TECHNICAL EDUCATION

JOB AID 4317409

KAC-47

TOUCH-ACTIVATED

ELECTRONIC

INDUCTION COOKTOP

MODELS: KICU508SBL & KICU568SBL

FORWARD

This KitchenAid Job Aid “Touch-Activated Electronic Induction Cooktop” (Part No. 4317409), provides the In-Home Service Professional with information on the installation, operation, and service

of the Touch-Activated Electronic Induction Cooktop. For specific information on the model being

serviced, refer to the “Use and Care Guide,” or “Wiring Diagram” provided with the cooktop.

The Wiring Diagrams used in this Job Aid are typical and should be used for training purposes

only. Always use the Wiring Diagram supplied with the product when servicing the cooktop.

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide information that will enable the In-Home Service Professional

to properly diagnose malfunctions and repair the Touch-Activated Electronic Induction Cooktop.

The objectives of this Job Aid are to:

• Understand and follow proper safety precautions.

• Successfully troubleshoot and diagnose malfunctions.

• Successfully perform necessary repairs.

• Successfully return the cooktop to its proper operational status.

WHIRLPOOL CORPORATION assumes no responsibility for any repairs made on

our products by anyone other than authorized In-Home Service Professionals.

Copyright

© 2007, Whirlpool Corporation, Benton Harbor, MI 49022

- ii -

TABLE OF CONTENTS

Page

GENERAL .............................................................................................................................. 1-1

Cooktop Safety ..................................................................................................................

Model & Serial Number Designations ................................................................................

Model & Serial Number Label And Wiring Diagram Locations ...........................................

Specifications .....................................................................................................................

1-1

1-2

1-3

1-4

INSTALLATION INFORMATION

Installation Instructions ......................................................................................................

PRODUCT OPERATION

Theory Of Operation ..........................................................................................................

Troubleshooting .................................................................................................................

COMPONENT ACCESS

Component Locations ........................................................................................................

Removing The Cooktop Glass ........................................................................................... 4-2

Removing The Touch Control Board ..................................................................................

Removing An Induction Element Assembly .......................................................................

Removing A Negative Temperature Coefficient (NTC) Sensor ..........................................

Removing A Cooling Fan And An Electronic Board ............................................................

Removing A 20A Line Fuse ................................................................................................

COMPONENT TESTING ........................................................................................................ 5-1

Induction Elements ............................................................................................................

Negative Temperature Coefficient (NTC) Sensor ...............................................................

Electronic Board IC Check .................................................................................................

20A Line Fuses ..................................................................................................................

DIAGNOSTICS & TROUBLESHOOTING ............................................................................. 6-1

Electronic Board Error Codes ............................................................................................

Touch Control Board Error Codes ......................................................................................

....................................................................................................... 3-1

........................................................................................................ 4-1

............................................................................................ 2-1

2-1

3-1

3-4

4-1

4-3

4-4

4-6

4-7

4-8

5-1

5-2

5-3

5-3

6-1

6-2

WIRING DIAGRAMS ............................................................................................................. 7-1

30

36

˝ Cooktop ...................................................................................................................... 7-1

˝ Cooktop ...................................................................................................................... 7-2

- iii -

— NOTES —

- iv -

GENERAL

DANGER

WARNING

COOKTOP SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on the appliance.

Always read and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word

“DANGER” or “WARNING.” These words mean:

You can be killed or seriously injured if you don’t

immediately follow instructions.

You can be killed or seriously injured if you don’t

follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance

of injury, and tell you what can happen if the instructions are not followed.

1-1

MODEL & SERIAL NUMBER DESIGNATIONS

MODEL NUMBER K IC U 50 8 S BL 0

PRODUCT GROUP

K = KITCHENAID

PRODUCT IDENTIFICATION

EC = ELECTRIC COOKTOP

GC = GAS COOKTOP

IC = INDUCTION COOKTOP

MERCHANDISING SCHEME

C = CERAMIC GLASS

S = STANDARD / PORCELAIN METAL

T = TEMPERED GLASS

U = ULTIMA

V = VBL PRO LINE SERIES

X = 208 VOLTS

CAPACITY / SIZE / SERIES / CONFIGURATION

1ST POSITION 2ND POSITION

0 = 2 BURN. / ELEM. 0 = 30

1 = STANDARD 2 = 42˝ OR 12˝ WIDE

2 = GRILL / GRIDDLE 3 = 33˝ WIDE

3 = TEMP. GLASS 5 = 15˝ WIDE

4 = COMMERCIAL 6 = 36˝ WIDE

5 = CERAMIC GLASS 8 = 48˝ WIDE

FEATURE CODE

0 = STANDARD ELEMENTS / BURNERS

1 = RADIANT ELEMENTS

2 = DUAL ELEMENTS OR SEALED BURNERS W/GRILL

6 = 5 BURNERS / ELEMENTS

7 = HALOGEN ELEMENTS / OR 6 BURNERS

8 = TOUCH CONTROLS

9 = INDUCTION

YEAR OF INTRODUCTION

S = 2006

COLOR CODE

BL = BLACK

ENGINEERING CHANGE (0, 1, 2, ETC.)

