Page 1

KODAK VISION3 500T Color

Negative Film 5219 / 7219 / SO-219

TECHNICAL DATA /

COLOR NEGATIVE FILM

The first in a new family of films, VISION3 500T Film gives

you more control and flexibility at every phase of the

filmmaking process—from capture through post, in both

digital and traditional workflows.

VISION3 500T Film retains the overall look and image

structure of KODAK VISION2 Films—then adds technical

innovations that provide improved exposure latitude—at

both ends of the curve. Proprietary, advanced Dye Layering

Technology (DLT) gives you noticeably reduced grain in

shadows, so you can shoot at higher speeds, with less light,

in darker corners, and know you can capture an amazing

amount of shadow detail with noticeably lower grain.

VISION3 500T Film also features extended highlight

latitude, so you can follow the action into bright light-in a

single shot-without worrying about blown-out details.

When the film is scanned and digitized, you'll find you can

recover two stops of highlight detail. This technology is

enabled by the use of sub-micron imaging sensors.

VISION3 500T Film fits seamlessly into your digital

workflow. And when scanning low-light scenes, VISION3

500T Film yields higher signal-to-noise ratios for

unprecedented image quality.

BASE

KODAK VISION3 500T Color Negative Films 5219 and

7219 have an acetate safety base with rem-jet backing.

KODAK VISION3 500T Color Negative Film SO-219 has

an ESTAR Safety Base with rem-jet backing

STORAGE

Store unexposed film at 13°C (55°F) or lower. For extended

storage, store at -18°C (0°F) or lower. Process exposed film

promptly. Store processed film according to the

recommendations in ANSI/PIMA IT9.11-1998: for

medium-term storage (minimum of ten years), store at

10°C(50°F) or lower at a relative humidity of 20 to 30

percent; for extended-term storage (for preservation of

material having permanent value), store at 2°C (35°F) or

lower at a relative humidity of 20 to 30 percent. For active

use, store at 25°C(77°F) or lower, at a relative humidity of

50 +/- 5 percent. This relates to optimized film handling

rather than preservation; static, dust-attraction and

curl-related problems are generally minimized at the

higher relative humidity. After usage, the film should be

returned to the appropriate medium- or long-term storage

conditions as soon as possible.

For more information about medium- and long-term

storage, see ANSI/PIMA IT9.11-1998, SMPTE RP131-2002,

and KODAK Publications No. H-1, KODAK Motion Picture

Film and No. H-23, The Book of Film Care.

November 2007 • H-1-5219t

EXPOSURE INDEXES

Tungsten (3200K) - 500 Daylight1 - 320

Use these indexes with incident- or reflected-light

exposure meters and cameras marked for ISO or ASA

speeds or exposure indexes. These indexes apply for meter

readings of average subjects made from the camera

position or for readings made from a gray card of

18-percent reflectance held close to and in front of the

subject. For unusually light- or dark-colored subjects,

decrease or increase the exposure indicated by the meter

accordingly.

