Page 1

Kitchen_kid _

INSTALLATION INSTRUCTIONS

30" (76.2 CM) COMMERCIAL STYLE DUAL FUEL

RANGE WITH SELF-CLEANING THERMAL/

CONVECTION OVEN

INSTRUCTIONS D'INSTALLATION

CL_SINIERE STYLE COMMERCIAL- 30" (76,2 CM)

A BI-COMBUSTIBLE AVEC FOUR

AUTONETTOYANT THERMIQUE A

CONVECTION

_.... __ _ _ __:D__ _:_ °D _::_ ___ _ _

Table of Contents/Table des matieres ............................................................................. 2

IMPORTANT: Save installation instructions for local electrical inspector's use.

IMPORTANT : Conserver les instructions d'installation & I'usage de I'inspecteur local des installations 61ectriques.

9759121A

Page 2

TABLEOF CONTENTS

TABLEDES MATIERES

RANGE SAFETY ............................................................................. 2

INSTALLATION REQUIREMENTS ................................................ 4

Tools and Parts ............................................................................ 4

Location Requirements ................................................................ 4

Electrical Requirements- U.S.A. Only ......................................... 6

Electrical Requirements - Canada Only ....................................... 6

Gas Supply Requirements ........................................................... 7

INSTALLATION INSTRUCTIONS .................................................. 8

Unpack Range .............................................................................. 8

Level Range .................................................................................. 8

Install Anti-Tip Bracket ................................................................. 9

Make Electrical Connection ......................................................... 9

Attach Backguard or Island Trim ............................................... 10

Make Gas Connection ............................................................... 11

Electronic Ignition System ......................................................... 12

Reinstall Bottom Vent ................................................................ 13

Complete Installation ................................................................. 13

WIRING DIAGRAMS ..................................................................... 13

SECURITE DE LA CUISINIERE ................................................... 15

EXIGENCES D'INSTALLATION ................................................... 16

Outillage et pieces ...................................................................... 16

Exigences d'emplacement ......................................................... 16

Specifications de I'installation electrique ................................... 18

Specifications de I'alimentation en gaz ..................................... 18

INSTRUCTIONS D'INSTALLATION ............................................. 20

Deballage de la cuisiniere .......................................................... 20

Reglage de I'aplomb de la cuisiniere ......................................... 20

Installation de la bride antibasculement .................................... 20

Raccordement electrique ........................................................... 21

Fixation du dosseret ou de lagarniture en 1lot .......................... 23

Raccordement a la canalisation de gaz ..................................... 23

Systeme d'allumage electronique .............................................. 24

Reinstallation de I'event du fond ................................................ 25

Achever I'installation .................................................................. 25

SCHEMAS DE C,&,BLAGE............................................................ 26

RANGE SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

2

Page 3

WARNING: If the information in this manual is not followed exactly, a fire or explosion

may result causing property damage, personal injury or death.

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the fire department.

- Installation and service must be performed by a qualified installer, service agency or

the gas supplier.

In the State of Massachusetts, the following installation instructions apply:

[] Installations and repairs must be performed by a qualified or licensed contractor, plumber, or gasfitter qualified or licensed by

the State of Massachusetts.

[] If using a ball valve, it shall be a T-handle type.

[] A flexible gas connector, when used, must not exceed 3 feet.

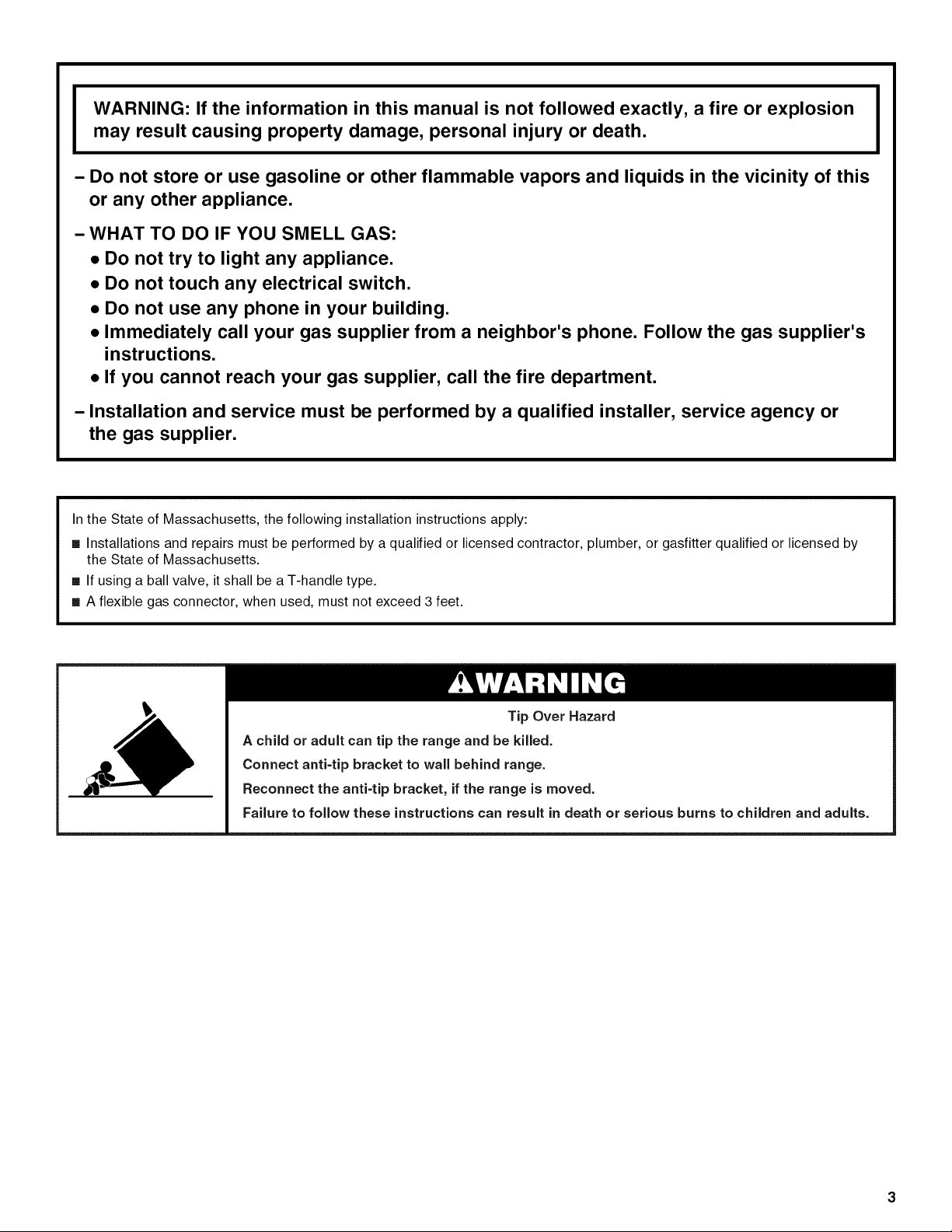

Tip Over Hazard

A child or adult can tip the range and be killed.

Connect anti=tip bracket to wall behind range.

Reconnect the anti=tip bracket, if the range is moved.

Failure to follow these instructions can result in death or serious burns to children and adults.

Page 4

INSTALLATION REQUIREMENTS

_-_, -_ _ _ _ _i_4. C

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools needed

• Tape measure • 1%e"combination wrench

• Flat-blade screwdriver • Marker or pencil

• Phillips screwdriver • Masking tape

• Level • Pipe-joint compound

• Hand or electric drill

• Channel lock pliers • Noncorrosive leak-detection

• Pipe wrench

resistant to LP gas

solution

• Stud finder

• Island trim and attachment screws (3).

NOTE: The island trim included with the range may be used if

installed with 1" (2.5 cm) clearance from a combustible rear

wall or with 0" (0 cm) clearance from a noncombustible rear

wall.

• LP conversion kit.

NOTE: The cooktop is manufactured for use with Natural gas.

To convert to LP gas, see the gas conversion instructions

provided in the literature package.

Check local codes and consult gas supplier. Check existing gas

supply and electrical supply. See "Electrical Requirements" and

"Gas Supply Requirements" sections.

All electrical connections should be made by a licensed, qualified

electrical installer.

Parts needed

• A UL listed or CSA approved conduit connector

• UL listed wire connectors

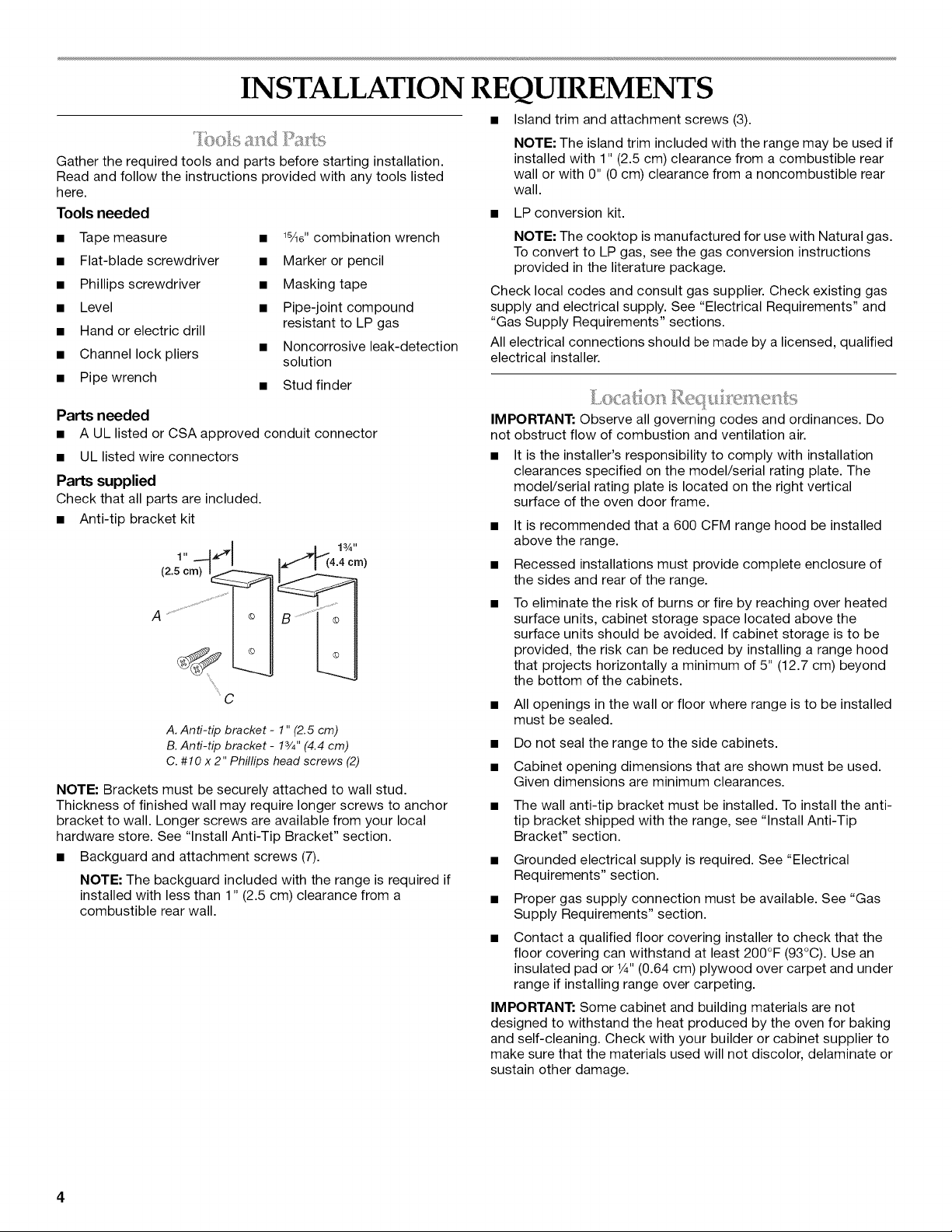

Parts supplied

Check that all parts are included.

