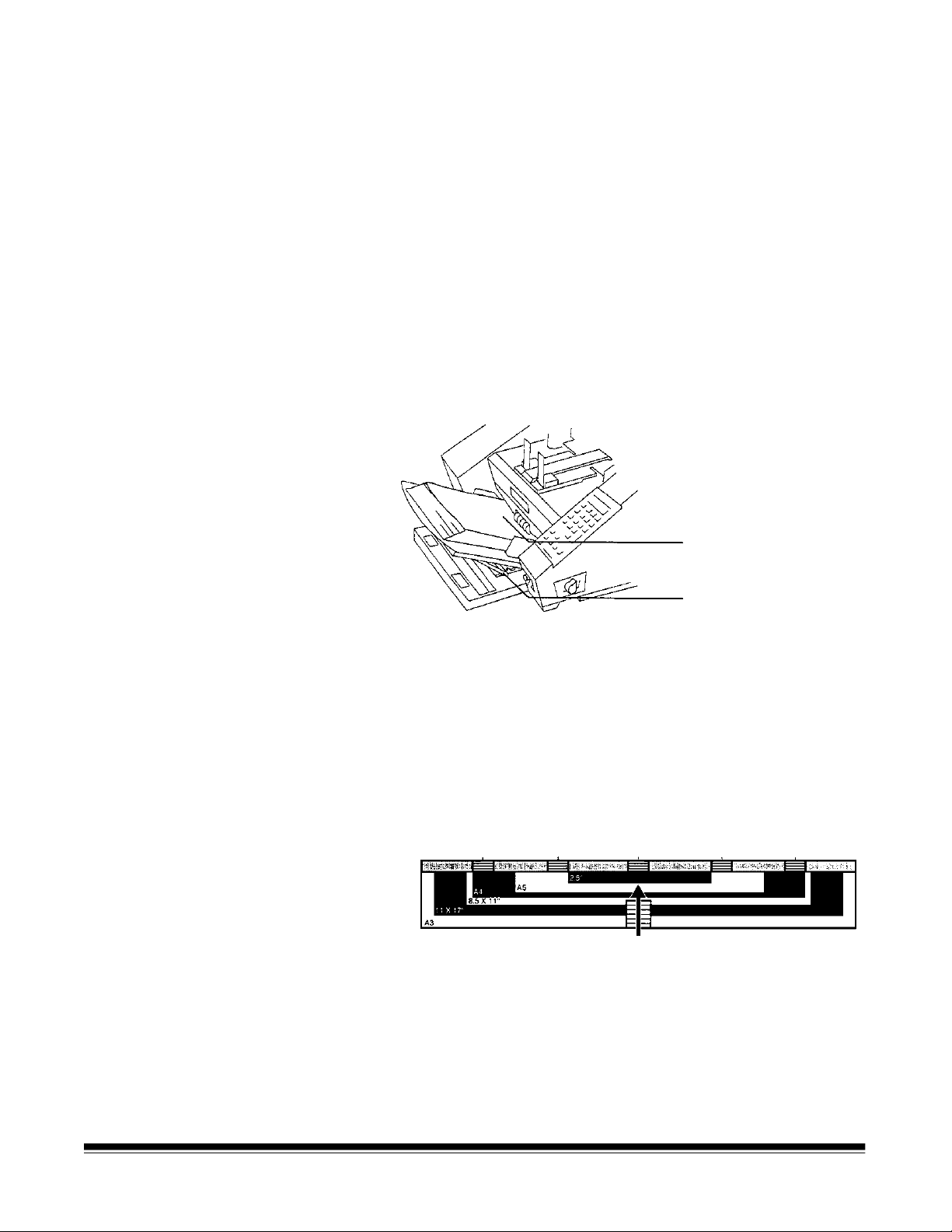

6. Place one document on top of the other. Hold the documents firmly

by their trailing edges. Insert them into the gap approximately 1/8 in.

(3 mm).

Bottom document

separates from

top document

7. If the documents separate, repeat the following steps until the

documents do not separate:

• Turn the gap adjustment knob clockwise 1/2 turn.

• Insert the documents again.

If the documents do not separate, proceed with Step 8.

8. Rotate the gap adjustment knob counterclockwise 1 or 2 clicks.

IMPORTANT: Do not make a gap adjustment while documents are

in the feeder or transport system; doing so will

produce an inaccurate adjustment.

9. Hold the trailing edges of the documents firmly. Insert them into the

gap.

• If the bottom document is not separating from the top document,

remove the documents and repeat Steps 7 and 8 until the bottom

document separates from the top document by approximately 1

in. (25.4 mm).

• If the bottom document is separating from the top document,

proceed with Step 10.

10. When you have adjusted the gap so the bottom document separates

consistently from the top document, rotate the gap adjustment knob

counterclockwise another 1 or 2 clicks to complete the adjustment.

11. Feed a stack of 50 to 100 documents twice through the transport

system. Verify the final count reflects the total number of documents

fed and that the counter shows the same amount each time the

documents are counted.

If the count is not the same, the gap is not adjusted correctly. Rotate

the gap adjustment knob counterclockwise another 1 or 2 clicks and

repeat Step 9. Repeat until corrected.