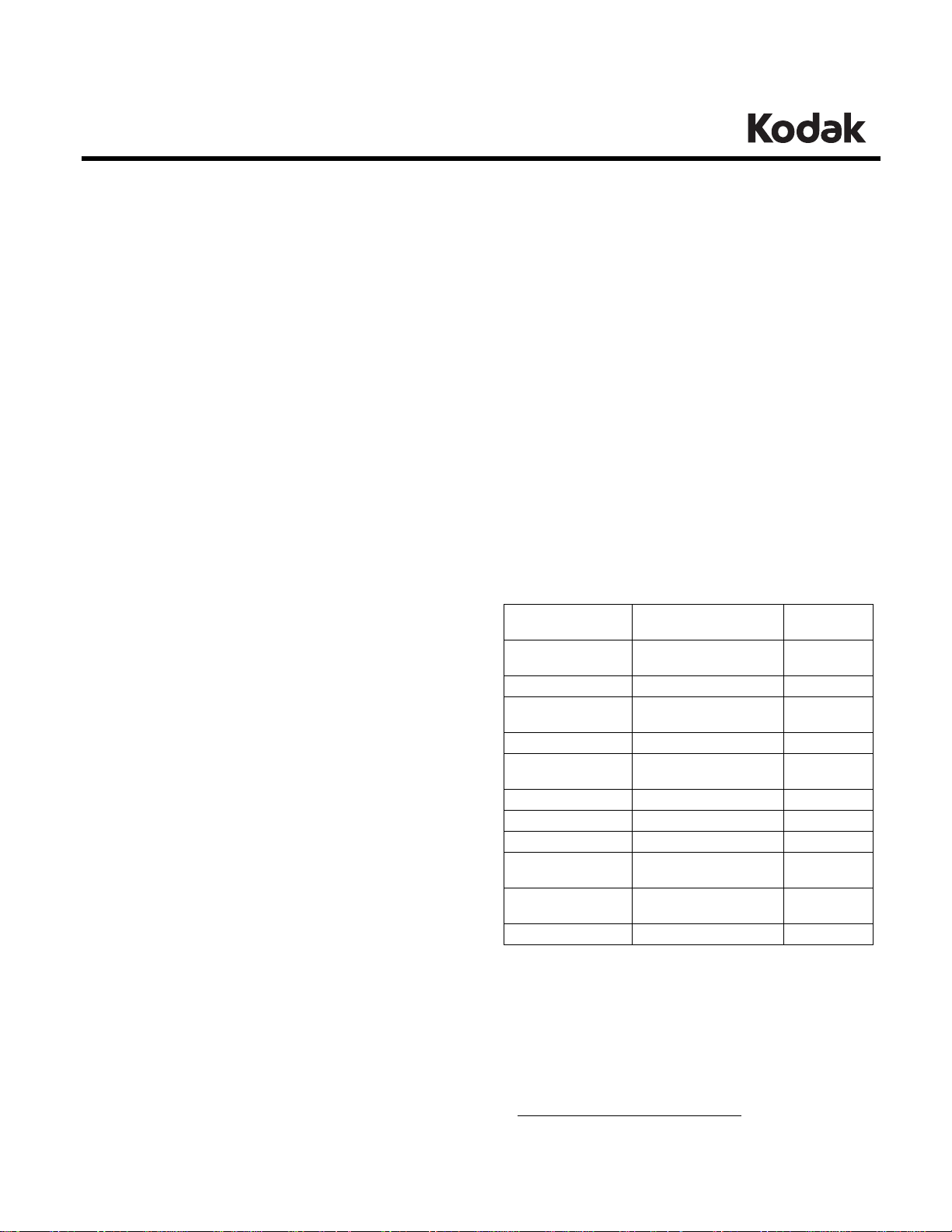

COLOR BALANCE

These films are balanced for exposure with tungsten

illumination (3200K). You can also expose them with

tungsten lamps that have slightly higher or lower color

temperatures (+/- 150K) without correction filters, since

final color balancing can be done in printing. For other light

sources, use the correction filters in the table below.

Light Source

Tungsten (3000 K) WRATTEN Gelatin No.

Tungsten (3200 K) None 500

Tungsten photoflood

(3400 K)

Daylight (5500 K) WRATTEN Gelatin No. 85 320

White-Flame Arcs WRATTEN Gelatin No.

Yellow-Flame Arcs Color Compensating 20Y 320

OPTIMA 32 None 500

VITALITE WRATTEN Gelatin No. 85 320

Fluorescent, Cool

†

White

Fluorescent, Deluxe

Cool White

Metal Halide WRATTEN Gelatin No. 85 320

*

These are approximate corrections only. Make final corrections during

printing.

†

These are starting-point recommendations for trial exposures. If the kind of

lamp is unknown, a KODAK Color Compensating Filter CC 40R can be used

with an exposure index (EI) of 250.

†

KODAK Filters

on Camera

WRATTEN Gelatin No. 85

+ 10M

WRATTEN Gelatin No.

85C + 10R

*

82B

None 500

85B

Note: Consult the manufacturer of high-intensity

ultraviolet lamps for safety information on ultraviolet

radiation and ozone generation.

1. With a KODAK WRATTEN Gelatin Filter No. 85.

Exposure

Index

320

200

200

320

©Eastman Kodak Company, 2007

Page 2

DARKROOM RECOMMENDATIONS

Do not use a safelight. Handle unprocessed film in total

darkness.

