KitchenAid KDRP463LSS05, KDRP463LSS07, KDRP463LSS08, KDRP463LSS0, KDRP463LSS04 Installation Guide

...Page 1

W

[] []

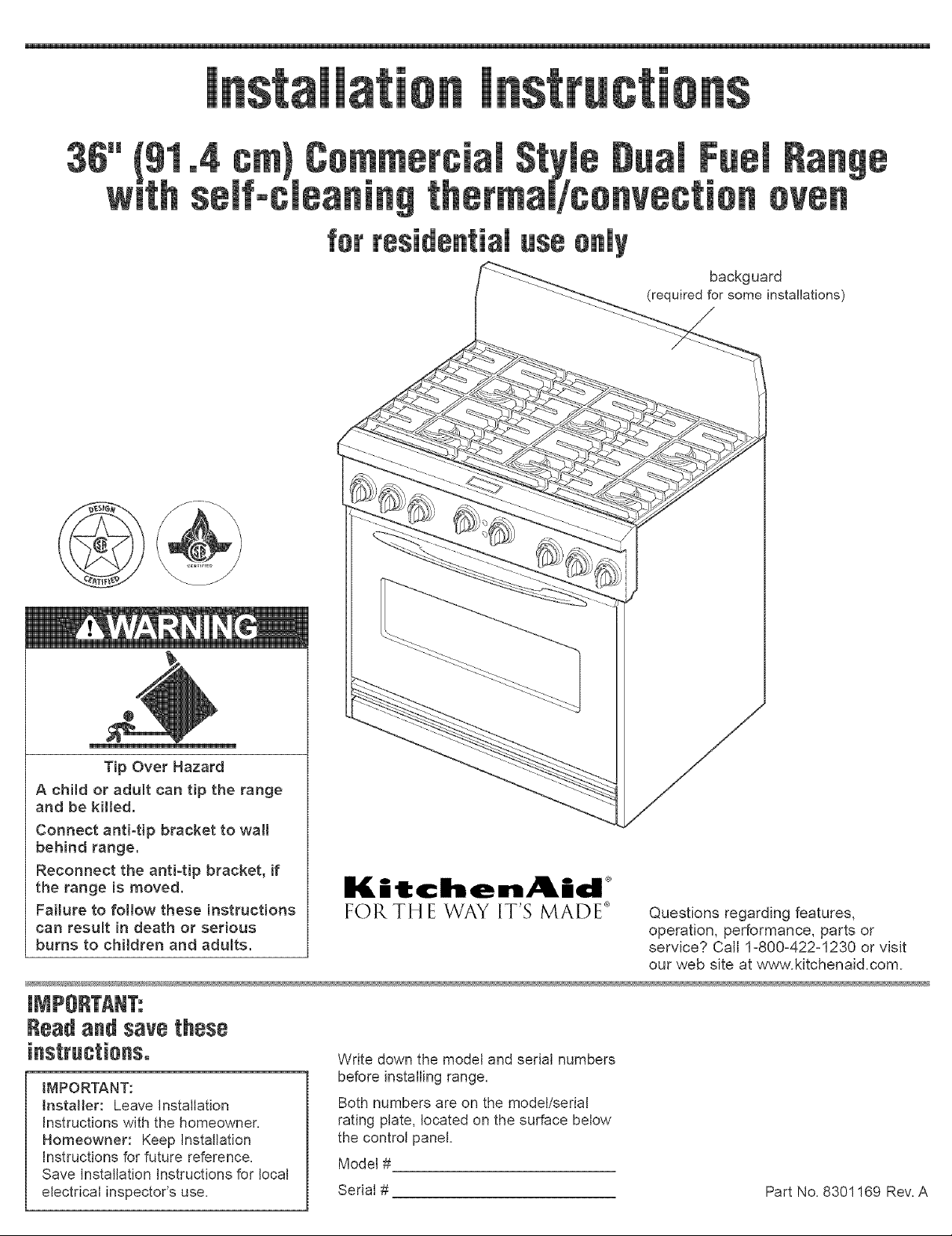

for residentiaJuse enJy

backguard

(required for some installations)

Tip Over Hazard

A child or adult can tip the range

and be killed.

Connect anti-tip bracket to wall

behind range.

Reconnect the anti-tip bracket, if

the range is moved.

Failure to follow these instructions

can resuJt in death or serious

burns to chitdren and adults.

Readandsave these

IMPORTANT:

Installer: Leave installation

instructions with the homeowner=

Homeowner: Keep installation

instructions for future reference.

Save installation instructions for local

electrical inspector's use.

KitchenAid _

FORTHE WAY IT'S MADE _

Write down the model and serial numbers

before installing range.

Both numbers are on the model/serial

rating plate, located on the surface below

the control panel.

Model #

Serial #

Questions regarding features,

operation, performance, parts or

service? Call 1=800o422=1230 or visit

our web site at www.kitchenaid.com.

Part No. 8301169 Rev. A

Page 2

Before youstart,,,

Your safety and the safety of

others are very important.

We have provided many important

safety messages in this manual and

on your appliance. AK_'ays read and

obey all safety messages.

This is the safety alert

symbol.

This symbol alerts you to

potential hazards that can kill or hurt

you and others.

All safety messages will follow the

safety alert symbol and either the

word "DANGER" or "VVARNING".

These words mean:

You can be killed or seriously

injured if you don't immediately

follow instructions.

You can be killed or seriously

injured if you don't foltow

instructions.

All safety messages will tell you

what the potential hazard is, tell you

how to reduce the chance of injury,

and tell you what can happen if the

instructions are not followed.

IMPORTANT: Observe all governing

codes and ordinances.

WARNING: If the

information in this manua_

is not followed exactly, a

fire or explosion may result

causing property damage,

persona_ injury or death.

m Do not store or use

gasoline or other

flammable vapors and

_iquids in the vicinity of

this or any other

appliance.

WHAT TO DO _FYOU

SMELL GAS

o Do not try to _ight any

appliance.

o Do not touch any

electrica_ switch.

o Do not use any phone in

your building.

o _mmediately cal_ your

gas supplier from a

neighbor's phone. Follow

the gas supp_ier's

instructions.

o _fyou cannot reach your

gas supplier, call the fire

department.

Installation and service

must be performed by a

qualified installer, service

agency or the gas

supplier.

NOTE: The range cooktop is

manufactured for use with Natural gas. To

convert to LR/Propane gas, see the Gas

Conversion instructions provided in

literature package.

Proper gas and electrical supply

connections must be available. See "Gas

supply requirements," Page 4 and

"Electrical requirements," Page 5.

IMPORTANT: Observe all governing

codes and ordinances.

Do not obstruct flow of combustion and

ventilation air.

Proper installation is your responsibility.

Have a qualified technician install this

range. Make sure you have everything

necessary for correct installation. It is the

installer's responsibility to comply with the

installation clearances specified on the

gas information label. The gas information

label and model/serial rating plate are

located on the surface below the control

panel.

This installation must conform with all

local codes and ordinances, in the

absence of local codes, installation must

conform with American National

Standard, National Fuel Gas Code ANSI

Z223.1 --latest edition* or CAN/CGA --

B149 -- latest edition* installation codes=

it is the customer's responsibility:

o To contact a qualified electrical installer.

• To assure that electrical installation is

adequate and in conformance with

National Electrical Code, ANSI/NFPA

70 -- latest edition**, or CSA Standard,

C22.! Canadian Electrical Code, Part 1

-- latest edition*, and all local codes

and ordinances.

Cabinet opening dimensions shown must

be used. Given dimensions are minimum

clearances=

When installing a range under existing

cabinets and installation does not meet

the minimum cabinet clearances, install a

range hood above the range to avoid burn

hazards.

NOTE: Some cabinet and building

materials are not designed to withstand

the heat produced by the oven for baking

and self-cleaning. Check with your builder

or cabinet supplier to make sure that the

materials used will not discolor,

delaminate or sustain other damage.

All openings in the wall or floor where the

range is to be installed must be sealed.

it is recommended that a range hood be

installed above this range.

Copies of the standards listed may be obtained

from:

* CSA International

8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

** National Fire Protection Association

One Batterymarch Park

Quincy, Massachusetts 02269

Page 3

Parts

. . suppliedfor

ns aiia men

2 - #10 x 2" anti-tip

phillips headscrews brackets

° Anti=tip bracket must be securely

attached to a wall stud. Thickness of

finished wail may require using

longer screws to anchor the bracket.

* LR conversion kit is included in

literature package.

. Backguard and island trim. The

backguard included with the range

must be installed when a standard

24" (61 cm) deep base cabinet is

used and there is zero clearance

between the back edge of range

and combustible rear wall.

For island installations or other

installations with more than 5"

(12.7 cm) clearance to back wall,

use the optional stainless steel

island trim, includedwith the range,

to cover the backguard mounting

flanges.

NOTE:regulator

locatedat center

bottom of range, 36" (91,4 cm)

9ol/4"

1/4"(6,4 ram)

spacer ,,_

26-1/2"_

width with

control panel

13" (33 cm) max.

upper cabinet depth 36" (91.4 cm) rain.

cooktop width

upper cabinet width

36" 91_4cm

wdth

36" (91,4cm) rangewith

all sealedburnersdrown

clearance to top of

dimensions

45" (1143 cm)

overall height

36" (914 cm)

cooktop

heightwith

feetloosened

3/4turns

For minimum

range,see NOTE,*

*NOTE: 42" (106.7 cm) rain. when bottom of wood or

metal cabinet is protected by not less than 1/4" (6.4 ram)

flame retardant millboard covered with not less than

No. 28 MS6 sheet steel,0.015" 0.4 ram) stainless steel,

0,024" 0.6 mm a um num or 0.020" 05 mm copper,

48" (121.9 crn) rain. clearance between the top of the

cooking platform andthe bottom of an unprotected wood

or metal cabinet.

3-1/2" (8.9 crn)

maximum junction

box height

18" (45.7 cm)

upper cabinet

to countertop

junction box to be

located in this area

36-1/4" (92.1

opening width

8"

(20.3 cm)

3" (7.6 cm) rnaximurn

gas line height

I

gas line opening to be

located in this area

(10.2 cm) rain.

clearance from both sides

of range to side wall or

other combustible rnaterial

above cooking surface

0" (0 cm) clearance from

both sides and back of

rangeto adjacent

combustible construction

below cooking surface

Page 4

GaS $U

Explosion Hazard

Use a new AGA or CSA approved

gas supply line,

Install a shutoff valve.

Securely tighten all gas

con nections.

if connected to LP, have a

qualified person make sure gas

pressure does not exceed 14"

(35.6 cm) water column.

Examples of a qualified person

include:

Licensed heating personnel,

Authorized gas company

personnel_ and

Authorized service personnel.

Failure to do so can result in

death, explosion, or fire.

Observe all governing codes and

ordinances.

IMPORTANT: Range cooktop must be

connected to a regulated gas supply.

