Page 1

Multi-Feed Detector

For use with the:

Document Scanner 9500

Document Scanner/Microimager 990

Kodak Imagelink

Kodak Imagelink

Scanners 900 and 923

Microimager 70

A-61120

Part No. 1E8110

User’s

Guide

Page 2

Using the Multi-Feed Detector

The

Introduction

Kodak Digital Science

processing by detecting documents that may go through the feeder

one on top of the other. Multi-feeds can easily happen due to damp

documents, adhesives on documents, electrostatically charged

documents, or a maladjusted feeder gap.

The Multi-Feed Detector is an accessory on the following models:

•

Kodak Digital Science

Multi-Feed Detector aids in document

Scanner 9500 (S or D)

Before you begin

Kodak Digital Science

•

Kodak Imagelink

•

Kodak Imagelink

•

For the purpose of this User’s Guide, the equipment listed above will

be generically referred to as “scanner”.

NOTE: This accessory is not intended for use on machines with the

Check Feeder accessory.

For the Multi-Feed Detector to function properly be sure of the

following:

• Documents must be greater than or equal to 2.5 inches (104 mm)

in length. (Length is measured parallel to the direction of feeding.)

• Minimum document width is 4.5 inches.

• The thickness of the documents within a batch must be the same

within ±10% from any nominal value from 2.0 to 7.0 mils.

• Documents should be in good condition.

• The document stack is fanned before feeding to aid in document

separation.

Scanner/Microimager 990 (S or D)

Scanners 900 and 923 (S or D)

Microimager 70

• For a microimager, be sure the Advanced Document Controller*

and skew detection is installed and enabled in the desired mode.

* All

Kodak Digital Science

Imagelink

Controller installed.

