Page 1

TECHNICAL DATA / COLOR REVERSAL FILM

EASTMAN EKTACHROME

February 1999 • H-1-5239

H-1-5247

August 1996

Film (Daylight) 7239

™

DESCRIPTION

EASTMAN EKTACHROME Film 7239 (Daylight) is a

high-speed color reversal film intended for photography

under low-level daylight illumination. Among its many

applications are news photography, sporting events, and

high-speedphotography.Theprocessedoriginalcamerafilm

is ready for projection; because it is balanced for projection

at 5400 K, it is suitable for television broadcasting.

You can expose this film at effective film speeds ranging

from1⁄2 to 2 times the normal exposure indexes with little

loss in quality. For emergency situations when some loss in

quality is acceptable, increase the normal exposureindex by

the equivalent of 2 to 3 stops. When you expose the film at

other than the normal exposure index, tell the processing

laboratory so they can adjust the processing.

The processed camera original on EASTMAN

EKTACHROME Film (Daylight) is meant for direct

projection; however, you can make color duplicates on

EASTMAN EKTACHROME Print Film 7399.

BASE

This film has a clear acetate safety base.

DARKROOM RECOMMENDATIONS

Handle unprocessed film intotaldarkness until afterthestop

bath following first development. You can do the remaining

operations in anormally lighted room.Use a safelight with a

KODAK Safelight Filter No. 3 / dark green to illuminate

dials, meters, etc, duringfirst development; do not shine the

light directly on the film.

STORAGE

Store unexposed film at 13˚C (55˚F) or lower. Process

exposed film promptly. Store processed film at 21˚C (70˚F)

or lower ata relative humidity of40 to 50percent for normal

commercial storage. For more information on long-term

storage, see KODAK Publications No.H-1,KODAK Motion

Picture Film, and No. H-23, The Book of Film Care.

COLOR BALANCE

This film is balanced for daylight exposure. For other light

sources, use the correction filters in the table below.

Light Source

Daylight (5500 K) None 160/23

Tungsten (3000 K) WRATTEN Gelatin No. 80A 40/17

Tungsten lamps

(3200 K)

Tungsten photoflood

(3400 K)

Metal halide H.M.I. None 160/23

White-flame arcs None 160/23

Yellow-flame arcs WRATTEN Gelatin No. 80A 40/17

Optima 32 WRATTEN Gelatin No. 80A 40/17

Vitalite None 160/23

Fluorescent Cool

White†

Fluorescent Deluxe

Cool White†

* These are approximate corrections only. Make final corrections during

printing.

† Thesearestarting-pointrecommendationsfortrial exposures. When you

don’t know the type of fluorescent lamps, use a CC20M filter with an

exposure index of 100/21.

KODAK Filters

on Camera*

WRATTEN Gelatin No. 80A 40/17

WRATTEN Gelatin No. 80B 50/18

Color Compensating 30M 100/21

Color Compensating 20B 100/21

Exposure Index/DIN

Note: Consult the manufacturer of high-intensity ultraviolet

lamps for safety information on ultraviolet radiation and

ozone generation.

EXPOSURE INDEX/DIN

Daylight—160/23

Tungsten* (3200 K)—40/17

Use these indexes with incident- or reflected-light exposure

meters and cameras marked for ISO or ASA speeds or

exposure indexes. These indexes apply for meter readings of

average subjects made from the camera position or for

readings made from a gray card of 18-percent reflectance

held close to and in front of the subject. For unusually lightor dark-colored subjects, decrease or increase the exposure

indicated by the meter accordingly.

©Eastman Kodak Company, 1998

*With a KODAK WRATTEN Gelatin Filter No. 85B.