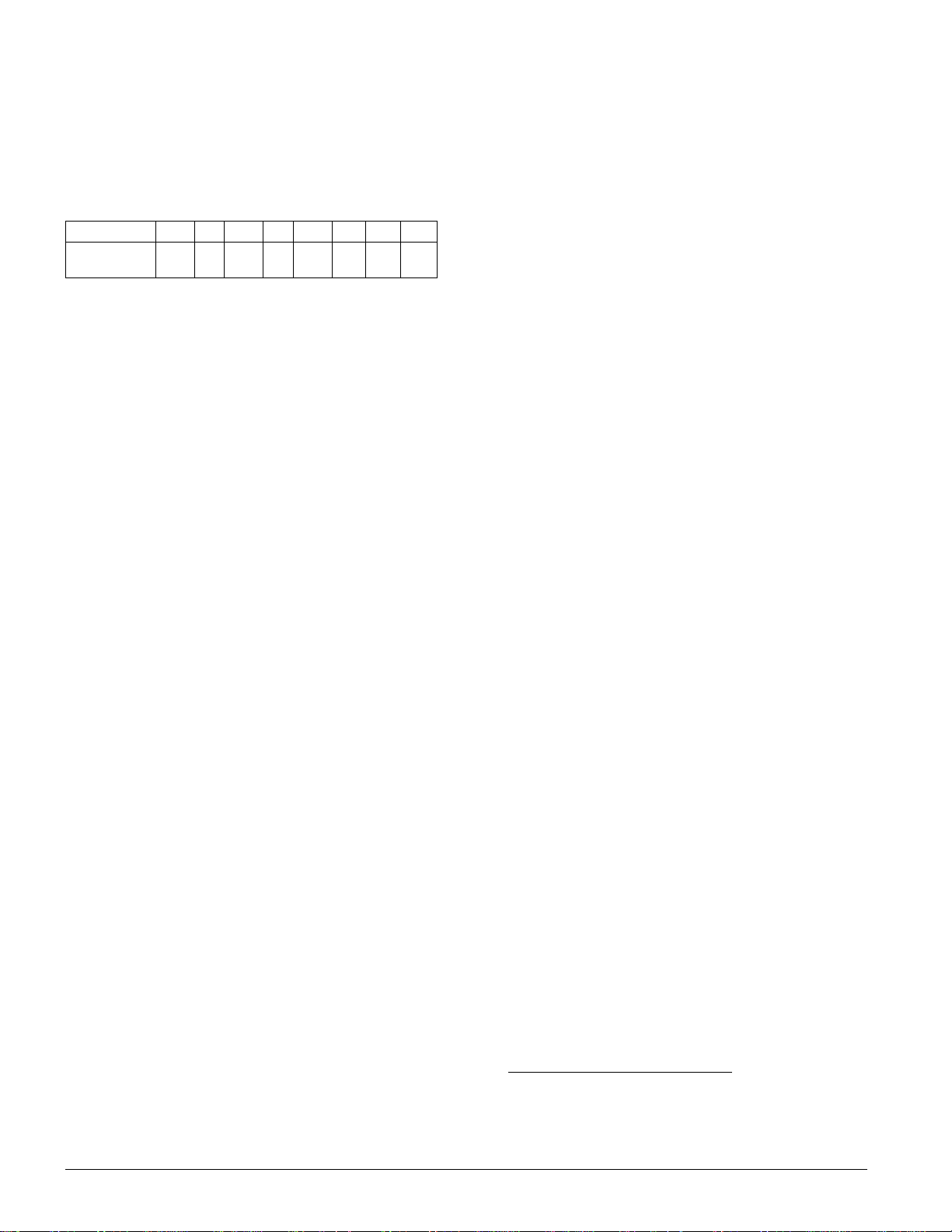

EXPOSURE TABLE - TUNGSTEN LIGHT

At 24 frames per second (fps), 170-degree shutter

opening:

Lens Aperture f/1.4 f/2 f/2.8 f/4 f/5.6 f/8 f/11 f/16

Footcandles

Required

510204080160320640

Use this table for average subjects that contain a

combination of light, medium, and dark colors. When a

subject includes only pastels, use at least 1/2 stop less

exposure; dark colors require 1/2 stop more exposure.

