Page 1

Publication No. SM 2547-1

Kodak

SERVICE MANUAL

for the

K O DAK EKTAPRO

Slide Projector

Model 4020, 5020, 7020, 9020, (9020/CINE)

03/98

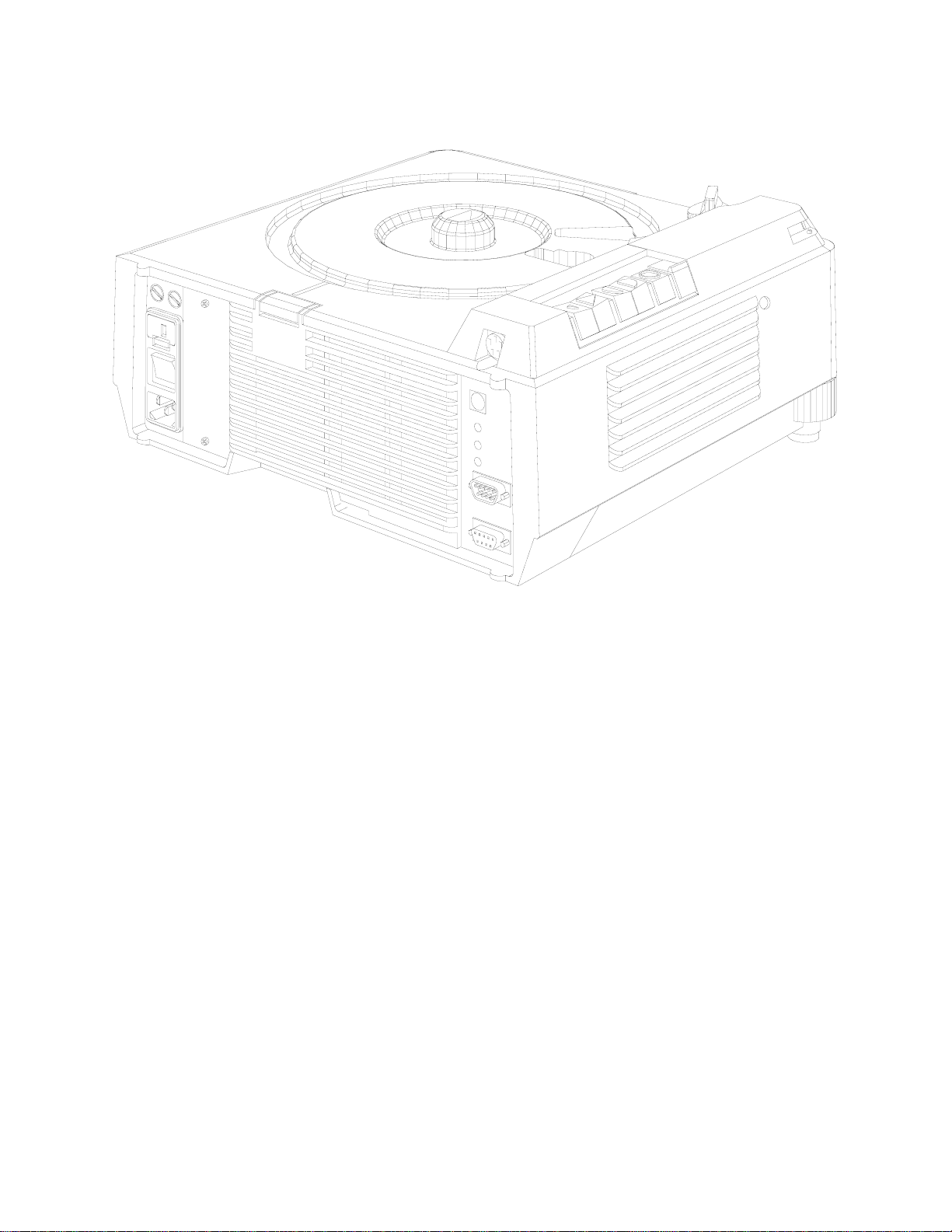

Model 9020

© Kodak AG, Stuttgart 1998

Kodak AG, Stuttgart I 03/98

Page 2

Service Manual SM 2547-1

PLEASE NOTE

The information contained herein is based on the experience and knowledge relating to the subject

matter gained by Kodak prior to publication. No patent license is granted by this information. Kodak

reserves the right to change this information without notice, and makes no warranty, express or

implied, with respect to this information. Kodak shall not be liable for any loss or damage, including

consequential or special damages, resulting from the use of this information, even if loss or damage

is caused by Kodak’s negligence or other fault.

03/98 II Kodak AG, Stuttgart

Page 3

SM 2547-1 Service Manual

TABLE OF CONTENTS

ELECTROSTATIC DISCHARGE......................................................................................................... 1-1

Overview.....................................................................................................................................1-1

Awareness.................................................................................................................................. 1-1

Action ......................................................................................................................................... 1-1

Every Day...................................................................................................................................1-2

During Maintenance and Repair.................................................................................................1-2

1. GENERAL INFORMATION.............................................................................................................. 1-3

Service Tools ...................................................................................................................................... 1-3

For Models 4020/5020/7020/9020 and 9020/CINE ............................................................................ 1-3

Safety Precaution................................................................................................................................ 1-4

Safety Check ...................................................................................................................................... 1-5

2. INTRODUCTION .............................................................................................................................. 2-1

Projector Models................................................................................................................................. 2-2

EKTAPRO Model 4020............................................................................................................... 2-2

Features and Functions:............................................................................................................. 2-2

EKTAPRO Model 4020............................................................................................................... 2-3

EKTAPRO Model 5020............................................................................................................... 2-4

Features and Functions:............................................................................................................. 2-4

EKTAPRO Model 7020............................................................................................................... 2-5

Features and Functions:............................................................................................................. 2-5

EKTAPRO Model 9020............................................................................................................... 2-6

Features and Functions:............................................................................................................. 2-6

Overview .................................................................................................................................... 2-7

Accessories......................................................................................................................................... 2-8

DUAL LAMP MODULE...............................................................................................................2-8

CABLE REMOTE .......................................................................................................................2-8

Kodak AG, Stuttgart III 03/98

Page 4

Service Manual SM 2547-1

CONDENSER KIT 4X4 (with CLIP)............................................................................................2-9

IR REMOTE System RA/LP (Laser Pointer) ............................................................................ 2-10

12/7-PIN MODULE...................................................................................................................2-10

LENS SUPPORT......................................................................................................................2-10

12/7-PIN ADAPTER CABLE.....................................................................................................2-11

TWIN SOCKET ADAPTER.......................................................................................................2-11

SLIDE SYNCHRONIZER .........................................................................................................2-12

LAMPS .....................................................................................................................................2-12

Specification...................................................................................................................................... 2-13

CONNECTORS ................................................................................................................................ 2-13

Remote SOCKET on Projector:................................................................................................ 2-13

P-Bus / RS 232 “IN”..................................................................................................................2-14

P-Bus / RS 232 “OUT”.............................................................................................................2-14

ACCESSORY SLOT.................................................................................................................2-15

OEM ACCESSORIES ........................................................................................................................2-16

COPYWRITE............................................................................................................................2-16

SLIDE SYNCHRONIZER ADAPTER by KODAK AUSTRALIA................................................2-17

ADAPTER by MÜWO............................................................................................................... 2-18

ADAPTERS by MAYER & ZELLER..........................................................................................2-19

ADDRESSES .....................................................................................................................................2-20

CONTROL SYSTEMS..............................................................................................................2-20

SOFTWARE for direct PC CONTROL......................................................................................2-21

RACKS ..................................................................................................................................... 2-21

EXTERNAL TIMER ..................................................................................................................2-21

3. THEORY GUIDE .............................................................................................................................. 3-1

Block Diagram..................................................................................................................................... 3-1

Microcontroller Unit.............................................................................................................................3-3

Description of Functions .....................................................................................................................3-4

03/98 IV Kodak AG, Stuttgart

Page 5

SM 2547-1 Service Manual

Power Supply .............................................................................................................................3-4

The TRANSFORMER supplies the following voltages: .............................................................. 3-4

The POWER REGULATION PCB contains:...............................................................................3-4

The output voltages and signal are:............................................................................................ 3-4

Switch On / Initialize Procedure..................................................................................................3-6

Slide Change Sequence.............................................................................................................3-7

Tray Motion.................................................................................................................................3-8

Tray Motion Sequence: ..............................................................................................................3-9

LAMP Control ........................................................................................................................... 3-11

a) Dual LAMP Operation .......................................................................................................... 3-11

b) Low/High LAMP Setting .......................................................................................................3-12

c) LAMP Protection................................................................................................................... 3-12

d) LAMP Voltage Control.......................................................................................................... 3-12

e) Lamp Dimming ..................................................................................................................... 3-13

Focus........................................................................................................................................ 3-15

Auto focus.................................................................................................................................3-16

P-BUS .....................................................................................................................................3-17

Command Structure .................................................................................................................3-18

Accessory slot ..........................................................................................................................3-19

Remote Control ........................................................................................................................3-20

4. DISASSEMBLY/ASSEMBLY........................................................................................................... 4-1

UPPER HOUSING..............................................................................................................................4-1

BUTTONS and COVER PLATES....................................................................................................... 4-2

Assembly....................................................................................................................................4-3

CENTER HOUSING...........................................................................................................................4-4

FAN, KEYBOARD PCB and TRAY MOTION PCB.............................................................................4-8

BACK PANEL PCB...........................................................................................................................4-10

TRANSFORMER, POWER SUPPLY PCB and BACK PLATE ASSEMBLY....................................4-11

Kodak AG, Stuttgart V 03/98

Page 6

Service Manual SM 2547-1

MECHANISM FRAME and LENS MOUNT.......................................................................................4-12

LENS MOUNT ..................................................................................................................................4-13

Model 4020/7020......................................................................................................................4-15

RETAINER AF ASSEMBLY.............................................................................................................. 4-16

Model 5020/9020 and 9020/CINE ............................................................................................ 4-16

MECHANISM FRAME ...................................................................................................................... 4-18

AUTO FOCUS PCB and FOCUS MOTOR.......................................................................................4-21

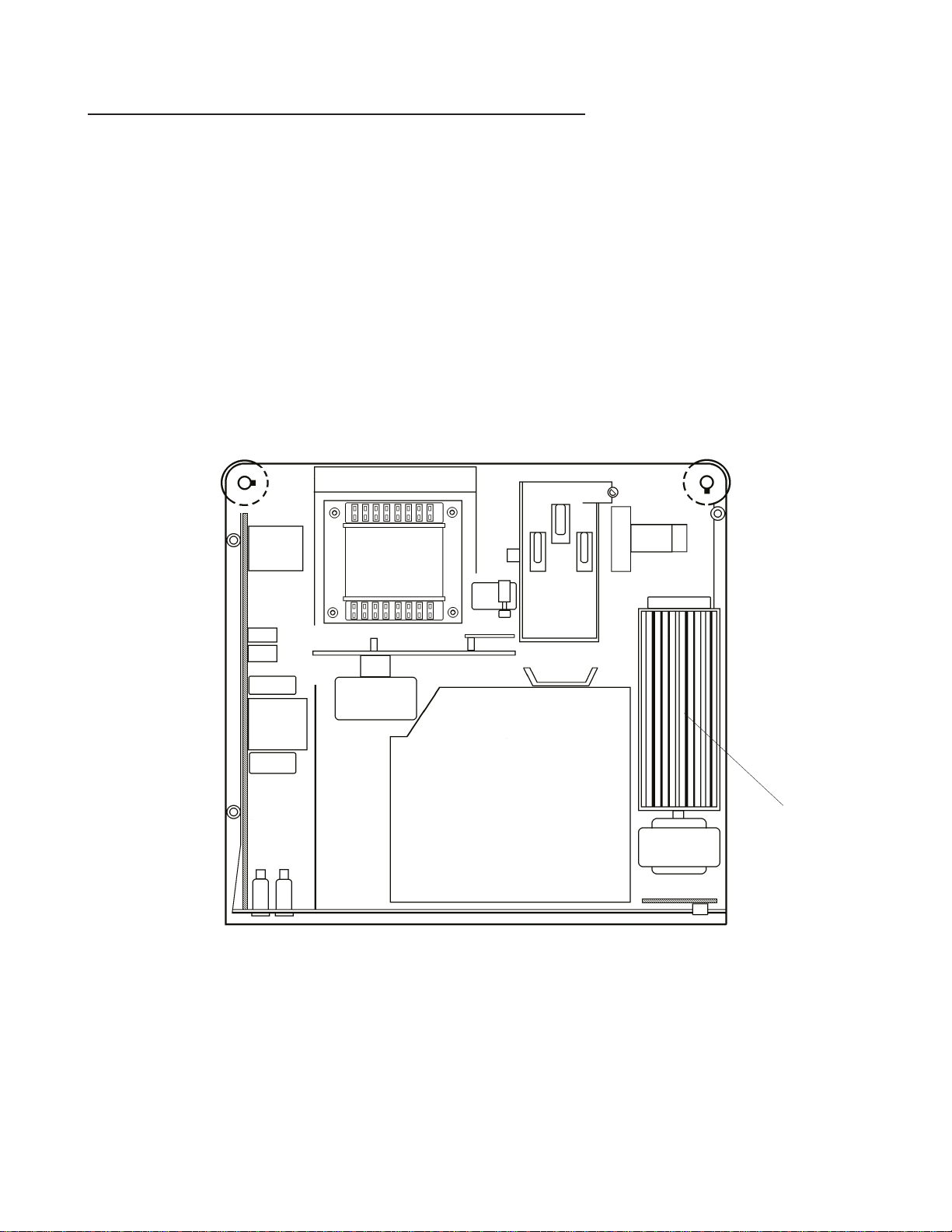

Master Board PCB............................................................................................................................ 4-22

Master Board PCB Connectors................................................................................................4-23

MICROCONTROLLER............................................................................................................. 4-24

LOWER HOUSING........................................................................................................................... 4-25

DUAL LAMP MODULE.....................................................................................................................4-26

DUAL LAMP MODULE.............................................................................................................4-29

Lubrication ........................................................................................................................................4-30

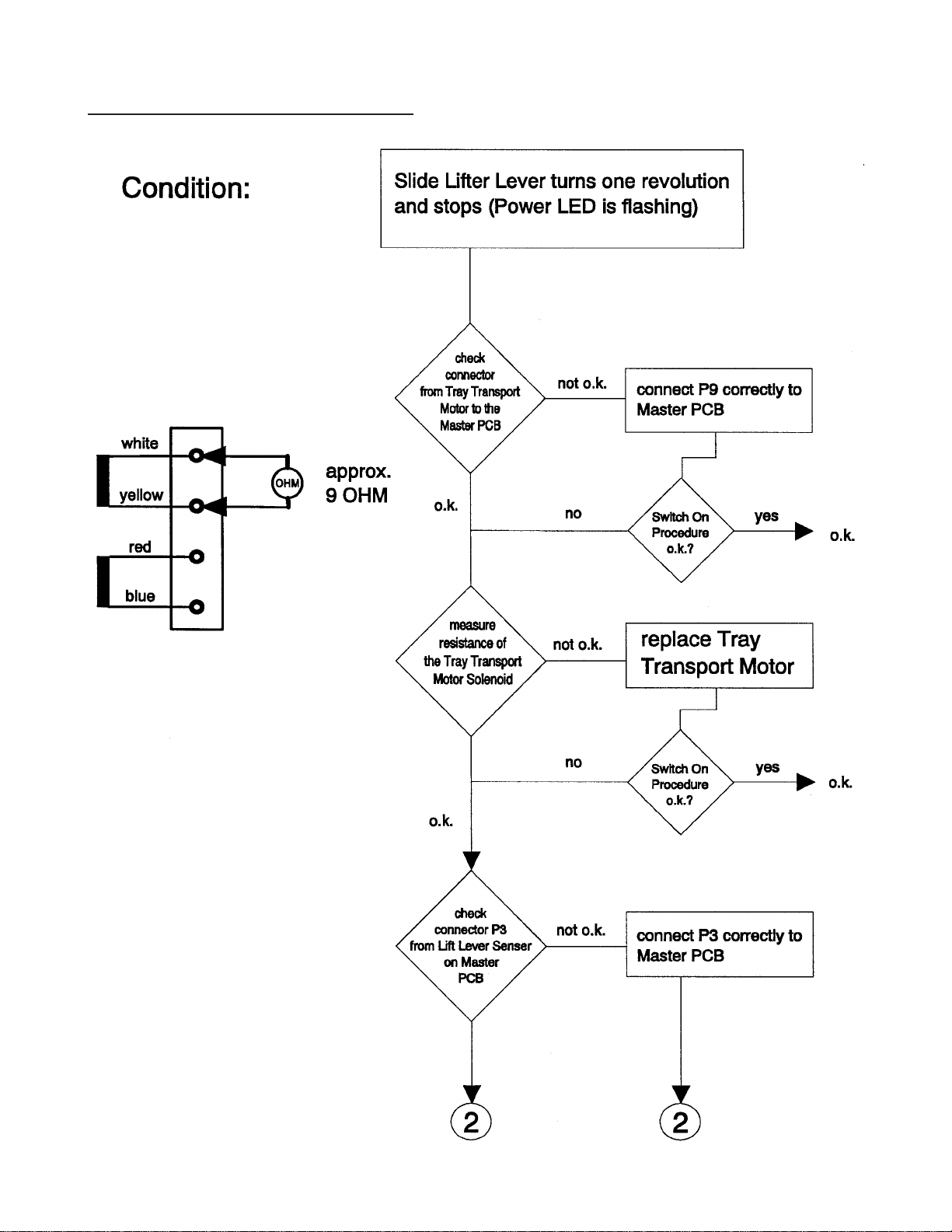

5. DIAGNOSTICS.................................................................................................................................5-1