˝ WIDE

SERIAL NUMBER XT U 24 01234

DIVISION RESPONSIBILITY

XT = OXFORD

YEAR OF PRODUCTION

U = 2007

WEEK OF PRODUCTION

24 = 24TH WEEK

PRODUCT SEQUENCE NUMBER

1-2

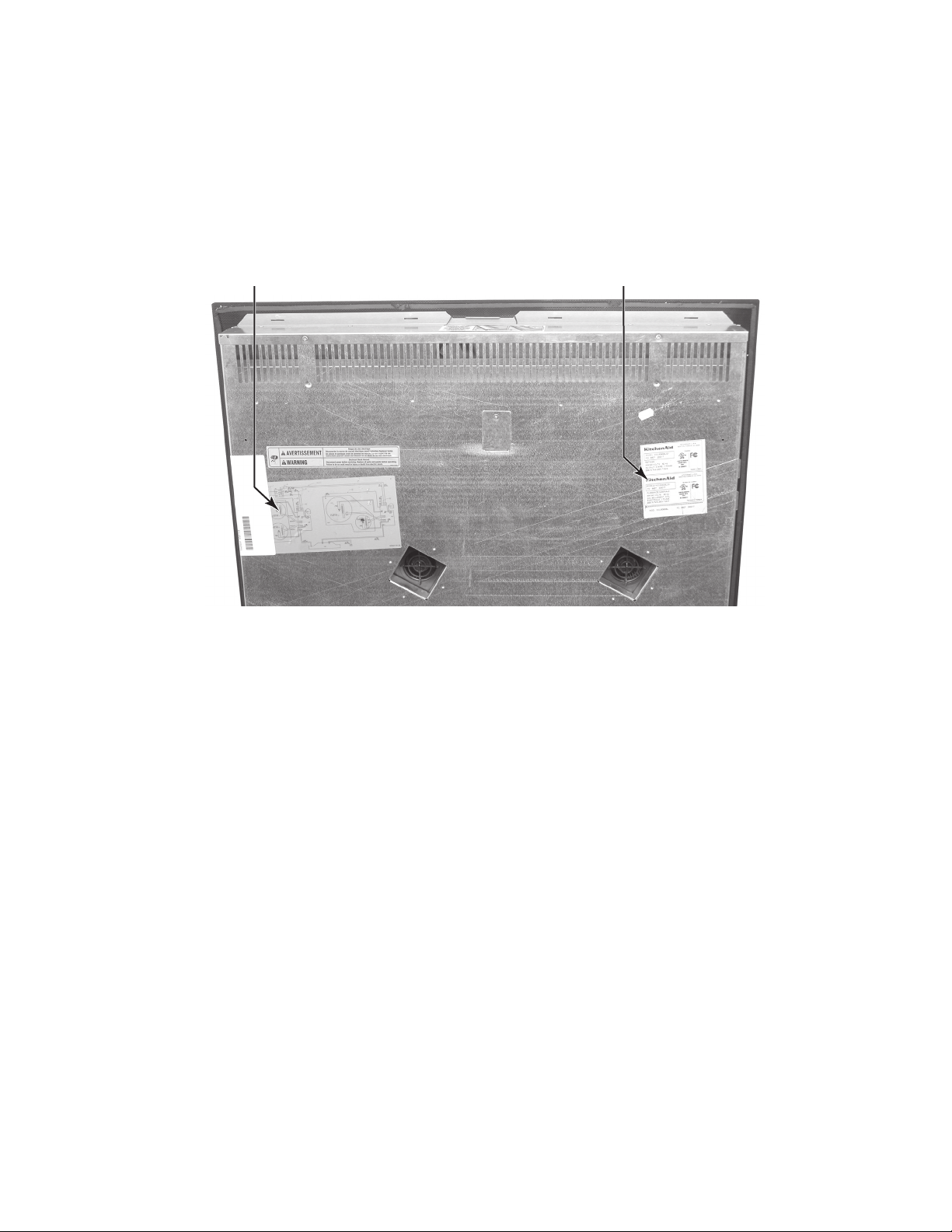

MODEL & SERIAL NUMBER LABEL

AND WIRING DIAGRAM LOCATIONS

The Model/Serial Number label and Wiring Diagram locations are shown below.

Wiring Diagram Location

(On Bottom Of Cooktop)

Model & Serial Number

Label Location

1-3

SPECIFICATIONS

Model Number KICU508SBL KICU568SBL

Model Description

Size-Configuration

Dimensions/Specifications

Exterior Dimensions

Overall Height (in)

Overall Width (in)

Overall Depth (in)

Cutout Dimensions

Burner Box Height

Cutout Width (in)

Cutout Depth (in)

Weight

Net Weight (lbs)

Ratings

Electric Voltage/Phase/Frequency (Hz) 240/208 Volt,Single Phase,60Hz 240/208 Volt,Single Phase,60Hz

Total Connected Load In kW

240 Volts (Preferred) 7.2 10.6

208 Volts 6.65 10.3

Circuit Amps 30 Amp (240V) / 32 Amp (208V) 45 Amp (240V) / 48 Amp (208V)

Exterior

Cooktop Finish Ceramic Glass Ceramic Glass

Cooktop Color Premium Black Premium Black

Cooktop Controls Touch Activated Touch Activated

Cooktop Control Type LED LED

Cooktop Control # 4 5

Electronic Control Yes - Touch Activated LED Control Yes - Touch Activated LED Control

Keep Warm Yes (“h”) Yes (“h”)

Keep Warm Switch Yes (Press + and - at the same time) Yes (Press + and - at the same time)

Cooktop Features

Power On Light 4 5

Autofocus Light No Yes

Hot Surface Indicator 4 (“H”) 5 (“H”)

Kitchen Timer Yes (99 Min.) Yes (99 Min.)