Lighting Contrast -

The recommended ratio of key-light-plus-fill-light to fill

light is 2:1 or 3:1. However, you may use 4:1 or greater when

a particular look is desired.

RECIPROCITY CHARACTERISTICS

You do not need to make any filter corrections or exposure

adjustments for exposure times from 1/1000 of a second

to 1 second. In the 10-second range, increase exposure 1

stop and use a KODAK Color Compensating Filter CC 10R.

PROCESSING

Process in Process ECN-2.

Most commercial motion-picture laboratories provide a

processing service for these films. See KODAK Publication

No. H-24.07, Processing KODAK Color Negative Motion

Picture Films, Module 7 available online at http://

www.kodak.com/US/plugins/acrobat/en/motion/

support/processing/h247/h2407.pdf, for more

information on the solution formulas and the procedure for

machine processing these films. There are also

pre-packaged kits available for preparing the processing

solutions. For more information on the KODAK ECN-2 Kit

Chemicals, check Kodak's Motion Picture Films for

Professional Use price catalog.

IDENTIFICATION

After processing, the product code numbers 5219 (35

mm), 7219 (16 mm), or SO-219 (16, 35, and 65 mm;

edgeprint shows 0219) emulsion, roll, and strip number

identification, KEYKODE Numbers, and manufacturer/film

identification code (EJ) are visible along the length of the

film.

LABORATORY AIM DENSITIES (LAD)

To maintain optimum quality and consistency in the final

prints, the laboratory must carefully control the color

timing, printing, and duplicating procedures. To aid in color

timing and curve placement, negative originals should be

timed relative to Laboratory Aim Density (LAD) Control

Film supplied by Eastman Kodak Company.

2

The LAD

Control Film provides both objective sensitometric control

and subjective verification of the duplicating procedures

used by the laboratory.

In the LAD Control Method,

3

the electronic color

analyzer used for color timing is set-up with the LAD

Control Film to produce a gray video display of the LAD

patch, corresponding to 1.0 neutral density (gray) on the

print. The negative printing original is then scene-to-scene

timed. There are specific LAD values for each type of print

or duplicating film that the original can be printed on. For

print films, the LAD patch is printed to a neutral gray of 1.0

visual density. For duplicating films, the specified aims are

at the center of the usable straight-line portion of the

sensitometric curve of the film.

Due to normal variations in exposure and processing of

color negative films, particular scenes may not print

exactly at the same printer lights as the LAD Control Film.

The LAD Control Film is intended as a set-up tool for

electronic color analyzers and printers. It is NOT a

reference that every scene must match. Normal

film-to-film and scene-to-scene exposure variability is

accommodated by the color timing (grading) process, on

an electronic color analyzer set up with the LAD Control

Film. Normally exposed and processed color negatives will

typically print well within the range of an additive printer

setup with the LAD Control Film, although SIGNIFICANT

or UNEXPECTED departures from this center point

balance may indicate an exposure/filtration problem with

the cinematography or with the process control. Some

specialized films and/or specialized negative processing

techniques (push-processing, pull-processing,

"skip-bleach" processing, etc.) may require more extreme

adjustment from the LAD printing condition to attain

desired results.

More information is contained in KODAK Publication

H-61, Laboratory Aim Density, available online at

http://www.kodak.com/US/en/motion/support/

lad.jhtml.

FILM-TO-TAPE TRANSFERS

When you transfer the film directly to tape, you can set up

the telecine using KODAK Telecine Analysis Film (TAF)

2. Direct any inquiries to one of the regional sales offices.

3. Use of the LAD Control Method is described in the paper, "A Simplified

Motion-Picture Laboratory Control Method for Improved Color

Duplication," by John P. Pytlak and Alfred W. Fleischer in the October 1976

SMPTE Journal.

2 KODAK VISION3 500T Color Negative Film 5219 / 7219 / SO-219 • H-1-5219t

Page 3

supplied by Eastman Kodak Company. The TAF consists of

Characteristic Curves

a neutral density scale and an eight-bar color test pattern

with a LAD gray surround.

The TAF gray scale provides the telecine operator

(colorist) with an effective way to adjust subcarrier

balance and to center the telecine controls before timing

and transferring a film. The TAF color bars provide the

utility of electronic color bars, even though they do not

precisely match the electronically generated color bars.