Diagnostic Overview EKTAPRO 4020/5020/7020/9020 and 9020/CINE...........................................5-1

Preparation .........................................................................................................................................5-3

Conditions:..................................................................................................................................5-3

No Function......................................................................................................................................... 5-4

Switch on Procedure Problems........................................................................................................... 5-9

Lamp Problems EP 4020/5020/7020/9020 and 9020/CINE.............................................................5-12

Mirror Position...................................................................................................................................5-17

Brightness Test......................................................................................................................... 5-17

Switch On Procedure........................................................................................................................5-18

Switch On Procedure complete - No Keyboard Function .................................................................5-19

No function with REMOTE CONTROL ............................................................................................. 5-20

IR Remote Control.................................................................................................................... 5-20

Cable Remote................................................................................................................................... 5-23

03/98 VI Kodak AG, Stuttgart

Page 7

SM 2547-1 Service Manual

No Slide Transport forward/reverse and other projection problems .................................................5-24

Shutter Problems.............................................................................................................................. 5-35

Fan Problems.................................................................................................................................... 5-27

Slide Obstruction in Slide Tray..........................................................................................................5-29

Conditions for a correct transport cycle .................................................................................... 5-29

Wrong Transport Step by 80/140 SLIDE TRAY................................................................................ 5-30

No Focus Actuation...........................................................................................................................5-32

No Standby Function .............................................................................................................. ..........5-33

Communication Trouble 4010/5010/9010......................................................................................... 5-35

AUTO FOCUS 5020/9020 and 9020/CINE: No AUTO FOCUS Function.........................................5-39

Accessory Slot 7020/9020 ................................................................................................................5-40

Malfunction of the 12/7 PIN Module.......................................................................................... 5-40

6. Projector Checking.........................................................................................................................6-1

Slide Transport Problems ...................................................................................................................6-1

Slide jam (all models) ............................................................................................................ .....6-2

CODER DISK ..................................................................................................................................... 6-2

7. MAINTENANCE ...............................................................................................................................7-1

Maintenance Intervals.........................................................................................................................7-1

Maintenance Procedure......................................................................................................................7-1

Cleaning..............................................................................................................................................7-1

Ultrasonic cleaning ..................................................................................................................... 7-2

Lubrication ..........................................................................................................................................7-3

Kodak AG, Stuttgart VII 03/98

Page 8

Service Manual SM 2547-1

blank page

03/98 VIII Kodak AG, Stuttgart

Page 9

SM 2547-1 Service Manual

ELECTROSTATIC DISCHARGE

CAUTION

This equipment includes parts and assemblies sensitive to damage from electrostatic discharge. Use caution

to prevent damage during all service procedures.

Overview

Electrostatic discharge (ESD) is a primary source of

- product downtime

- lost productivity

- costly repair.

While we cannot feel a static charge of less than 3,500 volts, as few as 30 volts can damage or destroy essential

components in the electronic equipment. As technology advances, these components will be even more

vulnerable to ESD destruction.

Therefore, to maintain and increase productivity and profitability, you must observe ESD guidelines.

Effective ESD control requires the following things.

Awareness

Everyone in your organization should be aware of ESD because partial ESD control is no ESD control at all.

Everyone needs to remember that:

- ESD is a primary source of equipment failures and intermittent malfunctions.

- ESD affects productivity and profitability.

- ESD can be controlled.

Action

Everyone from senior management to the evening security crew, must observe ESD guidelines.

- If you repair and maintain electronic equipment, always wear grounding straps and work

at ESD protected sites.

- If you work around electronic equipment, keep static generators like plastic trash bags

away from sensitive components.

- Observe ESD guidelines everyday. (See the following sections for special tips).

- Remember, effective ESD control is everyone’s responsibility:

Kodak AG, Stuttgart 1-1 03/98

Page 10

Service Manual SM 2547-1

Every Day

1. Keep trash away from static-sensitive equipment. Plastic materials, such as trash can liners and plastic

foam cups, generate the static electricity that damages or destroys electronic components.

2. Look at the label. Static-sensitive components are marked with bright graphic labels. Follow the label

directions.

3. Spray the carpet. ESD that is generated when you walk over carpet is a major cause of component

destruction. In some cases, especially in low-humidity environments, you may need to periodically spray

carpets with an anti-static spray that is available at local stores.

During Maintenance and Repair

1. Wear a grounding strap when you work with static-sensitive components. Always make certain that the

clip is attached to a properly grounded, unpainted surface.

2. Use a portable grounding mat if you cannot repair components at an ESD-protected workstation.

(Kodak’s Customer Equipment Services Division can help you in set up ESD-protected workstations.)

3 . Use protective packaging when you transport components from one area to another. Transparent

antistatic bags, available from a variety of manufacturers, shield the components from further damage.

03/98 1-2 Kodak AG, Stuttgart

Page 11

SM 2547-1 Service Manual

1. GENERAL INFORMATION

Service Tools

Use the following tools to repair a KODAK EKTAPRO Slide Projector:

TORX Screw Driversize 206

TORX Screw Driversize 210

TORX Screw Driversize 215 or TORX bits TL-3255

TORX Screw Driversize 220

Logic Probe TTL/CMOS

Oscilloscope - only for checks on the AUTO FOCUS PCB.

Digital Multimeter Voltage 5 to 240 V AC

0to 50VDC

Current 1 to 100 mA DC Accuracy: 1%

0,1to2ADC

0,1to5AAC

The multimeter should have RMS capability

Accuracy 1%

Fixture Tool 622 0454

For Models 4020/5020/7020/9020/9020/CINE

PLCC Extractor Tool TL-4430

Service Computer 100% IBM compatible

Hard disk

CGA/EGA/VGA Monitor/Display

1 RS 232 Serial Interface

1 Centronics Printer Interface

1 720kB Floppy Disk Drive

1 9pin Serial Interface CORD

Diagnostic Software: TL-4575

Ejector Microcontroller G 990 3250

Kodak AG, Stuttgart 1-3 03/98

Page 12

Service Manual SM 2547-1

Safety Precaution

1. Do not operate or repair the projector without proper accessories. Add all COVERS before use to

prevent mechanical hazards and electrical shock.

2. Before operating the projector, check the VOLTAGE SELECTOR. Make sure that the correct line voltage

is selected.

3. Do not use a damaged POWER CORD. The damaged CORD can cause malfunctions and current

leakage or electrical shock.

4. If there is any abnormal noise, smell or smoke during operation, deenergize the projector immediately

and contact authorized personal for support.

5. Do not operate the projector in unsafe locations such as outdoors or in wet places. Do not allow liquids,

gaseous or solid-state materials to enter the projector.

6. When doing electrical measurements, use an isolation transformer or a leakage current detector in the

power line to avoid an electrical shock.

7. Use only original parts from the Parts List to repair the projector.

8. Make sure that the requirements of UL 122 - Splices and Connection - paragraph 13.10 and EN 60 950,

section 4.39 are observed. When replacing AC primary components, such as wires, sockets or capacitors ,

wrap the ends of the wire completely around the terminal before soldering.

03/98 1-4 Kodak AG, Stuttgart

Page 13

SM 2547-1 Service Manual

Safety Check

NOTE

Check the area around the repaired location.

Make sure that parts and wires have been returned to the correct positions.

Completely assemble the projector before doing an electrical safety test.

The safety tests:

Ground Continuity Test

Insulation Resistance Test

Equivalent Leakage Current Test

Use a safety tester that measures all 3 tests at one time.

Such a test device would be a Mini Tester 0701 N (Manufacturer:Gossen, Germany) or an equivalent device.

Details for safety standards can be found in the regulations:

IEC 380, 435, 950,

UL 478, 1012.

Prerequisites for measurements:

- The projector is energized

- FUSE with VOLTAGE SELECTOR insert

- COVERS in place

- LAMP MODULE installed

Test values for Mini Tester 0701N

- Ground Continuity Test .......< 300 mOHM

- Insulation Resistance Test .......< = 0,5 OHM

- Equivalent Leakage Current .......< = 7 mA

Interfaces

Models 7020 and 9020 have an accessory slot. The 7/12pin module from Kodak is safety tested, and has

approval from VDE and other institutions. If an OEM module is installed, inform the customer:

- the OEM is responsible for the safety and function of the module.

- the module is not part of the repair order.

- the specifications and safety warnings for the accessory in the slot are found in the

“Operator’s Manual”.

Kodak AG, Stuttgart 1-5 03/98

Page 14

Service Manual SM 2547-1

blank page

03/98 1-6 Kodak AG, Stuttgart

Page 15

SM 2547-1 Service Manual

2. INTRODUCTION

The Kodak EKTAPRO Slide Projector series is a new family of Projectors that uses the latest mechanical and

electronic technology.

The Projector is modular designed, and equipped with a modern 1-chip MICROCONTROLLER, STEPPER

MOTORS, optical sensors, and digital and analog circuits. All functions and displays are controlled by the

MICROCONTROLLER software.

Four models with different features and functions are available worldwide top 2 models can be attached to the

old CAROUSEL and EKTAGRAPHIC family processors with optional ADAPTERS in the accessory slot.

This new feature allows the future use of other equipment manufacturers Projector systems and accessories.

The Models 4020, 5020, 7020 and 9020 are equipped with an RS 232 interface (P-Bus). This bus allows

communication with a computer and multi Projector shows in a new way. The P-Bus can also be used for Service

Diagnostics.

The total amount of slide cycles for the models 7020 and 9020 can be read out with the Diagnostic Software

TL-4575 (“SYSTEM RE PORT” menu).

The modular design, the LAMP MODULE and the accessory slot for special MODULE´s are needed to adapt

the Projector to future applications.

All models can be operated with 80 and 140 slide trays.

Compliance w ith international safety regulations has been approved.

All models are available in two versions:

a) for 120/220/230/240 V, 50/60 Hz

b) for 100/220V 50/60 Hz (Japan)

Kodak AG, Stuttgart 2-1 03/98

Page 16

Service Manual SM 2547-1

Projector Models

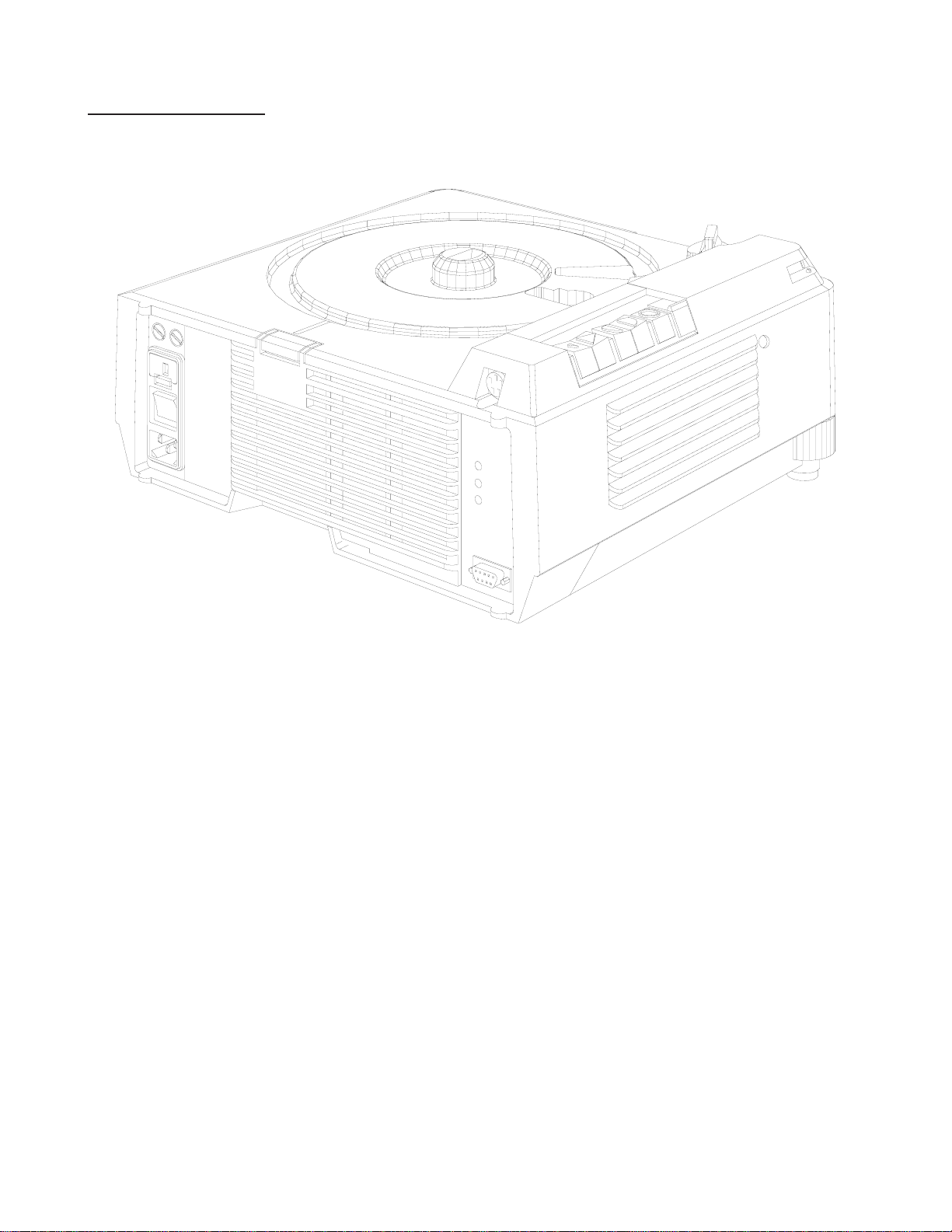

EKTAPRO Model 4020

figure 2-1

Features and Functions:

Line voltages : 120/220/230/240V or 100/220VAC can be select with an

external VOLTAGE SELECTOR

Line frequency : 50/60 Hz

Power consumption : 380 W

Dual Lamp Module

Extra Bright: 35h EXR 82V/300 W

: 70h FHS 82V/300W

: 200h EXY 82V/250W

Slide change time : approx. 0,9s (single step)

: approx. up to 3s (random access)

Focus : Manual and electrically

Standby function : If the standby mode is activated the Keyboard will be disabled

Economy LAMP setting : 75% light output

No SLIDE No LIGHT function: Using an IR REMOTE CONTROL the keycode 550* will disable this

function, enter of the same keycode enables this function again

Slide Tray capability : 80/140 slides

Slide Tray Switch : After changing the switch position the Projector is running automatically

through a initialization procedure

03/98 2-2 Kodak AG, Stuttgart

Page 17

SM 2547-1 Service Manual

EKTAPRO Model 4020

Adjustable Tray Motion : Tool PN 622 0454 has to used on Projectors from SN 85 xxx and

above

Manual elevator mechanism : Two height adjustment feet are attached on the front side of the

Projector

Indicator LED on front : LED continuously on Projector O.K. If the LED is blinking fast a slide

jam occurs. In standby mode the LED is blinking short off and long on.

If the LED is blinking continuously (on/off) a checksum error occurs

(only during programming the processor)

Remote SOCKET : 8 pin mini DIN

Slide change buttons : A single step will happen after pressing the “Forward" or the “Reverse”

button less than 0.9s. Multiple steps will be done by pressing the

“Forward”buttonmorethan0.9s

A run into the “Zero” position will immediately be done after press and

hold the “Reverse” button until the Slide Tray is in “Zero” position

Last Lamp used : After switching on the Projector the last used lamp will be selected

(memory function). This memory function can be disabled by pressing

the STANDBY button during switching on the projector

Line up : Pressing both transport keys will enable the lamp to adjust the projector

(green LED on the Backpanel is blinking). The Standby key will disable

this function

NEW

In case of using a IR Remote Control single steps are possible independent how long the button is pressed.

By pressing the “Reverse button” on the IR Remote Control random access is possible.

To select the Slide Tray capacity (80 or 140 slides) a ball point pen or a small screwdriver has to be used.

The Lamp Module has no longer a Heat Absorbing Glass installed. Due to the new mirror the light output is

increased up to 30%.

NOTE

In case of changing the mirror take care of the type (see NEWSLETTER #4).

Kodak AG, Stuttgart 2-3 03/98

Page 18

Service Manual SM 2547-1

EKTAPRO Model 5020

figure 2-2

Features and Functions:

All features and functions of Model 4020

Additional:

AUTO FOCUS : Each slide will be focused, independent of the slide mount

Timer : Slide change can be set from 1 up to 60 sec.

03/98 2-4 Kodak AG, Stuttgart

Page 19

SM 2547-1 Service Manual

EKTAPRO Model 7020

figure 2-3

Features and Functions:

All features and functions as Model 4020.

