Page 1

Using the

KODAK PROFESSIONAL Device Calibration

Software with the

KODAK PROFESSIONAL LED II

Printers 20P/20R

Part No. 6B6640

Page 2

©Eastman Kodak Company, 2001

All rights reserved. Contents of this publication may not be reproduced in any form

without permission from Eastman Kodak Company.

Page 3

Contents

1 Calibrating the Printer ...........................................................................................................................1-1

Starting the Device Calibration Software ..............................................................................................1-2

Starting the Calibration Application and Exposing a Test Target .........................................................1-3

Obtaining Densities ...............................................................................................................................1-6

Obtaining Densities from a File ......................................................................................................1-6

Using the Densitometer to Read Densities ....................................................................................1-7

Obtaining Densities from the Centralized Densitometer (NT Only) ................................................1-8

Completing the Calibration .................................................................................................................1-10

2 Troubleshooting ....................................................................................................................................2-1

Calibration Graph ..................................................................................................................................2-1

Calibration Errors ..................................................................................................................................2-2

Numeric Calibration Error Codes ...................................................................................................2-2

Non-Numeric Calibration Error Messages ...................................................................................2-11

Densitometer Errors ............................................................................................................................2-12

3 Using Additional Calibration Features ..................................................................................................3-1

Installing the Calibration Software .... ....... ...... ............................................. ....... ...................................3-1

System Requirements ... ....... ...... ....... ...... ....... ...... ....... ...... ............................................. ....... .........3-1

Installation Procedure ....................................................................................................................3-2

About the Kodak Professional Device Calibration Software .................................................................3-5

Application Window Definitions ......................................................................................................3-5

Starting the Device Calibration Software ..............................................................................................3-7

Editing the Log Settings .................... ....... ...... ....... ...... ....... ............................................. .... ..................3-7

Adding, Updating, and Deleting Devices ..............................................................................................3-9

Adding a Device .............................................................................................................................3-9

Updating a Device ........................................................................................................................3-10

Deleting a Device .........................................................................................................................3-12

March 2001 iii

Page 4

Contents

Advanced Features of the LED II Calibration Software ......................................................................3-13

Viewing Graphs .................... ............................................. ...... .....................................................3-13

Applying a Master Balance (NT Systems Only) ................ ...... .............................................. ...... .3-18

Sending LUTs ................................... ...... ....... ...... ....... ............................................. ...... ..............3-20

Sending Targets .......................................................... ...... ...... .....................................................3-22

Editing the Device Configuration ..................................................................................................3-25

Creating a Density File for Use with Calibration ...........................................................................3-36

File Formats .................................................................................................................................3-36

Installing the Densitometer ......... ...... ....... ...... ....... ............................................. ...... ...........................3-37

4 Installing and Using the Centralized Densitometer Application ............................................................4-1

Installing the Centralized Densitometer Applic at ion ............................. ...... ........................................ ..4-1

System Requirements ... ....... ...... ....... ...... ....... ...... ....... ...... ............................................. ....... .........4-1

Installation Procedure ....................................................................................................................4-2

Using the Centralized Densitometer Application ..................................................................................4-5

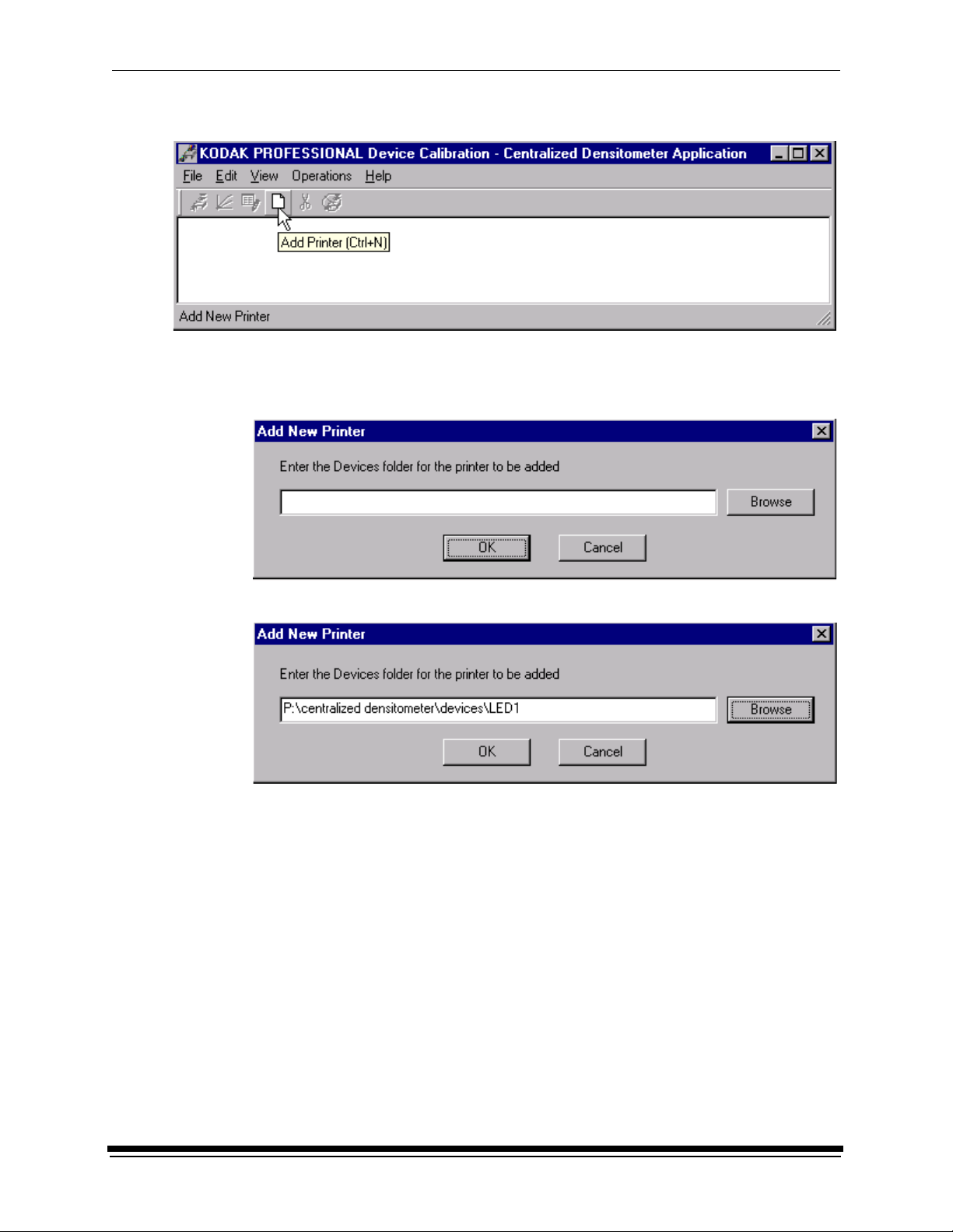

Adding a Printer .............................................................................................................................4-6

Deleting a Printer ...........................................................................................................................4-7

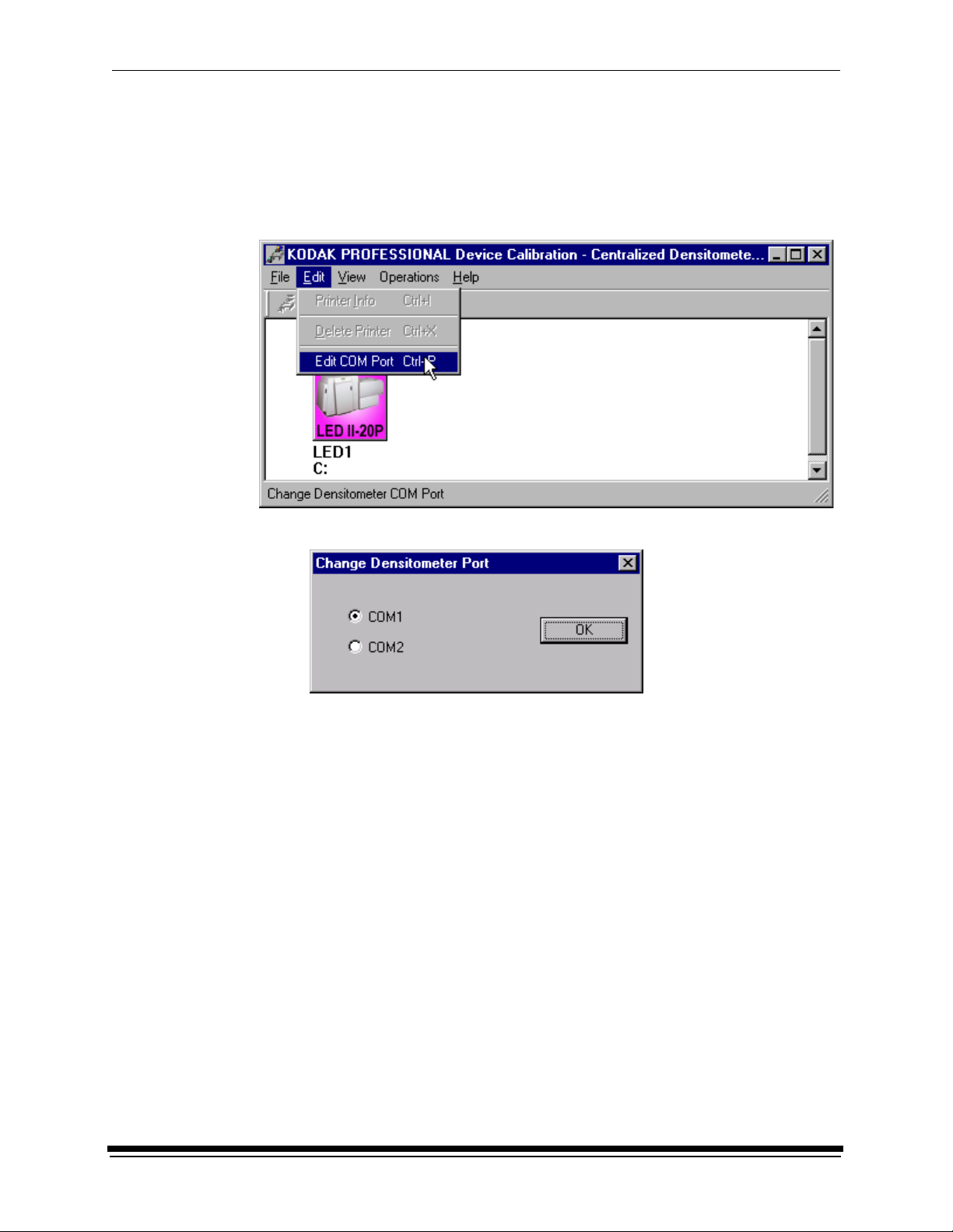

Changing Printer Information .........................................................................................................4-9

Changing the Densitometer Port ..................................................................................................4-10

Measuring Densities During a Calibration Cycle ..........................................................................4-12

Viewing Calibration Graphs .................................. ....... ...... ............................................. ....... . ......4-13

iv March 2001

Page 5

1 Calibrating the Printer

This section includes instructions for calibrating the Kodak Professional LED

Printers 20P/20R, Generations l and ll.

Kodak provides calibration applications for Windows NT and Macintosh systems.

See “Installing the Calibration Software” on page 3-1 for installation instructions.

See Section 3, Using Additional Calibration Features, for details about the

windows and dialog boxes for the application software and for additional

procedures not performed with each calibration.

Calibration is the process for creating and maintaining a Look-Up Table (LUT) that

produces the correct color balance for all images printed on the Printer. There is

sufficient variation among printers that each printer must be calibrated separately.

Before calibrating, make sure that:

• the paper path is threaded

• the printer status is “Online and Ready”

• no other printer applications are active

• the calibration application is running

• within the Kodak Professional Device Calibration software:

— at least one device is defined (see “Adding, Updating, and Deleting

Devices” on page 3-9)

— any needed changes to the configuration file are in place (see “Editing the

Device Configuration” on page 3-25)

• the densitometer is connected and calibrated

• the paper processor is in control

March 2001 1-1

Page 6

Calibrating the Printer

You need to calibrate the printer when you start the system up each day. You also

need to calibrate the printer when

• you change paper

• print quality is questionable

• the temperature at the site changes more than 5° F (2.8° C)

• if running more than one shift, at the beginning of each shift

NOTE: Most windows displayed in this section are from the Windows NT version

of the software. The windows for the Macintosh version of the software are

similar.

For information about editing the calibration settings (for example, you may want

to display a calibration graph only if calibration is out of tolerance), see “Editing

the Device Configuration” on page 3-25.

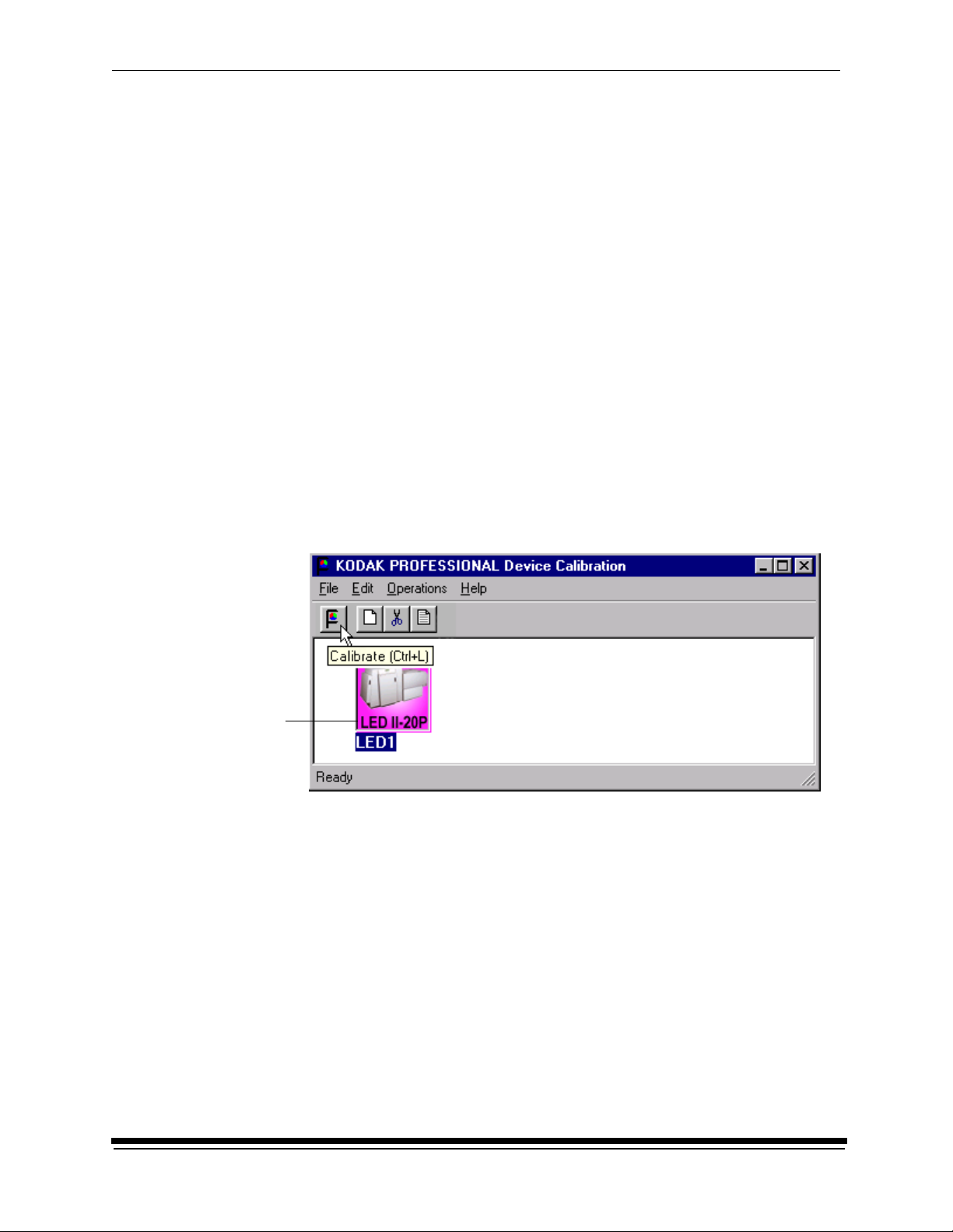

Starting the Device Calibration Software

1. Open the KODAK PROFESSIONAL Device Calibration application.

The display shows the KODAK PROFESSIONAL Device Calibration window.

If the device you need to calibrate does not appear on the window, you need

to add a calibration device. See “Adding, Updating, and Deleting Devices” on

page 3-9.