AE This installation must conform

with local codes and ordinances. In the

absence of local codes, installations must

conform with American National

Standard, National Fuel Gas Code

ANSI Z223.1 -- latest edition* or

CAN/CGA-B149 -- latest edition*

installation codes.

C mThe range is equipped for use with

NATURAL gas. it is design=certified by

international Approval Services (I.A.S.) for

NATURAL and L.R gases with appropriate

conversion. The model/serial rating plate,

located on the surface below the control

panel, has information on the type of gas

that can be used. if this information does

not agree with the type of gas available,

check with the local gas supplier.

L.R Gas:

No attempt shall be made to convert the

cooktop from the gas specified on the

model/serial rating plate for use with a

different gas without consulting the

serving gas supplier. Conversion must be

done by a qualified service technician. To

convert to L.R gas, use L.R gas

conversion kit part no. 8301439. The parts

for this kit are in the literature package

supplied with range.

Provide a gas supply line of 3/4"

(1.9 cm) rigid pipe to the range location. A

smaller size pipe on long runs may result

in insufficient gas supply. Pipe=joint

compounds, appropriate for use with L.R

gas, must be used. With L.R gas, piping or

tubing size can be 1/2" (1.3 cm) minimum.

L.R gas suppliers usually determine the

size and materials used on the system.

E E If local codes permit, a new AGA

or CSA design-certified, 4-5 foot (122-

152.4 cm)long, 5/8" (1.6 cm) I.D. flexible

metal appliance connector is

recommended for connecting this range

to the gas supply line. Do not kink or

damage the flexible tubing when moving

the range. A 1/2" (1.3 cm) male pipe

thread is needed for connection to

pressure regulator female pipe threads.

G E if rigid pipe _T

is used as a gas

supply line, a combination of pipe UI'

fittings must be used to obtain an in-line

connection to the range. All strains must

be removed from the supply and fuel lines

so range will be level and in line.

EThe regulatormust be checked at a

minimum 1-inch (25.4 mm) water column

above the set pressure.The inlet pressure to

the regulatorshould be as followsfor

operation and checking the regulator setting:

NATURAL GAS:

Manifold pressure =

5 inches (12.7 cm) W.C.

Maximum pressure =

14 inches (35.6 cm) W.C.

LR GAS:

Manifold pressure =

10 inches (25.4 cm)W.C.

Maximum pressure =

14 inches (35.6 cm) W.C.

E Line pressure testing:

Testing above 1/2 psi (3.5 kPa) (gauge):

The range and its individual shutoff valve

must be disconnected from the gas

supply piping system during any pressure

testing of that system at test pressures

greater than 1/2 psig (3.5 kPa).

Testing at 1/2 psi (3.5 kPa) (gauge)

or lower: The range must be isolatedfrom

the gas supply piping system by closing

its individual manual shutoff valve during

any pressure testing of the gas supply

piping system at test pressures equal to

or less than 1/2 psig (3.5 kPa).

BE Input ratings shown on the

model/serial rating plate are for elevations

up to 2,000 feet (610 m). For elevations

above 2,000 feet (610 m), ratings are

reduced at a rate of 4% for each 1,000

feet (305 m) above sea level. (Not

applicable for Canada.)

shutoffvalve

"0pen"I

gassupply_,

Die

F to range

E The supply line shall be equipped

with an approved shutoff valve. This valve

should be located in the same room, but

external to the range, and should be in a

location that allows ease of opening and

closing. Do not block access to the

shutoff valve.

Copies of the standards listed may be

obtained from:

* CSA International

8501 East Pleasant Valley Road

Cbvetand, Ohio 44131=5575

Page 5

if codes permit and a separate ground

wire is used, it is recommended that a

qualified electrician determine that the

ground path and wire gauge are in

accordance with local codes.

Do not ground to a gas pipe.

Check with a qualified electrician if you

are not sure the range is properly

grounded.

Do not have a fuse in the neutral or

ground circuit.

This range must be connected to a

grounded metal, permanent wiring

system.

Am A four-wire or three-wire, single

phase, 240-volt, 60-Hz, AC-only electrical

supply is required on a separate, 30-

ampere circuit, fused on both sides of the

line. A time-delay fuse or circuit breaker is

recommended. The fuse size must not

exceed the circuit rating of the range

specified on the model/serial rating plate

located on the horizontal surface below

the control panel.

BE Wire sizes and connections must

conform to the requirements of the

National Electrical Code ANSI/NFPA 70 -

latest edition*, or CSA Standards C22.1-

94, Canadian Electrical Code, Part 1 and

C22.2 No. 0-M91 - latest edition** and all

local codes and ordinances.

C E The range should be connected

directly to the fused disconnect or circuit

breaker box through flexible, armored or

nommetallic sheathed, copper cable. The

flexible, armored cable extending from the

fuse box or circuit breaker box should be

connected directly to the junction box.

F_ Connection at connection block must

be copper wire only.

If the house has aluminum wiring, follow

the procedure below:

a) Connect the aluminum wiring to the

copper wiring using special connectors

designed and Undep,_/riters

Laboratoriesqisted for joining copper to

aluminum. Follow the electrical

connector manufacturer's recommended

procedure.

b) Aluminum/copper connection must

conform with local codes and industry-

accepted wiring practices.

Copies of the standards listed may be obtained

from:

* National Fire Protection Association

One Batterymarch Park

Quincy, Massachusetts 02269

** CSA international

8501 East Pteasant ',/alley Road

Cleveland, Ohio 44131-5575

lastaiiatiea

ExcessBve Weight Hazard

Use two or more people to move

and Bnstall range.

Failure to do so can result in back

or other injury.

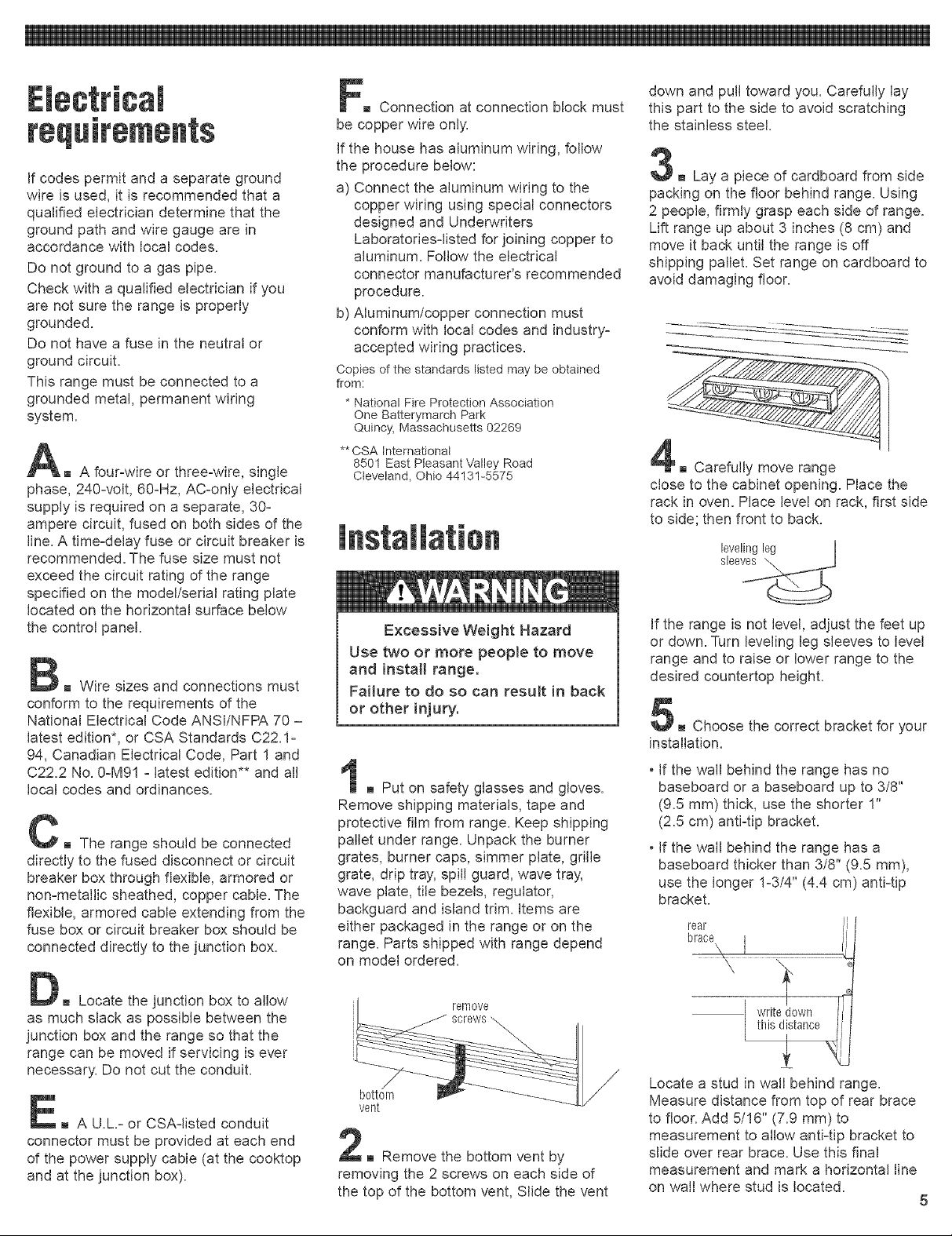

m Put on safety glasses and gloves.

Remove shipping materials, tape and

protective film from range. Keep shipping

pallet under range. Unpack the burner

grates, burner caps, simmer plate, grille

grate, drip tray, spill guard, wave tray,

wave plate, tile bezels, regulator,

backguard and island trim. Items are

either packaged in the range or on the

range. Parts shipped with range depend

on model ordered.

down and pull toward you. Carefully lay

this part to the side to avoid scratching

the stainless steel.

3E Lay a piece of cardboard from side

packing on the floor behind range. Using

2 people, firmly grasp each side of range.

Lift range up about 3 inches (8 cm) and

move it back until the range is off

shipping pallet. Set range on cardboard to

avoid damaging floor.

4E Carefully move range

close to the cabinet opening. Place the

rack in oven. Place level on rack, first side

to side; then front to back.

leveling leg

slee J

if the range is not level, adjust the feet up

or down. Turn leveling leg sleeves to level

range and to raise or lower range to the

desired countertop height.

5m Choose the correct bracket for your

installation.

• If the wail behind the range has no

baseboard or a baseboard up to 3/8"

(9.5 ram) thick, use the shorter 1"

(2.5 cm) anti-tip bracket.

• If the wall behind the range has a

baseboard thicker than 3/8" (9.5 mm),

use the longer 1-3/4" (4.4 cm) anti-tip

bracket.

rear

brace,

\

Locate the junction box to allow

as much slack as possible between the

junction box and the range so that the

range can be moved if servicing is ever

necessary. Do not cut the conduit.

E mA U.L.- or CSA-listed conduit

connector must be provided at each end

of the power supply cable (at the cooktop

and at the junction box).

remove

screws ',,

bottom

vent

m Remove the bottom vent by

removing the 2 screws on each side of

the top of the bottom vent, Slide the vent

write down

this distance

Locate a stud in wall behind range.