Additional features:

Application Slot : for Kodak and OEM ADAPTERS

Bus CONNECTORS (RS232): IN (female) and OUT (male)

Address Switch : 16 addresses can be selected

Initializing procedure : After power on the Projector the SLIDE LIFTER and the RING DRIVE

will be checked, the LAMP and the FAN will be switched off

High Light : 20% more light output, lamp life time approx. 30% reduced

NEW (only on Models 7020/9020)

If the parallel Mode “970*” is set on the IR Remote Control it is possible to toggle with “666*” between two

projectors to control the focus functions. These functions are only visible on the screen.

Kodak AG, Stuttgart 2-5 03/98

Page 20

Service Manual SM 2547-1

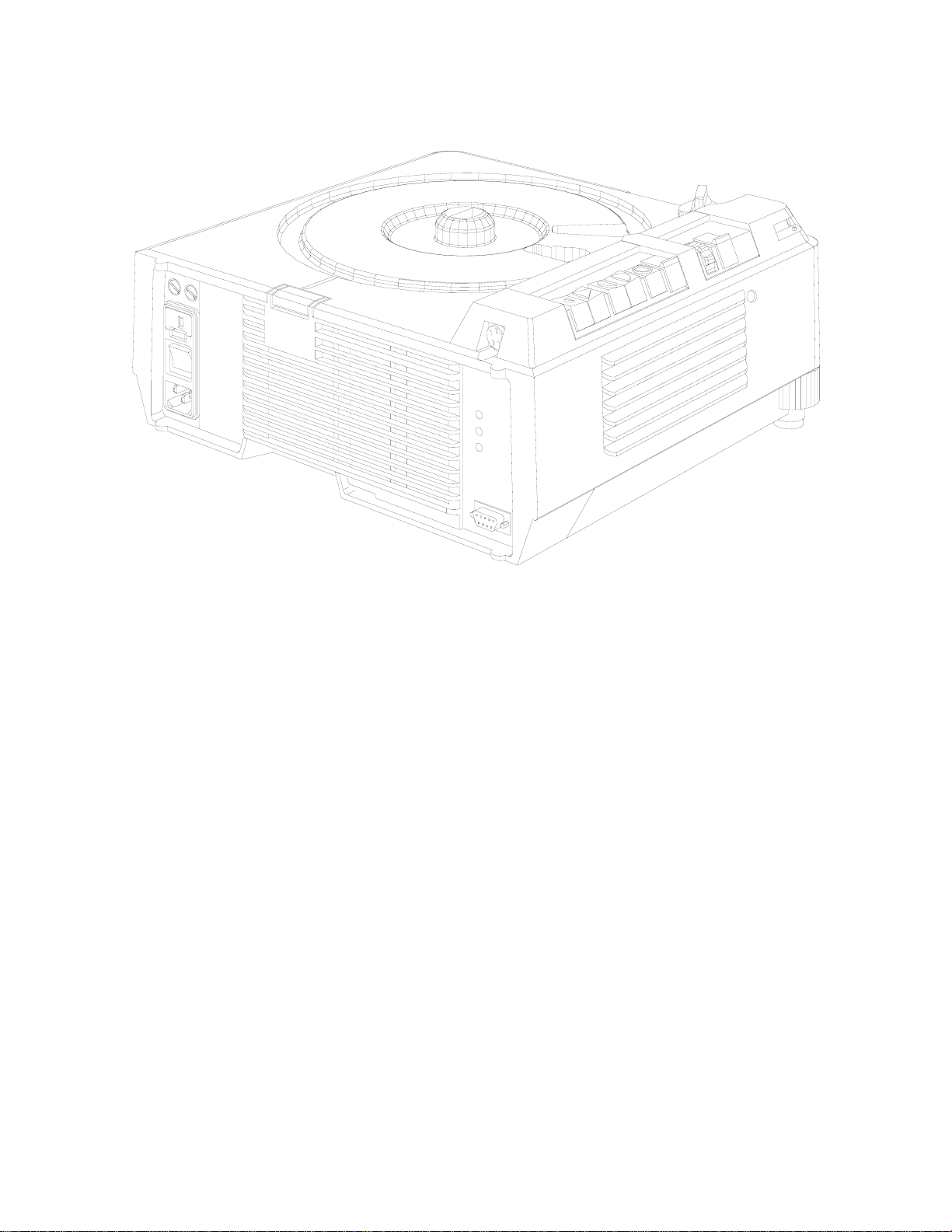

EKTAPRO Model 9020

figure 2-4

Features and Functions:

This multi purpose Projector has all of the features of the EKTAPRO 7020.

Additional features include:

AUTO-ZERO function: : When the Projector senses an empty, gate the Projector automatically

returns the tray to zero and begins the projection cycle again.

This function can be deenergized.

Timer : Slide change can be set from 1 up to 60 sec.

AUTO FOCUS : Same as in E KTAPRO 5020

High Light : 20% more light output, lamp life time approx. 30% reduced

NOTE (new Model EKTAPRO 920/CINE)

For special applications (cinema promotion) the Model EKTAPRO 920/CINE is available. This model has a

build in memory function which knows the last projected slide after switching off the projector.

Switching the projector on again the slide tray will run into that position after the initialization procedure.

If the timer is switched on at that time a soft dissolve will be started immediately.

New parts (NAMEPLATE and MICROCONTROLLER) see Illustrated parts list.

03/98 2-6 Kodak AG, Stuttgart

Page 21

SM 2547-1 Service Manual

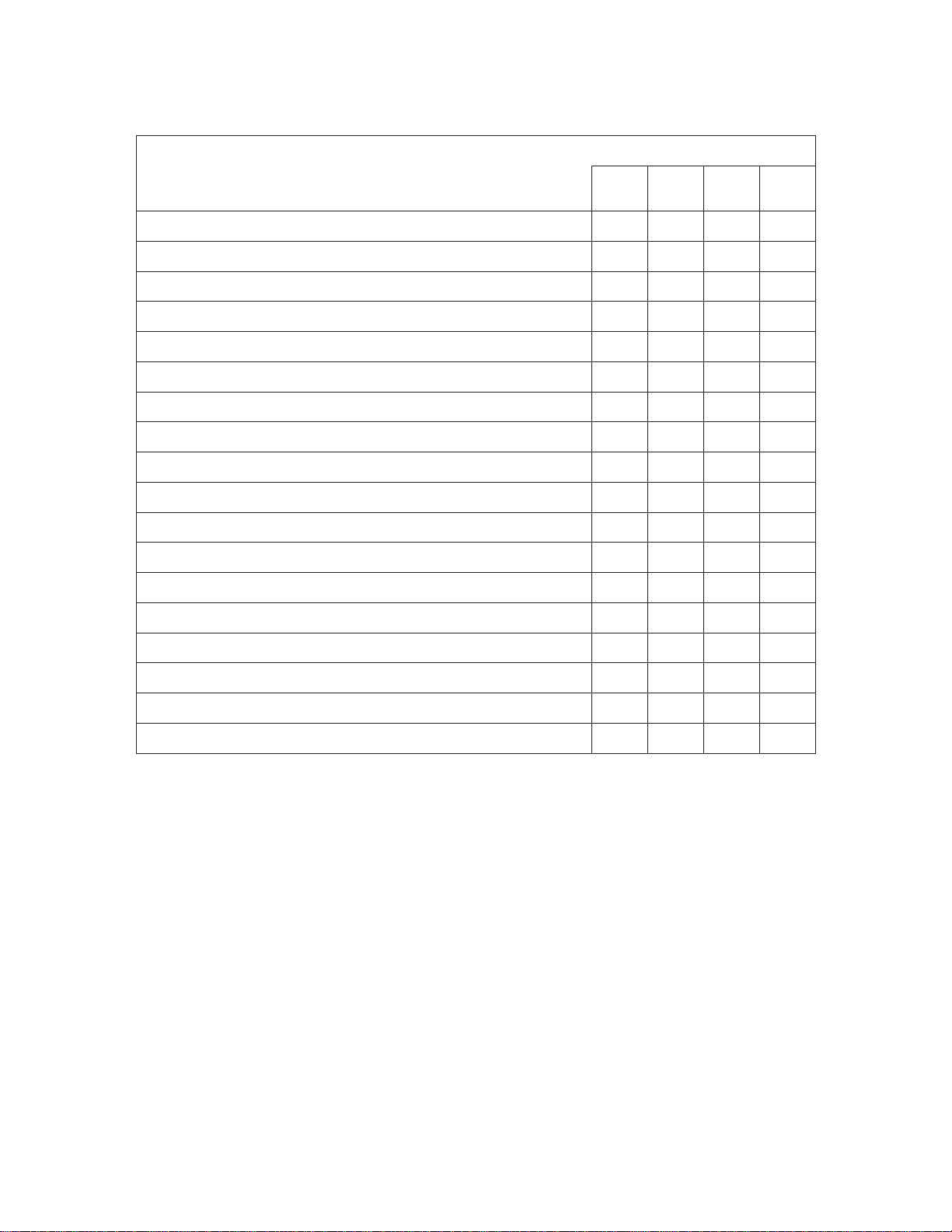

Overview

Model

FUNCTIONS/ACCESSORIES

DUAL LAMP MODULE (Extra BRIGHT)

TIMER

AUTO-ZERO

ADDRESS SWITCH

APPLICATION SLOT

AUTO FOCUS

PRESENTATION BUS “IN”

PRESENTATION BUS “OUT”

RANDOM ACCESS

EXTERNAL DIAGNOSTICS

12/7-PIN MODULE

SLIDE SYNCHRONIZER (1000Hz)

4020 5020 7020 9020

XXXX

-X-X

---X

--XX

--XX

-X-X

XXXX

--XX

XXXX

XXXX

--OO

--OO

TWIN SOCKET

CABLE REMOTE

IR REMOTE SYSTEM RA

IR REMOTE SYSTEM RA/LP

X = Standard Feature O = Accessory - not possible

OOOO

OOOO

OOOO

OOOO

Kodak AG, Stuttgart 2-7 03/98

Page 22

Service Manual SM 2547-1

Accessories

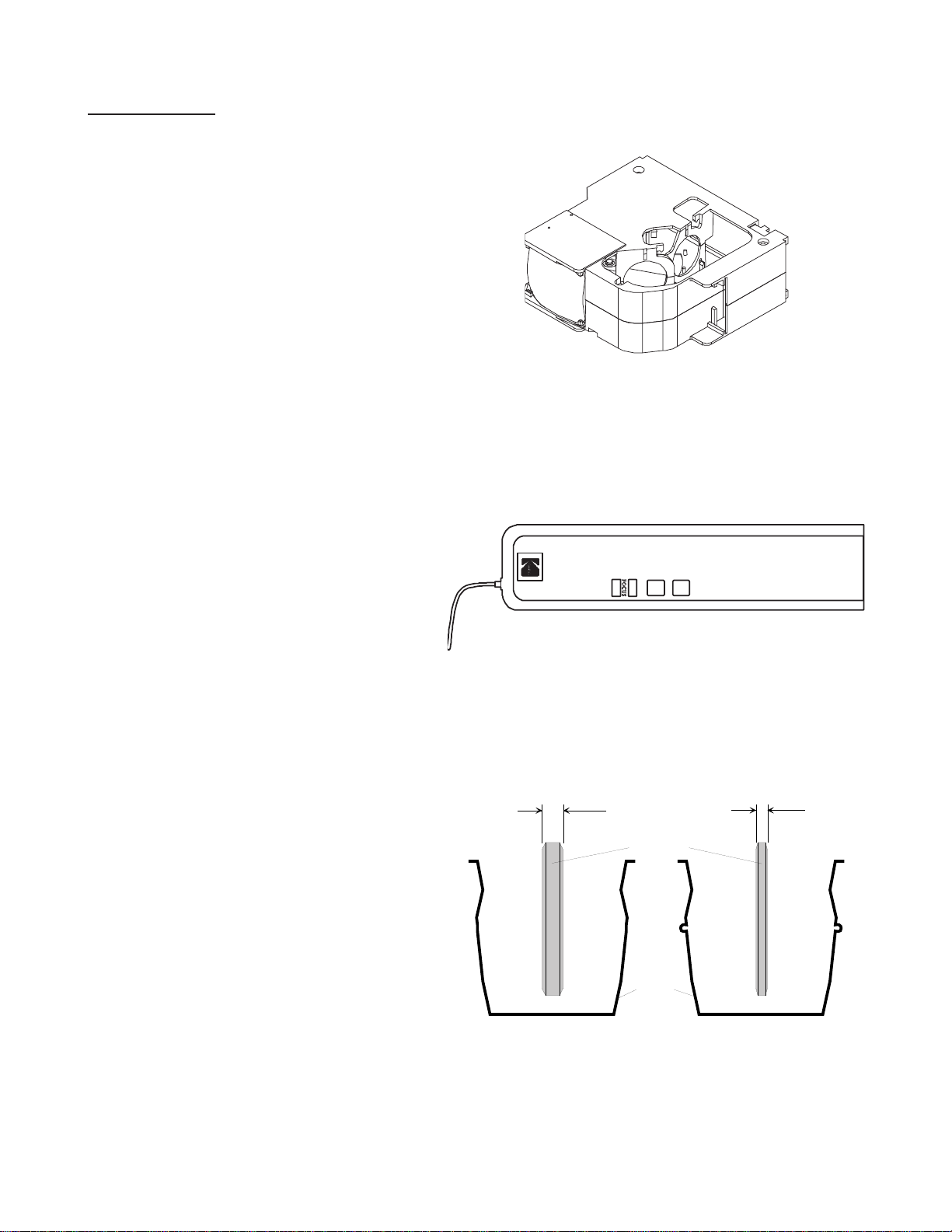

DUAL LAMP MODULE

CAT No. 718 4369

figure 2-5

CABLE REMOTE

CAT No. 712 1080

HEAT ABSORBING GLASS with CLIP

(not installed in Model 3020)

CAT No. 717 7140 (6mm thick)

CAT No. 717 7157 (3mm thick)

see NEWSLETTER #3/MAY/1996 page 5

figure 2-6

6mm 3mm

HEAT ABSORBING

GLASS

CLIP

figure 2-7

03/98 2-8 Kodak AG, Stuttgart

Page 23

SM 2547-1 Service Manual

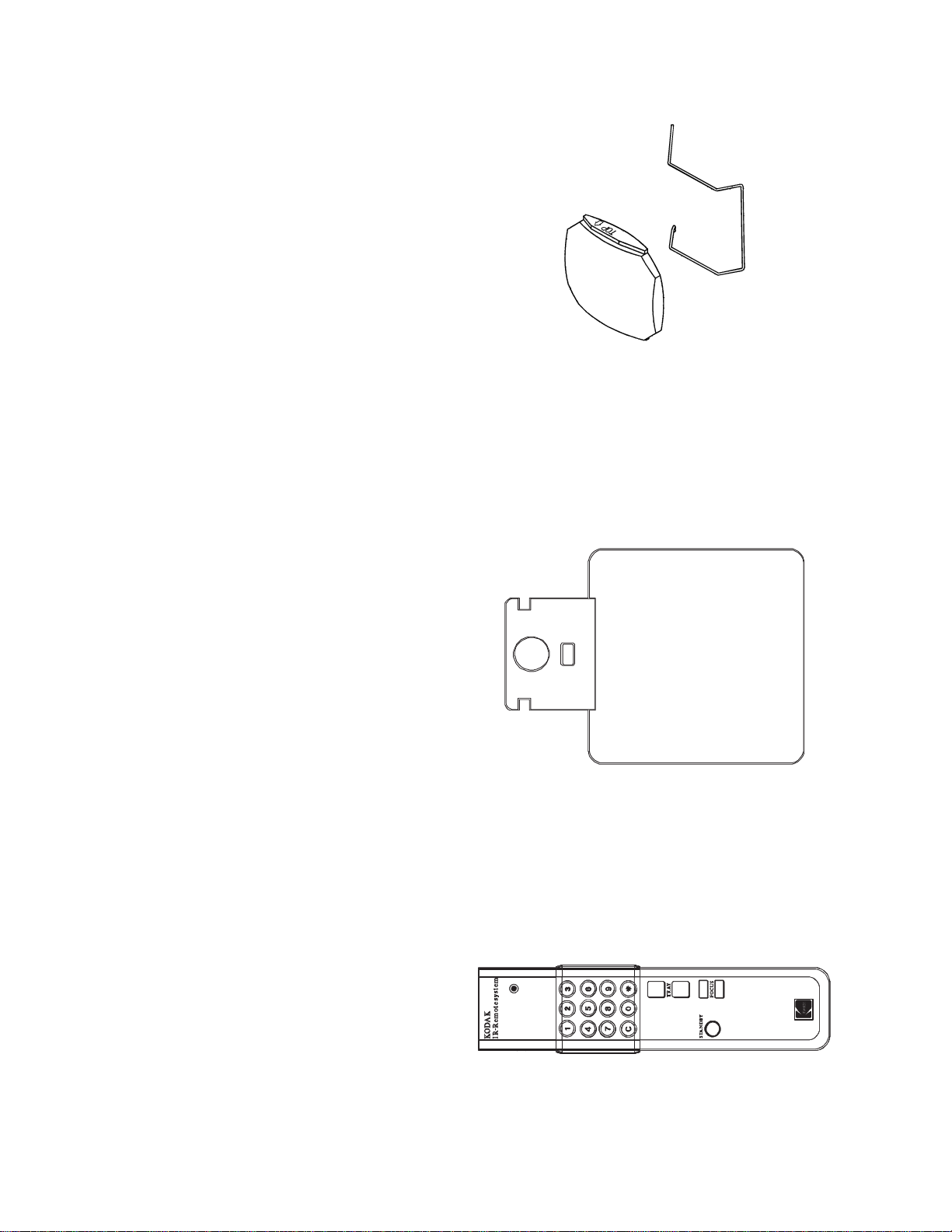

CONDENSER KIT 4X4 (with CLIP)