• Anti-tip bracket kit

1"-4 I m_"q'24.4ore)

a ..................................................

ULU L_q

\

C

A. Anti-tip bracket - 1" (2.5 cm)

B.Anti-tip bracket - 13/4'' (4.4 cm)

C. #10 x 2" Phillips head screws (2)

NOTE: Brackets must be securely attached to wall stud.

Thickness of finished wall may require longer screws to anchor

bracket to wall. Longer screws are available from your local

hardware store. See "Install Anti-Tip Bracket" section.

• Backguard and attachment screws (7).

NOTE: The backguard included with the range is required if

installed with less than 1" (2.5 cm) clearance from a

combustible rear wall.

IMPORTANT: Observe all governing codes and ordinances. Do

not obstruct flow of combustion and ventilation air.

• It is the installer's responsibility to comply with installation

clearances specified on the model/serial rating plate. The

model/serial rating plate is located on the right vertical

surface of the oven door frame.

• It is recommended that a 600 CFM range hood be installed

above the range.

• Recessed installations must provide complete enclosure of

the sides and rear of the range.

• To eliminate the risk of burns or fire by reaching over heated

surface units, cabinet storage space located above the

surface units should be avoided. If cabinet storage is to be

provided, the risk can be reduced by installing a range hood

that projects horizontally a minimum of 5" (12.7 cm) beyond

the bottom of the cabinets.

• All openings in the wall or floor where range is to be installed

must be sealed.

• Do not seal the range to the side cabinets.

• Cabinet opening dimensions that are shown must be used.

Given dimensions are minimum clearances.

• The wall anti-tip bracket must be installed. To install the anti-

tip bracket shipped with the range, see "Install Anti-Tip

Bracket" section.

• Grounded electrical supply is required. See "Electrical

Requirements" section.

• Proper gas supply connection must be available. See "Gas

Supply Requirements" section.

• Contact a qualified floor covering installer to check that the

floor covering can withstand at least 200°F (93°C). Use an

insulated pad or 1¼,,(0.64 cm) plywood over carpet and under

range if installing range over carpeting.

IMPORTANT: Some cabinet and building materials are not

designed to withstand the heat produced by the oven for baking

and self-cleaning. Check with your builder or cabinet supplier to

make sure that the materials used will not discolor, delaminate or

sustain other damage.

Page 5

Mobile Home - Additional Installation Requirements

The installation of this range must conform to the Manufactured

Home Construction and Safety Standard, Title 24 CFR, Part 3280

(formerly the Federal Standard for Mobile Home Construction

and Safety, Title 24, HUD Part 280). When such standard is not

applicable, use the Standard for Manufactured Home

Installations, ANSI A225.1/NFPA 501A or with local codes.

In Canada, the installation of this range must conform with the

current standards CAN/CSA-A240-1atest edition, or with local

codes.

Mobile home installations require:

• When this range is installed in a mobile home, it must be

secured to the floor during transit. Any method of securing

the range is adequate as long as it conforms to the standards

listed above.

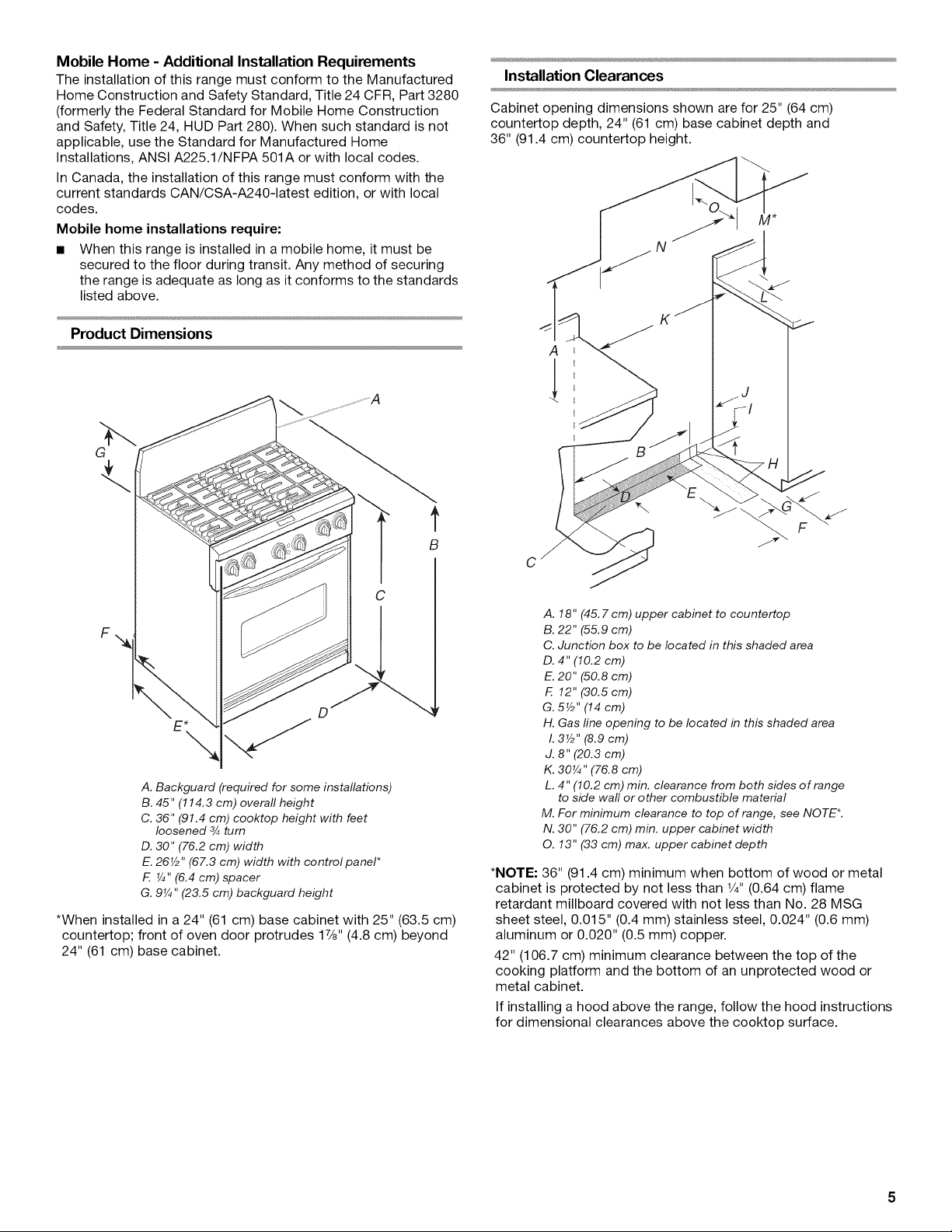

Product Dimensions

G

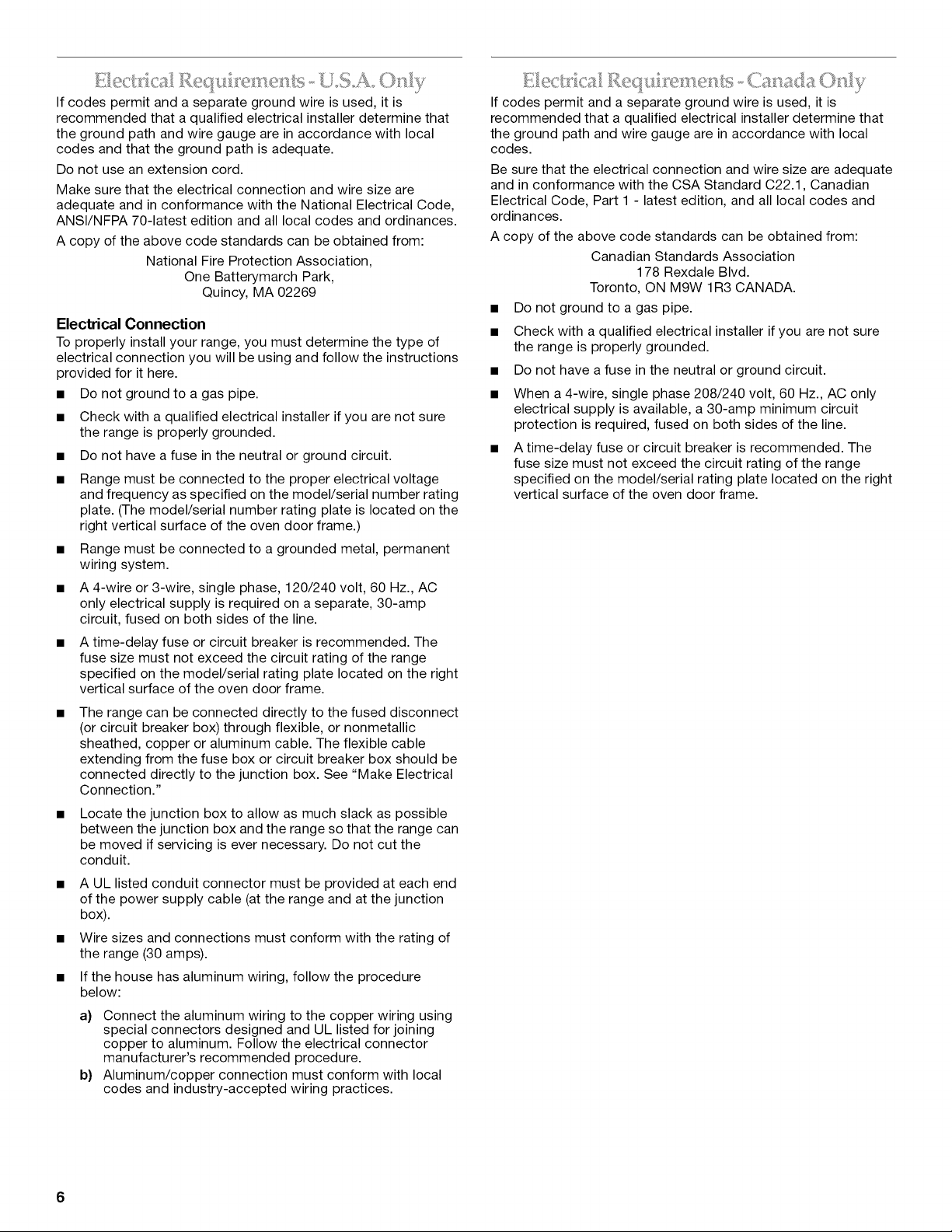

Installation Clearances

Cabinet opening dimensions shown are for 25" (64 cm)

countertop depth, 24" (61 cm) base cabinet depth and

36" (91.4 cm) countertop height.

A

t

B

C

F\

D

A. Backguard (required for some installations)

B. 45" (114.3 cm) overall height

C. 36" (91.4 cm) cooktop height with feet

loosened 3/4turn

D. 30" (76.2 cm) width

E. 26Y2" (67.3 cm) width with control panel*

F. ¼" (6.4 cm) spacer

G. 9¼" (23.5 cm) backguard height

*When installed in a 24" (61 cm) base cabinet with 25" (63.5 cm)

countertop; front of oven door protrudes 17/8"(4.8 cm) beyond

24" (61 cm) base cabinet.

u

A. 18" (45. 7 cm) upper cabinet to countertop

B. 22" (55.9 cm)

C. Junction box to be located in this shaded area

D. 4" (10.2 cm)

E. 20" (50.8 cm)

F. 12" (30.5 cm)

G. 5Y2" (14 cm)

H. Gas line opening to be located in this shaded area

I. 3V2" (8.9 cm)

J. 8" (20.3 cm)

K. 30¼" (76.8 cm)

L. 4" (10.2 cm) min. clearance from both sides of range

to side wall or other combustible material

M. For minimum clearance to top of range, see NOTE*.

N. 30" (76.2 cm) min. upper cabinet width

O. 13" (33 cm) max. upper cabinet depth

*NOTE: 36" (91.4 cm) minimum when bottom of wood or metal

cabinet is protected by not less than 1/4"(0.64 cm) flame

retardant millboard covered with not less than No. 28 MSG

sheet steel, 0.015" (0.4 mm)stainless steel, 0.024" (0.6 mm)

aluminum or 0.020" (0.5 mm) copper.