Measure distance from top of rear brace

to floor. Add 5/16" (7.9 mm) to

measurement to allow anti-tip bracket to

slide over rear brace. Use this final

measurement and mark a horizontal line

on wall where stud is located.

5

Page 6

TipOverHazard

A childor aduJtcantip the range

andbekiiJed.

Connectanti-fipbrackettowa!I

behindrange.

Reconnecttheanti-tip bracket, if

the range is moved.

Failure to follow these instructions

can result in death or serious

burns to children and aduJts.

line I

aHti-tip --_._ I _;

bracket _ _

Position top of anti-tip bracket at

line marked in step 5 and mark holes.

Drill two 1/8" (3 mm) holes. Use screws

provided to fasten anti-tip bracket to wall.

NOTE: Anti-tip bracket must be mounted

securely to stud in wall behind the range.

Depending on thickness of the wall

covering, longer screws may be required.

mMake electrical connection.

If your house has aluminum wiring, see

"Electrical requirements" page 5.

I

I

I

__f_ wall stud

I

I

I

_ mounting

screws

I

I

I

I

Electrical Shock Hazard

Disconnect power before servicing.

Use 8 gauge copper wire.

Electrically ground range.

Failure to follow these instructions

can result in death, fire, or

eJectricaJ shock.

This range must be connected to a

grounded, metallic permanent wiring

system or a ground connector should be

connected to the ground terminal or wire

lead on the range.

This range is manufactured with a frame-

connected, green or bare ground wire

factory-crimped to the neutral (white)

wire. Connect the range cable to the

junction box through the U.L- or CSA=

listed conduit connector. Complete

electrical connection according to local

codes and ordinances.

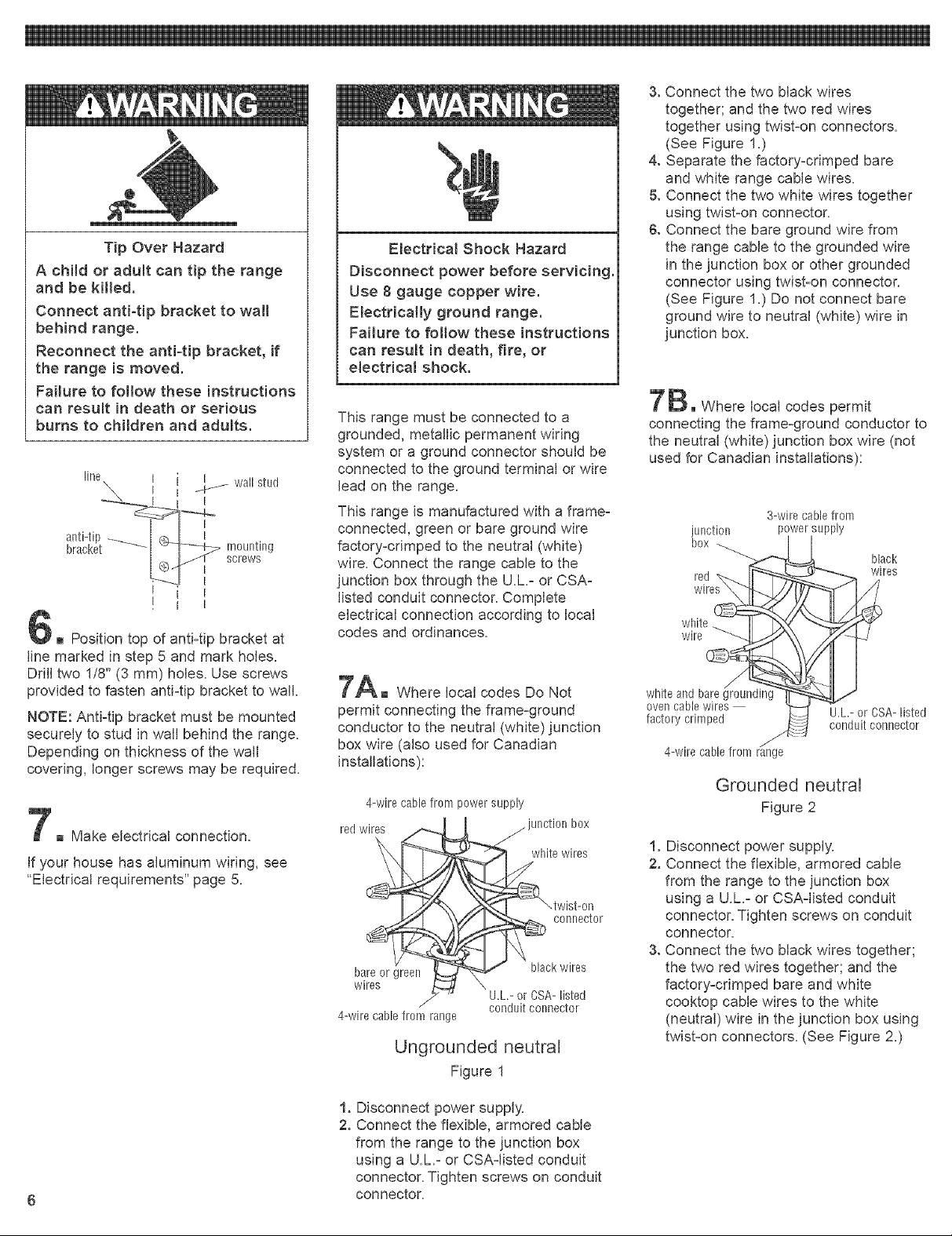

Am Where local codes Do Not

permit connecting the frame-ground

conductor to the neutral (white) junction

box wire (also used for Canadian

installations):

4-wire cable from power supply

red wires ,._,j [ ./junction box

lite wires

J iY'_'X /_t_'_._J ".twist-on

connector

bare_ greel__ / black wires

wires _d] \ U.L- ozCSA- listed

4-wire cable from range

/ conduit connector

Ungrounded neutral

Figure 1

3oConnect the two black wires

together; and the two red wires

together using twist-on connectors.

(See Figure 1.)

4. Separate the factory-crimped bare

and white range cable wires.

5oConnect the two white wires together

using twist=on connector.

6oConnect the bare ground wire from

the range cable to the grounded wire

in the junction box or other grounded

connector using twist-on connector.

(See Figure 1.) Do not connect bare

ground wire to neutral (white) wire in

junction box.

B. Where local codes permit

connecting the frame-ground conductor to

the neutral (white) junction box wire (not

used for Canadian installations):

3-wire cable from

junction

box

red

white

wire

white and bare

oven cable wires --

factory crimped

4-wire cablefrom range

power supply

black

wires

U.L.- or CSA- listed

conduit connector

Grounded neutral

Figure 2

1. Disconnect power supply.

2. Connect the flexible, armored cable

from the range to the junction box

using a U.L.- or CSAqisted conduit

connector. Tighten screws on conduit

connector.

3. Connect the two black wires together;

the two red wires together; and the

factory-crimped bare and white

cooktop cable wires to the white

(neutral) wire in the junction box using

twist-on connectors. (See Figure 2.)

1. Disconnect power supply.

2. Connect the flexibJe, armored cable

from the range to the junction box

using a U.L- or CSAqisted conduit

connector. Tighten screws on conduit

connector.

Page 7

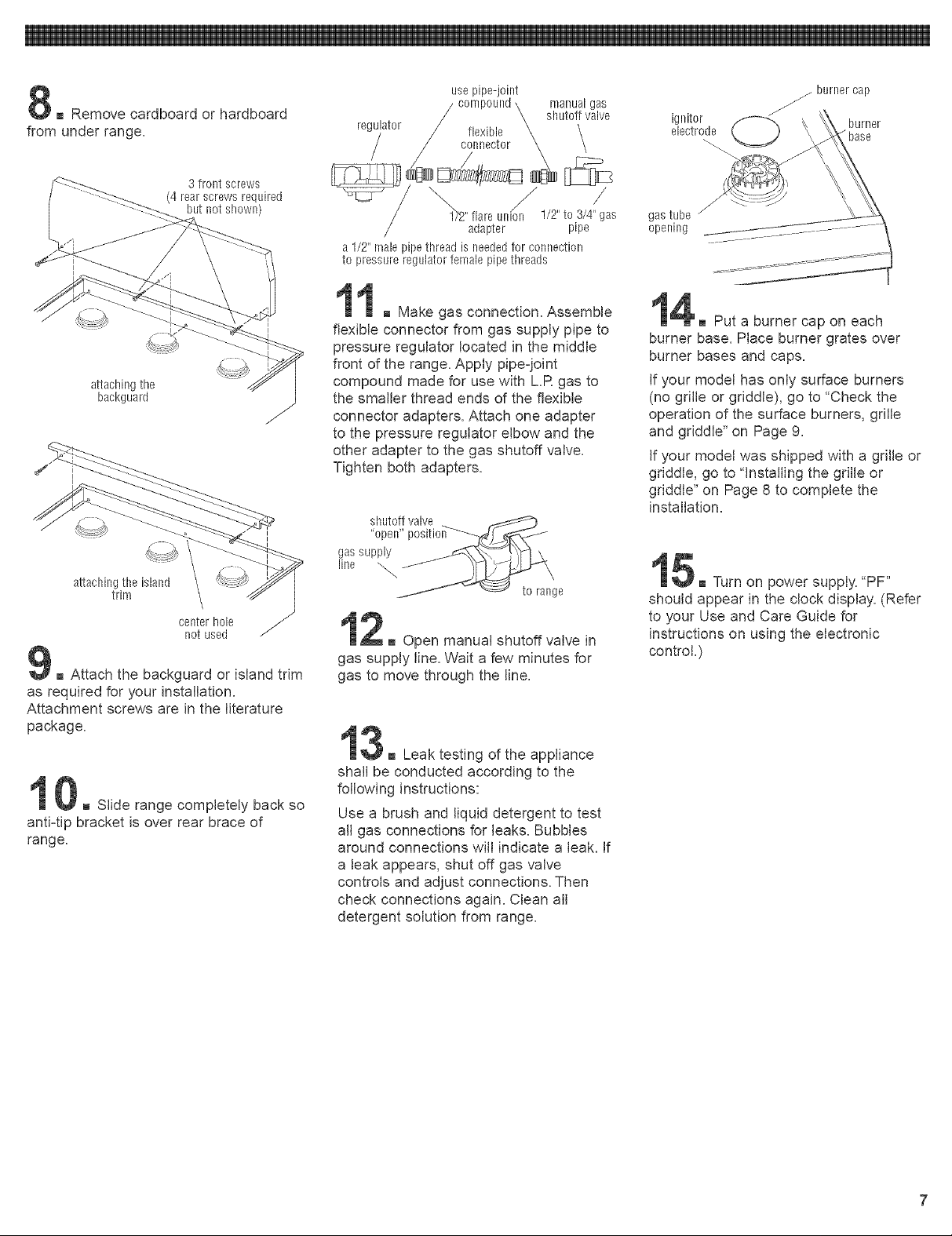

ERemovecardboardorhardboard

fromunderrange.