LED Printer

icon

2. Select the icon for the LED Printer.

3. Click the Calibrate icon.

1-2 March 2001

Page 7

Calibrating the Printer

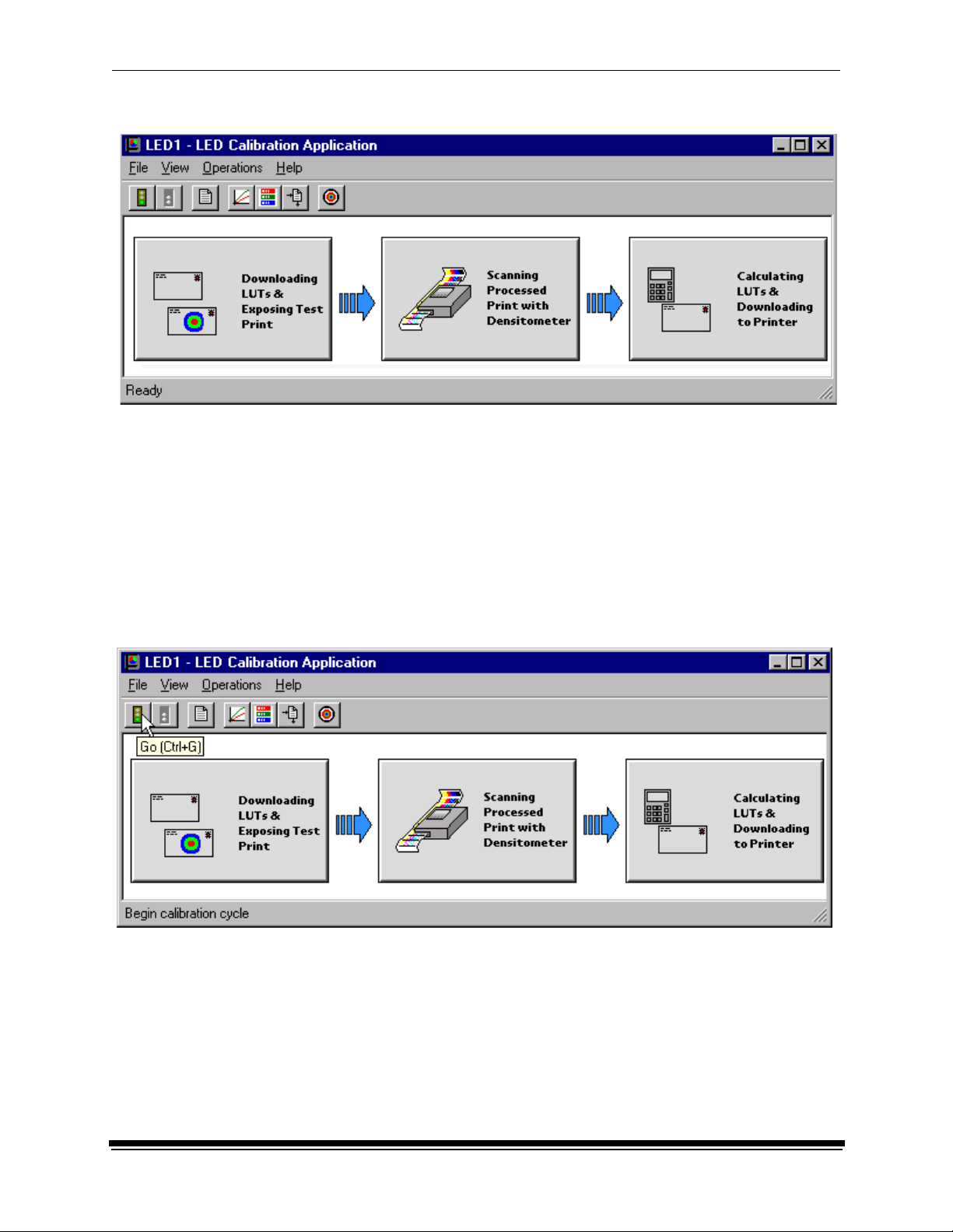

The display shows the LED Calibration Application window.

Starting the Calibration Application and Exposing a Test Target

IMPORTANT: The settings in the configuration file for the selected device

determine some of the actions and messages in this procedure.

The configuration file is specific to your lab and its operations. For

more information about the configuration file, see “Editing the

Device Configuration” on page 3-25.

1. Click Go to start the calibration cycle.

Downloading LUTs and Sending Test Print highlights.

March 2001 1-3

Page 8

Calibrating the Printer

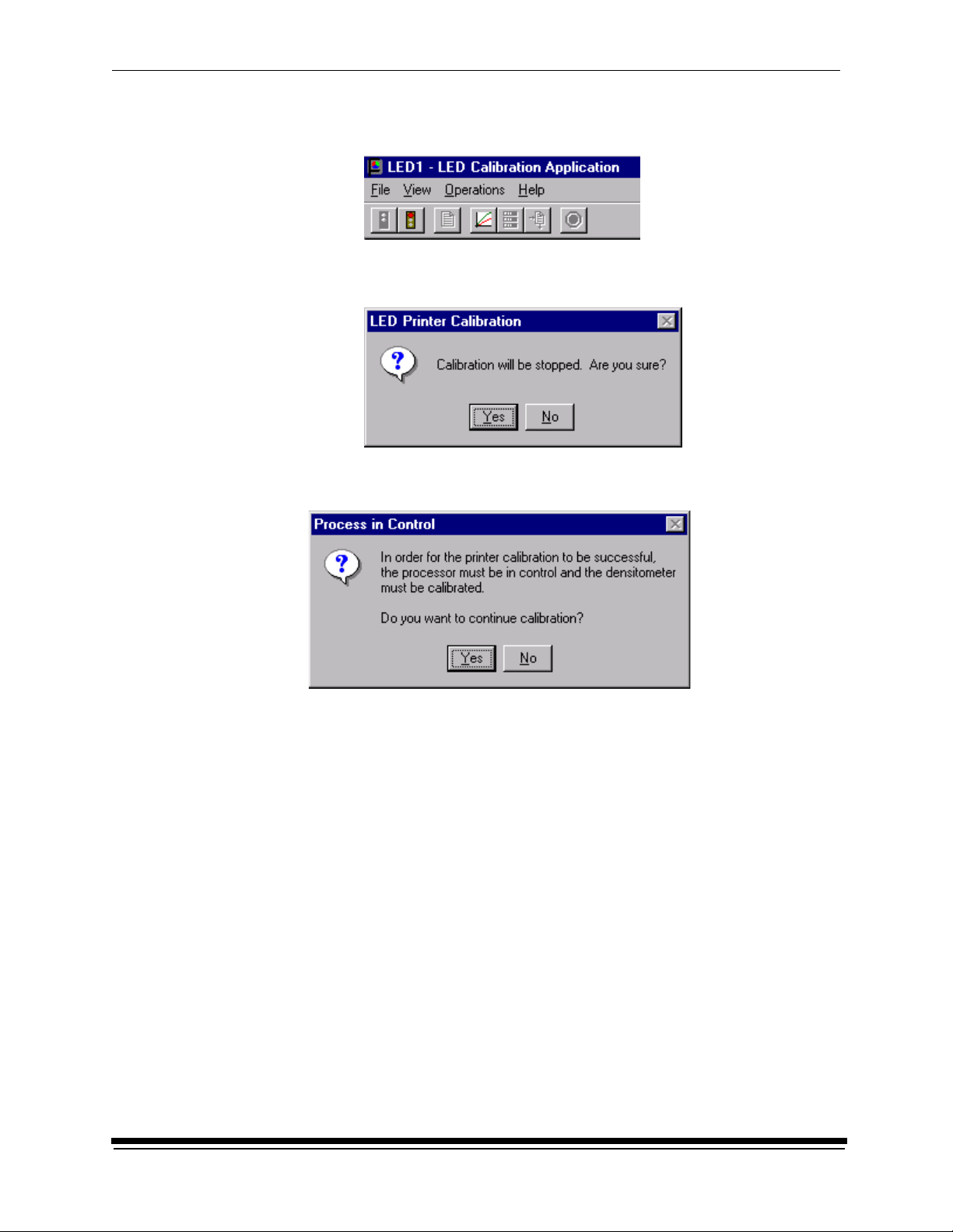

NOTE: Once the application has started, the red stoplight is active and you

can click the icon to stop the calibration procedure.

If you click the red stoplight icon, the display shows the following dialog

box.

Otherwise, if the configuration file specifies to Ask if processor is in control,

the display shows the Process In Control dialog box.

The processor is critical to printer calibration. You can calibrate the printer

only if the processor is in control.

1-4 March 2001

Page 9

Calibrating the Printer

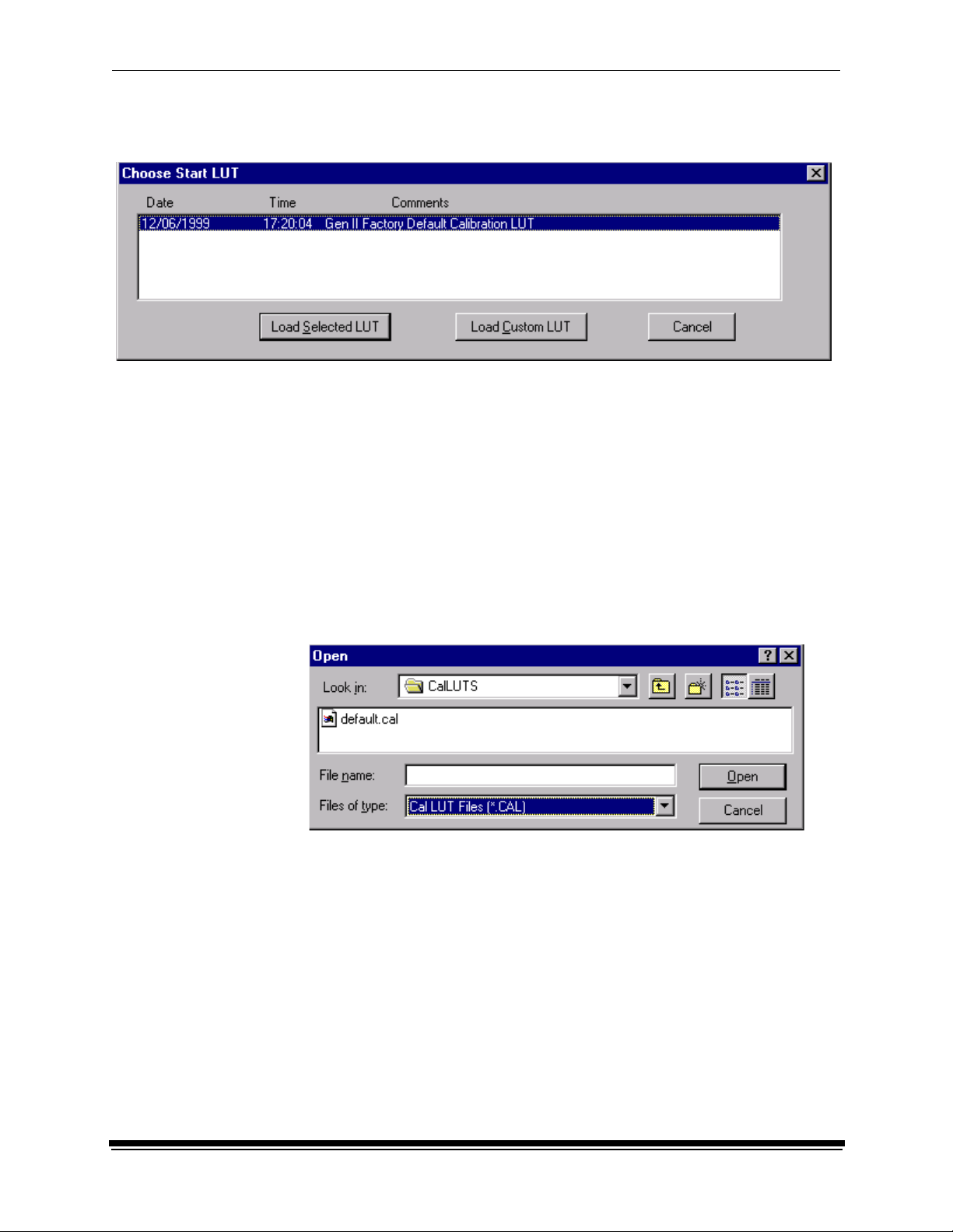

2. Click Yes.

The display shows the Choose Start LUT dialog box.

NOTE: The highlighted LUT in the dialog box above is the most recent

calibration LUT.

3. Click either Load Selected LUT or Load Custom LUT (or Cancel to cancel

the calibration process).

If you click Load Selected LUT, the system automatically down lo ads the

highlighted LUT to the printer to create a test print. When the test print has

been sent, the Scanning Processed Print with Densitometer status icon on

the LED Printer Calibration window highlights.

Continue with “Obtaining Densities” on page 1-6.

4. If you selected Load Custom LUT in step 3:

From the Open dialog box, select or type the name of the LUT file you want

and click Open.

The system automatically downloads the LUT file to the printer.

When the test print has been sent to the printer, the Scanning Processed

Print with Densitometer status icon on the KODAK LED Printer Calibration

window highlights.

March 2001 1-5

Page 10

Calibrating the Printer

Obtaining Densities

There are three methods for obtaining densities:

• from a file

• from a densitometer

• from a centralized densitometer (NT only and if the Centralized Densitometer

application is installed on your network)

The contents of the calibration configuration file determine which method you use

(see “Editing the Device Configuration” on page 3-25).

Obtaining Densities from a File

If the configuration settings include obtaining the density data from a file, the

display shows the Waiting for Density File dialog box.

If the configuration settings do not include obtaining the density data from a file,

go to either:

• “Using the Densitometer to Read Densitie s” on page 1-7

• “Obtaining Densities from the Centralized Densitometer (NT Only)” on

page 1-8

NOTE: T o create a density file, see “Creating a Density File for Use with Calibration”

on page 3-36.

1. Click OK to continue with the calibration process.

2. Go to “Completing the Calibration” on page 1-10.

1-6 March 2001

Page 11

Calibrating the Printer

Using the Densitometer to Read Densities

NOTE: For LED Gen I devices, you read only one neutral strip.

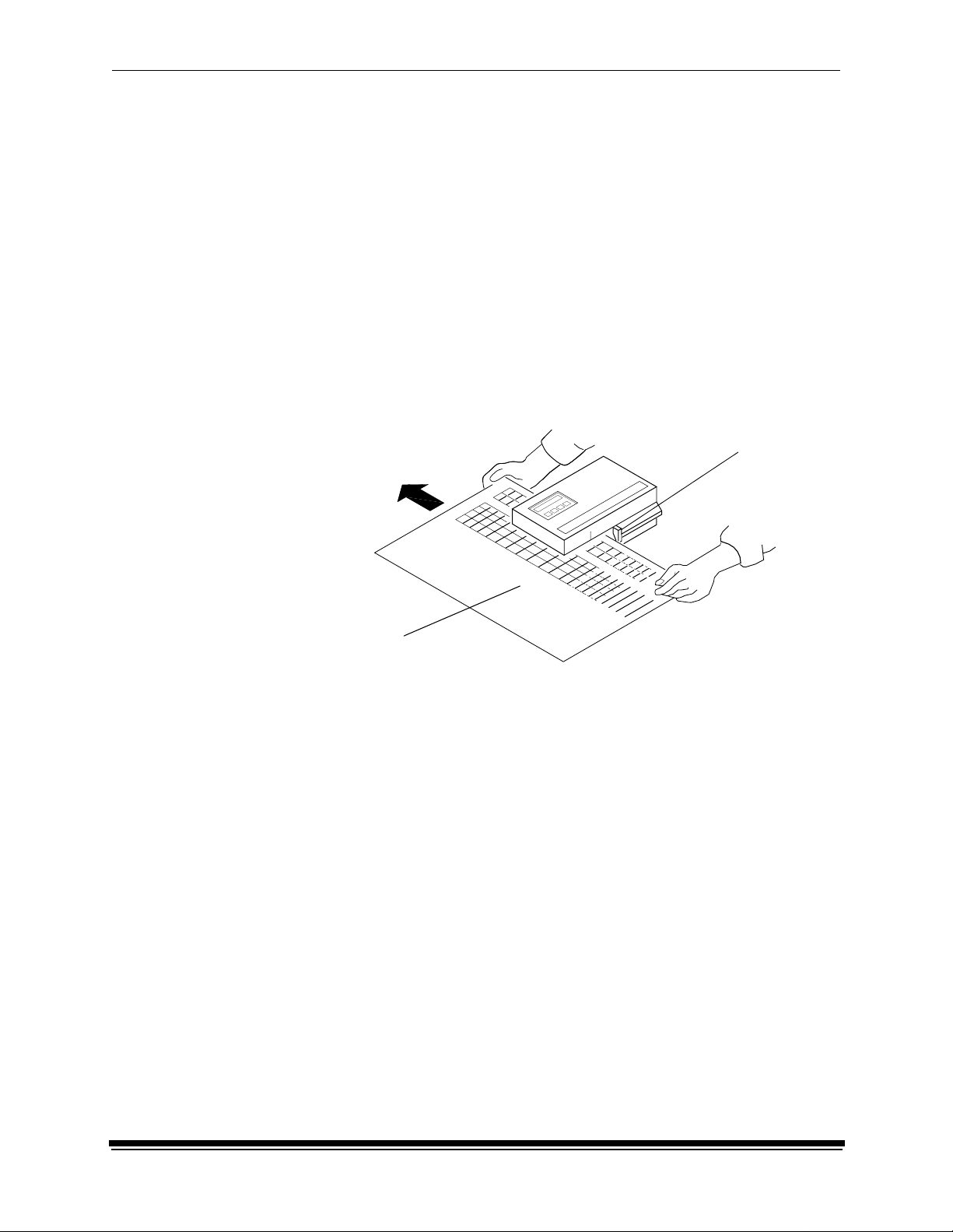

Do the following to scan the neutral (gray) patches on the processed test print into

the densitometer (refer to your densitometer manual for detailed instructions on

using the densitometer):

1. Slide the lever on the densitometer to position 15. Align the edge of the test

print with the lever on the densitometer. Gently feed the test print through the

densitometer to scan the patches labeled “even”.

