Page 1

Wire Pulling griP guide

FOR DISTRIBUTION AND TRANSMISSION APPLICATIONS

Bare Conductor

Covered Conductor Wire Rope Guy Strand

Page 2

Original Klein® Grip,

patented in 1892

WARNINGS:

• Gripsaretobeusedfortemporaryinstallation,notforpermanentanchorage.

• Whenusedonornearenergizedlines,ground,insulateorisolategripbeforepulling.

• Donotexceedratedcapacity.

• Alwaysmatchpropersizeandtypeofgriptoapplication.

• Beforeeachuse,cleanjawareaandinspectgripforproperoperationtoavoidslippage.

Section Application

Grip Recommendation

Klein Tools offers a free service of recommending the proper grip for a particular application based on a sample of cable. All that is required is a

minimum 6'-9' (2-3 meters) length of cable.

If there is ever a question about the safe condition of any grip, contact Customer Service at 847.821.5500 or 800.553.4676 or email HiSupport@kleintools.com.

DISTRIBUTION ................... 1-2

BARE CONDUCTORS ..................... 1

C

OVERED CONDUCTORS

................ 2

WIRE ROPE (STEEL) ................... 3

GUY STRAND & EHS

................. 4

WIDE RANGE GRIPS .................... 5

TRANSMISSION ...................... 6-13

ACSR .........................................6-7

AAC ............................................8-9

ACSS ......................................10-11

ACSS/TW ................................12-13

RELATED PRODUCTS .................... 14

RECOMMENDED CARE ................. 15

COMMON OVERHEAD

APPLICATIONS ........................16-17

www.kleintools.com

Page 3

www.kleintools.com

See Wire Pulling Grip Warnings on the inside cover.

All dimensions are in inches (millimeters).

Distribution

BARE CONDUCTORS

Chicago

TM

Grips

Authentic Chicago Grips are designed for

use on aluminum, copper and ACSR.

•

Lockingloophandlesallowthejaws

tobeheldinanopenpositionfor

easy

placementonwireorcable.

Pulls #6 and #8 bare copper

wire without damaging

or deforming the cable.

Grip Outside Diameter Safe Load

1613-35 #6-#8 Copper 4,500 lbs.

1656-20 .20" - .40"

(5.08 mm - 10.16 mm)

1656-30 .31" - .53"

(7.88 mm - 13.46 mm)

1656-40 .53" - .74"

(13.46 mm - 18.79 mm)

1656-50 .74" - .86"

(18.80 mm - 21.84 mm)

1656-60 .86" - .96"

(21.84 mm - 24.38 mm)

4,500 lbs.

4,500 lbs.

8,000 lbs.

8,000 lbs.

8,000 lbs.

(2,041 kg)

(2,041 kg)

(2,041 kg)

(3,629 kg)

(3,629 kg)

(3,629 kg)

1613-35

Cat. No. Hot Latch

4,500 lbs. (2,041 kg) Maximum Safe Load

1613-35 1613-35H NA #6 and #8 AWG Bare Copper 4-3/16" (106 mm) 6.25 lbs. (2.8 kg)

1656-20 1656-20H S1656-20H .20" - .40" (5.08 mm - 10.16 mm) 4" (102 mm) 3.0 lbs. (1.36 kg)

1656-30 1656-30H S1656-30H .31" - .53" (7.88 mm - 13.46 mm) 4-3/4" (121 mm) 3.75 lbs. (1.70 kg)

8,000 lbs. (3,629 kg) Maximum Safe Load

1656-40 1656-40H S1656-40H .53" - .74" (13.46 mm - 18.79 mm)

1656-60 1656-60H S1656-60H .86" - .96" (21.84 mm - 24.38 mm)

Model No.

Hot Latch/Spring

Model No.

Min. to Max. Cable

Diameter inches (mm)

1656-301656-40H

Jaw

Length

5-1/2" (140 mm) 8.30 lbs. (3.76 kg)1656-50 1656-50H S1656-50H .74" - .86" (18.80 mm - 21.84 mm)

See Wire Pulling Grip Warnings on the inside cover.

Approx.

Weight

Each

www.kleintools.com

1

Page 4

www.kleintools.com

All dimensions are in inches (millimeters).

See Wire Pulling Grip Warnings on the inside cover.

Distribution

COVERED CONDUCTORS

Chicago

TM

Grips for Covered Cable

“Smiley Jaw”

•

Speciallymachinedserpentinejawsallow

use

oninsulatedconductors.

•

Eliminatesnecessityofstripping

insulation

fromconductor.

Coming in 2016

A grip specifically designed to pull spacer

cable or tree wire like Hendrix®.

1659-30

Grip Outside Diameter Safe Load

1659-20 .20" - .40"

(5.1 mm - 10.2 mm)

1659-30 .31" - .53"

(7.9 mm - 13.5 mm)

1659-40 .49" - .79"

(12.45 mm - 20.1 mm)

1659-50 .79" - 1.0"

(20.1 mm - 25.6 mm)

4,500 lbs.

4,500 lbs.

8,000 lbs.

8,000 lbs.

(2,041 kg)

(2,041 kg)

(3,629 kg)

(3,629 kg)

Hendrix® is a registered trademark of Marmon Utility, LLC.

Cat. No. Min. to Max. Cable

4,500 lbs. (2,041 kg) Maximum Safe Load

1659-20 .20" - .42" (5.08 mm - 10.67 mm) 4-3/16" (106 mm) 3 lbs. (1.36 kg)

1659-30 .31" - .50" (7.87 mm - 12.70 mm) 4-3/4" (121 mm) 3.75 lbs. (1.70 kg)

8,000 lbs. (3,629 kg) Maximum Safe Load

1659-40 .49" - .79" (12.45 mm - 20.07 mm)

1659-50 .79" - 1.0" (20.07 mm - 25.56 mm)

2

Diameter inches (mm)

Jaw

Length

5-11/16" (144 mm) 7.75 lbs. (3.52 kg)

Approx.

Weight

Each

Page 5

www.kleintools.com

See Wire Pulling Grip Warnings on the inside cover.

All dimensions are in inches (millimeters).