3 fl'0nt screws

(4 rear screws required

but not shown)

use pipe-joint

regulator flexible

a 1/2" male pipe thread is neededfor connection

to pressure regulator female pipe threads

connector

/

union 1/2"t0 3/4" gas

adapter pipe

ignitor

electrode

_burnercap

burner

base

attaching the

backguard

attaching the island

trim

centerh01e

notused

E Attach the backguard or island trim

as required for your installation.

Attachment screws are in the literature

package.

Slide range completely back so

anti-tip bracket is over rear brace of

range.

E Make gas connection. Assemble

flexible connector from gas supply pipe to

pressure regulator located in the middle

front of the range. Apply pipe-joint

compound made for use with L.R gas to

the smaller thread ends of the flexible

connector adapters. Attach one adapter

to the pressure regulator elbow and the

other adapter to the gas shutoff valve.

Tighten both adapters.

shutoff valve

"open" p

gas supply

line \..,

to range

mOpen manual shutoff valve in

gas supply line. Wait a few minutes for

gas to move through the line.

E Leak testing of the appliance

shall be conducted according to the

following instructions:

Use a brush and liquid detergent to test

all gas connections for leaks. Bubbles

around connections will indicate a leak. If

a leak appears, shut off gas valve

controls and adjust connections. Then

check connections again. Clean all

detergent solution from range.

m Put a burner cap on each

burner base. Place burner grates over

burner bases and caps.

if your model has only surface burners

(no griNe or griddle), go to "Check the

operation of the surface burners, grille

and griddle" on Page 9.

if your model was shipped with a grille or

griddle, go to "Installing the grille or

griddle" on Page 8 to complete the

installation.

5 mTurn on power supply. "PF"

should appear in the clock display. (Refer

to your Use and Care Guide for

instructions on using the electronic

control.)

Page 8

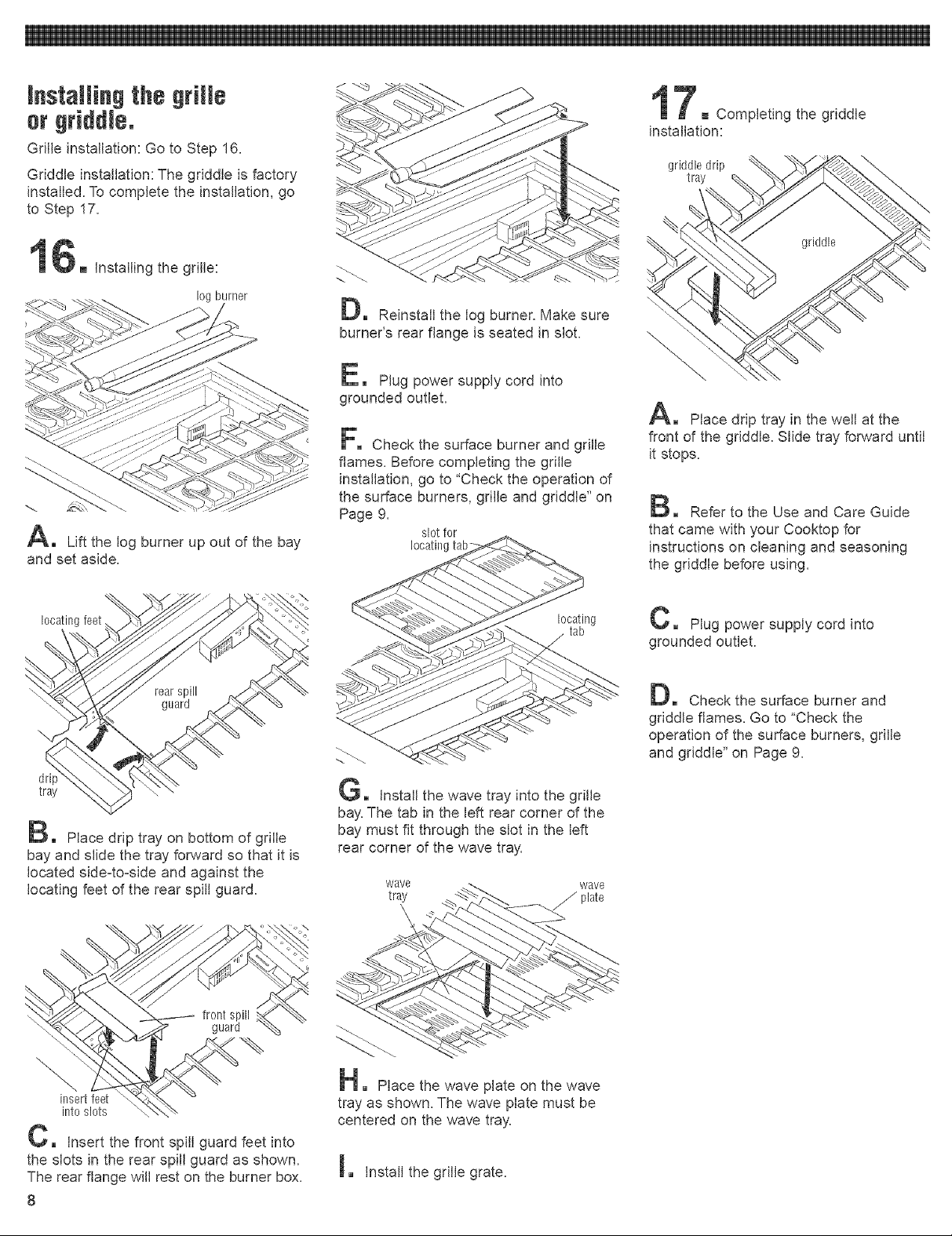

installingthe griJie

or griddJe.

Grille installation: Go to Step 16.

Griddle installation: The griddle is factory

installed. To complete the installation, go

to Step 17.

m Installing the grille:

log burner

A, Lift the log burner up out of the bay

and set aside.

D, Reinstall the log burner. Make sure

burner's rear flange is seated in slot.

E,, Plug power supply cord into

grounded outlet.

F, Check the surface burner and grille

flames. Before completing the grille

installation, go to "Check the operation of

the surface burners, grille and griddle" on

Page 9.

slotfor

locatingtab

m Completing the griddle

installation:

griddle dlip

tray

A, Place drip tray in the well at the

front of the griddle. Slide tray forward until

it stops.

B, Refer to the Use and Care Guide

that came with your Cooktop for

instructions on cleaning and seasoning

the griddle before using.

locating feet

tray

B, Place drip tray on bottom of grille

bay and slide the tray forward so that it is

located side-to-side and against the

locating feet of the rear spill guard.

locating

tab

/,

G, Install the wave tray into the grille

bay.The tab in the left rear corner of the

bay must fit through the slot in the left

rear corner of the wave tray.

wave wave

tray J plate

\

C, Plug power supply cord into

grounded outlet.

D, Check the surface burner and

griddle flames. Go to "Check the

operation of the surface burners, grille

and griddle" on Page 9.

insert feet

into slots

C, Insert the front spill guard feet into

the slots in the rear spill guard as shown.

The rear flange will rest on the burner box.

8

H, Place the wave plate on the wave

tray as shown. The wave plate must be

centered on the wave tray.

_, install the grille grate.

Page 9

Checkthe eperatJeflof the

surfaceburners,griJJeand

m

Electronic Ignition System --

initial lighting

Surface burners use electronic ignitors in

place of standing pilots. When the

cooktop control knob is pushed in and

turned to the "LFE" position, the system

creates a spark to light the burner. This

sparking continues until the control knob

is turned to the desired setting.

The grille and griddle burner use an

ignitor glow bar that is either on or off in

place of standing pilots. When the glow

bar is hot, it sends a signal back to the

safety valve which opens allowing gas

to flow.

co0kt0p grille griddle

burners knob knob

A. Push in and turn the surface

burners and grille control knobs to "LITE"

position. For griddles, turn the griddle

control knob to a temperature degree

mark (300F° recommended). The surface

burner flame should light within 4

seconds and the grille and griddle flame

in 30-40 seconds.

NOTE: The griddle flame cannot be seen,

but you should hear it ignite and feel heat

from the griddle.

After lighting the burners, turn the control

knobs to "OFF".

if burners do not light properly, turn

control knob to the "OFF" position. Check

that burner cap is in the proper position.

Check that circuit breaker or house fuse

has not blown. Check that the shutoff

valve is in the "ON" position. Check

operation again.

if a surface burner, grille or griddle does

not light at this point, contact your

KitchenAid dealer for assistance.

valve

B. Adjusting the surface burner or

grille flame:

NOTE: There is no adjustment for the

griddle flame. Gas flow is at 100%,

temperature is controlled by thermostat.

Push in and turn each control knob to the

"LO" position. The "LO" setting of each

burner has been factory set to the lowest

position available to provide reliable

reignition of the burner, if it does not stay

lit on the "LO" position, check "LO"

position as follows:

a. Turn control knob to "LITE" until burner

ignites.

b. Quickly turn control knob down to "LO"

position.

c. if burner goes out, readjust valve as

follows:

Remove control knob. insert a flat-blade

screwdriver into the hollow valve stem

and engage the slotted screw. Flame size

can be increased or decreased by turning

the screw. Adjust flame until you can

quickly turn control knob from "HI" to "LO"

position without extinguishing the flame.

Flame should be as small as possible

without going out.

ports

typical surface

burner flame at

highest setting

C. Check flame on "HI" for a blue

color, it should be clean and soft in

character. No yellow tip, blowing or lifting

of flame should occur. Occasional orange

flashes are normal and reflect different

elements in the air or gas.

9E Check operation of oven

element. Turn oven selector to "BAKE".

"350F" will show on display. Press "Enter".

First Preheat light comes on when oven

temperature begins to rise. When second

Preheat light comes on, open oven door

and hold hand above oven floor and feel

for heat. Do not touch oven floor. Press

"Cancel" and turn oven selector to

"Reset".

Check the operation of the

broiler element. Turn oven selector to

"BROIL". "HI" will show on display.Press

"Enter". Look through oven window. The

top element should glow red and heat

should be radiating out of the door. Press

"Cancel" and turn oven selector to

"Reset".

If the oven does not operate, check that

power supply is turned on, that nofuses

are blown, or circuit breakers tripped, if

the oven still does not operate, contact

your KitchenAid dealer or designated

service company.

E Reinstall lower vent by inserting

tabs into the slots on the front trim. Push

vent upward until the holes line up at top

of vent. Reattach the vent using the two

screws.

Place burner grates over

burner caps. The simmer plate may set

on one of the grates or be stored for

future use. (See Use and Care Guide.)

To get the most efficient use

from your new dual fuel range,

read your KitchenAid Use and

Care Guide. Keep Installation

Instructions and Guide close to

the range for easy reference.

Page 10

Installer checkoff

If range

dees net eperate

RANGE

[_ Range correctly positioned in

countertop cutout.

[_ Maintained specified distances to

cabinet surfaces.

[_ Range level - front to back - side to

side.