CAT No. 714 4967

figure 2-8

IR REMOTE System RA (with Random Access)

CAT No. 712 1072

complete with RECEIVER and TRANSMITTER

RECEIVER

TRANSMITTER

figure 2-9

figure 2-10

Kodak AG, Stuttgart 2-9 03/98

Page 24

Service Manual SM 2547-1

IR REMOTE System RA/LP (Laser Pointer)

CAT No. 712 1064 complete with RECEIVER

TRANSMITTER

RECEIVER as use with IR REMOTE System RA.

figure 2-11

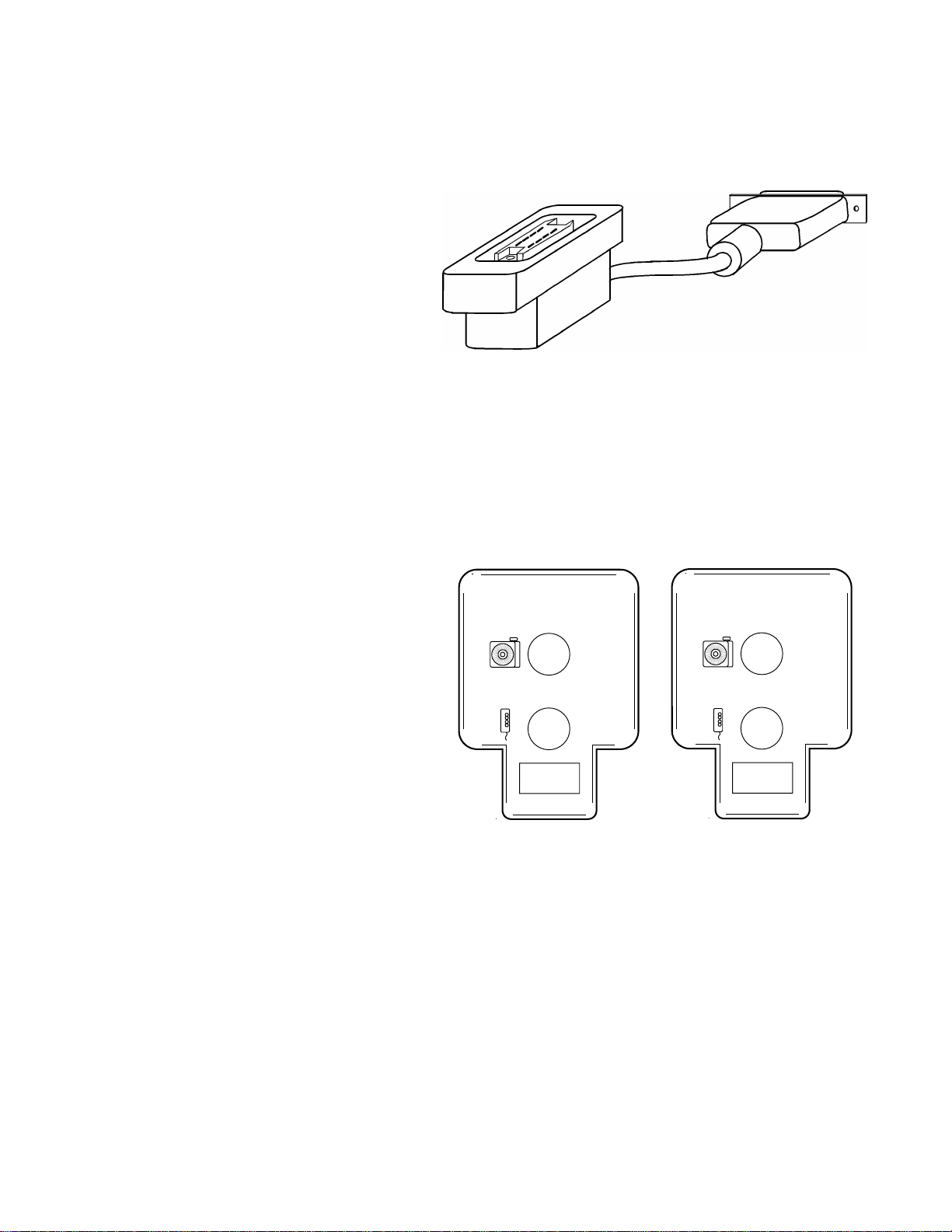

12/7-PIN MODULE

CAT No. 712 5875

LENS SUPPORT

CAT No. 715 1335

Int.

Ext.

figure 2-12

figure 2-13

03/98 2-10 Kodak AG, Stuttgart

Page 25

SM 2547-1 Service Manual

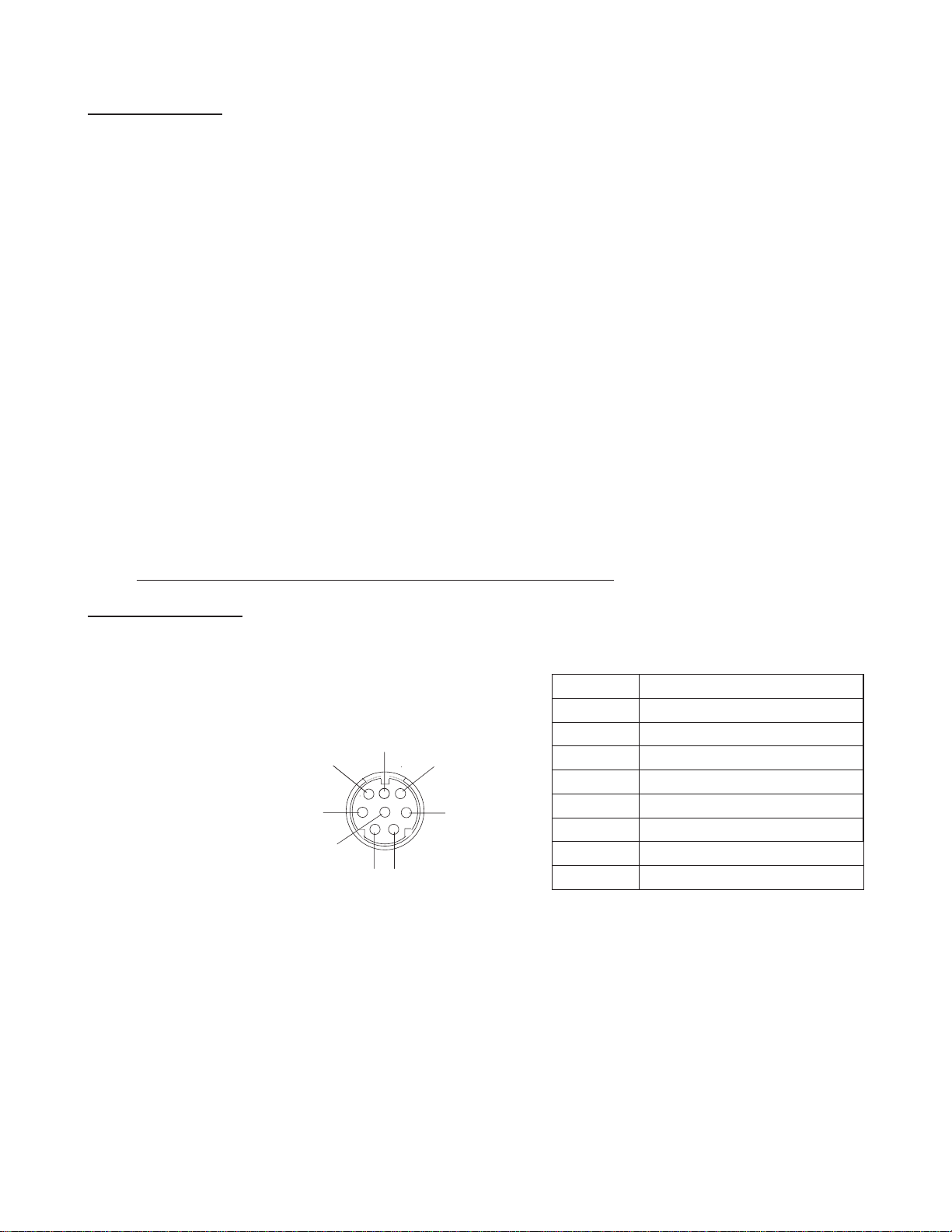

12/7-PIN ADAPTER CABLE

CAT No. 712 5883

figure 2-14

TWIN SOCKET ADAPTER

CAT No. 712 5909

see NEWSLETTER #3/MAY/1996 page 7

B

C

figure 2-15

Kodak AG, Stuttgart 2-11 03/98

Page 26

Service Manual SM 2547-1

SLIDE SYNCHRONIZER

CAT No. 712 5891 (not available)

see page 16 OEM ACCESSORIES

LAMPS

Catalog No. Description Lifetime

145 2259 EXR 82V/300 W life time about 35 hours

147 7678 EHS 82V/300 W life time about 70 hours

145 2143 EXY 82V/250 W life time about 200 hours

03/98 2-12 Kodak AG, Stuttgart

Page 27

SM 2547-1 Service Manual

Specification

Electrical Supply : 120/220/230/240 V

: or 100/220 V

: 50/60 Hz

Power Consumption : 380 W

Dimensions : 310 x 355 x 145 mm max. (l/w/h) with tray and lens

(12.2 x 14 x 5.7 in)

Weight : 6300 g (13.9 lb)

Slide size : 24 x 36 mm (0.9 x 1.4 in)

Slide change time : < 0,8 s

Slide search time : <3 s

Slide temperature : 50°C (104°F) max. above room temperature

LAMP (standard) : EXR 82V/300W

Automatic LAMP change : 0.3 s

Operating temperature : 0°C to 40°C (32°F to 113°F)

Humidity : 20 to 85% r.H.

Air consumption : approx. 700 l/min. (20,000 cuft/min.)

Approvals : VDE, UL , CSA

Leveling : 0° to 18° with internal elevation mechanism 30° max. allowed

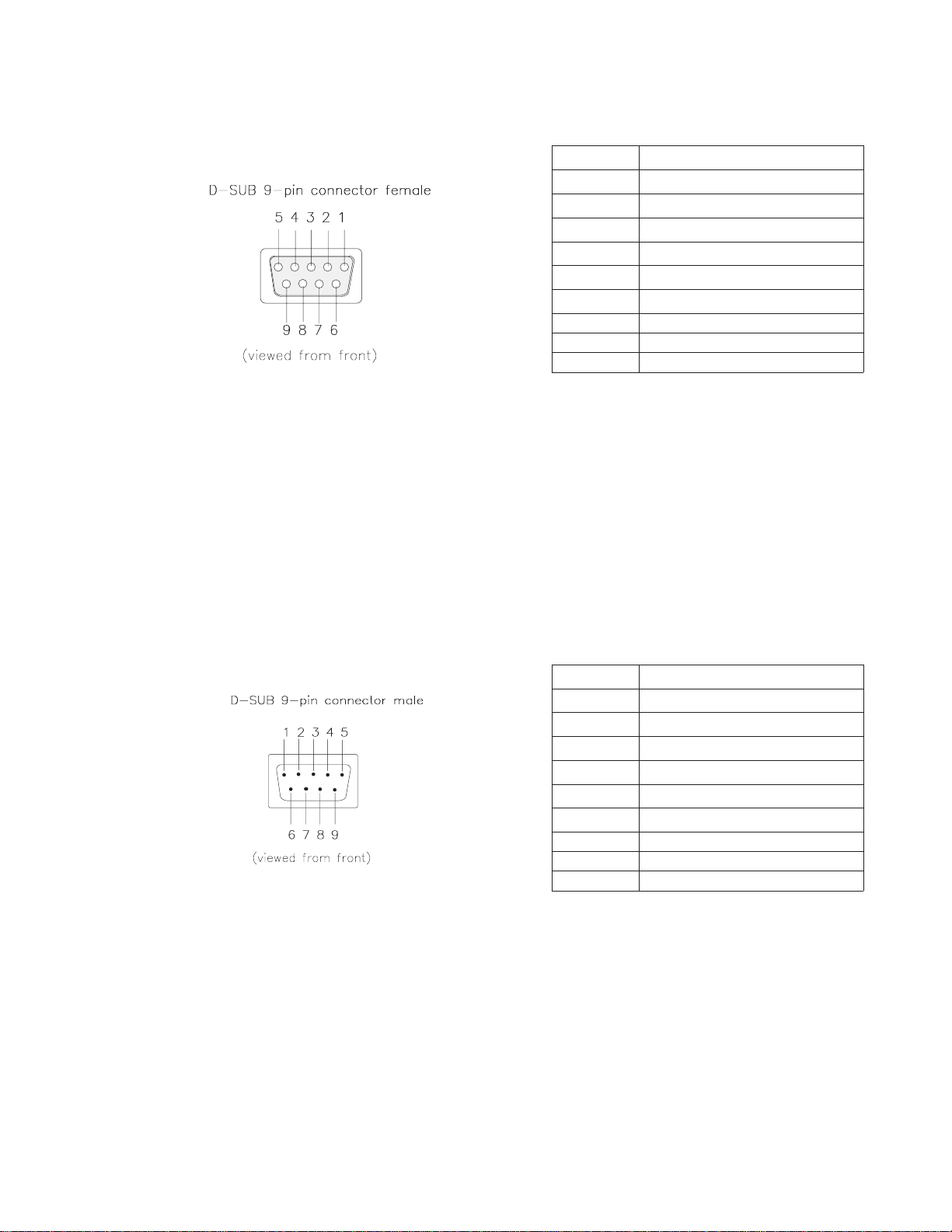

CONNECTORS

Remote SOCKET on Projector:

5

(viewed from front )

figure 2-16

Type Mini DIN

7

8

4

2

1

PIN No.

1

2

6

3

3

4

5

6

7

8

12 V DC =

average value between 7.2 and 14.5 V DC

Signal

12 VDC

Gnd

Signal 1 (LSB)

Signal 2

Signal 3

Signal 4

Signal 5 (MSB)

Interrupt

Kodak AG, Stuttgart 2-13 03/98

Page 28

Service Manual SM 2547-1

P-Bus / RS 232 “IN”

P-Bus / RS 232 “OUT”

figure 2-17

PIN No.

1

2

3

4

5

6

7-

89-

Signal

Connected to 4 and 6

Receive Data (RxD)

Transmit Data (TxD)

Connected to 1 and 6

Signal Ground

Connected to 1 and 4

figure 2-18

PIN No.

