Knight Equipment RMP-300 Installation Manual

RMP-300 Digital

Instruction Manual

A101453 Rev: x1 (4/11) Page 1 of 24

TABLE OF CONTENTS

Specifications ....................................................................................................... 3

Unit and Remote Dimensions ............................................................................... 4

Package List ......................................................................................................... 5

Installation Diagram .............................................................................................. 6

Installation and Assembly

Mounting..................................................................................................... 7

Plumbing .................................................................................................. 8-9

Dry Detergent Plumbing .......................................................................... 10

Probe Installation ................................................................................. 10-11

Product Wiring ..................................................................................... 12-13

Operation ....................................................................................................... 14-16

Programming ................................................................................................. 17-22

Declaration of Conformity……………………………………………………………..23

Warranty ............................................................................................................. 24

SAFETY SYMBOL EXPLANATIONS

Listed below are explanations of the safety symbols that appear either on the unit, in the instruction manual, or both.

Please familiarize yourself with the meaning of each symbol.

GENERAL CAUTION: This symbol indicates a general safety caution.

Page 2 of 24 A101453 Rev: x1 (4/11)

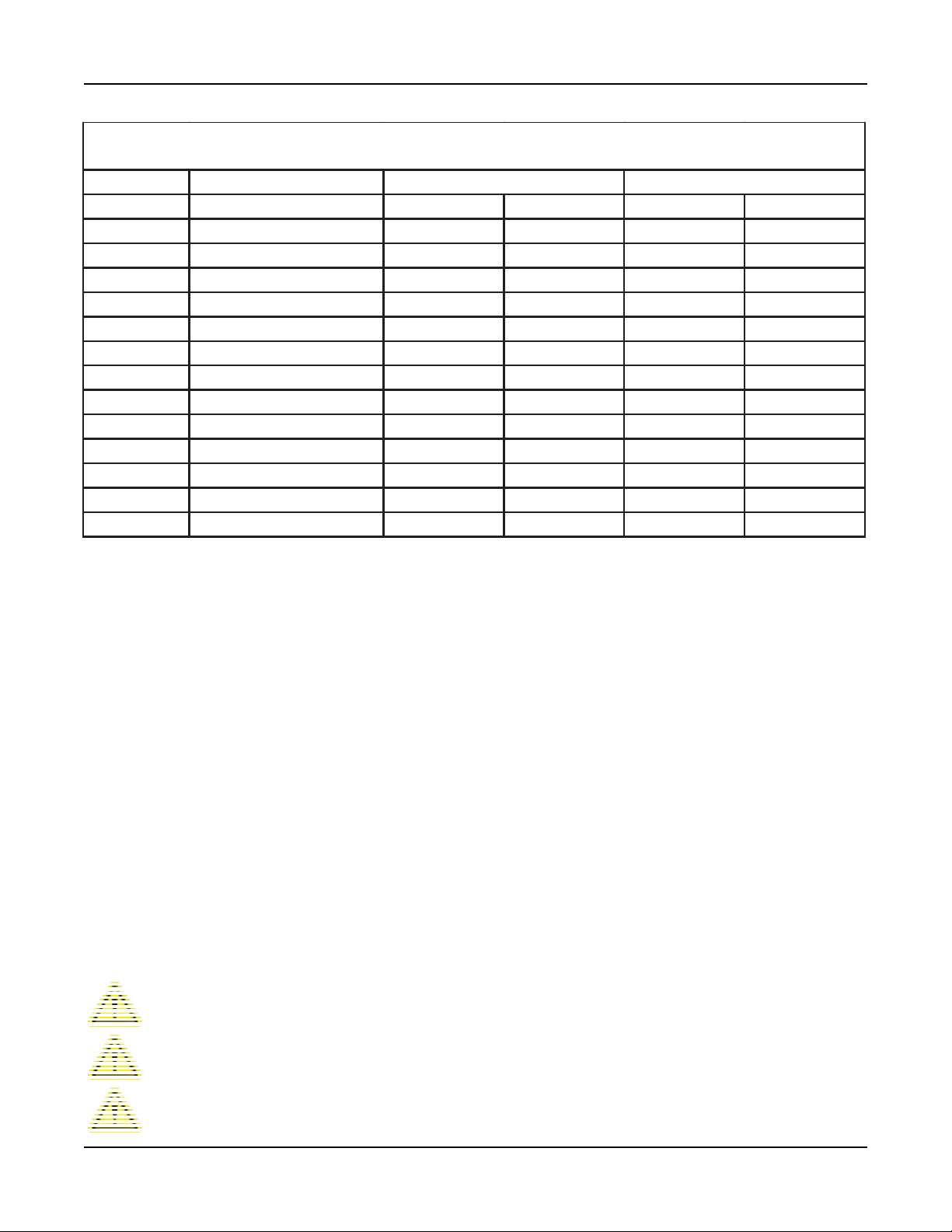

SETTING GUIDE

RMP VALUE RANGES

MODE DESCRIPTION

DetConcen Detergent Concent ration 0 - 100K 0 - 100K N/A N/A

AlarmDelay Alarm Delay 0 - 512s 0 - 512s N/A N/A

Rac k Ti me Rac k Time N/ A 0 - 30 s N/ A 0 - 3 0s