[_ Burner caps positioned properly on

sealed burner bases.

[_AII packing material removed.

[_ Backguard or island trim attached

(see page 3).

[_ Depending on model, grille parts

correctly assembled.

[_ Depending on model, griddle parts

correctly assembled.

GAS SUPPLY

[_The range is connected only to type

of gas for which it is certified for use.

[_ Check that the circuit breaker is not

tripped or the house fuse blown.

[_] Check that gas valves are turned to

the "ON" position.

[_See Use and Care Guide for

troubleshooting list.

If youneed

The KitchenAid Customer Interaction

Center will answer any questions about

operating or maintaining your range not

covered in the Installation Instructions.

The KitchenAid Customer Interaction

Center is open 24 hours a day, 7 days a

week. Just dial 1o800o422o1230-- the

call is free within the continental United

States, or visit our web site at

www.kitchenaid,com.

When you call, you will need the range

model number and serial number. Both

numbers can be found on the

model/serial rating plate located on the

surface below the control panel.

In the event that your KitchenAid

appliance should need service, call the

dealer from whom you purchased the

appliance or a KitchenAid-designated

service company. A KitchenAid-

designated service company is listed in

the Yellow Pages of your telephone

directory under "Appliances -- Household

-- Major -- Service and Repair."

You can also obtain the service

company's name and number by dialing,

free within the continental United States,

the KitchenAid Customer Interaction

Center telephone number, 1o800o422o

1230. A special operator will tell you the

name of your nearest KitchenAid-

designated service company.

Maintain the quality built into your

KitchenAid appliance -- call a

KitchenAid-designated service company.

If removing the range is necessary for

maintenance, shut off gas supply.

Disconnect the gas and electric supply.

Finish removing the range.

L1

) (

w

w

(

BK

GROUND_It GRN

}K BK

SURFACE BURNER

I/ALIIE

S//VITCHES

120VAC60 Hz

15OR 20A_,4P

1 PHASE

o W

L N _:IOD ULE GRILLE

: SPARK

/

_ji- YELsRNOR

GNITOR

GRILLE

//AD/E

W

j_j_ 4ELCS

:r fSDRFACEBURNER

GRILLE

VAB/E

SWITCH

±±±± ,GN,TOR

.... ELECTRODES

Cooktop schematic

with grille

LI

W

BE

w

BK

THERMOSTA_

_K BK

SURFACEBURNER

VALVE

SWTCHES

I I

L

GRIDDLE

GROUND'1t GRN

W

L N _ODULE GRIDDLE

±±±2_ GN,TOR

.... ELECTRODES

120VACEOHz

1 PHASE

15OR20 AMP

W

o

: SEARK

: IGNITOR

i YELOR

: BRN

i ...... J 4 PLCS

!_'_ --_ _ SURFACE BURNER

GRIDDLE

VALVE

W

Cooktop schematic

with griddle

10

Page 11

LI N L2

BK W R

LATCH ASSY

GDN €_:_o--_

i u u SPARK

u u MODULE ¢-_c--_

L .................... u

L1 SUPPRESSOR WP#4451985

BK

DOOR

SWITCH 1

TAN ©_L BRN

LATCH

SWITCH

TAN

F

W'

u

uu VALVE SWITCHES

uu YEL OR BRN (6) PLCS

TOR ELECTRODES

P4-1

BKK

P4-2

P9-1

P9-3

P7-4

P7-5

BREAK RELAY

P7-1

Bt

P7-2

TAB

P7-3

Oven schematic

- P8-2 Y

P8-3

P8-4

BU BROIL-3000W

P5-3

P5-4

==4)_

P3-3

P3-2

P1-1

P1-3

Cooktop schematic

l

ON LATCH ASSY

DOOR LOCK

MOTOR LATCH

TOD - NON RESETABLE

N L2

w

w

F

P1-5

-o-

P3-1

(*). BLOWER REMAINS OFF UNTIL OVEN REACHES 190F (88C) AND MA_

CONTINUE RUNNING UP TO 45 MINUTES AFTER OVEN HAS TURNED OFF

NOTE: CIRCUIT SHOWN IN STANDBY/OFF

MODE WITH OVEN DOOR CLOSED

11

Page 12

Part No. 8301169 Rev. A

© 2003 KitchenAid.

® Registered Trademark/Trademark of

KitchenAid U.S.A., KitchenAid

Canada licensee in Canada

KJtchen kid ®

HOME APPLIANCES

Prepared by KitchenAid, Benton Harbor, Michigan 49022

Printed in U.S.A.

Page 13

[] []

° Cm

u co

peerutilisation r sidentielle seulement

(necessaire pour certaines configurations

Dosseret

d'installation)

Risque de basculement

Un enfant ou une personneadulte peut

faire basculer la cuisiniere ce qui peut

causer un d@ees.

Joindre ia bride antibasculement au pied

ardere de la cuisiniere.

Joindre de nouveau la bride

antibasculemeat si la ¢uisiniere est

d@plac@e.

Voir detaiJs dans les instructions

d'instaliation.

Le non-respect de ¢es instructions peut

causer un d@cesou des brQlures graves

aux enfants et aux aduites.

mMP@RTANT: Lifeet

censerverces

iMPORTANT :

Jnstallateur : Remettre les instructions

d'instaHation au proprietaire.

Propri_taire : Conserver les

instructionsd'instalJation pour

consultation ultedeure. Conserver les

instructionsd'instaJJation pour

consultation par I'inspecteur local des

installations electdques.

Kitchen_kid _

BIEN PENSE, BIEN FABRI©_JE_'

Inscrire ci=dessous les num@rosde

modele et de serie avant d'installer la

cuisiniere.

On trouve cette information sur la plaque

signaletique, fixee au=dessous du tableau

de commande.

N° de modele

N° de serie

Pour toute question concernant

caracteristiques, utilisation,

performance, pieces ou service,

tel6phoner au !-800-422-1230 ou

consulter notre site Internet a I'adresse

www.kitchenaid.com

Piece n° 8301169 Rev. A

Page 14

Avant de commencer,,,,

Votre s_curit_ et celle des autres

est tr_s [mportante.

Nous donnons de nombreux

messages de securit6 importants

dans ce manuel, et sur votre appareil

menager. Assurez:vous de toujours

fire tousles messages de securit6 et

de vous y conformer.

Voici le symbole d'alerte de

securit6.

Ce symboie d'alerte de

securit6 vous signale les dangers

potentiels de deces et de blessures

graves a vous et a d'autres.

Tousles messages de securit6

suivront le symbole d'alerte de

securit6 et le mot "DANGER" ou

"AVERTISSEMENT". Ces mots

signifient :

Risque possible de d_c_s ou de

blessure grave si vous ne suivez

pas imm_diatement les instructions.

Risque possible de d_c_s ou de

blessure grave si vous ne suivez

pas les instructions.

Tous les messages de securit6 vous

diront quel est le danger potentiel et

vous disent comment reduire le risque

de blessure et ce qui peut se produire

en cas de non:respect des instructions.

IMPORTANT : Observer les dispositions

de tousles codes et reglements en

vigueur.

AVERTISSEMENT : Si ies

instructions pr_sent_es

clans ce manuel ne sont pas

respect_es, un incendie ou

une explosion peut causer

des dommages aux biens,

une blessure ou un d_c_s.

m Ne pas remiser ou utiliser

de l'essence ou un autre

produit liquide ou gazeux

inflammable _ proximit_ de

cet appareil ou de tout

autre appareil

_lectrom_nager.

QUE FAIRE Sl UNE ODEUR

DE GAZ EST

PERCEPTIBLE?

• Ne pas essayer de mettre

un appareil en marche.

, Ne toucher aucun

commutateur _lectrique.

• N'utiliser aucun t_l_phone

de l'_difice.

• Contacter imm_diatement

le fournisseur de gaz

depuis le t_l_phone d'un

voisin. Ex_cuter les

instructions du

fournisseur.

• Si le fournisseur de gaz

n'est pas accessible,

appeler [es pompiers.

L'installation et les travaux

de service doivent _tre

effectu_s par un _lectricien

qualifi_, ou par le personnel

d'une agence de service ou

du fournisseur de gaz.

REMARQUE : Cette cuisini@e est congue

pour I'alimentation au gaz natureL Pour la

conversion pour Falimentation au propane,

voir les instructions de conversion

present6es dans les documents qui

accompagnent le produit.

On doit disposer d'un raccord de

connexion a la canalisation d'arrivee de

gaz et d'une connexion au reseau

electrique. Voir "Alimentation en gaz" & la

page 4 et "installation electrique" a la

page 5.

IMPORTANT : Observer les dispositions

de tousles codes et reglements en

vigueur.

Ne pas entraver la circulation d'air de

combustion et d'air de ventilation.

La responsabilite de laqualite de

I'installation incombe au proprietaire.

Demander a un technicien qualifie

d'executer I'instaJlation. V@ifier que tout le

mat@iel necessaire pour une installation

correcte est disponible. C'est

I'installateur qu'incombe la responsabilite

de respecter les degagements de

separation specifi6s sur la plaque

signaletique. On trouve la plaque

signaletique et Fetiquette d'information sur

les gaz combustibles sous le tableau de

commande de I'appareiL

L'installation realis6e selon ces

instructions dolt 6tre conforme aux

dispositions des codes et reglements

Iocaux. En I'absence d'un code local,

I'installation dolt _tre conforme aux

dispositions de la plus recente edition de

la norme American National Standard,

National Fuel Gas Code ANSI Z223.1",

ou de la norme CAN/CGA B149".

C'est au client qu'incombe la

responsabilite :

o de contacter un electricien qualifie pour

I'instaJlation.

o de s'assurer que I'installation electrique

est adequate et conforme aux

dispositions du Code national des

installations electriques ANSI/NFPA 70

- derni@e edition**, ou norme de CSA

C22.1 du Code canadien de I'electricite,

1re partie (derni@e edition)*, et aux

dispositions des codes et reglements

Iocaux.

On dolt respecter les dimensions

indiquees pour I'espace d'installation

entre les placards. Ces dimensions

tiennent compte des degagements de

separation necessaires.

Lors de I'installation de la cuisiniere sous

un placard existant, s'il n'est pas possible

de respecter la distance de separation

minimale entre la table de cuisson et les

placards, installer une hotte au-dessus de

la cuisiniere pour eviter les risques

d'incendie.

NOTE : Certains placards et mat@iaux

de construction ne peuvent resister a la

chaleur emise par le four Iors des

op@ations de cuisson au four et

d'autonettoyage. \i@ifier aupres du

constructeur de la maison ou du

fournisseur des placards que les

mat@iaux utilises ne subiront pas de

dommage (changement de couleur,

destratification, etc.).

On dolt parfaitement obturedsceller

toutes les ouvertures dans lemur et le

plancher dans I'espace d'installation de la

cuisiniere.

On recommande qu'une hotte d'extraction

soit installee au-dessus de la cuisiniere.