42" (106.7 cm) minimum clearance between the top of the

cooking platform and the bottom of an unprotected wood or

metal cabinet.

If installing a hood above the range, follow the hood instructions

for dimensional clearances above the cooktop surface.

Page 6

/,,! 1_%d_ •-_ _,,_, _ _ %_" -_ _,,,/- , _/_, _%,_,_,

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrical installer determine that

the ground path and wire gauge are in accordance with local

codes and that the ground path is adequate.

Do not use an extension cord.

Make sure that the electrical connection and wire size are

adequate and in conformance with the National Electrical Code,

ANSl/NFPA 70-latest edition and all local codes and ordinances.

A copy of the above code standards can be obtained from:

National Fire Protection Association,

One Batterymarch Park,

Quincy, MA 02269

Electrical Connection

To properly install your range, you must determine the type of

electrical connection you will be using and follow the instructions

provided for it here.

• Do not ground to a gas pipe.

• Check with a qualified electrical installer if you are not sure

the range is properly grounded.

• Do not have a fuse in the neutral or ground circuit.

• Range must be connected to the proper electrical voltage

and frequency as specified on the model/serial number rating

plate. (The model/serial number rating plate is located on the

right vertical surface of the oven door frame.)

• Range must be connected to a grounded metal, permanent

wiring system.

• A 4-wire or 3-wire, single phase, 120/240 volt, 60 Hz., AC

only electrical supply is required on a separate, 30-amp

circuit, fused on both sides of the line.

• A time-delay fuse or circuit breaker is recommended. The

fuse size must not exceed the circuit rating of the range

specified on the model/serial rating plate located on the right

vertical surface of the oven door frame.

The range can be connected directly to the fused disconnect

(or circuit breaker box) through flexible, or nonmetallic

sheathed, copper or aluminum cable. The flexible cable

extending from the fuse box or circuit breaker box should be

connected directly to the junction box. See "Make Electrical

Connection."

Locate the junction box to allow as much slack as possible

between the junction box and the range so that the range can

be moved if servicing is ever necessary. Do not cut the

conduit.

• A UL listed conduit connector must be provided at each end

of the power supply cable (at the range and at the junction

box).

• Wire sizes and connections must conform with the rating of

the range (30 amps).

• If the house has aluminum wiring, follow the procedure

below:

a} Connect the aluminum wiring to the copper wiring using

special connectors designed and UL listed for joining

copper to aluminum. Follow the electrical connector

manufacturer's recommended procedure.

b} Aluminum/copper connection must conform with local

codes and industry-accepted wiring practices.

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrical installer determine that

the ground path and wire gauge are in accordance with local

codes.

Be sure that the electrical connection and wire size are adequate

and in conformance with the CSA Standard C22.1, Canadian

Electrical Code, Part 1 - latest edition, and all local codes and

ordinances.

A copy of the above code standards can be obtained from:

Canadian Standards Association

178 Rexdale Blvd.

Toronto, ON M9W 1R3 CANADA.

• Do not ground to a gas pipe.

• Check with a qualified electrical installer if you are not sure

the range is properly grounded.

• Do not have a fuse in the neutral or ground circuit.

• When a 4-wire, single phase 208/240 volt, 60 Hz., AC only

electrical supply is available, a 30-amp minimum circuit

protection is required, fused on both sides of the line.

• A time-delay fuse or circuit breaker is recommended. The

fuse size must not exceed the circuit rating of the range

specified on the model/serial rating plate located on the right

vertical surface of the oven door frame.

6

Page 7

Gas

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut=off valve.

Securely tighten all gas connections.

if connected to LP, have a qualified person make sure

gas pressure does not exceed 14" (36 cm) water

column.

Gas Supply Line

Provide a gas supply line of 3A,,(1.9 cm) rigid pipe to the

range location. A smaller size pipe on longer runs may result

in insufficient gas supply. Pipe-joint compounds that resist

the action of LP gas must be used. Do not use TEFLON ®t

tape. With LP gas, piping or tubing size can be 1/2"(1.3 cm)

minimum. Usually, LP gas suppliers determine the size and

materials used in the system.

Flexible metal appliance connector:

• If local codes permit, a new CSA design-certified,

4 - 5 ft (122 - 152.4 cm) long, %" (1.6 cm) or

%" (1.9 cm) I.D., flexible metal appliance connector may

be used for connecting range to the gas supply line.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

Observe all governing codes and ordinances.

IMPORTANT: This installation must conform with all local codes

and ordinances. In the absence of local codes, installation must

conform with American National Standard, National Fuel Gas

Code ANSI Z223.1 -latest edition or CAN/CGA B149 -latest

edition.

IMPORTANT: Range cooktop must be connected to a regulated

gas supply.

Type of Gas

Natural Gas:

This range is design-certified by CSA International for use with

Natural gas or, after proper conversion, for use with LP gas.

• This range is factory set for use with Natural gas. The model/

serial rating plate located on the right vertical surface of the

oven door frame has information on the types of gas that can

be used. If the types of gas listed do not include the type of

gas available, check with the local gas supplier.

LP Gas conversion:

Conversion must be done by a qualified service technician.

No attempt shall be made to convert the appliance from the gas

specified on the model/serial rating plate for use with a different

gas without consulting the serving gas supplier. To convert to LP

gas, use the LP gas conversion kit provided with your range. The

parts for this kit are in the literature package supplied with the

range.

• A 1/2"(1.3 cm) male pipe thread is needed for connection

to the female pipe threads of the inlet to the appliance

pressure regulator.

• Do not kink or damage the flexible metal tubing when

moving the range.

Rigid pipe connection:

The rigid pipe connection requires a combination of pipe

fittings to obtain an in-line connection to the range. The rigid

pipe must be level with the range connection. All strains must

be removed from the supply and fuel lines so range will be

level and in line.

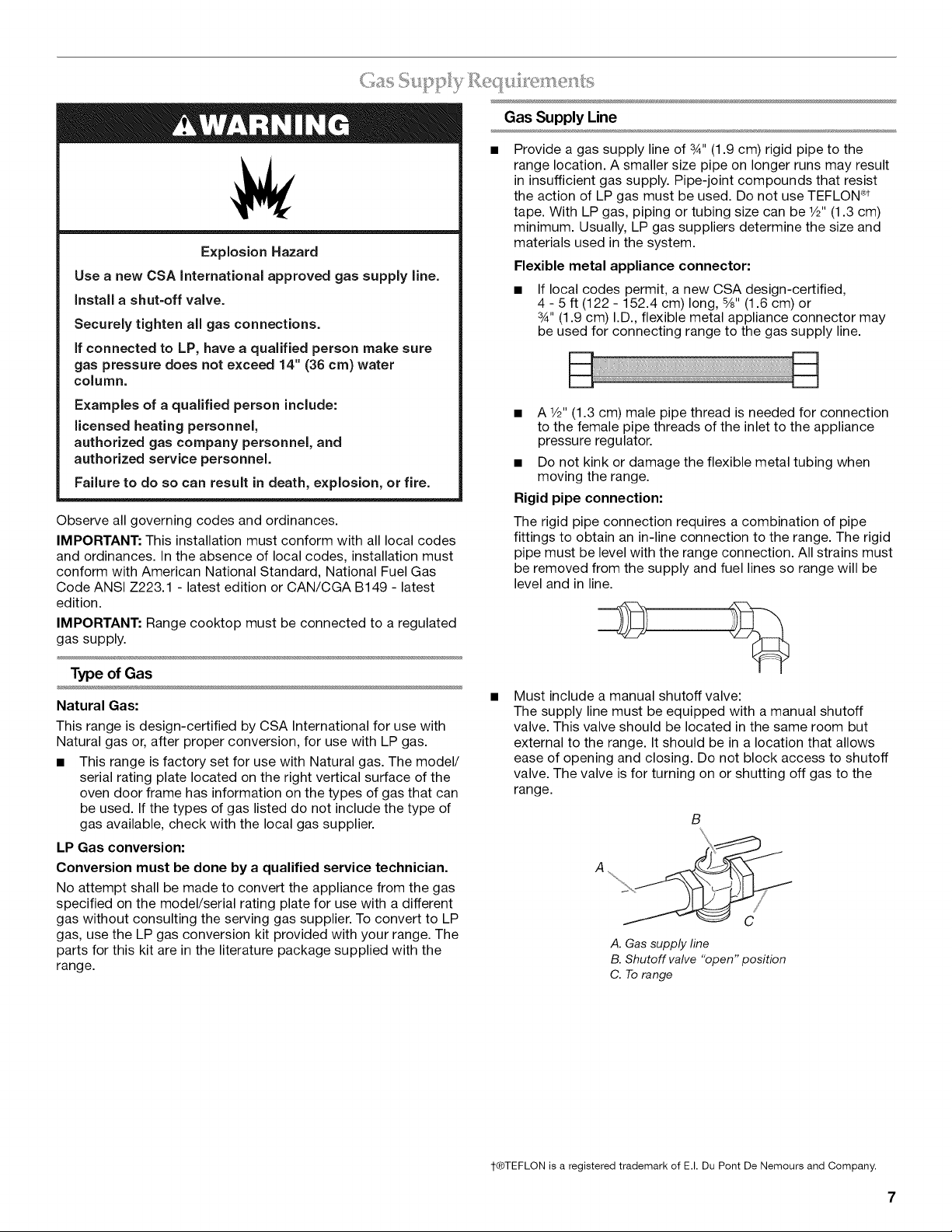

Must include a manual shutoff valve:

The supply line must be equipped with a manual shutoff

valve. This valve should be located in the same room but

external to the range. It should be in a location that allows

ease of opening and closing. Do not block access to shutoff

valve. The valve is for turning on or shutting off gas to the

range.

B

A. Gas supply line

B. Shutoff valve "open" position

C. To range

1-®TEFLON is a registered trademark of E.I. Du Pont De Nemours and Company.

Page 8

Gas Pressure Regulator Burner Input Rating - Altitude

The gas pressure regulator supplied with this range must be

used. The inlet pressure to the regulator should be as follows for

proper operation:

Natural Gas:

Minimum pressure: 6" (15.2 cm) WCP

Maximum pressure: 14" (35.6 cm)WCP

LP Gas:

Minimum pressure: 11" (27.9 cm) WCP

Maximum pressure: 14" (35.6 cm)WCP

Contact local gas supplier if you are not sure about the inlet

pressure.

INSTALLATION INSTRUCTIONS

Excessive Weight Hazard

Use two or more people to move and install range.

Failure to do so can result in back or other injury.

Input ratings shown on the model/serial rating plate are for

elevations up to 2,000 ft (609.6 m).

For elevations above 2,000 ft (609.6 m), ratings are reduced at a

rate of 4% for each 1,000 ft (304.8 m).

Gas Supply Pressure Testing

Line pressure testing above 1/2psi gauge (14" WCP)

The appliance and its individual shutoff valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of

1/2psi (3.5 kPa).

Line pressure testing at 1/2psi gauge (14" WOP) or lower

The appliance must be isolated from the gas supply piping

system by closing its individual manual shutoff valve during any

pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2psi (3.5 kPa).

