Page 1

30" (76.2 CM) AND 36" (91.4 CM)

LI3ZTB/W10342489E

IMPORTANT: READ AND SAVE THESE INSTRUCTIONS.

FOR RESIDENTIAL USE ONLY.

IMPORTANT : LIRE ET CONSERVER CES INSTRUCTIONS.

POUR UTILISATION RÉSIDENTIELLE UNIQUEMENT.

RETRACTABLE (POP-UP) DOWNDRAFT VENT

SYSTEM

Installation Instructions and Use & Care Guide

For questions about features, operation/performance, parts, accessories or service, call: 1-800-422-1230

In Canada, for assistance, installation and service, call: 1-800-807-6777

or visit our website at...

www.kitchenaid.com or www.KitchenAid.ca

SYSTÈME DE VENTILATION RÉTRACTABLE

(CLAPET) DE 30" (76,2 CM) ET 36" (91,4 CM)—

ASPIRATION PART LE BAS

Instructions d’installation et Guide d’utilisation et d’entretien

Au Canada, pour assistance, installation ou service composez le 1-800-807-6777

ou visitez notre site web à...

www.KitchenAid.ca

Table of Contents/Table des matières.............................................................................2

Page 2

TABLE OF CONTENTS

VENT SYSTEM SAFETY.................................................................3

INSTALLATION REQUIREMENTS................................................5

Tools and Parts ............................................................................5

Location Requirements................................................................5

Electrical Requirements ...............................................................8

Venting Requirements..................................................................8

INSTALLATION INSTRUCTIONS

INTERIOR-MOUNTED VENT MOTOR..........................................9

Venting Methods..........................................................................9

Install Vent System.....................................................................11

Rear Mounting—Blower Motor..................................................12

Complete Installation (Interior-Mounted Motor) ........................13

Make Electrical Connections .....................................................15

Check Operation ........................................................................15

INSTALLATION INSTRUCTIONS

EXTERIOR-MOUNTED VENT MOTOR.......................................16

Venting Methods........................................................................16

Install Vent System.....................................................................17

Complete Installation (Exterior-Mounted Motor) .......................18

TABLE DES MATIÈRES

SÉCURITÉ DU SYSTÈME DE VENTILATION.............................29

EXIGENCES D'INSTALLATION...................................................31

Outils et pièces...........................................................................31

Exigences d'emplacement.........................................................31

Spécifications électriques..........................................................35

Exigences concernant l’évacuation...........................................35

INSTRUCTIONS D’INSTALLATION

VENTILATEUR MONTÉ À L’INTÉRIEUR....................................36

Méthodes d’évacuation .............................................................36

Installation du conduit d’évacuation..........................................37

Montage du ventilateur à l’arrière ..............................................39

Achever l’installation ..................................................................40

Raccordements électriques.......................................................41

Contrôle du fonctionnement ......................................................42

INSTRUCTIONS D’INSTALLATION

VENTILATEUR MONTÉ À L’EXTÉRIEUR...................................43

Méthodes d’évacuation .............................................................43

Installation du conduit d’évacuation..........................................44

Achever l’installation (Ventilateur monté à l’extérieur)...............45

Install Downdraft Vent In-Line

(External Type) Blower Motor.....................................................18

Make Electrical Connections

for In-Line Blower Motor System...............................................20

Make Electrical Power Supply Connection

to Downdraft Vent ......................................................................21

Check Operation ........................................................................22

VENT SYSTEM USE .....................................................................23

Operating Downdraft Vent .........................................................23

VENT SYSTEM CARE...................................................................24

Surface of Downdraft Vent.........................................................24

Filters ..........................................................................................24

WIRING DIAGRAMS.....................................................................25

Interior-Mounted Blower Motor .................................................25

Exterior-Mounted Blower Motor ................................................26

ASSISTANCE OR SERVICE.........................................................27

In the U.S.A. ...............................................................................27

In Canada ...................................................................................27

Accessories ................................................................................27

WARRANTY ..................................................................................28

Installation du ventilateur en ligne

(type externe) du système d’extraction par le bas.....................45

Raccordements électriques

du système de ventilation en ligne.............................................47

Raccordement de l’alimentation électrique

au système d’extraction par le bas............................................48

Contrôle du fonctionnement ......................................................49

UTILISATION DU SYSTÈME D’EXTRACTION...........................50

Utilisation du système d’extraction par le bas...........................50

ENTRETIEN DU SYSTÈME D’ÉVACUATION .............................51

Surface du système d’extraction par le bas..............................51

Filtres ..........................................................................................51

SCHÉMA DE CÂBLAGE...............................................................52

Ventilateur monté à l'intérieur ....................................................52

Ventilateur monté à l'extérieur ...................................................53

ASSISTANCE OU SERVICE.........................................................54

Aux États-Unis............................................................................54

Au Canada..................................................................................54

Accessoires ................................................................................54

GARANTIE.....................................................................................55

2

Page 3

VENT SYSTEM SAFETY

You can be killed or seriously injured if you don't immediately

You

can be killed or seriously injured if you don't

follow

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

follow instructions.

instructions.

DANGER

WARNING

3

Page 4

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

WARNING: TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK, OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

■ Use this unit only in the manner intended by the

manufacturer. If you have questions, contact the

manufacturer.

■ Before servicing or cleaning the unit, switch power off at

service panel and lock the service disconnecting means to

prevent power from being switched on accidentally. When

the service disconnecting means cannot be locked,

securely fasten a prominent warning device, such as a tag,

to the service panel.

■ Installation work and electrical wiring must be done by

qualified person(s) in accordance with all applicable codes

and standards, including fire-rated construction.

■ Do not operate any fan with a damaged cord or plug.

Discard fan or return to an authorized service facility for

examination and/or repair.

■ Sufficient air is needed for proper combustion and

exhausting of gases through the flue (chimney) of fuel

burning equipment to prevent backdrafting. Follow the

heating equipment manufacturer's guideline and safety

standards such as those published by the National Fire

Protection Association (NFPA), the American Society for

Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE), and the local code authorities.

■ When cutting or drilling into wall or ceiling; do not damage

electrical wiring and other utilities.

■ Ducted fans must always be vented outdoors.

CAUTION: For general ventilating use only. Do not use

to exhaust hazardous or explosive materials and vapors.

CAUTION: To reduce risk of fire and to properly exhaust

air, be sure to duct air outside - do not vent exhaust air into

spaces within walls or ceilings, attics or into crawl spaces,

or garages.

WARNING: TO REDUCE THE RISK OF FIRE, USE ONLY

METAL DUCTWORK.

WARNING: TO REDUCE THE RISK OF A RANGE TOP

GREASE FIRE:

■ Never leave surface units unattended at high settings.

Boilovers cause smoking and greasy spillovers that may

ignite. Heat oils slowly on low or medium settings.

■ Always turn hood ON when cooking at high heat or when

flambeing food (i.e. Crepes Suzette, Cherries Jubilee,

Peppercorn Beef Flambé).

■ Clean ventilating fans frequently. Grease should not be

allowed to accumulate on fan or filter.

■ Use proper pan size. Always use cookware appropriate for

the size of the surface element.

WARNING: TO REDUCE THE RISK OF INJURY TO

PERSONS IN THE EVENT OF A RANGE TOP GREASE

FIRE, OBSERVE THE FOLLOWING:

a

■ SMOTHER FLAMES with a close fitting lid, cookie sheet, or

metal tray, then turn off the burner. BE CAREFUL TO

PREVENT BURNS. If the flames do not go out

immediately, EVACUATE AND CALL THE FIRE

DEPARTMENT.

■ NEVER PICK UP A FLAMING PAN - you may be burned.

■ DO NOT USE WATER, including wet dishcloths or towels -

a violent steam explosion will result.

■ Use an extinguisher ONLY if:

– You know you have a class ABC extinguisher, and you

already know how to operate it.

– The fire is small and contained in the area where it

started.

– The fire department is being called.

– You can fight the fire with your back to an exit.

a

Based on "Kitchen Fire Safety Tips" published by NFPA.

■ WARNING: To reduce the risk of fire or electrical shock,

do not use this fan with any solid-state speed control

device.

4

Page 5

INSTALLATION REQUIREMENTS

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools Needed

■ Jigsaw or keyhole saw

■ Drill

■ ¹⁄₈" (3 mm) drill bit for pilot holes

■ Pencil

■ Tape measure or ruler

■ Flat-blade screwdriver

■ Phillips screwdriver

■ ³⁄₈" (9.5 mm) nut driver

■ Level

■ Pliers

■ Metal snips

■ Wire stripper or utility knife

■ Caulking gun and weatherproof caulking compound

Parts Supplied

■ Top trim - stainless

■ 2 - End caps

■ 2 - Lower support legs

■ 2 - Undercounter mounting brackets

■ 16 - 4 x 8 mm screws

■ 3 - 3.5 x 9.5 mm screws

■ 3¹⁄₄" x 10" (8.3 x 25.4 cm) rectangular damper

■ 4³⁄₄" (12.0 cm) motor box

■ ¹⁄₄" (6.4 mm) deep cover

■ Flat vent cover plate

■ 6" (15.2 cm) diameter vent transition with damper (interior-

mounted blower motor models only)

■ 10" (25.4 cm) diameter vent collar (exterior-mounted blower

model only)

Parts Needed

■ UL listed or CSA approved ½" (12.7 mm) conduit connector

■ Wall or roof cap with damper to match vent system

■ Vent system

■ Home power supply cable

■ 3 - UL listed wire connectors

■ Wiring cable for optional remote blower kit

■ Vent clamps/duct tape as required

Location Requirements

NOTE: Downdraft vent is installed directly behind the cooktop.

Install the downdraft vent first, then install the cooktop.

IMPORTANT: Observe all governing codes and ordinances.

■ Have a qualified technician install the downdraft vent. It is the

installer’s responsibility to comply with installation clearances

specified on the model/serial rating plate. The model/serial

rating plate is located on the front of the downdraft vent

above the terminal box cover.

■ Downdraft vent location should be away from strong draft

areas, such as windows, doors, and strong heating vents or

fans.

■ Cabinet opening dimensions that are shown must be used.

Given dimensions provide minimum clearance.

■ Consult the cooktop manufacturer installation instructions

before making any cutouts.

Check that the downdraft vent and cooktop location will

clear the cabinet walls, backsplash, and rear wall studs

inside the cabinet.

Check for the minimum distance between the front edge

of the countertop and the front edge of the cooktop. The

minimum horizontal distance between the overhead

cabinets is the same as the width of the installed

downdraft vent.

■ All openings in ceiling and wall where the downdraft vent will

be installed must be sealed.

■ Grounded electrical outlet is required. See “Electrical

Requirements” section.

■ When installing the downdraft vent, the cabinet drawer will

need to be removed and the drawer front installed

permanently to the cabinet.

Cabinet Construction:

Downdraft vent is designed for use in a cabinet with a depth of

24" (61 cm). Some installations require a countertop deeper than

25" (63.5 cm). See the Countertop Cutout Dimensions chart.

The maximum depth of the overhead cabinet is 13" (33 cm).

Overhead cabinets installed at either side of the downdraft vent

must be 18" (45.7 cm) above the cooking surface.

For Mobile Home Installations

The installation of this downdraft vent must conform to the

Manufactured Home Construction Safety Standards, Title 24

CFR, Part 328 (formerly the Federal Standard for Mobile Home

Construction and Safety, title 24, HUD, Part 280) or when such

standard is not applicable, the standard for Manufactured Home

Installation 1982 (Manufactured Home Sites, Communities and

Setups) ANSI A225.1/NFPA 501A*, or latest edition, or with local

codes.