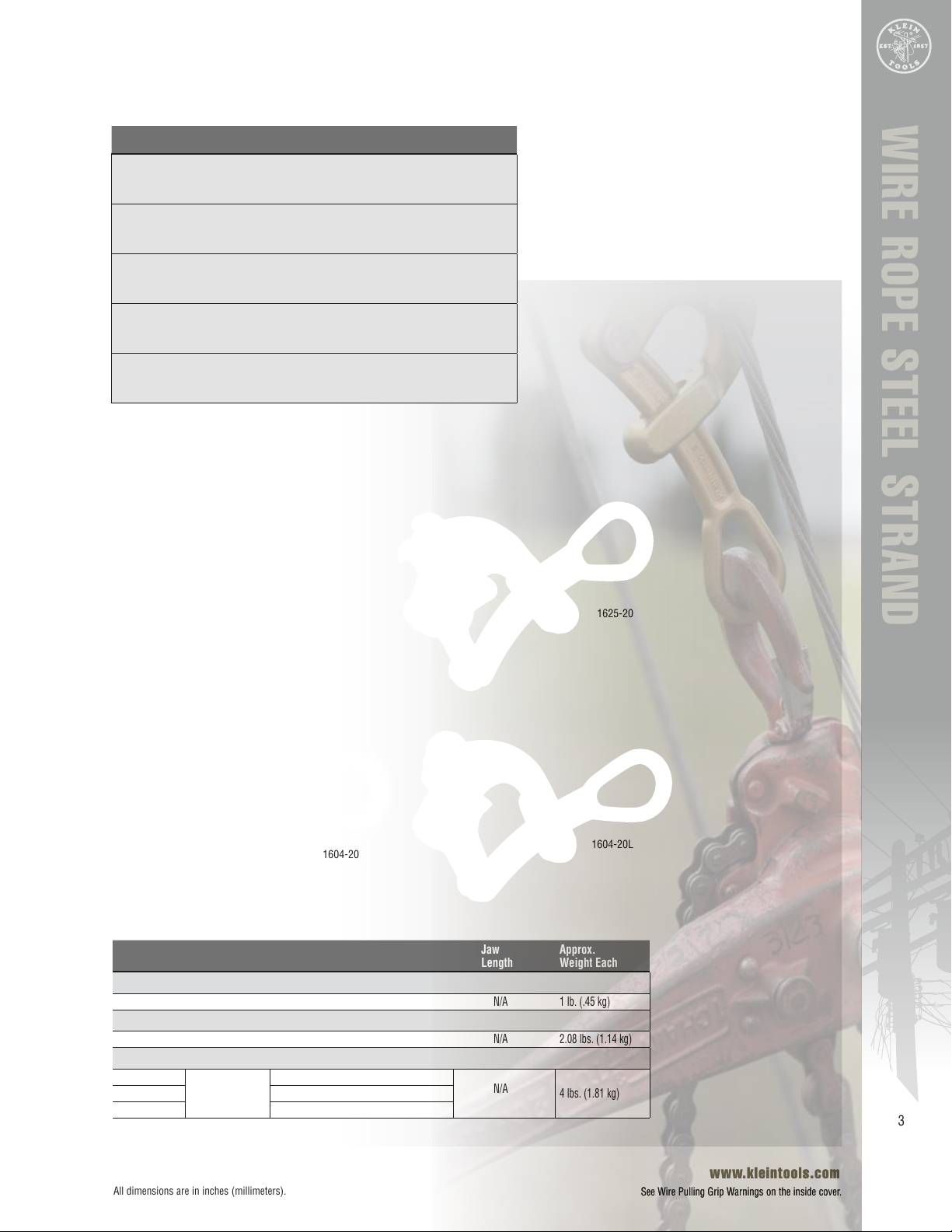

Wire rope Steel Strand

WIRE ROPE (STEEL)

1625-20

1604-20

1604-20L

Grip Outside Diameter Safe Load (lbs.)

1604-10 1/16" - 3/16"

(1.59 mm - 4.76 mm)

1604-20L 1/8" - 1/2"

(3.18 mm - 12.70 mm

1625-20 5/16" - 3/4"

(7.94 mm - 19.05 mm

1625-20 7/8 7/16" - 7/8"

(11.11 mm - 22.23 mm)

1625-20 1 1/2" - 1"

(12.70 mm - 25.4 mm)

2,500 lbs.

5,000 lbs.

8,000 lbs.

8,000 lbs.

8,000 lbs.

Haven’sTM Grips

“Pork Chop”

Haven’s Grips are designed for use when

a light, compact grip is desired where

conductor deformation is not a factor.

Gripping pressure of the knurled jaw is

•

applied to 1/4" (6.35 mm) cable area.

All 1625 series have a swing latch

•

to help hold cable in the jaw.

(1,134 kg)

(2,268 kg)

(3,629 kg)

(3,629 kg)

(3,629 kg)

Cat. No. Latch

2,500 lbs. (1,134 kg) Maximum Safe Load

1604-10 NA .06" - .25" (1.52 mm - 6.35 mm) N/A 1 lb. (.45 kg)

5,000 lbs. (2,268 kg) Maximum Safe Load

1604-20 1604-20L .125" - .50" (3.18 mm - 12.70 mm) N/A 2.08 lbs. (1.14 kg)

8,000 lbs. (3,629 kg) Maximum Safe Load

1625-20

1625-20 1 .50" - 1.00" (12.70 mm - 25.40 mm)

Model

Latch Included

Min. to Max. Cable

Diameter inches (mm)

.28" - .75" (7.11 mm - 19.05 mm)

Jaw

Length

N/A

Approx.

Weight

4 lbs. (1.81 kg)1625-20 7/8 .38" - .88" (9.65 mm - 22.35 mm)

Each

3

www.kleintools.com

See Wire Pulling Grip Warnings on the inside cover.

Page 6

www.kleintools.com

See Wire Pulling Grip Warnings on the inside cover.

Distribution

GUY STRAND &

GUY STRAND / EHS

Coming in 2016

A grip specifically designed to

pull coated guy strand larger

than .50" (12.70 mm).

•

Sawtoothjawprofileprovides

extra

grippingpower.

1613-40

1628-16

1684-5C

EHS

Grip Outside Diameter Safe Load (lbs.)

(

EXTRA HIGH-STRENGTH)

1613-40 1/8" - 5/16"

(3.05 mm - 9.40 mm)

1684-5C 3/16" - 1/2"

(4.06 - 13.97 mm)

1628-16 5/16" - 9/16"

(7.94 mm - 14.29 mm)

1628-17 1/2" - 3/4"

(12.70 mm - 19.05 mm)

1628-18 3/4" - 1"

(19.05 mm - 25.4 mm)

4,500 lbs.

8,000 lbs.

15,000 lbs.

15,000 lbs.

15,000 lbs.

(2,041 kg)

(3,629 kg)

(6,803 kg)

(6,803 kg)

(6,803 kg)

Cat. No. Hot Latch

4,500 lbs. (2,041 kg) Maximum Safe Load

1613-40 1613-40H S1613-40H .12" - .37" (3.05 mm - 9.40 mm) 4-3/16" (106 mm) 3 lbs. (1.36 kg)

8,000 lbs. (3,629 kg) Maximum Safe Load – EHS Specic

1684-5C NA NA .160" - .550" (4.06 - 13.97 mm) 5" (127 mm) 6.25 lbs. (2.84 kg)

15,000 lbs. (6,803 kg) Maximum Safe Load

1628-16

1628-17 .50" - .75" (12.70 mm - 19.05 mm) 16.30 lbs. (7.40 kg)

4

1628-18 .75" - 1.00" (19.05 mm - 25.40 mm) 15.70 lbs. (7.10 kg)

All dimensions are in inches (millimeters).

Model No.

NA NA

Hot Latch/Spring

Model No.

Min. to Max. Cable

Diameter inches (mm)

.31" - .62" (7.87 mm - 15.75 mm)

Jaw

Length

7-1/4" (184 mm)

Approx.