2. Slide the lever on the densitometer to position 20. Align the edge of the test

print with the lever on the densitometer. Gently feed the test print through the

densitometer to scan the patches labeled “odd”.

3. Slide the lever on the densitometer to position 30. Align the edge of the test

print with the lever on the densitometer. Gently feed the test print through the

densitometer to scan the patches labeled “both”.

Lever

Test print

If the test print is read successfully, several messages will appear in the status

bar; the final message indicates that the densitometer values have been

successfully received. Go to “Completing the Calibration” on page 1-10.

If the test print is not read successfully, refer to Section 2, Troubleshooting.

March 2001 1-7

Page 12

Calibrating the Printer

Obtaining Densities from the Centralized

Densitometer (NT Only)

NOTE: For more information about installing and using the Centralized

Densitometer Application, see Section 4, Installing and Using the

Centralized Densitometer Application.

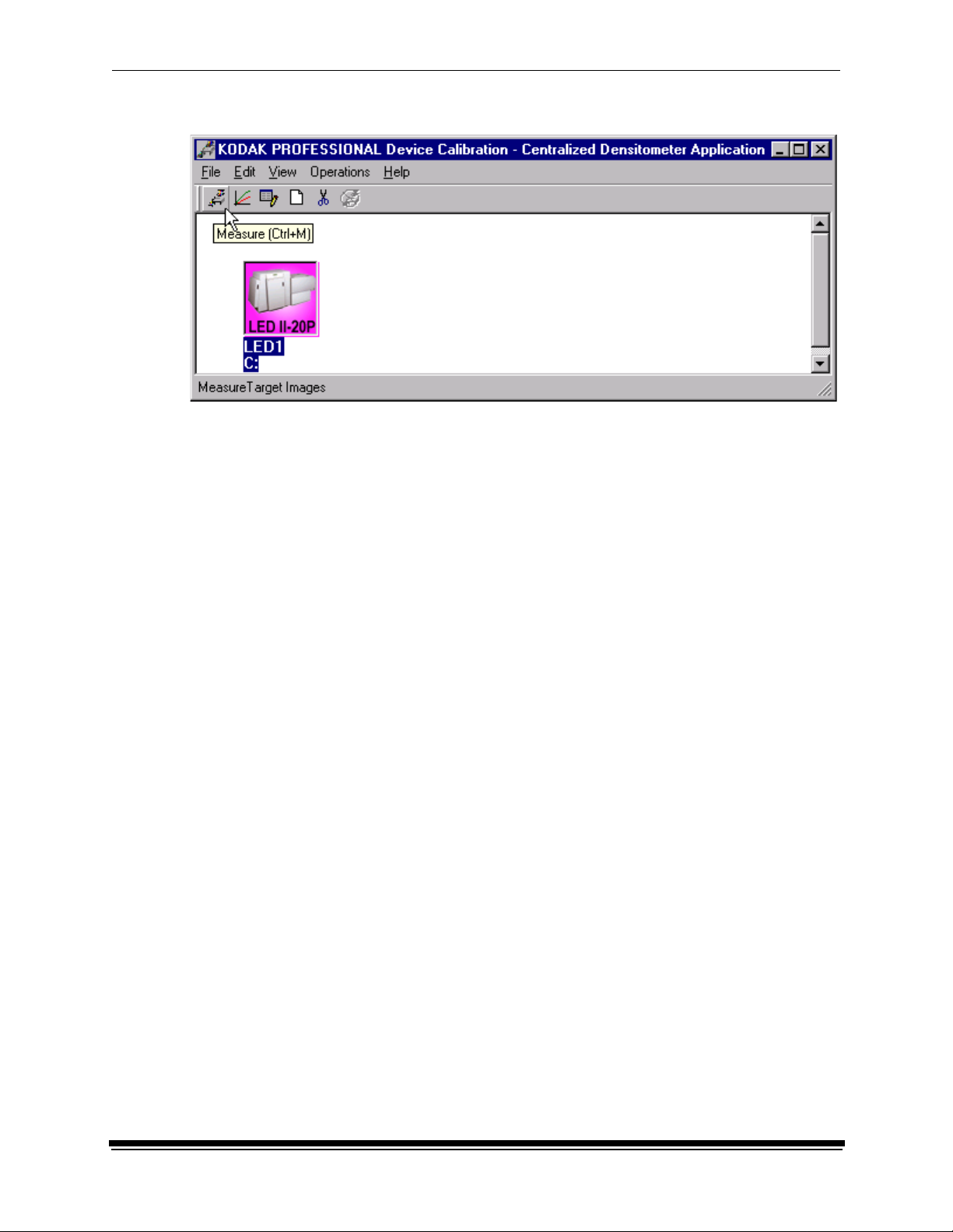

If the configuration settings include obtaining the density data from the centralized

densitometer application, the status bar shows a message.

1. Open the Centralized Densitometer Application.

1-8 March 2001

Page 13

Calibrating the Printer

The display shows the window for the Centralized Densitometer Application.

2. Highlight the device.

3. Click Measure (or select Operations->Measure) to measure the target

images.

4. At the densitometer, measure the densities (see “Using the Densit ome ter to

Read Densities” on page 1-7).

When the densities are measured, the status bar on the Centralized

Densitometer Application window shows “Ready.”

The density measurements are automatically sent to the LED printer’s host

computer.

Continue with “Completing the Calibr at ion .”

March 2001 1-9

Page 14

Calibrating the Printer

Completing the Calibration

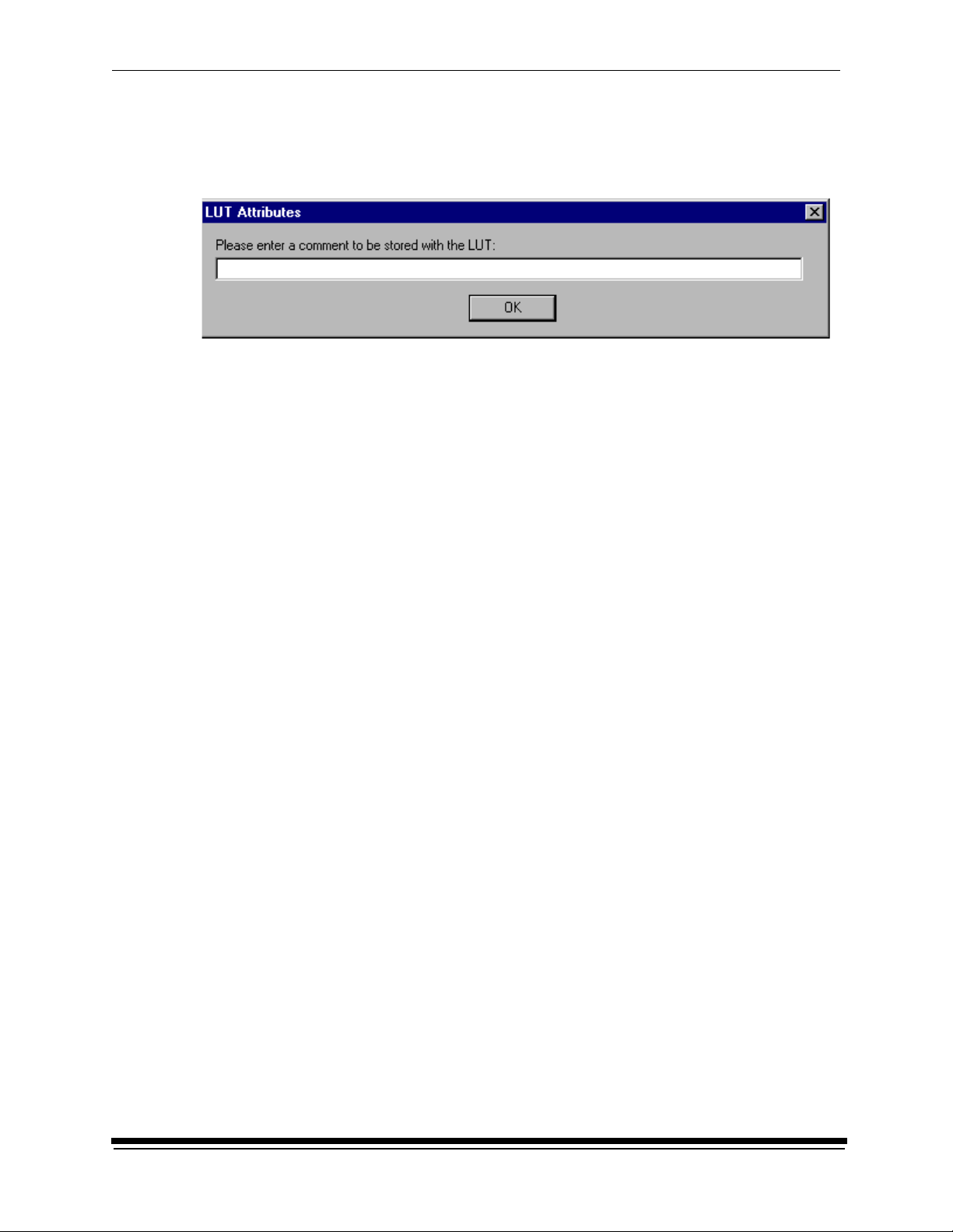

1. If calibration is in tolerance, the display shows the LUT Attributes dialog

box.

a. Type a name or comment in the dialog box. The comment you enter will

appear on the Send LUT to Printer dialog box to identify the LUT file with a

name that is meaningful to you (up to 75 characters).

b. Click OK.

The new printing LUT is calculated and downloaded. The status bar shows

“Calibration Complete.”

2. If calibration is out of tolerance, it may be necessary to run four or more

iterations of the calibration cycle to achieve a successful calibration.

1-10 March 2001

Page 15

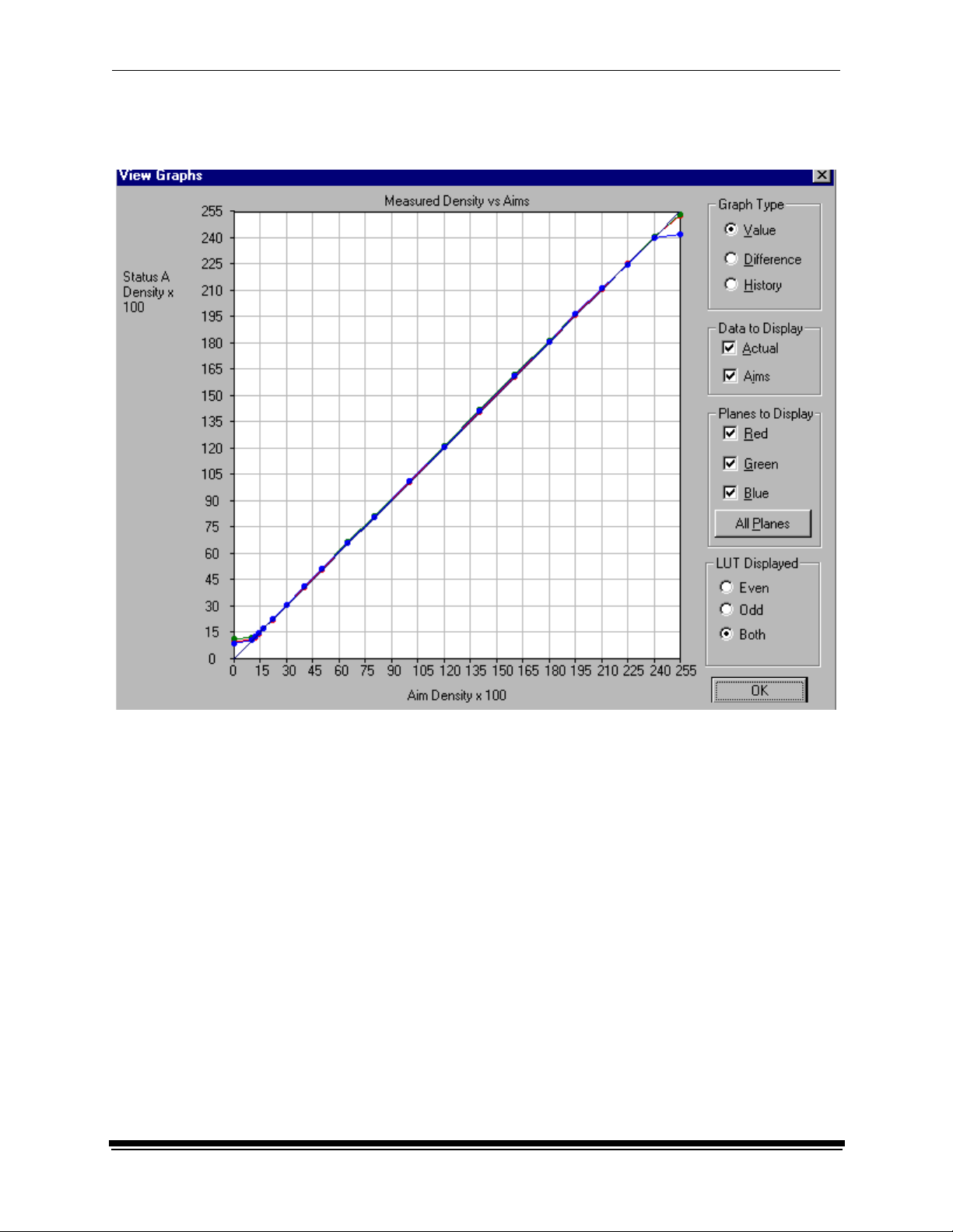

Calibrating the Printer

If the print densities are out of tolerance, the display shows a graph that

allows you to select the type of data and planes that you want to see

displayed.

a. Click OK.

March 2001 1-11

Page 16

Calibrating the Printer

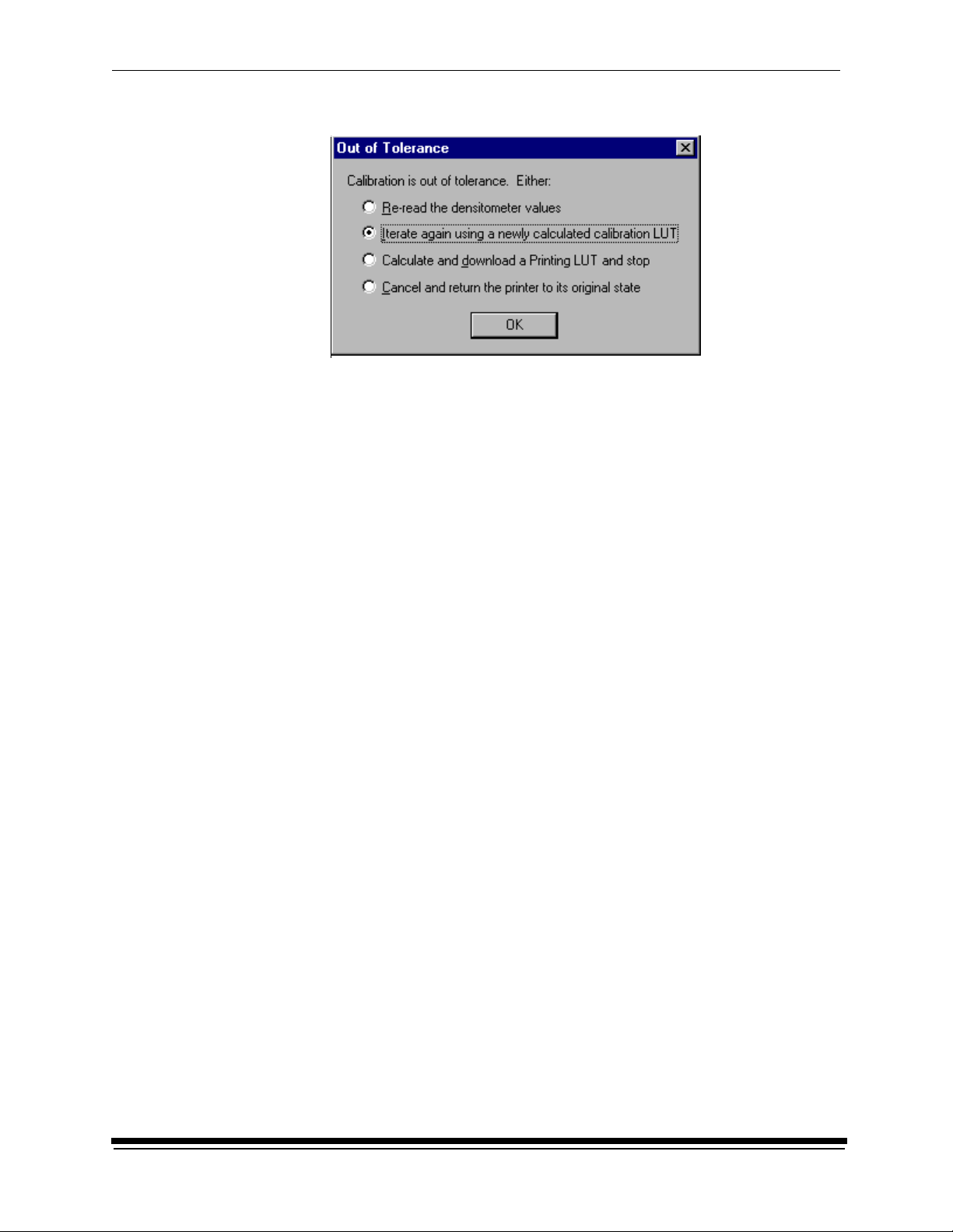

If specified in the configuration file, the display shows a list of options.