12. Press Stop.

A-61140 January 2000 2-5

Page 17

13. Enter F04 and disable Counting only.

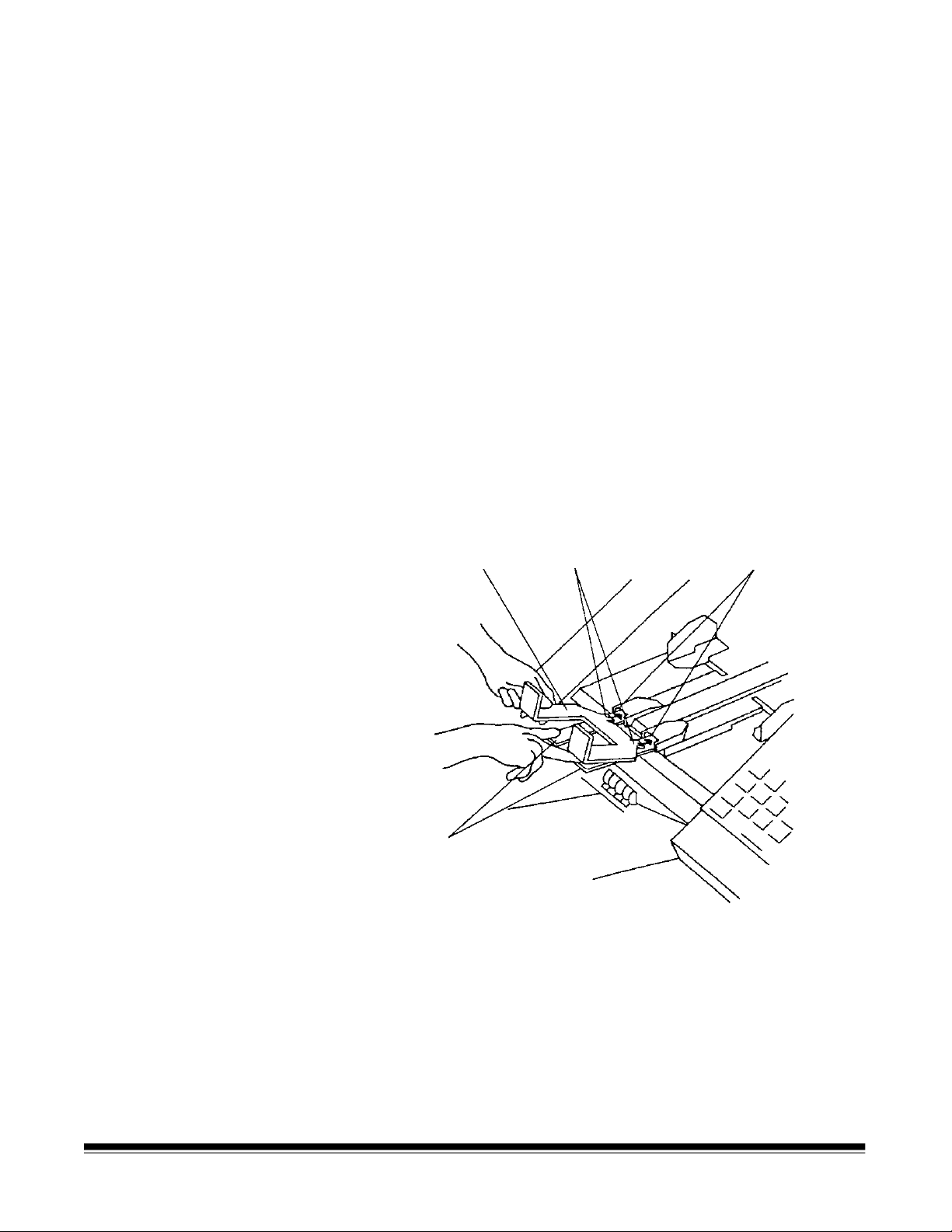

Thick document

14. Press Enter.

Adjusting the separator roller to scan thick documents

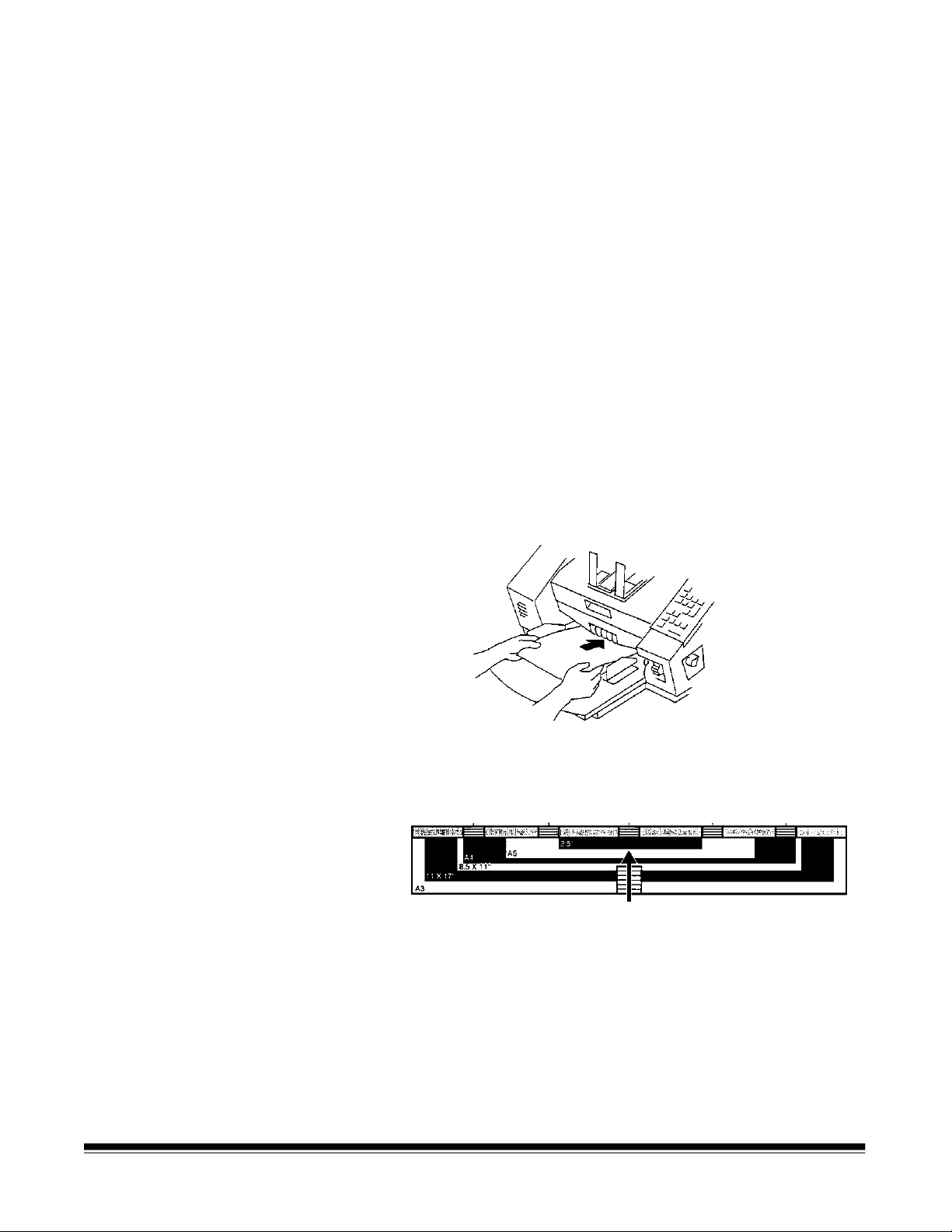

To scan thick documents (card or cover stock), use the gap release

lever to increase the gap between the feed roller and separator roller.

Gap release lever

1. Press down and hold the gap release lever. This opens the gap

between the feed and separator rollers and allows thick documents

to pass between the rollers.

2. Manually feed the thick documents while holding down the gap

release lever.

2-6 A-61140 January 2000

Page 18

Adjusting the feed

shelf position (semi-

automatic feeder only)

For manual feeding, the feed shelf can be adjusted in the 0°, 30° or 40°

position. For automatic feeding, raise the feed shelf to the 30° or 40°

position.

