Page 1

TECHNICAL DATA

/ PRINT FILM

EASTMAN Fine Grain Release

February 1999 • H-1-5302

A-009

Month 1996

Positive Film 5302

™

/ 7302

DESCRIPTION

EASTMAN Fine Grain Release Positive Film 5302 (35 mm)

and 7302 (16 mm) is a low-speed, high-resolutionprintfilm.

This blue-sensitive black-and-white film is designed for

general release printing. It is also useful for making both

positive and negative titles, and dubbing prints for sound.

BASE

This film has a clear acetate safety base with anti-static

protection, and a base thickness of 5.6 mils. In addition,

7302 Film has an anti-curl layer applied to the base.

DARKROOM RECOMMENDATIONS

Use a KODAK OA Safelight Filter / greenish yellow, with a

15-watt bulb, no closer to the film than 1.2 metres (4 feet).

STORAGE

Store unexposed film at 13˚C (55˚F) or lower. For extended

storage, store at -18˚C (0˚F) or below. Process exposed film

promptly. Store processed film according to the

recommendations in NAPM IT9.11-1992: for medium-term

storage (minimum of ten years), store at 25˚C (77˚F) or

lower at a relative humidity of 20 to 50 percent; for

extended-term storage (for preservation of material having

permanent value), store at 21˚C (77˚F) or lower at a relative

humidity of 20 to 50 percent; for extended-term storage (for

preservation of material having permanent value), store at

21˚C (70˚F) or lower at a relative humidity of 20 to 30

percent. For active use, store at 25˚C (77˚F) or lower at a

relative humidity of 50 ± 5 percent. Thisrelates to optimized

filmhandlingratherthanpreservation;static, dust-attraction,

and curl-related problems are generally minimized at the

higher relative humidity. After usage, the film should be

returned to the appropriate medium- or long-term storage

conditions as soon as possible.

For more information about medium- and long-term

storage, see NAPM IT9.11-1992, andKODAK Publications

H-1, KODAK Motion Picture Film, and

H-23, The Book of Film Care.

™

PRINTING CONDITIONS

You can make satisfactory prints using negatives of average

density if run on a continuous additive printer(such as aBell

& Howell Model C) at 180 feet per minute, equipped with a

1000-watt lamp at 80 volts dc (85 volts for 35 mm) and a

ground glass in the beam. Typical starting-point printer

settings are as follows:

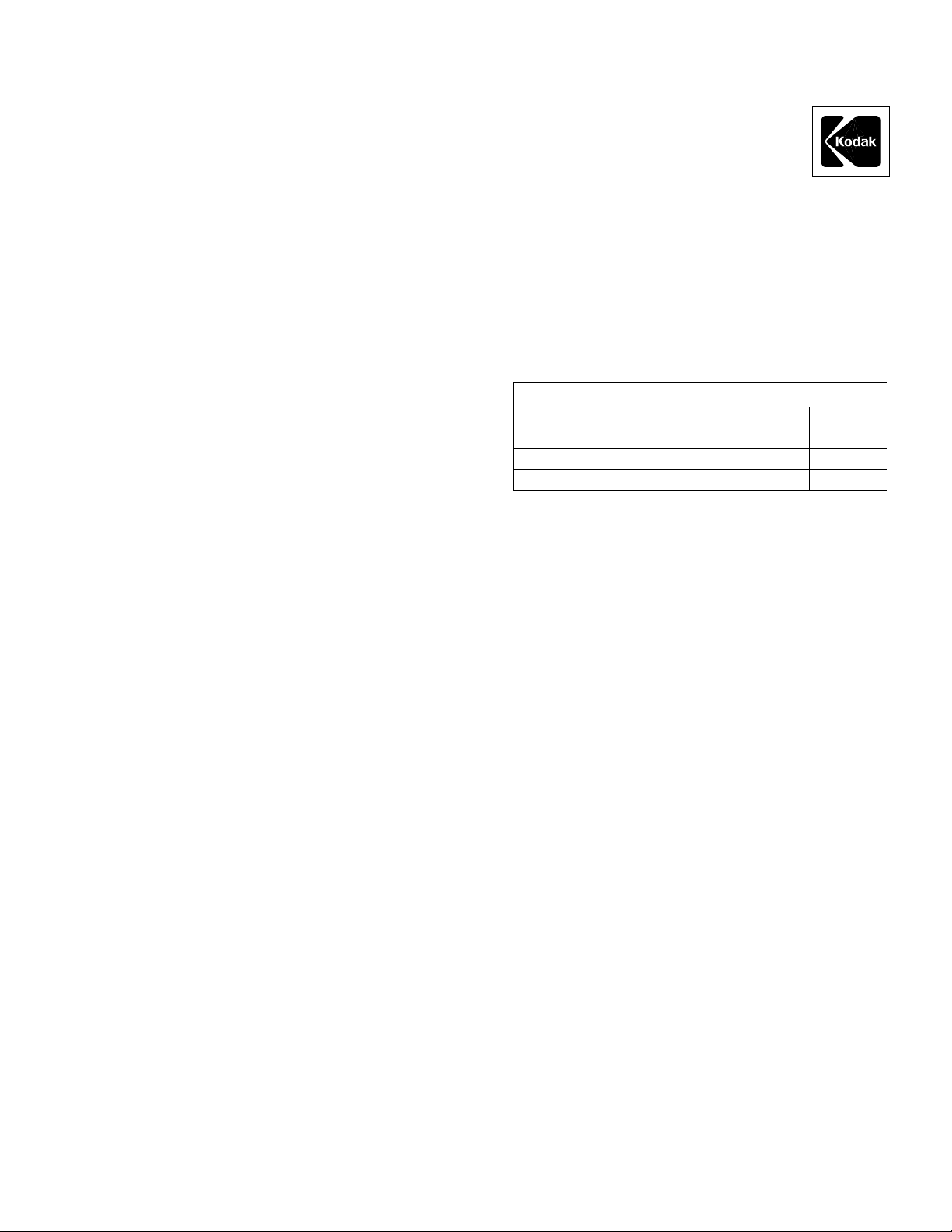

Trim Setting Tape Setting

Beam 16 mm 35 mm 16 mm 35 mm

Red 17 21 32 24

Green 17 21 32 24

Blue 17 21 32 24

For laboratories with subtractive printers, such as a

Bell & Howell Model J, use the following starting-point

recommendations for 16 mm film: 1000-watt lamp at

55 volts dc and a printer speed of 62 feet per minute. For

35 mm films with a Bell & Howell Model D Printer, use

these starting-point recommendations: 500-watt lamp at

75 volts dc and 90 feet per minute. For both 16 and 35 mm

setups, use a neutral density filter (such as the KODAK

WRATTEN NeutralDensityFilter,No. 96) with a density of

0.50 in the beam and a diaphragm setting of 13.

SOUND-TRACK PRINTING

A variable-area positive silver sound track can be printed on

5302 / 7302 Film from a negative sound record on

EASTMAN EXR Sound Recording Film 5378™ / 7378™.

The optimum variable-area sound-track density for the print

liesbetween 1.2and 1.4,measured visuallyfor both16 and

35 mm films. This print density is chosen to provide a good

compromise between signal-to-noise ratio and frequency

response. The densities of the sound-track negatives

requiredto produce optimal printdensities are determined by

using recognized cross-modulation test procedures.