Re-read the densitometer values is most useful when the graphs show

an unusual plot. Rereading the test print lets you validate the graph, then

returns you to the Out of Tolerance dialog box.

Iterate again using a newly calculated calibration LUT allows you to

keep printing test prints with the newly created LUT without having to save

the LUT table.

Calculate and download a printing LUT and s top: When you select this

option, the LUT is calculated and the file is saved with the creation date

and time as its name.

Cancel and return the printer to its original state saves nothing. Any

corrupted data created after you saved the last time is thrown away.

b. Select one of the four options to try to complete the calibration

successfully.

1-12 March 2001

Page 17

This section describes the problems that you may occasionally have when using:

• the KODAK Device Calibration Software and the Calibration Software for the

KODAK PROFESSIONAL LED II Printer

• the X-RITE DTP36 Densitometer

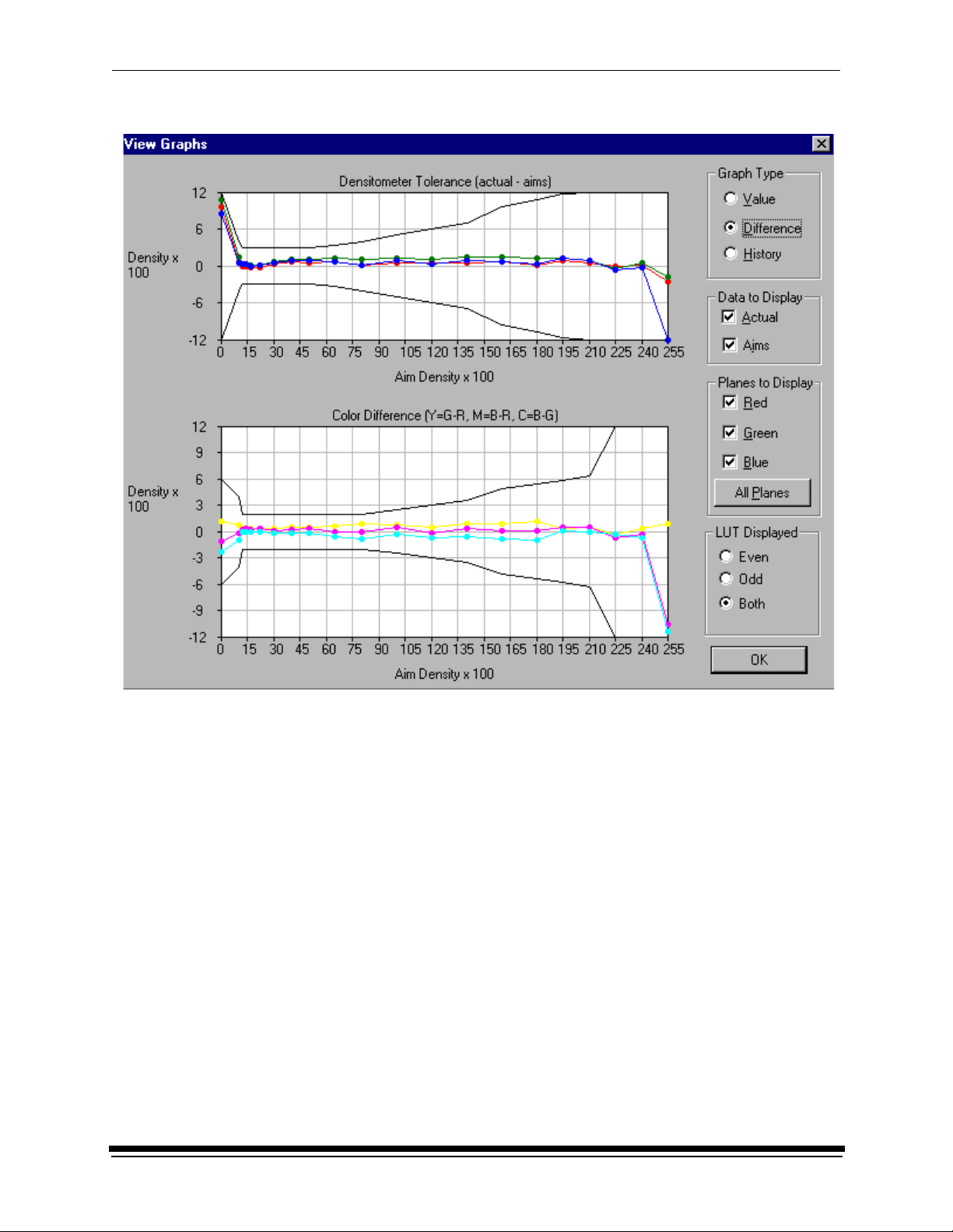

Calibration Graph

The graph below is an indication that the calibration performed was out of

tolerance.

2 Troubleshooting

This may be result from invalid densitometer readings. It is necessary to perform

another calibration cycle if you see a graph that looks like the one above.

March 2001 2-1

Page 18

Troubleshooting

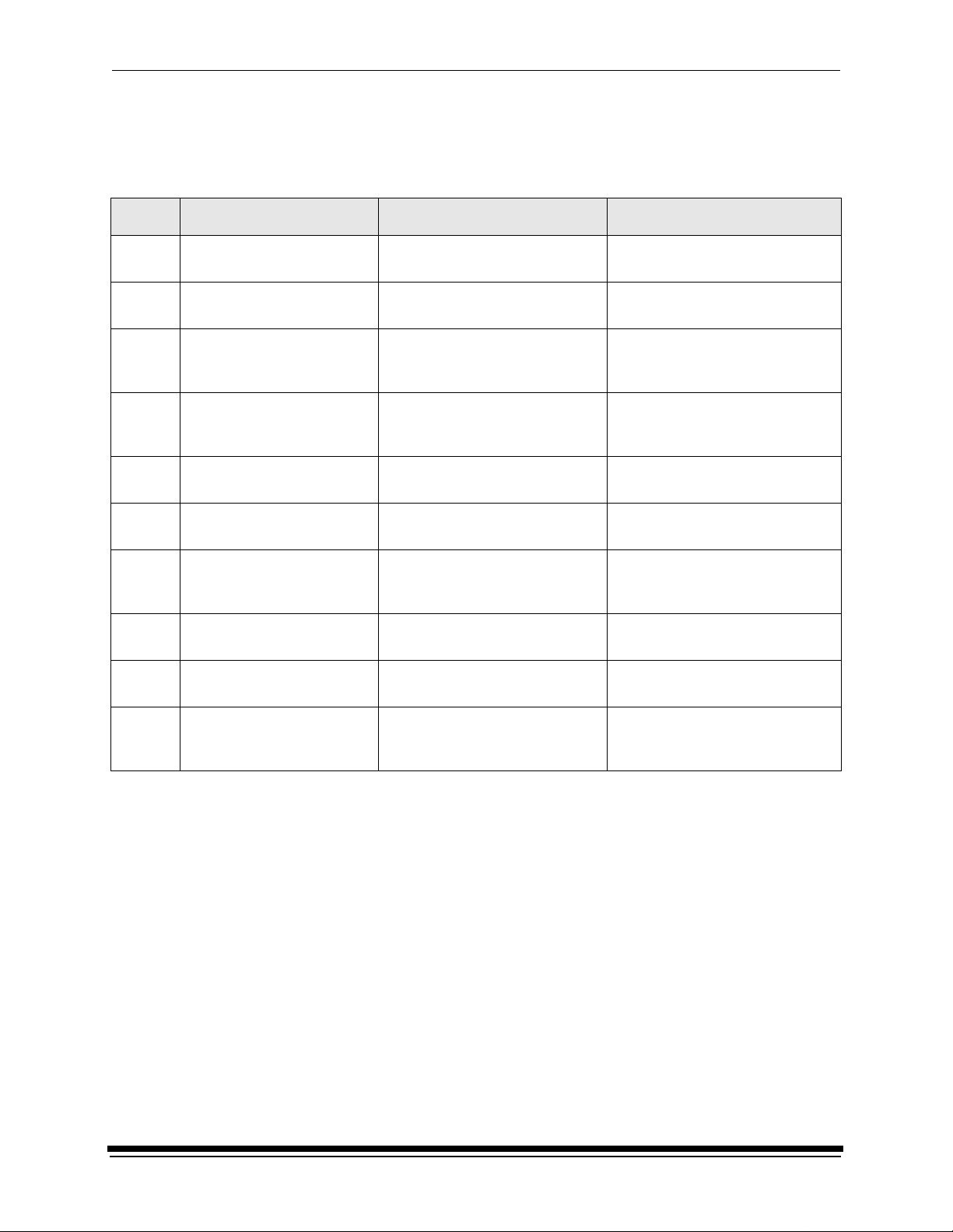

Calibration Errors

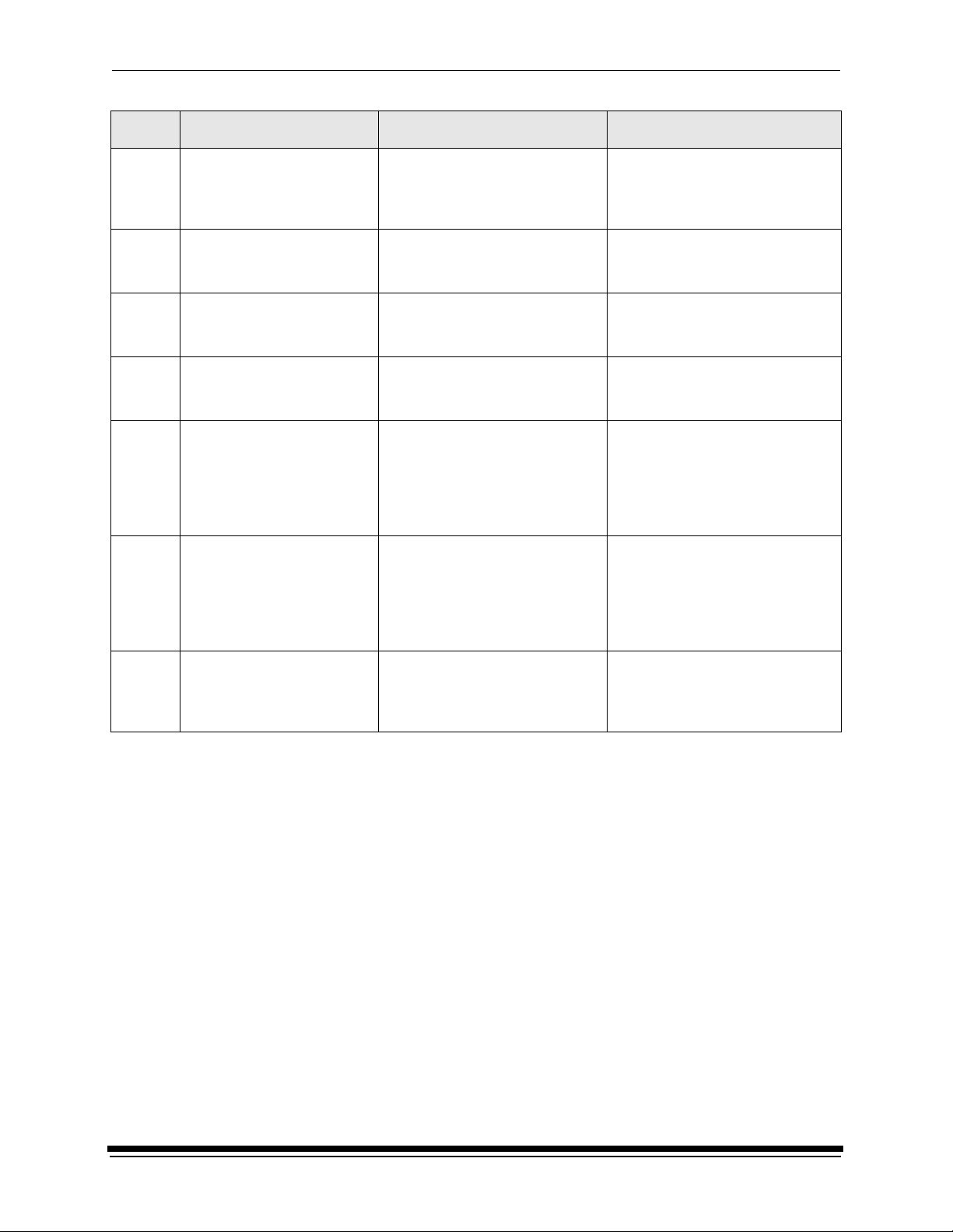

Numeric Calibration Error Codes

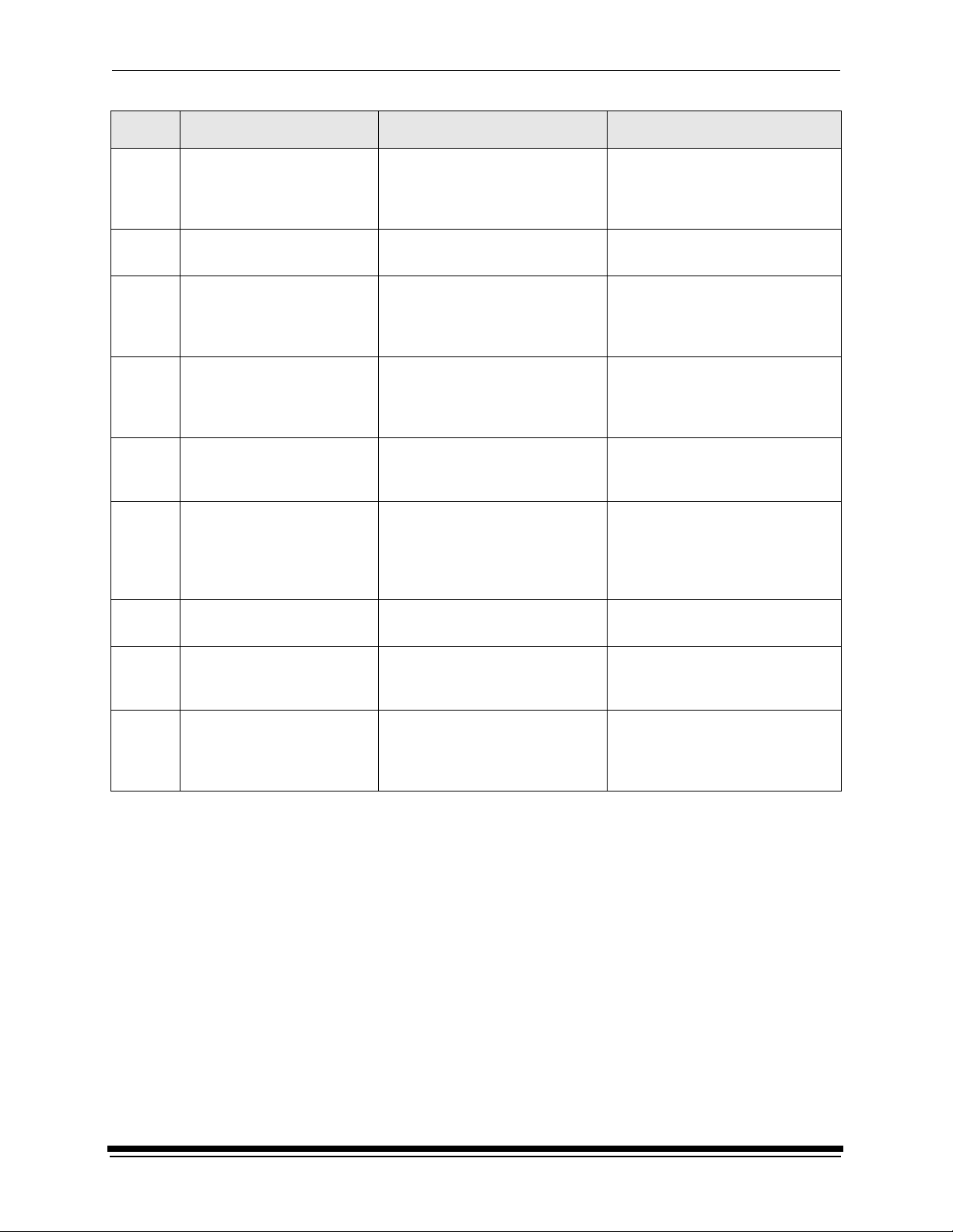

Code Status Message Possible Cause/Subsystem Possible Solution

1 The following file is

locked:_filename_.