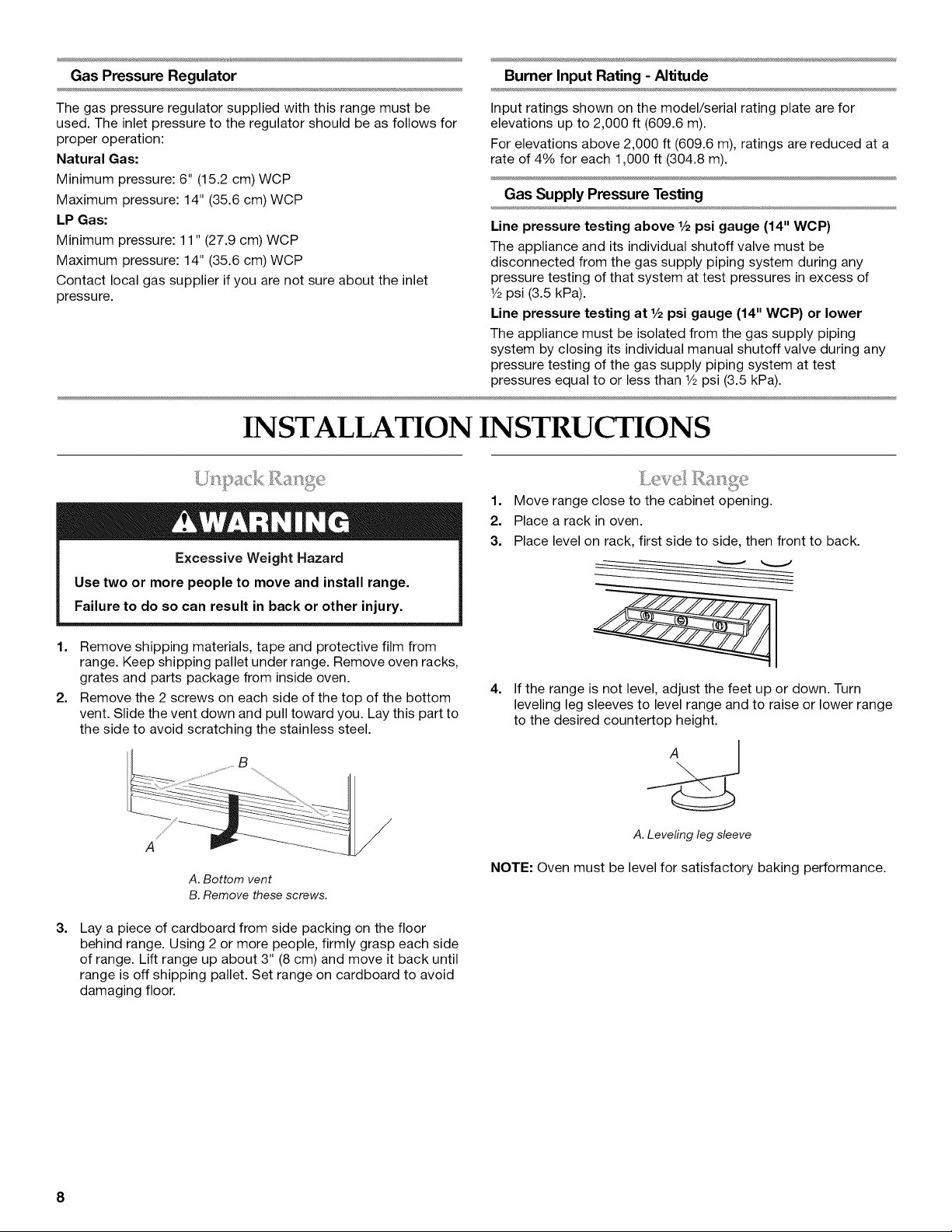

1. Move range close to the cabinet opening.

2. Place a rack in oven.

3. Place level on rack, first side to side, then front to back.

1. Remove shipping materials, tape and protective film from

range. Keep shipping pallet under range. Remove oven racks,

grates and parts package from inside oven.

2. Remove the 2 screws on each side of the top of the bottom

vent. Slide the vent down and pull toward you. Lay this part to

the side to avoid scratching the stainless steel.

A

A. Bottom vent

B. Remove these screws.

3.

Lay a piece of cardboard from side packing on the floor

behind range. Using 2 or more people, firmly grasp each side

of range. Lift range up about 3" (8 cm) and move it back until

range is off shipping pallet. Set range on cardboard to avoid

damaging floor.

4.

If the range is not level, adjust the feet up or down. Turn

leveling leg sleeves to level range and to raise or lower range

to the desired countertop height.

A. Leveling leg sleeve

NOTE: Oven must be level for satisfactory baking performance.

8

Page 9

==I_=.:,,;=_ I!II klt.]I ell

....... i

I > ......'"_

Tip Over Hazard

A child or adult can tip the range and be killed.

Connect anti-tip bracket to wail behind range.

Reconnect the anti-tip bracket, if the range is moved.

Failure to follow these instructions can result in death

or serious burns to children and adults.

1.

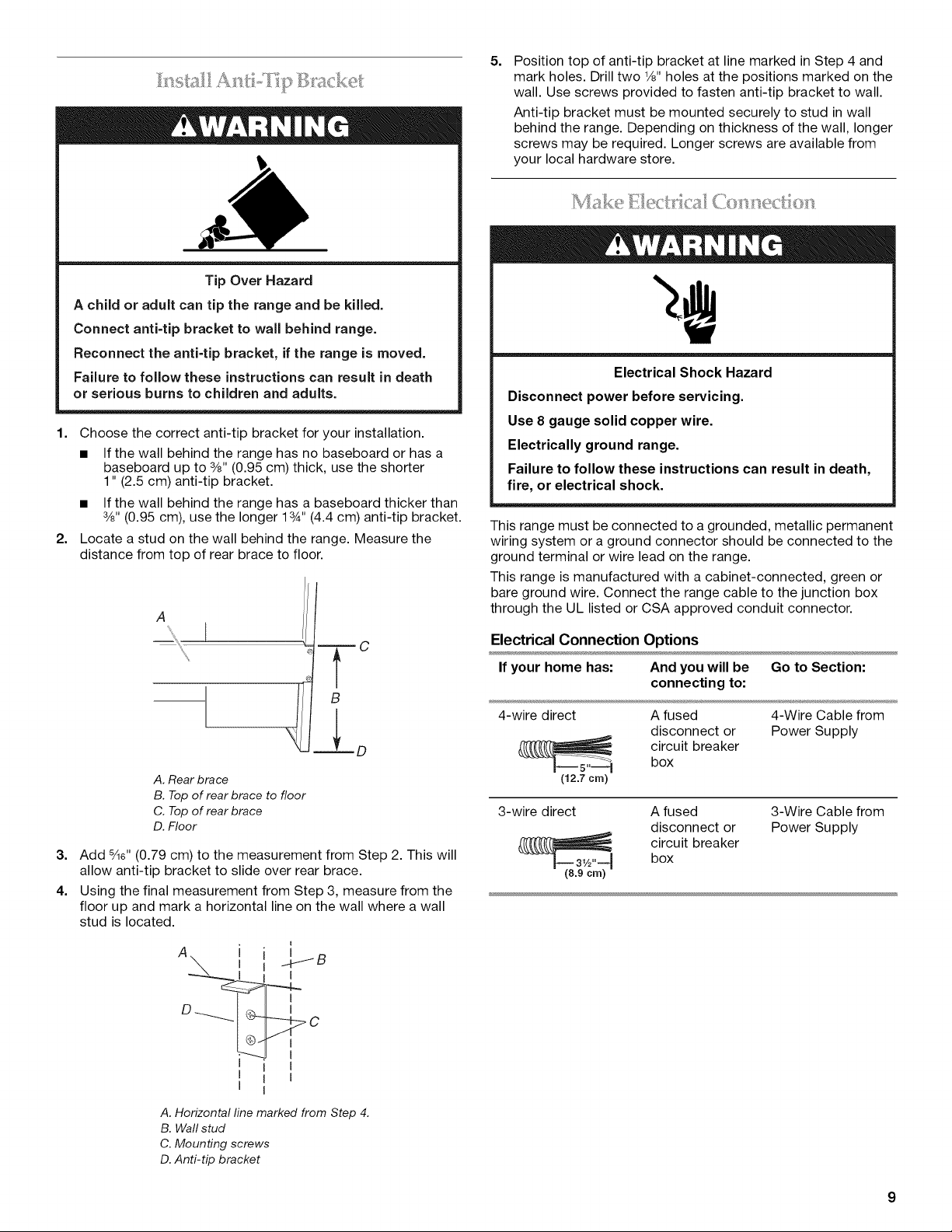

Choose the correct anti-tip bracket for your installation.

• If the wall behind the range has no baseboard or has a

baseboard up to 3/8"(0.95 cm) thick, use the shorter

1" (2.5 cm) anti-tip bracket.

• If the wall behind the range has a baseboard thicker than

3/8"(0.95 cm), use the longer 13A"(4.4 cm) anti-tip bracket.

2.

Locate a stud on the wall behind the range. Measure the

distance from top of rear brace to floor.

A

5.

Position top of anti-tip bracket at line marked in Step 4 and

mark holes. Drill two 1/8"holes at the positions marked on the

wall. Use screws provided to fasten anti-tip bracket to wall.

Anti-tip bracket must be mounted securely to stud in wall

behind the range. Depending on thickness of the wall, longer

screws may be required. Longer screws are available from

your local hardware store.

al

Electrical Shock Hazard

Disconnect power before servicing.

Use 8 gauge solid copper wire.

Electrically ground range.

Failure to follow these instructions can result in death,

fire, or electrical shock.

This range must be connected to a grounded, metallic permanent

wiring system or a ground connector should be connected to the

ground terminal or wire lead on the range.

This range is manufactured with a cabinet-connected, green or

bare ground wire. Connect the range cable to the junction box

through the UL listed or CSA approved conduit connector.

Electrical Connection Options

If your home has: And you will be Go to Section:

connecting to:

A. Rear brace

B. Top of rear brace to floor

C. Top of rear brace

D. Floor

3. Add SAd'(0.79 cm) to the measurement from Step 2. This will

allow anti-tip bracket to slide over rear brace.

4. Using the final measurement from Step 3, measure from the

floor up and mark a horizontal line on the wall where a wall

stud is located.

I

(

(

(

D_

(

I

I

A. Horizontal line marked from Step 4.

B. Wall stud

C. Mounting screws

D. Anti-tip bracket

(

(

I

4-wire direct A fused 4-Wire Cable from

disconnect or Power Supply

circuit breaker

box

(12.7 crn)

3-wire direct A fused 3-Wire Cable from

disconnect or Power Supply

box

circuit breaker

Page 10

4-Wire Cable from Power Supply

3-Wire Cable from Power Supply

IMPORTANT: Use the 4-wire cable from power supply where

local codes do not permit connecting the frame-ground

conductor to the neutral (white) junction box wire.

A

H

A. Cable from power supply

B. Red wires

C. Green (or bare) ground wires

D. 4-wire flexible cable from range

E.Junction box

F. White wires

G. UL listed wire connectors

H. Black wires

I. UL fisted or CSA approved

conduit connector

1. Disconnect power.

2. Remove junction box cover if present.

3. Connect the 4-wire flexible cable from the range to the

junction box using a UL listed or CSA approved conduit

connector.

4. Tighten screws on conduit connector if present.

5. Connect the 2 black wires together using the UL listed wire

connectors.

6. Connect the 2 white wires together using the UL listed wire

connectors.

7. Connect the green or bare ground wire from the range cable

to the green or bare grounded wire (in the junction box) using

the UL listed wire connectors.

8. Install junction box cover.

9. Reconnect power.

IMPORTANT: Use the 3-wire cable from power supply where

local codes permit connecting the frame-ground conductor to

the neutral (white) junction box wire (not used for Canadian

installations).

A

B

H

D

F

G

A. Cable from power supply

B. Junction box

C. Red wires

D. White wire (from power supply)

E. Green (or bare) grounding wires

(from range)

F. White wire (from range)

G. 4-wire flexible cable from

range

H. Black wires

I. UL listed wire connectors

J. UL listed or CSA

approved conduit

connector

J

1. Disconnect power.

2. Remove junction box cover if present.

3. Connect the 4-wire flexible cable from the range to the

junction box using a UL listed or CSA approved conduit

connector.