Control Lock Yes Yes

Ele R Front Size & Type

Ele RF Output (W@240/208V) 1400W/1320W 2200W/2075W

Ele L Front Size & Type

Ele LF Output (W@240/208V) 1800W/1700W 1800W/1700W

Ele R Rear Size & Type

Ele RR Output (W@240/208V) 2400W/2200W 1400W/1320W

Ele L Rear Size & Type

Ele LR Output (W@240/208V) 1800W/1700W 1800W/1700W

Ele C Front Size & Type

Ele CF Output (W@240/208V) 3600W - 1800W/3120 - 1700W

Touch Activated 30

Premium Black Induction Cooktop

3-1/4˝ 3-1/4˝

21-9/16˝ 21-9/16˝

29-1/2˝ 35-1/2˝

20-1/2˝ 20-1/2˝

5-7/8˝ Single Induction 8-1/4˝ Single Induction

7-1/8˝ Single Induction 7-1/8˝ Single Induction

˝ Single Induction 5-7/8˝ Single Induction

11

7-1/8˝ Single Induction 7-1/8˝ Single Induction

˝ Ceramic

30˝ 36˝

31˝ 37˝

3˝ 3˝

44.1 50.7

Touch Activated 36˝ Ceramic

Premium Black Induction Cooktop

˝/ 7-1/8˝ Dual Zone Induction

11

1-4

Model Number KICU508SBL KICU568SBL

Miscellaneous

Product Literature

Installation Instructions Yes Yes

Parts List Yes Yes

Service Manual/Job Aid Yes Yes

Tech Sheet Yes Yes

Use & Care Guide Yes Yes

Other

Agency Approvals UL, CUL UL, CUL

Approved to Install Over BI Oven Yes Yes

Hardware Yes Yes

Power Cord Length & # Wires 3 Foot/3 Wire 3 Foot/3 Wire

Residential Use Only Yes Yes

Warranty

Limited 12 Mo 12 Mo

Extended

Ceramic Glass Cooking Surface 60 Mo. Parts only 60 Mo. Parts Only

Electronic Controls 60 Mo. Parts only 60 Mo. Parts Only

Electrical Elements 60 Mo. Parts only 60 Mo. Parts Only

1-5

— NOTES —

1-6

INSTALLATION INFORMATION

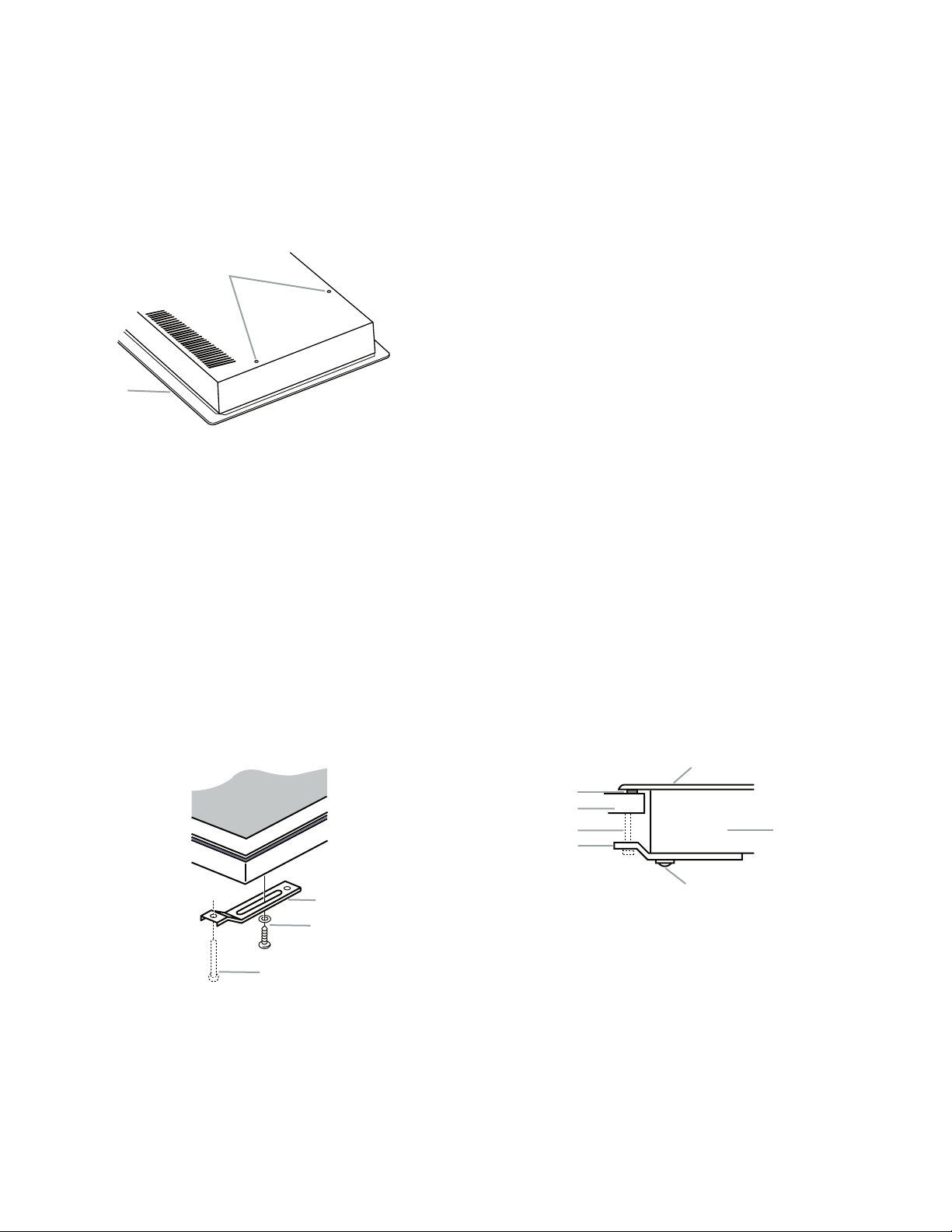

A. Heat shield

B. Remove scre

ws

A

B

A. Heat shield

B. Predrilled hole

s

A

B

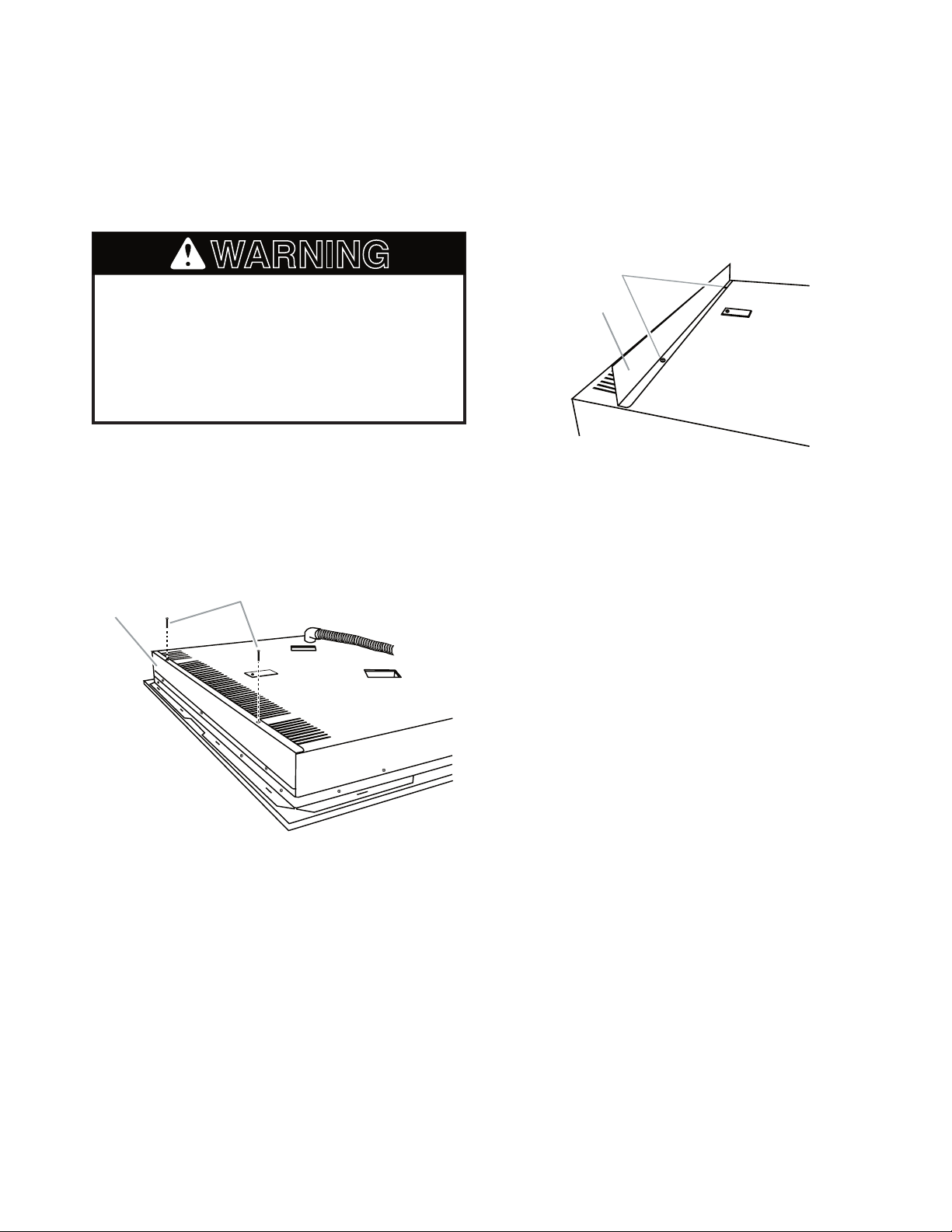

WARNING

INSTALLATION INSTRUCTIONS

INSTALL HEAT SHIELD

1. Decide on the final location for the cooktop.

Excessive Weight Hazard

Use two or more people to move and

install cooktop.

Failure to do so can result in back or

other injury.

2. Using two or more people, place the

cooktop upside down on a covered work

surface.

3. Remove the heat shield from the cooktop.

Set the two screws aside for reattaching

the heat shield.

4. Using two screws, reattach the heat shield

to the underside of the cooktop at the

predrilled holes as shown in the following

illustration.

INSTALL COOKTOP

Style 1: Cooktop over undercounter

built-in oven

IMPORTANT:

•

Your cooktop may not be approved for use

over an undercounter built-in oven. Contact

your dealer to confirm that your cooktop is

approved.

•

Clamping brackets should not be used.

1. Turn cooktop right side up.

2. Place cooktop in cutout.

NOTE: Make sure that the front edge of

the cooktop is parallel to the front edge of

the countertop. If repositioning is needed,

lift entire cooktop up from cutout to avoid

scratching the countertop.

2-1

A. Glass cooktop

B. Cookto

p base

C. Attachment scre

w

D. Clamping

bracket

(extends far enough beyond

cooktop base to allow

installation of clamping

screws)

E. 2-1/2

" (6.4 cm) clamping screw

(to be installed in “Attach

Cooktop to Countertop”

section)

F. Counte

rtop

G. Foam seal

A

B

D

C

E

F

G

A. Attachment screw holes, side or back locations

B. Front of cookto

p

A

B

A. Clamping bracket

B. Attachment screw

and

washer

C. Clamping scre

w

A

B

C

Style 2: Cooktop over cabinets

1. Determine whether your cabinet construction provides clearance for installing clamp

ing brackets at cooktop base ends. This

is the recommended location. Clamping

brackets can be installed on the back of

cooktop base bottom, if necessary.

2. The clamping brackets can be installed

before or after the cooktop is placed into

the cutout. Complete the following steps

for the option you choose.