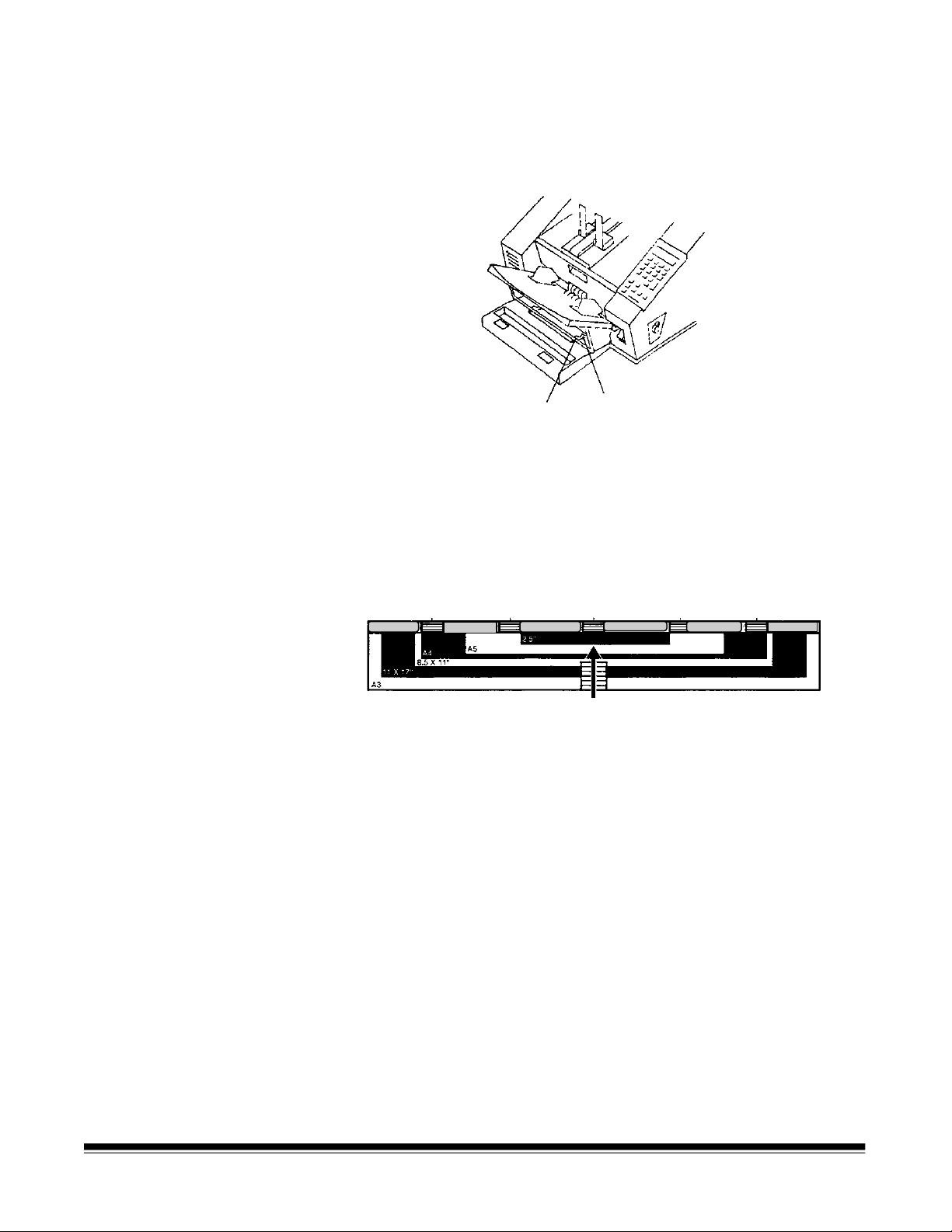

Adjusting the side guides

40° position

Before you begin feeding documents into the scanner, adjust the

position of the side guides and feed shelf position.

• Adjust the width of the feed shelf side guides to hold the widest

document you will be scanning. Leave approximately 1/16-inch

(2 mm) clearance on each side of the largest document to allow for

proper feeding.

NOTE: Ensure that the documents are center-fed so each

document covers the 2 ½-inch required width as indicated

by the label on the feed tray.

30° position

A-61140 January 2000 2-7

Page 19

Adjusting the exit

End stop extension

Tabs

Slits

hopper side guides

and end stop

The exit hopper side guides and end stop must be adjusted so

documents are stacked properly.

1. Adjust the exit hopper side guides to hold the widest document you

will be scanning. Leave ¼-inch (5 mm) clearance on each side of

the document.

2. Adjust the end stop to hold the longest document you will be

scanning.

An end stop extension is included to accommodate documents up to

17 inches in length.

To attach the end stop extension:

• Fold the spring-loaded exit hopper end stop down and slide the

extension’s tabs into the slits just above the exit hopper end

stop.

To remove the end stop extension:

• Press the spring-loaded exit hopper end stop and pull the

extension out from the exit hopper.

2-8 A-61140 January 2000

Exit hopper

end stops

Page 20

3. Adjust the height of the exit hopper so the scanned documents

Standard position

naturally fall between the exit hopper side guides and exit hopper end

stop. The exit hopper has three height positions:

• Standard position

• 10° from standard position

• 20° from standard position (specifically for use with A4 size,

onion skin documents)

10° from standard position

20° from standard position

A-61140 January 2000 2-9

Page 21

3 Operating the Scanner

Overview This chapter provides instructions for selecting modes, image level

settings and feeding documents using the semi-automatic feeder and

the automatic feeder.

The scanning process consists of the following steps:

1. Prepare the scanner for operation (refer to Chapter 2, Getting

Started for more information).

2. Select an application mode for the application.

3. Select the appropriate operating values required for the application

on the host computer.

4. Press the Run key.

5. Feed documents into the transport (refer to “Feeding Documents

using the semi-automatic (or automatic) feeder” later in this

chapter).

• The scanner assigns a sequential ID number, the document

image level and image address.

• The document is scanned.

• The document image header is created.

• The host computer initiates transfer of the document image

header and document image to the host system for storage on

magnetic or optical disk media.

• Documents are deposited in the exit hopper, face down, in the

order in which they were fed into the transport.

6. Press Stop to disable the transport after the last document has

been scanned or press End to alert the host computer that the batch

or job has ended.

NOTE: If Stop or End is pressed while scanning a stack of

documents, the feeder will stop. Any documents in the

transport system will be scanned and deposited face down in

the exit tray before the transport system is disabled.

A-61140 January 2000 3-1

Page 22

Setting image levels Image levels are used to identify specific types of documents (or sets of

documents) for later indexing and retrieval. The image level assigned to

each document is inserted into the image header associated with the

document image.

There are four document image levels:

• Level 0

• Level 1

• Level 2

• Level 3

Setting Levels

Levels 1, 2, and 3 can be set by pressing a document Image Level key

on the control panel, or by using the optional Footswitch or Patch

Reader accessories.

Level 0 can be set by entering function code F07.

Selecting a mode The scanner offers 18 modes that may be programmed for a particular

application or group of applications.

When you select a mode for use with a particular application, you are

selecting the format/appearance of the output. Each mode is composed

of definitions that affect the output of the scanner. The required mode

definitions include language display, measurement format, index format,

image address rules, level rules, accessory status, etc.

The modes are programmed at the time of installation and stored for

easy access and use.

Many of the optional mode definitions set up during installation may be

overridden using function codes. The overrides are temporary, unless it

is specified during installation that the mode overrides are to be saved.

Detailed information regarding application modes, can be found in Kodak

publication, A-61097, Mode Setup Software.

Typically, the mode is selected via the host system, using a scannerunique command. However, you may manually select a mode.

To select a mode do the following:

1. Enter function code F01 (Select Mode) by pressing the F key and the

numeric keys 0 and 1.

2. Press Enter.

3. Enter the desired mode number (modes range from 1 to 18).

4. Press Enter.

3-2 A-61144 January 2000

Page 23

Temporary operating values

Each of the 18 modes programmed at the time of installation contain

definitions that affect the output of the scanner. Each mode is

programmed to conform to the output requirements of a particular

application or group of applications.