On peut se procurer un exemplaire des normes

mentionn@es aux adresses suivantes :

* CSA international

8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

** National Fire Protection Association

One Batterymarch Park

Quincy, Massachusetts 02269

Page 15

Pi ces feurnies

pourJ'instaiJation

NOTE : D_tendeur

plac_ en bas/au centre

de la cuisini6re

Largeur de la table /..

de cuisson

91.4 crn (36 pe)

Dimensions

du produit

4,4C?o>

2 vis _t_te Phillips antibasculement

n° I0 x 2 po

On dolt solidement fixer la bride

antibasculement sur un poteau du

colombage mural. Eepaisseur des

panneaux de gypse peut necessiter

I'emploi de vJs plus Iongues pour

une bonne fixation de la bride.

Les pieces necessaires pour la

conversion pour I'alimentation au

propane sont placees darts le

sachet des brochures.

Dosseret et garniture pour 'riot. Le

dosseret fourni avec la table de

cuisson doit #tre installe darts le

cas de I'installation avec des

placards de cuisine de profondeur

standard de 61 cm (24 po), s'il n'y a

pas de separation de securit6 entre

le bord arri@e de la cuisini@e et un

mur de mat@iaux combustibles

I'arriere.

Pour I'installation au sein d'un riot

ou une autre configuration

d'installation dans laquelle il y a un

espace fibre de plus de 12,7 cm

(5 po) entre la cuisini@e et le mur

arri@e, utiliser la garniture d'acier

inoxydable pour riot (option) fournle

avec la table de cuisson pour

recouvrir les brides de montage du

dosseret.

* NOTE: Distance de 106,7 cm (42 po) rain. Iorsque le fend

de bois ou de m_tal du placard est pret_g_ par un

mat_riau ignifug_ d'au meins 6,4 mm (1/4 po) recouvert

d'une t61ed'acier au moins 28 MSG, d'acier inoxydable

0,4mm/0015po,daumnum 0,6mm/0,024pe eu

de cuivre (0,5 mm/ 0,020 po).

Distance de 121,9 cm (48 po) rain. entre le sommet de la

table de cuisson et le fmrd d'un placard non pret_g_de

beis eu de m_tal.

Bride

23,5 crn

(9-1/4 po)

But@

d'espacement

6,4 mm (1/4 po)

Prof

67.3 cm (26-1/2 po)

(tableau de

commande inclus)

Dimensions de

d'installation

Prefondeur max. des

placards muraux

33 cm (13 pe)

45,7 cm (18 pe)

entre placard mural et

plan de travail

Hauteurdela bottedeconnexion-

8.9 cm(3,5po) maximum

Placerla bo'itede connexion

dans cette zone

I _ de 3/4 tour)

Largeur rain. entre

les placards muraux

91,4 cm (36 pe)

Largeur de

I'euveFture

92,1 cm (36-1/4 po)

71_1cm

,2 cm

(4 po)

j_' Hauteur de la

kargeur

91.4 crn (36 pe)

Cuisini_re de 91,4 cm (36 po) -teus les

brGleursde la table de cuissen sent visibles

J'espace

20,3 cm

(8 pe)

50,8 crn

(20 po)

Hauteurhers-tout

114,3cm (45 po)

table de cuisson

J 91,4 cm (36 pe)

_ (pieds d@iss@

Pour la distance libre

minimale entre la table de

cuisson et les placards voir

la NOTE,*

Ddgagementde @paration de

4 po (10,2 crn) rain. entre la

cuisini_re et un tour des

matdriaux combustibles, des

deux cOt_sde la cuisini_re et

au-dessus de la surface de

D_gagementde s@aration de

0 po 0 cm) entre les deux

c6t_s et arr_re de a

cuisini_re et la construction

combustible adjacente sous la

surface de cuisson

la canalisation de gaz

crn (3 po) maximum

Placerla canalisatien de

dans cette zene

Page 16

en 9az

Risque d'expJosion

Utiliserun conduit de

raccordement _ lacanalisationde

gaz approuv_ par AGA ou CSA.

installer un robinet d'arr_t.

Bien setterchaque raccord de

connexion du circuitde gaz.

Si Vappareilest reli_a une

canalisationde propane, demander

une personne qualifi_e de v_rifier

que Japressionde gaz ne d_passe

pas 35,6cm (14 po) colonne d'eau.

(Personnes qualifi_es =

personnel competent d'un

fournisseur d'_quipement de

chauffage,

d'une compagnie de distribution

de gaz, ou

d'une entreprise d'entretien

agr_e).

Le non=respect de ces instructions

peut causer un accidentmortel,

une explosion ou un incendie.

Observer les dispositions de tousles

codes et reglements en vigueur.

IMPORTANT : La table de cuisson dolt

_tre connectee a une source de gaz

pression regul6e.

Am IZinstailation r6alis6e selon ces

instructions doit 6tre conforme aux

dispositions des codes et reglements

Iocaux. En I'absence d'un code local,

I'installation doit 6tre conforme aux

dispositions de la plus recente 6dition de

la norme* American National Standard,

National Fuel Gas Code ANSI Z223.1 ou

de la norme* CAN/CGA-B149.

La capacite thermique indiquee

sur la plaque signaletique correspond

une altitude d'utilisation inferieure

610 m (2 000 pi). Pour une altitude

superieure a 610 m (2 000 pi), reduire la

capacite thermique a raison de 4 % pour

chaque tranche de 305 m (1 000 pi) au-

dessus du niveau de lamer (ceci n'est

pas applicable au Canada).

4

C mCette cuisiniere est equip6e pour

I'alimentation au gaz NATUREL Sa

conception est homologuee par

International Approval Services (I.A.S.)

pour I'alimentation au gaz NATUREL ou

au PROPANE (avec conversion

appropdee). La plaque signaletique,

situee sous le tableau de commande,

mentionne le type de combustible

utilisable; si cette information ne concorde

pas avec le type de gaz disponible,

consulter le fournisseur de gaz local.

Propane•

Ne jamais tenter sans avoir d'abord

consulte le fournisseur de gaz de modifier

la cuisiniere pour I'alimentation avec un

autre gaz que celui qui est specifi6 sur la

plaque signaletique. Toute conversion

dolt _tre execut6e par un technicien

qualifi& Pour la conversion pour

I'alimentation au propane, utiliser

I'ensemble de conversion n° 8301439.

Ces pieces accompagnent les documents

fournis avec la cuisiniere.

Installer une canalisation de gaz

rigide de 1,9 cm (3/4 po) jusqu'a

I'emplacement de la cuisiniere. LJemploi

d'une canalisation de diametre inferieur

sur une grande distance peut rendre le

debit de gaz insuffisant. Utiliser un

compose d'etanch6it6 des jointures congu

pour I'utilisation en presence de propane.

Pour I'alimentation au propane, utiliser

une canalisation de diametre d'au moins

1,3 cm (1/2 po). Habituellement le

fournisseur de propane specifie la taille et

les matedaux des canalisations a utiliser

avec le systeme.

E mSi ceci est permis par le code

local en vigueur, on recommande de

raccorder la cuisiniere a la canalisation

de gaz au moyen d'un conduit de

raccordement metallique flexible

(homologation AGA ou CSA.) de Iongueur

de 122 a 152,4 cm (4 a 5 pieds) et de

diametre interne de ! ,6 cm (5/8 po).

Veiller a ne pas ecraser, deformer ou

endommager le conduit flexible Iors d'un

deplacement de I'appareil. Un filetage

m_le de ! ,3 cm (1/2 po) est necessaire

pour la connexion sur le raccord femelle

du detendeur.

r0binet d'arr_t '0uvert"

canalisati0n

d'arriv_e de gaz

vers la cuisini_re

F_ La canalisation d'arrivee de gaz

devra comporter un robinet d'arr_t

homologue. Ce robinet d'arr_t devrait

_tre situe darts la m_me piece que la

cuisiniere, a un emplacement permettant

un acces aise pour les manoeuvres

d'ouverture et de fermeture. Ne pas

entraver I'acces au robinet d'arr_t.

.....

tuyauterie rigide, utiliser une

combinaison de raccords de tuyauterie

pour realiser un raccordement dans

I'alignement de la cuisiniere. Toute

tension mecanique doit _tre eliminee de

la canalisation de gaz, de maniere ace

que la cuisiniere demeure horizontale et

alignee.

Contr61er le fonctionnement du

detendeur a une pression d'au moins

25,4 mm (1 po) (colonne d'eau) au=

dessus de la pression nominale. La

pression a I'entree du detendeur en

service devrait _tre comme suit :

GAZ NATUREL :

Pression de distribution =

12,7 cm (5 po) (colonne d'eau)

Pression maximale =

35,6 cm (14 po) (colonne d'eau)

PROPANE :

Pression de distribution =

25,4 cm (10 po) (colonne d'eau)

Pression maximale =

35,6 cm (14 po) (colonne d'eau)

Test sous pression relative

supedeure a 3,5 kPa (1/2 Ib/po2)° La

cuisiniere et son robinet d'arr_t individuel

doivent _tre deconnectes de la

canalisation de gaz au cours des tests du

circuit d'alimentation a une pression

relative superieure a 3,5 kPa (1/2 Ib/po2).

Test sous pression relative de 3,5 kPa

(1/2 Ib/po2) ou moins. La cuisiniere dolt

_tre isolee de la canalisation de gaz par

fermeture de son robinet d'arr_t individuel

au cours des tests du circuit

d'alimentation sous une pression egaie

ou infedeure a 3,5 kPa (1/2 Ib/po2).

On peut se procurer un exemplaire des normes

mentionnees a I'adresse suivante :

* CSA International

8501 East Pleasant Valley Road

Cleveland, Ohio 44131=5575

Page 17

Si on utilise un conducteur distinct de

liaison a la terre Iorsque le code en

vigueur le permet, ilest recommande

qu'un electricien qualifie v@ifie la qualite

de la liaison a la terre.

Ne pas utiliser une tuyauterie de gaz pour

la liaison a la terre.

En cas de doute quanta la qualite de la

liaison a la terre de I'appareil, consulter

un electricien qualifie.

Ne jamais installer un fusible en s@ie

avec le conducteur neutre ou le

conducteur de liaison a la terre.

On dolt relier cette cuisini@e a un

c_blage electrique permanent avec

conducteur de liaison a la terre.

Cet appareil doit 6tre alimente

seulement par un circuit monophase de

240 V CA / 60 Hz, a quatre ou trois

conducteurs; utiliser un circuit independant

de 30 A avec protection de chaque phase

par fusible ou disjoncteur. On recommande

I'emploi de fusibles temporises ou de

disjoncteurs. La capacite de protection des

fusibles ne dolt pas 6tre superieure a la

demande de courant maximale de

I'appareil, mentionnee sur la plaque

signaletique placee sous le tableau de

commande.

E m II y a un raccord de conduit

(homologation UL ou CSA) a chaque

extremit6 du cSble d'alimentation (c6te table

de cuisson et c6te bo'fte de connexion).

Fm N'utiliser qu'un conducteur de cuivre

pour la connexion a la bo'_tede connexion.