Page 2

EXPOSURE TABLE FOR DAYLIGHT

At 24 frames per second (fps), 170˚ shutter opening:

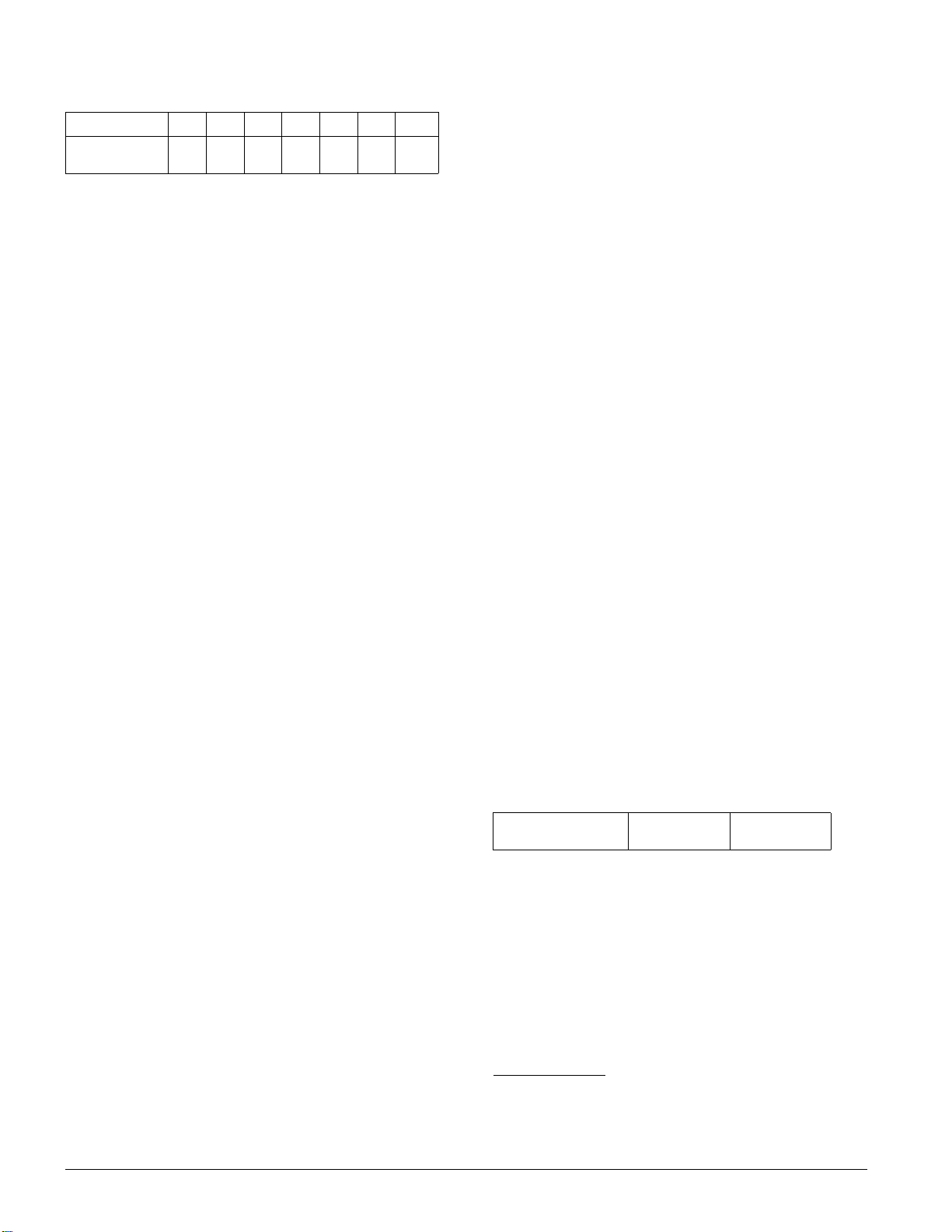

Lens Aperturef/1.4f/2f/2.8 f/4f/5.6f/8f/11

Footcandles

required

Use this table for average subjects that contain a

combination of light, medium, and dark colors. When a

subject includes only pastels, use at least1⁄2 stop less

exposure; dark colors require1⁄2 stop more exposure.

16 32 63 125 250 500 1000

In the LADcontrol method,*the electronic coloranalyzer

used for color timing is set upwith the LAD Control Film to

produce a gray video display of the LAD patch,

corresponding to 1.0 neutral density (gray)on theprint. The

negative printing original is then scene-to-scene timed.