5

Page 6

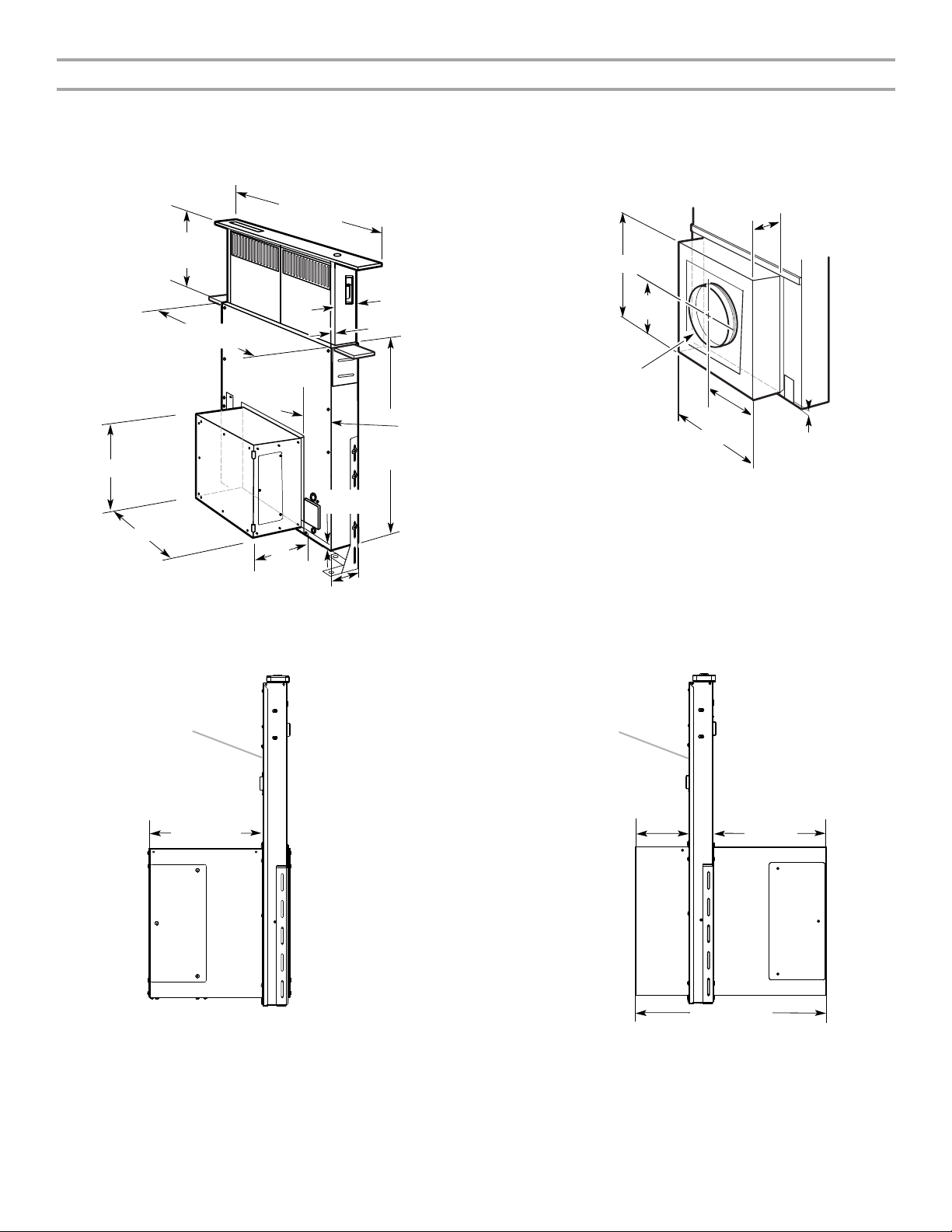

Product Dimensions

Models with interior-mounted blower motor

Models with exterior-mounted blower motor

4³⁄₄" (12.1 cm)

13¹⁄₈" (33.4 cm)

6⁹⁄₁₆"

(16.7 cm)

10" (25.4 cm)

diameter

vent collar

16¹⁄₂" (42.0 cm)

8¹⁄₄"

(21.0 cm)

³⁄₄" (1.9 cm)

Top trim widths:

30" (76.2 cm)

36" (91.4 cm)

13¹⁄₂" (34.3 cm)

retractable

vent height

27" (68.6 cm) for 30" (76.2 cm) vent

33" (83.8 cm) for 36" (91.4 cm) vent

16¹⁄₂" (42.0 cm)

10"

(25.4 cm)

2¹⁄₈" (5.4 cm)

28¹⁄₂"

(72.4 cm)

³⁄₈" (0.95 cm)

1¹⁄₂" (3.8 cm)

13¹⁄₈" (33.4 cm)

5¹⁄₄"(13.3 cm)

for 30" (76.2 cm) vent

8¹⁄₄"(21.0 cm)

for 36" (91.4 cm) vent

³⁄₄

(1.9 cm)

As-Received Blower

Reversed Blower

10" (25.4 cm)

4³⁄₄"

(12 cm)

16¹⁵⁄₁₆" (43 cm)

10"

(25.4 cm)

Front of

Range Hood

Front of

Range Hood

6

Page 7

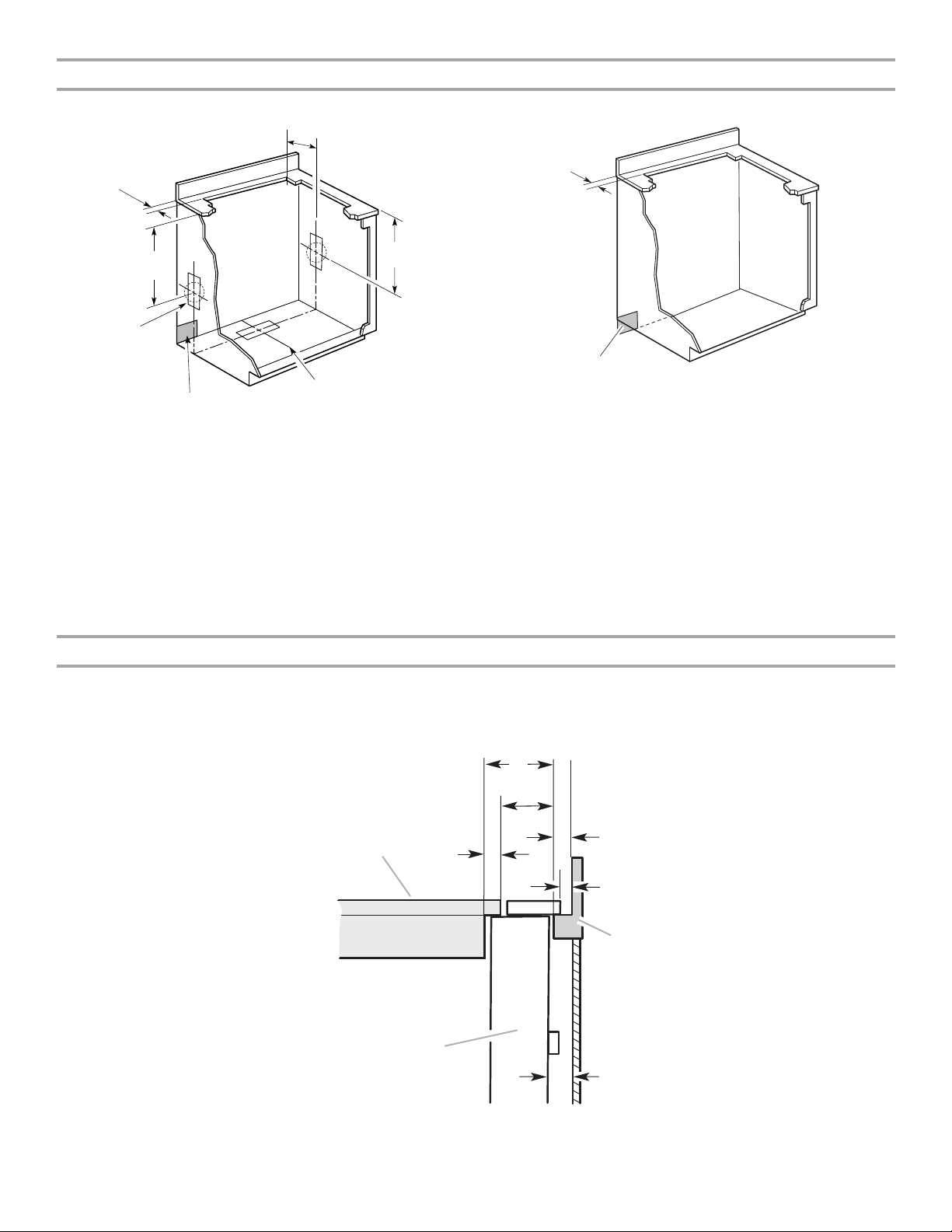

Cabinet Dimensions

A= ¹⁄₂" (12.7 mm)

minimum

21⁵⁄₁₆"

(54.1 cm)

Cutouts are

for 3¹⁄₄" x 10"

(8.3 x 25.4 cm)

rectangular or 6"

(15.2 cm) round

vent system.

Centerline of cooktop cutout

21⁵⁄₁₆"

(54.1 cm)

Locate power

supply junction

box at lower

left hand

rear corner

of the cabinet.

10" (25.4 cm)

¹⁄₂" (12.7 mm)

minimum

Locate power

supply junction

box at lower

left hand

rear corner

of the cabinet.

A

B

C

E

H

D

I

G

F

Interior-mounted blower motor model Exterior-mounted blower motor model

NOTES:

■ See cooktop manufacturer’s instructions for cooktop cutout

■ Use dimensions for vent system cutout location that applies

■ Interior-mounted blower systems connect with 3¹⁄₄" x 10"

Countertop Cutout Dimensions

IMPORTANT: Countertops with a bull-nosed front edge are not recommended for these installations.

Some models require a countertop deeper than 25" (63.5 cm); see the following Countertop Cutout Dimensions Chart.

To avoid mistakes, it is recommended that the cooktop and vent cutouts be drawn on the countertop before making any cutouts.

See Cooktop Installation Instructions for complete cutout dimensions, location dimensions and installation details.

depth and width.

to your installation.

(8.3 x 25.4 cm) rectangular or 6" (15.2 cm) round vent

system. The cutout locations for this vent system will

depend on your specific installation.

NOTES:

■ See cooktop manufacturer’s instructions for cooktop cutout

depth and width.

■ Exterior-mounted blower systems connect with 10" (25.4 cm)

round vent. The cutout locations for this vent system will

depend upon your specific installation.

A. Downdraft vent

B. Cooktop

C. Measurement of cooktop rear overhang.

D. D = Measurement of cooktop rear overhang

(C) + 1

¹³⁄₁₆

E. 1

¹³⁄₁₆

F. ½" (12.7 mm) minimum

" [46.2 mm] (E)

" (46.2 mm)

G. ¼" (6.4 mm) minimum

H. Countertop and backsplash

I. ½" (12.7 mm) minimum

7

Page 8

Countertop Cutout Dimensions Chart

A

B

C

D

A. ½" (12.7 mm) minimum to backsplash or rear wall

B.

³⁄₄

" (19.1 mm) maximum backsplash depth

C. 27

¹⁄₂

" (69.9 cm) on 30" (76.2 cm) models 33

D. D = Measurement of cooktop rear overhang + 1

Electrical Requirements

Observe all governing codes and ordinances.

Ensure that the electrical installation is adequate and in

conformance with National Electrical Code, ANSI/NFPA 70 (latest

edition), or CSA Standards C22.1-94, Canadian Electrical Code,

Part 1 and C22.2 No. 0-M91 (latest edition) and all local codes

and ordinances.

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that the

ground path is adequate.

A copy of the above code standards can be obtained from:

National Fire Protection Association

1 Batterymarch Park

Quincy, MA 02169-7471

CSA International

8501 East Pleasant Valley Road

Cleveland, OH 44131-5575

■ A 120 volt, 60 Hz., AC only, 15-amp, fused electrical circuit is

required.

■ If the house has aluminum wiring, follow the procedure

below:

1. Connect a section of solid copper wire to the pigtail

leads.

2. Connect the aluminum wiring to the added section of

copper wire using special connectors and/or tools

designed and UL listed for joining copper to aluminum.

Follow the electrical connector manufacturer's recommended

procedure. Aluminum/copper connection must conform with

local codes and industry accepted wiring practices.

■ Wire sizes and connections must conform with the rating of

the appliance as specified on the model/serial rating plate.

The model/serial plate is located on the front of the downdraft

vent, above the wiring box cover.

■ Wire sizes must conform to the requirements of the National

Electrical Code, ANSI/NFPA 70 (latest edition), or CSA

Standards C22. 1-94, Canadian Electrical Code, Part 1 and

C22.2 No. 0-M91 (latest edition) and all local codes and

ordinances.