There may be instances, however, when a particular application requires

some variation of an existing mode. In such instances, mode definitions

may be changed using available function codes. See Chapter 4,

Function Codes, for a listing and description of the available function

codes.

NOTE: Changes to mode definitions remain in effect until another

mode is selected or the side panel switch is turned off. The

original mode definition is only affected by these changes if the

mode overrides are saved (the mode override option may be

selected at installation and if selected, a plus sign (+) appears

in the first line of the status display).

A-61140 January 2000 3-3

Page 24

Feeding documents

using the semiautomatic feeder

Following are feeder instructions using the semi-automatic feeder. After

the scanner has been prepared for operation, the desired mode and any

temporary operating values have been defined, you are ready to feed

documents into the transport.

1. Verify that the power is on and that all of the proper adjustments

have been made (feeder side guides, exit hopper side guides, etc.).

2. Place the feed shelf in the Up position.

3. Select a stack of documents that is no more than 1.5 in. (38 mm)

thick. Hold the stack with the front sides facing up and the top of the

documents facing toward the scanner. Tap the bottom edge of the

stack against a flat surface so the documents are in an even bundle.

4. Fan the stack of documents so the leading edge of the top document

sticks out the farthest.

Fanned documents

5. Press Run.

6. Place the stack of fanned documents into the feeder so the leading

edge of the top document contacts the feed/separator rollers. The

documents are drawn into the transport, with the top document

being fed first. The documents are deposited in the exit hopper face

down, in the order in which they were fed into the transport.

NOTE: Be sure the documents are center-fed so each document

covers the 2 ½-inch required width as indicated by the label

on the feed tray.

Each document should automatically go into the feeder. If

the automatic flow is inhibited, gently push the top document

toward the feeder to re-establish automatic feeding.

40° position

3-4 A-61144 January 2000

Page 25

7. As you scan documents, set the image level, as required, and

periodically remove documents from the exit hopper.

NOTE: When the image buffer is full, the feeder will turn off and the

image buffer status light will turn red. There may be a

momentary pause in scanning while images are being

transferred to the host computer. Scanning will resume and

the status indicator will change to green when the image

buffer is clear.

8. Press Stop to disable the transport system after the last document

has been scanned, or press End to alert the host computer the

batch or job has ended and to disable the transport system after the

last document has been scanned.

Feeding documents manually

To manually feed documents, follow the steps below:

1. Select the correct scanning operating values.

2. Place the feed shelf in the up or down position (semi-automatic

feeder only), whichever is most convenient.

3. Insert the documents one at a time.

NOTE: Be sure the documents are center-fed so each document

covers the 2 ½-inch required width as indicated by the label

on the feed tray.

A-61140 January 2000 3-5

Page 26

Feeding thick

lever is used)

lever

documents

The gap release lever is used to feed thick documents such as card

stock or cover stock. The lever is located on the front panel of the

scanner next to the gap adjustment knob.

(Graphic depicts movement

of separator rollers when

(Graphic depicts gap

adjustment)

Gap

release

To feed thick documents using the gap release lever:

1. Press down and hold the gap release lever; this opens the gap

between the feed and separator rollers allowing thick documents to

pass between them. You will be able to see the gap open as the

lever is pushed down.

2. Insert the thick document past the rollers until it is taken into the

transport system.

NOTE: If more than one thick document is to be scanned, feed

them into the transport one at a time.

3. After the thick document(s) have been scanned, release the gap

release lever; it will return to its original position. The feed and

separator rollers will return to their previously adjusted positions.

3-6 A-61144 January 2000

Page 27

Feeding documents using the automatic feeder

Following are document feeder instructing using the automatic feeder.

After the scanner has been prepared for operation, the desired mode

and any temporary operating values have been defined, you are ready to

feed documents into the transport.

1. Verify that the power is on and that all of the proper adjustments

have been made (feeder side guides, exit hopper side guides, etc.).

2. Select a stack of documents that is no more than 1.5 in. (38 mm)

thick. Hold the stack with the front sides facing up and the top of the

documents facing toward the scanner. Tap the top edge of the stack

against a flat surface so the documents are in an even bundle.

3. Fan the stack of documents so the leading edge of the top document

sticks out the farthest.

4. Lift the feeder module and slide the top edge of the documents

underneath the feeder module. To help prevent multiple feeds, after

you place the documents under the feeder module, pull the

documents back slightly (about ¼-inch) from the separator roller.

5. Press Run.

NOTE: Be sure the documents are center-fed so each document

covers the 3 ½-inch required width.

6. As you scan documents, set the image level, as required, and

periodically remove documents from the exit hopper.

NOTE: When the image buffer is full, the feeder will turn off and the

image buffer status light will turn red. There may be a

momentary pause in scanning while images are being

transferred to the host computer. Scanning will resume and

the status indicator will change to green when the image

buffer is clear.

7. Repeat Steps 2 through 4 until all the application documents have

been fed into the transport.

8. Press Stop to disable the transport system after the last document

has been scanned, or press End to alert the host computer the

batch or job has ended and to disable the transport system after the

last document has been scanned.

A-61140 January 2000 3-7

Page 28

4 Function Codes

Using function codes

There are a variety of functions available which may be used to

temporarily change operating values, and to obtain system and

accessory status information.

These functions are listed in the Function Code Summary later in this

chapter. Following are the procedures for using function codes:

1. Press the F key.

2. Press the numeric keys which correspond to the desired function

code.

3. Press Enter.

If the function is used to enable or disable an operation (turn an option on

or off):

1. Press 1 to turn the option On, or 0 to turn the option Off.

2. Press Enter.

If the function requires numeric input:

1. Press the numeric key(s) required.

2. Press Enter.

If the function is used to increment or decrement a measurement:

1. Press the arrow keys to increment or decrement as follows:

• Press the Up arrow to increment the measurement by

1 inch (25 mm), or

• Press the Down arrow to decrement the measurement by

1 inch (25 mm), or

• Press the Right arrow to increment the measurement by 1/8-

inch (3 mm), or

• Press the Left arrow to decrement the measurement by

1/8-inch (3 mm).

2. Press Enter.

To cancel a function (before pressing Enter) or clear the status display

after executing a function code:

• Press C (Clear/Cancel).