Si le c_blage du domicile est en

aluminium, proceder comme suit :

a) Connecter le c_blage d'aluminium au

cSblage de cuivre au moyen des

connecteurs speciaux homologues par

Underwriters Laboratories et con_us pour

raccorder le cuivre et !'aluminium. Suivre

la methode recommandee par le fabdcant

des connecteurs electriques.

b) Le raccordement aluminium/cuivre doit

6tre conforme aux codes Iocaux et aux

pratiques d'installation de fils acceptees

par I'industrie.

On peut se procurer un exemplaire des normes

mentionn@es aux adresses suivantes :

* National Fire Protection Association

One Batterymarch Park

Quincy, Massachusetts 02269

** CSA international

8501 East Pleasant ',/alley Road

Cleveland, Ohio 44131-5575

lnstallatien

Enlever I'event du fond; 6ter les deux

vis de part et d'autre de I'event du fond.

Faire glisser I'event vers le bas pour pouvoir

le tirer. Placer soigneusement cette piece

de c6te - eviter d'@afler I'acier inoxydable.

3_ Placer sur le sol derri@e la cuisini@e

un morceau de carton provenant du c6te de

I'emballage. Saisir fermement la cuisini@e de

chaque c6te (participation de deux personnes).

Soulever la cuisini@e d'environ 8 cm (3 po) et

transf@er la cuisiniere de la palette a la

feuille de carton - eviter d'endommager le

plancher.

Approcher prudemment la cuisiniere

de I'ouverture d'encastrement. Placer la

grille dans le four. Placer un niveau sur la

grille pour contr61er I'ap!omb

transversalement, puis dans le sens

avant/arriere.

Si la cuisiniere n'est pas bague du pied

d'aplomb, ajuster la r_glable

Iongueur des pieds. Faire

tourner la bague des pieds

reglables pour soulever ou

abaisser la cuisiniere et la

placer au niveau desire.

Le c_blage et les connexions

doivent 6tre conformes aux prescriptions de

la derni@e edition* du Code national des

installations electriques ANSI/NFPA 70 - ou

des normes CSA C22.1°94, Code canadien

de I'electricit6, partie 1 et C22.2 n° 0-M91

(derni&,re edition)**, et aux prescriptions de

tousles codes et r&_glements Iocaux en

vigueur.

C m On devrait directement raccorder la

cuisini@e au tableau de distribution ou a un

coupe-circuit par I'intermediaire d'un cgble

flexible blinde ou a gaine non metallique et

conducteurs de cuivre. Le c_ble flexible

blinde sortant du tableau de distribution ou

du coupe-circuit dolt 6tre raccorde

directement dans la bo_te de connexion de

I'appareil.

Installer la boTtede connexion a un

emplacement permettant autant de

mouvement libre que possible entre la bofte

de connexion et la cuisiniere, pour qu'il soit

facile de deplacer I'appareil si des

r@arations sont necessaires. Ne pas

couper le conduit.

Risque du poids excessif

Utiliser deux ou plus de

personnes pour d_plaeer et

installer la cuisini_re.

Le non-respect de cette

instruction peut causer une

blessure au dos ou d'autre

E Porter des lunettes de securit6 et des

gants de protection. Retirer de la cuisini@e

mat@iaux d'emballage, rubans adhesifs et

film de protection. Laisser la palette sous la

cuisini@e. Deballer tousles composants :

grille de brOleur, chapeau de br01eur, plaque

de mijotage, grille du gril, plateau de

recup@ation, plateau ondule, plaque de

support, garnitures, detendeur, dosseret et

garniture pour installation en riot. Ces

articles emballes peuvent 6tre places darts

la cuisini@e ou sur la cuisiniere. La liste des

pieces fournies avec la cuisiniere depend du

modele commande.

@ent

du fond

5m Choisir la bride correcte pour

I'installation.

• Si sur lemur derriere la cuisiniere i! y a une

plinthe de 9,5 mm (3/8 po) ou moins ou pas

de plinthe, utiliser la bride antibasculement

plus courte de 2,5 cm (1 po).

• Si sur lemur derriere la cusiniere i! y a

une plinthe de plus de 9,5 mm (3/8 po),

utiliser la bride antibasculement plus Iongue

de 4,4 cm (1o3/4 po).

eJ[ preudre uote de

entr

arri_re _,Lj /

Identifier la position d'un poteau du

colombage mural derri@e la cuisiniere.

Mesurer la distance entre le sommet de

I'entretoise arriere et le plancher. Ajouter

7,9 mm (5/16 po) a cette dimension, pour

que la bride antibasculement puisse passer

par-dessus I'entretoise arriere. Utiliser cette

mesure finale pour tracer une ligne

horizontale sur lemur a I'emplacement du

poteau. 5

cette distance

Page 18

Risque de basculement

Un enfant ou une personne adulte

peut faire basculer la cuisini_re ¢e

qui peut causer un deces.

Joindre Ja bride antibasculement au

pied arriere de Jacuisiniere.

Joindre de nouveau la bride

antibasculement si Ja¢uisini_re est

d@plac@e.

Voir details darts les instructions

d'installatiom

Le non-respect de ces instructions

peut causer un dec&s ou des brQlures

graves au× enfants et au× adultes.

)oteau du

,.4/

I

I

I

color@age

fixation

ligne .._

bride _ .....

antibasculernent

@ -_ vis de

@ i

Positionner le sommet de la bride

antibasculement sur la ligne tracee sur le

mur & I'etape 5; marquer la position des

trous. Percer deux avant=trousde 3 mm

(!/8 po).Avec les vis fournies, fixer labride

antibasculement sur le mur.

NOTE : On dolt sol!dement fixer labride

antibasculement sur le poteau du colombage

mural derriere lacuisiniere. Selon I'epaisseur

du panneau de gypse, il peut 6tre

necessaire d'employer des vis plus Iongues.

Risque de choc _lectrique

D_connecter la source de courant

_lectrique avant I'entretien.

Utitiser un fii en cuivre de calibre 8.

V_rifier que la cuisini_re est

_lectriquement reli_e a la terre.

Le non-respect de ces instructions

peut causer un accident mortel, un

imcendie ou un choc _lectMque.

Cette cuisiniere dolt 6tre reliee au reseau

electrique par un c&blage permanent

metallique avec conducteur de liaison a la

terre, ou bien un conducteur distinct de

liaison a la terre dolt 6tre raccord@au fil

ou a la borne de liaison a la terre de la

cuisini@e.

Cette cuisiniere comporte un conducteur

nu ou a gaine verte connecte au ch&ssis

pour la liaison a la terre, qui est

egalement relie au conducteur neutre

(blanc). Faire passer le c&ble de la

cuisiniere darts la bo'_tede connexion

travers un connecteur de conduit

(homologation UL ou CSA). Executer le

raccordement electrique conformement

aux prescriptions des codes et

regJements Iocaux en vJgueur.

A =1Si le code local ne permet pas le

raccordement du conducteur de liaison

la terre connecte au ch&ssis au

conducteur neutre (blanc) darts la bo'_te

de connexion (configuration egalement

utilisee au Canada).

circuit d'alimentati0n -4 conducteurs

conducteurs J ! beirede connexion

rouges _, _ /

I ,'Y'_\ /:;_'_ j \connecteur

conducteurV --_J> heirs

verts ou nus _ X

@.bb_ 4 c0nducteurs CSA

de la cuisini_re

._ " connecteur de conduit -

/ homologati0n U,L, ou

"_conducteurs

Conducteur neutre non reli6

Jaterre

Figure 1

1. Interrompre I'alimentation du circuit.

2, Faire passer dans la bo'_tede

connexion atravers un connecteur de

conduit (homologation UL ou CSA) le

c&ble blinde flexible provenant de la

cuisiniere. Serrer les vis sur le

connecteur de conduit.

3. Avec des connecteurs de ills (volt la

Figure 1), connecter ensemble les

deux conducteurs heirs et les deux

conducteurs rouges.

4. Separer le conducteur nu et le

conducteur blanc du c&blede la

cuisiniere (connectes ensemble

I'usine).

7m Executer le raccordement electrique.

Si le c&blage du domicile est en

aluminium, voir "Installation electdque"

la page 5.

Page 19

5.Avecunconnecteurdeills,connecter

ensemblelesdeuxconducteursblanc&

6.Connecterleconducteurnuduc_ble

delacuisiniereauconducteurde

liaisonalaterredartslabottede

connexionoua unautreconducteur

relica laterre(utiliserunconnecteur

deills).VoirlaFigure1.Nepas

connecterleconducteurnuau

conducteurneutre(blanc)dartslabotte

deconnexion.

B mSilecodelocalpermetle

raccordementduconducteurdeliaison&

laterreconnecteauch&ssisau

conducteurneutre(blanc)danslabo'_te

deconnexion(cetteconfigurationn'est

pasutiliseeauCanada).

circuit d'alimentati0n -

bo'_tede

connexion

conductet_

blanc @_

conducteur blanc et

conducteur iw de liaison

la terre, du cablede la

cuisini_re - connectas

ensembb a I'usine

cable a 4 conducteurs de

la cuisini_re

Conducteur neutre reli6

1. Interrompre I'alimentation du circuit.

2° Faire passer dans la bo'_tede

connexion a travers un connecteur de

conduit (homologation UL ou CSA) le

c_ble blinde flexible provenant de la

cuisiniere. Serrer les vis sur le

connecteur de conduit.

3. Avec des connecteurs de ills,

connecter ensemble les deux

conducteurs noirs et les deux

conducteurs rouges, puis connecter

ensemble les conducteurs blanc et nu

connectes ensemble & I'usine (du

c&ble de la cuisiniere) et le conducteur

(neutre) blanc darts la botte de

connexion. (Voir la Figure 2.)

m Enlever la feuille de carton ou

planche placee sous la cuisiniere pour la

protection du plancher.

3 c0nducteurs

__ c°!ldsUCteurs

_necteur d_ e

d_ conduit-

/.

h0rnologation U,L ou

CSA

la terre

Figure 2

3 vis avant

(4 vis n@essaires& I'arri_re,

male pas repr_sent_es)

installation du

dosseret

2 vis

installationdela

garniture(pourriot)

troucentral

pasutili@

9m Fixer le dosseret ou la garniture

pour '_lot, seion la configuration

d'installation. Les vis fournJes sont

placees dans le sachet des brochures.

Pousser completement ia

cuisiniere vers I'arriere pour que la bride

antibasculement puisse accrocher la

tringle transversaie arriere de la

culsmlere.

appliquer un produit

d'dtanch_it_

@tendeur

\ jz /

racc0rd droit canalisati0n de gaz

1/2 p0 1/2 pc a 3/4 p0

un filetage male de 1/2 pc est n_cessaire pour la

connexion sur le raccord fernelle du @tendeur.

m Reaiiser le raccordement & la

canalisation de gaz. installer le conduit de

raccordement flexible entre la canalisation

de gaz et le detendeur (situe au milieu/a

I'avant de la cuisiniere). Appliquer sur les

filetages des raccords un compose

d'6tanch6it4_compatible avec le propane.