Venting Requirements

IMPORTANT: Make sure there is proper clearance within the wall

or floor before making exhaust vent cutouts.

■ Use heavy (rigid) metal vent.

■ Venting system must terminate to the outside.

¹⁄₂

" (85.9 cm) on 36" (91.4 cm) models

¹³⁄₁₆

" (46.2 mm)

■ Do not terminate the vent system in an attic or other enclosed

area.

■ Do not use 4" (10.2 cm) laundry-type wall caps.

■ Do not install 2 elbows together.

■ Do not use plastic or metal foil vent.

■ The length of vent system and number of elbows should be

kept to a minimum to provide efficient performance.

■ Use no more than three 90° elbows

■ Make sure there is a minimum of 24" (61 cm) of straight vent

between the elbows if more than one elbow is used.

■ Use clamps or duct tape to seal all joints in the vent system.

■ Use caulking tape to seal the exterior wall or floor opening

around cap.

■ Do not cut joist or stud. If vent cutout falls over a joist or stud,

a supporting frame must be constructed.

Flexible metal vent is not recommended. If it is used, calculate

each foot of flexible vent as 2 ft (0.6 m) of rigid metal vent.

Flexible elbows count twice as much as standard elbows.

Recommended Vent System Length:

For either interior-mounted or exterior-mounted blower

installations, the vent system length should not exceed the

maximum lengths listed in the Maximum Length of Vent System

chart. See “Calculating Vent System Length” in the “Venting

Methods” section in the Installation Instructions for the interior- or

exterior-mounted vent motor.

Cold Weather Installations

An additional back draft damper should be installed to minimize

backward cold air flow and a thermal break should be installed to

minimize conduction of outside temperatures as part of the vent

system. The damper should be on the cold air side of the thermal

break.

The break should be as close as possible to where the vent

system enters the heated portion of the house.

Makeup Air

Local building codes may require the use of makeup air systems

when using ventilation systems greater than specified CFM of air

movement. The specified CFM varies from locale to locale.

Consult your HVAC professional for specific requirements in your

area.

8

Page 9

INSTALLATION INSTRUCTIONS

A

A

B

C

A

A

B

C

D

E

F

G

H

I

J

K

L

M

A

B

C

D

E

F

G

H

I

J

K

L

M

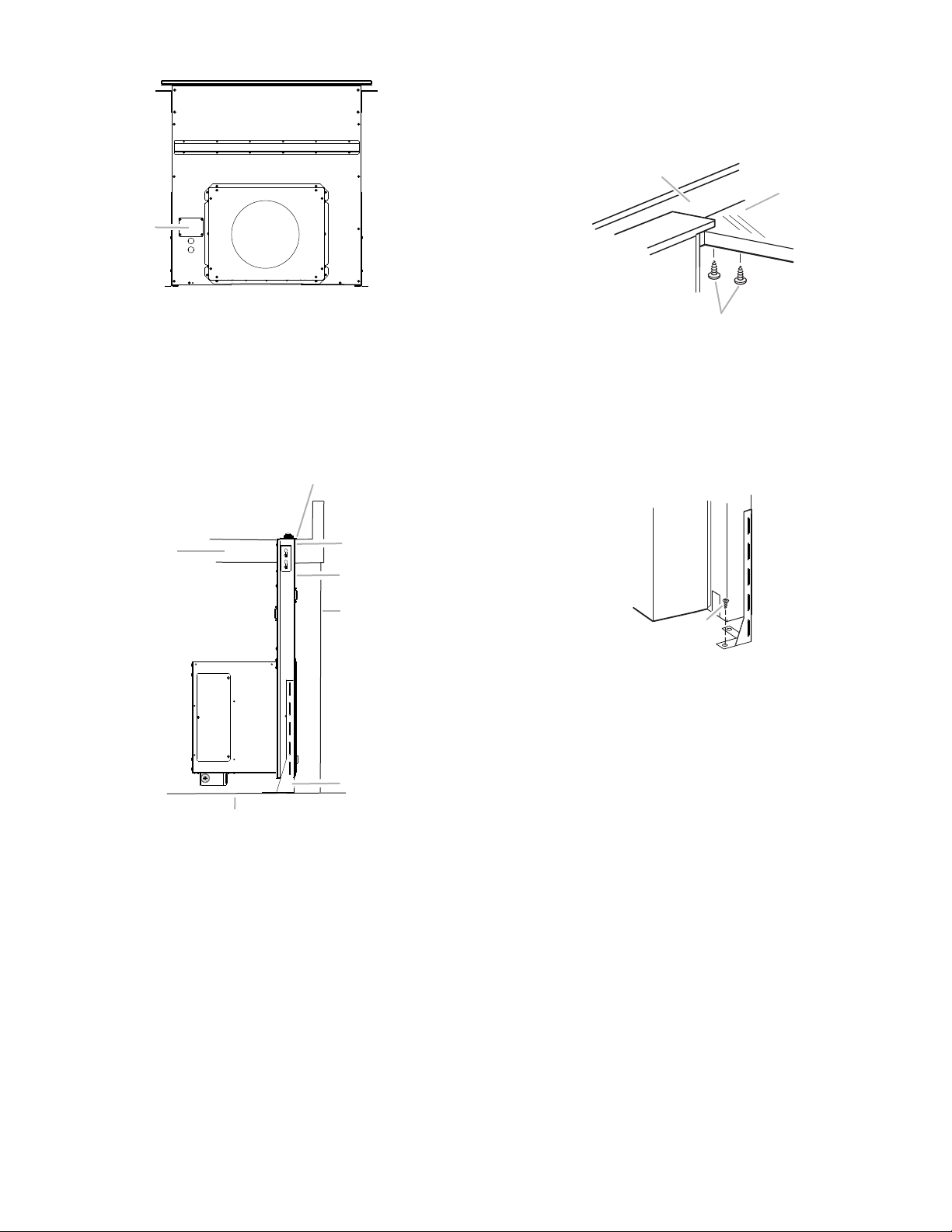

INTERIOR-MOUNTED VENT MOTOR

Venting Methods

Determine which venting method is best for your application.

Vent system can terminate either through the wall or floor.

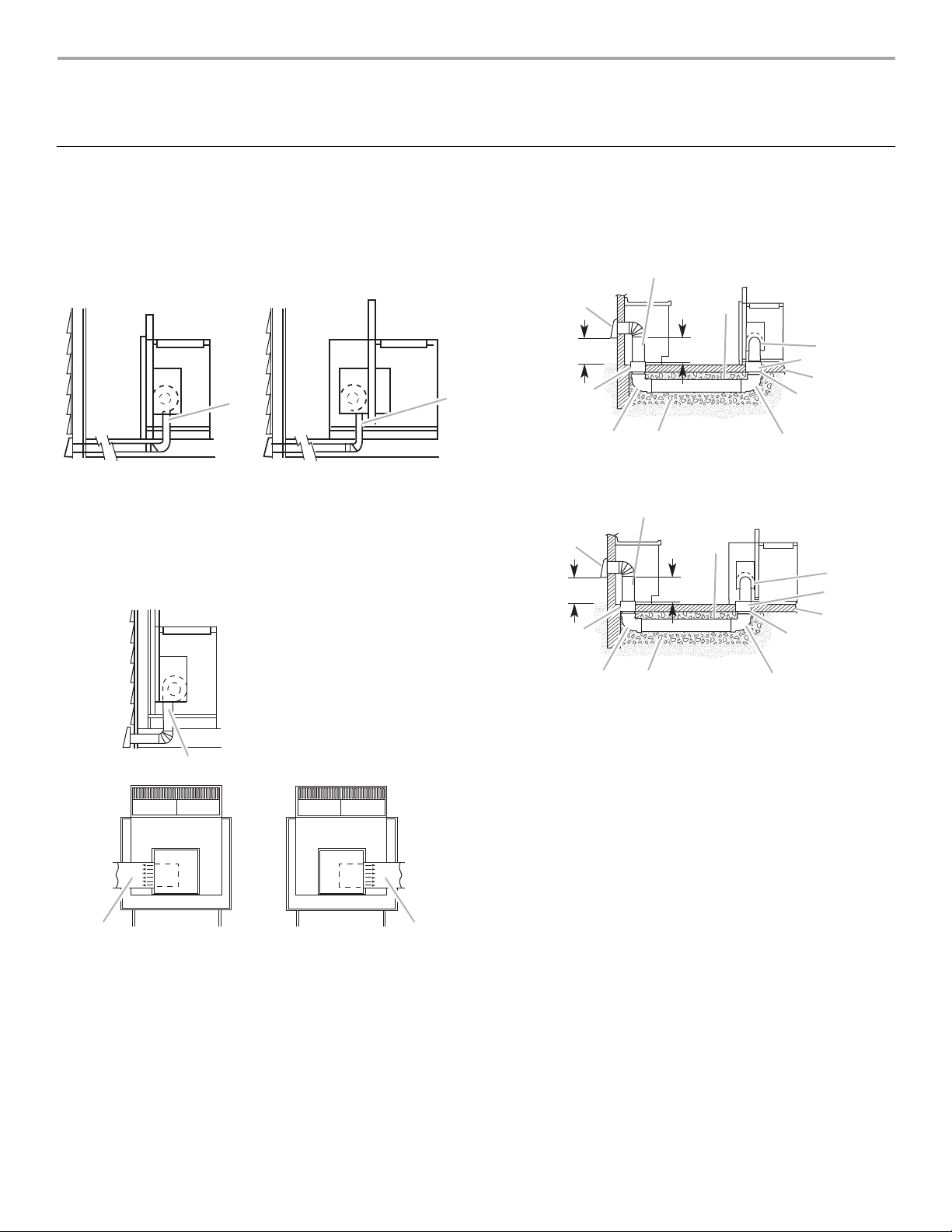

Island Location

Front (Standard)-Mounted

Blower Motor

Rear-Mounted Blower

Motor

Island Location—Vent System Installed Under a Concrete

Slab Using PVC Sewer Pipe

Front (Standard)-Mounted Blower Motor

A. Down vent

NOTE: For island locations, a front or rear mounted blower motor

can also be mounted for right or left venting if needed for your

application. Most island applications would still require the

venting to be directed down through the floor.