4. Tighten screws on conduit connector if present.

5. Connect the 2 black wires together using UL listed wire

connectors.

6. Connect the 2 red wires together using UL listed wire

connectors.

7. Connect the green (or bare) and white range cable wires to

the white (neutral) wire in the junction box using UL listed

wire connectors.

8. Install junction box cover.

9. Reconnect power.

10

Excessive Weight Hazard

Use two or more people to move and install range.

Failure to do so can result in back or other injury.

1. Using 2 or more people, move range close to cabinet

opening.

2. Remove cardboard or hardboard from under range. Move

range into it's final location.

3. Attach the backguard or island trim as required for your

installation. See "Tools and Parts." Attachment screws are

included in the literature package.

Page 11

Attaching the Backguard

4.

Use a _sAe"combination wrench and channel lock pliers to

attach the flexible connector to the adapters. Check that

A

connector is not kinked.

A B C

D

E

H G F

A. Three front screws (4 rear screws

required but not shown)

Attaching the Island Trim

A

A. Center hole not used

4.

Using 2 or more people, tip the range back so that the front

feet lift off the ground. Slide range toward the wall until the

rear brace is under the anti-tip bracket. Stand range up,

making sure the anti-tip bracket catches the rear brace.

A. Gas pressure regulator

B. Use pipe-joint compound.

C. Adapter (must have V2"male

pipe thread)

D. Flexible connector

E.Manual gas shutoff valve

F V2"or 3/4"gas pipe

G. Use pipe-joint compound.

H. Adapter

Complete Connection

1. Open the manual shutoff valve in the gas supply line. The

valve is open when the handle is parallel to the gas pipe.

A. Closed valve

B. Open valve

2=

Test all connections by brushing on an approved

noncorrosive leak-detection solution. If bubbles appear, a

leak is indicated. Correct any leak found.

3=

Remove cooktop burner caps, grates and simmer plate from

parts package. Align notches in burner caps with pins in

burner base. Burner caps should be level when properly

positioned. If burner caps are not properly positioned,

surface burners will not light. Place burner grates over

burners and caps.

1. Assemble flexible connector from gas supply pipe to pressure

regulator located in the middle front of the range.

2. Apply pipe-joint compound made for use with LP gas to the

smaller thread ends of the flexible connector adapters (see B

and G in following illustration).

3. Attach one adapter to the gas pressure regulator and the

other adapter to the gas shutoff valve. Tighten both adapters.

G

B _HHHHHHHHHH_C; _

A _

A. Burner base

B. Burner cap

C. Burner grate

D. Simmer plate

4.

Turn on power supply. "PF" should appear on the clock

display. For further information, please refer to the user

instructions located in the Use and Care Guide.

11

Page 12

T7 '¸ _ _ _ _ _ _ -_ _ ,_ _ _ _ d'_ _ _ ....

Initial lighting and gas flame adjustments

Cooktop and oven burners use electronic igniters in place of

standing pilots. When the cooktop control knob is turned to the

"LITE" position, the system creates a spark to light the burner.

This sparking continues, as long as the control knob is turned to

"LITE."

Check Operation of Cooktop Burners

Push in and turn each control knob to the "LITE" position.

The flame should light within 4 seconds. The first time a burner is

lit it may take longer than 4 seconds to light because of air in the

gas line.

If burners do not light properly:

• Turn cooktop control knob to the "OFF" position.

• Check that the range is plugged in and the circuit breaker has

not tripped or the fuse has not blown.

• Check that the gas shutoff valves are set to the "open"

position.

• Check that burner caps are properly positioned on burner

bases.

Repeat start-up. If a burner does not light at this point, contact

your dealer or authorized service company for assistance.

Adjust Flame Height

Adjust the height of top burner flames. The cooktop "low" burner

flame should be a steady blue flame approximately 1¼. (0.64 cm)

high.

A _1_ ___

The flame can be adjusted using the adjustment screw in the

center of the valve stem. The valve stem is located directly

underneath the control knob.

A. Adjustment screw

If the "low" flame needs to be adjusted:

1. Remove the control knob.

2. Hold the knob stem with a pair of pliers. Use a small flat-

blade screwdriver to turn the screw located in the center of

the control knob stem until the flame is the proper size.

3. Replace the control knob.

4. Test the flame by turning the control from "LO" to "HI,"

checking the flame at each setting.

Check Operation of Oven Element

1. Turn oven selector to BAKE. Default temperature appears in

the temperature display.

2. Press ENTER. The first preheat light comes on when the oven

temperature begins to rise.

3. When the second preheat light comes on, open oven door

and hold hand above oven floor and feel for heat. Do not

touch oven floor. Press CANCEL and turn oven selector to

RESET.

A. Low flame

B. High flame

Check Operation of Oven Broil Element

1. Close the oven door.

2. Turn oven selector to BROIL. "HI" will appear in the

temperature display.

3. Press ENTER. Look through oven window. The top element

should glow red, and heat should be radiating out of the door.

Press CANCEL and turn oven selector to RESET.

If oven does not operate:

• Check that power supply is turned on.

• Check that the range is plugged in and the circuit breaker has

not tripped or the household fuse has not blown.

Repeat start-up. If the oven still does not operate at this point,

contact your dealer or authorized service company for

assistance.

Install Burner Grates

Place burner grates over burner caps. The simmer plate may sit

on one of the grates or be stored for future use.

12

Page 13

1. Insert lower vent tabs into the slots on the front trim.

2. Push vent upward until the holes line up at top of vent.

3. Reattach the vent using the 4 screws.

A

A. Bottom vent

B. Reattach these screws.

1. Check that all parts are now installed. If there is an extra part,

go back through the steps to see which step was skipped.

2. Dispose of/recycle all packaging materials.

3. Check that range is correctly positioned in countertop cutout

and that the range is level. See "Level Range."

4. Check that the specified distances to cabinet surfaces were

maintained. See "Location Requirements."

5. Check that burner caps are positioned properly on sealed

burner bases.

6. Check that backguard or island trim is installed. (If horizontal

clearance to combustible materials behind cooking surface is

less than 1" [2.5 cm]).

7. Check that the range is connected only to the type of gas for

which it is certified for use.

8. Use a mild solution of liquid household cleaner and warm

water to remove waxy residue caused by protective shipping

material. Dry thoroughly with a soft cloth. For more

information, see the "Range Care" section of the Use and

Care Guide.

9. Read "Range Use" in the Use and Care Guide.

10. Turn on surface burners and oven. See the Use and Care

Guide for specific instruction on range operation.

If range does not operate, check the following:

• Household fuse has not blown, or circuit breaker has not

tripped.

• Gas valves are turned to the "open" position.

• If the gas supply line shutoff valve is open, contact a qualified

technician.

• Electrical supply is connected.

• See "Troubleshooting" in the Use and Care Guide.

WIRING DIAGRAMS

Cooktop Schematic

L1

BK

GND R R

VALVE SWITCHES

ll_'_ SPAR K MODULE

(4) PLCS

IGNITER ELECTRODES

L2

13

Page 14

Oven Schematic

ELECTRONIC FILTER q

WP#4451985 W

N

L2 L1

q

R Bt<

L1

)BK

BK BK

BK BK

WiSP CONNECTOR

(MANUFACTURINGUSE ONLY)

TEMP SENSOR

1080 _ AT 21 ° C (70 ° F) _ _)W V

1654 _')_AT 177 ° C (350 ° F)_

-_ BR

>-

<

T

u

DOOR SWITCH

%-0

LATCH SWITCH

(OPERATEDBY

MOTOR)

BU

P4-1

P9-1

P9-3

P7-4

P7-5

P7-1

( P7-2

P7-3

-----------___

_------------O---

DOUBLE LiNE {-<b

BREAK RELAY

--_________

----------O--

o

P3-1

,--o

P5-1

P5-3

P5-4

P8-1

,-o

-- P8-2

P8-3

-- P8-4

P3-3

P3-2

P1-1

P1-3

P1-5

)BU BROIL-3OOOW

?R B_ R

OVEN SHUTDOWN

)

y,

(

)R

THERMAL FUSE

DOOR LOCK

MOTOR LATCH

OR _ W

BK

BU ° II ROLPOWER

ll& -]_RANSFORMER

CONTROLPANELTHERMAL FUSE

GY _ W W

84 ° C (183 ° F)

BLOWER

DR

LIGHT POWER

BK

SUPPLY

(SEE NOTE*)

@w w

CONV,

FAN

HALOGEN

5W/BULB

R

W

/___f

W

GROUND

(CHASSIS) _

PLUG WITH

FEMALE "_

CONNECTOR

RECEPTACLE

WITH MALE _]

CONNECTOR

LIGHT oJ_o

AC DRIVE

MOTOR

COIL

RELAY ]_]

RELAY

CONTACTS

HEATING

ELEMENT c!_

AC MOTOR__

LATCH

ENCLOSED

THERMISTOR - _

OPERATED rqm

BY DOOR I

OPERATED T

BY HAND

OVEN

SHUTDOWN @

THERMAL

FUSE

NOTES:

*Blower remains off until oven reaches 190°F (88°C) and may continue running up to 45 minutes after oven has turned off.

Dots indicate connections.

Circuit shown in standby/off mode with oven door closed.

14

Page 15

p p ,_

SECURITE DE LA CUISINIERE

Votre securite et celle des autres est tres importante.

Nous donnons de nombreux messages de s_curit_ importants dans ce manuel et sur votre appareil m_nager. Assurez-vous de

toujours lire tousles messages de s_curit_ et de vous y conformer.

Ce symbole d'alerte de s_curit_ vous signale les dangers potentiels de d_c_s et de blessures graves & vous

et & d'autres.

Voici le symbole d'alerte de s_curit&

Tousles messages de s_curit_ suivront le symbole d'alerte de s_curit_ et le mot "DANGER" ou

"AVERTISSEMENT". Ces mots signifient •

Risque possible de d6cbs ou de blessure grave si vous ne

suivez pas imm6diatement les instructions.

Risque possible de d6cbs ou de blessure grave si vous

ne suivez pas les instructions.

Tousles messages de s_curit_ vous diront quel est le danger potentiel et vous disent comment r_duire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

AVERTISSEMENT • Pour votre securite, les renseignements dans ce manuel doivent

_tre observes pour reduire au minimum les risques d'incendie ou d'explosion ou pour

eviter des dommages au produit, des blessures ou un deces.

- Ne pas entreposer ni utiliser de ressence ou d'autres vapeurs ou liquides inflammables

proximite de cet appareil ou de tout autre appareil electromenager.

- QUE FAIRE DANS LE CAS D'UNE ODEUR DE GAZ :

• Ne pas tenter d'allumer un appareil.

• Ne pas toucher a un commutateur electrique.

• Ne pas utiliser le telephone se trouvant sur les lieux.

• Appeler immediatement le fournisseur de gaz d'un telephone voisin. Suivre

ses instructions.

• .&.defaut de joindre votre fournisseur de gaz, appeler les pompiers.

- L'installation et rentretien doivent _tre effectues par un installateur qualifie, une agence

de service ou le fournisseur de gaz,

Risque de basculement

Un enfant ou une personne adulte peut faire basculer la cuisini_re ce qui peut causer un d6c6s.

Joindre la bride antibasculement au mur derribre la cuisinibre.

Joindre de nouveau la bride antibasculement si la cuisinibre est d6plac6e.

Le non-respect de ces instructions peut causer un d6cbs ou des bn)lures graves aux enfants et

aux adultes.

15

Page 16

EXIGENCES D'INSTALLATION

O,ti ageet ¢ces

Rassembler les outils et pi@cesn@cessaires avant de commencer

I'installation. Lire et suivre les instructions fournies avec les outils

indiqu6s ici.