Weight

Each

15.30 lbs. (7.00 kg)

Page 7

www.kleintools.com

See Wire Pulling Grip Warnings on the inside cover.

All dimensions are in inches (millimeters).

WIDE RANGE GRIPS

•

Latchhelpsmaintaincableposition.

•

Large-diametereyeaccommodateslarge

hooks

onhoists,winchesandtackleblocks.

•

Designedforuseonbareconductorcables.

KT4500

KT4502

KT4650

Grip Outside Diameter Safe Load (lbs.)

WIDE RANGE GRIPS

KT4500 .18" - .60"

(4.57 mm - 15.2 mm)

KT4650 .16" - .90"

(4.00 mm - 23.0 mm)

KT4600 .30" - .80"

(7.62 mm - 20.3 mm)

KT4800 .70" - 1.25"

(17.8 mm - 31.8 mm)

5,000

5,000

(2,268 kg)

(2,268 kg)

10,000

12,000

(4,536 kg)

(5,443 kg)

Cat. No. Min. to Max. Cable

5,000 lbs. (2,268 kg) Maximum Safe Load

KT4500

KT4502

KT4650

KT4652

10,000 lbs. (4,536 kg) Maximum Safe Load

KT4600

KT4602

12,000 lbs. (5,443 kg) Maximum Safe Load

KT4800

KT4802

Diameter inches (mm)

.180" - .600" (4.57 mm - 15.2 mm)

.160" - .900" (4.00 mm - 23.0 mm)

.300" - .800" (7.62 mm - 20.3 mm)

.700" - 1.25" (17.8 mm - 31.8 mm)

Hot

Latch

● ● ●

●

● ●

● ● ●

●

● ● ●

●

Spring Locking

●

●

●

●

Handle

Jaw

Length

4" (101.3 mm) 3.75 lbs. (1.70 kg)KT4501

4-1/2" (114 mm) 4.90 lbs. (2.22 kg)

5" (127 mm) 7 lbs. (3.18 kg)KT4601

5-1/8" (130 mm) 9 lbs. (4.1 kg)KT4801

Approx.

Weight

www.kleintools.com

See Wire Pulling Grip Warnings on the inside cover.

Each

5

Page 8

AWG or MCM Size Diameter inches (mm) No. of Alum. & Steel Strands Code Word Grip

Safe Load

605 MCM .966" (24.54 mm) 26x7 Squab 1628-30P

605 MCM .994" (25.25 mm) 30x7 Wood Duck 1628-30P

605 MCM .994" (25.25 mm) 30x19 Teal 1628-30P

636 MCM .940" (23.88 mm) 18x1 Kingbird 1628-30O

636 MCM .977" (24.82 mm) 24x7 Rook 1628-30P

636 MCM .991" (25.17 mm) 26x7 Grosbeak 1628-30P

636 MCM 1.019" (25.88 mm) 30x7 Scoter 1628-30R

636 MCM 1.019" (25.88 mm) 30x19 Egret 1628-30R

666.6 MCM 1.000" (25.40 mm) 24x7 Flamingo 1628-30P

666.6 MCM 1.014" (25.76 mm) 26x7 Gannet 1628-30P

715.5 MCM 1.051" (26.70 mm) 26x7 Starling 1628-30R

715.5 MCM 1.081" (27.46 mm) 30x19 Redwing 1628-30S

795 MCM 1.040" (26.42 mm) 36x1 Coot 1628-30R

795 MCM 1.063" (27.00 mm) 45x7 Tern 1628-30R

795 MCM 1.092" (27.74 mm) 54x7 Condor 1628-30S

795 MCM 1.092" (27.74 mm) 24x7 Cuckoo 1628-30S

795 MCM 1.107" (28.12 mm) 26x7 Drake 1628-30S

795 MCM 1.140" (28.96 mm) 30x19 Mallard 1628-30S

900 MCM 1.131" (28.73 mm) 45x7 Ruddy 1628-30S

900 MCM 1.162" (29.52 mm) 54x7 Canary 1628-30T

954 MCM 1.165" (29.59 mm) 45x7 Rail 1628-30T

954 MCM 1.165" (29.59 mm) 20x7 Corncrake 1628-30T

954 MCM 1.175" (29.85 mm) 48x7 Towhee 1628-30T

954 MCM 1.196" (30.38 mm) 54x7 Cardinal 1628-30T

954 MCM 1.196" (30.38 mm) 24x7 Redbird 1628-30T

1033.5 MCM 1.212" (30.79 mm) 45x7 Ortolan 1628-30U

1033.5 MCM 1.245" (31.62 mm) 54x7 Curlew 1628-30U

1113 MCM 1.258" (31.95 mm) 45x7 Bluejay 1628-30U

1113 MCM 1.292" (32.82 mm) 54x19 Finch 1628-40W

1192.5 MCM 1.302" (33.07 mm) 45x7 Bunting 1628-40W

1192.5 MCM 1.337" (33.96 mm) 54x19 Grackle 1628-40X

1272 MCM 1.317" (33.45 mm) 36x1 Skylark 1628-40W

1272 MCM 1.345" (34.16 mm) 45x7 Bittern 1628-40X

1272 MCM 1.381" (35.08 mm) 54x19 Pheasant 1628-40X

1351.5 MCM 1.386" (35.20 mm) 45x7 Dipper 1628-40X

1351.5 MCM 1.424" (36.17 mm) 54x19 Martin 1628-40Y

1431 MCM 1.427" (36.25 mm) 45x7 Bobolink 1628-40Y

1431 MCM 1.465" (37.21 mm) 54x19 Plover 1628-40Z

1590 MCM 1.504" (38.20 mm) 45x7 Lapwing 1628-40Z

1590 MCM 1.544" (39.22 mm) 54x19 Falcon 1628-40A

1780 MCM 1.602" (40.70 mm) 84x19 Chukar 1628-50B

2034.5 MCM 1.681" (42.70 mm) 72x7 Mockingbird 1628-50C

2156 MCM 1.762" (44.75 mm) 84x19 Bluebird 1628-50D

2167 MCM 1.735" (44.07 mm) 72x7 Kiwi 1628-50D

2312 MCM 1.802" (45.77 mm) 76x19 Thrasher 1628-50E

2515 MCM 1.880" (47.75 mm) 76x19 Joree 1628-50F

www.kleintools.com

See Wire Pulling Grip Warnings on the inside cover.

Transmission

All dimensions are in inches (millimeters).

ACSR

20,000 lbs.

(9,072 kg)

25,000 lbs.

(11,340 kg)

(Aluminum Conductor Steel Reinforced)

6

Page 9

All dimensions are in inches (millimeters).

TRANSMISSION

See Wire Pulling Grip Warnings on the inside cover.

www.kleintools.com

See Wire Pulling Grip Warnings on the inside cover.

www.kleintools.com

ACSR TRANSMISSION CABLES

1628 Series

•

Roundjawsareshapedtoprovidemaximumcontact

with

thecable,virtuallyeliminatingcabledeformation.