Built-In Cabinet Locations

Rear-Mounted Blower Motor

A. Wall cap

B. 6" (15.2 cm) round metal vent

C. 16" (40.6 cm) maximum

D. 6" (15.2 cm) round PVC sewer pipe

E. 6" (15.2 cm) round metal vent transition with damper (supplied)

F. 6" (15.2 cm) round PVC coupling

G. Concrete slab

H. 6" (15.2 cm) round PVC sewer pipe

I. 6" (15.2 cm) round 90° PVC sewer pipe elbow

J. Tightly pack gravel or sand completely around pipe.

K. 6" (15.2 cm) round 90° PVC sewer pipe elbow

L. 6" (15.2 cm) round PVC coupling

M. 12" (30.5 cm) minimum

A. Down vent

B. Left vent

C. Right vent

9

Page 10

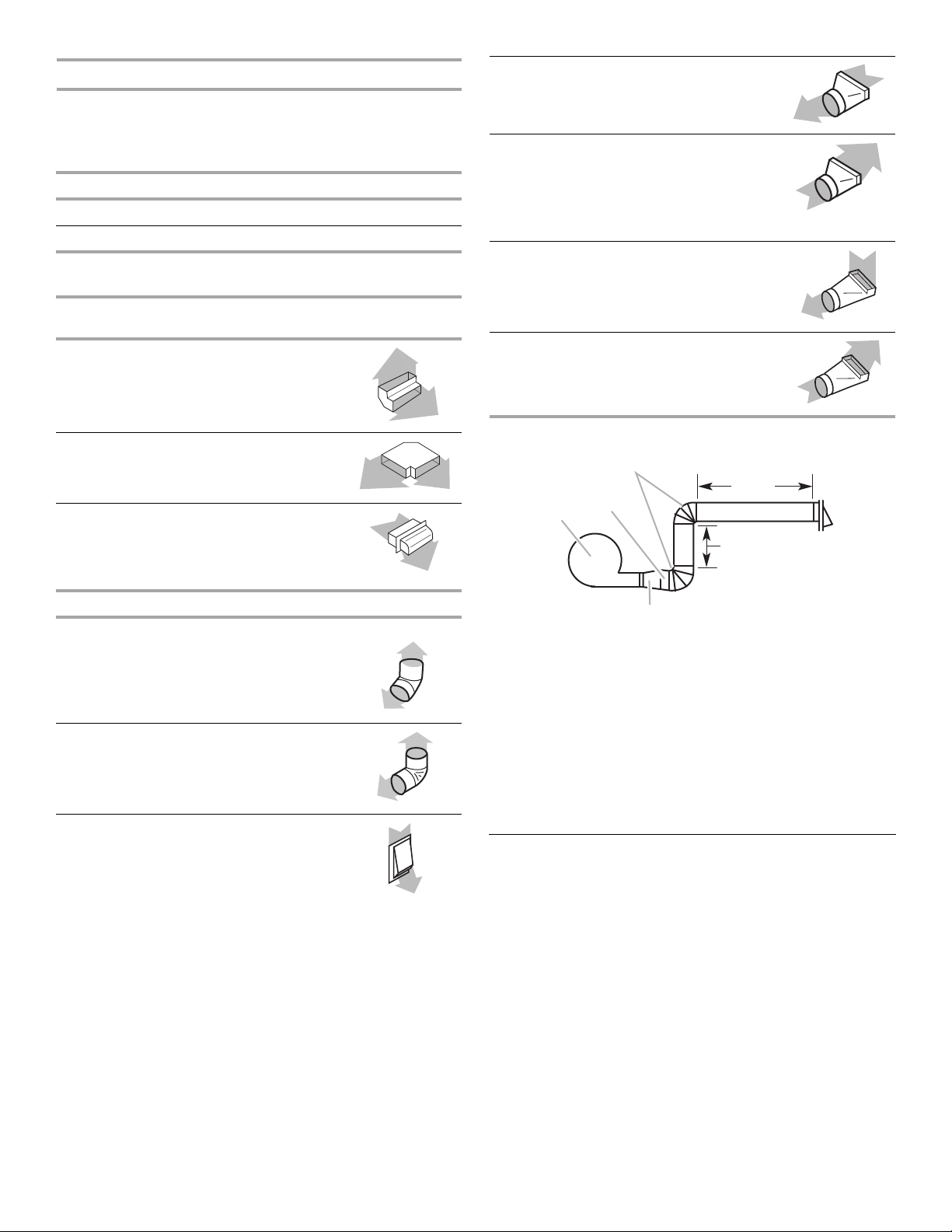

Calculating Vent System Length

A

B

C

6 ft

(1.8 m)

2 ft (0.6 m)

D

3¼" x 10" (8.3 x 25.4 cm) rectangular vent is required from the

blower motor box. It can be transitioned to 6" (15.2 cm) round

vent if needed.

Maximum Length of Vent System

Vent Length

6" (15.2 cm) round 35 ft (8.9 m)

3¹⁄₄" x 10" (8.3 cm x 25.4 cm) 35 ft (8.9 m)

3¹⁄₄" x 10" (8.3 cm x 25.4 cm)

to 6" (15.2 cm) transition

6" (15.2 cm) to 3¹⁄₄" x 10"

(8.3 cm x 25.4 cm) transition

4.5 ft

(1.4 m)

1 ft

(0.3 m)

To calculate the length of the system you need, add the

equivalent feet (meters) for each vent piece used in the system.

3¹⁄₄" x 10" (8.3 cm x 25.4 cm)

Vent Piece

3¹⁄₄" x 10" (8.3 cm x 25.4 cm)

90° elbow

3¹⁄₄" x 10" (8.3 cm x 25.4 cm)

flat elbow

3¹⁄₄" x 10" (8.3 cm x 25.4 cm)

wall cap

Rectangular

5.0 ft

(1.5 m)

12.0 ft

(3.7 m)

0.0 ft

(0.0 m)

Vent Piece 6" (15.2 cm) Round

45° elbow 2.5 ft

(0.8 m)

90° elbow 5.0 ft

(1.5 m)

6" (15.2 cm)

wall cap

0.0 ft

(0.0 m)

3¹⁄₄" x 10" (8.3 cm x 25.4 cm)

to 6" (15.2 cm) 90° elbow

5.0 ft

(1.5 m)

transition

6" (15.2 cm) to 3¹⁄₄" x 10"

(8.3 cm x 25.4 cm) 90° elbow

5.0 ft

(1.5 m)

transition

Example Vent System

A. Blower motor

B. Transition

C. 90° elbows

D. Back draft damper

The following example falls within the maximum vent length of

35 ft (8.9 m).

2 - 90° elbow = 10.0 ft (3 m)

1 - wall cap = 0.0 ft (0.0 m)

8 ft (2.4 m) straight = 8.0 ft (2.4 m)

Transition = 4.5 ft (1.4 cm)

Length of 6" (15.2 cm)

or 3¹⁄₄" x 10"

(8.3 cm x 25.4 cm)

system

= 22.5 ft (6.8 m)

10

Page 11

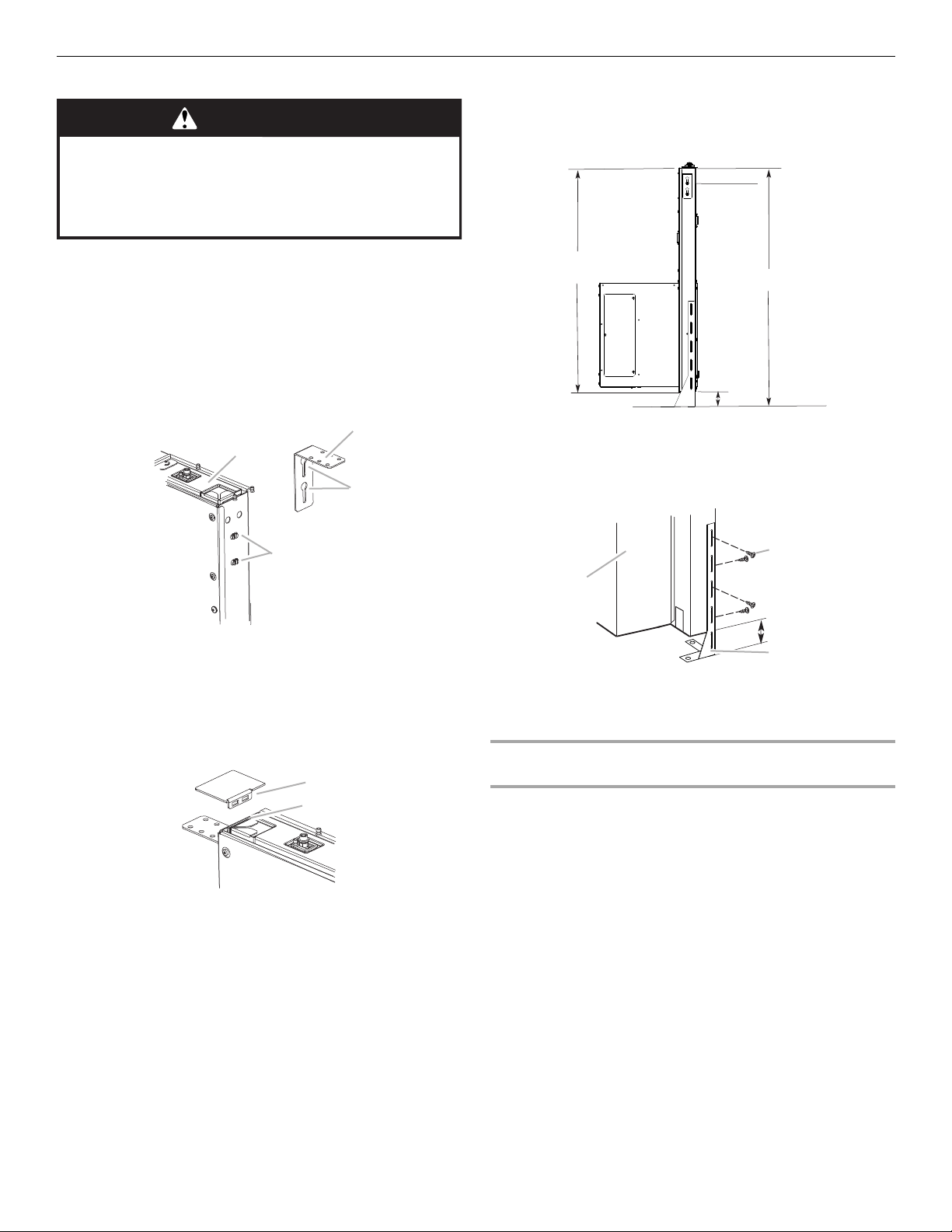

Install Vent System

WARNING

Excessive Weight Hazard

Use two or more people to move and install

downdraft vent.

Failure to do so can result in back or other injury.

B

C

D

A

A

B

Cabinet floor

Top of countertop

Downdraft vent

“X”

“Y”

28¹⁄₂"

(73 cm)

A

B

Dim. “Y”

C

1. Place cardboard or similar material on top of a flat surface

where you can easily assemble the downdraft vent system.

2. Remove parts packages, downdraft vent and blower box

from the carton.

3. Remove all shipping materials, tape and film from the

downdraft vent and blower box.

4. Install the right and left undercounter mounting brackets to

the vent box. Slide the keyhole slots over the guide tabs and

push the brackets up to set them in place.

6. Measure distance “X” from the cabinet floor to the top of the

countertop. Subtract 28¹⁄₂" from distance “X” to determine

dimension “Y” (X - 28¹⁄₂ = Y).

7. Attach the support legs to the side of the vent box with

4-4x8mm screws in each support leg. Adjust to dimension

“Y” from the bottom of the vent box to the bottom of the

support legs. Tighten screws.

A. Vent box

B. Undercounter mounting bracket

C. Keyhole slots

D. Guide tabs

5. Attach the right and left end caps to the vent box. Place the

tab into the mounting slot at each end of the downdraft vent

as shown and push down to lock into place.

A. End cap tab

B. Mounting slot

A. Motor box

B. Support leg

C. 4 x 8 mm screws (4)

Determine Which Vent Direction Is Best for Your

Installation

When installed in a cabinet, vent system can exhaust through the

bottom, right or left of the cabinet.

NOTE: When using the 6" (15.2 cm) vent transition (supplied) for

6" round venting, only left or right venting is recommended.

11

Page 12

Bottom Venting:

A

B

C

E

D

G

F

B

A

C

A

A

B

A

C

NOTE: If installing the vent damper in the down position, a wall or

roof cap with a damper at the exit end of the vent system is

required.

■ Downdraft vent is shipped with blower in down venting

position so no modification is required.

■ If rear mounting of the blower motor is not required, go to

the “Complete Installation (Interior-Mounted Motor)”

section.

■ To mount the blower motor to the rear side of the vent

box, go to the “Rear Mounting - Blower Motor” section.

Left or Right Venting:

1. Using two or more people, place the downdraft vent system

on its back.

2. Remove the 4 screws from the cover plate mounted to the

face of the motor box and set them aside.

Rear Mounting—Blower Motor

NOTE: Optional blower motor rear mounting position (opposite

side) for island cabinet locations. The blower motor box

assembly can be moved to the opposite side (rear) of the vent

box.

1. Remove 7 screws from the mounting flanges of the blower

motor box.

Front View

A. Screws (7)

B. Keyhole slot shoulder screws (2)

C. Blower motor box

2. Lift blower motor box off the shoulder screws in the keyhole

slots. Disconnect wire connection from blower motor and set

blower motor box aside.

3. Remove 6 screws from the mounting flange of the ¹⁄₄"

(6.4 mm) deep cover.

Rear View

A. Cover plate

B. Cover plate screws (4)

C. Cover plate keyhole slot

shoulder screws (4)

D. Motor mounting screws (4)

E. Vent cover plate

F. M ot o r b ox

G.Vent cover screws (3)

3. Slide the cover plate up and slip it over the keyhole slot

shoulder screws. Set the cover aside.

4. Remove 4 screws from the bottom of the motor box that hold

the motor assembly to the motor box.

NOTE: Disconnect the electrical wiring connection from

motor if needed.