©Eastman Kodak Company, 1997

Page 2

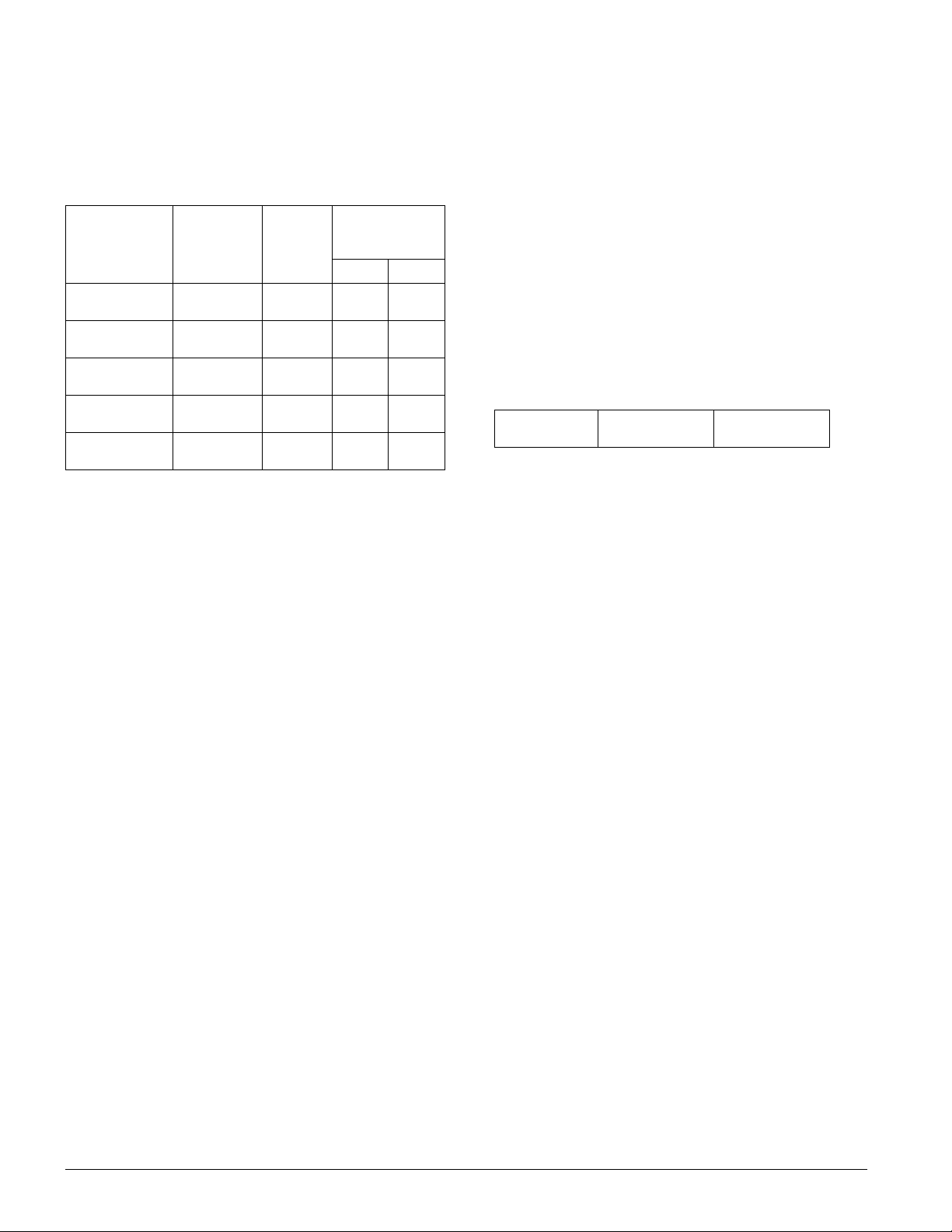

PROCESSING

Use the following process recommendations as starting

points for a typical continuous-immersion processor using

formulas presented in KODAK Publication No. H-24.15,

Manual for Processing EASTMAN Motion Picture Films,

Module 15. The processing times may require modification

for a particular machine.

LUBRICATION

All films destined for projection require some lubrication to

prevent problems during early projection life. Edge waxing

with a paraffin wax solvent solution provides a simple,

inexpensive, and adequate lubrication for 35 and 70 mm

projection prints. For 8 and 16 mm prints, an overall

lubricant may be required.

Replenishment

Processing

Step

KODAK

Developer D-97*

Stop Rinse‡

KODAK

Fixing Bath F-5*

Wash

(countercurrent)

Dry

* Agitation in the developer and in the fixing bath should be by

recirculation through submerged spray jets that impinge on the film

strands.

† Develop to the recommended control gamma of 2.4 to 2.6 Status M

Densitometry (Blue).

‡ Fixer-laden water overflow from the first wash tank (pH approximately

6.0).

§ Drying depends on many factors such as air temperature, relative

humidity (RH), volume, rate and distribution of the air flow, final

squeegeeing, etc. In a conventional convectional-type drying cabinet

with air at about 35˚F (95˚C) and 40- to 50-percent RH, drying will take

15 to 20 minutes. In an impingement-type drying cabinet, however, with

a higher temperature and lower RH, drying time is greatly reduced. WIth

either type of dryer, the film should be dry without tackiness

the way through. Upon cooling to room temperature after leaving the

dryer,the film should be at equilibrium with the room air atapproximately

50-percent RH.

Temperature

˚C (˚F)

21 ± 0.3

(70 ± 0.5)

21 ± 1

(70 ± 2)

21 ± 1

(70± 2)

21 ±1

(70 ± 2)

35

(95)

Time

(min:sec)

†

0:50 12,000 6,000

6:00 600 300

10:00 12,000 6,000

§

Rate

(mL per 100 ft)

35 mm 16 mm

650

(D-97R)

——

325

(D-97R)

1

⁄2to2⁄3 of

Notice: Observe precautionary information on product

labels and on Material Safety Data Sheets.

IMAGE STRUCTURE

The modulation-transfer curves, the diffuse rms granularity,

and the resolving power data were generated from samples

of 5302 Film exposed with tungsten light and processed as

recommended in KODAK Developer D-97 at 21˚C (70˚F) to

the recommended control gamma. For more information on

image-structure characteristics, see KODAK Publication

No. H-1, KODAK Motion Picture Film.

Diffuse RMS Granularity* 8

Resolving

Power†

* Read at a net diffuse visual density of 1.0, using a 48-

micrometre aperture.

† Determined according to a method similar to the one described

in ISO 6328-1982,

Determination of ISO Resolving Power.