InitCharge Initial Charge N/A N/A 0 - 64s 0 - 128s

Recharge Recharge N/A N/A 0 - 20s 0 - 20s

RecAfRac ks Recharge After N Rack s N/A N/A 0-5 0-5

RinseDelay Rins e Delay 0 - 14s N/A 0 - 14s N/A

RinseLimit Rinse Limit 0 - 30s N/A 0 - 30s N/A

ResetRackCNT Reset Rack Count Y/N Y/N Y/N Y/N

ResetInitCNT Reset Initial Charge Count N/A N/A Y/N Y/N

InitChaRepeat Initial Charge Repeat N/A N/A Y/N Y/N

SanRunWith Sanitizer Run With Det/Rinse Det/Rinse Det/Rinse Det/Rinse

SanSpeed Sanitizer S peed 0 -100% 0 -100% 0 -100% 0 -100%

PROBE MODE PROBELESS MODE

DOOR CONVEYOR DOOR CONVEYOR

SPECIFICATIONS

Pollution degree ................................................................................................ 2

Installation category ......................................................................................... 2

Altitude .............................................................................. <2187 yard (<2000 m)

Humidity ......................................................................................... 50% to 80%

Electrical supply

Main supply voltage fluctuations are not to exceed 10 percent of the

nominal supply voltage Indoor use only

Replacement Fuse…………………….1Amp, 250V, 5x20mm, Fast-Acting

Ambient Temperature

Rinse flow rate ............................................... .1-1.5 oz/min (3-45 ml/min)

Detergent flow rate ................................................ 7.8 oz/min (230 ml/min)

Sanitizer flow rate .............................................. .2-3 oz/min (6-90 ml/min)

Main Unit Weight ........................................................................ 8 lb. (3 kg)

SAFETY PRECAUTIONS

CAUTION: Wear protective clothing and eyewear when dispensing chemicals or other

materials. Observe safety handling instructions (MSDS) of chemical mfrs.

........................................... 115, 208, or 230 Vac, 50/60 Hz

..................................... 41°F to 104°F (5°C to 40°C )

CAUTION: To avoid severe or fatal shock, always disconnect main power when

servicing the unit.

CAUTION: When installing any equipment, ensure that all national and local safety,

electrical, and plumbing codes are met.