Using the TAF will help obtain optimum quality and

consistency in the film-to-tape transfer. For more

information regarding TAF, see KODAK Publication No.

H-9, TAF User's Guide.

IMAGE STRUCTURE

The modulation-transfer and diffuse rms granularity

curves were generated from samples of 5219 Film exposed

with tungsten light and processed as recommended in

Process ECN-2 chemicals. For more information on

image-structure characteristics, see KODAK Publication

No. H-1, KODAK Motion Picture Film available online at

http://www.kodak.com/US/en/motion/support/h1.

Modulation Transfer Function

The "perceived" sharpness of any film depends on various

components of the motion picture production system. The

camera and projector lenses and film printers, among other

factors, all play a role. But the specific sharpness of a film

can be measured and is charted in the Modulation Transfer

Function Curve.

CURVES

Sensitometric Curves

-4.0 -3.0 -2.0 -1.0 0.0 1.0

3.0

Exposure: 3200K Tungsten 1/50 sec

Process: ECN-2

Densitometry: ECN-2

2.0

Density

1.0

0.0

-8 -7 -6 -5 -4

TI2647F

The curves describe this film's response to red, green,

and blue light. Sensitometric curves determine the change

in density on the film for a given change in log exposure.

Note: The exposure scale for VISION3 5219 / 7219 Film is

longer than previous VISION and VISON2 Films. Because

of the extended highlight latitude of and because we need

to measure in this region, we expanded the exposure scale

from a zero to four increment to a zero to five scale. In

addition to the longer exposure scale, we are plotting

twenty-one steps instead of twenty.

LOG EXPOSURE (lux-seconds)

-3 -2 -1 0 1 2 3 4 5 6 7 8

Camera Stops

B

G

R

4

rms Granularity:

Refer to curve.

Read with a microdensitometer, (red, green, blue) using

a 48-micrometer aperture.

The "perception" of the graininess of any film is highly

dependent on scene content, complexity, color, and

density. Other factors, such as film age, processing,

exposure conditions, and telecine transfer may also have

significant effects.

NOTICE: The sensitometric curves and data in this

publication represent product tested under the conditions

of exposure and processing specified. They are

representative of production coatings, and therefore do

not apply directly to a particular box or roll of photographic

material. They do not represent standards or specifications

that must be met by Eastman Kodak Company. The

company reserves the right to change and improve

KODAK VISION3 500T Color Negative Film 5219 / 7219 / SO-219 • H-1-5219t 3

Page 4

Modulation-Transfer Function Curves

200

100

70

50

30

20

R

G

B

10

7

5

RESPONSE (%)

Exposure: 3200K Tungsten

3

Process: ECN-2

2

Densitometry: Status M

1

1001 2 3 4 5 10 20 50 200 600

TI2647B

SPATIAL FREQUENCY (cycles/mm)

This graph shows a measure of the visual sharpness of

this film. The x-axis, "Spatial Frequency," refers to the

number of sine waves per millimeter that can be resolved.

The y-axis, "Response," corresponds to film sharpness.

The longer and flatter the line, the more sine waves per

millimeter that can be resolved with a high degree of

sharpness—and, the sharper the film.

Diffuse rms Granularity Curves

3.0

Process: ECN-2

2.0

DENSITY

1.0

0.0

0.0 1.0

TI2647C

Blue Density

Green Density

Red Density

Blue Grain

Green Grain

Red Grain

G

R

3.0

LOG RELATIVE EXPOSURE

B

G

R

0.10

0.05

0.04

B

4.0 5.02.0

0.03

0.02

0.01

0.006

0.005

0.004

0.003

0.002

.001

To find the rms Granularity value for a given density, find

the density on the left vertical scale and follow horizontally

to the characteristic curve and then go vertically (up or

down) to the granularity curve. At that point, follow

horizontally to the Granularity Sigma D scale on the right.

Read the number and multiply by 1000 for the rms value.

Note: This curve represents granularity based on modified

measuring techniques.

4

4.0

3.0

*

2.0

LOG SENSITIVITY

1.0

0.0

TI2647D

These curves depict the sensitivity of this film to the

spectrum of light. They are useful for determining,

modifying, and optimizing exposure for blue- and

green-screen special-effects work.