Installing Brackets Before Placing

Cooktop in Cutout

1. Position bracket to allow the clamping bracket

to extend far enough out from the cooktop for

the installation of 2-1/2˝ (6.4 cm) clamping

screws. See “Attach Cooktop to Countertop”

for illustration of clamping screw installa

tion.

2. Rotate brackets so they do not extend

beyond edge of cooktop base.

3. Tighten screws enough to hold brackets

in place when cooktop is placed into the

cutout.

4. Turn the cooktop right side up and place

in cutout.

NOTE: Make sure that the front edge of

the cooktop is parallel to the front edge of

the countertop. If repositioning is needed,

lift entire cooktop up from cutout to avoid

scratching the countertop.

5. Loosen the screws and rotate the brackets

so that they are perpendicular to the edge

of the cooktop base and extend beyond its

edge. Securely tighten screws.

Installing Brackets After Placing

Cooktop in Cutout

1. Place cooktop in cutout.

NOTE: Make sure that the front edge of

the cooktop is parallel to the front edge of

the countertop. If repositioning is needed,

lift entire cooktop up from cutout to avoid

scratching the countertop.

2. Position clamping bracket to allow the

bracket to extend far enough out from the

cooktop for the installation of 2-1/2

-

clamping screws

˝ (6.4 cm)

3. Attach brackets to cooktop base bottom

with bracket attachment screws using the

bracket mounting holes. Securely tighten

screws.

2-2

MAKE ELECTRICAL CONNECTION

WARNING

A. UL listed or CSA approved conduit connector

A

If your home has: Go to Section:

4-wire 4-Wire Cable fr

om Home

Power Supply

3-wire 3-Wire Cable fr

om Home

Power Supply

½"

(1.3 cm)

½"

(1.3 cm)

A. Cable from home power

supply

B. Red wires

C. Green

(or bare) ground wire

(from cooktop)

D. 3-Wire cable from cookto

p

E. Junction bo

x

F. White wire (from home

power supply)

G. UL listed wire connecto

r

H. Black wire

s

I. UL listed or CSA approved

conduit connector with

wire bushin

g

A

B

C

D

E

F

H

G

I

Electrical Shock Hazard

Disconnect power before servicing.

Use 8 gauge copper wire.

Electrically ground cooktop.

Failure to follow these instructions can

result in death, fire, or electrical shock.

4-Wire Cable from Home Power Supply

IMPORTANT: Use the 4-wire cable from home

power supply in the U.S. where local codes do

not allow grounding through neutral, New Branch

circuit installations (1996 NEC), mobile homes

and recreational vehicles, new construction,

and in Canada.

This cooktop is manufactured with a frame-con

-

nected, green (or bare) ground wire.

1. Disconnect power.

2. Remove junction box cover if it is pres

-

ent.

3. Connect the flexible cable conduit from the

cooktop to the junction box using a UL listed

or CSA approved conduit connector.

1. Connect the two red wires (B) together

using a UL listed wire connector.

2. Connect the green (or bare) ground wire

(C) from the cooktop cable to the green

(or bare) ground wire (in the junction box)

using a UL listed wire connector.

3. Put a UL listed wire connector on the end

4. Tighten screws on conduit connector if

present.

5. See “Electrical Connection Options Chart”

to complete installation for your type of

electrical connection.

Electrical Connection Options Chart

of the white wire (F).

NOTE: Do not connect the green (or bare)

ground wire to the neutral (white) wire in

the junction box.

4. Connect the two black wires (H) together

using a UL listed wire connector.

5. Install junction box cover.

2-3

3-Wire Cable from Home Power Supply

A. Cable from home power supply

B. Red wire

s

C.

Green (or bare) ground wire

from cookto

p

D. 3-wire cable (from cooktop)

E. Junction bo

x

F. White wire (from home

power supply)

G. UL listed wire connector

H. Black wire

s

I. UL listed or CSA approved

conduit connector

with wire

bushing

G

A

B

C

D

E

F

H

I

A. Clamping screw

B. Countertop

C. Foam seal

D. Cookto

p

A

B

D

C

- U.S. Only

IMPORTANT: Use the 3-wire cable from power

supply where local codes permit a 3-wire con

nection.

ATTACH COOKTOP TO

COUNTERTOP

NOTE: This section applies only if you are using

-

clamping brackets.

1. Connect the two red wires (B) together

using a UL listed wire connector.

2. Connect the green (or bare) cooktop cable

wire (C) to the white (neutral) wire (F) in

the junction box using a UL listed wire

connector.

3. Connect the two black wires (H) together

using a UL listed wire connector.

4. Install junction box cover.

1. Place the 2-1/2

˝ (6.4 cm) clamping screws

into the brackets.

2. Check that the cooktop is level.

3. Use a flat-blade screwdriver to tighten the

screws against the countertop. Do not

overtighten.

2-4

PRODUCT OPERATION

THEORY OF OPERATION

Principles Of Induction Heating

The use of induction heating in glass-ceramic

cooking devices has existed since 1987.

With this technique, the container is heated

directly. Therefore the cooking surface heats

up only as a result of the heat transmitted from

the container to the glass, which is much lower

than in conventional systems.

The base of the container is heated by the elec

tric currents that circulate in its base and which

are induced by a variable, medium-frequency

magnetic field generated by the inductors located underneath the ceramic glass.

Only containers with a base made of ferromag

netic steel or iron can be used with induction

cooktops. Containers that cannot be used for in

duction can be recognized by a magnet test.

Even though it is recommendable to use con

tainers that fit the size of the cooking zone,

containers of a smaller diameter can be used

without causing notable reductions of efficiency.

The cooktop control reduces the power deliv

ered to small containers and, if applicable, stops

supplying power when the container does not

have the minimum required diameter.

The power inverter transforms the 50 Hz of

the power grid into an alternating current with

a frequency between 20 and 60 Hz.

Direct heating of the container base provides

the induction system with very fast heating.

Likewise, the system reacts very quickly to

power level changes.

Induction provides very precise control of the

power levels, wherefore it allows delicate recipes

to be prepared.

A temperature sensor under the glass is used

in order to protect the inductor, and it moreover

allows detecting that an empty container is

being over-heated and stopping the heating

process.

-

Advantages Of Induction Heating

Faster Cycle Time

Heat is developed directly and instantly within

•

-

-

-

1 second inside the pot or pan, allowing a

much quicker startup than other heating

equipment. Heating process times can be

dramatically reduced & production output

can be significantly increased.

With induction cooking the heat level is every

•

bit as instantaneous, and as exact, as with gas,

yet with none of the many drawbacks of gas

(carbon monoxide, loss of flame etc.). Induc

tion elements can be adjusted to increments

as fine as the cooking utensil cares to supply,

just like gas, and—again very important to

serious cooks—such elements can run at as

low a cooking-heat level as wanted for gentle

simmering and suchlike (something even gas

is not always good at).

High Thermal Efficiency And

Increased Profitability

This energy-efficient process converts up to

•

90% of the energy expended into useful heat

to reduce utility costs. (With gas ranges up to

60% of the heat is normally wasted through

indirect gas combustion.) Stand-by losses

are reduced to a minimum.

-

3-1

The costs of exhaust duct installation and air

•

conditioning running costs are saved.