There are specific LAD values for each type of print or

duplicating film that the originalcan be printed on. Forprint

films, the LAD patchis printed to aneutral gray of 1.0visual

density. For duplicating films, the specified aims are at the

center of theusable straight-line portionof the sensitometric

curve of the film.

Lighting Contrast

The recommended ratio of key-light-plus-fill-light to fill

light is 2:1 or 3:1; you may use a 4:1 ratio if you want a

special look.

RECIPROCITY CHARACTERISTICS

You do not need any filter or exposure adjustments for

exposure times from 1 second to 1/10,000 second.

PROCESSING

This film may be processed in Process VNF-1, using either

ferricyanide or persulfate bleach, and in Process RVNP.

Force processing beyond 2 stops is not recommended.

EASTMAN EKTACHROME Film can be processed by

theindividual user, if desired. For information onprocedures

for machine processing the film, see KODAK Publication

No. H-24, Manual for Processing EASTMAN Motion

Picture Films.

IDENTIFICATION

The words “Eastman VND Safety Film” is latent-image

printed along the edge of the film.

FILM TO VIDEO TRANSFER

When you transfer the film directly to video, you can set up

the telecine with a negative Telecine Analysis Film (TAF)

supplied by Eastman Kodak Company. The TAFconsists of

aneutraldensity scale and an eight-bar color testpattern with

a LAD gray surround.

The TAF gray scale provides the telecine operator

(colorist) with an effective way to adjust subcarrier balance

and to center the telecine controls before timing and

transferring a film. The TAFcolor bars provide the utilityof

electronic color bars, even though they do not precisely

matchtheelectronically generated color bars. Using the TAF

will help obtain optimum quality and consistency in the

film-to-video transfer.

For more information, see KODAK Publication

No. H-822, KODAK Telecine Analysis Film User’s Guide.

IMAGE STRUCTURE

The modulation-transfer curve, the diffuse rms granularity,

and the resolving-power data were generated from samples

of 7239 Film exposed to daylight and processed as

recommended in Process VNF-1. For more information on

image-structure characteristics, see KODAK Publication

No. H-1, KODAK Motion Picture Film.

LABORATORY AIM DENSITY (LAD) CONTROL METHOD

To maintain optimum quality and consistency in the final

prints, the laboratory mustcarefully controlthecolor timing,

printing, and duplicating procedures. To aid in color timing

and curve placement, negative originals should be timed

relative to the Laboratory Aim Density(LAD) ControlFilm

Diffuse RMS Granularity* 14

Resolving Power†

* Read at a net diffuse visual density of 1.0, using a

48-micrometer aperture.

† Determined according to a method similar tothe one described

in ISO 6328-1982,

Determination of ISO Resolving Power.

TOC 1.6:1

TOC 1000:1

Photography—Photographic Materials—

40 lines/mm

100 lines/mm

supplied by Eastman Kodak Company. The LAD Control

Film provides both objective sensitometric control and

subjective verification of theduplicating procedures usedby

the laboratory.

* The LAD control method is described in the paper “A Simplified

Motion-Picture Laboratory Control Method for Improved Color

Duplication,” by John P. Pytlak and Alfred W. Fleischer in the

October 1976 SMPTE Journal. Also refer to KODAK Publication

No. H-61, LAD—Laboratory Aim Density.

2 EASTMAN EKTACHROME Film (Daylight) 7239™ • H-1-5239

Page 3

4.0

3.0

2.0

DENSITY

1.0

0.0

3.0

Sensitometric Curves

Exposure:

Process:

Densitometry:

B

R

G

2.0

LOG EXPOSURE (lux-seconds)

Daylight, 1/100 second

VNF-1

Status A

G

1.0

0.0 1.0

F002_0149AC

2.0

1.0

*

0.0

LOG SENSITIVITY

Effective Exposure:

1.0

1.4 seconds

Process:

Densitometry:

2.0

F002_0150AC

*Sensitivity = reciprocal of exposure (ergs/cm ) required

Spectral-Sensitivity Curves

Magenta-

Yellow-

Forming

Forming

Layer

Layer

VNF-1

1.0Density:

E.N.D.