1.8

1.6

1.4

1.2

1.0

0.8

GRANULARITY SIGMA D

0.6

0.4

DIFFUSE SPECTRAL DENSITY

0.2

0.0

-0.2

400 450 500 550 600 650 700 750 800

TI2647E

These curves depict the spectral absorptions of the dyes

formed when the film is processed. They are useful for

adjusting or optimizing any device that scans or prints the

film.

Note: Cyan, Magenta, and Yellow Dye Curves are

peak-normalized.

Spectral Sensitivity Curves

Yellow-

Forming

Layer

Effective Exposure: 1/25 sec

Process: ECN-2

Densitometry: Status M

Densitry: 0.2>D-min

WAVELENGTH (nm)

*Sensitivity = reciprocal of exposure (erg/cm ) required

to produce specified density

Magenta-

Forming

Layer

Cyan-

Forming

Layer

2

Spectral Dye Density Curves

Process: ECN-2; D-mins subtracted

Midscale Neutral

Cyan

Magenta

WAVELENGTH (nm)

Yellow

Minimum Density

700 750650600550500450400350300250

4. Sensitometric and Diffuse RMS Granularity curves are produced on

different equipment. A slight variation in curve shape may be noticed.

4 KODAK VISION3 500T Color Negative Film 5219 / 7219 / SO-219 • H-1-5219t

Page 5

SIZES AVAILABLE

Standard Products Available

Identification No.

65 mm SP332 305 (1000) P Emulsion In KS-4740 (KS-1866)

35 mm SP417 30 (100) S-83 100-ft. spool BH-4740 (BH-1866)

35 mm SP718 61 (200) U BH-4740 (BH-1866)

35 mm SP718 122 (400) U BH-4740 (BH-1866)

35 mm SP718 305 (1000) U BH-4740 (BH-1866)

16 mm SP449 30 (100) R-90 100-ft. spool 2R-7605 (2R-2994)

16 mm SP451 122 (400) T 2R-7605 (2R-2994)

16 mm SP578 122 (400) S-153 400-ft. spool 2R-7605 (2R-2994)

16 mm SP445

16 mm SP455 30 (100) R-90 100-ft. spool Winding B 1R-7605 (1R-2994)

16 mm SP457 122 (400) T Winding B 1R-7605 (1R-2994)

16 mm SP458 244 (800) Z Winding B 1R-7605 (1R-2994)

16 mm SP462N 15 (50) R-236 50-ft.spool 2R-7605 (2R-3000)

S8 mm SP464 15 (50) Super 8 cartridge

*

for AATON A-MINIMA Cameras

*

Length in

Metres (Feet)

61 (200) A Winding A 1R-7620 (1R-3000)

Core Description Perforations

MORE INFORMATION

Outside the United States and Canada, please contact your Kodak representative.

You can also visit our web site at www.kodak.com/go/motion for further information. You may want to bookmark our

location so you can find us easily the next time.

Film s Film for the Cinematographer

Image Structure KODAK Motion Picture Film

Storage KODAK Moti on Picture Film

Processing Manual for Processing KODAK Motion Picture Films, Process

LAD LAD—Laboratory Aim Density

Tr a n s f e r KODAK Telecine Analysis Film User’s Guide

KODAK Publication No. H-5

KODAK Publication No. H-1

KODAK Publication No. H-1

The Book of Film Care

KODAK Publication No. H-23

ECN-2 Specifications, Module 7

KODAK Publication No. H-24.07

KODAK Publication No. H-61

KODAK Publication No. H-822

KODAK Telecine Exposure Calibration Film User’s Guide

KODAK Publication No. H-807

KODAK VISION3 500T Color Negative Film 5219 / 7219 / SO-219 • H-1-5219t 5

Page 6

KODAK VISION3 500T Color Negative Film 5219 / 7219 / SO-219

FOR DIRECT ORDERING IN THE UNITED STATES AND CANADA: 1-800-621-FILM

KODAK SHOOTSAVER Film Delivery Service (U.S. only) 1-800-404-2016

Kodak Locations

NORTH AMERICA REGION

UNITED STATES

Hollywood, California

6700 Santa Monica Boulevard

Los Angeles, California

90038-1203

Tel: 323-464-6131

Orders: 1-800-621-FILM

New York, New York

360 West 31st Street

New York, New York

10001-2727

Tel: 212-631-3400

Orders: 1-800-621-FILM

CANADA

Kodak Canada Inc.