2 The following file is

protected:_filename_.

3 The following file was not

found:_filename_.

4 Error:_oserror_occurred

during operation:_operation_

on file:_filename_.

5 The following file is in an

incorrect format:_filename_.

6 The following file already

exists:_filename_.

7 There is not enough space to

create:_filename_.

8 There are too many files to

open _filename_.

9 You do not have permission

to open file _filename_.

The system is trying to access a

file that is currently in use.

The system is trying to access a

protected file.

The system was trying to access

a file that it could not find.

An operating system error

occurred.

The file does not conform to the

application specification.

The system is trying to save to a

file that already exists.

The system is trying to save a file

but there is not enough disk

space.

Too many files are open. Close some files and or

The file permission is invalid. Rerun the application.

Close any other applications that

may be accessing the file.

Change the protections on the file

to grant access to the user.

Verify that the filename on one of

the configuration dialog windows i s

correct.

• Rerun the application.

• Reboot the operating system

Verify the file format.

• Delete the existing file.

• Change the filename.

Remove any unnecessa ry fil es to

increase free disk space.

applications.

10 Error copying print LUT to

DP2 folder (can’t open

_filename_.

2-2 March 2001

The folder doesn’t ex is t o r is readonly.

Modify the protection on the folder.

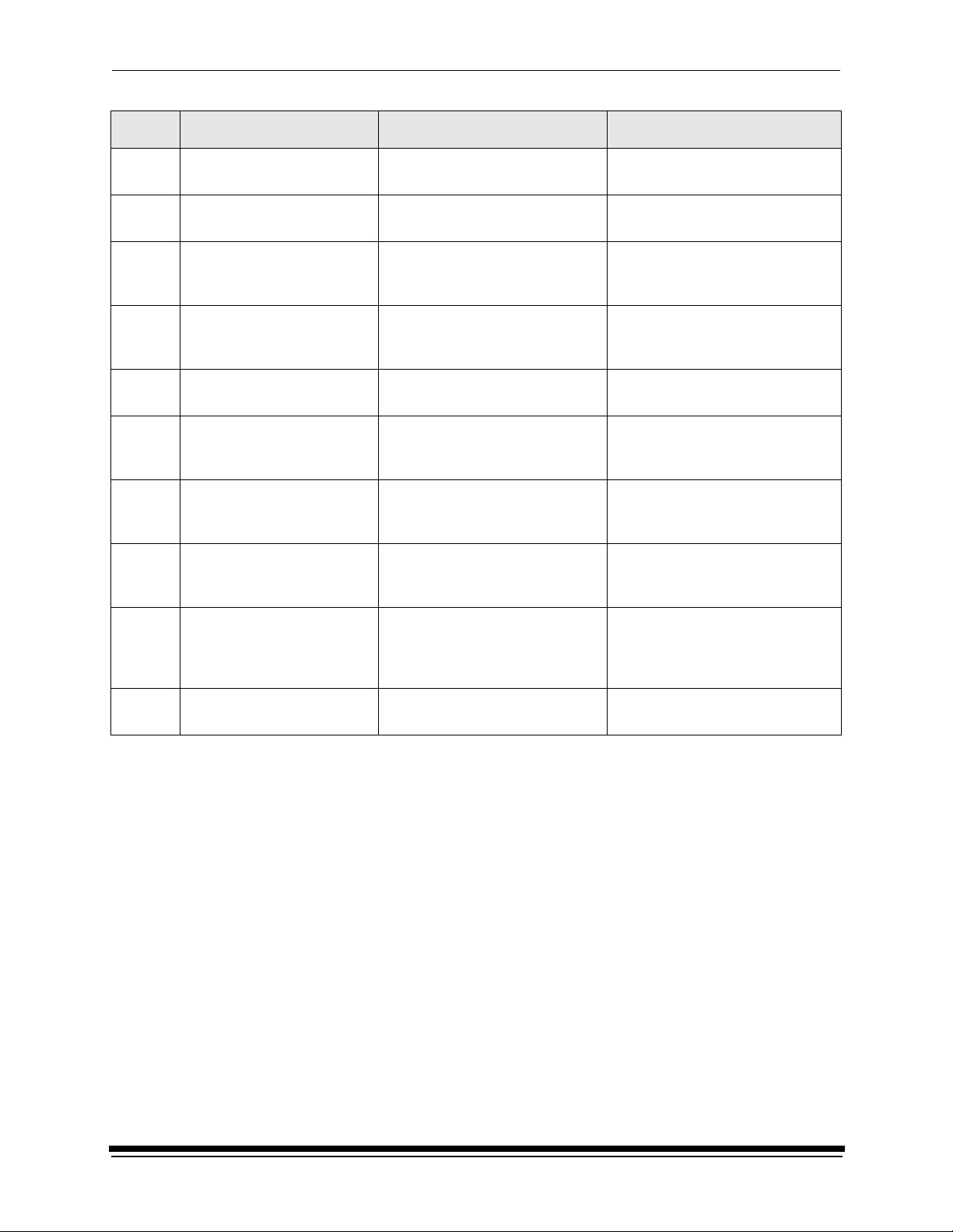

Page 19

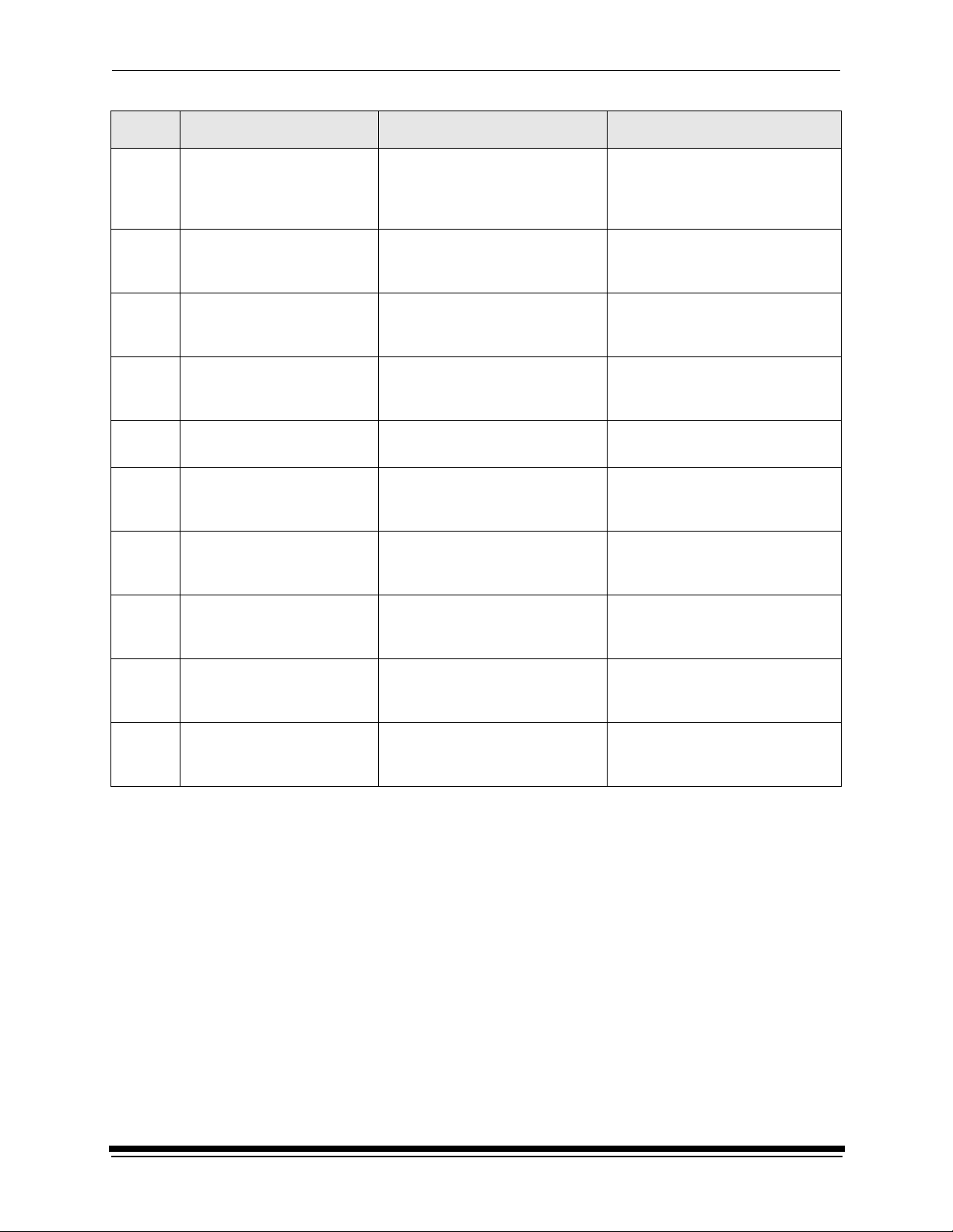

Troubleshooting

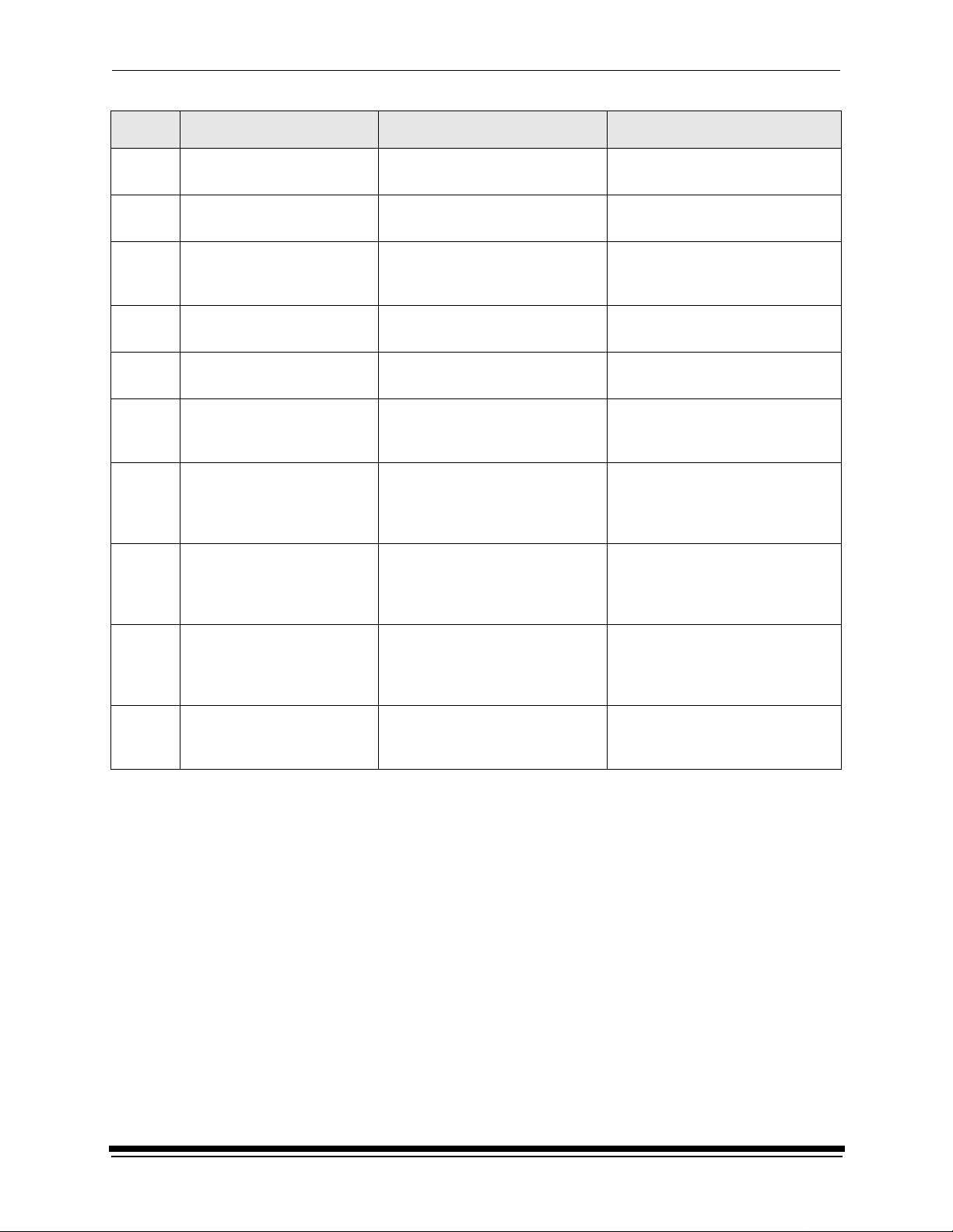

Code Status Message Possible Cause/Subsystem Possible Solution

11 Error creating DP2 LUT

folder

101 No response from

device:_devicename_.

102 Device not

found:_devicename_.

103 The following device is

indicating it is not

ready:_devicename_.

104 The following device is

busy:_devicename_.

105 The following device is not a

TTY port:_devicename_.

106 The following device is

closed:_devicename_.

107 No data on

device:_devicename_.

A folder of the same name may

exist.

The device is not responding to

the system.

The system was trying to access

a device that it could not find.

The device is not ready. Wait several minutes and try the

The device is busy. Wait several minutes and try the

The port name in the

configuration file do es no t re fer t o

a valid serial port.

The serial port closed during

system reading.

No data is available for the

system to read on the serial port.

Change the selected folder name.

Verify tha t the dev ic e i s c onn ec ted

and on-line.

Verify that the device n ame on on e

of the configuration dialog

windows is correct.

activity again.

activity again.

Change the port name in the

configuration file to a valid serial

port.

• Verify that no other application

is accessing the port.

• Restart the application.

• Verify that the densitometer is

connected correctly.

• Restart the application.

108 Error:_oserror_occurred

during operation:

_operation_ on device:

_devicename_.

109 Invalid Device ID:

_devicename_.

An operating system error

occurred.

A new device was created with an

incorrect device ID.

• Rerun the application.

• Reboot the operating system

• If problem continues, call for

service.

Edit the device ID to reflect the

correct device ID.

March 2001 2-3

Page 20

Troubleshooting

Code Status Message Possible Cause/Subsystem Possible Solution

110 Unable to perform operation:

_operation_

Status Message:_statmsg_

Error Message:_errmsg_.

111 There is insufficient memory

for the requested operation

on device:_devicename_.

112 A communications time-out

occurred during operat ion on

device:_devicename_.

113 A device driver for the

following device c ould not b e

found:_devicename_.

114 An error occurred during

communications to the

following device:

_devicename_.

115 An operation error occurred

during communications to

the following device:_

devicename_.

An unknown device error

occurred.

The application does not have

enough memory to complete the

operation.

The connection between the

printer and host computer was

lost.

The application could not find the

necessary device software to

communicate with the printer.

• The cable between the printer

and the host computer is worn.

• One or more of the

connections between the

printer and the host computer

has malfunctioned.

• The cable between the printer

and the host computer is worn.

• One or more of the

connections between the

printer and the host computer

has malfunctioned.

Use the information in the status

message and error message to

resolve the device error.

Close the other applications and

unnecessary windows.

Check that all cables are properly

connected.

Make sure that the Calibration

Application and ASPI SCS I de vice

driver are installed correctly.

• Check that all cables are

properly connected.

• Check the cables and

connections between the printer

and the host computer for wear

and if necessary, replace them.

• Check that all cables are

properly connected.

• Check the cables and

connections between the printer

and the host computer for wear

and if necessary, replace them.

116 A software warning has be en

issued by the following

device: _devicename_ Error

Message: _errmsg_

A software error has occurred on

the printer.

Resolve printer error condition.

2-4 March 2001

Page 21

Troubleshooting

Code Status Message Possible Cause/Subsystem Possible Solution

117 A software error has been

detected by the following

device: _devicename_ Error

Message: _errmsg_

118 A SCSI ID for the following

device was not found:

_devicename_.

119 The wrong SCSI ID was

specified for the following

device: _devicename_.

120 This device has been setup

for the wrong model of

printer: _devicename_.

121 Unable to read ST A T US from

device: _devicename_.

122 The se lected LUT contains

data that exceeds the limits

of this printer .

201 An error occurred while

trying to allocate memory.

202 The following parameter is

invalid:_parametername:

_parametervalue_.

An error has occurred on the

printer.