1

2

3

4

5

6

7-

89-

Signal

Connected to 4 and 6

Transmit Data (TxD)v

Receive Date (RxD)

Connected to 1 and 6

Signal Ground

Connected to 1 and 4

03/98 2-14 Kodak AG, Stuttgart

Page 29

SM 2547-1 Service Manual

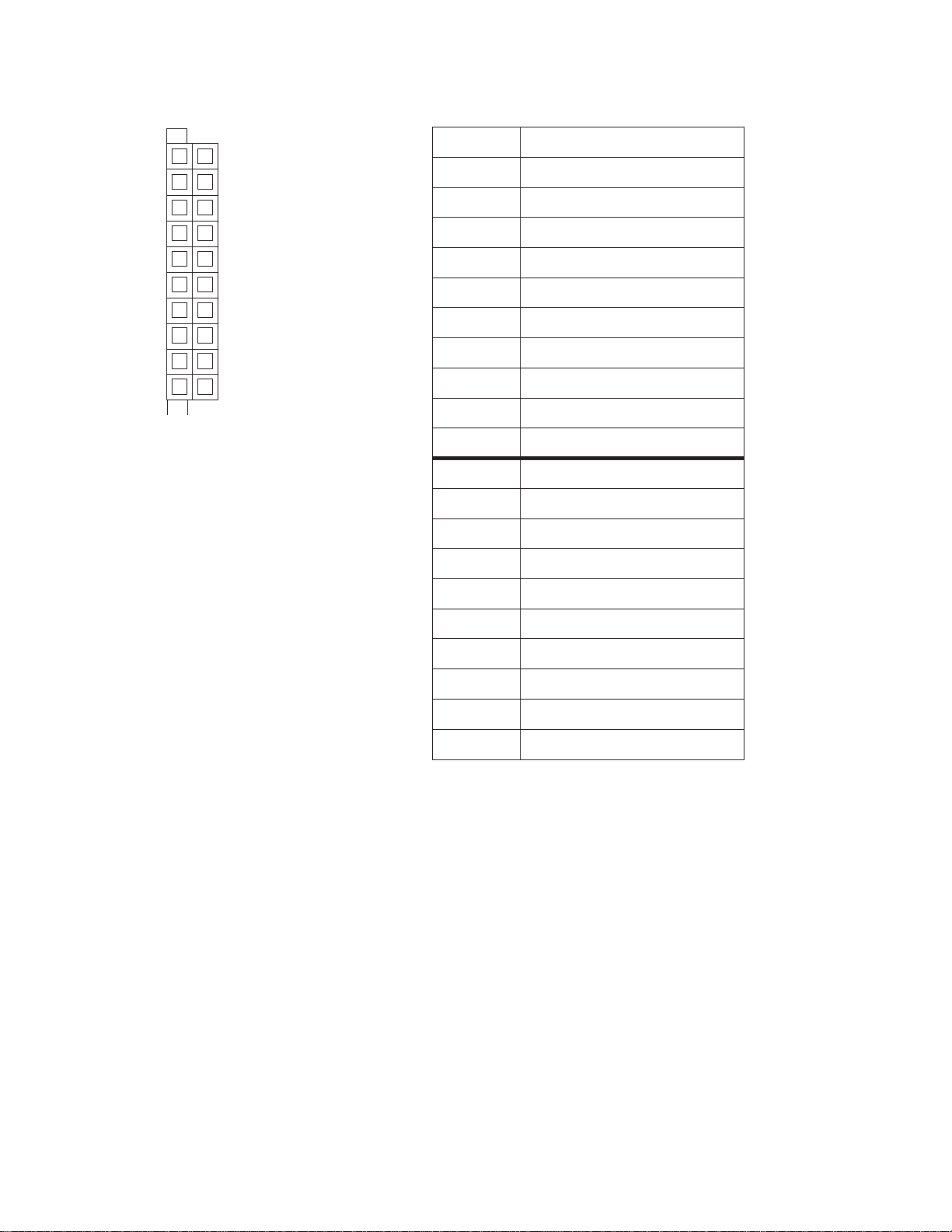

ACCESSORY SLOT

a

1

2

3

4

5

6

7

8

9

10

figure 2-19

b

1

2

3

4

5

6

7

8

9

10

PIN No.

a1

a2

a3

a4

a5

a6

a7

a8

a9

a10

b1

b2

b3

b4

Signal

SDA (I

I

2

C Data)

2

C_INT (Interrupt)

SLOT_232_R, TTL Level

not used

SLOT_A

SLOT_C

not used

12V DC 200mA max.

34V DC 750mA max.

26V AC_N 750mA max.

2

SLC (I

C Clock)

PLL_DISS

SLOT_232_T (TTL-Level)

SLOT_DIS

b5

b6

b7

b8

b9

b10

SLOT_B

SL_DISS

not used

VSS 12 (Ground)

VSS 34 (Ground)

26V AC_L

Kodak AG, Stuttgart 2-15 03/98

Page 30

Service Manual SM 2547-1

OEM ACCESSORIES

COPYRIGHT

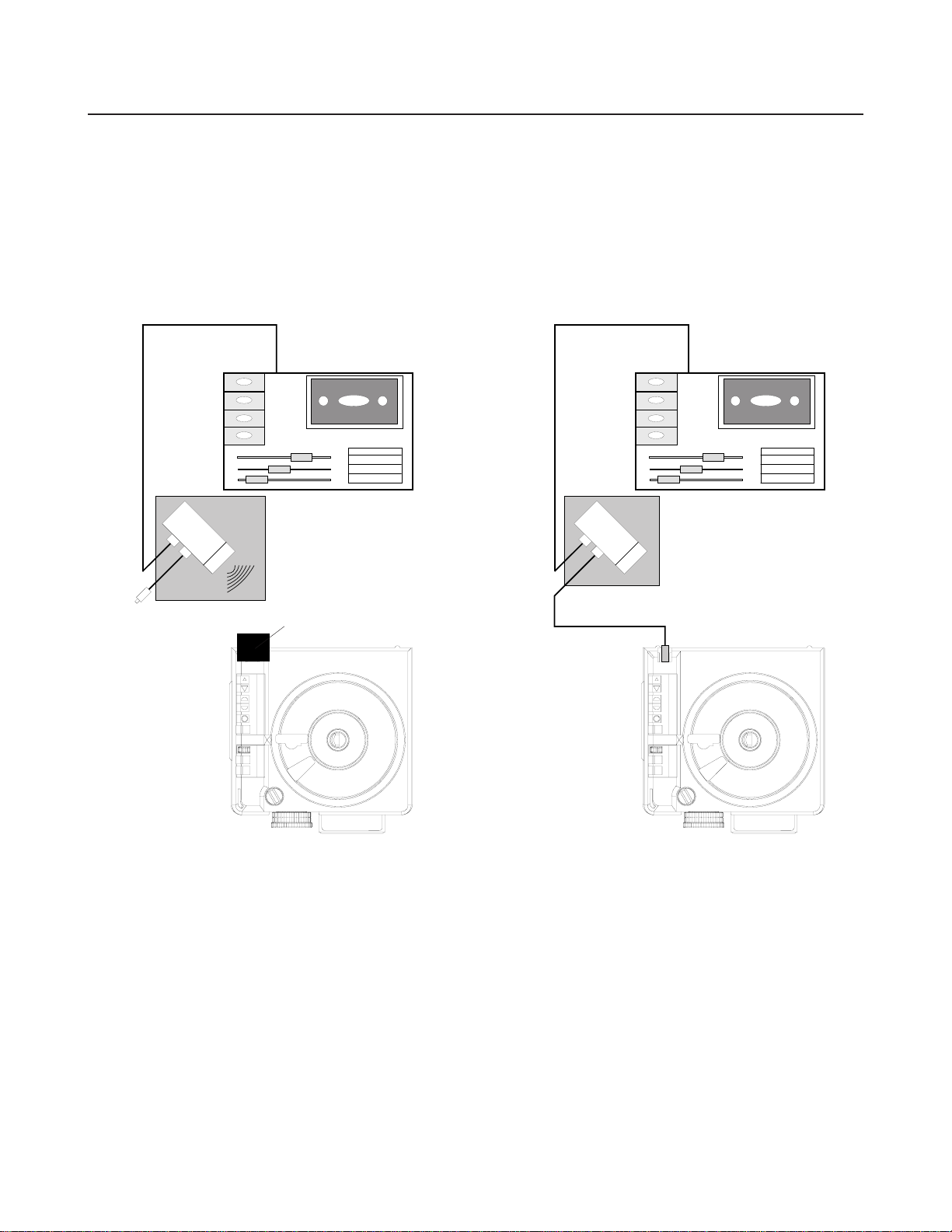

The adapter of this English company is only designed to use traditional AV cassette recorders. Cue pulses

recorded on the tape trigger the interface unit to generate digital commands to advance the EKTAPRO Projector.

It is an interesting feature that the adapter works either by plugging directly into the remote socket or works

remotely by additional use of the EKTAPRO IR Receiver. In this case the system can simultaneously used with

both the EKTAPRO IR Transmitter and the adapter. The adapter is powered by a 9 volt A PP3 battery.

The illustration (figure 2-20) shows both possibilities to run the Projectors.

EKTAPRO IR Receiver

figure 2-20

IR-USE.

The advantage is that the Adapter and Projector can be separated. In addition, the use of the

EKTAPRO Remote Transmitter is possible without disconnecting the Adapter.

CABLE USE

If no IR receiver is available the Adapter can be plugged with the fixed installed cable to the remote socket.

03/98 2-16 Kodak AG, Stuttgart

Page 31

SM 2547-1 Service Manual

SLIDE SYNCHRONIZER ADAPTER by KODAK AUSTRALIA

Kodak Australia offers an own solution of a slide synchronizer adapter. This unit is built in the IR Receiver

housing and is therefor directly to be plugged onto the remote socket. A 6pin socket is built into the housing.

The system supports most of traditional AV cassette recorders. The S-AV cable remote can also be used with

the possibility to give transport commands and to focus. Speaker desk (lecterns) installations can be fully used.

The system is able to switch the Projector into the standby mode (press forward and reverse button

simultaneously) or run to the Projector to the zero position (press and hold down forward and reverse button).

NOTE

The S-AV Timer does not work on this adapter!

EKTAPRO IR

Receiver Housing

with built in Slide

Synchronizer Adapter

Speaker´s Desk

Professional AV Cassette

Recorder

S-AV Remote Control

figure 2-21

Kodak AG, Stuttgart 2-17 03/98

Page 32

Service Manual SM 2547-1

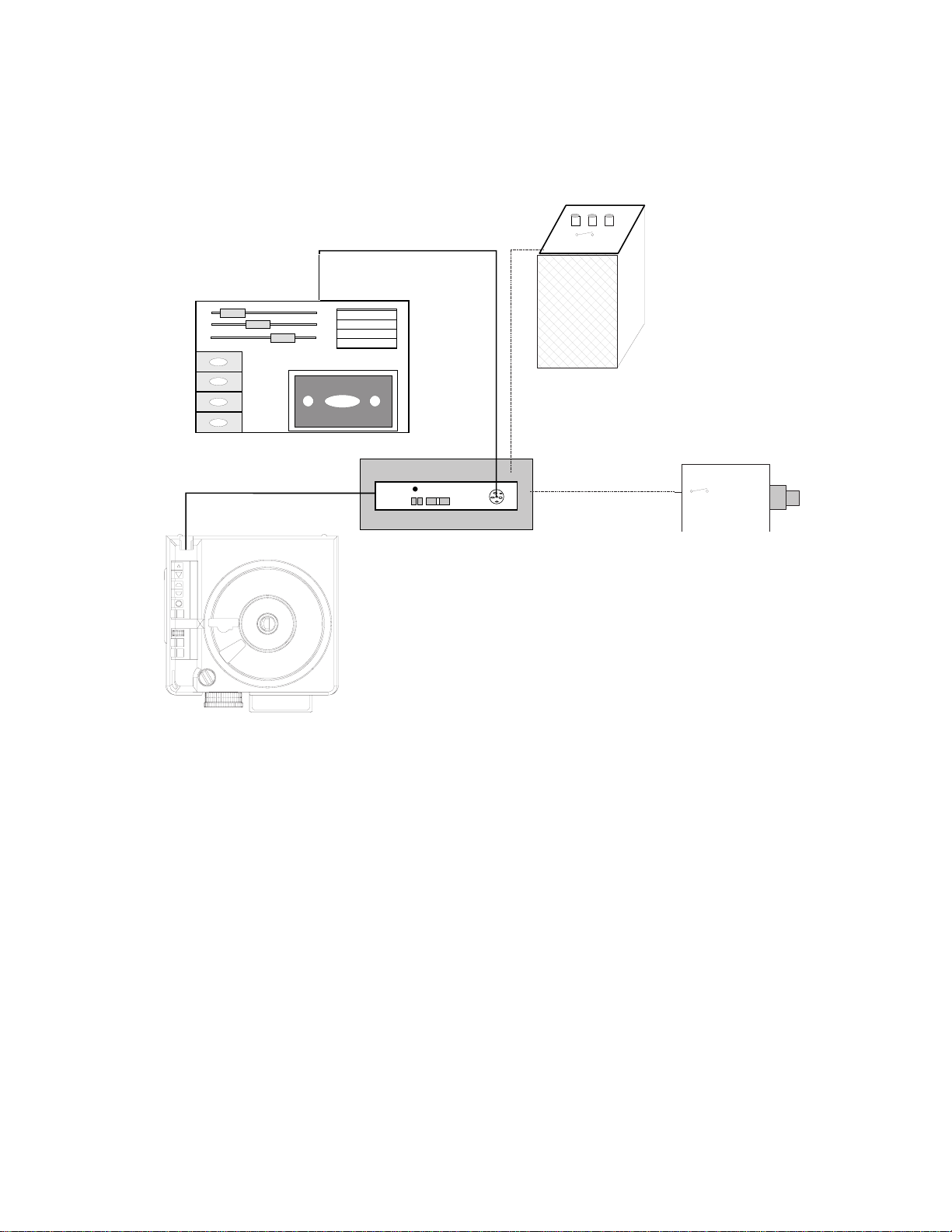

ADAPTER by MÜWO

The German company offers a slide synchronizer adapter which is built into the EKTAPRO Cable Remote

Control. A 6pin socket provides connection with external devices which are traditional AV cassette recorders,

S-AV Timer and speaker desks. Even if any devices are connected, the remote still works.

Professional AV

Cassette Recorder

Speaker´s Desk

EKTAPRO Remote Control

with built in Slide Synchronizer

Adapter

figure 2-22

S-AV Timer

03/98 2-18 Kodak AG, Stuttgart

Page 33

SM 2547-1 Service Manual

ADAPTERS by MAYER & ZELLER

The Swiss company Mayer & Zeller offers a 1000 Hz adapter which comes along in a small black plastic box

with a standard 6pin female receptacle and an integrated cable with the new 8pin male connector for the

EKTAPRO Projectors.

The adapter offers the possibility either to connect a traditional AV cassette recorder to advance the Projector

or

to connect the standard cable S-AV remote control or to use the cable already installed in the speakers desks.

The adapter is also offered in a special version which also enables the control of the focus via the remote control

(or speakers desks).

S-AV Cable Remote Control

Professional AV Cassette Recorder

figure 2-23

NOTE

The S-AV Timer cannot be used because of the lack of a support voltage . But Mayer & Zeller offers a

special Timer for controlling the EKTAPRO Projectors. The timer is built into the EKTAPRO Cable Remote

Control. This a quite sophisticated solution and an interesting offer for those who intend buying a cable

remote.

For further details contact the company.