•

As mentioned earlier, induction cooking energy is supplied directly to the cooking utensil

by the magnetic field; thus, almost all of the

source energy gets transferred to that cooking utensil. With gas or conventional electric

elements (including halogen), the energy is

first converted to heat and only then directed

to the pot or pan with a lot of that heat go

ing to waste heating up your kitchen instead

of heating up your food. (As a comparison,

40%—less than half—of the energy in gas

gets used to cook, whereas with induction

84% percent of the energy in the electricity

used gets used to cook (and the rest is not

waste heat as it is with gas). There are two

important heat-related consequences of that

fact:

Cooler kitchens:

•

Of course the cooking vessel and the food

itself will radiate some of their heat into the

cooking area—but compared to gas or other

forms of electrically powered cooking, induc

tion makes for a much cooler kitchen.

Cool stove top:

The stove top itself barely gets warm except

•

directly under the pan (and that only from such

heat as the pan bottom transfers). No more

burned fingers, no more baked-on spills, no

more danger with children around.

Environmentally Sound

Induction heating is a clean, non-polluting

•

process. It produces much less smoke or

waste heat to alter the surrounding environ

ment.

•

It is an obvious but still very important fact that

induction cooktops are powered by electricity.

Not every home actually has a gas pipeline

available to it—for many, the only “gas” option

is propane, with the huge propane tank and

regular truck visits. But everyone has clean,

silent, ever-present electricity.

•

Burning gas has byproducts that are vapor

ized, but eventually condense on a surface

somewhere in the vicinity of the cooktop.

Electrical cooking of any kind eliminates such

byproducts.

User-Friendly

Working conditions are improved with the

•

absence of smoke and heat produced by

heating equipment. You can touch the outer

casing without getting burned.

If the electricity supply to your home is inter-

•

-

rupted, you will be unable to cook; gas sup

plies can be interrupted, too, but such inter

ruptions are normally somewhat less likely

than electricity interruptions. If the electricity

where you are frequently goes out for hours

at a time, the loss of cooking ability may be

an issue for you.

Pinpoint Accuracy

Power input is precisely controlled to achieve

•

the exact temperature required for heating.

Heat is developed directly inside the pot or

kettle or cooktop.

With gas, when you adjust the element set-

•

ting, the energy flow adjusts instantly.

-

•

But with induction cooking the heat level is

every bit as instantaneous, and as exact, as

with gas, yet with none of the many drawbacks

of gas. Induction elements can be adjusted to

increments as fine as the cooker maker cares

to supply, just like gas, and—again very important to serious cooks—such elements can

run at as low a cooking-heat level as wanted

for gentle simmering and suchlike (something

even gas is not always good at).

•

Moreover, gas—induction’s only real com

petition—has special risks of its own, not all

-

of which are as well known as they perhaps

should be. While the risk of a gas flame, even

a pilot light, blowing out and allowing gas to

escape into the house is relatively small, it

does exist.

Maximum Repeatability

With modern induction heating equipment,

•

the heating pattern is always the same for a

given set-up, cycle after cycle and day after

-

day.

-

-

-

3-2

Noises that are Common to the

Normal Operation of Induction

Cooktops

Induction heating technology is based on the

capacity that certain metal materials have to

vibrate when they are subject to high frequency

waves.

Under certain circumstances, these vibrations

may make certain sounds of a low volume due

to the following:

Low tone noise, similar to that of a trans

•

former: It occurs when cooking at high power

levels. It is due to the enormous amount of

energy that the cooktop is supplying to the

container. It disappears or attenuates as the

power level used is reduced.

Soft whistling: They occur when the con

•

tainer is empty. They disappear or attenu

ate when water or the food to be cooked is

added.

Crackling: This kind of noise may occur in

•

containers composed of layers of different

materials. The noise is due to the vibration

in the separation zones between the various

layers of material. This noise is proper to the

container. It can change according to the

quantity and type of food that is cooked.

Sharp whistling (beeps): They occur basi

•

cally with containers composed of different

layers of materials when two adjacent cook

ing zones are started up at the same time

and at maximum power. They disappear or

attenuate when the power is reduced.

Intermittent clicks: They are noises caused

•

by the commutations of the control electron

ics, above all when low power levels are

selected.

Fan noise: In order to control the correct

•

operation of the electronics, they must work at

a controlled temperature. To achieve this, the

cooktop is equipped with a fan that works at

different speeds according to the temperature

detected. The fan can also continue operating

when the cooktop is turned off after being

used if the detected temperature continues

to be high.

NOTE: All these noises are normal and inher

ent to induction technology, and they are not a

sign of any breakdown.

The noises that occur with greatest frequency

are those with containers that have a “sandwich”

type base.

-

Overview of Induction Cookware

All pots and pans with a ferromagnetic base

•

are valid for induction.

•

Only containers that have a base where a

magnet remains adhered can be used.

-

-

The induction system does not heat up other

•

kinds of containers, and the power level indicator on the display will blink.

•

The minimum diameter of the container must

likewise be taken into account.

Pots and Pans good for Induction

Cooking

Enamelled steel pots and pans.

•

Cast iron pots and pans.

•

Special stainless steel utensils for induction

•

cooking.

-

Pots and Pans not good for Induction Cooking

Non-ferromagnetic or non-metallic materials.

•

Aluminum pots and pans.

•

-

Copper pots and pans.

•

Brass pots and pans.

•

Standard stainless pots and pans.

•

Glass (“Pyrex”) containers.

•

Earthenware pans.

•

-

3-3

TROUBLESHOOTING

Nothing will operate

•

Is the cooktop wired properly? See the In

stallation Instructions for more information.

•

Has a household fuse blown, or has a

circuit breaker tripped? Replace the fuse

or reset the circuit breaker. If the problem

continues, call an electrician.

Cooktop will not operate

Is the cooktop control set correctly? Touch

•

SELECT before selecting a setting.

•

Is the “Control Lock” Cooktop Lockout

set? See “Control Lock” in the Use & Care

Guide.

Has the cooktop turned off by itself? The

•

power off key was unintentionally touched.

Press power key again. Reset the cooktop.

Excessive heat around cookware on cooktop

•

Is the cookware the proper size? Use

cookware about the same size as the surface

cooking area. Cookware should not extend

more than 1/2

area.

Cooktop cooking results not what expected

Is the proper cookware being used? See

•

“Cookware” in the Use & Care Guide.

•

Is the cooktop control set to the proper

heat level? See “Cooktop Controls” in the

Use & Care Guide.

˝ (1.3 cm) outside the cooking

Display shows messages

-

•

Is “E” flashing on the surface cooking

area display? Thoroughly wipe or remove

any object on touch keys. When finished

cleaning, touch the correct key. The flashing

should stop.

Is “E” flashing on all the surface cooking

•

area displays with a signal beeping? The

main switch has been kept on for more than

5 seconds. Wipe up any soil on the touch

keys. Remove any objects on the touch keys.

Reset the cooktop.

•

Is the display flashing when you place a

saucepan on an induction surface cooking

area? Check that the saucepan is magnetic.

Check that the diameter of the saucepan is

large enough. Center the saucepan on the

surface cooking area. Allow the saucepan to

cool down in the event that it has become hot

when used. Switch the surface cooking area

off, then on again. If the display still does not

light up, turn power off at the circuit breaker.

Wait 20 seconds and turn power back on.

Is the Performance boost function display

•

flashing and switching off? The Perfor-

mance boost function operates the surface

cooking area with the most power. During

long cooking times, it is possible that the

function will switch the surface cooking area

off to protect the cooktop from overheating.

You can continue to use the cooktop if the

display is not flashing.

Is the appliance level? Level the appliance.

•

See the Installation Instructions.

3-4

Error

Code

Error Solution

F0 An internal error

was detected

.

Disconnect power. Wait

5 seconds before reconnecting

power. If the symbol appears

again, call customer service.

F2 The surface

cooking area is

too hot and has

turned off.