5. Remove 3 screws and the vent cover plate from the left or

right side of the motor box for the venting direction to be

used.

6. Rotate the blower motor assembly 90 degrees to the left or

7. Install the vent cover plate over the rectangular opening in the

NOTE: Reinstall the electrical wiring connection to motor if

removed.

right side to the chosen venting direction and secure to the

blower box with motor mounting screws previously removed.

Do not twist or bind the wires.

bottom of the motor box and secure with vent cover screws.

A. Screws (6)

B. Keyhole slot shoulder screws (2)

C.

¹⁄₄

" (6.4 mm) deep cover

4. Lift the ¹⁄₄" (6.4 mm) deep cover off the shoulder screws in the

keyhole slots and set the cover aside.

8. Reinstall the cover plate to the face of the motor box and

secure with 4 cover plate screws previously removed.

9. For mounting the blower motor to the back of the vent box,

go to the “Rear Mounting - Blower Motor” section. Otherwise,

go to the “Complete Installation (Interior-Mounted Motor)”

section.

12

Page 13

5. Remove the screws from the wire mounting plate.

A

A

B

C

A

B

A

A

B

A

B

A. Screws

B. Wire mounting plate

C. Blower motor box

6. Hold the wire mounting plate and push the grommet out of

the mounting plate.

Complete Installation

(Interior-Mounted Motor)

NOTE: The downdraft vent system is supplied with a 3¹⁄₄" x 10"

(8.3 x 25.4 cm) back draft damper and a 6" (15.2 cm) round vent

transition with damper. Refer to “3¹⁄₄" x 10" (8.3 x 25.4 cm) back

draft damper” or “6" (15.2 cm) round vent transition with

damper,” depending upon the type of venting you are using.

3¹⁄₄" x 10" (8.3 x 25.4 cm) Back Draft Damper

1. Attach the 3¼" x 10" (8.3 x 25.4 cm) back draft damper to the

vent opening in the blower motor box, using three 3.5 x

9.5 mm screws.

A. 3.5 x 9.5 mm screws

B. 3¼" x 10" (8.3 x 25.4 cm)

back draft damper

A. Wire mounting plate

B. Grommet

7. Slide the wire assembly through the slot in the wire mounting

plate to remove it.

8. Place the wire assembly through the opening to the opposite

side of the vent box.

9. Reassemble the wire assembly and grommet to the wire

mounting plate

10. Install the wire mounting plate to the vent box using the 4

screws previously removed.

11. Place the blower motor box assembly with the keyhole slots

over the 2 shoulder screws on the rear of the vent box and

reconnect the wire connection to the blower motor.

12. Mount the blower motor box to the vent box and secure using

the 6 screws previously removed.

13. Mount the 4³⁄₄" (12.0 cm) cover box (supplied) to the front of

14. Go to the “Complete Installation (Interior-Mounted Motor)”

the vent box. Place the keyhole slots over the 2 shoulder

screws, align the mounting holes, and secure the cover box

to vent box using the 6 screws previously removed from the

¹⁄₄" (6.4 mm) deep cover.

section.

6" (15.2 cm) Round Vent Transition with Damper

1. Attach the 6" (15.2 cm) round vent transition to vent opening

(left or right side venting only is recommended), using two

3.5 x 9.5 mm screws.

A. 3.5 x 9.5 mm screws

B. 6" (15.2 cm) round vent transition with damper

13

Page 14

2. Remove 4 screws attaching the terminal box cover.

A

A

C

B

D

E

F

G

A

B

C

A

A. Terminal box cover

5. Drill 2 pilot holes through each of the undercounter mounting

brackets into the underside of the countertop. Using 2 screws

(not provided) of the appropriate length, mount the brackets

to the countertop.

IMPORTANT: Select a screw length that will not allow the

screws to go through the countertop when tightened.

3. Determine which direction (front or rear) the home power

supply cable will enter the terminal box. Remove the

appropriate knockout from the front or rear panel and install a

¹⁄₂" (12.7 mm) UL listed or CSA approved conduit connector.

4. Using 2 or more people, insert the downdraft vent into the

countertop cutout. Position downdraft vent so it is centered

in the cutout with the rear flange over the edge of the cutout

and the rear of the vent box against the edge of the cutout.

A. Screws

B. Backsplash

C. Countertop

6. Check that the downdraft vent is level vertically. Loosen the

lower support legs screws and position the legs against the

cabinet floor.

7. Fasten the lower support legs to the cabinet floor with screws

(not provided).

A. Screw (not provided)

8. Tighten the lower support legs screws.

A. Rear flange of downdraft vent

B. Edge of cutout in countertop

C. Rear of downdraft vent

D. Cabinet back

E. Lower support leg

F. Cabinet floor

G. Countertop

14

Page 15

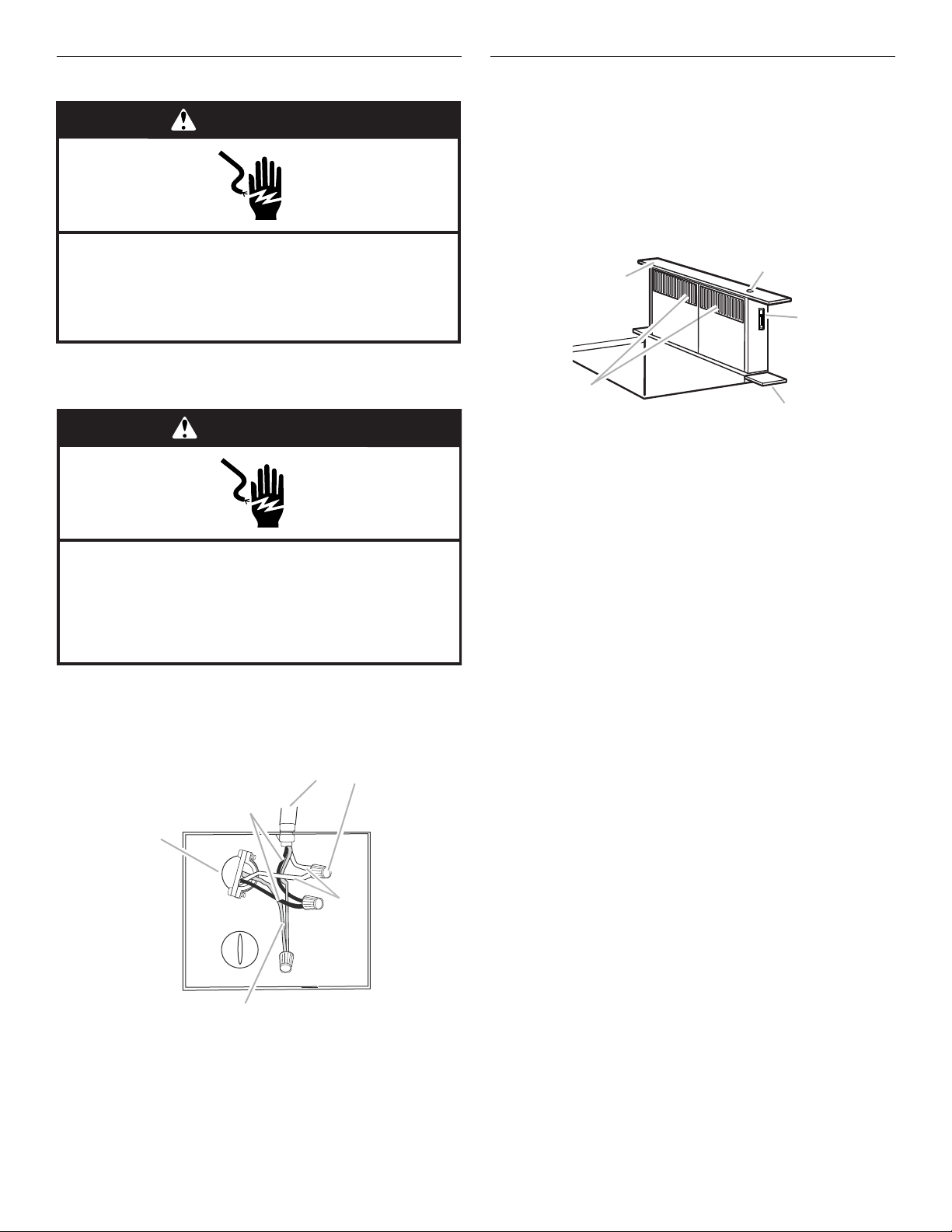

Make Electrical Connections

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

WARNING

Electrical Shock Hazard

Electrically ground blower.

Connect ground wire to green and yellow ground wire

in terminal box.

Failure to do so can result in death or electrical shock.

A

B

C

D

E

F

C

Check Operation

1. Push and hold the button on the top of the downdraft vent for

a few seconds. The retractable section of the downdraft vent

will rise, and the blower will start. Position the top trim over

the retractable section and snap trim into place.

Trim kits for matching your cooktop color are available from

your dealer.

For information on ordering, see the “Assistance or Service”

section.

1. Disconnect power.

2. Feed the power supply cable through the conduit connector

and into the terminal box.

3. Connect the green (or green/yellow) ground wire to the green

or yellow/green ground wire using UL listed wire connectors.

Tighten the screw on the conduit connector.

4. Connect the 2 white wires together using UL listed wire

connectors.

A

B

E

D

A. Top trim

B. ON/OFF button

C. Blower control slider

2. Slide the control slider on the side of vent to check the

operation and speed of the blower.

3. If the blower does not operate:

■ Check that filter or filters are pressed in as far as they will

go.

■ Check that the circuit breaker has not tripped or a

household fuse blown.

4. Connect vent system to blower. Vent system must end with a

wall or roof cap. Use clamps or duct tape to seal all joints.

5. Install cooktop according to manufacturer’s instructions.

Check that rear of cooktop overlaps edge of retractable

downdraft vent by ³⁄₈" (9.5 mm). See “Countertop Cutout

Dimensions” in the “Location Requirements” section.

NOTE: To get the most efficient use from your new retractable

downdraft vent, read the “Vent System Use” section.

D. End cap

E. Filters

A. Green or green and yellow

ground wire

B. White wires

C. UL listed wire connectors

5. Connect the 2 black wires together using UL listed wire

connectors.