In some transmission applications –

commonly using the 1628-30, 1628-40 or 1628-50 series Chicago Grips – there is a

risk of cable deformation under high tensions. To avoid this risk, Klein Tools recommends using two grips in tandem if the load

is expected to exceed the lesser of 12,500 lbs. (5670 kg) or 40% of the ACSR conductor's tensile strength.

1628-50

•

1628-50equippedwith

removableboltonfloating

jaw,securedbyaslottednut

andcotterpin.Jawprovides

increasedcablecoverage.

These grips are special order only. Application must be

confirmed prior to ordering. Allow 30 days for delivery.

Note: Jaw must be removed to

insert cable for model 1628-50.

ChicagoTM Grips

1628-40

Cat. No. Min. to Max. Cable

20,000 lbs. (9,072 kg) Maximum Safe Load

1628-30P .95" - 1.02" (24.23 mm - 25.78 mm)

1628-30R

1628-30S 1.08" - 1.14" (27.41 mm - 28.96 mm)

1628-30T 1.14" - 1.20" (28.98 mm -30.56 mm)

1628-30U 1.21" - 1.26" (30.59 mm - 32.13 mm)

25,000 lbs. (11,340 kg) Maximum Safe Load

1628-40W

1628-40X 1.33" - 1.39" (33.76 mm - 35.30 mm)

1628-40Y 1.39" - 1.45" (35.33 mm - 36.91 mm)

1628-40Z 1.45" - 1.52" (36.93 mm - 38.48 mm)

25,000 lbs. (11,340 kg) Maximum Safe Load with bolt on jaw

1628-50A 1.52" - 1.58" (38.51 mm - 40.08 mm)

1628-50B 1.58" - 1.64" (40.11 mm - 41.66 mm)

1628-50C 1.64" - 1.70" (41.68 mm - 43.26 mm)

1628-50D 1.70" - 1.77" (43.28 mm - 44.83 mm)

1628-50E 1.77" - 1.83" (44.86 mm - 46.43 mm)

1628-50F

Diameter inches (mm)

1.02" - 1.08" (25.81 mm - 27.38 mm)

1.27" - 1.33" (32.16 mm - 33.73 mm)

1.83" - 1.89" (46.46 mm - 48.00 mm)

Jaw

Length

10-3/4"

(273 mm)

10-3/4"

(273 mm)

10-3/4"

(273 mm)

Approx.

Weight

27 lbs.

(12.27 kg)

34 lbs.

(15.45 kg)

34 lbs.

(15.45 kg)

Each

7

Page 10

www.kleintools.com

All dimensions are in inches (millimeters).

See Wire Pulling Grip Warnings on the inside cover.

Transmission

AAC

AWG or MCM Size Diameter inches (mm) No. of Alum. Strands Code Word Grip Safe Load

700 MCM .963" (24.46 mm) 37 Verbena 1628-30P

700 MCM .964" (24.49 mm) 61 Flag 1628-30P

715.5 MCM .973" (24.71 mm) 37 Violet 1628-30P

715.5 MCM .975" (24.77 mm) 61 Nasturtium 1628-30P

750 MCM .998" (25.35 mm) 61 Cattail 1628-30P

750 MCM .997" (25.32 mm) 37 Petunia 1628-30P

795 MCM 1.026" (26.06 mm) 37 Arbutus 1628-30R

795 MCM 1.027" (26.09 mm) 61 Lilac 1628-30R

800 MCM 1.029" (26.14 mm) 37 Fuschia 1628-30R

800 MCM 1.031" (26.19 mm) 61 Heliotrope 1628-30R

874.5 MCM 1.076" (27.37 mm) 37 Anemone 1628-30R

874.5 MCM 1.077" (27.36 mm) 61 Crocus 1628-30R

900 MCM 1.092" (27.74 mm) 37 Cockscomb 1628-30S

954 MCM 1.124" (28.55 mm) 37 Magnolia 1628-30S

954 MCM 1.125" (28.58 mm) 61 Goldenrod 1628-30S

1000 MCM 1.151" (29.24 mm) 37 Hawkweed 1628-30T

1000 MCM 1.152" (29.26 mm) 61 Camellia 1628-30T

1033.5 MCM 1.170" (29.72 mm) 37 Bluebell 1628-30T

1033.5 MCM 1.171" (29.74 mm) 61 Larkspur 1628-30T

1113 MCM 1.216" (30.89 mm) 61 Marigold 1628-40U

1192.5 MCM 1.258" (31.95 mm) 61 Hawthorn 1628-40U

1272.MCM 1.300" (33.02 mm) 61 Narcissus 1628-40W

1351.5 MCM 1.340" (34.04 mm) 61 Columbine 1628-40X

1431 MCM 1.378" (35.00 mm) 61 Carnation 1628-40X

1510.5 MCM 1.416" (35.97 mm) 61 Gladiolus 1628-40Y

1590 MCM 1.453" (36.91 mm) 61 Coreopsis 1628-40Z

1750 MCM 1.524" (38.71 mm) 61 Jessamine 1628-40A

2000 MCM 1.631" (41.43 mm) 91 Cowslip 1628-50B

2250 MCM 1.729" (43.92 mm) 91 Sagebrush 1628-50D

2500 MCM 1.823" (46.30 mm) 91 Lupine 1628-50E

20,000 lbs.

(9,072 kg)

25,000 lbs.

(11,340 kg)

(All Aluminum Conductor)

8

Page 11

All dimensions are in inches (millimeters).

TRANSMISSION

See Wire Pulling Grip Warnings on the inside cover.

www.kleintools.com

AAC

•

1628-50equippedwith

removableboltonfloating

jaw,securedbyaslottednut

andcotterpin.Jawprovides

increasedcablecoverage.

In some transmission applications –

commonly using the 1628-30, 1628-40 or 1628-50 series Chicago Grips – there is a

risk of cable deformation under high tensions. To avoid this risk, Klein Tools recommends using two grips in tandem if the load is

expected to exceed the lesser of 12,500 lbs. (5,670 kg) or 40% of the AAC conductor's tensile strength.

These grips are special order only. Application must be

confirmed prior to ordering. Allow 30 days for delivery.

Note: Jaw must be removed to

insert cable for model 1628-50.

TRANSMISSION CABLES

ChicagoTM Grips

1628 Series

Round jaws are shaped to provide maximum contact

•

with the cable, virtually eliminating cable deformation.

1628-40

Cat. No. Min. to Max. Cable

20,000 lbs. (9,072 kg) Maximum Safe Load

1628-30P .95" - 1.02" (24.23 mm - 25.78 mm)

1628-30R

1628-30S 1.08" - 1.14" (27.41 mm - 28.96 mm)

1628-30T 1.14" - 1.20" (28.98 mm -30.56 mm)

1628-30U 1.21" - 1.26" (30.59 mm - 32.13 mm)

25,000 lbs. (11,340 kg) Maximum Safe Load

1628-40U 1.20" - 1.27" (30.58 mm - 32.13 mm)

1628-40W

1628-40X 1.33" - 1.39" (33.76 mm - 35.30 mm)

1628-40Y 1.39" - 1.45" (35.33 mm - 36.91 mm)

1628-40Z 1.45" - 1.52" (36.93 mm - 38.48 mm)

1628-40A 1.52" - 1.58" (38.51 mm - 40.08 mm)

25,000 lbs. (11,340 kg) Maximum Safe Load with bolt on jaw

1628-50B 1.58" - 1.64" (40.11 mm - 41.66 mm)

1628-50D 1.70" - 1.77" (43.28 mm - 44.83 mm)

1628-50E 1.77" - 1.83" (44.86 mm - 46.43 mm)

Diameter inches (mm)

1.02" - 1.08" (25.81 mm - 27.38 mm)

1.27" - 1.33" (32.16 mm - 33.73 mm)

Jaw

Length

10-3/4"

(273 mm)

10-3/4"

(273 mm)

10-3/4"

(273 mm)

Approx.