A101453 Rev: x1 (4/11) Page 3 of 24

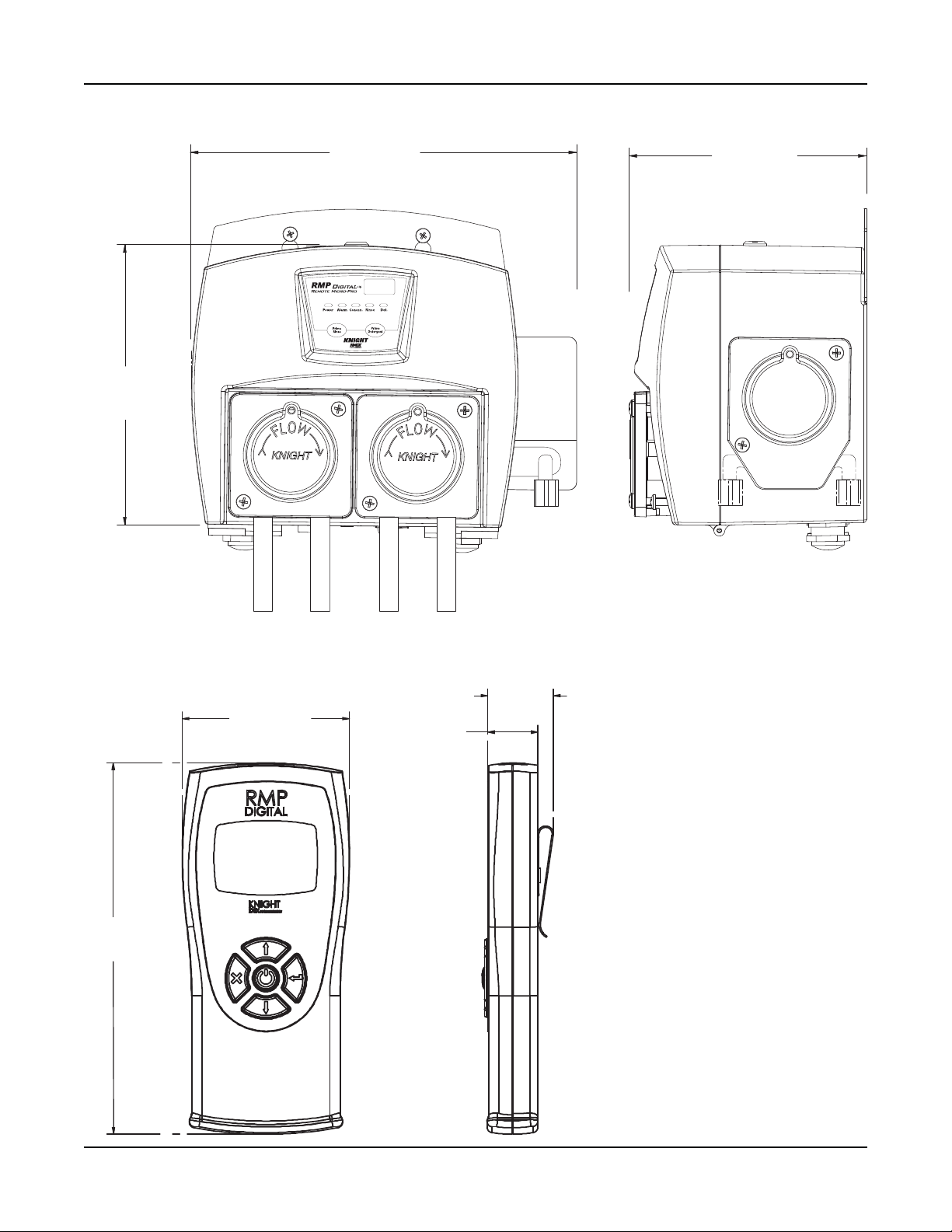

MAIN UNIT DIMENSIONS

”

7.088”

(180 mm)

9.75”

(248 mm)

6.041”

(153 mm)

REMOTE DIMENSIONS

2.528”

(64 mm)

5.620”

(143 mm)

.994

(25 mm)

.758”

(19 mm)

Page 4 of 24 A101453 Rev: x1 (4/11)

PACKAGE CHECKLIST

1

4

3

2

7

8

10 12 13 11

1. 1/4 “ Poly-tubing, 6 meters (7005190)

2. RMP-300D

3. RMP Remote (7150000)

Note: Not included in all RMP

4. Mounting Plate (A100609)

5. Pick-up tube (7020180)

6. Instruction Manual (A101453)

7. Check Valve, 1/4 tube (7901320)

8. 2 x Flat head rolling screw (S100076)

5

6

9

15

14

9. 2 x Expansion screw: includes wall anchor

and screw (7600121)

10. Probe: includes gasket & nut lock (7005190)

11. 2 x Bullet connector, blue (0300650)

12. 2 xTerminal ring tongue (2000682)

13. 4 x Nut, #8-32, hex, S.S. (1400438)