A-61140 January 2000 4-1

Page 29

Function code summary

Following is a summary of the functions and their corresponding

function code:

Application Modes

Select Application Mode...........................................................F01

Restore Application Mode.........................................................F02

Index/Image Address

Level 0...................................................................................... F07

Last Image Address.................................................................F08

Status

Accessory Status.....................................................................F05

Transport System Operation Time ...........................................F17

Date and Time .........................................................................F23

Counters

Count Only...............................................................................F04

Total Document Count.............................................................F09

Level 0 Count...........................................................................F10

Level 1 Count............................................................................F11

Level 2 Count...........................................................................F12

Level 3 Count...........................................................................F13

Reset Level Counts..................................................................F14

Setup

Display Language.....................................................................F19

Measurement System.............................................................. F20

Set Time .................................................................................. F21

Set Date ..................................................................................F22

Controls

Length Monitor..........................................................................F70

Omit Length Monitor on Next Document..................................F71

Skew Monitor............................................................................F72

Host

Latch Flag.................................................................................F73

Momentary Flag........................................................................F74

Patch Reader

Patch Reader .......................................................................... F50

Confirmation Tone.................................................................... F53

Omit Patch Reading on Next Document.................................F54

Patch Test................................................................................ F55

4-2 A-61140 January 2000

Page 30

Bar Code Reader

Bar Code Reader .................................................................... F60

Confirmation Tone.................................................................... F63

Omit Patch Reading on Next Document.................................F64

Bar Code Test.......................................................................... F65

Document Printers

Front and Rear Document Printers ........................................ F40

Front Document Printer ..........................................................F41

Rear Document Printer ...........................................................F42

Omit Printing on Next Document............................................. F44

Print Test.................................................................................. F45

Vertical Start Print Position (Front)...........................................F46

Vertical Start Print Position (Rear)...........................................F47

Purge Print Head......................................................................F48

Footswitch

Confirmation Tone.................................................................... F75

A-61140 January 2000 4-3

Page 31

Function code listing

Following is a listing of the function codes and descriptions.

Code Function Code Name Description

F01 Select Mode Allows you to select one of the predefined application

modes. Enter a value from 1 to 18 and press Enter.

F02 Restore Mode Allows you to restore the current application mode to its

default status, provided mode overrides are not saved.

F04 Counting Only

Allows you to count the number of documents entering the

scanner without scanning. Enter 1 to turn Counting Only

on, or 0 to turn Counting Only off and press Enter.

F05 Accessory Status Displays the current status of each accessory installed.

Press the Down arrow to view the status of the next

accessory, or press the Up arrow to view the status of the

previous accessory.

F07 Level 0 Allows you to define the next document scanned as a

Level 0 document.

F08 Last Image Address Allows you to display the image address of the last

document scanned.

F09 Total Document Count

Allows you to display the total number of documents that

entered the feeder (Level 3, Level 2, Level 1 or Level 0).

Press 0 to reset the counter and then press Enter.

F10 Level 0 Count Allows you to display the total number of documents that

have entered the feeder as Level 0 documents. Press 0 to

reset the counter and then press Enter.

F11 Level 1 Count Allows you to display the total number of documents that

have entered the feeder as Level 1 documents. Press 0 to

reset the counter and then press Enter.

F12 Level 2 Count Allows you to display the total number of documents that

have entered the feeder as Level 2 documents. Press 0 to

reset the counter and then press Enter.

F13 Level 3 Count Allows you to display the total number of documents that

have entered the feeder as Level 3 documents. Press 0 to

reset the counter and then press Enter.

F14 Reset Level Counts

Allows you to reset all the level counters (Level 0, Level 1,

Level 2, and Level 3) to 0.

4-4 A-61140 January 2000

Page 32

Code Function Code Name Description

F16 Alarm Tone Allows you to adjust the pitch of the alarm tone. Press the

Up arrow to increase the pitch or press the Down arrow to

decrease the pitch, then press Enter.

F17 Transport System

Operation Time

Allows you to display the elapsed time of operation of the

transport system. This time is recorded in the software

and will be reset if a ROM replacement is performed.

Therefore, the software time displayed and the time

displayed inside the side access door can vary.

F19 Display Language Allows you to choose your preferred language. The options

are:

0 = English

1 = Japanese

2 = French

3 = German

F20 Measurement System Allows you to choose your preferred measurement

system. The options are:

0 = millimeters

1 = inches

F21 Set Time Allows you to set the time on the status display. The

format is HH:MM. HH represents the hours (on a 24-hour

clock) and MM represents the minutes (valid values are

00 to 59). Enter the new time in the format illustrated and

press Enter.

F22 Set Date Allows you to set the date on the status display. The

format is YYYY/MM/DD. YYYY represents the year, MM

represents the month (valid values are 01 to 12), and DD

represents the day (valid values are 01 to 31). Enter the

new date in the format illustrated and press Enter.

F23 Time and Date Display Allows you to view the current time and date.

F40 Front and Rear Document

Printers On/Off

F41 Front Document Printer

On/Off

F42 Rear Document Printer

On/Off

F44 Omit Printing on the Next

Document Only

Allows you to turn the Front and Rear Document Printers

on or off. Enter 1 to turn on or 0 to turn off.

Allows you to turn the Front Document Printer on or off.

Enter 1 to turn on or 0 to turn off.

Allows you to turn the Rear Document Printer on or off.

Enter 1 to turn on or 0 to turn off.

Allows you to specify no information be printed on the next

document scanned. Printing will resume on subsequent

documents. Enter 1 to omit printing on the next document,

or enter 0 to print on the next document then press Enter.

A-61140 January 2000 4-5

Page 33

Code Function Code Name Description

F46 Front Document Printer

Vertical Start Print Position

Allows you to specify how far from the leading edge of the

document printed information will appear. Use the numeric

keys to input values between 0.125 and 20 inches (3 to

508 mm) in increments of 0.125 (3mm). The value will

correspond to the selected measurement system and

should not exceed the document length. The horizontal

start print position is changed manually.

F47 Rear Document Printer

Vertical Start Print Position

Allows you to specify how far from the leading edge of the

document printed information will appear. Use the numeric

keys to input values between 0.125 and 20 inches (3 to

508 mm) in increments of 0.125 (3mm). The value will

correspond to the selected measurement system and

should not exceed the document length. The horizontal

start print position is changed manually.

F48 Purge Print Heads Allows you to purge and clean slightly hardened ink from

the print head of the document printers. Feed a single

blank document after the feed clutch engages.

F50 Patch Reader On/Off Allows you to turn the Patch Reader on or off. Enter 1 to

turn on or 0 to turn off, then press Enter.

F53 Patch Reader Confirmation

Tone On/Off

Allows you to turn the confirmation tone on or off which

informs you when the Patch Reader has successfully read

a patch document. Enter 1 to turn on or 0 to turn off, then

press Enter.

F54 Omit Patch Reading on

Next Document On/Off

Allows you to omit patch reading on the next document

scanned. Normal patch reading resumes with subsequent

documents. Enter 1 to turn on or 0 to turn off, then press

Enter.

F55 Patch Test Allows you to test for patch position and patch quality. The

test result will indicate: T-Patch, 2-Patch, 3-Patch or

Patch Not Read.

F60 Bar Code Reader On/Off Allows you to turn bar code reading on or off. Enter 1 to

turn on or 0 to turn off and then press Enter.

F63 Bar Code Reader

Confirmation Tone

Allows you to turn the confirmation tone on or off which

informs you when the Bar Code Reader has successfully

read a bar code document. Enter 1 to turn on or 0 to turn

off and then press Enter.

F64 Omit Bar Code Reading on

the Next Document Only

Allows you to omit bar code reading on the next document

scanned. Bar Code Reading will resume on subsequent

documents. Enter 1 to turn on or 0 to turn off, then press

Enter.

F65 Bar Code Test

Allows you to perform a test to verify bar code position, bar

code quality and bar code read rate.

4-6 A-61140 January 2000

Page 34

Code Function Code Name Description

F70 Length Monitor On/Off Allows you to turn the length monitor on or off. The length

monitor checks the length of the documents scanned

against the predefined minimum/maximum allowable

lengths. Messages and/or confirmation tones alert you if

the document is shorter or longer than the predefined

length.