6. Replace the terminal box cover and secure with screw.

7. Reconnect power.

D. Black wires

E. UL listed or CSA approved

F. Downdraft vent wiring

conduit connector

15

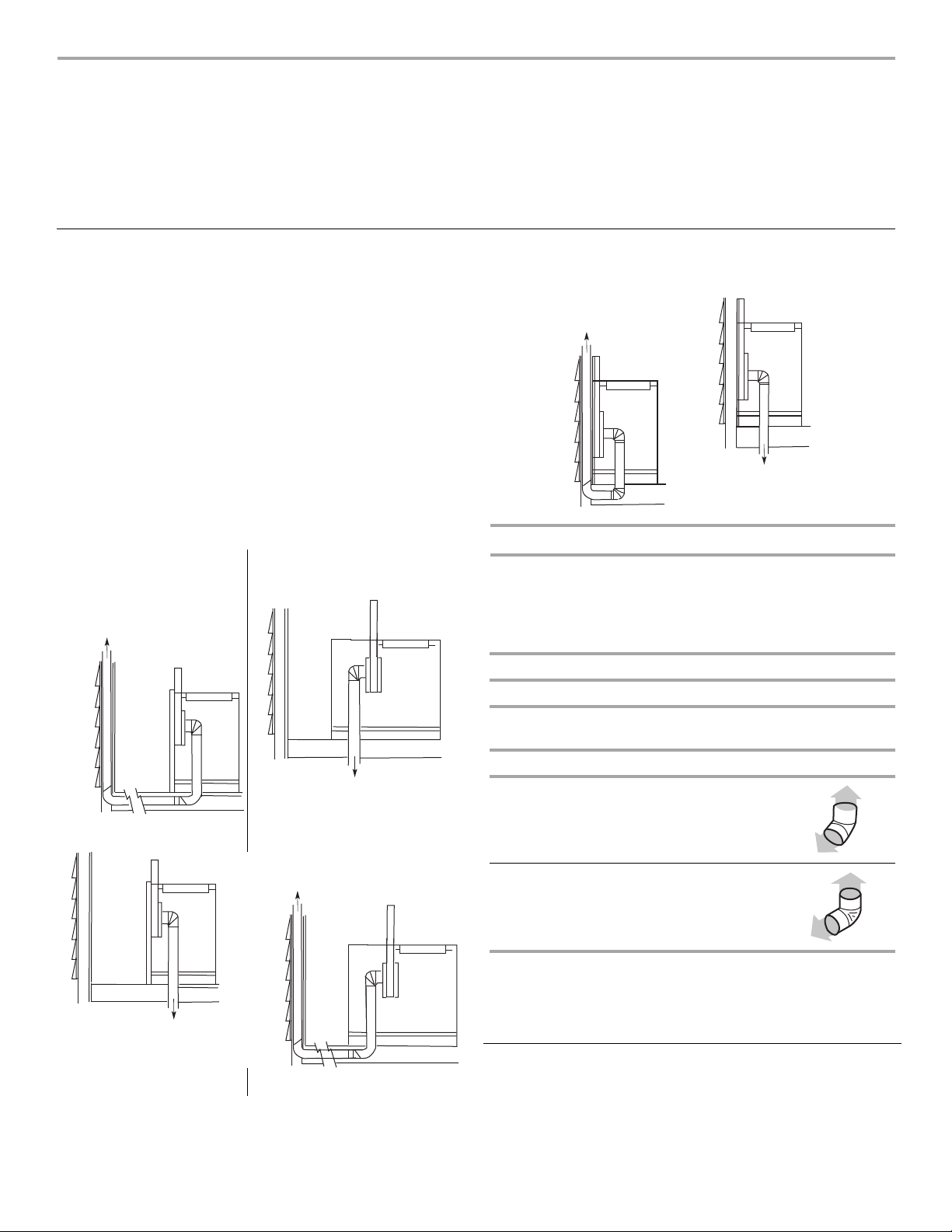

Page 16

INSTALLATION INSTRUCTIONS

To attic

installed in-line

blower motor system

To basement, crawlspace

or utility room installed

in-line blower motor system

To basement, crawlspace

or utility room installed

in-line blower motor system

To attic

installed in-line

blower motor system

To attic

installed in-line

blower motor system

To basement, crawlspace

or utility room installed

in-line blower motor system

EXTERIOR-MOUNTED VENT MOTOR

CAUTION: To reduce the risk of fire and electrical shock,

install the downdraft only with remote blower systems that

are sold by Whirlpool Corporation. Model numbers

UXI0600DYS (600 cfm) and UXI01200DYS (1200 cfm).

Venting Methods

Determine which venting method is best for your application.

Vent system can terminate through the wall or roof. A wall cap or

roof cap is required.

NOTES:

■ Venting through a concrete slab is not recommended.

■ The in-line blower motor system must be placed in an

enclosed area and can be located in a utility room, basement,

crawl space or attic. Observe all governing codes and

ordinances.

■ 10" (25.4 cm) round vent duct is required for connections to

the retractable downdraft vent system outlet cover and the

in-line blower motor inlet and outlet covers. 10" (25.4 cm)

round vent duct is recommended for the retractable

downdraft vent system with in-line blower motor system.

Transitioning to different size ducting will reduce the

efficiency of the retractable downdraft vent system.

Island Location—Front

Vent

Island Location—Rear Vent

NOTE: Exterior-mounted vent motor installations require an

approved in-line blower motor system. Model numbers

UXI0600DYS (600 cfm) and UXI1200DYS (1200 cfm) are available

from your dealer or authorized parts supplier. See “Blower motor

system” in the “Accessories” section.

Built-In Cabinet Locations

Calculating Vent System Length

It is recommended that you use round vent instead of rectangular

vent, especially if elbows are required. If rectangular vent is

required, it should be transitioned to 10" (25.4 cm) round vent as

soon as possible.

Maximum Length of Vent System

Vent Length

10" (25.4 cm) round 60 ft (18.3 m)

To calculate the length of the system you need, add the

equivalent feet (meters) for each vent piece used in the system.

Vent Piece 10" (25.4 cm) Round

45° elbow 2.5 ft

(0.8 m)

90° elbow 5.0 ft

(1.5 m)

The maximum equivalent vent lengths of 10" (25.4 cm) round

vents - 60 ft (18.3 m).

2 - 90° elbows = 10.0 ft (3 m)

10 ft (3 m) straight = 10.0 ft (3 m)

Length of 10" (25.4 cm)

= 20 ft (6 m)

system

NOTE: The exterior-mounted vent motor requires a separate

wiring cable that should be installed at the same time the vent

work is installed.

16

Page 17

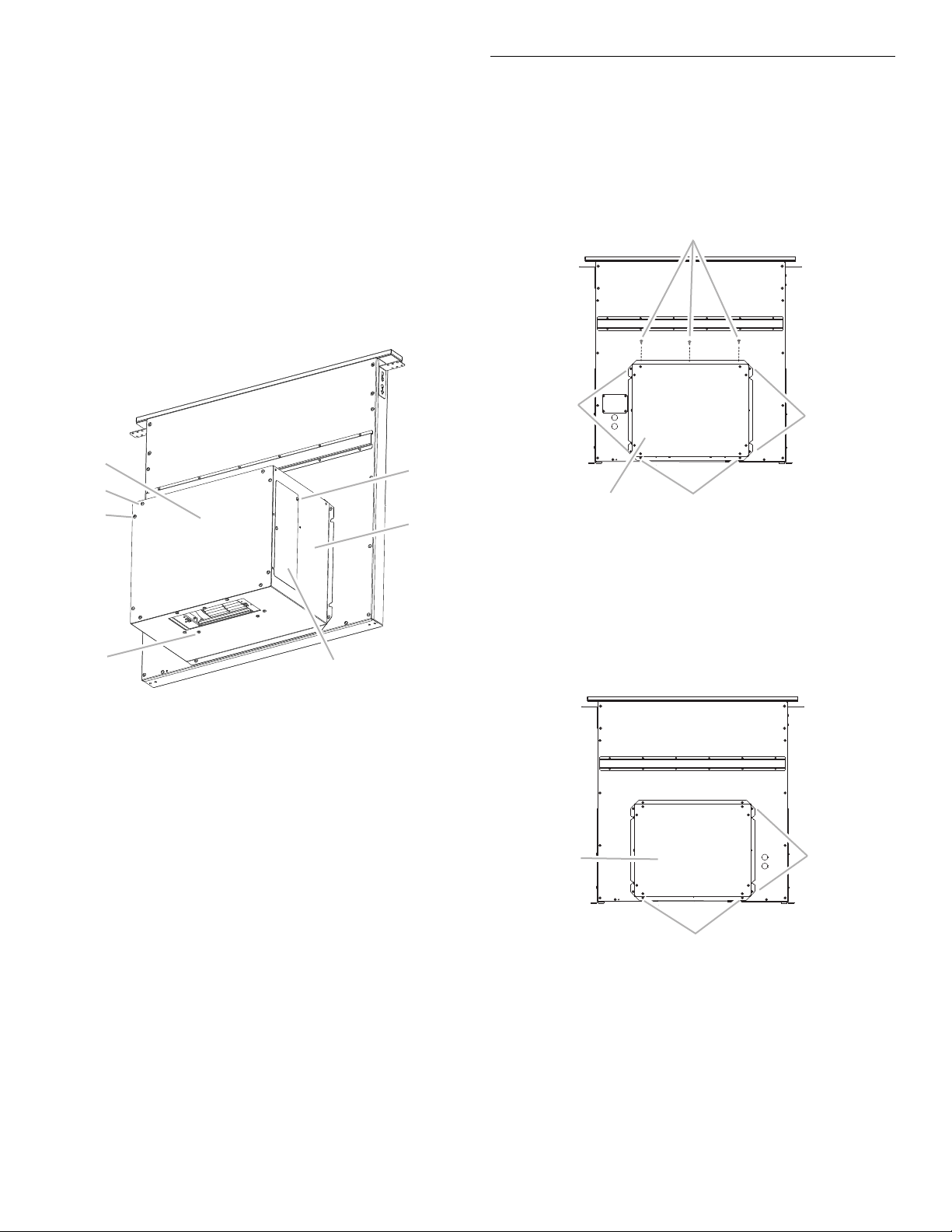

Install Vent System

WARNING

Excessive Weight Hazard

Use two or more people to move and install

downdraft vent.

Failure to do so can result in back or other injury.

B

C

D

A

A

B

Cabinet floor

Top of countertop

Downdraft vent

“X“

“Y“

28¹⁄₂"

(73 cm)

A

B

Dim. “Y”

C

1. Place cardboard or similar material on top of a flat surface

where you can easily assemble the downdraft vent system.

2. Remove parts packages, downdraft vent and blower box

from the carton.

3. Remove all shipping materials, tape and film from the

downdraft vent and blower box.

4. Install the right and left undercounter mounting brackets to

the vent box. Slide the keyhole slots over the guide tabs and

push the brackets up to set them in place.

6. Measure distance “X” from the cabinet floor to the top of the

countertop. Subtract 28¹⁄₂" from distance “X” to determine

dimension “Y” (X - 28¹⁄₂" = Y).

7. Attach the support legs to the side of the vent box with

4 - 4 x 8 mm screws in each support leg. Adjust to dimension

“Y” from the bottom of the vent box to the bottom of the

support legs. Tighten screws.

A. Vent box

B. Undercounter mounting bracket

C. Keyhole slots

D. Guide tabs

5. Attach the left and right side end caps to the downdraft vent.

Place the end cap upon the overcounter support, slide the

tab into the slot and snap into place over the plastic tabs.

A. End cap tab

B. Mounting slot

A. Motor box

B. Support leg

C. 4 x 8 mm screws (4)

Determine Which Vent Direction Is Best for Your

Installation

When installed in a cabinet the vent system can exhaust through

the front or rear of the vent box. The downdraft vent is shipped

with a 10" diameter vent collar plate.

Front or Rear Venting:

1. Using two or more people, place the downdraft vent system

on the opposite side for venting.

2. Remove the 4 screws from the cover plate mounted to the

face of the motor box and set them aside.

3. Slide the cover plate up and slip it over the keyhold slot

shoulder screws. Set the cover aside.

4. Install the 10" diameter vent collar plate to the vent box

where the cover plate was removed in the previous step.

Secure using the 4 screws from the cover plate.

5. Go to the “Complete Installation (Exterior-Mounted Motor)”

section.

17

Page 18

Complete Installation

A

A

C

B

D

E

F

G

A

B

C

A

(Exterior-Mounted Motor)

1. Remove 4 screws attaching the terminal box cover.

A. Terminal box cover

2. Determine which direction (front or rear) the home power

supply cable and the wiring conduit from the in-line blower

system will enter the terminal box. Remove the appropriate

knockout from the front or rear panel and install two

¹⁄₂" (12.7 mm) UL listed or CSA approved conduit connectors.

3. Using 2 or more people, insert the downdraft vent into the

countertop cutout. Position downdraft vent so it is centered

in the cutout with the rear flange over the edge of the cutout

and the rear of the vent box against the edge of the cutout.

4. Drill 2 pilot holes through each of the undercounter mounting

brackets into the underside of the countertop. Using 2 screws

(not provided) of the appropriate length, mount the brackets

to the countertop.

IMPORTANT: Select a screw length that will not allow the

screws to go through the countertop when tightened.

A. Screws

B. Backsplash

C. Countertop

5. Check that the downdraft vent is level vertically. Loosen the

lower support legs screws and position the legs against the

cabinet floor.

6. Fasten the lower support legs to the cabinet floor with screws

(not provided).

A. Screw (not provided)

7. Tighten the lower support legs screws.

Install Downdraft Vent In-Line (External

Type) Blower Motor

NOTE: Your downdraft vent requires you to purchase an in-line

(external type) blower motor system. See “Blower Motor System”

in the “Accessories” section.

Prepare for Mounting the In-Line Blower System

A. Rear flange of downdraft vent

B. Edge of cutout in countertop

C. Rear of downdraft vent

D. Cabinet back

E. Lower support leg

F. C ab in et f lo or

G. Countertop

The in-line blower system must be fastened to a secure structure

of the roof, ceiling, wall, floor, or new or existing frame

construction. The 4 holes on either the inlet (bottom) side or the

outlet (top) side of the blower must be used to mount the in-line

blower system to the structure.