Connecter un raccord droit sur le coude

du detendeur et I'autre sur le robinet

d'arr_t. Serrer les connexion&

rennet d'arr_t - position

d'ouverture

canalisation

d'arriv@ de gaz

vers la cuisini_re

Ouvrir le robinet d'arr_t manuel

de la canalisation de gaz. Attendre

quelques minutes pour que le gaz

expulse Fair de la canalisation.

3 m Pour rechercher les fuites au

niveau des connexions de la canalisation

de gaz, utiliser un pinceau et du

detergent liquide. La formation de bulbs

au voisinage d'une connexion indique la

presence d'une fuite. En cas de fuite,

fermer le robinet d'arr6t et le robinet de

commande, et resserrer les connexion&

inspecter de nouveau pour rechercher

des fuites. Nettoyer pour enlever tous les

residus de detergent.

61ectroded'allulr_

ouverture du tube

d'arriv@ de gaz

chapeaude

_ brGleur

basedu

br01eur

4 m Placer un chapeau de brOleur

sur chaque base de brOleur, Placer la

grille par-dessus chaque brOleur.

Si le produit commande ne comporte que

des brOleurs standard (et non pas un gril

ou une plaque a frire), voir a la page 8

"Contr61edu fonctionnement des brOleurs

de la table de cuisson, du grii et de la

plaque & frire".

Si le produit expedie comporte un gril ou

une plaque & frire, voir & la page 8

"Installation du gnl ou de la plaque

fdre'.

5 _ Mettre I'appareil sous tension.

Le message "PF" dolt apparattre sur

I'afficheur de I'horloge (voir darts le Guide

d'utiiisation et d'entretien les instructions

d'utilisation du systeme de commande

electronique).

Page 20

lnstallatien du

oe de la plaqeea

#ire°

Installation du gril "passer & I'etape 16.

Installation de la plaque &fdre la plaque

frire a et6 installee a I'usine. Pour

terminer I'installation, passer & I'etape 17.

C, ins@er les pieds de la plaque de

recup@ation avant darts les fentes de la

plaque de recup@ation arri@e (voir

I'illustration). Le rebord arri@e reposera

sur le Iogement du brOleur.

H, Placer le plateau ondule sur le

plateau de support - voir I%ustration. Le

plateau ondule dolt _tre centre sur le

plateau de support.

_, Installer la grille du griL

7m Phase finale de I'installation de

la plaque &frire "

installation du gril

br01eurallonge

A, Soulever le br01eurallonge pour le

retireK conserver le brOleur a part.

pieds de positionnement ,".-"

plateaude

r6cup_ration

B, Placer le plateau de recup@ation au

fond de la section du gril; faire giisser le

plateau vers I'avant pour le juxtaposer

avec le pied de positionnement sur la

plaque de recup@ation arri@e.

./

D, installer le brOieur allong& Placer le

rebord arri@e darts la fente destinee ale

recevoir.

E, Brancher le cordon d'alimentation

sur une prise de courant reiiee a la terre.

F, Observer les flammes du brOleur du

gril et des brOleurs standard. Avant de

terminer I'installation du gril, voir a la

page 8 "Contr61e du fonctionnement des

brOleurs de la table de cuisson, du gril et

de la plaque & frire".

fentepourpattede

positionnement

pattede

)ositionneFnent

G, installer le plateau ondule dans

I'espace destine au gril. La patte de

I'angle arri@e gauche dolt s'engager

dans lafente de I'angle arri@e gauche du

plateau de support.

plateau de r_cup@ation pour

la plaque Afrire

\

A, Placer le plateau de recup@ation &

I'avant du Iogement de la plaque &frire.

Faire glisser le plateau vers I'avant

jusqu'au point de butee.

B, Consulter le guide d'utilisation et

d'entretien fourni avec la table de

cuisson, au sujet de la preparation de la

plaque a fdre avant la premi@e utilisation

et au sujet du nettoyage.

C, Brancher le cordon d'alimentation

sur une prise de courant reliee a la terre.

D, Contr61erles flammes des brOleurs

standard et du brOleur de la plaque

frire. Avant de terminer I'installation du

gril, voir a la page 8 "Contr61e du

fonctionnement des brOleurs de la table

de cuisson, du gril et de la plaque a frire".

plateau ondul_

,/

Systeme d'allumage

electronique - allumage initial

insurer les pieds dans

lesfentes

plaque de

r_cup@ation _

avant

plateaude

support

Les brOleurs de la table de cuisson sont

8 dotes d'un dispositif d'allumage

Page 21

electronique,sansflammedeveille.

Lorsqu'onplaceleboutondecommande

lapositionLITE(enfoncementet

rotation),lesystemegen@edes

etincellesquiprovoquentI'allumagedu

brOleur.IJemissiond'etincellessepoursuit

jusqu'acequ'onplaceleboutonde

commandealapositioncorrespondant

lapuissancedechauffagedesir6e.

LesbrOleursdugriletdelaplaqueafrire

sontdotesd'unsystemed'allumage&

barreincandescente,sansflammede

veille.Lorsquelabarreaincandescence

estchaude,lesystemetransmetun

signal&I'electrovannedesecurit6,qui

commandeI'arriveedugaz.

br01eursdela br8leursdugril bnileursdela

tabledecuisson plaque9frire

A. Placer le bouton de commande du

brOleur (brOleur standard ou gril) a la

position LITE (enfoncement et rotation).

Pour la plaque a frire, placer le bouton de

commande (rotation) a la position

correspondant a la temp@ature d6siree

(on recommande 300°F). Le brOleur

standard de la table de cuisson devrait

s'allumer en moins de 4 secondesl le

brOleur du gril ou de la plaque a frire

devrait s'allumer en 30 a40 secondes.

NOTE : la flamme du brOleur de la plaque

frire n'est pas visible, mais on dolt

percevoir le son emis Iors de I'allumage

et I'echauffement de la plaque.

Apres I'allumage de chaque brOleur,

ramener le bouton de commande a la

position d'arrSt OFR

Si un brOleur ne s'allume pas

correctement, ramener le bouton de

commande a la position d'arrSt OFR

Determiner si le chapeau de brOleur est

la position convenable. D6terminer si

I'alimentation electrique a et6 interrompre

(fusible grills ou disjoncteur ouvert).

V@ifier que le robinet d'arr6t est ouvert.

Contr61er de nouveau le fonctionnement.

Si ace point un brOleur standard ou le

brOleur du gril ou de la plaque a frire ne

s'allume pas, demander I'aide du

revendeur KitchenAid.

tige du robinet

de gaz

B. Reglage de la flamme des brOleurs

= brOleur standard ou brOleur du gril :

NOTE : il n'y a aucun reglage pour le

brOleur de la plaque & frire; le d¢bit de

gaz est contr61epar un thermostat

(100 %).

Placer le bouton de commande de

chaque brOleura la position LO

(enfoncement et rotation). Un reglage a

etS effectue & I'usine pour la position LO

de chaque brOleur, pour la puissance

thermique minimum permettant un

reallumage fiable du brOleur.Si un brOieur

ne reste pas allume a la position LO,

contr61er le reglage comme suit :

a. Placer le bouton de commande a la

position LITE jusqu'a ce que le brOleur

s'allume.

b. Ramener rapidement le bouton de

commande a la position LO.

c. Si le brOleur s'@teint,ajuster le reglage

du robinet de gaz comme suit :

Oter le bouton de commande. Inserer un

tournevis a lame plate dans la tige creuse

du robinet pour pouvoir faire tourner la vis

de r@glage.Une rotation de la vis de

reglage produit une augmentation ou

diminution de la tailie des flammes.

Ajuster la taille des flammes de telle

maniere qu'il soit possible de faire passer

rapidement le bouton de commande de

la position HI a la position LO sans

provoquer I'extinction du brOleur.II faut

que les flammes soient aussi petites que

possible, sans que le brOleur s'@teigne

Iors de la manoeuvre d@criteci-dessus.

orifices

flamrne typique

standard de la z

table de cuisson

pour le d_bit

thermique

reaxilTaJre

C. Lorsqu'on selectionne la position HI

(debit thermique maximum) pour un

brOieur,on doit observer des flammes de

teJntebleue et de forme nette et douce,

sans pointe jaune et sans separation

entre les flammes et le brOleur.II est

normal d'observer occasionnellement des

teintes orange; ceci est dO a la presence

de divers 61ements darts I'air ou le gaz.

R Contr61e du fonctionnement de

1'61ementdu four. Placer le bouton de

selection a la position BAKE (cuisson au

four). Le message "350 F" appara'_tsur

I'afficheur. Appuyer sur "Enter". Le temoin

de prechauffage s'illumine d'abord, puis

la temperature commence a augmenter

dans lefour. Lorsque le second temoin de

prechauffage s'illumine, ouvrir la porte et

placer une main au-dessus du plancher

du four pour percevoir la chaleur. Ne pas

toucher le plancher du four. Appuyer sur

la touche "Cancel" et ramener le bouton

de selection a la position "Reset".

Contr61edu fonctionnement de

I'el6ment du griL Placer le bouton de

s61ectiona la position BROIL (gril). Le

message "HI" apparatt sur I'afficheur.

Appuyer sur "Enter". Observer a travers le

hublot. IJelsment sup@ieur devrait devenir

incandescent et le rayonnement

thermique devrait Stre perceptible.

Appuyer sur la touche "Cancel" et

ramener le bouton de selection a la

position "Reset".

Si le four ne fonctionne pas, v@ifier que

le c&blage electrique a 6te correctement

r6alise et que le circuit est aliments

(disjoncteur ouvert? fusible grill6?). Si le

four ne fonctionne toujours pas, contacter

le concessionnaire KitchenAid ou une

entreprise de service apr6s-vente agre6e.

m Reinstaller 1'6ventinf@ieur.

Inserer les pattes dans les fentes sur la

garniture avant. Pousser 1'6ventvers le

haut pour realiser I'alignement des trous

au sommet de 1'6vent.Reinstaller les

deux vis de fixation.

Installer la grille par-dessus le

brOleur.On peut placer la plaque de

mijotage sur I'une des grilles de brOleur,

ou la remiser pour utilisation ultSrieure.

(Wir le Guide d'utilisation et d'entretien.)

Pour obtenir la plus grande

efficacit6 de cette cuisiniSre 8

deux combustibles, life

attentivement le Guide

d'utilisation et d'entretien de

KitchenAid. Conserver le guide

et les instructions d'insta/lation

en lieu sot pour pouvoir

facflement les consulter.

Page 22

8i une assistance

[_ Cuisiniere correctement placee darts

la cavite d'encastrement.

[_ Respect des distances de separation

specifi6es entre les surfaces.

[_ Aplomb de la cuisini@e -

avant/arri@e et transversalement.

[_ Chapeau de brOleur correctement

place sur la base de chaque brOleur

scell&

[_ Tous les mat@iaux d'emballage

enleves.

[_ Dosseret ou garniture pour 'riot

installe(e) (voir page 3). Selon le

modele, composants du gril