6 Monogram Place

2nd Floor

Toronto, Ontario

Canada M9R 0A1

Te l : 4 16 -7 6 1- 46 4 6

Orders: 1-800-621-FILM

Fax: 416-760-4592

Toll Free Fax: 1-866-211-6311

Kodak Canada Inc.

4 Place du Commerce, Suite 100

Ile des Soeurs

Verdun, Quebec

Canada H3E 1J4

Orders: 1-800-621-FILM

Fax: 1-866-211-6311

Kodak Canada Inc.

3700 Gilmore Way

Burnaby, BC

Canada V5G 4M1

Orders: 1-800-621-FILM

Fax: 1-866-211-6311

EUROPEAN, AFRICAN AND

MIDDLE EASTERN REGION

Kodak Business Centre

Hemel One, Boundary Way

Hemel Hempstead

HP2 7YU

England, UK

Tel: + 44 1442 846945

Fax: + 44 1442 846 594

Eastman Kodak SARL

29-31 Route de L'Aeroport

Le Grand Saconnex

Case Postale 271

1215 Geneva 15

Switzerland

Tel: +41-22-747-2000

Fax: +41-22-747-2200

LATIN AMERICA REGION

1900 NW 97 Ave.

Miami, Florida 33172 USA

Tel: 305 378-0566 / 305 229-0422

Fax: 305 378-0495 / 305 229-5075

www.kodak.com/go/latinmotion

MEXICO

Kodak Mexicana S.A. de C.V.

Blvd. Adolfo Ruiz Cortinez 3642, Piso 14

Col. Jardines del Pedregal

Del. Alvaro Obregon

CP 01900 México, D.F, Mexico.

Tel: 01 (55) 110517-30

Fax: 01 (55) 110517-07

www.kodak.com/go/latinmotion

BRAZIL

KODAK BRASILEIRACOM. PROD.

PARA IMAGEME SERVIÇOS LTDA

Rodovia Presidente Dutra Km154.7

Sao José dos Campos-SP

CEP 12240-427, Brazil

Tel: 0800 015 0002

Tel: 55 11 2132-6003 (Kodak Sao Paulo)

Tel: 55 21 8151-9923 (Kodak Rio de

Janeiro)

Fax 55 12 3932-6721

www.kodak.com/go/latinmotion

VENEZUELA

Kodak Venezuela S. A.

Av. Francisco deMiranda

Centro Lido, Torre B, Piso 7, Of. 71A y

72B

El Rosal, Caracas-Venezuela

Tel: (58-212) 955-2081

Fax: (58-212) 955-2009

www.kodak.com/go/latinmotion

PERU

Kodak Américas, Ltd.

Avenida Larco # 1301, Piso 14,

Miraflores

Lima, Perú

Tel: (51-1) 610-8700

Fax: (51-1) 610-8801

www.kodak.com/go/latinmotion

ARGENTINA

EI Business Center

Bonpland 1930-32

CP 1414 Buenos Aires, Argentina

Tel: 54-11-4778-7009 /

54-911-5932-9503

Fax: 54-11-4773-6105

www.kodak.com/go/latinmotion

CHILE

Kodak Chilena S.A.F.

Edificio Torre Oriente

Av.Alonso de Córdoba# 5151, Piso 14

Comuna Las Condes

Santiago, Chile

Te l : 5 6. 99 .2 20 .5 60 9

www.kodak.com/go/latinmotion

ASIA PACIFIC REGION

AUSTRALIA

Melbourne

Kodak (Australasia) Pty. Ltd.