TOC 1.6:1

TOC 1000:1

Photography—Photographic Materials—

63 lines/mm

125 lines/mm

2 EASTMAN Fine Grain Release Positive Film 5302™ / 7302™ • H-1-5302

Page 3

Characteristic Curves

4.0

y

Exposure:

Process:

D-97, at 21 C (70 F)

Densitometry:

GAMMA

3.4

3.2

3.0

2.8

2.6

2.4

2.2

2.0

Visual

2

DEVELOPMENT TIME

Time-

Gamma

Time-Fog

46810

3.0

2.0

DENSITY

1.0

0.0

1.0

Spectral-Sensitivity Curves

1.0

D=0.3 Above

gross fog

0.0

*

_

1.0

_

LOG SENSITIVITY

2.0

_

3.0

D=1.0 Above

gross fog

*Sensitivity = reciprocal of exposure (ergs/cm ) required

Characteristic Curves

Tungsten

KOKAK Developer

Diffuse

NET

FOG

0.10

0.00

(Minutes)

0.0

LOG EXPOSURE (lux-seconds)

Effective Exposure:

1.4 seconds

Process:

D-97 at 21 C(70 F) to

recommended control

gamma

Densitometry:

WAVELENGTH (nm)

to produce specified density

9 min.

7 min.

5 min.

3 1/2 min.

2 min.

2.01.0

KODAK Developer

Diffuse Visual

2

3.0

F010_0023AC

700 750650600550500450400350300250

F010_0024AC

Modulation-Transfer Curve

200

100

70

50

30

20

10

Effective Exposure:

7

1.4 seconds

5

RESPONSE (%)

Process:

D-97 at 21 C(70 F) to

3

recommended control

2

gamma

Densitometry:

KODAK Developer

Diffuse Visual

1

1001 2 3 4 5 10 20 50 200 600

SPATIAL FREQUENCY (cycle/mm)

F010_0025AC

Notice: While the data presented are typical of production

coatings, they do not represent standards which must be met

by Kodak. Varying storage, exposure, and processing

conditionswill affect results. Thecompanyreserves the right

to change and improve product characteristics at any time.

These photographic modulation-transfer values were

determined by using a method similar to the one described in

ANSI Standard PH2.39-1977(R1990). The film was

exposed with the specified illuminant to spatially varying

sinusoidal test patterns having an aerial image modulation of

a nominal 35 percent at the image plane, with processing as

indicated. In most cases, the photographic modulationtransfer values are influenced by development-adjacency

effects and are not equivalent to the true optical modulationtransfer curve of the emulsion layer in the particular

photographic product.

EASTMAN Fine Grain Release Positive Film 5302™ / 7302™ • H-1-5302 3

Page 4

EASTMAN Fine Grain Release Positive Film 5302™ / 7302™

KODAK LOCATIONS

FOR DIRECT ORDERING IN THE UNITED STATES:

1-800-621-FILM

FOR DIRECT ORDERING IN CANADA:

1-800-621-FILM

ATLANTA, GEORGIA

4 Concourse Parkway

Suite 300

Atlanta, Georgia 30328-6105

Information: 800-800-8398

CHICAGO, ILLINOIS

815 West Van Buren, Suite 320

Chicago, Illinois 60607

Information: 312-492-1423

DALLAS, TEXAS

11337 Indian Trail

Dallas, Texas 75229

Information: 972-481-1170

312-492-1423

HOLLYWOOD, CALIFORNIA

6700 Santa Monica Boulevard

P. O. Box 38939

Hollywood, California 90038-1203

Information: 323-464-6131

NEW YORK, NEW YORK

360 West 31st Street

New York, New York 10001-2727

Information: 212-631-3450

MONTREAL, CANADA

Kodak Canada Inc.

4 Place du Commerce, Suite 100

1le des Soeurs

Verdun, Quebec, Canada, H3E 1J4

Information: 514-761-7001

TORONTO, CANADA

Kodak Canada Inc.

3500 Eglinton Avenue West

Toronto, Ontario, Canada, M6M 1V3

Information: 416-761-4922

VANCOUVER, CANADA

Kodak Canada Inc.

4185 Still Creek Drive, Suite C150

Burnaby, British Columbia, Canada, V5C 6G9

Information: 604-570-3526

KODAK On Line At:

http://www.kodak.com/go/motion

LATIN AMERICAN REGION

8600 NW 17th Street, Suite 200

Miami, Florida 33126

Information: 305-507-5656

EASTMAN Fine Grain Release Positive

Film 5302™ / 7302™

KODAK Publication No. H-1-5302

CAT 831 2100

Professional

Motion Imaging

Kodak, Eastman, 5302, 7302, Wrratten, 5373, 7373,

and D-97 are trademarks

Minor Revision 2/99

Printed in U.S.A.

Loading...

Loading...