Outillage n6cessaire

• Metre-ruban • Cle mixte de 15Ae"

• Tournevis & lame plate • Marqueur ou crayon

• Tournevis Phillips • Ruban adhesif de masquage

• Niveau • Compose d'etancheite des

• Perceuse manuelle ou

electrique au propane

• Pince multiprise ordinaire • Solution non-corrosive de

• Cle & tube

Pi6ces n6cessaires

• Un connecteur de conduit (homologation UL ou CSA)

• Un connecteurs de ills homologue UL

Pi_ces fournies

Verifier que toutes les pieces sont presentes.

• Trousse de bride antibasculement

C

A. Bride antibasculement - 1" (2,5 cm)

B. Bride antibasculement - 1a_,,(4,4 cm)

C. Vis _ t@tePhillips n° 10 x 2" (2)

REMARQUE : Les brides doivent etre solidement fixees au

poteau mural. La profondeur du mur peut necessiter des vis plus

Iongues pour I'ancrage de la bride dans le mur. Des vis plus

Iongues sont disponibles aupres de votre quincaillerie locale. Voir

la section "Installation de la bride antibasculement".

• Dosseret et vis de fixation (7).

REMARQUE : Le dosseret inclus avec la cuisiniere doit etre

installe en cas d'installation & moins de 1" (2,5 cm) de la

cloison arriere combustible.

Garniture en ilot et vis de fixation (3).

REMARQUE : La garniture en _lot incluse avec la cuisiniere

peut etre utilisee en cas d'installation & 1" (2,5 cm) d'une

cloison arriere combustible ou &0" (0 cm) d'une cloison

arriere non combustible.

Trousse de conversion pour I'alimentation au propane.

REMARQUE : La table de cuisson est congue pour une

utilisation au gaz naturel. Pour effectuer la conversion pour

une alimentation au propane, voir les instructions de

conversion de gaz fournies dans le sachet de documentation.

raccords filetes - resistant

detection des fuites

• Detecteur magnetique de vis

Verifier les codes Iocaux et consulter le fournisseur de gaz.

Verifier I'alimentation en gaz et I'alimentation electrique

existantes. Voir les sections "Specifications electriques" et

"Specifications de I'alimentation en gaz".

Toutes les connexions electriques doivent etre effectuees par un

electricien qualifie et certifi&

IMPORTANT : Respecter tousles codes et reglements en

vigueur. Ne pas obstruer le flux de combustion et la ventilation.

• C'est a I'installateur qu'incombe la responsabilite de

respecter les distances de separation, specifiees sur la

plaque signaletique de I'appareil. La plaque signaletique des

numeros de modele et de serie est situee sur la surface

verticale sous le panneau de commande a droite.

• II est recommande qu'une hotte de cuisiniere de 600 CFM

soit installee au-dessus de la cuisiniere.

• Dans le cas d'une cuisiniere encastree, I'enceinte doit

recouvrir completement les c6tes et I'arriere de la cuisiniere.

• Afin de supprimer le risque de brQlures ou d'incendie en se

penchant au-dessus des unites de surface chauffees, le

rangement en armoire au-dessus des unites de chauffage

doit etre evit& Si le rangement en armoire est envisage, le

risque peut etre reduit par I'installation d'une hotte de cuisine

operant horizontalement sur un minimum de 5" (12,7 cm)

au-del& du bas des placards.

• Toutes les ouvertures dans lemur ou le plancher de

I'emplacement d'installation de la cuisiniere doivent etre

scellees.

• Ne pas realiser un scellement entre la cuisiniere et les

placards lateraux.

• Respecter les dimensions indiquees pour la cavite

d'installation entre les placards. Ces dimensions tiennent

compte des valeurs minimales des degagements de

separation.

• La bride antibasculement murale doit etre installee. Pour

I'installation de la bride antibasculement expediee avec la

cuisiniere, voir la section "Installation de la bride

antibasculement".

• Une source d'electricite avec liaison & la terre est necessaire.

Voir la section "Specifications electriques".

• Une source de gaz adequate doit etre disponible. Voir la

section "Specifications de I'alimentation en gaz".

• Contacter un installateur de revetement de sol qualifie, qui

pourra determiner si le revetement de sol peut resister a une

temperature d'au moins 200°F (93°C). Dans le cas de

I'installation de la cuisiniere sur de la moquette, placer sous la

cuisiniere une plaque d'appui isolee, ou une plaque de

contreplaque de 1¼,,(0,64 cm).

IMPORTANT : Les materiaux de certains placards et certains

materiaux de construction ne sont pas congus pour resister a la

chaleur generee par le four durant la cuisson au four ou

I'autonettoyage. Consulter le constructeur de la maison ou le

fabricant des placards pour determiner si les materiaux utilises

pourraient subir un changement de couleur, une destratification

ou d'autres dommages.

16

Page 17

R6sidence mobile - Sp6cifications additionnelles

respecter Iors de I'installation

L'installation de cette cuisiniere doit etre conforme aux

dispositions de la norme Manufactured Home Construction and

Safety Standard, Title 24 CFR, Part 3280 (anciennement Federal

Standard for Mobile Home Construction and Safety, Title 24,

HUD Part 280). Lorsque cette norme n'est pas applicable,

I'installation doit satisfaire aux criteres de la norme Standard for

Manufactured Home Installations, ANSI A225.1/NFPA 501A ou

les dispositions des codes Iocaux.

Au Canada, I'installation de cette cuisiniere doit satisfaire aux

stipulations de la version la plus recente de la norme CAN/CSA-

A240, ou des codes Iocaux en vigueur.

Autres crit_res a respecter pour une installation en r_sidence

mobile :

• Dans le cas de I'installation de cette cuisiniere dans une

residence mobile, la cuisiniere doit etre fixee au plancher

durant tout deplacement du vehicule. Toute methode de

fixation de la cuisiniere est adequate dans la mesure oQ elle

satisfait aux criteres des normes mentionnees ci-dessus.

Dimensions de I'appareil

D6gagements de s6paration & respecter

Les dimensions de I'espace d'installation entre les placards sont

valides pour I'installation entre des placards de 24" (61 cm) avec

plan de travail de 25" (64 cm) a hauteur de 36" (91,4 cm).

K

A

G

t

B

C

F\

D

A. Dosseret (exig_ pour certaines installations)

B. Hauteur hors-tout 45" (114,3 cm)

C. Hauteur de la table de cuisson 36"

(91,4 cm) avec pieds d_viss_s de 3/4de tour

D. 30" (76,2 cm) de largeur

E. 26Y2" (67,3 cm) de largeur (tableau de

commande indus*)

F. Butte d'espacement de ¼" (6,4 cm)

G. Hauteur du dosseret 9¼" (23,5 cm)

*Dans le cas d'une installation entre des placards de 24" (61 cm)

avec plan de travail de 25" (63,5 cm), I'avant de la porte du four

sera en saillie de 17/8'' (4,8 cm) au-del& de la fagade des placards

de 24" (61 cm).

qf

A. 18" (45, 7 cm) entre placard mural et plan de travail

B. 22" (55,9 cm)

C. Placer la boTte de connexion dans cette zone ombr_e

D. 4" (10,2 cm)

E.20" (50,8 cm)

F. 12" (30,5 cm)

G. 5Y2" (14 cm)

H. Placer la canalisation de gaz dans cette zone ombr_e

I.3Y2" (8,9 cm)

J. 8" (20,3 cm)

K. 30¼" (76,8 cm)

L. D_gagement de 4" (10,2 cm) minimum entre les deux c6t_s

de la cuisiniere et la paroi lat_rale ou toute autre matiere

combustible

M. Pour la distance fibre minimale vers la partie sup_rieure de

la cuisiniere, voir la REMARQUE*.

N. Largeur min. des placards muraux 30" (76,2 cm)

O. Profondeur max. des placards muraux 13" (33 cm)

*REMARQUE • Distance de separation de 36" (91,4 cm) ou plus

Iorsque le fond d'un placard de bois ou de metal est protege par

une planche ignifugee d'au moins 1¼,,(0,64 cm) recouverte d'une

feuille metallique d'epaisseur egale ou superieure & : acier

calibre 28 MSG, acier inoxydable 0,015" (0,4 mm), aluminium

0,024" (0,6 mm), ou cuivre 0,020" (0,5 mm).

Distance de separation de 42" (106,7 cm) ou plus entre le

dessus de la table de cuisson et le fond d'un placard de bois ou

de metal non protege.

En cas d'installation d'une hotte au-dessus de la cuisiniere,

suivre les instructions fournies avec la hotte concernant les

dimensions de degagement & respecter au-dessus de la surface

de la table de cuisson.

17

Page 18

Si le code en vigueur le permet et qu'un conducteur distinct de

liaison & la terre est utilise, on recommande qu'un electricien

qualifie verifie que la liaison & la terre et la taille du conducteur de

liaison & la terre sont conformes aux prescriptions du code local.

Verifier que le raccordement & la source d'electricit6 et le calibre

des conducteurs sont adequats et conformes aux prescriptions

de la plus recente edition de la norme CSA C22.1, partie 1 - Code

canadien de I'electricite, et de tout code ou reglement local en

vigueur.

On peut obtenir un exemplaire de la norme ci-dessus aupres de :

Canadian Standards Association

178 Rexdale Blvd.

Toronto, ON M9W 1R3 CANADA.

• Ne pas utiliser une tuyauterie de gaz pour le raccordement &

la terre.

• En cas de doute quant &la qualite de la liaison & la terre de la

cuisiniere, consulter un electricien qualifi&

• Ne pas installer un fusible dans le conducteur neutre ou le

conducteur de liaison & la terre.

Lorsqu'une source d'electricite monophase de 208/240 volts,

60 Hz/4 conducteurs (CA uniquement) est disponible, le

circuit dolt comporter un dispositif de protection de

30 amperes, fusionne aux deux extremites de la ligne.

On recommande I'emploi de fusibles temporises ou

disjoncteurs. On recommande I'emploi de fusibles

temporises ou disjoncteurs. La taille du fusible ne dolt pas

depasser le calibre du circuit specific sur la plaque

signaletique de modele/serie situee sur la surface verticale

droite du chassis de la porte du four.

de". °

Risque d'explosion

Utiiser une canalisation neuve d'arriv_e de gaz

approuv_e par la CSA International.

Installer un robinet d'arr_to

Bien setter chaque organe de connexion de la

canaisation de gaz.

En cas de connexion au gaz propane, demander a une

personne quaifi_e de s'assurer que la pression de gaz

ne d_passe pas 36 cm (14 pc) de la colonne d'eau.

Par personne qualifiee, on comprend :

le personnel autoris_ de chauffage,

le personnel autoris_ d'une compagnie de gaz, et

le personnel d'entretien autoris&

Le non=respect de ces instructions peut causer

un d_c_s, une explosion ou un incendie.

Observer toutes les prescriptions des codes et reglements en

vigueur.

IMPORTANT : L'installation dolt satisfaire aux criteres de tousles

codes et reglements Iocaux. En I'absence de code local,

I'installation dolt satisfaire aux prescriptions de la plus recente

edition du code national en vigueur : National Fuel Gas Code

ANSI Z223.1 (American National Standard), ou CAN/CGA B149.

IMPORTANT : La table de cuisson de la cuisiniere dolt _tre

raccordee & une source d'alimentation en gaz regulee.

18

Type de gaz

Gaz naturel :

La conception de cette cuisiniere a et6 homologuee par CSA

International pour I'alimentation au gaz naturel, ou pour

I'alimentation au propane apres conversion adequate.

• Cette cuisiniere a et6 configuree a I'usine pour I'alimentation

au gaz naturel. La plaque signaletique des numeros de

modele et de serie situee sur la surface verticale a droite du

cadre de la porte du four. Si le type de gaz disponible n'est

pas mentionne sur la plaque signaletique, consulter le

fournisseur de gaz local.