181 Victoria Parade

Collingwood, Victoria, 3066

Australia

Tel: 61 3 8417 8520

Fax: 61 3 8417 8011

E-mail:mpfilmoz@kodak.com

www.kodak.com.au/go/motion

Sydney

Level 4, 68-72 Waterloo Road

North Ryde, NSW2113

Australia

Tel: 61 2 9870 4378

Fax: 61 2 9870 4292

CHINA (Peoples Republic)

Kodak (China) Limited

Beijing Liaison Office

9th Floor, Beijing Kerry Centre

1 Guanghua Road

Chaoyang District

Beijing 100020 China

Tel: 8610 6561 6561

Fax: 8610 6561 2199

Shanghai Liaison Office

Building 8 Jinqiao Office Park

No 27 Xin Qiao Road

Pudong, Shanghai 201206 China

Tel: 8621 5884 1000

Fax: 8621 58841666

Guangzhou Liaison Office

10F, Office Tower

China Hotel by Marriott

Liu Hua Road

GuangZhou 510015 China

Tel: 8620 8666 9888

Fax: 8620 8667 2230

www.kodak.cn/go/motion

HONG KONG

Kodak (Hong Kong) Ltd.

13/F, Cityplaza Four

12 Taikoo Wan Road

Taikoo Shing

Hong Kong

Tel: 852 2564 9352

Fax: 852 2564 9830

www.kodak.com.hk/go/motion

INDIA

Kodak India Private Limited

3rd Floor, Kalpataru Synergy

Off Western Express Highway

Vakola, Santacruz (East)

Mumbai 400 055 India

Tel: 91 22 6641 6762

Fax: 91 22 6641 6769

www.kodak.co.in/go/motion

INDONESIA

PT. Interdelta Tbk (Kodak Motion

Picture Authorized Distributor in

Indonesia)

Tel: 6221 652 333 ext. 250

Mobile: 6281 896 6655

Email:motionpicture@intedelta.co.id

JAPAN

Kodak Japan Ltd.

Tokyo Sumitomo Twin Building (East)

27-1, Shinkawa 2-chome, Chuo-ku

Tokyo 104-0033

Japan

Tel: 813 5540 2280

Fax: 813 5540 2281

e-mail:motionjp@kodak.com

www.kodak.co.jp/go/motion/

KOR EA

Kodak Korea Ltd

7th Floor. Yakult Building

28-10, Jamwon-dong, Seocho-gu

Seoul 137-904

Korea

Tel: 822 3438 2620

Fax: 822 3438 2663/2664

wwwkr.kodak.com/go/motion

MALAYSIA

5th Floor, Block A

Peremba Square

Saujana Resort, Sec. U2

40150 Shah Alam

Selangor

Malaysia

Tel: 603 7680 3338

Fax: 603 7680 3333

NEW ZEALAND

Kodak New Zealand Ltd.

Suite 4B

125 The Strand

Parnell 1010

Auckland

New Zealand

Tel: 64 9 3028665

Fax: 649 302 8639

www.kodak.co/nz/go/motion

PAK IS TAN

Kodak Ltd Pakistan Branch

5th Floor Bahria Complex 2

M.t.Khan Road

Karachi

Pakis tan

Tel: 92 21 561 0150 & 561 1402

Fax: 92 21 5 61 0776

PHILIPPINES

Kodak Philippines Ltd.

2247 Chino Roces Avenue

Makati City

Philippines 1231

Tel: 632 810 0331 (trunkline) or 632

813 7916 (direct line)

Fax: 632 840 1956

SINGAPORE

Kodak (Singapore) Pte Ltd

151 Lorong Chuan (Lobby A)

#05-01, New Tech Park

Singapore 556741

Tel: 65 6371 3388

Fax: 65 6371 3377

TA IW AN

Kodak Taiwan Limited

Shin Kong Life Neihu Technology

Building

3F-1, No.301, Sec. 2, Tiding Blvd.

Neihu District

Taipei 11493

Taiwan, R.O.C.

Tel: 886 2 8751 8282

www.kodak.com.tw/go/motion

THAILAND

Kodak (Thailand) Ltd.

Floors 6 - 8th Kasemsap Bldg.

89/1 Moo 14, Vibhavadee-rangsit Rd.

Chatuchak

Bangkok 10900

Thailand

Tel: 66 2 515 8092

KODAK VISION3 500T Color

Negative Film 5219 / 7219 / SO-219

KODAK Publication No. H-1-5219t

Kodak, Eastman, Keykode, Vision, and Wratten are trademarks.

New 11-07

Printed in U.S.A.

Loading...

Loading...