A-61120 March 1999 1

900 series Scanners come with the Advanced Document

9000 series Document Scanners and

Kodak

Page 3

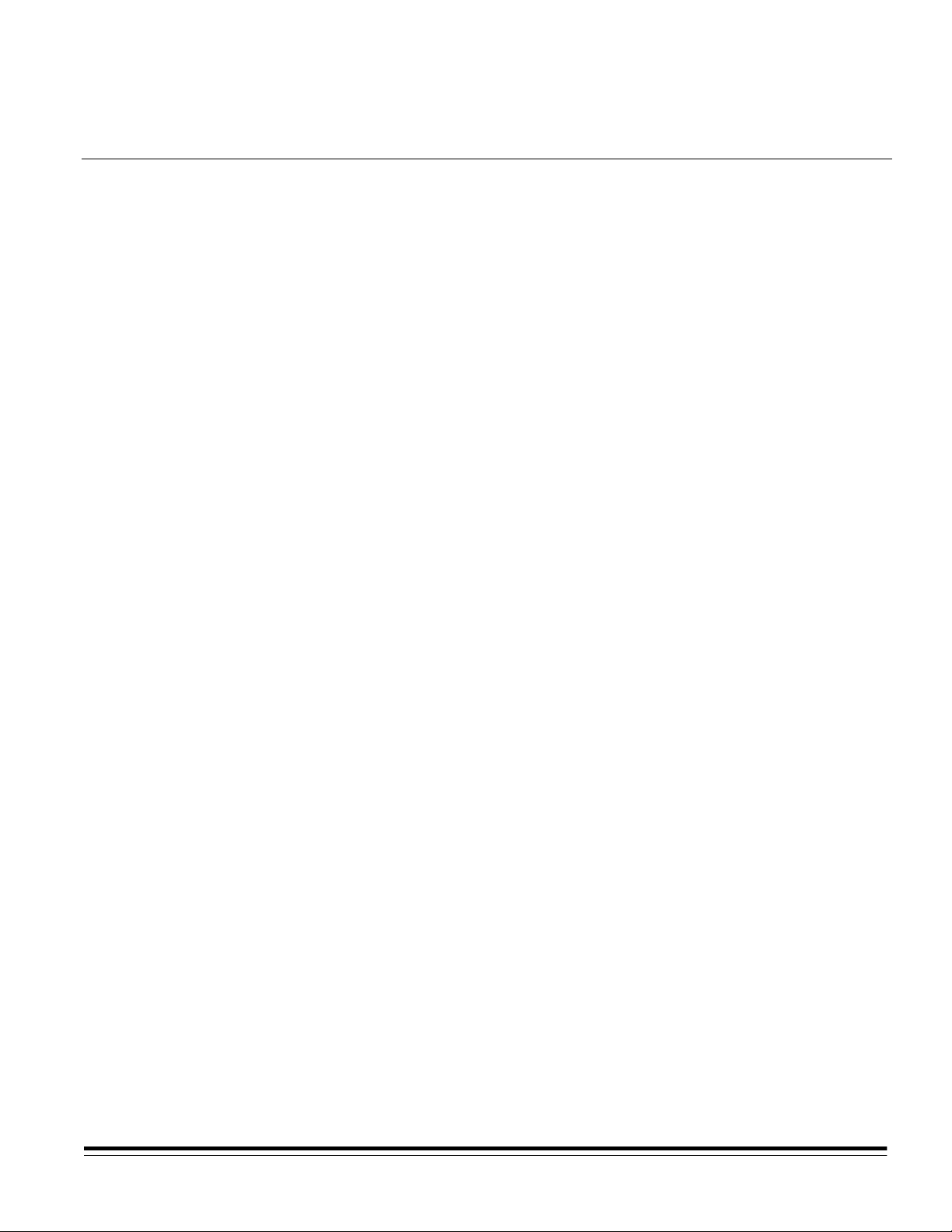

• Labels should be placed on the documents so they do not pass

under the thickness sensor. If the labels on the document will pass

under the thickness sensor, they must be less than or equal to

½-inch in length and spaced greater than 1 inch. They must be

placed 2 inches or more from the trail and lead edges of a

document.

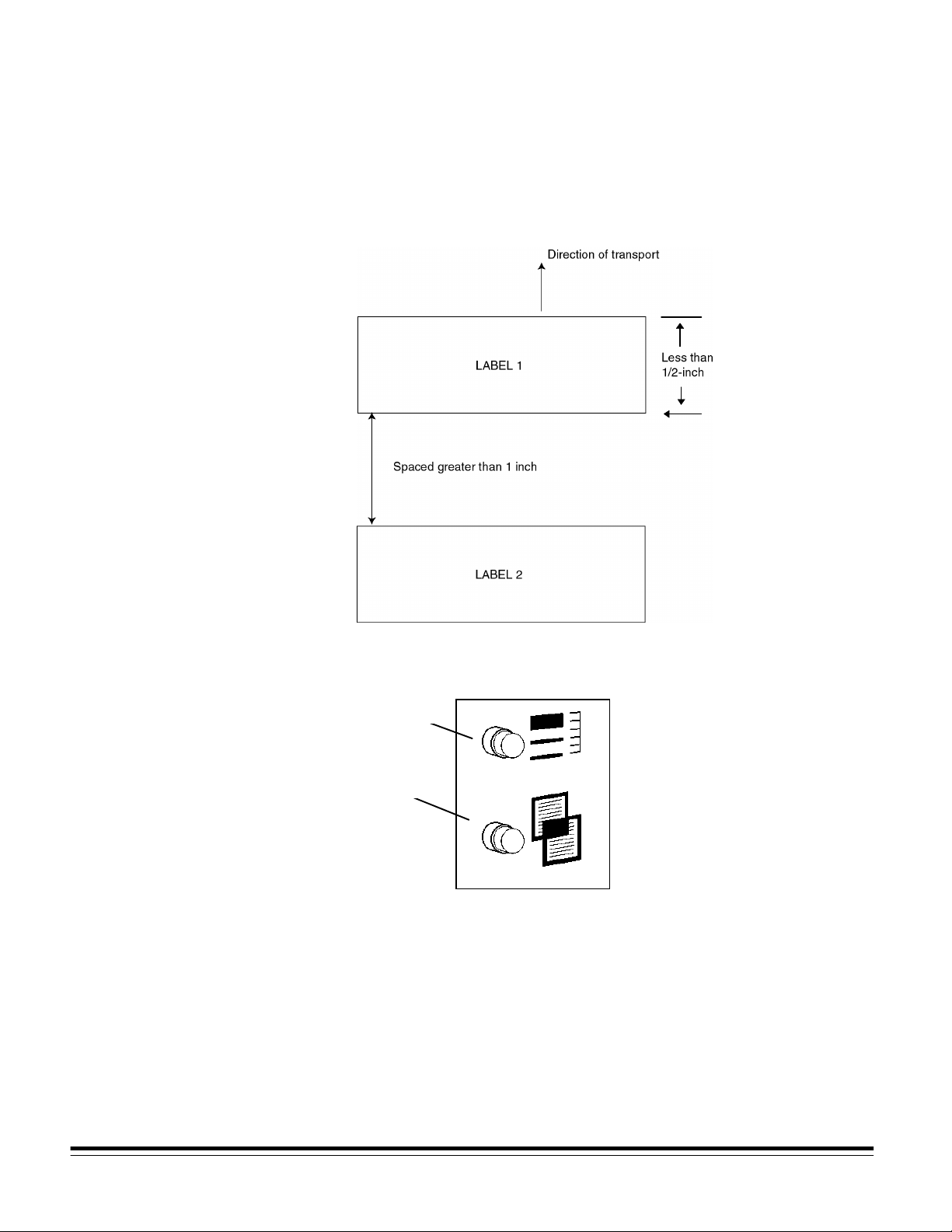

Enabling/disabling the Multi-Feed Detector

The Multi-Feed Detector is controlled by two buttons located to the

left of the document output tray as you are facing the machine.