SCSI driver not found. Reinstall the SCSI driver on host

SCSI ID is incorrect. Set the Target SCSI ID to the

The chosen device has not been

found.

Unable to see the printer. Check SCSI cable connections.

Trying to send a 12-bit LUT to a

10-bit printer.

The system is trying to allocate

memory; however, no memory is

available.

An internal error occurred wi th the

software.

Resolve printer error condition.

computer.

printer SCSI ID.

Verify chosen device matches the

printer model.

Select a 10-bit LUT file.

Close any unnecessary

applications.

• Restart the application.

• If problem continues, call for

service.

203 The function is not support ed

by the class.

204 This function has not been

implemented.

An internal error occurred wi th the

software.

An internal error occurred wi th the

software.

• Restart the application.

• If problem continues, call for

service.

• Restart the application.

• If problem continues, call for

service.

March 2001 2-5

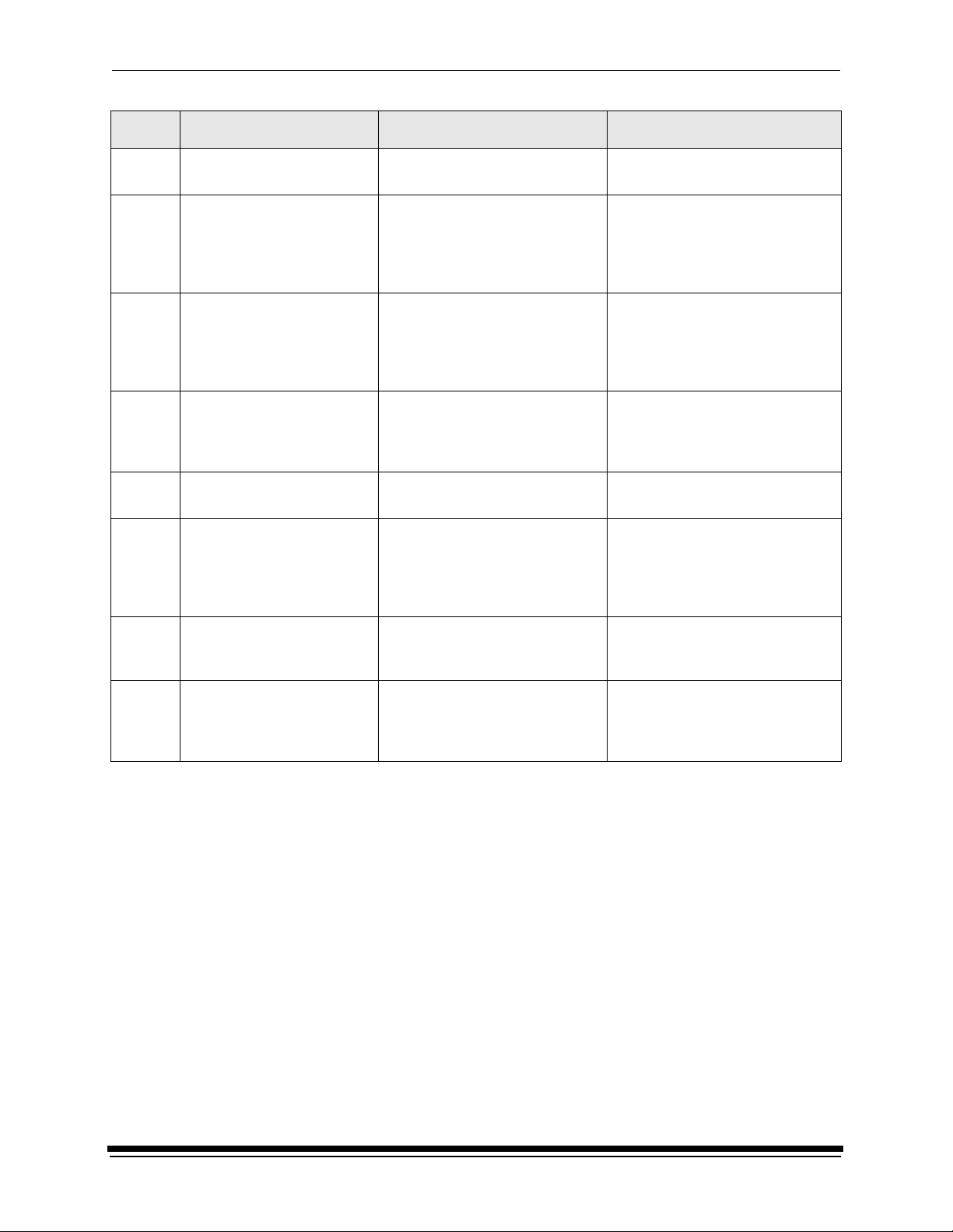

Page 22

Troubleshooting

Code Status Message Possible Cause/Subsystem Possible Solution

205 Must enter the following

field:_field_.

301 The following key was not

found: _key_.

302 The following grouper was

not found:_grouper_.

303 The call depends on a

current grouper, but the

current grouper has not be en

set.

501 An error occurred while

applying the data.

601 A bad count was entered.

The expected count

was:_count_.

The operator left a configuration

field blank.

• An internal error occurred with

the software.

• One of the files was edited

manually and a key was

changed.

• An internal error occurred with

the software.

• One of the files was edited

manually and a grouper was

changed.

An internal error occurred wi th the

software.

• A file was edited manually and

an incorrect number of rows

was entered.

• An internal software error

occurred.

Enter information in the blank

configuration field.

• Restart the application.

• Restore the key to its previous

value.

• If problem continues, call for

service.

• Restart the application.

• Restore the grouper to its

previous value.

• If problem continues, call for

service.

• Restart the application.

• If problem continues, call for

service.

• Manually enter the correct

number of rows in the file.

• If problem continues, call for

service.

602 An error occurred during the

calculation process.

701 Patch _patch_, column

_column_, value _value_ is

beyond tolerance

_tolerance_ for aim _aim_.

An internal error occurred wi th the

software.

A density patch was out of

tolerance.

• Restart the application.

• If problem continues, call for

service.

Perform another calibration cycle.

2-6 March 2001

Page 23

Troubleshooting

Code Status Message Possible Cause/Subsystem Possible Solution

702 Patch _patch_ has a spread

of _spread_ which is out of

range _range_.

703 CalT ol eranceFile can on ly be

initialized once.

704 CalToleranceFile::

initialize must be called first.

801 Could not find row:_row_. An internal error occurred with th e

802 Could not find

column:_column_.

803 Could not find element -

column:_column_.

row:_row_.

804 Row value was not set

before using.

805 Column value was not set

before using.

The spread between colors for a

given density patch is out of

tolerance.

An internal error occurred wi th the

software.

An internal error occurred wi th the

software.

software.

An internal error occurred wi th the

software.

An internal error occurred wi th the

software.

An internal error occurred wi th the

software.

An internal error occurred wi th the

software.

Perform another calibration cycle.

• Restart the application.

• If problem continues, call for

service.

• Restart the application.

• If problem continues, call for

service.

• Restart the application.

• If problem continues, call for

service.

• Restart the application.

• If problem continues, call for

service.

• Restart the application.

• If problem continues, call for

service.

• Restart the application.

• If problem continues, call for

service.

• Restart the application.

• If problem continues, call for

service.

806 Error deleting row:_row_. An internal error occurred wi th the

software.

807 Element at row:_row_;

column:_col_

value:_val_ failed audit.

An input file had incorrectly

formatted data in it at the loca tion

indicated.

• Restart the application.

• If problem continues, call for

service.

• Verify that you are using the

correct file.

• Edit the file and correct the

format.

March 2001 2-7

Page 24

Troubleshooting

Code Status Message Possible Cause/Subsystem Possible Solution

910 Configuration file

field:_filename_is invalid.

Calibration will be cancelled.

911 Error_errcode_occurred.

Processing stopped.

919 Error occurred preparing to

handle exit from Kodak

Device Calibration. Will not

perform cleanup at exit.

921 Unable to return the printer

to its original state. Fix

printer problem and recalibrate.

922 There is already a printer

open. Please close the op en

printer first.

923 An error occurred during the

loading of a printer. Please

check to make sure the file

chosen was of the correct

type and/or format.

The user entered an incorrect

value in a configuration file.

An internal error occurred wi th the

software.

An internal error occurred wi th the

software.

The application was trying to

cancel but received an error when

sending the original LUT back to

the printer.

User tried to open a printer when

the printer was already open.

An error occurred during the

loading of a printer.

• Enter the correct value.

• Reinstall the application.

• If problem continues, call for

service.

Restart the application.

Restart the application.

Printer is in an unknown state.

Correct any printer problems and

restart the application.

Close the open printer.

Check that the file chosen was the

correct format or type.

924 No printer loaded. The operator has not yet opened

a printer.

941 The height and width values

do not agree with the size of

the target file.

942 Unable to configure

densitometer. Densitometer

configuration file may be

corrupt or lost.

The specified size does not match

the file size.

The file CalDevDensGen2.cfg is

corrupt or lost.

Open a printer.

Enter the correct file size.

Restart the application. If problem

continues, call for service.

2-8 March 2001

Page 25

Troubleshooting

Code Status Message Possible Cause/Subsystem Possible Solution

1003 Unable to load default

configuration file:_filename_.

1004 Unable to set values

in new configuration file.

1005 Unable to save configu rati on

file:_filename_.

1006 Configuration file fiel d:_field_

is invalid.

1007 Unable to remove

directory:_directory_.

1101 Density DMIN/DMAX points

are invalid.

1102 Density data is not

monotonic increasing.

1 103 Exceeded maximum number

of allowable data errors.

The default configuration file was

deleted or renamed or moved.

An internal error occurred wi th the

software.

The system is trying to save a file

but there is not enough disk

space.

The user entered an incorrect

value in a configuration file.

The user does not have the

authority to update the directory.

Density po ints are invalid. Reread density values on

Density da ta is invalid. Reread density values on

Density da ta is invalid. Reread density values on

Restore the file manually or

reinstall the software.

Restart the application.

Remove any unnecessa ry fil es to

increase free disk space.

• Enter the correct value.

• Reinstall the application.

Verify that the user has update

authority on the directory.

densitometer or make a new

calibration print.

densitometer or make a new

calibration print.

densitometer or make a new

calibration print.

1104 Asymmetric Density

Groupings are invalid.

1201 Unknown response from

densitometer.

Density da ta is invalid. Reread density values on

densitometer or make a new

calibration print.

During initialization , the

application received an unknown

response from the densitometer.

Verify that the baud rate of the

densitometer matches that of the

applications configuration.

March 2001 2-9

Page 26

Troubleshooting

Code Status Message Possible Cause/Subsystem Possible Solution

1202 Error:_error_from

densitometer.

1203 Error: Number of patches

seen by densitometer is

incorrect.

1300 Values have not been loaded The matrix file is missing. Create a new device.

1301 Data or Matrix files have not

yet been loaded

1302 Data cannot be saved, must

first apply the matrix

An unexpected error was returned

from the densitometer.

Unable densities on densitometer. Try adjusting frame counts or

The matrix file is missing. Create a new device.

The matrix file is missing. Create a new device.

Calibrate the densitometer. If the

problem continues, check the

manual for the densitometer.

reread the density patches on the

densitometer.

2-10 March 2001

Page 27

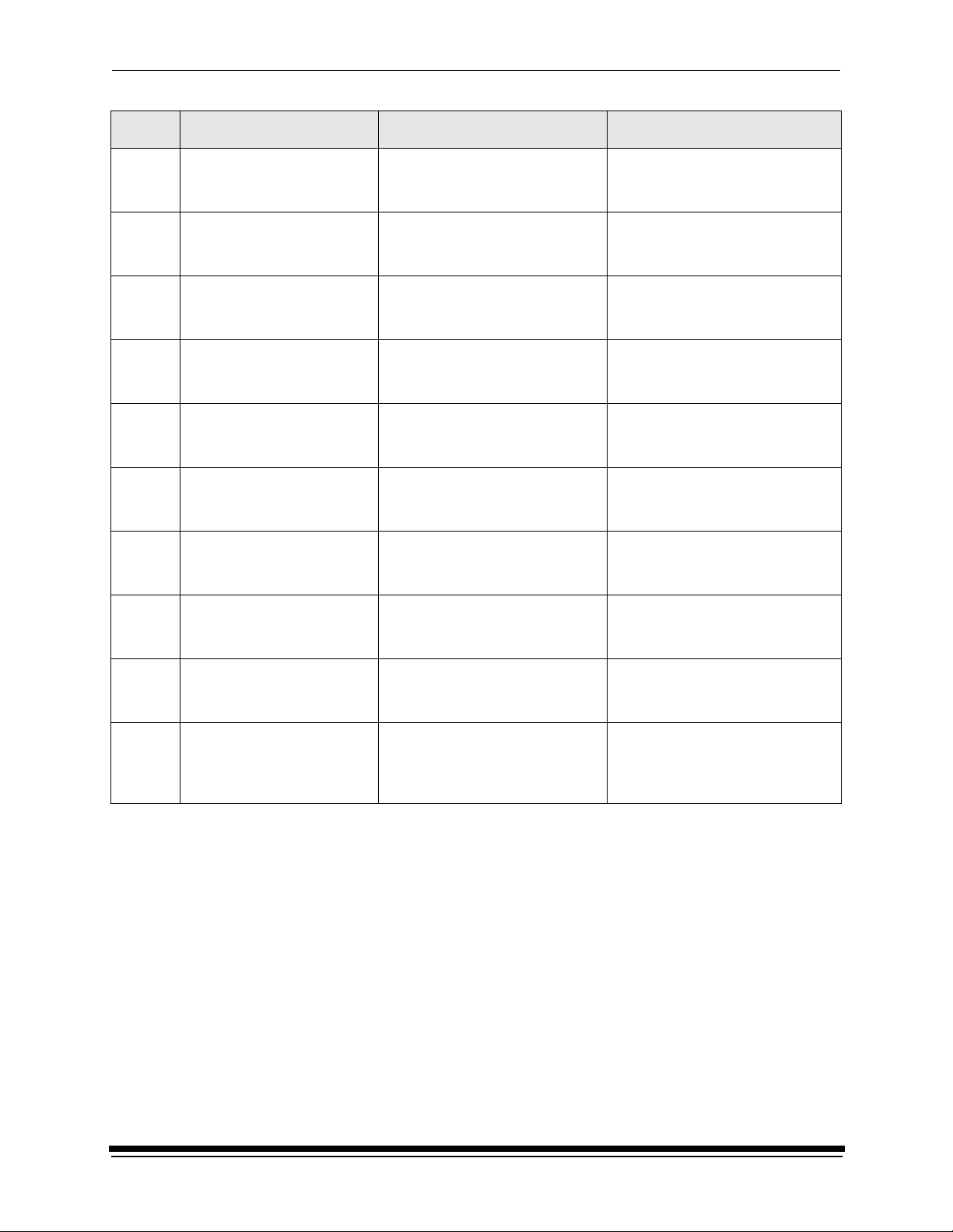

Troubleshooting

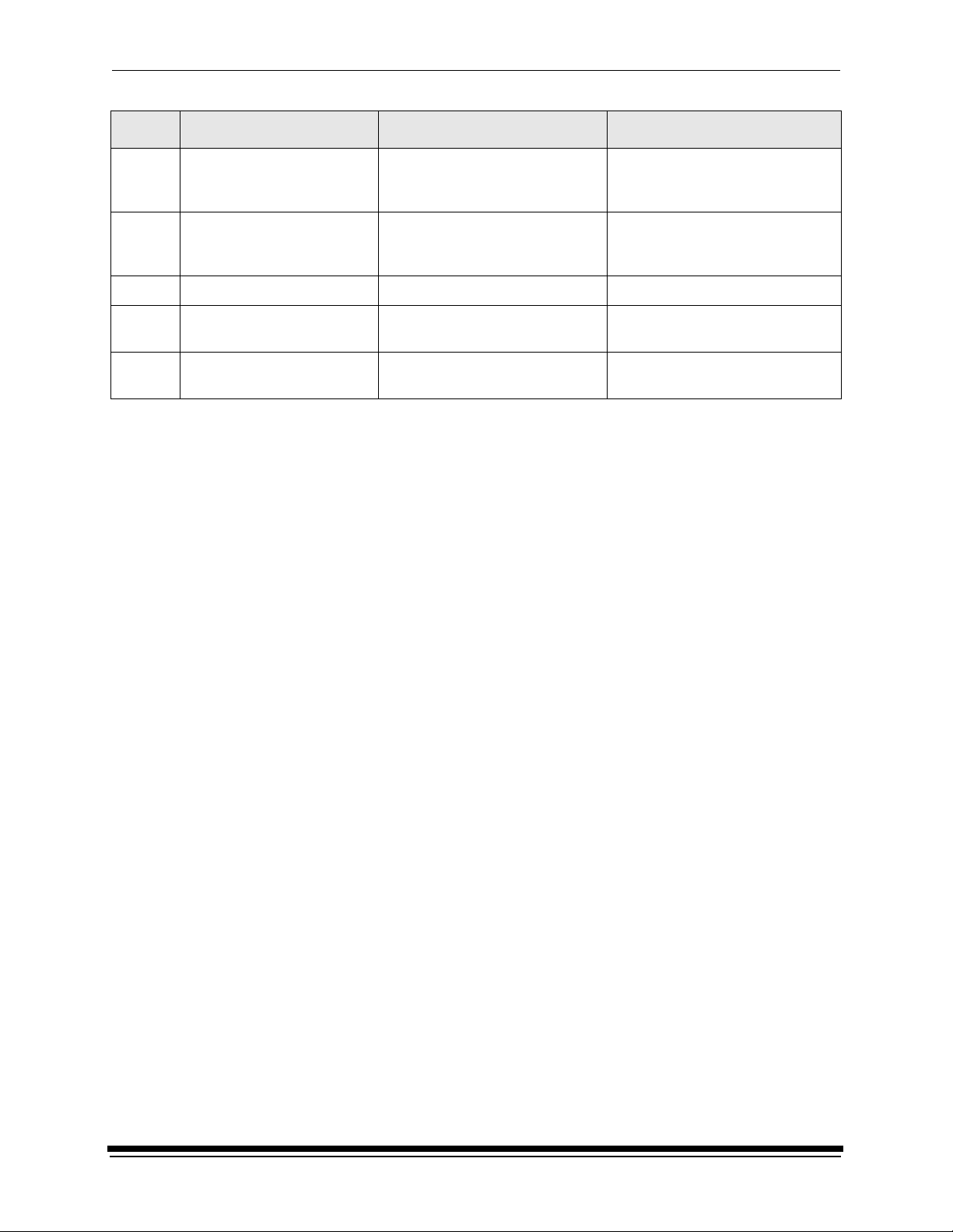

Non-Numeric Calibration Error Messages

Error Message Possible Cause/Subsystem Possible Solution

An underrun error occurred during

communications to the following

device.