NOTE: The mounting hole locations must span the studs.

Additional stud framing may be required. Plywood may be used

to span open areas between ceiling or floor joists or roof rafters

to aid installation. This structure must be strong enough to

support the weight of the in-line blower system (50 lb

[22.6 kg] min).

18

Page 19

Prepare the In-line Blower System

WARNING

Excessive Weight Hazard

Use two or more people to move and install in-line

blower motor system.

Failure to do so can result in back or other injury.

A

B

C

D

A

A

A

A

A

A

1. Using 2 or more people, move the in-line blower motor

system to the mounting location.

2. Remove the 10 screws from the front cover of the in-line

blower motor housing and set them aside.

3. Remove the front cover of the in-line blower motor housing

and set it aside.

NOTE: To make the blower motor housing easier to mount,

the blower motor assembly can be removed. If you do not

want to remove the blower motor assembly, proceed to

“Install In-line Blower System” in this section.

4. Disconnect the motor electrical plug from the blower motor

assembly.

5. Remove the screws that secure the blower motor assembly

to the in-line blower housing and set them aside.

6. Pull the spring clip to release the blower motor assembly.

Remove the blower motor assembly from the housing and

place it on a covered surface.

Install In-line Blower System

NOTE: The blower motor housing can be mounted using 4 holes

from either the inlet side or the outlet side of the blower.

Outlet Side

A. Mounting holes

Inlet Side

A. Front cover

B. Blower mounting screws

C. Spring clip

D. Motor electrical plug

A. Mounting holes

1. Position the in-line blower motor housing in its mounting

location and mark the 4 mounting hole locations.

2. Drill 4 mounting pilot holes using a ³⁄₁₆" (4.8 mm) drill bit.

3. Attach the in-line blower motor housing to the mounting

location with four 6 x 80 mm mounting screws and washers.

4. If it is removed, reinstall the blower motor assembly and

secure it with the screws previously removed.

5. If it is removed, reattach the motor electrical plug to the

connector on the blower motor assembly.

Complete Preparation

1. Determine and make all necessary cuts for the vent system.

IMPORTANT: When cutting or drilling into the floor, ceiling or

wall, do not damage electrical wiring or other hidden utilities.

2. Determine the location where the ¹⁄₂" (1.3 cm) wiring conduit

will be routed through the floor, ceiling or wall between the inline blower and the downdraft vent.

3. Drill a 1¹⁄₄" (3.2 cm) hole at this location.

19

Page 20

4. Locate the electrical terminal boxes in the in-line blower

A

B

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

A

B

C

D

E

F

G

H

I

housing and downdraft vent. Remove the terminal box covers

and set the covers and screws aside.

A. Electrical terminal box

B. Electrical knockout

5. Remove the electrical knockout from the in-line blower

housing and downdraft vent to prepare for the installation of

the UL listed or CSA approved ¹⁄₂" (1.3 cm) wiring conduit and

conduit connector.

6. With the downdraft vent mounted, run the ¹⁄₂" (1.3 cm) wiring

conduit between the in-line blower motor housing and the

downdraft vent. Pull enough ¹⁄₂" (1.3 cm) wiring conduit to

allow for easy connection to the terminal boxes in the in-line

blower housing and downdraft vent.

7. Run the six 18 AWG wires through the ¹⁄₂" (1.3 cm) wiring

conduit and conduit connectors and into the terminal boxes

on the in-line blower housing and downdraft vent. Leave

enough wire length in each terminal box to make the wiring

connections.

8. Install the conduit connectors and conduit to the in-line

blower housing and downdraft vent electrical terminal boxes.

9. Connect the vent system to the downdraft vent and in-line

blower system and seal all joints with clamps.

Make Electrical Connections for In-Line

Blower Motor System

Electrical Connection Inside In-line Blower System

1. Disconnect power.

2. Connect the wires from the wiring conduit to the wires from

the motor electrical plug cable inside the in-line blower

housing terminal box.

20

A. UL listed or CSA approved

¹⁄₂

" (1.3 cm) wiring conduit

B. UL listed wire connectors

C. Black wires

D. White wires

E. Red wires

3. Use UL listed wire connectors and connect the black wires

(C) together.

4. Use UL listed wire connectors and connect the white wires

(D) together.

5. Use UL listed wire connectors and connect the red wires (E)

together.

6. Use UL listed wire connectors and connect the blue wires (F)

together.

F. Blue wires

G. Gray wires

H. Green (or yellow/green) and

green/yellow wires

I. Motor electrical plug cable

Page 21

7. Use UL listed wire connectors and connect the gray wires (G)

WARNING

Electrical Shock Hazard

Electrically ground blower.

Connect ground wire to green and yellow ground wire

in terminal box.

Failure to do so can result in death or electrical shock.

A

B

C

D

E

F

G

H

I

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

A

A

B

C

D

E

F

together.

Make Electrical Power Supply Connection to

Downdraft Vent

8. Connect the green (or yellow/green) ground wire to the

green/yellow ground wire (H) in the terminal box using UL

listed wire connectors.

9. Reinstall the in-line blower terminal box cover and screw.

10. Reinstall the front cover of the in-line blower housing and

secure it with 10 mounting screws.

Electrical Connection Inside Downdraft Vent Between Inline Blower System and Downdraft Vent

NOTE: Discard the 6-wire connector assembly supplied with

the in-line blower motor system.

1. With the downdraft vent mounted, locate the bottom wiring

cable (5 wires) inside the downdraft vent terminal box.

2. Connect the wires from the bottom wiring cable (5 wires)

inside the downdraft vent terminal box to the wires from the

in-line blower wiring conduit inside the downdraft vent

terminal box.

3. Connect the same color wires to each other (black to black,

white to white, etc.) using UL listed wire connectors.

NOTE: Connect the green (or green/yellow) ground wire from

the wiring conduit to the green (or bare) ground wire from the

home power supply using UL listed wire connectors (see the

“Make Electrical Power Supply Connections to Downdraft

Vent” section).

1. Disconnect power.

2. Locate the downdraft vent terminal box.

A. Terminal box

A. UL listed or CSA approved

B. UL listed wire connectors

C. Black wires

D. White wires

E. Red wires

4. Go to “Make Electrical Power Supply Connection to

Downdraft Vent” section.

¹⁄₂

" (1.3 cm) wiring conduit

F. Blue wires

G. Gray wires

H. Green (or green/yellow)

wire

I. Bottom wiring cable

(5 wires)

A. Green or green and yellow

ground wires

B. White wires

C. UL listed wire connectors

3. Use UL listed wire connectors and connect black wires (D)

together.

D. Black wires

E. UL listed or CSA approved

conduit connector

F. Downdraft vent wiring

21

Page 22

4. Use UL listed wire connectors and connect white wires (B)

WARNING

Electrical Shock Hazard

Electrically ground blower.

Connect ground wire to green and yellow ground wire

in terminal box.

Failure to do so can result in death or electrical shock.

C

together.

Check Operation

1. Push and hold the button on the top of the downdraft vent for

a few seconds. The retractable section of the downdraft vent

will rise, and the blower will start. Position the top trim over

the retractable section and snap trim into place.

Trim kits for matching your cooktop color are available from

your dealer.

For information on ordering, see the “Assistance or Service”

section.

NOTE: The green (or green/yellow) ground wire in the conduit

from the In-line blower motor system is to be connected with the

green (or bare) wire of the home power supply cable and with the

green/yellow wire (A) in the terminal box.

5. Connect green (or bare) ground wire from home power supply

to the green/yellow ground wires (A) in terminal box using UL

listed wire connectors.

6. Install terminal box cover.

7. Reconnect power.

A

B

E

D

A. Top trim

B. On/Off button

C. Blower control slider

2. Slide the control slider on the side of vent to check the

operation and speed of the blower.

3. If the blower does not operate:

■ Check that filter or filters are pressed in as far as they will

go.

■ Check that the circuit breaker has not tripped or a

household fuse blown.

4. Connect vent system to blower. Vent system must end with a

wall or roof cap. Use clamps or duct tape to seal all joints.

NOTE: To get the most efficient use from your new retractable

downdraft vent, read the “Vent System Use” section.

D. End cap

E. Filters

22

Page 23

VENT SYSTEM USE

The retractable downdraft vent system is designed to remove

smoke, cooking vapors and odors from the cooktop area.

■ For best results, the vent should be operating before cooking

is started.

■ If you use large or tall utensils, place them on the large rear

element or burner surface.

■ A higher heat setting than normally used may be needed

when the downdraft vent is operating.

■ For gas cooktops, the downdraft vent system may affect the

flame stability and cooking performance. To improve the

burner performance, either decrease the downdraft vent

blower speed or increase the cooktop burner flame setting.

■ For gas cooktops with flame sensing ignitions, the downdraft

vent system may disperse the flame away from the spark

igniter and may cause it to continually spark while trying to

reignite a burner that is already lit. To resolve the issue of the

cooktop igniter continuously sparking, either decrease the

downdraft vent blower speed or increase the cooktop flame

setting for that burner.

Operating Downdraft Vent

To U se :

1. Push and hold the button on top of downdraft vent for a few

seconds. (This slight delay helps avoid unintentional raising of

the vent during cleaning of the cooktop area.) Retractable

section of downdraft vent will rise. Blower will begin to vent

immediately if blower control knob slider is set to an “On”

position.

2. Slide the control slider on the right-hand side of the

downdraft vent to adjust the blower motor speed.

When Cooking Is Complete:

1. Push the button on top of the retractable downdraft vent. The

blower will turn off, and the retractable section of the vent will

return to the closed position.

NOTE: If a spill occurs on the cooktop that allows liquids to seep

inside the downdraft vent, you must turn the downdraft vent off

immediately. It is possible to cause damage to the downdraft

vent if water is allowed inside the downdraft vent while it is

operating.

2. Immediately turn off the downdraft vent at the speed control

located on the right-hand side of the downdraft vent.

3. Turn off the power supply to the downdraft vent at the circuit

breaker box or fuse box.

4. Allow plenty of time for the downdraft vent to dry naturally. Do

not open the downdraft vent to remove the water.

23

Page 24

VENT SYSTEM CARE

C

A

B

Surface of Downdraft Vent

To avoid damaging the finish, clean downdraft vent with soap

and water. Do not use scouring powder or abrasive solutions.

Exterior Surfaces:

To avoid damage to the exterior surface, do not use steel wool or

soap-filled scouring pads.

Always wipe dry to avoid water marks.

Cleaning Method:

■ Liquid detergent soap and water, or all-purpose cleanser

■ Wipe with damp soft cloth or nonabrasive sponge, then rinse

with clean water and wipe dry.

Filters

Frequently remove and clean the filter(s) in the retractable section

of the downdraft vent. This will improve the operating efficiency

of the downdraft vent system.

To Replace:

1. Remove each filter by pulling the spring release handle and

then pulling down the filter.

2. Wash metal filters as needed in dishwasher or hot detergent

solution.

3. Reinstall the filter by making sure the spring release handles

are toward the front. Insert metal grease filter into upper

track.

4. Pull the spring release handle down.

5. Push up on metal filter and release handle to latch into place.

6. Repeat steps 1-5 for the other filter.

To C le an :

1. Remove the filter(s) and clean them in a dishwasher or in a

hot detergent solution. The downdraft vent will not operate

when the filters are not in place.

2. Dry the clean filter(s) and reinstall, making sure that they lock

into place.

If Retractable Downdraft Vent Does Not Operate After

Clean Filters Have Been Installed:

Push the filter in as far as it will go. When the filter is removed, the

microswitch behind the filter is inactivated. This feature will not

allow the vent system to operate until the filter is properly

installed.

A. Spring release handles

B. Left metal filter

C. Right metal filter

24

Page 25

WIRING DIAGRAMS

S50

7

Y

Y/G

BR

9

2

Neutral

4˚ Speed

3˚ Speed

2˚ Speed

1˚ Speed

R

R

R

R

R

GY

GY

GY

GY

BUBU

BU

BK

BK

W

W

W

BK

R

R

BR

BR

BR

BR

BR

BU

R

GY

BK

BK

GY GY

R

R

W

W

BR BR

BR

BR

GY

GY

GY

GY

GY

R

BU

BK

W

Y/G

G

LN

SEL0015061

NOTE: Wiring diagram is drawn

with plenum in down position.