14. 4 x Tie wrap

15. Bulkhead fitting (7023342)

A101453 Rev: x1 (4/11) Page 5 of 24

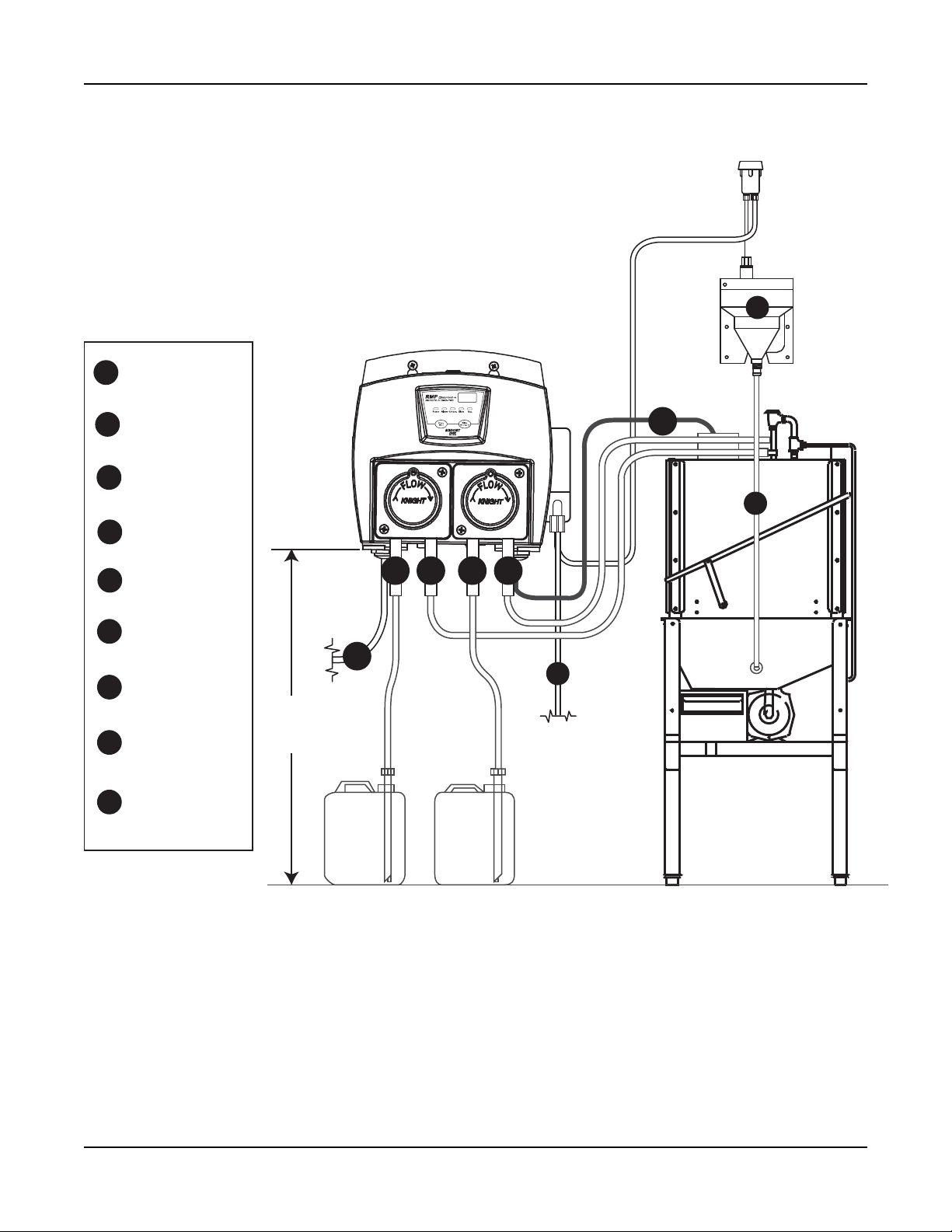

INSTALLATION DIAGRAM (RMP-300)

A

Rinse Suction

I

Rinse Discharge

B

Sanitizer Suction

C

Sanitizer

D

Discharge

E

Power

Rinse & Detergent

F

Signals

Water

G

Detergent

H

Discharge

Powder/Solid

I

type feeder

MAX

2 m

A B C D

E

Rinse

F

H

G

Sanitizer

Page 6 of 24 A101453 Rev: x1 (4/11)

INSTALLATION & ASSEMBLY

MOUNTING

Mount the unit on a nearby wall (using suitable

hardware) or on top of the dishwasher if desired.

Try to keep the unit within three feet from the

final rinse line to avoid long tubing runs.

CAUTION: Do not mount the unit in the

direct path of steam. This can short

circuit and permanently damage the

unit. Mounting the unit on the side, on

the back, or on the vents of the

dishwasher may cause thermal

overload and damage or hinder the

performance of the unit.

Check all applicable plumbing and

electrical codes before proceeding with

the installation. This will help to ensure

that the system is installed in safe and

suitable manner. A wiring schematic of

the dishwasher should be used as

reference for making electrical

connections — this is typically provided

by the dishwasher manufacturer if one

cannot be located on the machine itself.

Step 2: Pre-drill pilot holes at the marked

location. Insert wall anchor into the wall. Screw

expansion screw (10) into wall anchor in wall.

Step 3: Install mounting bracket on back of

RMP dispenser (2) using flat head rolling screw

(8).

Step 1: Use level to mark hole location for

mounting bracket (4)

Step 4: Hang unit on two screws installed in

step 2

A101453 Rev: x1 (4/11) Page 7 of 24

INSTALLATION & ASSEMBLY

PLUMBING

LIQUID RINSE & SANITIZER PLUMBING

Step 1: Insert 1/4" OD poly tube (1) in suction

(left) side of the peristaltic pump.

Step 2: Secure with tie wrap (14)

Step 4: Insert suction end of 1/4" OD poly tube

into pick-up tube (5)

Step 5: Insert poly-tube to the end of 1/4" OD

poly tube leaving 5 mm from the end of the tube.

Step 3: Cut 1/4" OD poly tube to the appropriate length from pump to chemical container

Page 8 of 24 A101453 Rev: x1 (4/11)

Step 6: Tighten grey compression nut on top of

pick-up tube to secure poly-tube in place.

Loading...

Loading...