Weight

27 lbs.

(12.27 kg)

34 lbs.

(15.45 kg)

34 lbs.

(15.45 kg)

Each

1628-50

9

Page 12

AWG or MCM Size Diameter inches (mm) No. of Alum. & Steel Strands Code Word Grip Safe Load

266.8 MCM .642" (16.31 mm) 26x7 Partridge/ACSS 1656-40*

266.8 MCM .660" (16.76 mm) 30x7 Junco/ACSS 1656-40*

300 MCM .680" (17.27 mm) 26x7 Ostrich/ACSS 1656-40*

336.4 MCM .720" (18.29 mm) 26x7 Linnet/ACSS 1656-40*

336.4 MCM .741" (18.82 mm) 30x7 Oriole/ACSS 1656-50*

397.5 MCM .772" (19.61 mm) 24x7 Brant/ACSS 1656-50*

397.5 MCM .783" (19.89 mm) 26x7 Ibis/ACSS 1656-50*

397.5 MCM .806" (20.47 mm) 30x7 Lark/ACSS 1656-50*

477 MCM .846" (21.49 mm) 24x7 Flicker/ACSS 1656-50*

477 MCM .858" (21.79 mm) 26x7 Hawk/ACSS 1656-50*

477 MCM .883" (22.43 mm) 30x7 Hen/ACSS 1656-60*

556.5 MCM .914" (23.22 mm) 24x7 Parakeet/ACSS 1656-60*

556.5 MCM .927" (23.55 mm) 26x7 Dove/ACSS 1656-60*

556.5 MCM .953" (24.21 mm) 30x7 Eagle/ACSS 1656-60*

605 MCM .953" (24.21 mm) 24x7 Peacock/ACSS 1656-60*

605 MCM .994" (25.25 mm) 30x7 Wood Duck/ACSS 1628-50P

605 MCM .994" (25.25 mm) 30x19 Teal/ACSS 1628-50P

636 MCM .977" (24.82 mm) 24x7 Rook/ACSS 1628-50P

636 MCM .991" (25.17 mm) 26x7 Grosbeak/ACSS 1628-50P

636 MCM 1.019" (25.88 mm) 30x19 Egret/ACSS 1628-50R

636 MCM 1.019" (25.88 mm) 30x7 Scoter/ACSS 1628-50R

666.6 MCM 1.000" (25.40 mm) 24x7 Flamingo/ACSS 1628-50P

666.6 MCM 1.014" (25.76 mm) 26x7 Gannet/ACSS 1628-50P

715.5 MCM 1.051" (26.70 mm) 26x7 Starling/ACSS 1628-50R

715.5 MCM 1.081" (27.46 mm) 30x19 Redwing/ACSS 1628-50S

795 MCM 1.063" (27.00 mm) 45x7 Tern/ACSS 1628-50R

795 MCM 1.092" (27.74 mm) 24x7 Cuckoo/ACSS 1628-50S

795 MCM 1.092" (27.74 mm) 54x7 Condor/ACSS 1628-50S

795 MCM 1.107" (28.12 mm) 26x7 Drake/ACSS 1628-50S

795 MCM 1.139" (28.93 mm) 30x19 Mallard/ACSS 1628-50S

900 MCM 1.131" (28.73 mm) 45x7 Ruddy/ACSS 1628-50S

900 MCM 1.162" (29.52 mm) 54x7 Canary/ACSS 1628-50T

954 MCM 1.165" (29.59 mm) 20x7 Corncrake/ACSS 1628-50T

954 MCM 1.165" (29.59 mm) 45x7 Rail/ACSS 1628-50T

954 MCM 1.175" (29.85 mm) 48x7 Towhee/ACSS 1628-50T

954 MCM 1.196" (30.38 mm) 54x7 Cardinal/ACSS 1628-50T

954 MCM 1.196" (30.38 mm) 24x7 Redbird/ACSS 1628-50T

954 MCM 1.248" (31.70 mm) 30x19 Canvasback/ACSS 1628-50U

1033.5 MCM 1.212" (30.79 mm) 45x7 Ortolan/ACSS 1628-50U

1033.5 MCM 1.245" (31.62 mm) 54x7 Curlew/ACSS 1628-50U

1113 MCM 1.258" (31.95 mm) 45x7 Bluejay/ACSS 1628-50U

1113 MCM 1.292" (32.82 mm) 54x19 Finch/ACSS 1628-50W

1192.5 MCM 1.302" (33.07 mm) 45x7 Bunting/ACSS 1628-50W

1192.5 MCM 1.337" (33.99 mm) 54x19 Grackle/ACSS 1628-50X

1272 MCM 1.345" (34.16 mm) 45x7 Bittern/ACSS 1628-50X

1272 MCM 1.381" (35.08 mm) 54x19 Pheasant/ACSS 1628-50X

1351 MCM 1.386" (35.21 mm) 45x7 Dipper/ACSS 1628-50X

1351 MCM 1.424" (36.17 mm) 54x19 Martin/ACSS 1628-50Y

1431 MCM 1.427" (36.25 mm) 45x7 Bobolink/ACSS 1628-50Y

1431 MCM 1.465" (37.21 mm) 54x19 Plover/ACSS 1628-50Z

1590 MCM 1.504" (38.20 mm) 45x7 Lapwing/ACSS 1628-50Z

1590 MCM 1.544" (39.22 mm) 54x19 Falcon/ACSS 1628-50A

1780 MCM 1.601" (40.67 mm) 84x19 Chukar/ACSS 1628-50B

2034.5 MCM 1.681" (42.70 mm) 72x7 Mockingbird/ACSS 1628-50C

2167 MCM 1.735" (44.12 mm) 72x7 Kiwi/ACSS 1628-50D

2156 MCM 1.762" (44.76 mm) 84x19 Bluebird/ACSS 1628-50D

2312 MCM 1.802" (45.77 mm) 76x19 Thrasher/ACSS 1628-50E

2515 MCM 1.880" (47.75 mm) 76x19 Joree/ACSS 1628-50F

*

Must use two of recommended grips in tandem. See grip use instructions on pages 16-17.

www.kleintools.com

See Wire Pulling Grip Warnings on the inside cover.

Transmission

All dimensions are in inches (millimeters).

ACSS

25,000 lbs.

(11,340 kg)

10

(Aluminum Conductor Steel Supported)

(3,629 kg)

8,000 lbs.