An UNKNOWN error occurred

during communications to the

following device.

Device not found. The host computer attempted to

Invalid Device ID. The host computer attempted to

The following device is busy. The printer at the specified SCSI ID

• The cable between the printer

and the host computer is worn.

• One or more of the connections

between the printer and the host

computer has malfunctioned.

An unknown error occurred in the

application.

contact the printer at the specified

SCSI ID but did not get a response.

contact the printer at the specified

SCSI ID but did not get a response.

is busy.

• Check that all cables are pro perl y

connected.

• Check the cables and

connections between the printer

and the host computer for wear

and, if necessary, replace them.

• Restart the calibration application.

• If the problem continues, make

sure that the Calibration

Application and ASPI SCSI

device driver are installed

correctly.

• Make sure that the printer is

turned on and is on-line.

• Make sure that the Calibration

Application and ASPI SCSI

device driver are installed

correctly.

Make sure that the printer is turned

on and is on-line.

Check that all cables are properly

connected.

The following device is closed. The connection between the printer

and host computer was lost.

Check that all cables are properly

connected.

March 2001 2-11

Page 28

Troubleshooting

Densitometer Errors

Code Message Explanation

<01> BAD_COMMAND The densitometer does not recognize a command.

<02> PRM_RANGE_ERROR One or more data or address parameters is out of range. See the

command guide for parameter limits.

<03> DISPLAY_OVERFLOW_

ERROR

<04> MEMORY_OVERFLOW_

ERROR

<05> INVALID_BAUD_RATE The parameter included with the BR command was invalid. Valid

<06> INVALID_PHOTO_STRIP The specified photographic control strip does not exist.

<07> TIMEOUT The time interval between characters has exceeded 5 seconds.

<08> PRM_SYNTAX_ERROR. An invalid character was found in the command string.

<09> INVALID_PASS The requested pass does not exist for the currently stored strip (e.g.,

<0a> INVALID_STEP The requested step does not exist for a given pass in the cu rrent ly s tore d

<0b> NO_DATA_AVAILABLE Data was requested but no data is stored in memory.

<0c> MISSING_PARAMETER One or more required parameters was omitted.

<10> LAMP_MARGINAL The lamp output is at approximately 50% of its original brightness. Strip

An attempt was made to rea d or wri te bey ond the end of the dis play. Valid

addresses for the display range from 0x00 to 0x20 (0 to 31 decimal).

An attempt was made to read or write beyond the end of the external

RAM within the densit ometer. Valid addresses for t he external RAM range

from 0x0000 to 0x7fff (0 to 32767 decimal).

parameters are 06 (1200), 0C (2400), 18 (4800), 30 (9600), and 60

(19200).

specifying pass 5 for a 4-pass strip).

strip (e.g., specifying step 25 or step 0 on a 21-step pass).

readings can still take place, but to maintain proper accuracy and

repeatability, replace the lamp as soon as possible.

2-12 March 2001

Page 29

Troubleshooting

Code Message Explanation

<11> LAMP_FAILURE The lamp is either burned out or its output is at a level too low for

acceptable readi ngs. The densitome ter will not read strip s until the lam p is

replaced and the densitometer is re-calibrated.

<12> STRIP_RESTRAINED During calibration, the calibration s trip was hel d or restrai ned as it pas sed

through the unit. Do not hold the strip as it is reading and make sure the

read path is clear of any foreign matter.

<13> BAD_CAL_STRIP During calibration, the calibrat ion stri p was un recogn izabl e. The s trip ma y

have been inserted backwards, upside down, or held so that it slipped on

the internal rollers. This also may be an indication that the strip needs to

be replaced.

<14> MOTOR_ERROR During calibration, a problem was detected with the drive motor. This can

occur if the strip is held back while reading.

<20> INVALID_READING The strip just read was not recognized by the densitometer.

<21> WRONG_COLOR After a strip reading, the step wedge just read was not the color specified

for that pass or strip as defined in the densitometer editor menu.

<23> NEEDS_CALIBRATION The calibration check that was done immediately after reading a strip

indicated that the unit needs calibration. This occurs when the reading

taken from the opal glass after the strip exits the unit differs from the

reading taken during calibration by more than the internal tolerance

(default is 0.1 X, Y, or Z). The tolerance can also be changed by the RCI

command CC (Check Cal tolerance).

<26> NO_VALID_DATA The measure type is set to CONT and the strip that was read contained

nothing but base material. Base material is defined as measuring less

than 0.5D in the visual channel. For negative (black) based materials,

base material is defined as me asurin g less than twice the reflect anc e of a

measurement taken near the trailing edge of the strip. the densitometer

uses a measurement taken at about 0.25 inches from the trailing edge of

the strip to determine i f it is posi tive o r negati ve bas ed. Any m easu rement

greater than 10% reflectance is considered positive based; anything else

is considered negative based.

March 2001 2-13

Page 30

Troubleshooting

Code Message Explanation

<27> BAD_PATCH If the Pattern Recognition comparison window is set to 0 or 1, this error

may result when a single patch on the strip is bad due to dirt, smears,

creases, etc. (See expl anation of CW command for more informat ion.)

<30> BAD_STRING_LENGTH A strip definition string received as part of the DS (Define Strip) R CI

command did not contain the correct number of characters.

<31> BAD_CHARACTER A non-printable character was received in one of the name fields (strip

name or pass name). Print abl e cha rac ters are in the range 0x20 to 0x7E,

inclusive.

<32> BAD_MEAS_TYPE The value for the measure type field was greater than 3. Valid values are

0 through 3.

<33> BAD_COLOR The value for the color field was greater than 9.

<34> BAD_STEPS The value for the number of steps was greater than 72.

<35> BAD_STOP_LOCATION The value for t he guide setting was less than 4 or greater than 30.

<36> BAD_OUTPUT_TYPE The value for the output type was greater than 5.

<37> MEMORY_ERROR The definition could not be stored.

<38> BAD_N_FACTOR The n-factor (used in Dot calculations) is either less than 0500 (0.500) or

greater than 4500 (4.500).

<39> STRIP_DOESNT_EXIST The SD command was issued and the requested strip does not exist.

<3A> BAD_MIN_MAX_VALUE The value for the min/max field was greater than 4.

<40> BAD_SERIAL_NUMBER An attempt was made to redefine one of the stored serial numbers with a

number containing one or more invalid digits.

2-14 March 2001

Page 31

3 Using Additional Calibration Features

The topics covered in this section include:

• Installing the Calibration Software

• An overview of the Kodak Professional Dev ice Cali br ati on Software

• Advanced Features of the LED II Calibration Software

• Installing the Densitometer

IMPORTANT: For the step-by-step procedure to calibrating the printer, see

Section 1, Calibrating the Printer.

Installing the Calibration Software

Installing the software includes installing both the Kodak Professional Device

Calibration Software (which manages the calibration of multiple Kodak devices)

and the Calibration Software for the Kodak Professional LED II Printer 20P/20R.

Y ou can install the software either from a supplied CD or by downloading from the

Kodak web site.

System Requirement s

MACINTOSH Systems

• Power MACINTOSH System 7.5 or above

• Minimum of 35 MB free disk space

• 608 K free disk space for each of as many as six configured devices

• 256 colors at 640 x 480 spatial resolution

• CD ROM Drive

WINDOWS NT Systems

• 100 MHz PENTIUM Processor

• 64 MB Main System Memory

• VGA Monitor (640 x 480 spatial resolution)

• CD ROM Drive

March 2001 3-1

Page 32

Using Additional Calibration Features

Installation Procedure

1. If you are installing the software from the supplied CD-ROM:

a. Place the CD in your CD-ROM drive.

b. When the Browser is displayed, select LED Printer.

2. If you are downloading the installation files from the Kodak web site, go to

http://www.kodak.com/global/en/service/printers/led2Printer/led2Printer.shtml.

3. Under the heading Product Support, select Drivers, Softwa re and F irmwa re.

4. Select Calibration Utilities.

5. Under the heading Download File, select KODAK PROFESSIONAL Device

Calibration.

The display shows the Save As dialog box.

6. Either accept the default path and file name or select another path and file

name and save the file.

3-2 March 2001

Page 33

Using Additional Calibration Features

NOTE: The installation is similar for NT and Macintosh systems. When the

instructions say, for example, click Next or Install, the first option is for NT

systems and the second is for Macintosh systems.

CAUTION: T o avoid possible damage, do not connect or disconnect the cable

between your host computer and the printer when either device

is powered up.

7. Open the installation file (KODAK PROFESSIONAL Device Calibration.exe).

The display shows a splash screen for KODAK PROFESSIONAL Device

Calibration and a Setup message.

8. After the Welcome screen is displayed, click Next or Continue.

9. For Macintosh systems only, read the readme information, then click

Continue.

10. Read the license agreement.

• To accept the terms and continue the installation, click Yes or Agree.

• Or, to cancel the installation, click No or Disagree.

11. For NT systems only, read the readme information, then click Next.

12. Select the installation type:

For NT systems, select one of the following:

NOTE: The Compact option is not supported.

• Typical includes Device Calibration Applications for the Kodak

Professional LED Printer and for the Kodak Professional

Digital Mutliprinter, plus the Linearization Calibration

Application for the Kodak Professional RFS 3570+ (Speed

Up) Film Scanner

• Custom allows you to choose specific features for the application you

choose to install, including the Centralized Densitometer

Application; for the LED Printer, you may choose to install

either Gen I or Gen II.

For Macintosh systems, select Easy Install.

March 2001 3-3

Page 34

Using Additional Calibration Features

13. Click Next to install the software on your system.

The display shows a dialog box for you to designate where to install the

calibration software.

14. Either accept the default path and folder or select another path and folder.

15. Click Finish or OK.

NOTE: For NT systems, the dialog box gives you the option of reading the

16. If you installed the software from a CD-ROM, remove the CD and store it in a

safe place.

readme file associated with your installed applications.

3-4 March 2001

Page 35

Using Additional Calibration Features

About the Kodak Professional Device Calibration Software

The Kodak Professional Device Calibration software manages and launches

customized calibration software applications, including the calibration software for

the LED 20P and 20R printers.

Application Window Definitions

The window below and the tables that follow define the application window for the

KODAK PROFESSIONAL Device Calibration Software.

Tool bar

Menu bar

Device icon

(this is displayed

when you add

a calibration

device)

Title bar

Status bar

Window Area Description

Title Bar Contains the application name, “KODAK PROFESSIONAL D evice Calibration”

Menu Bar Contains selectable menu items

Tool Bar Contains the user selectable menu choices and is activated by a shortcut keystroke or

by a mouse pointer and left mouse button

Client Area Contains the icons that represent devices available for calibration

Device Icon Represents a device that can be calibrated

Status Bar Displays messages to the user to indicate actions that are occurring or the status of

the occurring action and the currently selected device

Client area

March 2001 3-5

Page 36

Using Additional Calibration Features

The table below defines the functions and their corresponding icons on the main

window of the Device CalibrationSoftware.

Menu

Access

Function Icon/Key Availability Description

Operations C

File N

alibrate

ew

Edit Cut

File E

dit

NT Systems: Ctrl+L

MAC Systems: +L

NT Systems: Ctrl+N

MAC Systems: +N

NT Systems: Ctrl+X

MAC Systems: +X

NT Systems: Ctrl+E

MAC Systems: +E

When the

device is

selected

Passes control to calibration

software for the device; doubleclicking on a device icon

performs the same action

Always Displays Create a New Device

dialog box; adds a device to

control area

When a

calibration

device is

selected

Removes object from control

area. All history data files

(including log data, LUT files

etc.) will be deleted for this

device. The display shows a

confirmation dialog box so you

cancel the action.

Always If no object is selected, Edit

Application Configuration dialog

box is displayed. If an object is

selected, Update a Device

Registry dialog box for that

device is displayed.

File

MAC Systems:

Quit

NT Systems:

NT Systems: Ctrl+Q

MAC Systems: +Q

Always Exits application

Exit

Help Product Info NA Always Displays Product Information

dialog box

3-6 March 2001

Page 37

Using Additional Calibration Features

Starting the Device Calibration Software

Load the Calibration Software according to the table below. (If needed, see

“Installing the Calibration Software” on page 3-1.)

MACINTOSH Systems NT Systems

1. Open the folder that cont ai ns th e fil es fo r the

calibration application.

2. Click the icon for KODAK PROFESSIONAL

Device Calibration.

Editing the Log Settings

Your Device Calibration application has specific “log settings” for the purpose of

keeping a history of the calibration. You may want to change the settings—the

type of messages written to the log file, the number of days to keep the log file,

and the name of the log file. (See also “Editing Information on the History Tab” on

page 3-30.)

T o change the log settings for the Device Calibration:

1. On the Device Calibration window, deselect all devices.

Select:

Eastman Kodak/KPRO Applications/KODAK

PROFESSIONAL Device Calibration

from the WINDOWS NT Start menu.

All devices

must be

deselected

2. Click the Edit icon or select File->Edit.

March 2001 3-7

Page 38

Using Additional Calibration Features

The display shows the Edit Configuration dialog box with the default settings:

3. Edit the device settings as needed or click Default to refresh the dialog box

with the default settings.

The log operations/settings include:

Device Setting Options

Log Type None: No logging of events or errors

Events: Log events only (status messages that are displayed on the

Errors: Log errors only

Log all actions: Log all actions

screen)

Keep log for

(days)

Enter the number of days you want to keep logged information – for up to

99 days

Log File Name Enter the name that you want to give to the log file

4. Click OK to save (or Cancel to cancel) the changes.

3-8 March 2001

Page 39

Using Additional Calibration Features

Adding, Updating, and Deleting Devices

You can:

• add new printer calibration devices

• update the name or SCSI ID (Target ID) of an existing device

• delete devices

• update the configuration files for devices

Adding a Device

1. Click the New icon or select File->New on the Device Calibr ation w indow.

The display shows the Create a New Device dialog box.

2. Enter the correct device settings. Use a unique identifying word for the device

name.

NOTES: The default SCSI ID for the printer is 5. The printer’s OCP menu

displays the current SCSI ID for the printer.

Make sure the Device Type field matches the type of printer that

is being calibrated (for example: Digital LED II 20P).

3. Click OK to accept the changes.

March 2001 3-9

Page 40

Using Additional Calibration Features

A new printer device icon is displayed on the Device Calibration window.

NOTE: If an error message is displayed, refer to Section 2, Troubleshooting.

Updating a Device

T o update the device name or the SCSI information for a device:

1. Select the device by clicking once on the device icon on the Device

Calibration window.

Device

icon

2. Click the Edit icon or select File->Edit.

3-10 March 2001

Page 41

Using Additional Calibration Features

The display shows the Update a Device dialog box.

3. Enter the correct device settings.

The options for the device settings include:

Device Setting Options

Device name Enter the name that you want to give to the device.

NOTE: The MACINTOSH platform limits the device

name to 10 characters.