F71 Omit Length Monitor on the

Next Document Only

Allows you to omit length checking on the next document

scanned. Length monitoring will resume on subsequent

documents. Enter 1 to turn on or 0 to turn off, then press

Enter.

F72 Skew Monitor Allows you to turn skew detection on or off which monitors

the amount of skew using predefined skew angle(s).

F73 Latched Flag On/Off Allows you to set a flag in the image headers which alerts

the host system that this document, and those which

follow, are of special interest. The flag will remain activated

for every document until it is turned off. Enter 1 to turn on

or 0 to turn off, then press Enter.

F74 Momentary Flag Allows you to set a flag in the image header which alerts

the host system that this document is of special interest.

This flag is set only for that one document. Enter 1 to turn

the momentary scanning flag on, then press Enter.

F75 Footswitch Confirmation

Tone

Allows you to turn the confirmation tone on or off which

informs you when the Footswitch is pressed and/or

released. Enter 1 to turn on or 0 to turn off, then press

Enter.

A-61140 January 2000 4-7

Page 35

5 Maintenance

This chapter provides maintenance procedures for the scanner

including cleaning and part replacement procedures.

Cleaning tasks To keep your scanner in good operating condition, the following tasks

must be performed periodically:

• Cleaning the imaging guides (daily)

• Cleaning the feed and separator roller (semi-automatic feeder)

(daily)

• Cleaning the feeder module and separator roller (automatic feeder)

(daily)

• Cleaning the paper path (daily)

• Vacuuming inside the scanner (weekly)

• Cleaning the cabinet (weekly)

For additional maintenance and feeder adjustment information, see

Kodak publication A-61603. Feeder and Maintenance Adjustment

Procedures.

Cleaning materials Materials needed to perform all maintenance procedures are:

• A mild cleaning agent

• A soft, clean, lint-free cloth

• A soft-bristled cleaning brush

• A vacuum cleaner

• Staticide Wipes

• Paper Path Cleaner

IMPORTANT: Do not use any unauthorized commercial cleaning

solvent in any of the cleaning procedures.

Replacement parts Consumable parts that can be replaced by the customer include:

• Imaging guides

• Exposure lamps

• Automatic Document Feeder Module

• Automatic Document Feeder Separator Roller

Instructions on how to replace these parts are included later in this

chapter.

A-61140 January 2000 5-1

Page 36

Daily maintenance

Thumbscrew

procedures

Maintenance procedures that should be performed daily include

cleaning the imaging guides, feed and separator rollers and the paper

path.

Cleaning the imaging guides

To clean the imaging guides, follow the steps below:

IMPORTANT: Do not use any abrasive materials when cleaning the

imaging guides. This includes abrasive cleansers,

commercial solvents, paper towels, or coarse cloths.

1. Open the side access door.

2. Release and open the vertical transport plate by rotating the release

handle 180° clockwise.

3. Release and remove the front imaging guide by rotating the

thumbscrew 90° counterclockwise, and lifting the guide’s two green

saddle mounts from the mounting shaft.

Magnets

Front imaging guide

Rear imaging guide

5-2 A-61140 January 1999

Page 37

4. Release and remove the rear imaging guide by swinging the guide

saddle mount

mounting pin

transport plate

toward the front of the scanner (to release it from the two magnets),

and lifting it from the scanner’s two mounting pins.

5. Clean the surfaces of both the front and rear imaging guides with an

antistatic wiper or a clean, soft, lint-free cloth, slightly moistened with

water or lens cleaner.

6. Dry the imaging guides with a dry, lint-free cloth.

7. Hold the rear imaging guide by the edges and carefully set it back

into the scanner by seating it on the mounting pins. Swing the guide

toward the rear of the scanner to fix it to the two magnets.

NOTE: Look through the upper access door and side access door

to make sure the imaging guide is mounted correctly. There

are two sets of pins. Make sure the guide is seated on the

small, lower set of pins. When the rear imaging guide is

seated correctly, the top of the guide will sit approximately a

½-inch (10 mm) from the vertical transport plate. The rear

imaging guide will become flush with the plate when the

plate is closed.

Rear imaging guide

Rear imaging guide

8. Hold the front imaging guide by the edges and carefully set it back

into the scanner by seating the guide’s two green saddle mounts on

to the mounting shaft, and rotating the front imaging guide

thumbscrew 90° clockwise.

NOTE: Look through the upper access door and side access door

to make sure the imaging guide is mounted correctly. The

bottom of the front imaging guide must be seated just inside

the vertical transport plate. The front imaging guide could be

damaged if it is seated incorrectly when the vertical

transport plate is closed.

Front imaging

guide saddle mount

Vertical

A-61140 January 2000 5-3

Page 38

9. Swing the vertical transport plate closed and rotate the release

Red arrow

handle 180° counterclockwise (so the red arrow aligns with the red

rectangle) to latch the plate.

Red rectangle

10. Close the side access door.

11. Release and lower the horizontal transport plate back into its original

position.

12. Lower the release bar and latch the front scan module into its

original position.

13. Close the lower access door.

14. Close the upper access door.

5-4 A-61140 January 1999

Page 39

Cleaning the feed and

separator rollers (semiautomatic feeder)

Clean the feed and separator rollers daily to prevent ink, toner, and dust

from collecting on the rollers and preventing documents from

separating.

1. Lift open the lower access door.

CAUTION: Open and close the doors slowly.

2. Lift the release bar to raise the front scan module.

3. Rotate the feed roller cover release lever downward while rotating

the feed roller cover to expose the rollers. Do not attempt to remove

the assembly.

A-61140 January 2000 5-5

Page 40

4. Lift up and latch the horizontal transport plate into its open position.

NOTE: If the Patch Reader accessory is installed, it must be

removed from the mounting plate in order to lift up the

horizontal transport plate.

5. Rotate the feed roller downward and clean with a water-moistened

cloth. Continue cleaning until all residue is removed from the roller

ribs.

6. Clean the surface of the feed roller assembly with a dry cloth.

7. Clean the separator roller with a dry cloth.

IMPORTANT: You can only rotate the separator roller outward

(toward you). Do not try to rotate it in the opposite

direction or you could damage the separator roller

assembly.

8. Dry all cleaned areas with a dry, lint-free cloth.

9. Rotate the feed roller cover down to its original position.

10. Lower the release bar and latch the front scan module in its original

position.

11. Close the lower access door.

5-6 A-61140 January 1999

Page 41

Cleaning the feeder module and separator roller (automatic feeder)

Clean the feeder module and separator roller daily to prevent ink, toner,

and dust from collecting on the rollers and preventing documents from

separating.

To clean the feeder module and separator roller:

1. Open the front cover.

2. Push the roller cover release lever toward the back of the machine.

3. Grasp and rotate the roller cover toward the back of the machine,

exposing the feeder module and separator roller.

Roller cover

release lever

Roller cover

Feeder

module

4. Remove the feeder module by pushing it to the right and lifting it out

of its position.

5. Clean both rollers of the feeder module.

6. Replace the feeder module, by aligning the pins and fitting it into

position.