Calibrate

Enable

Calibrate (upper button) — allows you to calibrate the thickness threshold

limit.

Multi-Feed Detector Enable/Disable (lower button) — allows you to

enable or disable theMulti-Feed Detector.

NOTE: When the transport is running, you cannot change the Enable

or Calibrate state of the Multi-Feed Detector.

2 A-61120 March 1999

Page 4

F72 Skew/Double Detection On/Off— allows you to use a function code

to enable and disable the system. The lights do not change.

When a multi-feed is detected, both buttons illuminate. Depending upon the

scanner or scanner/microimager firmware and how the unit is configured,

one of the following messages will be displayed:

•

•

MCP Version 8.40 or greater displays the following message:

• •

E204

Skewed/Double document - refeed

E107

Warning Skewed/Double document - refeed

•

•

Versions less than 8.40 displays the following message:

• •

E204

Skewed document - refeed

E107

Warning Skewed/Double document - refeed

The Multi-Feed Detector Enable/Disable button indicates the state of the

accessory. If the lamp is ON, the accessory is enabled. While the transport

is stopped, press the lower button to enable or disable the accessory as

desired. The Multi-Feed Detector automatically enables after power-up or a

successful calibration as described in the next section.

Calibrating the MultiFeed Detector

You need to calibrate the Multi-Feed Detector to set the double

thickness threshold. Calibration should be performed every time a

set of documents with different thicknesses have to be scanned.

The optimum threshold set value is one that is very close to the actual

document thickness that is being imaged. Documents must be very close to

the same thickness in order for the Multi-Feed Detector to function properly.

To calibrate the thickness threshold follow the steps below:

1. Stop the transport.

2. Disable the Multi-Feed Detector by pressing the lower button so it is not

illuminated.

3. Press the Calibrate button (it should illuminate).

4. Start the transport by pressing the greenRun key.

5. When bothMulti-Feed Detector buttons are flashing together, feed a

representative sample of the calibration document so that it passes

under the thickness sensor. This document thickness will be measured

and stored as the new thickness threshold.

When calibration is complete, the buttons will stop flashing and the MultiFeed Detector will automatically be enabled (the Multi-Feed Detector

Enable button will be illuminated).

NOTE: The thickness calibration document will be scanned and/or

microfilmed unless the machine is placed in a non-filming or

scanning mode (i.e., Count Only mode) prior to thickness

calibration.

A-61120 March 1999 3

Page 5

Operating the scanner with the Multi-Feed Detector enabled

When the Multi-Feed Detector is enabled, the scanner is

continuously checking documents for multi-feeds when the transport

is running. When a multi-fed document is encountered, an error will

be reported. The scanner will report a document as a true multi-fed

document if it overlaps another document by ¾ of an inch or more.

When a multi-feed is detected, one of the following errors will occur

(depending upon how the scanner is configured):

• If the scanner is setup to stop and display an error, an E204

message will be displayed. The transport will stop and both MultiFeed Detector indicators will be illuminated. To recover from an

E204 error:

- reset the image address

- reset the document stack

- start the transport again

• If the scanner is setup to beep and display an error or just display

an error, an E107 message will be displayed. The transport will

continue to run, and both Multi-Feed Detector indicators will be

illuminated. To recover from an E107 error:

- reset the image address

- reset the document stack

- press either the Enable, Calibrate or Stop button in order to

reactivate the Multi-Feed Detector.

NOTES:

• A skewed document can also trigger an E107 or E204 error. If

only the Multi-Feed Detector Enable button is illuminated when an

E107 or E204 error is displayed, then the document was skewed.

• If for some reason, a document misses the Multi-Feed Detector

sensor, the error situation described above will also occur

(according to the setup of the scanner).

4 A-61120 March 1999

Page 6

Retracting the thickness sensor

Under normal circumstances, you should not need to adjust the

thickness sensor manually. However, if you are feeding documents

of mixed thickness or lightweight documents, you may need to

manually retract the thickness sensor. To do this:

1. Open the front cover of the scanner.

2. Release the feeder latch and lift the top of the feeder upward.

3. Press the extended portion of the sensor in until it snaps up into the

retracted position.

NOTE: The Multi-Feed sensor is located approximately 1 inch left

of the feeder centerline as you face the scanner.