Page 13

All dimensions are in inches (millimeters).

TRANSMISSION

See Wire Pulling Grip Warnings on the inside cover.

www.kleintools.com

Best Practices for ACSS Conductors

1.

Larger than 0.953" outside diameter (approximately

600 MCM)

- Use the 1628-50 or 1628-40 series

Chicago Grips. The necessary grip size should be

determined based on the cable outside diameter.

For applications where the load is expected to exceed

10,000 lbs.

(4,536 kg),

use two of the appropriate

grips in tandem to prevent cable deformation. See

instructions for using two grips in tandem on page 17.

2.

Smaller than 0.953" outside diameter (approximately

600 MCM)

- Use two of the appropriate 1656 series

Chicago Grips in tandem. The necessary grip size

should be determined based on the cable outside

diameter. See instructions for using two grips

in tandem on page 17.

3.

For grip recommendations,

contact us

at hisupport@kleintools.com.

ACSS TRANSMISSION CABLES

1628-50

1628-40

•

1628-50equippedwith

removableboltonfloating

jaw,securedbyaslottednut

andcotterpin.Jawprovides

increasedcablecoverage.

•

Roundjawsareshapedtoprovidemaximumcontact

with

thecable,virtuallyeliminatingcabledeformation.

Note: Jaw must be removed to

insert cable for model 1628-50.

ChicagoTM Grips

1628 Series

Cat. No.

8,000 lbs. (3,629 kg) Maximum Safe Load

1656-40 1656-40H S1656-40H .53" - .74" (13.46 mm - 18.79 mm)

1656-50 1656-50H S1656-50H .74" - .86" (18.80 mm - 21.84 mm)

1656-60 1656-60H S1656-60H .86" - .96" (21.84 mm - 24.38 mm)

25,000 lbs. (11,340 kg) Maximum Safe Load with bolt on jaw

1628-50P*

1628-50R* 1.02" - 1.08" (25.81 mm -27.38 mm)

1628-50S* 1.08" - 1.14" (27.41 mm - 28.96 mm)

1628-50T* 1.14" - 1.20" (28.99 mm - 30.55 mm)

1628-50U* 1.20" - 1.27" (30.58 mm - 32.13 mm)

1628-50W* 1.27" - 1.33" (32.16 mm - 33.73 mm)

1628-50X* 1.33" - 1.39" (33.76 mm - 35.30 mm)

1628-50Y* 1.39" - 1.45" (35.33 mm - 36.91 mm)

1628-50Z* 1.45" - 1.52" (36.93 mm - 38.48 mm)

1628-50A* 1.52" - 1.58" (38.51 mm - 40.08 mm)

1628-50B* 1.58" - 1.64" (40.11 mm - 41.66 mm)

1628-50C* 1.64" - 1.70" (41.68 mm - 43.26 mm)

1628-50D* 1.70" - 1.77" (43.28 mm - 44.83 mm)

1628-50E* 1.77" - 1.83" (44.86 mm - 46.43 mm)

1628-50F* 1.83" - 1.89" (46.46 mm - 48.00 mm)

*These grips are special order only. Application must be confirmed prior to ordering. Allow 30 days for delivery.

Hot Latch

Model No.

Hot Latch/Spring

Model No.

NA NA

Min. to Max. Cable

Diameter inches (mm)

.95" - 1.02" (24.23 mm - 25.78 mm)

Jaw

Length

5-1/2"

(140 mm)

10-3/4"

(273 mm)

Approx.

Weight

8.30 lbs.

(3.76 kg)

34 lbs.

(15.45 kg)

Each

11

Page 14

www.kleintools.com

See Wire Pulling Grip Warnings on the inside cover.

Transmission

All dimensions are in inches (millimeters).