Remove the pans from the

surface cooking area

. “F2” will

disappear when the surface

cooking area has cooled down. If

you turn the surface cooking area

back on and “F2” reappears, the

cooktop is still too hot. Turn off

the surface cooking area and

allow it to cool

.

F4 The pot or pan is

too close to the

control panel.

Make sure the pot or pan is

centered on the surface cooking

area and nothing hot is on the

touch control panel. Wait

5 minutes for control panel to

cool. If “F4” appears after turning

the surface

cooking area back on,

call customer service.

F8 The surface

cooking area has

been in operation

for too long

.

The surf

ace cooking area

automatic shutoff was activated.

Turn

off the surface cooking area.

c1 The power

voltage is too

low.

Turn off the cooktop. Wait

5 seconds, then turn it back on. If

this continues, contact a qualified

electrician.

c2/c3 The surface

cooking area has

overheated.

The surf

ace cooking area

automatic shutoff wa

s activated.

Wait 5 minutes, for it to cool

down, then turn it back on.

Is the display flashing “Er” and numbers?

•

If an “Er” and a series of numbers appear in

the display panel, turn power off at the circuit

breaker. Turn on again. If a problem continues, call customer service. See “Assistance

or Service” in the Use & Care Guide.

Is the display flashing “F” and numbers?

•

If “F” and a number are alternately flashing

on the display, refer to the following table for

possible solutions.

Operational cooktop sounds

Is there a low humming? This occurs when

•

cooking at high power. The cause of this is

the amount of energy which is transmitted

from the appliance to the cookware. This

sound will quiet or go away when the power

is turned down.

Is there a crackling? This sound occurs

•

when cookware is used which consists of

different materials. The noise is caused by

vibrations in the joint faces between the dif

ferent layers. It may change depending on the

amount and type of food being cooked.

-

Is there a fan noise? The electronics re

•

quire a controlled temperature in order to

function reliably. The cooktop is fitted with a

fan which runs at various speeds according

to the temperature detected. The fan may

also continue to run even after the cooktop

has been switched off, if the temperature it

detects is too high.

3-5

— NOTES —

3-6

COMPONENT ACCESS

This section instructs you on how to service each component inside the KitchenAid Touch-Activated

Electronic Induction Cooktop. The components and their locations are shown below.

COMPONENT LOCATIONS

Negative Temperature Coefficient (NTC) Sensor

(1 For Each Element)

Left Induction Element Assembly Right Induction Element Assembly

Left Cooling Fan Right Cooling Fan

Touch Control Board

Left Electronic Board Right Electronic Board

2 20A Fuses (Inside Burner Box)

4-1

REMOVING THE COOKTOP GLASS

WARNING

3. Remove the fourteen flat-head screws

from the front, rear, and side ceramic glass

brackets.

4. Remove the two small side brackets from

the cooktop base.

Front/Rear Bracket Screws

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug cooktop or disconnect power.

2. Remove the cooktop from its mounting

location, (see “Installation Instructions” in

Section 2). Position the cooktop so that

you can access the bracket screws below

the cooktop glass.

Cooktop Glass

Side Bracket Screws

Small Side Bracket

Cooktop Base

5. Lift and remove the ceramic glass from the

cooktop base.

Cooktop Glass

4-2

REMOVING THE TOUCH CONTROL BOARD

WARNING

3. Press and unlock the two holder tabs, raise

the touch control board, and remove the

board from the holder.

Touch Control Board Holder Tabs

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug cooktop or disconnect power.

2. Remove the cooktop glass from the cooktop

(see page 4-2 for the procedure).

Touch Control Board

4. Slide the three edge connectors off the

touch control board.

Touch Control Board Connectors

5. To remove the touch control board holder,

remove the four mounting screws.

Touch Control Board Holder & Screws

4-3

REMOVING AN INDUCTION ELEMENT ASSEMBLY

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug cooktop or disconnect power.

2. Remove the cooktop glass from the cooktop

(see page 4-2 for the procedure).

Left Induction Element

Mounting Plate Screws (3)

Left Induction Elements

3. Remove the screws from the left or right

induction element assembly mounting plate

(see the right photos).

Right Induction Elements

Right Induction Element

Mounting Plate Screws (4)

4-4

4. Disconnect the induction element assembly

connectors from the electronic board as

follows:

2-wire connector at CNT3.

2-wire connector at CNT1.

Red wire at FST1.

Green wire at FST2.

Induction element screw terminals at CNX1,

CNX2, CNX3 & CNX4.

FST1

FST2

5. Remove the induction element assembly

from the cooktop.

6. Unhook the two cover tabs and remove

the cover from the induction element you

are replacing.

LR Element

Cover & Tabs

CNT1

CNX2

CNX1

Assembly Shown

Left Induction Element

CNX3

CNX4

CNT3

Electronic Board

Left Induction Element Assembly

RR Element

Cover & Tabs

LF Element

Cover & Tabs

RF Element

Cover & Tabs

4-5

Right Induction Element Assembly

REMOVING A NEGATIVE TEMPERATURE

WARNING

COEFFICIENT (NTC) SENSOR

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

5. Unplug the NTC sensor connector from

the electronic board as shown in the chart

below. NOTE: If necessary, refer to the

Wiring Diagrams in Section 7 for the connector locations.

ELEMENT LOCATION NTC CONNECTOR

LF CNT3 (LEB)

LR CNT1 (LEB)

C CNT1 (MEB)

RF CNT3 (REB)

RR CNT1 (REB)

Failure to do so can result in death or

electrical shock.

1. Unplug cooktop or disconnect power.

2. Remove the cooktop glass from the cooktop

(see page 4-2 for the procedure).

Left NTC Sensors

Right NTC Sensors

3. Depending on the negative temperature

coefficient (NTC) sensor you are servicing,

remove the screws from the left or right

induction element assembly mounting plate

(see page 4-4 for the procedure).

LEB = Left Electronic Board

MEB = Middle Electronic Board (5 element models)

REB = Right Electronic Board

6. Unhook the tabs on the NTC sensor, pull

the sensor off the element, and remove it.

Tabs

NTC Sensor

Tabs

4. Unhook the two cover tabs and remove

the cover from the induction element NTC

sensor you are replacing (see page 4-5 for

the procedure).

4-6

REMOVING A COOLING FAN AND AN ELECTRONIC BOARD

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug cooktop or disconnect power.

2. Remove the cooktop glass from the cooktop

(see page 4-2 for the procedure).

3. Remove the left or right induction element

assembly, depending on which cooling fan

or electronic board you are removing (see

page 4-4 for the procedure).

Left Cooling Fan Right Cooling Fan

Electronic Board

CNT5

Tabs

Cooling Fan

5. To remove an electronic board:

a) Remove the cooling fan (see step 4).

b) Disconnect the following wires from the

electronic board terminals:

Black at N.

Red at L.

Green at FST3

4-wire connector at CNT4.

c) Press and unlock the two tabs from

the right side of the board and lift the

electronic board from its holder.

RD (L)GN (FST3)

BK (N)

Left Electronic Board Right Electronic Board

4. To remove a cooling fan (see the top

right photo):

a) Disconnect the 2-wire fan connector

from electronic board pins CNT5.

b) Press and unlock the two tabs from

the cooling fan and lift the fan from the

electronic board.

4-7

Electronic Board

CNT4

Tab

Tab

REMOVING A 20A LINE FUSE

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

NOTE: A fuse is installed for each relay board

to avoid short circuits in the cooktop.

1. Unplug cooktop or disconnect power.

4. LIft the front of the component panel approximately 8

bridge communication cable connector,

and rest the panel back against a sup

port.