A-61140 January 2000 5-7

Page 42

Cleaning the separator roller:

1. Open the front cover.

2. Push the roller cover release lever toward the back of the machine.

3. Grasp and rotate the roller cover toward the back of the machine,

exposing the feeder module and separator roller.

Roller cover

release lever

Roller cover

Feeder module

4. Lift and remove the separator roller cover plate.

5. Lift the separator roller out of the grooved brackets.

Separator roller

Grooved brackets

6. Clean the separator roller.

7. Replace the separator roller by aligning the pins in the grooved

brackets.

8. Reinsert the separator roller cover plate.

9. Close the feeder cover.

10. Close the front door.

5-8 A-61140 January 1999

Page 43

Cleaning the paper path

NOTE: Before doing the following procedure, clean the machine

thoroughly and use the roller cleaning pads to clean the feed

and separator rollers — start with a clean machine.

Use the Paper Path Cleaning sheet to clean the paper path rollers.

Periodically feed a cleaning sheet with the gum side up through the

machine in both the portrait and landscape orientation.

Regular use of Paper Path Cleaning sheets may result in fewer major

cleanings with the roller cleaning pads.

The paper path should be cleaned daily. Before you clean the paper

path, be sure the feed and separator rollers and imaging guides have

been cleaned.

To clean the paper path:

1. To ensure complete coverage of the transport rollers, feed the

cleaning sheet in the center, and to the left and right of the feeder

document guides.

2. Repeat the procedure until no further residue is picked up by the

cleaning sheet.

3. Using a clean Paper Path Cleaner sheet, repeat Step 1 to verify that

the rollers are clean.

4. Turn the gum side down, and repeat Steps 1 through 3.

NOTE: When the gum side is down, it may be necessary to hold

down the gap release lever to allow the Paper Path Cleaner

sheet to feed past the separator roller.

NOTE:If there are feeder errors after cleaning the feed and separator

rollers, refer to the section entitled “Adjusting the feed and

separator roller gap”, in Chapter 2.

A-61140 January 2000 5-9

Page 44

Weekly maintenance procedures

Maintenance procedures that should be performed weekly are

vacuuming the inside of the scanner and cleaning the cabinet.

Vacuuming inside the scanner

Vacuum the inside of the scanner weekly or as required to remove any

dust or debris.

Vacuuming the horizontal transport area

1. Turn the power off.

2. Lift open the lower access door.

CAUTION: Open and close the doors slowly.

3. Lift the release bar to raise the front scan module.

5-10 A-61140 January 1999

Page 45

4. Lift up and latch the horizontal transport plate into its open position.

NOTE: If the Patch Reader accessory is installed, it must be

removed from the mounting plate in order to lift up the

horizontal transport plate.

5. Vacuum the lower belt module and transport belts.

WARNING: Do not make contact with any electrical

components when vacuuming inside the scanner.

6. Release and lower the horizontal transport plate back into its original

position.

7. Lower the release bar and latch the front scan module into its

original position.

8. Close the lower access door.

A-61140 January 2000 5-11

Page 46

Vacuuming inside the side access door

1. Turn the power off.

2. Open the side access door.

3. Open the upper access door.

4. Release and open the vertical transport plate by rotating the release

handle 180° clockwise.

5. Use a natural bristle cleaning brush to remove debris from inside the

transport system.

5-12 A-61140 January 1999

Page 47

6. Swing the vertical transport plate closed and rotate the release

handle 180° counterclockwise.

7. Vacuum the side access door area.

WARNING: Do not make contact with any electrical

components when vacuuming inside the scanner.

Cleaning the cabinet

8. Close the upper access door and side access doors.

Clean the exterior of the scanner, the feed shelf, and exit hopper with a

soft cloth. Remove any fingerprints, stains, or stubborn dirt with a cloth

dampened with water or a mild cleaning agent.

A-61140 January 2000 5-13

Page 48

Replacement procedures

Replacement procedures should be performed on an as-needed basis.

Components that need periodic replacement include the exposure

lamps and imaging guides.

Changing the lamps

The exposure system consists of two special, long-life fluorescent

lamps. The lamps slide in and out of the scanner for easy lamp

replacement:

• Always replace both lamps at the same time. If both lamps are not

replaced, exposures may not be acceptable.

• Use recommended lamps only. Other lamps may result in

unacceptable image quality.

Change the lamps every 500 hours, when required for error recovery, or

when image quality is poor.

WARNING: Make sure the lamps are cool before attempting to

remove them from the lamp socket holder.

To change the lamps:

1. Turn the power switch off.

2. Open the side access door.

3. Release the rear lamp cable connector from the scanner electrical

system.

5-14 A-61140 January 1999

Page 49

4. Pull the green rear lamp socket holder out from the scanner frame.

Be sure to pull the lamp socket holder straight out along its axis.

WARNING: Even though you can always handle the green lamp

socket holder, the lamp may be very hot. Do not

remove the lamp or the lamp socket holder until

the lamp has cooled.

NOTE: If the lamp socket holder pulls off from the lamp when

removing the lamp and socket from the scanner, remove the

lamp by grasping the lamp at the end, once it has cooled.

5. Once the lamp has cooled, remove the lamp from the lamp socket

holder by carefully pulling the lamp straight out along its axis.

6. Replace the lamp, making sure that the clear slit on the lamp faces

toward the document path. In the case of the rear lamp, the clear slit

should face toward the front.

CAUTION: Lamps are fragile. Do not force the lamp into place.

A-61140 January 2000 5-15

Page 50

7. Carefully insert the green rear lamp sock holder and rear lamp into

the scanner frame. Be sure to insert the lamp socket holder straight

in along its axis.

8. Connect the rear lamp cable connector to the scanner electrical

system.

9. Repeat Steps 3 through 8, referring to the front lamp, noting that in

Step 3 the front lamp cable must be released from the front lamp

cable clip, and in Step 6 the clear slit should face towards the rear. In

Step 8, the front lamp cable connector must be fashioned to the front

lamp cable clip.

10. Close the side access door.

11. Perform the Calibration function. See the section entitled,

“Calibrating the scanner” in Chapter 2.

5-16 A-61140 January 1999

Page 51

Replacing the imaging

Thumbscrew

guides

To replace the imaging guides, follow the steps below:

1. Open the side access door.

2. Release and open the vertical transport plate by rotating the release

handle 180° clockwise.

3. Release and remove the front imaging guide by rotating the

thumbscrew 90° counterclockwise, and lifting the guide’s two green

saddle mounts from the mounting shaft.

Front imaging guide

4. Release and remove the rear imaging guide by swinging the guide

Magnets

Rear imaging guide

toward the front of the scanner (to release it from the two magnets),

and lifting it from the scanner’s two mounting pins.

A-61140 January 2000 5-17

Page 52

5. Grasp and hold the new lower imaging guide by the green handle

saddle mount

mounting pin

transport plate

and carefully slide it into place. Make sure the grooves fully engage

the track.

Rear imaging guide

Rear imaging guide

6. Hold the new front imaging guide by the edges and carefully set it

back into the scanner by seating the guide’s two green saddle

mounts on to the mounting shaft, and rotating the front imaging guide

thumbscrew 90° clockwise.

NOTE: The imaging guides are not interchangeable. They can only

be inserted one way.