Page 19

Conversion pour I'alimentation au propane :

L'op_ration de conversion doit _tre ex_cut_e par un

technicien qualifi&

Consulter le fournisseur de gaz avant toute conversion de

I'appareil pour I'utilisation d'un type de gaz qui n'est pas

mentionne sur la plaque signaletique. Pour convertir au gaz

propane, utiliser le kit de conversion fourni avec la cuisiniere. Les

pieces pour ce kit se trouvent dans le sachet de documentation

fourni avec la cuisiniere.

Canalisation de gaz

• Installer une canalisation de gaz rigide de 3_,,(1,9 cm) jusqu'&

I'emplacement d'installation de la cuisiniere. L'emploi d'une

canalisation de plus petit diametre sur une plus grande

Iongueur peut susciter une deficience du debit

d'alimentation. On doit utiliser un compose d'etancheite des

tuyauteries resistant a I'action du gaz propane. Ne pas utiliser

de ruban TEFLON ®t. Pour I'alimentation au propane, le

diametre des canalisations doit _tre de 1/2"(1,3 cm) ou plus.

En general le fournisseur de gaz propane determine les

materiaux & utiliser et le diametre appropri&

Raccord m_tallique flexible :

• Si le code local le permet, on peut utiliser pour raccorder

la cuisiniere a la canalisation de gaz un raccord

metallique flexible neuf (homologation CSA) de

4 - 5 pi (122 - 152,4 cm) de Iongueur, de diametre interne

de %" (1,6 cm) ou 3_,,(1,9 cm).

• Un raccord avec filetage male de 1/2"(1,3 cm) est

necessaire pour la connexion sur le raccord & filetage

femelle a I'entree du detendeur de I'appareil.

• Veiller a ne pas deformer/ecraser/endommager le tube

metallique flexible Iors d'un deplacement de la cuisiniere.

Raccordement par un ensemble rigide :

On doit utiliser une combinaison de raccords pour realiser un

raccordement rigide entre la cuisiniere et la canalisation de

gaz. Le tuyau rigide doit se trouver au m_me niveau que le

raccord de connexion de la cuisiniere. On doit veiller a ne

soumettre les sections de canalisation d'alimentation &aucun

effort de traction ou flexion, pour que la cuisiniere soit

d'aplomb et correctement alignee.

Robinet d'arr_t manuel necessaire :

La canalisation d'alimentation doit comporter un robinet

d'arr_t manuel. Le robinet d'arr_t manuel doit _tre separ6 de

la cuisiniere, mais doit se trouver dans la m_me piece en un

endroit oQil sera facilement accessible pour les manoeuvres

d'ouverture/fermeture. Ne pas entraver I'acces au robinet

d'arr_t manuel. Le robinet d'arr_t manuel est prevu pour

ouvrir ou fermer I'alimentation en gaz de la cuisiniere.

B

A. Canalisation de gaz

B. Robinet d'arr_t manuel - position d'ouverture

C. Vers la cuisiniere

D_tendeur de gaz

Le detendeur fourni avec cette cuisiniere doit _tre utilise. Pour un

fonctionnement correct, la pression d'alimentation du detendeur

doit _tre comme suit :

Gaz naturel :

Pression minimum : 6" (15,2 cm) (colonne d'eau)

Pression maximum : 14" (35,6 cm) (colonne d'eau)

Gaz propane :

Pression minimum : 11" (27,9 cm) (colonne d'eau)

Pression maximum : 14" (35,6 cm) (colonne d'eau)

En cas d'incertitude quant & la pression d'alimentation & etablir,

contacter le fournisseur de gaz local.

Debit thermique des br_leurs - Altitude

Les debits thermiques indiques sur la plaque signaletique

correspondent a une altitude d'utilisation inferieure

2000 pi (609,6 m).

Lorsque I'appareil est utilise a une altitude superieure

2000 pi (609,6 m), on doit reduire le debit thermique indiqu6 de

4 % pour chaque tranche de 1000 pi (304,8 m).

Tests de pressurisation de la canalisation de gaz

T®TEFLON est une marque depos&e de E.I. Du Pont De Nemours et Compagnie.

Pressurisation a une pression sup_rieure a 1/2Ib/po 2

(14" - colonne d'eau)

Lors de tout test de pressurisation de ce systeme & une pression

superieure &1/2Ib/po 2(3,5 kPa), on doit deconnecter I'appareil et

son robinet d'arr_t individuel de la canalisation de gaz.

Pressurisation a une pression relative de 1/2Ib/po 2

(14" - colonne d'eau) ou moins

Lors de tout test de pressurisation de la canalisation de gaz & une

pression egale ou inferieure & 1/2Ib/po 2(3,5 kPa), on doit isoler

I'appareil de la canalisation de gaz par fermeture de son robinet

d'arr_t manuel individuel.

19

Page 20

INSTRUCTIONS D'INSTALLATION

Risque du poids excessff

Utiliser deu× ou plus de personnes pour d_placer et

installer la cuJsJni_re.

Le non-respect de cette instruction peut causer

une blessure au dos ou d'autre blessure.

4.

Si la cuisiniere n'est pas d'aplomb, ajuster les pieds vers le

haut ou vers le bas. Toumer les manchons des pieds de

nivellement pour mettre la cuisiniere d'aplomb et pour

soulever ou abaisser la cuisiniere a la hauteur de comptoir

desiree.

A. Manchons de pieds de nivellement

1. Oter les materiaux d'emballage, le ruban adhesif et le film

protecteur de la cuisiniere. Maintenir la palette d'expedition

sous la cuisiniere. Retirer les grilles de four et le sachet de

pieces de I'int&ieur du four.

2. Oter les 2 vis de chaque c6te de la partie superieure de

I'event du fond. Faire glisser I'event vers le bas et tirer vers

soi. Faire reposer cette piece sur le c6te pour eviter d'erafler

I'acier inoxydable.

A. Event du fond

B. Oter ces vis

3.

Disposer un morceau de carton (provenant du c6te de

I'emballage) sur le plancher derriere la cuisiniere. A 2

personnes ou plus, saisir fermement chaque c6te de la

cuisiniere. Soulever la cuisiniere d'environ 3" (8 cm) et la

deplacer vers I'arriere jusqu'a la faire descendre de la palette

d'expedition. Installer la cuisiniere sur le carton pour eviter

d'endommager le plancher.

REMARQUE : Le four doit _tre d'aplomb pour pouvoir obtenir

des resultats de cuisson satisfaisants.

Risque de basculement

Un enfant ou une personne adulte peut faire basculer

la cuisini_re ce qui peut causer un d_c_s.

Joindre la bride antibasculement au mur derriere la

cuisini_re.

Joindre de nouveau la bride antibasculement si la

cuisini_re est d_plac_e.

Le non-respect de ces instructions peut causer un

d_c_s ou des brOlures graves aux enfants et aux

adultes.

1. Deplacer la cuisiniere pres de I'ouverture d'encastrement.

2. Placer une grille dans le four.

3. Placer un niveau sur la grille, d'abord transversalement, puis

dans le sens avant/arriere.

20

1.

Choisir la bride antibasculement correcte pour votre

installation.

Si lemur derriere la cuisiniere ne comporte pas de plinthe

ou comporte une plinthe mesurant jusqu'a 3/8"(0,95 cm)

d'epaisseur, utiliser la bride antibasculement de

1" (2,5 cm) la plus courte.

• Si lemur derriere la cuisiniere comporte une plinthe dont

I'epaisseur est superieure a 3/8"(0,95 cm), utiliser la bride

antibasculement de 1%" (4,4 cm) la plus Iongue.

Page 21

2. Localiser un poteau sur le mur derriere la cuisiniere. Mesurer

la distance entre la partie superieure de I'entretoise arriere et

le plancher.

A

!

A. Entretoise arriere

B.Distance entre la partie sup_rieure de

I'entretoise arriere et le plancher

C. Partie sup_rieure de I'entretoise arriere

D. Plancher

3. Ajouter 5/le" (0,79 cm) & la mesure effectuee & I'etape 2. Ceci

permettra & la bride antibasculement de glisser par-dessus

I'entretoise arriere.

4. A I'aide de la mesure finale effectuee & I'etape 3, mesurer &

partir du plancher vers le haut et marquer une ligne

horizontale sur le mur & I'endroit du poteau mural.

i

I

I

I

I

I

I

A. Ligne horizontale marquee _ I'_tape 4.

B. Poteau mural

C. Vis de montage

D. Bride antibasculement

5.

Placer la partie superieure de la bride antibasculement sur la

ligne marquee & I'etape 4 et marquer les trous. Percer deux

trous de 1/8"aux positions marquees sur lemur. Utiliser les vis

fournies pour fixer la bride antibasculement au mur.

La bride antibasculement doit _tre montee solidement sur le

poteau du tour derriere la cuisiniere. En fonction de

I'epaisseur du mur, des vis plus Iongues peuvent _tre

necessaires. Des vis plus Iongues sont disponibles aupres de

votre quincaillerie locale.

I

I

Risque de choc _lectrique

D_connecter la source de courant _lectrique avant

d'entreprendre le travail.

Utiliser des conducteurs de cuivre rigides de calibre 8.

Relier la cuisini_re a la terre.

Le non-respect de ces instructions peut causer un

d_c_s, un incendie ou un choc _lectrique.

Cette cuisiniere doit _tre raccordee & un systeme de c&blage

m6tallique permanent avec liaison & la terre; ou alors un

connecteur de liaison & la terre doit _tre raccorde au terminal de

liaison & la terre ou & la borne de fil conducteur de la cuisiniere.

Un conducteur de liaison & la terre vert ou nu est connecte au

chassis de la table de cuisson Iors de la fabrication. Raccorder le

cable de la table de cuisson a la boite de connexion a travers un

connecteur de conduit (homologation UL ou CSA).

Options de raccordement _lectrique

C&blage de la Point de Voir la section

maison : distribution : suivante :

Direct - 4 conducteurs Boite de Cable a 4

disjoncteur ou conducteurs

coupe-circuit depuis point de

avec fusible distribution

(12,7 crn)

Direct - 3 conducteurs Boite de Cable a 3

disjoncteur ou conducteurs

avec fusible distribution

coupe-circuit depuis point de

21

Page 22

C&ble & 4 conducteurs depuis point de distribution

C&ble & 3 conducteurs depuis point de distribution

IMPORTANT : Si le code local ne permet pas le raccordement du

conducteur de liaison & la terre au conducteur neutre (blanc)

dans la bofte de connexion, utiliser le c&ble & 4 conducteurs

provenant du point de distribution.

A

B

H

A. C#ble d'afimentation

B. Conducteurs rouges

C. Conducteurs verts ou nus de

fiaison _ la terre

D. C#ble flexible _ 4 conducteurs

depuis la cuisiniere

E. Bofte de connexion

F. Conducteurs blancs

G. Connecteurs de ills

(homologation UL)

H. Conducteurs noirs

I. Connecteur de conduit

(homologation UL ou CSA)

1. Deconnecter la source de courant electrique.

2. Le cas ech6ant, enlever le couvercle de la bolte de

connexion.

3. Avec un connecteur de conduit (homologation UL ou CSA),

connecter le c&ble flexible a 4 conducteurs de la cuisiniere

la bolte de connexion.

4. Serrer les vis du connecteur de conduit si existant.

5. Connecter ensemble les deux conducteurs noirs avec un

connecteur de ills (homologation UL).

6. Connecter ensemble les deux conducteurs blancs avec un

connecteur de ills (homologation UL).

7. Connecter le conducteur vert ou nu de liaison & la terre du

c&ble de la cuisiniere au conducteur vert ou nu de liaison & la

terre (dans la bolte de connexion) avec un connecteur de ills

(homologation UL).