˝, disconnect the 4-wire

Component Panel

4-Wire Bridge

Communication

Cable Connector

-

2. Remove the cooktop glass from the cooktop

(see page 4-2 for the procedure).

3. Remove the ten flat-head screws from the

component panel and burner box.

Component Panel

Burner Box

Screw

(1 of 10)

5. Remove the defective fuse from its fuse

holder clips and install a new 20A fuse in

its place.

4-8

20A Line Fuses

COMPONENT TESTING

WARNING

Level

(%)

(W)

(%) (%)

(W) (W)

0 0.0 0.0

0.00.0 0

0

1

2.7 37.2 2.9

52.7 3.1 68.2

1-1/2

4.0 56.4 4.4

79.9 4.7

103.4

2

5.4 75.6

6.0

107.1

6.3

138.6

2-1/2 6.7 93.6 7.4

132.6

7.8

171.6

3

9.3 130.8

10.3 185.6

10.9

239.8

3-1/2

10.7

150 11.8 212.5

12.5

275.0

4 13.4 187.2

14.7 265.2

15.6 343.2

4-1/2

16.1 225.6

17.8 319.6

18.8

413.6

5 18.8 262.8

20.7 372.3

21.9

431.8

5-1/2

21.4

300 23.6 425.0

25.1 550.0

6 25.5 356.4

28.1

504.9

29.7

653.4

6-1/2

30.8 430.8

33.9 610.3 35.9

789.8

7

37.5 525.6

41.4 744.6

43.8 963.6

7-1/2

45.5 637.2

50.2 902.7 53.1 1168.2

8 54.9 769.2

60.5 1089.7 64.1

1410.2

8-1/2 68.3 956.4

75.3

1354.9

79.7

1753.4

9

100.0

1400 100.0 1800.0 100.0 2200.0

B 128.6

1800

141.7 2500.0 150.0 3300.0

5.90˝

7.08˝

8.27˝

Small

Medium Big

Level

)

%

( )W(

0

0.0

0

1 3.1 77.5

1-1/2 4.7 117.5

2 6.3 157.5

2-1/2 7.8 195.0

3

10.9 272.5

3-1/2 12.5 312.5

4

15.6 390.0

4-1/2

18.8

470.0

5

21.9 547.5

5-1/2

25.0

625.0

6 29.7 742.5

6-1/2

35.9

897.5

7 4

3.8 1095.0

7-1/2 53.1 1327.5

8 6

4.1 1602.5

8-1/2 7

9.7 1992.5

9

B 1

00.0

100.0

2500.0

2500.0

Big

11.02*7.08˝

Before testing any of the components, perform

the following checks:

•

The most common cause for control failure

is corrosion on connectors. Therefore, dis

connecting and reconnecting wires will be

necessary throughout test procedures.

All tests/checks should be made with a

•

VOM or DVM having a sensitivity of 20,000

ohms-per-volt DC, or greater.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

INDUCTION ELEMENTS

Check all connections before replacing

•

components, looking for broken or loose

wires, failed terminals, or wires not pressed

-

into connectors far enough.

Resistance checks must be made with

•

power cord unplugged from outlet, and

with wiring harness or connectors discon

nected.

Refer to page 4-4 for the procedure for accessing the induction elements.

-

1. Unplug cooktop or disconnect power.

2. Disconnect the induction element wires

from the electronic board.

3. Set the ohmmeter to the R x 1 scale.

4. Touch the ohmmeter test leads to the in-

duction element wire terminals. The meter

should indicate less than 1

Ω.

5-1

Electrical Shock Hazard

WARNING

R (k Ω

)

Temp (°F)

R (k Ω)

Temp (°F)

47.788

78.8

98.26450

45.794

80.6

93.22951.8

43.873

82.4

88.63253.6

42.019

84.2

84.40455.4

40.228

86

80.48957.2

38.496 87.8

76.845

59

36.819 89.6

73.435

60.8

35.193

91.4

70.23362.6

33.616 93.267.21364.4

32.085

9564.35766.2

30.597

96.861.647

68

29.150 98.659.070

69.8

27.741 100.4

56.613

71.6

26.369

102.2

54.26473.4

26.065 10452.01675.2

49.86077

— —

R (k Ω

)

Temp (°C)

R (k Ω)

Temp (°C)

47.788

26

98.26410

45.794

27

93.22911

43.873

28

88.63212

42.019

29

84.40413

40.228

30

80.48914

38.496 31

76.845

15

36.819 32

73.435

16

35.193

33

70.23317

33.616 3467.21318

32.085

3564.35719

30.597

3661.647

20

29.150 3759.070

21

27.741 38

56.613

22

26.369

39

54.26423

26.065 4052.01624

49.86025

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

NEGATIVE TEMPERATURE

COEFFICIENT (NTC) SENSOR

Refer to page 4-6 for the procedure for accessing the negative temperature coefficient

(NTC) sensor.

NOTE: Each of the inductors uses a negative

temperature coefficient (NTC) sensor for monitoring the operating temperature. The sensors

are interchangeable. Use conductive grease

when replacing a sensor to aid in thermal conduction.

1. Unplug cooktop or disconnect power.

2. Disconnect the NTC wires from the elec

tronic board.

3. Set the ohmmeter to the R x 1 scale.

4. Touch one of the ohmmeter test leads to

the pins of the NTC connector. The meter

should indicate as shown in the charts.

-

5-2

Electrical Shock Hazard

WARNING

A

B

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

ELECTRONIC BOARD IC CHECK

Electronic Board

ICs

IC Lead

Configuration

Refer to page 4-7 for the procedure for accessing an electronic board.

20A LINE FUSES

Refer to page 4-8 for the procedure for accessing the 20A line fuses.

1. Unplug cooktop or disconnect power.

2. Set the ohmmeter to the R x 1 scale.

3. Touch one of the ohmmeter test leads to the

red (L1) line wire terminal. Touch the other

lead to terminal FST1 of each electronic

board. The meter should indicate continuity

(infinite). If there is no continuity, the fuse

is damaged and it must be replaced by a

new one.

1. Unplug cooktop or disconnect power.

2. Perform a visual inspection, checking for

any burned or discolored components.

3. Set the ohmmeter to R x 1K.

4. Touch the ohmmeter test leads to each of

the IC leads at A and B, as shown. The

meter readings should be as follows:

Leads A should be greater than 10 K

Leads B should be greater than 5 K

Ω.

Ω.

5-3

— NOTES —

5-4

DIAGNOSTICS & TROUBLESHOOTING

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

ELECTRONIC BOARD ERROR CODES

Error Description Burners Solution

F0 No communications between the touch 2 or 4 1. Unplug cooktop or disconnect power.

control and electronic boards. 2. Check the electronic board connections.

3. If failure remains, replace the electronic board.

FOP No communications between the right — 1. Unplug cooktop or disconnect power.

and left electronic boards. 2. Check the electronic board connections

(CNT7-CNT6) and the relay board connection.

3. If failure remains, replace the relay board.

4. If failure remains, replace the right electronic

board.

5. If failure remains, replace the left electronic

board.

e0 Electronic board failure (shorted or 2 1. Replace electronic board.

damaged component).

e1 Electronic board failure (problem in 1 1. Replace electronic board.

damaged component).

e2 Fan will not operate. 2 or 4 1. Check fan connection.