ACSS/TW

AWG or MCM Size Diameter inches (mm) No. of Alum. & Steel Strands Code Word Grip

Safe Load

266.8 MCM .595" (15.11 mm) 14x7 Partridge/ACSS/TW 1656-40*

336.4 MCM .667" (16.94 mm) 16x7 Linnet/ACSS/TW 1656-40*

336.4 MCM .692" (17.58 mm) 16x7 Oriole/ACSS/TW 1656-40*

477 MCM .776" (19.71 mm) 18x7 Flicker/ACSS/TW 1656-50*

477 MCM .798" (20.27 mm) 18x7 Hawk/ACSS/TW 1656-50*

477 MCM .820" (20.83 mm) 20x7 Hen/ACSS/TW 1656-50*

556.5 MCM .835" (21.21 mm) 18x7 Parakeet/ACSS/TW 1656-50*

556.5 MCM .850" (21.59 mm) 20x7 Dove/ACSS/TW 1656-50*

636 MCM .893" (22.68 mm) 20x7 Rook/ACSS/TW 1656-60*

636 MCM .909" (23.09 mm) 20x7 Grosbeak/ACSS/TW 1656-60*

636 MCM .942" (23.93 mm) 22x7 Scoter/ACSS/TW 1656-60*

762.8 MCM .990" (25.15 mm) 17x7 Wabash/ACSS/TW 1628-50P

768.2 MCM .960" (24.38 mm) 17x7 Tern/ACSS/TW 1628-50P

795 MCM .980" (24.89 mm) 18x7 Puffin/ACSS/TW 1628-50P

795 MCM .993" (25.22 mm) 20x7 Condor/ACSS/TW 1628-50P

795 MCM 1.010" (25.65 mm) 20x7 Drake/ACSS/TW 1628-50P

795 MCM 1.055" (26.80 mm) 20x7 Canary/ACSS/TW 1628-50P

900 MCM 1.044" (26.52 mm) 30x7 Phoenix/ACSS/TW 1628-50R

954 MCM 1.061" (26.95 mm) 32x7 Rail/ACSS/TW 1628-50R

954 MCM 1.080" (27.43 mm) 20x7 Cardinal/ACSS/TW 1628-50R

954 MCM 1.089" (27.66 mm) 30x7 Snowbird/ACSS/TW 1628-50S

1033.5 MCM 1.102" (27.99 mm) 32x7 Ortolan/ACSS/TW 1628-50S

1033.5 MCM 1.132" (28.75 mm) 22x7 Curlew/ACSS/TW 1628-50S

1033.5 MCM 1.129" (28.68 mm) 30x7 Avocet/ACSS/TW 1628-50S

1113 MCM 1.143" (29.03 mm) 33x7 Bluejay/ACSS/TW 1628-50S

1113 MCM 1.185" (30.10 mm) 38x19 Finch/ACSS/TW 1628-50T

1113 MCM 1.170" (29.72 mm) 30x7 Oxbird/ACSS/TW 1628-50T

1192.5 MCM 1.181" (29.99 mm) 34x7 Bunting/ACSS/TW 1628-50T

1192.5 MCM 1.225" (31.12 mm) 38x19 Grackle/ACSS/TW 1628-50T

1192.5 MCM 1.203" (30.56 mm) 30x7 Scissortail/ACSS/TW 1628-50U

1272 MCM 1.224" (31.09 mm) 38x7 Bittern/ACSS/TW 1628-50T

1272 MCM 1.260" (32.01 mm) 39x19 Pheasant/ACSS/TW 1628-50U

1272 MCM 1.256" (31.90 mm) 35x7 Dipper/ACSS/TW 1628-50U

1351.5 MCM 1.300" (33.02 mm) 42x19 Martin/ACSS/TW 1628-50U

1351.5 MCM 1.291" (32.79 mm) 36x7 Bobolink/ACSS/TW 1628-50W

1431 MCM 1.337" (33.96 mm) 44x19 Plover/ACSS/TW 1628-50W

1431 MCM 1.340" (34.04 mm) 39x19 Merrimack/ACSS/TW 1628-50X

1433.6 MCM 1.380" (35.02 mm) 38x19 Rio Grande/ACSS/TW 1628-50X

1533.3 MCM 1.350" (34.29 mm) 36x7 Potomac/ACSS/TW 1628-50X

1557.4 MCM 1.334" (33.88 mm) 33x7 Platte/ACSS/TW 1628-50X

1569 MCM 1.358" (34.49 mm) 36x7 Lapwing/ACSS/TW 1628-50X

1590 MCM 1.410" (35.81 mm) 42x19 Falcon/ACSS/TW 1628-50X

1590 MCM 1.420" (36.07 mm) 39x19 Pecos/ACSS/TW 1628-50Y

1622 MCM 1.386" (35.20 mm) 36x7 Schuylkill/ACSS/TW 1628-50Y

1657.4 MCM 1.470" (37.34 mm) 34x19 James/ACSS/TW 1628-50X

1730.6 MCM 1.427" (36.25 mm) 38x7 Pee Dee/ACSS/TW 1628-50Z

1758.6 MCM 1.445" (36.70 mm) 38x19 Chukar/ACSS/TW 1628-50Y

1780 MCM 1.550" (39.37 mm) 42x19 Cumberland/ACSS/TW 1628-50Y

1926.9 MCM 1.504" (38.20 mm) 44x7 Athabaska/ACSS/TW 1628-50A

1949.6 MCM 1.602" (40.69 mm) 64x19 Powder/ACSS/TW 1628-50Z

2153.8 MCM 1.608" (40.84 mm) 64x19 Bluebird/ACSS/TW 1628-50B

2156 MCM 1.761" (44.73 mm) 64x19 Santee/ACSS/TW 1628-50B

2627.3 MCM 1.761" (44.73 mm) 64x19 Santee/ACSS/TW 1628-50D

*

Must use two of recommended grips in tandem. See grip use instructions on pages 16-17.

8,000 lbs.

(3,629 kg)

25,000 lbs.

(11,340 kg)

(Trapezoidal Wire)

12

Page 15

All dimensions are in inches (millimeters).

TRANSMISSION

See Wire Pulling Grip Warnings on the inside cover.

www.kleintools.com

ACSS/TW TRANSMISSION CABLES

1628-40

•

1628-50equippedwith

removableboltonfloating

jaw,securedbyaslottednut

andcotterpin.Jawprovides

increasedcablecoverage.

Note: Jaw must be removed to

insert cable for model 1628-50.

1628-50

•

Roundjawsareshapedtoprovidemaximumcontact

with

thecable,virtuallyeliminatingcabledeformation.

Best Practices for ACSS/TW Conductors

1.

Larger than 0.953" outside diameter (approximately

600 MCM)

- Use the 1628-50 or 1628-40 series

Chicago Grips. The necessary grip size should be

determined based on the cable outside diameter.

For applications where the load is expected to exceed

10,000 lbs. (4,536 kg), use two of the appropriate

grips in tandem to prevent cable deformation. See

instructions for using two grips in tandem on page 17.

2.

Smaller than 0.953" outside diameter (approximately

600 MCM)

- Use two of the appropriate 1656 series

Chicago Grips in tandem. The necessary grip size

should be determined based on the cable outside

diameter. See instructions for using two grips

in tandem on page 17.

3.

For grip recommendations,

contact us

at hisupport@kleintools.com.

ChicagoTM Grips

1628 Series

Cat. No.

8,000 lbs. (3,629 kg) Maximum Safe Load

1656-40 1656-40H S1656-40H .53" - .74" (13.46 mm - 18.79 mm)

1656-50 1656-50H S1656-50H .74" - .86" (18.80 mm - 21.84 mm)

1656-60 1656-60H S1656-60H .86" - .96" (21.84 mm - 24.38 mm)

25,000 lbs. (11,340 kg) Maximum Safe Load with bolt on jaw

1628-50P*

1628-50R* 1.02" - 1.08" (25.81 mm -27.38 mm)

1628-50S* 1.08" - 1.14" (27.41 mm - 28.96 mm)

1628-50T* 1.14" - 1.20" (28.99 mm - 30.55 mm)

1628-50U* 1.20" - 1.27" (30.58 mm - 32.13 mm)

1628-50W* 1.27" - 1.33" (32.16 mm - 33.73 mm)

1628-50X* 1.33" - 1.39" (33.76 mm - 35.30 mm)

1628-50Y* 1.39" - 1.45" (35.33 mm - 36.91 mm)

1628-50Z* 1.45" - 1.52" (36.93 mm - 38.48 mm)

1628-50A* 1.52" - 1.58" (38.51 mm - 40.08 mm)

1628-50B* 1.58" - 1.64" (40.11 mm - 41.66 mm)

1628-50C* 1.64" - 1.70" (41.68 mm - 43.26 mm)

1628-50D* 1.70" - 1.77" (43.28 mm - 44.83 mm)

*These grips are special order only. Application must be confirmed prior to ordering. Allow 30 days for delivery.

Hot Latch

Model No.

NA NA

Hot Latch/Spring

Model No.

Min. to Max. Cable

Diameter inches (mm)

.95" - 1.02" (24.23 mm - 25.78 mm)

Jaw

Length

5-1/2"

(140 mm)

10-3/4"

(273 mm)

Approx.

Weight

8.30 lbs.

(3.76 kg)

34 lbs.

(15.45 kg)

Each

13

Page 16

www.kleintools.com

All dimensions are in inches (millimeters).

See Wire Pulling Grip Warnings on the inside cover.

Distribution

RELATED PRODUCTS

Web Strap Ratchet Hoists

Large, non-conductive drum knob allows web slack

•

to be adjusted with ease.

3/4 ton single line and 1-1/2 ton double line load rating.

•

Tight ratcheting mechanism allows precise tensioning.

•

Meets ANSI/ASME B30.21-2005 & B30.10-2009 standards.

•

Hot rings for hot stick use (Cat No. KN1500P-EXH only).

•

Cat. No. Pull Type Weight (lbs.)

KN1500P-EX Single/ Double 12.5 lbs (5.7 kg)

KN1500P-EXH Single/ Double 13.6 lbs (6.2 kg)

Single Line

Load Rating: 1500 lbs. (675 kg)

Min. to Max. Pulling Distance: 20" - 138" (500 mm - 3500 mm)

Hot rings for

hot stick use.