4. Place the feeder top back into its original position.

5. Close the front cover.

6. Disable the

“Enabling/disabling the

To manually extend the thickness sensor:

1. Open the front cover of the scanner.

2. Release the feeder latch and lift the top of the feeder upward.

3. Use a pointed instrument; such as a ball-point pen, to press inon the

recessed area at the top end of the thickness sensor until it snaps

down into its operating position.

Multi-Feed Detector. See the section entitled,

Multi-Feed Detector” for more information.

4. Place the feeder top back into its original position .

A-61120 March 1999 5

Page 7

5. Close the front cover.

Error recovery

Interactive/online method

6. If desired, calibrate and re-enable the

section entitled, “Calibrating the

Multi-Feed Detector. See the

Multi-Feed Detector” for more

information.

Error recovery methods are required when a multi-feed has been

detected. The two methods described below meet the needs of most

users. However, other methods may be used.

IMPORTANT:

For scanners: Before beginning error recovery, make

sure all images and headers have been transferred from

the image buffer to the host system.

Use the Interactive/Online method when your primary concern is that

the scanned database or film has no duplicate images.

Follow these steps to use the Interactive/Online method:

1. At the host system, search through the most recently scanned files to

determine which images have been scanned and transferred.

2. Find the last successfully scanned image. Record/remember the

sequential ID number and/or the image address assigned to the last

successfully scanned image.

3. Sort through the stack of documents being scanned to find the

document that produced the last successfully scanned image. You will

have to rescan all of the documents that follow the last successfully

scanned document.

4. When using the Document Scanner/Microimager 990 or Microimager

70, determine the image address of the document that produced the last

successfully scanned image (documents that have been successfully

scanned and stored in the image buffer have been microfilmed).

Enter this image address into the Document Scanner/Microimager 990

or

Imagelink

F09, which may be programmed as a programmable key. When using

Image Management Code, this action serves to reset the image search

location on microfilm for subsequent documents scanned.

5. Download the sequential ID number and/or the next image address

using a scanner-unique command (DC and HC, respectively). The

value(s) you download should correspond to the document following the

last successfully scanned image.

6. Begin scanning the documents that follow the last successfully scanned

document.

Microimager 70 using the Next IA key or function code

NOTE: Documents detected as multi-feeds and the documents directly

following are not scanned or given image marks on film.

6 A-61120 March 1999

Page 8

Batch/offline method

Use the Batch/Offline method when your primary concern is efficient

use of time, duplicates in the database do not represent a problem,

and there is adequate space in the scanned image database or film

roll for the duplicate images (same images with different sequential

ID numbers and image addresses.)

Follow these steps to use the Batch/Offline method:

1. Remove the stack of successfully scanned documents from the exit

hopper.

2. Take the last three or four documents from the top of the stack and put

them into the feed tray or at the top of the next stack of documents.

3. Begin scanning the documents.

Troubleshooting

Valid multi-feed detection or

the document did not pass

under the document detection

sensor

Calibration out of range During calibration, a document that was too thick was fed.

Auto-zero function incomplete

or out of range

Under normal operating conditions, only the Multi-Feed Detector

Enable button is illuminated. Following are some reasons why both

Multi-Feed Detector buttons may be continually illuminated and an

E204 error is displayed on the operator interface.

Both Multi-Feed Detector buttons are constantly illuminated:

Condition Cause

The scanner has encountered a multi-fed document, or

the document missed the sensor. Depending upon the

scanner configuration, the transport will stop and display

an E204 error; just display a warning message or beep

and display a warning message.

•

• Press the green Run button or either

• •

button. This automatically re-enables the Multi-Feed

Detector

•

• Restart the transport and calibrate again.

• •

.

Upon starting the transport, it stops with an E204 error.

• Check to make sure the sensor is not stuck out of

position or the sensor is not retracted.

Multi-Feed Detector

•

• Restart the transport.

• •

Only one document goes

through the feeder and returns

an error

A-61120 March 1999 7

Thickness sensor may be mechanically retracted but the

Multi-Feed Detector is enabled.

•

• Extend the thickness sensor or disable the

• •

Detector

.

Multi-Feed

Page 9

Both Multi-Feed Detector buttons are not constantly illuminated:

Condition Cause

Skewed document, not a

multi-feed

Calibration — both lights

continue to flash

Encountered a skewed document.

•

• Press the green Run button to continue.

• •

Document feed missed the sensor during calibration.

•

• Refeed the document so it passes under the sensor to

• •

complete the calibration.

8 A-61120 March 1999

Page 10

A-61120 3/99

©Eastman Kodak Company, 1999

Printed in U.S.A.

EASTMAN KODAK COMPANY

Document Imaging

Rochester, New York 14650

Kodak, Imagelink, Digital Science and

the ds monogram symbol are

trademarks of Eastman Kodak

Company.

Printed on recycled paper.

DOCUMENT

IMAGING

Loading...

Loading...