Kodak AG, Stuttgart 2-19 03/98

Page 34

Service Manual SM 2547-1

ADDRESSES

CONTROL SYSTEMS

• ARION 701 South 7th Street Delano, MN 55328 USA

Tel: (001) 612 972 3351

Fax: (001) 612 972 3524

• Bässgen AV Technik GmbH Hauptstraße 58, 79104 Freiburg Germany

Tel: (0049) 761 23953

Fax: (0049) 761 35042

• Copyright Machines Limited 44/46 Sillwood Street Brighton, Sussex BNI 2PS UK

Tel: (0044) 273 720 175

Fax: (0044) 273 321 150

• Dataton AB Box 257 S-581 02 Linköping Schweden

Tel: (0046) 131 14325

Fax: (0046) 131 38445

• HEP Holland P.O.B. 33112, 3005 EC Rotterdam Niederlande

Tel: (0043) 10 418 3689

• Mechanische Weberei GmbH Neuhäuser Weg 2, 33175 Bad Lippspringe Germany

Tel: (0049) 52 52270

Fax: (0049) 52 522 7201

• Müwo electronic In den Maltwiesen 11, 72379 Hechingen-Stetten Germany

Tel: (0049) 7471 15830

• RMF Products Inc. P.O.B. 520, 1275 Paramount PKWY Batavia II, 60510 USA

Tel: (001) 708 879 0020

Fax: (001) 708 879 6749

• Stumpfl Rudigierstraße 8, A-4701 Bad Schallerbach Austria

Tel: (0043) 7249 2811

Fax: (0043) 7249 2811 18

• Zygo Systems Limited 48 Fallowfields Bicester Oxon OX67Qs UK

Tel: (0044) 869 248 261

Fax: (0044) 869 248 260

03/98 2-20 Kodak AG, Stuttgart

Page 35

SM 2547-1 Service Manual

SOFTWARE for direct PC CONTROL

• ARION 701 South 7th Street Delano, MN 55328 USA

Tel: (001) 612 972 3351

Fax: (001) 612 972 3524

• AVC Team Bieber Am Holling 3, 35649 Bischoffen Germany

Tel: (0049) 6444 1027

Fax: (0049) 6444 8527

• Martin Ballein Viktor Scheffel Straße 2, 74076 Heilbronn Germany

Tel: (0049) 7131 165170

Fax: (0049) 7131 52470

• Hilger & Bremen GbR Heinzenstraße 20, 52062 Aachen Germany

Tel: (0049) 241 49797

Fax: (0049) 241 49787

• Holidays Afloat Limited Schachterij 9920 Lovendegem Belgium

Tel: (0032) 9372 8908

Fax: (0032) 9233 5609

• Stumpfl Rudigierstraße 8, A-4701 Bad Schallerbach Austria

Tel: (0043) 7249 2811

Fax: (0043) 7249 2811 18

• Peter Ziegler Van Gogh Platz 6, 53844 Troisdorf Germany

Tel: (0049) 2241 46143

RACKS

• Chief Manufacturing Inc. 14310 Ewing Avenue South Burnsville MN 55337 USA

• Roha Projektionstechnik Bruno Jacoby Weg 11, 70597 Stuttgart Germany

Tel: (0049) 711 723 621

Fax: (0049) 711 23699

EXTERNAL TIMER

• Mayer & Zeller Wettsteinallee 15, 4058 Basel Switzerland

Tel: (0041) 61681 4343

Fax: (0041) 61681 3907

• Müwo electronic In den Maltwiesen 11, 72379 Hechingen-Stetten Germany

Tel: (0049) 7471 15830

• Wintron GmbH Egilolfstraße 70, 70599 Stuttgart Germany

Tel: (0049) 711 4567 258

Fax (0049) 711 4567 267

Kodak AG, Stuttgart 2-21 03/98

Page 36

Service Manual SM 2547-1

blank page

03/98 2-22 Kodak AG, Stuttgart

Page 37

SM 2547-1 Service Manual

3. THEORY GUIDE

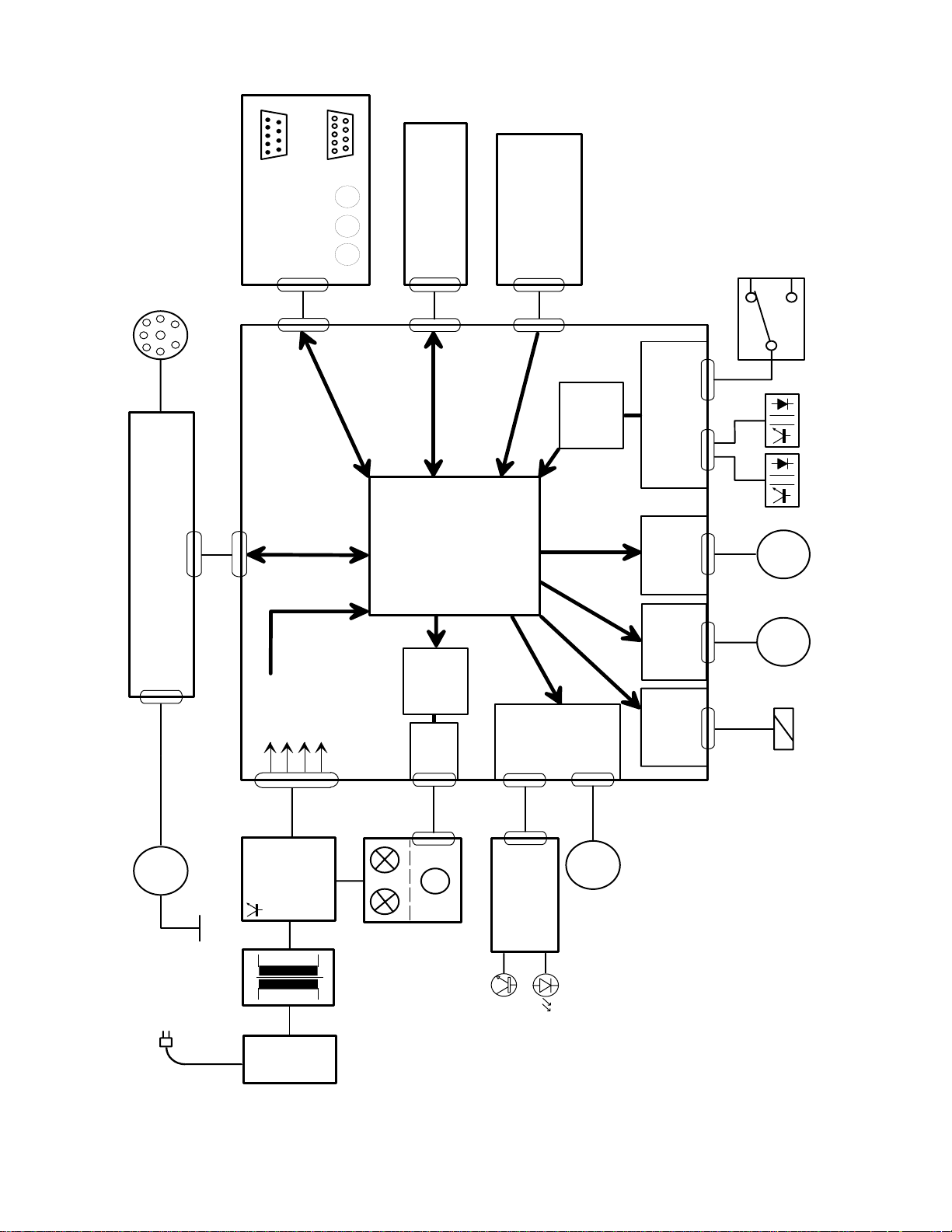

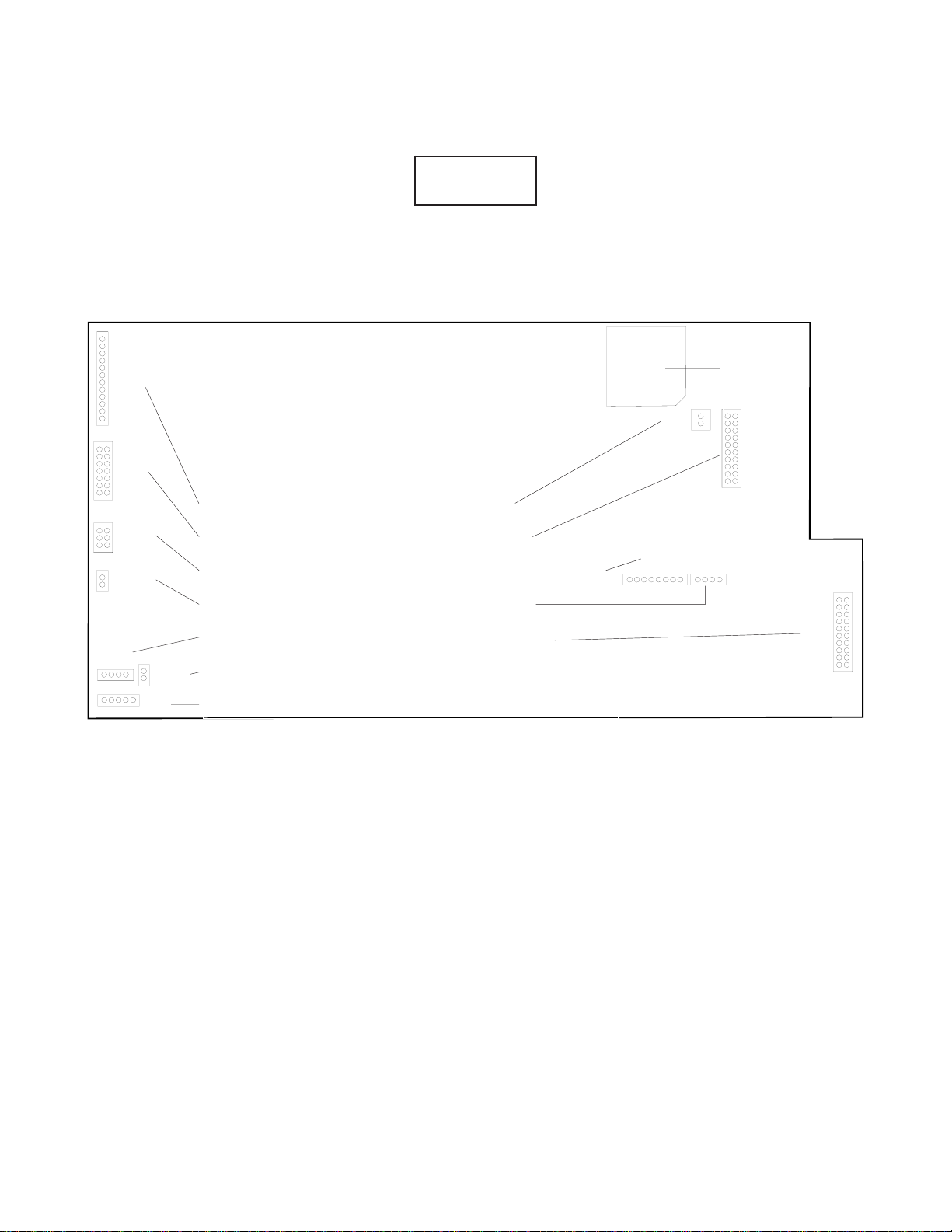

Block Diagram

All functions of the projector are controlled by the MICROCONTROLLER ( MC68HC016B with 16k ROM) on the

MASTER PCB.

The controlling software is loaded in the 16k ROM of the MICROCONTROLLER for Models 4020 - 9020 and

9020/CINE.

Located around the MICROCONTROLLER on the MASTER PCB there are the inputs, outputs and drivers for

the sensors, LAMP, MOTOR´s and other functions.

The block diagram (figure 3-1) shows all of the functions of Model 7020 and 9020.

All model is equipped with the same MASTER PCB´s.

MODEL MASTERBOARD MICROCONTROLLER

4020 LAYOUT No.7 Version 4.8

5020 LAYOUT No.7 Version 4.8

7020 LAYOUT No.7 Version 4.8

9020 LAYOUT No.7 Version 4.8

9020/CINE LAYOUT No.7 Version 4.9

Kodak AG, Stuttgart 3-1 03/98

Page 38

Service Manual SM 2547-1

PCB

Back

Remote Socket

Panel PCB

Accessory Slot

Tray Motion

Tray

Size

Gatel

Slide in

Software

Input

MASTERBOARD

MICRO

CONTROLLER

Keyboard PCB

Lamp

Control

Software

26V DC

5V DC

36V DC

12V DC

Mirror

Driver

Focus

Control

MASTERBOARD Model 4020 - 9020 (9020/CINE)

M

Fan

Lamp

Power and

Regulation

M

Mirror Motor

PCB

Autofocus

M

Driver

Driver

Driver

Focus Motor

M

M

CAM

Sensor

Gate

Sensor

Motor

Slide Lifter

Tray

Motor

Shutter

Solenoid

Module

Transformer

Line

03/98 3-2 Kodak AG, Stuttgart

Fuse

Switch

Dual Lamp

figure 3-1

Page 39

SM 2547-1 Service Manual

Microcontroller Unit

The main device on the MASTER PCB is the 16-bit MICROCONTROLLER unit MC68HC05B16 from

MOTORola

for the models EKTAPRO 4020 - 9020 and 9029/CINE

This MICROCONTROLLER has a microprocessor, timer, memory, analog/ digital converter and input/output ports

on one chip. Compared to a standard processor, where for each item a peripheral IC is necessary.

This MICROCONTROLLER with its on-chip software controls all functions of the projector plus peripheral circuits.

The main features of the MICROCONTROLLER are:

- 24 bi-directional I/O lines

- 8 input-only lines

- serial communication interface system

- 8 channel A/D converter

- 15120 Bytes ROM (Models 4020 - 9020 and 9020/CINE)

- 2 channel timer

The following block diagram shows the internal MICROCONTROLLER functions.

VPP1

RESET

IRQ

OSC2

OSC1

VDD

VSS

PD0/AN0

PD1/AN1

PD2/AN2

PD3/AN3

PD4/AN4

PD5/AN5

PD6/AN6

PD7/AN7

VRH

VRL

256 byte

EEPROM

Charge pump

MC68HC05B16 (15120 bytesROM)

Model 4020 - 9020 and 9020/CINE

COP watchdog

Oscillator

÷2 / ÷32

M68C05

CPU

PORT D

8-bit

A/D converter

496 bytes

self check ROM

352 bytes

static RAM

16-bit

timer

SCI

PLM

PORT APORT B

PORT C

PA0

PA1

PA2

PA3

PA4

PA5

PA6

PA7

PB0

PB1

PB2

PB3

PB4

PB5

PB6

PB7

PC0

PC1

PC2/ECLK

PC3

PC4

PC5

PC6

PC7

TCMP1

TCMP2

TCAP1

TCAP2

RDI

SCLK

TDO

PLMA D/A

PLMB D/A

figure 3-2

Kodak AG, Stuttgart 3-3 03/98

Page 40

Service Manual SM 2547-1

Description of Functions

Power Supply

The PROJECTOR POWER SYSTEM consists of a

• POWER INPUT ASSEMBLY with POWER ON/OFF SWITCH, PRIMARY FUSE HOLDER

and VOLTAGE SELECTOR

• TRANSFORMER, SECONDARY FUSE HOLDER

• POWER REGULATION PCB

The TRANSFORMER supplies the following voltages:

Primary voltage outputs:

92/81 VAC LAMP voltage for Models 4020 - 9020 and 9020/CINE (SOFTWARE CONTROLLED

LAMP CURVE)

Safety Extra Low Voltage outputs:

10 VAC for +5V DC and +12V DC

26 VAC for 36 VDC regulated and unregulated,

The POWER REGULATION PCB contains:

- line EMI filter

- rectifiers and regulators

- Triac LAMP Software Control Circuits (Models 4020 - 9020 and 9020/CINE)

The output voltages and signal are:

- 36 VDC unstabilized (36 VDC_12P) for slot interface

- 36 VDC capacitor- stabilized (36 VDC) for MOTOR´s, solenoid, fan

- 12 VDC unregulated for remote control and slot

- 5 VDC regulated for logic and MICROCONTROLLER

- 26 VAC for accessory slot

- Zero_cross signal for synchronization of the dissolve feature

Details can be obtained from circuit diagrams and the following block diagram.

IMPORTANT

Connect all the equipment to the same same power line, otherwise phase shifting will bring up problems !

03/98 3-4 Kodak AG, Stuttgart

Page 41

SM 2547-1 Service Manual

12V DC

Power Regulation BoardPower Module

5V DC

Regulator

10V

SS

V

26V AC_FL

Zero_Cross

36V DC_12P

Circuit

Zero Cross

15V DC

36V DC

Regulator

26V

SS

V

Triac

Relay

Lamp1

Lamp2

Relay

Triac

Economy

Normal

Neutral

Line

Filter

1.25A

240

230

220

Black

Red

White

Voltage Selector

Switch

N

L

)

120

Gray

)

91

Fuse

)

2A

USA 2.8A

Blue

82

figure 3-3

Kodak AG, Stuttgart 3-5 03/98

Page 42

No

Yes

No

START

Microcontroller

is active

Slide LIFT MOTOR On.Move

LIFTER to Up Positon

CAM Sensor

Signal

0 - 1

Move Slide Tray

about 3 Sl ides forw a rd

Zero

Sensor actuated

?

Reverse Slide Tr ay

Zero

Sensor actuated

?

Stop Tray Motor

Slide LIFT MOTOR On

Slide LIFTER to Down Positon

CAM Se ns or

Signal

1 - 0

Slide in Gate

Sensor actuated

?

Open Shutter

Autofocus On

Projector Ready

for Operation

END

Stop LI FT MOTOR

Powe r LED Blinki ng

Write the Failure into

Memory

Projector d oes not

Operate

Stop LI FT MOTOR

No

Yes

No

Yes

Yes

No

Yes

No

Stop LI FT MOTOR

Service Manual SM 2547-1

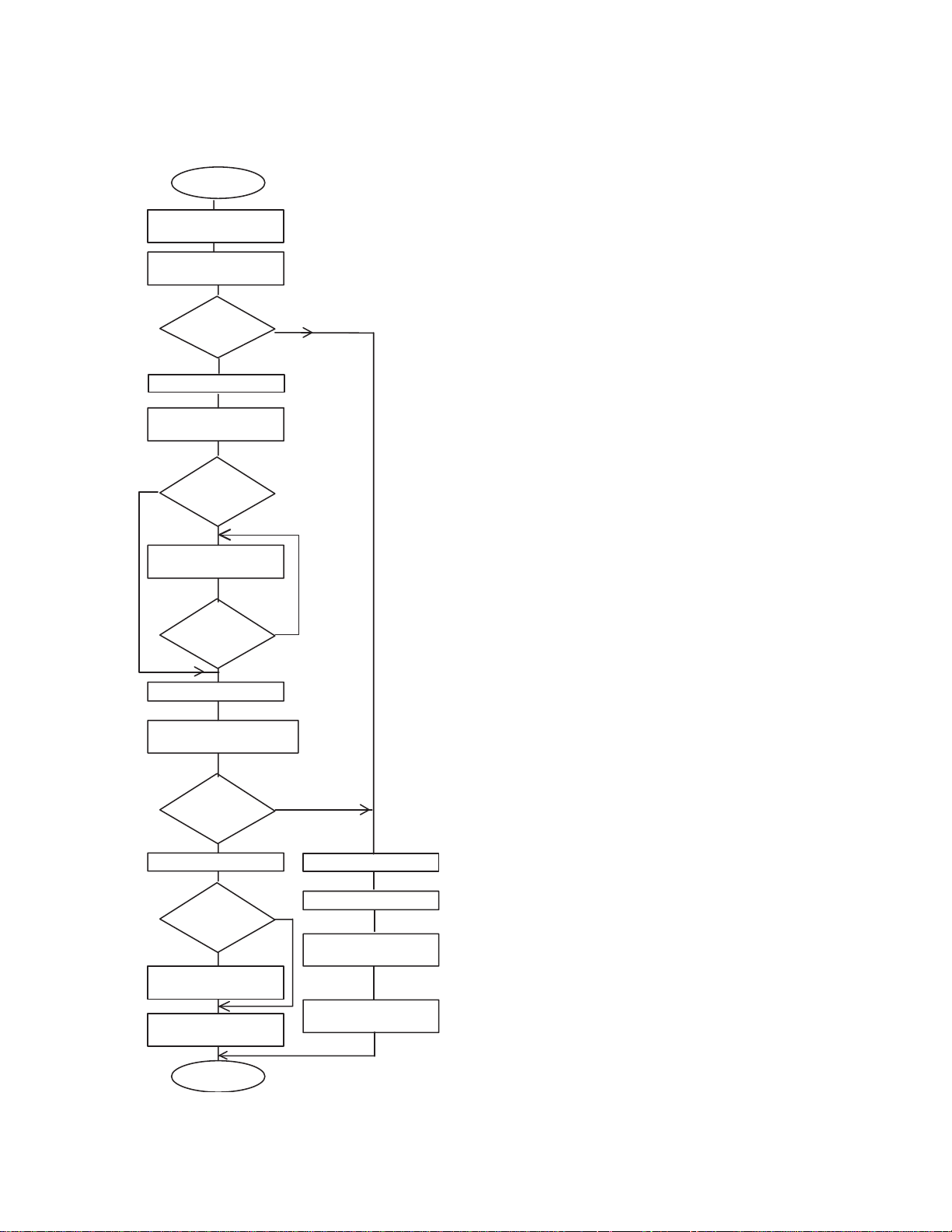

Switch On / Initialize Procedure

Projector Status: Mechanic position is not known

Projector is energized

The MICROCONTROLLER starts the initialization routine:

- load the look-up tables

- look at the accessory slot and projector address

- sets the ECONOMY LAMP RELAY to 82V

- completes a Hardware reset

SLIDE LIFT MOTOR rotates clockwise (max. of 805 steps = one SLIDE

LIFTER cycle).