8. Installer le couvercle de la bolte de connexion.

9. Reconnecter la source de courant electrique.

IMPORTANT : Si le code local permet le raccordement du

conducteur de liaison & la terre au conducteur neutre (blanc)

dans la bofte de connexion, utiliser le c&ble & 3 conducteurs

provenant du point de distribution (non utilise pour les

installations au Canada).

H

F

G

A. C#ble d'afimentation

B. Bofte de connexion

C. Conducteurs rouges

D. Conducteur blanc (depuis point

de distribution)

E. Conducteurs verts (ou nus) de

fiaison _ la terre (depuis la

cuisiniere)

F. Conducteur blanc (depuis la

cuisiniere)

G. C#ble _ 4 conducteurs depuis

la cuisiniere

H. Conducteurs noirs

I. Connecteurs de ills

(homologation UL)

J. Connecteur de conduit

(homologation UL ou CSA)

1. Deconnecter la source de courant electrique.

2. Le cas ech6ant, enlever le couvercle de la bolte de

connexion.

3. Avec un connecteur de conduit (homologation UL ou CSA),

connecter le c&ble flexible a 4 conducteurs de la cuisiniere

la bolte de connexion.

4. Serrer les vis du connecteur de conduit si existant.

5. Connecter ensemble les deux conducteurs noirs avec un

connecteur de fils (homologation UL).

6. Connecter ensemble les deux conducteurs rouges avec un

connecteur de fils (homologation UL).

7. Connecter les conducteurs verts (ou nus) et les conducteurs

blancs de la cuisiniere au conducteur blanc (neutre) dans la

bolte de connexion - utiliser des connecteurs de ills

(homologation UL).

8. Installer le couvercle de la bolte de connexion.

9. Reconnecter la source de courant electrique.

22

Page 23

I_I])ITI II)I} ('I I I]Of{-;)f!:';@iI'@]0111 _1@;::' _"_'....... _;_......

Risque du poids e×cessif

Utiliser deux ou plus de personnes pour d_placer et

installer Ja cuJsini_re.

Le non=respect de cette instruction peut causer

une blessure au dos ou d'autre blessure.

1. A deux personnes ou plus, deplacer la cuisiniere pres de

I'ouvertu re d'en castrem ent.

2. Retirer le carton ou le panneau de fibre dur de sous la

cuisiniere. Deplacer la cuisiniere & son emplacement final.

3. Fixer le dosseret ou la garniture en lot en fonction des

exigences de I'installation. Voir "Outillage et pieces". Des vis

de fixation sont incluses dans le sachet de documentation.

Fixation du dosseret

A

4=

A I'aide de 2 personnes ou plus, incliner la cuisiniere en

arriere pour que les pieds avant se soulevent du sol. Faire

glisser la cuisiniere vers lemur jusqu'& ce que I'entretoise

arriere se trouve sous la bride antibasculement. Placer la

cuisiniere en position verticale, en veillant & ce que la bride

antibasculement saisisse I'entretoise arriere.

I (ii III h II llOII I _ ,"_,",_,

1. Assembler le raccord flexible du tuyau d'alimentation en gaz

avec le detendeur situe sur la partie centrale avant de la

cuisiniere.

2. Appliquer un compose d'etancheite des filetages resistant au

propane sur I'extremite filetee la plus petite des adaptateurs

de raccord flexible (voir Bet G ci-dessous).

3. Fixer un raccord d'adaptation sur le detendeur et I'autre

raccord d'adaptation sur le robinet d'arr_t de la canalisation

de gaz. Serrer les deux raccords d'adaptation.

4. Utiliser une cle mixte de lS/le" et une pince multiprise pour

fixer le raccord flexible sur les raccords d'adaptation. Veiller

ne pas deformer/6craser le raccord flexible.

A B C

D

E

A. Trois vis _ I'avant (4 vis _ I'arriere sont

n_cessaires mais ne sont pas illustr_es)

Fixation de la garniture en lot

A. Le trou du mifieu n 'est pas utilis_

H G F

A. D_tendeur

B.Appliquer un compos_

d'_tanch_it&

C. Raccord d'adaptation (avec

filetage m_le NPT Y2")

D. Raccord flexible

E.Robinet d'arr_t manuel

F. Tuyau de gaz Y2"ou 3/4"

G. Appfiquer un compos_

d '_tanch_it&

H. Raccord d'adaptation

Completer le raccordement

1. Ouvrir le robinet d'arrSt manuel sur la canalisation de gaz (la

manette doit 8tre parallele au tuyau).

A. Robinet d'arr_t ferm_

B. Robinet d'arr_t ouvert

2=

Effectuer une recherche des fuites : appliquer au pinceau sur

les connexions une solution non corrosive de detection des

fuites; la formation de bulles identifiera une fuite, leliminer

A

toute fuite constatee.

23

Page 24

3.

Prendre les chapeaux de brQleur, les grilles de brQleur et la

plaque de mijotage dans le paquet de pieces. Aligner les

encoches des chapeaux de brQleur avec les broches dans la

base de chaque brQleur. Un chapeau de brQleur correctement

place doit _tre horizontal. Si le chapeau de brQleur n'est pas

correctement place, le brQleur ne peut s'allumer. Placer les

grilles de brQleur sur les brQleurs et les chapeaux.

R_glage de la taille des flammes

Regler la taille des flammes sur les brQleurs de la table de

cuisson. Pour le reglage au debit thermique minimum, on doit

observer des flammes stables bleues de 1¼.(0,64 cm).

A _ Lrd b-d Lr-d b-d Lrd _

/

C

B_O

A

A. Base de brDleur

B. Chapeau de brDleur

C. Grifle de brDleur

D. Plaque de mijotage

4.

Ouvrir I'alimentation electrique. "PF" devrait apparaYtre sur

I'affichage de I'horloge. Pour plus d'informations, se ref6rer

aux instructions de I'utilisateur situ6es dans le Guide

d'utilisation et d'entretien.

Allumage initial et r6glages des flammes

Un systeme d'allumage electronique est utilise & la place des

flammes de veille usuelles pour I'allumage des brQleurs (table de

cuisson et four). Lorsqu'on place le bouton de commande d'un

brQleur de la table de cuisson & la position "LITE" (allumage), le

systeme genere une etincelle pour I'allumage du brQleur. La

generation d'etincelles se poursuit aussi Iongtemps que le

bouton de commande est laisse a la position "LITE".

Contr61e du fonctionnement des br_leurs de la table de

cuisson

Pousser et tourner le bouton de commande du brQleur a la

position "LITE".

Les flammes doivent s'allumer sur le brQleur en moins de

4 secondes. Lors de I'allumage initial, le delai d'allumage peut

_tre superieur & 4 secondes du fait de la presence d'air dans la

canalisation de gaz.

Si le br_leur ne s'allume pas correctement :

• Ramener le bouton de commande de la table de cuisson &la

position d'arr_t.

• Verifier que la cuisiniere est branchee et correctement

alimentee (fusible grille? disjoncteur ouvert?)

• Verifier que chaque robinet d'arr_t est ouvert.

• Verifier que le chapeau de brQleur est correctement place sur

la base du brQleur.

Repeter le processus de mise en marche. Si a ce point un brQleur

ne s'allume pas, contacter le revendeur ou un depanneur agree.

B

Lrd Lrd Lrd Lrd Lrd Lrd

A. D_bit thermique minimum

B. D_bit thermique maximum

La vis de reglage au centre de la tige de commande du robinet

permet de regler la taille des flammes. La tige de commande est

situee directement au-dessous du bouton de commande.

A. Vis de r_glage

S'il est n_cessaire de r_gler la taille des flammes pour le

d_bit thermique minimum :

1. Oter le bouton de commande.

2. Immobiliser la tige de commande avec une pince. Utiliser un

petit tournevis & lame plate pour faire tourner la vis situee au

centre de la tige de commande; ajuster les flammes &la taille

desiree.

3. Reinstaller le bouton de commande.

4. Tester le fonctionnement du brOleur : faire passer le bouton

de commande de la position "LO" (bas) &la position "HI"

(eleve) et observer les flammes pour chaque position.

Contr61e du fonctionnement du br_leur du four

1. Tourner le selecteur du four & BAKE (Cuisson au four). La

temperature selectionnee par defaut apparait sur I'afficheur.

2. Appuyer sur ENTER. Le premier temoin lumineux de

prechauffage s'allume Iorsque la temperature du four

commence a augmenter.

3. Lorsque le deuxieme temoin lumineux s'allume, ouvrir la

porte du four et placer sa main au-dessus du fond du four

pour sentir la chaleur. Ne pas toucher le fond du four.

Appuyer sur CANCEL (annulation) et tourner le selecteur du

four a RESET (reinitialisation).

24

Page 25

ContrSle du fonctionnement du br_leur du gril

1. Fermer la porte du four.

2. Tourner le selecteur du four a BROIL (gril). "HI" apparaitra sur

I'afficheur de la temperature.

3. Appuyer sur ENTER. Regarder a travers le hublot du four.

L'el6ment superieur devrait s'illuminer en rouge et de la

chaleur devrait s'echapper par la porte. Appuyer sur CANCEL

et tourner le selecteur du four a RESET (reinitialisation).

Si le four ne fonctionne pas :

• Verifier que la source d'alimentation est ouverte.

• Verifier que la cuisiniere est branchee, qu'il n'y a pas de

fusible grille et de disjoncteur ouvert.

Repeter la procedure de mise en marche. Si le four ne fonctionne

toujours pas ace stade, contacter votre marchand ou la

compagnie de service autorisee pour obtenir de I'assistance.

Installation des grilles de br_leurs

Placer les grilles de brQleurs sur les chapeaux de brQleurs. La

plaque de mijotage peut reposer sur I'une des grilles ou etre

remisee pour utilisation ulterieure.

1. Inserer les languettes de la partie inferieure de I'event dans

les fentes de la garniture avant.

2. Pousser I'event vers le haut pour que les trous soient alignes

avec la partie superieure de I'event.

3. Fixer & nouveau I'event & I'aide des quatre vis.

A

A. Event du fond

B. Fixer _ nouveau ces vis

1. Verifier que toutes les pieces sont maintenant installees. S'il

reste une piece, passer en revue les differentes etapes pour

decouvrir laquelle aurait ete oubliee.

2. Jeter/recycler tousles materiaux d'emballage et les pieces

inutilisees.

3. Verifier que la cuisiniere est correctement placee sous le

comptoir et qu'elle est d'aplomb. Voir "Reglage de I'aplomb

de la cuisiniere".

4. Verifier que les distances specifiees entre la cuisiniere et les

surfaces du placard ont ete respectees. Voir "Exigences

d'emplacement".

5. Verifier que les chapeaux de brQleurs sont correctement

places sur les bases des brQleurs scelles.

6. Verifier que le dosseret ou la garniture en ilot est installe(e).

(Si le degagement horizontal jusqu'aux materiaux

combustibles derriere la surface de cuisson est inferieur & 1"

[2,5 cm]).

7. Verifier que la cuisiniere est raccordee uniquement au type de

gaz pour lequel le fonctionnement est aggree.

8. Utiliser une solution d'eau tiede et de nettoyant menager

doux pour eliminer tout residu de cire laisse par les materiaux

de protection de I'emballage. Secher parfaitement avec un

linge doux. Pour plus d'informations, consulter la section

"Entretien de la cuisiniere" dans le Guide d'utilisation et

d'entretien.

9. Lire la section "Utilisation de la cuisiniere" dans le Guide

d'utilisation et d'entretien.

10. Mettre en marche les brQleurs de surface et le four. Pour des

instructions specifiques concernant I'utilisation de la

cuisiniere, consulter le Guide d'utilisation et d'entretien.

Si la cuisini_re ne fonctionne pas, contrSler ce qui suit :

• Fusible grille ou desserre? Disjoncteur ouvert?

• Robinets de gaz & la position d'ouverture?

• Si le robinet d'arret de la canalisation de gaz est ouvert,

contacter un technicien qualifie.

• Prise de courant correctement alimentee?