Double Line

Load Rating: 3000 lbs. (1,350 kg)

Min. to Max. Pulling Distance: 26" - 79" (700 mm - 2000 mm)

Howe Wire Tool

Strap is made of tough Klein-KordTM.

•

Swivel hook is forged steel with large opening.

•

Shank of hook is lengthened to reach under insulator.

•

Other end has device to hold the load at any distance.

•

All metal parts are galvanized.

•

Max. safe load 500 lbs. (225 kg).

•

Cat. No. Description Weight (lbs.)

1702-20N Nylon Strap 1" (25 mm) wide, 7' (2.1 m) long 1.95 lbs. (0.9 kg)

Grip-Cleaning Brush Set

Set of four wire-bristle brushes designed for

•

cleaning Klein wire and cable-pulling grips.

Brushes have stiff wire bristles.

•

Available in round and square shapes and two lengths

•

for efficient cleaning of different jaw configurations.

Semi-flexible steel shafts set into comfortable wooden

•

handles provide the necessary reach into grip jaws.

Cat. No. Set Contains Weight (lbs.)

25450 1.00 lbs. (0.45 kg)

Description

round-bristle

square-bristle

14

round-bristle

square-bristle

Bristle Diameter

and Length

3/8" x 3"

(10 mm x 76 mm)

1-9/16" x 5"

(40 mm x 127 mm)

Overall

Length

12"

(305 mm)

14"

(356 mm)

KN1500P-EXH

KN1500P-EX

1702-20N

25450

1-9/16" 1-9/16"

3/8" 3/8"

Page 17

www.kleintools.com

See Wire Pulling Grip Warnings on the inside cover.

Distribution

RECOMMENDED CARE

Grip Cleaning, Lubricating and Inspecting

1

Step 1. Use the Klein Grip Cleaning

Wire Brush Set (Cat. No. 25450) or

emery cloth to clean the surfaces of grip

jaws (photo #1).

Step 2.

Spray de greaser on the grip jaws, all

joints and moving parts (photo #2).

Step 3. Use the Klein Grip

Cleaning Wire Brush to remove dirt and

debris from the grip jaws (photo #3).

Step 4.

Wipe grips dry with soft cloth.

Repeat all cleaning steps as necessary

until grip is completely clean (photo #4).

3

4

2

Never repair any grip. Grips that are bent, misaligned or otherwise distorted should be discarded and replaced.

If there is ever a question about the safe condition of any grip, contact Klein Tools Customer Service directly at

847.821.5500 or 800.553.4676 or email HiSupport@kleintools.com.

Step 6.

Carefully inspect jaw condition, proper alignment of jaws

and all parts, and possible distortion caused by exceeding safe-load

specifications. Grips should operate smoothly. Spring-loaded grips

should lock open with loop handle in “Down" position and should close

automatically with loop handle “Up." The Klein Parallel Jaw Grip may be

tested by opening and closing the jaws by hand, exercising proper caution.

All parts and rivets should be checked for distortion (illustration #6).

Step 5.

Apply lubricant to all joints and

moving parts. Do NOT lubricate

gripping surfaces of jaws

(photos left #5).

6

5

The following guidelines have been established to keep all grips in good working condition.

Cleaning

Lubricating

Jaws

closed

Side

plates

Loop

To lock

open

handle

www.kleintools.com

See Wire Pulling Grip Warnings on the inside cover.

Body Jaws

15

Page 18

Dead-Ending

COMMON OVERHEAD APPLICATIONS

See Wire Pulling Grip Warnings on the inside cover.

www.kleintools.com

1. Set up the ratchet hoist and Chicago

Grip as shown here.

2. Ratchet the hoist until the cable is

lined up with the dead-end fixture.

3.

After the tension is approximately where

it will need to be after termination,

ratchet the hoist a couple more times

to accommodate for tension loss

after hoist removal. Consult cable

specifications to ensure the maximum

cable tension is not exceeded.

4. When finished, break the tension using the hoist handle, then use either the handle or drum knob to continue releasing the tension.

Sagging Using a Dynamometer

1.

Set up ratchet hoist, Chicago Grip

and dynamometer as shown here.

2. Ratchet the hoist until the

dynamometer displays the desired

tension. Consult conductorspecifications

or company procedures to determine

the appropriate tension.

3. When finished, break the tension

using the hoist handle, then use either

the handle or drum knob to continue

releasing the tension.

Splicing

1. Set up ratchet hoist and Chicago

Grips as shown here.

2.

Connect the KN1500PEX Web Strap

Ratchet Hoist to each grip, and

ratchet to the desired tension to

make the splice.

The cable can now be spliced

according to standard work

procedures and material guidelines.

3.

When finished with the splice, break

the tension using the hoist handle, then

use either the handle or drum knob to

continue releasing the tension.

16

Page 19

www.kleintools.com

See Wire Pulling Grip Warnings on the inside cover.

COMMON OVERHEAD APPLICATIONS

COMMON OVERHEAD APPLICATIONS

Using Two ChicagoTM Grips in Tandem

For applications where the maximum load exceeds the safe load of an individual grip, or the cable is at risk of deformation, it is

recommended to use two Chicago Grips in tandem. Using two grips in tandem divides the weight load between both grips, allowing

for an effective work load increase of 1.5 times the safe load of each individual grip.

In some transmission applications—commonly using the 1628-30, 1628-40 or 1628-50 series Chicago Grips—there is a risk of cable

deformation under high tensions. To avoid this risk, Klein Tools recommends using two grips in tandem if:

For example, two Klein Tools 1628-40 Chicago Grips, each with a maximum safe load of 25,000 lbs. (11,340 kg) individually,

have a combined working safe load of 37,500 lbs. (17,009 kg).

• ACSR or AAC conductors – the load is expected to exceed the lesser of 12,500 lbs. (5,670 kg) or

40% of the conductor tensile strength.

• ACSS conductors—the load is expected to exceed the lesser of 10,000 lbs. (4,536 kg) or 40% of the

conductor tensile strength.

1. Place each grip on the same conductor, approximately five feet apart.

2. Connect a pulley block (leveling block) to the eye of each grip. This will maintain equal distribution of the weight

load between both grips.

3. Connect an anchored chain hoist of appropriate capacity to the block as shown in the image above.

4. Ratchet the chain hoist to the desired tension, as shown in the image below.

Materials Used:

Disclaimer: This is not intended to be a definitive instructional manual for completing the applications. Always consult company procedures

Klein Tools Chicago Grips, Klein Tools KN1500PEX web strap ratcheting hoist, Dillon Dynamometer, chain hoist, leveling block.

and material guidelines before attempting any application.

17

Page 20

Storage

POUCHES

Buckets

GLOVES

PLIERS

Wrenches

ClimbiNG bElTS

SKINNING KNIVES

Climbers

Block & Tackle

CaBLe & BoLt Cutters

HiGH-VOLTAGE TESTERS

© 2015 Klein Tools, Inc.

Lincolnshire, IL 60069-1418

Rev. 9/15 A 96427

See our complete line of Utility Tools & Accessories

HiSupport@kleintools.com

Questions? Contact Klein Tools at:

www.kleintools.com

Find Us Online

Loading...

Loading...