If SENSOR SIGNAL changes from not actuated to actuated, the SLIDE

LIFTER is in up position.

Yes = Start tray MOTION.

No = Begin a failure routine, after it has advanced 805 steps without

sensor signal change.

slide tray moves forward about 3,5 slides (with software version above

4.2).

Details about tray motion can be obtain from page 3-9.

If the ZERO SENSOR is not actuated, the tray reverses

03/98 3-6 Kodak AG, Stuttgart

figure 3-4

If the ZERO SENSOR is not actuated, the slide tray continues to

advance.

The SLIDE LIFT MOTOR moves clockwise.

When the CAM SENSOR changes from actuated to not actuated, the

LIFTER is in the down position.

If the SLIDE IN GATE SENSOR is actuated, the SHUTTER opens.

Page 43

SM 2547-1 Service Manual

Slide Change Sequence

Projector Status:

- SLIDE LIFTER down

- SHUTTER is open

- SLIDE is in GATE

START

Close Shutter

Switch Autofocus Off

Start: “Forward”/"Reverse" BUTTON is pressed.

The SHUTTER SOLENOID is deenergized.

- LAMP is energized

Signal from: P-Bus, Remote Control or Timer

max. 805 Steps of

Slid e Lift Motor

CAM

Sensor Signal

0 - 1

?

Slide Lift Motor off

Start Tray Motion

Next slide position

Slide Lift Motor On

CAM

Sensor Signal

1 - 0

?

Slide

No

in Gate Sensor

actuated

?

Yes

Yes

Yes

No

No

Slide Lift Motor off

The SLIDE LIFT MOTOR rotates clockwise to move the SLIDE LIFTER

up (max. 805 steps = one SLIDE LIFTER cycle).

The SLIDE LIFTER is in the up position when the CAM SENSOR

signal changes from not actuated to actuated.

If no: the failure routine begins after 805 steps a without signal change.

If yes: Starts the tray Motion. See page 3-10.

For details see page 3-10.

The SLIDE LIFT MOTOR moves clockwise to move SLIDE LIFTER

down. The MOTOR stops when signal changes from actuated to not

actuated.

Switch o n Autofocus

Open Shutter

Power LED blinking

Write Failure into

Memory

Projector does not

operate

When a TIMER is in use, a slide advance forward is done each time

Yes

Timer

activated

?

No

End

after the selected interval is reached (Model´s 4020, 7020 external

timer, Model 5020, 9020 and 9020/CINE internal timer).

The slide is projected.

figure 3-5

Kodak AG, Stuttgart 3-7 03/98

Page 44

Service Manual SM 2547-1

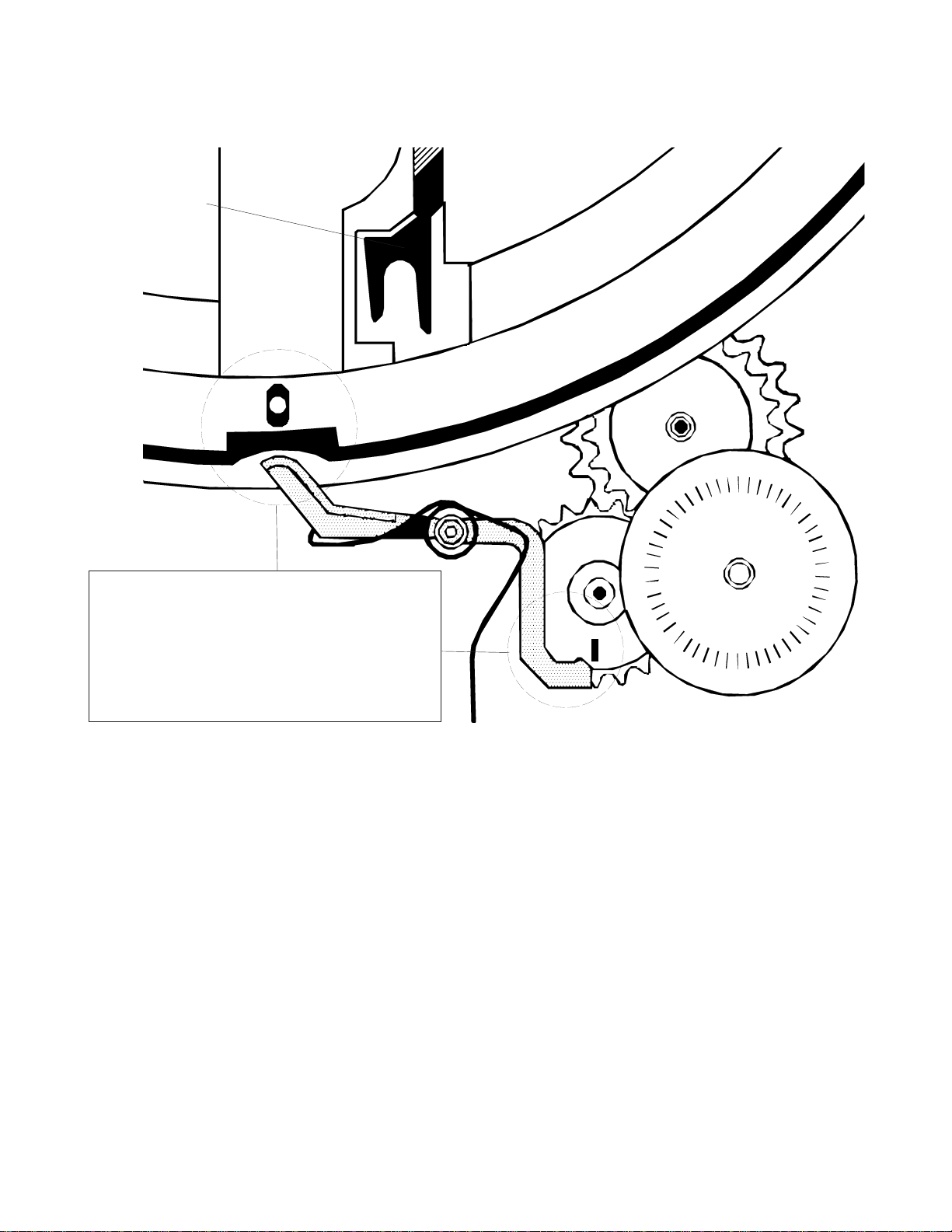

Tray Motion

The STEPPER MOTOR is responsible for the slide tray movement. To move the tray one slide forward or reverse

47 steps are necessary in case a tray for 80 slides is used and 27 steps in case a tray for 140 slides is used.

The tray movement is controlled by the TRAY MOTION CONTROL PCB. This PCB contains two optical sensors,

one for the code wheel and one for the Zero Position Gear.

This PCB is sending following feedback signals to the MICROCONTROLLER:

- Tray motion direction (forward or reverse)

- One pulse for each step of the STEPPER MOTOR

- Tray zero-position signal in case the tray is in the zero position

If the STEPPER MOTOR moves one step, a pulse will be send back from the TRY MOTION PCB to the

MICROCONTROLLER after the step is done.

If these pulses are missing, the MICROCONTROLLER assumes that the tray is not able move. The transport

stops immediately. A failure code is written into memory, the projector do not operate, the power LED is blinking

The projector must be deenergized. The jam must be cleared. As soon as the problem is solved, the projector

should operate after switching on again.

Direction

Tray Step

Tray Zero

Slide

Tray

Tray Control PCB

Zero-Pos.

Sensor

Direction

+ Step

Sensor

figure 3-6

The DIRECTION + STEP SENSOR is a special optical device which generates two independent output signals:

- step pulses (count signal for the MICROCONTROLLER to calculate the tray position)

- direction signal (low signal f or forward steps and high signal for reverse steps)

03/98 3-8 Kodak AG, Stuttgart

Page 45

SM 2547-1 Service Manual

Tray Motion Sequence:

a) Go To Zero Position Projector Status: - Energized

Zero Button

Close Shutter, Autofocus off, Move Slide

LIFTER in up position

distance to Zero

Tray Motor On

Forward

Shortest

?

Tray Motor ON

Reverse

Signal from: - P-Bus (Model´s 4020 and 5020 input only)

- Auto Zero (Model 9020 and 9020/CINE)

The MICROCONTROLLER selects shortest distance to the zero

position.

The TRAY MOTOR is energized.

More than

4 Step Signals

missed ?

No

Zero Sensor

actuated

?

Yes

Stop Tray Motor

Slide LIFTER Down

Set Tray Position

to Zero

END

Yes

Transport Failure

Power LED Blinking

NoNo

Write failure

into Memory

Projector does

not Operate

The TRAY MOTION CONTROL delivers a step signal for each MOTOR

step.

The ZERO SENSOR delivers a signal if the position is reached

Failure: A failure code is written into memory.

The power LED is blinking.

The position is reached. The TRAY POSITION in memory set to zero.

figure 3-7

Kodak AG, Stuttgart 3-9 03/98

Page 46

Yes

No

No

Set Tray Position

to next slide position

END

Tray Motor reverse

Tray Motor forward

More than

4 Step Signals

missed

?

No

Yes

Transport Failure

Write failure

into Memory

Projector

inoperable

requested

Position

reached

?

Start

Slide LIFTER Up

Next Slide

Position

?

Slide LIFTER down

Slide projected

forwards

Power LED Blinking

reverse

Service Manual SM 2547-1

b) Go to next slide position

Projector Status: There is a slide in the gate and it is projected.

Start action: The forward or reverse BUTTON is actuated

See Slide Change Sequence, page 3-7.

or next slide is selected with RANDOM

ACCESS.

RANDOM ACCESS: The MICROCONTROLLER selects shortest

distance to the next slide.

The MICROCONTROLLER energizes the TRAY MOTOR for 47 steps

(80 tray) or 27 (140 tray) for each slide.

The MICROCONTROLLER checks feedback from tray MOTION

CONTROL CIRCUIT.

If more than 4 feedback pulses are missed, exit to the failure routine.

For RANDOM ACCESS: The TRAY MOTOR ON until the position is

reached.

For FORWARD/REVERSE BUTTONS:

- tray moves only for one slide

- slide is projected

- if transport button is still pressed,

a slide is lifted up and the tray moves until button is released but

stops at the ZERO POSITION.

The MICROCONTROLLER sets the next position into memory.

The SLIDE LIFTER Down procedure starts.

For details, see Slide Change Sequence.

03/98 3-10 Kodak AG, Stuttgart

figure 3-8

Page 47

SM 2547-1 Service Manual

LAMP Control

a) Dual LAMP Operation

All Models are equipped with a DUAL LAMP MODULE (Extra Bright).

The POWER REGULATION PCB on all Models contains a LAMP current circuit that can detect if the active

LAMP is on, indicated by a LED on the BACK PANEL.

If a LAMP fails, the MICROCONTROLLER receives the LAMP_CURR signal from the POWER REGULATION

PCB. It activates the MIRROR MOTOR and moves the MIRROR to the second LAMP position. Then the relay

K1 is energized and second LAMP is energized. The MICROCONTROLLER also energizes the LED for the

second LAMP. The LED’s are located on the BACK PANEL.

The Models 4020 - 9020 and 9020/CINE have a memory. This memory is storing the the current used lamp as

long as the lamp is defective. That means the mirror of the DUAL LAMP MODULE do not change his position

after a new lamp is inserted. This function can be disabled (see page 2-3).

The characteristic of the lamp curve is no longer generated by a PLL circuit on the MASTERBOARD. Up to

now it is s tored in the Software LAMP C ontro l memory and the TRIAC will be triggered from the

MICROCONTROLLER.

91VAC

82VAC

Lamp Current

Detection and

Switch off

L2

L1

Lamp

Current

Zero-Cross

Circuit

Dual Lamp

Modul

Relay

Driver

Relay

Driver

M

Mirror

Motor

Zero_Cross

Economy

Relay

Mirror

Motor

Driver

Lamp_curr

SOFTWARE TRIGGER

DATA

Dissolve

Logic

SYNC

GND

Micro

Controller

Software

Lamp

Control

Power Regulation Board

Master Board

figure 3-9

Kodak AG, Stuttgart 3-11 03/98

Page 48

Service Manual SM 2547-1

b) LAMP setting

Models 4020 - 9020 and 9020/CINE:

a) Through the LAMP SWITCH or P-Bus

The settings of the LAMP are change by using the LAMP dimming function through the TRIAC

DISSOLVE LOGIC. The phase cut position for LOW is 75% of HIGH .

The LAMP supply voltage is 91 VAC only.

Resulting LAMP voltages: Standard: 82V RMS

Economy : 72V RMS

b) Via accessory slot

External units that are connected to the accessory slot cannot use the Standard/Economy LAMP

setting with phase cut. Therefore, the LAMP supply voltage is switched with the ECONOMY

SIGNAL and a relay to 82 VAC.

The functions of the STANDBY and Standard/Economy Buttons are disabled.

c) LAMP Protection

In the LAMP RETURN LINE on the POWER REGULATION PCB there is a small circuit that detects the actual

LAMP current.

LAMPS can explode when they reach the end of their life. The melting filament can create a short circuit with a

high current.

The high current is detected, and the LAMP is deenergized immediately by the TRIAC.

This procedure prevents the LAMP from exploding, and protects the TRIAC.

d) LAMP Voltage Control

All Models are equipped with a LAMP voltage regulation so that the LAMP voltage does not follow line voltage

fluctuation. The 5V AC outlet of the POWER REGULATION PCB i used to create the VAC_Value signal on the

MASTER PCB. This signal is fed to the MICROCONTROLLER (MC). The MC then selects a phase cut position

of the LAMP voltage which results in a reasonable constant LAMP voltage. This function is disabled if an

accessory is connected to the accessory slot. In this case the LAMP operates with 82 VAC.

03/98 3-12 Kodak AG, Stuttgart

Page 49

SM 2547-1 Service Manual

e) Lamp Dimming

The LAMP DIMMING FUNCTION is installed in Model 4020 - 9020. It is used for dissolving for Economy and

Standard LAMP settings. The main devices for dimming are the TRIAC, TRIAC CONTROL and Zero_Cross

circuit on the POWER REGULATION PCB, the dissolve logic and the MICROCONTROLLER (MC) on the

MASTER PCB.

The TRIAC FUNCTION is controlled by the MICROCONTROLLER and its software, it works according to phase

cut principals.

91VAC

82VAC

Lamp Current

Detection and

Switch off

L2

L1

Lamp

Current

Zero-Cross

Circuit

Dual Lamp

Modul

Relay

Driver

Relay

Driver

M

Mirror

Motor

Zero_Cross

Economy

Relay

Mirror

Motor

Driver

Lamp_curr

SOFTWARE TRIGGER

DATA

Dissolve

Logic

SYNC

GND

Micro

Controller

Software

Lamp

Control

Power Regulation Board

figure 3-10

Kodak AG, Stuttgart 3-13 03/98

Master Board

Page 50

Service Manual SM 2547-1

a) Lamp Voltage

b) Zero-Cross Signal

c) Internal Counter Clock Signal

4096 Pulses

4096 Pulses

The zero-cross circuit creates an impulse whenever the LAMP

voltage crosses the zero line (LAMP voltage close to zero).

Seefigureb.

Therefore, every 10ms for 50Hz or 8,3ms for 60Hz a signal

change occurs. This signal is sent to the DISSOLVE LOGIC on

the MASTER PCB. The DISSOLVE LOGIC generates a

clocksignal with 4096 pulses for the length of half a sine wave.

This clock signal is triggered by the zero-cross signal.

Seefigurec.

Through the DATA SIGNAL, the MICROCONTROLLER delivers

a value between 3 and 3700 to the DISSOLVE LOGIC. Values

of 0 to 4096 are possible, but these valves would cause

false phase cut positions because the zero-cross signal does not

detect zero on the sine wave.

At the next zero-cross of the LAMP voltage, the DISSOLVE

LOGIC reads the value in the MICROCONTROLLER. This value

can range from 0 to 1000, and is counted by internally generated

clock signal. The clock signal sends the TRIAC TRIGGER signal

to the TRIAC CONTROL on the POWER CONTROL PCB.