Com

Com

Com

ComCom

N.C.

N.C.

N.C.

N.O.

N.O.N.O.

N.O.

N.O.

N.C.

N.C.

1

8

5

43

6

1

1

1

1

2

3

4

5

6

7

8

9

10

11

12

1

23

Motor Specifications

Power supply 120 VAC

Frequency

60 Hz

Wattage rating

420 W

Amperage 3.7 A

Motor Resistance

BU/W 21.6 Ohms

BU/R 18 Ohms

BU/GY 14.3 Ohms

BU/BK 9.8 Ohms

Component Layout

Num.

Description

6

1

2

3

4

5

7

8

9

Filter microswitch

Filter microswitch

Plenum down limit switch

Plenum up limit switch

Motor microswitch

Plenum drive motor

Blower motor

Blower speed switches

Start sw. - plenum up/down

Blower Switch Operation

Contact

Function

1 - 3

OFF

3 - 5

1st Speed

5 - 7

2nd Speed

3rd Speed

8 - 10

10 - 12

4th Speed

Interior-Mounted Blower Motor

25

Page 26

SEL0016521

NOTE: Wiring for

external blower motor

Common

4º Speed

3º Speed

2º Speed

1º Speed

BU

BK

GY

R

W

W

BU

BK

GY

R

1

9

2

R

R

R

GY

BU

BR

1

BR

BR

BR

BR

GYGY

R

R

BU

BK

W

Y/G

GL

N

NOTE: Wiring diagram is drawn

with plenum in down position.

6

GY

GY

GY

BU

GY

GY

BR

BR

BR

BR

W

W

R

R

GY

GY

BK BK

1

1

5

43

BK

BK

GY

BR

8

BR

W

RR

W

BR

R

Motor Specifications

Power supply 120 VAC

Frequency

60 Hz

Wattage rating

420 W

Amperage 3.7 A

Motor Resistance

BU/W 21.6 Ohms

BU/R 18 Ohms

BU/GY 14.3 Ohms

BU/BK 9.8 Ohms

Component Layout

Num.

Description

6

1

2

3

4

5

7

8

9

Filter microswitch

Filter microswitch

Plenum down limit switch

Plenum up limit switch

Motor microswitch

Plenum drive motor

Blower motor

Blower speed switches

Start sw. - plenum up/down

Blower Switch Operation

Contact

Function

1 - 3

OFF

3 - 5

1st Speed

5 - 7

2nd Speed

3rd Speed

8 - 10

10 - 12

4th Speed

12

3

111111111

1

2

3

1

4

5

6

7

8

9

10

11

12

2

3

4

5

6

7

8

9

10

11

12

Com

Com

Com

ComCom

N.O.

N.O.

N.O.

N.O.

N.O.

N.C.

N.C.

N.C.

N.C. N.C.

Exterior-Mounted Blower Motor

26

Page 27

ASSISTANCE OR SERVICE

When calling for assistance or service, please know the purchase

date and the complete model and serial number of your

appliance. This information will help us to better respond to your

request.

If you need replacement parts

If you need to order replacement parts, we recommend that you

use only factory specified parts. Factory specified parts will fit

right and work right because they are made with the same

precision used to build every new appliance. To locate factory

specified replacement parts in your area, call us or your nearest

designated service center.

In the U.S.A.

Call the KitchenAid Customer eXperience Center toll free:

1-800-422-1230 or visit our website at www.kitchenaid.com.

Our consultants provide assistance with:

■ Features and specifications on our full line of appliances.

■ Installation information.

■ Use and maintenance procedures.

■ Accessory and repair parts sales.

■ Specialized customer assistance (Spanish speaking, hearing

impaired, limited vision, etc.).

■ Referrals to local dealers, repair parts distributors and service

companies. KitchenAid designated service technicians are

trained to fulfill the product warranty and provide afterwarranty service, anywhere in the United States.

To locate the KitchenAid designated service company in your

area, you can also look in your telephone directory Yellow

Pages.

For further assistance

If you need further assistance, you can write to KitchenAid with

any questions or concerns at:

KitchenAid Brand Home Appliances

Customer eXperience Center

553 Benson Road

Benton Harbor, MI 49022-2692

Please include a daytime phone number in your correspondence.

In Canada

Call the KitchenAid Canada Customer eXperience Centre toll

free: 1-800-807-6777 or visit our website at www.kitchenaid.ca.

Our Consultants Provide Assistance With:

■ Features and specifications on our full line of appliances.

■ Use and maintenance procedures.

■ Accessory and repair parts sales.

■ Referrals to local dealers, repair parts distributors and service

companies. KitchenAid Canada designated service

technicians are trained to fulfill the product warranty and

provide after-warranty service, anywhere in Canada.

For Further Assistance

If you need further assistance, you can write to KitchenAid

Canada with any questions or concerns at:

Customer eXperience Centre

KitchenAid Canada

200 - 6750 Century Ave.

Mississauga, Ontario L5N 0B7

Please include a daytime phone number in your correspondence.

Accessories

NOTE: Instructions are included with each kit.

For Model Series KXD4630

30" (76.2 cm) One-Piece Top Trim

Order Part Number W10387672 (black)

Order Part Number W10388169 (white)

For Model Series KXD4636 and KXD4736

36" (91.4 cm) One-Piece Top Trim

Order Part Number W10387675 (black)

Order Part Number W10388170 (white)

For Model Series KXD4736Y

Blower Motor System (1 system is required)

600 CFM In-Line Blower Motor System

Order model number UXI0600DYS

1200 CFM In-Line Blower Motor System

Order model number UXI1200DYS

27

Page 28

KITCHENAID® VENTILATION WARRANTY

LIMITED WARRANTY

For one year from the date of purchase, when this major appliance is operated and maintained according to instructions attached to or

furnished with the product, KitchenAid brand of Whirlpool Corporation or Whirlpool Canada LP (hereafter “KitchenAid”) will pay for

Factory Specified Parts and repair labor to correct defects in materials or workmanship. Service must be provided by a KitchenAid

designated service company. This limited warranty is valid only in the United States or Canada and applies only when the major

appliance is used in the country in which it was purchased. Outside the 50 United States and Canada, this limited warranty does not

apply. Proof of original purchase date is required to obtain service under this limited warranty.

ITEMS EXCLUDED FROM WARRANTY

This limited warranty does not cover:

1. Service calls to correct the installation of your major appliance, to instruct you on how to use your major appliance, to replace or

repair house fuses, or to correct house wiring or plumbing.

2. Service calls to repair or replace appliance light bulbs, air filters or water filters. Consumable parts are excluded from warranty

coverage.

3. Repairs when your major appliance is used for other than normal, single-family household use or when it is used in a manner that is

contrary to published user or operator instructions and/or installation instructions.

4. Damage resulting from accident, alteration, misuse, abuse, fire, flood, acts of God, improper installation, installation not in

accordance with electrical or plumbing codes, or use of consumables or cleaning products not approved by KitchenAid.

5. Cosmetic damage, including scratches, dents, chips or other damage to the finish of your major appliance, unless such damage

results from defects in materials or workmanship and is reported to KitchenAid within 30 days from the date of purchase.

6. Costs associated with the removal from your home of your major appliance for repairs. This major appliance is designed to be

repaired in the home and only in-home service is covered by this warranty.

7. Repairs to parts or systems resulting from unauthorized modifications made to the appliance.

8. Expenses for travel and transportation for product service if your major appliance is located in a remote area where service by an

authorized KitchenAid servicer is not available.

9. The removal and reinstallation of your major appliance if it is installed in an inaccessible location or is not installed in accordance

with published installation instructions.

10. Major appliances with original model/serial numbers that have been removed, altered or cannot be easily determined. This warranty

is void if the factory applied serial number has been altered or removed from your major appliance.

The cost of repair or replacement under these excluded circumstances shall be borne by the customer.

DISCLAIMER OF IMPLIED WARRANTIES; LIMITATION OF REMEDIES

CUSTOMER'S SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE PRODUCT REPAIR AS PROVIDED

HEREIN. IMPLIED WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE,

ARE LIMITED TO ONE YEAR OR THE SHORTEST PERIOD ALLOWED BY LAW. KITCHENAID SHALL NOT BE LIABLE FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES. SOME STATES AND PROVINCES DO NOT ALLOW THE EXCLUSION OR LIMITATION

OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, OR LIMITATIONS ON THE DURATION OF IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS, SO THESE EXCLUSIONS OR LIMITATIONS MAY NOT APPLY TO YOU. THIS WARRANTY GIVES

YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE OR PROVINCE

TO PROVINCE.

If outside the 50 United States and Canada, contact your authorized KitchenAid dealer to determine if another warranty applies.

If you need service, first see the “Troubleshooting” section of the Use & Care Guide. After checking “Troubleshooting,” you may find

additional help by checking the “Assistance or Service” section or by calling KitchenAid. In the U.S.A., call 1-800-422-1230. In Canada,

call 1-800-807-6777.

Keep this book and your sales slip together for future

reference. You must provide proof of purchase or installation

date for in-warranty service.

Write down the following information about your major appliance

to better help you obtain assistance or service if you ever need it.

You will need to know your complete model number and serial

number. You can find this information on the model and serial

number label located on the product.

Dealer name____________________________________________________

Address________________________________________________________

Phone number__________________________________________________

Model number __________________________________________________

Serial number __________________________________________________

Purchase date __________________________________________________

9/07

28

Page 29

SÉCURITÉ DU SYSTÈME DE VENTILATION

Risque possible de décès ou de blessure grave si vous ne

suivez pas immédiatement les instructions.

Risque possible de décès ou de blessure grave si vous

ne suivez pas les instructions.

Tous les messages de sécurité vous diront quel est le danger potentiel et vous disent comment réduire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

Votre sécurité et celle des autres est très importante.

Nous donnons de nombreux messages de sécurité importants dans ce manuel et sur votre appareil ménager. Assurez-vous de

toujours lire tous les messages de sécurité et de vous y conformer.

AVERTISSEMENT

DANGER

Voici le symbole d’alerte de sécurité.

Ce symbole d’alerte de sécurité vous signale les dangers potentiels de décès et de blessures graves à vous

et à d’autres.

Tous les messages de sécurité suivront le symbole d’alerte de sécurité et le mot “DANGER” ou

“AVERTISSEMENT”. Ces mots signifient :

29

Page 30

IMPORTANTES INSTRUCTIONS DE SÉCURITÉ

LIRE ET CONSERVER CES INSTRUCTIONS

AVERTISSEMENT : POUR RÉDUIRE LE RISQUE

D'INCENDIE, CHOC ÉLECTRIQUE OU DOMMAGES

CORPORELS, RESPECTER LES INSTRUCTIONS

SUIVANTES :

■ Utiliser cet appareil uniquement dans les applications

envisagées par le fabricant. Pour toute question, contacter

le fabricant.

■ Avant d'entreprendre un travail d'entretien ou de nettoyage,

interrompre l'alimentation de la hotte au niveau du tableau

de disjoncteurs, et verrouiller le tableau de disjoncteurs

pour empêcher tout rétablissement accidentel de

l'alimentation du circuit. Lorsqu'il n'est pas possible de

verrouiller le tableau de disjoncteurs, placer sur le tableau

de disjoncteurs une étiquette d'avertissement proéminente

interdisant le rétablissement de l'alimentation.

■ Tout travail d'installation ou câblage électrique doit être

réalisé par une personne qualifiée, dans le respect des

prescriptions de tous les codes et normes applicables, y

compris les codes du bâtiment et de protection contre les

incendies.

■ Ne pas faire fonctionner un ventilateur dont le cordon ou la

fiche est endommagé(e). Jeter le ventilateur ou le retourner

à un centre de service agréé pour examen et/ou réparation.

■ Une source d'air de débit suffisant est nécessaire pour le

fonctionnement correct de tout appareil à gaz (combustion

et évacuation des gaz à combustion par la cheminée), pour

qu'il n'y ait pas de reflux des gaz de combustion. Respecter