WAVELENGTH (nm)

to produce specified density

Cyan-

Forming

Layer

700 750650600550500450400350300250

2

Spectral-Dye-Density Curves

1.3

Normalized dyes to form a visual neutral density

of 1.0 for a viewing illuminant of 5400 K.

0.8

Yellow

0.3

DIFFUSE SPECTRAL DENSITY

VNF-1Process:

-0.2

250

F002_0151AC

WAVELENGTH (nm)

Modulation-Transfer Curve

200

100

70

50

30

Cyan

20

10

Magenta

7

5

RESPONSE (%)

3

2

1

1001 2 3 4 5 10 20 50 200 600

SPATIAL FREQUENCY (cycles/mm)

450350

650

750550

F002_0148AC

These photographic modulation-transfer values were determined by

using a method similar to the one described in ANSI Standard

PH2.39-1977(R1990). The film was exposed with the specified

illuminant to spatially varying sinusoidal test patterns having an aerial

image modulation of a nominal 35 percent at the image plane, with

processing as indicated. In most cases, these photographic

modulation-transfer values are influenced by development-adjacency

effects and are not equivalent to the true optical modulation-transfer

curve of the emulsion layer in the particular photographic product.

Note: While the data presentedare typicalof productioncoatings, they

do not represent standards which must be met by Kodak. Varying

storage, exposure, and processing conditions will affect results. The

company reserves the right to change and improve product

characteristics at any time.

EASTMAN EKTACHROME Film (Daylight) 7239™ • H-1-5239 3

Page 4

EASTMAN EKTACHROME Film (Daylight) 7239™

AVAILABLE ROLL LENGTHS

For information on film roll lengths, check Kodak’s

Professional Motion Imaging Price Catalog or see a Kodak

sales representative in your country.

KODAK

FOR DIRECT ORDERING IN THE UNITED STATES:

1-800-621-FILM

ATLANTA, GEORGIA

4 Concourse Parkway

Suite 300

Atlanta, Georgia 30328-6105

Information: 800-800-8398

CHICAGO, ILLINOIS

815 West Van Buren, Suite 320

Chicago, Illinois 60607

Information: 312-492-1423

DALLAS, TEXAS

11337 Indian Trail

Dallas, Texas 75229

Information: 972-481-1170

312-492-1423

HOLLYWOOD, CALIFORNIA

6700 Santa Monica Boulevard

P. O. Box 38939

Hollywood, California 90038-1203

Information: 323-464-6131

LOCATIONS

FOR DIRECT ORDERING IN CANADA:

1-800-621-FILM

MONTREAL, CANADA

Kodak Canada Inc.

4 Place du Commerce, Suite 100

1le des Soeurs

Verdun, Quebec, Canada, H3E 1J4

Information: 514-761-7001

TORONTO, CANADA

Kodak Canada Inc.

3500 Eglinton Avenue West

Toronto, Ontario, Canada, M6M 1V3

Information: 416-761-4922

VANCOUVER, CANADA

Kodak Canada Inc.

4185 Still Creek Drive, Suite C150

Burnaby, British Columbia, Canada, V5C 6G9

Information: 604-570-3526

Kodak On-Line At:

http://www.kodak.com/go/motion

NEW YORK, NEW YORK

360 West 31st Street

New York, New York 10001-2727

Information: 212-631-3450

LATIN AMERICAN REGION

8600 NW 17th Street, Suite 200

Miami, Florida 33126

Information: 305-507-5656

EASTMAN EKTACHROME Film

(Daylight) 7239

KODAK Publication No. H-1-5239

CAT 824 4295

Professional

Motion Imaging

Kodak, Eastman, Ektachrome, 5239, 7239, 7399,

and Wratten are trademarks.

Minor Revision 2-99

Printed in U.S.A.

Loading...

Loading...