The TRIAC is energized and the LAMP is energized for the rest

of that half sine wave.

d) Example

1000

0

1000

0

e) Trigger Impuls

d) Actual Lamp Voltage

If the MICROCONTROLLER sends a new value, the next half

would have a different phase cut position. If the value is not

changed, the cut position leaves unchanged.

The LAMP dissolve function operates between zero and high

with an accessory in the accessory slot or with RS232. High or

low on the LAMP is controlled by the BRIGHTNESS SWITCH.

The dissolve range of zero to full brightness is divided into 1000

steps. These steps can be used to create a linear LAMP

brightness change.

A lookup table is used in the MICROCONTROLLER software.

This table contains the corresponding phase cut value for each

one of the 1000 steps for a linear brightness setting.

figure 3-11

03/98 3-14 Kodak AG, Stuttgart

Page 51

SM 2547-1 Service Manual

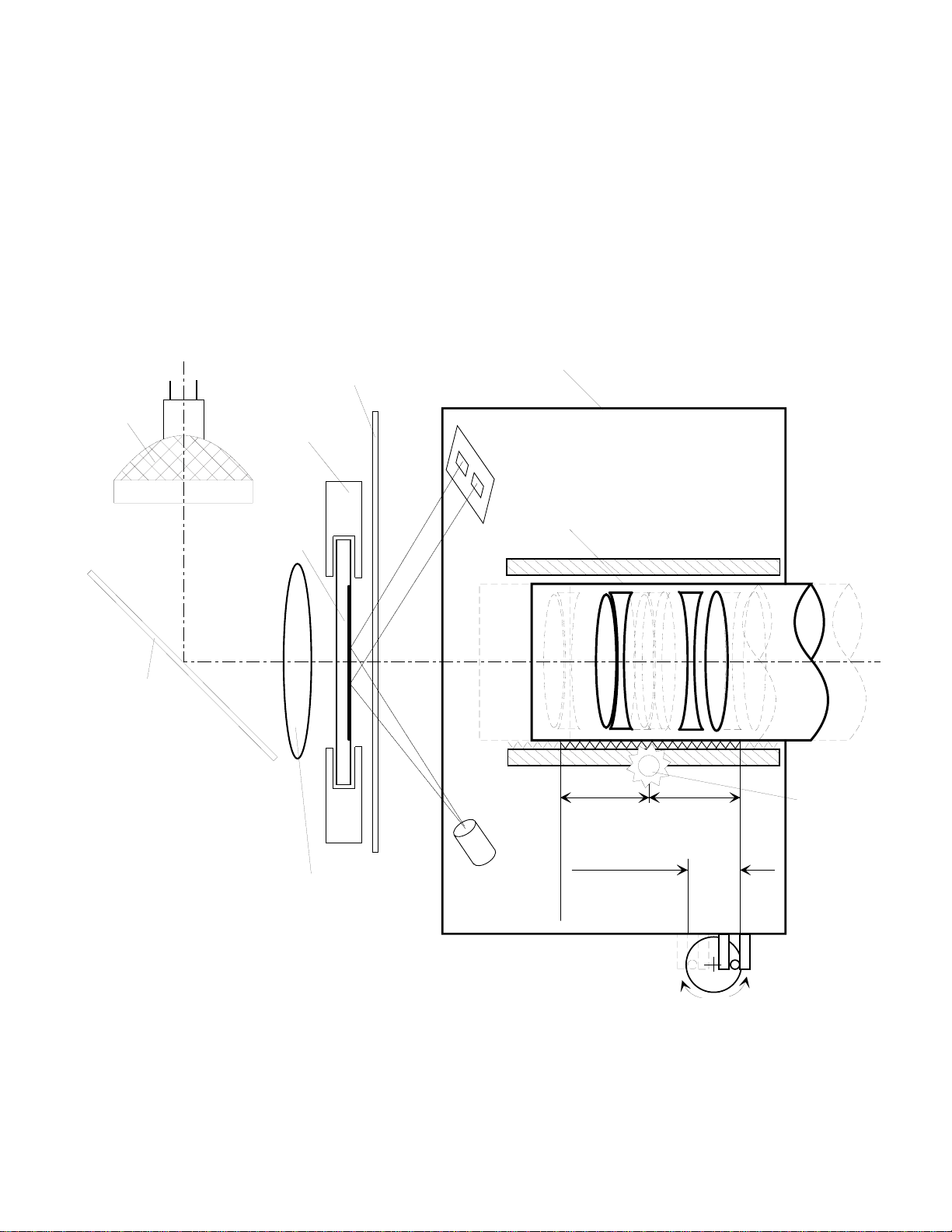

Focus

There are different possibilities to get a crisp and clear focused image on the screen.

1. Use the FOCUS KNOB. In this case the LENS will be moved inside the LENS CARRIER, while the LENS

CARRIER still keeps his position.

2. Use the FOCUSING BUTTONS either on the KEYBOARD of the PROJECTOR or on the REMOTE

CONTROL. In this case the LENS and the LENS CARRIER are moving together. The focus range

is limited, and depend on the ECCENTRIC of the FOCUS MOTOR (approx. 8mm / 0.3 in.).

Lens Carrier

Shutter

Lamp

Slide Gate

T2

T1

IR-Receiver

Mirror

Slide

Surface

Kondensor Lens

IR-

Transmitter

Lens

Manual

Focus Range

Autofocus

Range approx.

8mm (0.3in)

Manual

Focus Knob

Focus

Motor

figure 3-12

Kodak AG, Stuttgart 3-15 03/98

Page 52

Service Manual SM 2547-1

AUTO FOCUS

The AUTO FOCUS feature is installed in the EKTAPRO Model 5020,9020 and 9020/CINE.

A “low” FOCUS EXT signal from the MICROCONTROLLER enables the AUTO FOCUS PCB while a “high” signal

disables the AUTO FOCUS to ensure a sharpness correction for the projected slide. If a manual sharpness

correction was necessary the AUTO FOCUS MOTOR moves back to its primary position after the next slide

change. The AUTO FOCUS MOTOR is running until both receivers has the same light input. The FOCUS

MOTOR stops at the time the light input on both Photo transistors is equal. The direction for the focus movement

is defined by either receiver port 1 or port 2.

An electronic circuit will determine the operating voltage for the FOCUS MOTOR (running forwards or backwards)

to ensure to have the same speed in both directions. This regulation is necessary because the LENS CARRIER

is basic loaded with a spring in one direction.

To ensure that the AUTO FOCUS function works properly it is very important to use the same kind of slide

frames. Mixing up glass slides with other slides will bring the projected image out of focus because there is only

one reference point for the lens position to get a sharp and clear projected image on the screen.

If glassless slide frames are in use, it could be, that the borders of the projected image are out of focus.

It depends on the IR-Beam which is only sensing the center of the slide.

Slide

Prism

Focus Command

from Keyboard or

Remote Control

MICRO

CONTROLLER

Prism

IR-

Trnasmitter

AF

BOARD

FOCUS

LOGIC

T1

IR-

Receiver

T2

MASTER

BOARD

5V DC

GND

Foc Ext2

Foc Ext1

Speed

Direction

Focus Motor

FOCUS

M

MOTOR

CONTROL

figure 3-13

03/98 3-16 Kodak AG, Stuttgart

Page 53

SM 2547-1 Service Manual

P-BUS

All the Models are equipped with the P-Bus feature.

The Models 4020 and 5020 has only an Input Bus, Models 7020 and 9020 and 9020/CINE an IN/OUT Bus.

The P-Bus (Presentation Bus) is a serial asynchronous data transmission interface which uses the RS 232 /

V.24/ V.28 standard. This type of interface is used with Personal Computers for external communication.

figure 3-14

The purpose of the bus is to enable computer controlled projection with one or more slide projectors. Up to 16

different EKTAPRO 7020 or 9020 and 9020/CINE projectors can be addressed separately if they are connected

through a daisy chain configuration. The projector addresses can be selected on the PROJECTORS ADDRESS

SELECTOR SWITCH which is located above the P-Bus connectors.

The P-Bus interface configuration is initially set at:

- 1 Start bit

- 8 Data bit

- 1 Stop bit

- 9600 Baud rate

- No Parity

The signal levels must be equal to the RS232 specifications.

The signal lines are only “Transmit Data” and “Receive Data”. Bi-directional lines are not used.

The projector can be controlled by other control signals beside the P-Bus Interface. Details can be found in a

special marketing publication.

The P-Bus is also used as Service Interface for the Diagnostic Software.

Kodak AG, Stuttgart 3-17 03/98

Page 54

Service Manual SM 2547-1

Command Structure

The Command Structure is binary coded with three consecutive 8-bit bytes. Synchronization is achieved by a

break in the transmission of more than three byte times. The first five bit of each command specifies the address

of the selected projector.

The 16 hardware addresses are 0-F (hex).

The address 1F (hex) is a global address that all connected projectors will accept. Several projectors can be

combined in a group by assigning them a special group address of 10 - 19 hex with a software command. Note,

global or group addresses are separate from the position that is selected on the address switch.

Three 8-bit bytes:

AAAAA MM 1 CCCC XXXD XXXXXXXD

1. Byte 2. Byte 3. Byte

AAAAA address of projector

MM selects command mode

CCCC commands depending on selected mode

XXXX XXXX XXX commands or information depending on selected mode

An example of command modes is:

- parameter mode 00

- set/reset mode 01

- direct mode 10

- status request mode 11 In this mode, the projector returns (10 bit) data.

This mode can be used for diagnostics purposes.

Details can be obtained from special marketing literature.

03/98 3-18 Kodak AG, Stuttgart

Page 55

SM 2547-1 Service Manual

Accessory slot

This slot was designed for EKTAPRO Models 7020, 9020 and 9020/CINE to receive certain professional

dissolve

units. The 12/7 PIN ADAPTER is a PCB with:

• an “Intern/Extern” switch for a check. Intern means “Lamp on” and Extern means

“Projector is controlled by the dissolve unit”.

• connectors to connect the ADAPTER to the projector, and an ADAPTER CABLE for

different dissolve units. The ADAPTER CABLE has a 25 PIN SUB-D connector to connect

the PCB ADAPTER and a combination socket for 12 and 7 PINS.

Accessories that allow the EKTAPRO projectors to communicate with older dissolve equipment are available for

the 12/7 PIN sockets.

The slot contains an Inter IC Communication Interface (I

7/12 PIN Adapter. Typical I

2

C functions are not available.

a) Possible Control Functions

- P-Bus function in TTL Level through RS_232_R and RS232_T lines

- LAMP dissolve through SL_DISS line

2

-I

C Communication through SDA, I2C_INT and SLC lines

- Voltage Supply for accessory slot modules. See 2.4 CONNECTORS.

- Special Control lines SLOT_A, SLOT_B, SLOT_C

All lines are connected to ground means 12/7 PIN adapter present, PROJECTOR LAMP

off, waiting for dissolve pulses on SL_DISS line

- all high, no ACCESSORY installed

2

C). The I2C bus is used in a modified way only for the

Kodak AG, Stuttgart 3-19 03/98

Page 56

(

)

Service Manual SM 2547-1

Remote Control

Type Mini DIN

Pin No.

7

8

5

6

3

1

2

3

4

5

Signal

12 VDC

Gnd

Signal 1 (LSB)

Signal 2

Signal 3

4

6

2

1

viewed from fr ont

figure 3-16

Because of the microprocessor, the REMOTE CONTROL also works with digital signals on the TTL level.

RANDOM ACCESS is also available through a REMOTE CONTROL receptacle.

The data is sent parallel as a 5 bit code from the CABLE REMOTE or the IR RECEIVER to the projector

(Keyboard PCB) with an interrupt signal.

7

8

12 VDC = average value between

7.2VDCand14.5VDC

Signal 4

Signal 5 (MSB)

Interrupt

The example shows the binary code

10000.The code 10000 is for FORWARD.

When a button on the REMOTE CONTROL

is pressed, the INT signal is low with a

maximum value of 1 µ s. Then it becomes

high again. After that the data transmission

begins.

figure 3-15

While the focus and tray motion signal consist of only one 5 bit data record. The slide position values are always

sent as three successive 5 bit data.

For example:

Slide No. 3 = decimal 20 20 23 , binary 10100 10100 10111

Slide No. 140 = decimal 21 24 20 , binary 10101 11000 10100

03/98 3-20 Kodak AG, Stuttgart

Page 57

SM 2547-1 Service Manual

List of Remote Control Commands:

Key/Function Command decimal Command binary

54321

Slide forward

16 10000

Slide backwards

Focus forward

Focus backwards

Standby

Key 1

Key 2

Key 3

Key 4

Key 5

Key 6

Key 7

Key 8

Key 9

Key 0

Clear

8 01000

4 00100

2 00010

1 00001

21 10101

22 10110

23 10111

24 11000

25 11001

26 11010

27 11011

28 11100

29 11101

20 10100

Internal

Enter

3 words internal

Kodak AG, Stuttgart 3-21 03/98

Page 58

Service Manual SM 2547-1

blank page

03/98 3-22 Kodak AG, Stuttgart

Page 59

SM2547-1 Service Manual

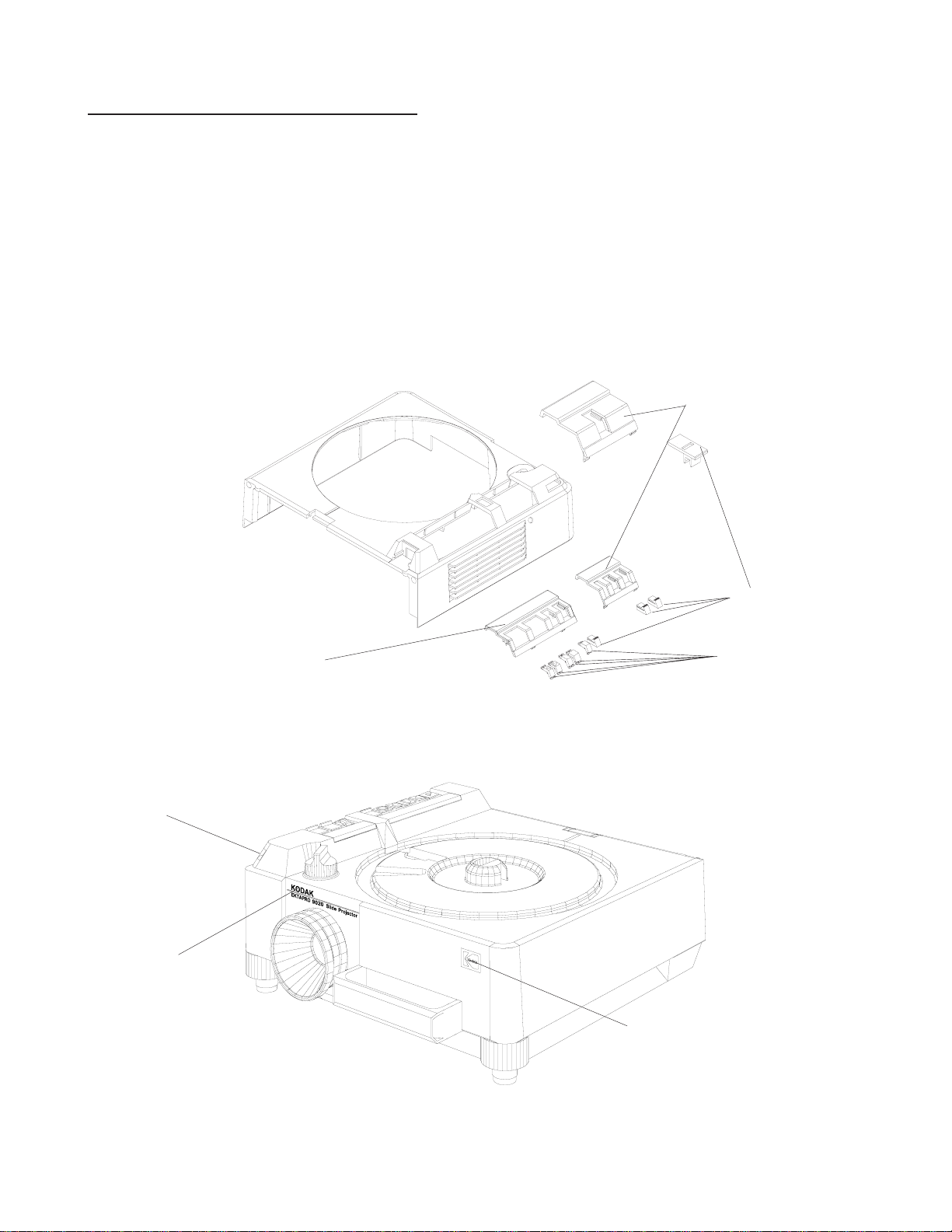

4. DISASSEMBLY/ASSEMBLY

UPPER HOUSING

1. Remove the LAMP MODULE.

2. Remove the KNOB.

3. Remove the 4 SCREWS.

4. Remove the UPPER HOUSING.

UPPER HOUSING

LAMP MODULE

BUTTONS ( 3)

KNOB

LABEL

SCREWS (4)

figure 4-1

Kodak AG, Stuttgart 4-1 03/98

Page 60

Service Manual SM2547-1