Look through the upper access door and side access door

to make sure the imaging guide is mounted correctly. There

are two sets of pins. Make sure the guide is seated on the

small, lower set of pins. When the rear imaging guide is

seated correctly, the top of the guide will sit approximately a

½-inch (10 mm) from the vertical transport plate. The rear

imaging guide will become flush with the plate when the

plate is closed.

Front imaging

guide saddle mount

Vertical

5-18 A-61140 January 1999

Page 53

7. Swing the vertical transport plate closed and rotate the release

Red arrow

handle 180° counterclockwise (so the red arrow aligns with the red

rectangle) to latch the plate.

Red rectangle

8. Close the side access door.

9. Release and lower the horizontal transport plate back into its original

position.

10. Lower the release bar and latch the front scan module into its

original position.

11. Close the lower access door.

12. Close the upper access door.

13. Locate and grasp the end of the front imaging guide. Carefully slide

the imaging guide out of its track.

14. Locate and grasp the end of the rear imaging guide. Carefully slide

the imaging guide out of its track.

15. Grasp and hold the new rear imaging guide by the green handle and

carefully slide it into place. Make sure the grooves fully engage the

track.

16. Grasp and hold the new front imaging guide by the green handle and

carefully slide it into place. Make sure the grooves fully engage the

track.

NOTE: The imaging guides are not interchangeable. They can only

be inserted one way.

17. Close the right-side access door.

A-61140 January 2000 5-19

Page 54

Replacing the feeder module and separator roller

To replace the feeder module and separator roller, follow the steps

below:

Replacing the feeder module:

1. Open the front cover.

2. Push the roller cover release lever toward the back of the machine.

3. Grasp and rotate the roller cover toward the back of the machine,

exposing the feeder module and separator roller.

Roller cover

release lever

Roller cover

Feeder

module

4. Remove the feeder module by pushing it to the right and lifting it out

of its position.

5. Reinsert a new feeder module, by aligning the pins and fitting it into

position.

5-20 A-61140 January 1999

Page 55

Replacing the separator roller:

1. Open the front cover.

2. Push the roller cover release lever toward the back of the machine.

3. Grasp and rotate the roller cover toward the back of the machine,

exposing the feeder module and separator roller.

Roller cover

release lever

Roller cover

Feeder module

4. Lift and remove the separator roller cover plate.

5. Lift the separator roller out of the grooved brackets.

Separator roller

Grooved brackets

6. Reinsert a new separator roller by aligning the pins in the grooved

brackets.

7. Reinsert the separator roller cover plate.

8. Close the feeder cover.

9. Close the front door.

A-61140 January 2000 5-21

Page 56

Ordering replacement parts

The following consumable parts can be ordered by calling:

1-800-431-7278.

• Imaging guides

− Front: Part No. 986448

− Rear: Part No. 986449

• Exposure lamps: 986472

• Automatic Document Feeder Module: CAT No. 123 6066

• Automatic Document Feeder Separator Roller: CAT No. 161 4908

Ordering cleaning materials

The following cleaning materials can be ordered:

• Paper Path Cleaner: Part No. 4C9073 (pack of 50)

• Staticide Wipes: Part No. 1C8102 (pack of 24)

5-22 A-61140 January 1999

Page 57

6 Operator Messages

This chapter outlines the actions that should be taken by the user and

system administrator when an error message appears in the status

display.

When a message appears in the status display, you should take the

action suggested in the Operator Message Listing. If you cannot solve

the problem, call the system administrator. If the problem persists, the

system administrator should call Service personnel.

When an error message is displayed, some keys on the control panel

may be temporarily invalid. However, the Jog key is available most of the

time so documents in the transport system can be removed.

IMPORTANT: Never power down the machine without first contacting

When a + (plus) sign is displayed between the error code and error

message, it indicates more than one error message has been

generated. Press the + key to view the other error messages.

In most cases, when error codes are displayed, you will have to press C

to clear the message. Then proceed with any additional procedures as

indicated in the Description/Action Required column of the Operator

Message Listing. Limited procedures are included in the Operator

Message Listing. Full procedures are documented in the following

chapters:

your system administrator.

Chapter 2, Getting Started

Chapter 3, Operating the Scanner

Chapter 5, Maintenance

Chapter 7, Troubleshooting

Refer to these chapters as needed.

Service Errors

If a message appears in the status display that is within the ranges

E600-E999, contact your system administrator; these are service errors

and Service personnel should be contacted.

A system administrator should contact Service when:

• the initial error recovery has been performed but the error message

persists.

• the initial error recovery has no effect on the error message.

• an indicated accessory must be replaced.

A-61140 January 2000 6-1

Page 58

Controlled powerdown sequence

Before performing the controlled power-down sequence , determine if

the error can be addressed from the host. If so, perform the required

host recovery procedures. If the error cannot be addressed from the

host, or if the scanner’s error message cannot be cleared when the

host recovery procedures are performed, continue with the following

power-down sequence.

1. Wait for all information currently held in the buffer to be transferred to

the host system.

2. If necessary, prepare the host and corresponding system

components for a scanner power-down, per host system

instructions.

3. Turn off the scanner power for at least 5 seconds, then turn the

power back on again.

4. If necessary, determine the last image transferred to the host, reset

the image address and image level to the correct values, and rescan

all documents whose images have not been transferred to the host.

5. If required, calibrate the scanner before rescanning.

6. If the error condition is not cleared using the controlled power-down

sequence, contact Service.

6-2 A-61140 January 2000

Page 59

Operator message listing

Code Message Displayed Description/Action Required

E101 Auto shut-off Transport will stop and the message will be displayed

if a document has not been scanned within one

minute. Press Run to continue. Feed documents.

E102 Press STOP and try again Tried to use a function code that is not valid while the

transport is running. Press Stop and try again.

E103 Select valid mode (1 - 18) Invalid application mode was selected. Enter function

code F01 to select another mode.

E104 Function not available Invalid function code entered. Enter a valid function

code.

E105 Parameter Value Invalid There is an invalid front/rear resolution mismatch or a

crop length/resolution mismatch. Check the scanner

configuration.

E106 Doc length monitor - warning Tried to scan a document that was shorter or longer

than the maximum or minimum length set up for the

application mode you are using. Potentially a multifeed condition. Check the document length to see if it

is shorter than the minimum or longer than the

maximum allowed or a multi-feed; refeed the

document.

E107 Doc skew monitor - warning Tried to scan a document that is skewed greater than

the maximum skew angle set up for the application

mode you are using and less than 30 degrees.

Refeed the document.

E112 Invalid patch level Invalid patch was used. The patch document is

ignored and the previous image level and image

address remain unchanged. Feed a correct patch

document.

E113 Incorrect image address Tried to use an invalid image address. The image

address was not completely input before pressing

Enter. Press Next to enter a correct image address.

E114 Check current IA/level Conflicting input regarding the proper level was

received. Check the current document image level

and image address.

E116 Accessory not mode enabled Tried to use an accessory that is not enabled in the

chosen mode. Enter a different function code or

select an application mode that is enabled. If the

selected accessory is desired, contact Service to

change the mode configuration.

A-61140 January 2000 6-3

Page 60