SCSI Host Adapter Adapter ID on host computer

SCSI ID The SCSI ID for the device; the default is 5 for the

LED Printer

4. Click OK to save (or Cancel to cancel) the changes.

March 2001 3-11

Page 42

Using Additional Calibration Features

Deleting a Device

T o delete a device and all files associated with the device:

1. Select the device by clicking once on the device icon.

Device

icon

2. Click the Cut icon or select Edit->Cut.

The display shows:

3. Click Yes to delete the device and associated files (or click No to stop the

deletion process).

3-12 March 2001

Page 43

Using Additional Calibration Features

Advanced Features of the LED II Calibration Software

The Calibration Software for the KODAK PROFESSIONAL LED II Printer

20P/20R provides automated neutral density printer calibration and is designed to

be used without assistance from technical experts. The advanced calibr ati on

features provided by this product enable you to customize the calibration of the

printer. To use the advanced features, you should understand image science

technology and the implications of manipulating neutral density calibrations.

IMPORTANT: Printer calibration should not be mistaken for color management.

Color management is provided by software applications that are

independent of the printer and the calibration software.

Viewing Graphs

The View Graphs feature provides access to the available graphs from the most

recently completed calibr ati on .

Examples of the Value, Difference, and History Graphs follow. The Value and

Difference Graphs reflect the densitometer values that were last read. The History

Graph displays the data from completed calibrations.

March 2001 3-13

Page 44

Using Additional Calibration Features

Value Graph

3-14 March 2001

Page 45

Difference Graph

Using Additional Calibration Features

March 2001 3-15

Page 46

Using Additional Calibration Features

History Graph

3-16 March 2001

Page 47

Using Additional Calibration Features

To view calibration graphs:

1. From the Device Calibration window, double-click the device for which you

want to view graphs.

The display shows the LED Calibration Application window.

2. Click the Graphs icon or select View->Graphs.

The display shows one of the graphs; typically it is the Value graph.

3. Select the Graph Type that you want to view. When the graph is displayed,

select the type of data and planes that you want to see displayed.

NOTE: The graph will be blank if the printer has not been calibrated.

March 2001 3-17

Page 48

Using Additional Calibration Features

Applying a Master Balance (NT Systems Only)

Master Balance is a method that allows you to temporarily modify printer neutral

calibration. This may be desired for customizing a particular job or correcting for a

short-term processing shift. It does not replace calibrating the printer.

1. From the Device Calibration window, double-click the device for which you

want to perform a master balance.

The display shows the LED Calibration Application window.

2. Click the Master Balance icon or select Operations->Master Balance.

3-18 March 2001

Page 49

Using Additional Calibration Features

The display shows the Master Balance dialog box.

3. Click and drag the sliders as needed for Density, Red, Green, or Blue

balance.

For Density, Red, Green, and Blue, 1 unit of change is equal to 0.01 log

exposure or 1 color correction (cc) units. For unit changes of less than one,

you can type the number directly into the edit box.

4. Click OK to accept the changes (or click Cancel to cancel the master

balance).

March 2001 3-19

Page 50

Using Additional Calibration Features

The display shows the Choose Master Balance LUT dialog box.

IMPORTANT:In the next step, do not select the default LUT.

5. Select one of the LUTs from the dialog box and click Load Selected LUT or

click Load Custom LUT and follow the prompts to load a custom LUT.

A new LUT is calculated based on the selected LUT and the input DRGB

values. The LUT is downloaded to the printer, overwriting the current LUT.

This LUT will be the current printer LUT until a new LUT is sent.

Sending LUTs

The Send LUT to Printer feature allows you to overwrite the current LUT in the

printer. You can create a valid printing LUT using an ASCII text editor. This option

sends the selected LUT to the printer, overwriting any existing LUT.

To send a LUT to the Printer:

1. From the Device Calibration window, double-click the device for which you

want to send a LUT.

3-20 March 2001

Page 51

Using Additional Calibration Features

The display shows the LED Calibration Application window.

2. Click the Send LUT icon or select Operations->Send LUT.

The display shows the Send LUT to Printer dialog box.

3. Select one of the LUTs from the dialog box and click Load Selected LUT or

click Load Custom LUT and follow the prompts to load a custom LUT. The

LUT is downloaded to the printer, overwriting the current LUT.

March 2001 3-21

Page 52

Using Additional Calibration Features

Sending Targets

The Send Target feature enables you to send any properly formatted target file to

the printer without performing a calibration. The target file must contain image

data in the format for the K oda k Pr ofe ss io nal LED II Printer 20P/20R. The format

of this file must be raw RGB pixel interleaved.

T o send a test target to the printer:

1. From the Device Calibration window, double-click the device for which you

want to se nd a test target.

The display shows the LED Calibration Application window.

2. Click the Send Target icon or select Operations->Send Target.

3-22 March 2001

Page 53

Using Additional Calibration Features

The display shows the Send Target to Printer dialog box. (The versions for

both NT and MACINTOSH Systems are shown.)

NT Systems

NOTE: Users of N T systems can click Browse to select another file name. The

display shows the Open dialog box. Select the file name, then click

Open.

March 2001 3-23

Page 54

Using Additional Calibration Features

MACINTOSH Systems

3. Enter the desired settings and click OK to save the settings (or Cancel to

keep the previous settings).

The selected test target is sent to the printer.

3-24 March 2001

Page 55

Using Additional Calibration Features

Editing the Device Configuration

The Edit Configuration feature allows you to change the printer’s calibration

configuration attributes. However, it is recommended that you use the default

settings for these attributes for most operations.

Edit Configuration consists of a set of six tabs—each with related configuration

attributes. There can be only one set of configuration attributes for the printer

calibration application at a time. If you make any changes to information on one or

more of the tabs and then click OK to save your changes, the changes will

overwrite the previous attributes used for the automated calibration.

T o edit the device configuration:

1. From the Device Calibration window, double-click the device for which you

want to change the calibration configuration.

March 2001 3-25

Page 56

Using Additional Calibration Features

The display shows the LED Calibration Application window.

2. Click the Edit icon or select File->Edit.

The display shows the Edit Configuration window with the Procedure tab

displayed.

3. To navigate among the tabs, click the tab you want and follow the instructions

for updating the information for that tab.

IMPORTANT:Whenever you c li ck OK, the software assumes ALL changes to

the Edit Configuration are complete and the Edit Configuration

window closes. Similarly, you can click Cancel at any time while

the Edit Configuration window is open; any changes you made

to any of the tabbed information are canceled and the Edit

Configuration window closes.

For Macintosh users only: you can click Default at any time to reset the attributes

to their factory defaults and then click OK to save the defaults.

3-26 March 2001

Page 57

Using Additional Calibration Features

Editing Information on the Procedure Tab

The Procedure tab contains general configuration attributes as shown and

described below. The values displayed in the example are the default settings.

Procedure

Attribute

Graphing Instructs the application when to display the graphs of the data

Tolerance Level Indicates whether the level of tolerance is Normal, Loose, Strict, or ColorMetallic

Normal.

NOTE: ColorMetallic paper requires its own tolerance file.

Out of Tolerance Provides the flexibility to interact at each step or to use a fully automated calibration

Maximum

Cycles

Processor In

Control

Indicates the maximum number of iterations the calibration procedure will perform if

“Out of Tolerance” is set to “Automatically iterate up to maximum cycles.”

Indicates whether the Processor In Control dialog box is to be displayed at the

beginning of the calibration process

To edit the configuration information on the Procedure tab:

1. Use the drop-down lists to change the Procedure information as needed.

2. If you have completed all editing (including information on the other tabs),

click OK to save the changes and close the Edit Configuration window. (Or,

click Cancel to cancel all changes.)

3. To continue making changes to the Edit Configuration, click another tab and

make changes as needed.

Description

March 2001 3-27

Page 58

Using Additional Calibration Features

Editing Information on the Density Source Tab

The Density Source tab specifies how the calibration application is to receive

density data. The values displayed in the example are the default settings.

Density Source

Attribute

Density Source Indicates the source (local densitometer or file or, for PC applications only,

centralized densitometer application) of the density data.

Density Source

Port

Density Source

File

Indicates the name of the RS-232 port that the densitometer is connected to. This

port is the source of the density data. The name of the port is specific to the

computer system platform.

NOTE: This is only used if the Density Source is DTP36.

Indicates the filename for the source of density data. This is only used if the Density

Source is a file. If you designate a file as the density source, this is the file name you

use for “Creating a Density File for Use with Calibration” on

page 3-36.

To edit the configuration information on the Density Source tab:

1. Use the drop-down lists to change the Density Source information as needed.

2. If you have completed all editing (including information on the other tabs),

click OK to save the changes and close the Edit Configuration window. (Or,

click Cancel to cancel all changes.)

3. To continue making changes to the Edit Configuration, click another tab and

make changes as needed.

Description

3-28 March 2001

Page 59

Using Additional Calibration Features

Editing Information on the Aim Tab

The Aim tab specifies:

• whether the aims used for calibration are Density Aims or Lightness Aims

• whether to apply the Channel-Independent Matrix

• which table to use if Copyright Detection is functional

The values displayed in the example are the default settings.

Attribute Description

Desired Aim Indicates whether to use Density Aims or Lightness Aims for calibration. Using

Lightness Aims will improve both the highlights and shadows of your prints.

Apply Channel

Independent Matrix?

Copyright Detection

Table

Indicates whether or not to apply the Channel-Independent Matrix to the aim

values. If the matrix is applied, the number of cycles required to successfully

calibrate the printer should be reduced.

Select the table to be used. This feature is available with Gen II LED printers

only . Only use this feature as instructed by Kodak.

To edit the configuration information on the Aim tab:

1. Change the Aim information as needed.

2. If you have completed all editing (including information on the other tabs),

click OK to save the changes and close the Edit Configuration window. (Or,

click Cancel to cancel all changes.)

3. To continue making changes to the Edit Configuration, click another tab and

make changes as needed.

March 2001 3-29

Page 60

Using Additional Calibration Features

Editing Information on the History Tab

The History tab specifies information about maintaining calibration history data.

The values displayed in the example are the default settings.

Attribute Description

Keep History For (days) Indicates the number of days that the calibration LUT, print LUT, density

data and LUT history information (LED trend data) are to be kept.

Information older than the specified number of days will be deleted.

Log Type Indicates the type of log file available during calibration. All recordable

events or just the recordable errors can be logged to a selected filename.

Keep log for (days) Indicates the number of days that the error and events information is to be

kept. Information older than the specified number of days will be deleted.

Log File Name The name of the file that contains the logged information.

To edit the configuration information on the History tab:

1. Change the History information as needed.

2. If you have completed all editing (including information on the other tabs),

click OK to save the changes and close the Edit Configuration window. (Or,

click Cancel to cancel all changes.)

3. To continue making changes to the Edit Configuration, click another tab and

make changes as needed.

3-30 March 2001

Page 61

Using Additional Calibration Features

Editing Information on the Paper Tab

The Paper tab allows you to specify the paper being calibrated. The value

displayed in the example is the default setting.

Attribute Description

Paper Type Select from the list of supported paper types.

To edit the configuration information on the Paper tab:

1. Change the Paper Type if needed.

2. If you have completed all editing (including information on the other tabs),

click OK to save the changes and close the Edit Configuration window. (Or,

click Cancel to cancel all changes.)

3. To continue making changes to the Edit Configuration, click another tab and

make changes as needed.

March 2001 3-31

Page 62

Using Additional Calibration Features

Editing Information on the DP2 (NT Systems) or KPIS

(MACINTOSH Systems) Tab

The DP2 (or for MACINTOSH Systems, KPIS) tab specifies whether to activate

DP2 (or KPIS) interoperability, and if so, names the directory and filename

designated for the DP2 (or KPIS) information.

There are minor differences in the editing of DP2 and KPIS information.

Editing DP2 Information (NT Systems)

When you click the DP2 tab of the Edit Configuration window, the tab is displayed.

The values in the example are the default settings.

Attribute Description

Activate DP2 Indicates if the calibration procedure should generate a LUT file to be used with the

DP2 system. When you select Operations->Send LUT or Operations>Master

Balance, the LUTS are also sent to the DP2 location to be used with the DP2 system.

DP2 Location Directory to contain generated LUT files for use with DP2

DP2 Filena me Name of the file containing the DP2 LUT files

To edit the configuration information on the DP2 tab:

1. If DP2 is not already activated, click the Activate DP2 checkbox (click again

to deactivate) so that the dialog box looks like the example above.

2. To change the DP2 Location, type a new directory name or click Browse and

select another director y.

3. If needed, change the DP2 Filename.

4. If you have completed all editing (including information on the other tabs),

click OK to save the changes and close the Edit Configuration window. (Or,

click Cancel to cancel all changes.)

5. To make other changes to the Edit Configuration, click another tab and make

changes as needed.

3-32 March 2001

Page 63

Editing KPIS Information (MACINTOSH Systems)

If you are using the calibration output files with the KPIS system, it is necessary to

activate KPIS and assign a filename and location to the output file.

When you click the KPIS tab of the Edit Configuration window, the following tab is

displayed. The values in the example are the default settings.

Attribute Description

Using Additional Calibration Features

Activate KPIS

Indicates if the calibration procedure should generate a LUT file to be used with the KPIS

system

KPIS Location Directory to contain generated LUT files for use with KPIS

KPIS Filename Name of the file containing the KPIS LUT files

March 2001 3-33

Page 64

Using Additional Calibration Features

To edit the configuration information on the KPIS tab:

1. Click the Activate KPIS checkbox (click again to deactivate).

The display shows the Edit Configuration window with the default settings for

KPIS Location and KPIS Filename.

2. To change the directory for the KPIS file:

a. Click KPIS Location. The display shows the Select KPIS Folder dialog

box.

b. If needed, browse to find the folder you want.

c. Click Select “directoryname” (the example above shows Select

“KodakLED”).

3-34 March 2001

Page 65

Using Additional Calibration Features

The display shows the updated Edit Configuration window with updated

File Location of CalDisk:CompositeMachine:Tables:KodakLED.

Completing the Edit Configuration

When you finish editing the configuration file, click OK to save the attributes.

(Click Cancel to exit without saving your changes. MACINTOSH System users:

you can click Default at any time to reset the attributes to their factory defaults

and then click OK to save the defaults.)

March 2001 3-35

Page 66

Using Additional Calibration Features

Creating a Density File for Use with Calibration

During calibration, you have the option of obtaining density data from a file or by

scanning a processed test target through an X-RITE DTP 36 densitometer. The

option is determined by the entry in the device configuration file. If the

configuration file is set up to receive density data from a file and you are creating

the file:

1. Scan the print into your densitometer.

2. Save the data to file using the density data file format specification (see “File

Formats” below). The Kodak Device Calibration Software does not perform

this function.

3. Move the density data file that you just saved to the “Dens” folder within the

device folder for your specific device. The filename should match the Density

Source File selected on the Density Source tab of the Edit Configuration

window (see “Editing Information on the Density Source Tab” on page 3-28).

File Formats

NOTE: If a file contains data in a tabular format, each entry may be separated by

multiple spaces and tabs; however, when the file is saved by the application,

each group of multiple spaces and tabs is automatically converted to a

single tab.

DensityDataRaw (TECHNET Format)

Example:

R2340 G1000 B2010

R2350 G1010 B2020

R2360 G1020 B2030

R2370 G1030 B2040

3-36 March 2001

Page 67

Installing the Densitometer

This section describes how to install the X-RITE DTP 36 Densitometer, including

changing some of the attributes on the Edit Configuration window to

accommodate the densitometer.

IMPORTANT: The supported densitometers use a RS-232 interface for

communication to the host. Each platform uses different

designations to identify the RS-232 ports.

To install the densitometer:

1. Connect the appropriate cable (provided by the user, supplier or with the

densitometer) between the densitometer and the host computer.

NOTE:For the X-RITE DTP 36 Densitometer:

• Remove the protective strip (for shipping) from the densitometer.

• Verify that the densitometer is configured with the factory defaults. (Refer

to the densitometer manual for this information.)

• Perform an initial calibration of the densitometer. (Refer to the

densitometer manual.)

2. Run the calibration software for the printer and click the Edit icon to access

the Edit Configuration window; see “Editing the Device Configuration”

beginning on page 3-25.

3. Click the Density Source tab.

Using Additional Calibration Features

4. Edit the attribute for the Density Source. Select the appropriate choice for

your densitometer from the list.

5. Edit the attribute for the Density Source Port. Enter the name of the port that

the RS-232 cable is connected to on the host computer system.

Host System Default Port

MACINTOSH System Printer

WINDOWS NT System COM 1

6. Click OK to save the changes to the configuration.

IMPORTANT:Densitometers require calibration at regular intervals. Refer to

your densitometer manual or instructions on how to calibrate your

densitometer and perform a calibration.

March 2001 3-37

Page 68

Using Additional Calibration Features

3-38 March 2001

Page 69

4 Installing and Using the Centralized

Densitometer Application

IMPORTANT: This chapter pertains only to users of WINDOWS NT Systems.

The Centralized Densitometer Application topics covered in this section include:

• Installing the application on a WINDOWS NT System

• Modifying printer and port information

• Viewing graphs

Installing the Centralized Densitometer Application