2. Replace electronic board.

e3 NTC open. 1 1. Replace the NTC sensor.

e4 NTC shorted. 1 1. Replace the NTC sensor.

c1 Insufficient line voltage (<185 VAC). 2 or 4 1. Error disappears with correct line voltage.

c2 Inductor temperature failure. 1 1. The cooktop has overheated. Turn off and

allow to cool.

c3 Radiator temperature failure. 1 1. The cooktop has overheated. Turn off and

allow to cool.

6-1

TOUCH CONTROL BOARD ERROR CODES

Error Description

U400 U400 appears static on the display and indicates an acoustic signal when the electronics have been

connected erroneously at 400 V. (This warning appears when the measured voltage on the power

grids reaches 280 volts, and cases have occurred in which this warning appears at 250 volts). The

electric company can divert the supplied voltage by ±7%. Disconnect the cooktop from the AC line.

The failure disappears when the incorrect voltage is corrected.

F8 F and 8 blink alternately on the display corresponding to the cooking zone if the maximum cooking

time has been exceeded. The times depend of the power level and go from 1 to 10 hours.

E “E” blinks alternately with the power level or the residual heat indicator when the corresponding sen-

sor has been pressed for too long (> 5 seconds), thereby sounding the acoustic signal. When the

“on” sensor is pressed for more than this time, “E” appears on all displays. It can occur due to liquids

spilled over the sensor zone, or due to an object that has been left on top. The indicator disappears

when the problem has been removed from the sensor and any other key is pressed.

F2 F and 2 blink alternately on the corresponding display if the NTC temperature of the touch control is

excessively high (>100°C). If F2 appears, cooking zones 1 and 4 will not work.

F4 F and 4 blink alternately on the corresponding display if the NTC temperature of the touch control is

excessively high (>100°C). If F4 appears, none of the 4 cooking zones will work.

ErXY The touch control has an internal failure (except with Er32).

Er32 This warning occurs when a touch control of a 2l cooktop is connected to a 4l cooktop, or vice versa.

Check the replacement part.

Cl The line power supply voltage is too low.

6-2

WIRING DIAGRAMS

TCB - Touch Control Board

LEB - Left Electronic Board

REB - Right Electronic Boar

d

LAP - Left Aluminum Plat

e

RAP - Right Aluminum Plate

SEB - Supressor Electronic Board

TB - Terminal Block

IF - Internal Frame

R.R. INDUCTOR

2400 W

FAN R

NTC

L.R. INDUCTOR

1800 W

L.F. INDUCTOR

1800 W

NTC

NTC

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

SAT

4 WIRES

RED, GREY,

YELLOW,

BLUE

FAN L

3 WIRES

RED,

BLACK,

WHITE

3 WIRES

RED, BLACK,

WHIT

E

GREEN

GREEN

GREE

N

GREE

N

BLACK

RED

GND

L2

L1

RED

RED

BLACK

BLAC

K

FST2

FST2

TCB

FST3

FST3

FST5

FST5

FST1

CNX2

CNX2

CNX3

FU1

FU2

4 WIRES

RED, GREY,

YELLOW,

BLUE

2 WIRES

YELLOW, BLUE

X4.1

X1.1

NT

C

R.F. INDUCTOR

1400 W

BLACK

LEB

GREEN

FST1

CNX3

CNX1

CNX1

RED

CNX4

CNX4

CNT1

CNT1

CNT5

CNT5

CNT3

CNT3

CNT4

CNT4

REB

RA

P

LA

P

TB

L1

X5.1

B

LA

C

K

/

BR

O

W

N

BL

A

CK

/

B

R

O

W

N

BROWN/

BL

AC

K

BROW

N/

BL

AC

K

BLACK

BLACK

BLACK

L2

SEB1

FST2FST1

FST3

FST4

FST4

FST

3FST2

FST1

SEB2

RED

BLACK

BLAC

K

RED

30˝ COOKTOP

7-1

36˝ COOKTOP

TCB - Touch Control Board

LEB - Left Electronic Board

MEB - Middle Electronic Board

REB - Right Electronic Board

LAP - Left Aluminum Plate

MAP - Middle Aluminum Plate

RAP - Right Aluminum Plate

SEB - Supressor Electronic Board

TB - Terminal Block

IF - Internal Frame

L.R. INDUCTOR

1800 W

4 WIRES

RED, GREY

,

YELLOW, BLUE

BLAC

K

BROWN

BROW

N

BLACK

BLAC

K

BROWN

BROW

N

L1

GREEN

3 WIRE

S

RED, BLACK,

WHITE

GREE

N

CNT4

CNX1

FST5

BLACK

FST1

CNX4

L.F. INDUCTOR

1800 W

3600 W

1400 W

2200 W

FAN R

CNX1

CNX3

CNX2

CNT5

CNT3

CNT1

CNT1

CNT4

BR

O

WN/B

L

A

CK

BROWN/

BL

A

CK

FAN M

FA

N L

SA

T

NTC

RAP

NTC

NT

C

NTC

NTC

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

2 WIRE

S

3 WIRE

S

RED,

BLACK,

WHITE

FST2

BLACK

BLACK

FST2

FST3

FST3

FST1

FST5

3 WIRES

RED, BLACK,

WHITE

CNX3

CNT

4

CNX1

CNT

1

FST1

CNX2

CNX4

BLACK

2 WIRE

S

BLUE, YELLOW

CNX3

CNT5

CNT

5

CNT

3

X5.1

4 WIRES

RED, GREY

,

YELLOW, BLUE

GREE

N

GREE

N

GREEN

RED

BLAC

K

R.C. INDUCTOR

BLACK

R.R. INDUCTOR

R.R. INDUCT

OR

RED

RE

D

BLACK

GREEN

LEB

MEB

REB

TC

B

TB

L1

L2

LA

P

CNT6

MAP

L2

X1.1

RED

RE

D

RE

D

FU1

X4.1

GREEN

CNX2

BLUE

YELLOW

CNX4

FST2

FST3

FU2

FST5

RED

RED

RED

BLAC

K

BLACK

BL

A

CK

SEB1

SEB2

SEB3

FST2

FST1

FST3

FST4

FST4

FST3

FST2

FST1

FST1

FST2

FST3

FST4

BROWN/BLACK

BLACK/BROWN

7-2

— NOTES —

7-3

— NOTES —

7-4

PRODUCT SPECIFICATIONS

AND

WARRANTY INFORMATION SOURCES

IN THE UNITED STATES:

FOR PRODUCT SPECIFICATIONS AND WARRANTY INFORMATION CALL:

FOR WHIRLPOOL PRODUCTS: 1-800-253-1301

FOR KITCHENAID PRODUCTS: 1-800-422-1230

FOR ROPER PRODUCTS: 1-800-447-6737

FOR TECHNICAL ASSISTANCE WHILE AT THE CUSTOMER’S HOME CALL:

THE TECHNICAL ASSISTANCE LINE: 1-800-832-7174

HAVE YOUR STORE NUMBER READY TO IDENTIFY YOU AS AN

AUTHORIZED IN-HOME SERVICE PROFESSIONAL

FOR LITERATURE ORDERS:

PHONE: 1-800-851-4605

FOR TECHNICAL INFORMATION AND SERVICE POINTERS:

www.servicematters.com

IN CANADA:

FOR PRODUCT SPECIFICATIONS AND WARRANTY INFORMATION CALL:

1-800-461-5681

FOR TECHNICAL ASSISTANCE WHILE AT THE CUSTOMER’S HOME CALL:

THE TECHNICAL ASSISTANCE LINE: 1-800-832-7174

HAVE YOUR STORE NUMBER READY TO IDENTIFY YOU AS AN

AUTHORIZED IN-HOME SERVICE PROFESSIONAL

Loading...

Loading...